Thermal grease composition

A technology of thermal conductive silicone grease and composition, which is applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of poor thermal conductivity, poor thermal conductivity, powder coating of thermal conductive silicone grease, etc., and achieves good use and weather resistance. performance, high thermal conductivity, the effect of thin coating thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

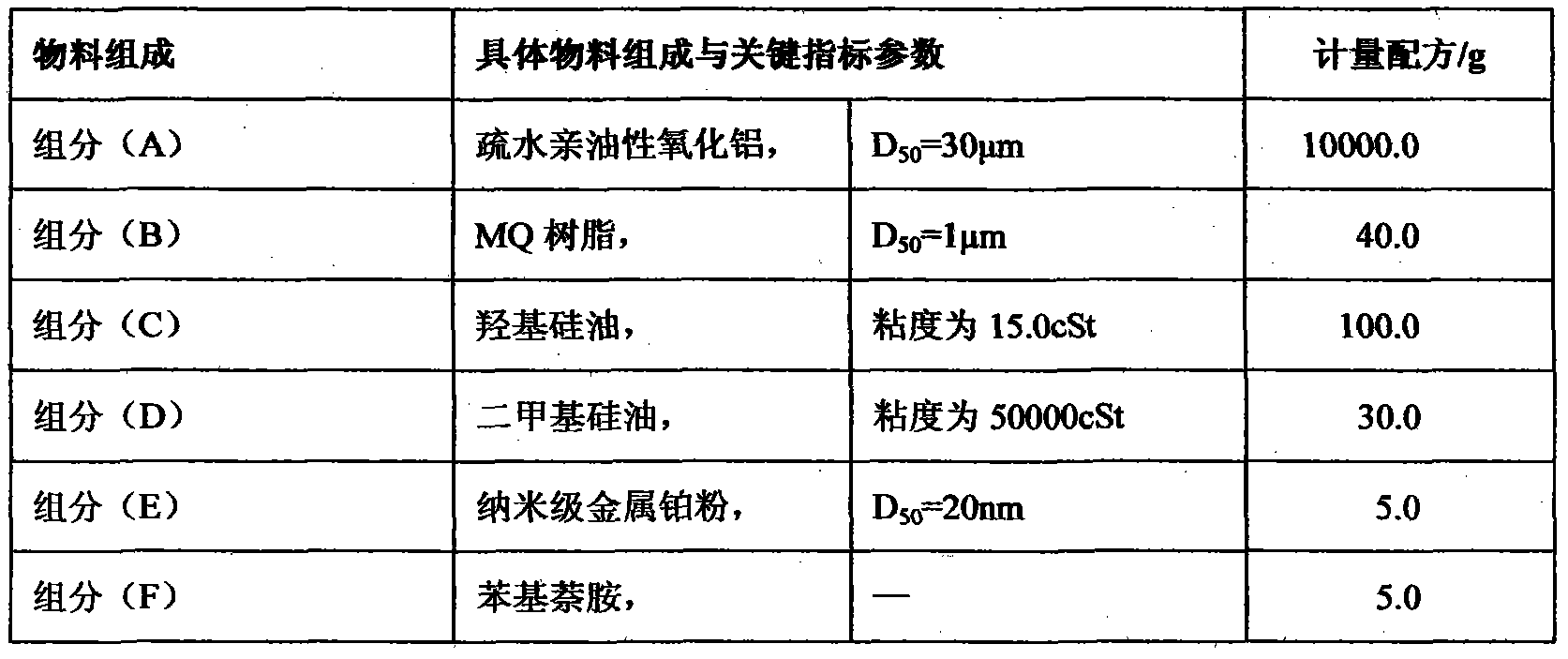

[0037] 1. Material composition and measurement formula

[0038]

[0039] 2. Manufacturing process steps

[0040] (1) Weighing materials: take by weighing according to the above-mentioned material measurement formula, and place in a 20L stirring tank;

[0041] (2) Uniform mixing: stir until uniform with a high-speed mixer, the stirring speed is 1000rpm, and it is in the form of a flowing paste;

[0042] (3) Colloid mill grinding: Grinding and dispersing the above paste on a high-speed colloid mill for 2 times;

[0043] (4) Three-roll grinding: Slowly grind and finely grind twice on three rolls to realize the densification and defoaming effect of thermal conductive silicone grease;

[0044] (5) Vacuum degassing: carry out in a vacuum stirred tank, and vacuumize for 2 hours.

[0045] The finished thermal conductive silicone grease is obtained through the above process steps. The obtained thermal conductive silicone grease was tested for thermal conductivity and heat treatm...

Embodiment 2

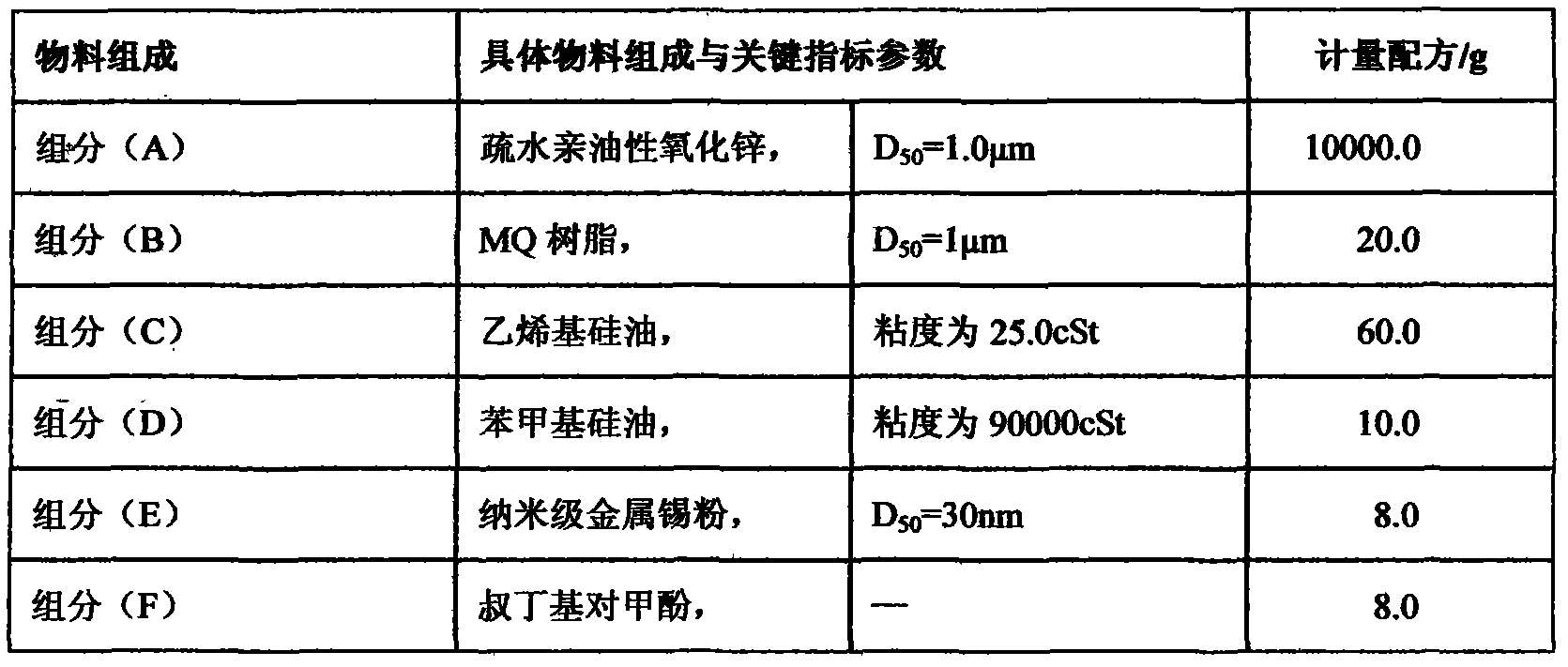

[0052] 1. Material composition and measurement formula

[0053]

[0054] 2. Manufacturing process steps

[0055] (1) Take the material, weigh it according to the above-mentioned material measurement formula, and place it in a 20L stirred tank;

[0056] (2) Mix evenly, stir until uniform with a high-speed mixer, the stirring speed is 2000rpm, and it is in the shape of a flowing paste;

[0057] (3) Grinding with a colloid mill, grinding and dispersing the above-mentioned paste on a high-speed colloid mill for 1 time;

[0058] (4) Three-roller grinding, slow grinding and fine grinding on the three-roller once, to achieve the densification and defoaming effect of thermal conductive silicone grease;

[0059] (5) Vacuum degassing is carried out in a vacuum stirred tank, and the vacuum treatment is carried out for 3 hours.

[0060]The finished thermal conductive silicone grease is obtained through the above process steps. The obtained thermal conductive silicone grease was tes...

Embodiment 3

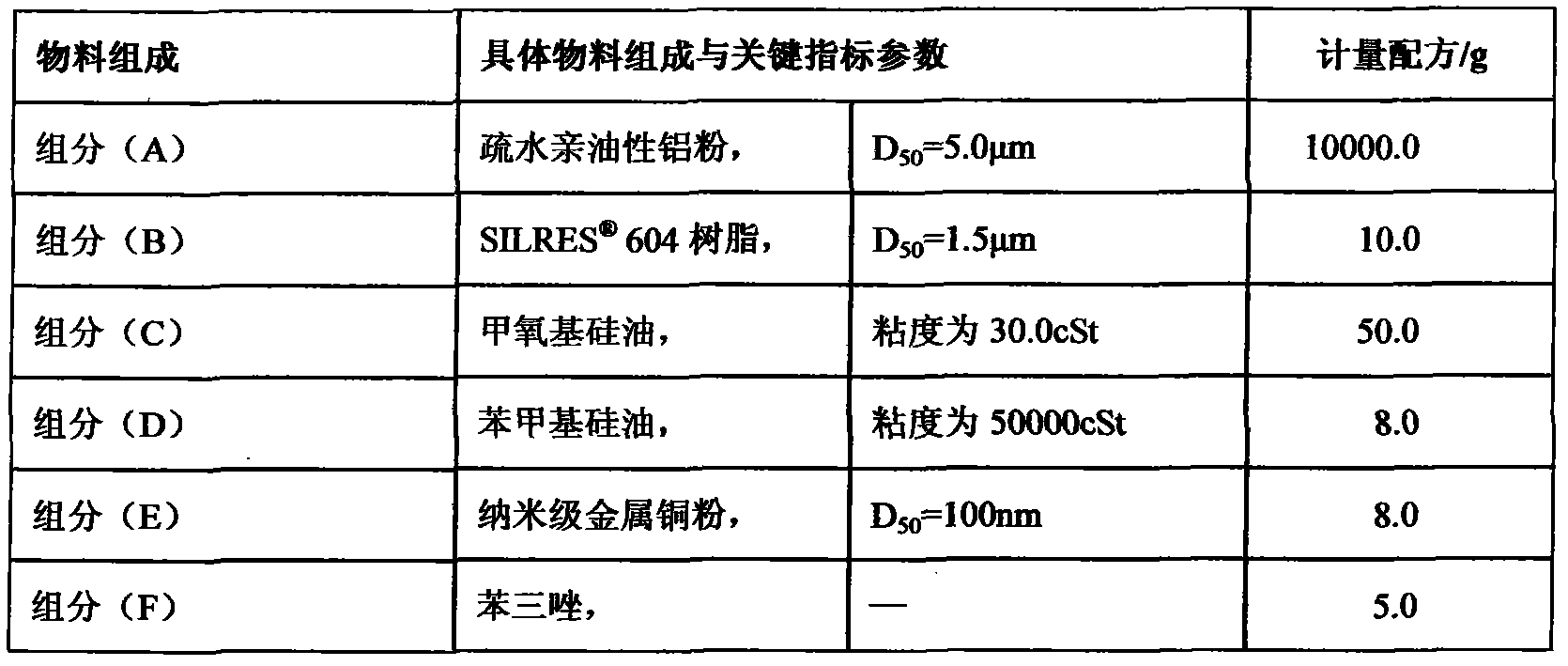

[0067] 1. Material composition and measurement formula

[0068]

[0069] 2. Manufacturing process steps

[0070] (1) Take the material, weigh it according to the above-mentioned material measurement formula, and place it in a 20L stirred tank;

[0071] (2) Mix evenly, stir until uniform with a high-speed mixer, and the stirring speed is 1500rpm;

[0072] (3) Colloid mill grinding, the above-mentioned paste is ground and dispersed on a high-speed colloid mill for 2 times, and the fluidity becomes better;

[0073] (4) Three-roller grinding, slow grinding and fine grinding on the three-roller once, to achieve the densification and defoaming effect of thermal conductive silicone grease;

[0074] (5) Vacuum degassing, carried out in a vacuum stirred tank, and vacuumized for 5 hours.

[0075] The finished thermal conductive silicone grease is obtained through the above process steps. The obtained thermal conductive silicone grease was tested for thermal conductivity and heat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com