Patents

Literature

72results about How to "Solve lubricity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-protein low-fat yogurt and preparation method thereof

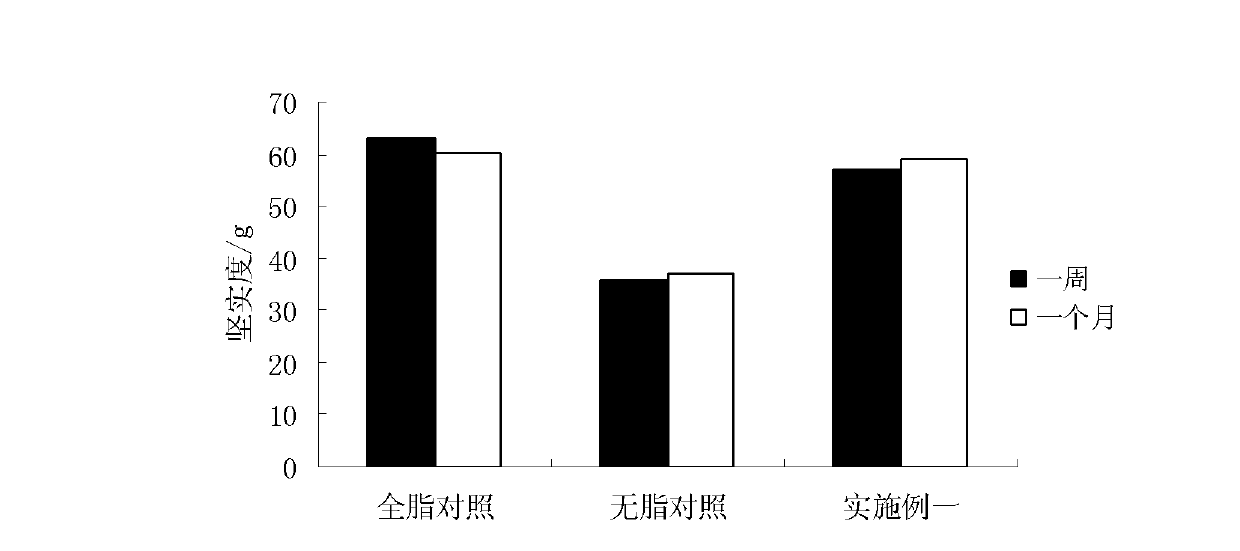

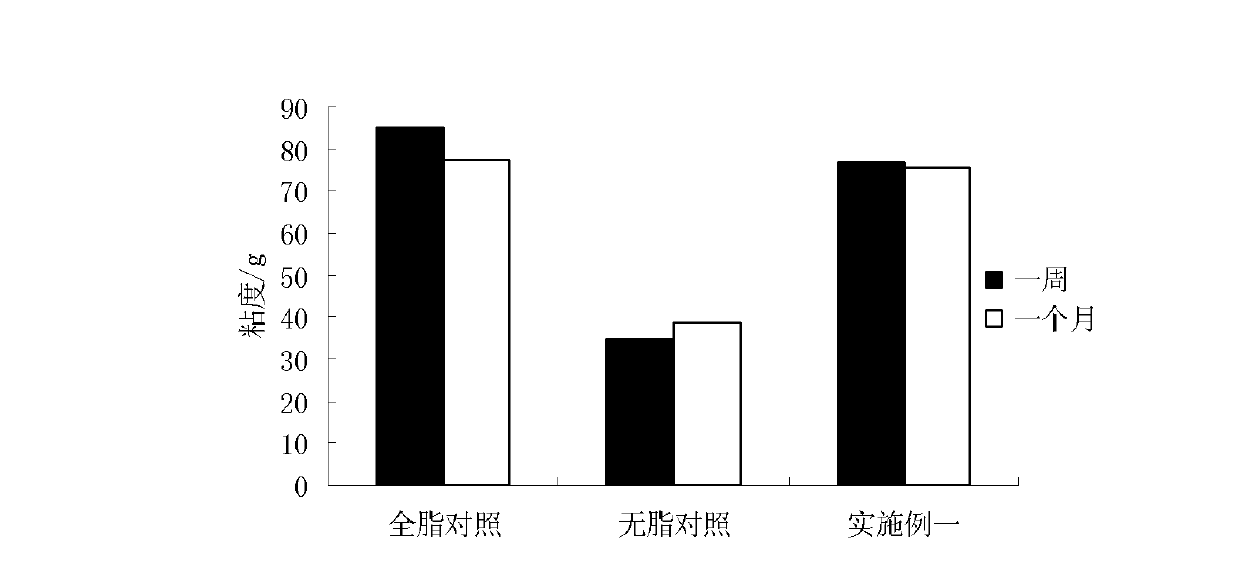

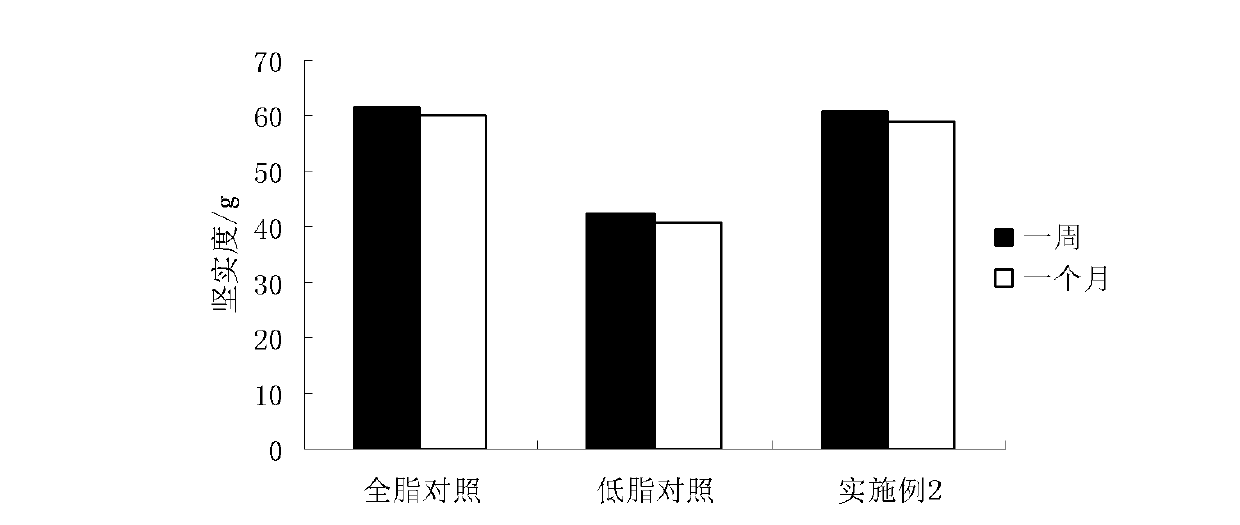

ActiveCN102550669ASuitable for aseptic fillingSolve the thin tasteMilk preparationWhey proteinWhole milk yogurt

The invention provides high-protein low-fat yogurt and a preparation method thereof. In the terms of the total weight of the high-protein low-fat yogurt, the yogurt comprises the following raw materials in percentage by weight: 0.01 to 8 percent of gel-type whey protein concentrate, and 0.02 to 10 percent of micro-particulated protein. One of the two kinds of protein has a function of improving the gel performance of yogurt, while the other of the two kinds of protein has a function of improving creamy smooth taste of yogurt, so that the low-fat yogurt prepared by the method has a solid and ropy structure similar to whole-milk yogurt and smooth and fine taste. Furthermore, on the premise of no addition of a stabilizing agent and a thickening agent, the defect of whey precipitation commonly happening in yogurt is overcome successfully, so that the low-fat yogurt manufactured by adopting the method has the characteristic of pure nature.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

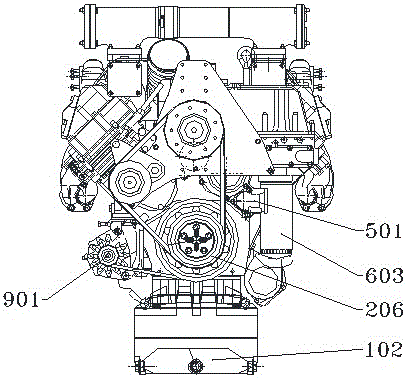

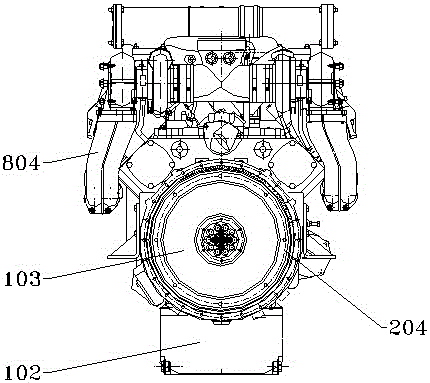

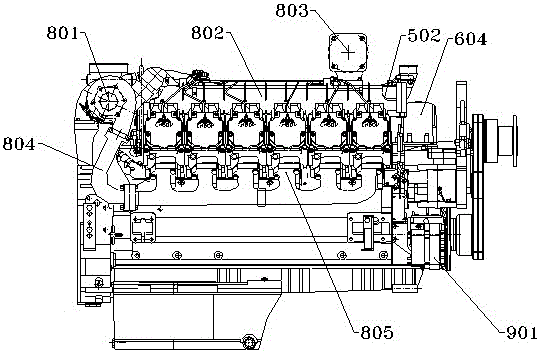

12-cylinder water cooling diesel engine

The invention discloses a 12-cylinder water cooling diesel engine. The engine comprises a crank connecting rod mechanism arranged on a fixed part, a gas distribution mechanism, a transmission mechanism, a cooling system, a lubricating system, a fuel supply system, an intake / exhaust system, an electric system and a starting mechanism. The water cooling engine widens the power range, increases the power from traditional 195-499 kW to 780 kW, preferably exerts the characteristics of high power, small size, compact structure and low fuel consumption of the series of diesel engines, adapts to the market demands, satisfies the use requirements of users, is better in market competitiveness, can be applied to such fields as engineering machinery and generator sets, and widens the application field of 132-series engines.

Owner:HEBEI HUABEI DIESEL ENGINE

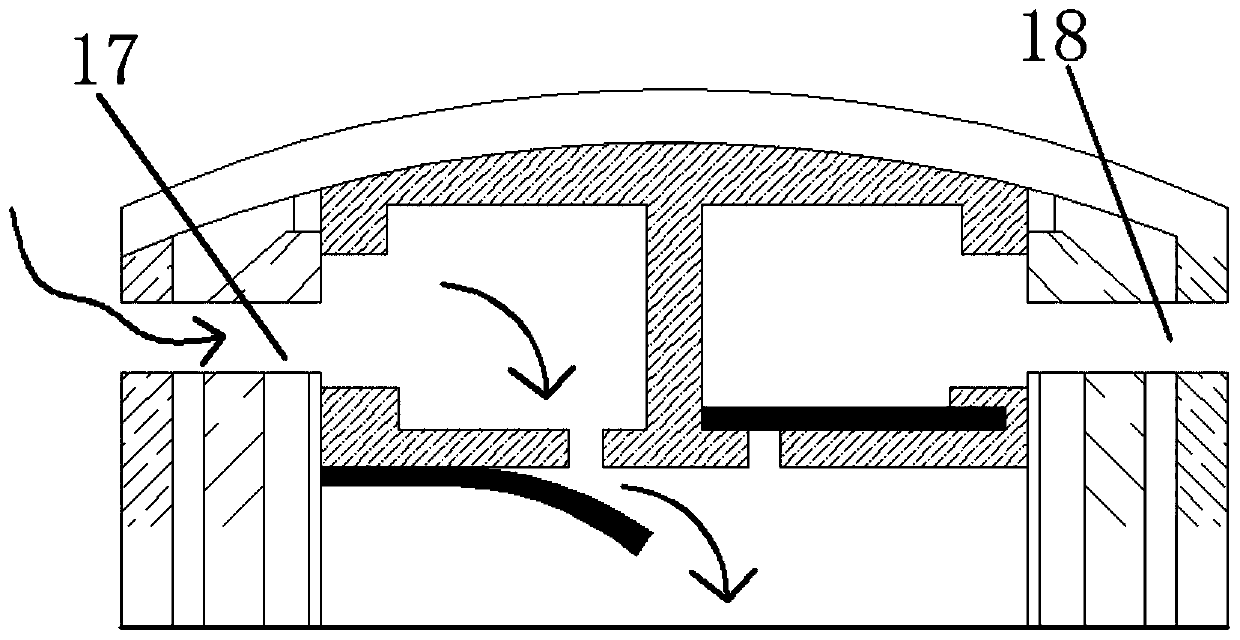

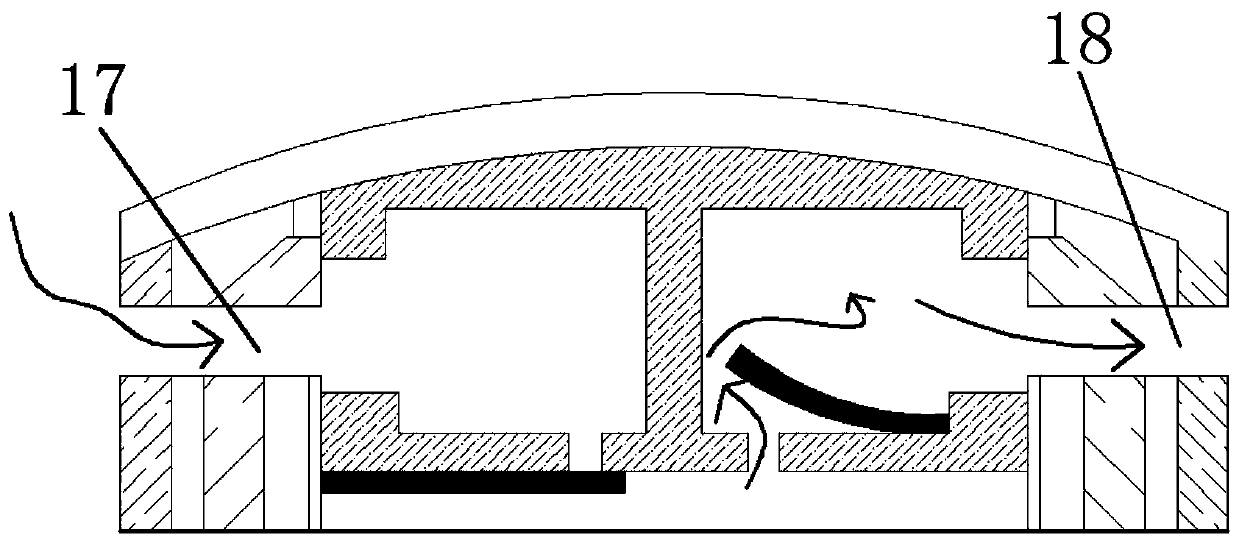

Method for preparing bionic laminar articular cartilage/bone compound implant

InactiveCN1961975AMeet the mechanicsSatisfy physiological functionJoint implantsPolyvinyl alcoholBiomechanics

The invention relates to a method for preparing bionic laminated cartilage / bone element, wherein it comprises preparing porous same heterogenous bone or different bone elements; preparing artificial cartilage and laminated cartilage / bone composite. The invention processes the bone into needed size and shape, to be washed and immunity treatment, to be put at the bottom of mould; then at positive and passive pressures, pouring the polyvinyl alcohol / biological active component preformed element and polyvinyl alcohol / lubricant molecule preformed element into mould; flattening the surface and compressing; freezing and fusing, shaping. The inventive product has surface layer as abrasion-resistant lubricant layer, middle layer as force layer, and bottom layer as biological active cartilage / bone combine layer, to meet biological physica property and physiological function.

Owner:UNIV OF SCI & TECH BEIJING

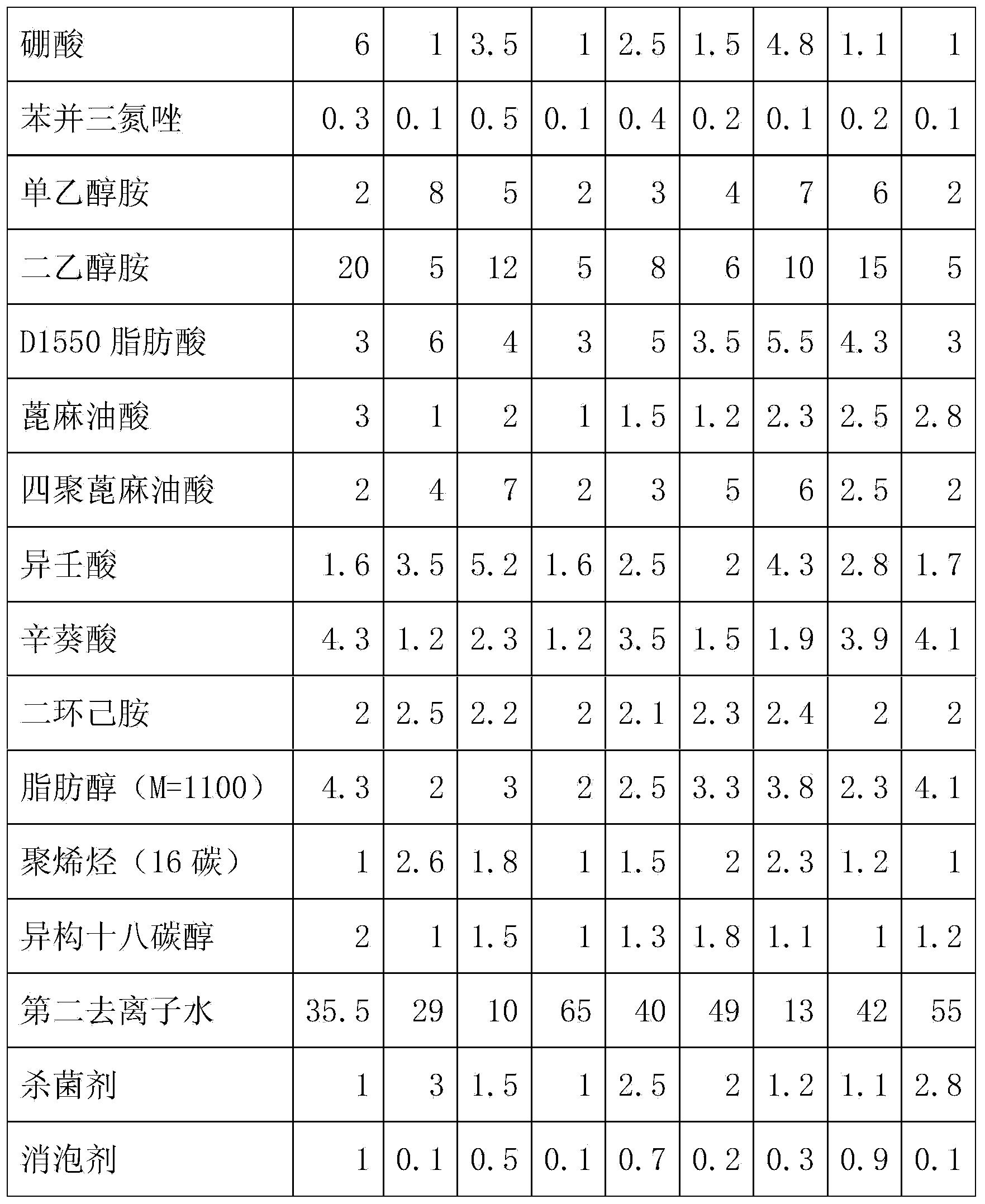

Polyethylene glycol monooleate fully-synthetic cutting fluid and preparation method thereof

ActiveCN102776060AComprehensive lubricationExtend the life cycleLubricant compositionPolyethylene glycolMaterials science

The invention relates to a cutting fluid for metal processing, and particularly relates to a polyethylene glycol monooleate fully-synthetic cutting fluid and a preparation method thereof. Polyethylene glycol monooleate is used as a lubricating agent, and borate generated by boric acid and monoethanolamine and triazine amino-acid ester are combined to form an anti-rust component which has better anti-rust property, thus solving the defects of poor lubricating property, easy deterioration and smelliness and short service life of polyethylene glycol lubricating agents, polyether lubricating agents, oleic acid soap lubricating agents and sulfonated caster oil lubricating agents, and further achieving a corrosion inhibition and synergy function by adding a proper amount of benzotriazole copper corrosion inhibitor and other anti-rust agents. The fully-synthetic cutting fluid prepared from the raw materials is complete in property, has excellent hard water resistance, can be used under a high hard water environment, is high in pH buffer capacity, is stable in quality, has excellent lubricating, anti-rust and anti-corrosion functions, belongs to an environment-friendly product, can be biodegraded, is suitable for various kinds of machining, and is especially suitable for various machining processes of a grinder.

Owner:温州宝罗润滑材料有限公司

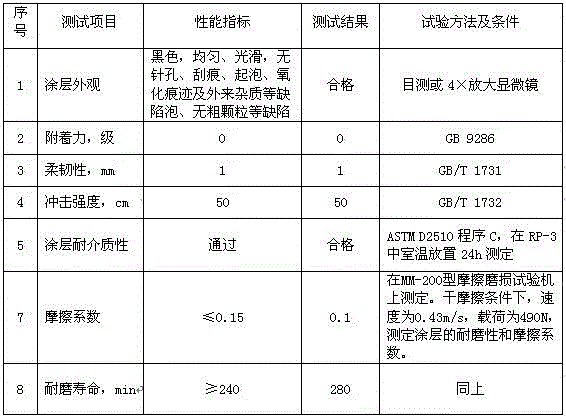

Polytetrafluoroethylene bonded solid lubricant

ActiveCN105132086ASolve lubricitySolve the wear and tear problemAdditivesLubrication ProblemPolyamide

The invention discloses a polytetrafluoroethylene bonded solid lubricant. The polytetrafluoroethylene bonded solid lubricant is prepared with polyamide-imide resin and epoxy resin as binders, polytetrafluoroethylene, melamine cyanurate and molybdenum disulfide as solid lubricants and a mixed solvent as a diluent, and contains various fillers and a modification additive. The lubricant is coated on the surfaces of mechanical components and test samples, and is heated and solidified to form polytetrafluoroethylene bonded solid lubrication coating layers. The lubricant solves the problems of lubrication and wearing of motion parts under low load and high speed conditions, such as wearing and lubrication problems between oil-free compressor rotors and between rotors and a shell, and is especially suitable for being used on screw type oil-free air compressors.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Polyimide base high temp.-resistant and radiation-resistant lubricating paint

InactiveCN1385487AImprove wear resistanceImprove carrying capacityCoatingsRadiation resistantAdhesive

The present invention relates toa polyimide based high temp. resistant and radiation resistant lubricating coating. It is characterized by that it uses the irradiation-proof thermosetting polyimide resin as adhesive, uses molybdenum disulfide as lubricant, uses antimony trioxide and basic lead phosphite as modifying agent, and adds the mixed solvent to form the invented lubricating coating. Said coating not only possesses good wear-resistant, loading and lubricating properties, but also has the functions of resisting high temp. and resisting radiation. The sliding component coated with said coating material can be used for a long period in the high-temp. (300-370 deg.C) and strong radiatino environment.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

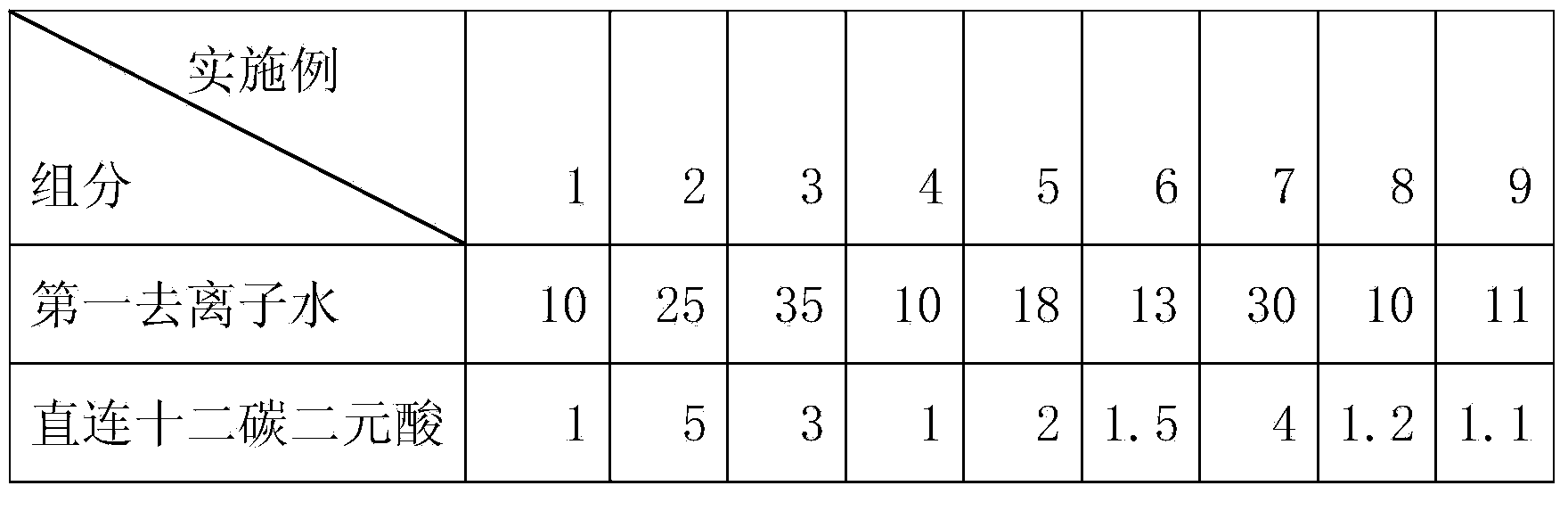

Fully synthetic cutting fluid for metal processing and preparation method thereof

InactiveCN104232283AGood adsorption and anti-rust effectImprove the lubrication effectLubricant compositionPolyolefinFatty acid

The invention discloses fully synthetic cutting fluid for metal processing. The cutting fluid is prepared from deionized water, linear chain dodecanedioic acid, boric acid, benzotriazole, monoethanolamine, diethanol amine, D1550 fatty acid, ricinoleic acid, tetraricinoleic acid, isononanoic acid, octanoic / decanoic acid, dicyclohexylamine, fatty alcohol, polyolefin, isooctadecanol, a sterilizing agent and an antifoaming agent according to a certain ratio. The fully synthetic cutting fluid for metal processing overcomes the defects that the using cost of the product is high, a diluent easily goes bad to generate foreign odor, lubrication is insufficient and the service time and cycle are short and the like existing in products in the market and also has excellent cooling and cleaning anti-rust performances, so that the metal processing and lubricating products are improved in the machining and lubricating aspects to a certain degree. The fully synthetic cutting fluid product for metal processing has the greatest characteristic that the lubricating property requirements of heavy processing modes of some materials which are difficult to machine in the machining process can be met, the fully synthetic cutting fluid does not contain base oil, and the service time can be greatly prolonged.

Owner:上海加美实业有限公司

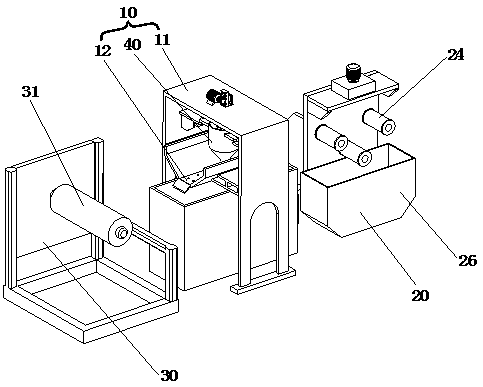

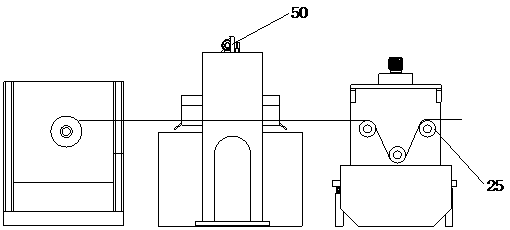

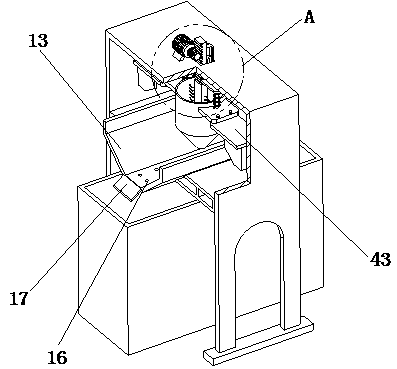

Automatic lubricating equipment for textile yarns

The invention discloses automatic lubricating equipment for textile yarns, and belongs to the technical field of textile equipment. The equipment comprises a lubricating assembly, a residual liquid removing assembly and a bearing frame, an upper winding roller is arranged on the bearing frame, the lubricating assembly comprises an oil outlet component, a gantry frame and a bearing platform, the oil outlet component comprises a heating cylinder, a buffer part, an oil outlet hopper, a limiting disc and a lifting part, the oil outlet hopper communicates with the interior of the heating cylinder,the bottom of the oil outlet hopper is provided with an oil outlet hole, and the bottom of the limiting disc is provided with a curve chamfer. Lubricating operation for the yarns can be achieved through the lubricating assembly, residual lubricating oil stuck on the yarns can be removed through the residual liquid removing assembly, lubricating oil can be vibrated through a vibration component, anair blower can be matched with the vibration component, and lubricating oil stuck on the yarns can fall down to an oil storage tank.

Owner:扬州金晟华线业有限公司

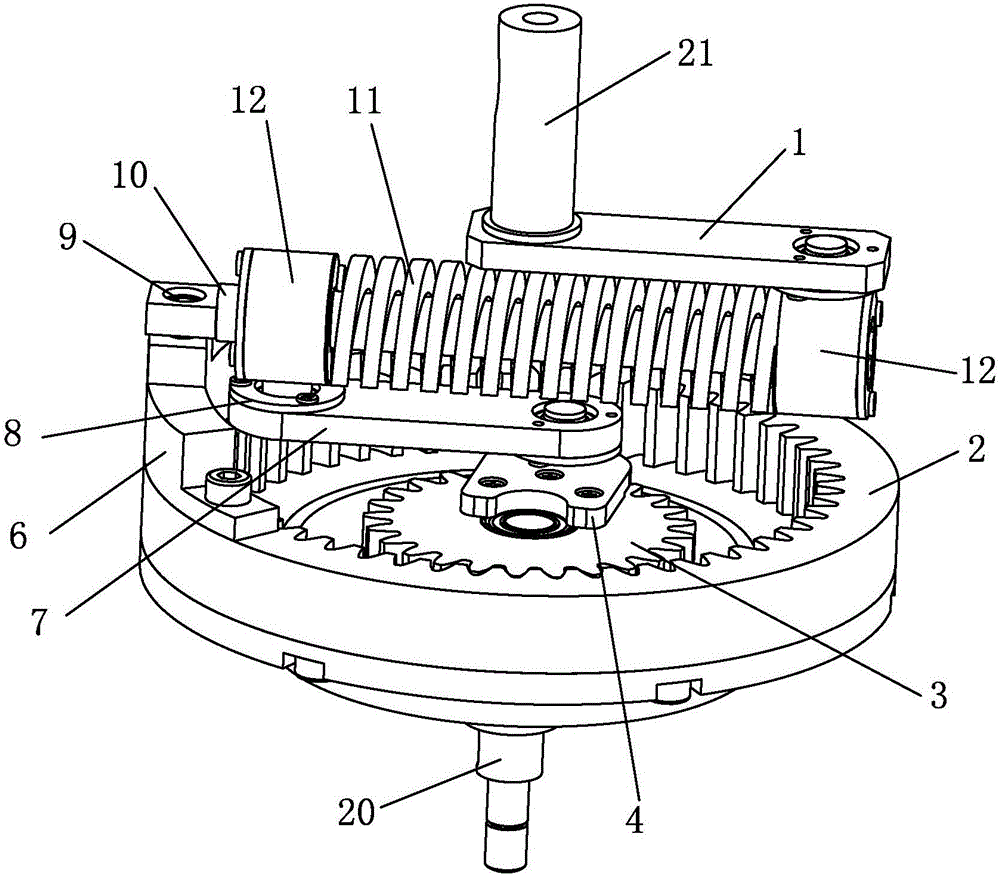

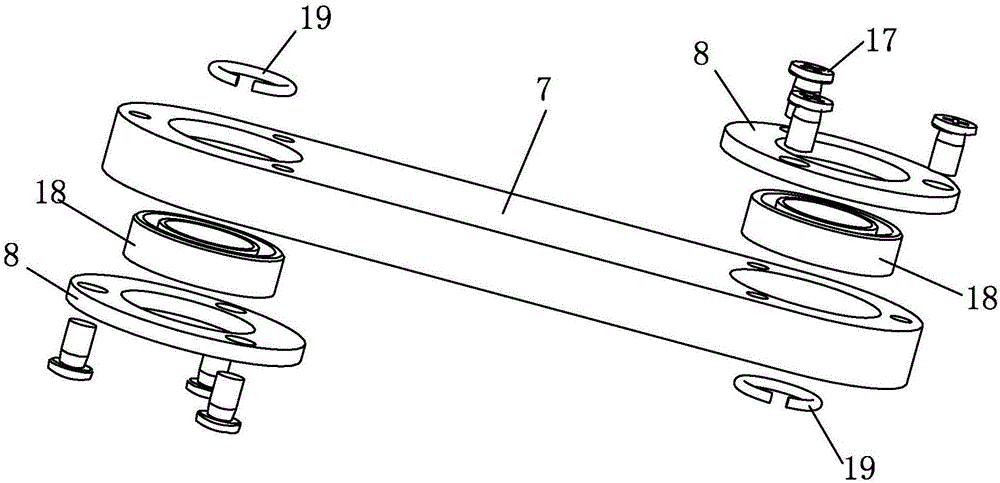

Variable-rigidity mechanism based on geometrical features

The invention relates to a joint variable-rigidity mechanism, in particular to a variable-rigidity mechanism based on geometrical features. The variable-rigidity mechanism aims to solve the problems that an existing variable-rigidity mechanism is complex in structure and poor in linearity, gaps and friction exist between the mechanism and a rod when the mechanism moves through a fulcrum, and consequently the position precision is low. The variable-rigidity mechanism comprises an output rod, a rigidity adjusting inner gear ring, a fulcrum gear, a fulcrum frame, a fulcrum bar, a middle rod, a spring, a shaft sleeve and two sliding blocks, wherein the sliding blocks are arranged at the two ends of the middle rod correspondingly, the spring is arranged on the middle rod located between the two sliding blocks in a sleeving mode, the shaft sleeve is arranged between the sliding blocks and the middle rod in a sleeving mode, and the shaft sleeve is axially positioned through bearing end covers arranged on the sliding blocks; and the fulcrum gear is engaged with the rigidity adjusting inner gear ring, and the fulcrum gear is arranged below the fulcrum frame and detachably connected with the fulcrum frame. The variable-rigidity mechanism is applied to a robot elbow joint.

Owner:HARBIN INST OF TECH

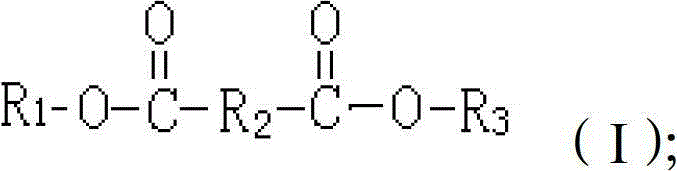

Synthetic lubricating oil composition for air compressor and preparation method thereof

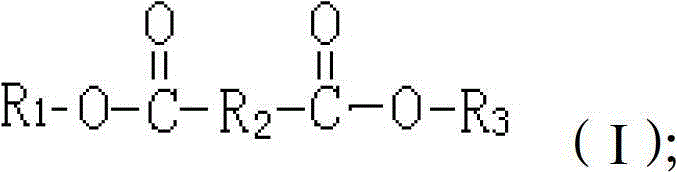

ActiveCN102911766AMeet the use requirementsExcellent coke cleaning functionAdditivesTO-18Chemical composition

The invention provides a synthetic lubricating oil composition for an air compressor. The synthetic lubricating oil composition comprises 0.1 to 10wt% of tackifier, 2 to 7wt% of antioxygen, 0.05 to 1wt% of corrosion inhibitor, 1 to 8wt% of extreme pressure anti-wear agent, 0.0001 to 0.05wt% of antifoaming agent, and the balance of ester oil. The ester oil is provided with a structure shown as formula (I), wherein R1 and R3 are independently selected from alkyl with 5 to 20 carbon atoms; and R2 is the alkylene with 5 to 18 carbon atoms. The ester oil is provided with a special molecular structure, so that the synthetic lubricating oil composition for the air compressor is excellent in function of cleaning the coking material, and original oil sludge and coking matter of the compressor system can be cleaned and carried out; and the synthetic lubricating oil composition for the air compressor is higher in coking resistance. The invention also provides a preparation method of the synthetic lubricating oil composition for the air compressor.

Owner:CHINA PETROLEUM & CHEM CORP

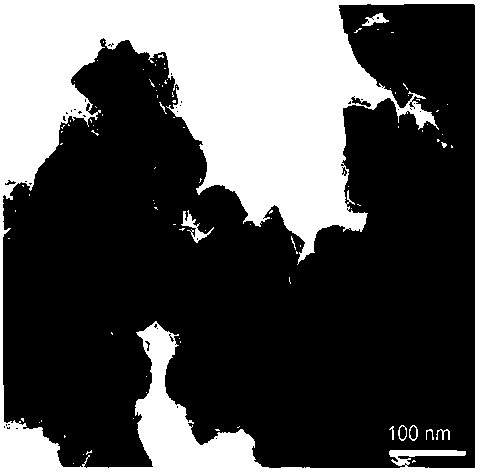

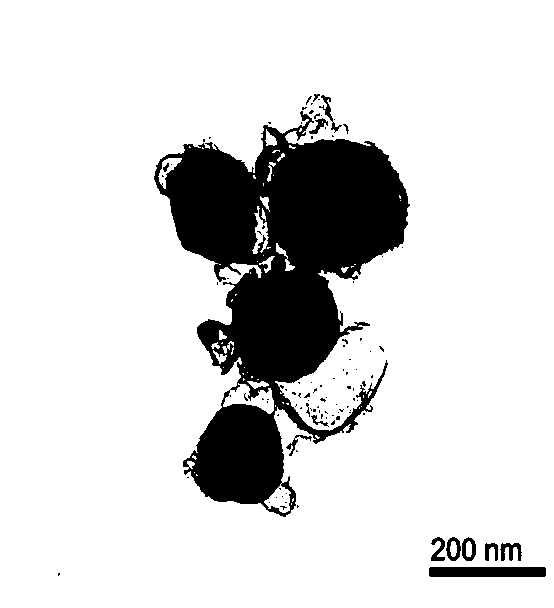

Quick in-situ preparation method of noctiluca-shaped graphene wrapped silicon carbide microsphere

The invention discloses a quick in-situ preparation method of a noctiluca-shaped graphene wrapped silicon carbide microsphere. The method comprises the following steps of dispersing silicon carbide particles in a liquid phase medium to form suspension with a certain concentration, aggregating irradiating pulse laser light with certain energy density to the suspension, allowing the silicon carbideparticles to achieve silicon carbide epitaxy graphene growth, partial multilayer graphene sheet stripping and irregular particle spheroidization in situ by the double action of light and heat of laserirradiation and quick cooling of a surrounding liquid environment, after irradiation, centrifuging, separating and pickling the suspension, and drying a precipitate to form the high-dispersity noctiluca-shaped graphene wrapped silicon carbide microsphere. The method is simple to operate; the preparation can be accomplished under a room temperature condition of normal temperature and pressure; thecost is low; a product is high in purity; and the graphene wrapped silicon carbide microsphere shows excellent dispersion stability and antiwear and friction-reducing performance in lubricating oil.

Owner:UNIV OF JINAN

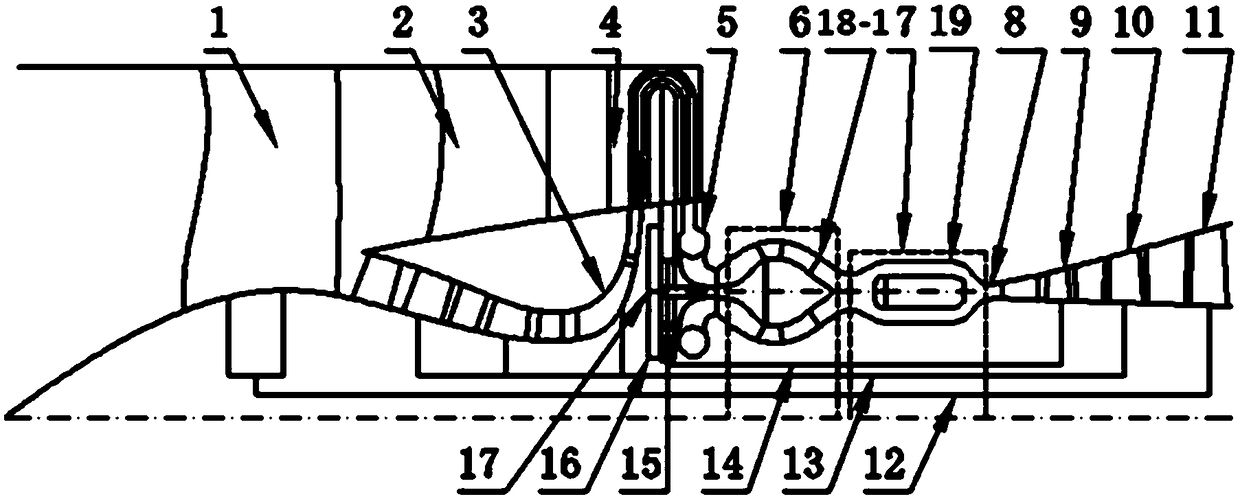

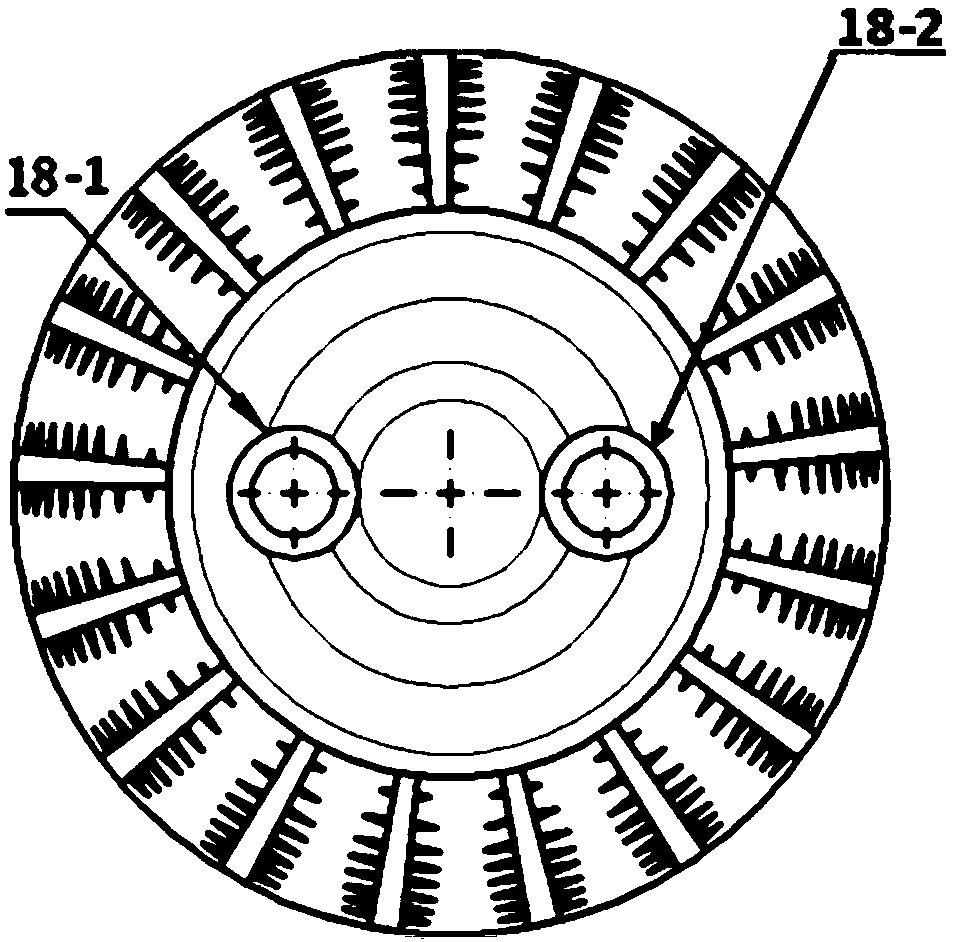

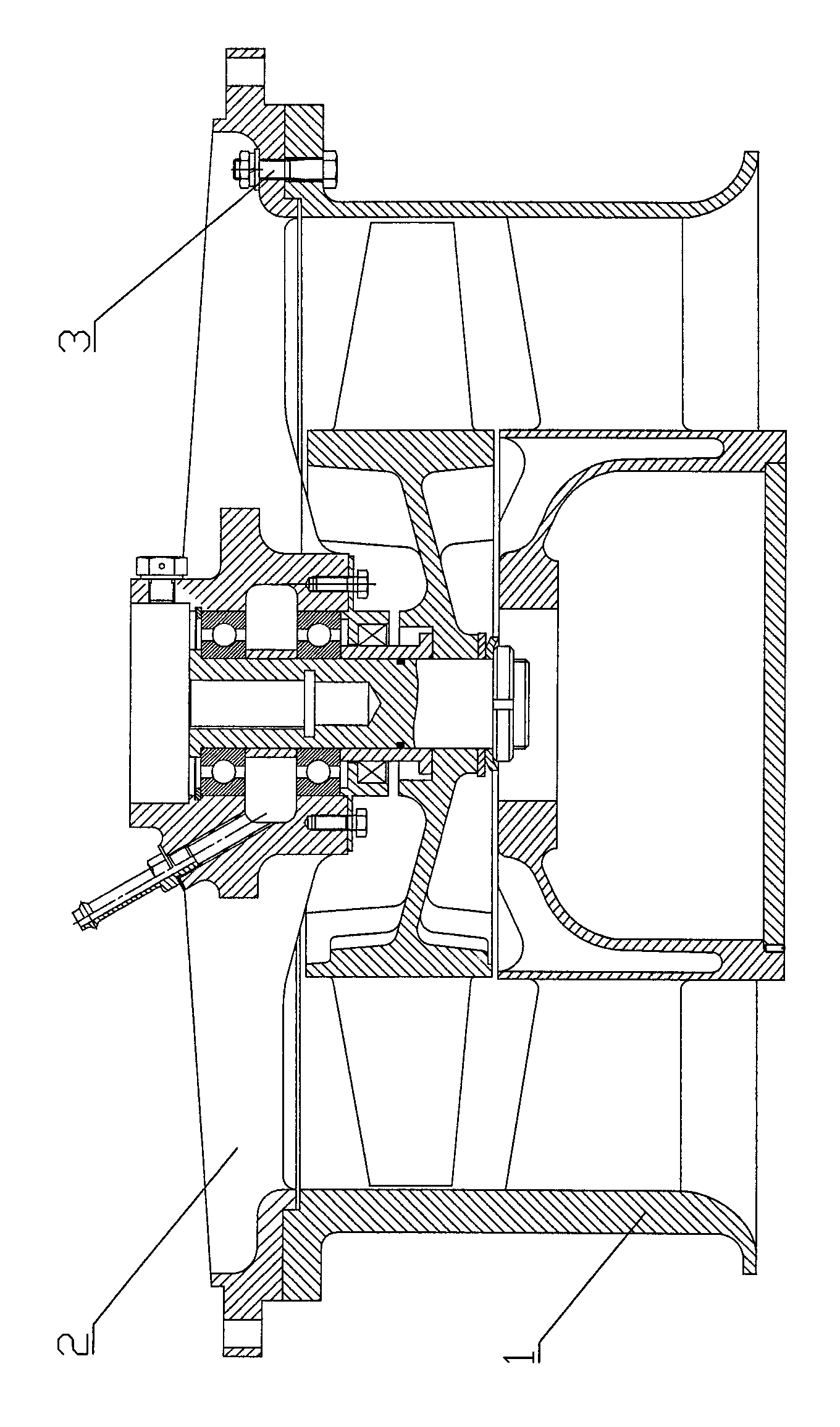

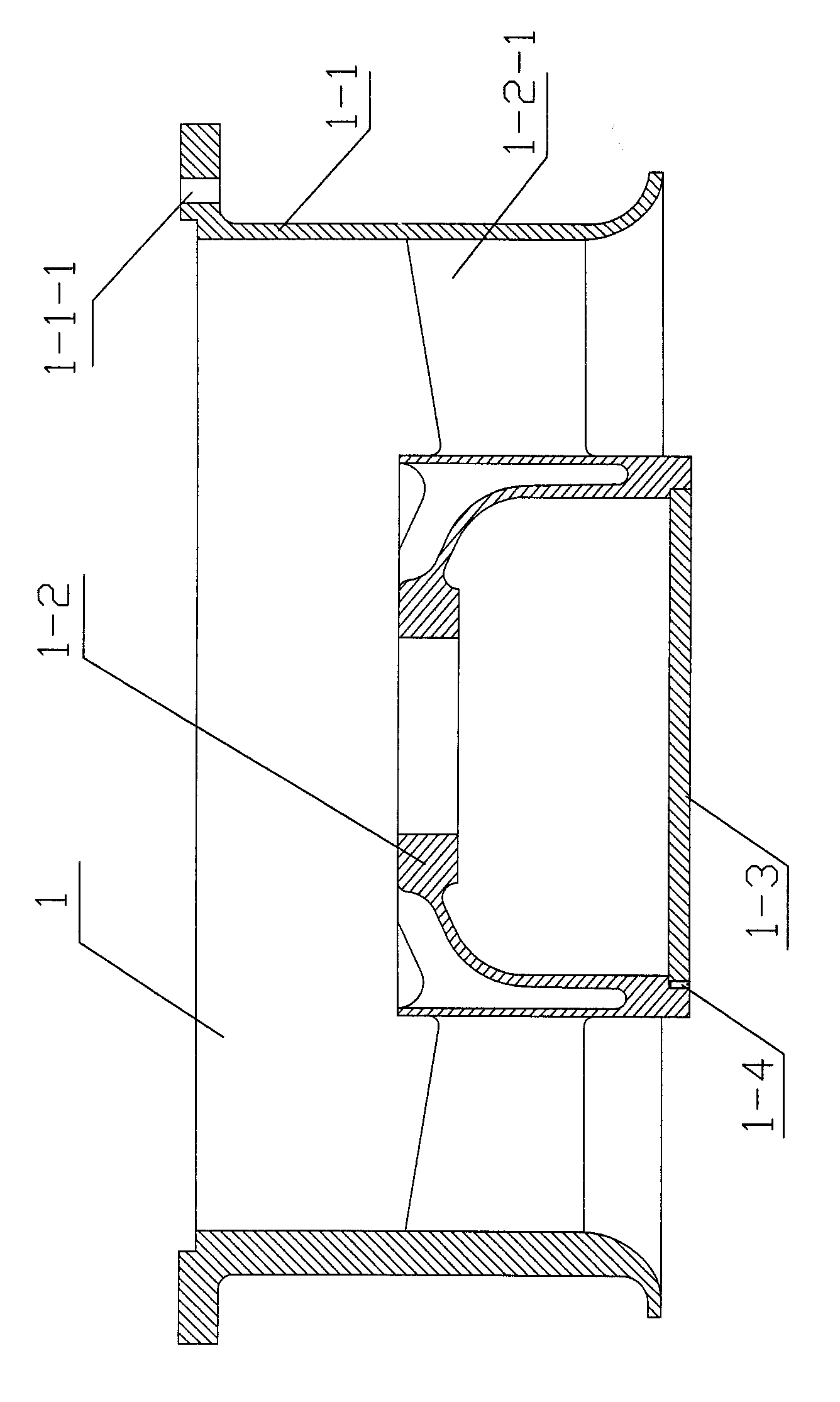

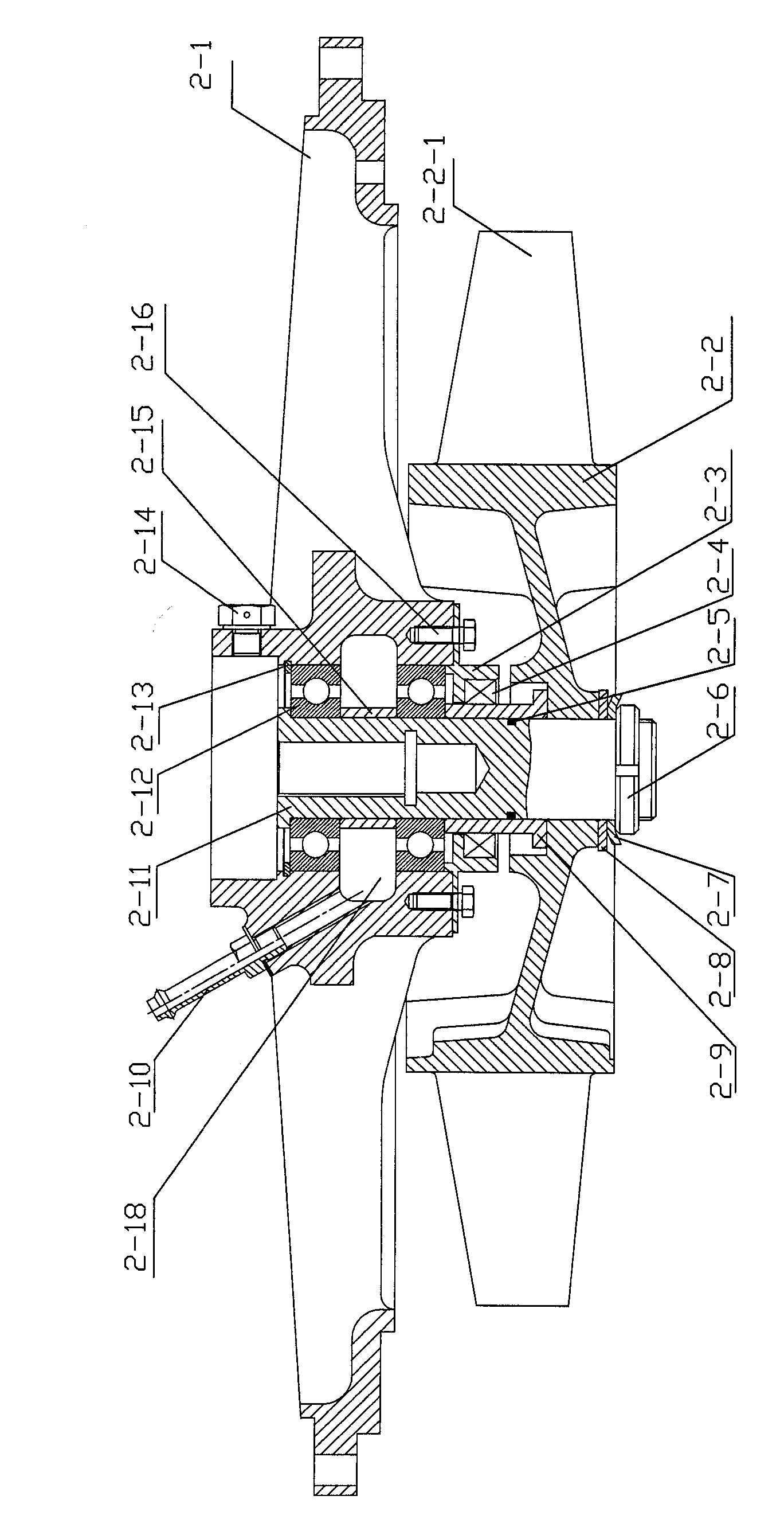

Very-high-pressure intercooling cycle turbofan engine

ActiveCN108661822ACompact structureIncrease stall marginGas turbine plantsJet propulsion plantsSingle stageCombustion chamber

The invention provides a very-high-pressure intercooling cycle turbofan engine. The engine comprises fans, a high-pressure air compressor, an intercooler, a very-high-pressure air compressor, a combustion chamber, a circular rotating fan transition section, a very-high-pressure turbine, a high-pressure turbine, a low-pressure turbine, a low-pressure shaft, a high-pressure shaft and a very-high-pressure shaft. The fans, the high-pressure air compressor, the intercooler, the very-high-pressure air compressor, the combustion chamber, the circular rotating fan transition section, the very-high-pressure turbine, the high-pressure turbine and the low-pressure turbine are connected in sequence. The very-high-pressure turbine drives the very-high-pressure air compressor to operate through the very-high-pressure shaft. The high-pressure turbine drives the high-pressure air compressor to operate through the high-pressure shaft. The low-pressure turbine drives the fans to operate through the low-pressure shaft. The rotation central axis of the very-high-pressure air compressor, and the axis of the combustion chamber are both parallel to the axis of the engine but not coincide with the axis ofthe engine. The high-pressure air compressor is composed of a multi-stage high-load axial flow air compressor and a single-stage high-through-flow centrifugal / oblique flow air compressor.

Owner:AERO ENGINE ACAD OF CHINA

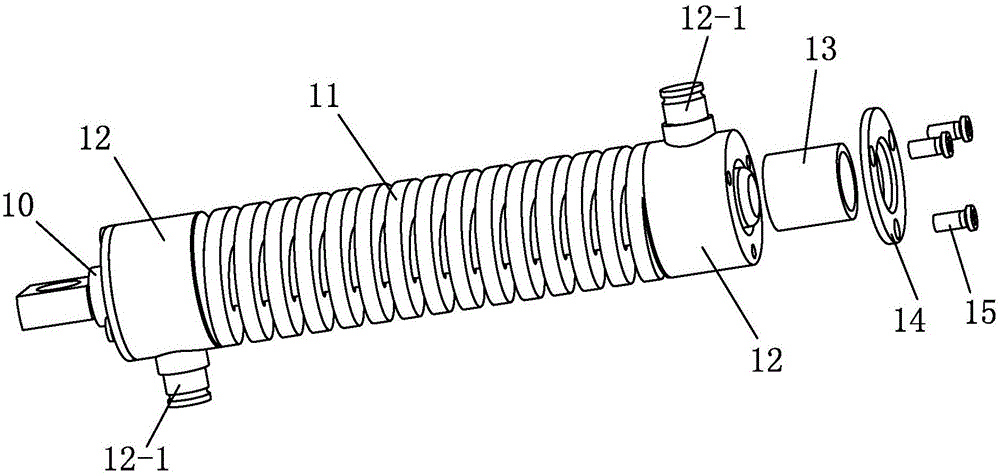

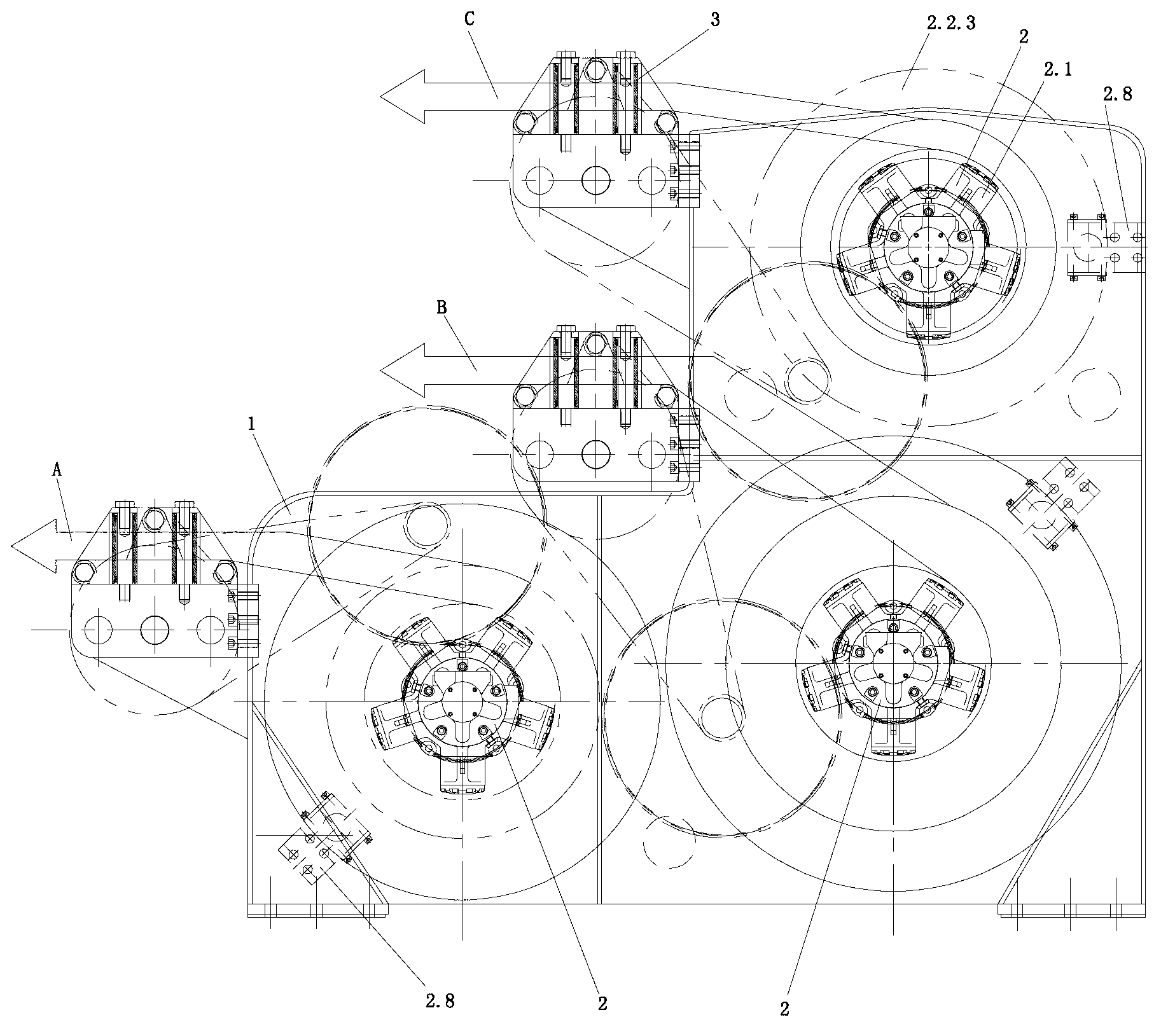

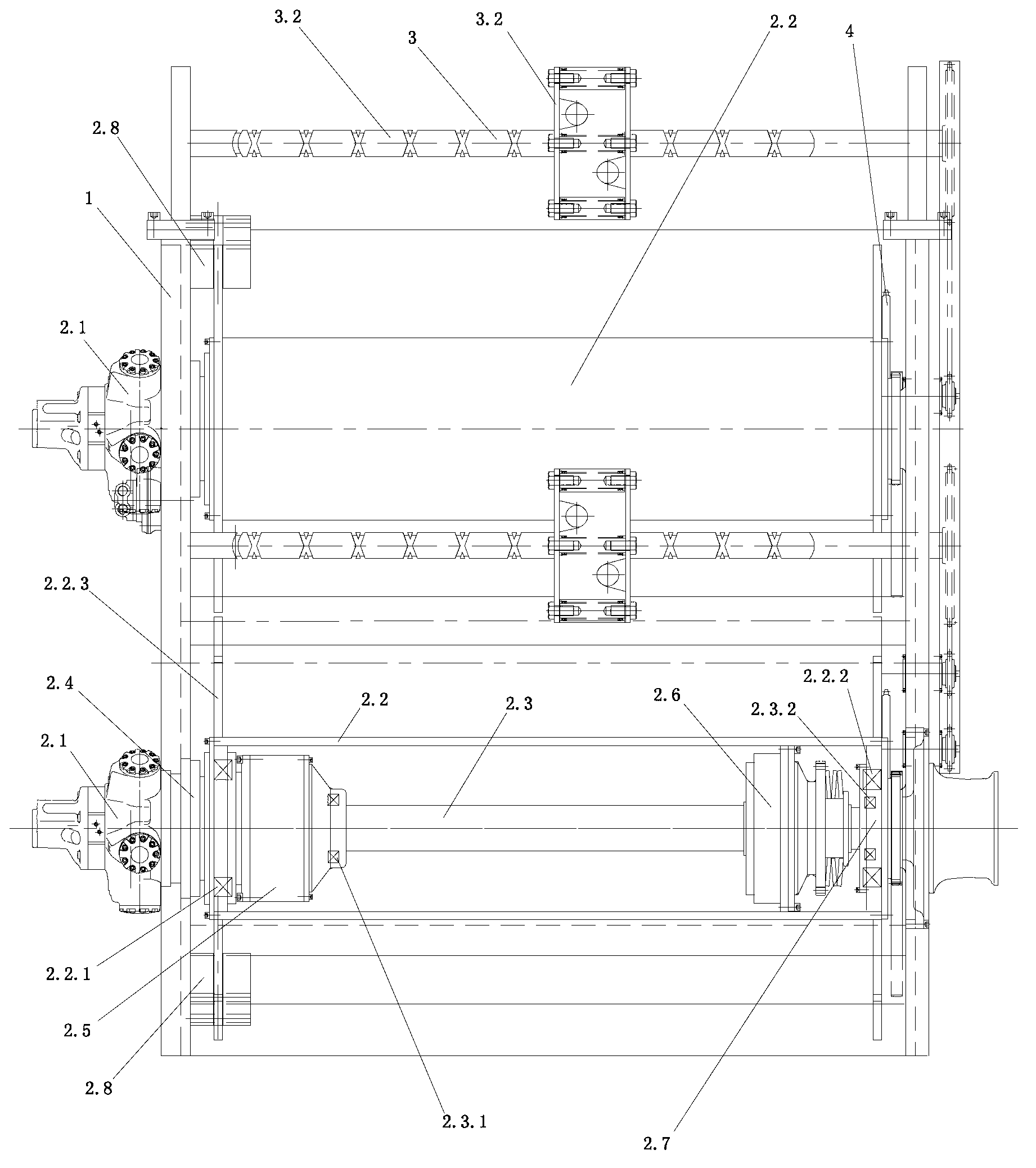

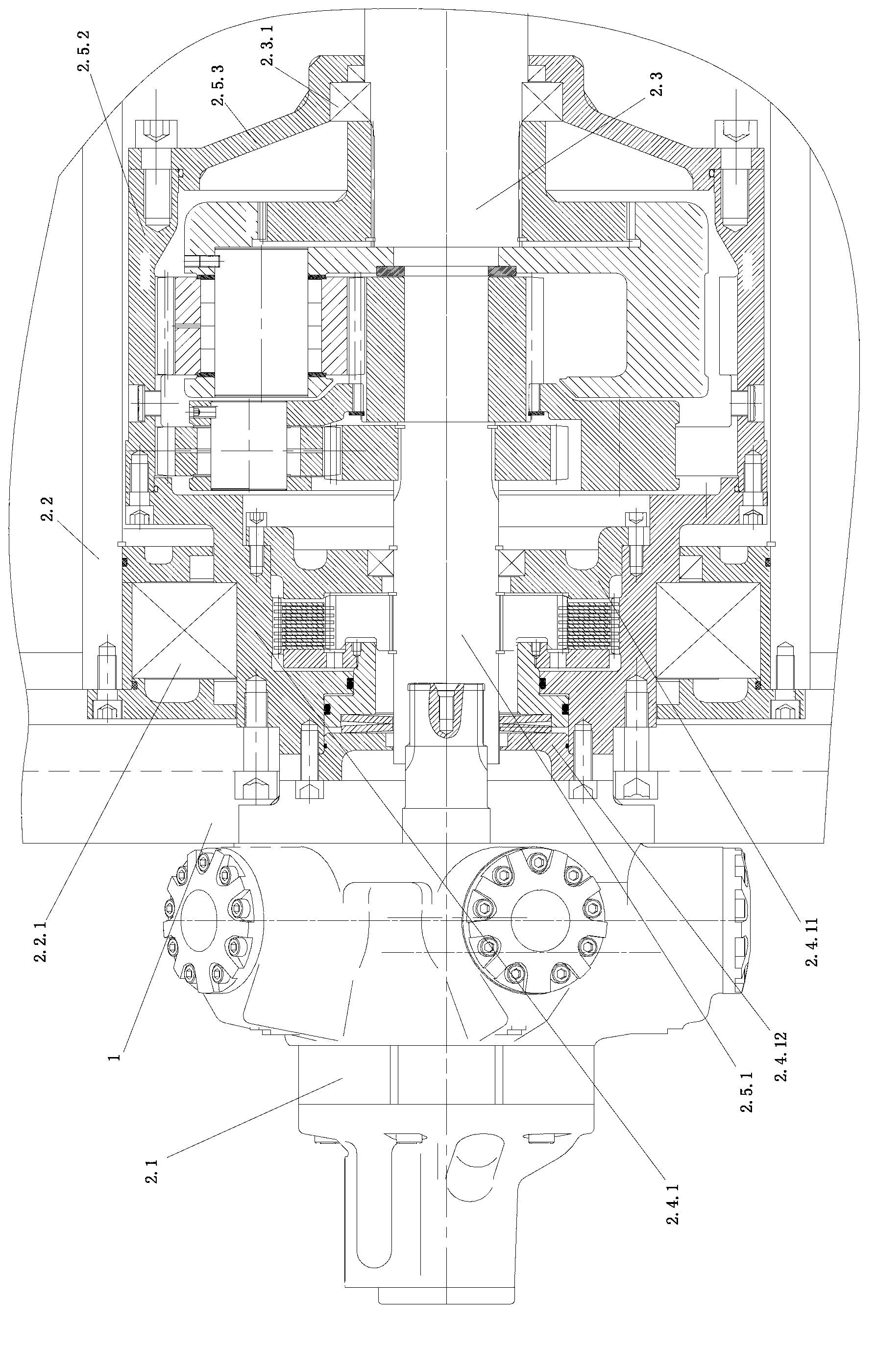

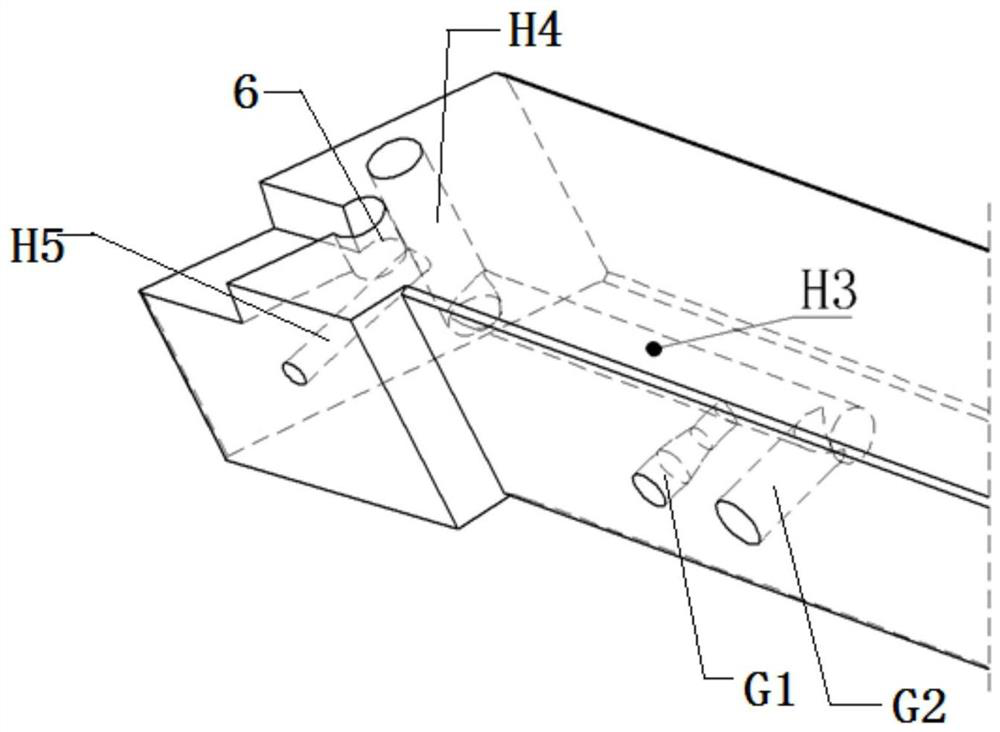

Three-roller purse seine winch

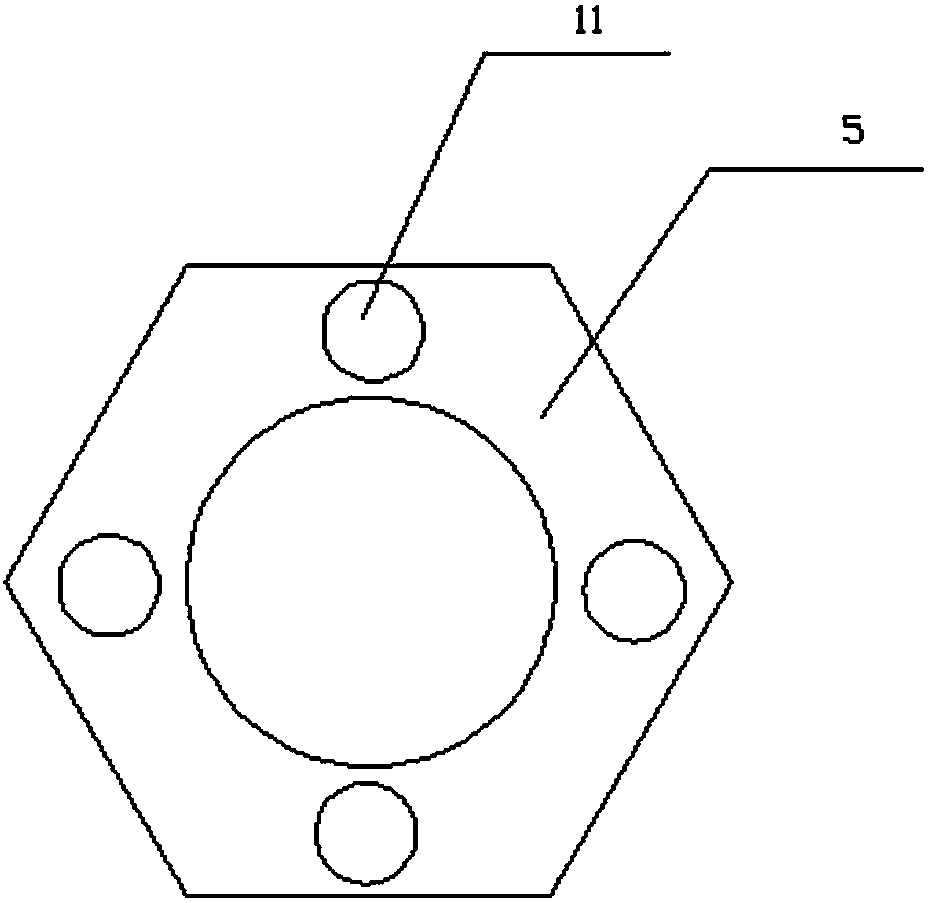

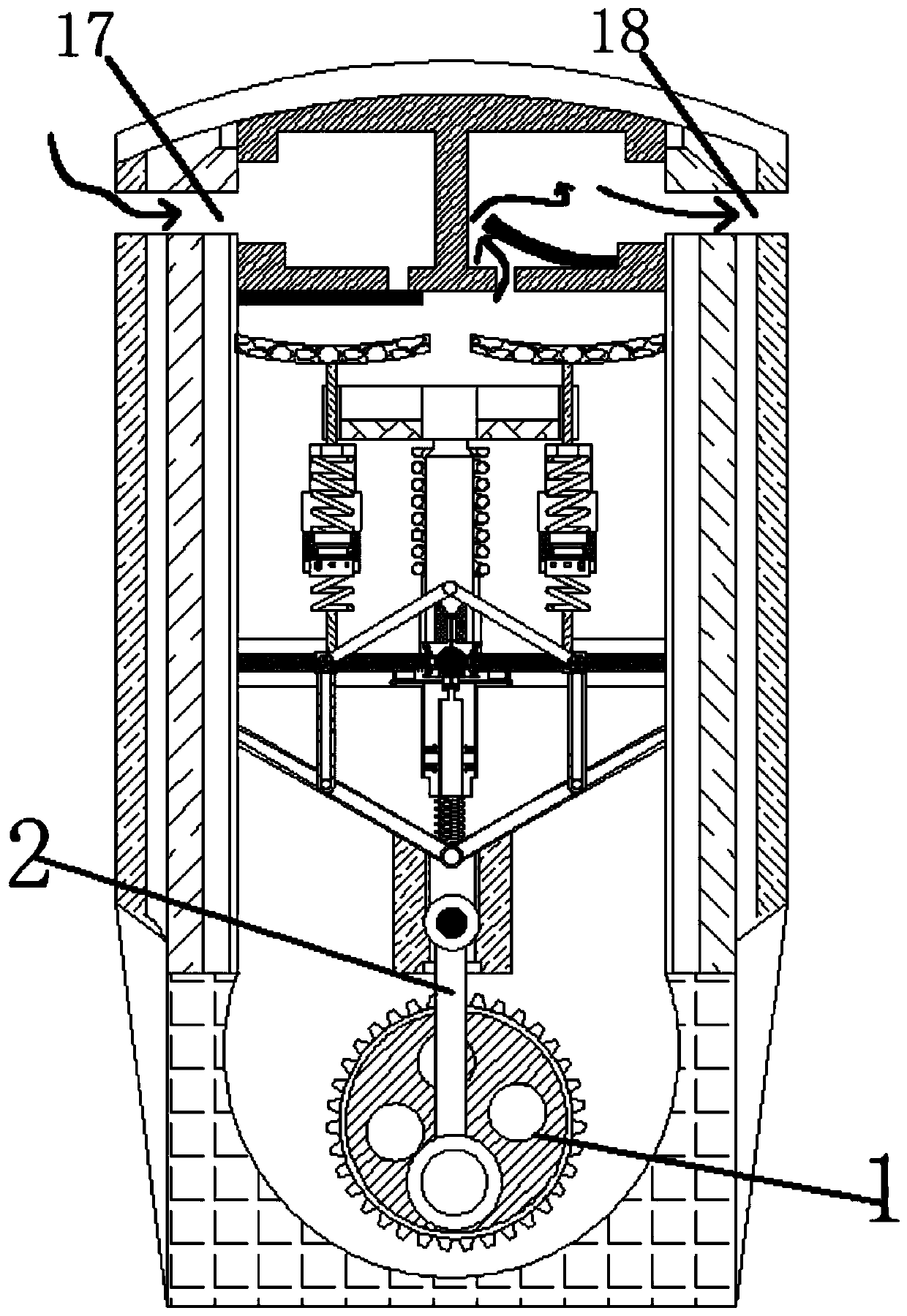

ActiveCN103264755ASolve lubricitySolve the problem of antifoulingFishing vesselsWinding mechanismsHydraulic motorDrive shaft

The invention discloses a three-roller purse seine, which comprises a rack, three roller assemblies and rope arrangement assemblies which respectively correspond to the three roller assemblies. The three roller assemblies are in a step arrangement. Each roller assembly comprises a hydraulic motor, a roller body, a transmission shaft, a brake, a speed reducer and a clutch, wherein the transmission shaft is coaxially arranged in the roller body; the input shaft and the output shaft of the speed reducer are coaxial; the speed reducer and the clutch are respectively arranged at both ends of the interior of the roller body; the brake is arranged between the hydraulic motor and the speed reducer; one end of a shell of the brake is fixedly connected with the rack; the other end of the shell of the brake is fixedly connected with the shell of the speed reducer; the input shaft of the speed reducer passes through the brake to be connected with the output shaft of the hydraulic motor in the manner of transmission; one end of the transmission shaft is connected with the output shaft of the speed reducer in a transmission manner; the other end of the transmission shaft is connected with one end of the clutch in a transmission manner and is supported on the stand in a rolling manner; the other end of the clutch is fixedly connected with the roller body, so that the roller body and the transmission shaft are connected in a separation and union manner; and both ends of the roller body are connected with the rack in a rolling manner. The three-roller purse seine winch disclosed by the invention is compact in structure, stable and reliable in operation and long in service life.

Owner:INI HYDRAULIC

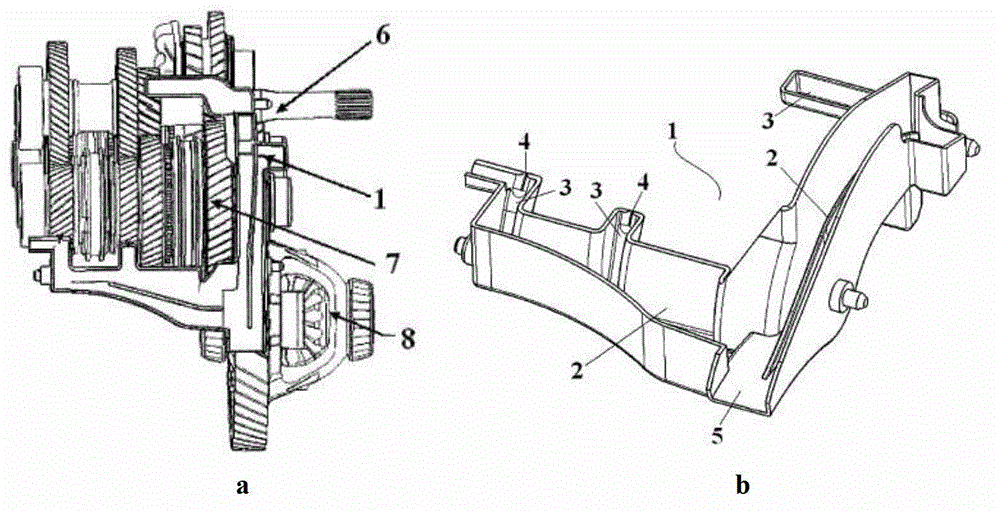

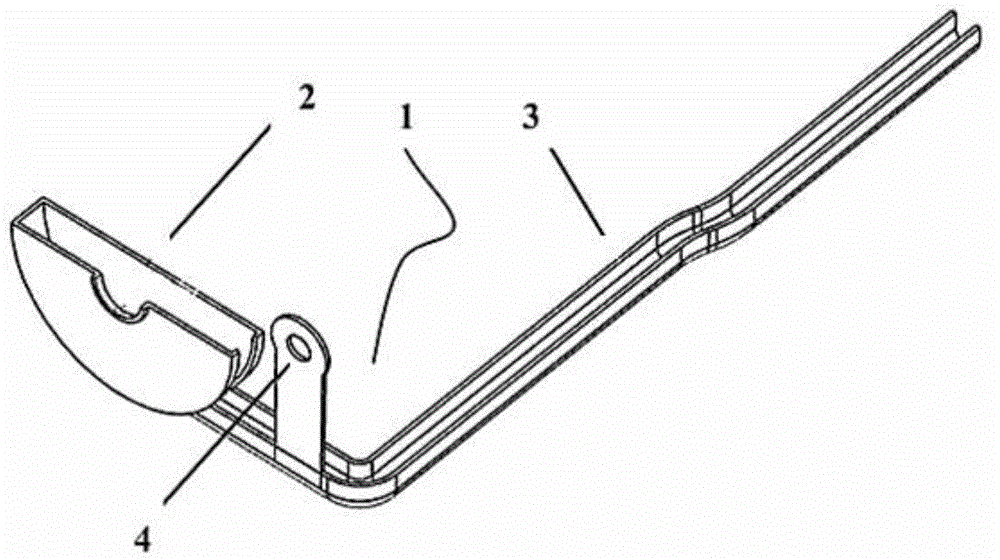

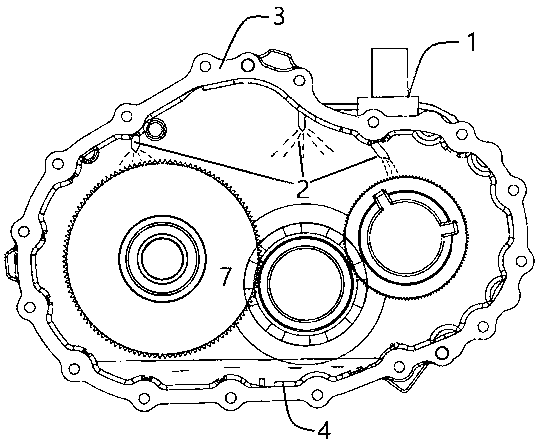

Lubricating mechanism of vehicle transmission case

ActiveCN102943867ASolve lubricityExtended service lifeGear lubrication/coolingLubricationEngineering

The invention relates to a lubricating mechanism of a vehicle transmission case. The lubricating mechanism is arranged in a transmission case and connected with a rear shell of the transmission case. The lubricating mechanism comprises an oil collecting tank, a feeding tank and an installation buckle, wherein the bottom of the oil collecting tank in a semi-opened structure is connected with the bending feeding tank in the semi-opened structure; and the installation buckle is vertically connected with the feeding tank and located on one side of a bending position nearby the oil collecting tank. Through the lubricating oil collecting and distributing functions of the mechanism, all parts required to be lubricated can be satisfactorily lubricated, and the mechanism overcomes the defects of low lubricating efficiency and complex structure of the traditional transmission case, the splash lubricated oil can be collected, the oil in the oil hole of a reverse gear shaft can be collected as well, meanwhile the oil is guided to a bearing lubrication dead zone, thus a bearing can be fully lubricated, the service life of the bearing is prolonged, and the lubricating effect is remarkable.

Owner:SHANGHAI AUTOMOBILE GEAR WORKS

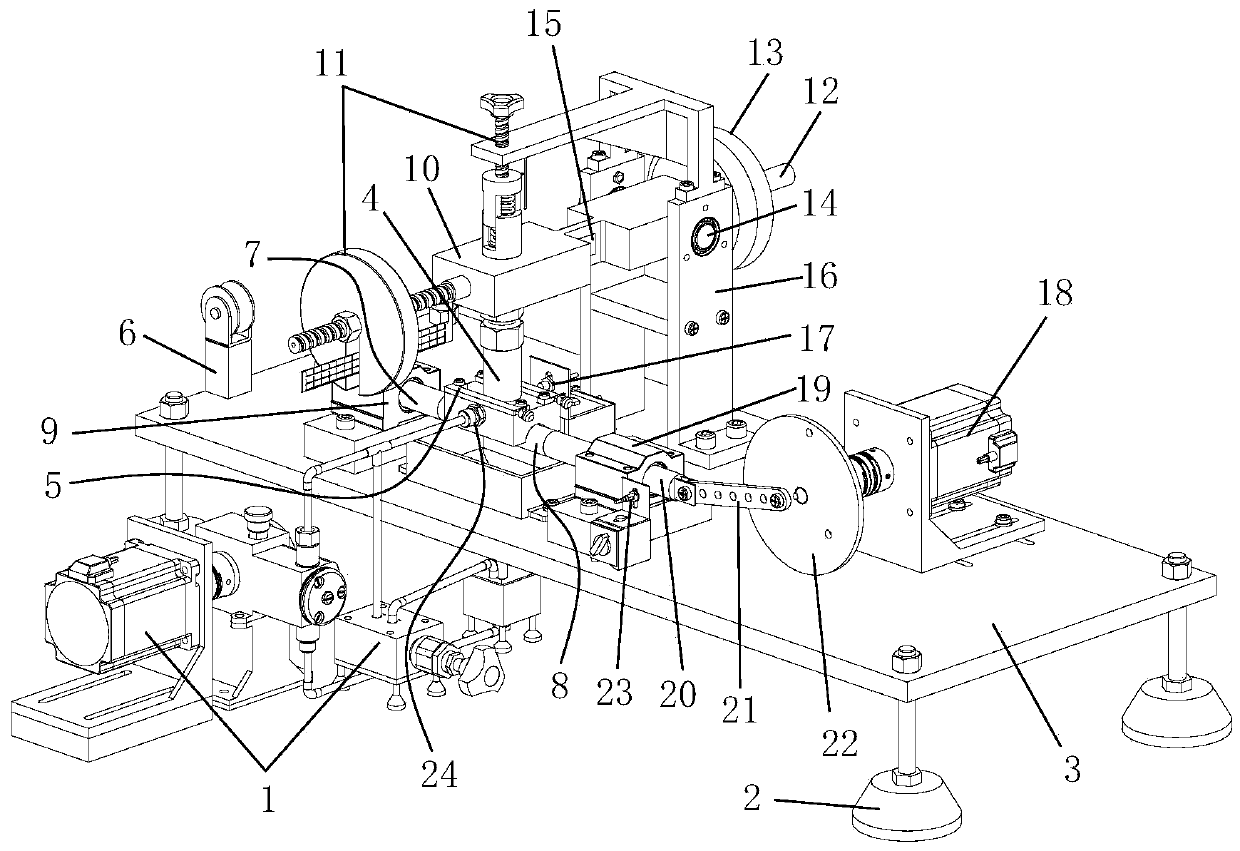

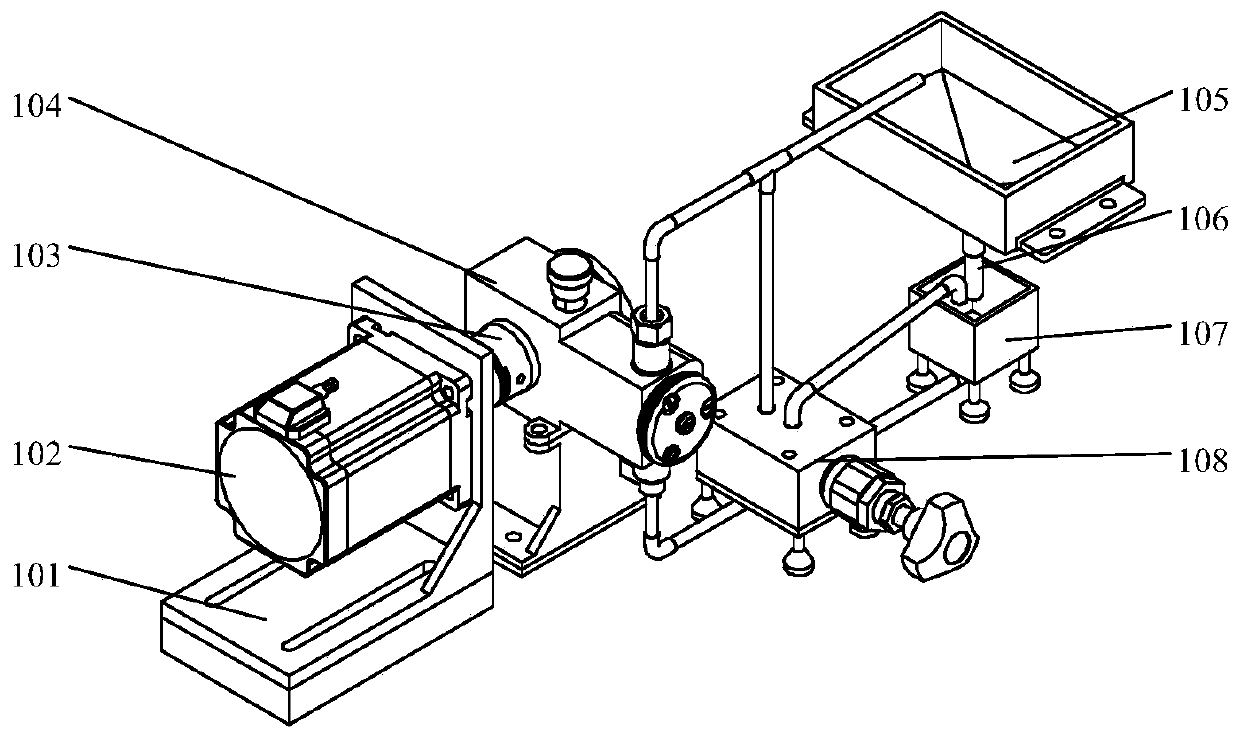

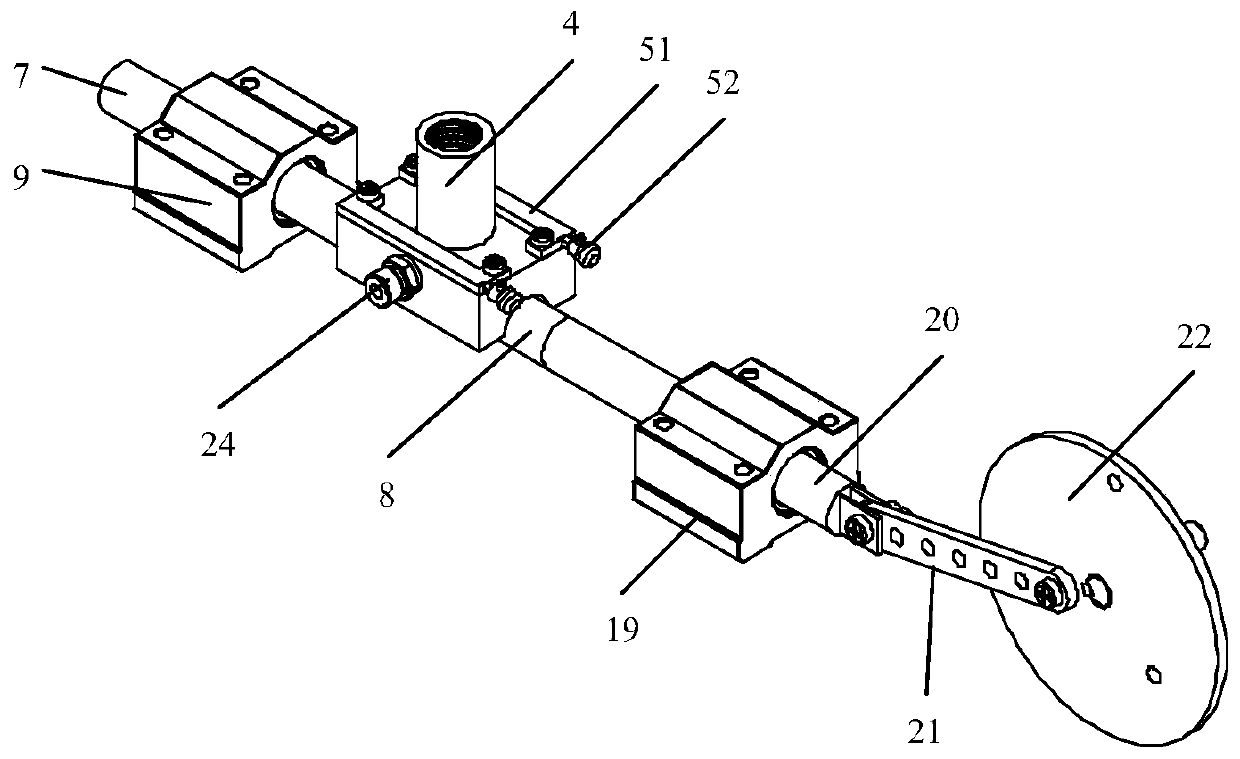

Reciprocating type friction wear testing machine with lubricating and complex force loading system

PendingCN110160906ASolve lubricityResolution statusInvestigating abrasion/wear resistanceWear testingEngineering

The invention discloses a reciprocating type friction wear testing machine with a lubricating and complex force loading system and belongs to the field of design of the friction test machines; the reciprocating type friction wear testing machine comprises a lubricating system, a base support leg, a base, an upper test piece, a heating device, a guide rod I, a lower test piece, a flexible beam, a complex force loading system, a balance weight rod, a balance weight, a rotating shaft, a strain gauge, an L-shaped support, a temperature sensor, a speed regulation motor, a guide rod II, a connectingrod, a crank disc, a speed sensor, a conversion joint and the like. The complex force loading system is arranged on the flexible beam and the L-shaped support, and is composed of a lever weight loading device and a bolt spring loading device; the flexible beam is in threaded connection with the upper test piece, and the upper test piece is connected with the lower test piece through a movable pair, and the friction force is measured through deformation of the flexible beam; and the lubricating system is connected with the inner channel of the upper test piece through a pipeline. According tothe testing machine, large load, high precision loading and friction pair real-time self-lubrication can be realized, and the reciprocating friction performance test of friction pairs in various formscan be achieved.

Owner:ANHUI UNIV OF SCI & TECH

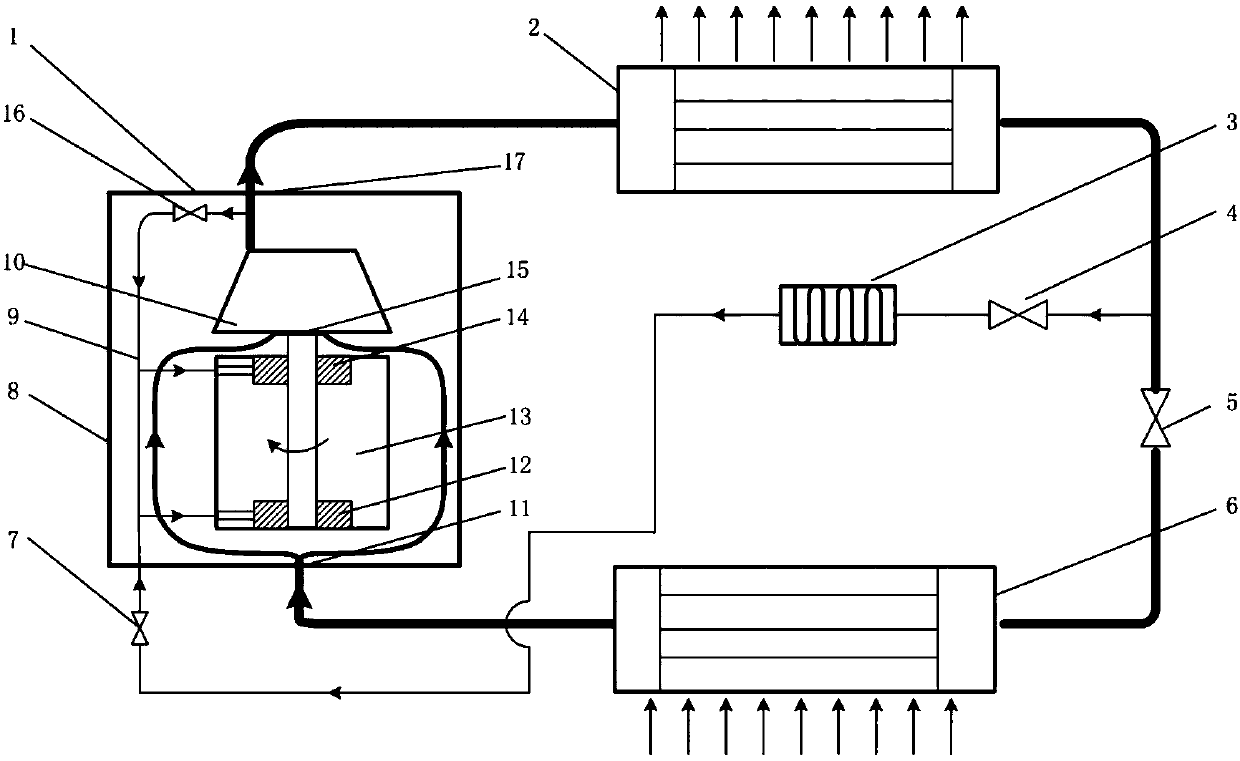

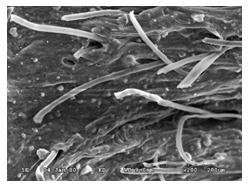

Enclosed type heat pump/refrigeration system achieving self-cooling and self-lubricating

InactiveCN109838940AIncrease superheatSolve the cooling effectCompressorMechanical apparatusAir bearingEngineering

The invention relates to an enclosed type heat pump / refrigeration system achieving self-cooling and self-lubricating. The enclosed type heat pump / refrigeration system mainly includes an air bearing-type centrifugal compressor assembly, a condenser / radiator, a heater, a first expansion valve, a second expansion valve, an evaporator / cold plate, a starting valve, a compressor outlet air entraining opening, an air entraining valve and an air bearing air entraining pipeline. The enclosed heat pump / refrigeration system achieving self-cooling and self-lubricating utilizes an own working medium to realize lubricating and cooling. The enclosed type heat pump / refrigeration system achieving self-cooling and self-lubricating has the characteristics of simple structure, no demand for other cooling working medium and high starting adaptability.

Owner:BEIHANG UNIV

Bionic cartilage material and preparation process thereof

InactiveCN102205145ASolve the mechanical propertiesSolve lubricityProsthesisWater bathsPolyvinyl alcohol

The invention discloses a bionic cartilage material and a preparation process thereof. A mixed material of polyvinyl alcohol, nano hydroxyapatite, silk and deionized water is adopted. The preparation process comprises the following steps of: weighing the polyvinyl alcohol, the nano hydroxyapatite, the silk and the deionized water in percentage by mass, putting the mixed material into a container, and stirring and mixing the mixed material uniformly; placing the container for a certain time at the temperature of 18 DEG C so that the polyvinyl alcohol in the mixture is fully swollen; putting the container in a thermostatic water bath of 95 DEG C, and heating and stirring till the polyvinyl alcohol is fully dissolved; taking the container out of the thermostatic water bath, and stirring and mixing uniformly to obtain polyvinyl alcohol mixture hydrogel; and pouring the obtained polyvinyl alcohol mixture hydrogel into a die, freezing the die in a low-temperature freezer of 20 DEG C below zero, taking out the frozen hydrogel, unfreezing the frozen hydrogel, freezing the unfrozen hydrogel in the low-temperature freezer, unfreezing the frozen hydrogel, and repeating the process for multiple times to obtain the bionic cartilage material. The process is simple; and the material has good bonding property and good mechanical property similar to that of natural cartilage.

Owner:CHINA UNIV OF MINING & TECH

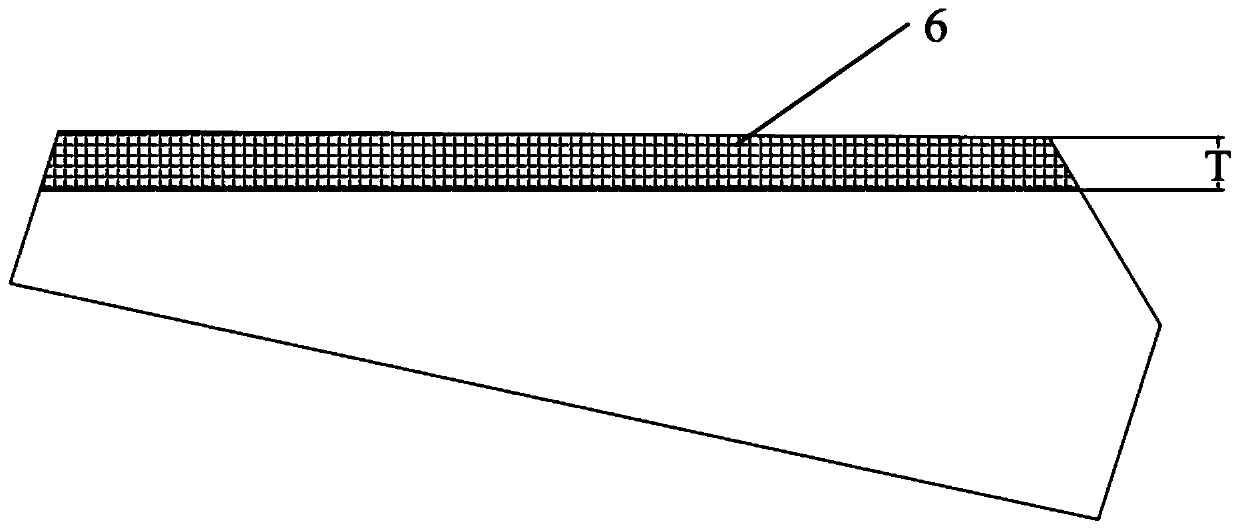

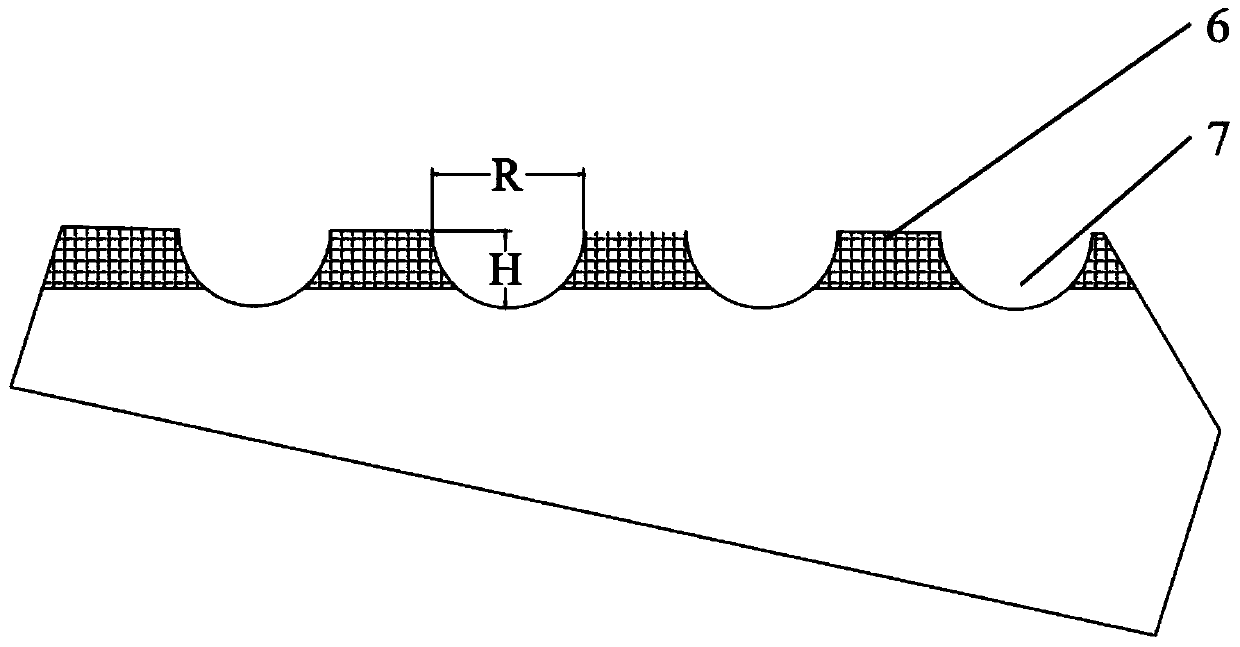

Self-lubricating method of textured coating of gear cold extrusion die

ActiveCN111570554AImprove the anti-wear and anti-friction performance of the surfaceIncrease surface lubricityExtrusion profiling toolsVacuum evaporation coatingGear wheelLubricant

The invention provides a self-lubricating method of a textured coating of a gear cold extrusion die. The method includes the following steps that the coating is deposited, wherein the hard coating isdeposited on the surface of the inner ring of a female die of the cold extrusion die through a PVD technology; the surface is micro-modeled, wherein a micro-texture is prepared on the surface of the hard coating on the inner ring of the female die of the cold extrusion die; a lubricant is prepared, wherein the composite solid lubricant is prepared; and filling of the lubricant is carried out, wherein the surface micro-texture of the hard coating on the inner ring of the female die is filled with the composite solid lubricant. In combination with a surface coating technology, a surface micro-modeling technology, a solid lubricant technology and a lubricant filling technology, the textured coating is prepared on the surface of the gear cold extrusion die for self-lubricating the surface, theanti-wear and friction-reducing performance of the surface of the cold extrusion die is improved, the lubricating effect of the surface of the die is improved, the forming quality is improved, the service life of the die is prolonged, and the problems that in the forming process of the cold extrusion die, the lubricating effect is poor, the die is seriously abraded, and the environment is polluted in a traditional lubricating manner are solved.

Owner:JIANGSU UNIV

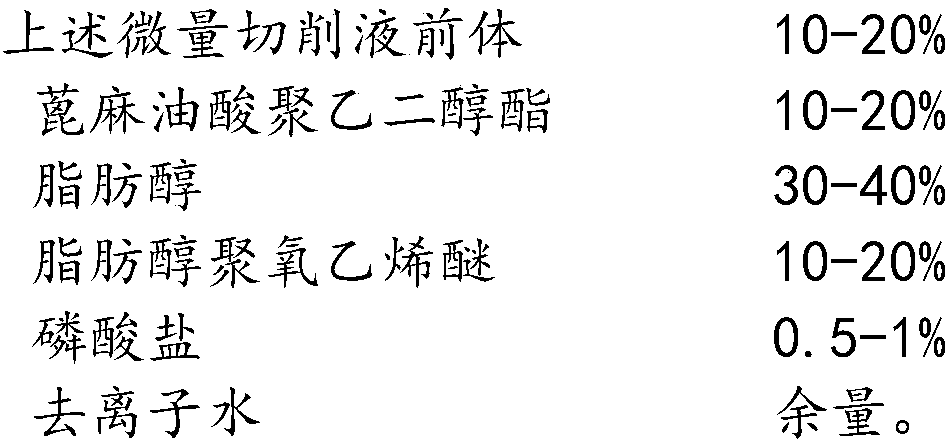

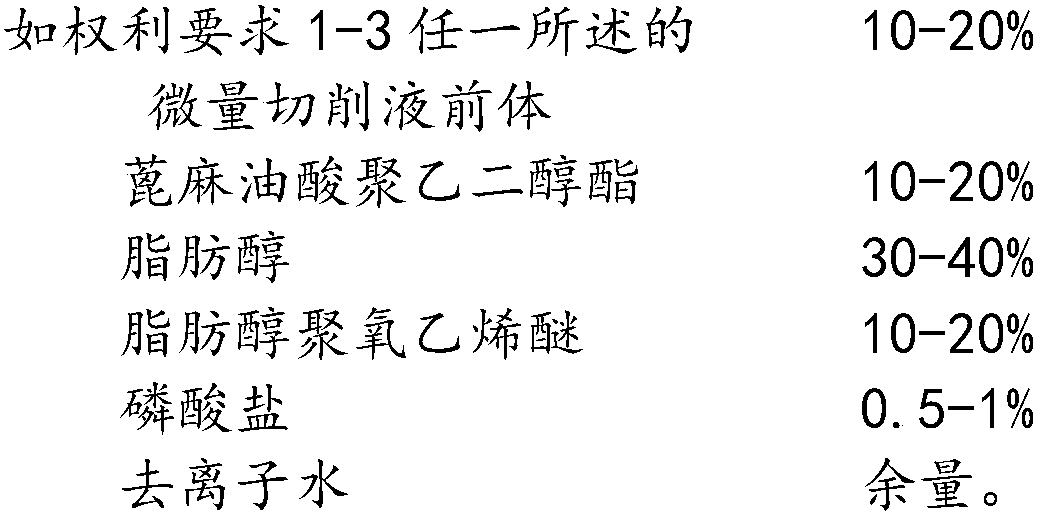

Environmental-friendly trace cutting fluid and preparation method thereof

InactiveCN108300537AGood anti-frictionImprove rust resistanceOrganic compound preparationCarboxylic acid esters preparationPhosphateSulfur

The invention provides a trace cutting fluid which is characterized by being prepared from the following components in percentage by weight: 10-20% of a trace lubricating oil precursor, 10-20% of a ricinoleic acid polyethylene glycol ester, 30-40% of fatty alcohol, 10-20% of fatty alcohol-polyoxyethylene ether, 0.5-1% of phosphate and the balance of deionized water. By adopting the product provided by the invention, the problems of workpiece lubrication and cooling in the processing process can be well solved, in addition, under the condition that no additive with sulfur, chlorine and the likewhich have relatively large burden to environments is added, the oil product provided by the invention is still very good in extreme pressure antiwear property, good in environment protection and capable of effectively prolonging the service life of a cutter.

Owner:SHANGHAI JINZHAO ENERGY SAVING TECH

Preparation method of Ni-Al based low friction and abrasion resistant composite material

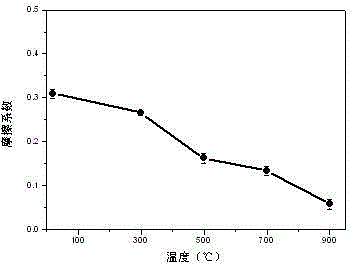

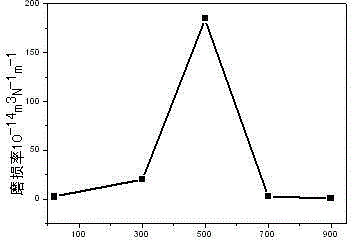

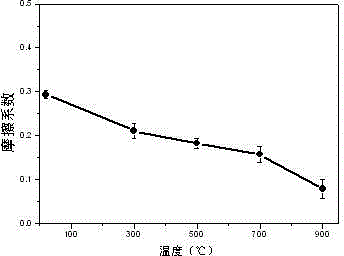

The invention discloses a preparation method of an Ni-Al based wide-temperature range high temperature low friction and abrasion resistant composite material. According to the invention, silver vanadate is added into Ni-Al alloy with good mechanical and high temperature resistant performance, a low temperature lubricating phase AG can be resolved from silver vanadate in a preparation process of the composite material, and during high temperature friction, a high temperature lubricating phase Ag3VO4 is regenerated on the surface, thus realizing wide-temperature range continuous lubrication function. The composite material has continuous and stable lubricating function in a temperature range from room temperature to 900DEG C, and has the characteristics of low friction and low abrasion at a high temperature stage (700-900DEG C), and can be used for solving the problems of lubrication and abrasion resistance between related sliding parts under wide-temperature range, special medium, high speed and other working conditions in high and new technology industries.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

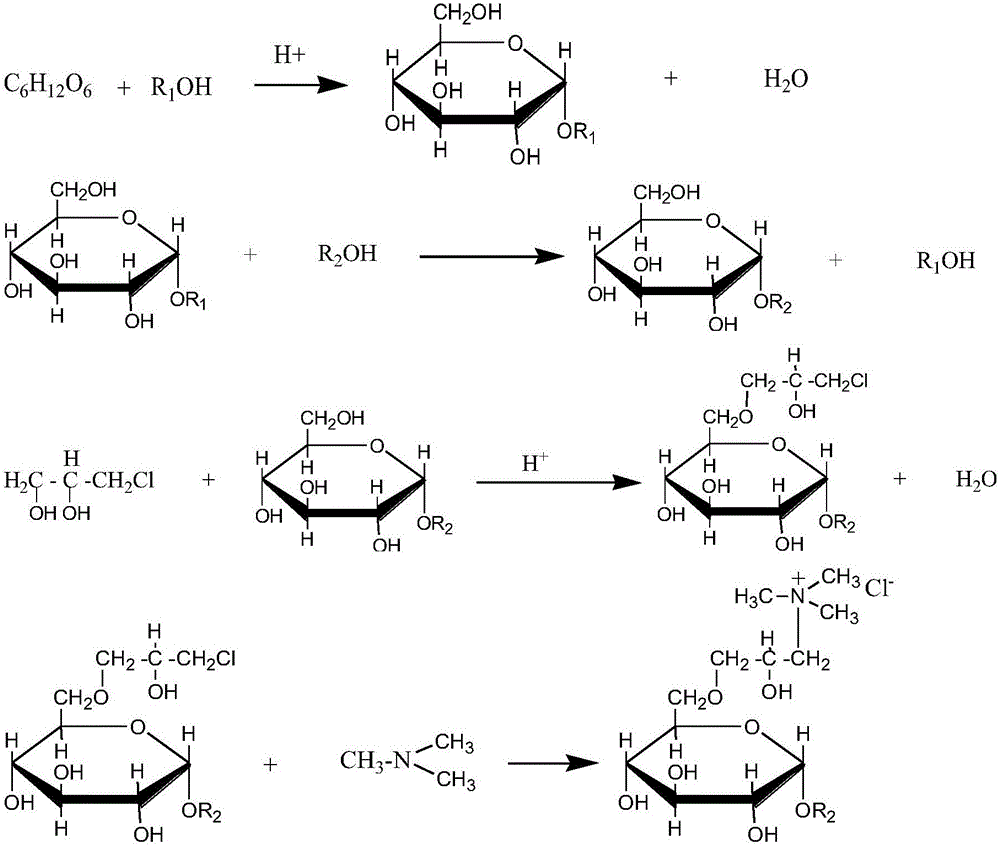

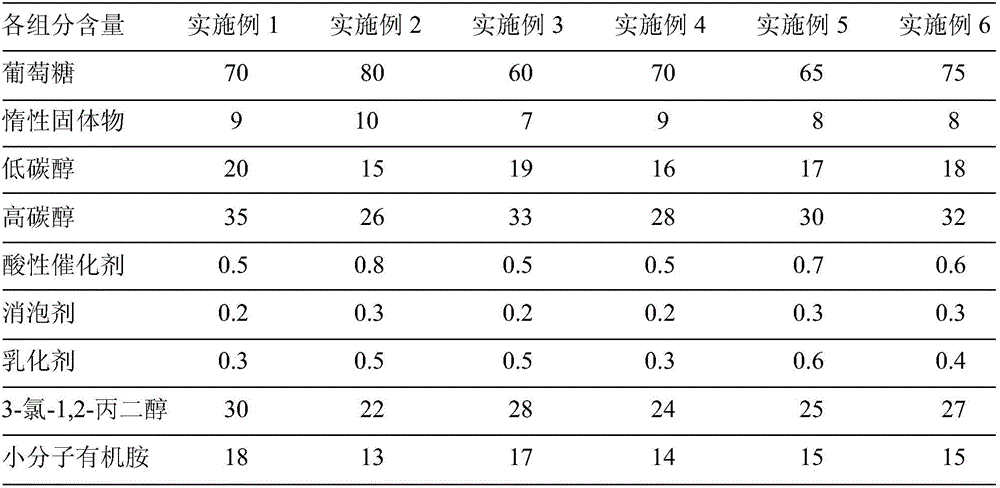

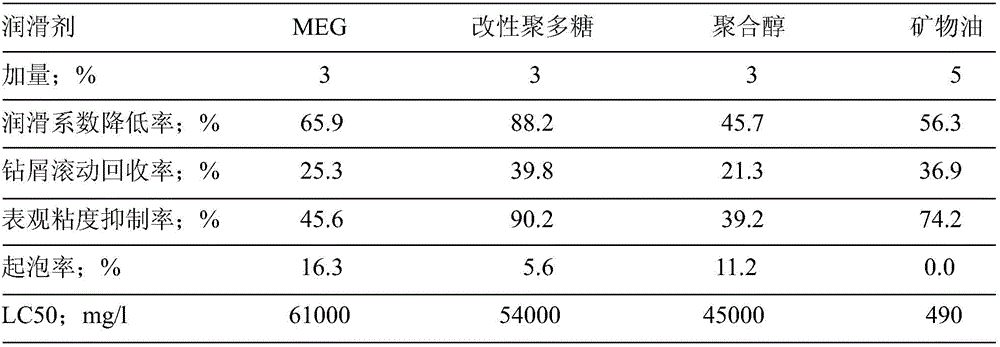

Preparation method of modified polysaccharides lubrication collapse inhibitor

InactiveCN106046068ASimple processImprove product qualitySugar derivativesDrilling compositionReaction temperaturePolysaccharide

The invention discloses a preparation method of a modified polysaccharides lubrication collapse inhibitor. The preparation method comprises the following steps: adding glucose in a reactor, then adding inert solid in the reactor, and mixing and stirring; adding an acid catalyst and lower alcohol, carrying out kneading reaction for 4 hours at the temperature of 80 DEG C, and carrying out suction filtering under reduced pressure; then adding high alcohol in the reactor, meanwhile adding an acid catalyst, a defoamer and an emulsifier, heating until the temperature is above 90 DEG C, controlling reaction temperature to be 90-100 DEG C and reaction time to be 3-5 hours, and carrying out suction filtering under reduced pressure; adding 3-chloro-1,2-propylene glycol in the reactor, controlling reaction temperature to be 90-110 DEG C and reaction time to be 3-6 hours, carrying out suction filtering under reduced pressure, and circulating water to reduce the temperature of the reactor to be 60-70 DEG C; adding organic amine as small molecules in the reactor, reacting for 3-5 hours at the temperature of 70-80 DEG C, and carrying out suction filtering under reduced pressure; and heating until the temperature reaches 120-140 DEG C. The preparation method disclosed by the invention is simple in process, stable in product quality and high in collapse inhibition; the problem that environmental pollution is always prevented by an oil lubricant in site can be solved.

Owner:YANGTZE UNIVERSITY

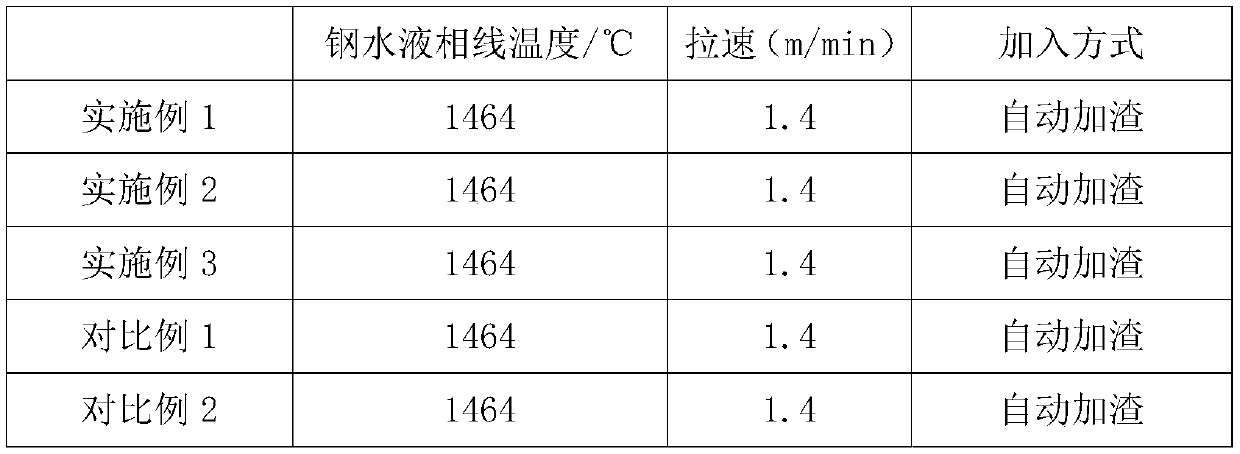

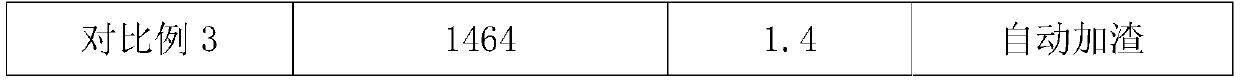

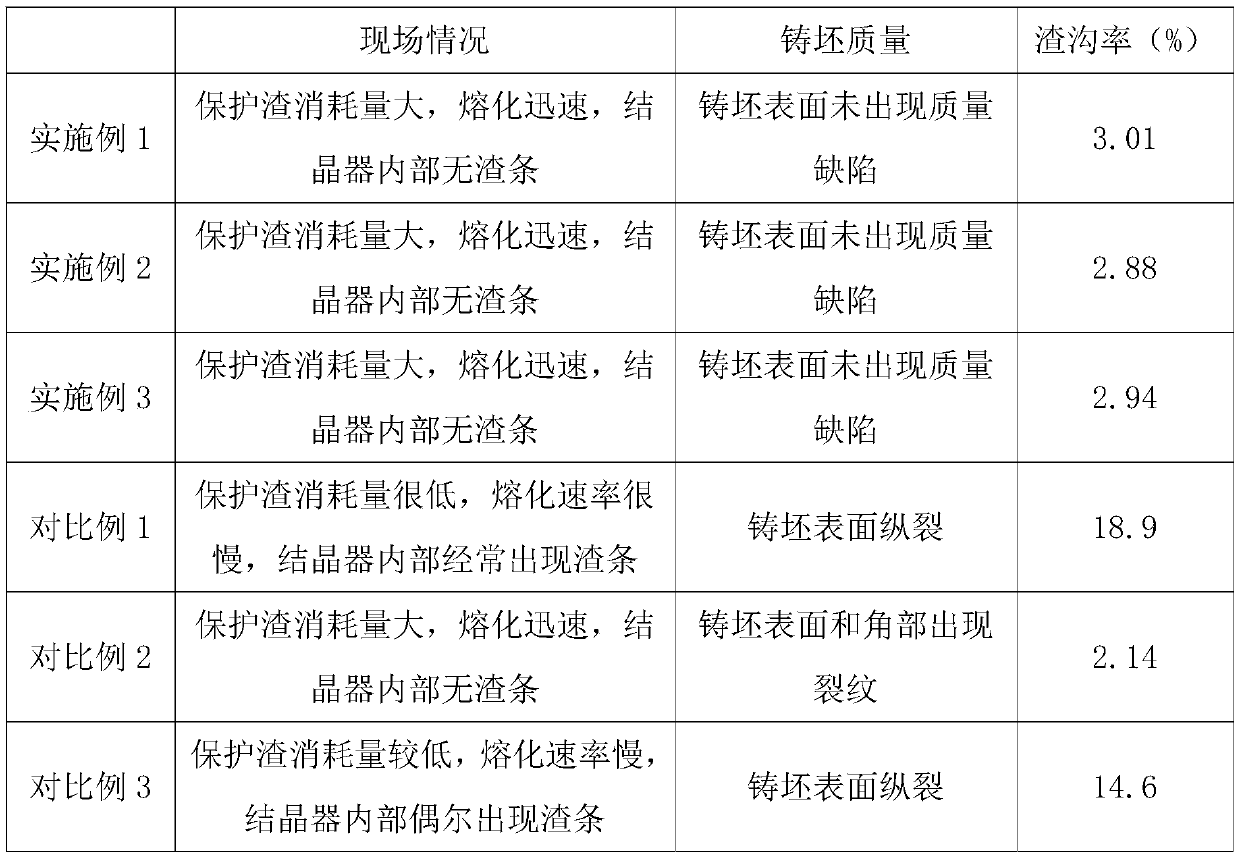

Continuous casting crystallizer protecting slag for medium-high carbon steel

The invention provides continuous casting crystallizer protecting slag for medium-high carbon steel. The continuous casting crystallizer protecting slag comprises, by mass percentage, 20.2-26.2% of CaO, 25.3-31.3% of SiO2, 1.1-2.7% of Al2O3, 5.5-8.3% of MgO, 7.4-12.2% of F, 9.5-14.1% of Na2O and 13.5-16.5% of C. Compared with the prior art, by designing the formula of the protecting slag, the problem that during practical use, lubrication of the protecting slag contradicts with heat transfer is solved, and thus the problem that currently, surface defects such as slag troughs and cracks frequently occur in medium-high carbon steel is solved. In the meanwhile, the yield of rolled products is increased, and the benefit of enterprise brands is increased.

Owner:WUHU XINXING DUCTILE IRON PIPES

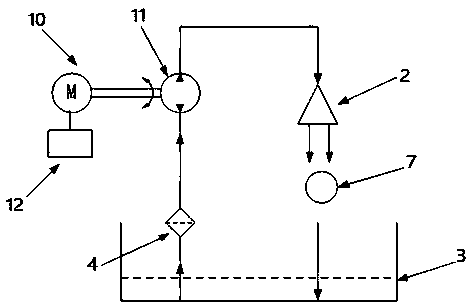

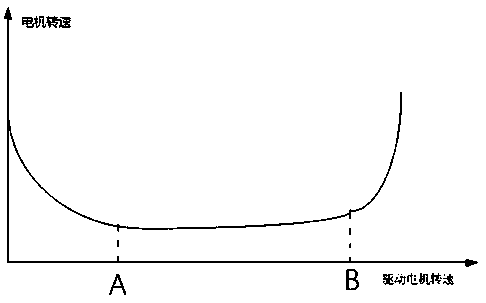

Method for actively lubricating reduction gearbox

The invention discloses a method for actively lubricating a reduction gearbox. The method for actively lubricating the reduction gearbox is characterized by being based on an electronic oil pump; theelectronic oil pump comprises a motor, a gear pump and a controller; the motor is connected with the gear pump; the controller is respectively connected with the motor and an automobile CAN bus, obtains the rotating speed of a driving motor through the CAN bus, and controls the rotating speed of the motor; and the motor controls the gear pump to inject oil through oil nozzles connected with the gear pump. By adopting the active lubricating mode, the problem that the lubricating effects are not ideal when the reduction gearbox runs at low speed and at ultra-high speed is solved, the reliabilityand durability of the reduction gearbox can be effectively improved, and the service life of the reduction gearbox is prolonged; meanwhile, the filling amount of the lubricating oil of the reductiongearbox can be reduced, so that the cost of a user is saved; and the lubricating oil can be directly and accurately injected to gears and gear shafts needing to be lubricated through the oil nozzles,so that the design difficulty is reduced without repeatedly modifying the design according to the positions of oil guide ribs.

Owner:ZHUZHOU GEAR CO LTD

Preparation method of ultrathin nanometer ion liquid lubricating film

InactiveCN101735883AImprove friction and wear propertiesImprove tribological propertiesLubricant compositionDip-coatingTotal thickness

The invention discloses a preparation method of an ultrathin nanometer ion liquid lubricating film. The lubricating film is prepared by a dip coating method, and the total thickness of a thin film is 2-5nm. The invention can be applied to fields of micro / nano electromechanical systems, magnetic recording systems and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation for treating angiocardiopathy and its preparation method

InactiveCN100998835AIncrease surface areaHas a wetting effectPharmaceutical product form changePill deliveryDiseaseVascular disease

Owner:SHANDONG TAITIAN NEW MEDICINE DEV

Bearing box and application thereof

ActiveCN103982554ADifficult to leakImprove sealingBearing unit rigid supportScrew threadTapered roller bearing

The invention relates to a bearing box and application thereof. The bearing box comprises a box body which comprises a box body inner ring and a box body outer ring, wherein the box body inner ring and the box body outer ring are respectively in a cylindrical shape of which both ends are open, the box body inner ring is arranged in the box body outer ring, taper roller bearings are arranged on both ends of the box body and between the box body inner ring and the box body outer ring, sealing devices are arranged on the outer sides of the taper roller bearings, adjusting nuts are arranged on the outer sides of the sealing devices, screw threads are formed on the inner walls of the adjusting nuts, other screw threads are formed on the outer wall of the box body inner ring, the adjusting nuts are connected with the box body inner ring through the screw threads, and the taper roller bearings comprise bearing outer rings and bearing inner rings. The invention further discloses the application of the bearing box to an automobile steering knuckle. The bearing box has the advantages that the sealing performance is good, lubricating oil is unlikely to leak and can be gear oil, and the bearing box can be repeatedly used, is less prone to damage, can be conveniently removed and installed and easily steered, and does not need to be maintained for years.

Owner:吴银辉

Air compressor for compressing air and improving air pressure

ActiveCN111271255AIncrease gas pressureAvoid wastingPositive displacement pump componentsPositive-displacement liquid enginesOil canGear wheel

The invention relates to the technical field of air compressors, and discloses an air compressor for compressing air and improving air pressure. The air compressor comprises a driving gear, a connecting rod is movably connected above the driving gear, a driving rod is movably mounted above the connecting rod, a pressing spring is movably mounted above a moving cross rod II, a pressing plate is movably connected to the upper portion of the pressing spring, a threaded rod is movably connected into the movable bearing, abutting rubber is movably connected to the left side of the threaded rod, anoil bag is movably connected to the left side of the abutting rubber, and an oil outlet pipe is movably connected to the upper portion of the oil bag. According to the air compressor for compressing the air and improving the air pressure, through the arrangement of the oil bag, the interior of the device can be lubricated without cut-off, the oil bag has resettability, redundant lubricating oil can be adsorbed again to be used next time, and the problems that lubricating oil filling of a traditional air compressor is troublesome, and continuous lubricating cannot be achieved are solved.

Owner:湖南诚跃新能源有限公司

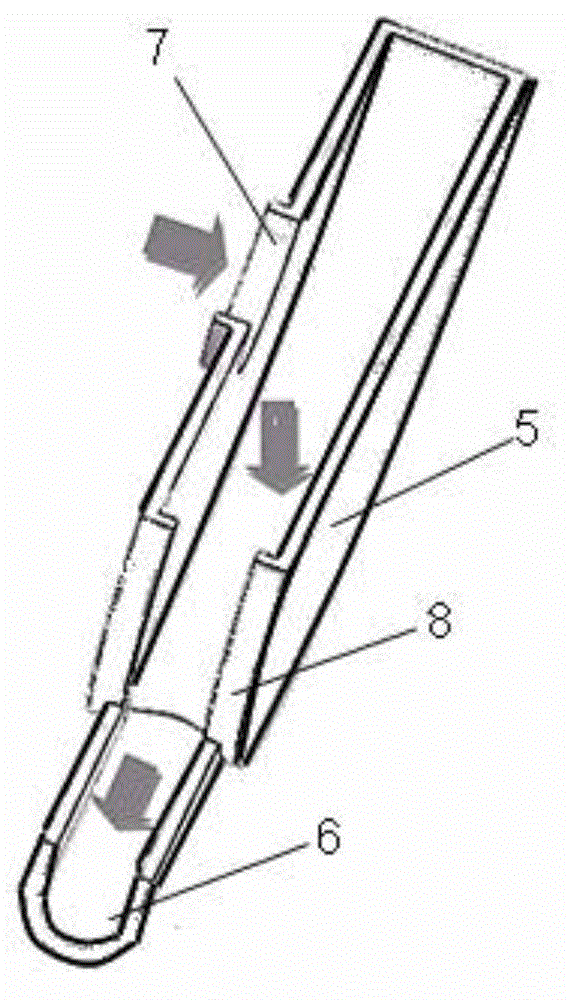

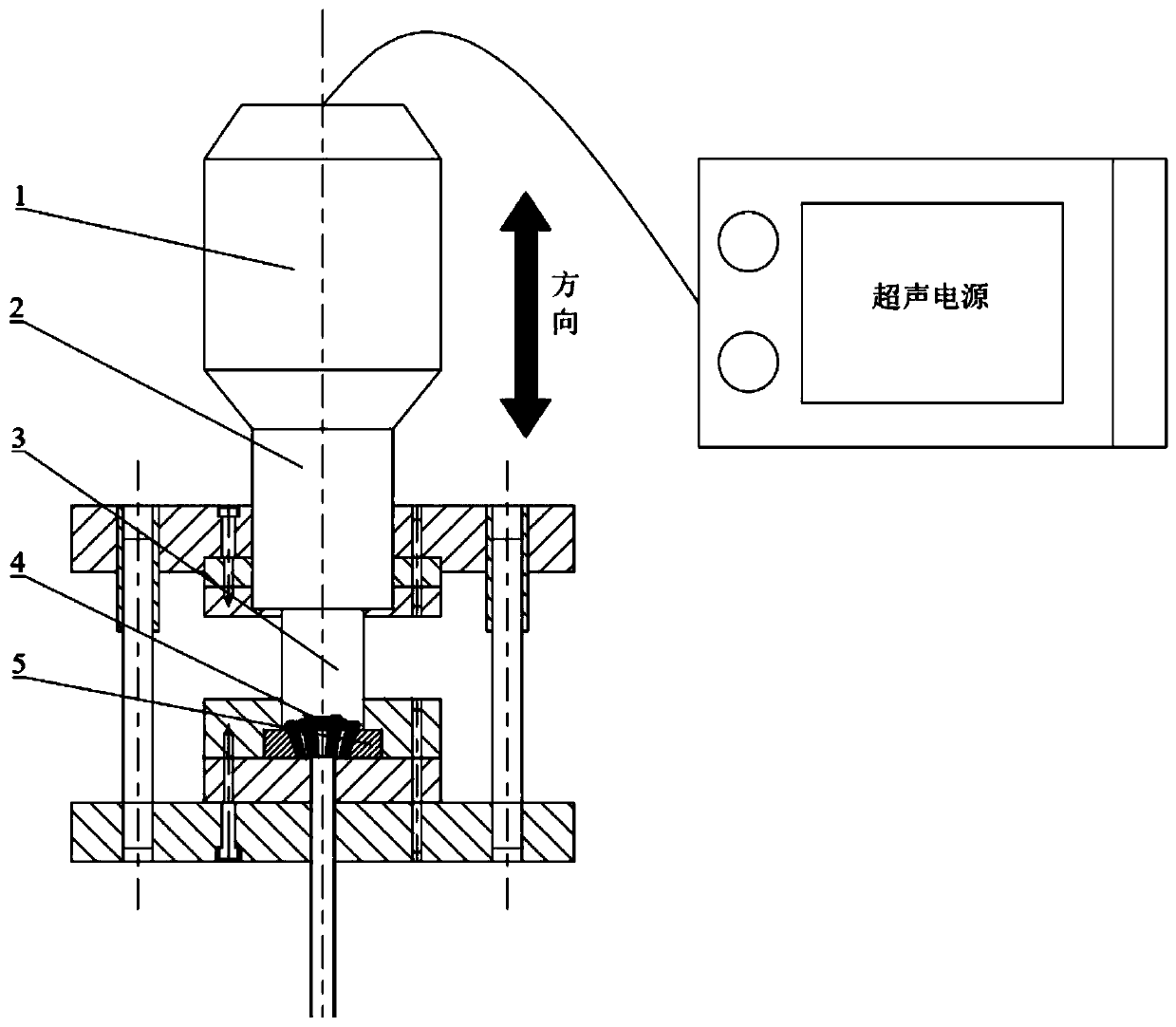

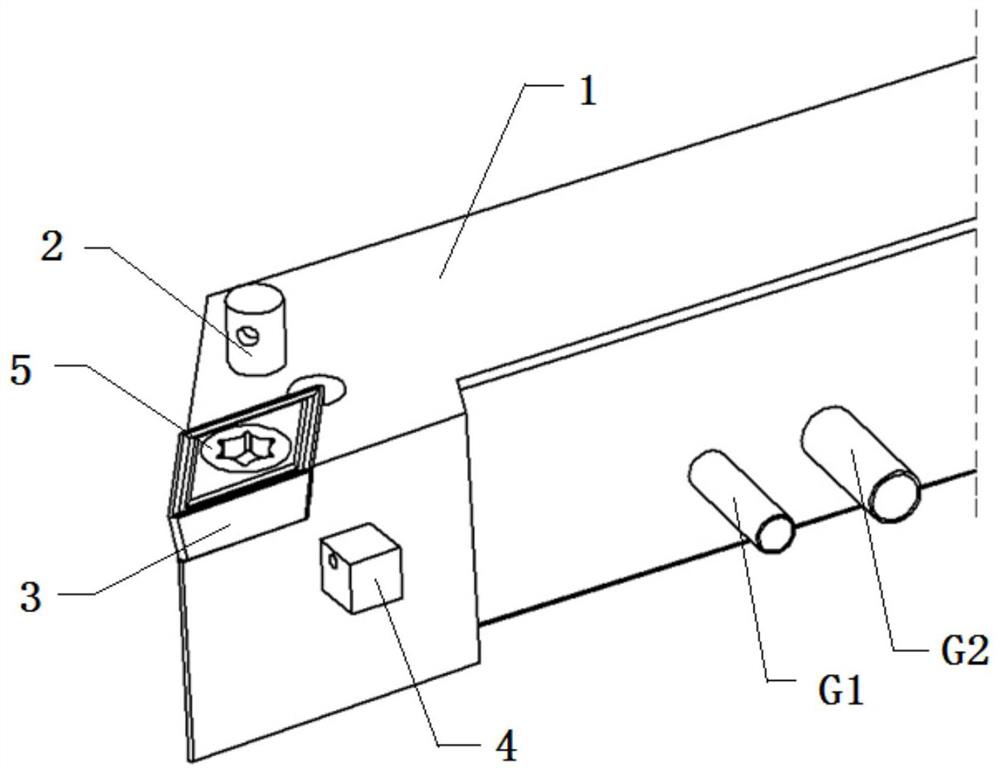

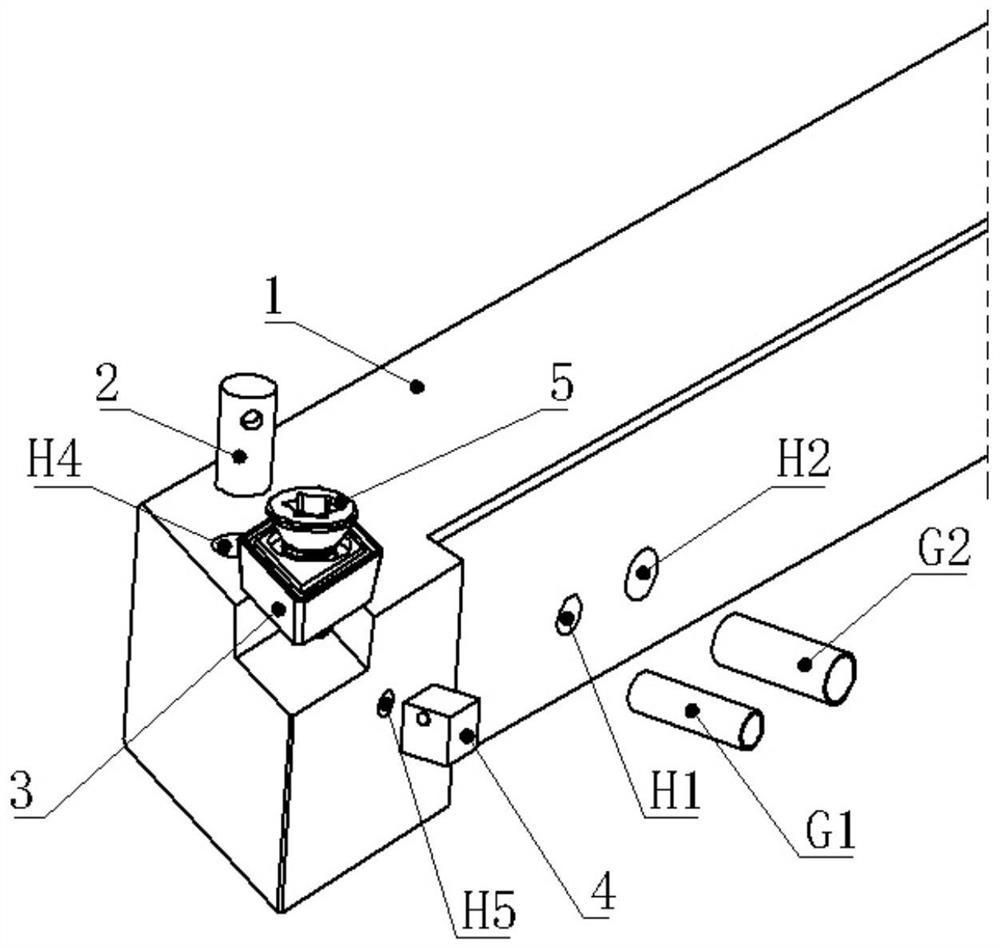

Minimal quantity lubrication cutter and lubrication method thereof

PendingCN111618323AAvoid troubleSimple and fast operationTurning toolsMaintainance and safety accessoriesEngineeringKnife blades

The invention relates to the technical field of minimum quantity lubrication, and discloses a minimum quantity lubrication cutter. The cutter comprises a cutter body, wherein a mixing channel used forintroducing a minimum quantity lubrication medium and high-pressure air and mixing and vaporizing the minimum quantity lubrication medium and the high-pressure air to form minimum quantity lubrication mixed gas, a first pipeline used for allowing the minimum quantity lubrication medium to enter, a second pipeline used for allowing high-pressure air to enter, and an outflow channel used for allowing the minimum quantity lubrication mixed gas to flow out are arranged in the cutter body, the first pipeline and the second pipeline communicate with the mixing channel, the outflow channel communicates with the mixing channel, a blade for cutting is arranged on the cutter body, the outflow channel comprises a fourth channel and a fifth channel which are located on the two sides of the blade, a first guide column for connecting and guiding the fourth channel is arranged on the cutter body, and a second guide column for connecting and guiding the fifth channel is arranged on the cutter body. The invention further discloses a lubrication method of the minimum quantity lubrication cutter. The problem that a cooling site is inaccurate is effectively solved.

Owner:CHENGDU TOOL RES INST

Cooling fan with hydraulic motor mounting support

InactiveCN103277325ASolve the installation locationHigh strengthEngine cooling apparatusPump installationsHydraulic motorImpeller

A cooling fan with a hydraulic motor mounting support is composed of a fixed impeller assembly and a movable impeller assembly. The fixed impeller assembly comprises a fixed ring, a fixed impeller, a cover plate and a locking screw. The movable impeller assembly comprises a support, a movable impeller, a bearing cap, a framework oil seal, an O-shaped sealing ring, a fastening nut, a lock washer, a flat washer, a support sleeve, a lubricating nozzle, a fan shaft, two rolling bearings, an elastic collar, a breather plug, a bearing limit bush and a bolt, wherein the lubricating nozzle is sleeved with another flat washer, and the bolt is sleeved with a spring washer. During mounting the fixed impeller assembly and the movable impeller assembly, an annular mouth on an inner edge end face of a support hub of the movable impeller assembly is fastened into a step hole on the fixed ring of the fixed impeller assembly, and the movable impeller assembly and the fixed impeller assembly are integrally connected through the bolt. The cooling fan is of front-loaded fixed impeller and movable impeller structure, and the hydraulic motor is mounted on the movable impeller assembly to drive the movable impeller to rotate.

Owner:HUNAN TYEN MACHINERY

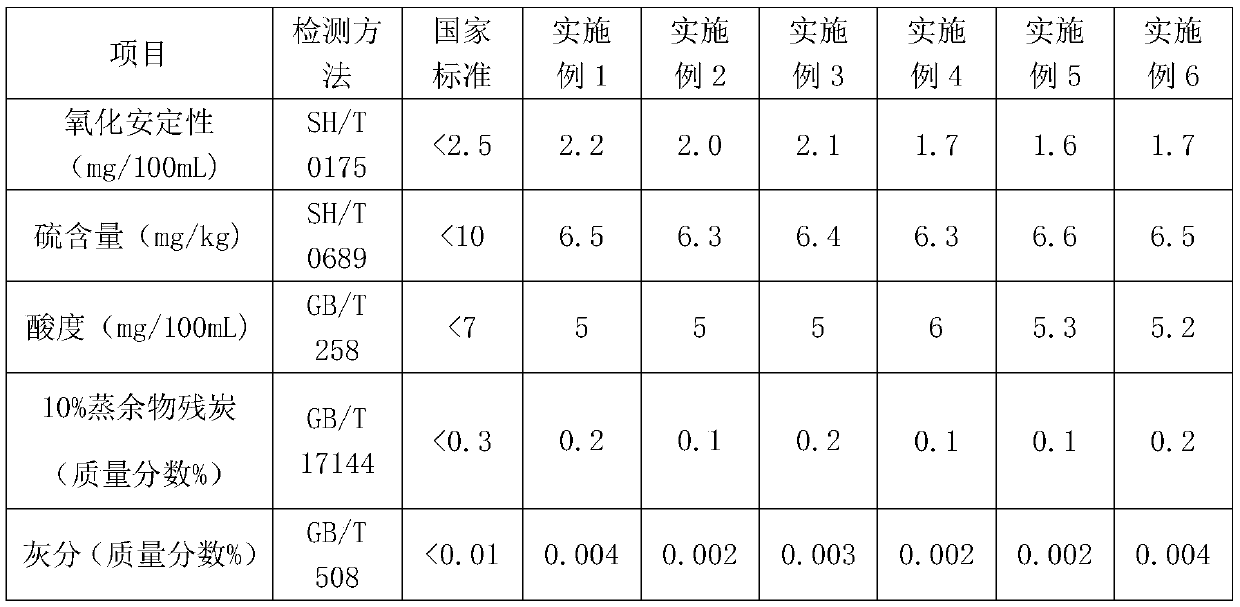

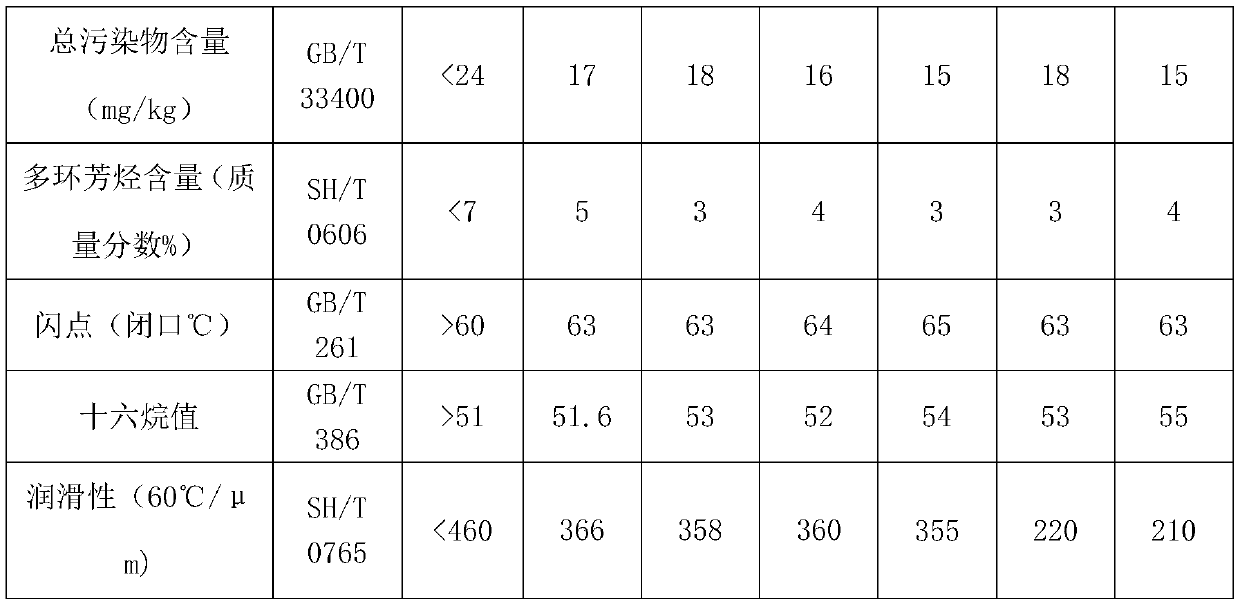

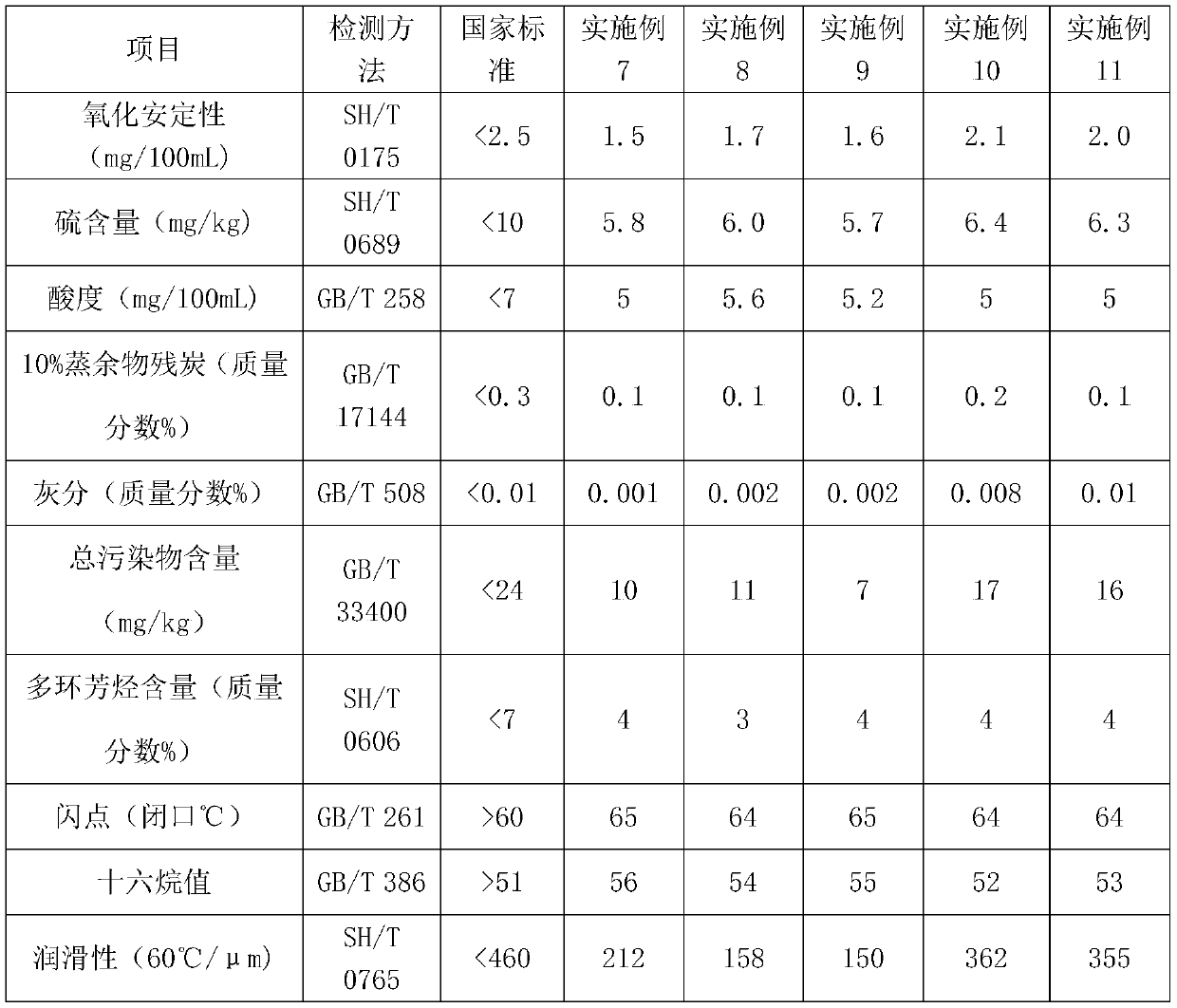

High-cleanness diesel fuel

InactiveCN110616093AImprove performanceEmission reductionLiquid carbonaceous fuelsFuel additivesWaxGasoline fuel

The invention belongs to the technical field of clean fuel, and particularly relates to high-cleanness diesel fuel which is mainly prepared from the following raw materials in parts by weight: 5-45 parts of coal-based Fischer-Tropsch synthesis liquid wax, 10-40 parts of No.3 jet fuel, 20-75 parts of a coal diesel fraction and 5-45 parts of a composite additive. The high-cleanness gasoline fuel hasthe advantages of improved fuel performance, reduced emission and fuel saving.

Owner:刘明波

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com