Polypropylene foamed sheet and preparation method thereof

A technology of foamed sheet and polypropylene, which is applied in the field of polypropylene foamed sheet and its preparation, can solve the problems of limiting the use of foamed sheet, the decline of polymer mechanical properties, and low melt extensibility, etc., and achieves good Physical and mechanical properties, excellent foaming state, and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

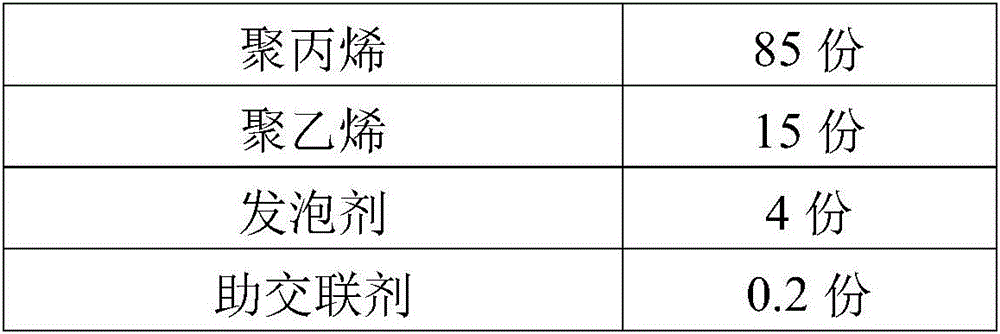

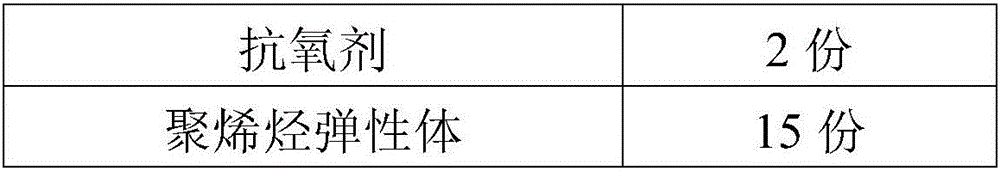

[0036] Polypropylene foam sheet 1 component and weight ratio:

[0037]

[0038]

[0039]The melt strength of polypropylene is 20cN, the melt tensile rate is 23mm / s, the melt index is 15g / 10min, the melt index of polyethylene resin is 15g / 10min, the foaming agent is azodicarbonamide (AC), and the crosslinking agent is It is triallyl isocyanurate, and the antioxidant is antioxidant 1010.

[0040] The preparation method of polypropylene foam sheet 1:

[0041] 1) Preparation of foam masterbatch: Knead 10 parts of polypropylene, 2 parts of polyethylene, and 4 parts of foaming agent at room temperature for 15 minutes, then discharge them into an extrusion granulator for mixing and granulation to obtain foam masterbatch .

[0042] 2) Preparation of antioxidant masterbatch: Knead 8 parts of polypropylene, 2 parts of polyethylene, and 2 parts of antioxidant at room temperature for 15 minutes, then discharge them into an extrusion granulator for mixing and granulation to obtain ...

Embodiment 2

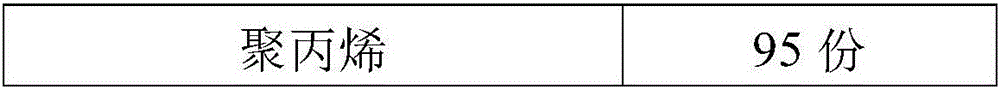

[0049] Polypropylene foam sheet 2 components and weight ratio:

[0050]

[0051]

[0052] The melt strength of polypropylene is 50cN, the melt stretching rate is 110mm / s, the melt index of polyethylene resin is 2.4 / 10min, and the melt index of polypropylene is 5.0g / 10min; the foaming agent is dinitrosopentamethylenetetramine ( DPT) and 4,4'-oxobisbenzenesulfonyl hydrazide (OBSH); the co-crosslinking agent is dimethyl siloxane; the antioxidant is antioxidant 1010.

[0053] The preparation method of polypropylene foam sheet 2:

[0054] 1) According to the raw materials of the above-mentioned foamed sheet, take by weight, polypropylene, polyethylene, foaming agent, auxiliary crosslinking agent, antioxidant and color masterbatch;

[0055] 2) Knead 15 parts of polypropylene, 0.4 parts of polyethylene and foaming agent at room temperature for 2 to 20 minutes, and then discharge them into an extrusion granulator for mixing and granulation to obtain foam masterbatch;

[0056] ...

Embodiment 3

[0064] 3 components and weight ratio of polypropylene foam sheet:

[0065] Polypropylene 50 copies polyethylene 50 copies Foaming agent 20 copies auxiliary crosslinking agent 10 copies antioxidant 0.15 parts Masterbatch 2 copies polyolefin elastomer 20 copies

[0066] The melt strength of polypropylene is 100cN, the melt tensile rate is 100mm / s, the melt index is 3g / 10min, the melt index of polyethylene resin is 2.5g / 10min, and the blowing agent is 4,4'-oxybisbenzenesulfonylhydrazide (OBSH), auxiliary cross-linking agent is triallyl isocyanurate, and antioxidant is antioxidant 1098.

[0067] The preparation method of polypropylene foam sheet 3:

[0068] 1) Preparation of foam masterbatch: knead 15 parts of polypropylene, 10 parts of polyethylene, and 20 parts of foaming agent at room temperature for 10 minutes, then discharge them into an extrusion granulator for mixing and granulation to obtain foam masterbatch .

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com