Patents

Literature

194 results about "Thermal grease" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal grease (also called CPU grease, heat paste, heat sink compound, heat sink paste, thermal compound, thermal gel, thermal interface material, or thermal paste) is a thermally conductive (but usually electrically insulating) compound, which is commonly used as an interface between heat sinks and heat sources such as high-power semiconductor devices. The main role of thermal grease is to eliminate air gaps or spaces (which act as thermal insulation) from the interface area in order to maximize heat transfer and dissipation. Thermal grease is an example of a thermal interface material.

Thermal management materials

InactiveUS6946190B2Reduce thermal resistanceImprove heat transfer performanceSemiconductor/solid-state device detailsSynthetic resin layered productsMetal alloyRoom temperature

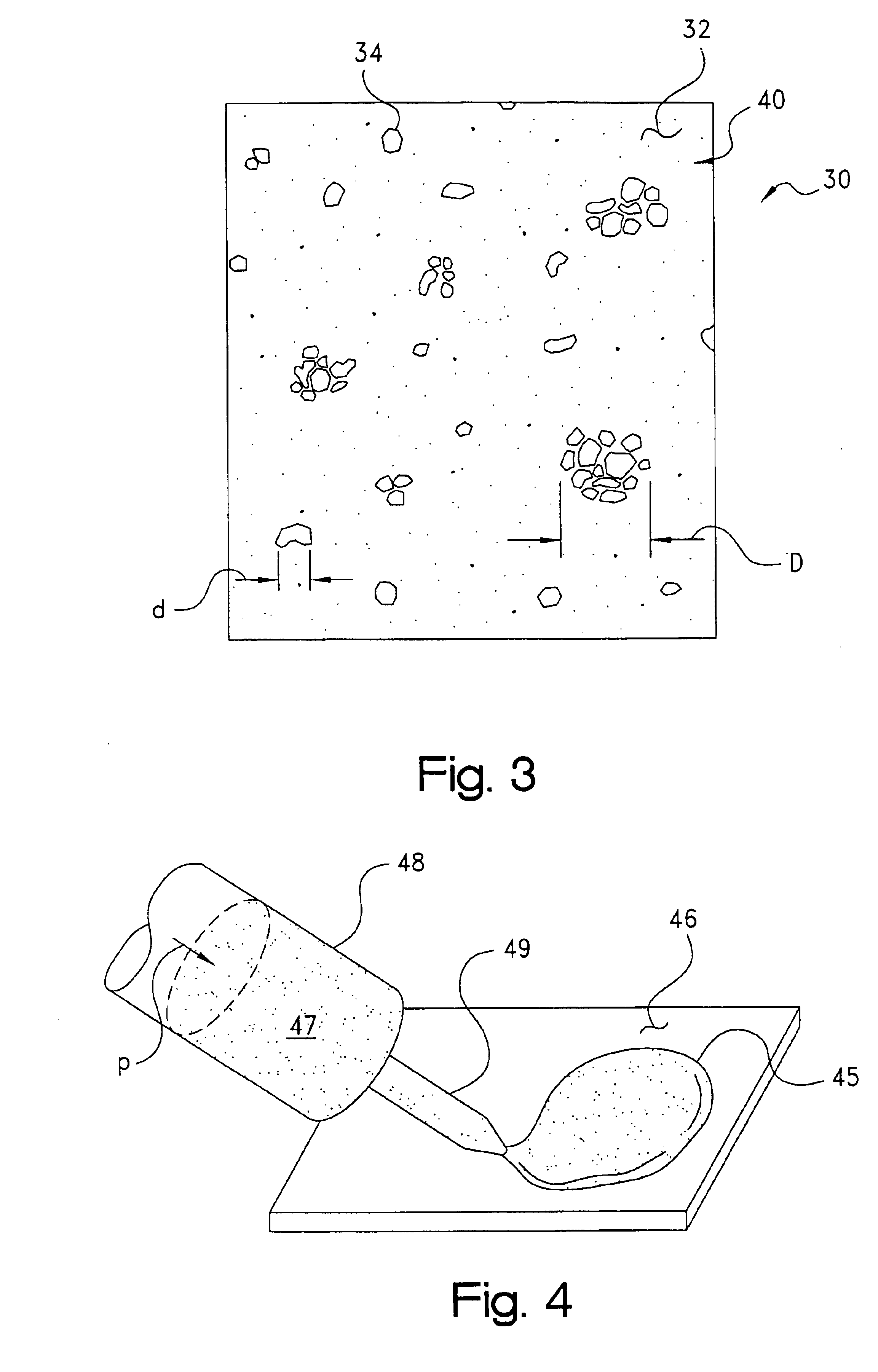

A thermally-conductive compound for forming a layer which is conformable between a first heat transfer surface and an opposing second heat transfer surface to provide a thermal pathway therebetween. The compound is an admixture of a thermal grease component and a dispersed constituent forming discrete domains within the grease component, the domains being form-stable at normal room temperature in a first phase and conformable between the first and second heat transfer surface in a second phase, and the domains having a domain transition temperature above normal room temperature from the first phase to the second phase. The dispersed constituent may be a fusible, i.e., low temperature melting, metal or metal alloy.

Owner:PARKER INTANGIBLES LLC

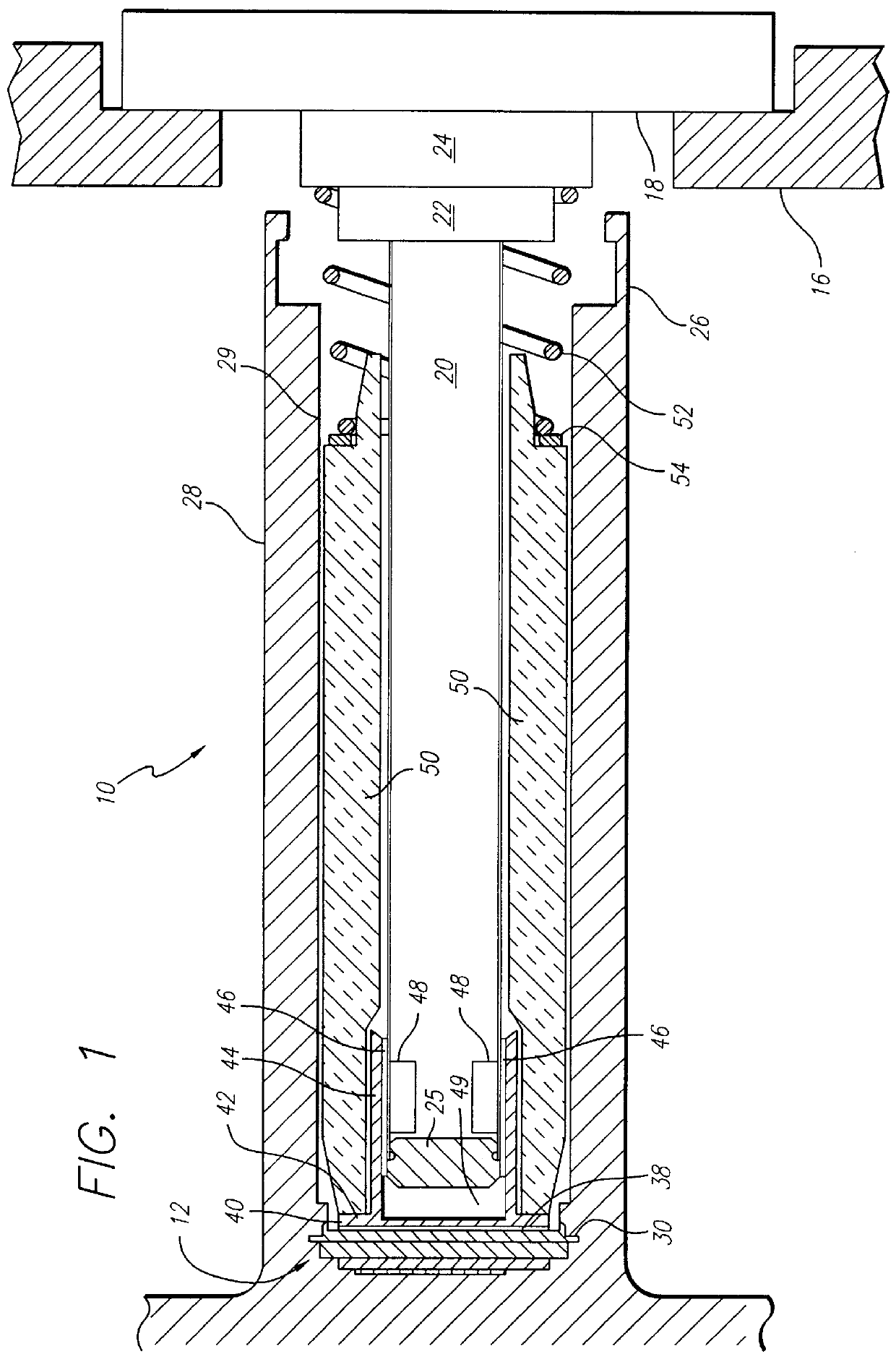

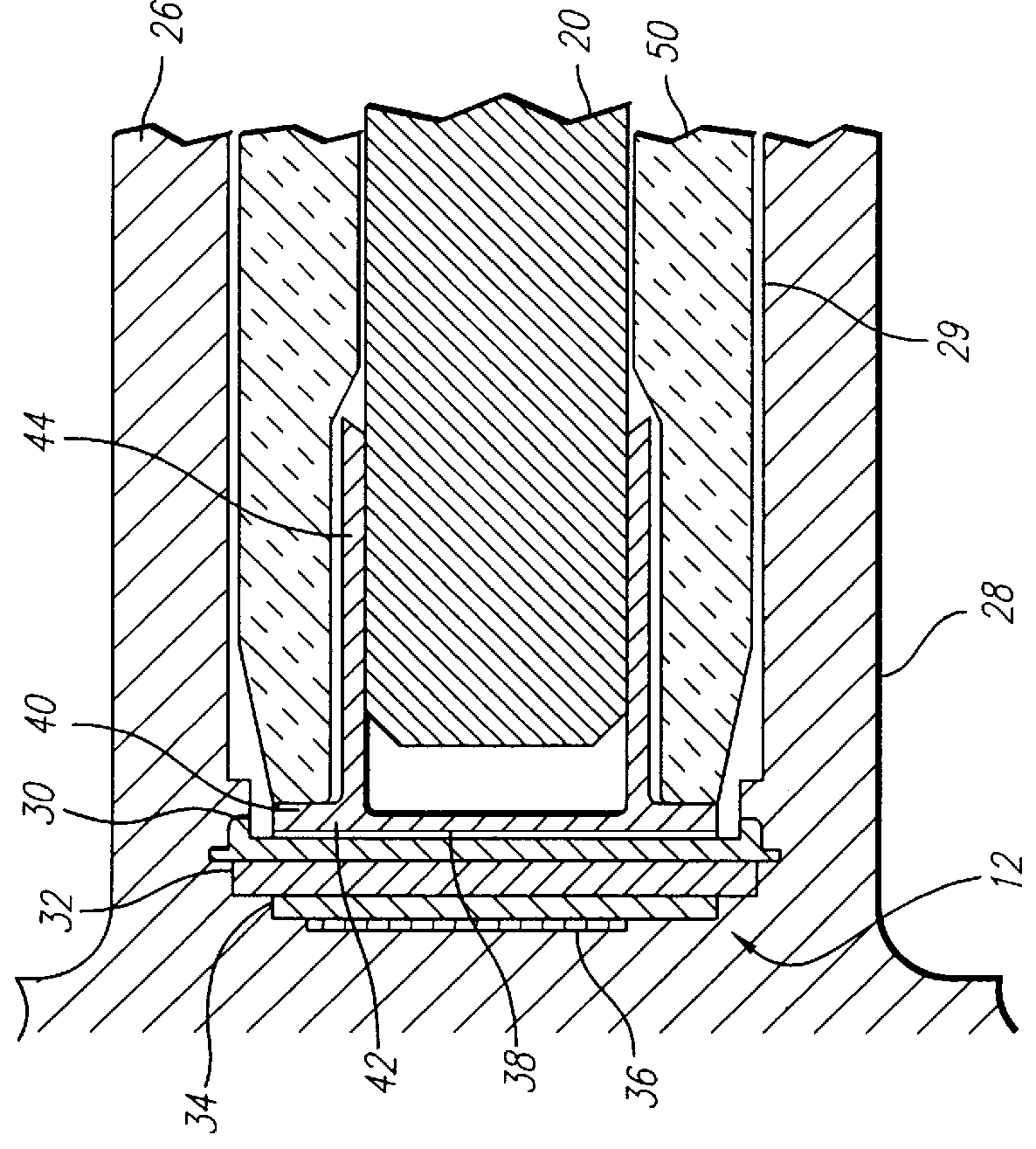

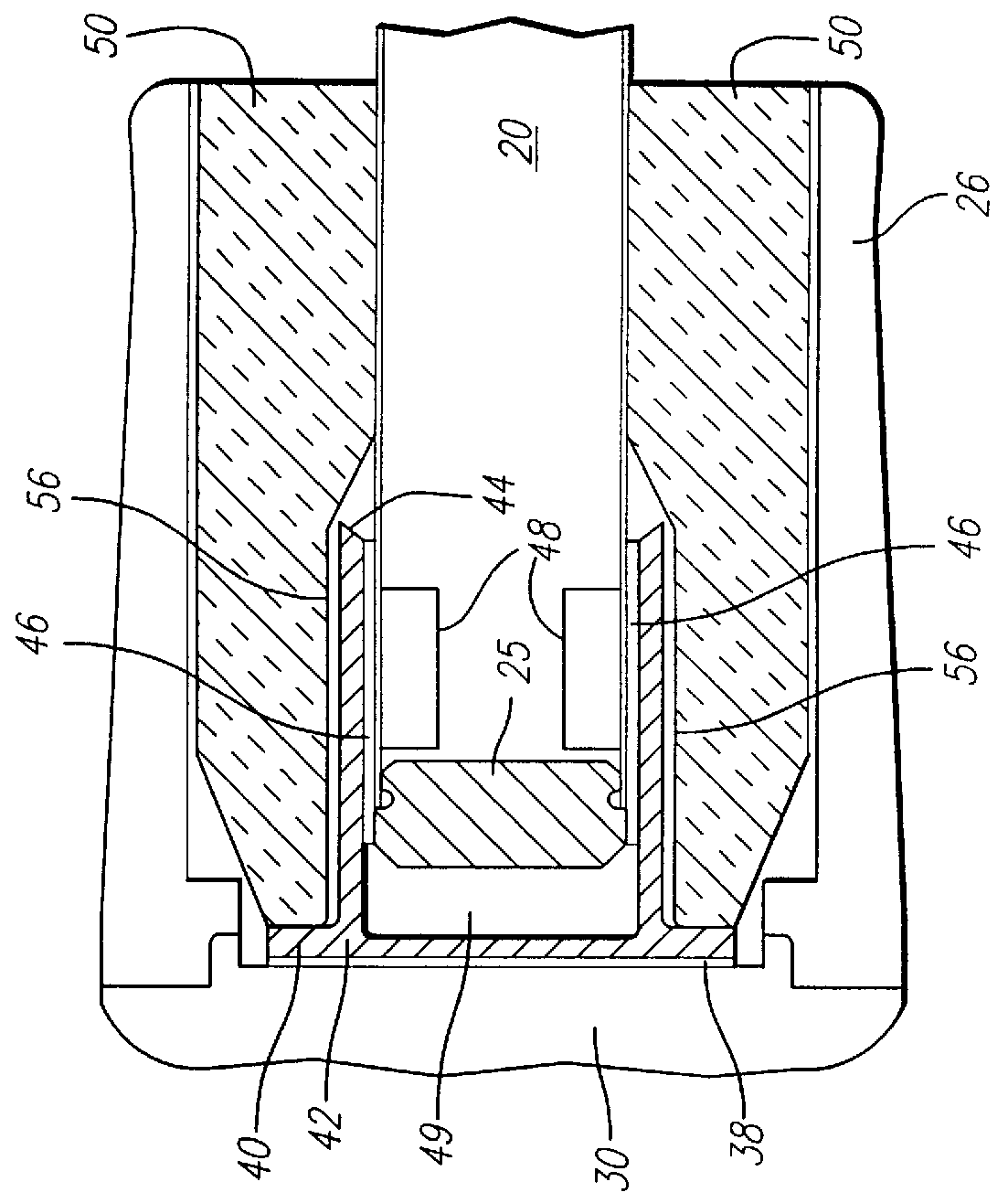

Cryogenic cooler with mechanically-flexible thermal interface

A cryogenic cooler and a dewar assembly including a cooled surface; a cooling surface for removing thermal energy from said cooled surface; and an adapter disposed between said cooling surface and the cooled surface for conducting thermal energy therebetween. A first fluid is disposed between the cooled surface and the adapter for conducting thermal energy from the cooled surface to the adapter. A second fluid is disposed between the cooling surface and the adapter for conducting thermal energy from the adapter to the cooling surface whereby the cooling surface remains free to move axially relative to the adapter at a temperature of the cooling surface at which the first fluid is susceptible to freezing. This allows for movement of the cold finger relative to the dewar and adapter, due to differential thermal coefficients of expansion or support structure motion, without adversely affecting the communication of thermal energy from the load. In the illustrative embodiment, the cooler is a Stirling cycle cooler, the first fluid is thermal grease and the second fluid is nitrogen. The cooling surface is a cylindrical cold finger of the Stirling cycle cooler and the cooled surface is an inner wall of a dewar assembly. The dewar is in thermal contact with a load. The adapter is disposed between the inner wall of the dewar and the cold finger. The adapter has an end cap and a cylindrical housing extending therefrom. The housing extends at least partially along a longitudinal axis of the cold finger. An insulator is disposed about the cold finger and the adapter housing. A spring is disposed between a proximal end of the insulator and a base of the cold finger to maintain a distal end of the insulator in contact with the adapter and the adapter in contact with the dewar.

Owner:RAYTHEON CO

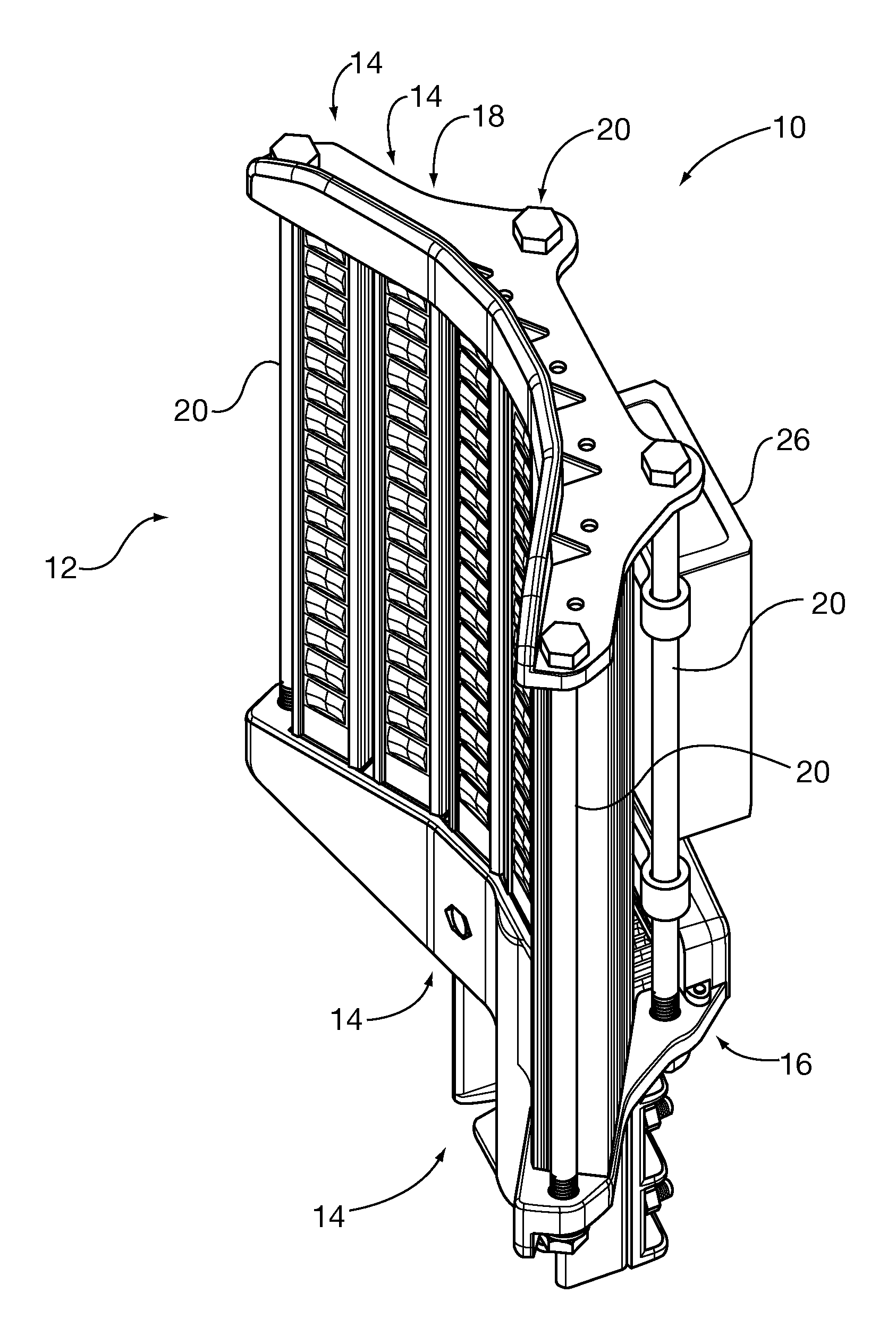

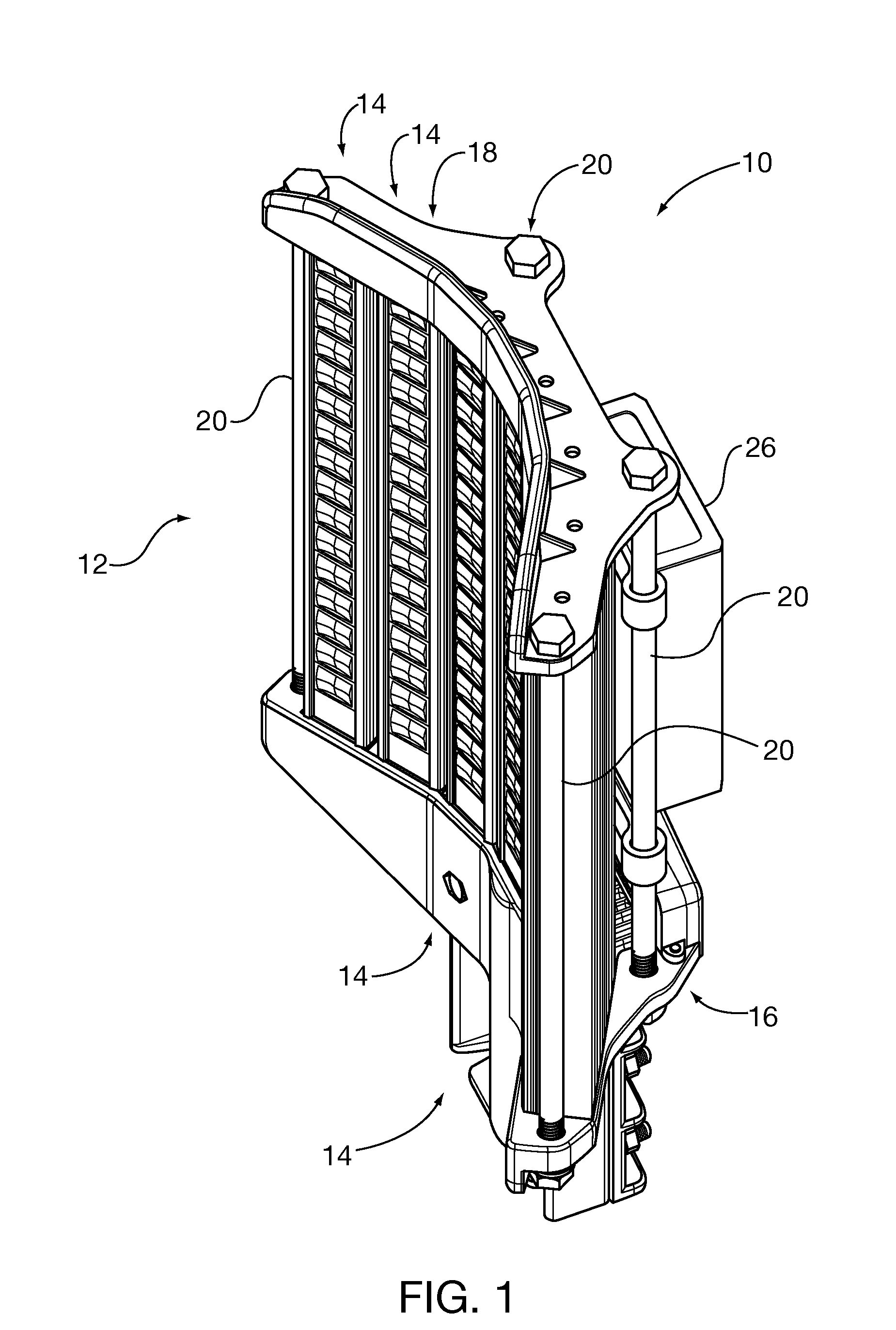

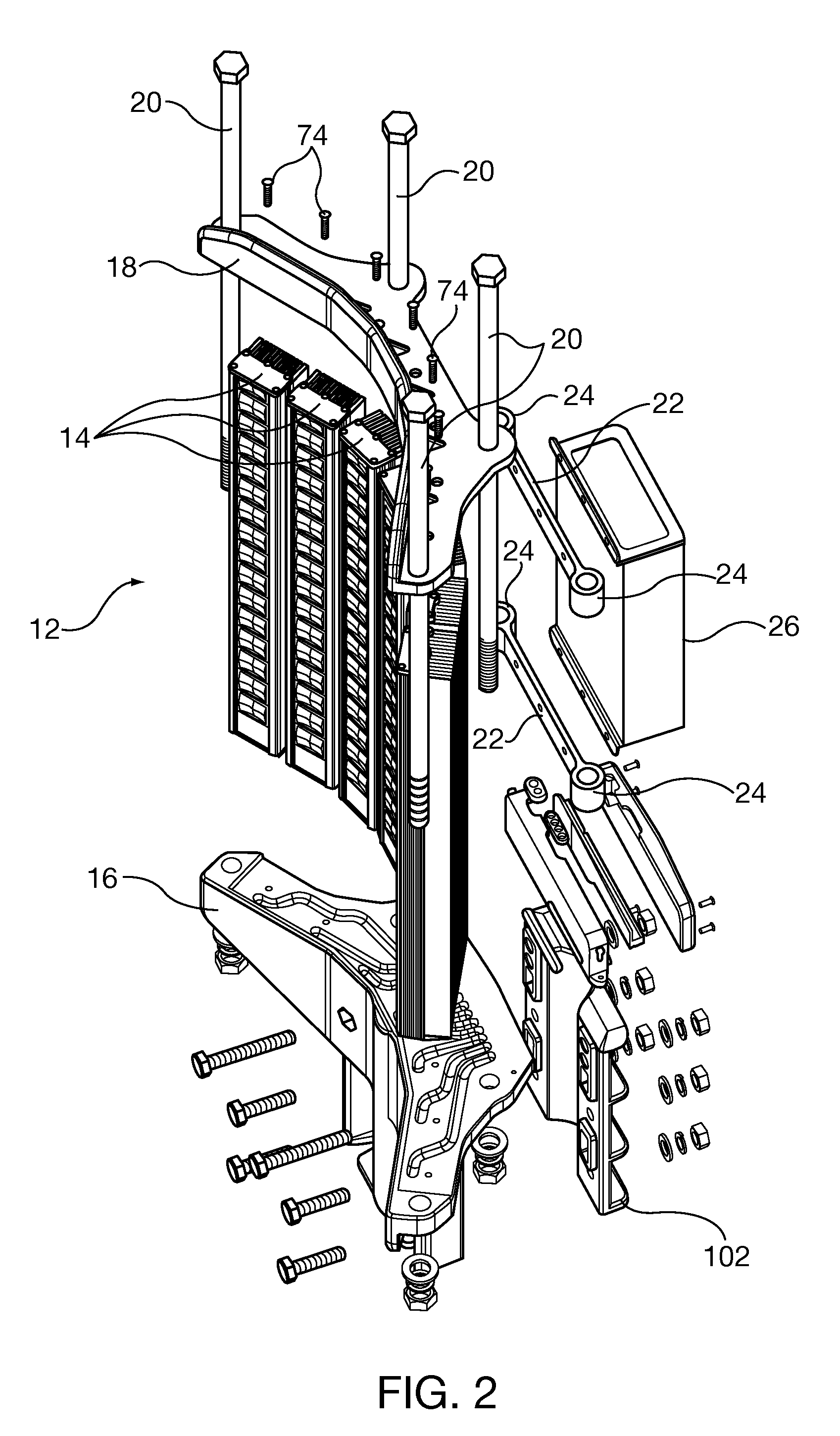

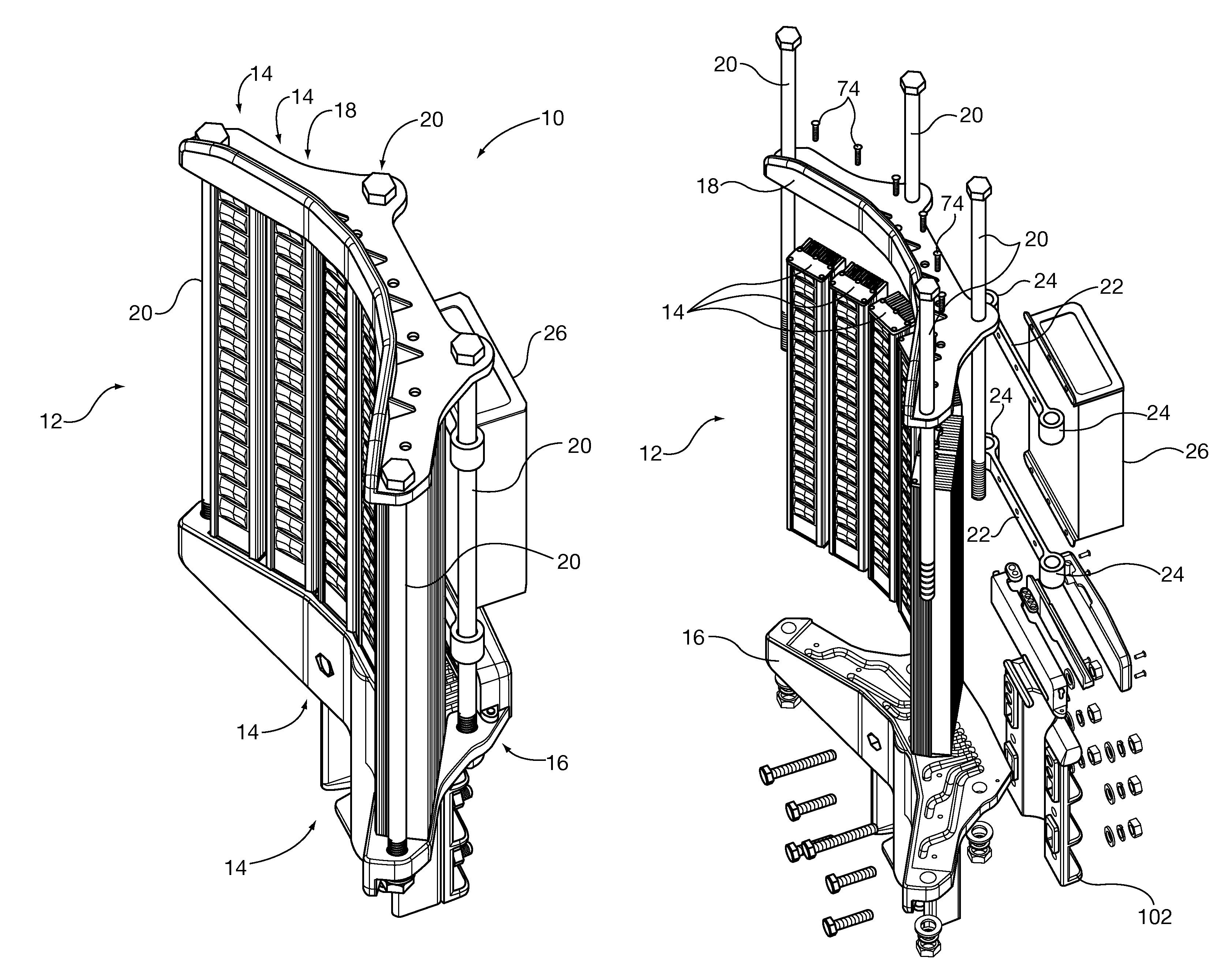

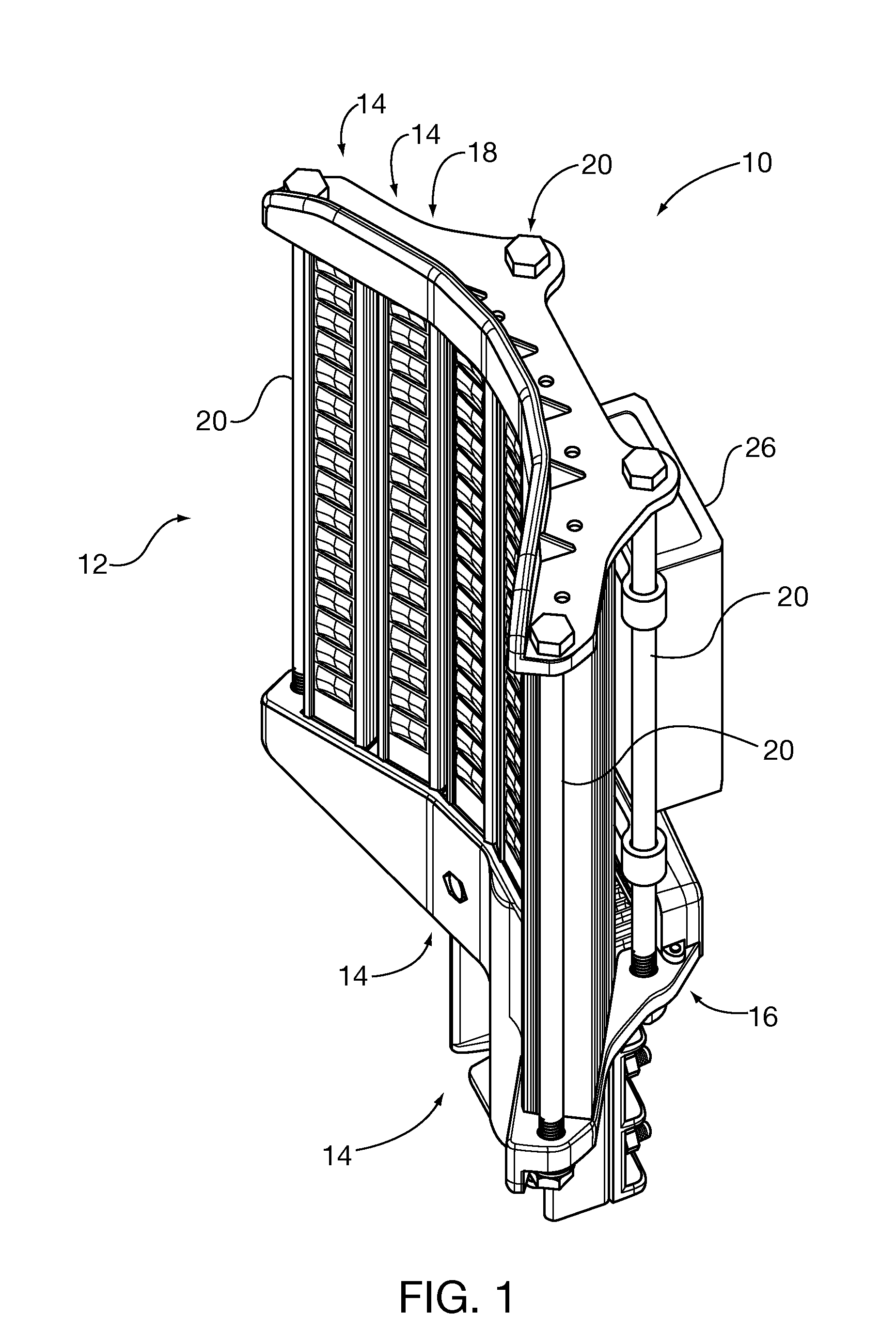

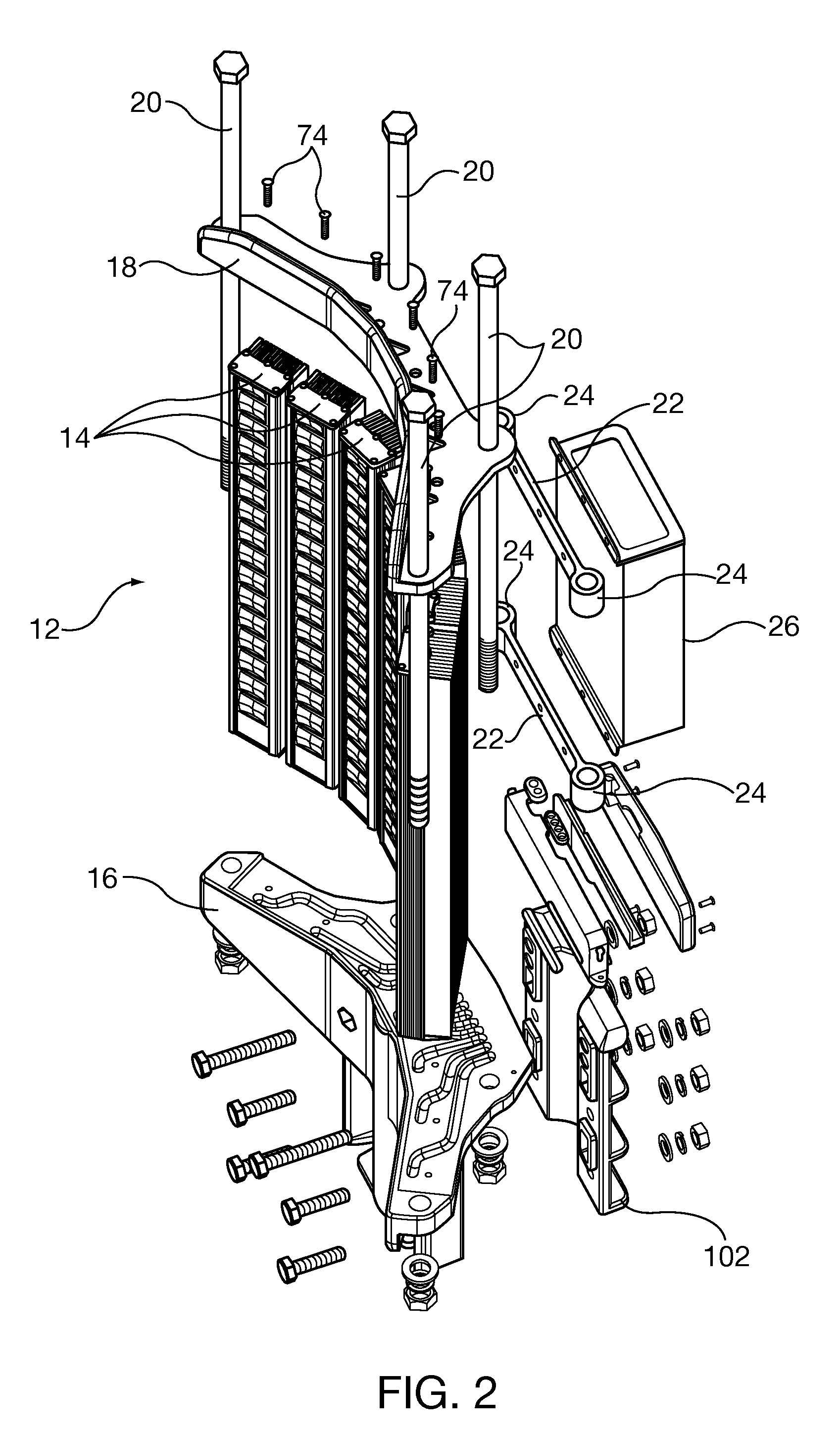

Modular LED flood light

ActiveUS20100118534A1Easy to adjustEasy to cutMechanical apparatusLight source combinationsThermal greaseEngineering

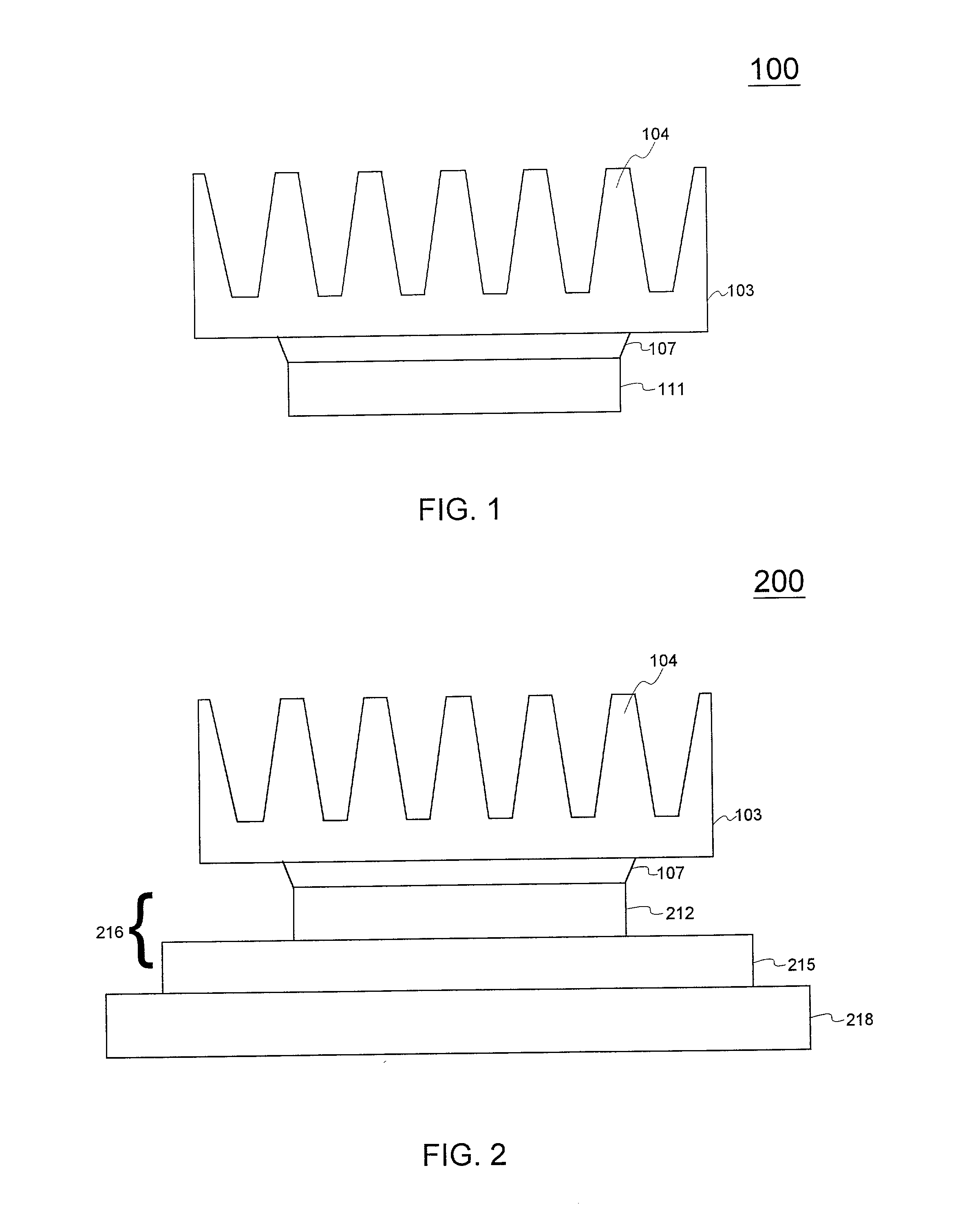

A modular luminaire which uses LED light sources. The basic frame comprises two end pieces compressed together by through bolts. At least one elongated heat sink is compressed between the end pieces. Each heat sink may bear a plurality of LEDs mounted on a printed circuit board which may have an integral metallic backplate, and is installed on one of the heat sinks with a layer of heat conductive grease therebetween. The heat sinks have fins projecting in three directions, the fourth direction being accounted for by the LEDs, and are rotatable about their longitudinal axes to adjust direction of light propagation. The heat sinks are arrayed in an arc, so that the outside heat sinks shield observers from direct glare from opposed heat sinks. Heat sinks may be extruded to form cooling fins and slots which may receive fasteners such as screws.

Owner:LOMAK IND COMPANY LIMITED

Thermal management materials

InactiveUS20030203188A1Reduce thermal resistanceImprove heat transfer performanceSemiconductor/solid-state device detailsSynthetic resin layered productsMetal alloyRoom temperature

A thermally-conductive compound for forming a layer which is conformable between a first heat transfer surface and an opposing second heat transfer surface to provide a thermal pathway therebetween. The compound is an admixture of a thermal grease component and a dispersed constituent forming discrete domains within the grease component, the domains being form-stable at normal room temperature in a first phase and conformable between the first and second heat transfer surface in a second phase, and the domains having a domain transition temperature above normal room temperature from the first phase to the second phase. The dispersed constituent may be a fusible, i.e., low temperature melting, metal or metal alloy.

Owner:PARKER INTANGIBLES LLC

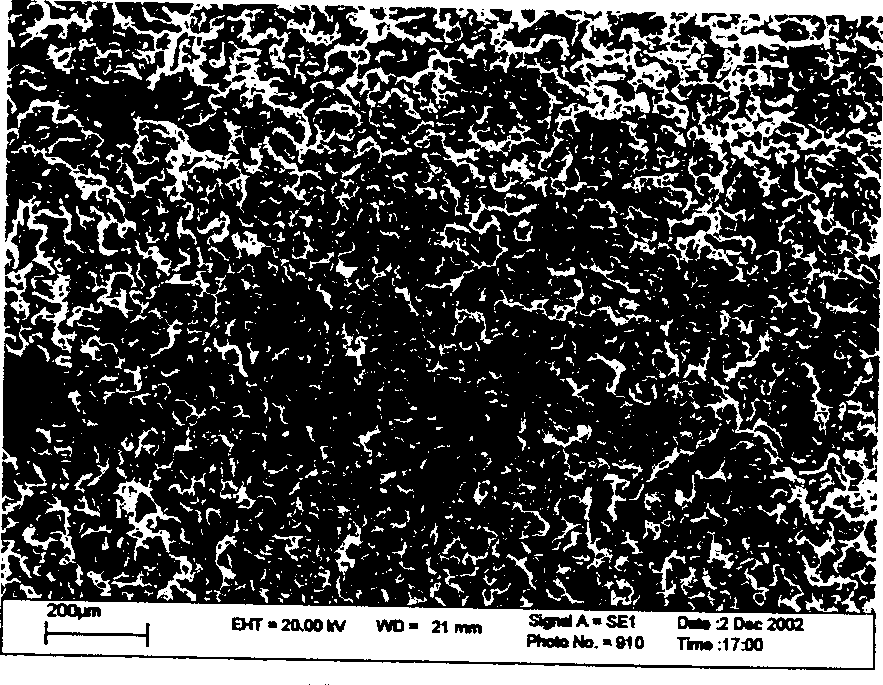

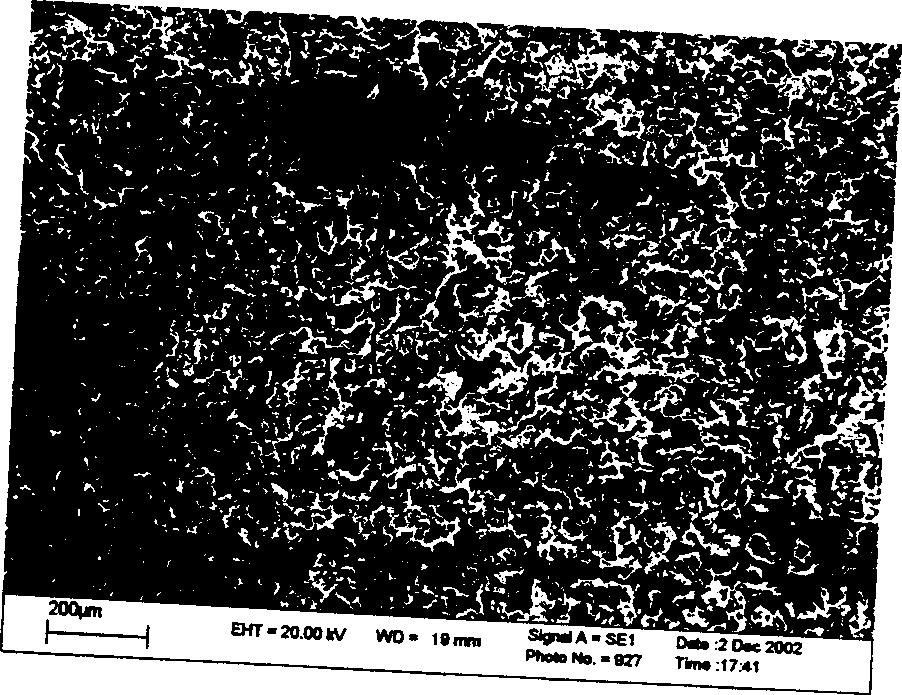

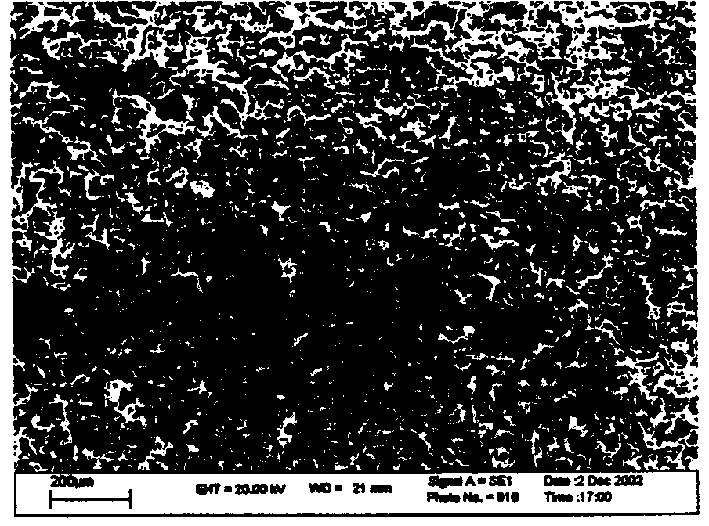

Thermal interface material (TIM) with carbon nanotubes (CNT) and low thermal impedance

According to embodiments of the present invention, a very thin thermal interface material (TIM) is developed, which is composed of carbon nanotubes, silicon thermal grease, and chloroform. The carbon nanotubes and chloroform comprise the filler and the silicone thermal grease comprises the matrix.

Owner:UNIV OF WASHINGTON

Modular LED flood light

ActiveUS8061869B2Easy to adjustEasy to cutMechanical apparatusLight source combinationsThermal greaseEngineering

Owner:LOMAK IND COMPANY LIMITED

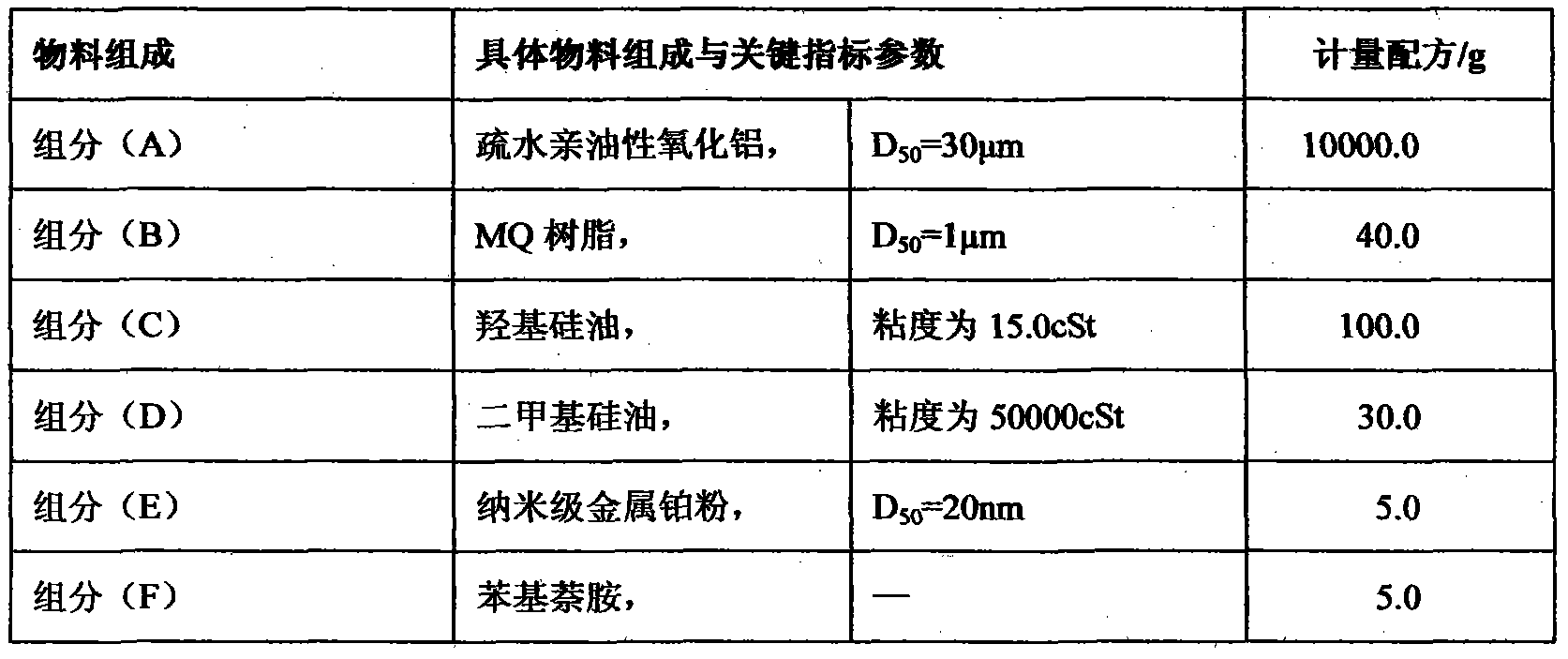

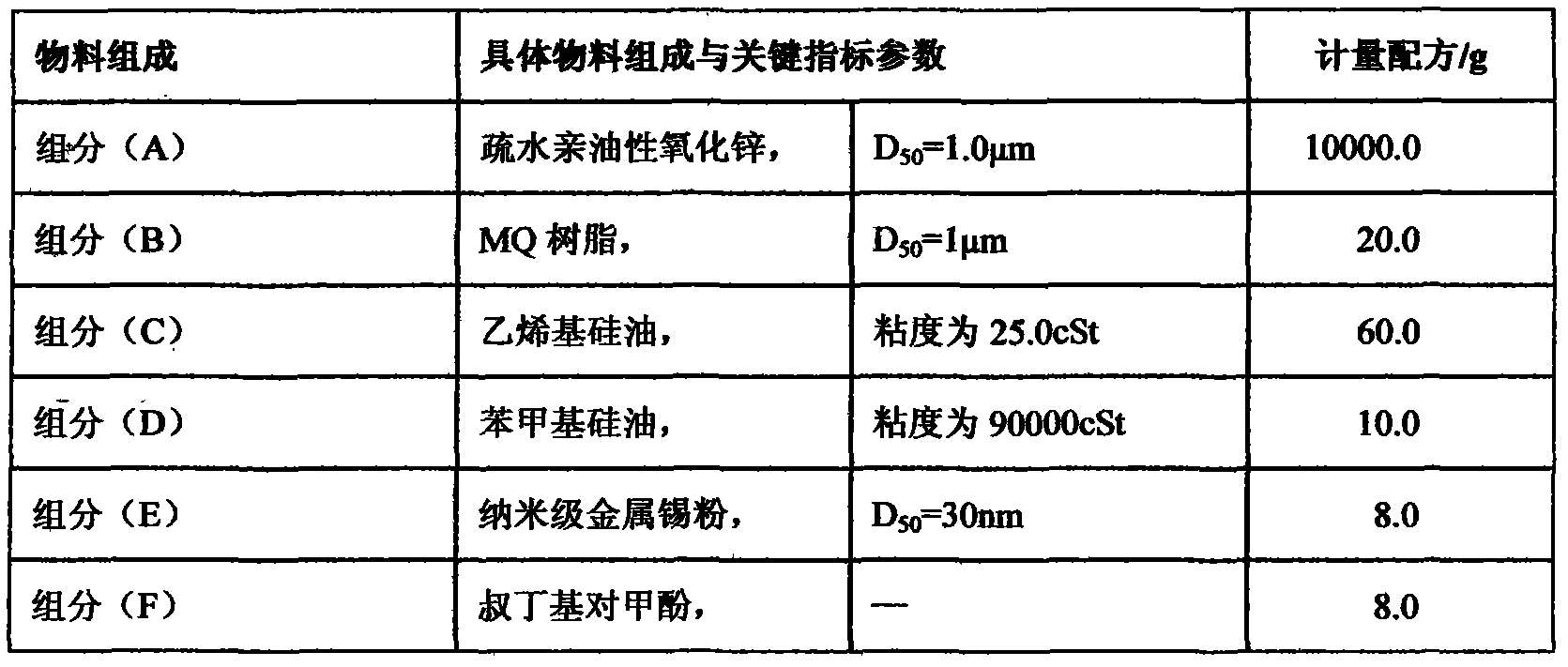

Thermal grease composition

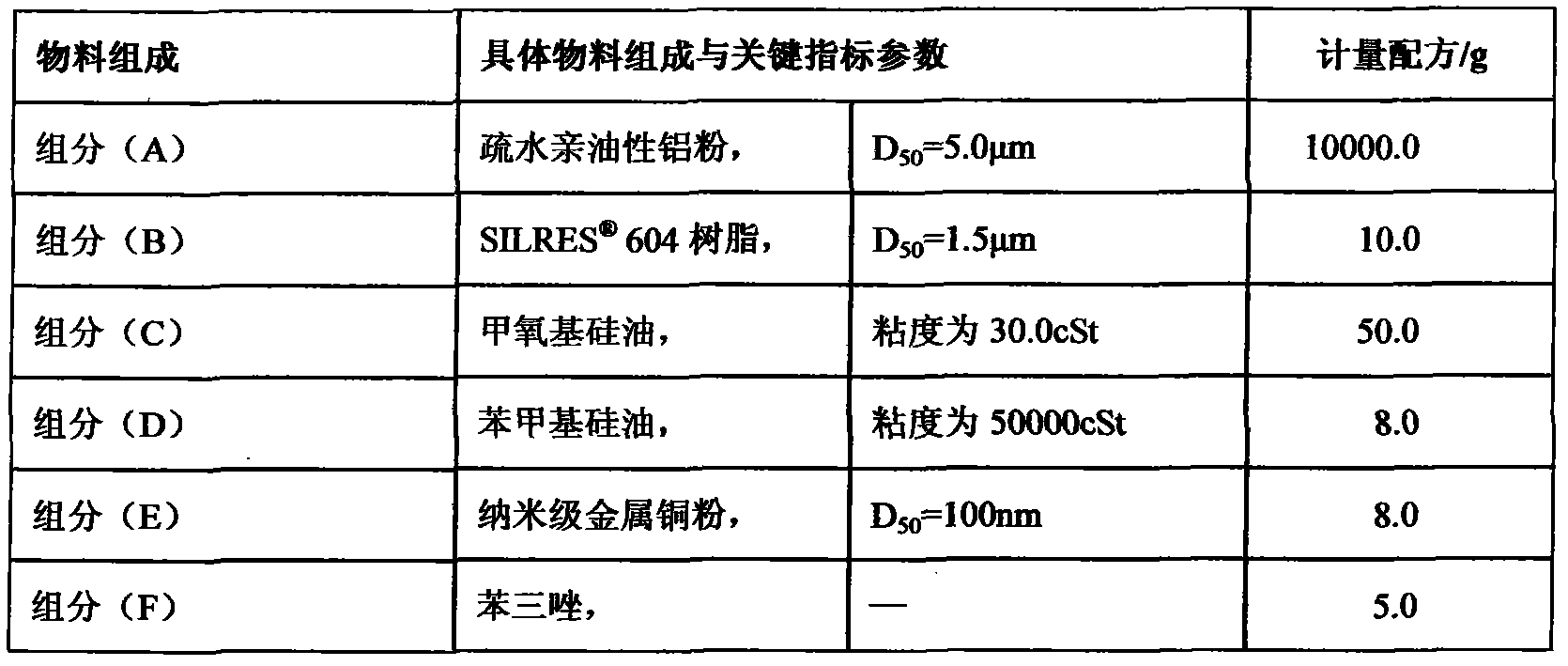

ActiveCN102134474ASolve the chalking problemResolve fragmentationHeat-exchange elementsNano catalystThermal grease

The invention relates to the field of thermal interface materials, and more particularly, provides a thermal grease composition, which contains the following components: (A) 100.0 parts by weight of thermally conductive filler, (B) 0.1 to 8.0 parts by weight of active solid silicone resin, (C) 0.1 to 15.0 parts by weight of active silicone oil, (D) 0.1 to 9.0 parts by weight of macromolecular polysiloxane, (E) 0.1 to 3.0 parts by weight of nano catalyst, and (F) 0.1 to 3.0 parts by weight of additive. The thermal grease composition provided by the invention has good thermal conductivity and using weatherability, can effectively solve the technical difficulty that the thermal grease composition in the prior art is pulverized and crushed and the thermal conductivity is therefore reduced as the service time increases. The manufacturing process has simple, convenient and easy steps and the thermal grease composition is suitable for large-scale match production.

Owner:SHENZHEN EUBO NEW MATERIAL TECH

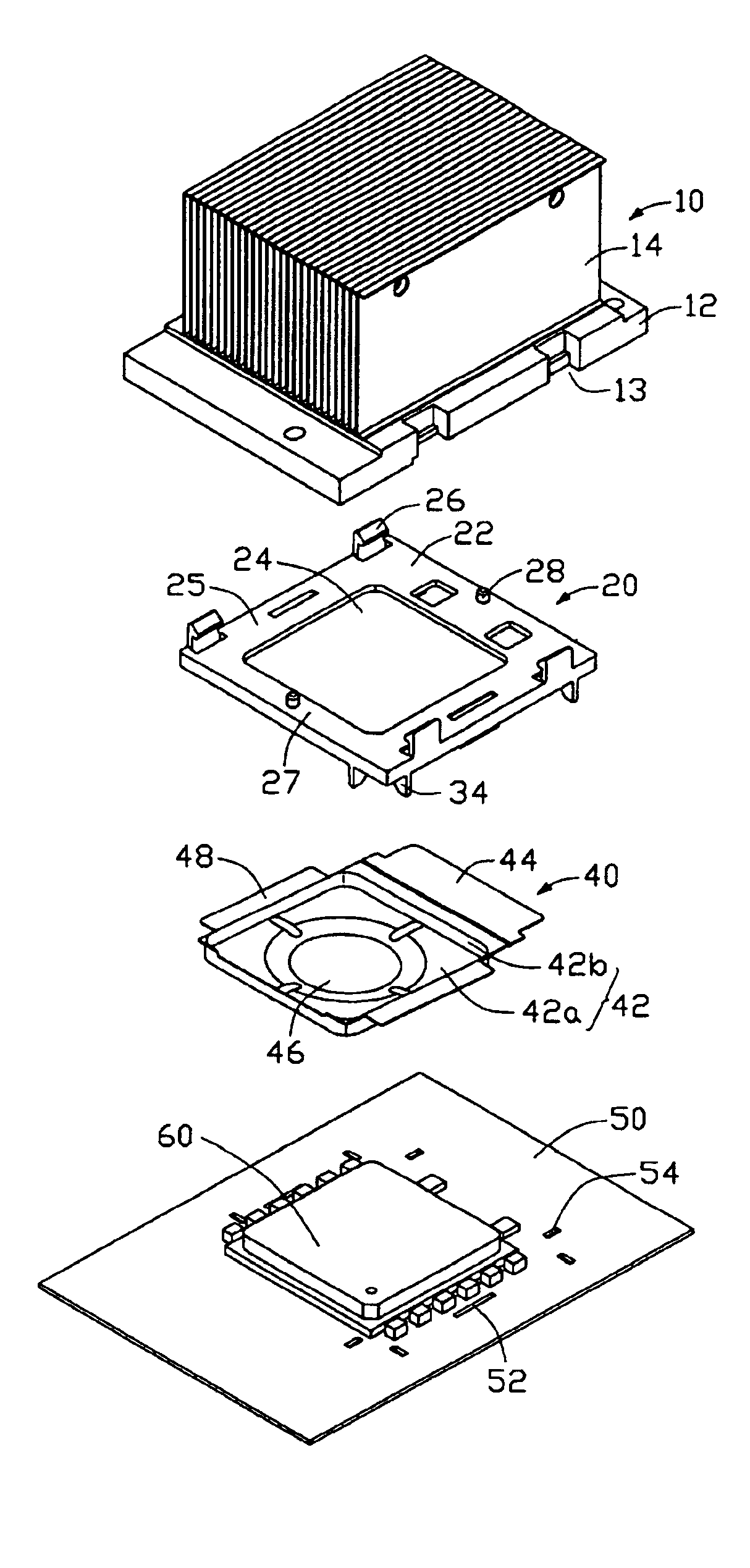

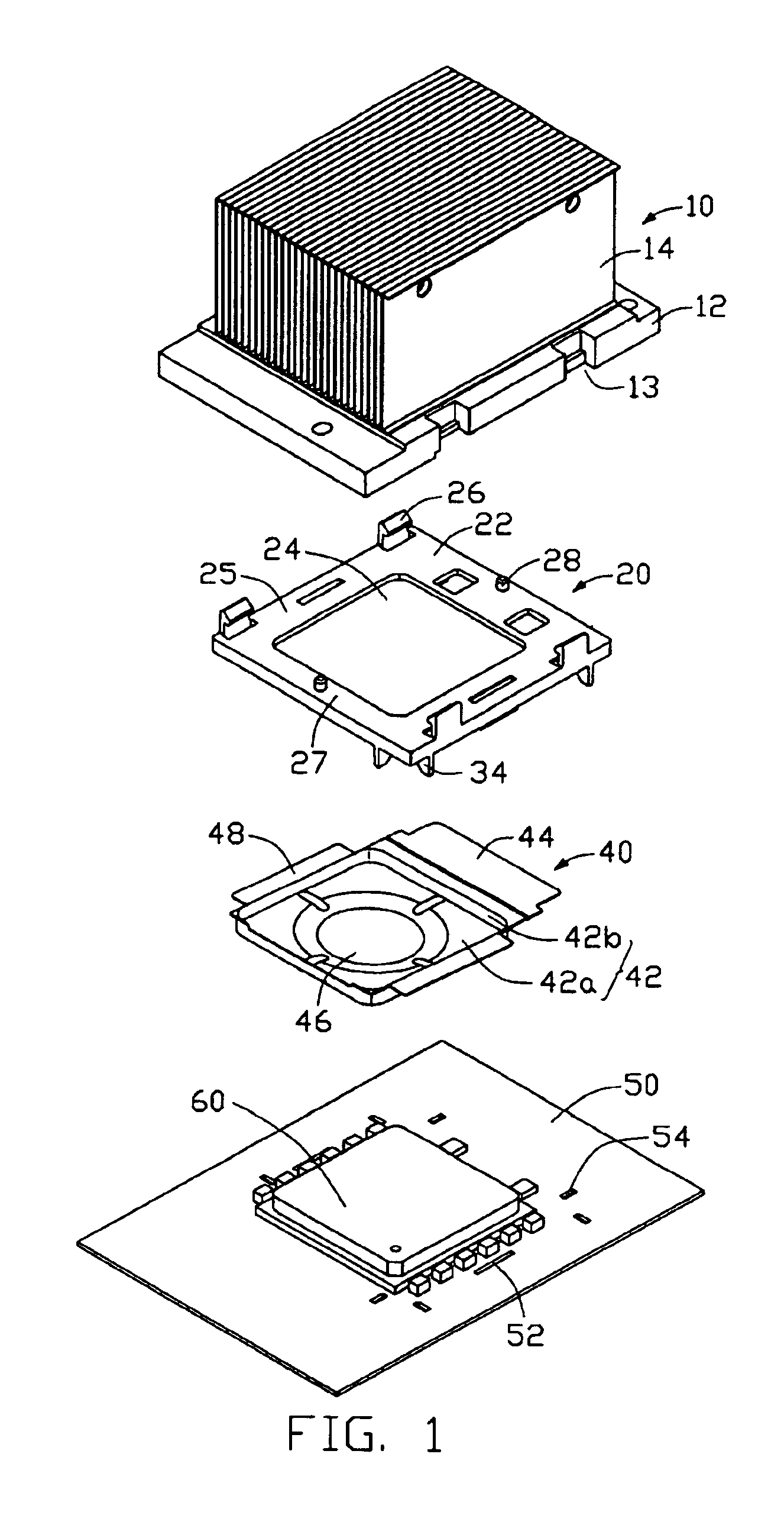

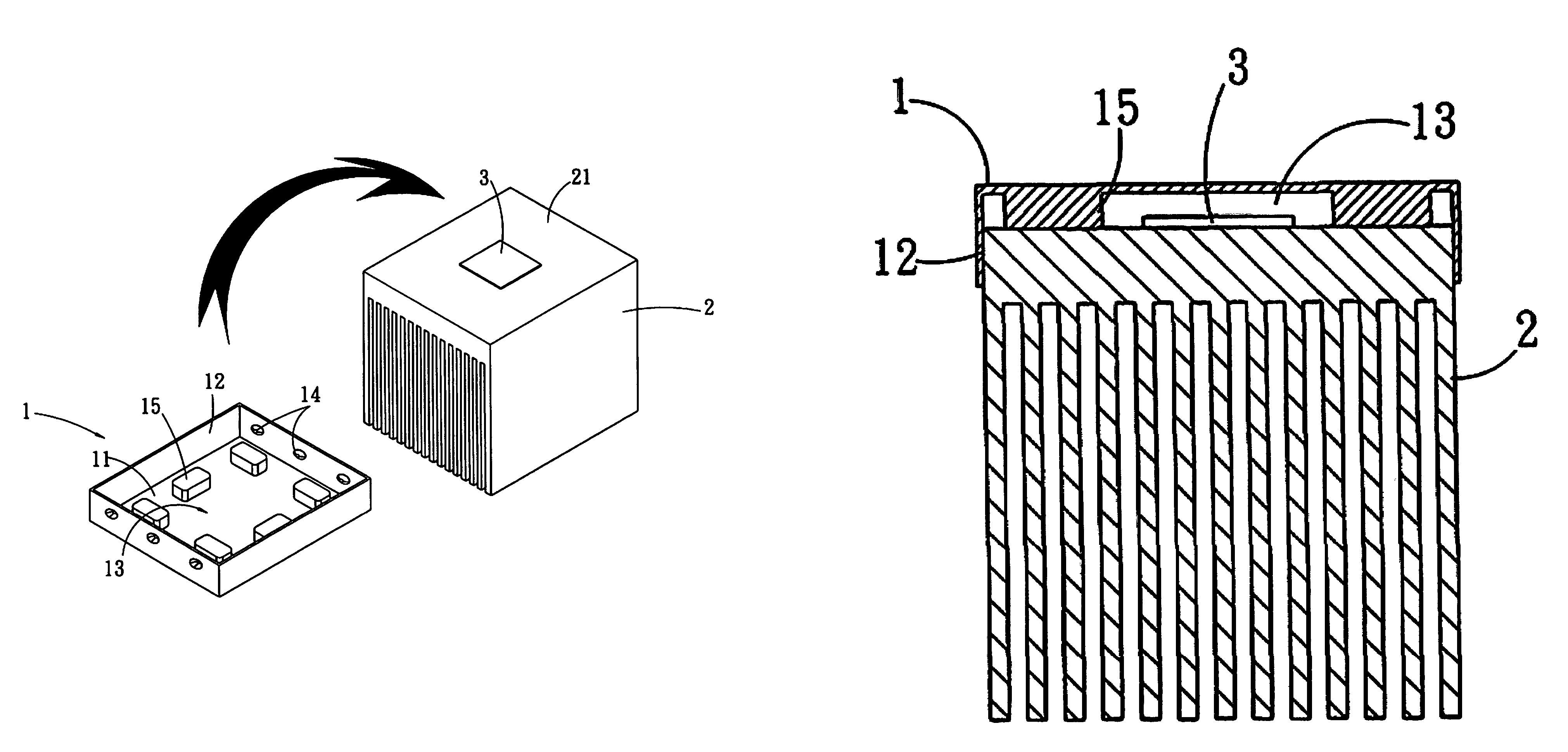

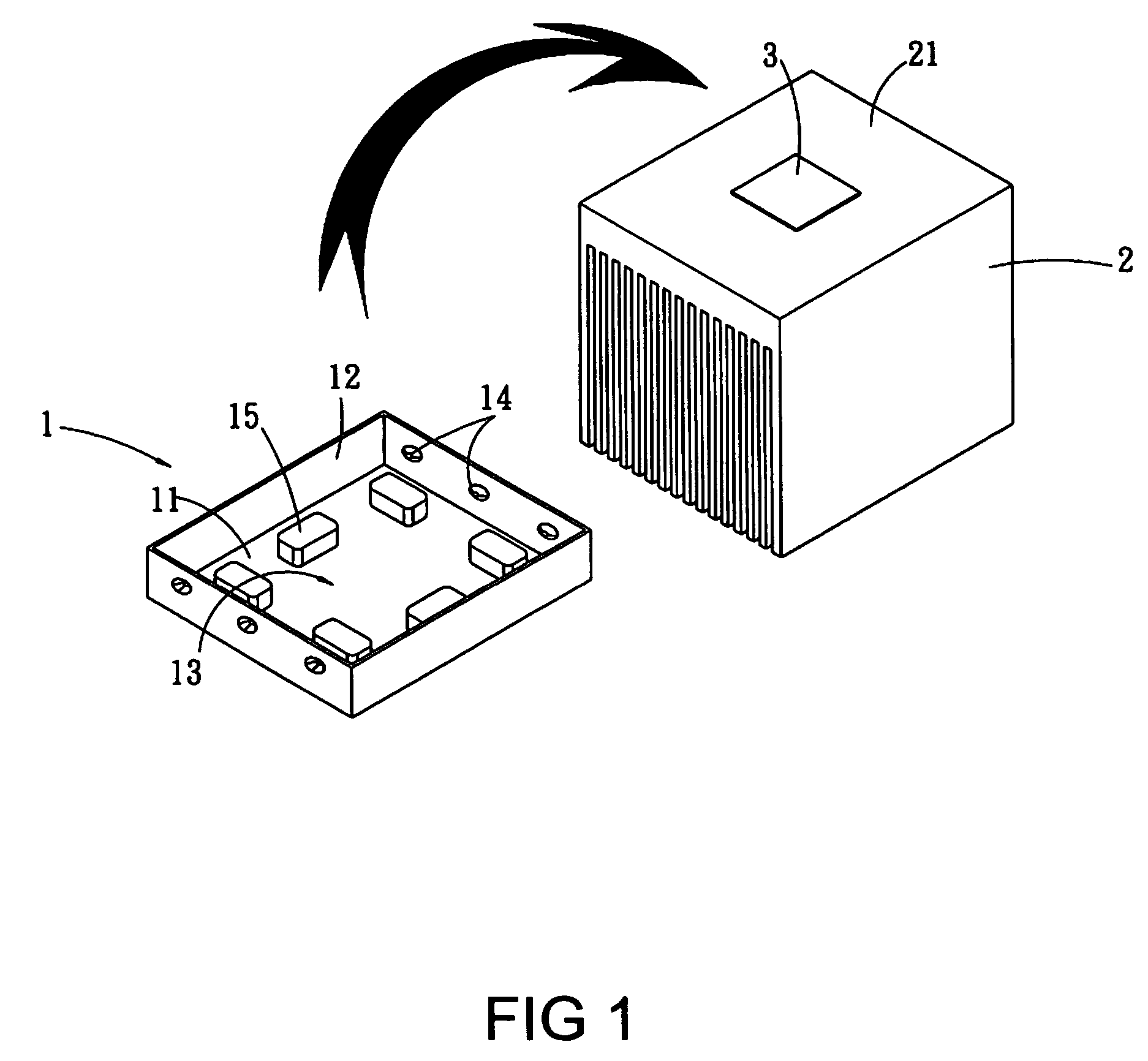

Heat sink assembly incorporating mounting frame

InactiveUS6952348B2The process is convenient and fastHeat dissipating area of the heat sink to be maximizedSemiconductor/solid-state device detailsSolid-state devicesThermal greaseEngineering

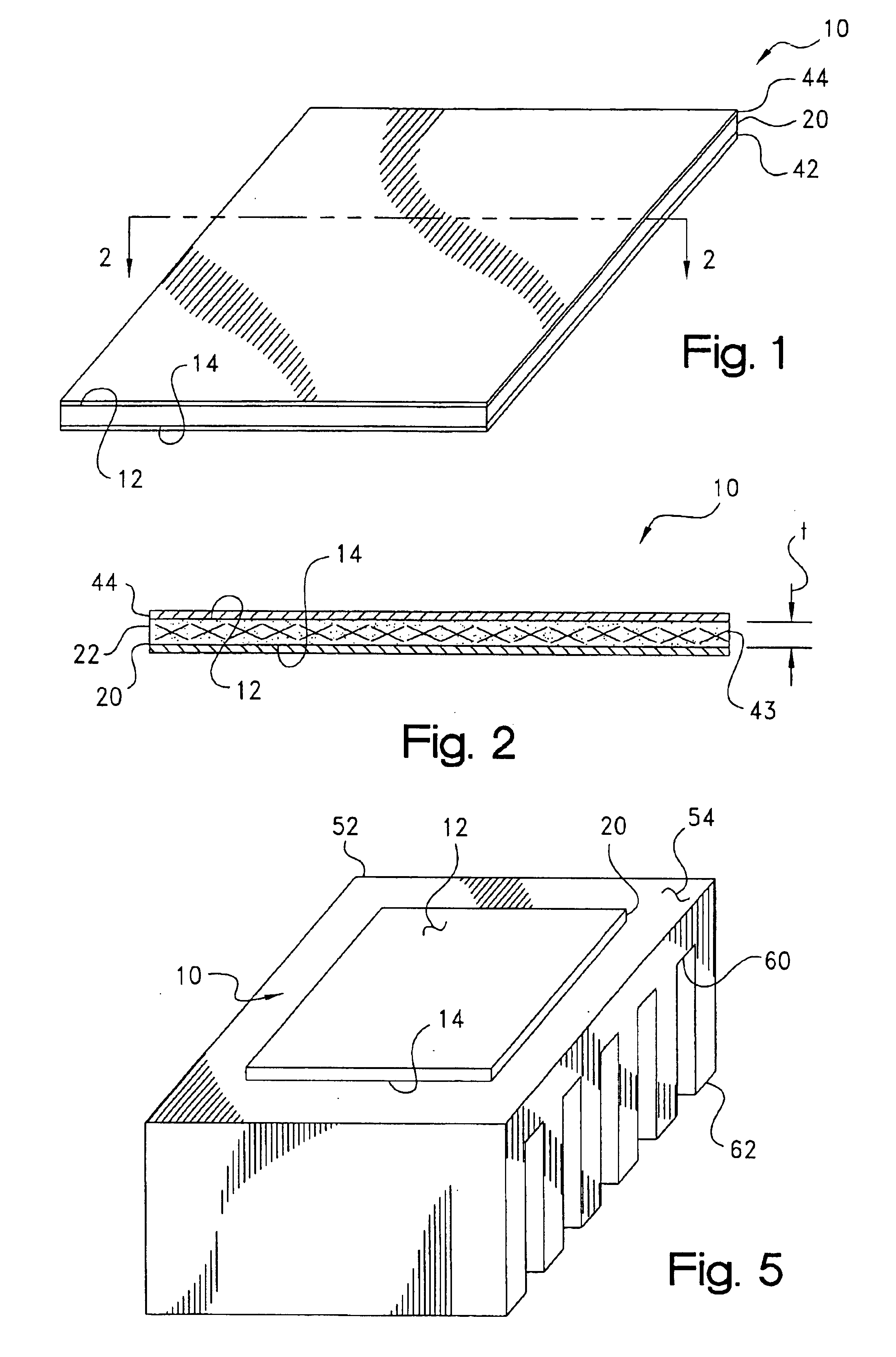

A heat sink assembly includes a heat sink (10), a mounting frame (20) for mounting the heat sink to an electronic component (60), and a grease cover (40). The heat sink includes a base (12) on which thermal grease (16) is spread. The mounting frame includes a body (22) defining an opening (24) for extension of the electronic component therethrough to contact the base. The body includes longitudinal and lateral beams (25, 27) surrounding the electronic component. A plurality of fasteners (26) is formed on the longitudinal beams and engaged in cutouts (16) defined in the base, respectively. The grease cover is detachably attached to the mounting frame, and includes a main portion (42) covering the opening of the mounting frame and the thermal grease, and an ear (44) extending from the main portion beyond one border of the mounting frame for facilitating operation of the grease cover.

Owner:HON HAI PRECISION IND CO LTD

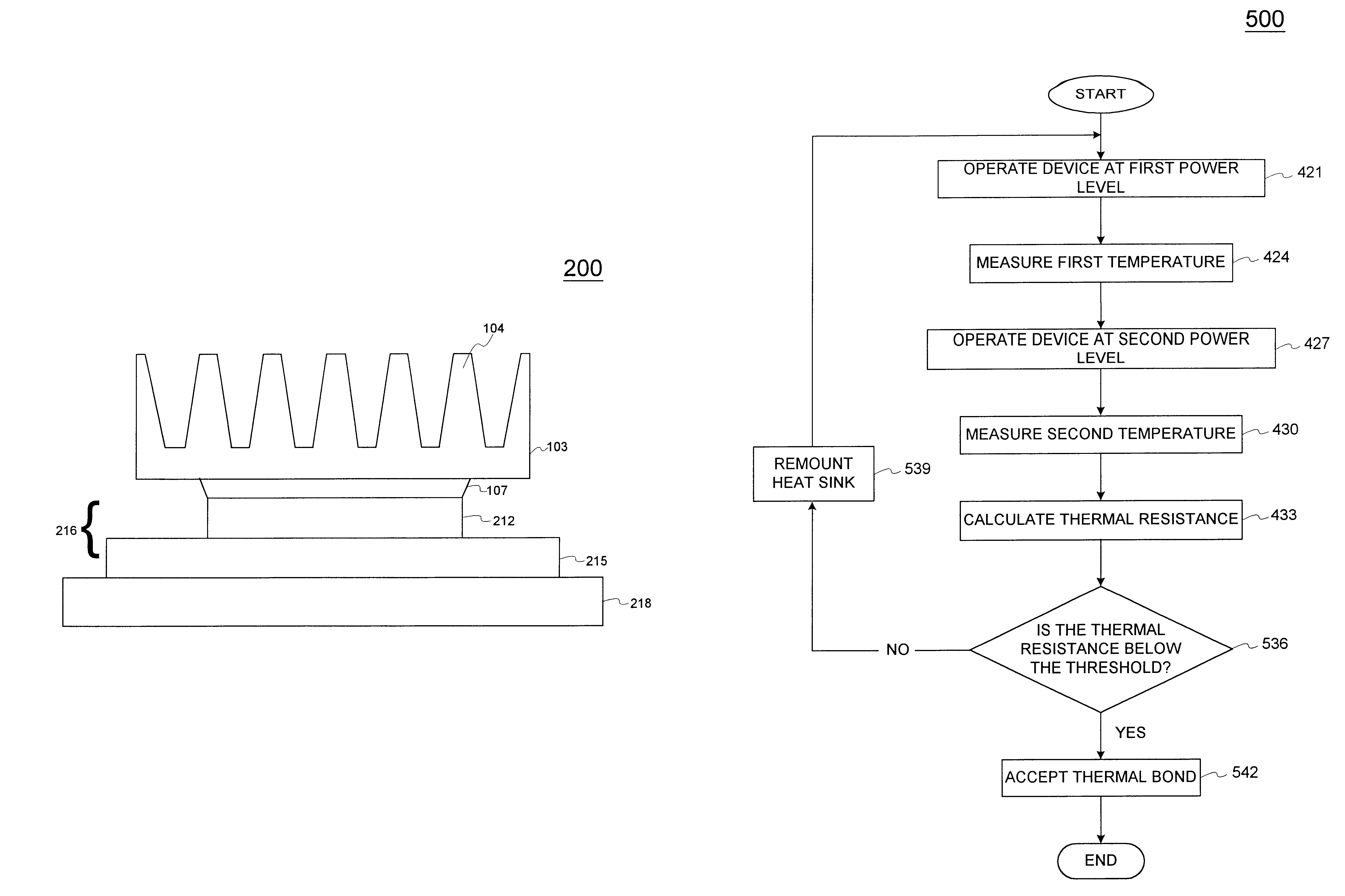

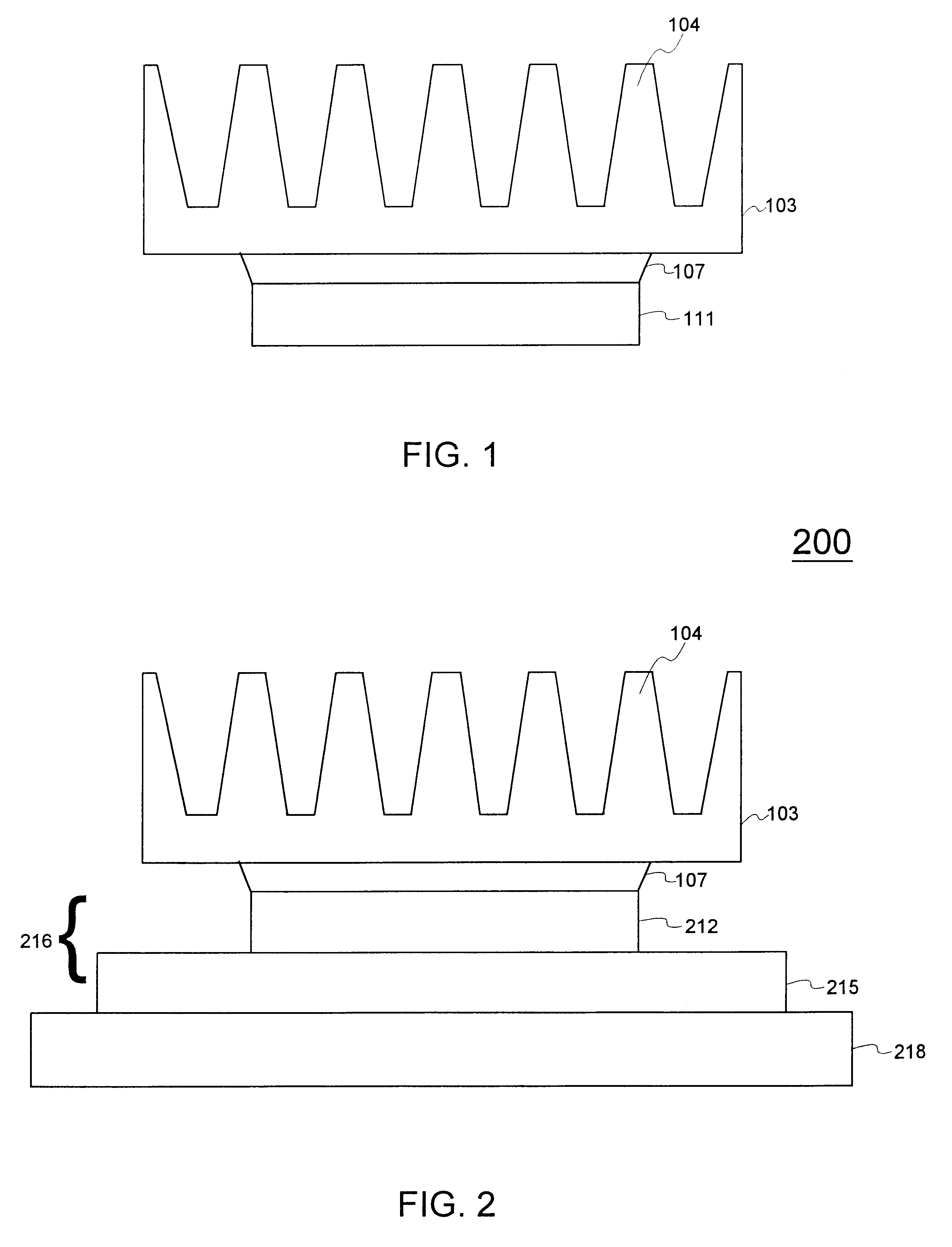

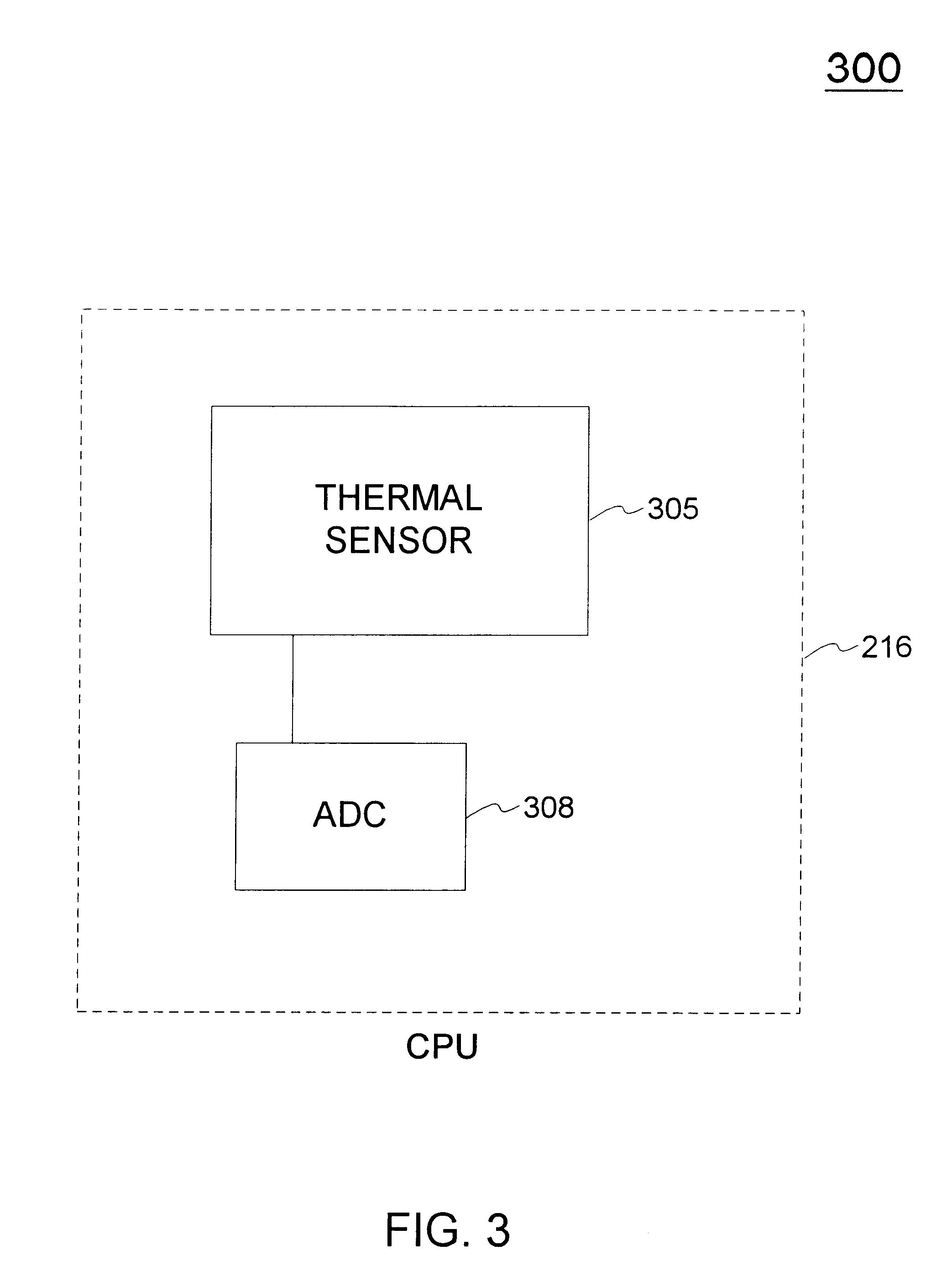

Thermal bond verification

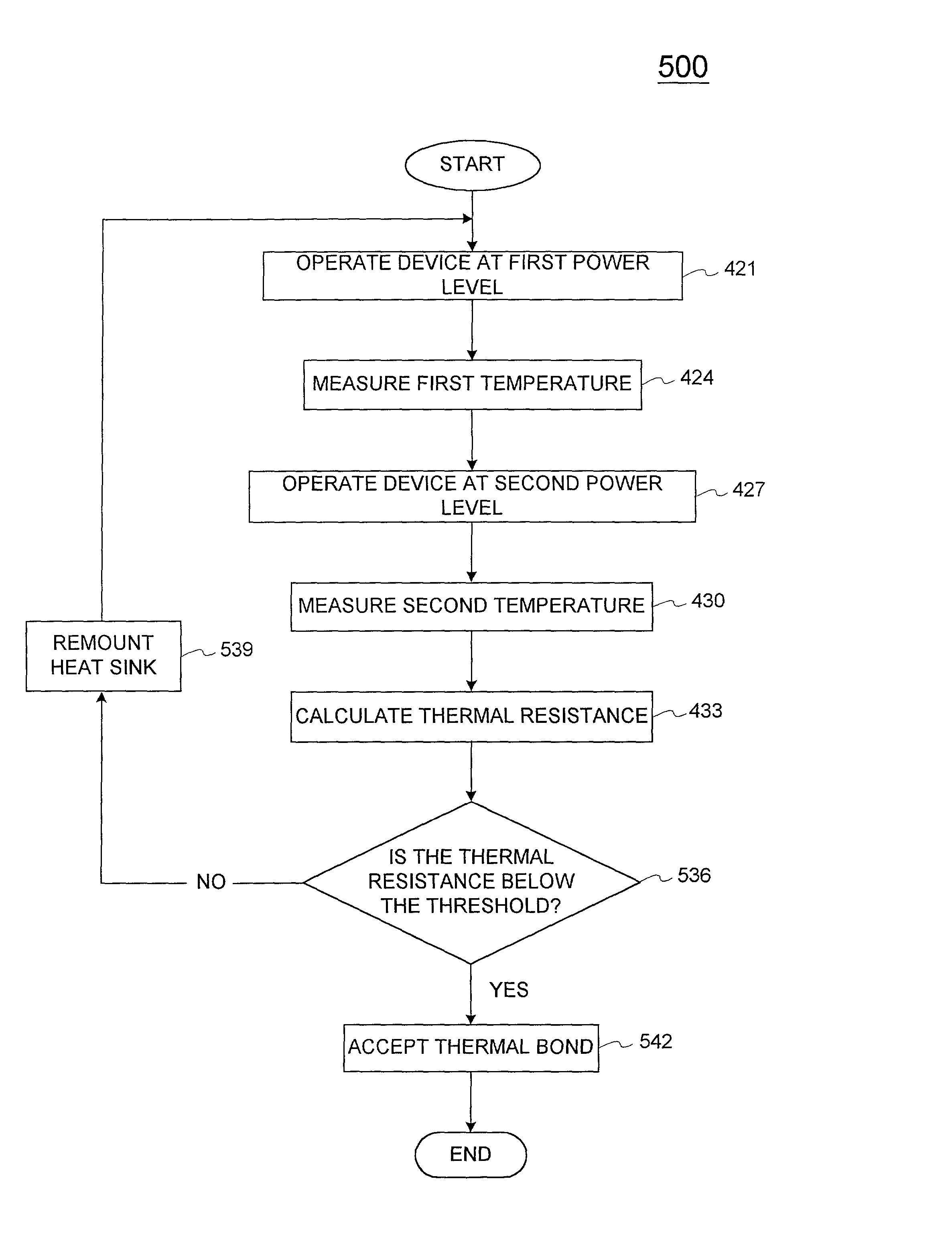

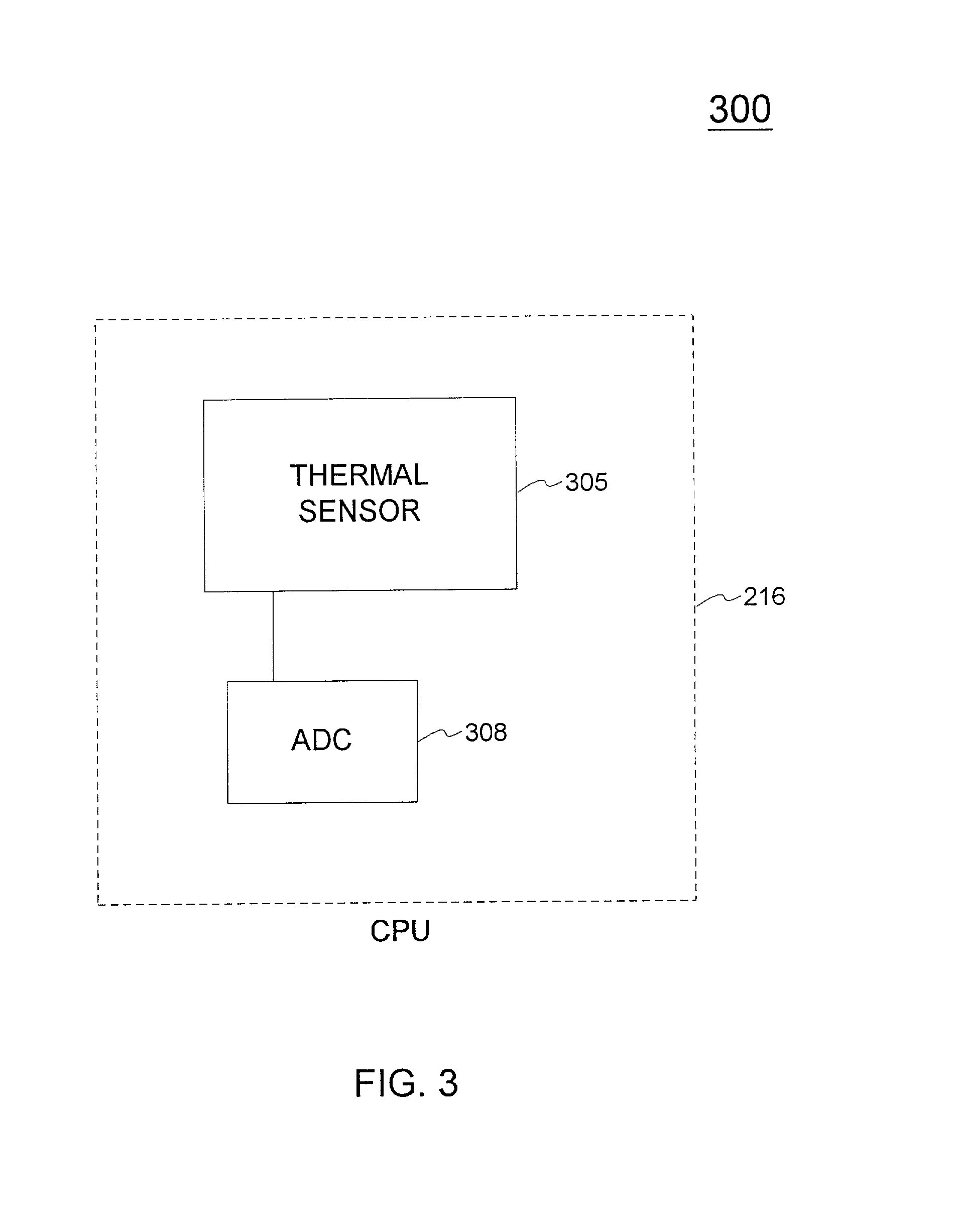

A system and method for evaluating the thermal bond between a heat-producing device and a heat-absorbing apparatus. The heat-producing device may be a CPU, such as an INTEL PENTIUM microprocessor, and the heat-absorbing apparatus may be a heat sink. The two may be joined with a heat-conducting substance such as thermal grease or adhesive. In one exemplary embodiment, the heat-producing device is operated at a first power level, a first temperature measurement is then taken, the device is operated at a second power level, and then a second temperature measurement is then taken. The thermal resistance is then calculated, which may involve subtracting the second temperature from the first, and may involve dividing by the power level. The first power level may be full power, and the second power level may be near zero. The first temperature may be measured when equilibrium temperatures have been reached, and the second temperature may be measured a predetermined amount of time after the second power level is initiated, which may be just enough time for the temperatures of the CPU and the heat sink to equalize. The CPU may perform the calculations, and the temperature may be measured with an on-board thermal sensor which may be a thermal diode.

Owner:SBS TECH

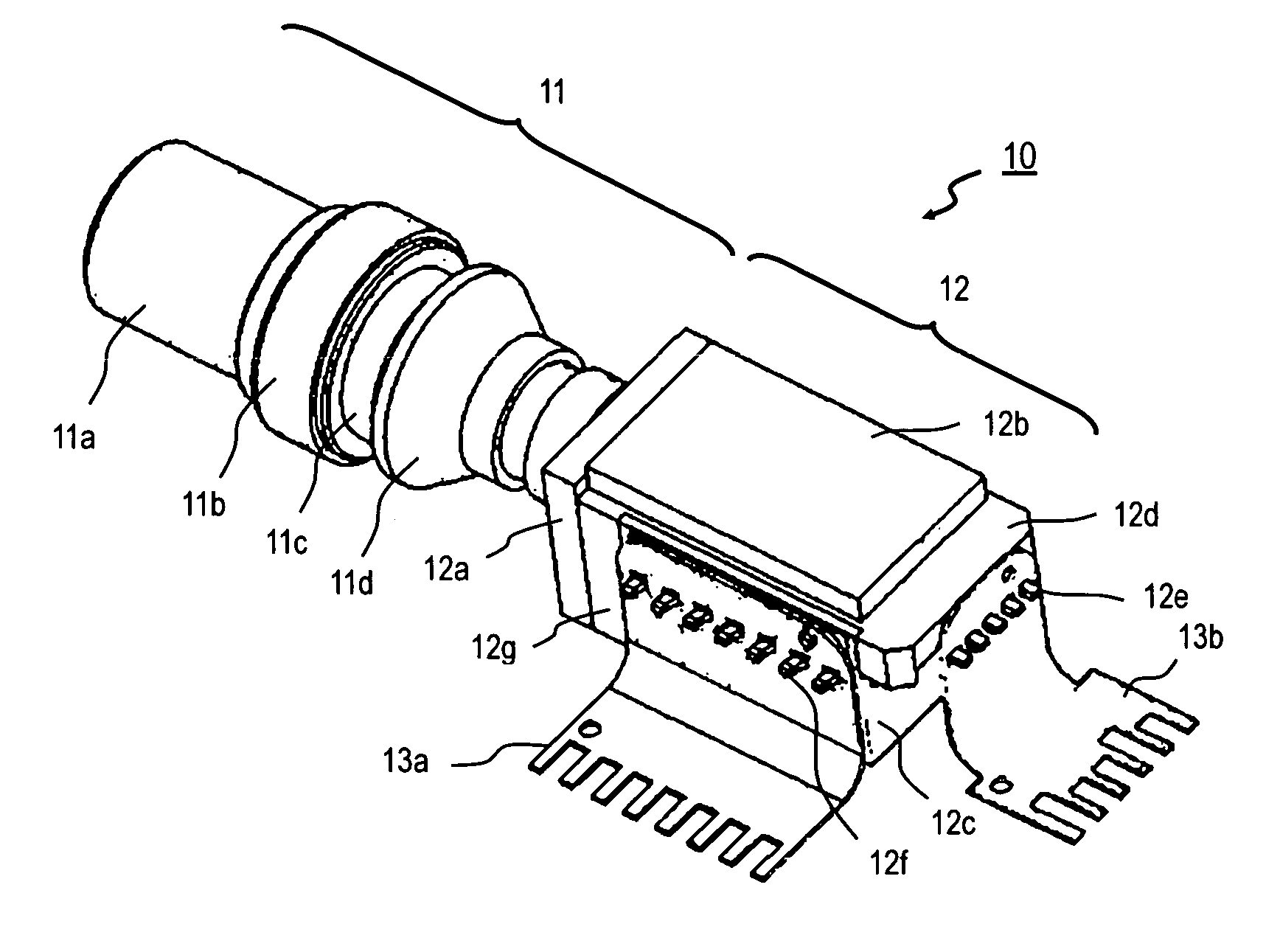

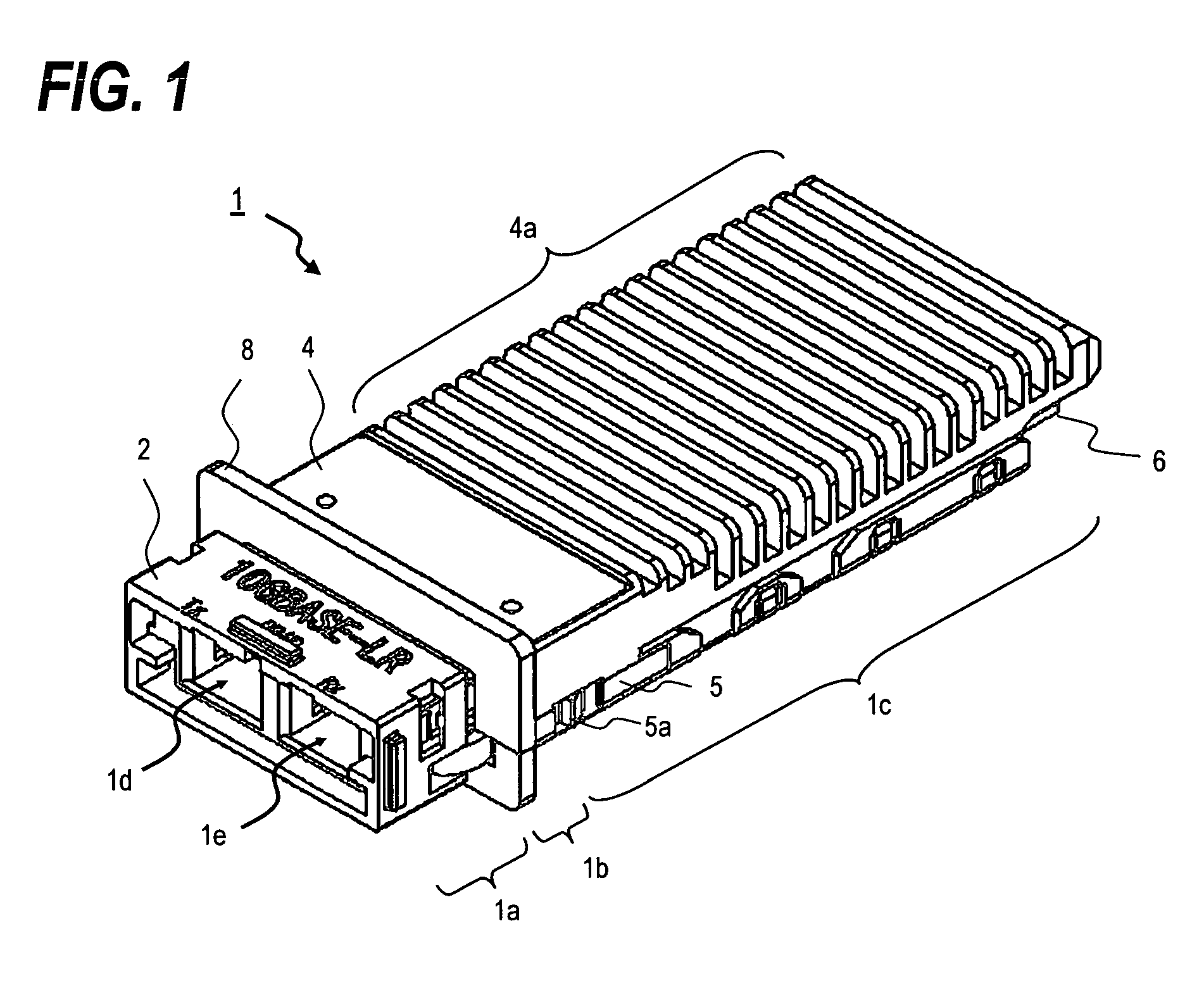

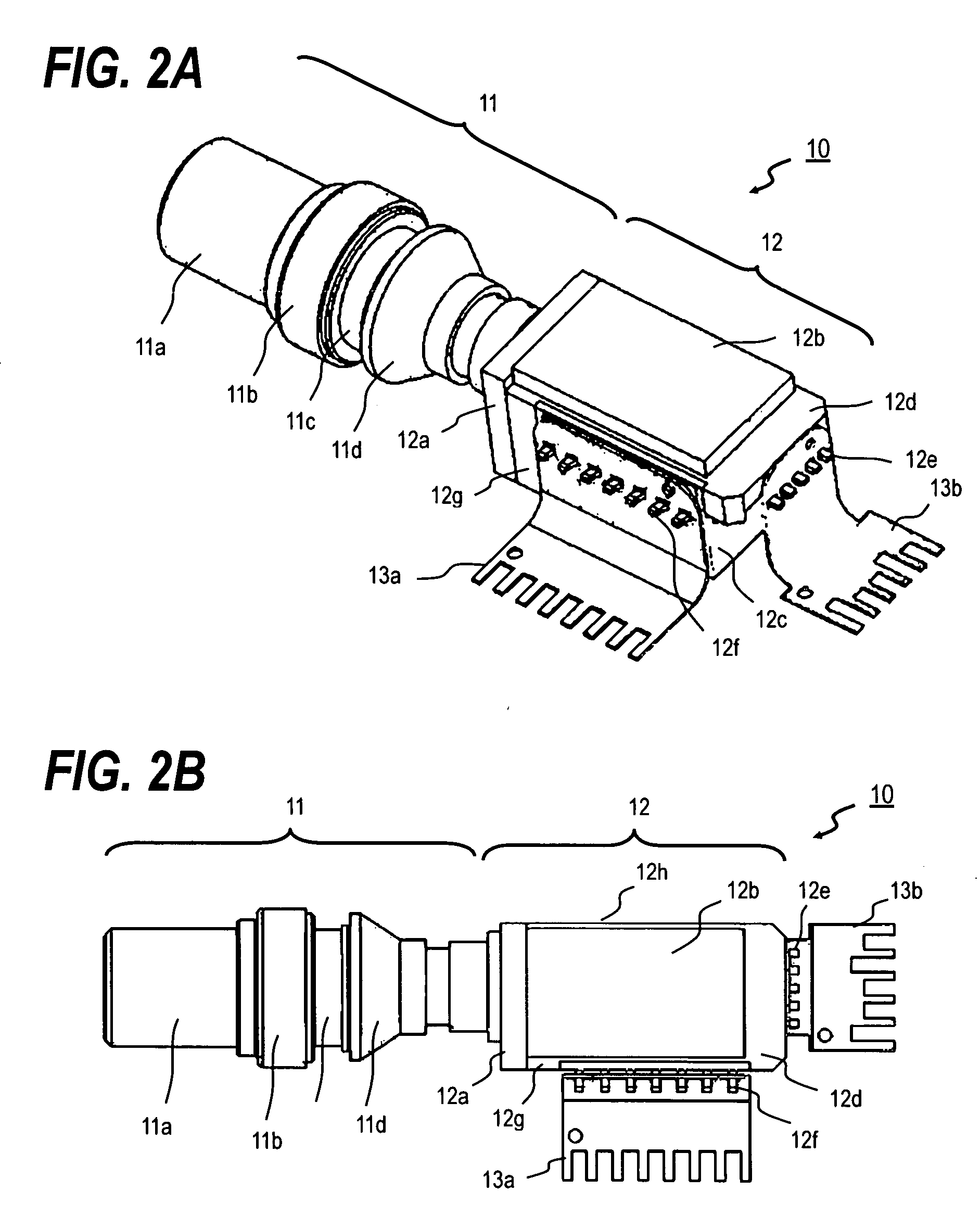

Optical transceiver with optical sub-module thermally couples with optical transceiver without mechanical stress

An optical module free from the mechanical stress and used in an optical transceiver is disclosed, even the position of the module is fixed with repect to the hosuing not only from the viewpoint of the optical alignment but also the heat conduction. The optical module comprises the sleeve portion and the box portion. The sleeve portion is directly fixed to the housing, but the box portion is indirectly fixed to the housing via the support member. Between the box portion and the support member is filled with the thermal grease in one end thereof, while the other end is pressed by the elastice member that presses the box portion against the support member. The box portion is free from the mechanical stress when the sleeve portion is rigidly fixed to the hosuing.

Owner:SUMITOMO ELECTRIC IND LTD

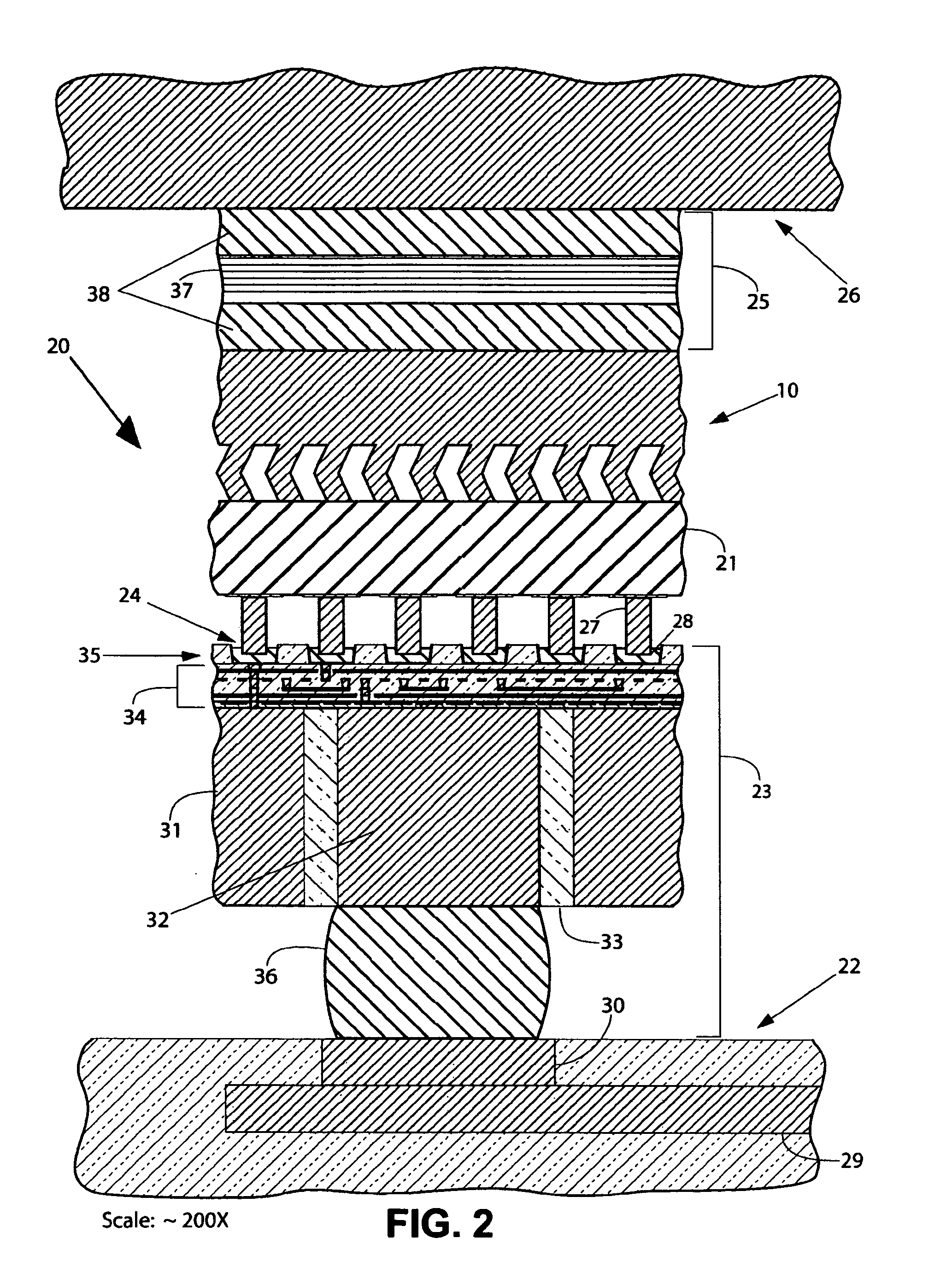

Thermal spreader cap and grease containment structure for semiconductor device

InactiveUS6285078B1Semiconductor/solid-state device detailsSolid-state devicesThermal greaseEngineering

An apparatus and method for protecting the various components of a microprocessor is provided. The apparatus includes a thermal spreader cap that is disposed between the processor die and thermal plate, and the OLGA and thermal plate. Thermal grease layers are also provided between the thermal spreader cap and the thermal plate, the thermal spreader cap and the processor die, and the thermal spreader cap and the OLGA. The apparatus provides a compliant assembly that protects the processor die from damage due to shock and / or vibration. It also provides multiple thermal paths along which heat generated by the various components of the microprocessor may be removed, and therefore allows for a higher performance processor.

Owner:INTEL CORP

Method for synthesizing NiTi shape memory alloy porous material

InactiveCN1418974AMeet the requirements for growthMeet strength requirementsSelf-propagating high-temperature synthesisAdhesive

The method for synthesizing NiTi marmen porous body material is characterized by that it uses Ti powder and Ni powder as raw material, and includes the following steps: uniformly mixing the above-mentioned raw materials, mixing them with adhesive in mixing machine, granulating to obtain feeding material, injecting to obtain blank piece, soaking said blank piece in gasoline to remove grease, drying and placing the blank into vacuum furnace to make thermal grease removal, finally connecting one end of blank with W spiral in flame igniter, placing it into vacuum reaction synthesizer, when the degree of vacuum is higher than 1X10(-2)Pa, starting heating, after the temp. is up to defined value, starting flame igniter so as to produce self-spreading high-temp. synthesis reaction to obtain finished product.

Owner:UNIV OF SCI & TECH BEIJING

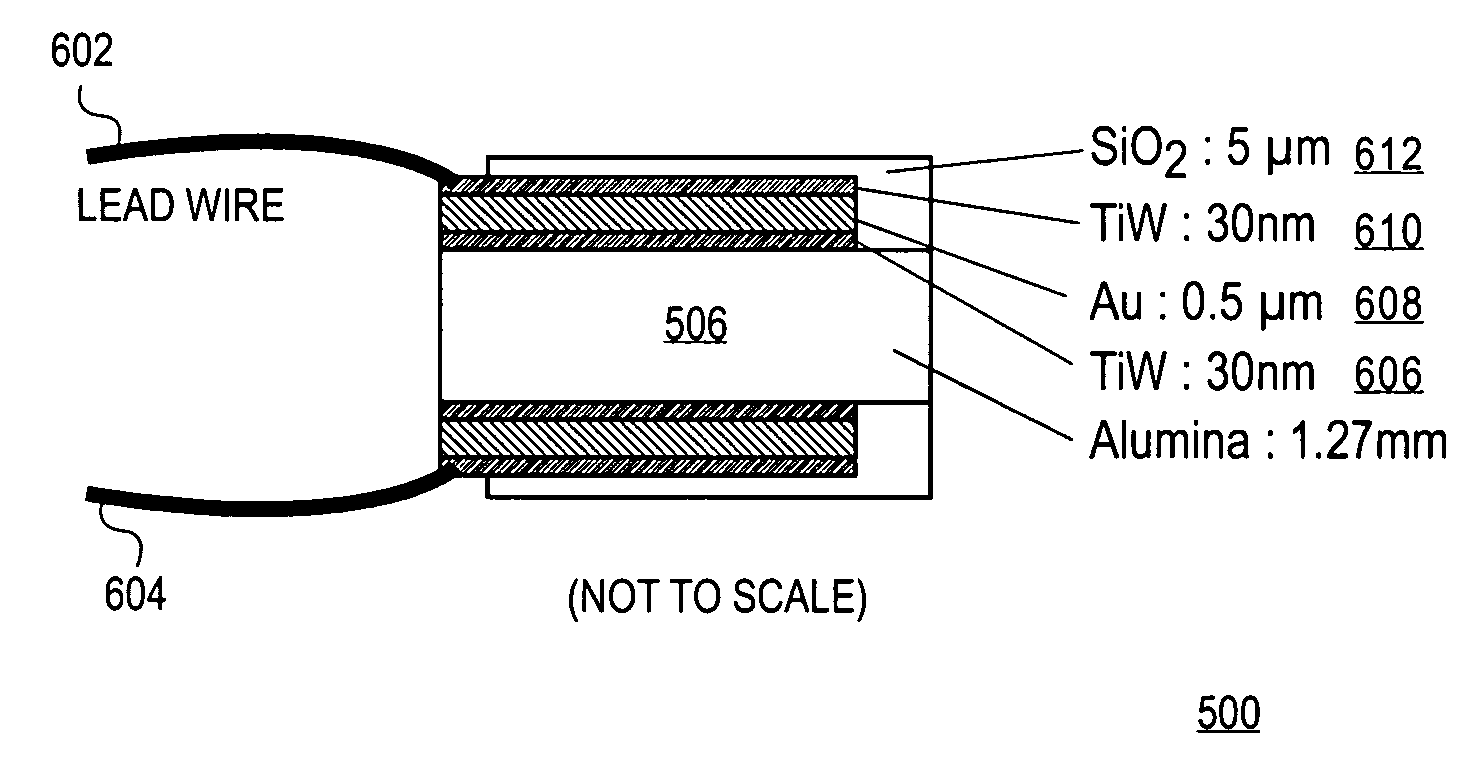

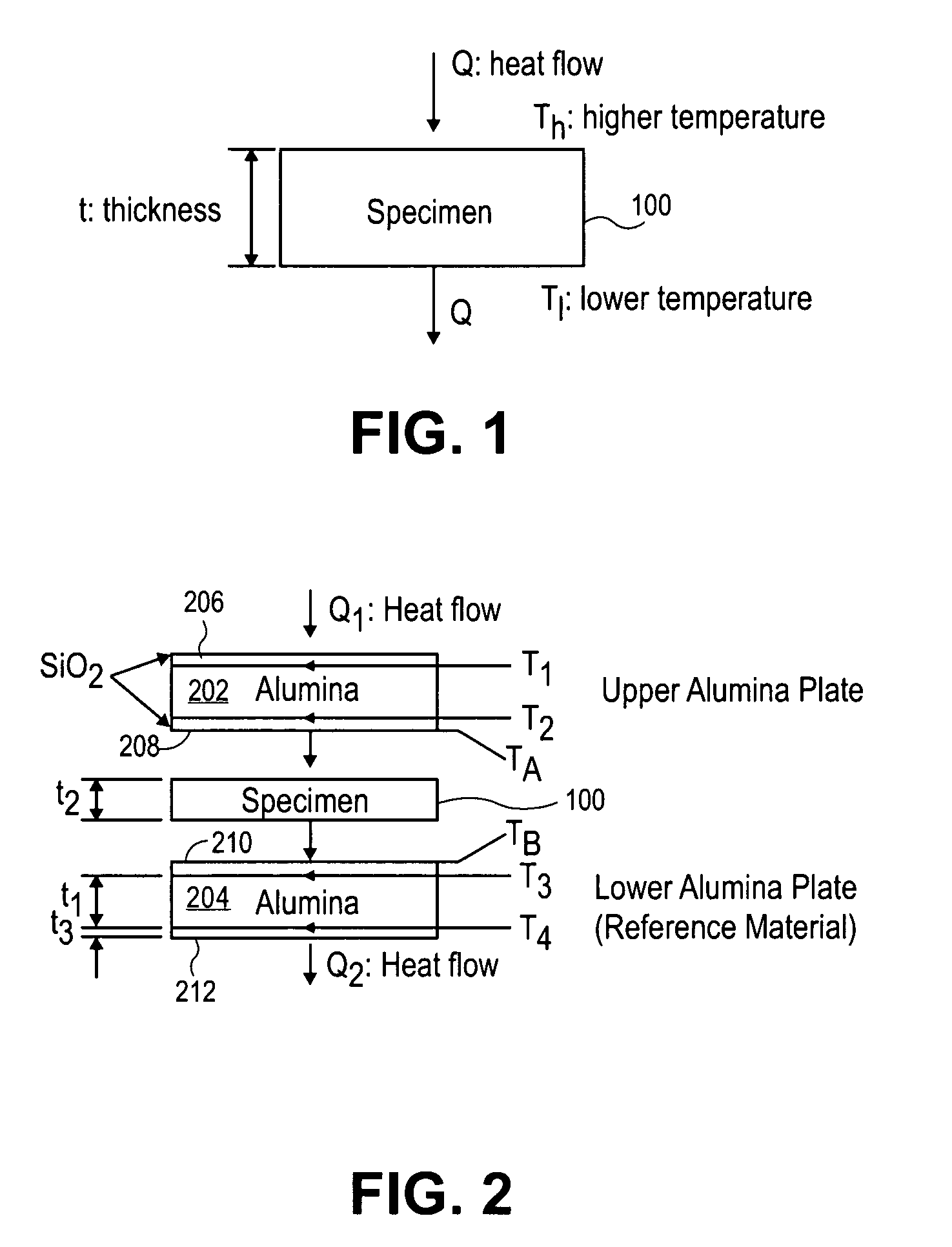

Thermally conductive grease and methods and devices in which said grease is used

ActiveUS7695817B2Semiconductor/solid-state device detailsSolid-state devicesOil and greaseThermal grease

Owner:DOW SILICONES CORP

Heat dissipation assembly and method for producing the same

ActiveUS20050205989A1Effective coolingConductible sheet can be preventedSemiconductor/solid-state device detailsSolid-state devicesDevice materialThermal grease

A heat dissipation assembly in which a heat generator and a heat dissipator are integrated via an electrically insulating and thermally conductive sheet, at least one surface of which a thermally conductive grease is applied to, in which the thermally conductive grease is incompatible with the electrically insulating and thermally conductive sheet. Heat from the heat generator such as a semiconductor device or the like can be effectively dissipated while an electrically insulating condition is maintained over a long period of time.

Owner:NISSAN MOTOR CO LTD +2

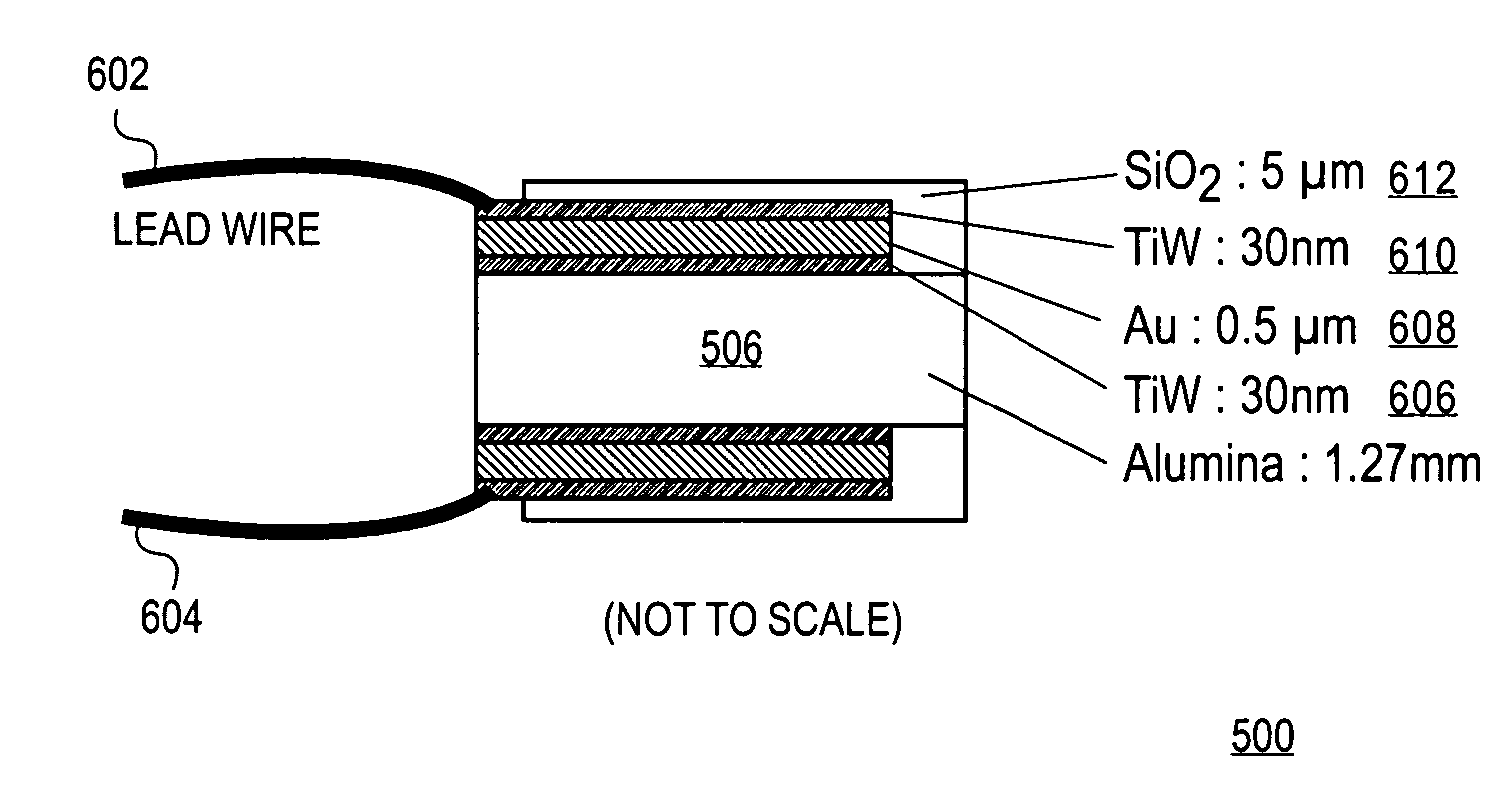

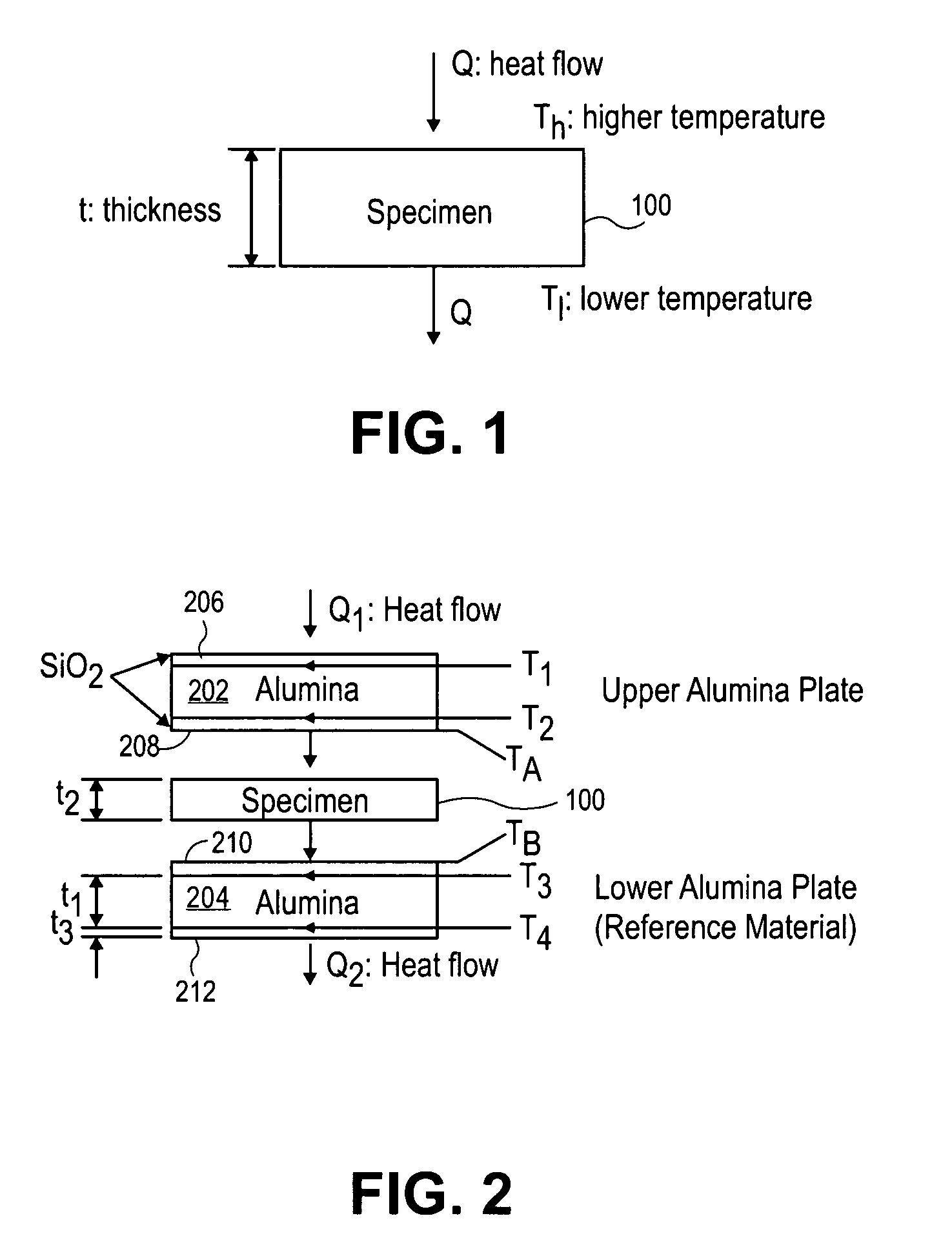

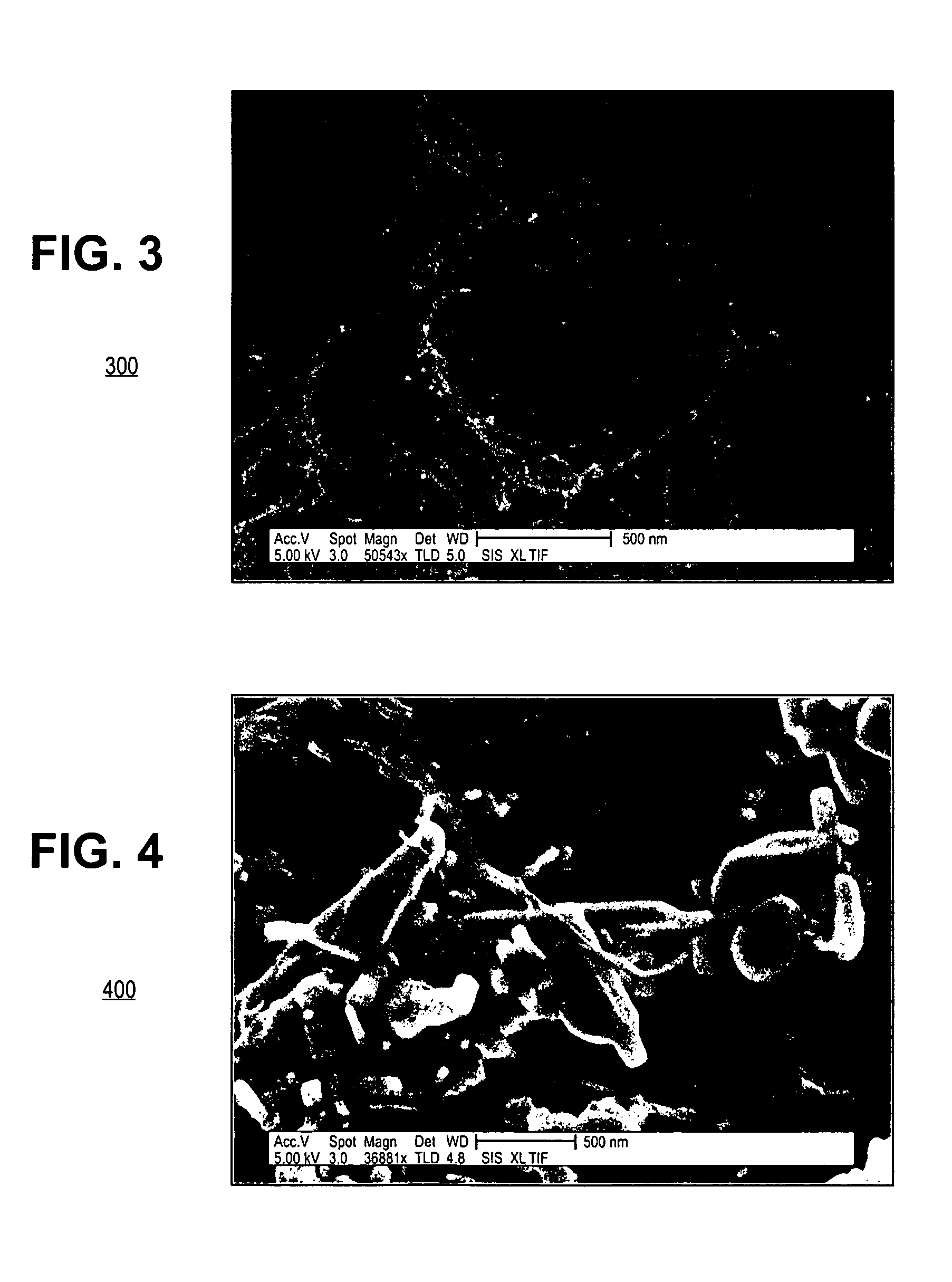

Thermal interface material (TIM) with carbon nanotubes (CNT) and low thermal impedance

According to embodiments of the present invention, a very thin thermal interface material (TIM) is developed, which is composed of carbon nanotubes, silicon thermal grease, and chloroform. The carbon nanotubes and chloroform comprise the filler and the silicone thermal grease comprises the matrix.

Owner:UNIV OF WASHINGTON

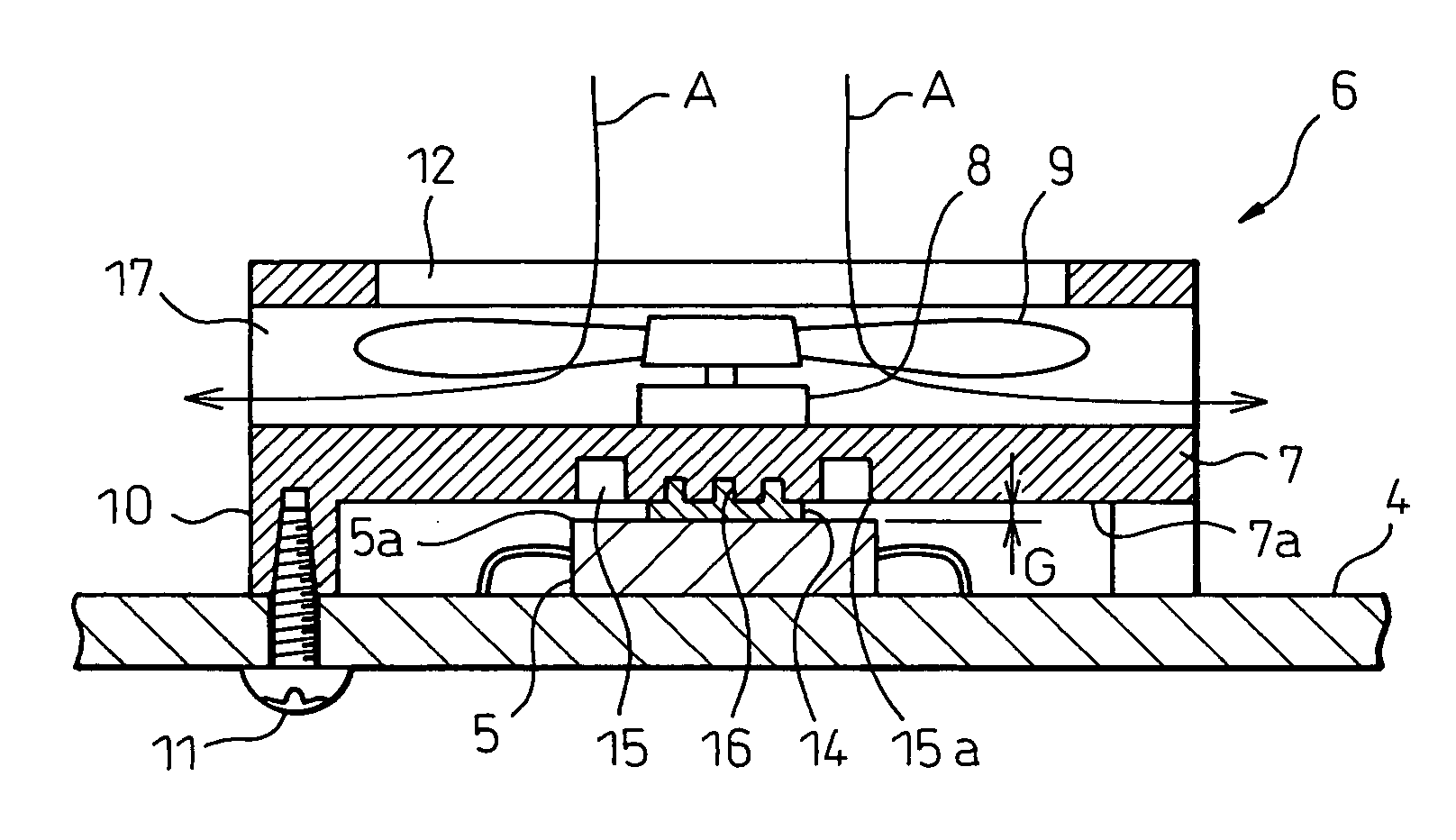

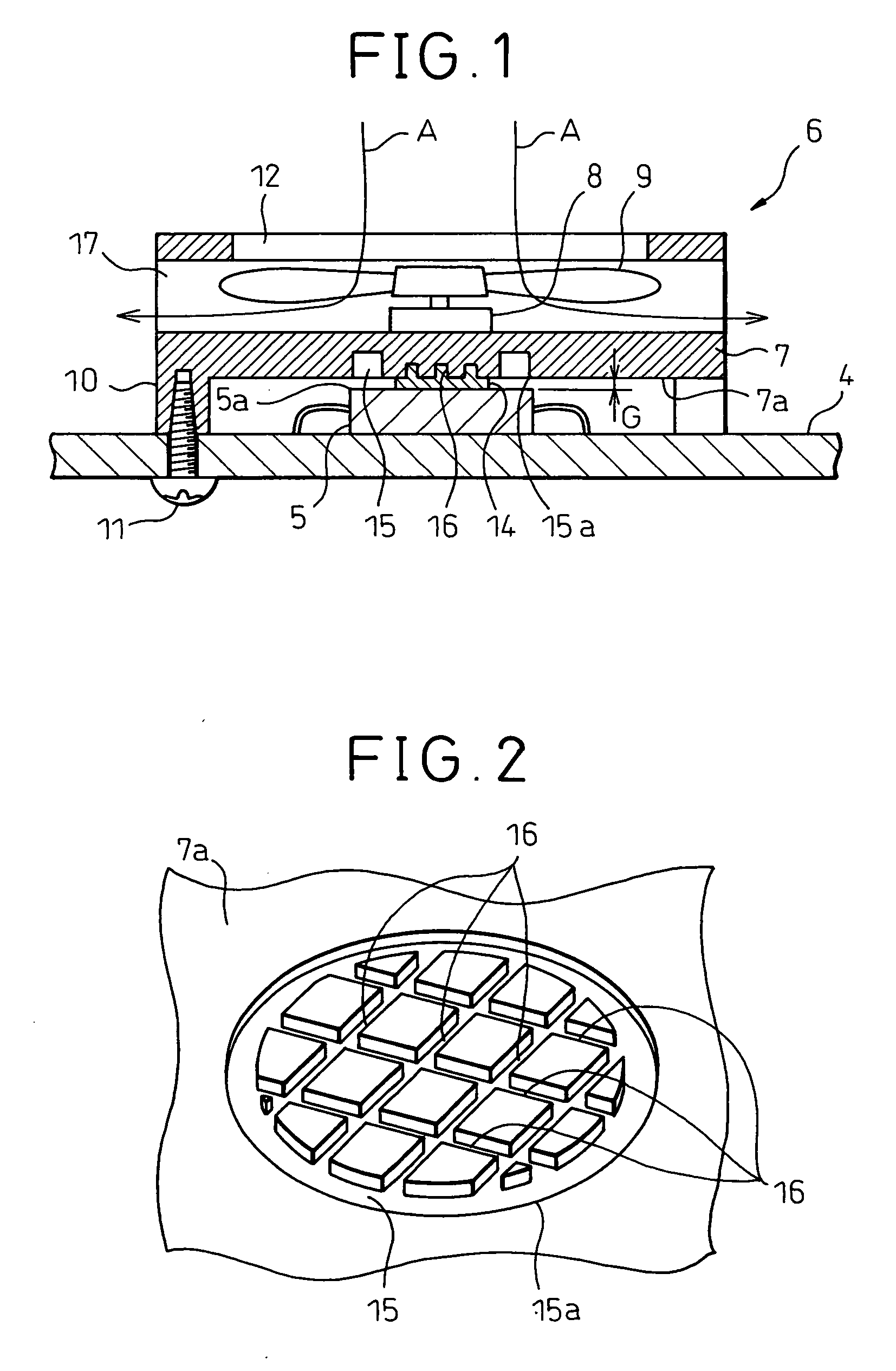

Heat radiating device and electronic equipment mounted on vehicle

InactiveUS20060215369A1Preventing heat-conductive greasePositively prevent being forced outSemiconductor/solid-state device detailsSolid-state devicesThermal greaseEngineering

In a heat radiating device and electronic equipment mounted on a vehicle, grid-shaped grooves 16 are formed on a lower face of a fan casing 7 which functions as a heat sink, and an annular ditch 15 is formed a round a region in which the grid-shaped grooves 16 are formed. Heat-conductive grease 14 interposed between IC chip 5 and a lower face of the fan casing 7 is prevented by the grid-shaped grooves 16 from slipping out. Even when a quantity of the coated heat-conductive grease 14 is excessively large in the beginning and forced out from a region in which the grid-shaped grooves 16 are formed, the heat-conductive grease 14, which has forced out in this way, is stored in an annular ditch 15 and not forced outside. In a cooling device in which heat of an object to be cooled is transmitted to a heat sink via the heat-conductive grease and radiated outside, the heat-conductive grease is prevented from being forced out from between the object to be cooled and the heat sink.

Owner:DENSO CORP

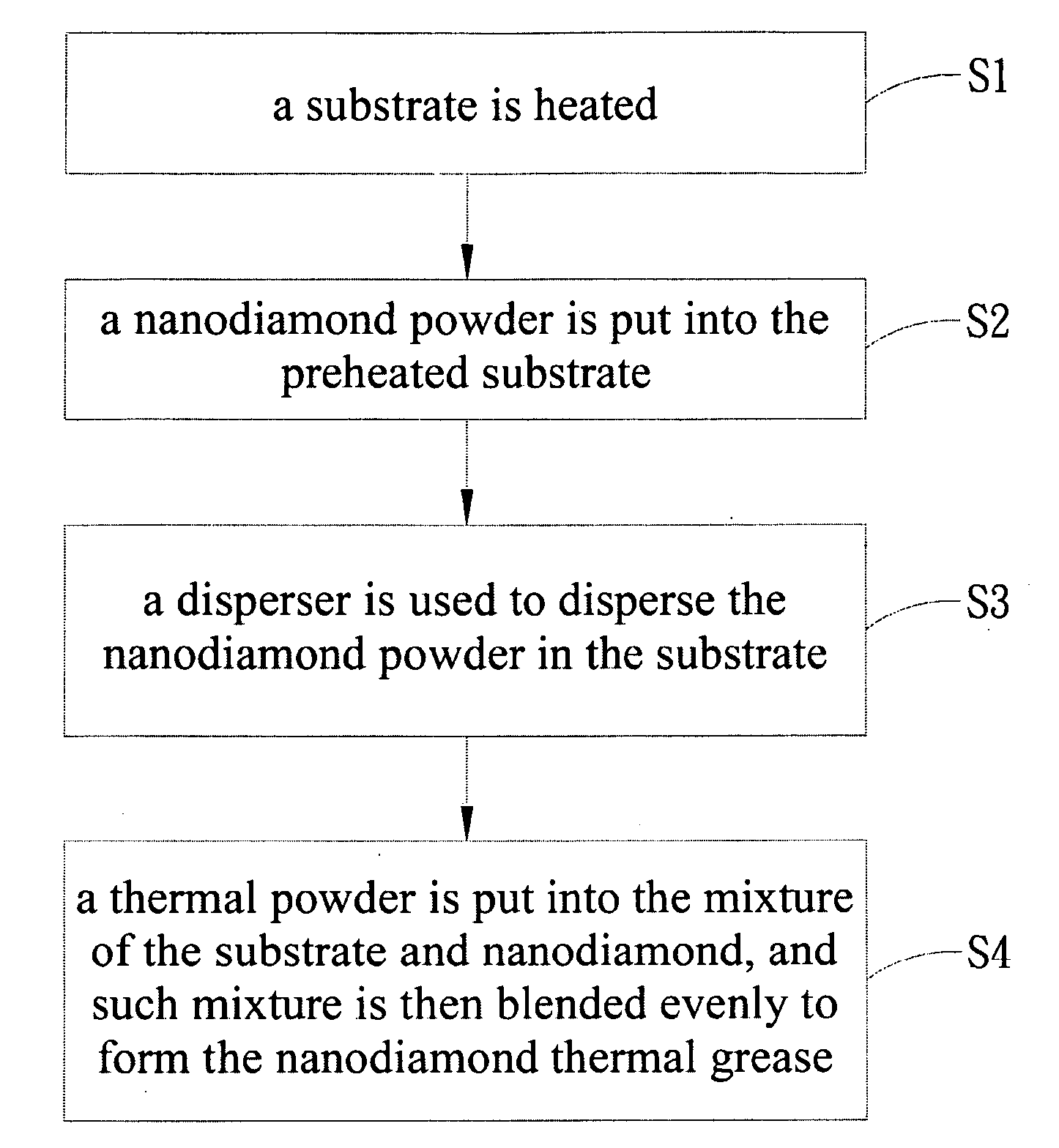

Nanodiamond thermal grease

ActiveUS20100022423A1Low costImprove cooling efficiencyMaterial nanotechnologySemiconductor/solid-state device detailsThermal greaseNanometre

The present invention discloses a nanodiamond thermal grease, which comprises a nanodiamond powder, a thermal powder and a substrate. The nanodiamond powder has volume percentage of 5% to 30%, the thermal powder has volume percentage of 40% to 90%, and the substrate has volume percentage of 5% to 30%. The nanodiamond powder and the thermal powder are distributed uniformly in the substrate to form the nanodiamond thermal grease having high thermal conductivity.

Owner:KUNSHAN NANO NEW MATERIAL TECH

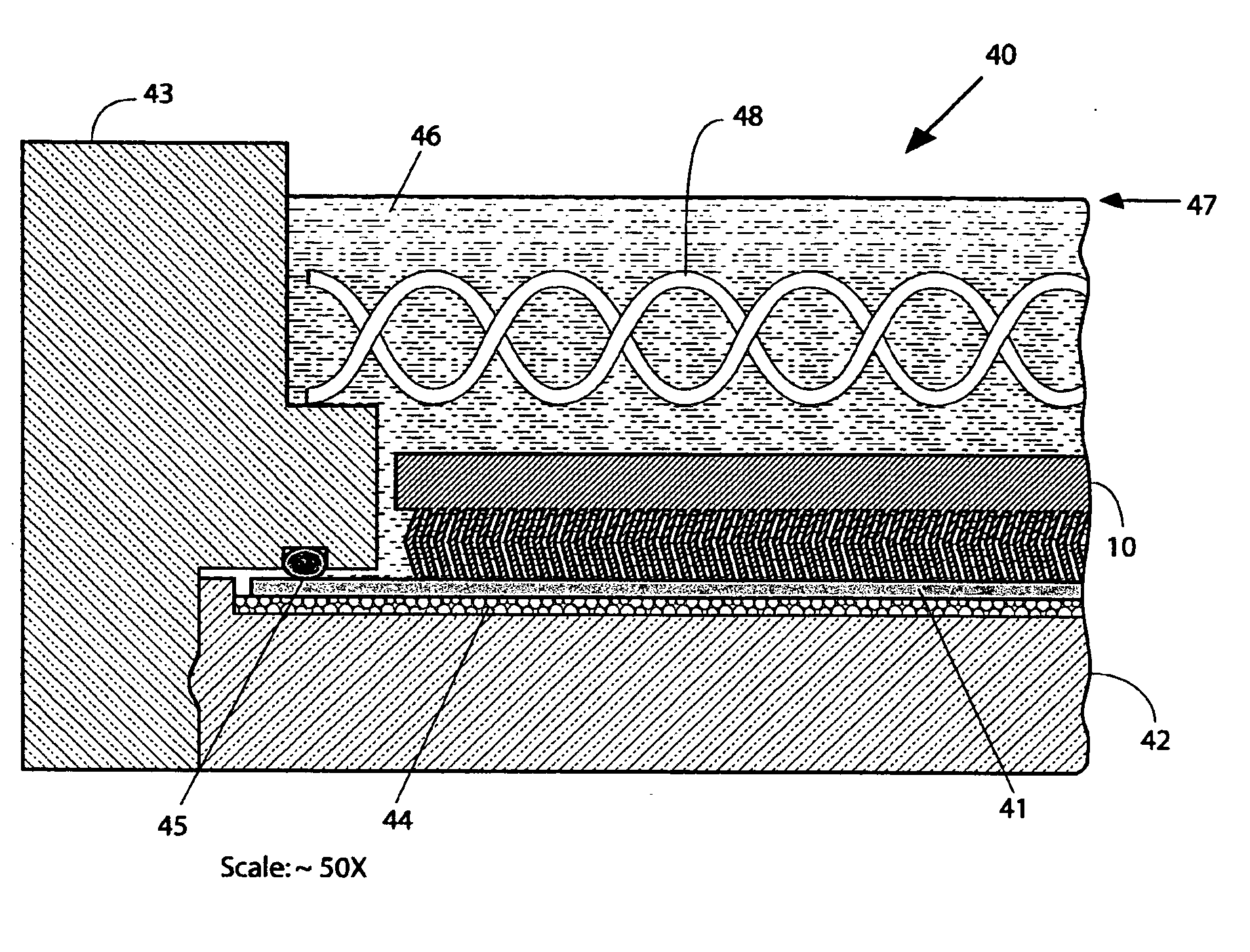

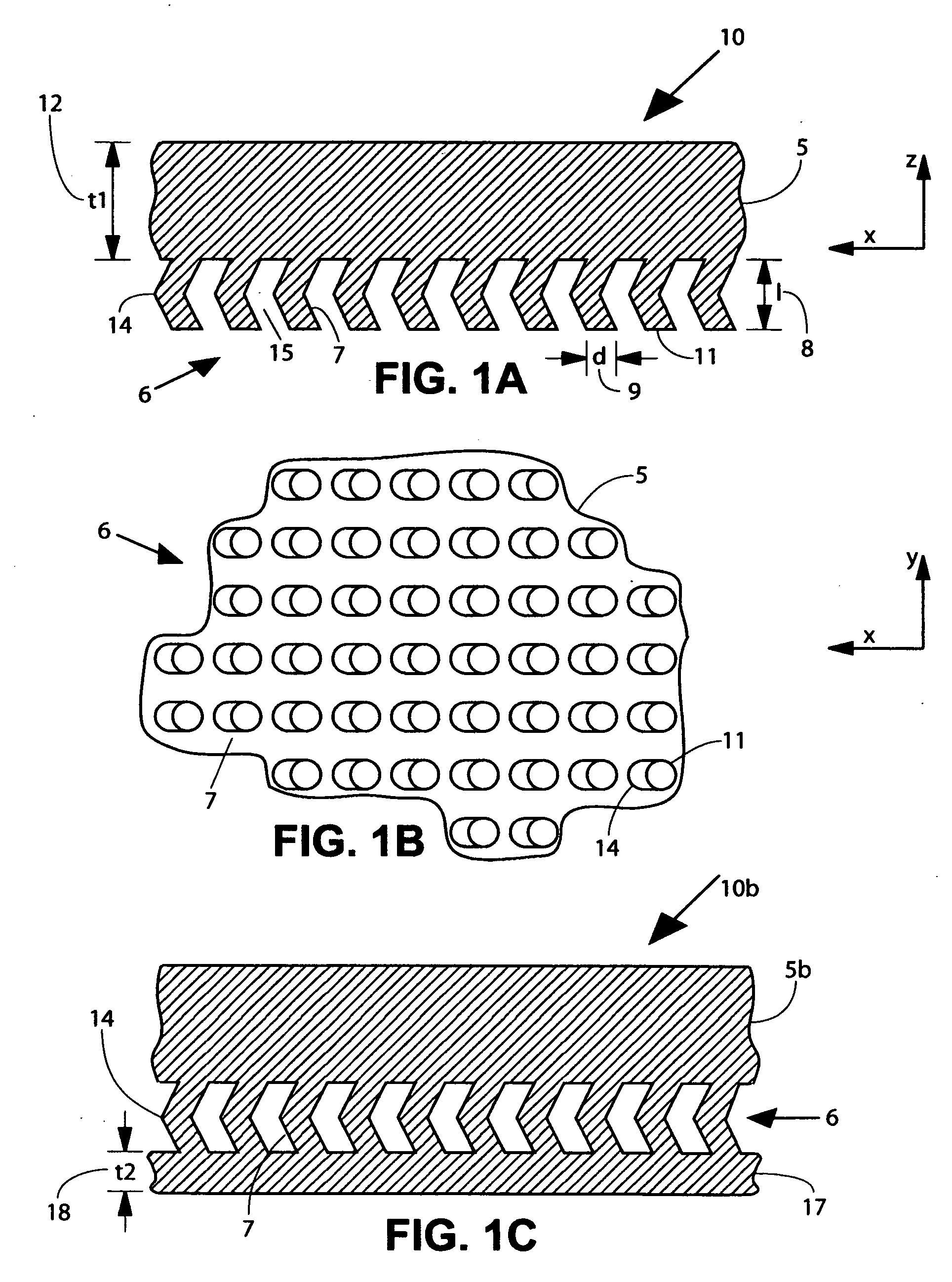

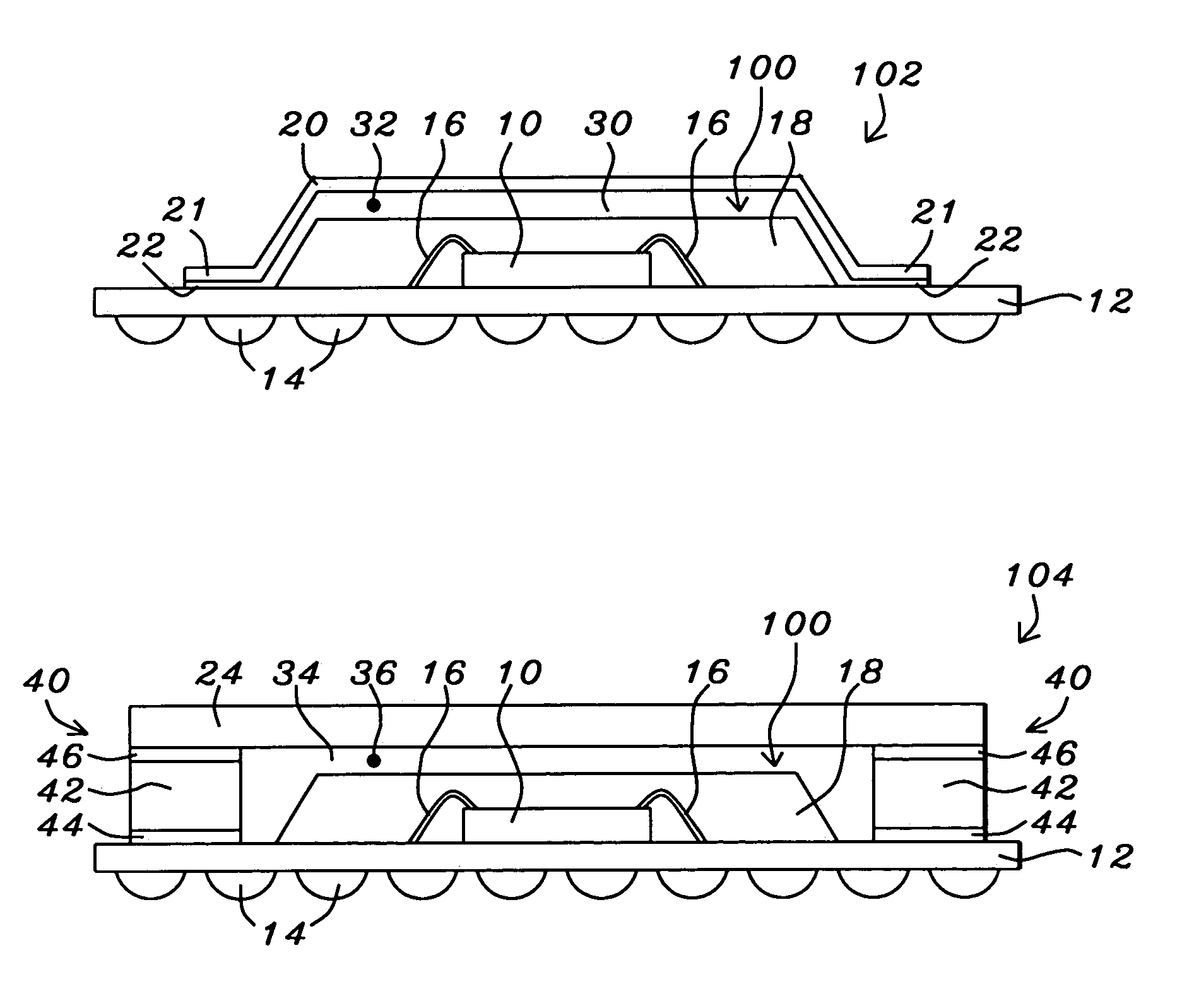

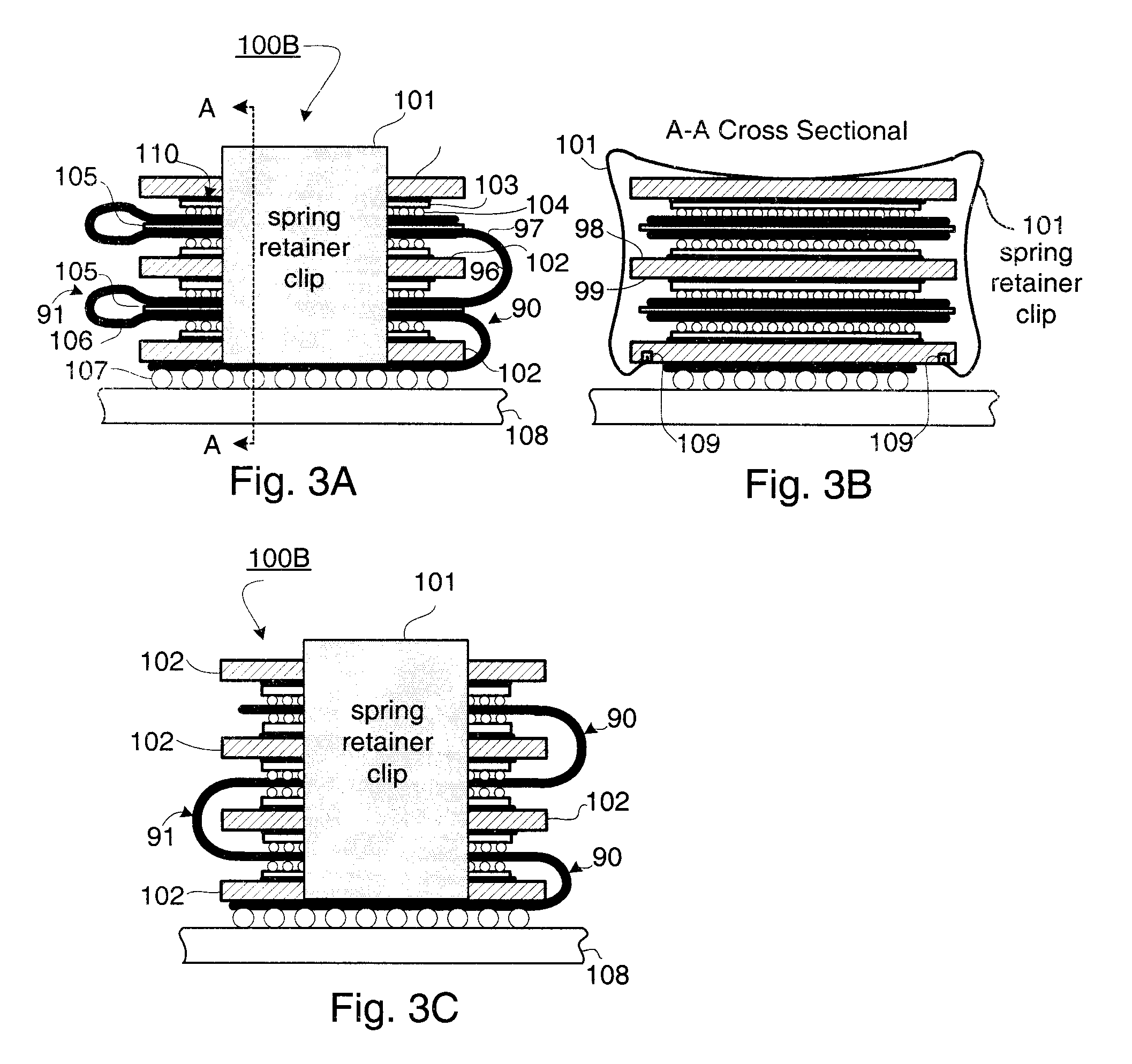

Adaptive interface using flexible fingers

InactiveUS20060077638A1Ease mechanical stressEase thermal stressSemiconductor/solid-state device detailsSolid-state devicesThermal greaseSemiconductor chip

A multi-function interface adaptor comprises a base layer and flexible fingers extending from it. The interface adaptor is interposed between two objects to provide a mechanical and / or thermal interface with stress relief or shock absorption. Using bent fingers operating like springs, shocks and distributed stresses can be relieved in the plane of the adaptor, as well as normal to the plane. A preferred embodiment is an Interface Adaptor that replaces thermal grease between a semiconductor chip and its associated heat sink.

Owner:PETER C SALMON LLC A CALIFORNIA LIMITED LIABILITY

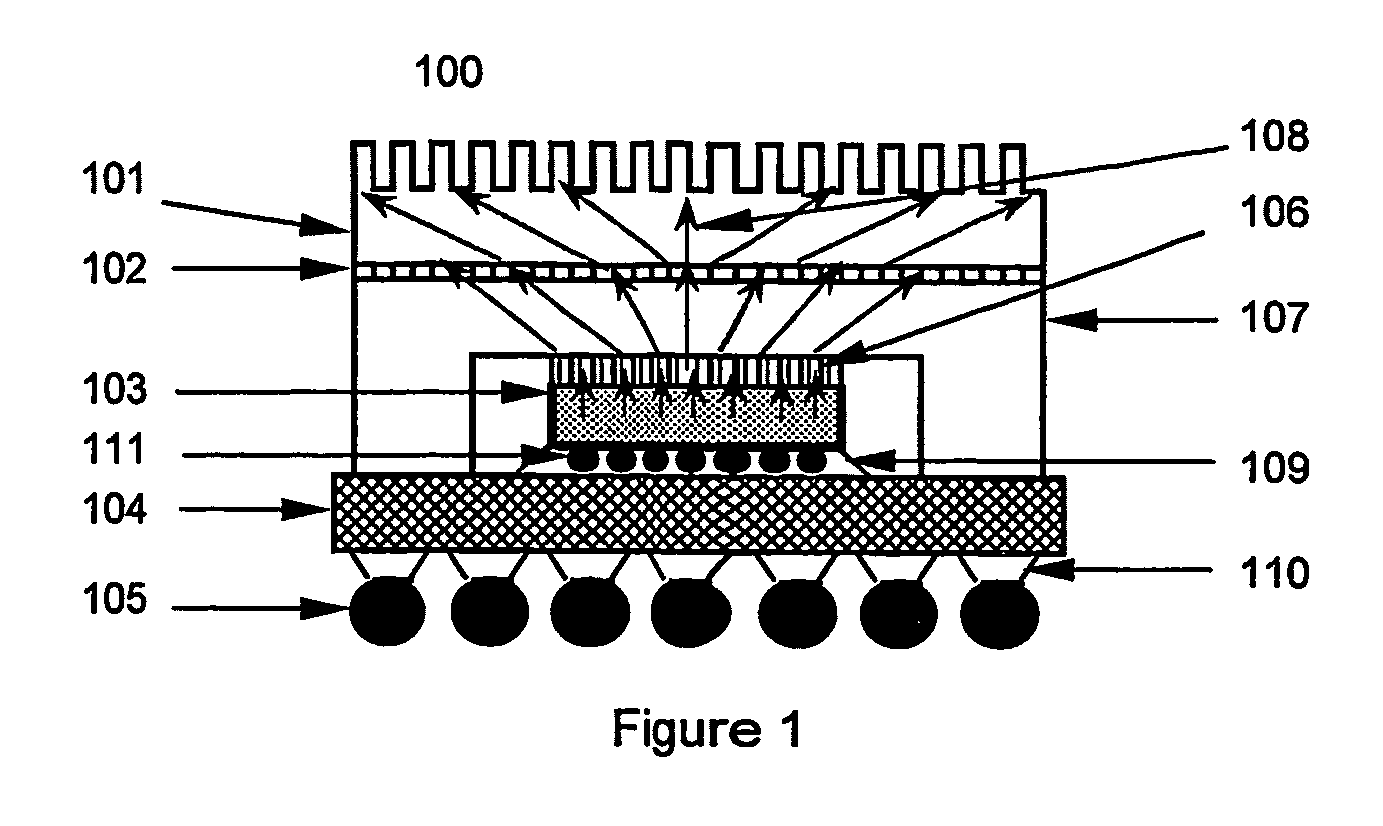

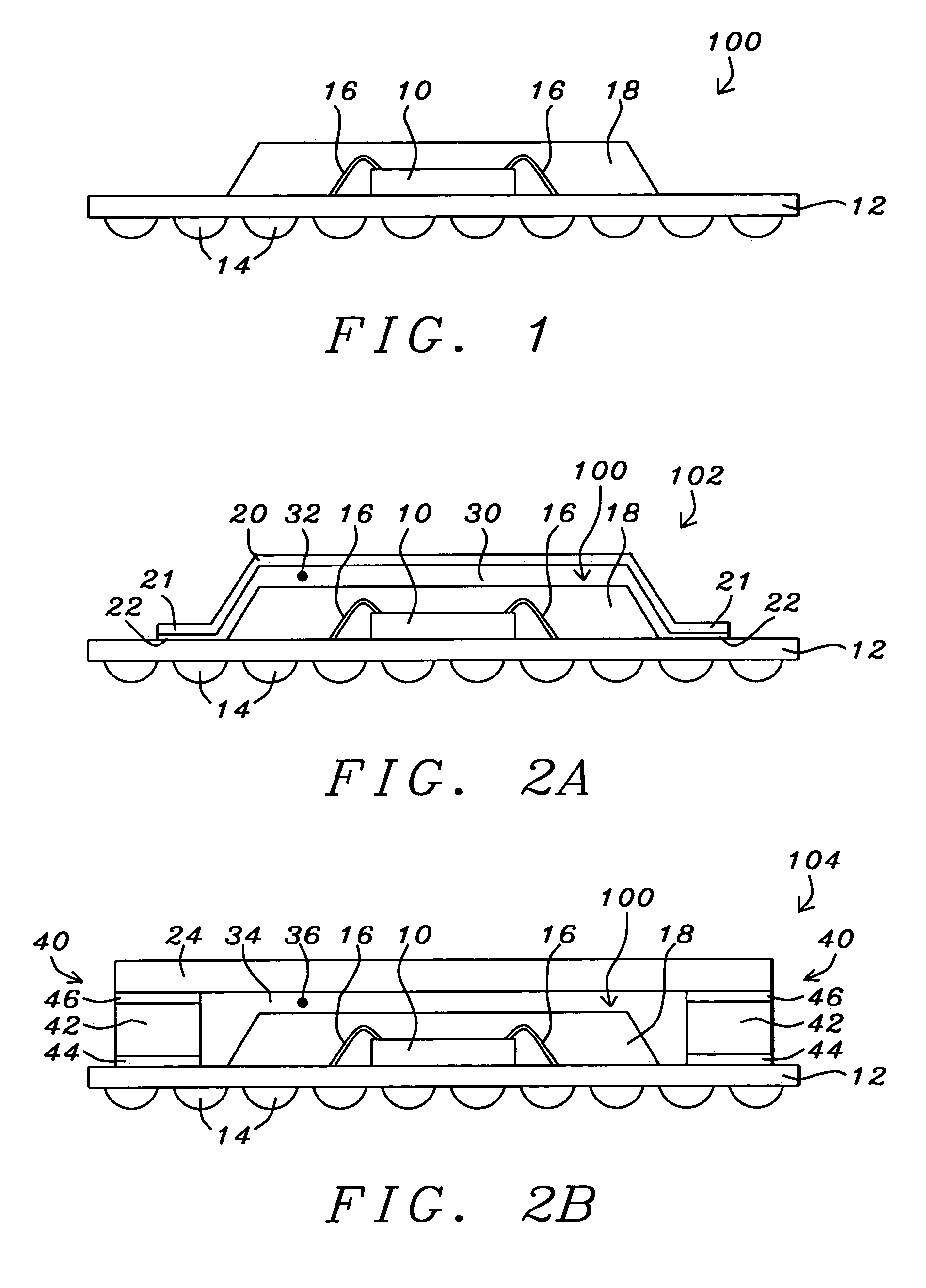

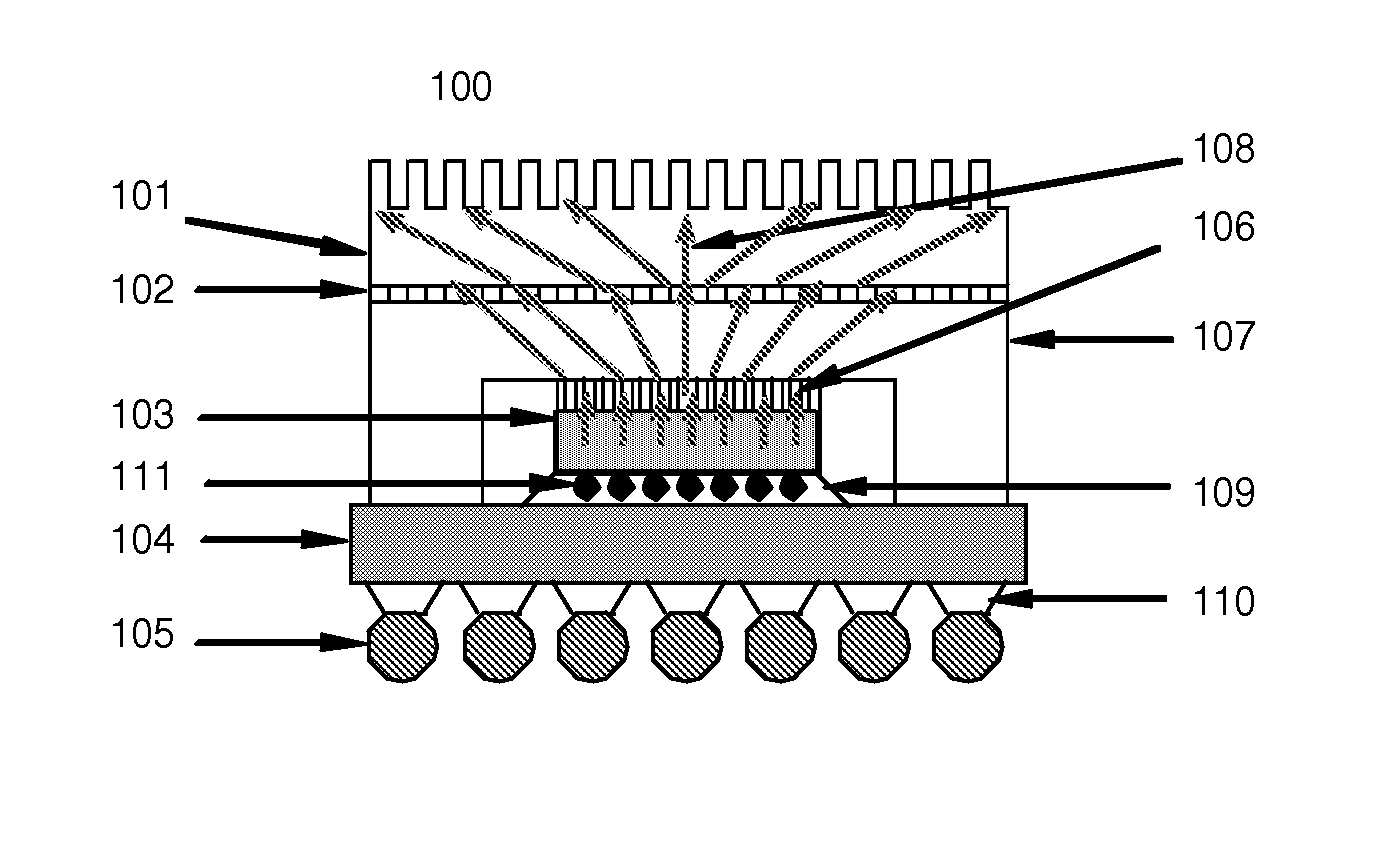

Heat spreader ball grid array (HSBGA) design for low-k integrated circuits (IC)

InactiveUS7180173B2Semiconductor/solid-state device detailsSolid-state devicesThermal greaseSemiconductor chip

A method of forming a heat spreader ball grid array package, and the resultant heat spreader ball grid array package, comprising the following steps. A semiconductor chip affixed to a ball grid substrate is provided. The semiconductor chip over the ball grid substrate is encased with a molding compound. A heat spreader is mounted over the ball grid substrate and spaced apart from the molding compound to form a gap. Thermal grease is placed into the gap, at least between the heat spreader and the molding compound, to form the heat spreader ball grid array package. It is also possible to place thermal grease over the molding compound and then mounting the heat spreader over the ball grid substrate.

Owner:TAIWAN SEMICON MFG CO LTD

Protect cover for a radiator

InactiveUS7051790B2Easy to packSemiconductor/solid-state device detailsSolid-state devicesThermal greaseEngineering

A protect cover for a radiator is utilized to protect thermal grease coated at the bottom of the radiator. The protect cover has a cover body with a bottom and lateral sides. Further, the cover body has a support unit projecting from the inner side of the bottom and enclosing a space accommodating the thermal grease so as to prevent the thermal grease from being accidentally touched with foreign substance or being stained with dust during the radiator being delivered or packed.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

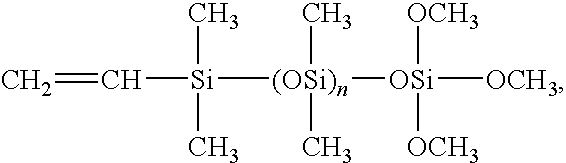

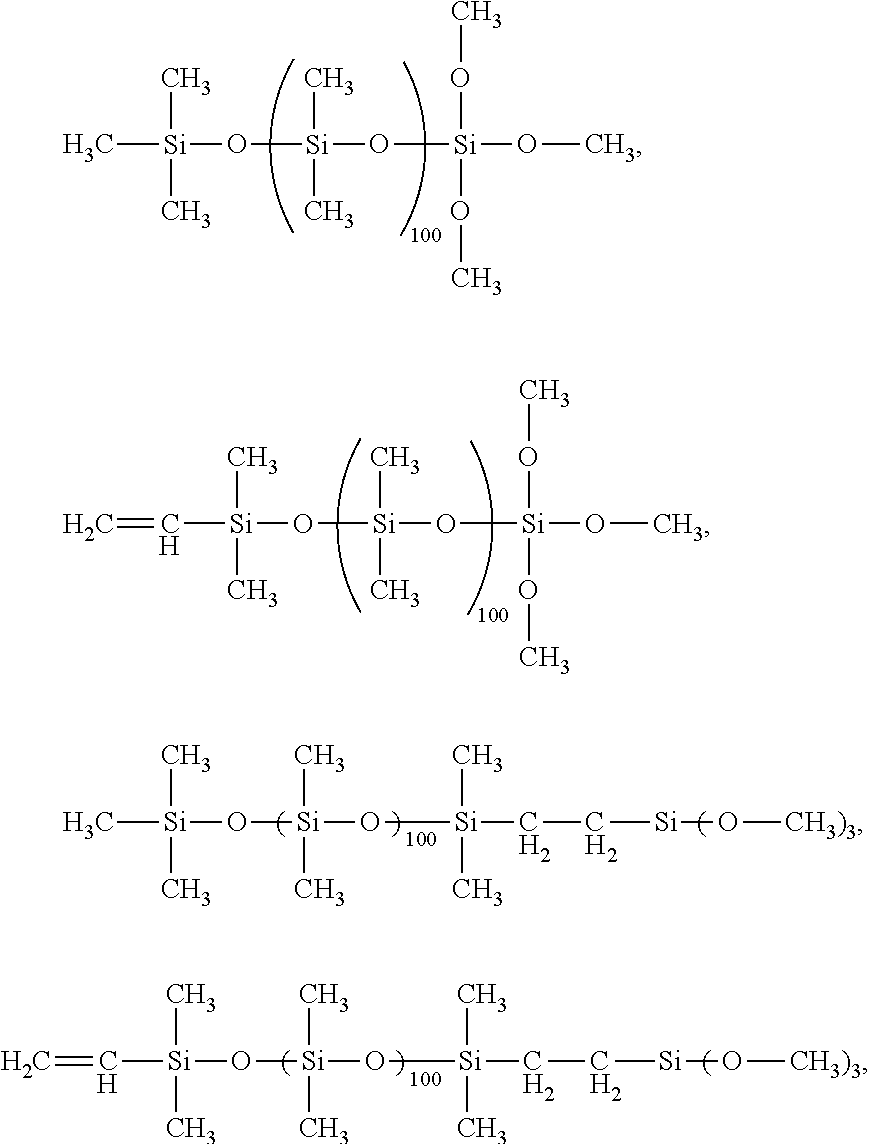

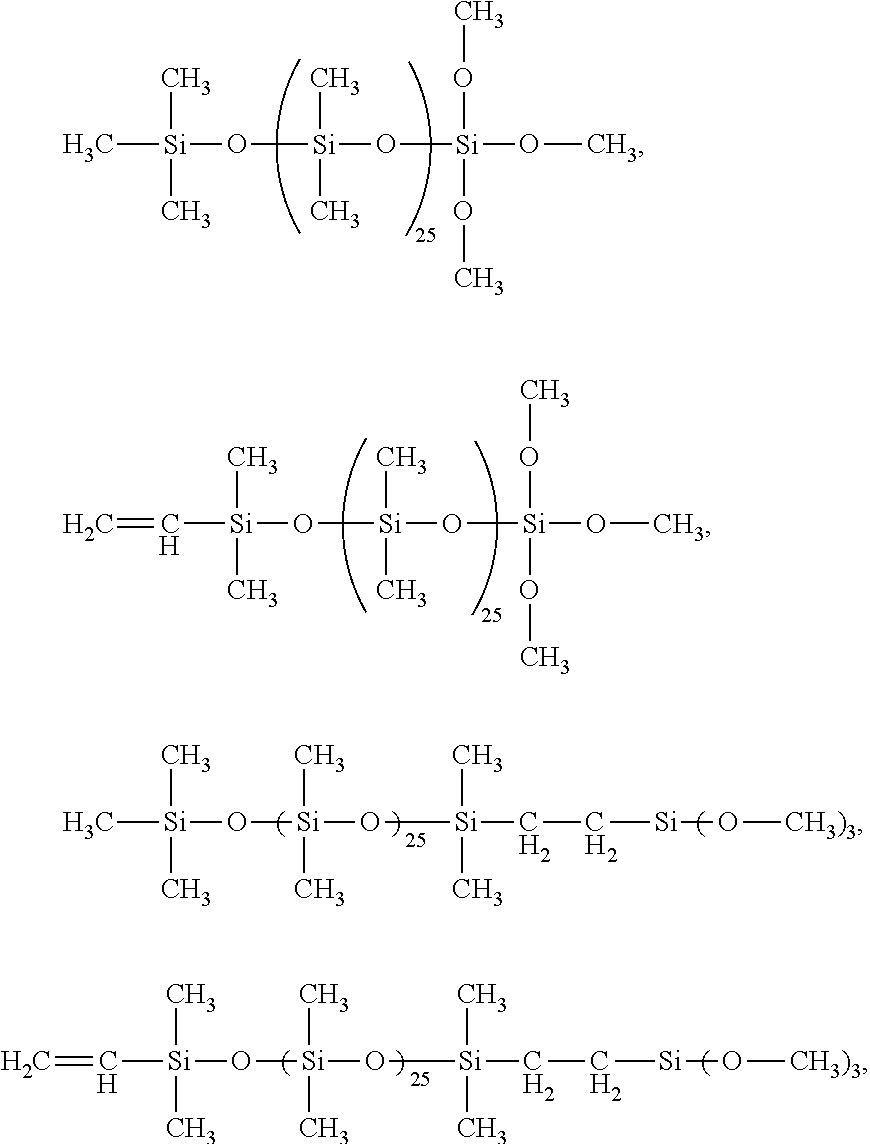

Thermally conductive grease and methods and devices in which said grease is used

ActiveUS8618211B2Not react significantlyHigh viscosityHeat-exchange elementsSolid ballsThermal greasePolymer chemistry

A thermally conductive grease includes 2 vol % to 15 vol % of a combination of three polyorganosiloxanes and 65 vol % to 98 vol % of a thermally conductive filler. The grease may be used as a thermal interface material for dissipating heat from (opto)electronic devices, in both TIM1 and TIM2 applications.

Owner:DOW SILICONES CORP

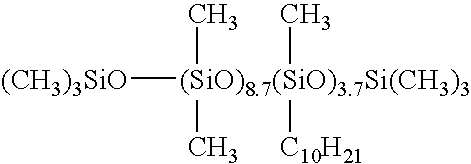

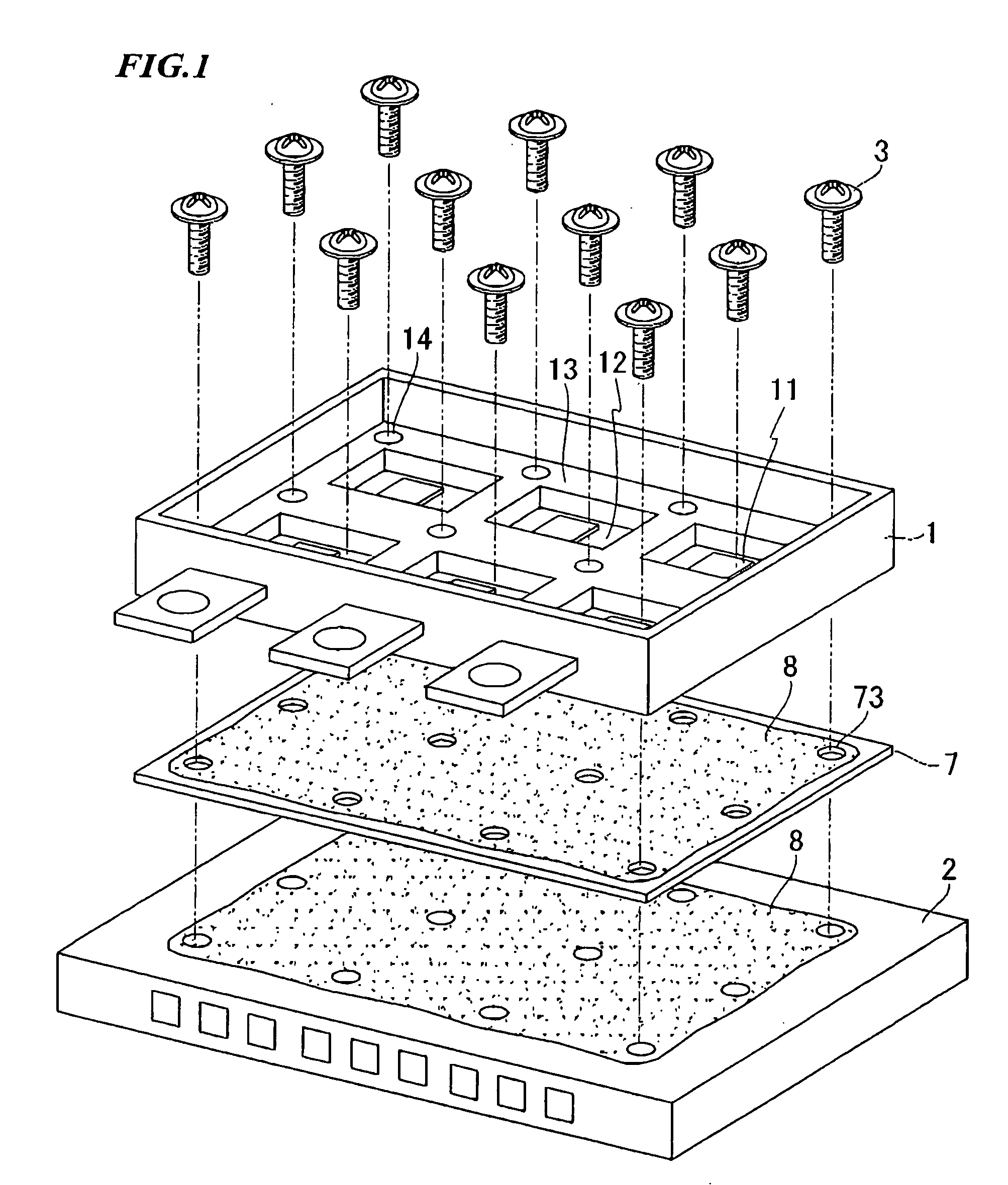

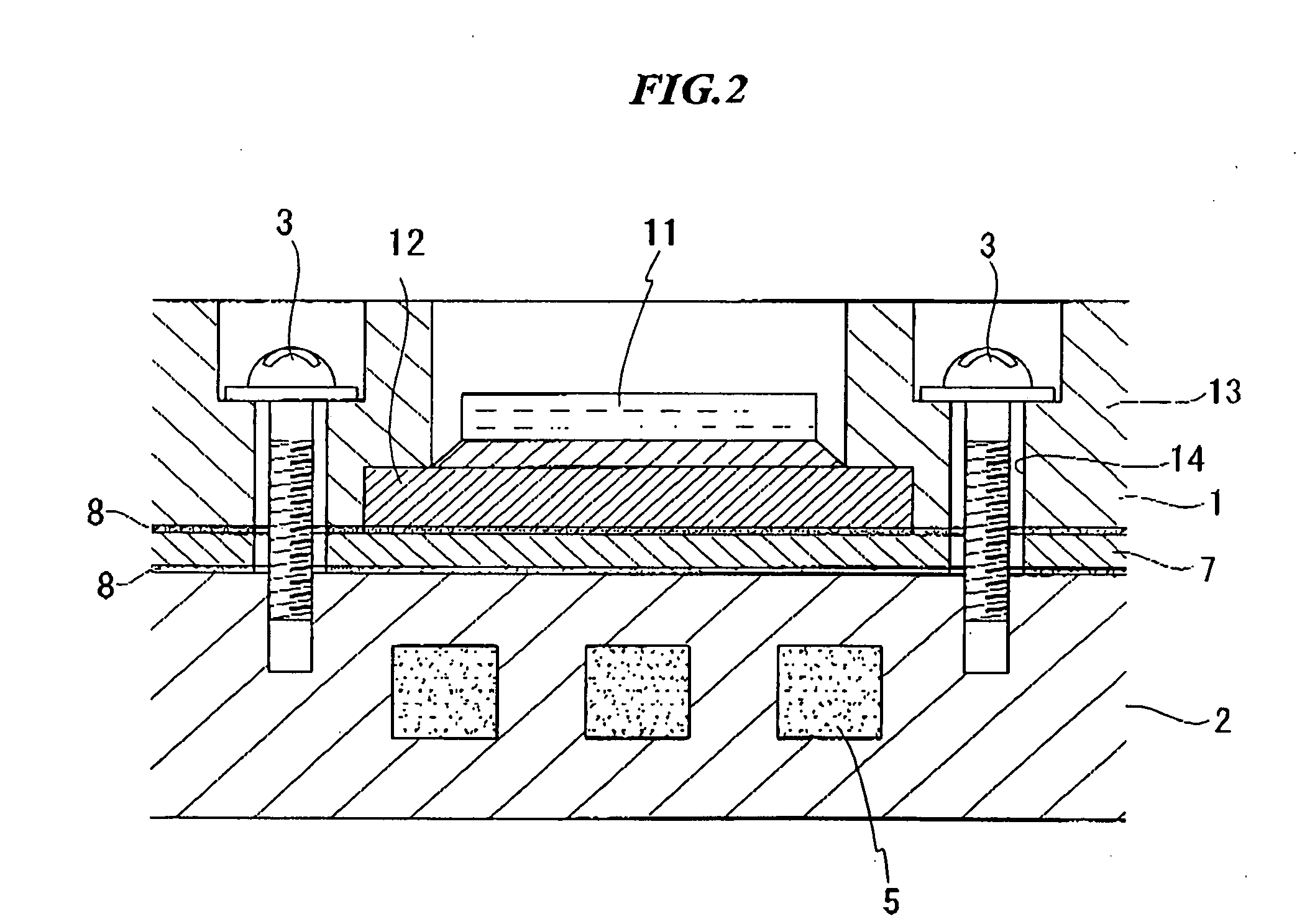

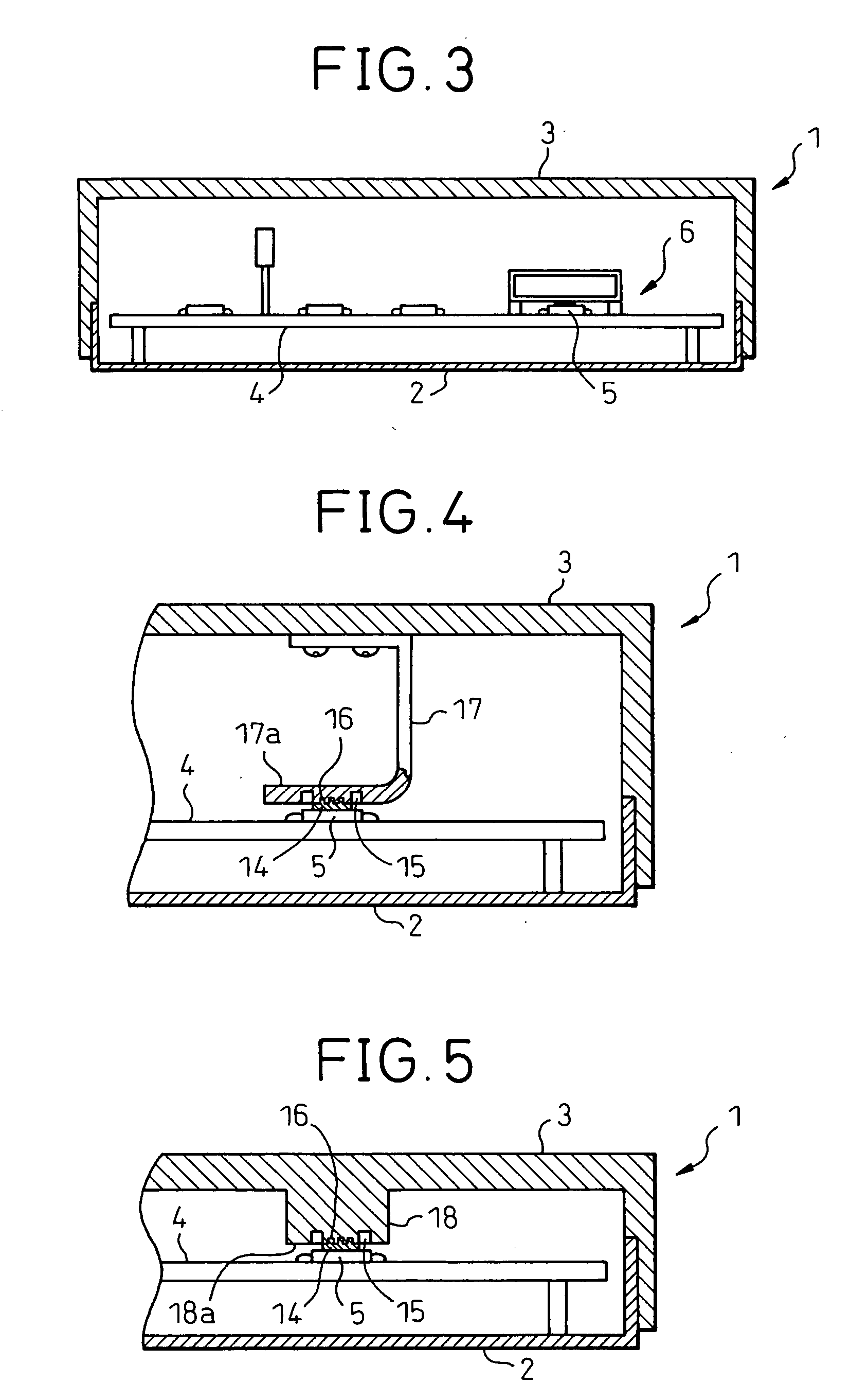

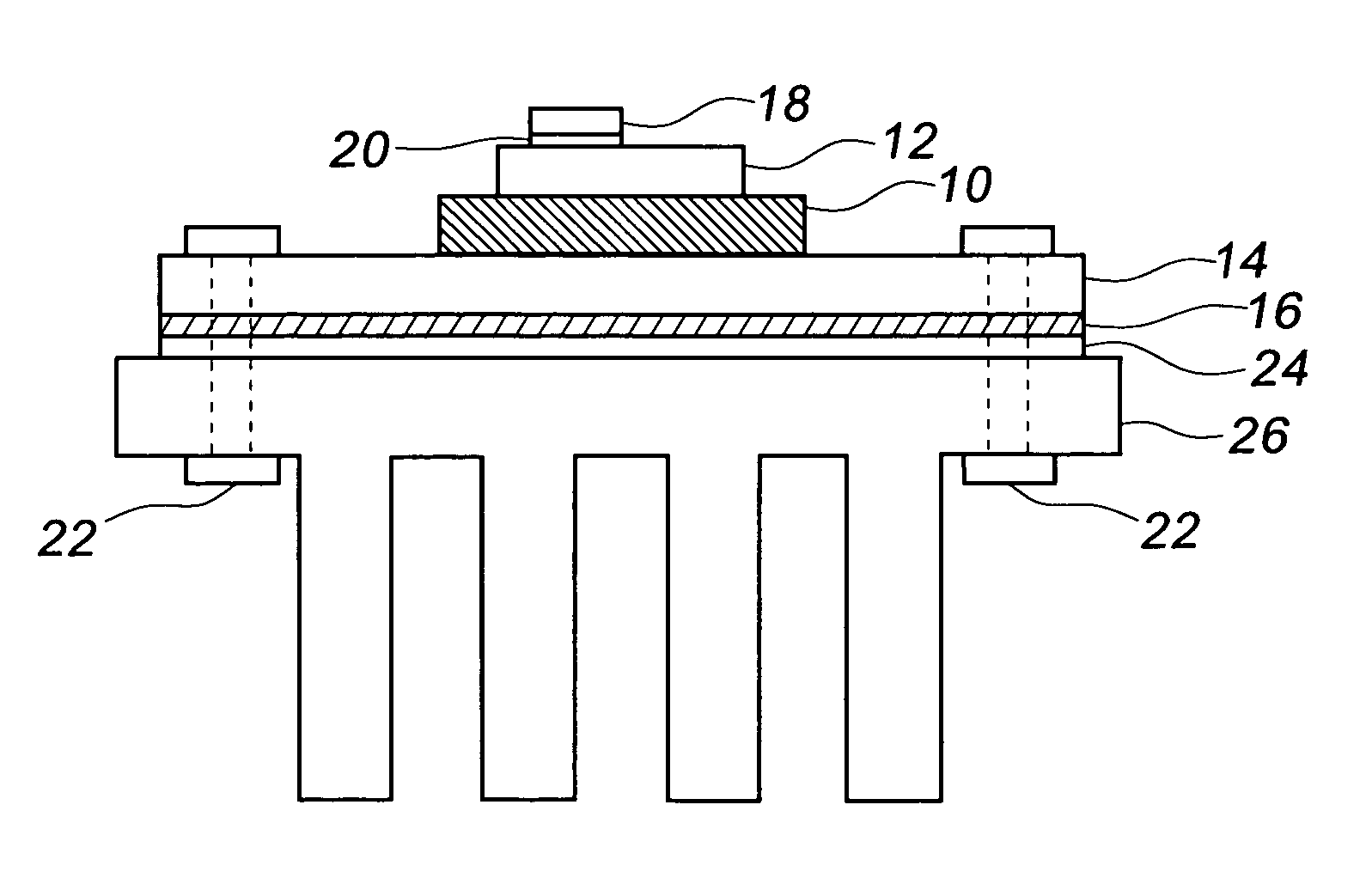

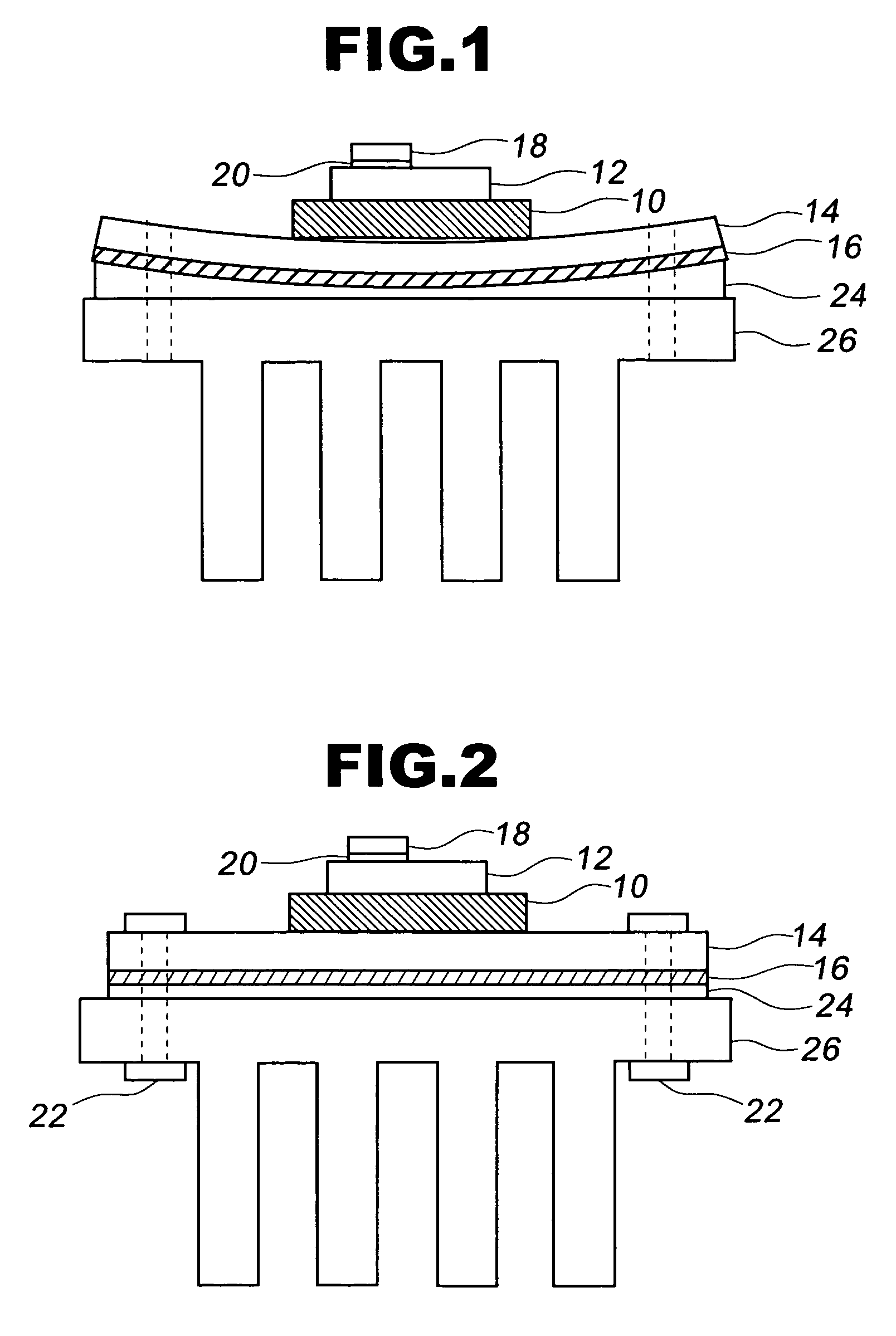

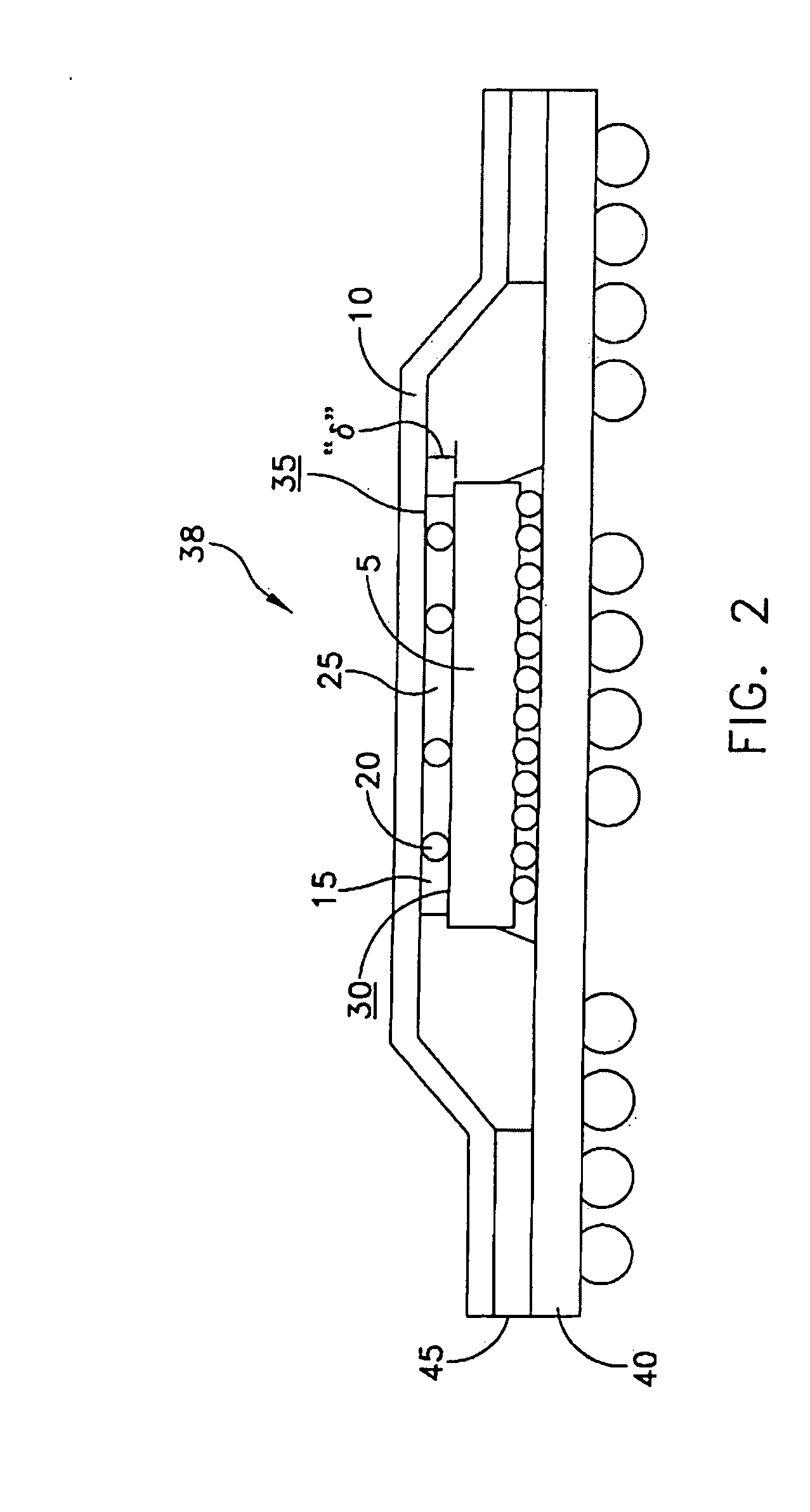

Metal/ceramic bonding substrate and method for producing same

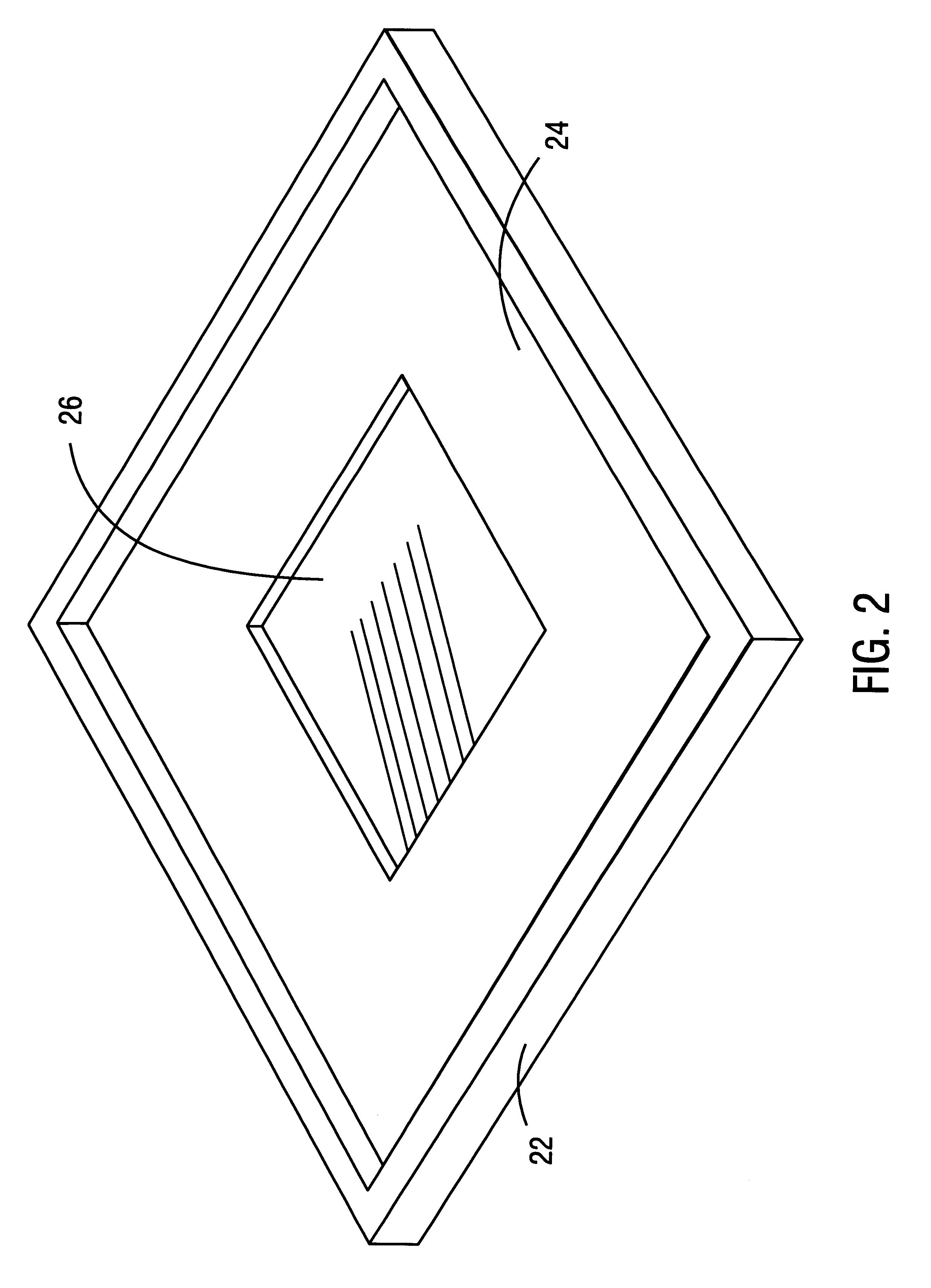

ActiveUS7256353B2Semiconductor/solid-state device detailsLaminating printed circuit boardsSemiconductor chipThermal grease

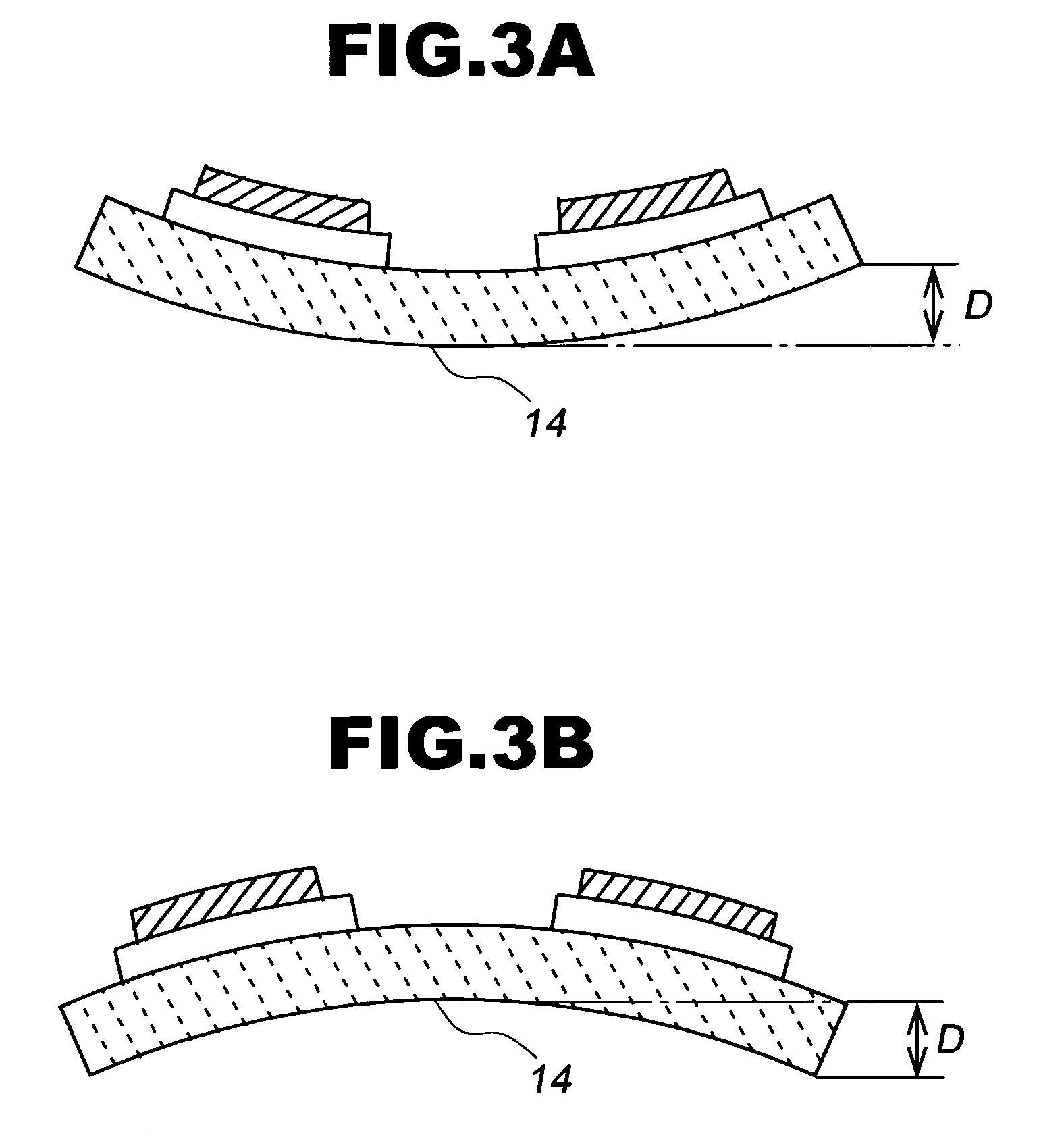

There is provided a metal / ceramic bonding substrate capable of preventing the reverse thereof from greatly warping so as to be concave even if it is heated for soldering. In the metal / ceramic bonding substrate, a metal circuit plate 12 is bonded to one side of a ceramic substrate 10, and a heat sink plate (metal base plate) 14 is bonded to the other side thereof. On the heat sink plate 14, a work-hardened layer 16 is formed by shot peening. On the metal circuit plate 12 of the metal / ceramic bonding substrate, semiconductor chips (Si chips) 18 are soldered (solder layer 20). Then, a power module is produced by a predetermined process. On the reverse (the side of the work-hardened layer 16) of the power module, a radiating fin 26 is mounted via a thermal grease 24 by means of screws 22 or the like.

Owner:DOWA METALTECH CO LTD

Thermal bond verification

InactiveUS20020196835A1Material thermal conductivityMaterial heat developmentOn boardHeat conducting

A system and method for evaluating the thermal bond between a heat-producing device and a heat-absorbing apparatus. The heat-producing device may be a CPU, such as an INTEL PENTIUM microprocessor, and the heat-absorbing apparatus may be a heat sink. The two may be joined with a heat-conducting substance such as thermal grease or adhesive. In one exemplary embodiment, the heat-producing device is operated at a first power level, a first temperature measurement is then taken, the device is operated at a second power level, and then a second temperature measurement is then taken. The thermal resistance is then calculated, which may involve subtracting the second temperature from the first, and may involve dividing by the power level. The first power level may be full power, and the second power level may be near zero. The first temperature may be measured when equilibrium temperatures have been reached, and the second temperature may be measured a predetermined amount of time after the second power level is initiated, which may be just enough time for the temperatures of the CPU and the heat sink to equalize. The CPU may perform the calculations, and the temperature may be measured with an on-board thermal sensor which may be a thermal diode.

Owner:SBS TECH

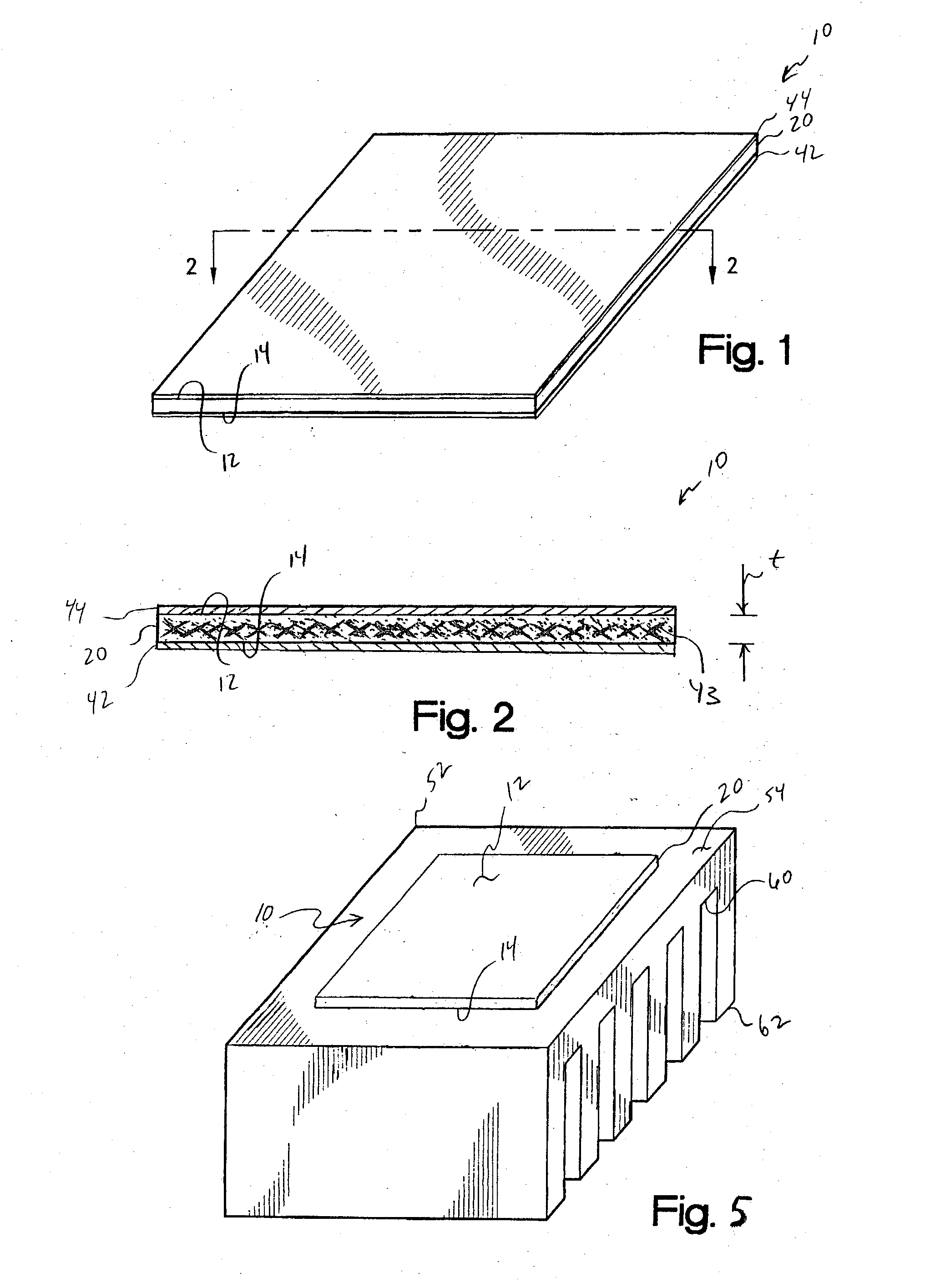

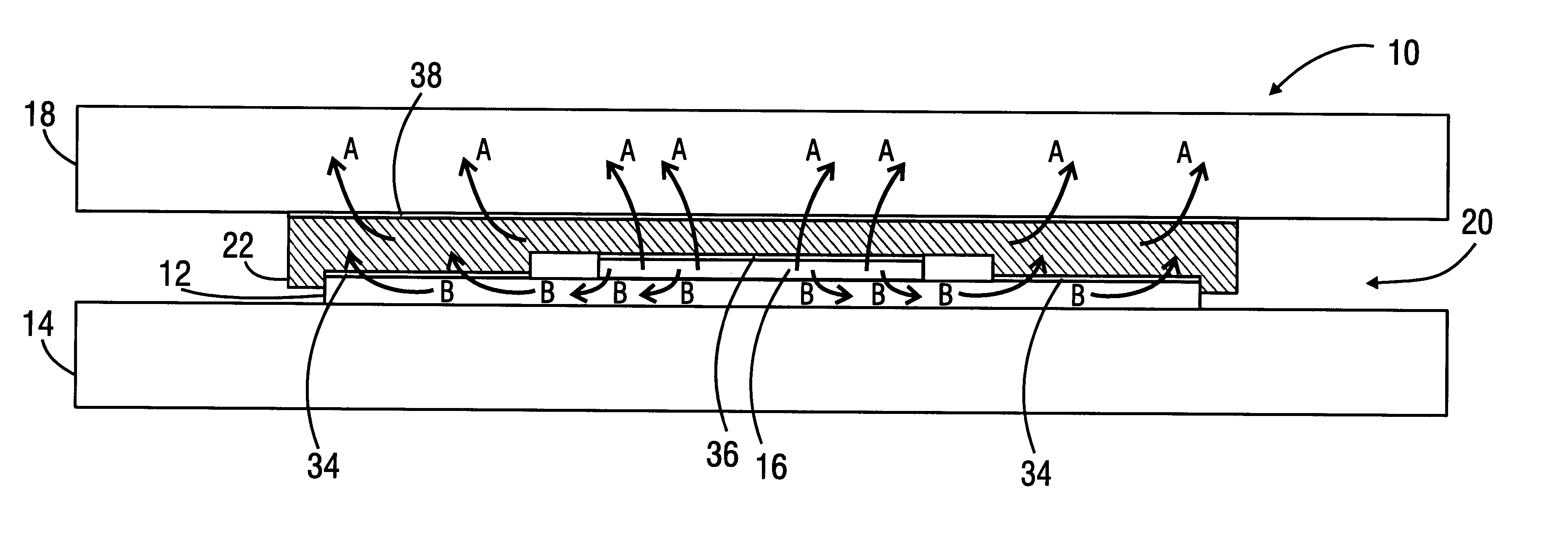

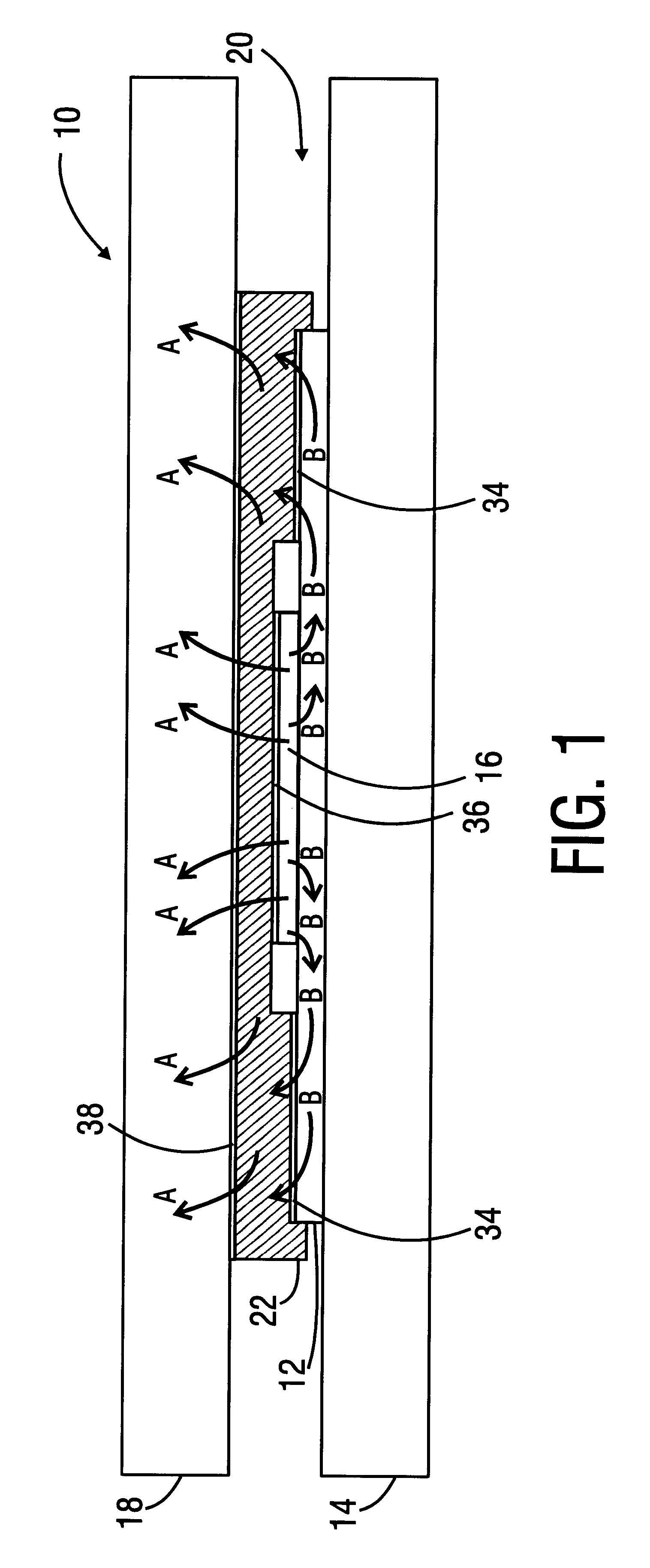

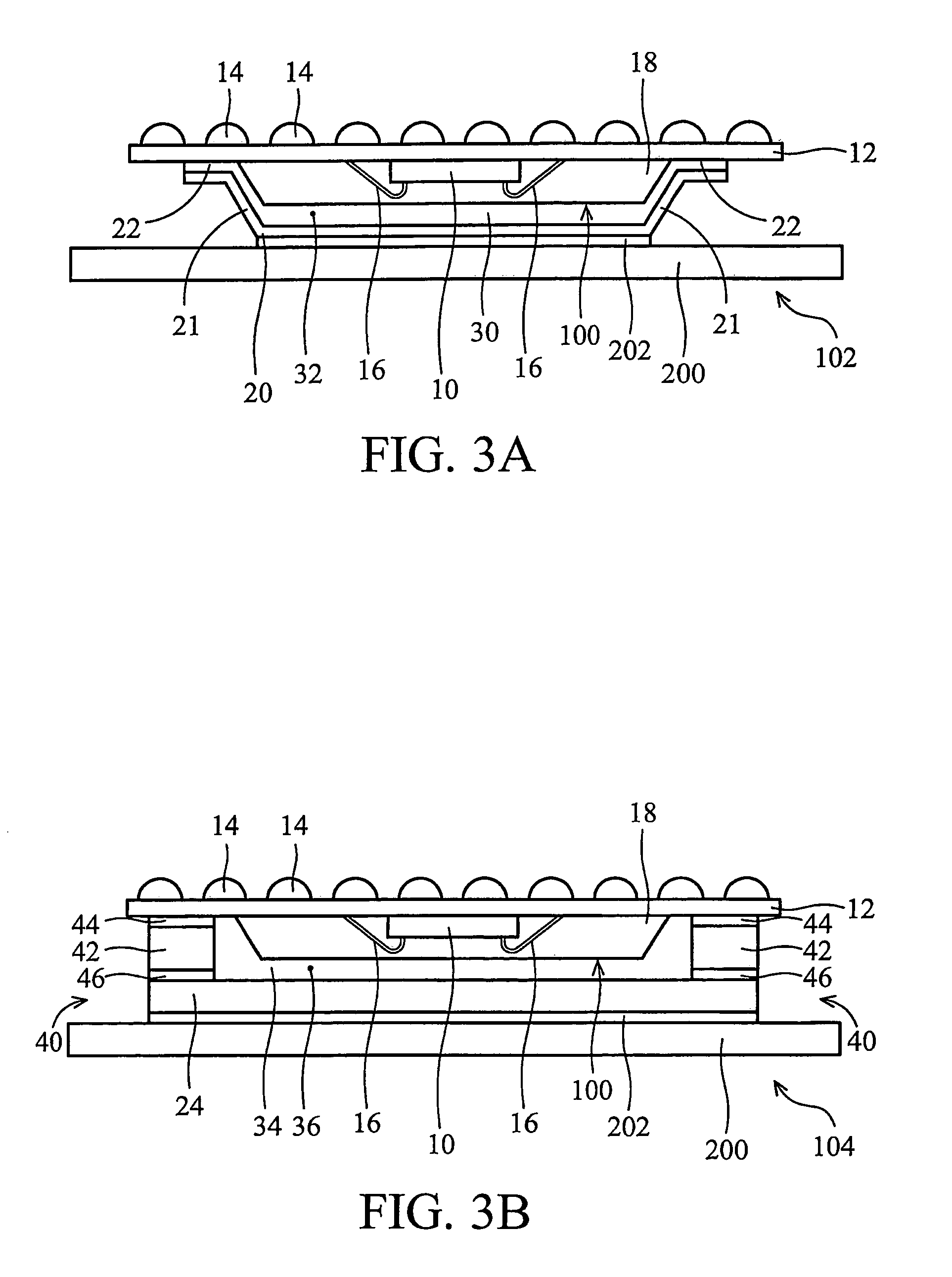

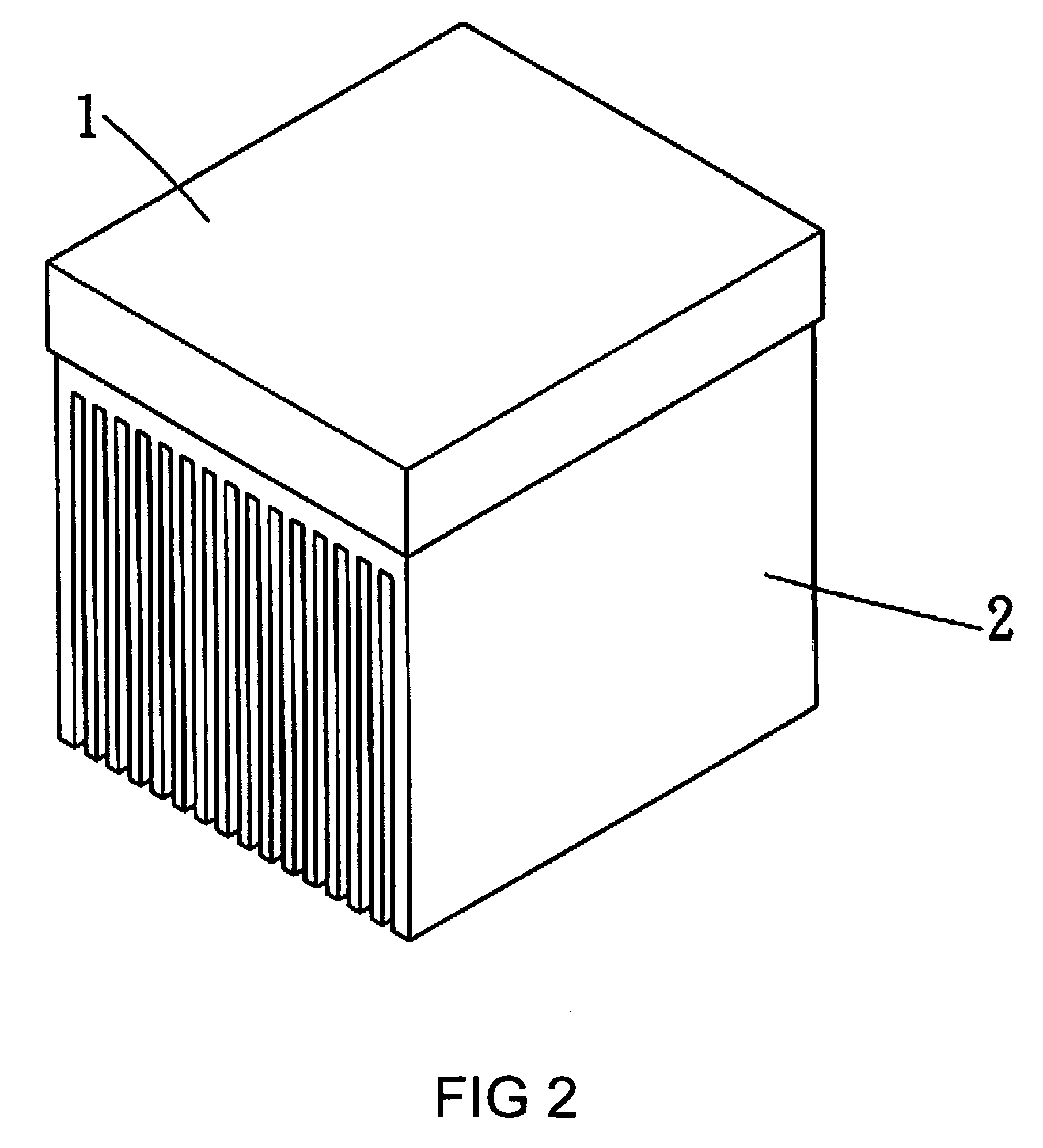

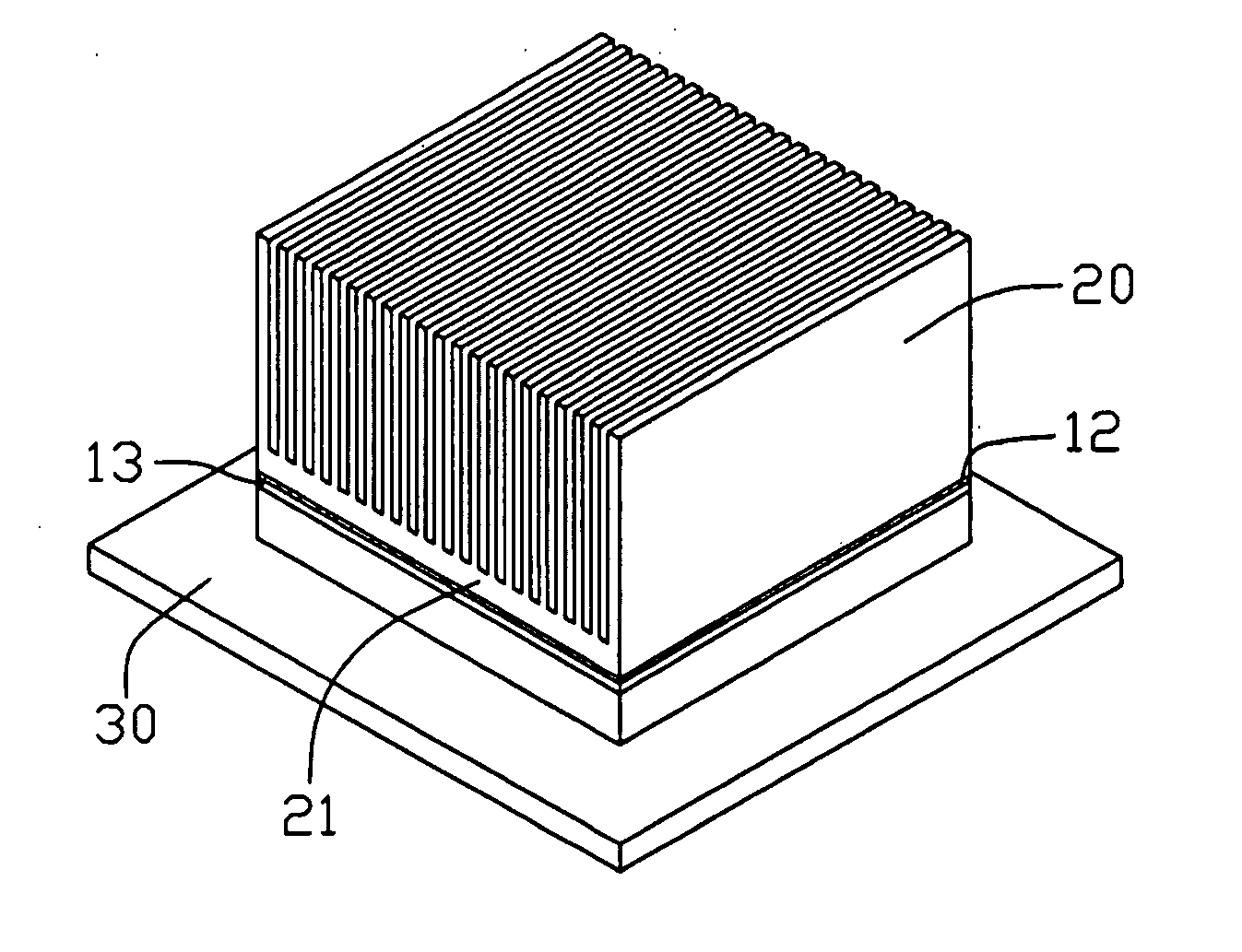

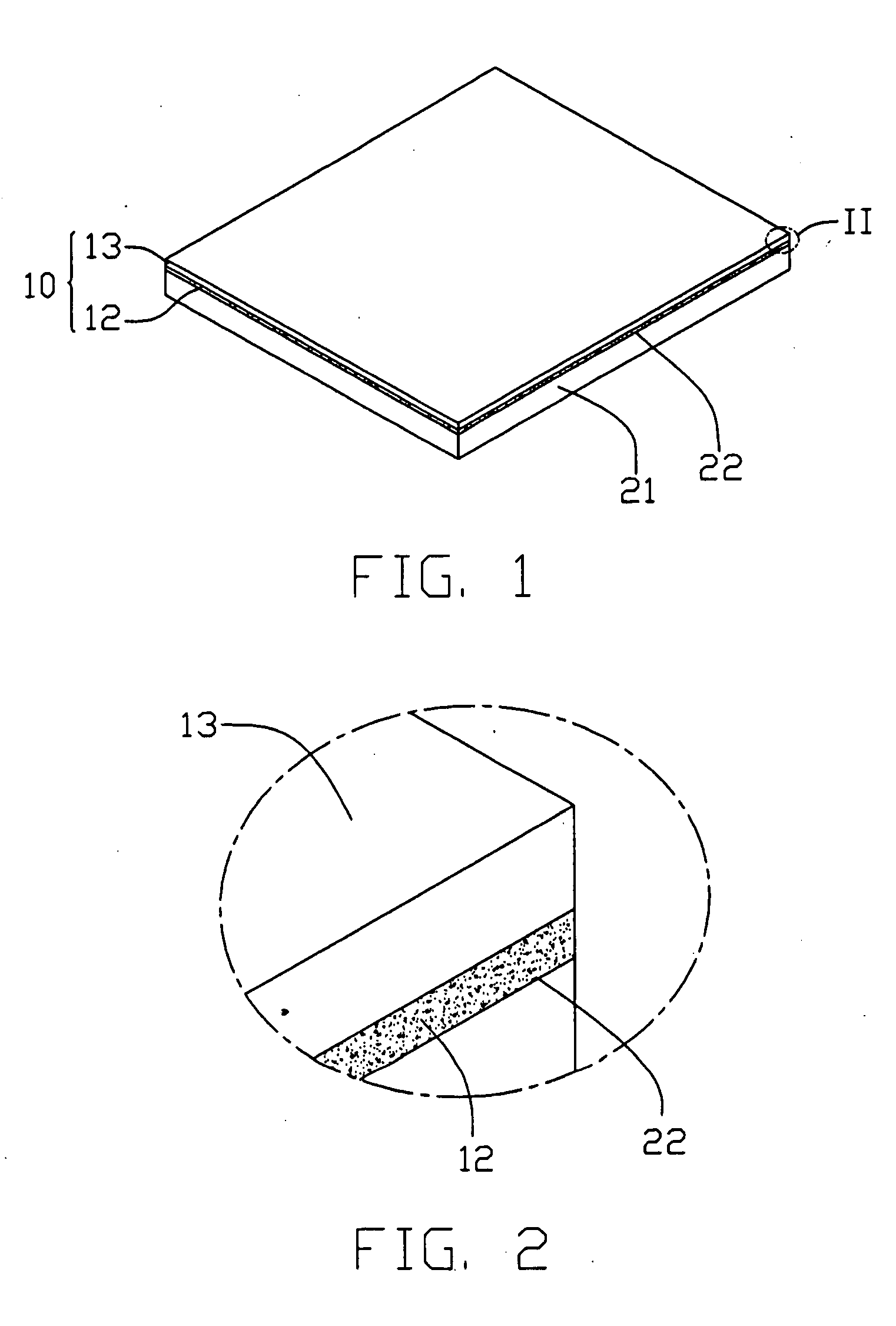

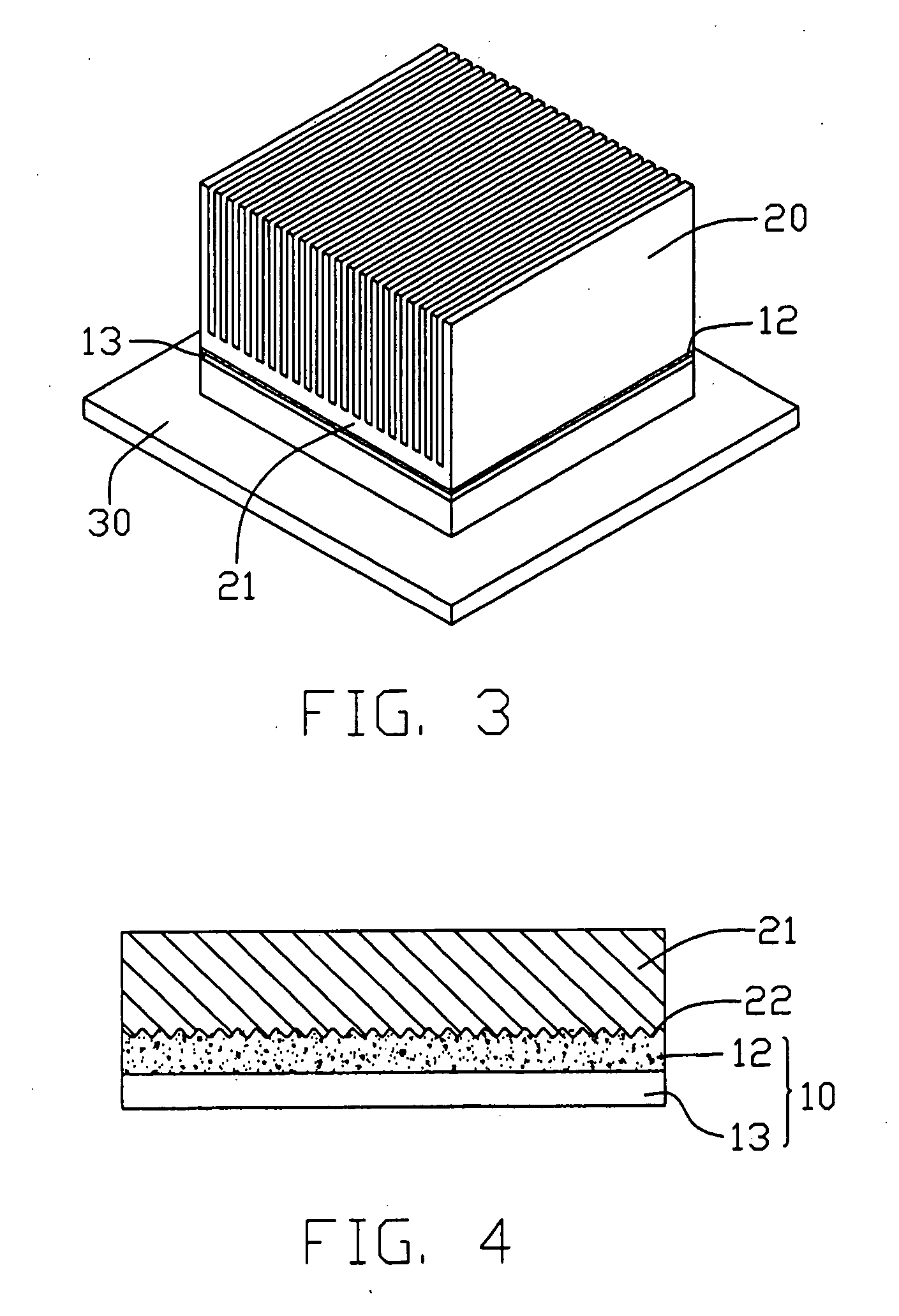

Thermal interface material and method for manufacturing same

InactiveUS20050230082A1Improve thermal conductivityIncrease surface areaSide-by-side/stacked arrangementsSemiconductor/solid-state device detailsSputteringShape-memory alloy

A thermal interface material (10) includes a shape memory effect thin film (12), and a thermal grease (13) attached on the film. The film is composed of a shape memory alloy, and is formed on a base (21) of a heat sink (20) at an operating temperature of a heat-generating electronic device (30). This is done by vacuum sputtering deposition or a like process. The shape memory alloy is a nano-NiTiCu alloy or a like alloy. In use, the thermal interface material enhances the thermal contact between the electronic device and the heat sink. A method for manufacturing the thermal interface material includes: (a) providing a base which is a portion of a heat sink; (b) depositing a film of a shape memory alloy on a surface of the base at an operating temperature of a heat source and under vacuum; and (c) applying a thermal grease on the film.

Owner:HON HAI PRECISION IND CO LTD

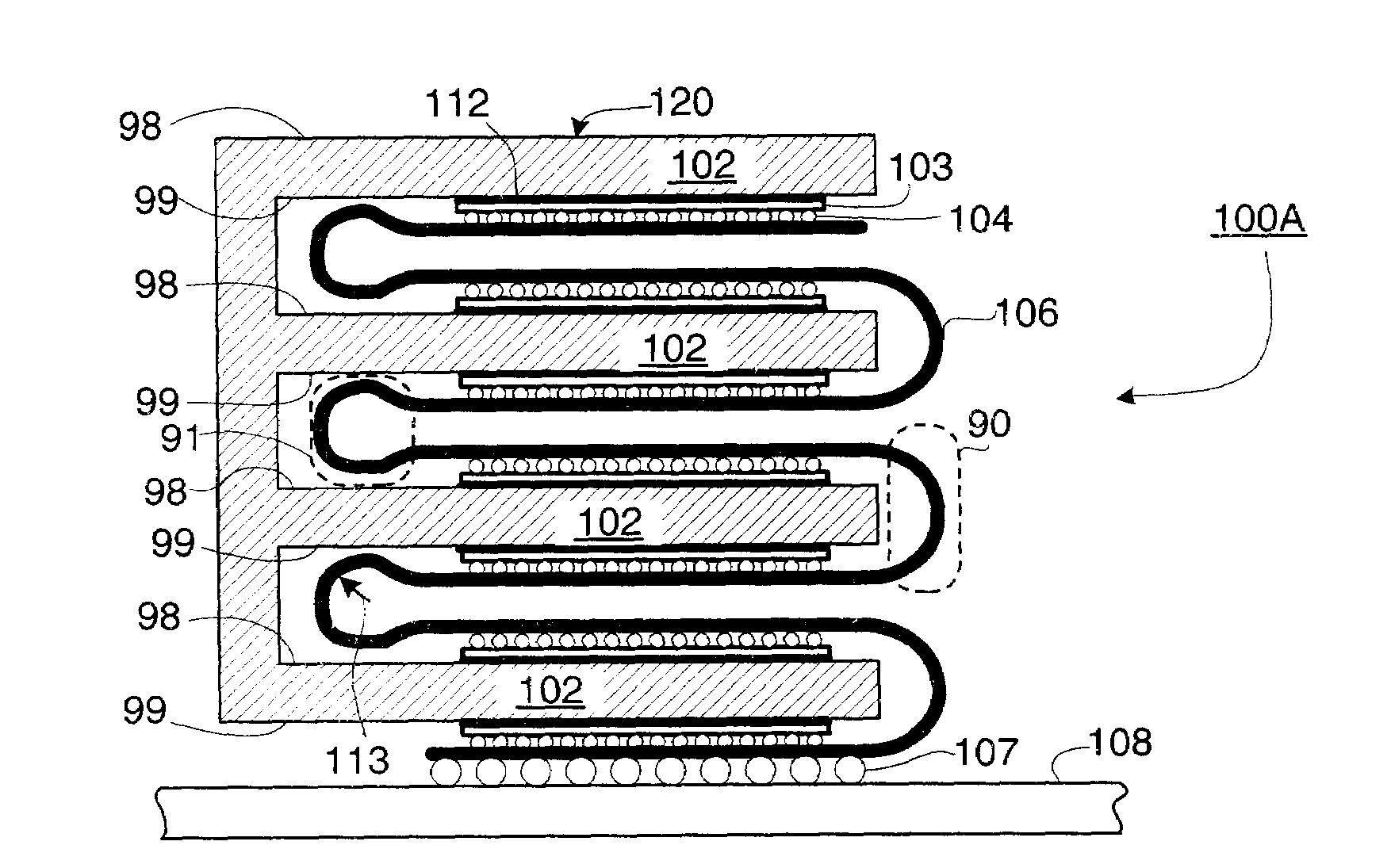

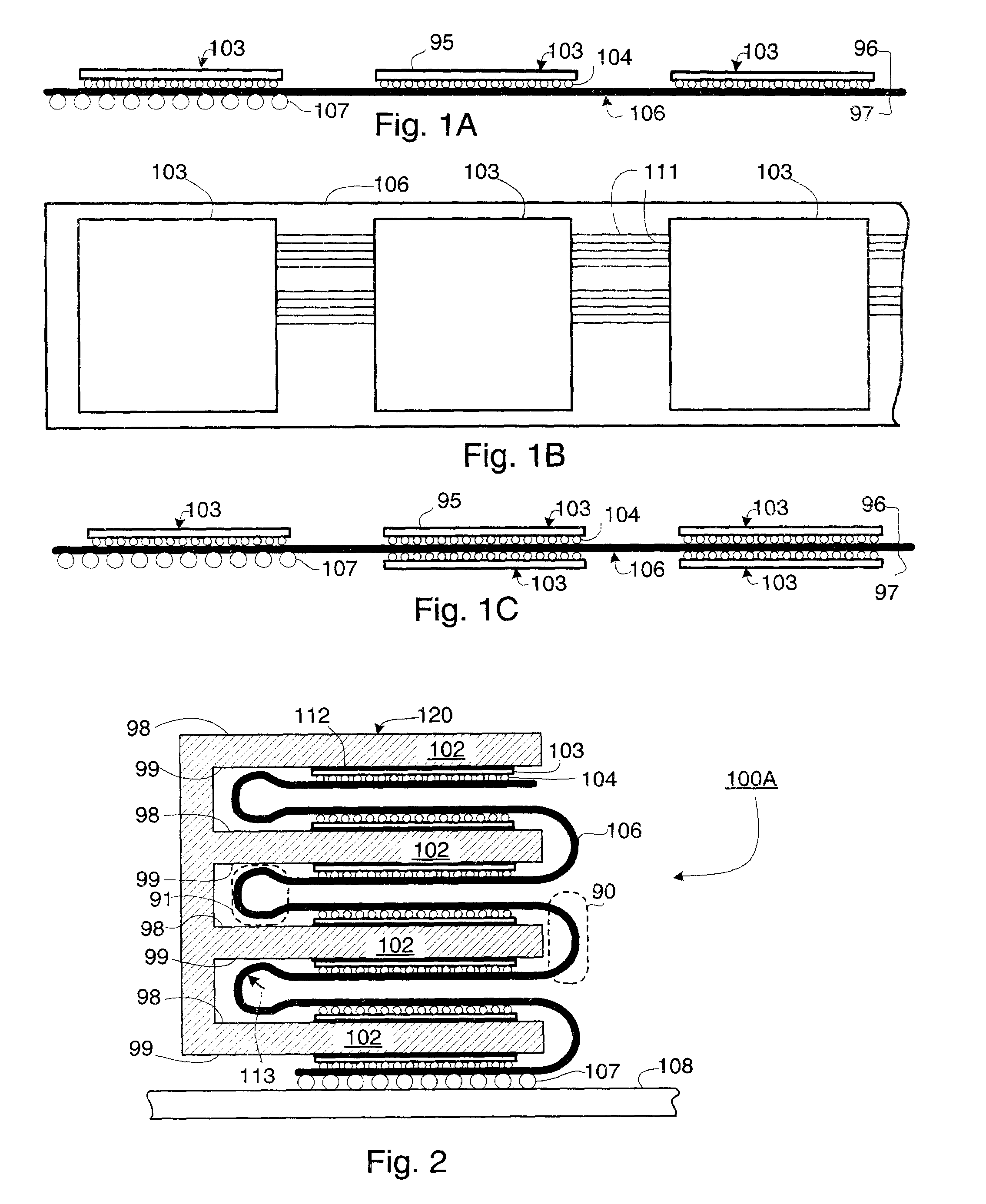

Method and Structure for Connecting, Stacking, and Cooling Chips on a Flexible Carrier

InactiveUS20080218974A1Semiconductor/solid-state device detailsSolid-state devicesAdhesiveThermal grease

A heat sink apparatus having a plurality of chips attached to a first surface of a flexible carrier and a plurality of heat sink fins. One or more additional chips may be attached to a second surface of the flexible carrier. The flexible carrier has at least one complementary fold, the complementary fold having a counterclockwise fold and a clockwise fold as seen from the side. A first chip back surface of a first chip and a second chip back surface of a second chip are in thermal contact with a particular heat sink fin, that is, sharing the same heat sink fin. Thermal contact between the chips and heat sink fins is effected by force, by thermally conducting adhesive, by thermal grease, or by a combination of force and / or thermally conducting adhesive and / or thermal grease.

Owner:IBM CORP

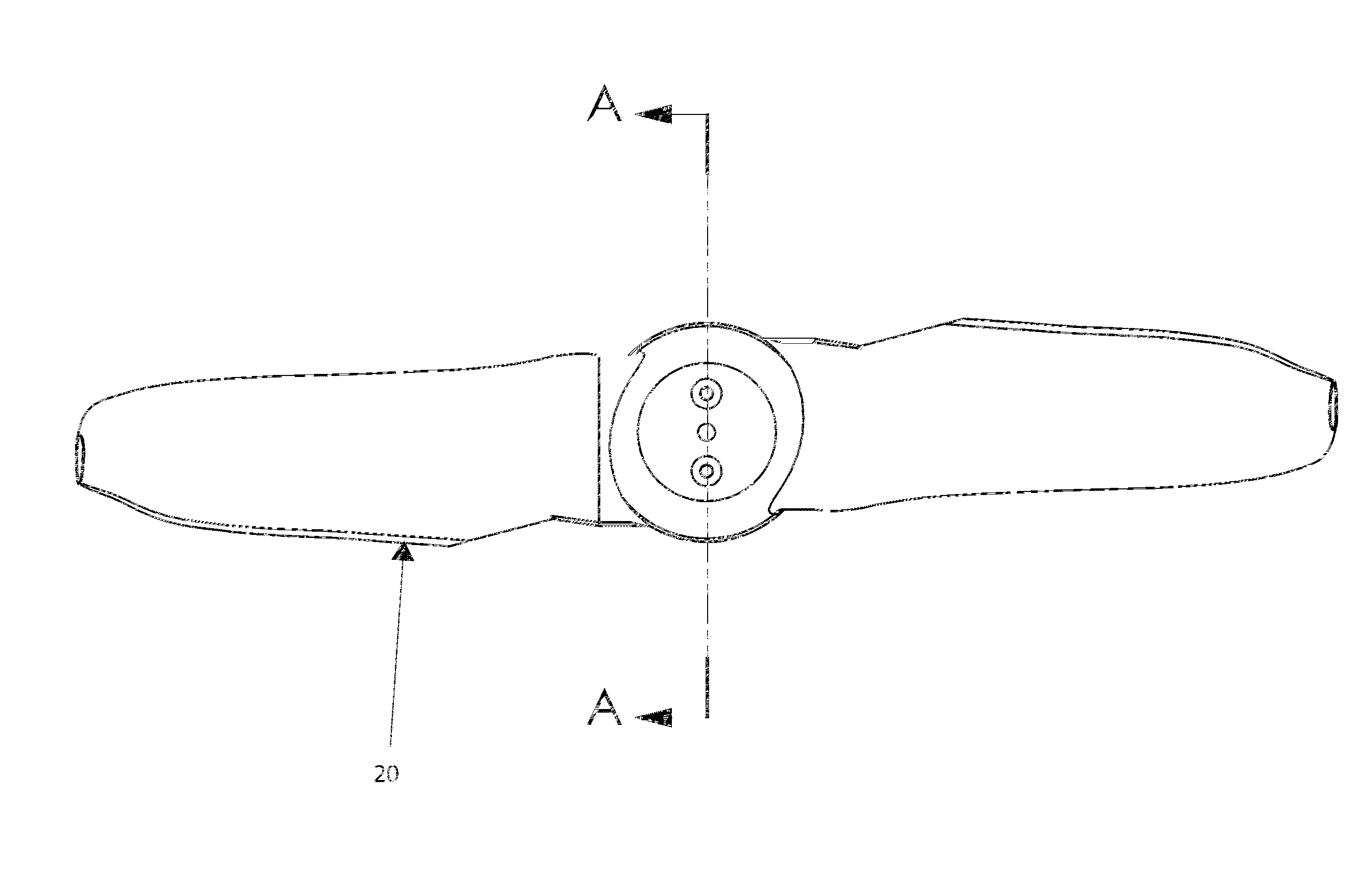

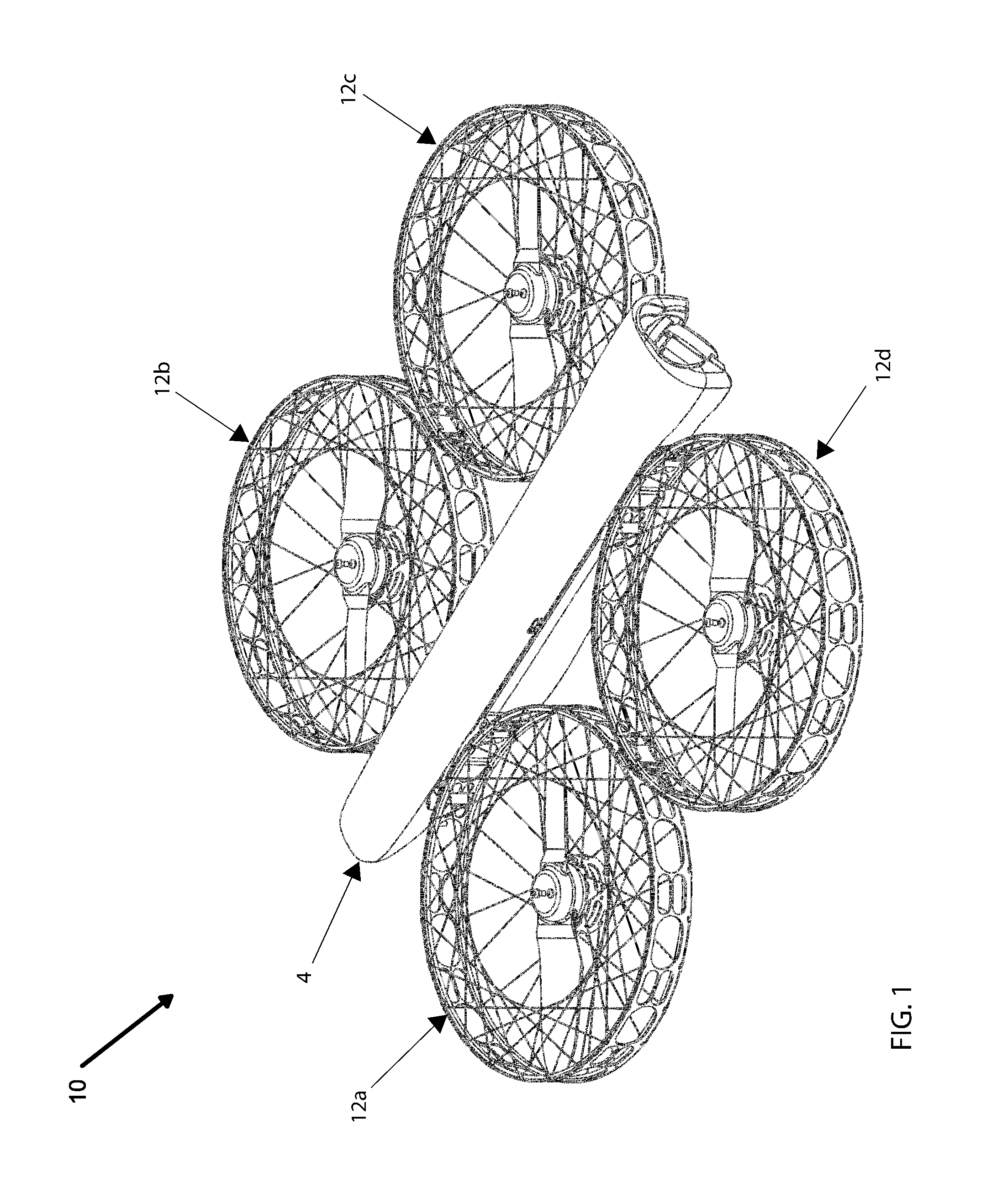

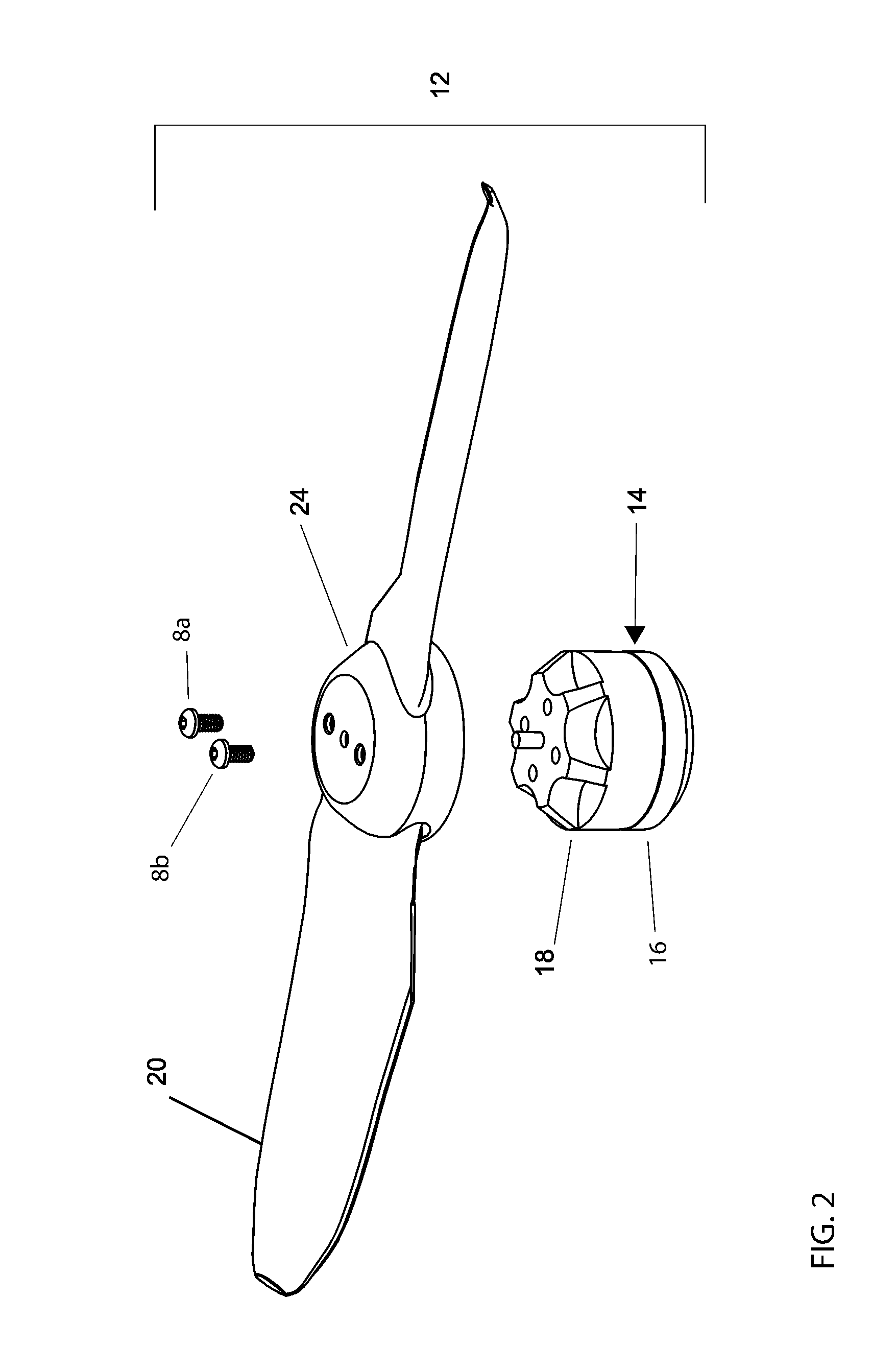

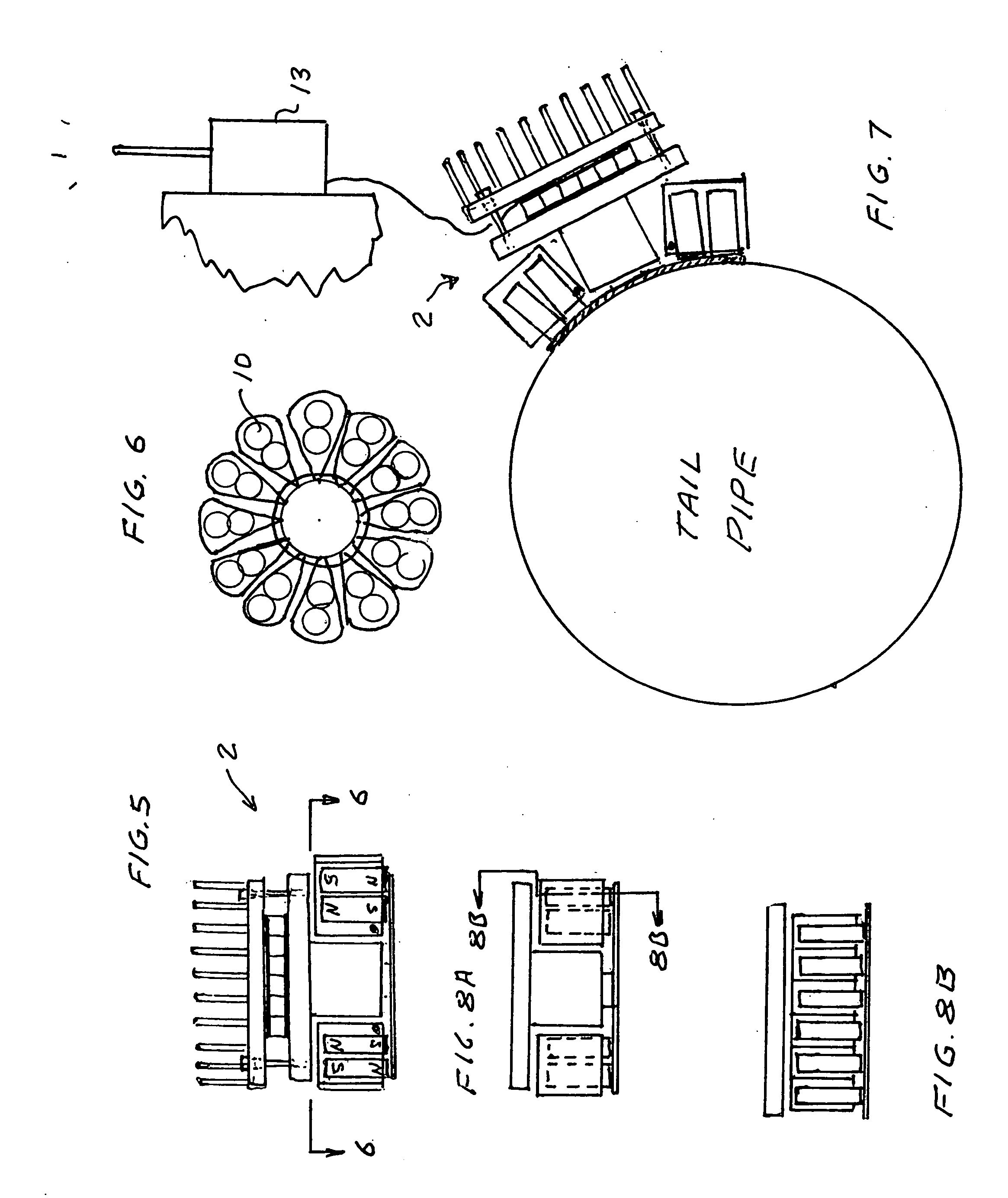

Propeller-motor assembly for efficient thermal dissipation

ActiveUS20160288901A1Increase ratingsPower plant cooling arrangmentsPropellersPropellerThermal grease

A propeller drive assembly includes an electric motor having a stator and a rotor. During operation the motor generates heat. A propeller made from a thermally conductive plastic includes a hub that is secured to the rotor portion of the motor so that the heat generated within the motor is transferred by conductance through the thermally conductive hub and propeller and then, by convection, is absorbed by the surrounding air, as the propeller rotates through the air. A thermally conductive interface material can be positioned between the rotor portion of the motor and the hub of the propeller to increase the thermal efficiency of the heat transfer between the motor and the propeller. A thermally conductive grease can be used as the interface material and an O-ring seal can be provided about the rotor to prevent the grease from escaping during motor operation.

Owner:VANTAGE ROBOTICS LLC

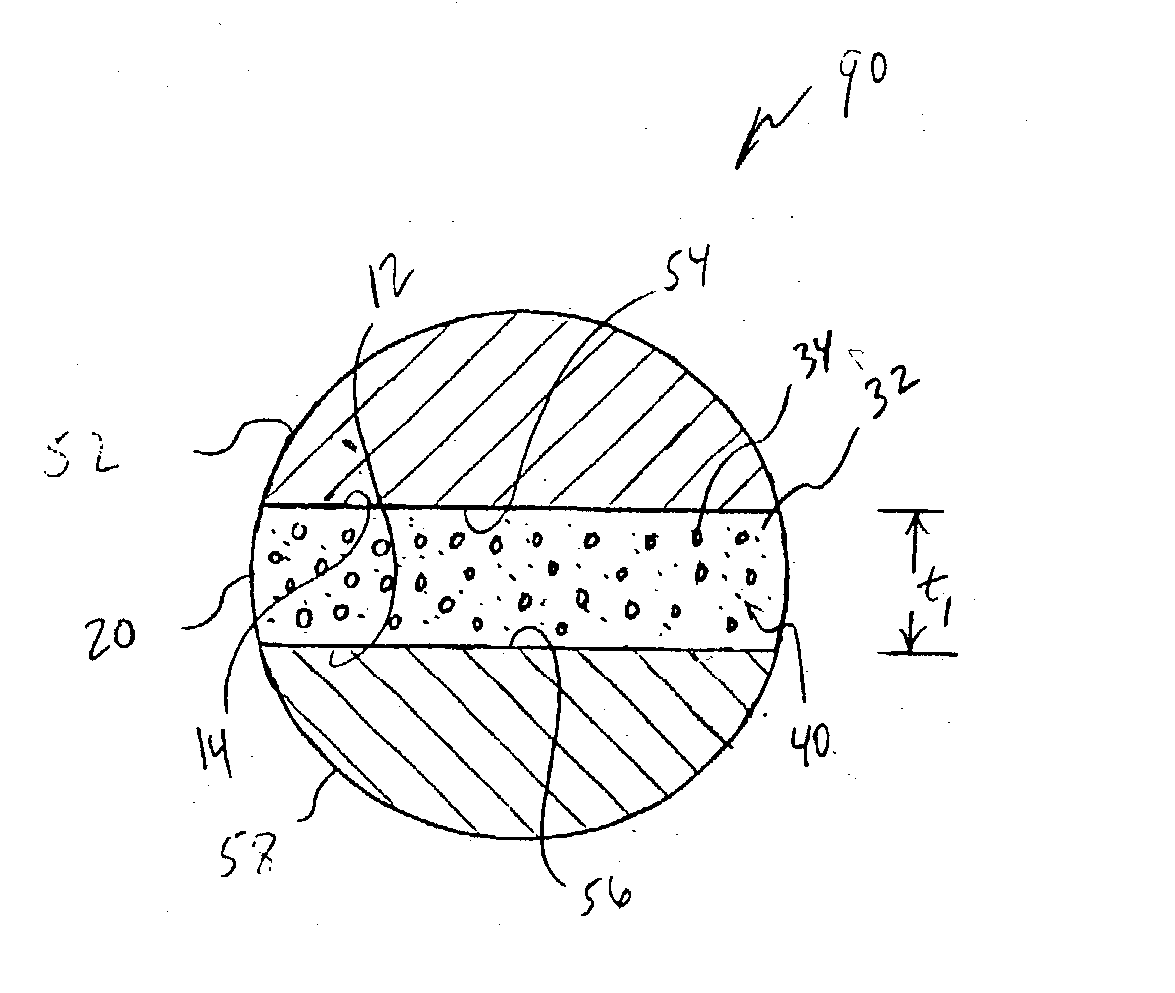

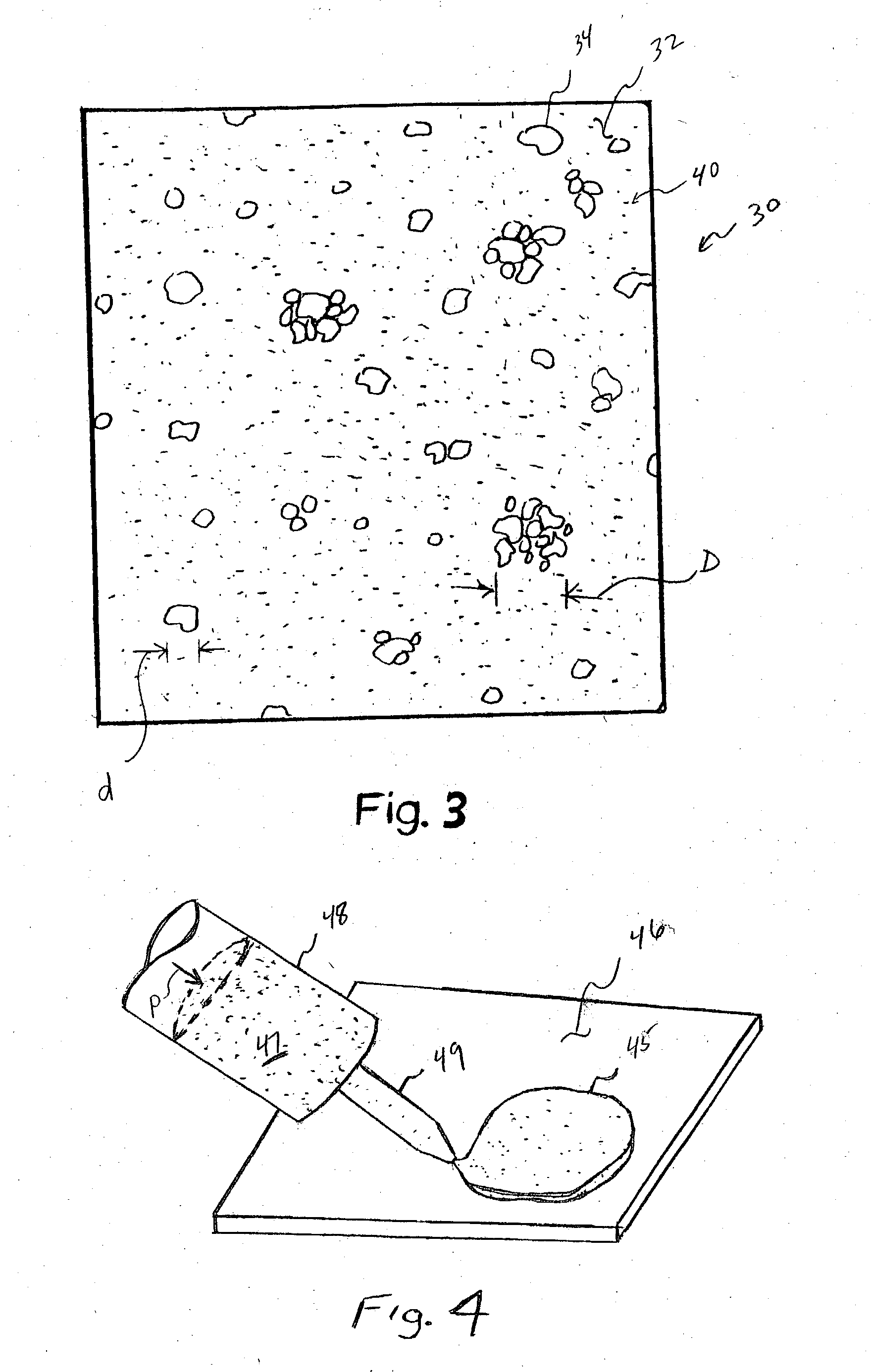

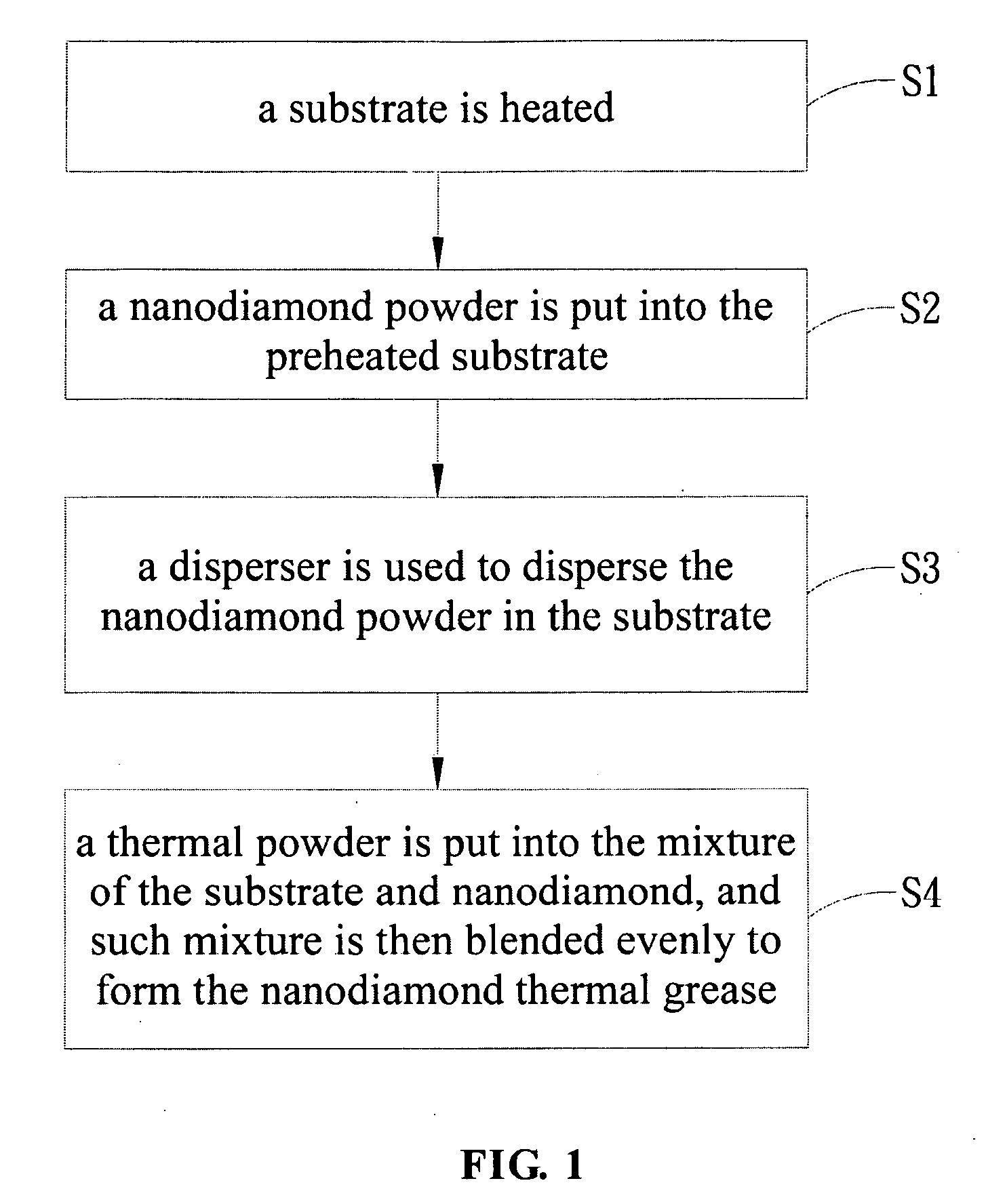

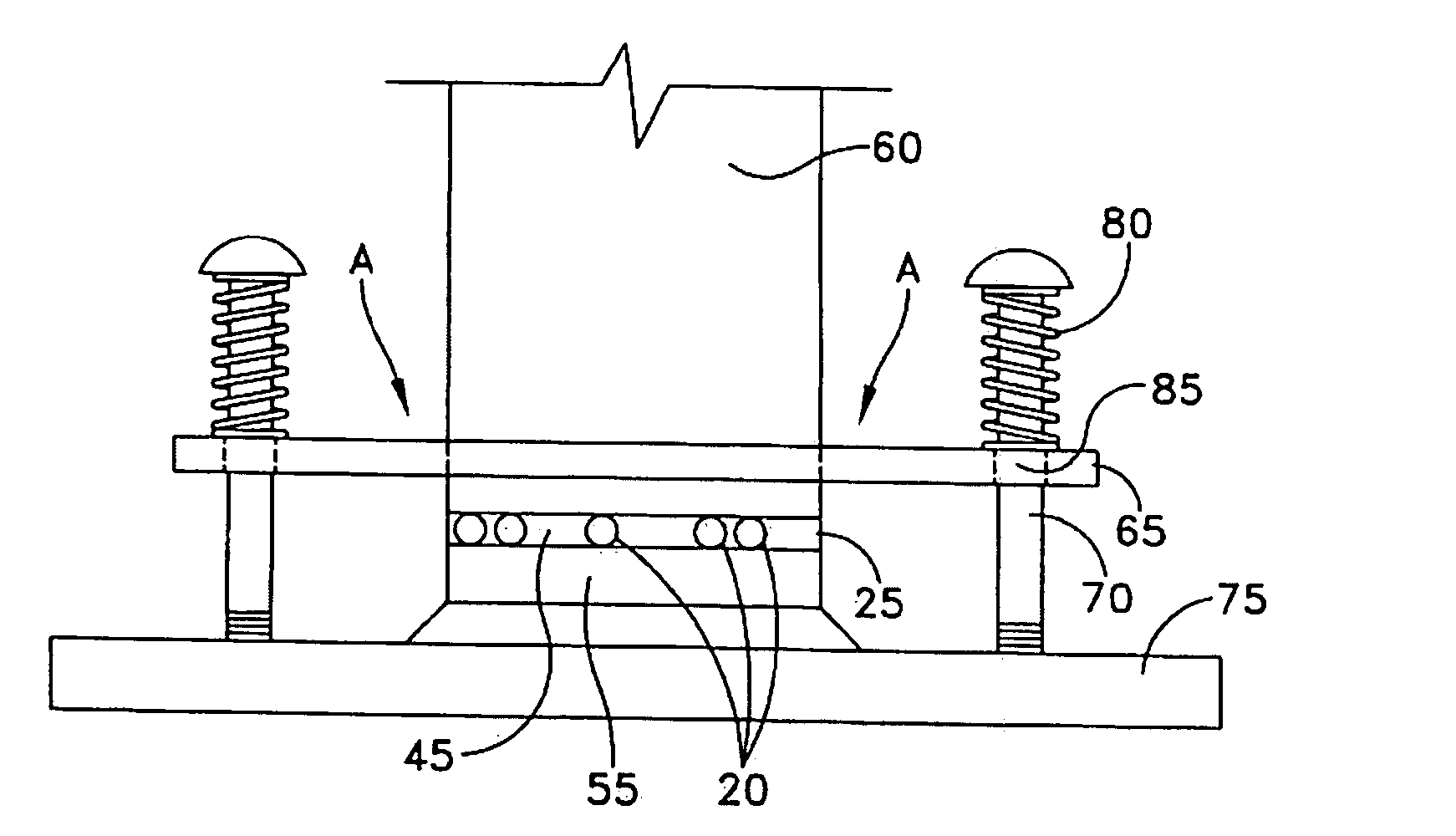

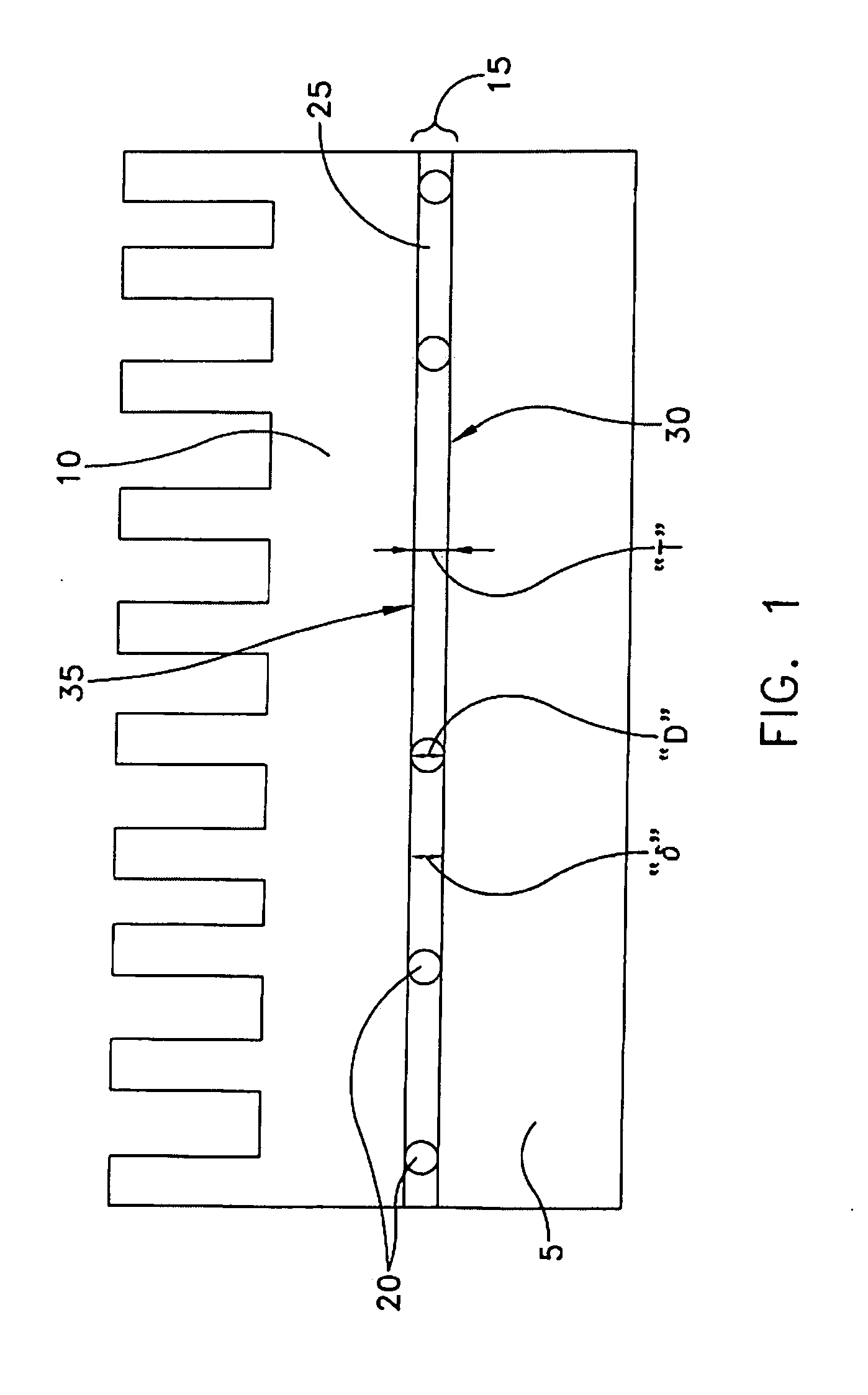

Thermally coupled surfaces having controlled minimum clearance

InactiveUS20060185836A1Semiconductor/solid-state device detailsSolid-state devicesThermal greaseEngineering

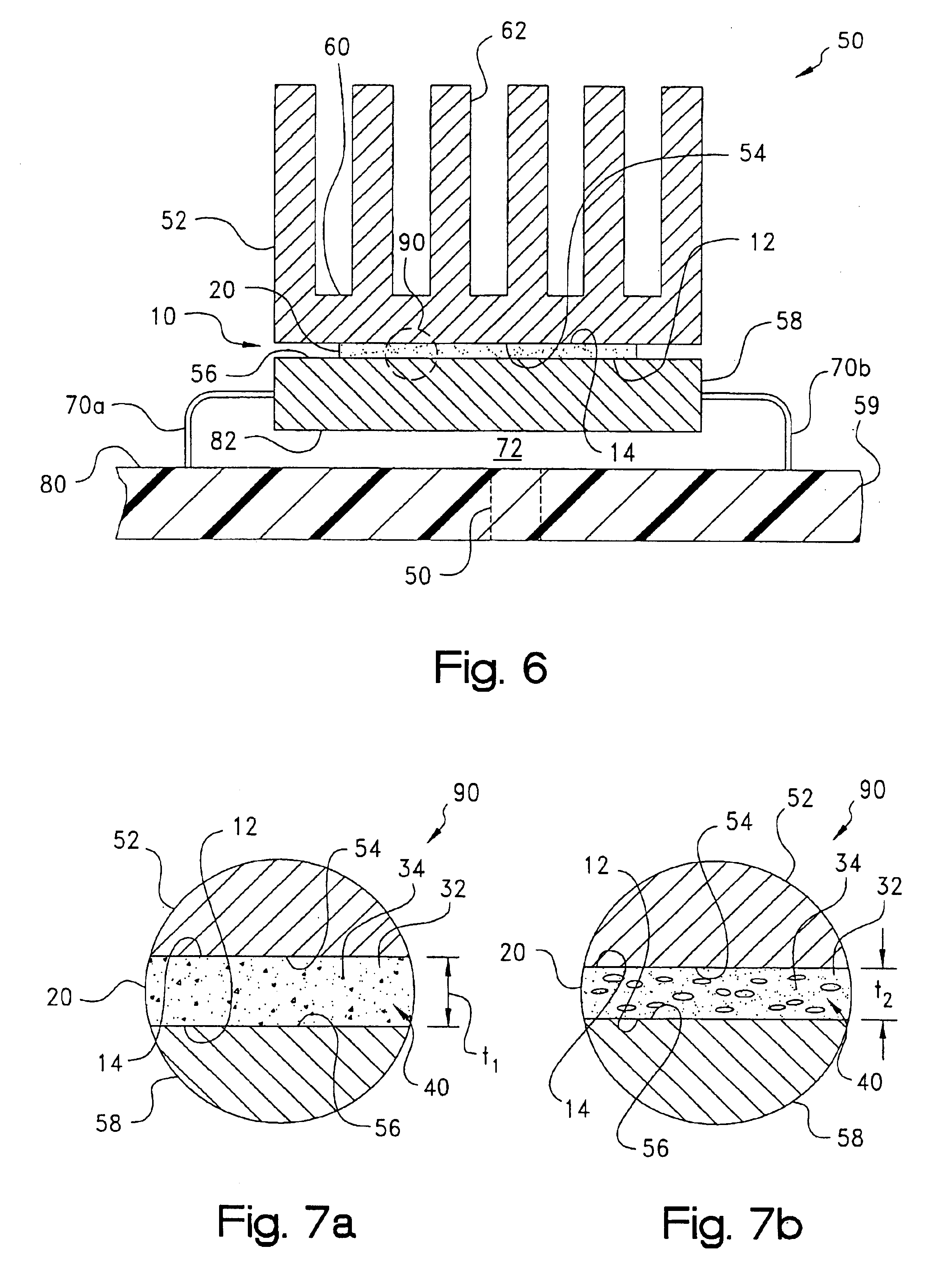

A conformable, thermally conductive layer is provided comprising a flowable component and a plurality of substantially incompressible spacer particles, wherein the conductive layer is disposed between a pair of heat exchange surfaces of an electronic device to maintain a desired spacing during operation. The thermally conductive layer enhances heat transfer between the surfaces while the spacer layer ensures a constant desired offset between the surfaces both to maintain an optimum level of heat transfer and to provide a desired voltage standoff between the surfaces to prevent arcing across the surfaces. The offset is substantially equal to the diameter of the spacer particles, and the particles align in a single layer between the heat exchange surfaces. The heat exchange surfaces can be a heat source such as an integrated circuit chip, and the heat sink can be a plate with a plurality of fins. The flowable component can be a thermal grease or paste, and the spacer particles can be ceramic or glass material. A method of applying the conductive layer and of assembling the heat source and heat sink is also disclosed.

Owner:THERMAL

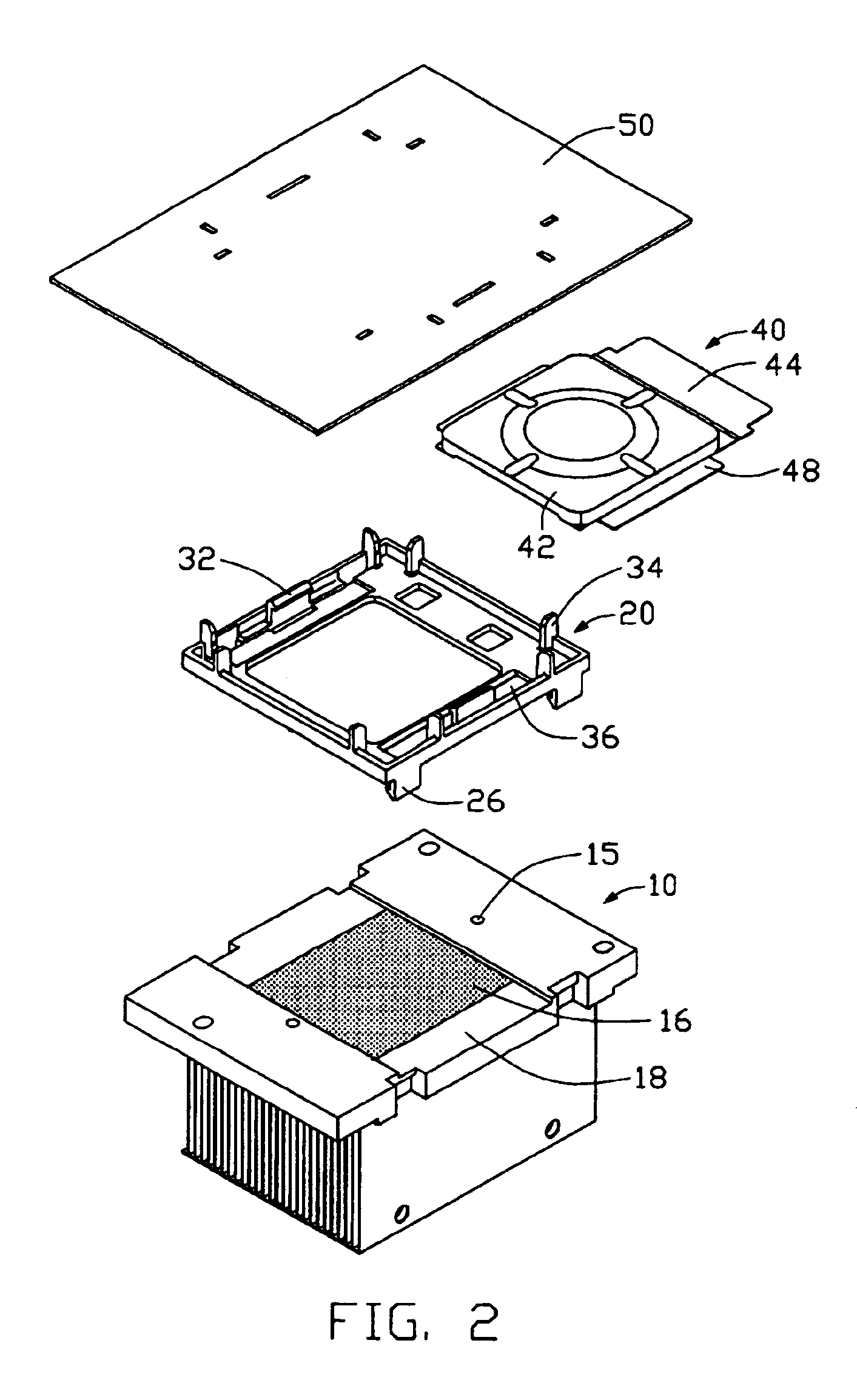

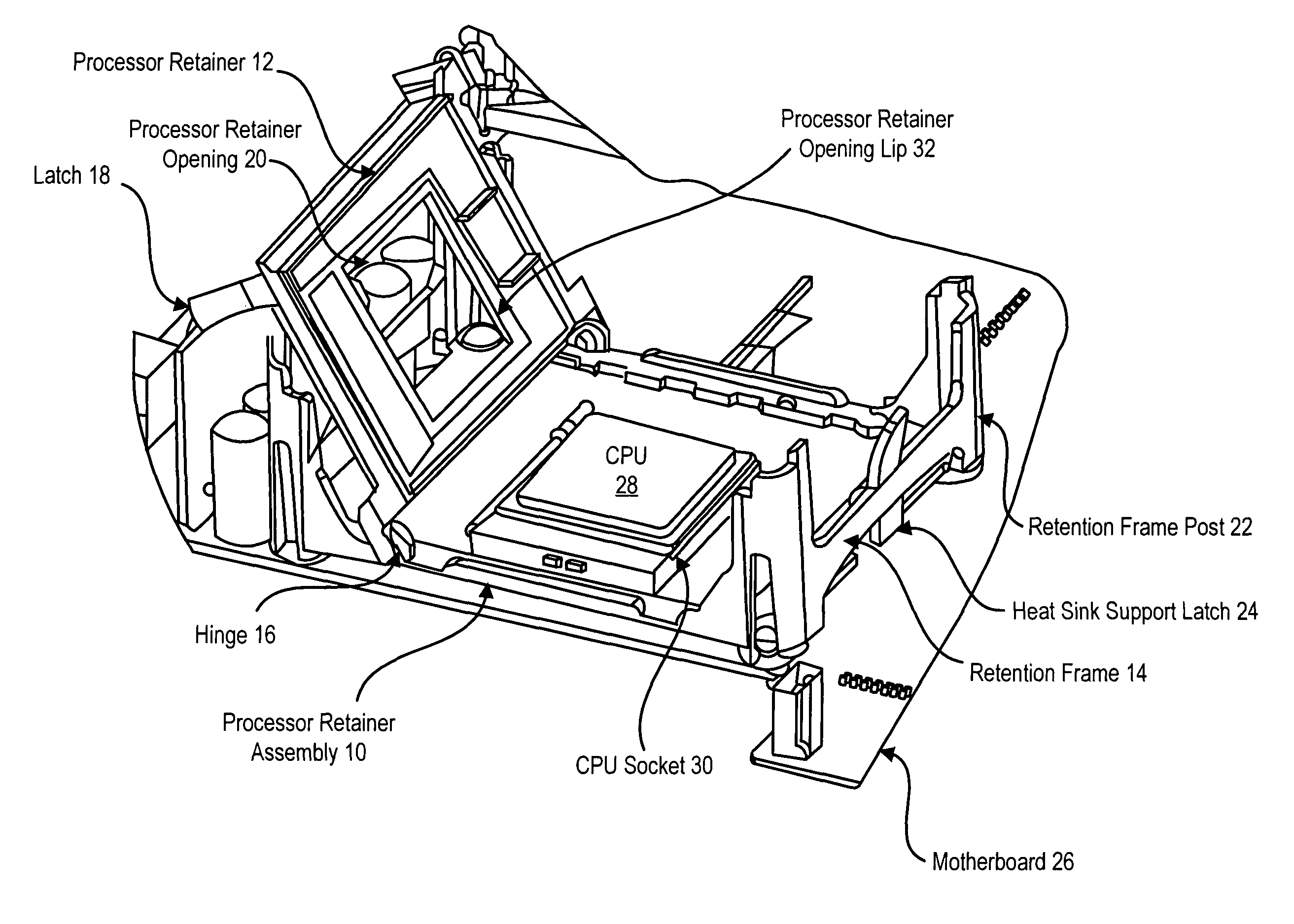

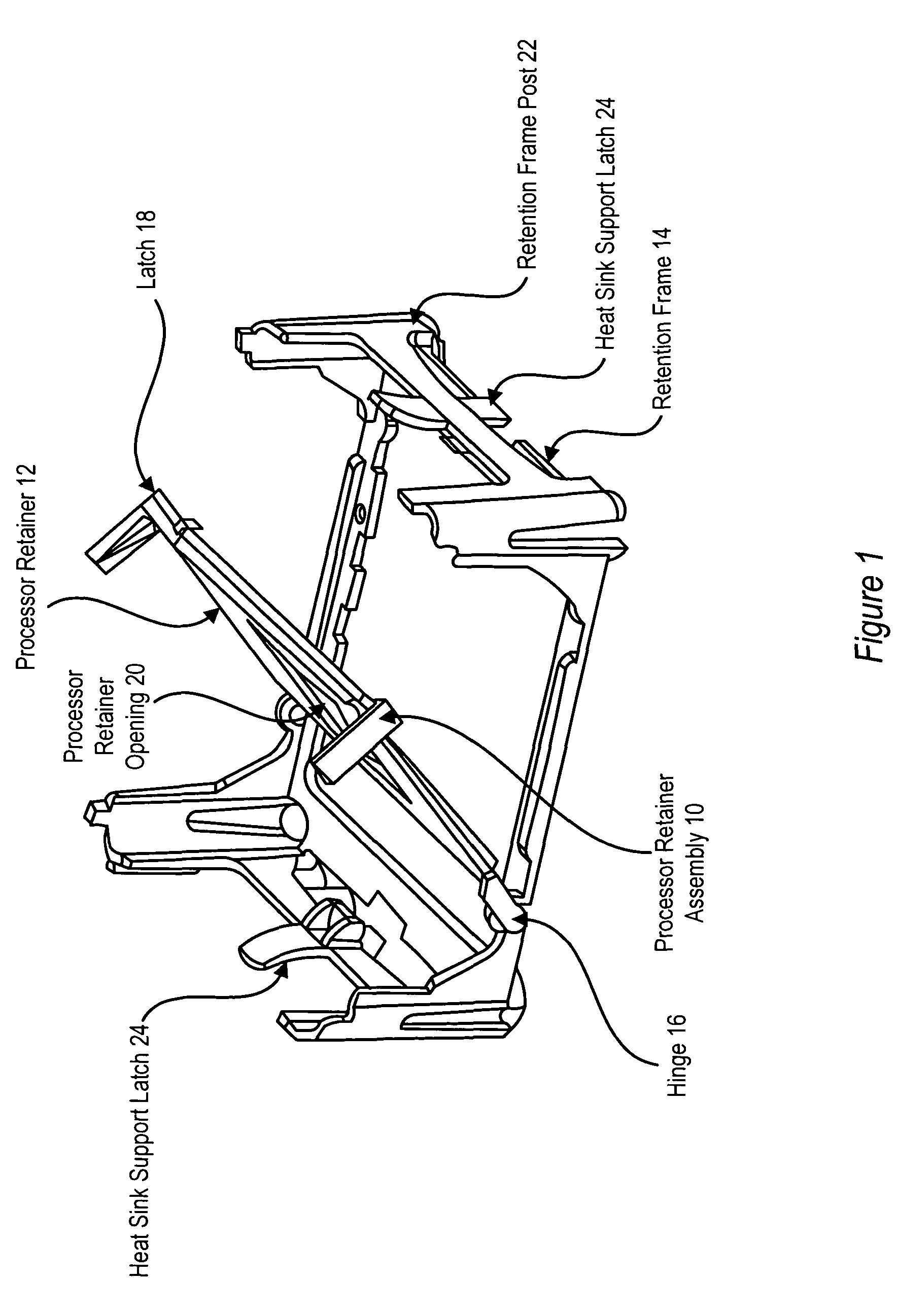

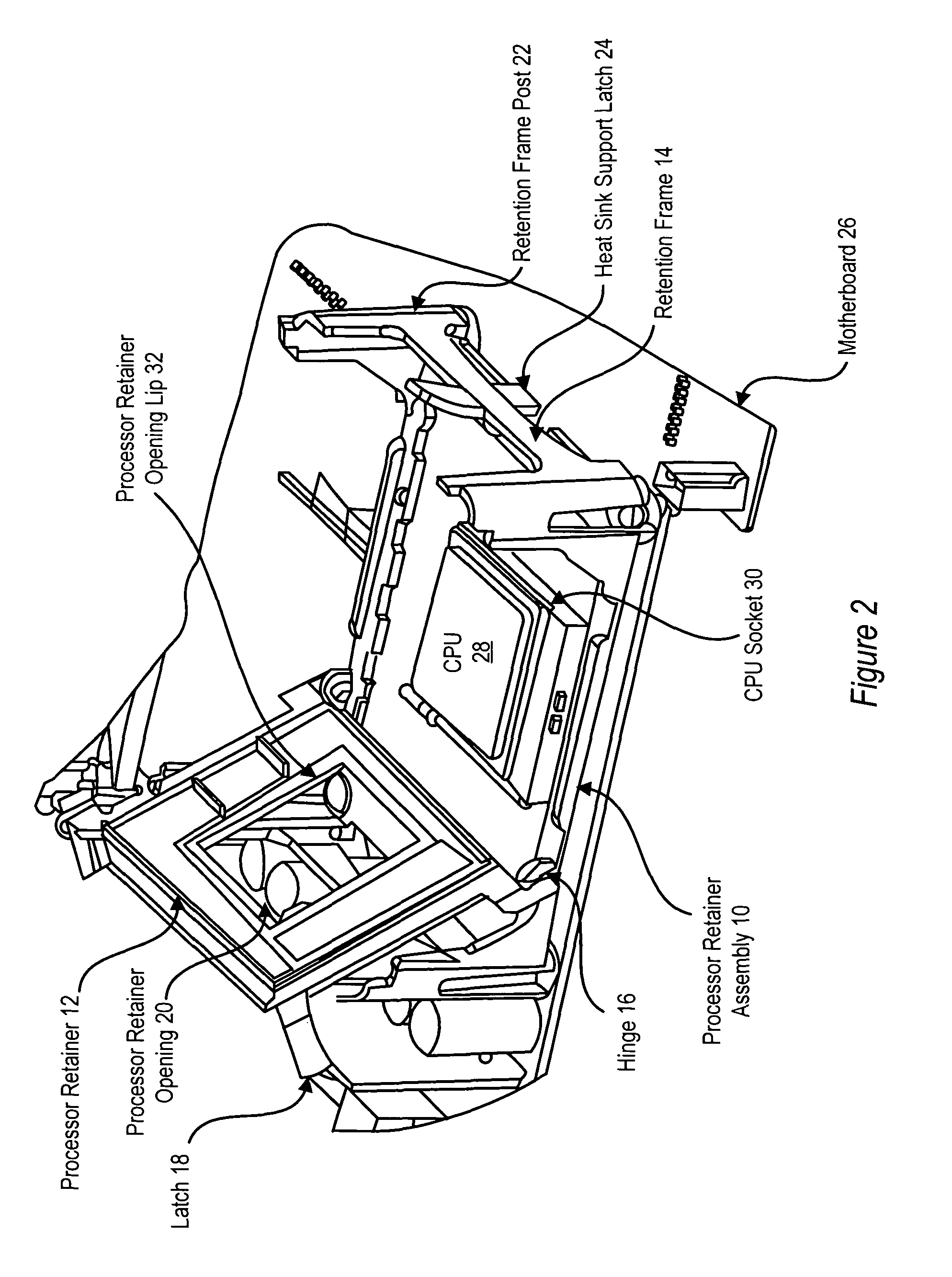

Processor retention system and method

ActiveUS6970354B2Reduce complexity and costMinimal impactSemiconductor/solid-state device detailsSolid-state devicesCouplingThermal grease

A processor retainer assembly prevents inadvertent removal of a processor from a circuit board socket by forces exerted on an information handling system that are translated from a heat sink to the processor by the coupling of thermal grease between the heat sink and the processor. A retention frame couples to a motherboard around the processor socket to support movement of the processor retainer between open and closed positions. A securing device hinge rotationally couples the processor retainer to the retention frame and a securing device latch locks the processor retainer in the closed position to restrict movement of the processor from the socket. A heat sink contacts the processor through an opening in the processor retainer. Heat sink supports extending from the retention frame engage the heat sink so that a single processor retainer assembly retains the processor in the socket and the heat sink proximate to the processor.

Owner:DELL PROD LP

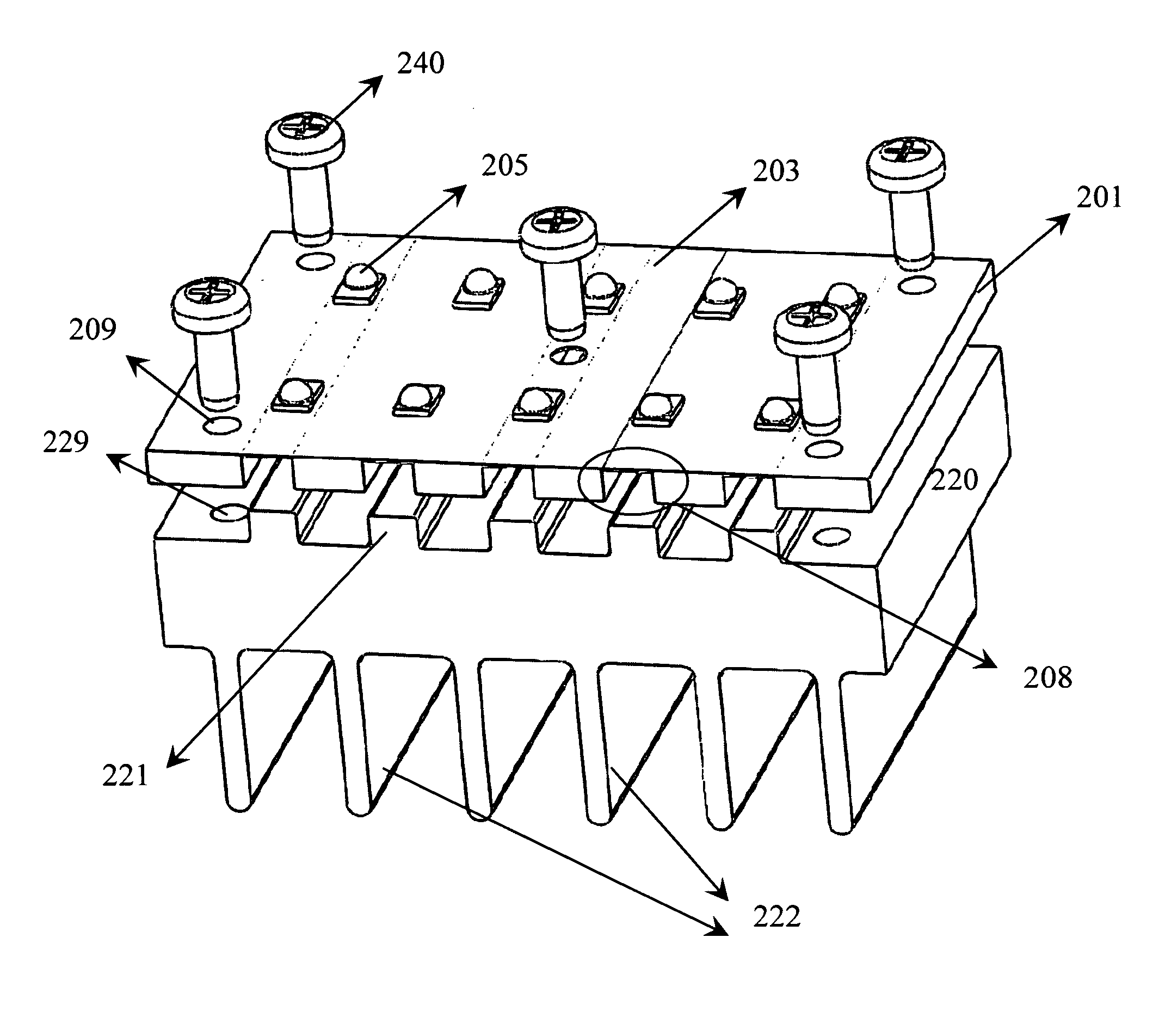

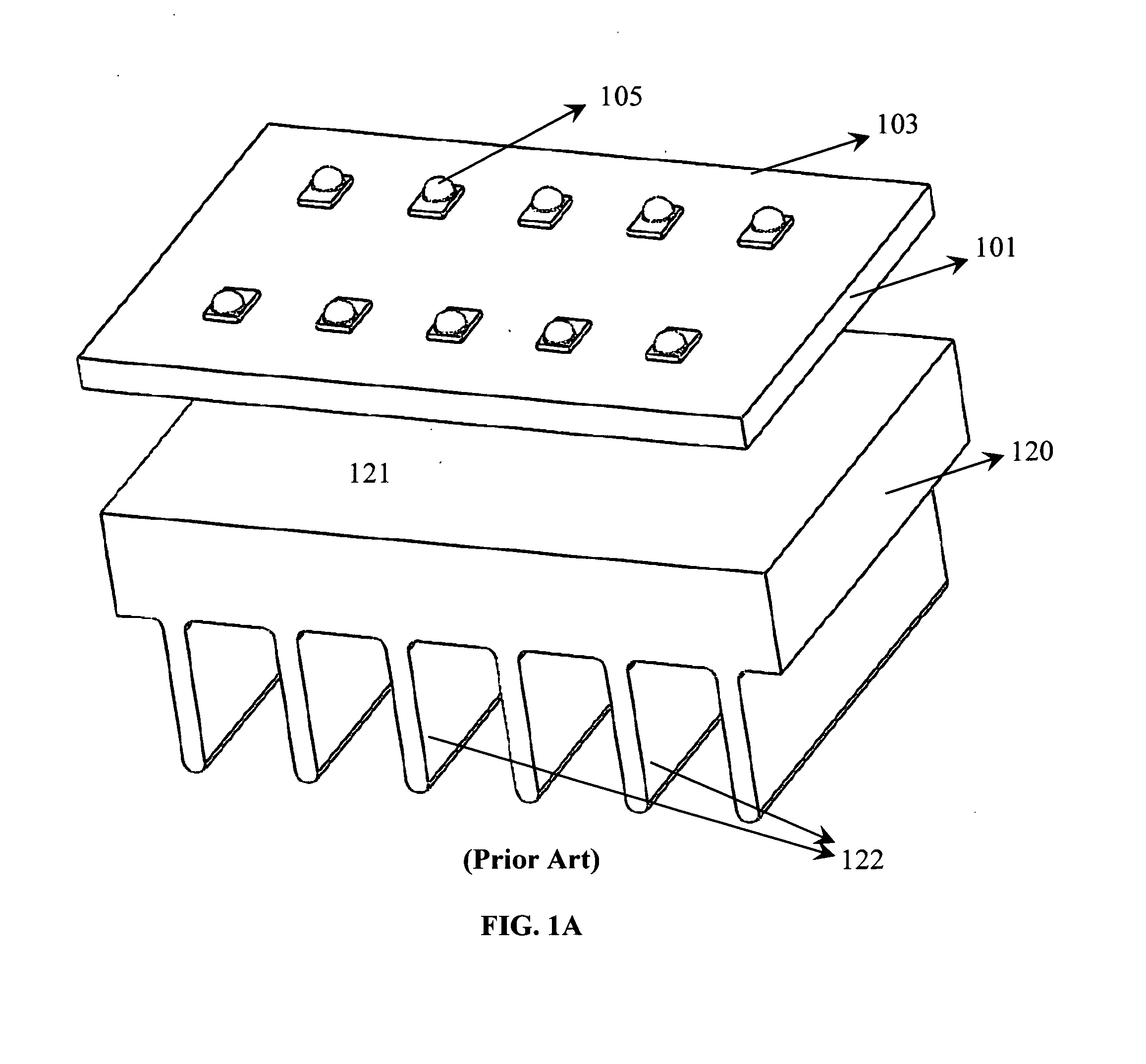

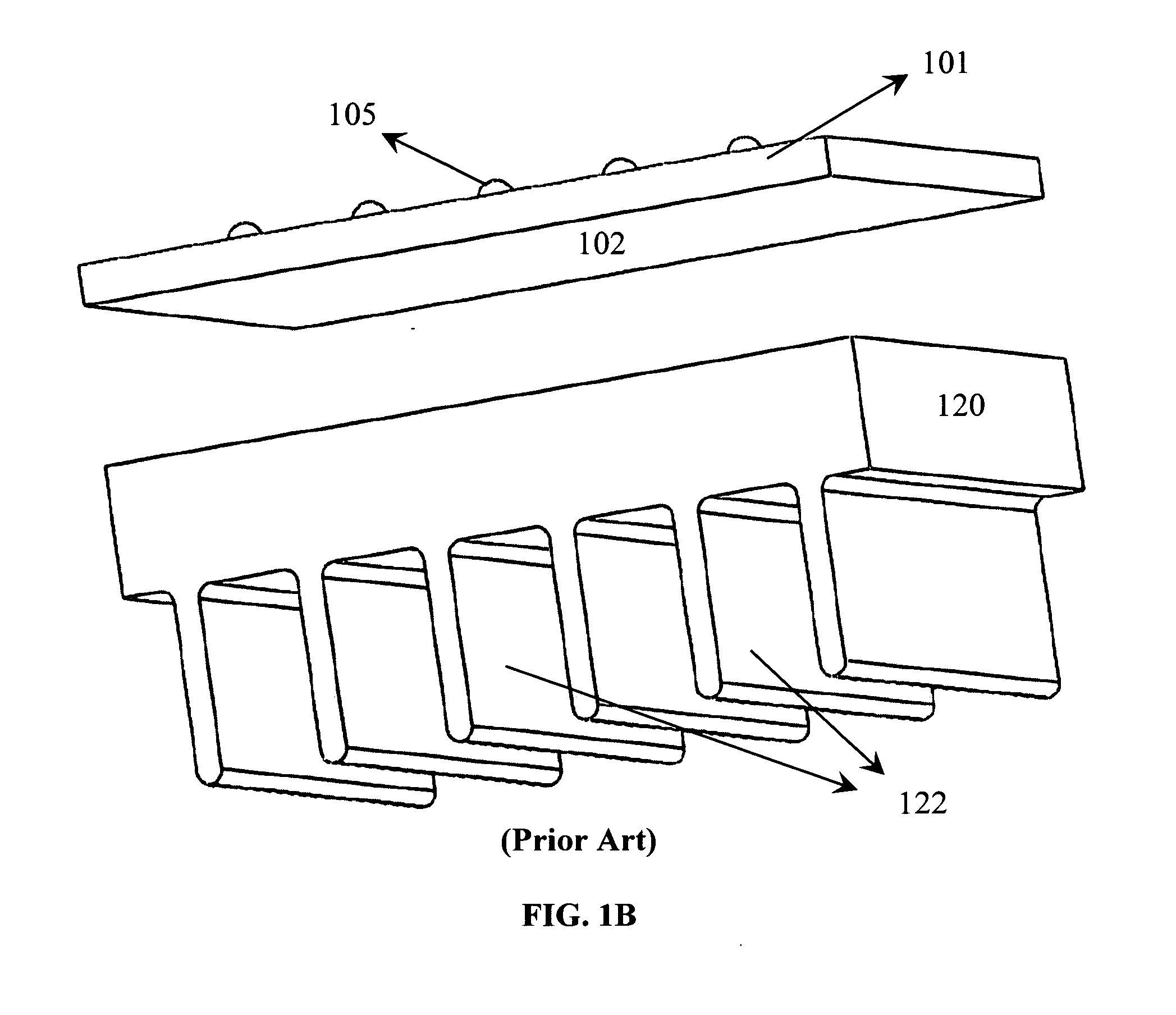

Composite Heat Sink For Electrical Components

InactiveUS20150260390A1Strong mechanical connectionPoint-like light sourceElectric circuit arrangementsEpoxyThermal grease

A composite heat sink with improved mechanical strength and thermal conductivity can be made using a printed circuit board with machined recesses on the back side. The printed circuit board is mated to a heat sink with surface features that match the machined side of the printed circuit board. A thin layer of thermally conductive material such as a gap filler pad, thermal grease, thermal gel, thermal epoxy or the like may be added between the printed circuit board and the heat sink prior to joining them together. Mechanical attachments such as screws, rivets and snap features may be used to form the printed circuit board and the heat sink into a single composite structure.The machined recesses in the printed circuit board are machined from the areas under and near surface mount components that generate a significant amount of heat. This reduces the thickness of printed circuit board material under the surface mount components and significantly improves thermal conduction.

Owner:BRETSCHNEIDER ERIC COLIN

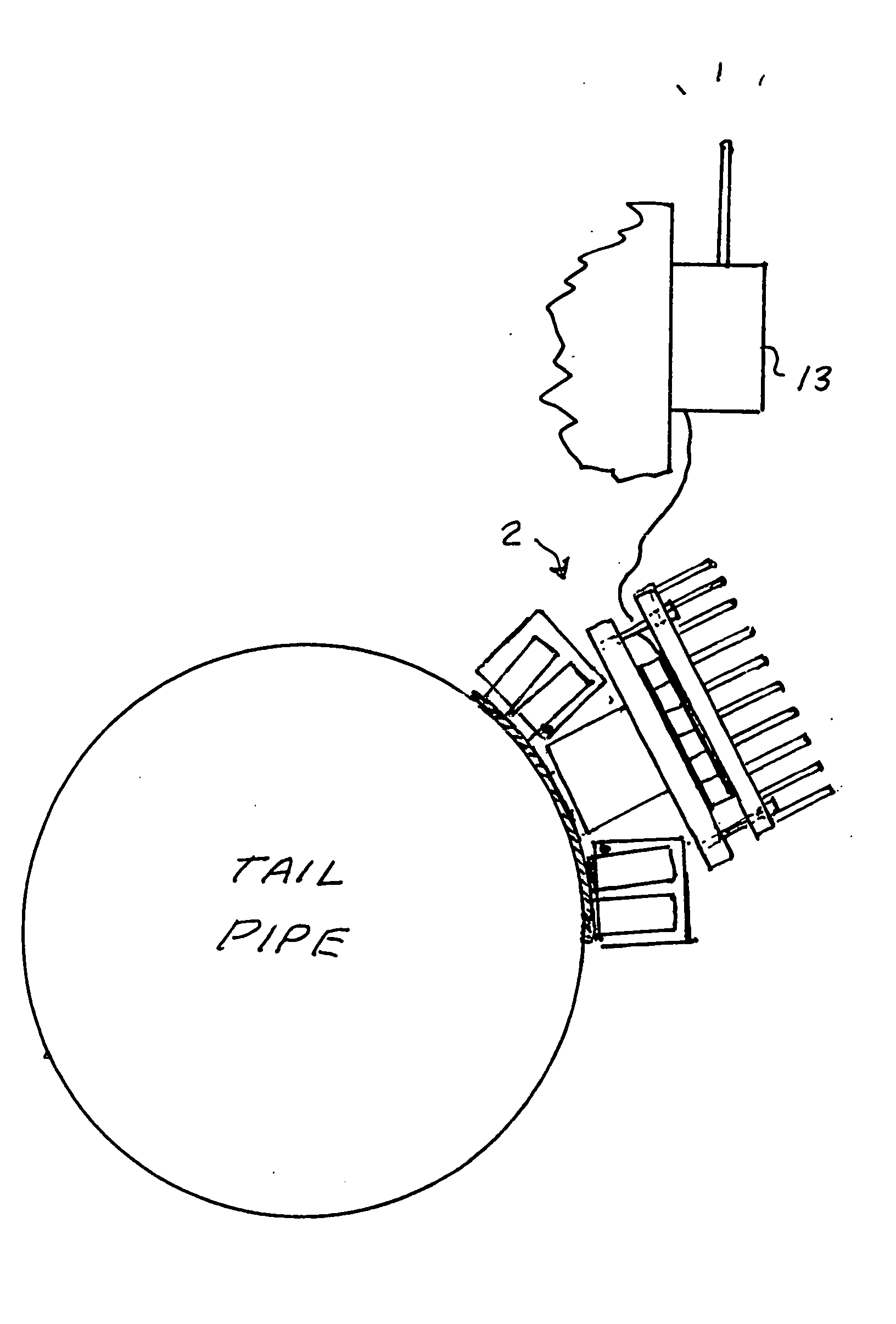

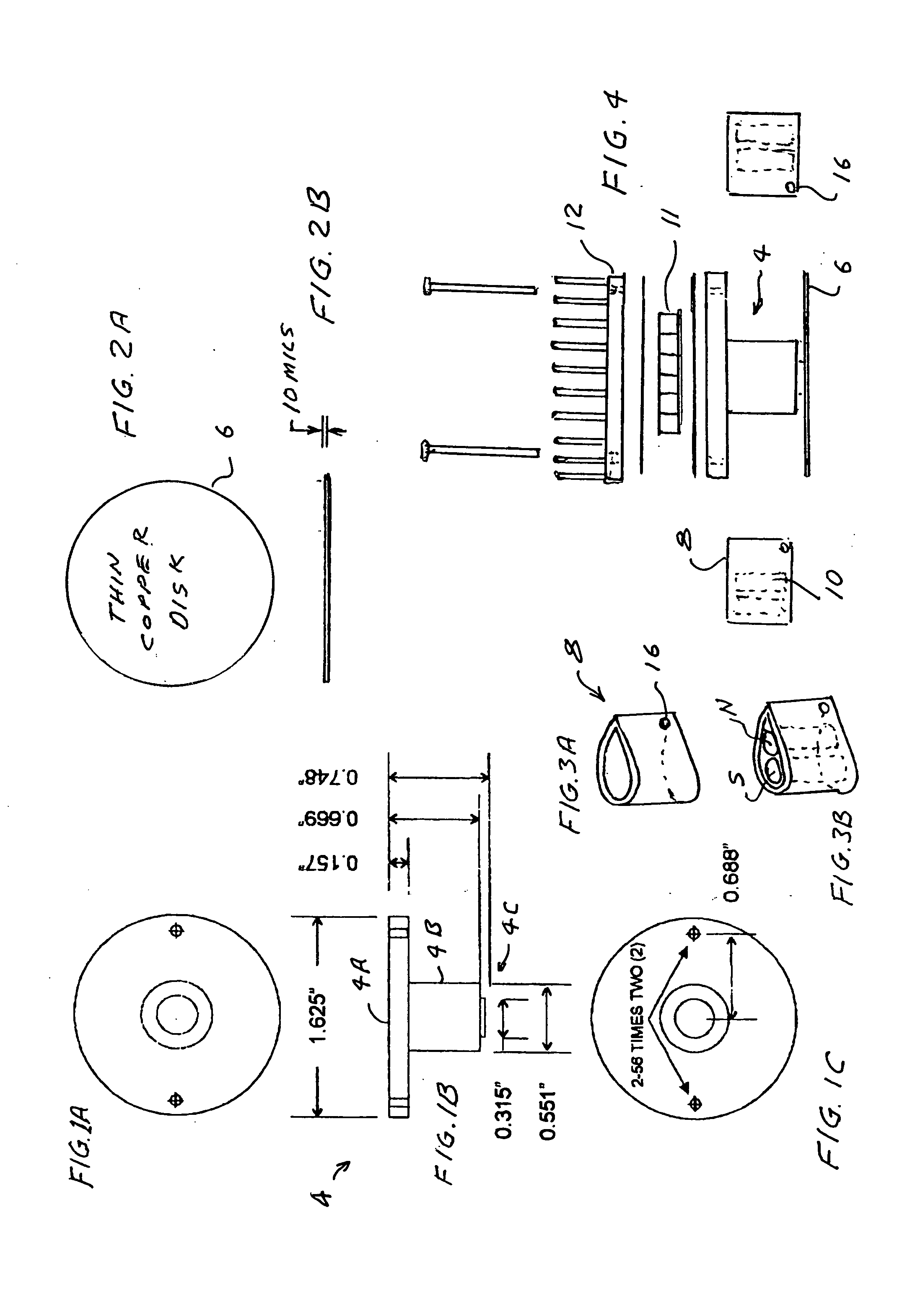

Quick attaching thermoelectric device

InactiveUS20060266403A1Quickly attachableImprove thermal conductivityThermoelectric device with peltier/seeback effectThermoelectric device junction materialsHeat conductingThermal grease

A quickly attachable electric generator system for producing electric power from hot or cold surfaces of magnetic materials. The system includes at least one permanent magnet for providing a magnetic attractive force to hold a surface of a thermoelectric module against the hot or cold surfaces. In a preferred embodiment, useful for attaching to the tail pipe or muffler of a motor vehicle, a thin flexible high heat conducting copper disk is braised to a thin bottom portion of a copper pedestal that has a wider flat upper portion. The wider flat upper portion is the heat source of a thermoelectric module that is compressed between it and an aluminum fin unit functioning as a heat sink. Insulating wafers on both the hot and cold sides to the thermoelectric module provide electrical insulation of the module from the copper pedestal and the finned heat sink. Heat conducting grease is used to improve thermal conductivity. In this preferred embodiment 24 small cylindrical magnets are positioned around a mid section of the pedestal in 12 aluminum bottomless cups positioned between the thin copper disk and the wide flat portion of the pedestal. When in use the thin flexible disk conforms to the surface shape of the steel (or other iron containing material) to which it is attached, and the disk along with the rest of the thermoelectric generator is held in place by the magnetic force of the 24 magnets. When attached to a tail pipe heat flows from the hot surface of the tail pipe through the thin flexible copper disk, through the pedestal to provide a heat source at a temperature in the range of about 450 degrees F. for the thermoelectric module. The fin unit provides the heat sink transferring heat to the atmosphere to provide a cold surface at about 85 degrees for a temperature difference of about 365 degrees F. In this preferred embodiment the module is utilized to provide electric power to power a transmitter to transmit information regarding the location of the motor vehicle to which it is attached. Standard thermoelectric modules available on the market can be utilized.

Owner:HILLER NATHAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com