Ultrasonic vibration assisted deep hole machining device

A processing device and ultrasonic technology, applied in metal processing equipment, manufacturing tools, boring/drilling, etc., can solve the problems of inconvenient oil supply, poor surface quality, and low processing efficiency of the oil supply device, and reduce surface roughness Value, reduce cutting temperature, improve the effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

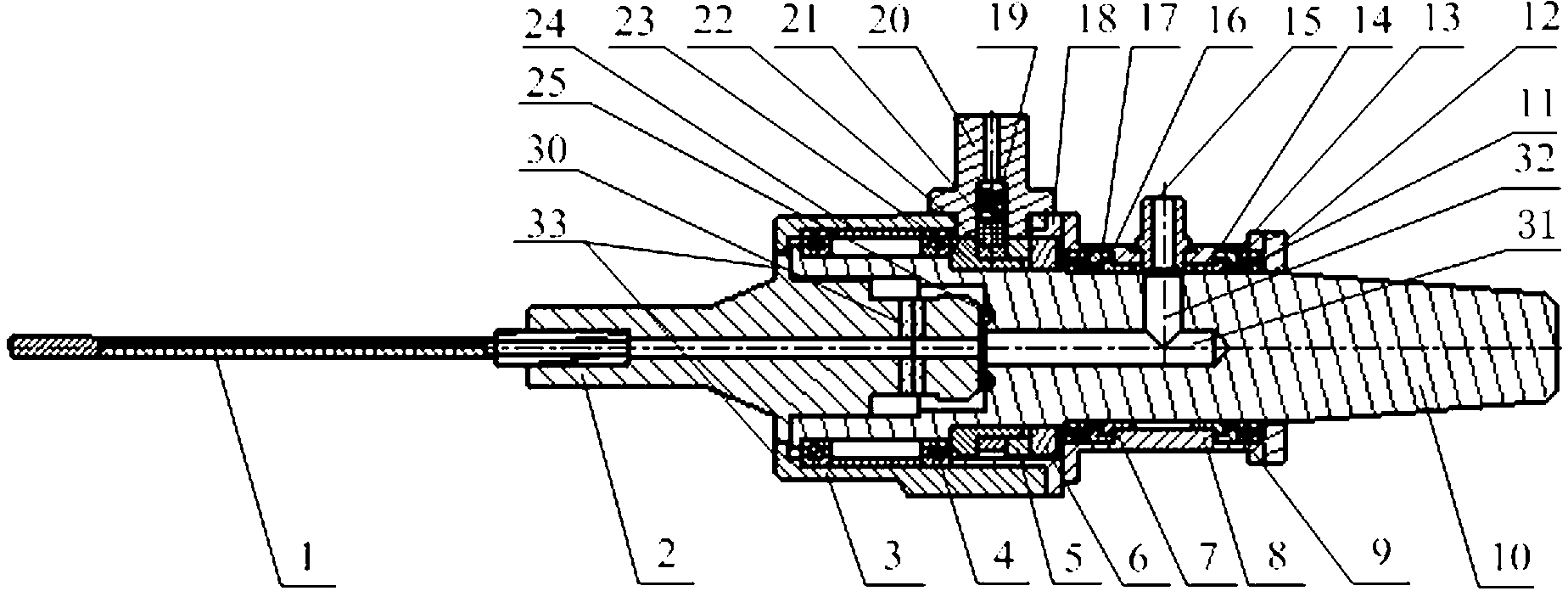

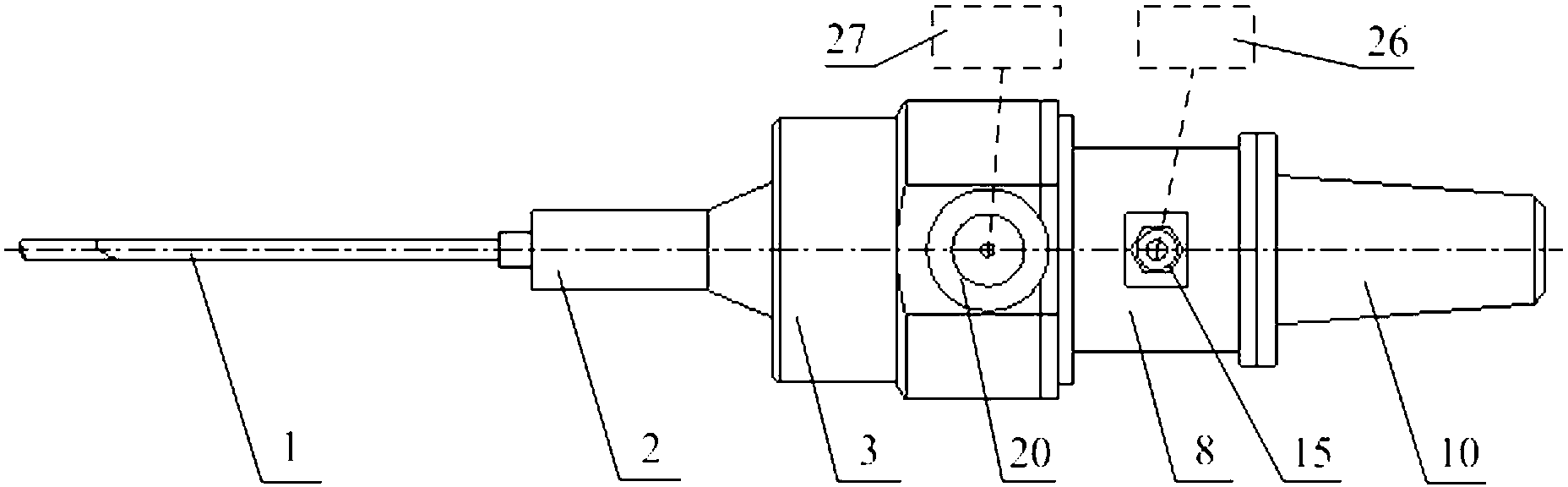

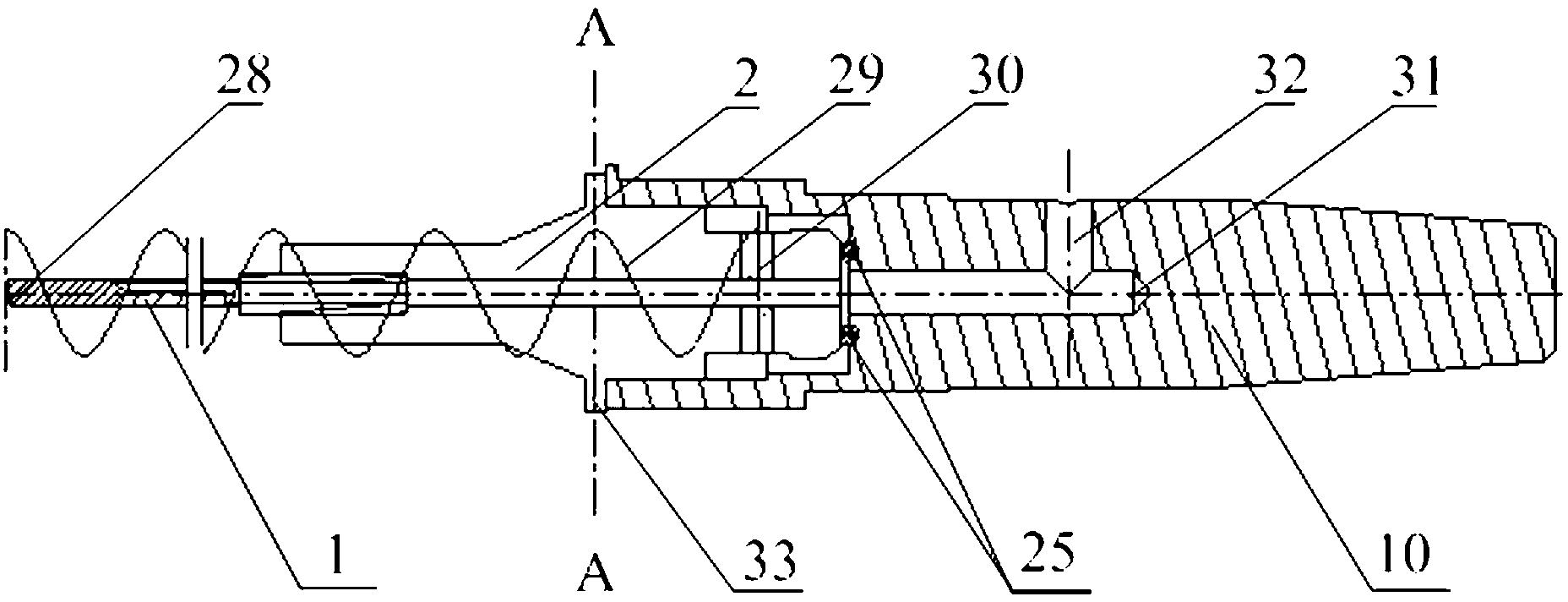

[0013] An ultrasonic vibration assisted deep hole processing device, which includes a drill pipe 1 with a hollow structure inside, and a coupling handle 10 with a cavity inside and an open end; it also includes an integrated horn 2 with a transducer 30 inside , the center of the integrated horn 2 is a cavity through the front and rear; the middle and rear part of the integrated horn 2 is located inside the cavity of the coupling handle 10 and is fixed and sealed with the coupling handle 10; the integrated horn 2 The middle part of the rod 2 is fixed and sealed with the opening of the connecting handle 10; the front end of the integrated horn 2 is fixedly connected with the rear end of the drill rod 1, and the cavity of the drill rod 1 communicates with the cavity of the integrated horn 2; The inner middle part of the coupling handle 10 is horizontally opened with an oil supply cavity 31 communicating with the cavity; the oil supply cavity 31 communicates with the cavity of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com