Patents

Literature

221 results about "Self-propagating high-temperature synthesis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Self-propagating high-temperature synthesis (SHS) is a method for producing both inorganic and organic compounds by combustion-like exothermic reactions in solids of different nature. A variant of this method is known as solid state metathesis (SSM). If the reactants, intermediates, and products are all solids, it is known as a solid flame. Since the process occurs at high temperatures, the method is ideally suited for the production of refractory materials with unusual properties, for example: powders, metallic alloys, or ceramics with high purity, corrosion–resistance at high–temperature or super-hardnessity.

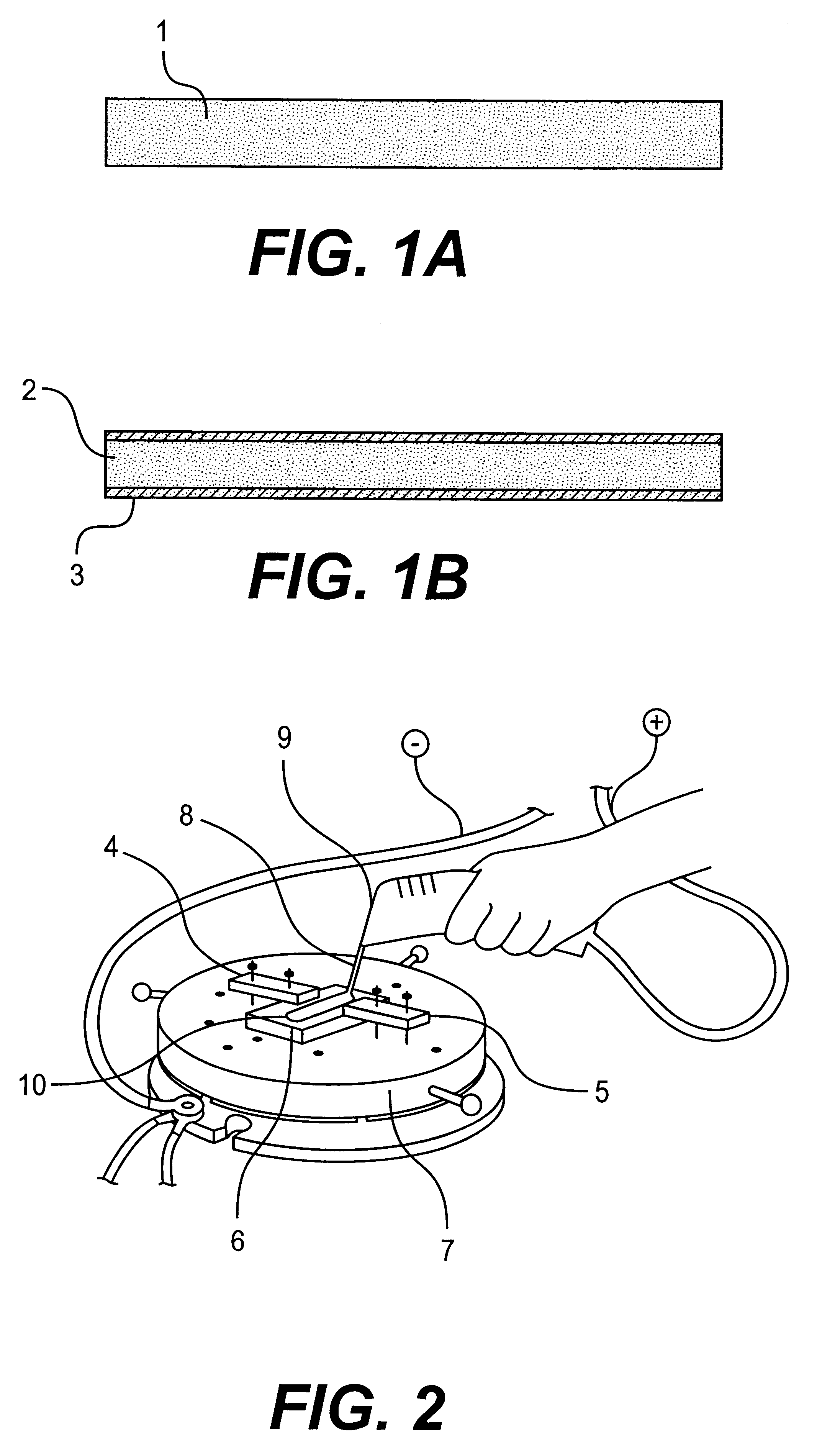

Electrode rod for spark deposition, process for the production thereof, and process for covering with superabrasive-containing layer

InactiveUS6336950B1Simple stepsSpark gapsMolten spray coatingSelf-propagating high-temperature synthesisBoride

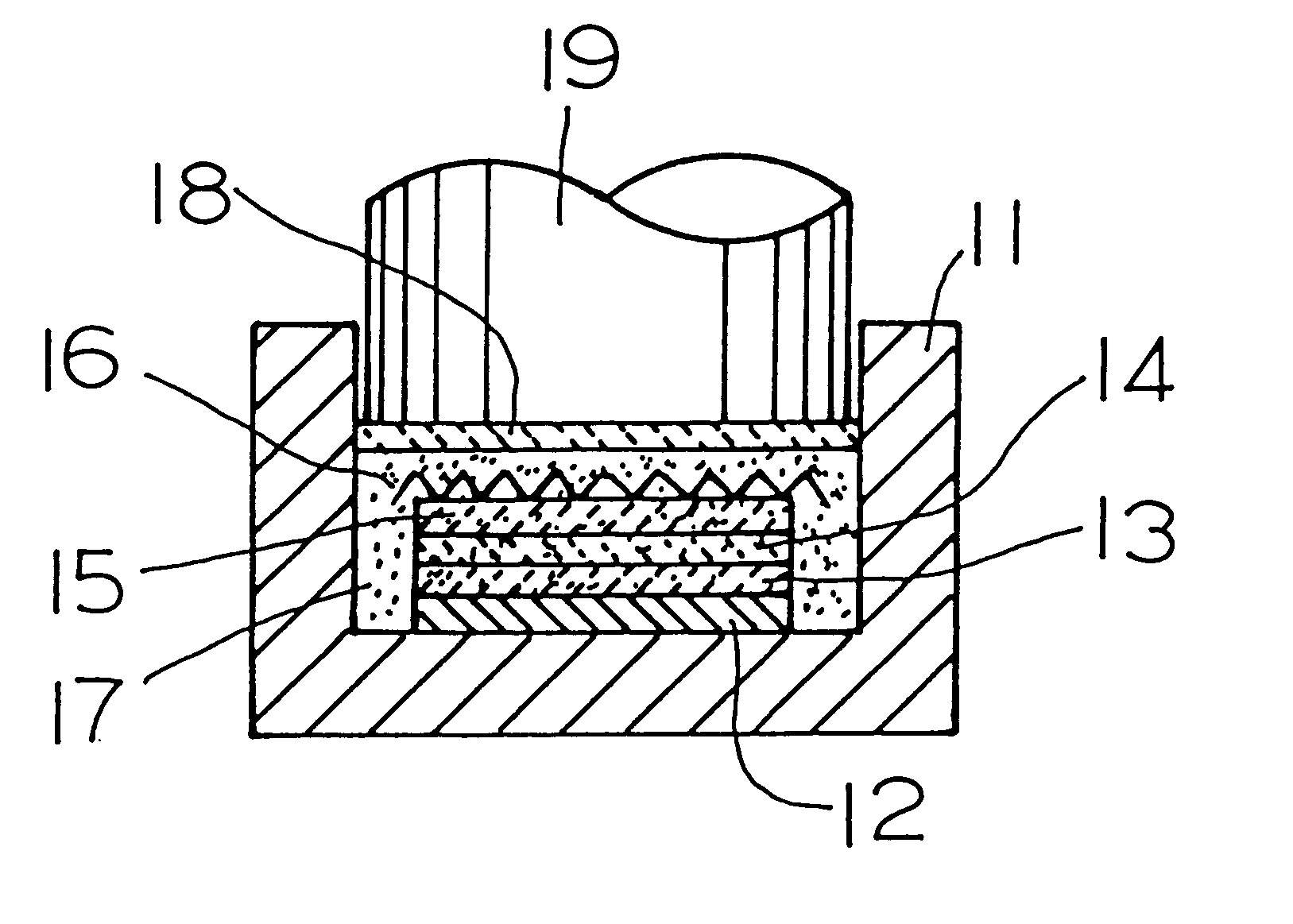

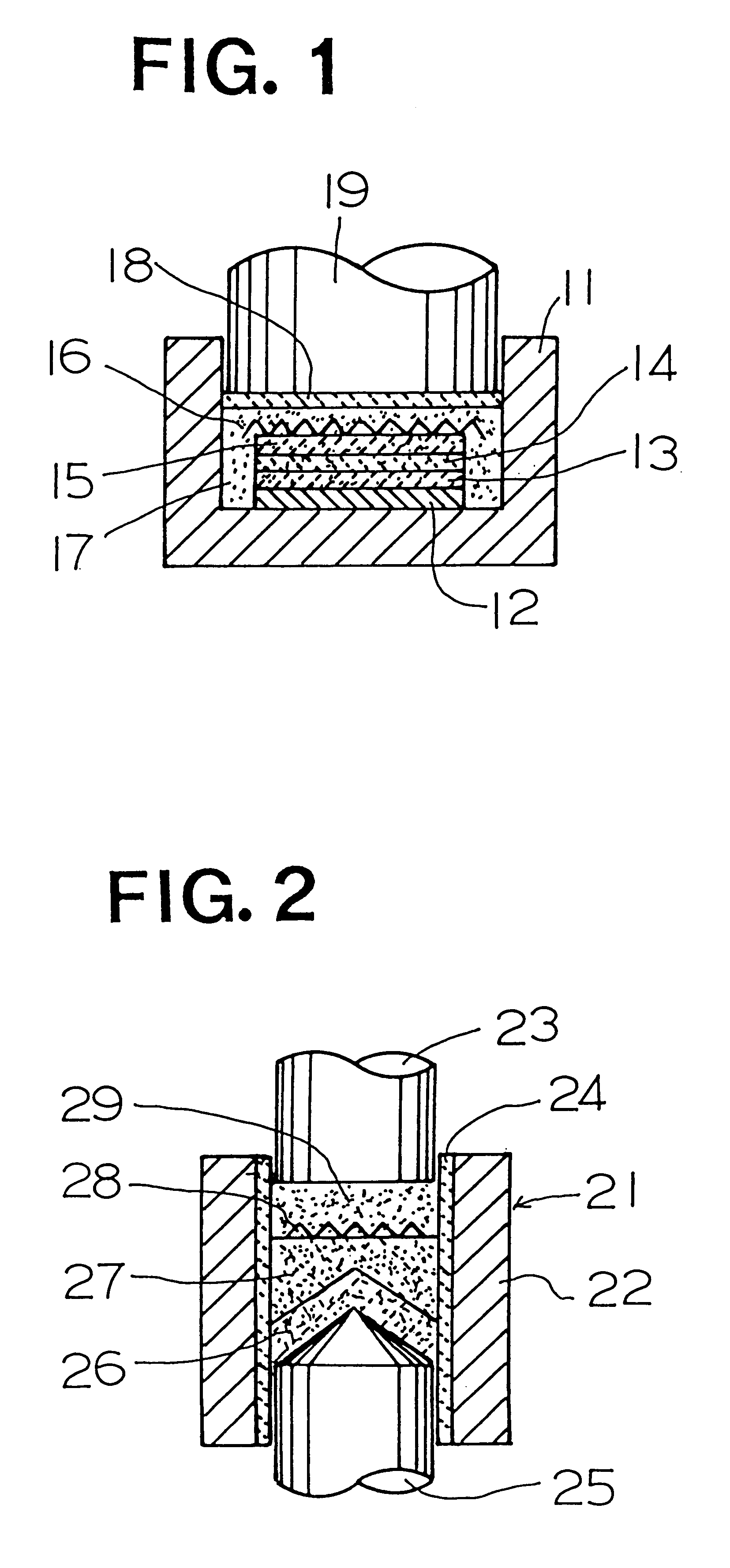

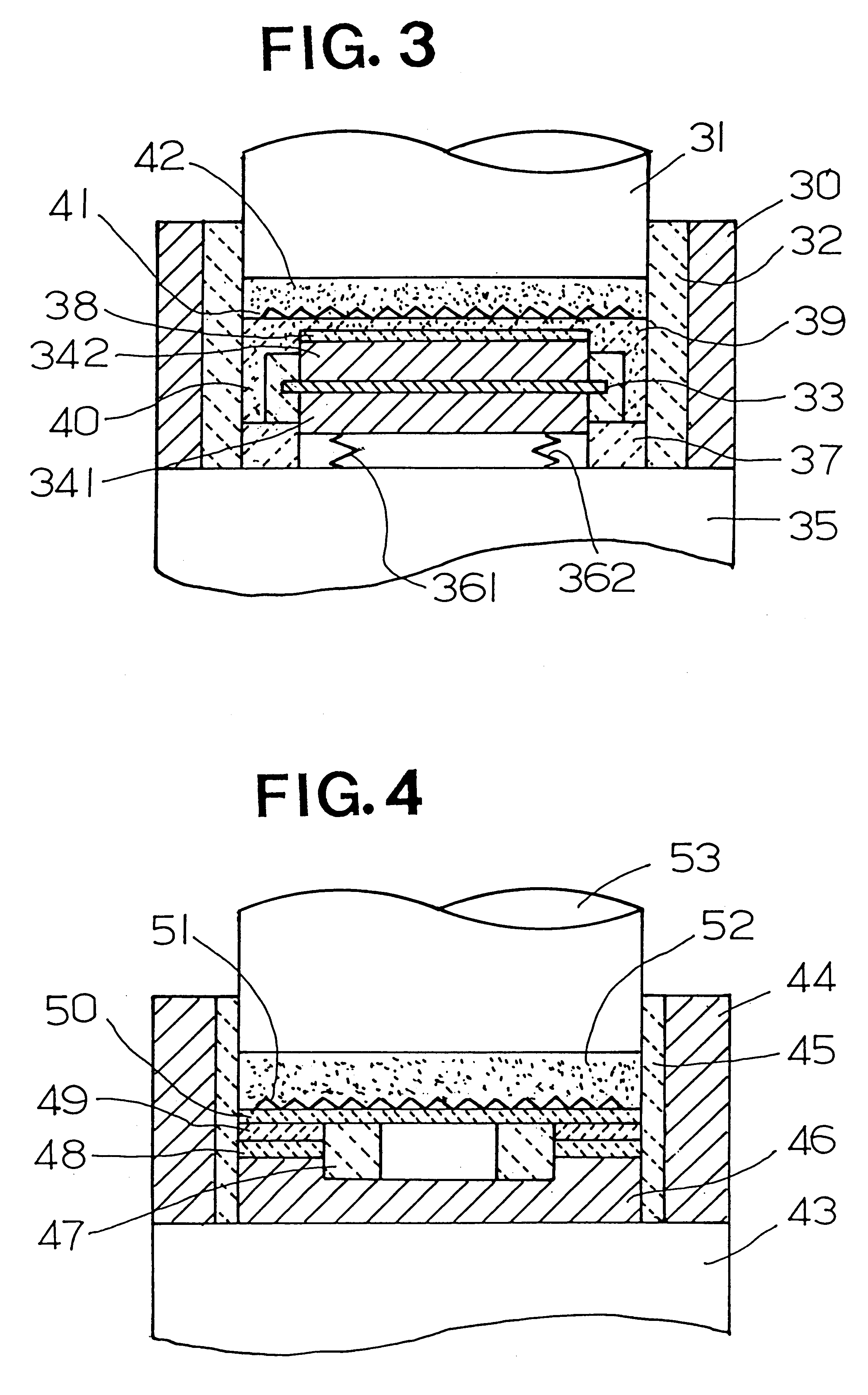

An aspect of this invention is an electrode rod for spark alloying, comprising a compact of a first powder of a first component which comprises a metal selected from a group of Fe, Co, Ni, metals of 4a, 5a and 6a of the periodic table and Si, and a second powder of a second component which is capable of self-propagating high temperature synthesis to form with said first component carbide, nitride, boride, silicide or intermetallic compound, said first and second powders being mixed intimately with each other and formed into an axial rod. Another aspect is a method for the production of the electrospark alloying rod, comprising: mixing intimately a first powder of first component and a second powder of second component, said first component comprising at least one selected from Fe, Co, Ni, metals of groups 4a, 5a and 6a, Sn, Zn, Pb, Al and Cu, said second component comprising materials capable of SHS process to form a refractory (or intermetallic) compound, compressing said mixture, followed or not by further firing, and thereby forming an axial body with a bulk density 0.50 to 0.86 time the theoretical values for the corresponding substances. Still another aspect is a method for the deposition of a coating on a work by causing and holding an electric spark between said electrode rod and work, whereby transferring the materials of said first and second components to the surface of said work, and depositing thereon as a layer or more layers of such compound.

Owner:2 KANAGAWA +3

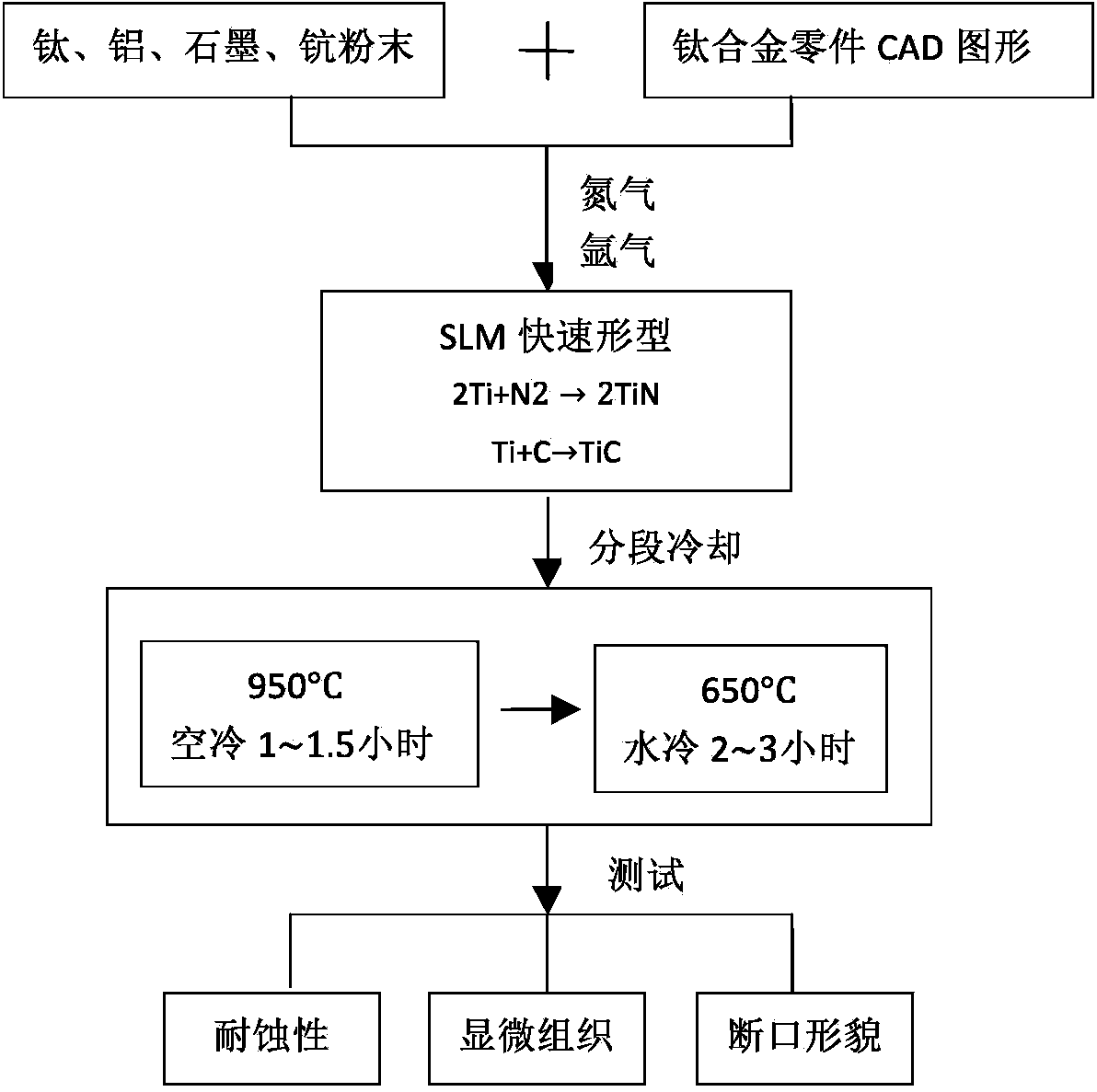

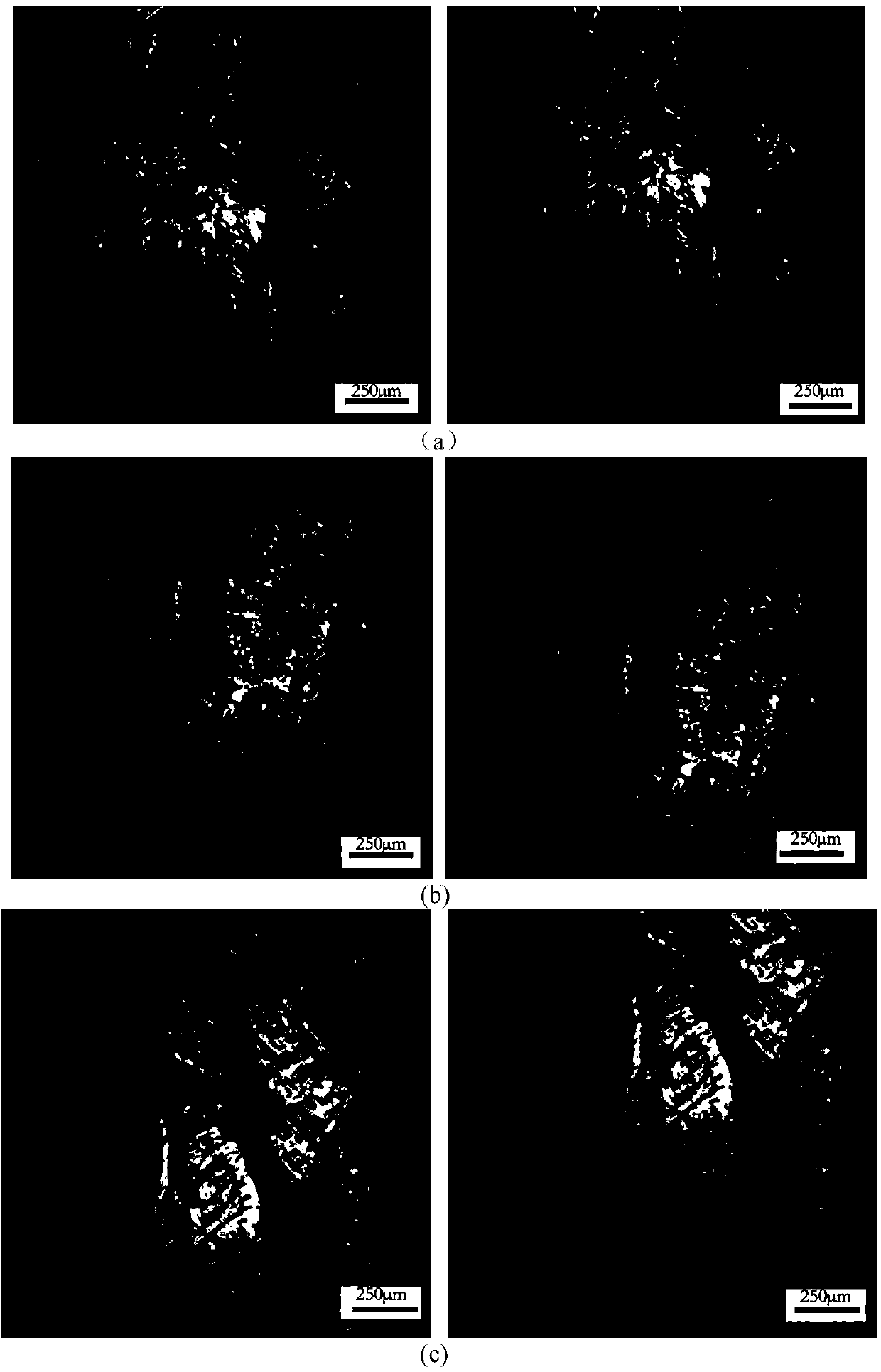

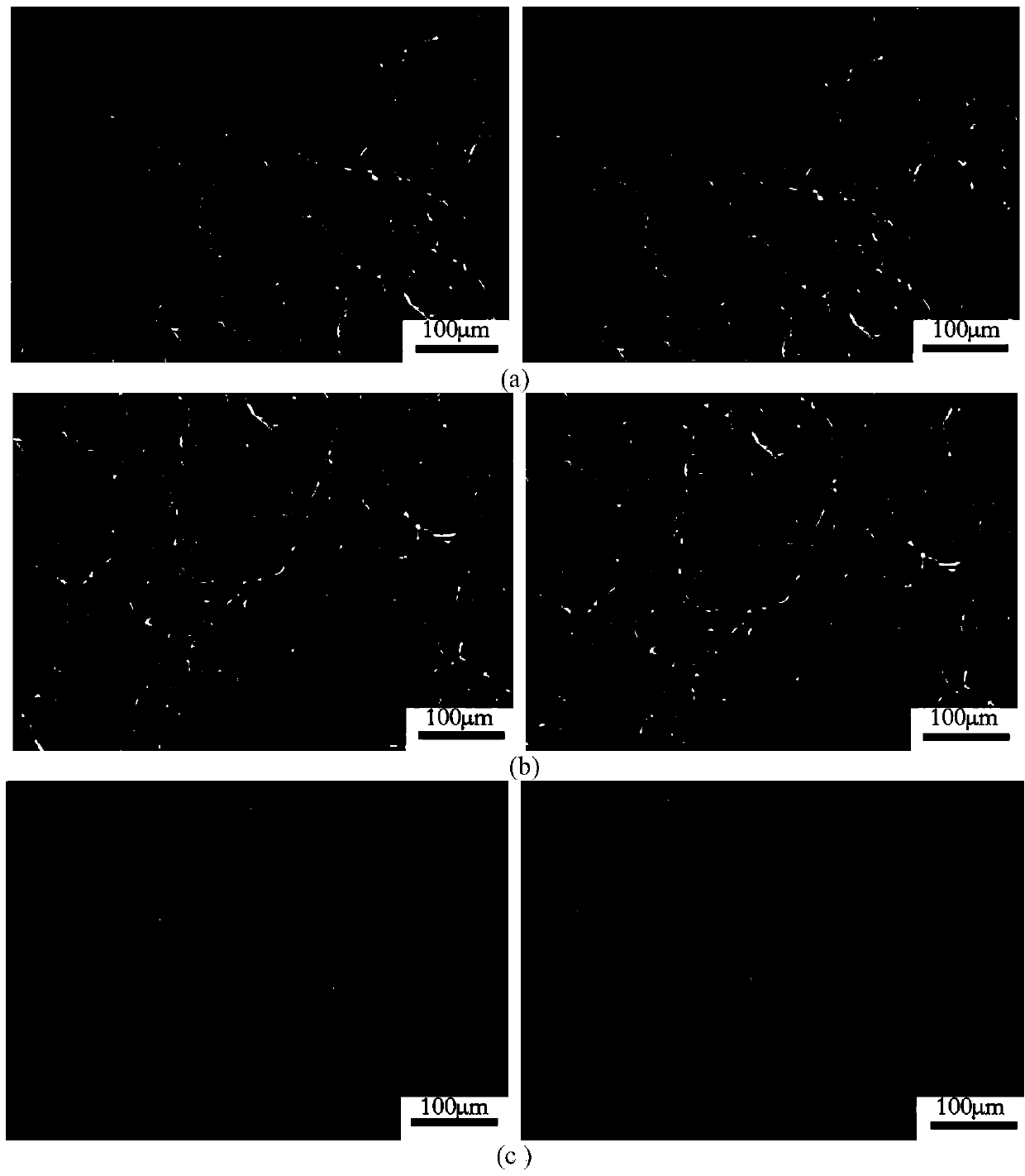

Selective laser melting forming method for preparing titanium alloy component

ActiveCN104174845AEasy to peel offLow costMetallic material coating processesSelf-propagating high-temperature synthesisSelective laser melting

The invention provides a selective laser melting forming method for preparing a titanium alloy component. The method comprises the steps as follows: firstly, after being subjected to ball-milling and mixing, titanium alloy powder is delivered to a selective laser melting quick forming device, and the titanium alloy component is formed according to a component CAD image imported into the selective laser melting quick forming device; secondly, during a forming process, a mixture of 35-45% of nitrogen and 55-65% of argon is input by the flow rate of 3-5 liter per minute at the same time, a self-propagating high-temperature synthetic reaction is performed on the titanium and the nitrogen under the temperature ranging from 1220 DEG C to 1480 DEG C so as to generate titanium nitride, and titanium carbide is generated through the reaction of the titanium and the carbon in graphite under the temperature ranging from 1260 DEG C to 1523 DEG C under the argon condition; thirdly, the titanium nitride and the titanium carbide generated from the reactions are melted with the titanium alloy component as an organic whole; fourthly, the formed titanium alloy component is subjected to segmental cooling. Through adopting the technical scheme of the method, the generated titanium alloy component has better abrasive resistance and corrosion resistance, and besides, the fact that the film layers of the traditional titanium nitride and titanium carbide composite coatings are easy to peel off from the titanium alloy is avoided, and the surface of the titanium alloy is not needed to be subjected to coating and anticorrosive treatment additionally, so that the cost is saved, and no other additional processing procedures are required.

Owner:南京博乔机械有限公司

Preparation of high-purity titanium biboride ceramic micropowder by using self-spreading high-temp. reduction synthesis process

InactiveCN1341576AHigh purityLow energy consumptionSelf-propagating high-temperature synthesisTitanium

The preparation method of high-purity TiB2 ceramic micropowder uses active metal reducing agent and cleap oxide raw material, and adopts the following steps: uniformly mixing TiO2, B2O3 and metal Mg powder, die-pressing and forming, placing the above-mentioned obtained material in a self-spreading high-temp. synthesis equipment with argon protection at normal temp. and normal pressure, lighting to make combustion, breaking combustion product, pickling so as to obtain the invented high-purity TiB2 ceramic micropowder. As compared with traditional carbon thermal reduced TiB2 ceramic powder saidinvention possesses the advantages of high purity, fine crystal grain, simple process and low energy consumption and time consumption, and as compared with SHS simple substance synthetic TiB2 ceramicpowder it is low in production cost.

Owner:WUHAN UNIV OF TECH

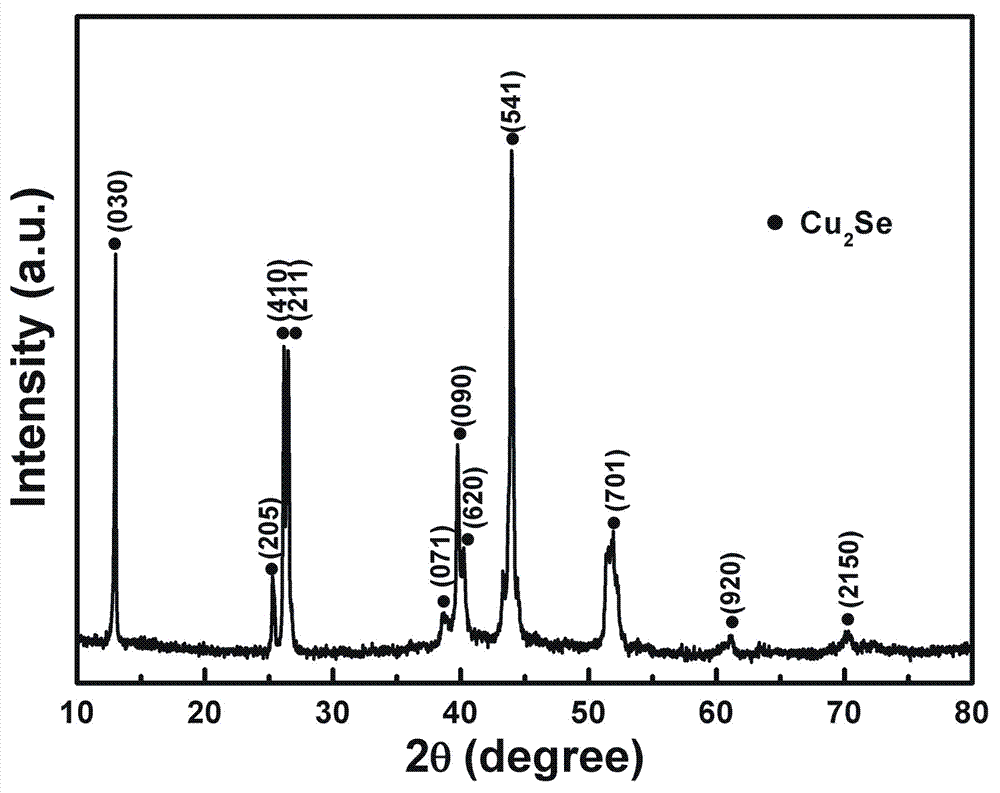

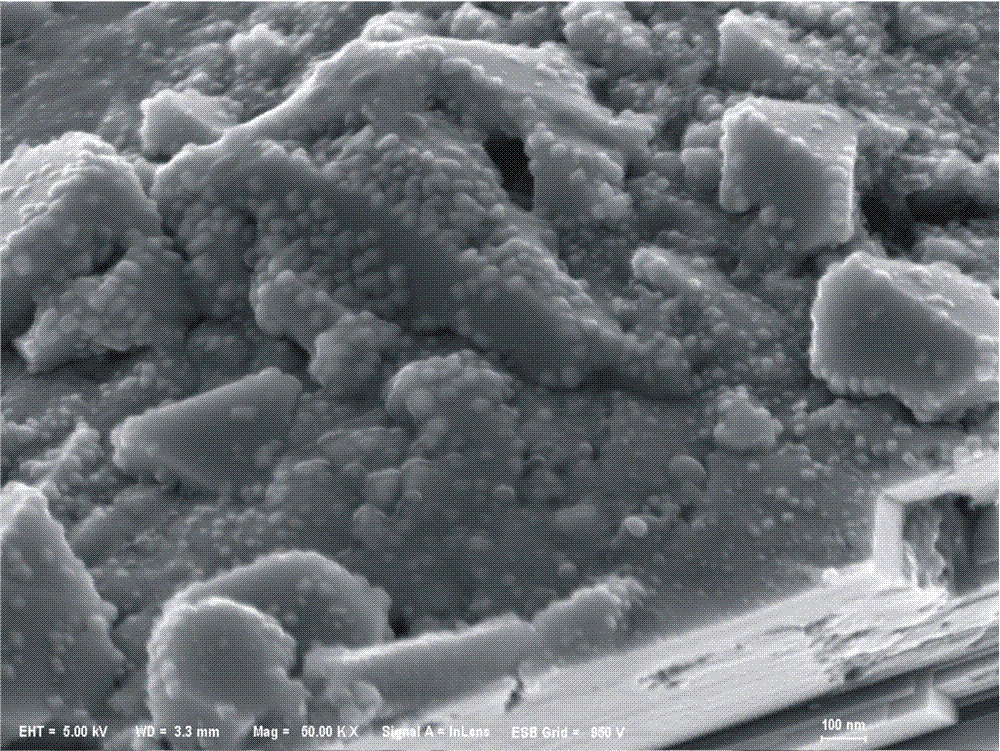

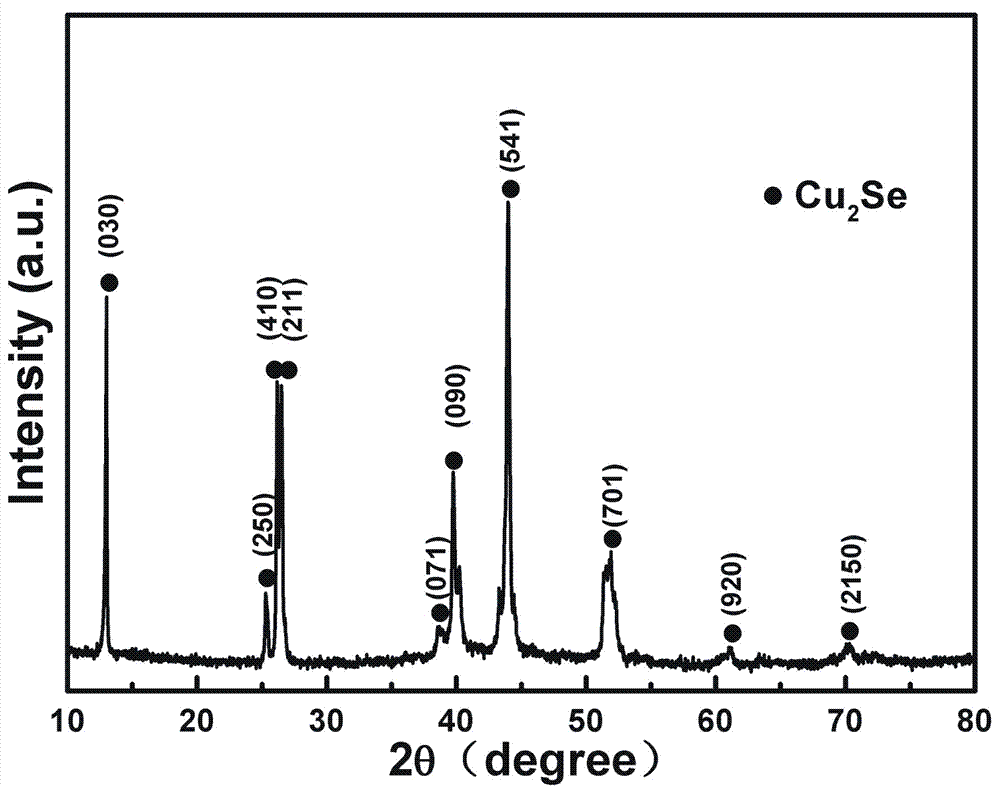

Self-propagating high-temperature rapid one-step synthesis thermoelectric material powder with nanostructure Cu2Se method

ActiveCN103165809APrecise control of stoichiometric ratioQuick responseNanotechnologyThermoelectric device junction materialsThermoelectric materialsSelf-propagating high-temperature synthesis

The invention provides a self-propagating high-temperature rapid one-step synthesis thermoelectric material powder with nanostructure Cu2Se method. The method includes: preparing stoichiometry of Cu powder and Se powder as 2 to 1 as raw materials, evenly mixing Cu powder with Fe powder to have reactants, adopting direct detonating or constant temperature detonating to trigger self-propagating reaction, natural cooling after reaction achievement and acquiring thermoelectric material powder with nanostructure Cu2Se. The method has the advantages of adoption of self-propagating high-temperature synthetic process, reaction for a short time, simple technique, low facility requirement, low energy consumption and environment friendliness. Further, stoichiometry of products is controlled accurately. Even distribution nanostructure is formed at normal positions.

Owner:WUHAN UNIV OF TECH

Composite material of metal / ceramic metal, manufacturing method and application

ActiveCN101003901ASimple processReduce manufacturing costMetallic material coating processesSelf-propagating high-temperature synthesisDissolution

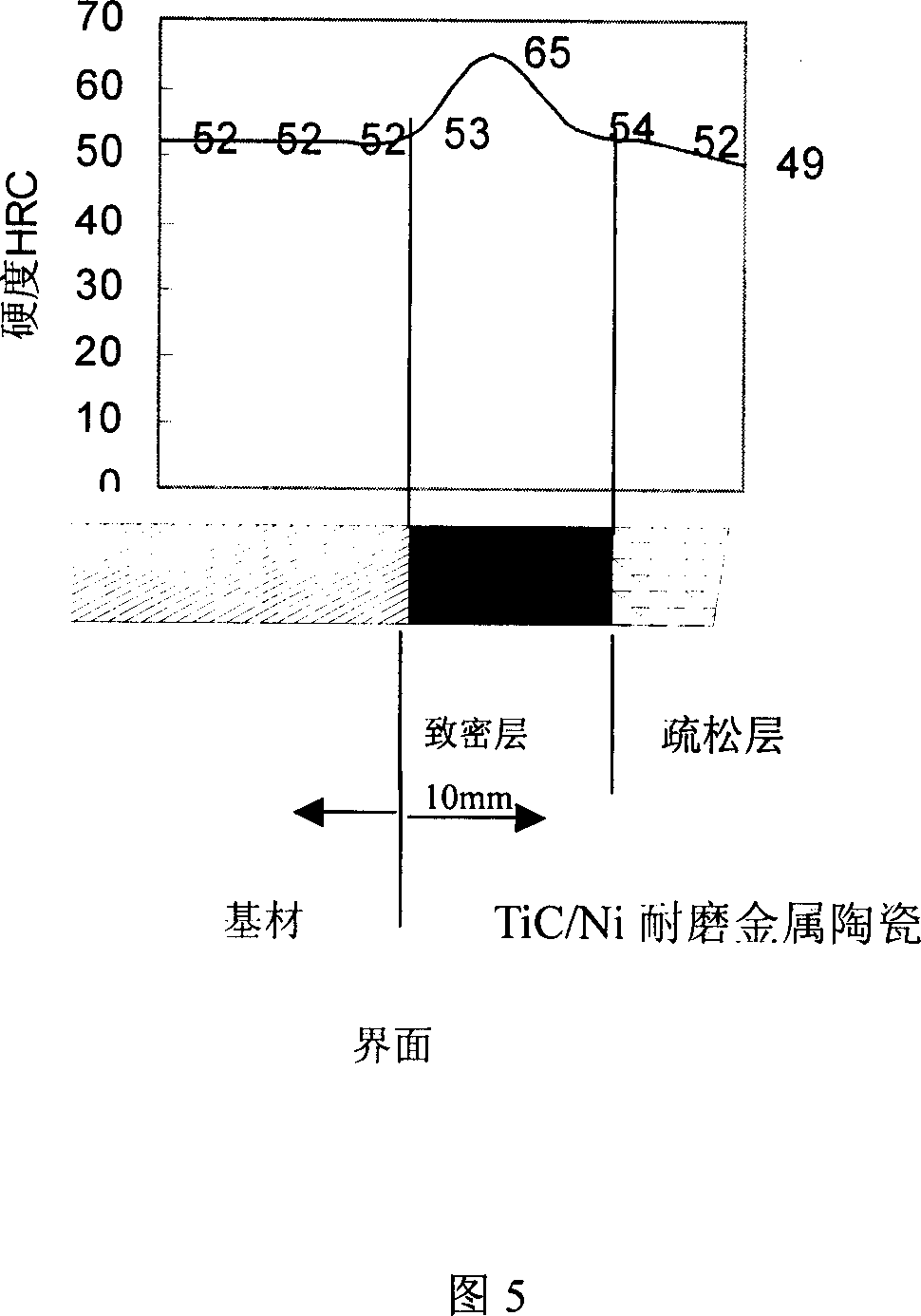

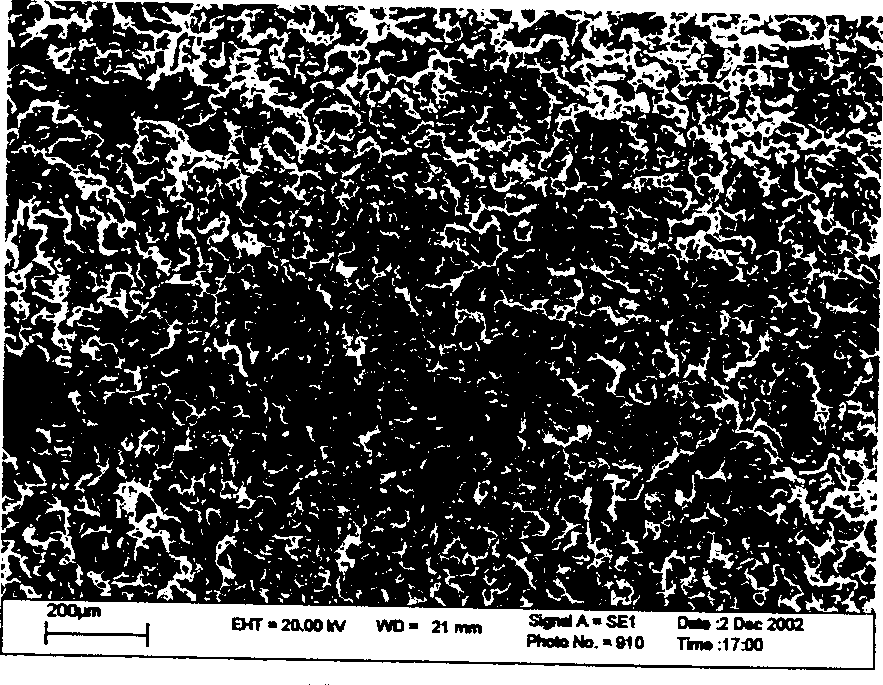

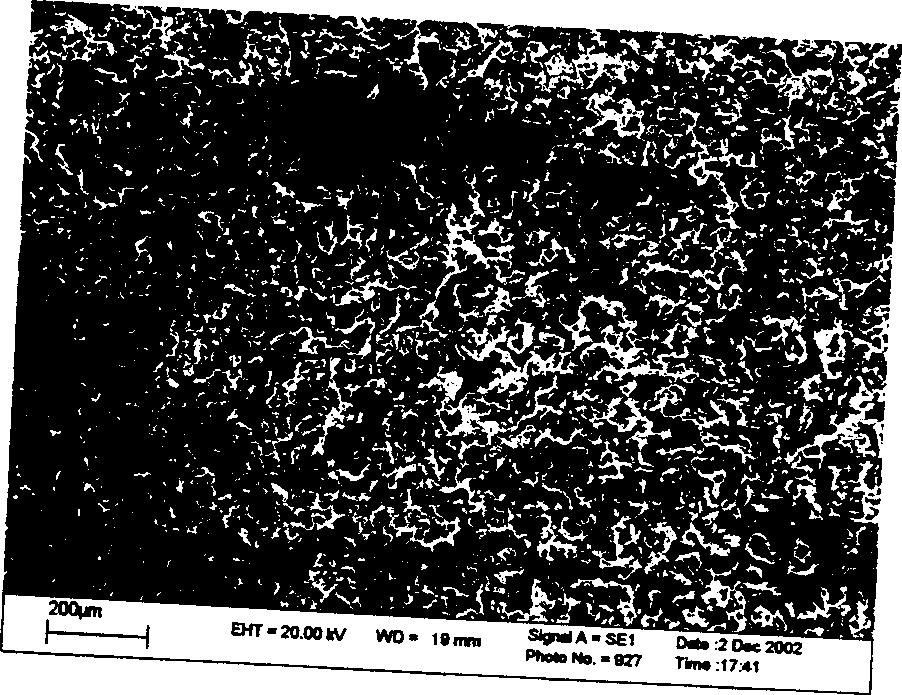

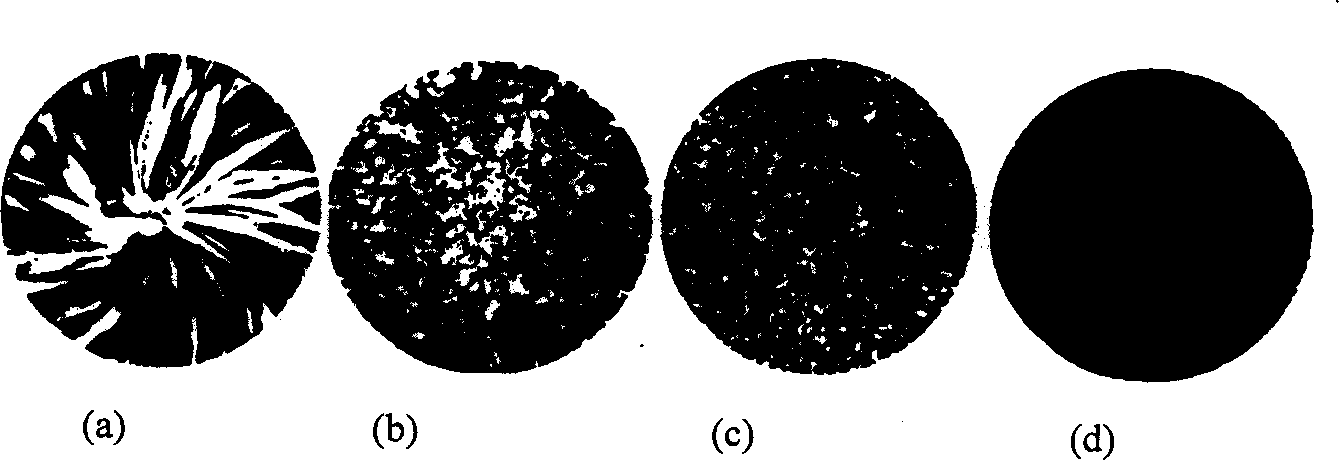

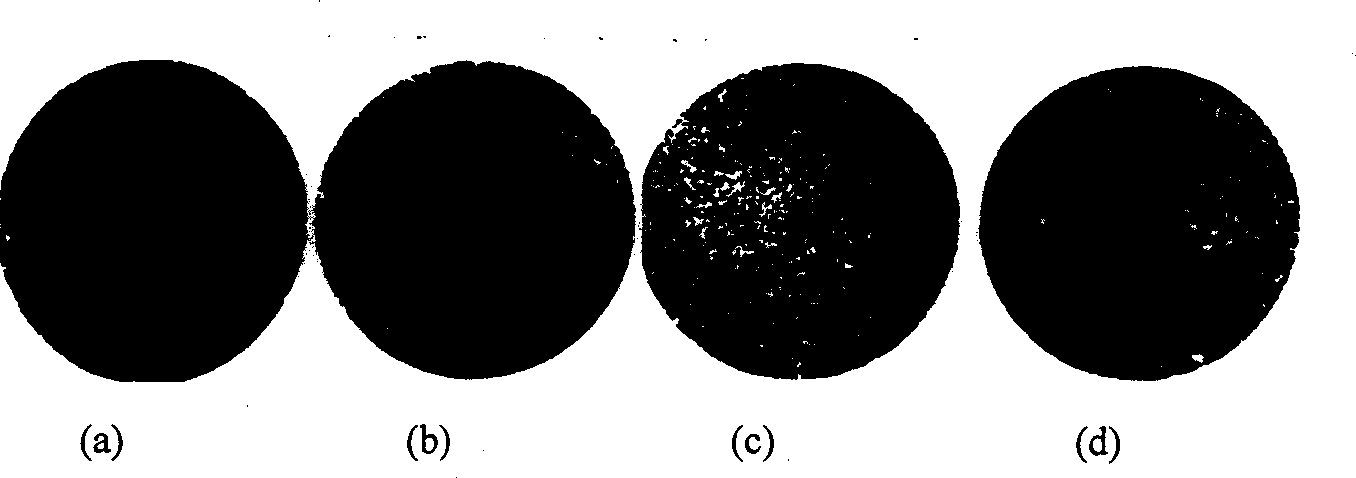

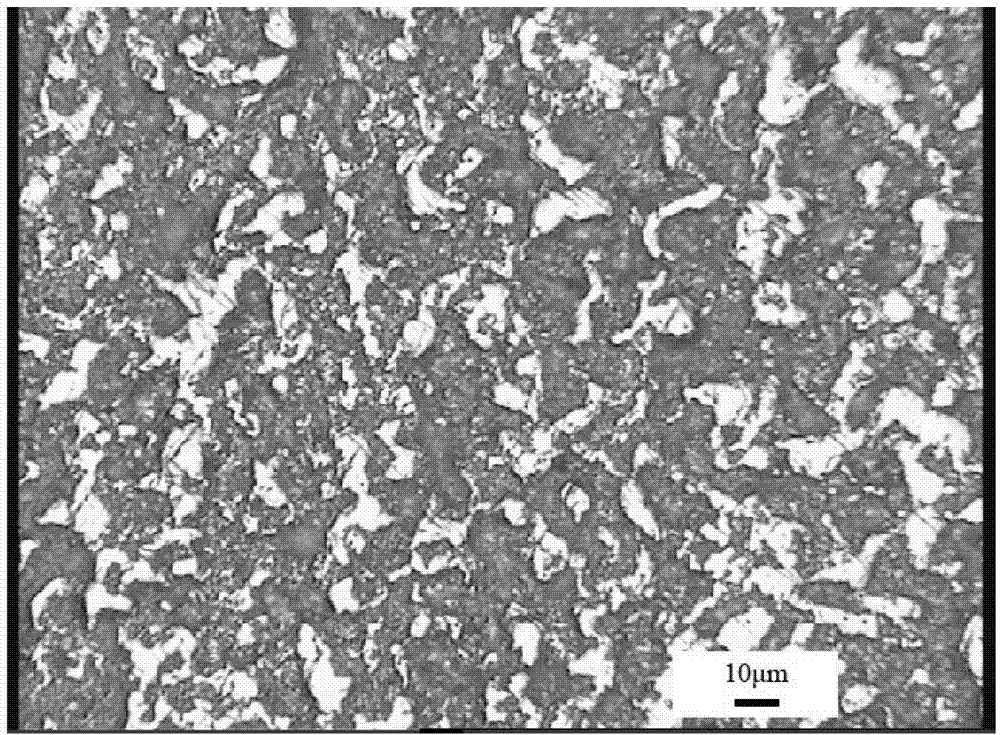

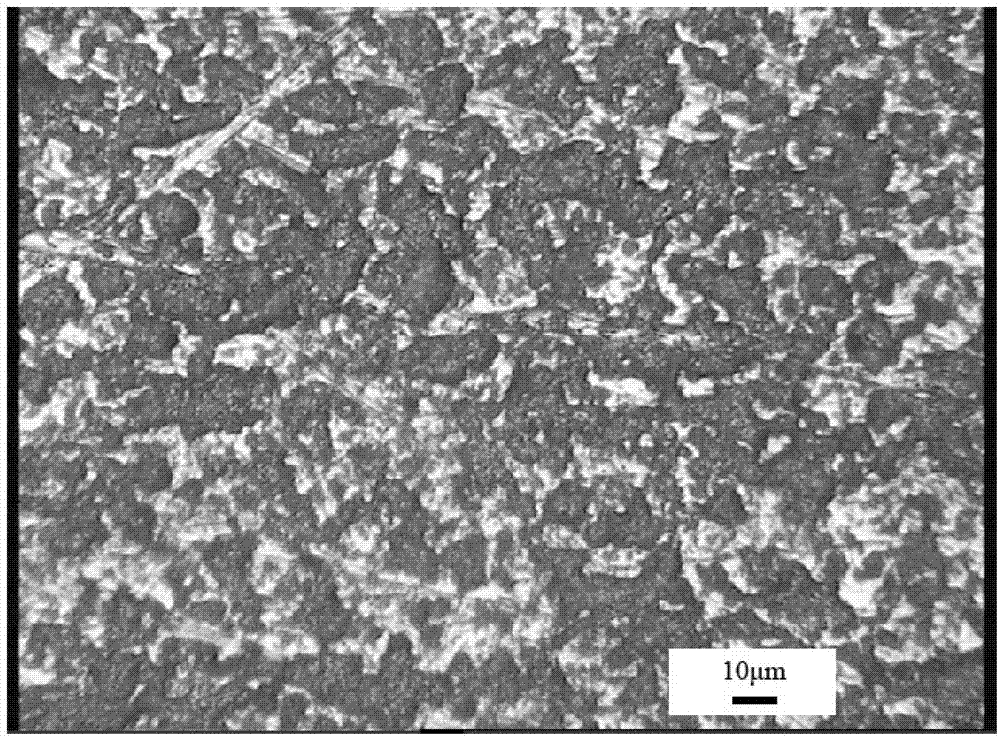

This invention discloses a method for producing metal / metal ceramic composite, and its application. The composite is produced by compositing metal ceramic onto low alloy steel matrix. The metal ceramic is metal-matrix TiC, which comprises binding phase metal and hard granular TiC dispersed in binding phase metal. The low alloy steel matrix and the metal ceramic are metallurgically composited, and a diffusion / dissolution zone exists at the interface of the binding phase metal and the low alloy steel. A gradient transition layer of hard granular phase exists in the diffusion / dissolution zone. The binding phase metal is selected from Fe, Co and Ni. The TiC is prepared by self-propagating high temperature synthesis of Ti and C during casting of the low alloy steel. The self-propagating high temperature synthesis system comprises: binding phase metal 35-45 wt. %, Ti 44-52 wt. %, and C 11-13 wt. %. The metallurgical composition of the metal ceramic and the matrix has high strength. Therefore, the composite has good wear resistance and good impact resistance, thus is suitable for producing relieving of excavator.

Owner:NINGBO HOPESUN NEW MATERIAL

Method for synthesizing NiTi shape memory alloy porous material

InactiveCN1418974AMeet the requirements for growthMeet strength requirementsSelf-propagating high-temperature synthesisAdhesive

The method for synthesizing NiTi marmen porous body material is characterized by that it uses Ti powder and Ni powder as raw material, and includes the following steps: uniformly mixing the above-mentioned raw materials, mixing them with adhesive in mixing machine, granulating to obtain feeding material, injecting to obtain blank piece, soaking said blank piece in gasoline to remove grease, drying and placing the blank into vacuum furnace to make thermal grease removal, finally connecting one end of blank with W spiral in flame igniter, placing it into vacuum reaction synthesizer, when the degree of vacuum is higher than 1X10(-2)Pa, starting heating, after the temp. is up to defined value, starting flame igniter so as to produce self-spreading high-temp. synthesis reaction to obtain finished product.

Owner:UNIV OF SCI & TECH BEIJING

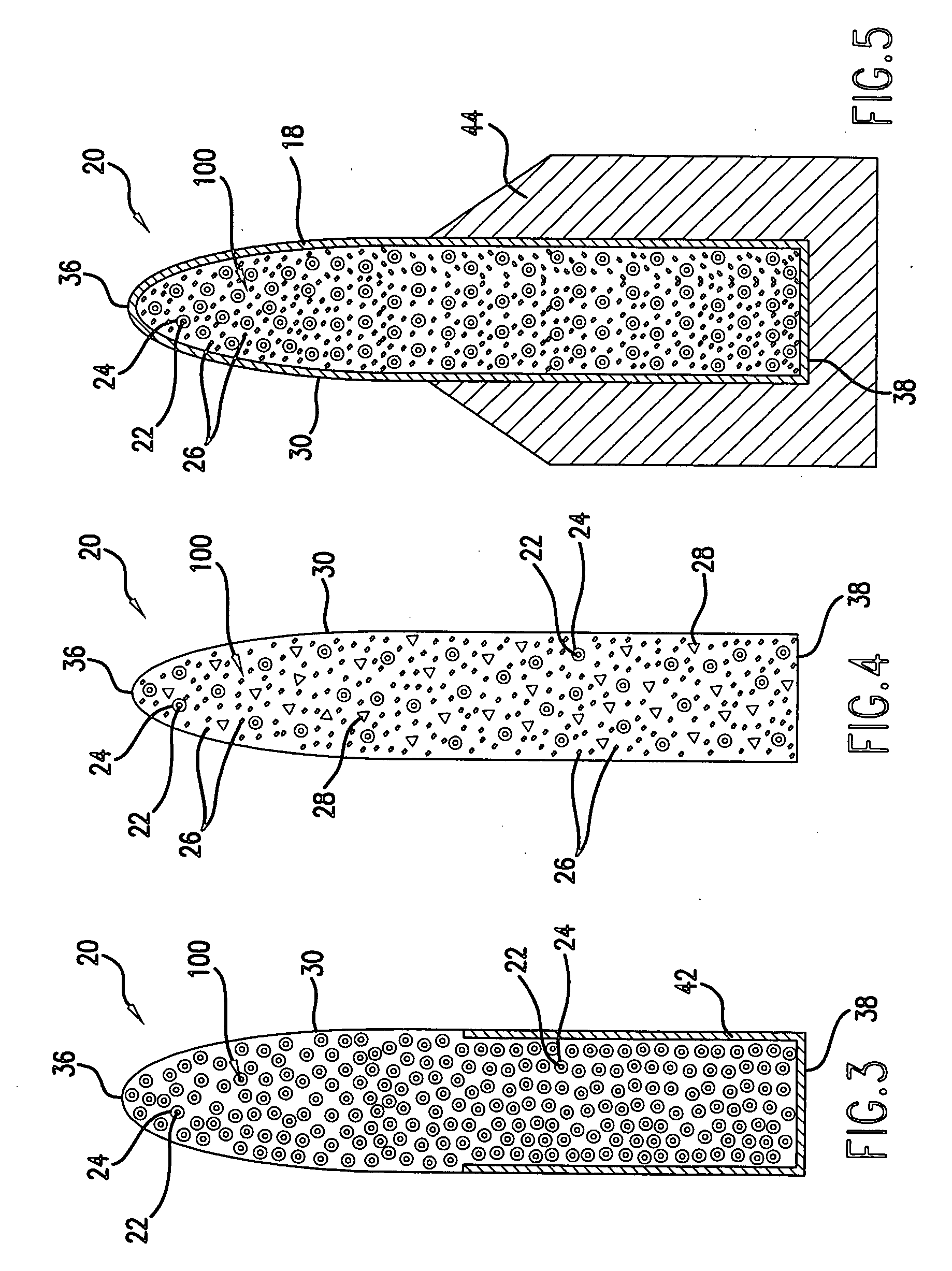

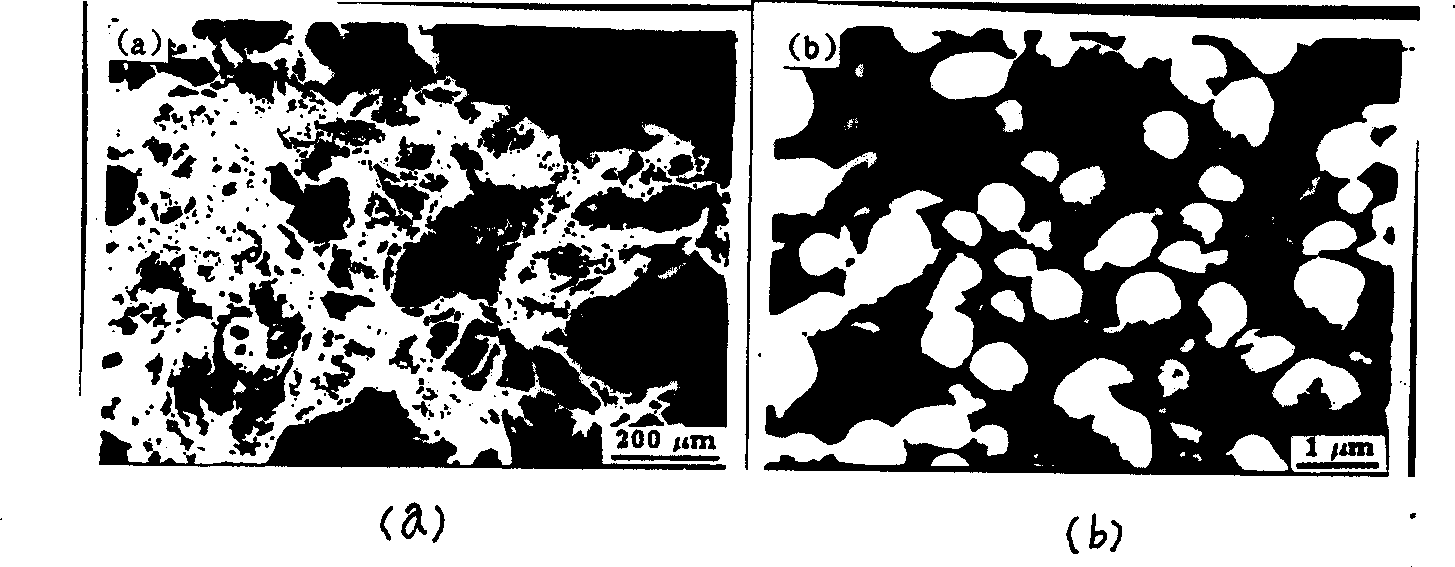

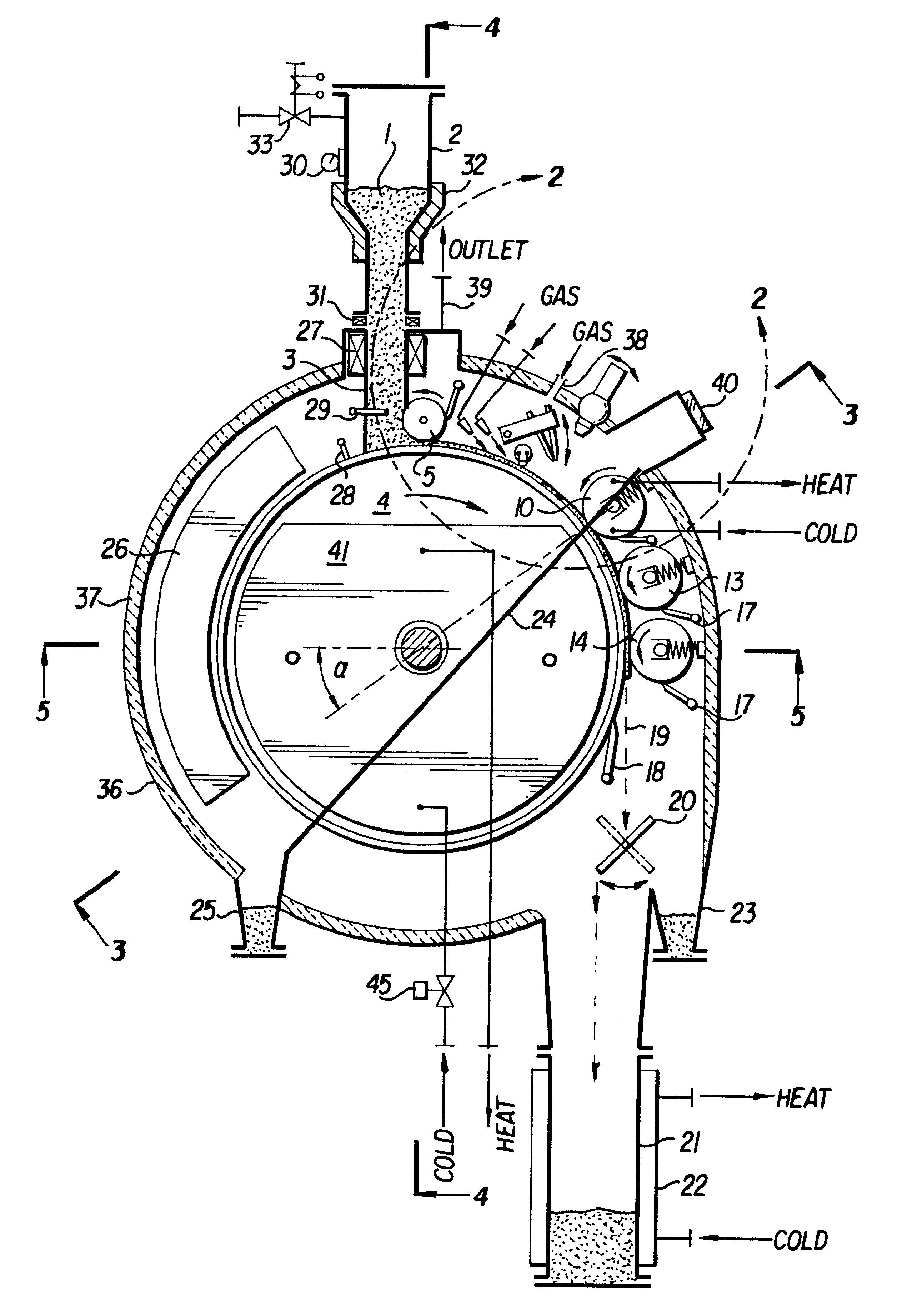

Super-abrasive grain-containing composite material and method of making

InactiveUS6171709B1Efficient productionThin material handlingSelf-propagating high-temperature synthesisMolten metal

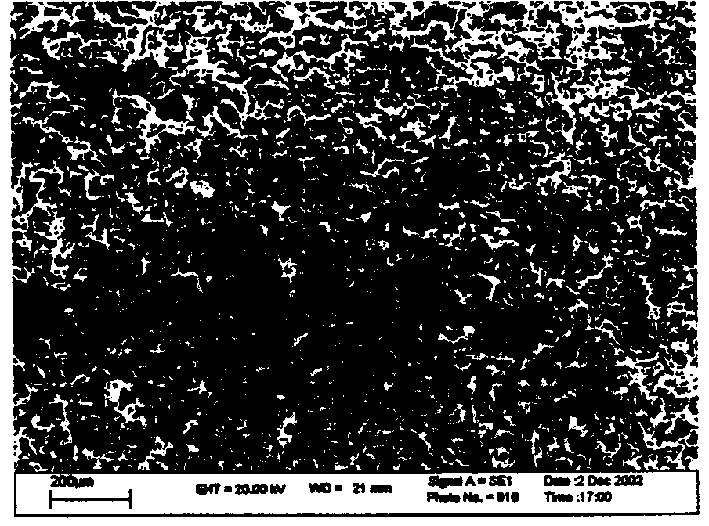

The invention provides a superabrasive containing composite product, comprising and / or prepared on the intense heating of an SHS process, self-propagating high-temperature synthesis. An effective method of such product is also provided. Said composite comprises a substrate of shaped metallic block and a functional layer of ceramic materials containing superabrasive particles, which is joined on a surface of the former, by means of and intermediated by molten metal which occurred during the SHS process.

Owner:2 KANAGAWA

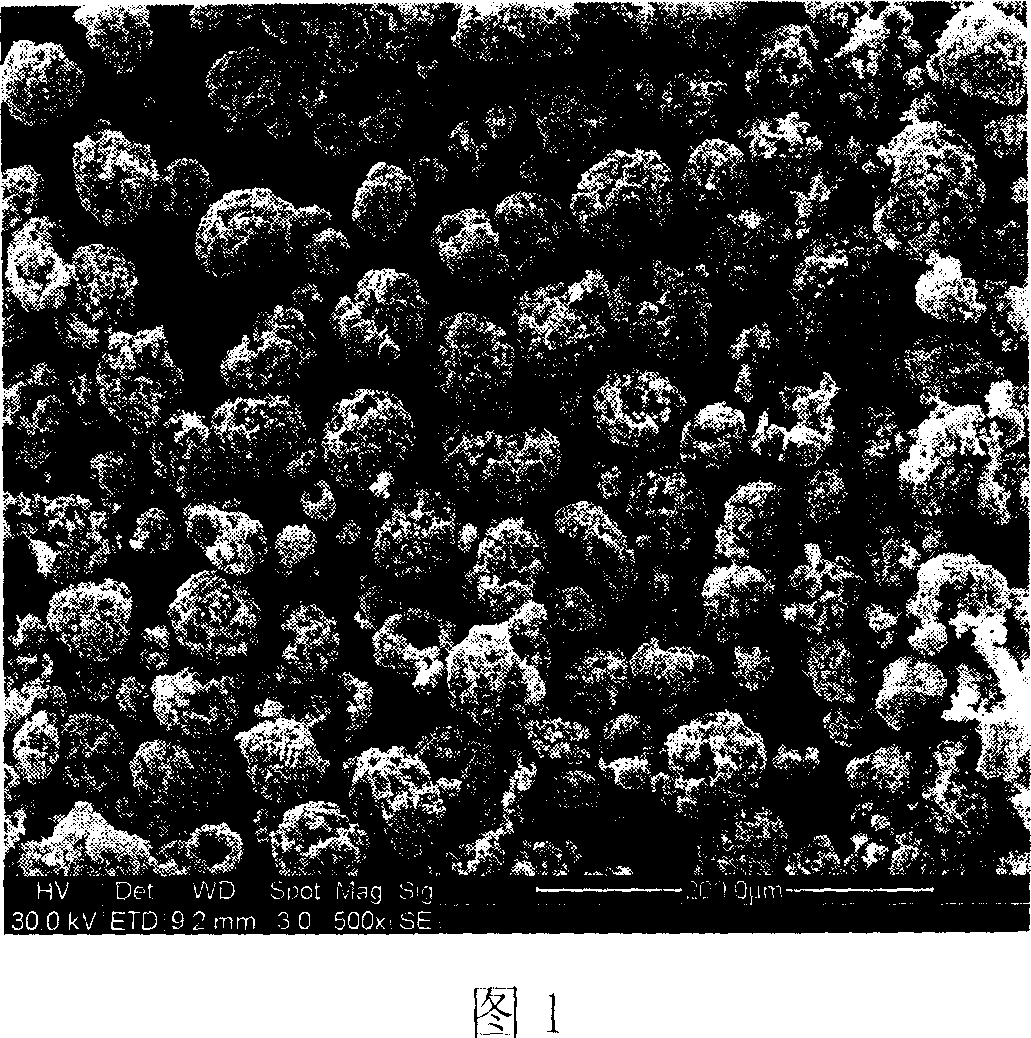

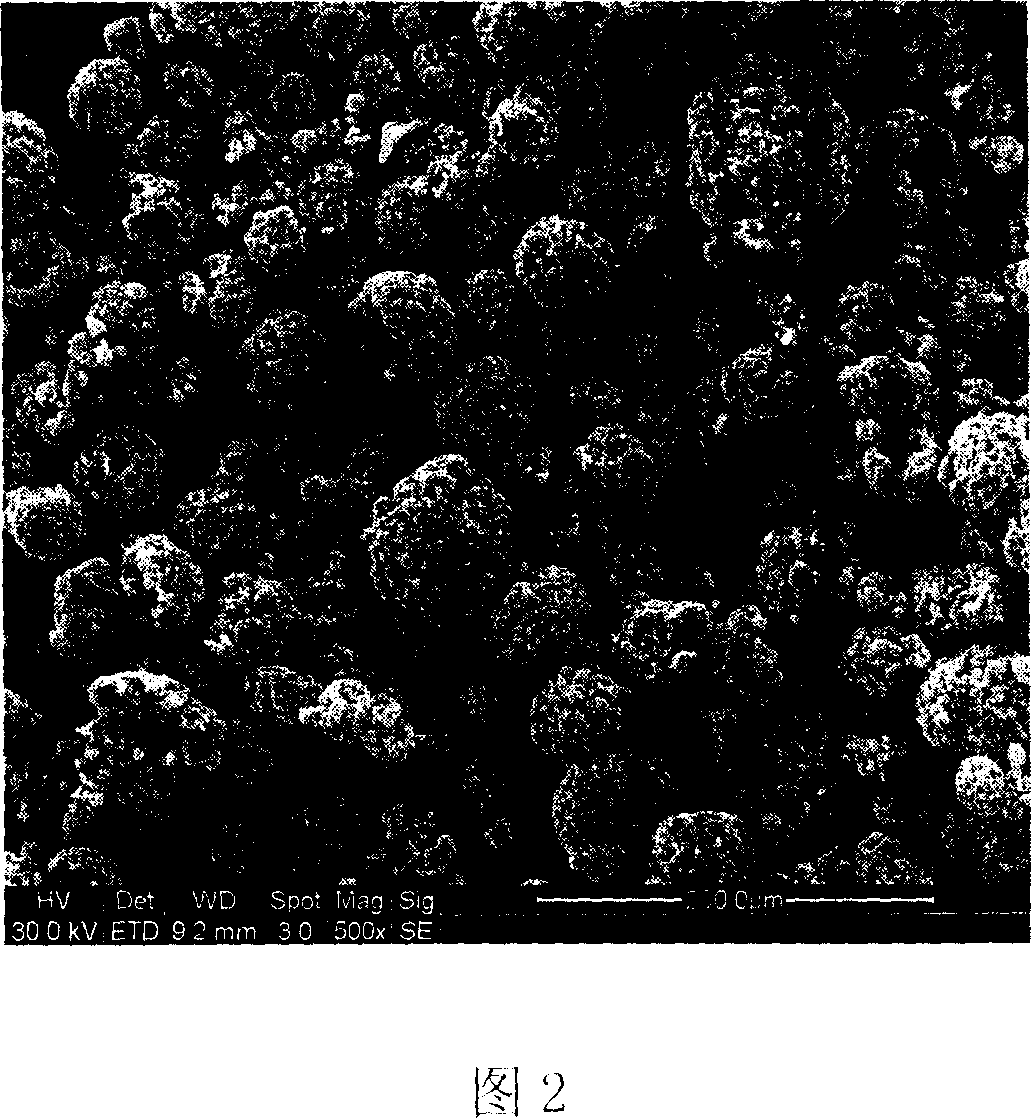

Preparation method of titanium carbide-based cermet powder material for thermal spraying

InactiveCN102166652AImprove wear resistanceReduce coefficient of frictionMolten spray coatingSelf-propagating high-temperature synthesisThermal spraying

The invention provides a preparation method of a titanium carbide-based cermet powder material for thermal spraying, which belongs to the field of powder materials for thermal spraying. The method comprises the following steps of: firstly, weighting titanium powder, graphite powder / soot carbon, and other metal components in a proportion to prepare raw material powder; putting the raw material powder into a ball mill pot for ball milling, briquetting the mixture to form a block after the mixing is finished, placing in a self-propagating high-temperature synthesis reactor, igniting the block after the air in the reactor is removed so that the whole block is ignited to undergo a self-propagating reaction; starting a mechanical pump to vacuumize after the reaction is finished, and cooling reaction products to room temperature with the reactor so as to obtain a loose porous titanium carbide-based cermet block; and finally, after the cermet block is taken out, removing contaminants on the surface of the cermet block, and then crushing and screening residual products to obtain titanium carbide-based cermet powder for thermal spraying in different grain sizes. The preparation method in the invention has the characteristics of short synthesis time, energy saving, environmental protection, low price, and the like, and is suitable for industrial production.

Owner:UNIV OF SCI & TECH BEIJING

Electromagnetic/ultrasonic preparation method of in-situ particle reinforced magnesium-based composite material

InactiveCN101608277AImprove bindingEnhancement effect is goodSelf-propagating high-temperature synthesisMagnesium matrix composite

An electromagnetic / ultrasonic preparation method of an in-situ particle reinforced magnesium-based composite material belongs to the technical field of metallurgy. The invention discloses a method for preparing the magnesium-based composite material with an electromagnetic continuous casting method, which is characterized by comprising the following steps of: melting a magnesium-based melt added with micro-alloying elements of Ca, rare earth Y, rare earth Ce; selecting an Al-Ti-C or Al-Ti-B reinforced system, adopting a self-propagating high-temperature synthesis method to synthesize a magnesium-based composite material melt containing reinforced particles in situ, and implementing electromagnetic / ultrasonic combined stirring to the magnesium-based composite material melt; and finally adopting a continuous casting process to form the magnesium-based composite material by continuous casting, and applying an electromagnetic field and an ultrasonic field within the range of a crystallizer so as to obtain a multi-phase reinforced magnesium-based composite material continuous-casting billet. The electromagnetic / ultrasonic preparation method has the effects and advantages of organically combining the self-propagating reaction method with the electromagnetic continuous casting technology and the ultrasonic technology, obtaining the magnesium-based composite material continuous-casting billet with smooth surface, uniform distribution of particle reinforcement phases in the basal body and good combination of the reinforced bodies and the basal body, and having simple preparation process.

Owner:DALIAN UNIV OF TECH

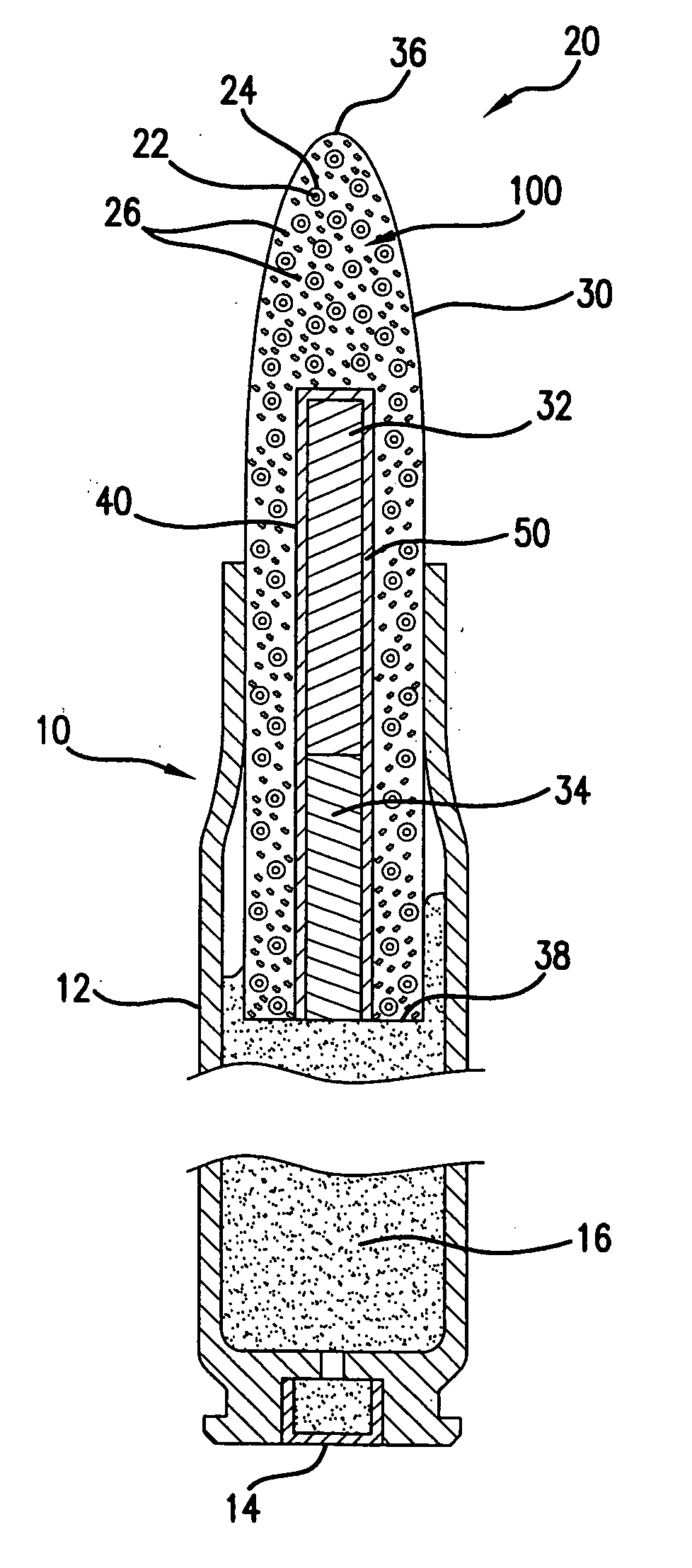

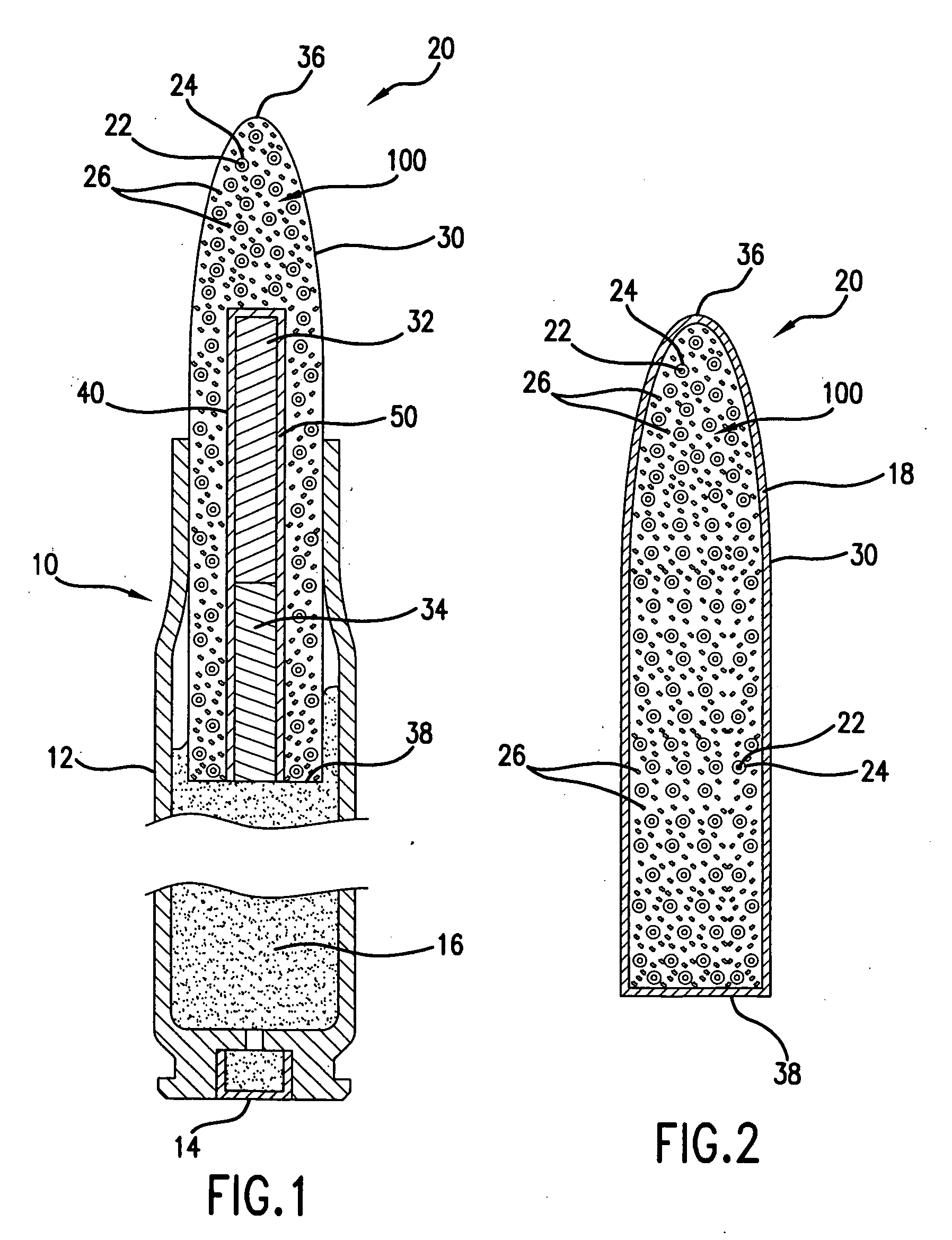

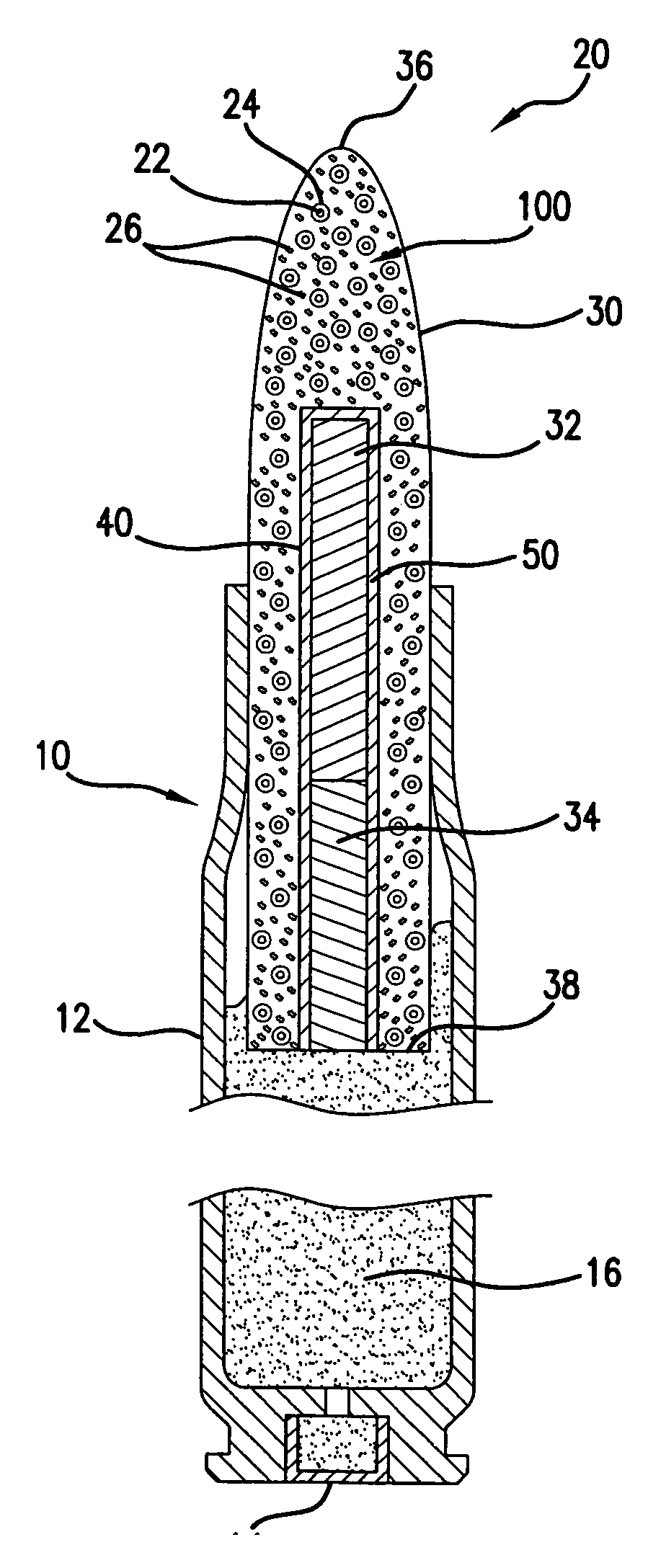

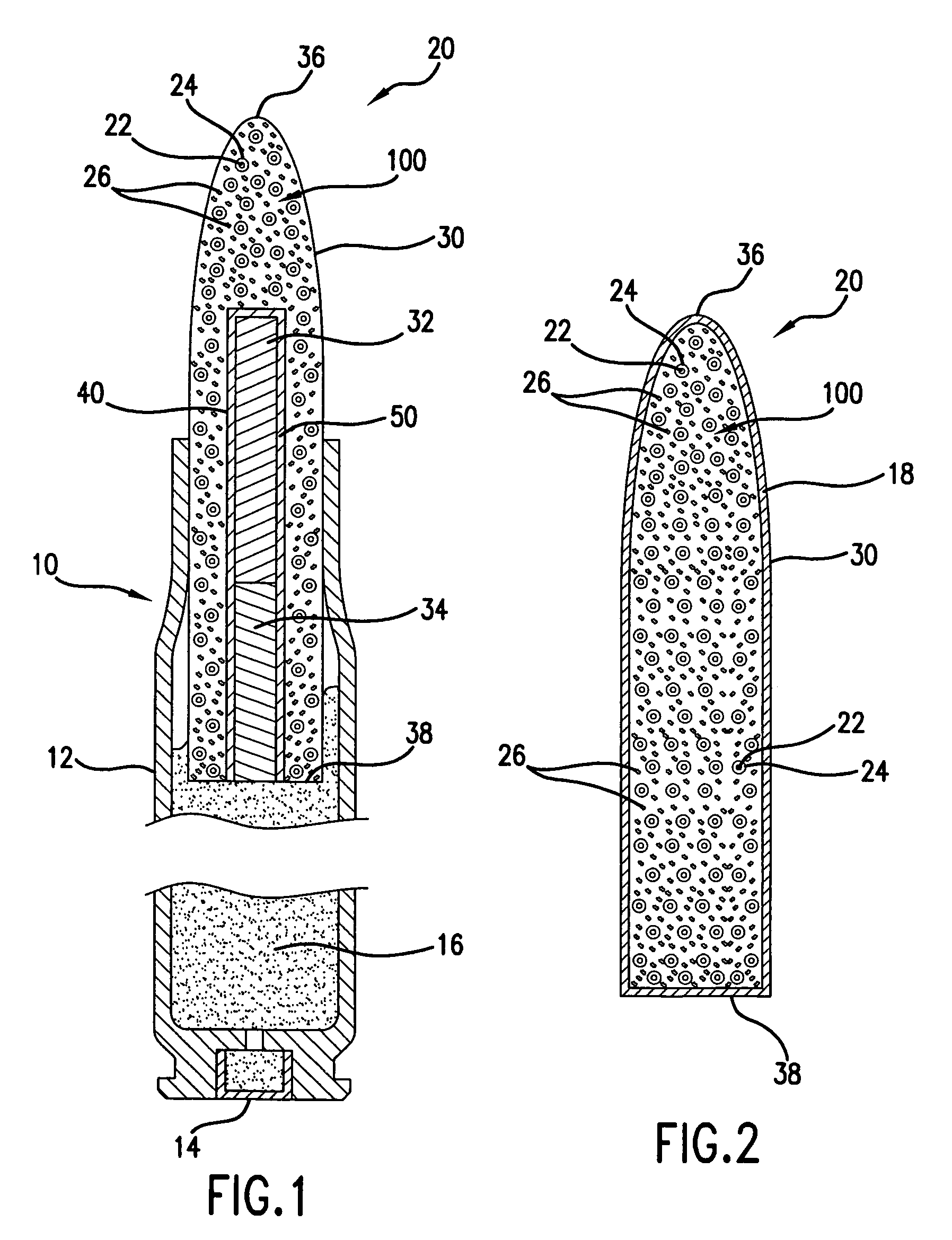

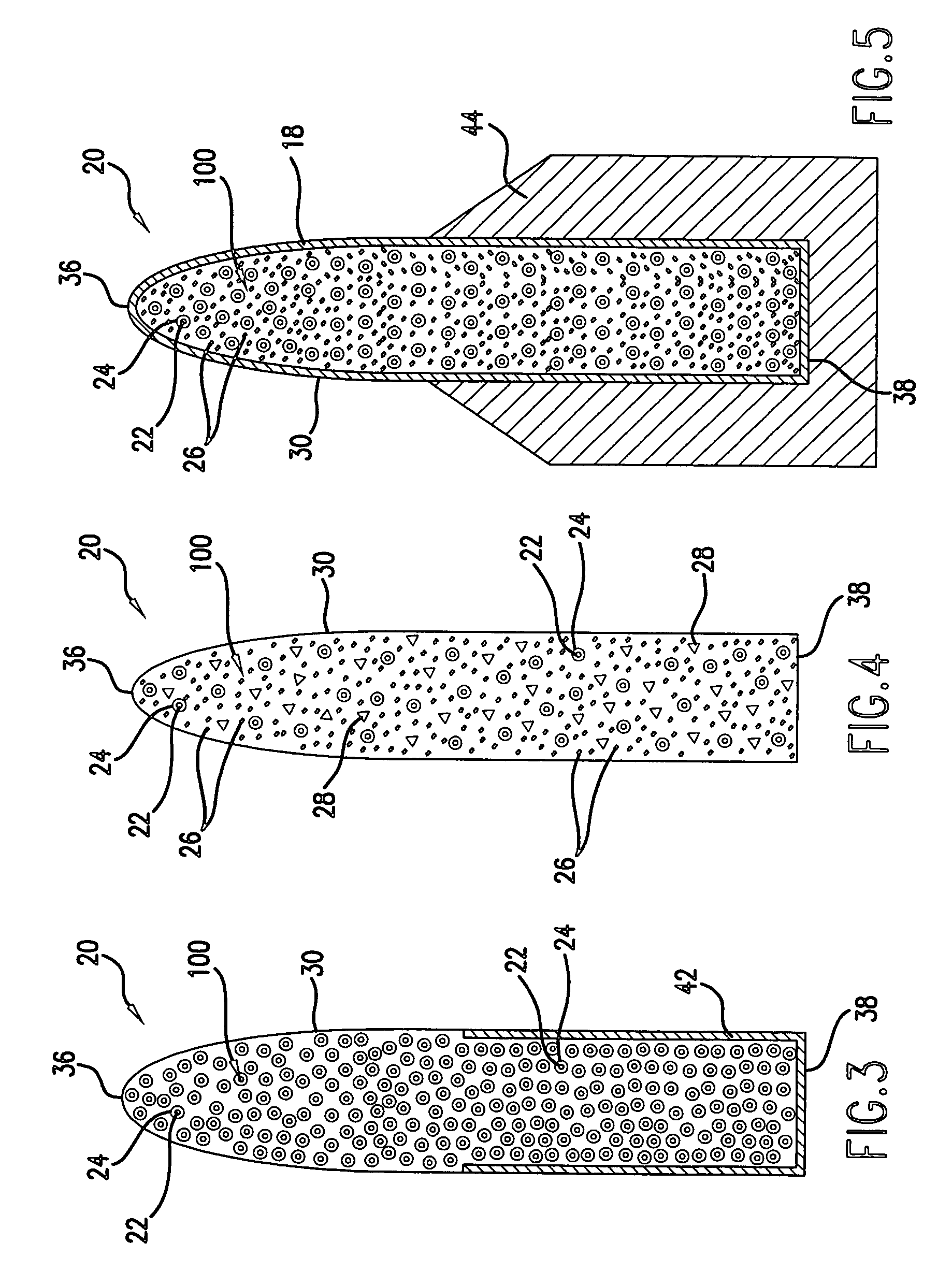

Method and apparatus for a projectile incorporating a metasable interstitial composite material

InactiveUS20060288897A1Rapid thermal oxidation effectHigh-temperature reactionAmmunition projectilesProjectilesSelf-propagating high-temperature synthesisThermal impact

A method and apparatus for incorporating nanophase elemental materials and metastable interstitial composite materials into projectiles, projectile fragments, ordnance casings, warheads and structural components. The projectile, fragments and casings include an elemental material capable of oxidizing. A coating material that is capable of preventing oxidation of the elemental material and an oxidizing agent may be present and be capable of reacting with the elemental material so that a self-propagating high temperature synthesis reaction from a stabilized solid material is yielded for the purpose of rendering terminal effects or thermal impact to a target at impact.

Owner:NEWTEC SERVICES GROUP

Al-Ti-C crystal grain fining agent and its producing process

InactiveCN1352312AEffective grain refinement effectImprove grain refinement effectSelf-propagating high-temperature synthesisHigh activity

The present invention relates to the field of metal material technology and aims at providing one technological process of producing crystal grain fining agent for aluminum and aluminum alloy at low cost. The said crystal grain fining agent has the ingredients of: Ti 30-60 wt% and C 7-15 wt% except Al. Its production process inclues the steps: ball milling to mix material, cold pressing of mixed material into lump with 30-60 % relative compactness, stoving the lump at 100-200 deg.c and self-pervasion high temperature composition to form the crystal grain fining agent inside one high pure argon reactor. The technological process is simple, low in power consumption and high in temperature and produce porous crystal grain fining agent with less impurity, high TiC particle content and very high activity and thermodynamic stability.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for preparing titanium carbide ceramic micro powder by utilizing self-propagating high temperature synthesis

InactiveCN101704682ASimple production processIncrease productionSelf-propagating high-temperature synthesisHigh energy

The invention discloses a method for preparing a titanium carbide micro powder ceramic material by utilizing self-propagating high temperature synthesis. Ti powder and C powder with the granularity being less than 100 meshes and the purity being more than 99% are taken as raw materials. The method comprises the following steps: evenly mixing the Ti powder and the C powder according to the mole ratio of 1:1; carrying out high energy ball mill for 3-10h at room temperature in the revolving speed of 1000-2000r / min; performing cold press molding on the mixed powder after ball mill; igniting and compacting green in a vacuum chamber |by an electric arc to obtain a combustion product; and finally cracking the combustion product to obtain the TiC micro powder ceramic material, wherein the average grain diameter of the power is 2-8mu m. The method of the invention takes pure Ti powder and pure C powder as raw materials, adopts ball mill and self-propagating high temperature synthesis to prepare TiC micro powder ceramic material, and has the advantages of simple production process, low cost, high product yield and quality and the like.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method of on-site synthesized TiB2+TiC two-phase particle-reinforced steel matrix surface wear-resistant extra hard steel and extra hard steel

InactiveCN103302267AFlexible designFull degrees of freedomFoundry mouldsFoundry coresSelf-propagating high-temperature synthesisWear resistant

The invention discloses a preparation method of metal matrix surface wear-resistant extra hard steel and the extra hard steel, particularly relates to a preparation method of on-site synthesized TiB2+TiC two-phase particle-reinforced steel matrix surface wear-resistant extra hard steel through a combination of a lost foam casting technology and an SHS (Self-propagating High Temperature Synthesis) synthesis technology and the extra hard steel, and aims at reinforcing specific areas or positions of casting through on-site two-phase particles generated through reaction, thereby not only guaranteeing the tenacity of metal matrix, but also improving the high hardness and the wear-resisting property of service areas or positions. The method comprises the steps as follows: firstly, mixing titanium powder, boron carbide powder, fluxing agent, additive and binder according to predetermined ratio, so as to produce SHS powder paste; secondly, coating the produced SHS powder paste onto the surface of a foamed plastic model corresponding to wear-resisting positions of the casting; and lastly, pouring high-temperature molten steel through an LFC (Load Frequency Control) method lost foam casting technology, so as to induce the self-propagating synthesis reaction of SHS powder to generate TiB2+TiC hard particle reinforced phase, and to produce particle-reinforced steel matrix surface wear-resistant extra hard casting.

Owner:JIANGSU LANRI ULTRA HARD MATERIAL

Production method of titanium-aluminum alloy target

ActiveCN103205721AHigh densityUniform grain size distributionVacuum evaporation coatingSputtering coatingAl powderSelf-propagating high-temperature synthesis

The invention relates to a production method of a titanium-aluminum alloy target. The method includes the steps of firstly, adding titanium powder and aluminum powder into a V-shaped mixer for mixing; secondly, placing the powder in an isostatic cool pressing capsule, vacuumizing in prior to sealing, pressing for 10-20 minutes, and placing in a vacuum self-propagating high-temperature synthesis furnace for self-propagating reaction to obtain foamed titanium-aluminum alloy; thirdly, crushing the alloy into 200-mesh powder, placing in an isostatic cool pressing capsule, and pressing to obtain titanium-aluminum alloy billets; fourthly, placing the alloy billets in a steel capsule, and vacuum degassing in prior to hot isostatic pressing sintering to obtain titanium-aluminum alloy ingots; and fifthly machining to obtain the finished titanium-aluminum alloy target. Due to the fact that the method adopts the second step for alloying after well mixing of raw materials and before hot isostatic pressing sintering and conditions of each step are strictly controlled, the prepared titanium-aluminum alloy target is high in density and even in crystallite size distribution.

Owner:泰安晶品新材料科技有限公司

Method and apparatus for a projectile incorporating a metastable interstitial composite material

InactiveUS7770521B2Quick effectHigh-temperature reactionAmmunition projectilesProjectilesSelf-propagating high-temperature synthesisThermal impact

A method and apparatus for incorporating nanophase elemental materials and metastable interstitial composite materials into projectiles, projectile fragments, ordnance casings, warheads and structural components. The projectile, fragments and casings include an elemental material capable of oxidizing. A coating material that is capable of preventing oxidation of the elemental material and an oxidizing agent may be present and be capable of reacting with the elemental material so that a self-propagating high temperature synthesis reaction from a stabilized solid material is yielded for the purpose of rendering terminal effects or thermal impact to a target at impact.

Owner:NEWTEC SERVICES GROUP

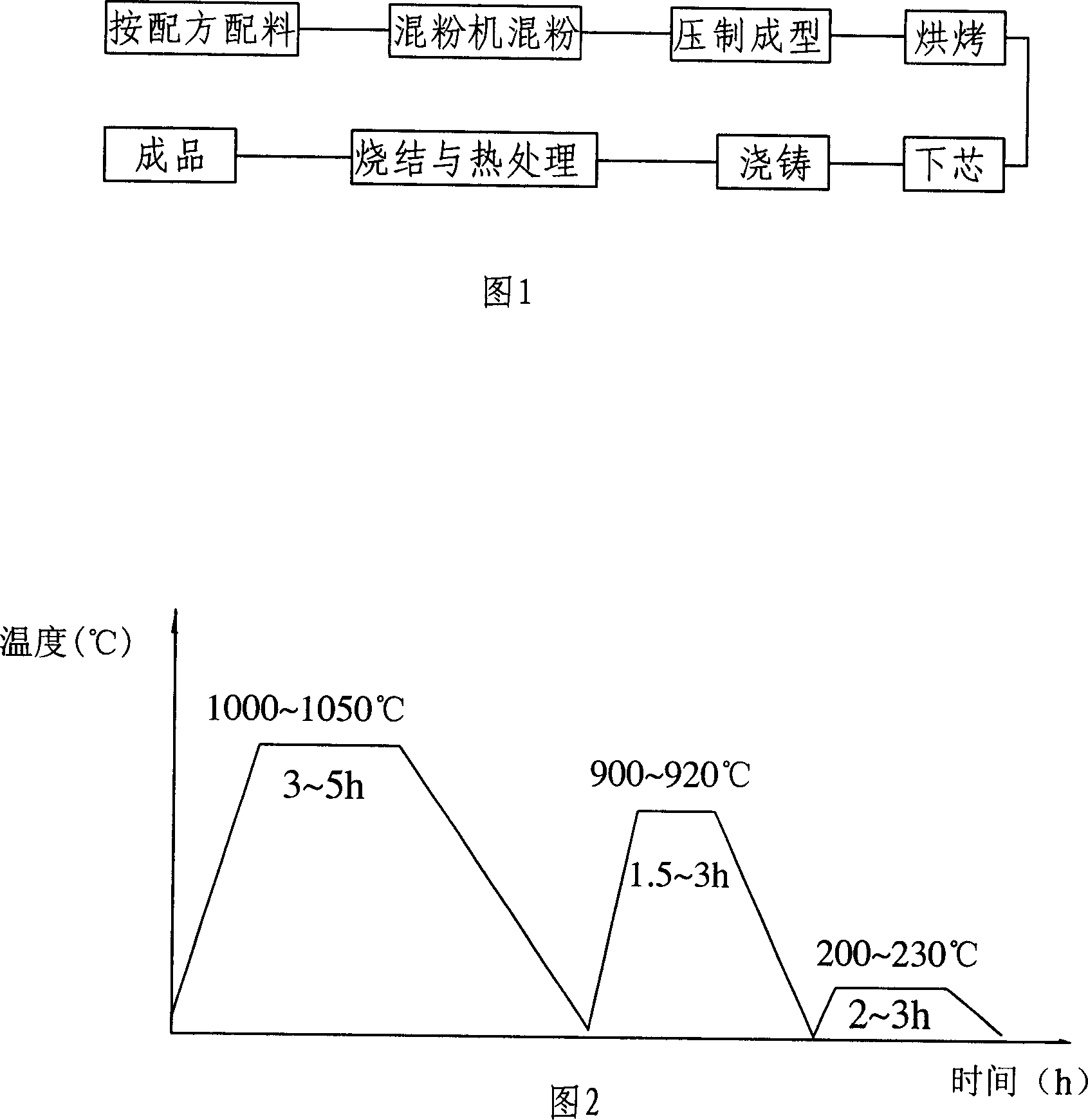

Method for manufacturing diamond grinding block with self-spreading high-temperature synthesis

InactiveCN101342686AExtended service lifeHigh bonding strengthAbrasion apparatusGrinding devicesSelf-propagating high-temperature synthesisBrick

The present invention provides a method for preparing for a diamond abrasive brick with self-propagating high temperature synthesis. The method uses the reaction of titanium and cobalt or titanium and nickel to synthesize an intermetallic compound; heat energy released from TiCo or TiNi intermetallic compound is used for keeping the reaction processing fast to prepare for the diamond abrasive brick with excellent performance. The method comprises a plurality of steps, such as mixing, pressing and shaping, heating and heat preserving, igniting, assembling, and the like, and the method has the advantages that the surface of diamond is reacted with matrix component Ti to generate carbide with high bonding strength during the self-propagating process; the matrix compound is TiCo intermetallic compound and has high intensity, wearing resistance and tarnish resistance; the abrasive brick has long service life; depended on the self-propagating reaction, the method has low energy consumption, short synthesizing time and high production efficiency.

Owner:KING STRONG MATERIAL ENG LTD

Method for preparing three-component composite steel pipe

InactiveCN1404945ACorrosion preventionPipe protection against corrosion/incrustationSelf-propagating high-temperature synthesisPolymer resin

The present invention relates to a new-type three-component composite steel pipe and its production method, which comprises three layers of material of metal, ceramics and macromolecular polymer resin. Its external layer metal is used as load-bearing structure component, its middle layer ceramic material is used as wear-resistant component and the macromolecular polymer resin applied on inner wall is a material with a certain anti-corrosive scale-inhibiting function. When it is prepared, the ceramic material is added into the steel pipe, and formed into a ceramic layer by utilizing self-spreading high-temp. synthesis centrifugal casting technique, then the polymer resin is added into the pipe, then the ceramic layer is impregnated with resin and solidified.

Owner:FUDAN UNIV

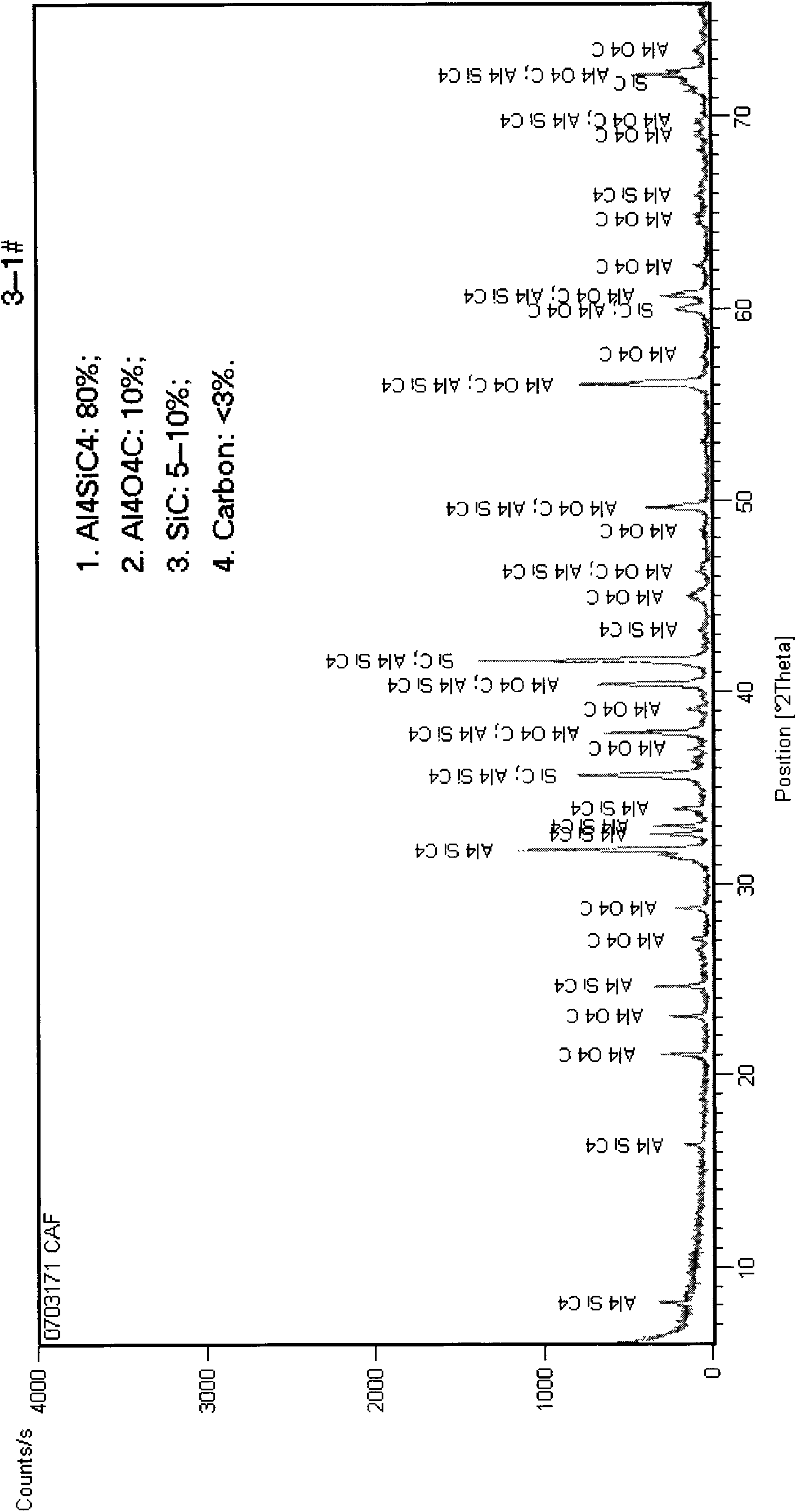

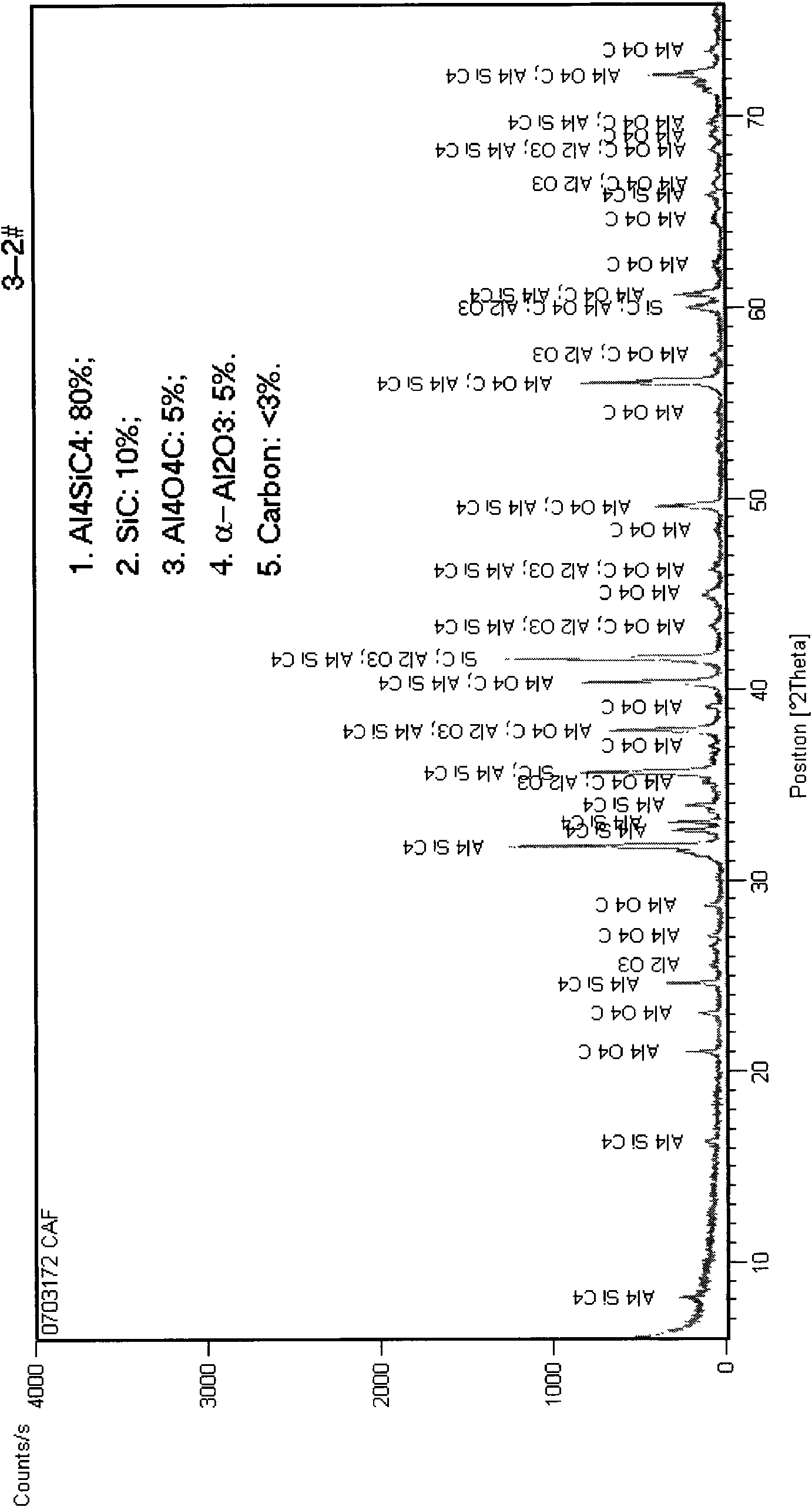

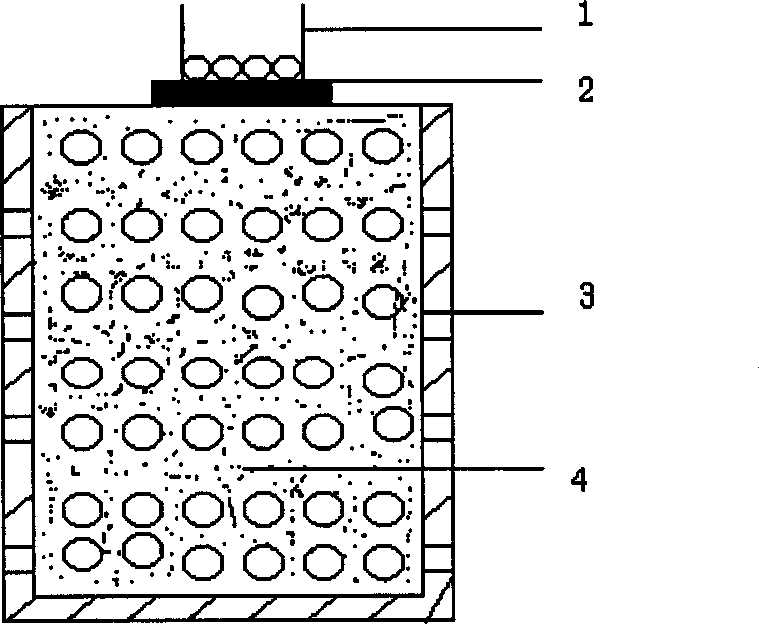

Preparation process of antioxidant composite powder

The invention belongs to the technical field of refractory materials and provides a preparation process of antioxidant composite powder. The preparation process comprises the following steps: ball-milling and blending raw materials according to a certain weight percentage; carrying out cold pressing to form precast blocks with the relative density of 30 percent to 60 percent; insulating and dryingthe precast blocks at a temperature of between 100 DEG C and 200DEG C; placing the precast blocks in the inner layer of a vessel made of carbon fiber felt, and filling an auxiliary incendiary agent in the an outer layer of the vessel, vacuumizing the vessel, leading in nitrogen gas in the vessel, and synthesizing the required powder at high temperature by self-propagation. The invention has the characteristics that the preparation process is suitable for large-scale production; the synthesized powder does not contai easily-hydrated raw materials of metallic aluminum and an intermediate product of Al3C4, thereby avoiding causing damage for later application. The synthesized Al4SiC4 crystal grains are fine with the average grain diameter of less than 20 microns, have uniform structures andhigh purity, and are in hexagon shapes. The generated intermediate products SiC in the powder and new-phase Al4SiC4 and Al4O4C are compounded and added in a functional refractory material, thereby theantioxidant composite powder has better oxidation resistance, hydrability resistance and high-temperature service performance.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Self-spread high-temp synthesis process for preparing beta-silicon nitride whisker

InactiveCN1334362AReduce energy consumptionNo pollution in the processPolycrystalline material growthSingle crystal growth detailsSelf-propagating high-temperature synthesisRare earth

A process for preparing beta-Si3N4 whisker by high-temp self-spread synthesis includes mixing Si powder with alpha-Si3N4 powder in a ratio of (5-9):(1-5), adding whisker growing aid, loading in porous graphite crucible with inner surface coated with boron nitride, igniting the raw materials, and reaction in nitrogen atmosphere under 3-10 MPa for 2-10 min. Its advantages are 7-10 of length / diameter ratio, complete structure and smooth surface of crystal, no environmental pollution, and high yield (near 100%).

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Preparation method of CuInxGa1-xSe2 powder

InactiveCN101531529AShort preparation timeQuick responseFinal product manufactureSemiconductor devicesSelf-propagating high-temperature synthesisArgon atmosphere

The invention relates to a preparation method of CuInxGa1-xSe2 powder which is material of absorption layer material of film solar battery, characterized in that the method comprises the following steps: step 1) of selecting raw materials: weighing Cu powder, In powder, Ga powder and Se powder according to molar ratio of 1:0.7:0.3:(2.1-2.5); step 2) of mixing; step 3) of molding to shape so as to obtain a mixture billet; step 4) of synthesizing: adopting self-propagating high-temperature synthesis, switching on power of igniting tungsten filament under condition of argon atmosphere at 0.1-0.6MPa, igniting the mixture billet to carry out self-propagating high-temperature synthesizing reaction at synthesizing reaction speed of 2-3mm / s; after the reaction, cooling in the furnace, ball milling to obtain the CuInxGa1-xSe2 powder. The preparation method has the features of short preparation time, stable stoichiometric proportion, controllable stoichiometric proportion of product, simple process, high production efficiency and low cost.

Owner:WUHAN UNIV OF TECH

Method for preparing (TiB2+TiC) dispersion-strengthening copper-based composites by adopting self-propagating high-temperature synthesis

InactiveCN101775514AShort process routeReduce manufacturing costSelf-propagating high-temperature synthesisMass ratio

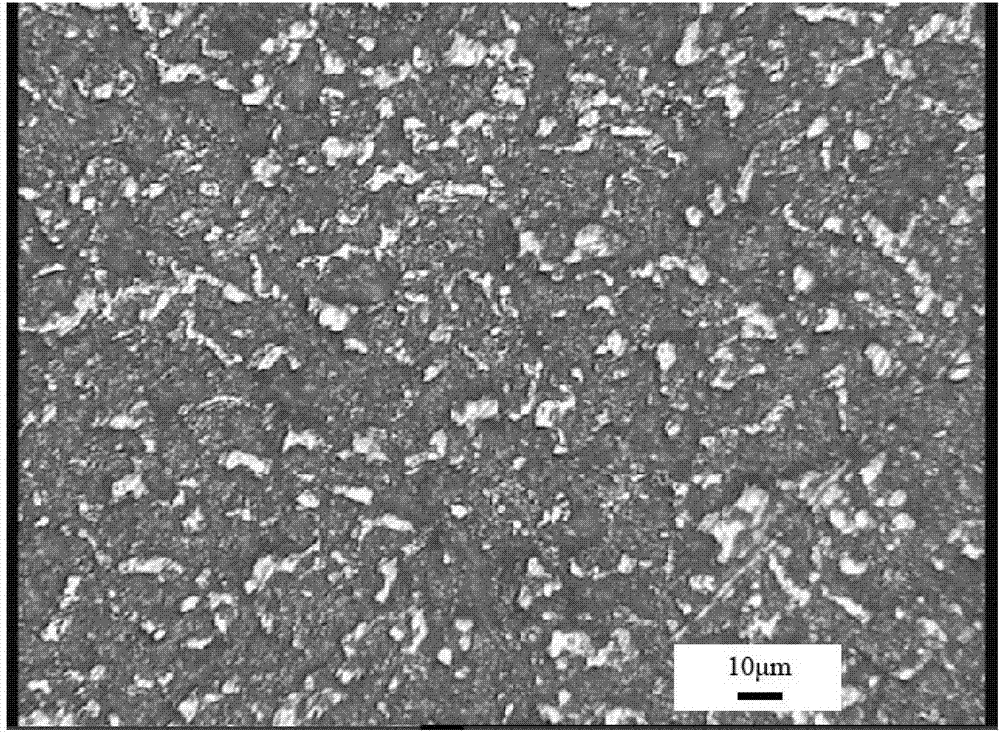

The invention discloses a method for preparing (TiB2+TiC) dispersion-strengthening copper-based composites by adopting self-propagating high-temperature synthesis, comprising the following steps of: mixing a certain amount of Cu power, Ti powder and B4C powder as raw materials (the mass ratio of the Cu powder to the Ti powder to the B4C powder is 50:50-60:40, wherein the molar ratio of the Ti powder to the B4C powder is 3:1) and then efficiently ball-milling mixed powder at high temperature, wherein the granularities of the Cu power, the Ti powder and the B4C powder are less than 100 meshes, and the purities are greater than 99%; then cold molding the mixed powder; and finally preparing the (TiB2+TiC) dispersion-strengthening copper-based composites in a vacuum furnace chamber by adopting electric arc igniting compact through the self-propagating high-temperature synthesis of the compact, wherein the average grain diameter of TiB2 and TiC grains is 2-8 mu m. The invention is used for preparing the TiB2 dispersion-strengthening copper-based composites through adopting the in-situ reactive synthesis of a simple self-propagating high-temperature synthesis method and has the advantages of simple process, low production cost, high product yield and quality and the like.

Owner:KUNMING UNIV OF SCI & TECH

Self-spreading pre-heating powder aqueous medium bidirectional blasting and concreting device

InactiveCN101138788AReduce strong reflectionsImproving the quality of explosive consolidationShock waveSelf-propagating high-temperature synthesis

A two-way explosion concrete device of self-spread preheat powder aqueous medium is used for manufacturing a high-density hard concrete metal or ceramic compound materials and functionally gradient materials of the ceramic compound materials, which consists of a plane wave generator, a high grade energy main charge, a pressure work steel tube, a waterseal unit, a wave impedance match unit, an outer protection tub or a protective unit, a self-spread dust electrical heating unit and a protective unit of sample. The present invention is designed to provide the two-way explosion concrete device of self-spread preheat powder aqueous medium that can produce a high-energy explosive detonated by plane detonation wave produced by two plane wave generators with symmetry layout and two-way explosion by making use of aqueous medium to transfer a plane explosive shock wave and self-spread high temperature synthetic reaction preheat powder.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

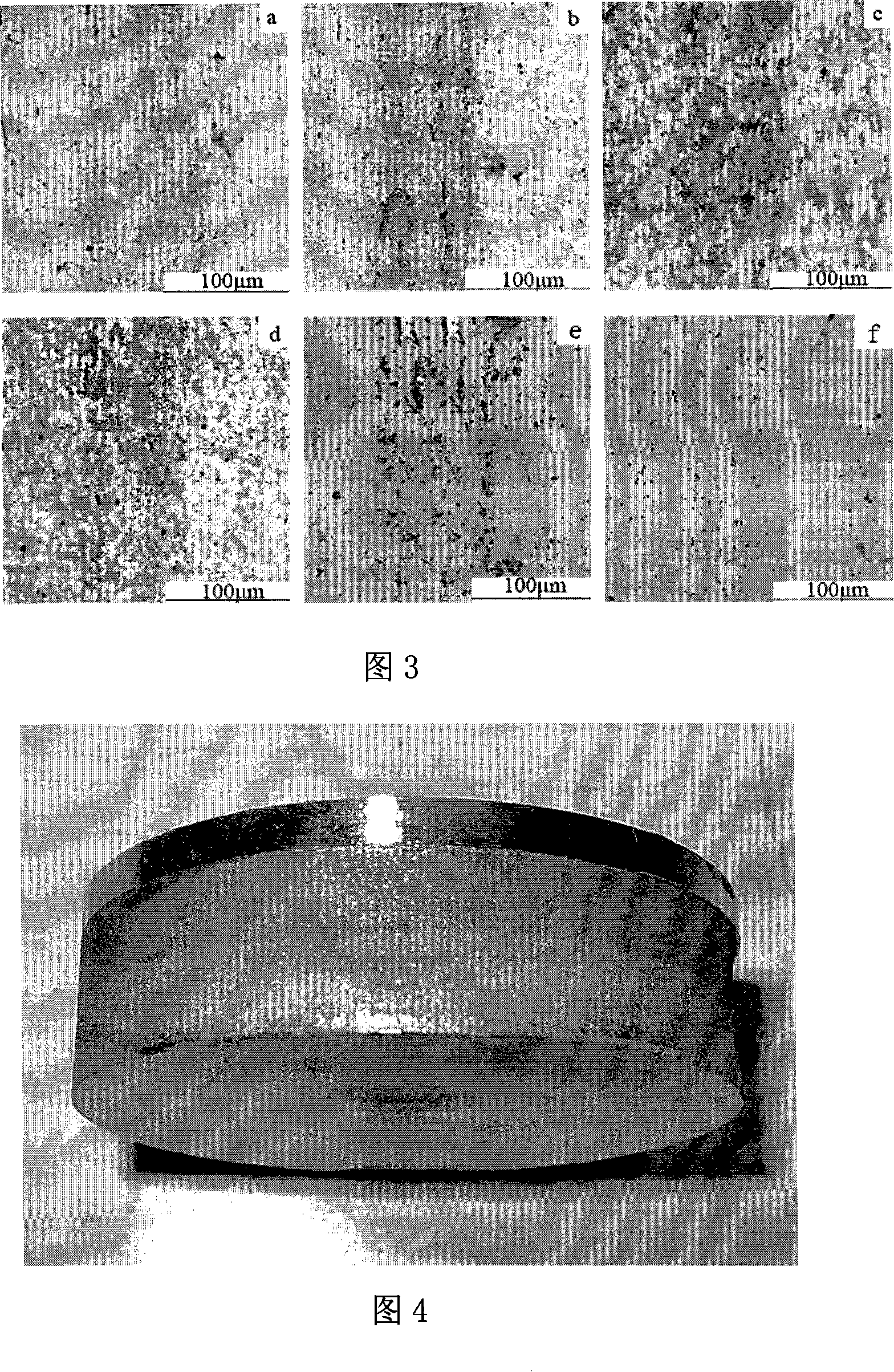

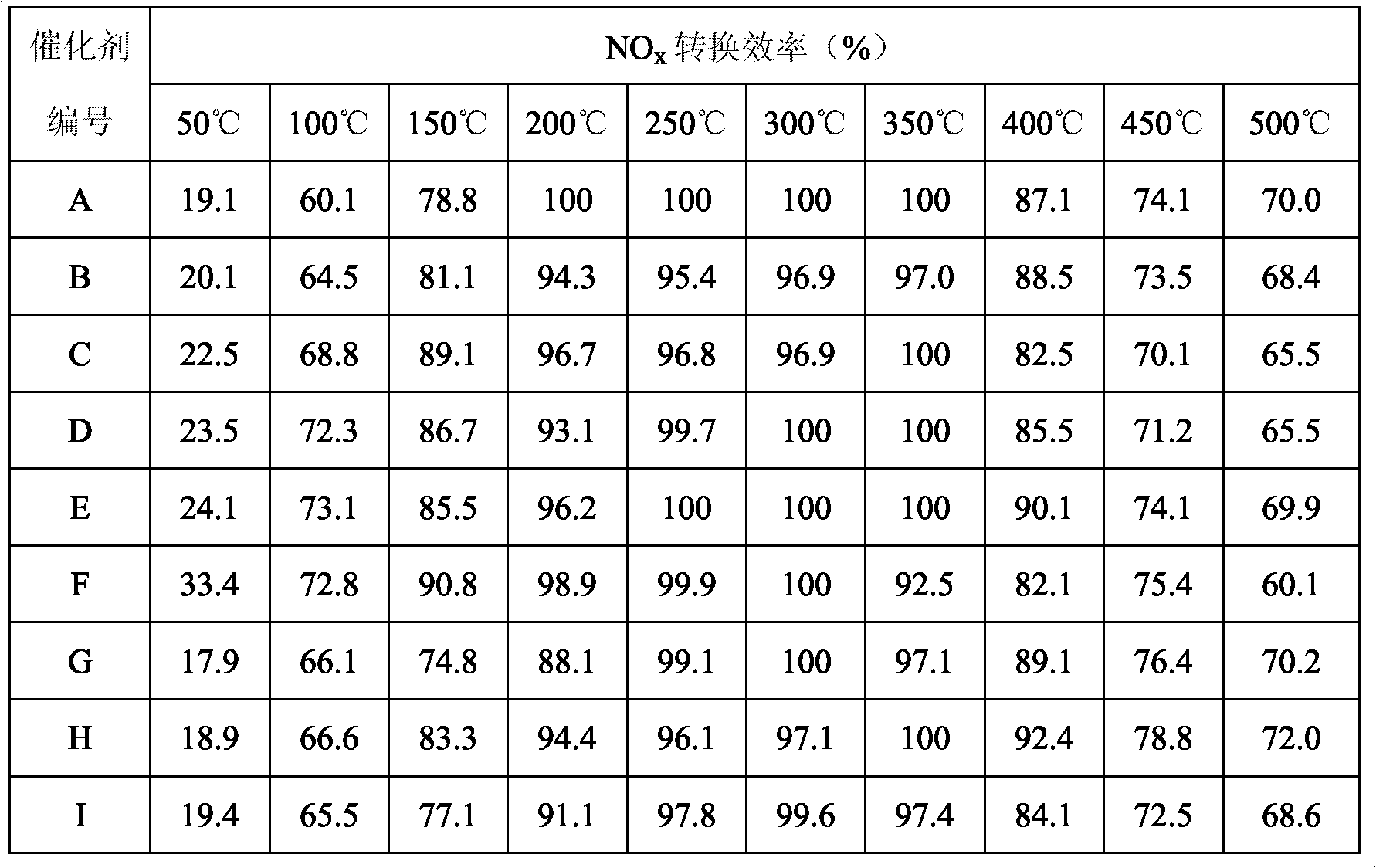

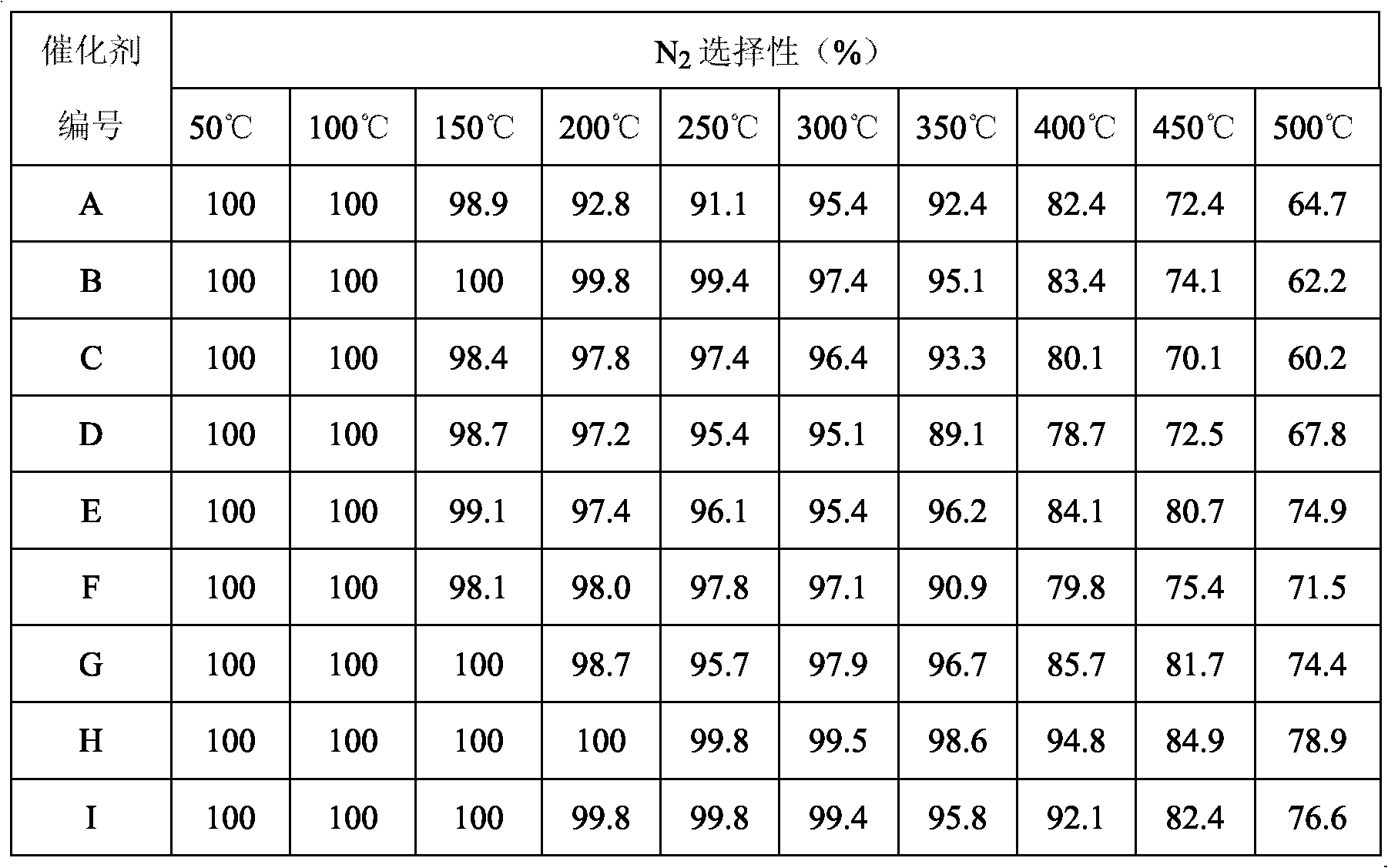

Titanium-based nano-composite metal oxide catalyst and preparation method thereof

InactiveCN102125834ASimple preparation processShort cycleDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsSelf-propagating high-temperature synthesisDiesel engine

The invention discloses a titanium-based nano-composite metal oxide catalyst and a preparation method thereof, belonging to the technical field of control on exhaust contaminants in diesel engine tail gas. In the invention, the titanium-based nano-composite metal oxide catalyst is prepared by taking TiO2 as a carrier and taking metal oxides (VOx, MnOx and CeOx) as active components by adopting a self-propagating high-temperature synthesis (SHS) method, wherein the molar percentage of the TiO2 is 80-95%, the molar percentage of the VOx is 2-20%, the molar percentage of the MnOx is 2-10%, and the molar percentage of the CeOx is 2-10%. The preparation method of the titanium-based nano-composite metal oxide catalyst comprises the following steps of: preparing a TiO(NO3)2 precursor solution; determining the loads of the active components of the metal oxides; preparing a precursor solution of the active components of the metal oxides; and preparing the catalyst by SHS. The catalyst prepared by the method disclosed by the invention has the advantages of large specific surface area, large pore volume, proper pore size distribution and low degree of crystallization, all active species are highly dispersed and are interactive, the catalyst has higher NOx removing rate and N2 selectivity in a wide temperature window at 100-450 DEG C, and the catalyst has strong anti-sulfur and anti-water poisoning performance and is suitable for treating NOx in diesel engine tail gas of automobiles and ships.

Owner:SHANGHAI JIAO TONG UNIV

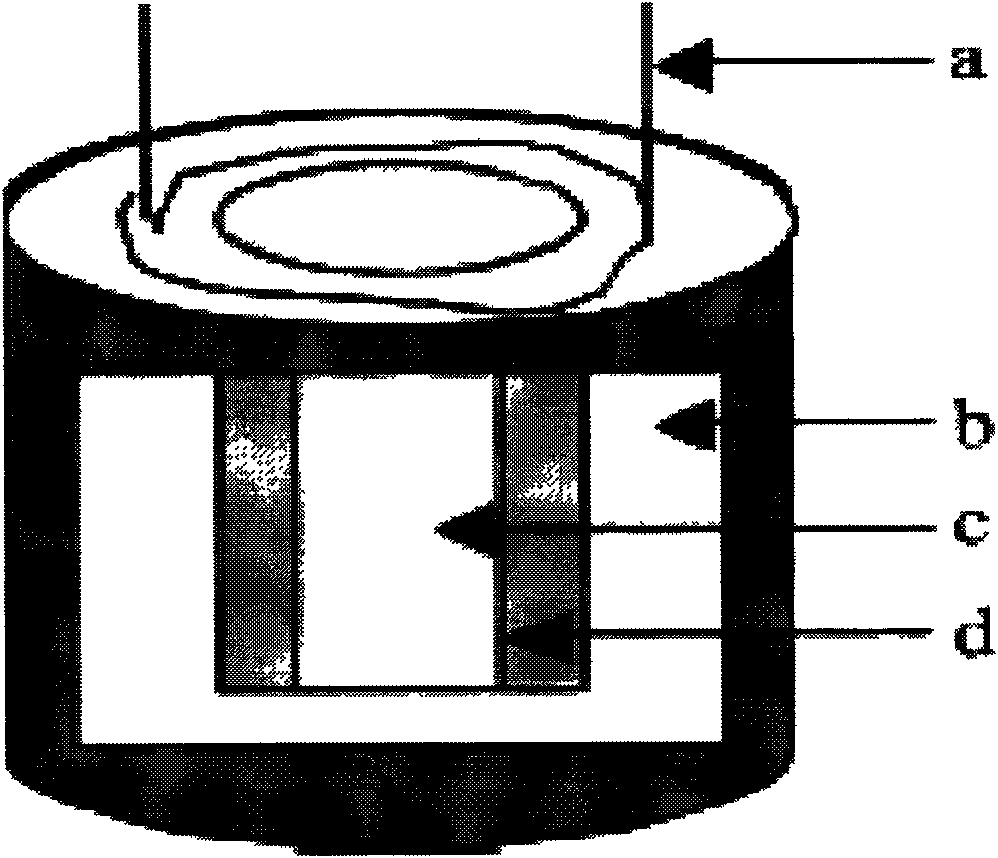

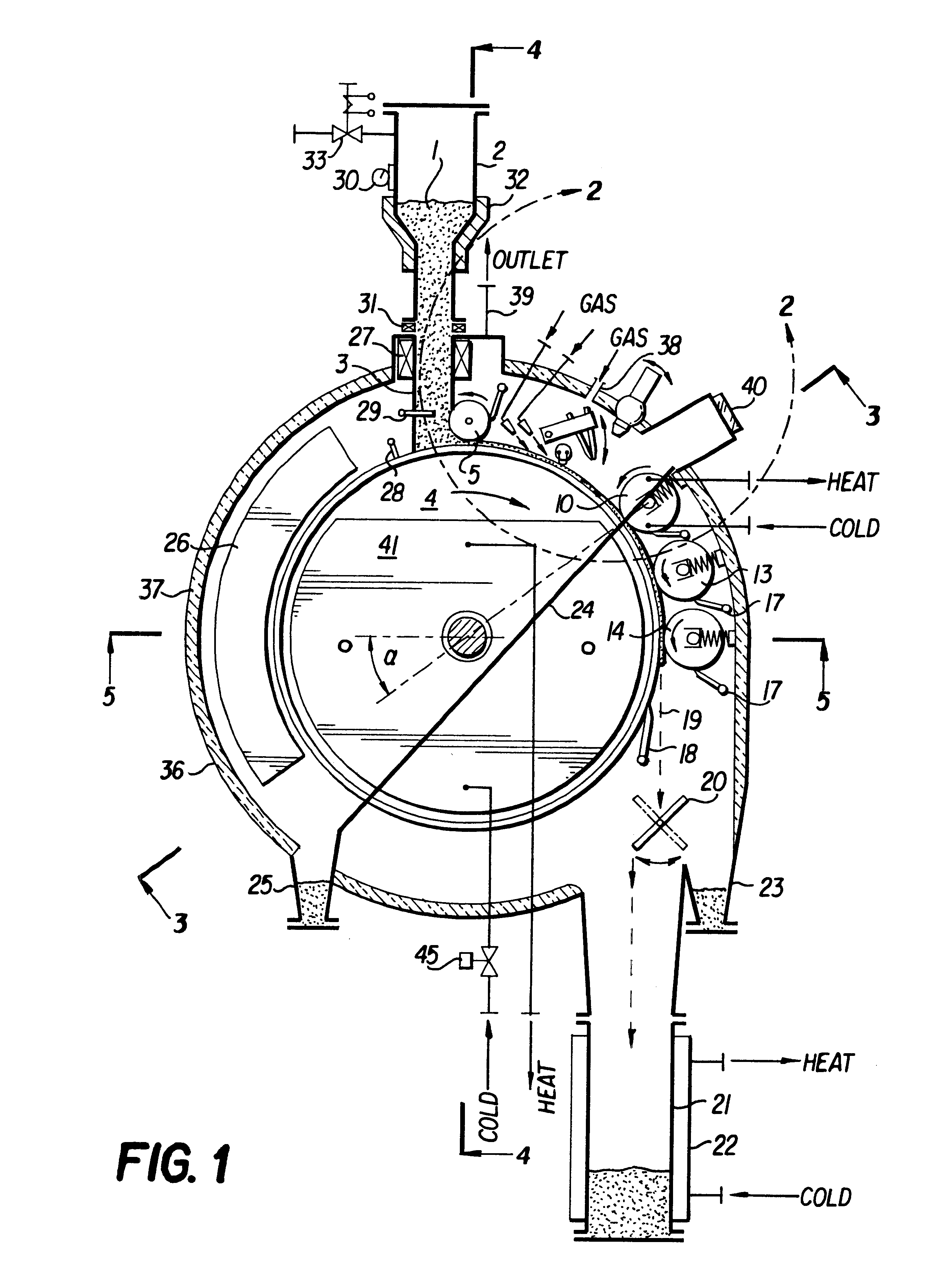

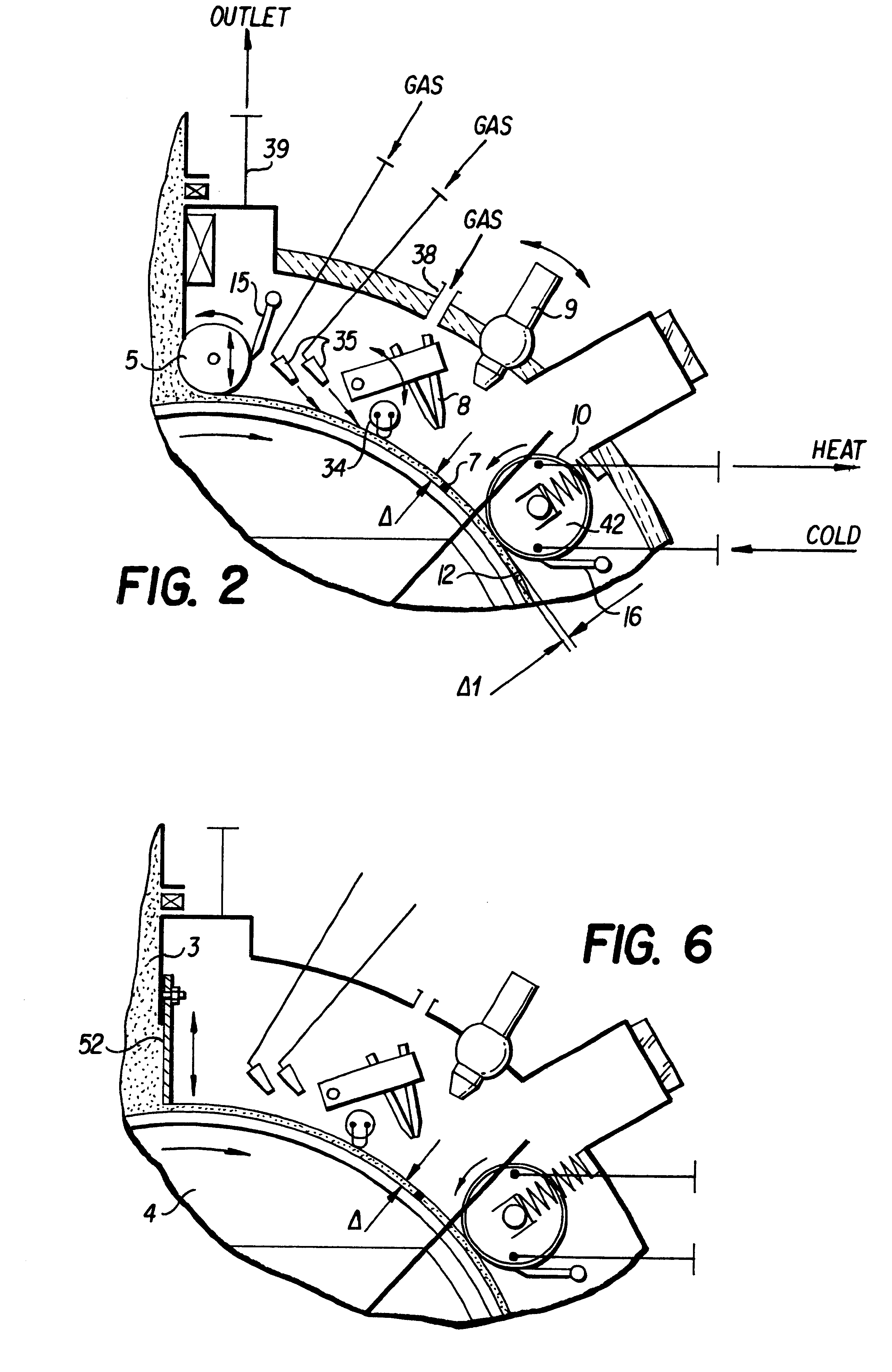

Apparatus for self-propagating high temperature synthesis

InactiveUS6436356B1Carry-out safelyAvoid expansionOxygen/ozone/oxide/hydroxideNitrogen compoundsSelf-propagating high-temperature synthesisInorganic compound

The present invention relates to an apparatus for self-propagating high temperature synthesis of an inorganic compound from a combustible charge mixture of initial ingredients. The apparatus comprises mechanisms for continuously feeding the combustible charge into a reaction chamber and removing the synthesized compound therefrom. The apparatus also contains sensors to control and contain the combustion inside a combustion zone of the reaction chamber.

Owner:COMSYNTECH

Preparation method of TiB2 nanometer micrometer structure feeding for hot spraying

InactiveCN1927511AMeet physical performance requirementsUniform particle size distributionCoatingsSelf-propagating high-temperature synthesisMetallurgy

The invention relates to a method for preparing TiB2 nanometer-micrometer feeding material used in thermal plating. Wherein, it mixes TiB2 powder whose diameter granularity is lower than 5 mum with other nanometer particles whose granularity is lower than 0.2 mum; uses wet ball grinding method and ultrasonic wave treatment to obtain nanometer-micrometer suspension; then atomizes and dries said suspension to obtain the group powder of TiB2 nanometer-micrometer structure; then thermally vacuuming the group powder to obtain said TiB2 nanometer-micrometer feeding. The inventive feeding has ball shape, uniform granularity, and flowability at 60-102s / 50g.

Owner:BEIJING UNIV OF TECH

Method for synthesizing in-situ formed ceramic particle reinforced iron-aluminum-based composites by laser combustion

InactiveCN101906572AIncrease profitImprove performanceSelf-propagating high-temperature synthesisIron powder

The invention discloses a method for synthesizing in-situ formed ceramic particle reinforced iron-aluminum-based composites by laser combustion, belonging to the technical field of materials. The in-situ formed ceramic particle reinforced iron-aluminum-based composites are prepared by the following steps of: putting tungsten ore powder, iron powder, aluminum powder and carbon powder in a ball mill for milling to obtain a mixed powder material; and compressing the mixed powder material into a pressed compact, transmitting a high-energy laser beam by employing a CO2 laser processing machine to ignite the surface of the pressed compact and trigger self-propagating high temperature synthesis of the pressed compact. By the invention, two ceramic particle reinforced phases are simultaneously formed on one substrate, which shortens the preparation process of the composites, lowers material manufacture cost and facilitates large-scale production and application.

Owner:LIAONING TECHNICAL UNIVERSITY

Self-propagating high temperature synthesis preparation method of titanium carbide dispersion strengthening copper-based composite material

InactiveCN101709398AIncrease productionQuality improvementSelf-propagating high-temperature synthesisHigh energy

The invention discloses a self-propagating high temperature synthesis preparation method of a titanium carbide dispersion strengthening copper-based composite material, which utilizes Cu powder, Ti powder and C powder with the granularity less than 100 meshes and the purity larger than 99% as raw materials, wherein the mass ratio of Cu powder to Ti powder to C powder is 50:50-70:30, and the mol ratio of Ti powder to C powder is 1:1. The preparation method comprises the following steps: mixing a certain amount of Cu powder, Ti powder and C powder, then carrying out high energy ball mill for 3-10 hours at room temperature, carrying out cold press molding on the mixed powder, finally adopting electric arc to ignite pressed shapes in a vacuum room to prepare the TiC dispersion strengthening copper-based composite material through the self-propagating high temperature synthesis of the pressed shapes, wherein, the average granularity of TiC granules is 2-8 mu m. The simple self-propagating high temperature synthesis method is adopted to lead the Cu powder, Ti powder and C powder to react in situ and synthesize, so as to prepare the TiC dispersion strengthening copper-based composite material, and has the advantages of simple process, low production cost, high product output, high quality and the like.

Owner:KUNMING UNIV OF SCI & TECH

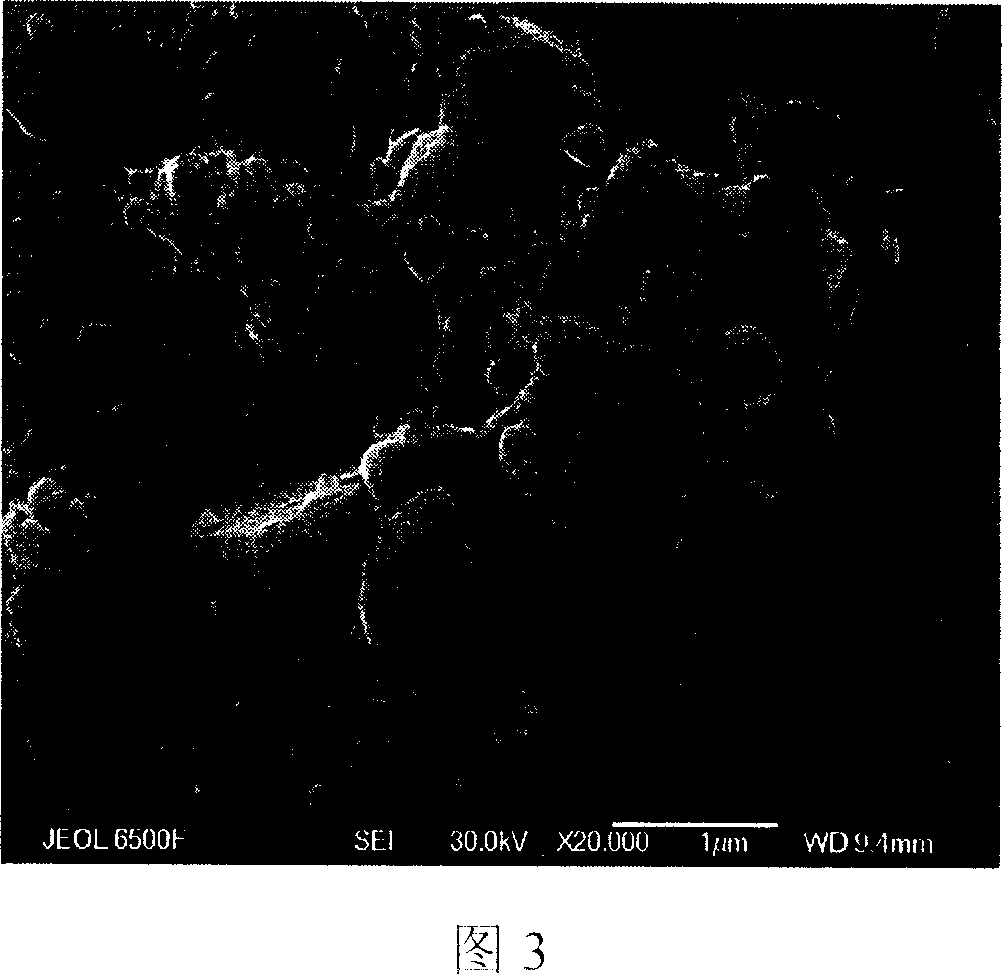

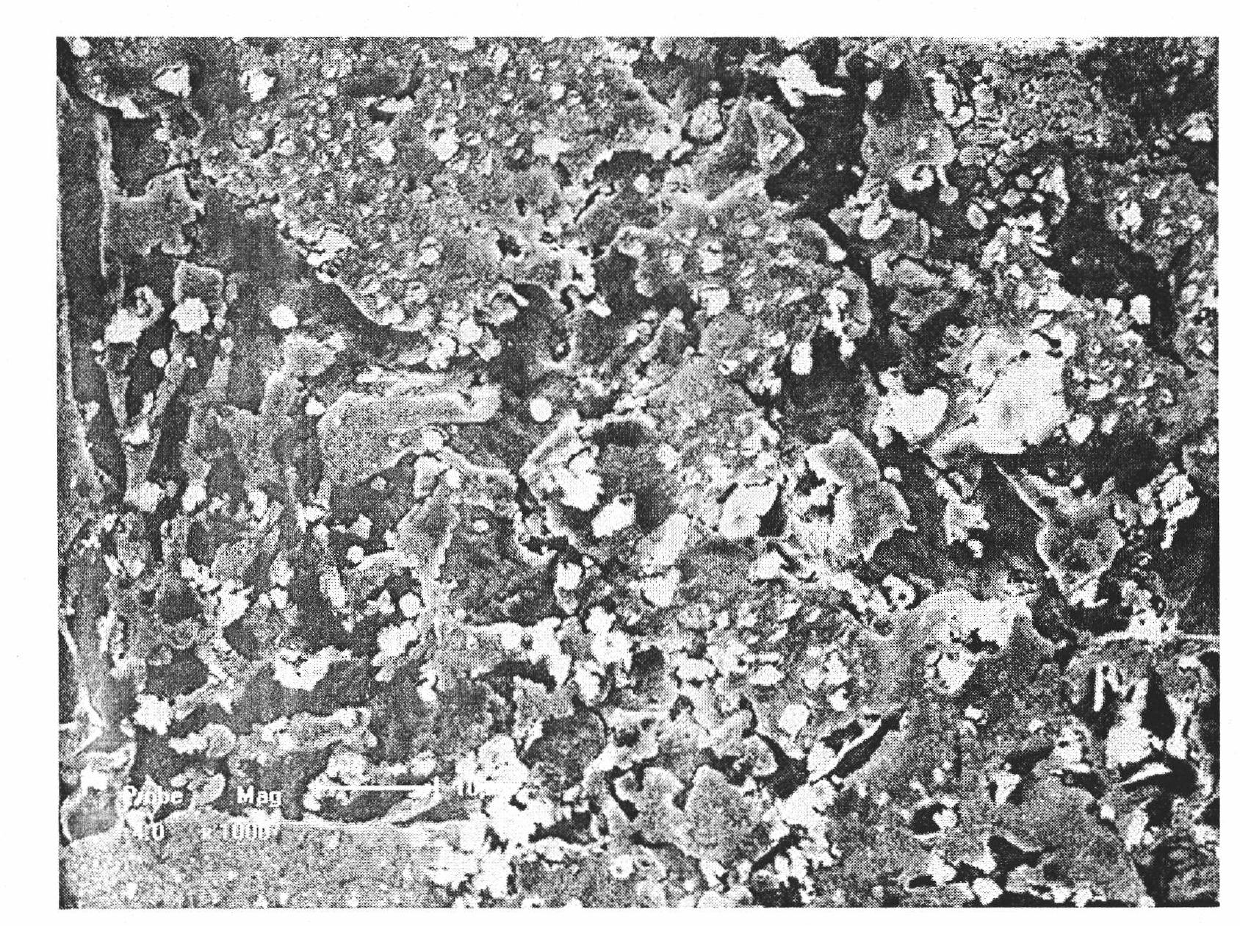

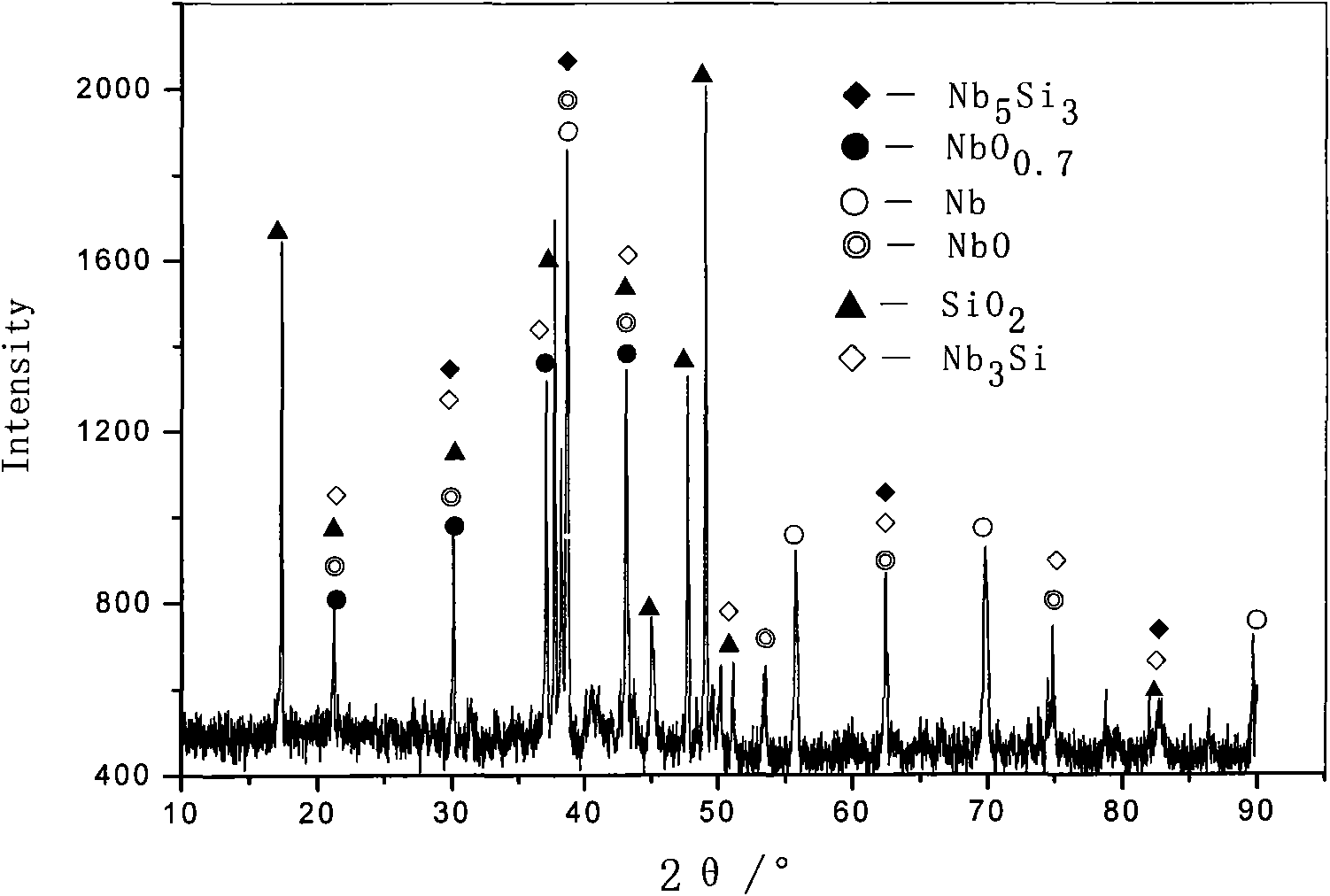

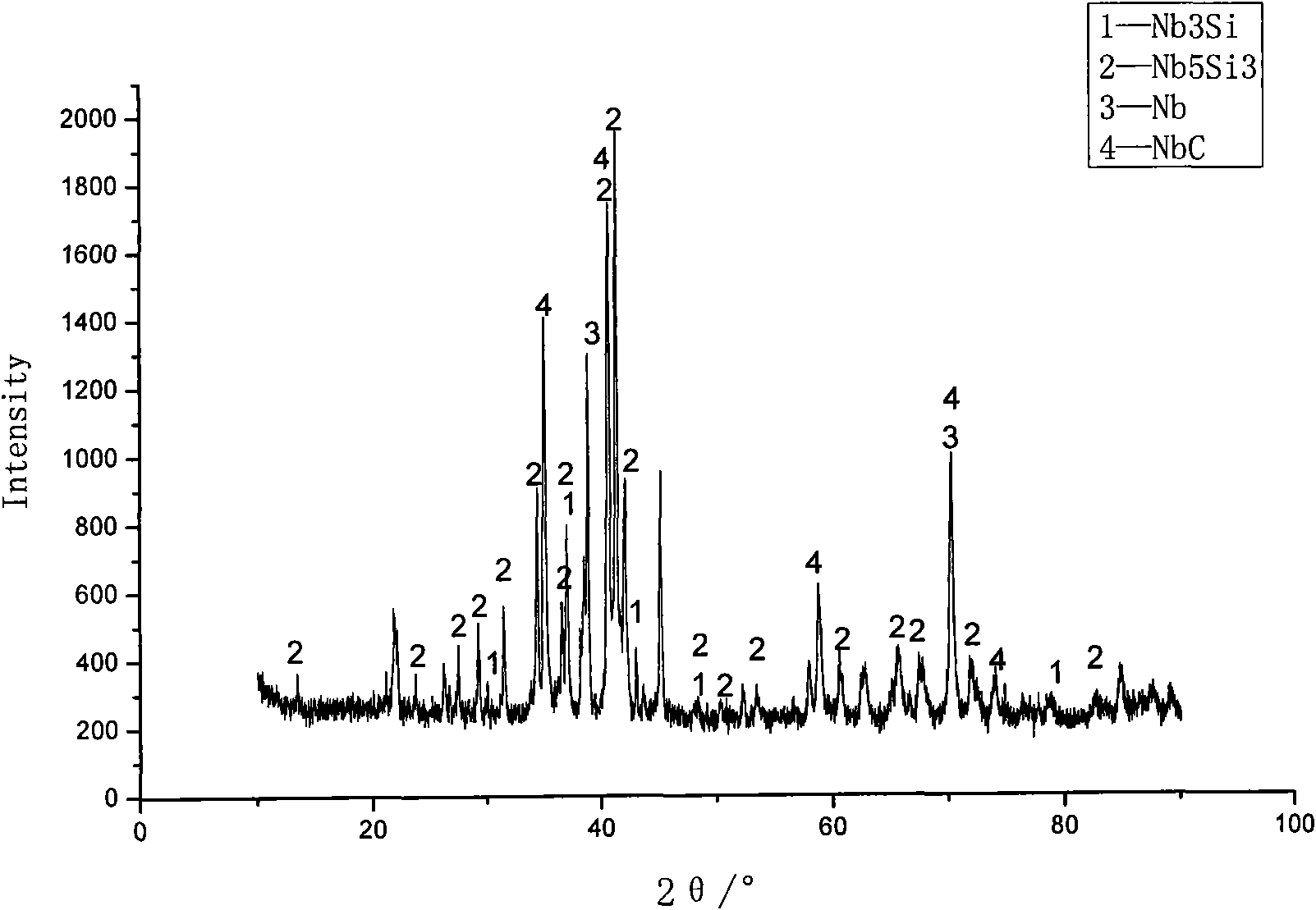

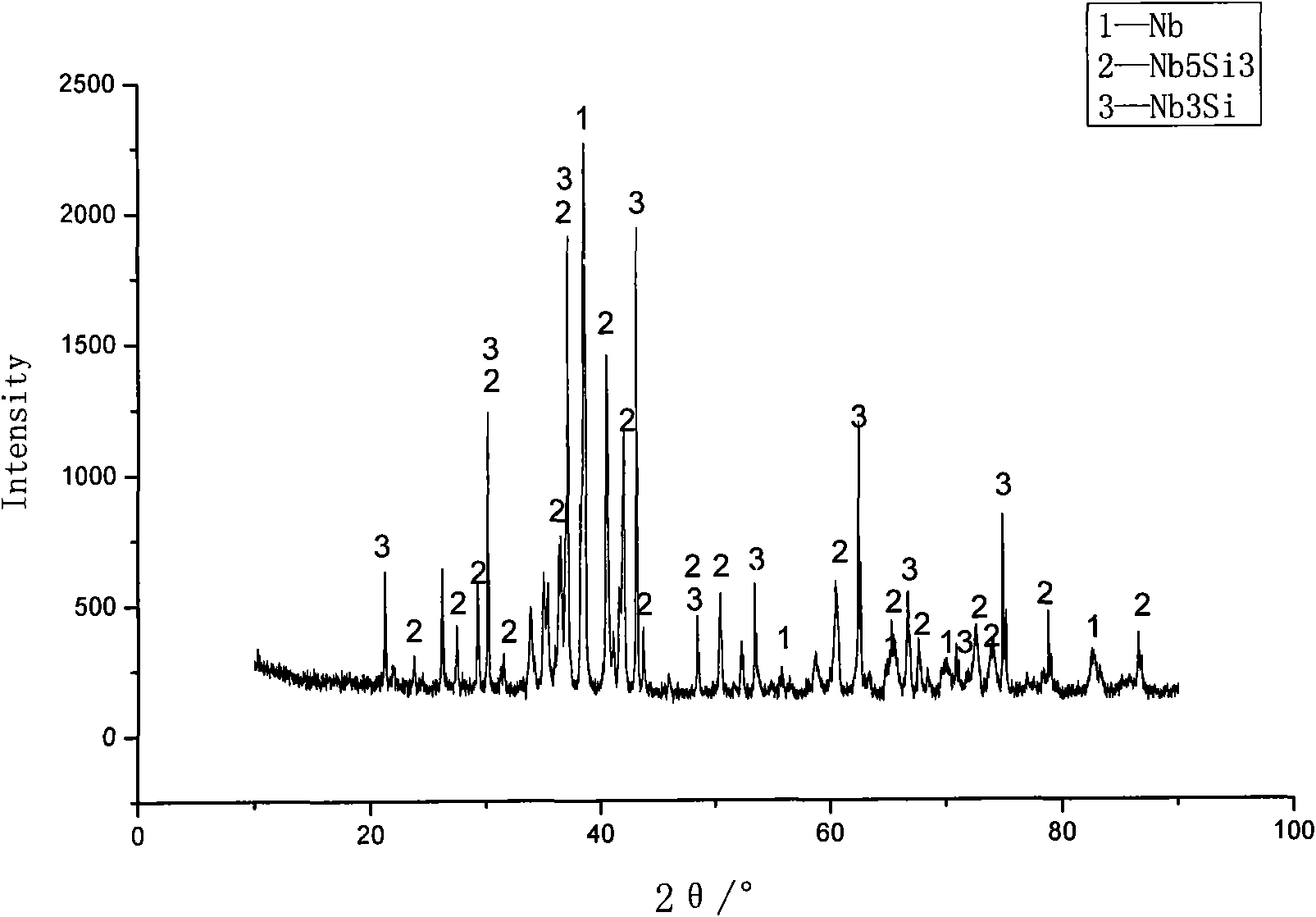

Method for synthesizing Nb/Nb5Si3 composite materials at high temperature through microwave induced self propagating

InactiveCN101786165AAvoid oxidation reactionsHigh puritySelf-propagating high-temperature synthesisNiobium

The invention provides a method for synthesizing Nb / Nb5Si3 composite materials at a high temperature through microwave induced self propagating, which consists of an ingredient recipe and a synthesis technology, wherein the ingredient recipe comprises pure niobium powder and pure silicon powder according to a mixing ratio of Nb-(5-37.5 at.%)Si, and the synthesis technology comprises the following steps: (1), firstly, proportionally and uniformly mixing all ingredient powder in the ingredient recipe to obtain composite powder; (2) grinding the composite powder into fine powder with the granularity of 800 meshes; (3) forming the ground composite powder at the pressure between 100 and 300 MPa; and (4) placing the formed materials into a microwave cavity for self propagating sintering by the microwaves under the protection of argon gas, and flowing argon gas is inflated into the microwave cavity during the self propagating sintering after vacuum pumping. The invention fully utilizes the advantages of the microwave sintering technology and the self propagating high-temperature synthesis, synthesized test samples do not contain oxide, the preparation time is short, and the reaction is complete.

Owner:HUAZHONG UNIV OF SCI & TECH

Reactive material for preparing ceramic composite steel pipe by adopting self-propagating high-temperature synthesis

InactiveCN101774801AHigh densityIncreased shear strengthRigid pipesSelf-propagating high-temperature synthesisChemical industry

The invention discloses a reactive material for preparing a ceramic composite steel pipe by adopting self-propagating high-temperature synthesis, comprising aluminum powder, iron oxide powder, silicon dioxide and sodium tetraborate. The invention has the advantages that (1) a ceramic layer has high density and smooth inner surface after using the reactive material; (2) after using the reactive material, the shearing strength and the pressing strength of the composite steel pipe are improved; (3) after using the reactive material, the abrasive resistance and the corrosion resistance of the composite steel pipe are improved, and the service life of the composite steel pipe is prolonged; and (4) the composite steel pipe prepared by using the reactive material can be used in the fields of electric power, mines, metallurgy, petroleum, chemical industry and the like.

Owner:NANTONG UNIVERSITY

In-situ ceramic partially-reinforced composite material hammerhead for crusher and preparation method

ActiveCN101905185AAvoid brittle fractureGood metallurgical bonding performanceGrain treatmentsSelf-propagating high-temperature synthesisCrusher

The invention relates to an in-situ ceramic partially-reinforced composite material hammerhead for a crusher and a preparation method. An in-situ ceramic granular partially-reinforced area with the thickness of 30-100 mm is formed on the striking surface of the hammerhead by utilizing a high-temperature synthetic reaction in a negative pressure cast die cavity. A hammer body of the in-situ ceramic partially-reinforced steel-based composite material hammerhead obtained according to the preparation method of the invention is alloy steel, high-Cr cast iron or high-manganese steel, the striking surface of the hammerhead comprises a steel matrix and cylindrical ceramic reinforced units evenly distributed in the steel matrix, wherein ceramics in the cylindrical ceramic reinforced units are in-situ TiC, TiB2 / TiC or TiB2 / TiN ceramic particles formed by a self-propagating reaction, and metallurgical bonding is adopted for bonding the cylindrical ceramic reinforced units in the in-situ ceramic partially-reinforced area and the matrix steel as well as ceramic particles and the metal in each cylindrical ceramic reinforced unit. The steel-based composite material hammerhead has excellent anti-abrasion performance.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com