Patents

Literature

60results about How to "Solve thermal conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon composite high-thermal-conductivity plastic material and preparation method thereof

The invention discloses a carbon composite high-performance thermal-conductive plastic and a preparation method thereof; the thermal-conductive insulating plastic is prepared from a resin basic material, a carbon composite material, a thermal-conductive agent, a coupling agent, an antioxidant and other processing agents; by means of the special crystalline structure of the carbon composite material added in the formula of the thermal-conductive insulating plastic disclosed by the invention, the inter-particle bridging effect is realized; a thermal-conductive passage composed of the thermal-conductive agent is more and more perfect; therefore, the thermal conductivity of the composite material can be rapidly increased; a filling material gathering and thermal-conductive passage is more and more perfect; simultaneously, with the help of the processes, such as a pre-mixing process, an extrusion process, a cooling process, an air drying process and a granulating process, the problems of being degraded in high filling property and low in thermal-conductive property of the plastic are solved; the thermal-conductive composite material having excellent mechanical property and good thermal-conductive effect and insulating property can be prepared; and the thermal-conductive composite material can be widely applied in the fields, such as electrons, automobiles and LED (Light Emitting Diode) lamps.

Owner:HUIZHOU KINGBALI TECH

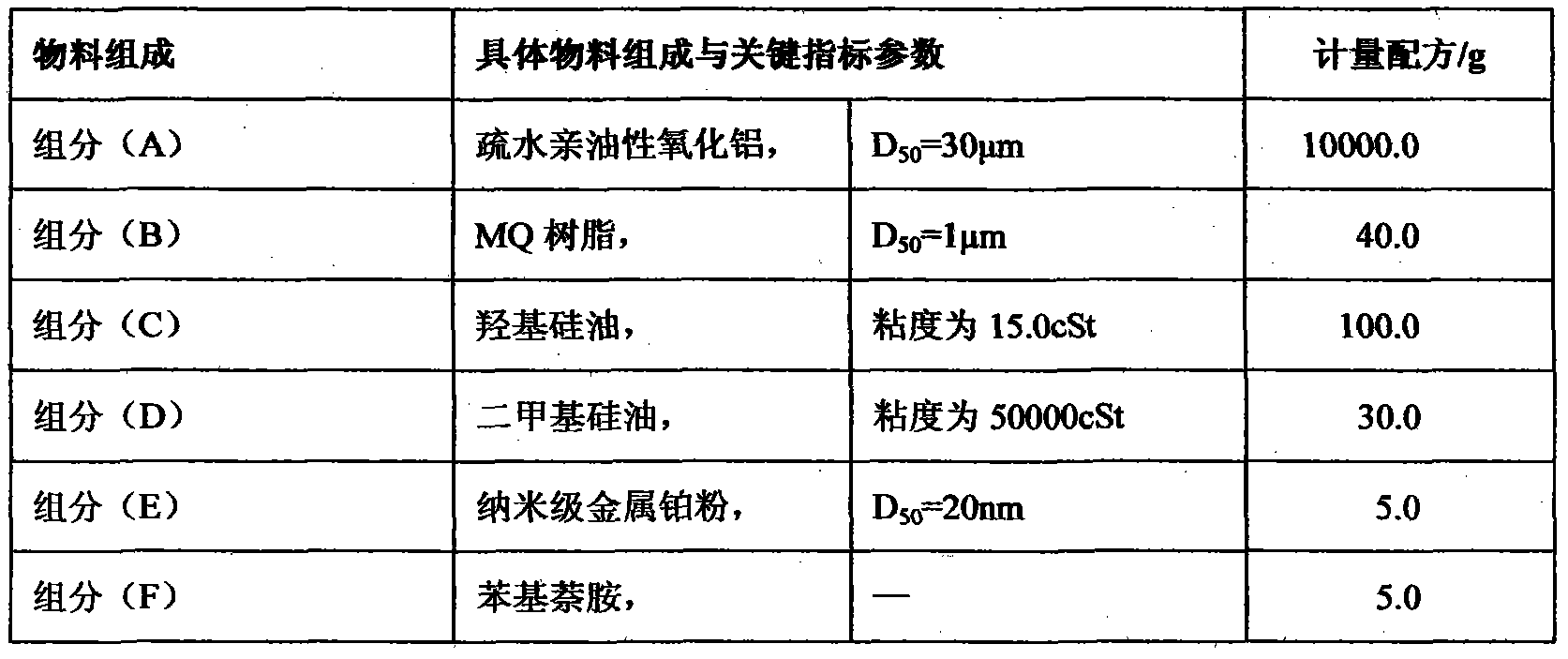

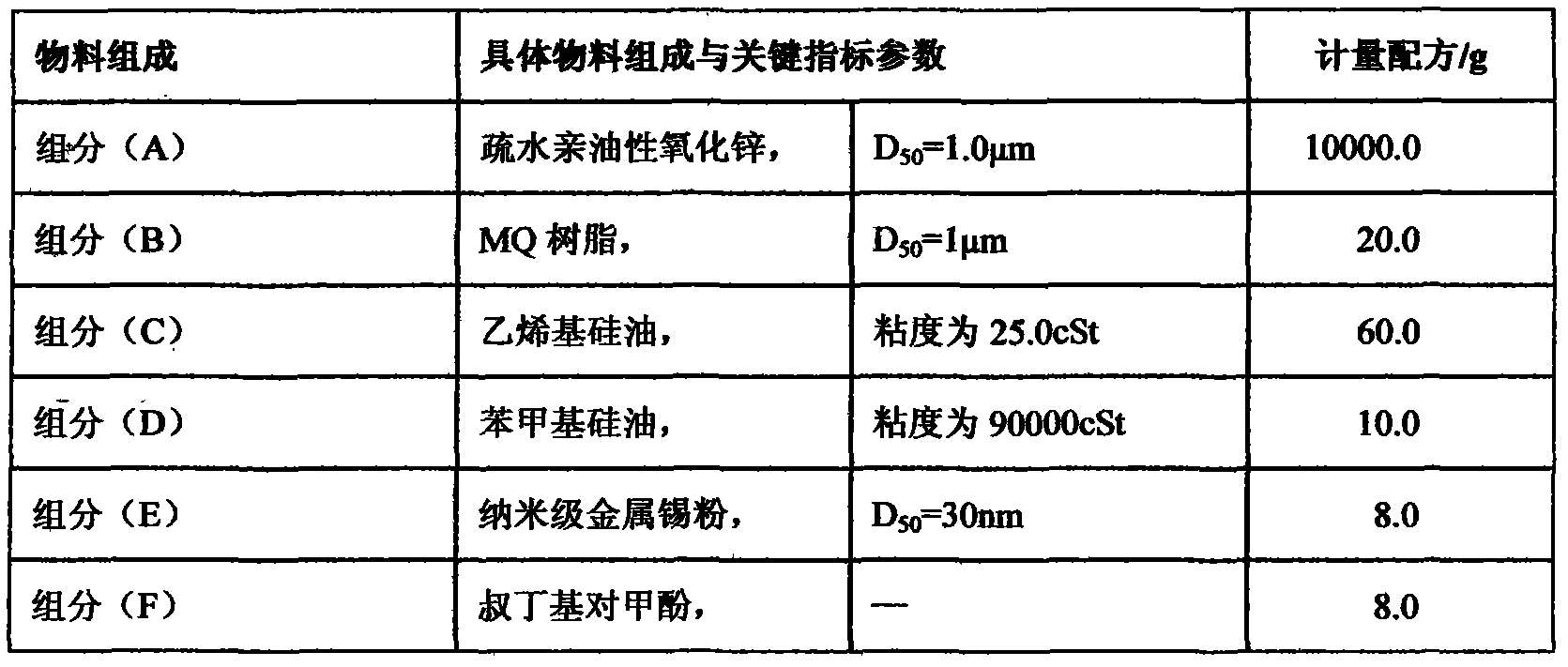

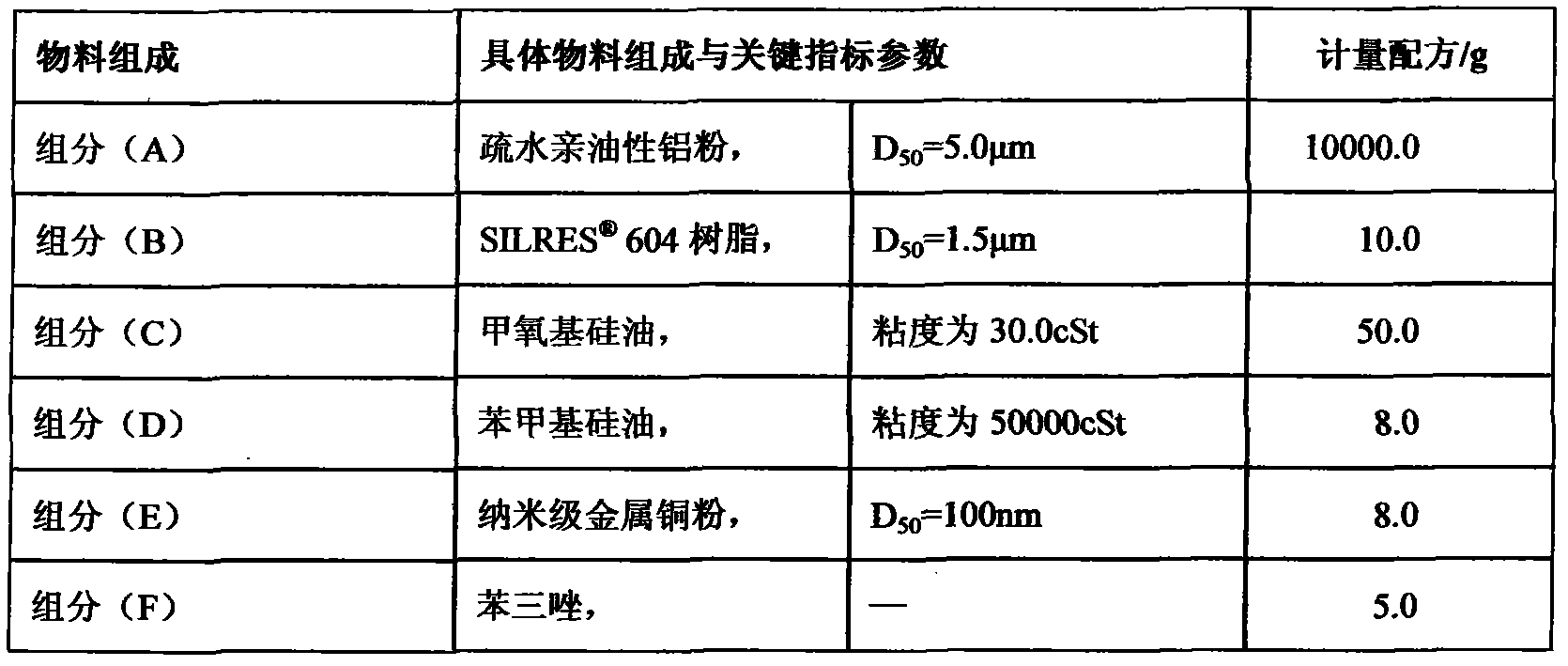

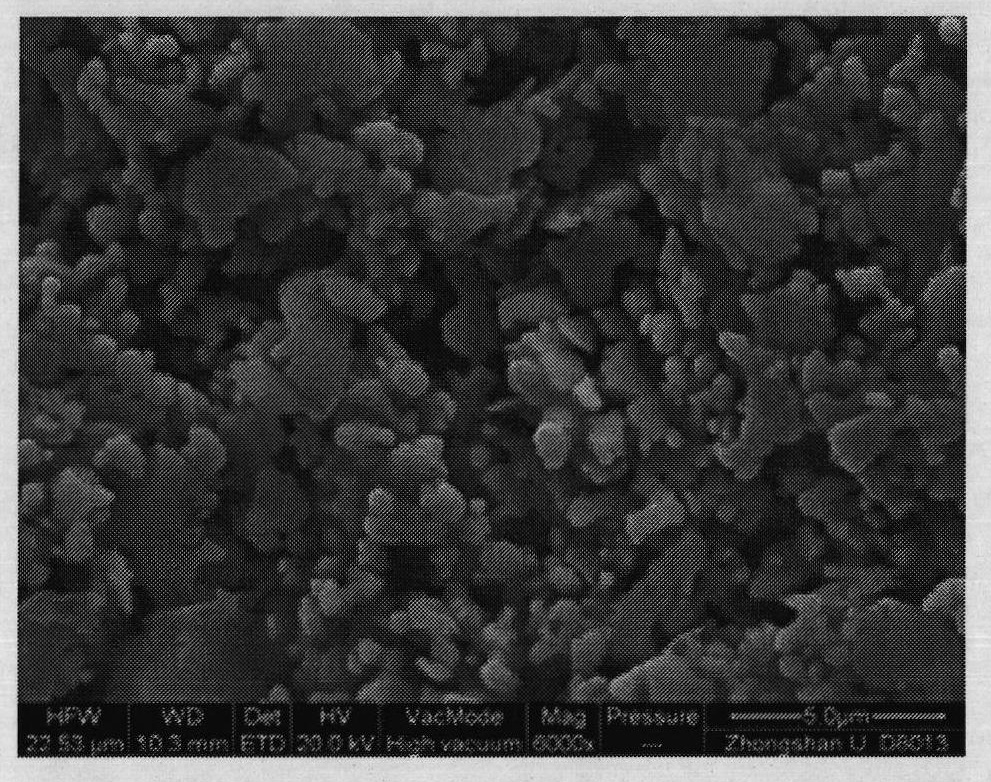

Thermal grease composition

ActiveCN102134474ASolve the chalking problemResolve fragmentationHeat-exchange elementsNano catalystThermal grease

The invention relates to the field of thermal interface materials, and more particularly, provides a thermal grease composition, which contains the following components: (A) 100.0 parts by weight of thermally conductive filler, (B) 0.1 to 8.0 parts by weight of active solid silicone resin, (C) 0.1 to 15.0 parts by weight of active silicone oil, (D) 0.1 to 9.0 parts by weight of macromolecular polysiloxane, (E) 0.1 to 3.0 parts by weight of nano catalyst, and (F) 0.1 to 3.0 parts by weight of additive. The thermal grease composition provided by the invention has good thermal conductivity and using weatherability, can effectively solve the technical difficulty that the thermal grease composition in the prior art is pulverized and crushed and the thermal conductivity is therefore reduced as the service time increases. The manufacturing process has simple, convenient and easy steps and the thermal grease composition is suitable for large-scale match production.

Owner:SHENZHEN EUBO NEW MATERIAL TECH

High-performance conductive silver paste and preparation method thereof

ActiveCN101805575AEvenly dispersedUniform size distributionNon-macromolecular adhesive additivesEpoxynovolac adhesivesEpoxyWorking temperature

The invention relates to a high-performance conductive silver paste, which is characterized by comprising the following raw materials in percentage by weight: 65-80% of micron-sized metal silver powder, 10-20% of epoxy resin, 1.4-3.5% of curing agent, 6-9% of solvent, 0.5-1.2% of accelerator, 0.05-0.1% of flexibilizer and 1-2% of additive. The invention also discloses a preparation method of the high-performance conductive silver paste. The conductive silver paste of the invention has high conductivity, very high thermal conductivity, high working temperature, strong viscosity and very high shear strength, and the performance indexes are apparently higher than the working performance of the conductive silver paste in the prior art, thereby solving the technical problems of poor shear performance, low working temperature, poorer thermal conductivity, long curing time, high curing temperature, poor viscosity, easy pollution of environment and the like in the field of the conductive silver paste in the prior art.

Owner:连云港市昭华光电科技有限公司

Method and device for detecting heat conductivity near melting point of phase change energy storage material

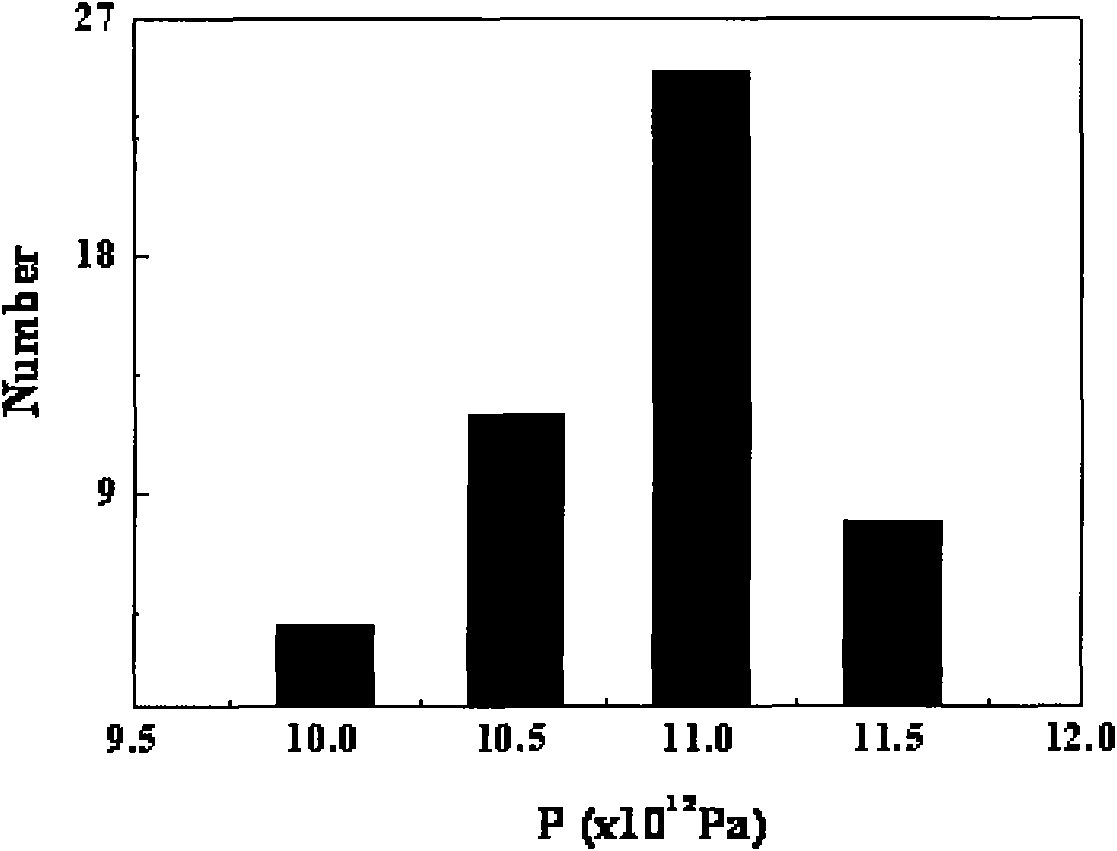

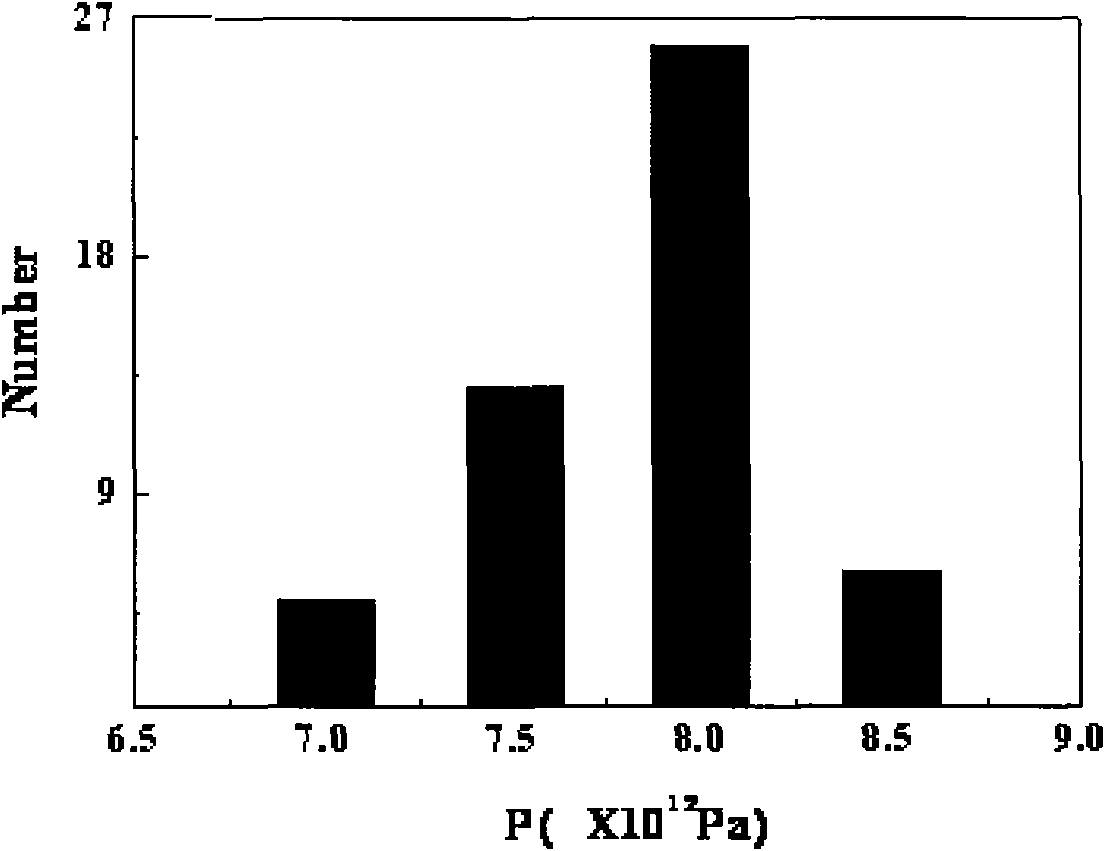

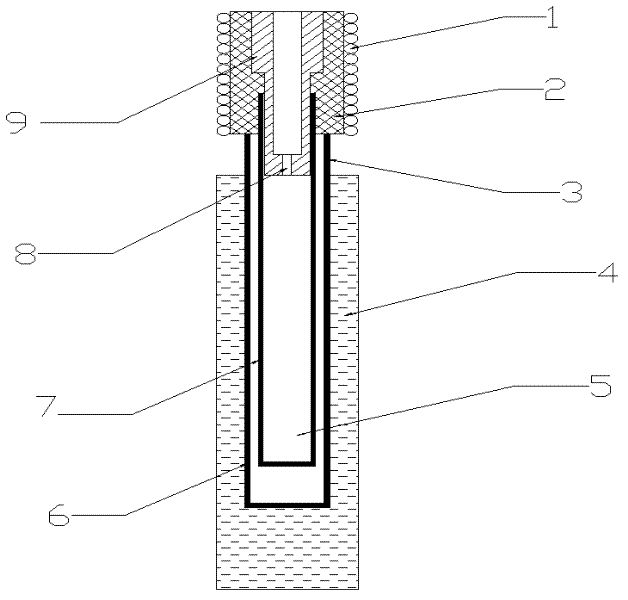

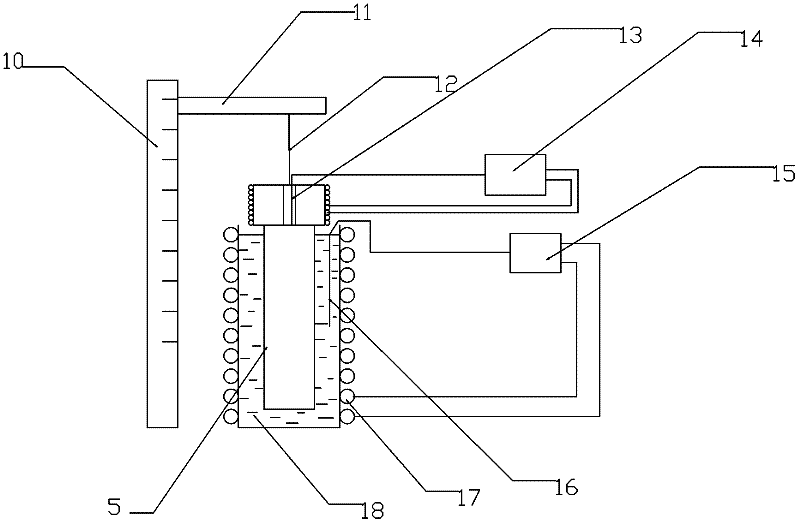

InactiveCN102305806ASolve thermal conductivityOvercoming problems such as lattice changesMaterial heat developmentPhase changePhase-change material

The invention discloses a method and a device for detecting heat conductivity near the melting point of a phase change energy storage material. The method comprises the following steps of: 1, calculating the approximate value of the heat conductivity near the melting point of the phase change energy storage material according to an analysis formula under the ideal phase change condition; and 2, introducing a numerical simulation correction method to obtain an experiment corrected value, namely the accurate value of the heat conductivity near the melting point of the phase change energy storage material. The method and the device for detecting the heat conductivity near the melting point of the phase change energy storage material are high in test result accuracy and solve the problems that the phase change material has a lattice change when temperature gradient is applied in the conventional measuring method, and the like.

Owner:CENT SOUTH UNIV

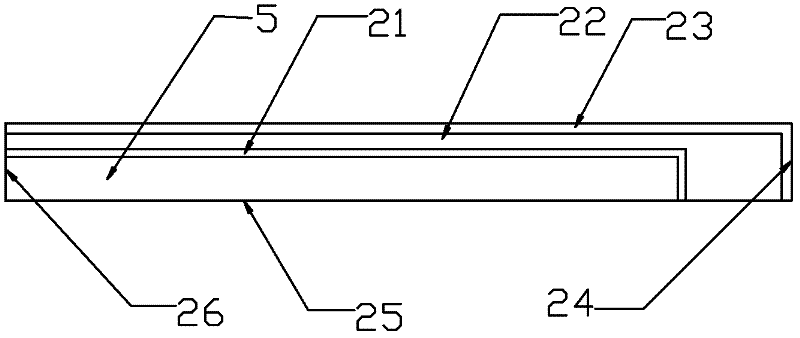

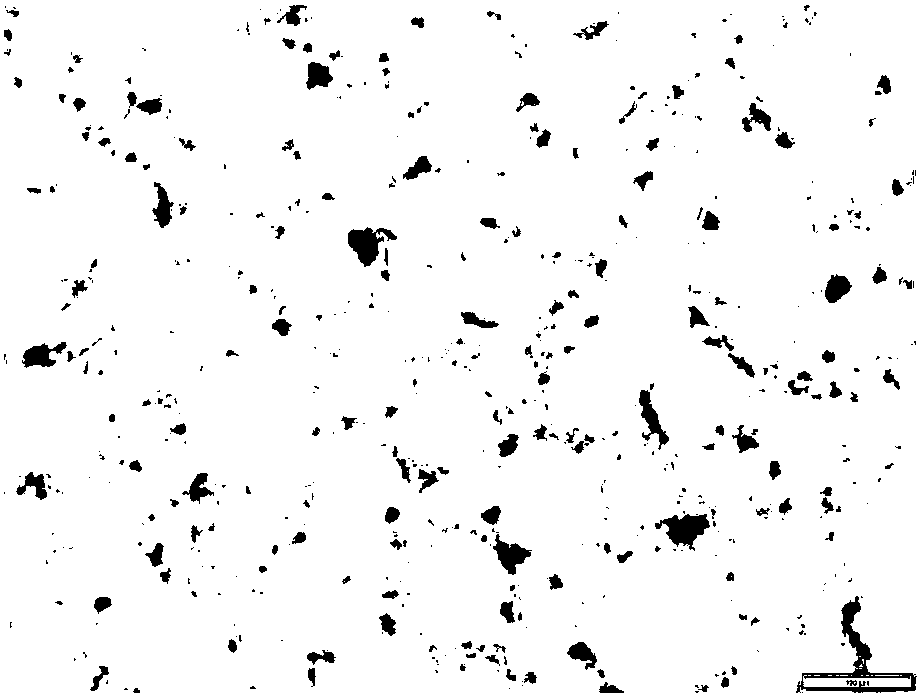

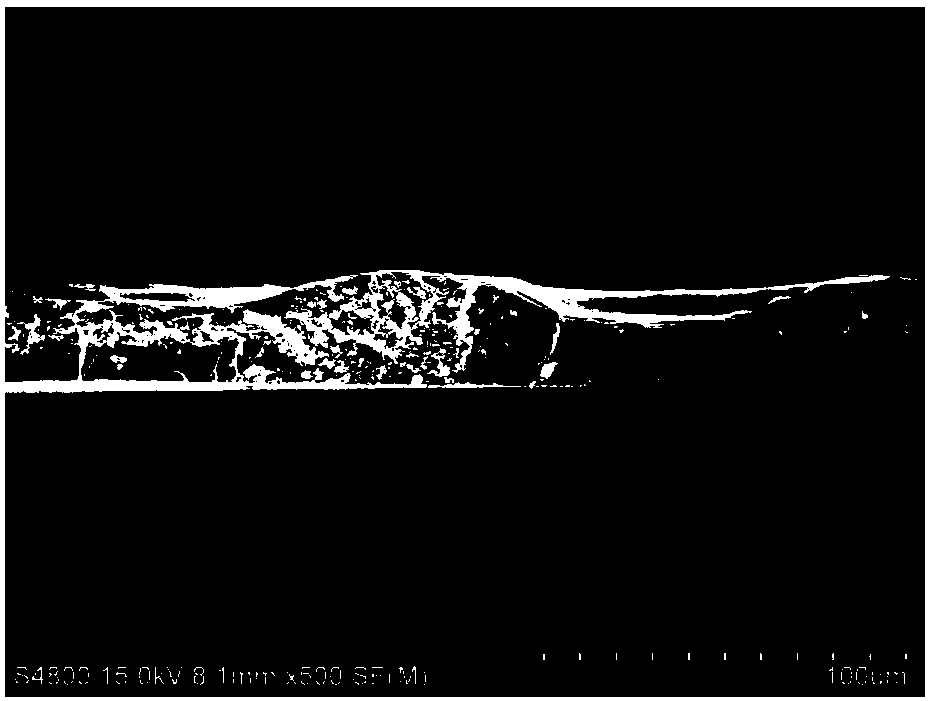

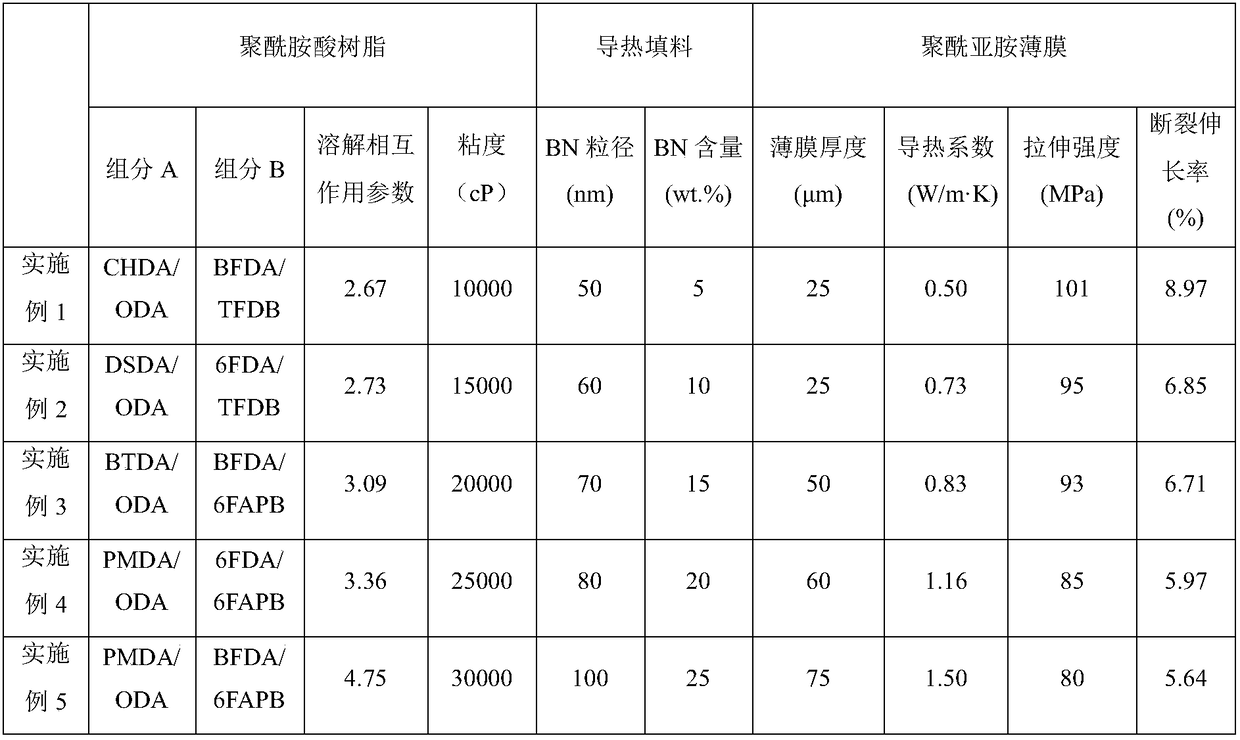

High thermal conductivity polyimide film and preparation method thereof

ActiveCN108610631AGood mechanical propertiesEffective exportHeat-exchange elementsPolyamic acidElectronic component

The invention relates to a high thermal conductivity polyimide film and a preparation method thereof and belongs to the technical field of polyimide films. According to the high thermal conductivity polyimide film, the problems that an efficient heat conduction channel is difficulty constructed by an existing doping method at low filling volume of thermal conductive filler and mechanical properties and the thermal conductivity of the polyimide film cannot be simultaneously obtained are solved. The film comprises a polyimide resin A, polyimide resin B and the thermal conductive filler; the thermal conductive filler is dispersed in A phase; a solution interaction parameter difference of polyamic acid resin A and polyamic acid resin B is 2.5 to 5.0; the heat conduction channel of the polyimide film is continuous and is perpendicular to the plane of the film. The preparation method comprises the following steps: preparing a thermal conductive filler solution doped with the polyamic acid resin A and a thermal conductive filler solution doped with the polyamic acid resin B; mixing the two solutions; coating a substrate with the mixed solution; heating in the procedures; carrying out thermal imidization and stripping to obtain the high thermal conductivity polyimide film. The high thermal conductivity polyimide film and the preparation method thereof can be used for insulated heat dissipation of electronic components.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

Heat-conducting lubricating grease for high-speed all-steel angular contact bearing and preparation method thereof

ActiveCN102703179ASimple manufacturing methodReduce manufacturing costLubricant compositionLow noiseElectricity

The invention relates to heat-conducting lubricating grease for a high-speed all-steel angular contact bearing and a preparation method of the lubricating grease; the heat-conducting lubricating grease for the high-speed all-steel angular contact bearing is composed of the following raw materials by weight: 85-95% of barium-base lubricating grease, 3-10% of a heat-conducting agent and 2-5% of antioxidant; according to a technical proposal of the invention, the heat-conducting agents namely nano particles are added based on composite barium-base lubricating grease; so that the heat-conducting lubricating grease has a higher speed coefficient and a preferable heat-conducting performance; the bearing is characterized by low noise, low temperature rising, low vibration and longer service life; in addition, situations that speed coefficient of current domestic lubricating grease is short of an operation demand and the current domestic lubricating grease has poor heat conductivity are solved; an electric main shaft oil supply device is eliminated; noise when the high-speed all-steel angular contact bearing is operated is reduced; and temperature rising and vibration values are reduced.

Owner:国创(洛阳)轴承产业技术研究院有限公司

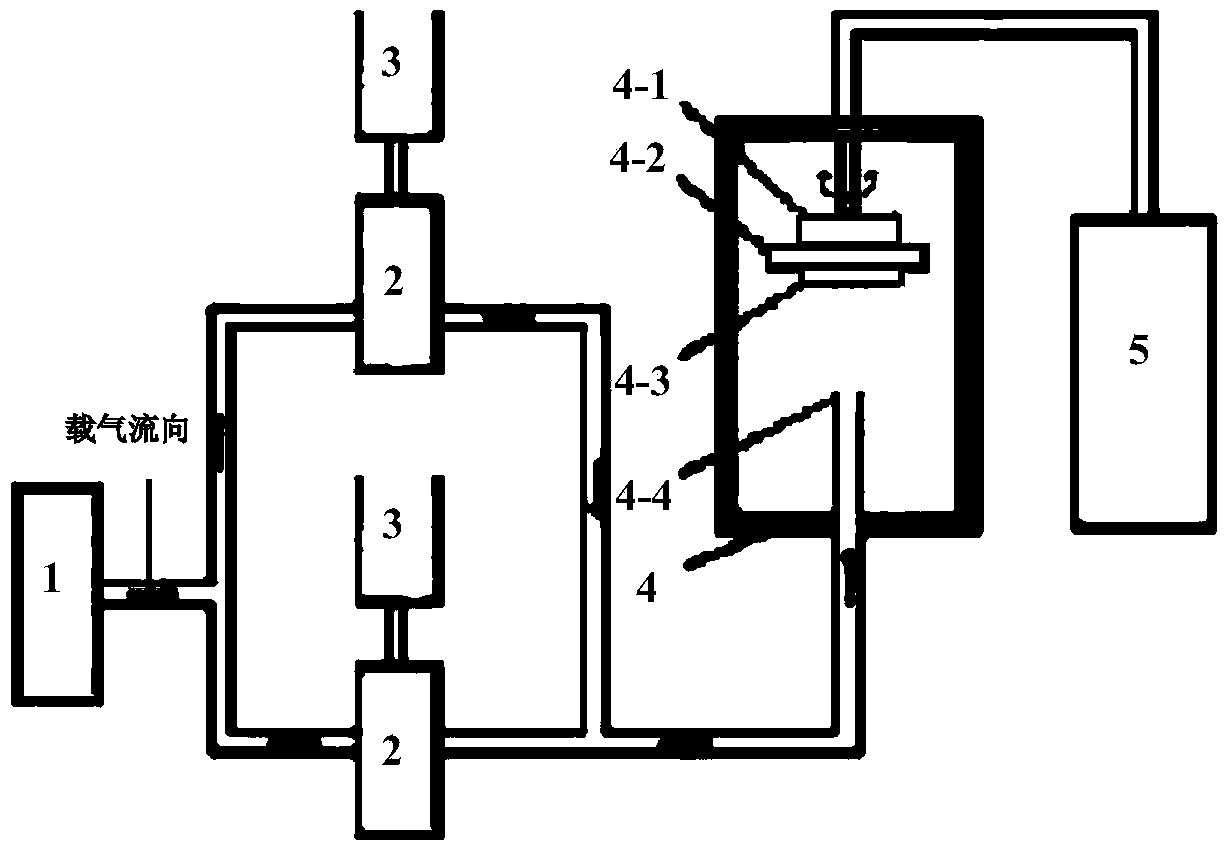

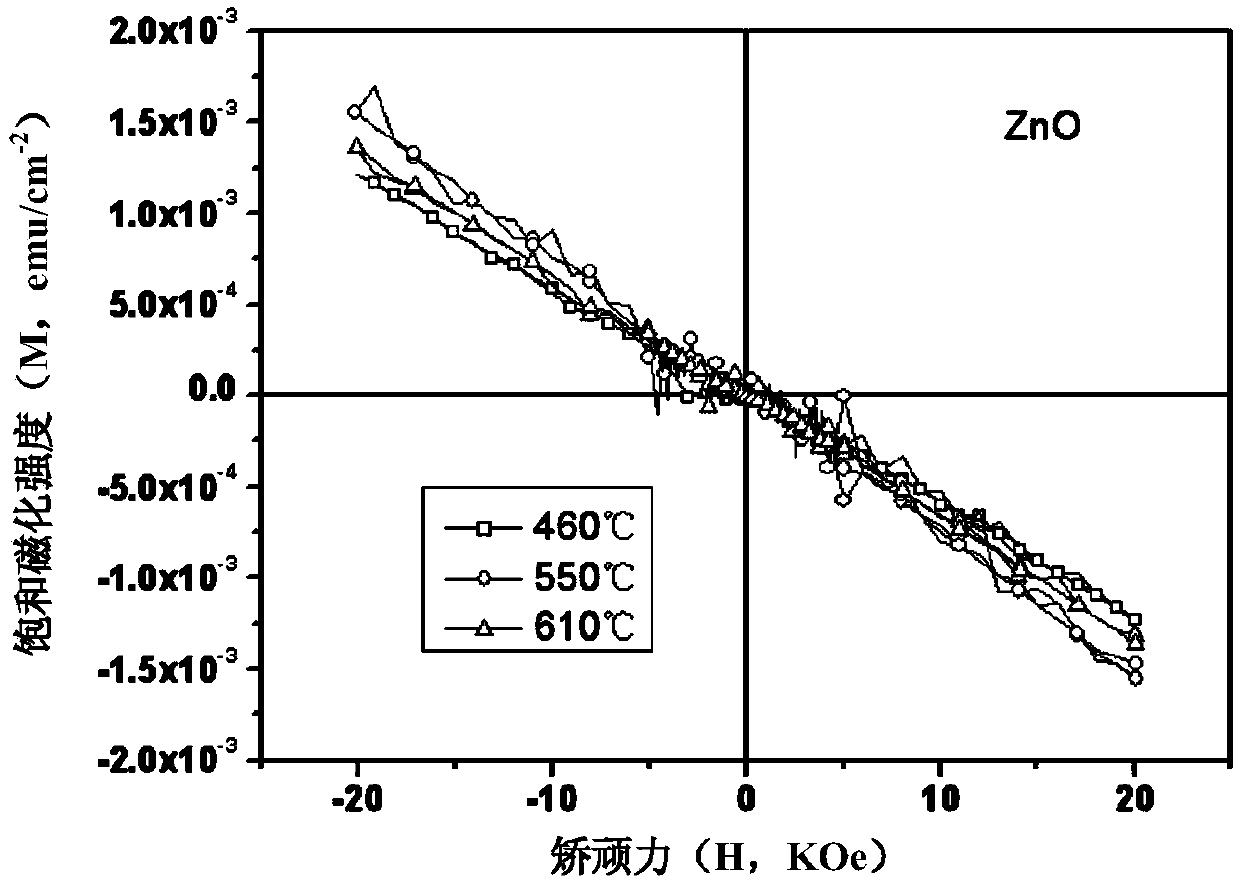

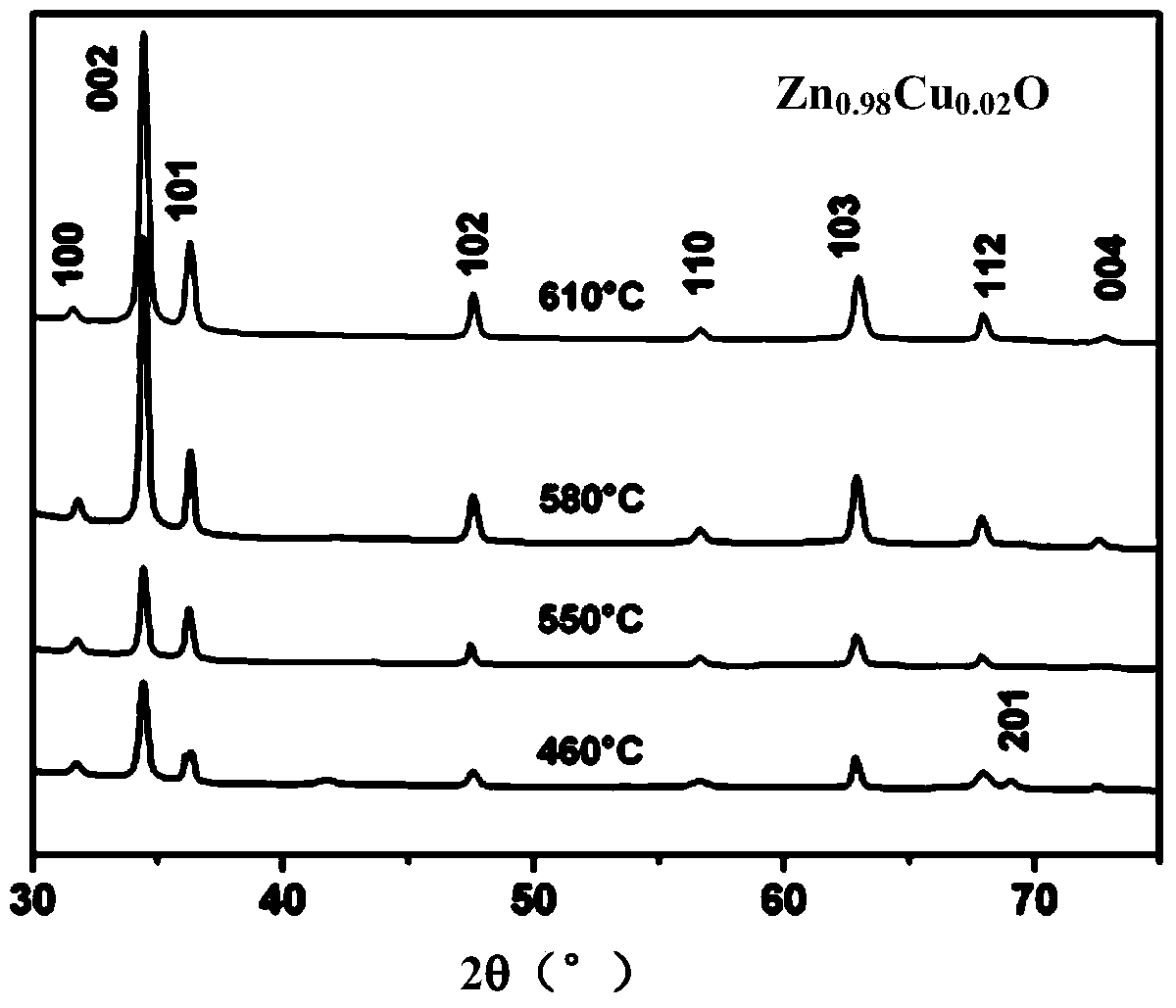

Nano-structure-controllable diluted magnetic semiconductor material and preparation method and device thereof

ActiveCN104200947AQuality improvementImprove performanceNanostructure applicationMaterial nanotechnologyZinc Acetate DihydrateNanostructure

The invention belongs to the technical field of semiconductor nano-material preparation, and discloses a nano-structure-controllable diluted magnetic semiconductor material having room-temperature ferromagnetism and a preparation method and device of the diluted magnetic semiconductor material. The material is prepared in the method comprising the steps that a zinc acetate solution and a copper acetate solution having the same volume are placed in two solution containing cups of a double-source ultrasonic atomization pyrolysis spraying instrument respectively, double-source ultrasonic atomization pyrolysis spraying is carried out, and the nano-structure-controllable diluted magnetic semiconductor material deposited on a substrate is obtained. Precursors are atomized through ultrasonic waves, and therefore smaller and more uniform mist can be obtained; double-source atomization is adopted, so that cross contamination between the solutions is avoided during mixing, meanwhile, component structures are easy to control, and preparation of a gradient film or a multilayer film structure is facilitated; the device is improved, so that purely diluted magnetic semiconductor materials with different nano-structures and various good properties are prepared, Ms can reach 3.8*10<-4>emu / cm<-2>, Hc can reach 0.1 KOe, and the materials have the characteristic of soft magnetism.

Owner:SOUTH CHINA UNIV OF TECH

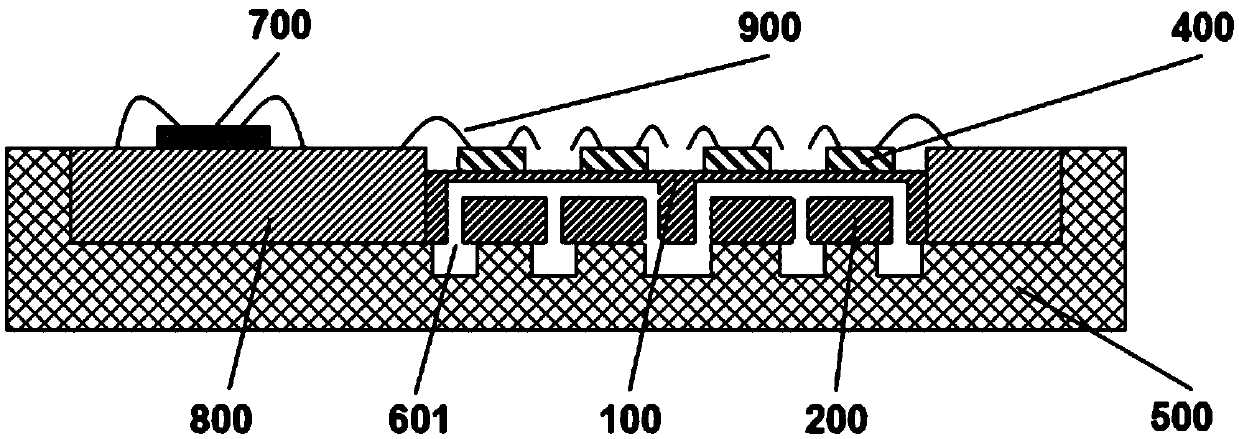

Metal microchannel heatsink structure applied to chip heat dissipation and manufacturing method thereof

PendingCN109560054ASolve thermal conductivityFix compatibility issuesPrecision positioning equipmentSemiconductor/solid-state device detailsHigh densityRadio frequency

The invention provides a metal microchannel heatsink structure applied to chip heat dissipation and a manufacturing method thereof. The structure has the beneficial effects that through the design ofa microchannel system with a three-dimensional vertical structure, microfluid flows in from the bottom layer of a packaging shell, climbs up the steps, is divided to cool hot spots of a high-power radio frequency chip, climbs down the steps and flows out to realize the high density of the chip and the efficient heat dissipation function at the same time, so that the problems of low heat conductivity of traditional microchannels, manufacturing process compatibility of metal microchannels and the like are solved and the structure is of great significance.

Owner:XIAMEN UNIV

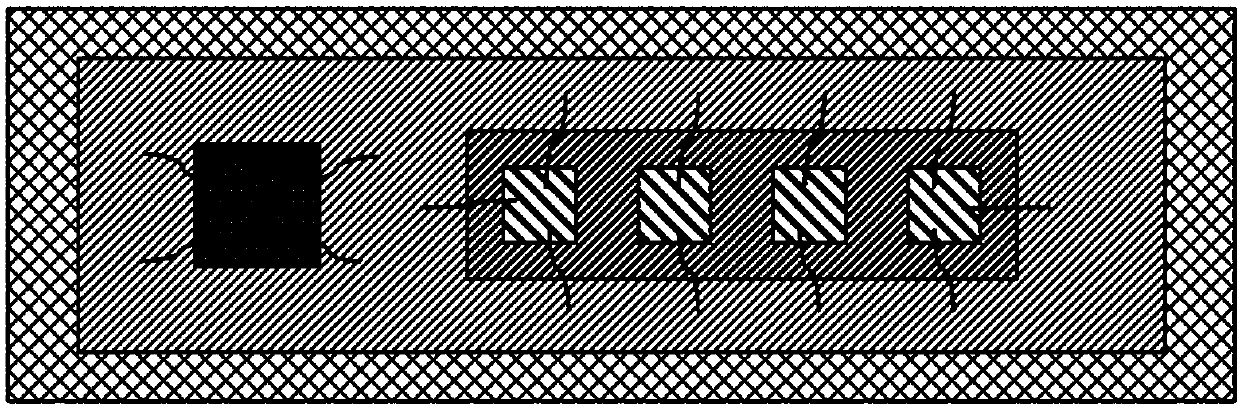

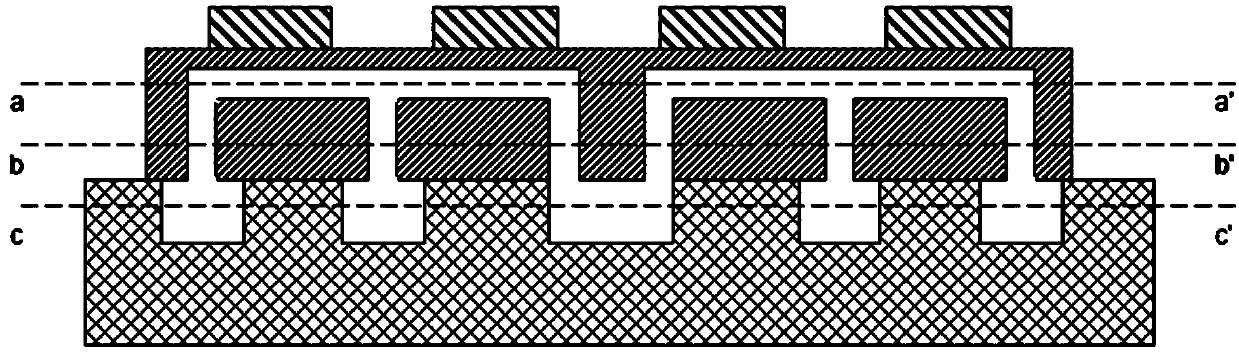

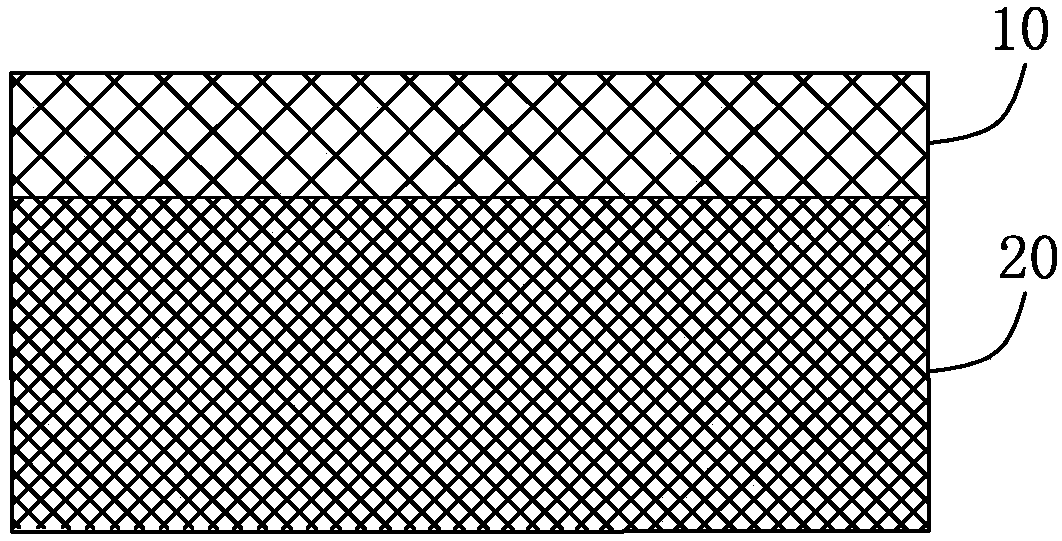

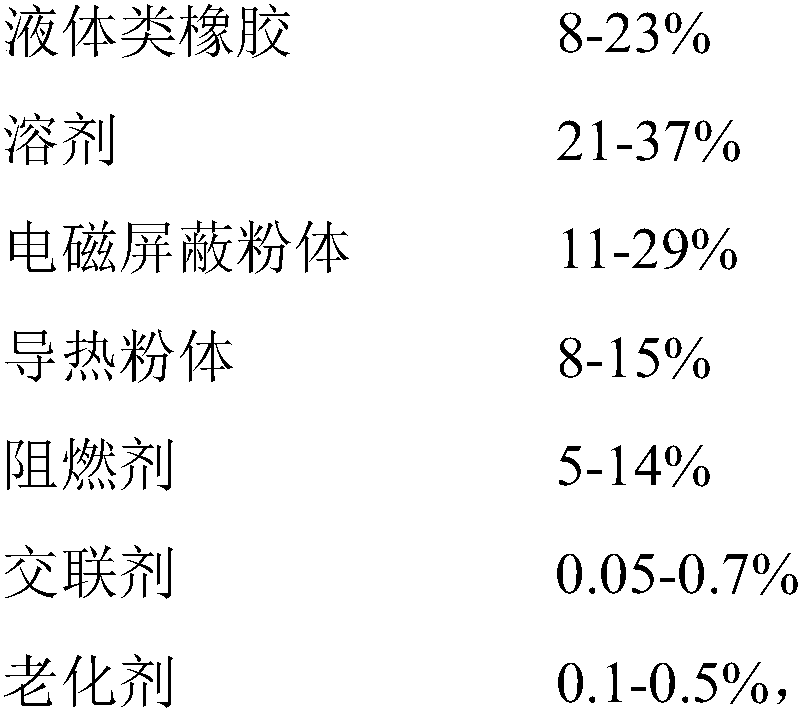

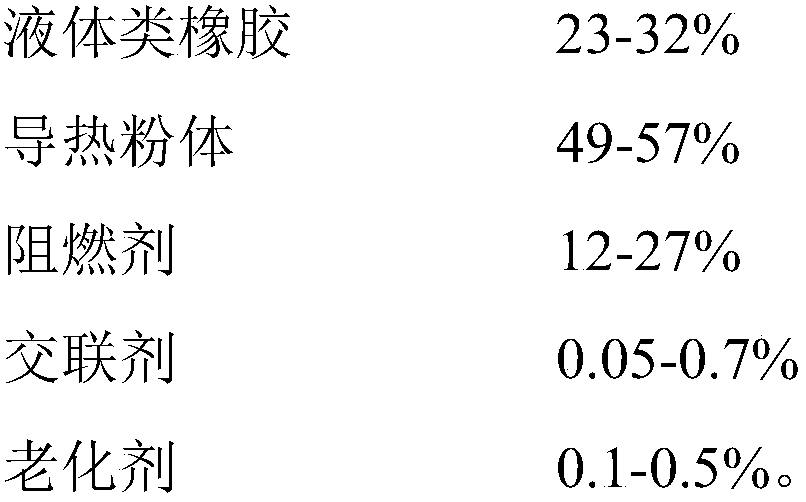

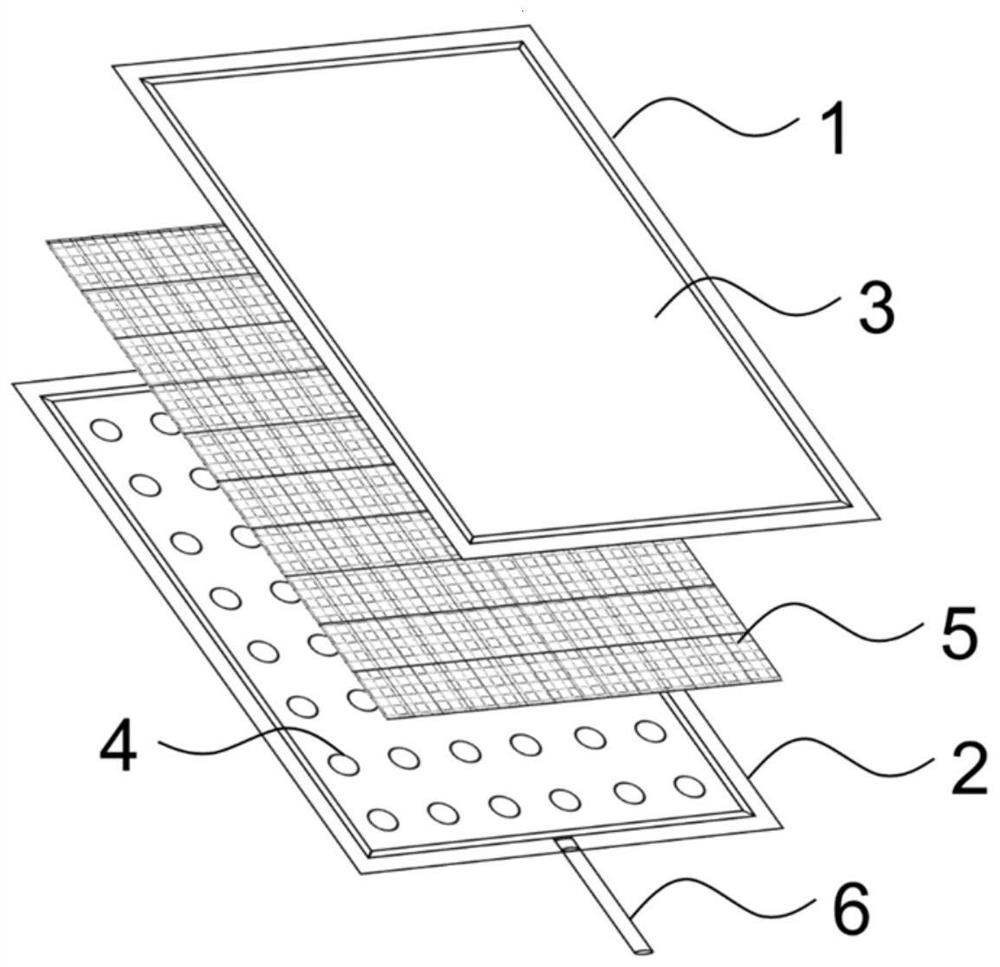

Composite material which has high thermal conductivity and electromagnetic shielding function and preparation method thereof

PendingCN108484948ASolve thermal conductivitySolve the shielding effectMagnetic/electric field screeningHeat-exchange elementsThermal conductivityOhm

The invention provides a composite material which has high thermal conductivity and an electromagnetic shielding function. The composite material is formed by compounding an upper layer material composition and a lower layer material composition through vulcanization, wherein the thickness of the upper layer material composition is 0.02-0.7 millimeters, the thickness of the lower layer material composition is 0.5-6.0 millimeters, the thermal conductivity coefficient of the composite material is 3.0-8.0 watt / meter*degree, and the resistivity of the composite material is smaller than or equal to0.01 ohm*centimeter. The invention further discloses a preparation method of the composite material which has high thermal conductivity and the electromagnetic shielding function. According to the composite material, not only can thermal conductivity and electromagnetic shielding be guaranteed, but also the compositions are made to have high mechanical strength, the thermal conductivity coefficient of the obtained composite material is higher than that, which is 0.2 watt / meter*degree, of normal materials, and the resistivity of the obtained composite material is smaller than or equal to 0.01ohm*centimeter so that application in a laser television can be fully achieved; moreover, by means of the composite material, the requirements of a thermal conductivity, shielding and elastic thermalconductivity interface material in conditions sensitive to organosilicone can be met, so that the requirements of heat dissipation and signal stabilization of a product are met.

Owner:SHENZHEN BORNSUN INDAL

High strength and wear resistant aromatic composite material, preparation method and application thereof

The invention relates to the field of materials, in particular to a high strength and wear resistant aromatic composite material, a preparation method and application thereof. The composite material includes: 65-85 parts of an aromatic polymer, 5-20 parts of ceramic filler and 10-30 parts of fiber. According to the invention, polyether ketone, polyether sulfone, polyether ether ketone and other aromatic polymers are adopted as the matrix resin to effectively improve the mechanical properties, thermal stability, corrosion resistance and the like of the product. The adding of the ceramic fillerinto the aromatic polymer matrix not only can improve the thermal conductivity coefficient of the product, but also can improve the product strength, and endows the product with the advantages of wearresistance, high hardness, flame retardance, aging resistance, environmental protection, etc. The high strength and wear resistant aromatic composite material provided by the invention has the characteristics of convenient shaping, simplicity and high efficiency, can achieve one-time shaping, and also can be used for secondary processing. The product has high degree of design freedom, is suitablefor large-scale production, and well solves the problems of low strength, poor hardness, no flame retardance, signal shielding and the like of the shells and shell components in existing electronic products, wearable equipment or household appliances.

Owner:大连疆宇新材料科技有限公司

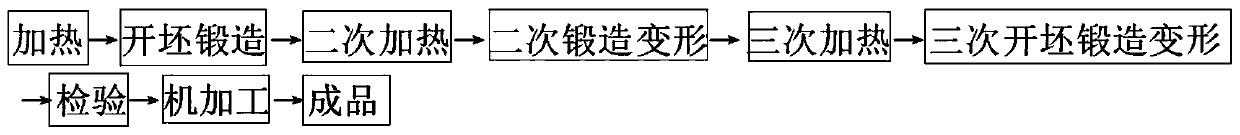

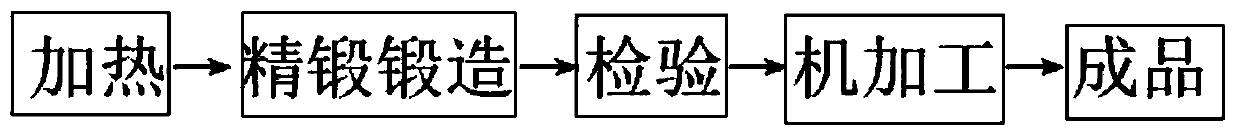

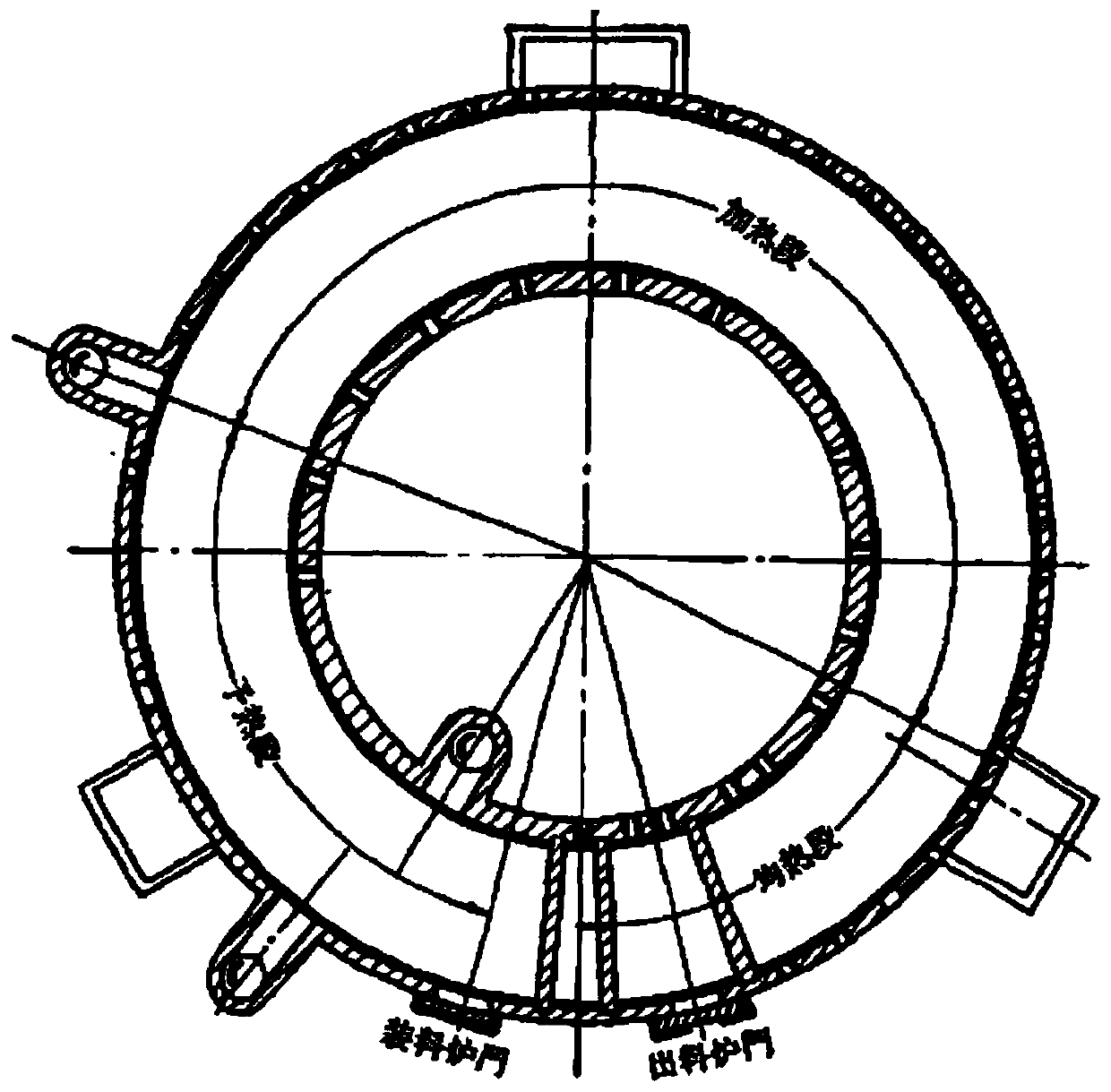

Efficient titanium and titanium alloy cast ingot short-process precision-forging blank forging process

ActiveCN110605353AControlled atmosphereControl heating temperatureForging/hammering/pressing machinesForging press detailsHeating timeThree stage

The invention provides a efficient titanium and titanium alloy cast ingot short-process precision-forging blank forging process. The process comprises a heating process, a precision forging machine precision forging deformation treatment, an inspection process and a machining process, then a titanium alloy bar material is obtained, wherein the heating process adopts an annular heating furnace, heating of titanium and titanium alloy ingot blanks is achieved through flame heating, three stages of preheating, heating and soaking are adopted to achieve heating in the heating process, the heating temperature of the preheating section is 800+ / -50 DEG C, the heating time is 60-70 min, the heating temperature of the heating section is 900-1150DEG C, the heating time is 70-90 min, the heating temperature of the soaking section is equivalent to the heating temperature of the heating section, the soaking time is 60-90 min, the precision forging machine precision forging deformation treatment comprises the steps of carrying out precision forging through a hydraulic precision forging machine and carrying out hammering forging by using four hammers, and the forging time is 10-30 min. According to the process, by adopting the annular heating furnace with an improved heating mode, an annular sectional heating mode is adopted, and the precision forging machine forging deformation treatment is combined, so that the fast, efficient and short-process preparation of the titanium and titanium alloy cast ingots is achieved.

Owner:江苏天工科技股份有限公司

Wear-resisting high-temperature-resistant high molecular material formula

InactiveCN106543543ASolve the problem of large linear expansion coefficientFix stability issuesPolymer scienceTemperature resistance

The invention discloses a wear-resisting high-temperature-resistant high molecular material formula. The material is prepared from the following raw materials in parts by weight: 100 parts of ultra high molecular weight polyethylene, 2 to 3 parts of graphene, 3 to 4 parts of talcum powder, 1 to 2 parts of glass beads, 2 to 5 parts of silicon dioxide and 4 to 5 parts of accessory ingredient. According to the formula provided by the invention, the raw materials including the graphene, the talcum powder, the glass beads, the silicon dioxide and the like are used for performing reinforcing and modifying treatment on the ultra high molecular weight polyethylene to improve the mechanical performance of the same, the prepared material does not only have the own excellent performance of the ultra high molecular weight polyethylene, and the indexes of hardness, toughness, high-temperature resistance, wear resistance and the like of the prepared material are all improved, devices for a pump and a valve made from the modified ultra high molecular weight polyethylene material are long in service life and safe and reliable in fireproof performance.

Owner:江苏环宇纺织科技有限公司

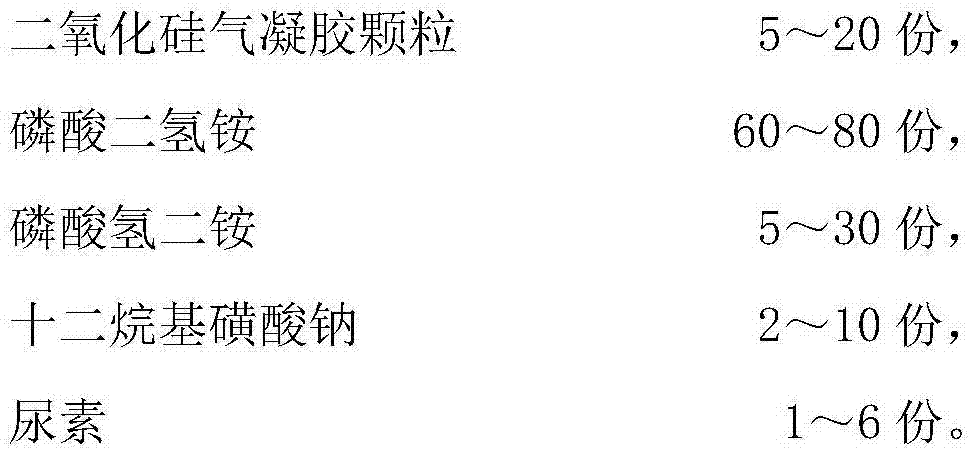

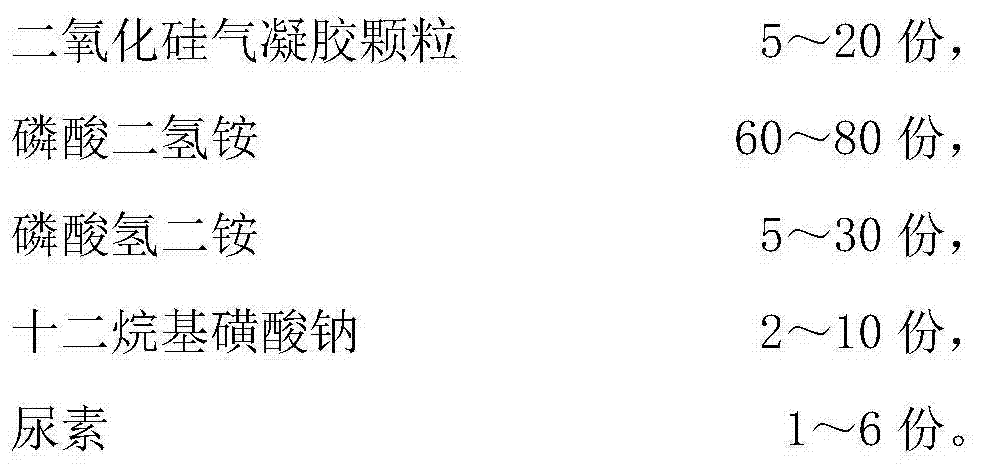

Aerogel composite modified fire retardant and preparation method and application thereof

InactiveCN104844830AImprove insulation effectImprove sound insulationFibre treatmentHydrophobic silicaHigh rise

The invention discloses an aerogel composite modified fire retardant and its preparation method and application. The aerogel composite fire retardant is formed by composite processing of silica aerogel particles, ammonium biphosphate, diammonium phosphate, sodium dodecanesulphonate and urea which are used as raw materials. The hydrophobic silica aerogel particle composite modified fire retardant provided by the invention has excellent fire resistance, heat preservation and insulation performance, sound insulation performance and light weight. Thus, problems of high heat conduction, heavy weight, high water absorption and the like of a traditional fire retardant are solved. The fire retardant provided by the invention can be used for fire protection and modification of building materials and in the fields of various cloth materials, plywood and the like. By the use of the product provided by the invention, safe and reliable fireproof guarantee can be provided for high-rise buildings, public amenities, hotels, residential buildings and the like.

Owner:上海英硕聚合材料股份有限公司

Graphene-base heat-conduction composite material as well as preparation method and application of composite material

The invention relates to a graphene-base heat-conduction composite material. The graphene-base heat-conduction composite material is characterized by containing the following components in percentageby weight: 40%-90% of graphene, 0.1%-10% of palladium or platinum, 9%-50% of nano-particles and 1-20% of resin macromolecules. The graphene-base heat-conduction composite material has the characteristics of good thermal conductivity and low cost.

Owner:江阴精醇新材料科技有限公司

Carbon nanotube modified carbon fiber composite for automobile hubs and preparation method of composite

InactiveCN106905695AExcellent leading mechanical propertiesImprove conductivityModified carbonEngineering plastic

The invention relates to the technical field of modified engineering plastics for lightweight production of automobiles, in particular to a carbon nanotube modified carbon fiber composite for automobile hubs and a preparation method of the composite. The composite is prepared from raw materials in parts by weight as follows: 55-80 parts of nylon PA66, 20-40 parts of carbon fibers, 2-5 parts of carbon nanotubes, 4-10 parts of a toughening agent, 0.1-0.6 parts of an anti-oxidant, 0.2-0.5 parts of a lubricant and 0.2-0.5 parts of a nucleating agent. The prepared nylon 66 (PA66)-filled carbon fiber / carbon nanotube composite adopts multi-scale mixed filling, good dominant mechanical performance of carbon fibers is maintained, interlaminar shear strength is improved, the interlaminar shear effect is improved, the electric conductivity and heat conductivity of the composite are also improved, and the problem that the mechanical performance and the heat conductivity of existing carbon fiber composites are poor is solved.

Owner:HUANGHE S & T COLLEGE

Phase change energy storage powder for building energy saving and preparation method thereof

ActiveCN106010456AGood dispersionSolve the overcooling defectHeat-exchange elementsActive agentHigh energy

Relating to the field of building energy-saving materials, the invention provides a phase change energy storage powder for building energy saving and a preparation method thereof. The phase change energy storage powder is characterized by containing an anti-supercooling agent and a powder type energy storage material subjected to screw extrusion coating, and is prepared from, by weight, 80-85 parts of a phase change material, 2-3 parts of an active agent, 0.1-0.3 part of an anti-supercooling agent, 8-12 parts of a wrapping agent, 1-2 parts of a thermal conductive agent, 0.5-1 part of a stabilizer, and 2-3 parts of a flame retardant. The phase change energy storage powder has the advantages of high energy storage density and no supercooling phenomenon, flame retardance, and excellent compatibility with most building materials, can be added in large quantities without affecting the strength of building materials, and is applicable to concrete, mortar, putty, paint and the like.

Owner:宁波运通新材料科技有限公司

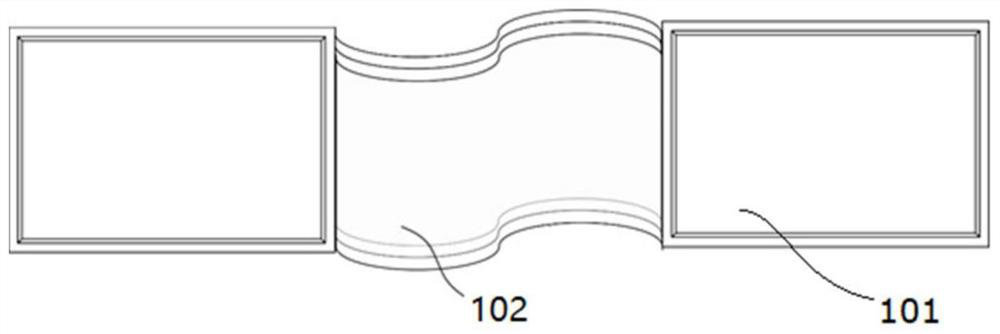

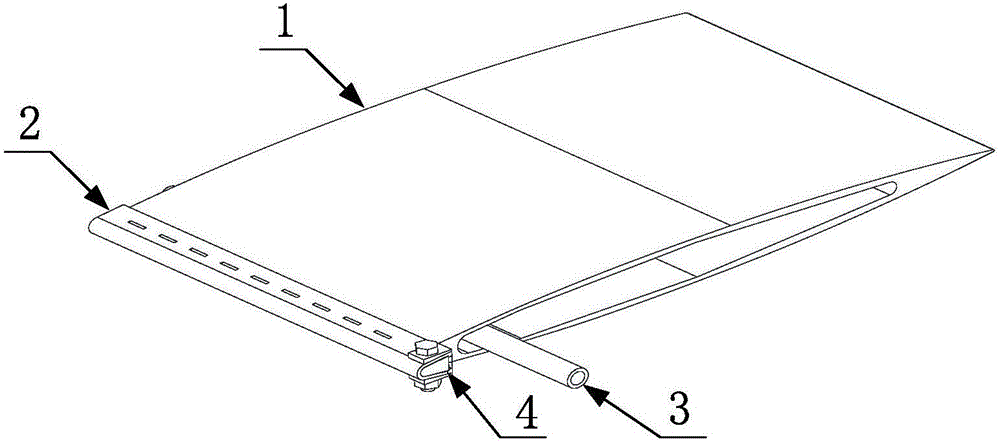

Heterogeneous temperature equalizing device

PendingCN112638123ASolve the small heat fluxSolve thermal conductivityModifications by conduction heat transferEnergy efficient computingWire rodHeat management

The invention relates to a heterogeneous temperature equalizing device, which comprises two planar temperature equalizing plates and a flexible connection part. The temperature equalizing plate is composed of an upper shell plate, a liquid absorbing core and a lower shell plate which are connected in sequence, a closed space is formed between the upper shell plate and the lower shell plate, the liquid absorbing core is located in the closed space, and the closed space is in a vacuum state and filled with a working media. And the temperature equalizing plates are connected through flexible connection. The upper shell plate and the lower shell plate are made of a flexible heat conduction material, the liquid absorbing core is made of a flexible porous material, and the flexible connection is made of metal or a carbonaceous membrane material and wire. The defect that a traditional temperature equalizing plate is poor in flexibility is overcome, and the heterogeneous temperature equalizing device can be used for thermal management of flexible electronic and foldable electronic products.

Owner:ZHEJIANG UNIV

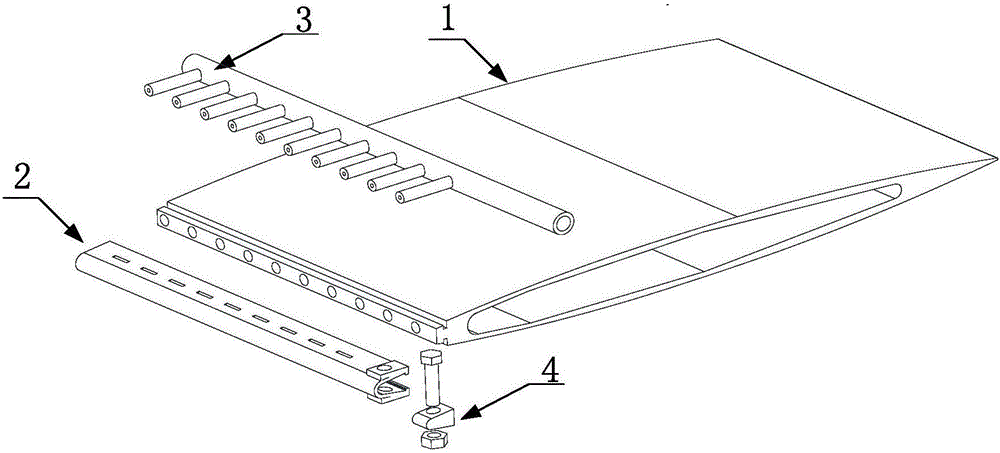

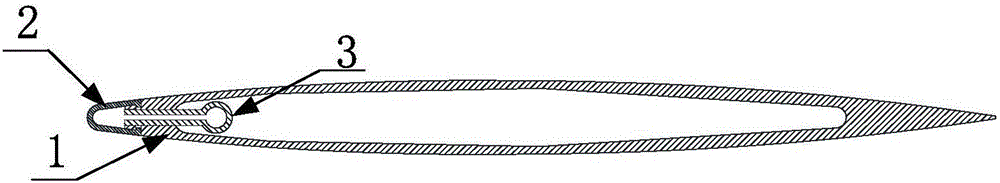

Hot air anti-icing structure of composite engine guide vane with metal leading edge

ActiveCN106762146AWith anti-icing effectImprove thermal conductivityPump componentsGas turbine plantsLeading edgeFiber

The invention discloses a hot air anti-icing structure of a composite engine guide vane with a metal leading edge and belongs to the field of aero-engine anti-icing. The hot air anti-icing structure is suitable for designing of the anti-icing structure of an aero-engine leading edge part. The hot air anti-icing structure comprises a composite vane substrate, a metal vane leading edge, a carbon fiber flute-shaped pipe, an end socket and the like. According to the hot air anti-icing structure of the composite engine guide vane with the metal leading edge, composite materials are used for manufacturing the substrate, and metal materials are used for manufacturing the vane leading edge, so that advantages of good thermal conductivity of metal and light weight of the composite material are combined, the hot air anti-icing effect of the engine guide vane can be improved, and the air entraining content and the air entraining temperature of an engine are decreased; and meanwhile, the weight of the engine is reduced, and performance, safety and economical efficiency of the aero-engine are improved.

Owner:BEIHANG UNIV +1

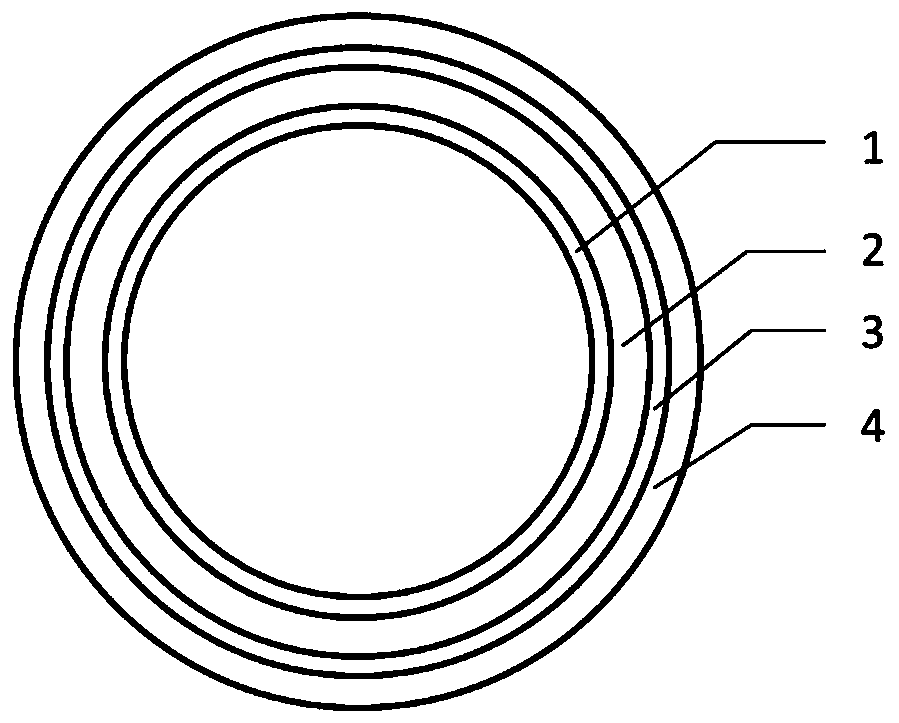

Pipeline suitable for conveying ultralow-temperature medium

PendingCN110513544AMeet craftFulfil requirementsPipeline expansion-compensationThermal insulationInsulation layerInsulation system

The invention discloses a pipeline suitable for conveying an ultralow-temperature medium. The pipeline comprises a pipeline body and a functional layer arranged on the outer surface of the pipeline body; the functional layer is sequentially provided with a heat-insulation system layer and an anti-collision protection outer layer from inside to outside; the heat-insulation system layer comprises acold-insulation material layer and / or a vacuum cold-insulation layer; the cold-insulation material layer is realized in the mode that the pipeline body is directly wrapped with a cold-insulation material; the vacuum cold-insulation layer comprises an inner-wall sleeve and an outer-wall sleeve, two layers of sleeve pipelines are connected through a support, and a vacuum is formed between the two layers of sleeve pipelines; and a concrete sleeve serves as the anti-collision protection outer layer. According to the pipeline, the pipeline body is paved with expansion joints and the cold-insulationto meet process and soil environment requirements, the pressure bearing capacity of the pipeline meets the road requirement, a comprehensive scheme meets the relevant requirements of the burying environment, and the problem that chemical raw materials at the ultralow temperature (minus 162 DEG C) cannot be conveyed in a buried mode can be solved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Aluminum nitride nanoparticle transformer oil with good antifouling scale inhibition performances, and preparation method thereof

ActiveCN104046438AImprove antioxidant capacityImprove moisture resistanceAdditivesHeat conductingPhosphate

The invention discloses an aluminum nitride nanoparticle transformer oil with good antifouling scale inhibition performances. The aluminum nitride nanoparticle transformer oil is characterized by being prepared from the following raw materials in parts by weight: 1000-1200 naphthenic base oil, 5-6 parts of aluminum nitride, 0.2-0.5 part of methyl benzotriazole, 0.2-0.5 part of sodium tripolyphosphate, 0.2-0.5 part of sodium nitilotriacetate, 0.3-0.5 part of lauryl phosphate, 0.2-0.5 part of tolyltriazole TTA, 0.2-0.5 part of polymaleic anhydride, 0.2-0.4 part of hydroquinone, and 0.5-1.0 part of auxiliaries. The aluminum nitride nanoparticle added in the transformer oil can enhance the heat conductivity, stability and insulating performance; the added auxiliaries enhance the oxidization resistance, moisture proofness and water resistance properties of the transformer oil; the added methyl benzotriazole and polymaleic anhydride increase the anticorrosion, antirust and scale inhibition properties of the transformer oil; nanoparticles are made by ball-milling absolute ethyl alcohol, and the used equipment is simple and easy to operate; according to the aluminum nitride nanoparticle transformer oil, the problems that the transformer oil is easy to oxide, age, corrode and moisten at high-temperature environment, poor in heat conducting property and the like can be effectively solved.

Owner:TONGLING SANJIA TRANSFORMER

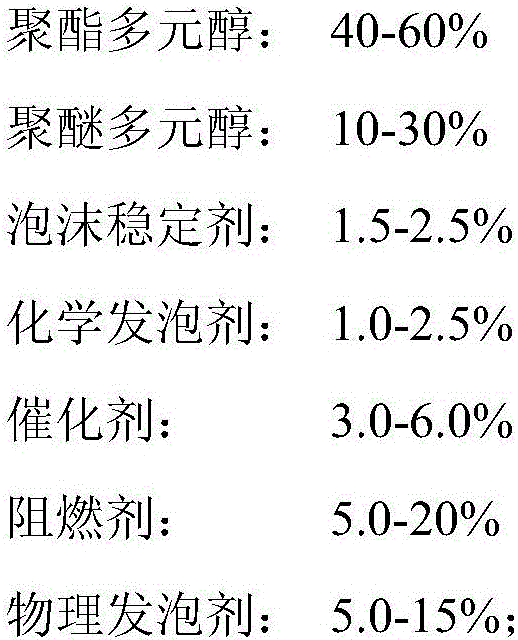

Combined polyether for continuous production of PIR block foam, as well as preparation method and application of combined polyether

The invention belongs to the technical field of polyurethane, and particularly relates to combined polyether for continuous production of PIR block foam, as well as a preparation method and application of the combined polyether. The combined polyether consists of a component A and a component B, wherein the component A consists of polyester polyol, polyether glycol, a foam stabilizing agent, a chemical foaming agent, a catalyst, a fire retardant and a physical foaming agent, and the component B is polymethylene polyphenyl polyisocyanate. While in use, materials in the component A and materials in the component B are mixed through a high-pressure foaming machine, so that PIR high-flame-resistant block foam can be in continuous production. According to the combined polyether disclosed by the invention, the production process of the materials in the component A is simple, and the discharge of three wastes is not generated; the production of a PIR type heat insulation material through the materials in the component A and the materials in the component B is simple in operation technology and easy to operate, the volatilization of gas destroying an atmospheric layer is not generated, the product quality is stable, the production cost is low, and when the environmental protection purpose is achieved, products are good in low-temperature size stability, good in flame resistance, uniform in density distribution, low in thermal conductivity, high in compressive strength and low in water absorption.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

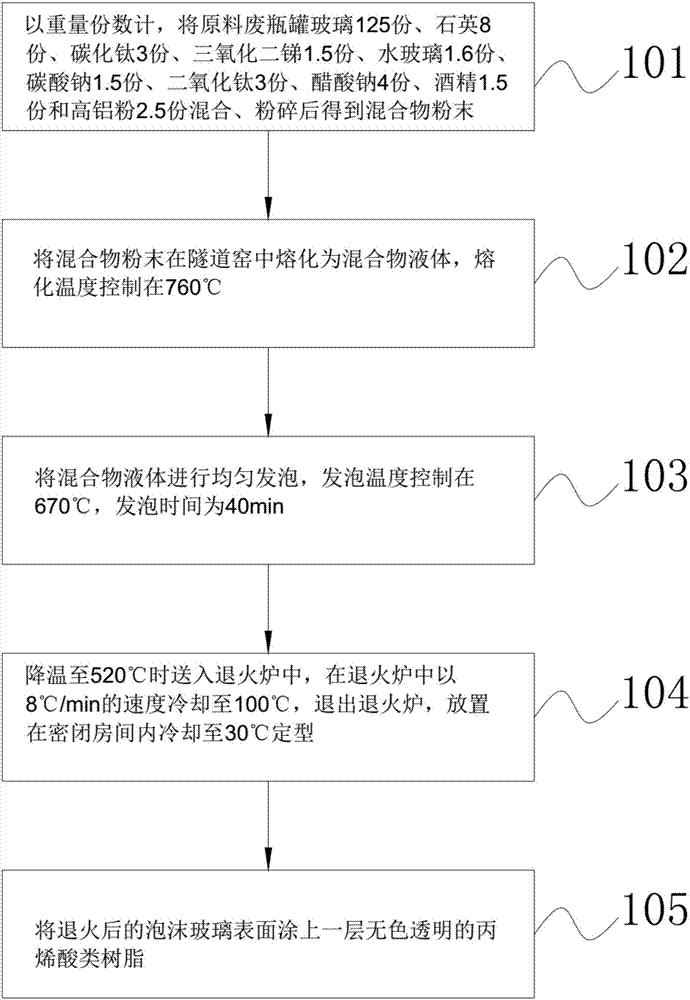

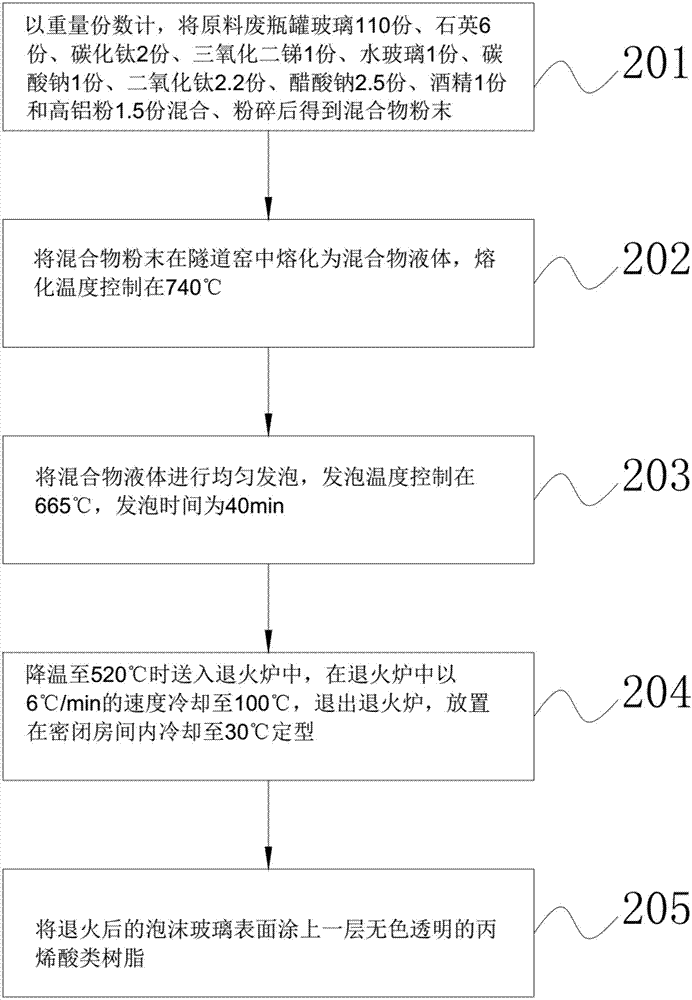

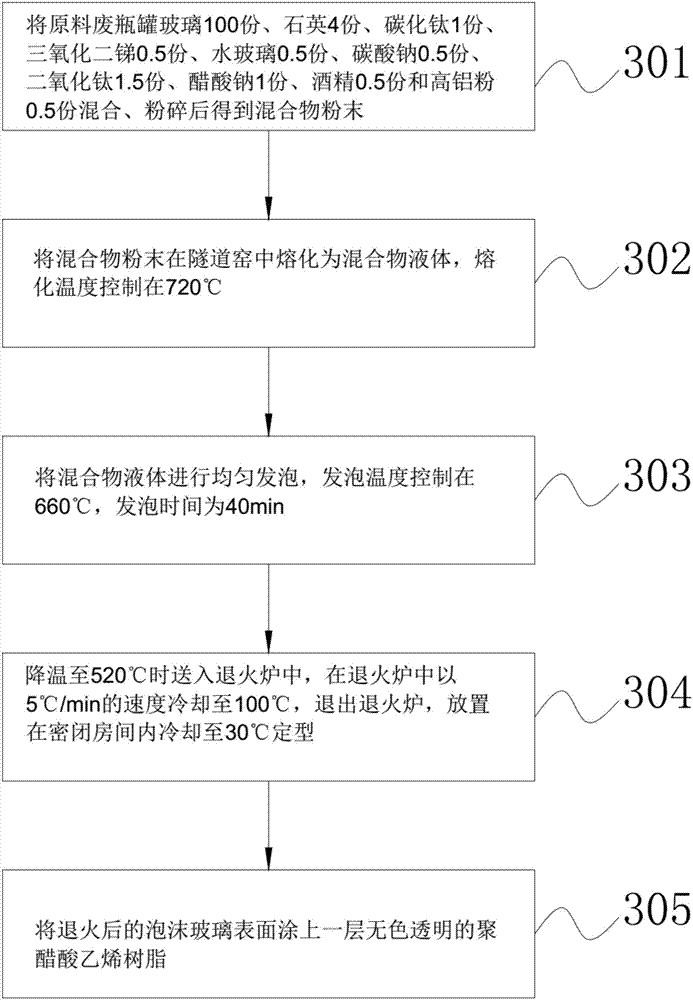

Manufacturing technique for sound-insulating foam glass

InactiveCN106957150ASolve thermal conductivitySolve the sound insulationGlass shaping apparatusCoatingsTunnel kilnAdhesive

The invention provides a manufacturing technique for a sound-insulating foam glass and relates to the technical field of glass production. The manufacturing technique comprises the following steps: (1) mixing and crushing the following raw materials in parts by weight: 100-125 parts of waste bottle glass, 4-8 parts of quartz, 1-3 parts of titanium carbide, 0.5-1.5 parts of antimonous oxide, 0.5-1.6 parts of adhesives, 1-4 parts of acetate, 0.5-1.5 parts of surface active agent and 0.5-2.5 parts of release agent, thereby acquiring mixture powder; (2) melting the mixture powder in a tunnel kiln under the melting temperature at 720-760 DEG C, thereby acquiring a liquid mixture; (3) uniformly foaming the liquid mixture for 30-40min under the foaming temperature of 660-670 DEG C; (4) while reducing the temperature to 500-520 DEG C, feeding into an annealing furnace, reducing to 100 DEG C in the annealing furnace at the rate of 5-8 DEG C / min, exiting from the annealing furnace, placing into an air-tight room, cooling to 30 DEG C and forming; (5) coating a layer of transparent organic protecting film on the surface of the annealed foam glass. The manufacturing technique has the advantages of low heat conductivity coefficient, excellent sound insulation, high strength, completeness and high heat stability.

Owner:合肥协耀玻璃制品有限公司

Insulating arc suppression nanomaterial modified transformer oil and preparation method thereof

InactiveCN107312603AAvoid hard clumpingGood dispersionLubricant compositionAntioxidantOxidation resistant

The invention discloses insulating arc suppression nanomaterial modified transformer oil which comprises the following raw materials in parts by weight: 6-8 parts of modified nanomaterial, 1-2 parts of metal deactivator, 2-4 parts of benzyl alcohol, 1-2 parts of magnesium stearate, 1-3 parts of sodium tungstate, 700-800 parts of compound base oil, 7-9 parts of hydroquinone, 0.3-0.5 parts of nitrilotriacetic acid tetrasodium salt, 0.2-0.5 parts of polymaleic anhydride, 0.8-1.2 parts of compound antioxidant, 0.4-0.6 parts of red phosphorus flame retardant and 0.4-0.8 parts of coupling agent. The transformer oil has better insulativity and arc suppression performance, and has better oxidation resistance under a high temperature condition; the nanomaterial is introduced, so that the possibility of oxidation, aging and corrosion of the transformer oil is low, and the stability is improved; and in addition, the transformer oil has good flame retardation, is safe and reliable in raw material component, lower in cost and concise in technology, and has a higher practical value and a good application prospect.

Owner:合肥轻风飏电气科技有限责任公司

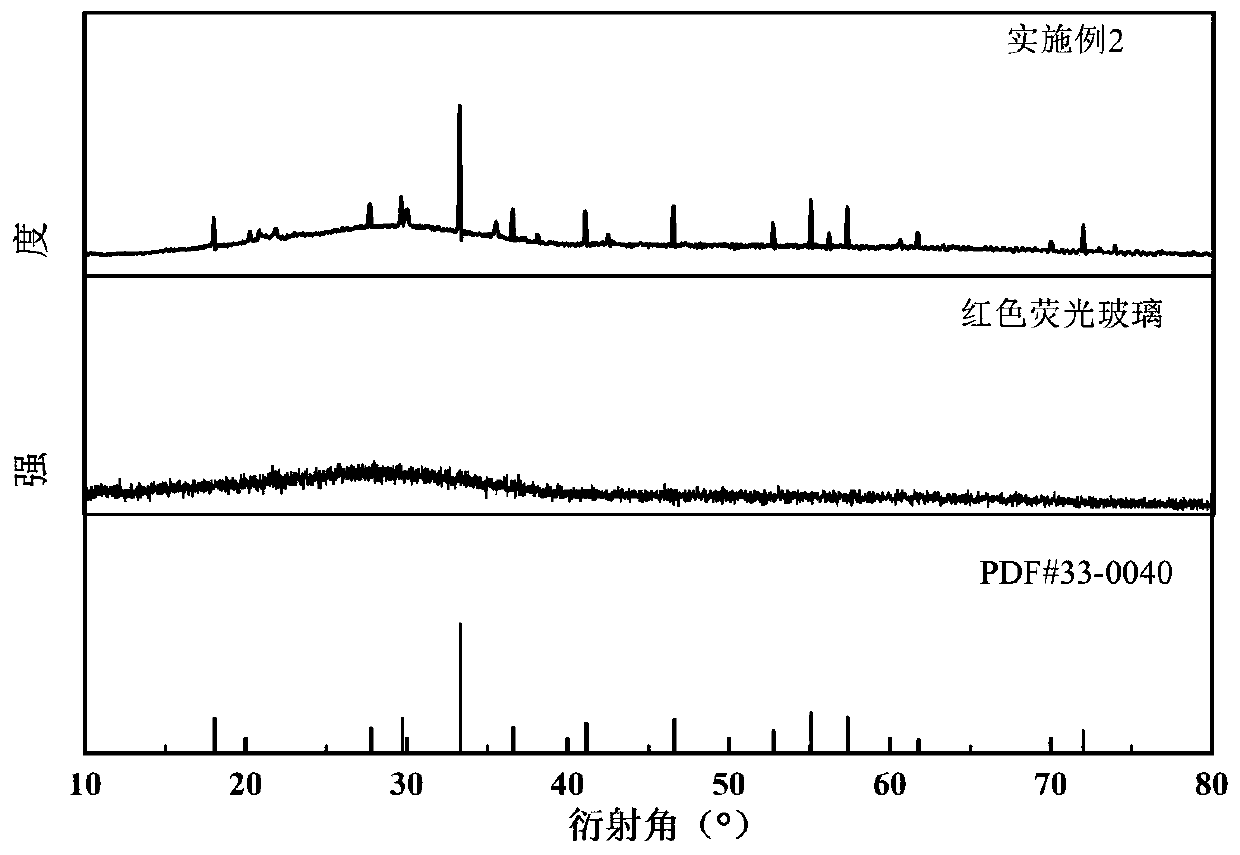

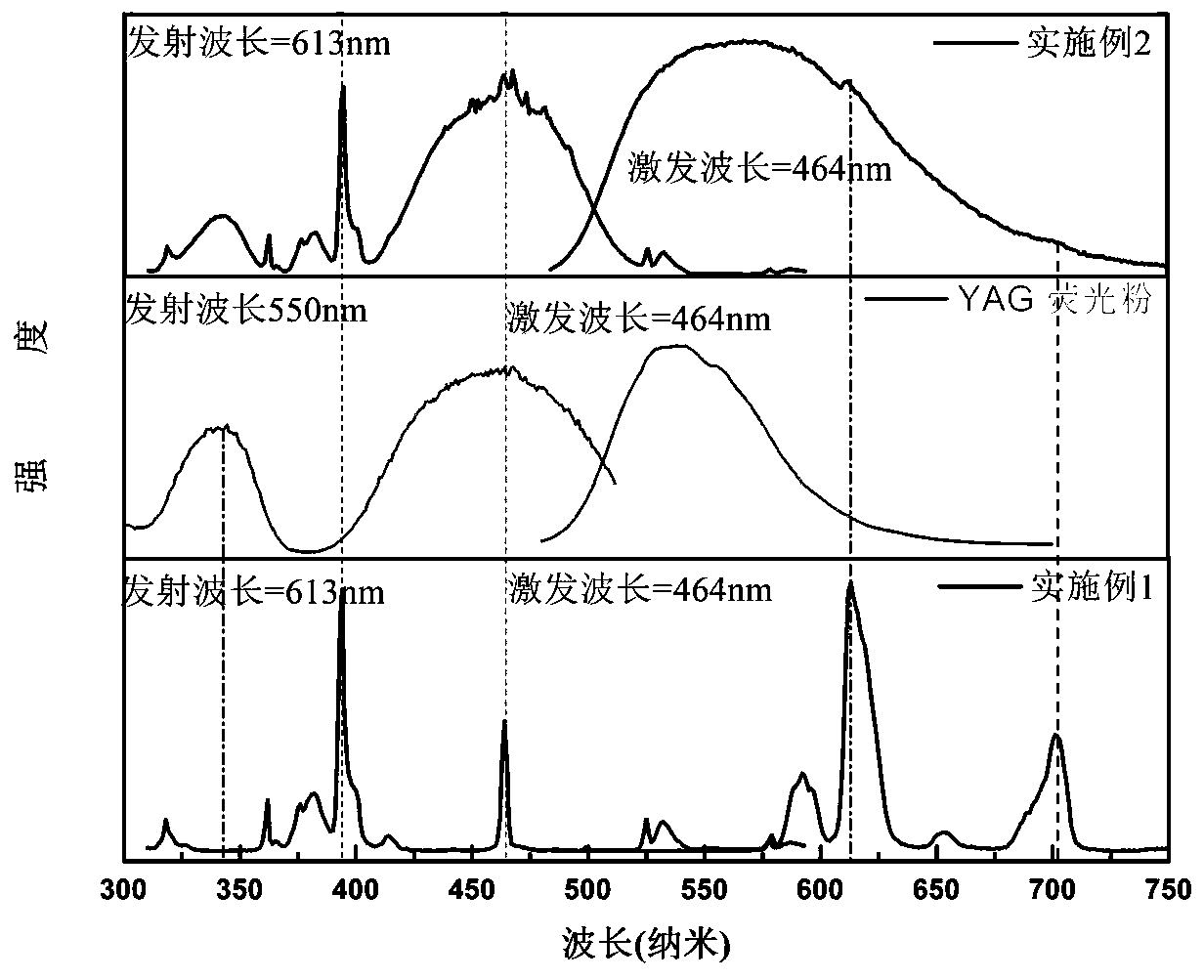

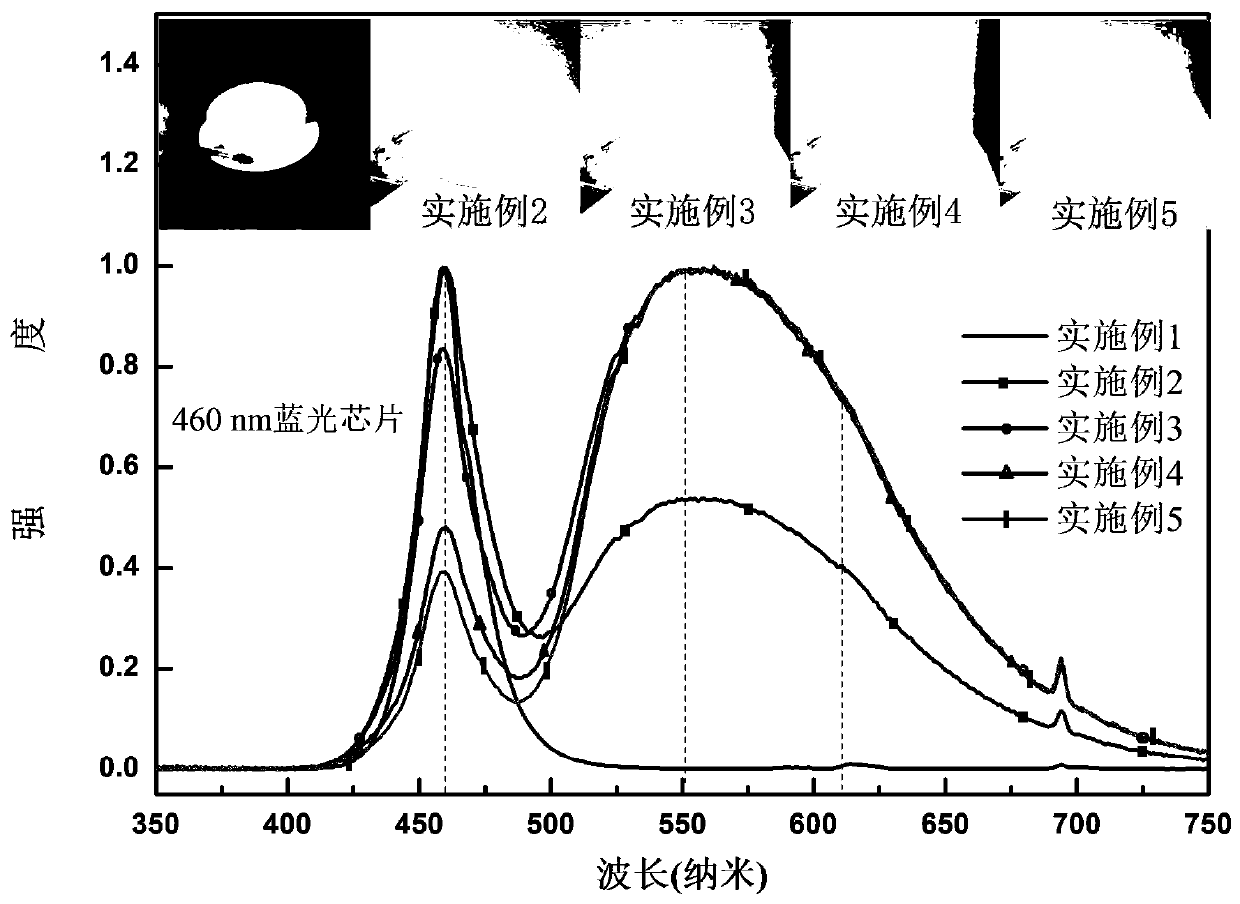

Red light compensation fluorescent glass ceramic, preparation method thereof and application thereof in white light LED device

InactiveCN110615613AImprove thermal stabilityAddressing Thermal StabilityGlass shaping apparatusSemiconductor devicesFluorescenceThermal stability

The invention discloses red light compensation fluorescent glass ceramic, a preparation method thereof and an application of the red light compensation fluorescent glass ceramic in a white light LED device. Red borophosphate fluorescent glass capable of being effectively excited by blue light is prepared through a high-temperature melting method, and then the red borophosphate fluorescent glass and YAG:Ce<3+> yellow fluorescent powder are compounded into the red light compensation fluorescent glass ceramic through a low-temperature co-firing method. The YAG:Ce<3+> yellow fluorescent powder anda glass substrate in the fluorescent glass ceramic can be excited by blue light at the same time to emit yellow light and red light, and an LED device emitting white light is obtained by compoundingthe blue light, the yellow light and the red light. Thermal stability of the glass ceramic is effectively improved, the glass ceramic is suitable for a high-power LED device, prolongs the service lifetime of the device, increases the red light component, improves the color rendering property of the device, and avoids weakening the transparency of the material and reducing the excitation efficiencyof a chip due to the fact that red fluorescent powder is additionally added to improve the color rendering property. The variety field and application range of the light-emitting material are broadened.

Owner:SHANGHAI UNIV

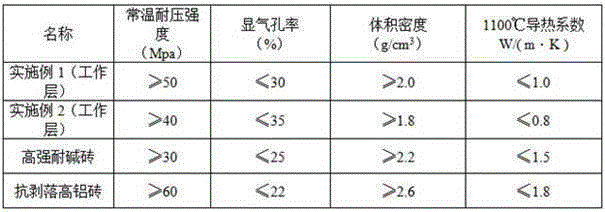

Low-heat conduction insulating brick and preparation method thereof

ActiveCN105198454ASolve the problem of longevitySolve thermal conductivityLayered productsBrickRefractory

The invention belongs to the technical field of refractory materials, and in particular relates to a low-heat conduction insulating brick and a preparation method thereof. The low-heat conduction insulating brick is composed of a working layer and an insulating layer, wherein the working layer and the insulating layer are adhered by a low-heat conduction high-temperature glue, the insulating layer is a nanometer-micropore insulating plate with the cold crushing strength being greater than or equal to 0.5MPa, and the working layer is prepared from a bauxite aggregate with the particle size being 0-1mm, a bauxite aggregate with the particle size being 1-3mm, a bauxite aggregate with the particle size being 3-5mm, high-alumina powder with the particle size being smaller than 0.074, nano-powder, a high-temperature fortifier and an additionally-added bonding agent. The average volume density of the low-heat conduction insulating brick is far lower than those of a high-strength alkali-resisting brick and an anti-stripping alumina brick, so the dead load of equipment can be greatly lowered; moreover, the heat preservation and heat insulation effect and the service life are both superior to those of the alkali-resisting brick, thus better energy conservation and emission reduction effects can be achieved.

Owner:郑州瑞泰耐火科技有限公司

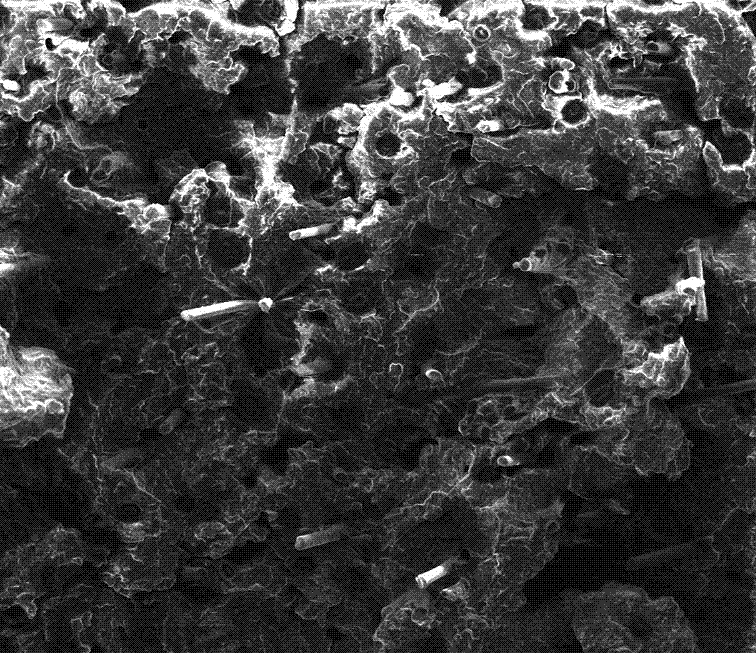

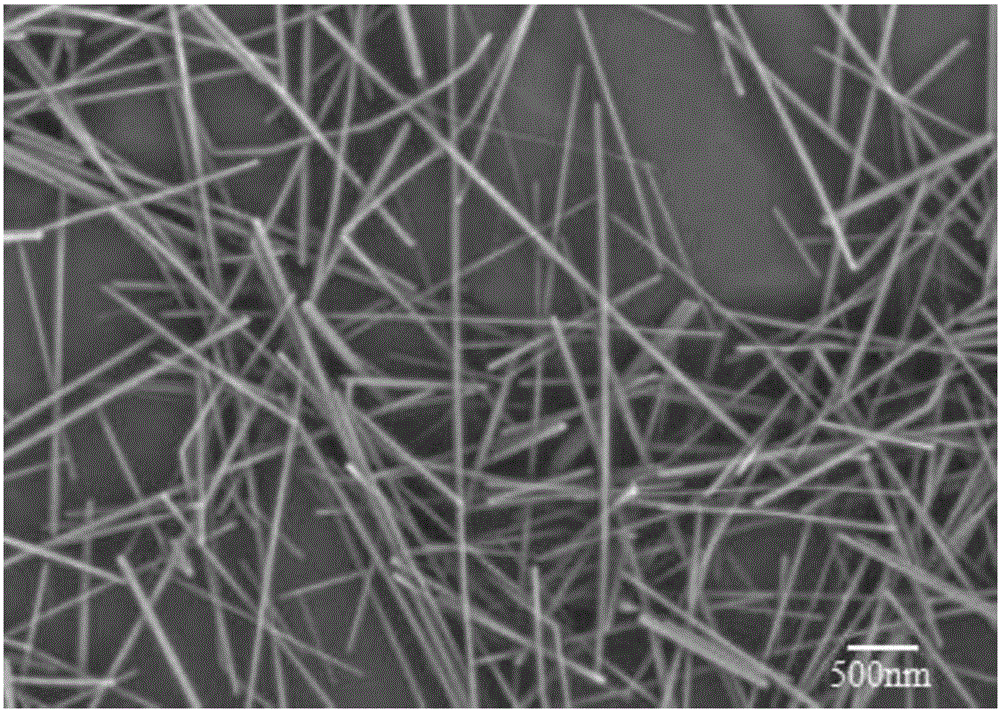

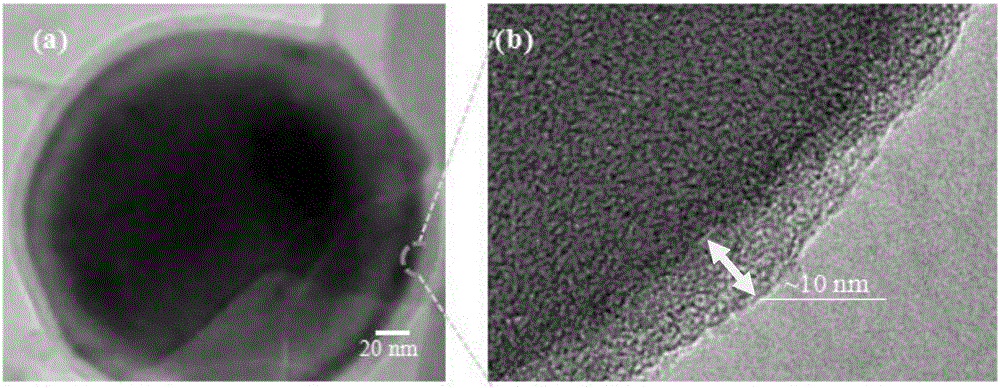

Polymer matrix composite and preparation method thereof

InactiveCN106189012ASolve thermal conductivitySolve insulation problemsLayered product treatmentLaminationStable statePolymer science

The invention provides a polymer matrix composite which comprises a polymer matrix and nano-scale metal fillers, wherein the nano-scale metal fillers comprise nano-scale metal fibers and nano-scale metal grains; the nano-scale metal fibers and the nano-scale metal grains are under stable state through surface modified treatment; the nano-scale metal fillers are scattered in the polymer matrix; in the polymer matrix composite, the weight percent of the polymer matrix is 85-97% and the weight percent of the nano-scale metal fillers is 3-15%; the sum of the weight percent of the polymer matrix and the nano-scale metal fillers is 100%; in the nano-scale metal fillers, the mass ratio of nano-scale metal fibers to nano-scale metal grains is (1-3):1. The polymer matrix composite provided by the invention can effectively promote the heat conduction property of the composite, can achieve the purpose of maintaining low dielectric loss characteristic and can greatly increase the thermal and electric properties of the polymer matrix composite.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

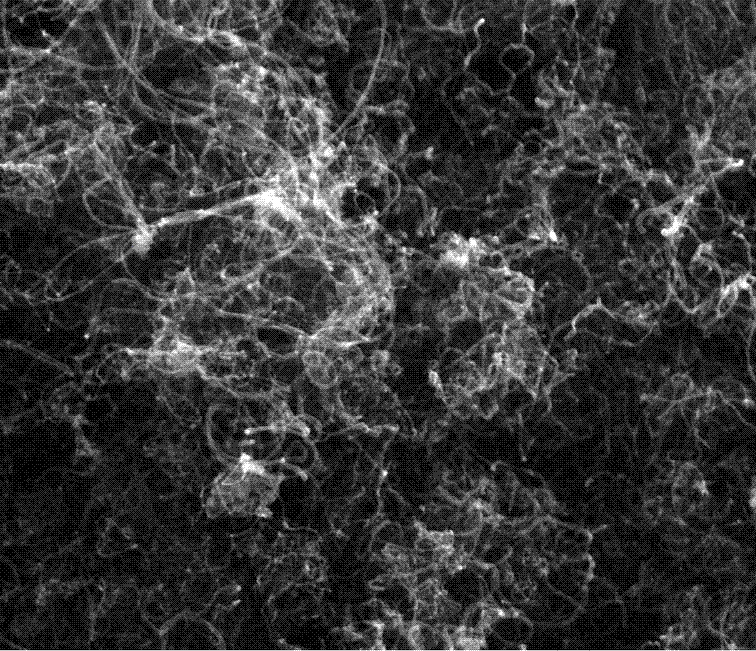

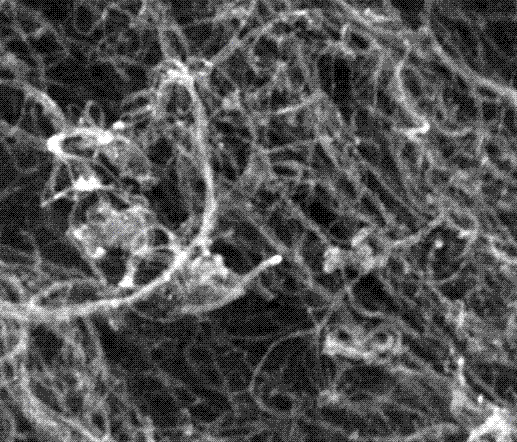

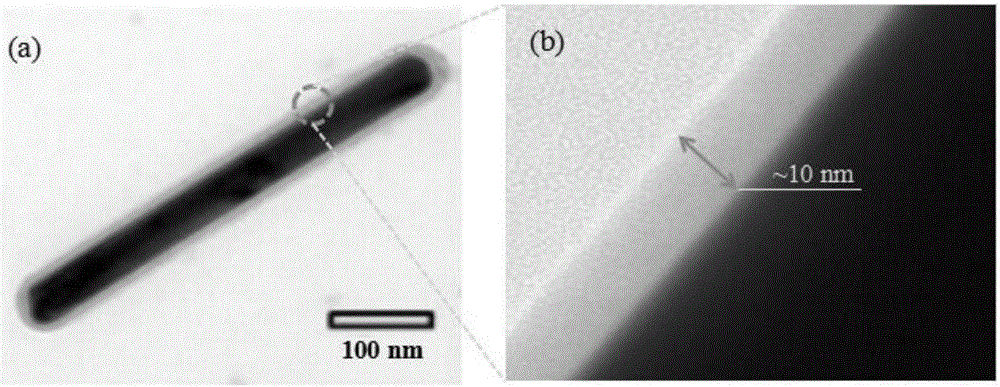

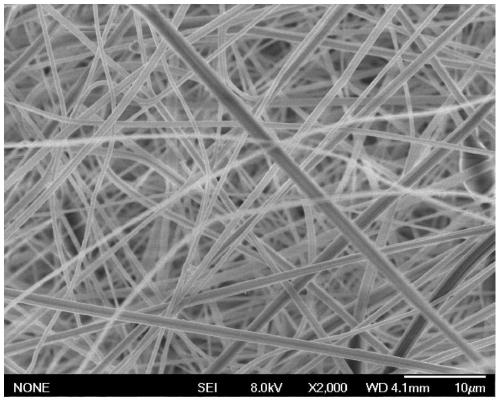

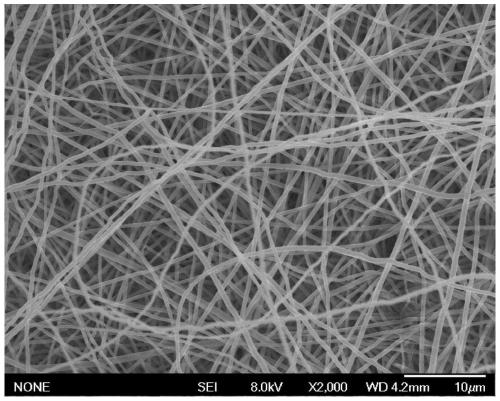

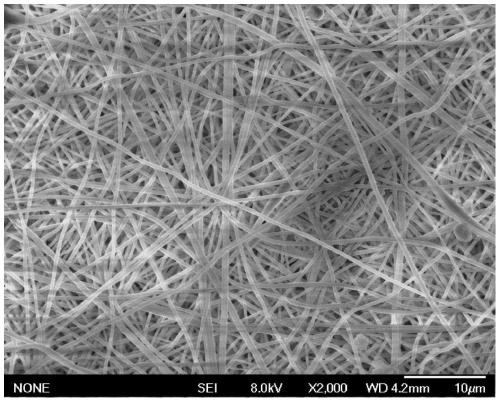

Preparation method of isotropic high-thermal-conductivity carbon nanofiber membrane, and product thereof

ActiveCN111170316ASolve thermal conductivityImprove thermal conductivityCarbon compoundsFilament/thread formingFiberPolymer science

The invention discloses a preparation method of an isotropic high-thermal-conductivity carbon nanofiber membrane, and a product thereof. The preparation method comprises the following steps: (1) electrostatic spinning; (2) rolling; (3) hot pressing; (4) pre-oxidation; (5) carbonizing; and (6) graphitization. According to the preparation method disclosed by the invention, the PAN fiber membrane isprepared by an electrostatic spinning technology; then rolling and hot pressing treatment is carried out on the PAN fiber membrane, so tightly cross-linked adhesion nodes are formed among PAN fibers;and then pre-oxidation, carbonization and graphitization treatment is carried out, so the carbon nanofibers are highly cross-linked and are in close contact with each other, a continuous heat transferpath is formed in each direction, a good heat conduction network is formed, the carbon nanofibers are ensured to have good heat conductivity in each direction, the defects that a traditional carbon nanofiber membrane is low in heat conductivity and a graphite heat conduction membrane has low a heat conductivity coefficient in a vertical direction are effectively overcome, and good heat conductioneffect is obtained.

Owner:SONGSHAN LAKE MATERIALS LAB

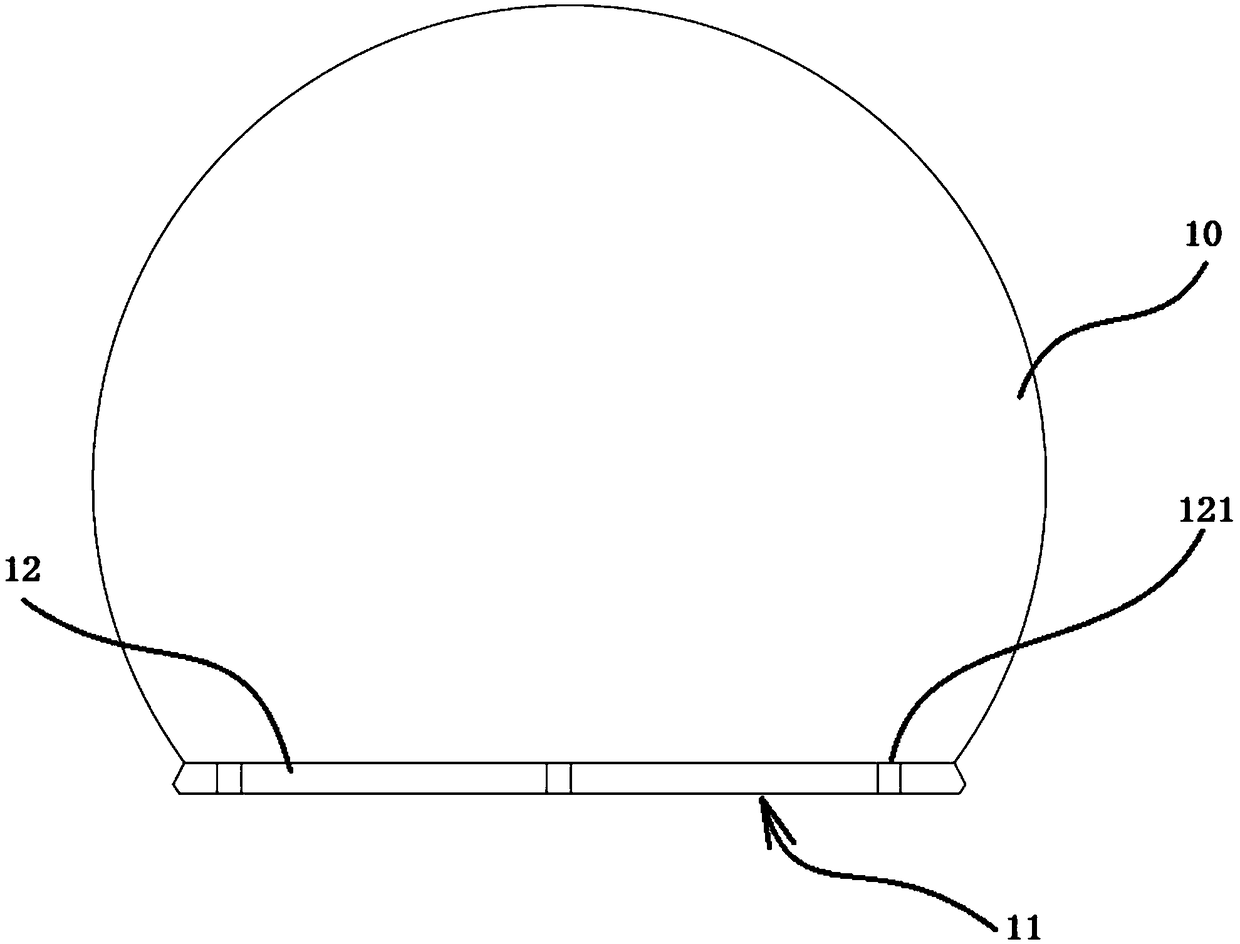

Manufacturing method of LED bulb heat dissipation lampshade and manufactured lampshade

InactiveCN109058931AImprove thermal conductivityImprove cooling effectLighting heating/cooling arrangementsHeat-exchange elementsSilanesPolymethyl methacrylate

The invention discloses a manufacturing method of an LED bulb lampshade. Polypropylene, polymethyl methacrylate, silicon resin, methyl acryloyloxy silane and other combinations are adopted to undergohybrid heating and then undergo integrally-formed injection molding to form the LED bulb lampshade, the related heat dissipation lampshade is formed in the way that hybrid heating of the above multiple kinds of materials is performed, then the materials flow into an injection molding machine mold for one-time forming, then the mold is cooled in a water-cooling mode, then the lampshade is turned tobe a final lampshade finished product through demolding, the problems of an existing LED bulb lamp lampshade in the aspects of heat conduction and heat dissipation are solved through the lampshade, so that the lampshade of the LED bulb lamp has a light mixing function and also has a heat dissipation function, meanwhile, innovation is also made in the aspect of the structure, so that the lampshadeis simpler and more convenient to install.

Owner:贵州杰芯光电科技有限公司

High thermal conductivity metal base circuit board and preparing method thereof

InactiveCN105120591AImprove thermal conductivityGood resistance to cold and heat cyclesPrinted circuit aspectsPrinted circuit manufactureInsulation layerPolyethylene glycol

The invention provides a high thermal conductivity metal base circuit board and a preparing method thereof. The circuit board comprises a metal base plate, a thermal conducting insulation layer arranged on the surface of the metal base plate, and a circuit formed on the thermal conducting insulation layer. The material of the thermal conducting insulation layer includes paint with following components by mass percentage: 40-60% by mass of a mixture of polyethylene glycol terephthalate and polybutylene terephthalate; 30-40% by mass of a mixture of aluminum oxide, aluminium nitride and boron nitride powder; 5-10% by mass of cosolvent; 3-10% by mass of diluent; and 0.5-1% by mass of curing agent. The above mentioned components account for 100% of the total mass percentage content. The heat conduction coefficient of the metal base circuit board ranges from 5W / k.M to 15W / k.M, enabling the metal base circuit board to achieve effective heat conduction, and therefore, the stability and service lifetime of an electronic component can be improved. It is also possible to make a circuit, including an abnormal-shaped circuit on a metal carrier, providing a new method to attain circuit boards of different purposes. The invention also provides a preparing method for such high thermal conductivity metal base circuit board.

Owner:SHENZHEN LAITENING NEW MATERIAL TECH

Hollow polyhedral metal auto-radiating circuit board

InactiveCN101598316ASolve thermal conductivitySolve the cooling problemPoint-like light sourceSemiconductor/solid-state device detailsAbnormal shapesAbnormal shaped

The invention is a hollow polyhedral metal auto-radiating circuit board which can effectively solve the problems of LED radiating and light attenuation. The invention comprises the following steps: a traditional metal base plate is changed into a hollow metal base plate the middle of which is in polyhedral column type; one side of the hollow metal base plate is leveled as a manufacturing surface of the circuit board; the shape of the hollow polyhedral metal auto-radiating circuit board can be designed in U-shaped or abnormal shape, slim shape or thickening shape according to the design requirements; the circuit board can be processed at will on the premise of adding no additional processes according to the product profile and the cambered surface requirement of the reflection surface to solve the problem of a plurality of reflection angles like streetlights. In the invention, the original massive cast aluminum is changed into an internal heat abstractor which is light, slim and flexible and has small volume and large area, and the internal heat abstractor consists of a polyhedral metal base plate and an insulating circuit layer; the polyhedral metal base plate can be processed into a circuit core board, the radiating surface of the base plate can be integral with the circuit core board, so one side of the integrated structure can radiate heat, the other side of the integrated structure can be as a circuit and the integrated structure close to lamp; the hollow column can form convection with outside air to realize the effect of efficient radiating heat.

Owner:NANJING NADI OPTOELECTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com