Device and method for machining metal beryllium single-blade outer chip removal deep hole

A processing method and technology of a processing device, applied in metal processing equipment, boring/drilling devices, manufacturing tools, etc., can solve the problems of chip breaking and chip removal difficulties, tool erosion, low stress brittle fracture of beryllium workpieces, etc. The effect of processing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

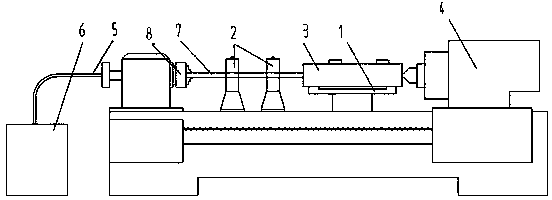

[0021] The metal beryllium single-edge external chip removal deep hole drilling processing method of the present invention is particularly suitable for small aperture (φ12mm) and large aspect ratio (50-150) deep hole processing of metal beryllium. The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0022] 1. According to the size and shape of the beryllium workpiece to be processed, process the auxiliary plate 1 for workpiece clamping. And install the auxiliary board 1 on the middle carriage of the lathe 4 (CA6140), and change the drilling position by moving the middle carriage during processing to realize the processing of the hole system.

[0023] 2. According to the design of the lathe and tool used, design and manufacture the connecting mechanism 5 between the oil supply system and the tool 7, and install it on the lathe for cooling and chip removal during processing. The deep hole drill has a hollo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com