Bionic cartilage material and preparation process thereof

A preparation process and cartilage technology, applied in the field of biomedical materials or biocomposite materials, can solve the problems of no biological activity, poor binding performance, affecting cartilage fixation and repair function, etc., achieving good buffering effect, reducing friction and wear, The effect of resolving conflicts between mechanical properties and lubricating properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

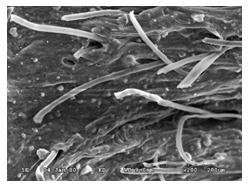

[0017] Embodiment 1, shred silk to a length less than 2mm, and put it in a sealed bag for subsequent use; weigh polyvinyl alcohol 11%, shred silk 0.1% to a length less than 2mm, nano-hydroxyapatite 4%, and 84.9% deionized water, put in a container and stir to mix evenly. After the mixed liquid in the container is still, mark the initial liquid level height of the mixture on the container, and then place the container at a temperature of 18°C for 12 hours to make the liquid in the mixture The polyvinyl alcohol is fully swollen; then the container is placed in a constant temperature water bath with a temperature of 95°C, and stirred while heating until the polyvinyl alcohol is completely dissolved; the container is taken out of the constant temperature water bath, due to the temperature in the evaporation process Part of the water is volatilized. At this time, add deionized water to the container until the liquid level reaches the height of the initial liquid level, and stir to...

Embodiment 2

[0018] Embodiment 2: Shred silk to a length less than 2mm, and put it in a sealed bag for subsequent use; weigh polyvinyl alcohol 17%, shredded silk 0.6%, nano-hydroxyapatite 0.1%, and deionized water 82.3% by mass percentage %, placed in the container and stirred evenly; after the mixed liquid in the container is still, mark the initial liquid level height of the mixture on the container, and then place the container at a temperature of 18°C for 12 hours to make the polyvinyl alcohol in the mixture Fully swell; place the container in a constant temperature water bath at a temperature of 95°C, heat and stir until the polyvinyl alcohol is completely dissolved; take the container out of the constant temperature water bath, and add deionized water to the container until the liquid level reaches the initial liquid level , stir and mix evenly, oscillate ultrasonically for 2 hours, and discharge the air bubbles in the mixture to obtain a polyvinyl alcohol mixture hydrogel; pour the...

Embodiment 3

[0019] Embodiment 3: Shred silk to a length less than 2mm, and put it in a sealed bag for subsequent use; weigh 15.0% polyvinyl alcohol, 1% shredded silk, 2% nano-hydroxyapatite, and 82% deionized water by mass percentage %, placed in the container and stirred evenly; after the mixed liquid in the container is still, mark the initial liquid level height of the mixture on the container, and then place the container at a temperature of 18°C for 12 hours to make the polyvinyl alcohol in the mixture Fully swell; place the container in a constant temperature water bath at 95°C, heat and stir until the polyvinyl alcohol is completely dissolved; take the container out of the constant temperature water bath, add deionized water to the container until the liquid level reaches the initial liquid level, Stir and mix evenly, ultrasonically oscillate for 2 hours, and discharge the air bubbles in the mixture to obtain a polyvinyl alcohol mixture hydrogel; pour the polyvinyl alcohol mixture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com