High thermal conductivity polyimide film and preparation method thereof

A technology of polyimide film and polyimide resin, which is applied in the field of high thermal conductivity polyimide film and its preparation, can solve the problem that it is difficult to build high-efficiency heat conduction channels, and the mechanical properties and thermal conductivity of polyimide films are incompatible To solve such problems as achieving good thermal conductivity, good mechanical properties and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

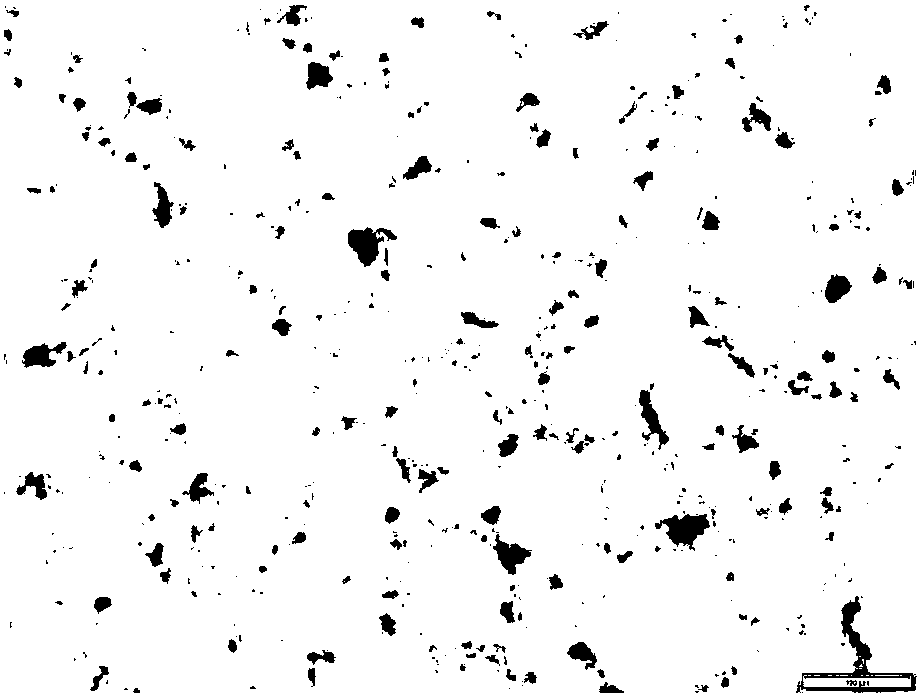

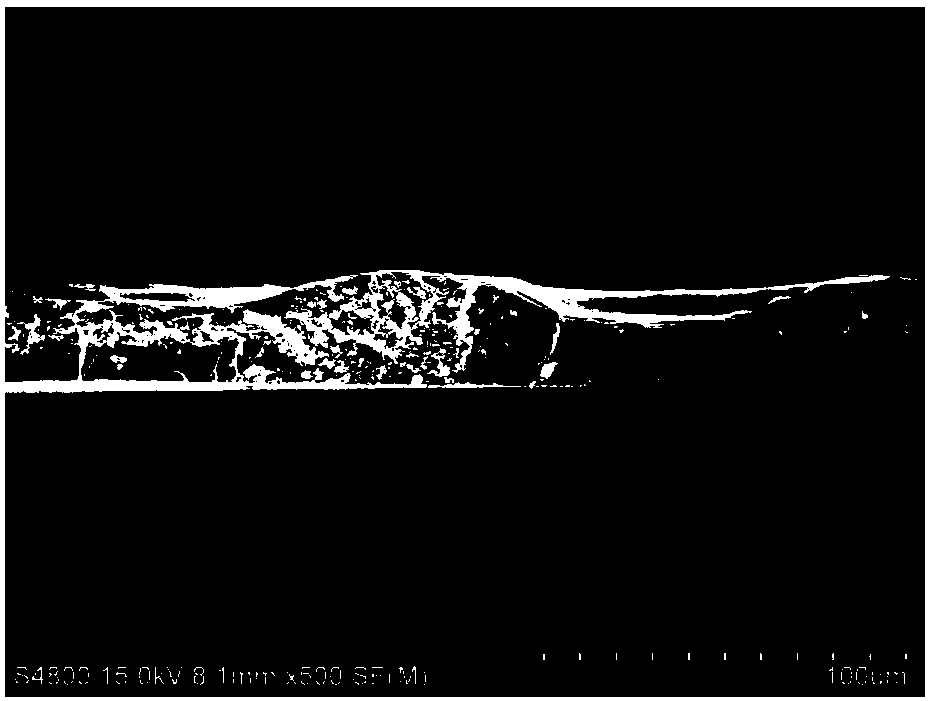

Image

Examples

preparation example Construction

[0041] On the other hand, the present invention also provides a kind of preparation method of high thermal conductivity polyimide film, and this preparation method comprises the following steps:

[0042] Step 1: Disperse the thermally conductive filler in an organic solvent to form a dispersion; mix the above dispersion with the amine reactive monomer of polyamic acid resin A, stir at room temperature for 8-12 hours until completely dissolved, and add polyamic acid resin A The acid anhydride reaction monomer is stirred to form a solution of thermally conductive filler doped polyamic acid resin A;

[0043] Mix the reactive monomers of polyamic acid resin B with an organic solvent, and stir at room temperature for 8-12h to form a solution of polyamic acid resin B;

[0044] Step 2: Mix the solution of thermally conductive filler doped with polyamic acid resin A and the solution of polyamic acid resin B, and stir at room temperature for 0.5-1 h to obtain a mixed solution;

[0045...

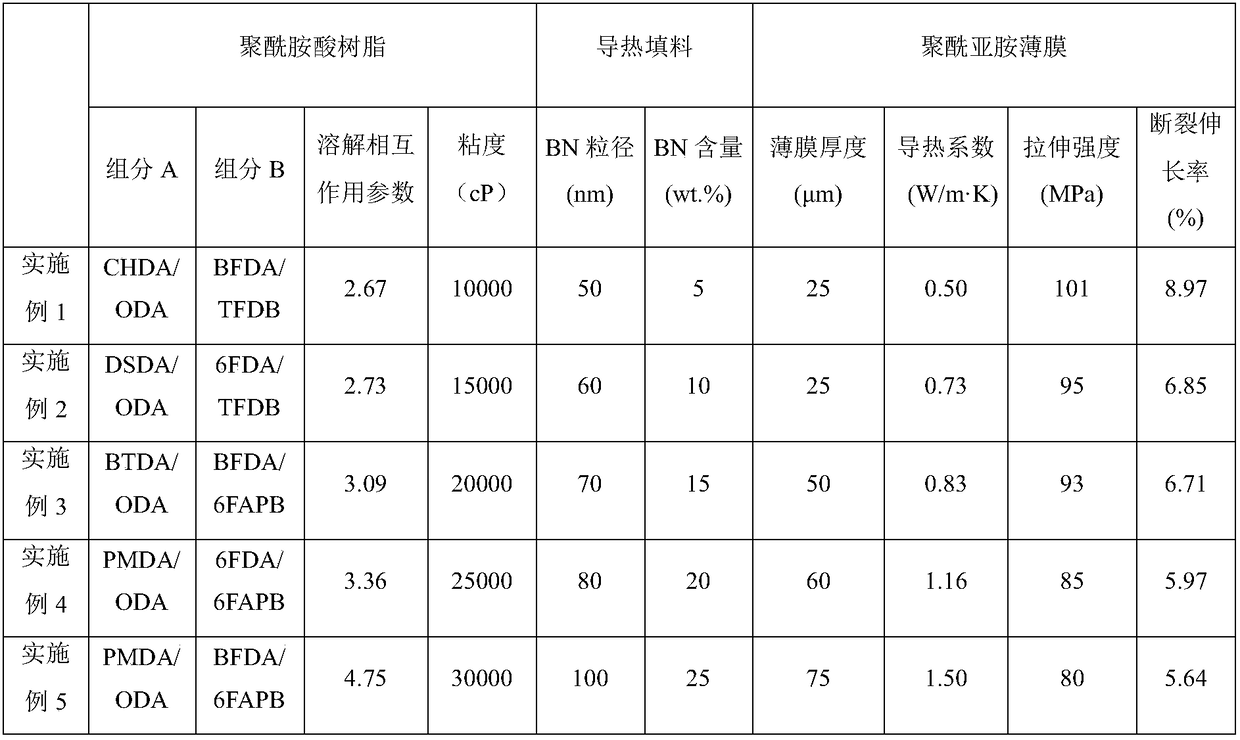

Embodiment 1

[0053] First, 1 gram of boron nitride with a particle size of 50 nm was dispersed in 57.68 grams of DMAc by ultrasonic to form a dispersion liquid. In a three-necked flask equipped with mechanical stirring, a nitrogen inlet and outlet, and a thermometer, add 4.8 grams (0.024 moles) of ODA and the above dispersion, stir under nitrogen protection until completely dissolved, then add 5.38 grams (0.024 moles) of CHDA, at room temperature Stir for 12 hours to obtain a boron nitride-doped polyamic acid resin solution A with a solid content of 15 wt.%, and a viscosity of 10000 cP. Similarly, in a three-necked flask equipped with mechanical stirring, nitrogen inlet and outlet, and a thermometer, add 3.52 grams (0.011 moles) of TFDB and 59.1 grams of DMAc, stir under nitrogen protection until completely dissolved, then add 6.91 grams (0.011 moles) of BFDA , stirred at room temperature for 10 hours to obtain a polyamic acid resin solution B with a solid content of 15wt.%, and a viscosit...

Embodiment 2

[0055] First, 2 grams of boron nitride with a particle size of 60 nm was dispersed in 40 grams of DMF by ultrasonic to form a dispersion liquid. In a three-necked flask equipped with mechanical stirring, a nitrogen inlet and outlet, and a thermometer, add 3.6 grams (0.018 moles) of ODA and the above dispersion liquid, stir under nitrogen protection until completely dissolved, then add 6.4 grams (0.018 moles) of DSDA, at room temperature Stir for 10 hours to obtain a boron nitride-doped polyamic acid resin solution A with a solid content of 20 wt.%, and a viscosity of 15000 cP. Similarly, in a three-necked flask equipped with mechanical stirring, nitrogen inlet and outlet, and a thermometer, add 4.19 grams (0.013 moles) of TFDB and 39.85 grams of DMF, stir under nitrogen protection until completely dissolved, then add 5.77 grams (0.013 moles) of 6FDA , stirred at room temperature for 10 hours to obtain a polyamic acid resin solution B with a solid content of 20wt.%, and a visco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com