Patents

Literature

53results about How to "Uniform grain size distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

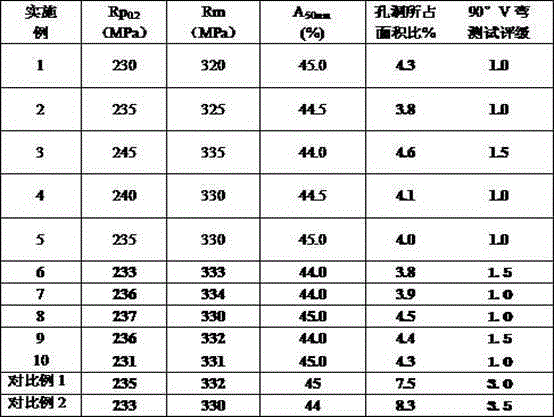

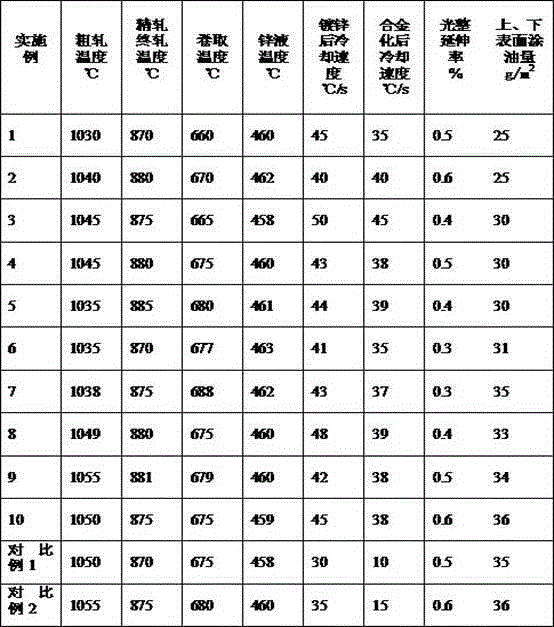

A production method of iron-zinc alloy coated steel plate with yield strength ≥ 220mpa

ActiveCN105274301BFreeze fastCompact structureHot-dipping/immersion processesZinc alloysUltimate tensile strength

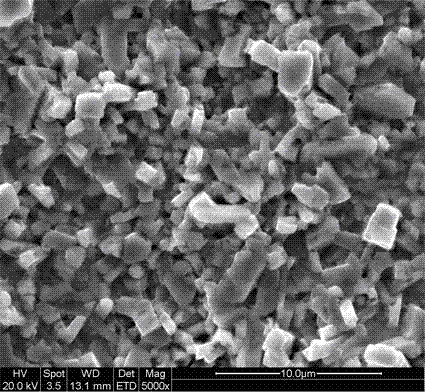

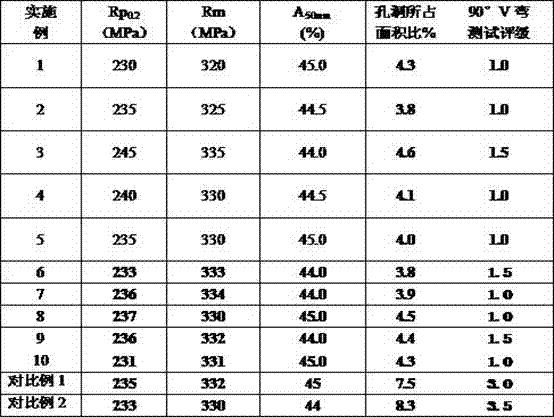

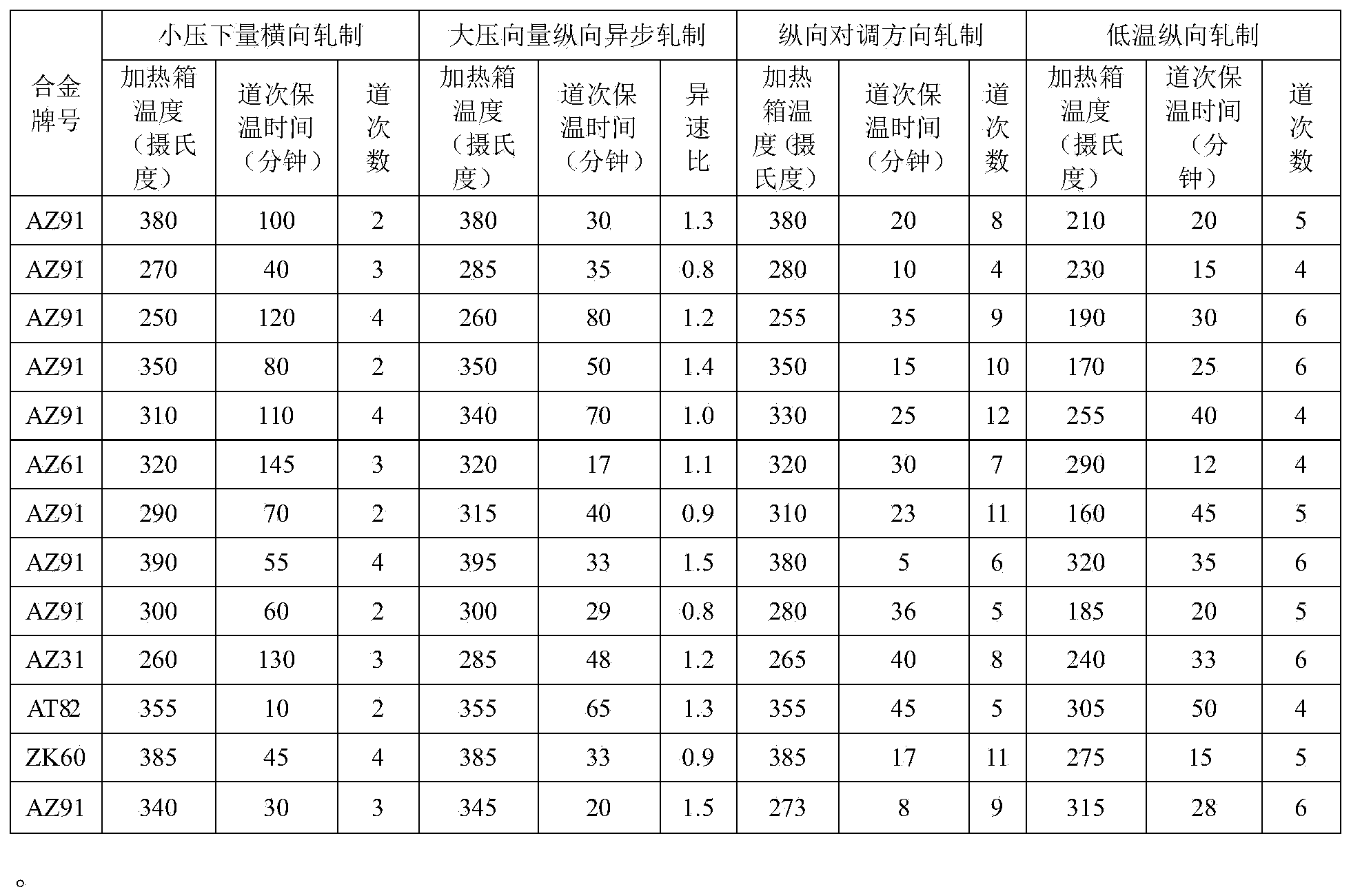

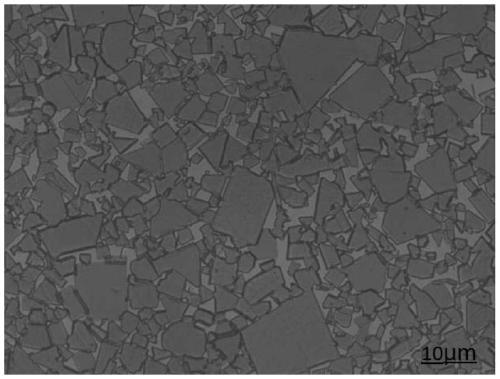

The invention discloses a method for producing an iron-zinc alloy coated steel plate with the yield strength being equal to or higher than 220 MPa. The method comprises the steps that molten iron desulphurization, smelting through a converter and continuous casting are conducted, so that a billet is formed; hot rolling is conducted; rolling is conducted; cold rolling is conducted till the billet reaches the required thickness; continuous hot galvanizing is conducted; rapid cooling is conducted; aerial fog is used for cooling after zinc and iron are alloyed; finishing is conducted; oiling treatment is conducted; and sampling, performance testing and subsequence procedure treatment are conducted. According to the method for producing the iron-zinc alloy coated steel plate with the yield strength being equal to or higher than 220 MPa, on the premise that the yield strength ranges from 220 MPa to 260 MPa, the tensile strength ranges from 300 MPa to 380 MPa, and the elongation is equal to or higher than 43%, grains on the surface of a zinc-iron alloy coating are fine and are even in size distribution, the area ratio of holes in the surface of the coating is equal to or smaller than 5%, no microcrack exists on the surface, and the phenomena of pulverization and falling of the coating are unlikely to occur during stamping forming, namely the 90-degree V bending test grade reaches the level 2.

Owner:武汉钢铁有限公司

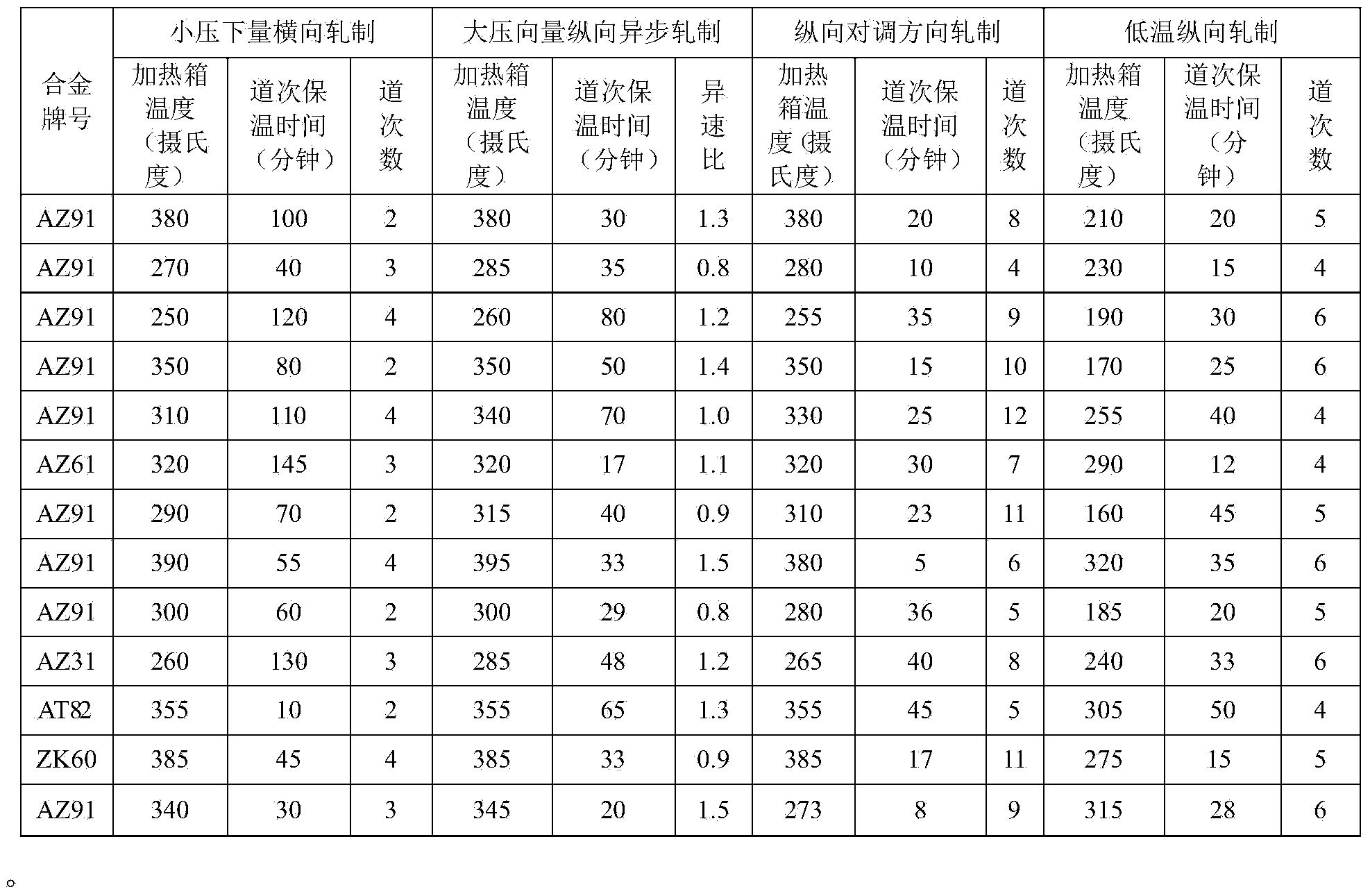

Method for preparing fine-grained magnesium alloy with superplastic deformability

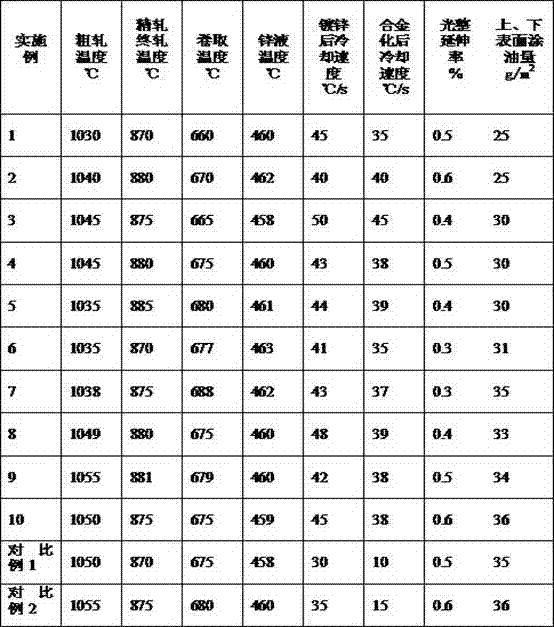

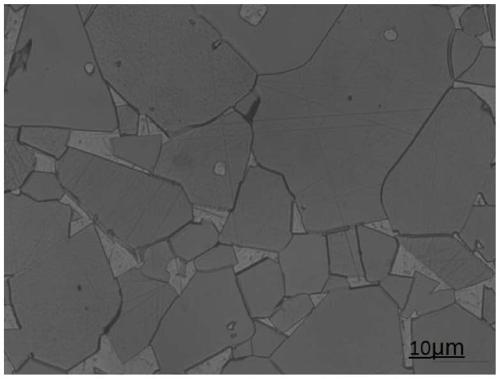

The invention relates to a method for rolling fine-grained magnesium alloy with superplastic deformability. The method comprises the steps of low-rolling-reduction transverse rolling, high-rolling-reduction longitudinal asynchronous rolling, longitudinal reversed-direction rolling, low-temperature longitudinal rolling and annealing, and comprises the specific steps of heating a commercial magnesium alloy blank in a heating box, standing to preserve heat for a period of time after heating to a preset temperature, firstly pushing the magnesium alloy blank to an entrance of a rolling roller along the transverse direction, carrying out transverse rolling firstly, then, carrying out high-rolling-reduction longitudinal asynchronous rolling, then, carrying out longitudinal 180-degree-reversed rolling, then, carrying out low-temperature longitudinal rolling, and finally, carrying out low-temperature long-time annealing treatment or high-temperature short-time annealing treatment. According to the method, cracking during the rolling of the magnesium alloy can be reduced, the crystal grain of the magnesium alloy is refined, the texture is weakened, and the high-temperature plasticity of the magnesium alloy is improved; moreover, the process is simple and easy to operate, large-sized wide-width sheet materials can be prepared, and the formability of the magnesium alloy is improved remarkably, so that the method is applicable to the mass production of superplastic magnesium alloy and is prone to popularization and application.

Owner:JILIN UNIV

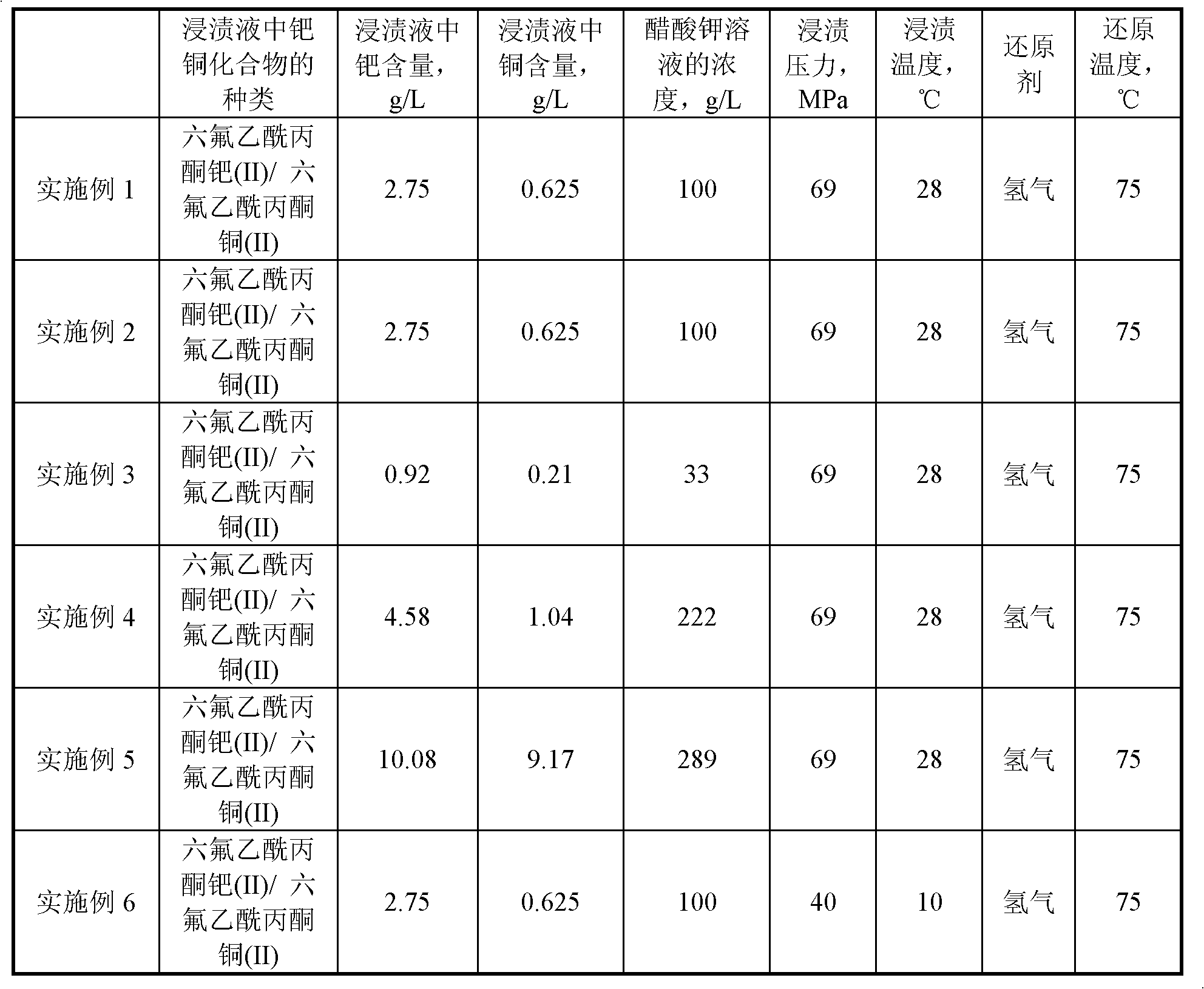

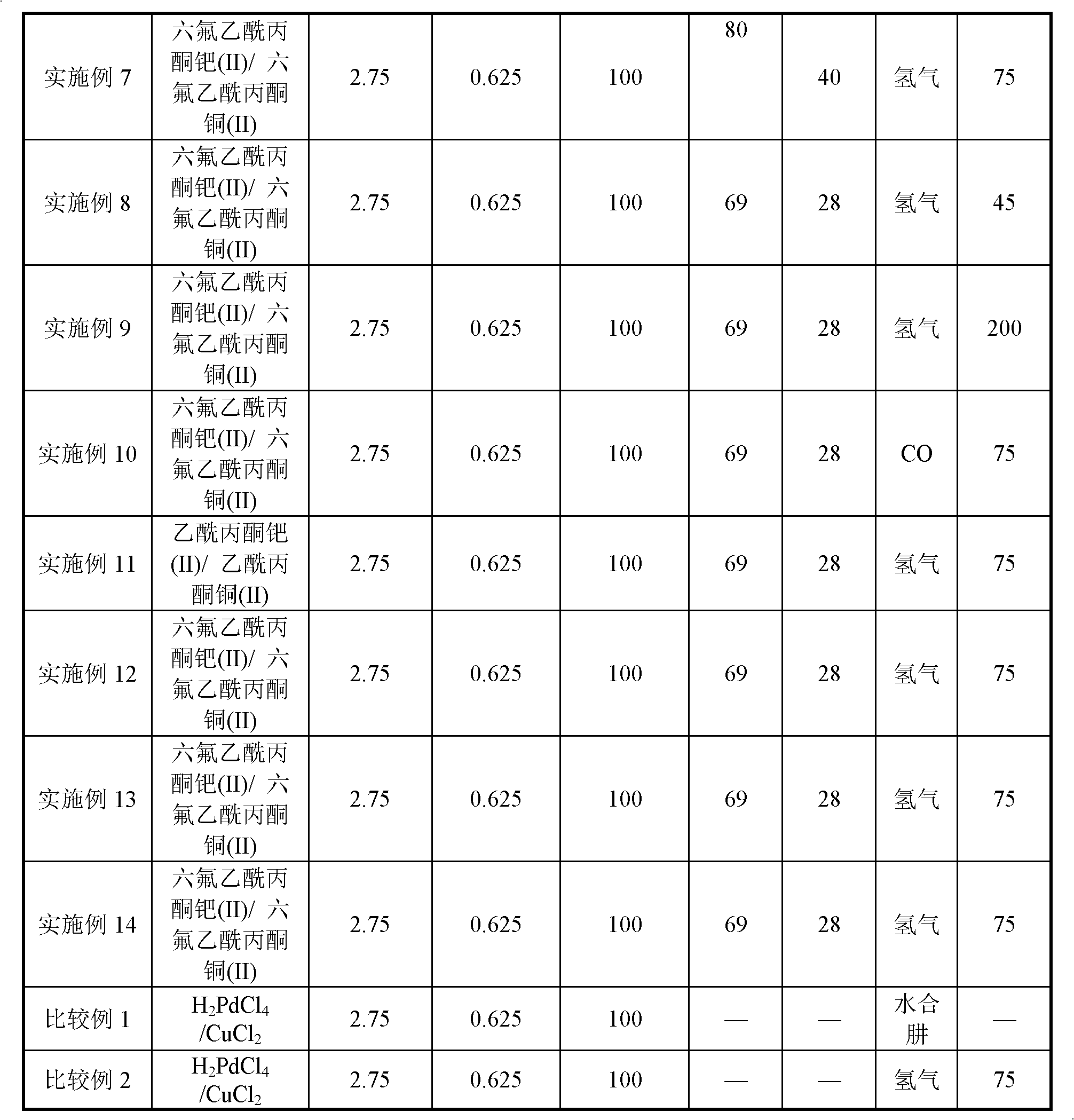

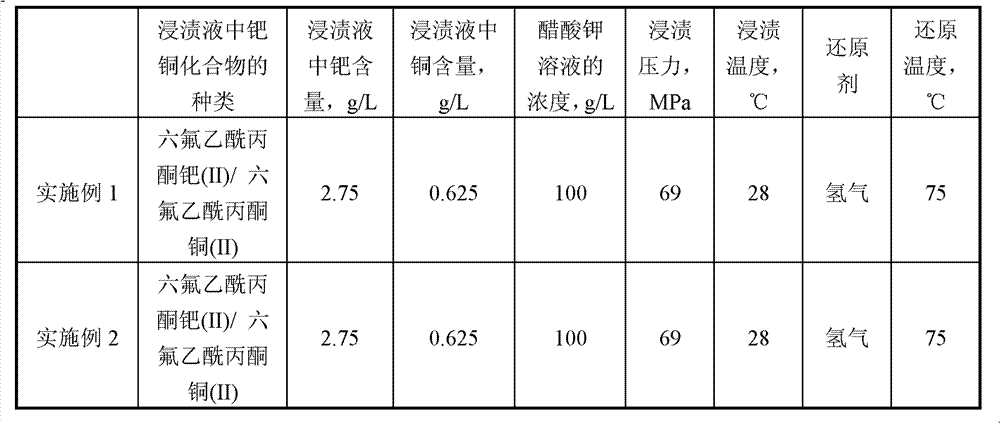

Method for preparing 1,4-cyclohexanedimethanol

ActiveCN102381938AGood dispersionHigh activityOrganic compound preparationHydroxy compound preparationCyclohexanedimethanolAlcohol

The invention relates to a method for preparing 1,4-cyclohexanedimethanol. The temperature of a catalyst bed layer is controlled to be from 150 to 150 DEG C, the operation pressure is controlled to be from 5.0MPa to 8.0MPa, 1,4-cyclohexanedicarboxylate dissolved in methyl alcohol is contacted with hydrogen with the existence of a polybasic composite metal oxide catalyst containing copper oxide, the proportion by weight of the methyl alcohol to the 1,4-cyclohexanedicarboxylate is equal to (0.1-9) to 1, the LHSV (Liquid Hourly Space Velocity) is 1-10h-1; H2 / DMCD (mol / mol) is 200-600, the flow of H2 is 17.7 to 177.4L / h, and the filling quantity of the catalyst is 3ml. The catalyst adopted in the method has the excellent properties of high dispersion, uniform crystallite dimension distribution, low cost, environment friendliness, and the like; the method is characterized in that the hydrogenation reaction pressure is low, the catalysis activity is high, and the like; and the selectivity of the 1,4-cyclohexanedimethanolcan be 95% to 98%.

Owner:PETROCHINA CO LTD

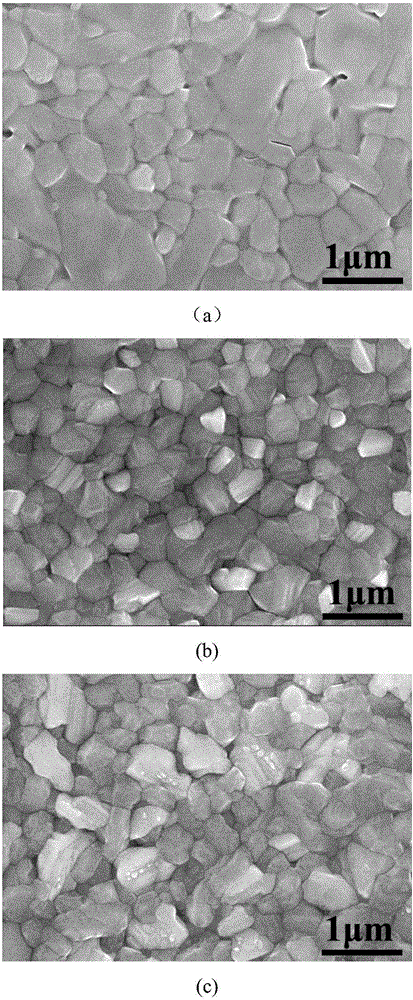

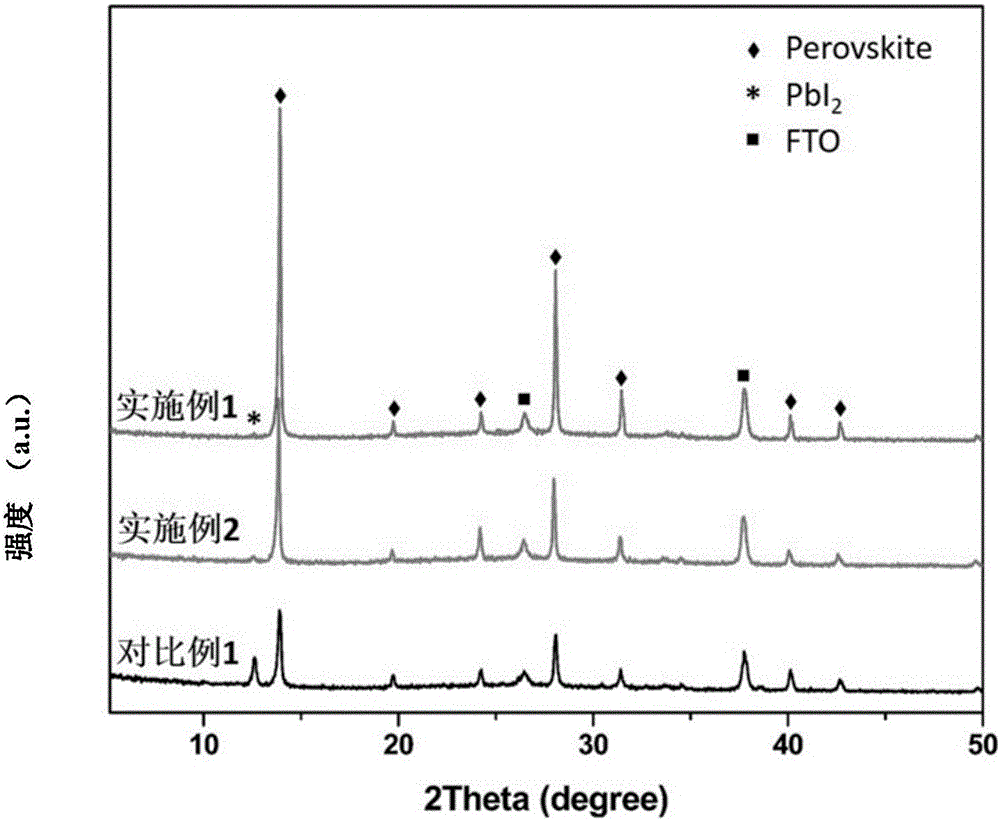

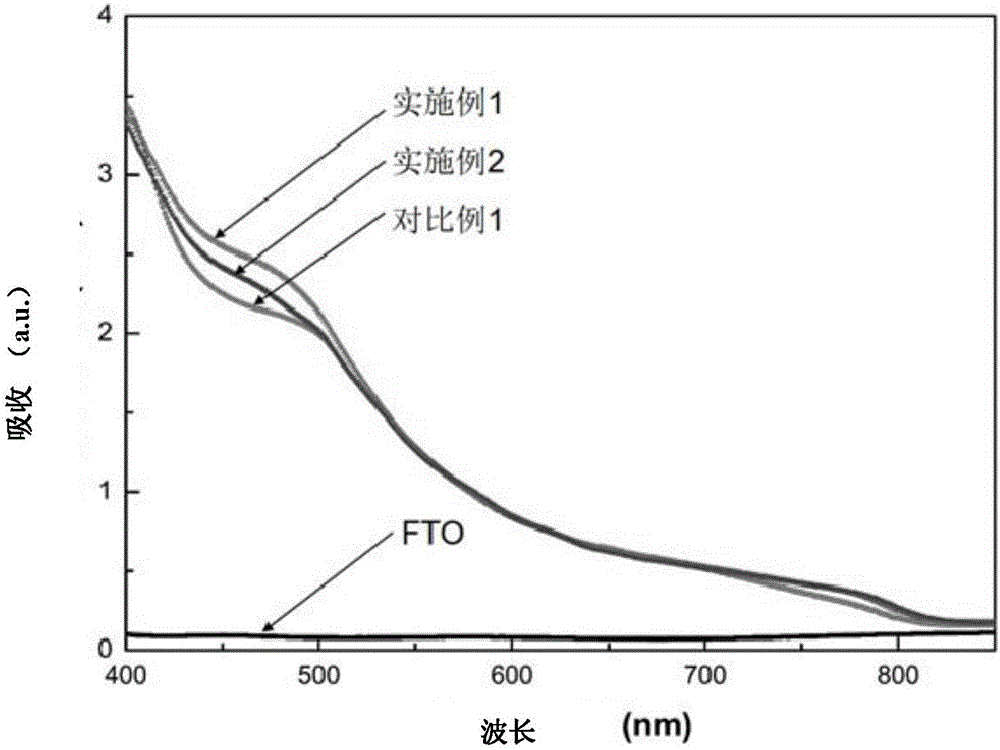

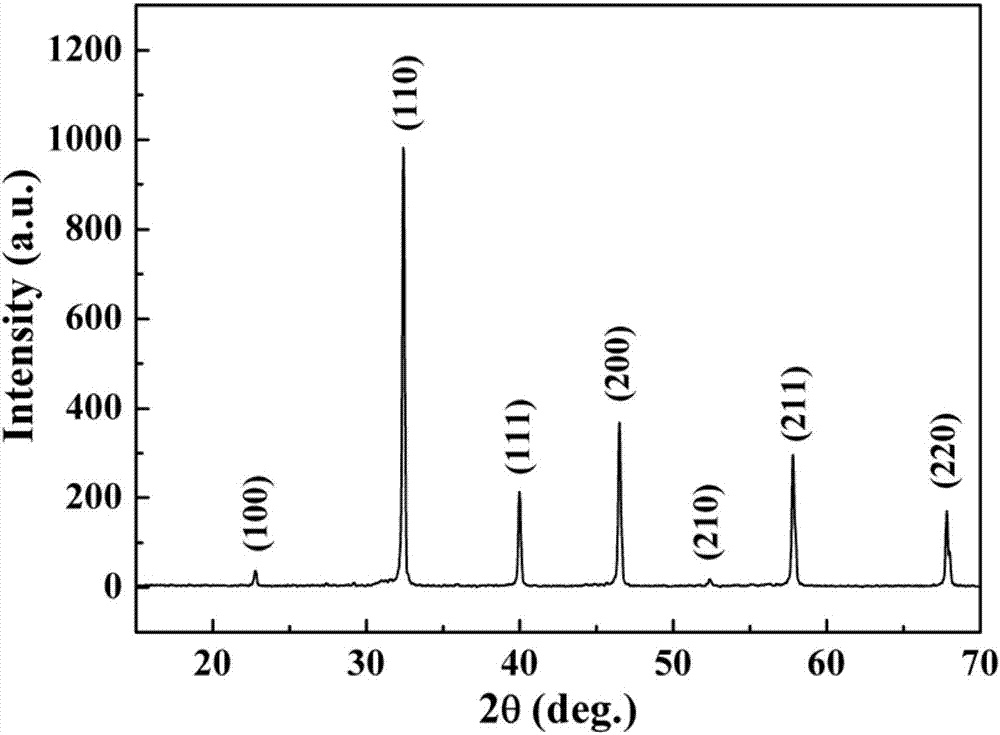

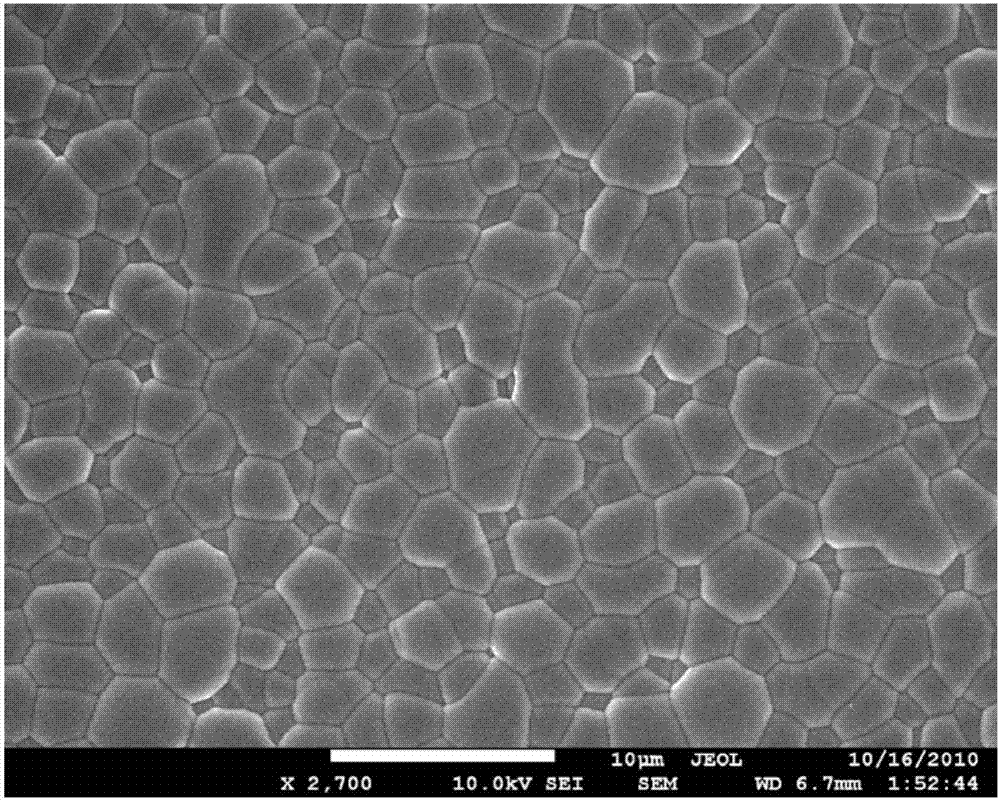

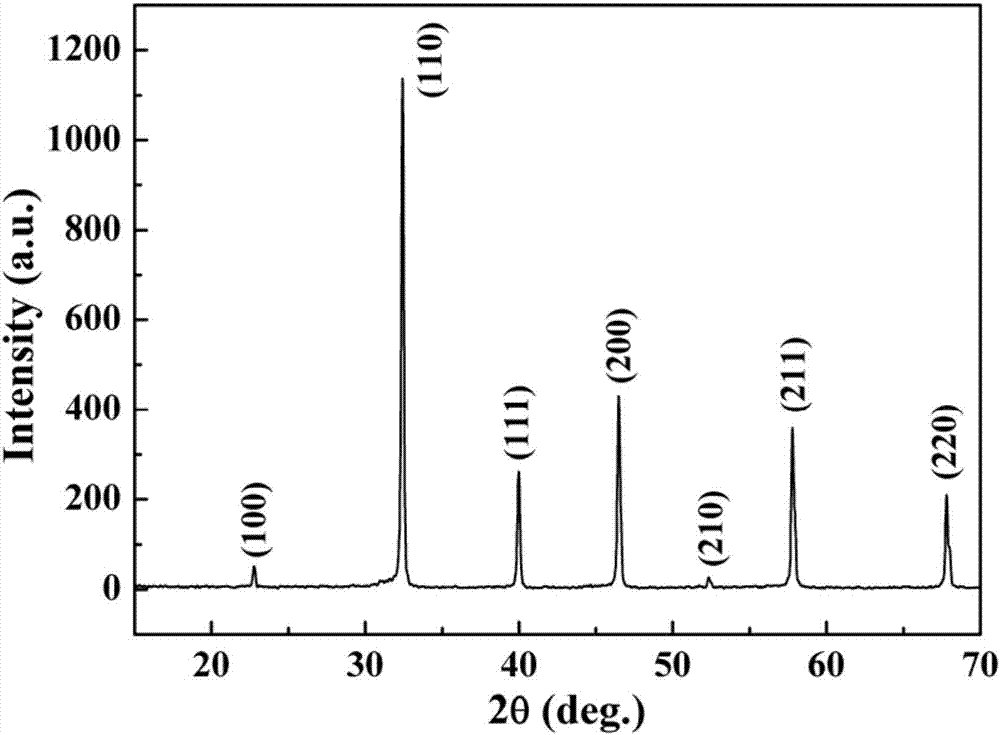

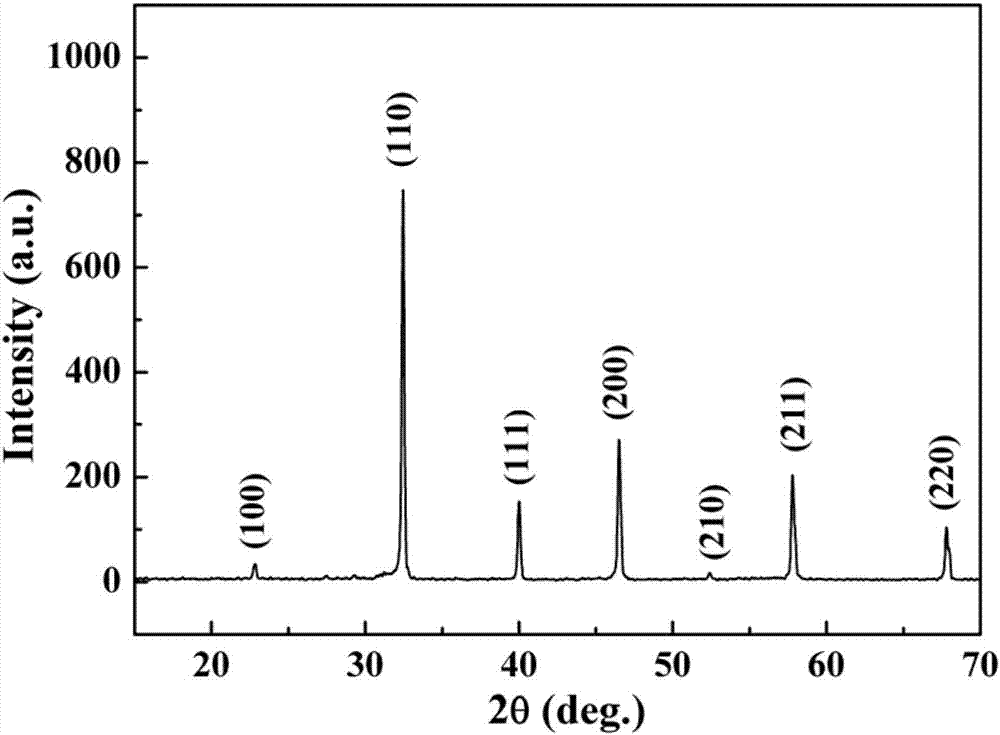

Method for preparing high-quality perovskite crystal thin film

InactiveCN106058060AHigh crystallinityUniform grain size distributionSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellCrystallinity

The invention discloses a method for simply and quickly preparing a high-quality perovskite crystal thin film, and belongs to the technical field of solar cells. The method comprises the main steps of firstly forming a flat lead iodide thin film on a substrate through a film forming technology; and then processing a PbI2 thin film through a mixed solution of CH<3>NH<3>X and HC(NH<2>)<2>X and carrying out thermal treatment to obtain the high-quality perovskite crystal thin film. Under the condition of not adopting the equipment of vacuum equipment, a glove box and the like, the perovskite crystal thin film which is controllable in thickness, good in crystallinity, high in coverage rate, flat and smooth in surface and good in light absorption performance can also be prepared by the method disclosed by the invention; the technology is simple in operation; and the preparation cycle is short. The perovskite crystal thin film prepared through the method is applied to the solar cell as a light absorption material; and the prepared cell device is high in efficiency and good in stability, and has important reference value for implementation of low-cost manufacturing of the high-efficiency perovskite solar cell.

Owner:XIAMEN UNIV

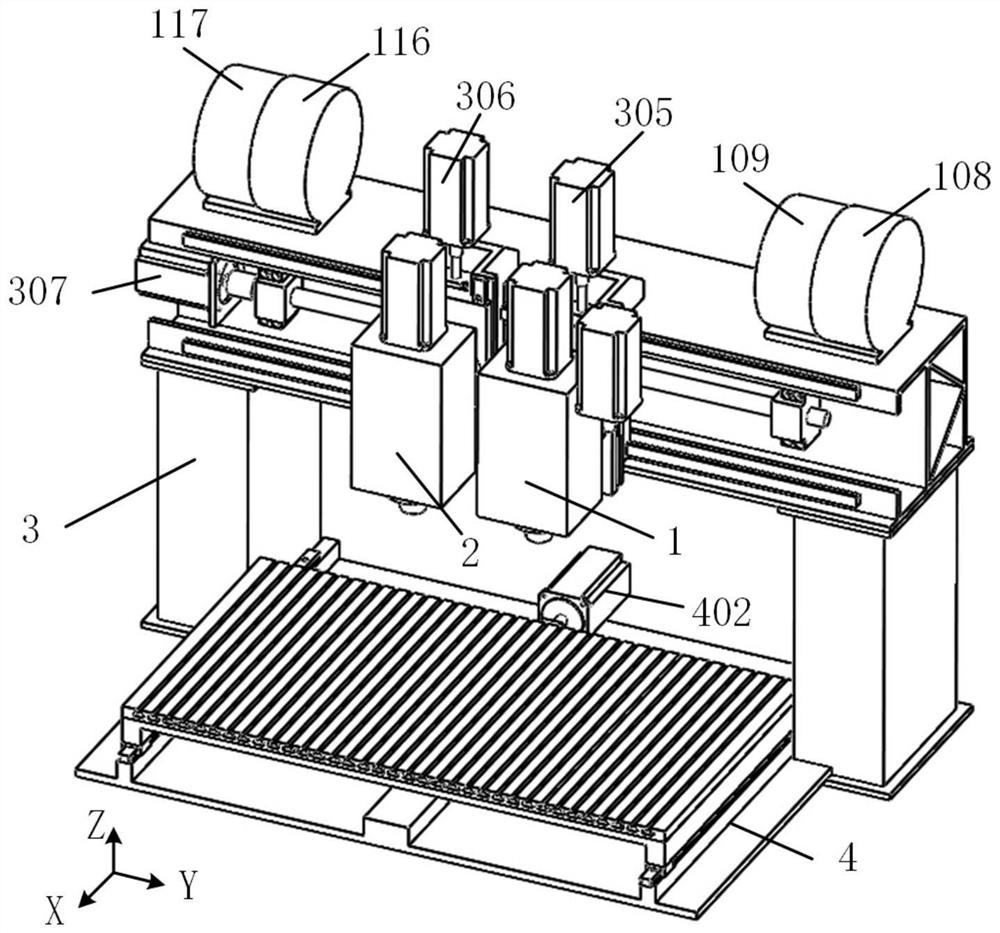

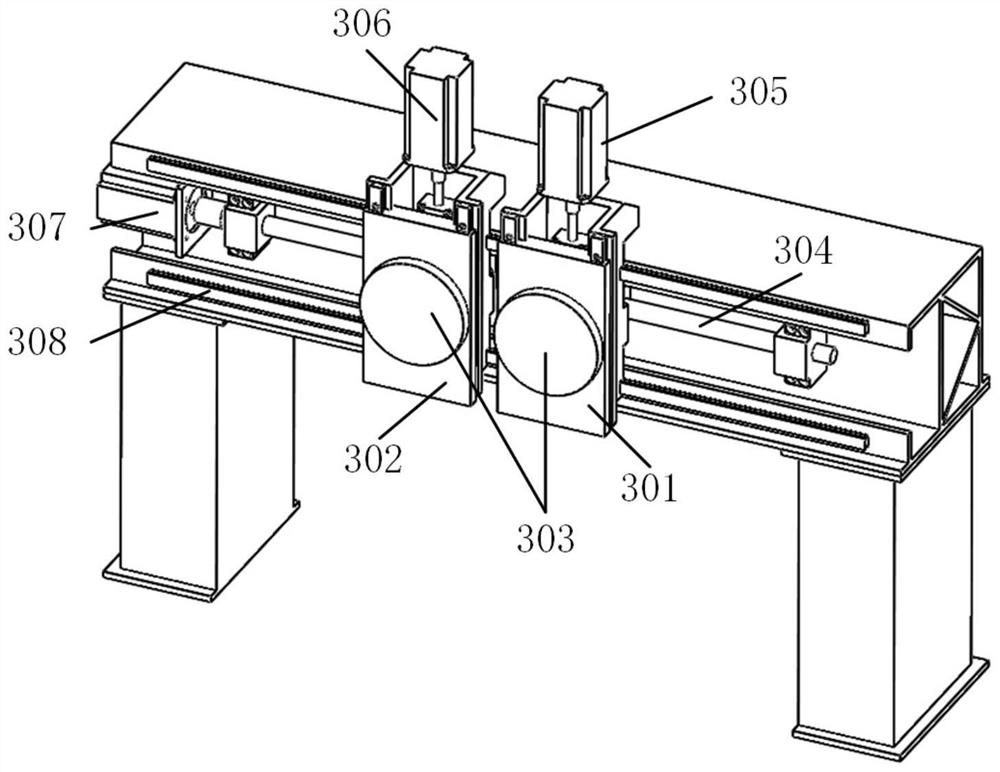

Stirring friction forging additional material manufacturing method and device of nano reinforcing composite materials

ActiveCN111804910AImprove performanceEfficient Quality Additive ManufacturingAdditive manufacturing apparatusTransportation and packagingMaterial supplyIsothermal forging

The invention relates to a stirring friction forging additional material manufacturing method and device of nano reinforcing composite materials. The device comprises four parts including a stirring friction additional material main shaft, an isothermal forging mechanism, a gantry type rack and a workbench; the stirring friction additional material main shaft is used for realizing mixing, preheating and supplying of powder or granular materials, conducting friction squeezing of materials output from a material supplying hole, and using friction heat and pressure to realize layer-by-layer additional material forming manufacturing; the isothermal forging mechanism is used for realizing isothermal forging and micro reshaping of an additional material layer; the gantry type rack is used for fixing the stirring friction main shaft and the isothermal forging mechanism and for realizing advancing as well as swaying angle adjustment of the stirring friction main shaft and the isothermal forging mechanism along the Y axis and the Z axis; and the workbench is used for fixing a substrate and realizing advancing of the substrate along the X axis. The method and the device can realize high-efficiency and high-quality additional material manufacturing of light alloy powder or granular materials, and have the advantages of higher efficiency, simple and convenient operation and lower energy consumption.

Owner:XI AN JIAOTONG UNIV

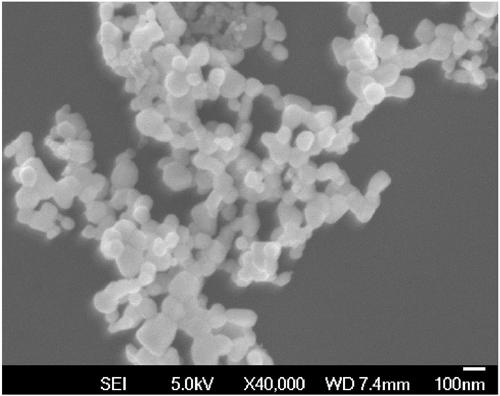

Method for preparing nano-zinc oxide used as photocatalyst

InactiveCN104307501AEnsure safetySimple processCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsWater bathsOrganic dye

A method for preparing nano-zinc oxide used as a photocatalyst comprises the following steps: dissolving zinc nitrate, a complexing agent and glucose in deionized water at room temperature under stirring so as to form a solution; adding acrylamide and methylene-bisacrylamide into the solution in sequence; uniformly stirring the solution to obtain colorless and transparent sol; heating the obtained colorless and transparent sol in a water bath to form white wet gel; drying the obtained wet gel to obtain dry gel; grinding the dry gel to powder; sintering the powder for 4-5 hours at 600-700 DEG C so as to obtain nano-zinc oxide powder. The nano-zinc oxide prepared by using the method provided by the invention has the advantages of very high degree of crystallinity, uniform distribution of grain size and very good photocatalytic degradation activity for various organic dyes under the ultraviolet light.

Owner:SOUTHWEST UNIVERSITY FOR NATIONALITIES

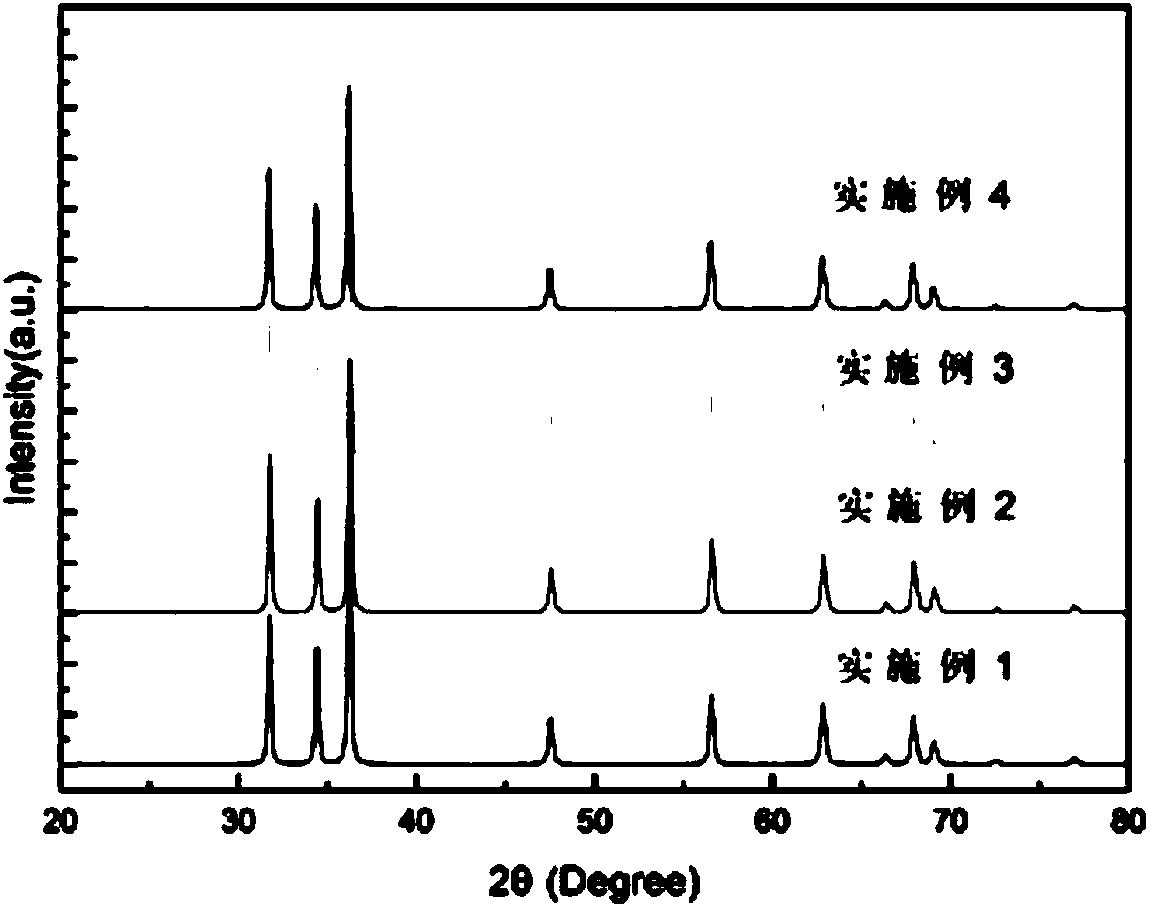

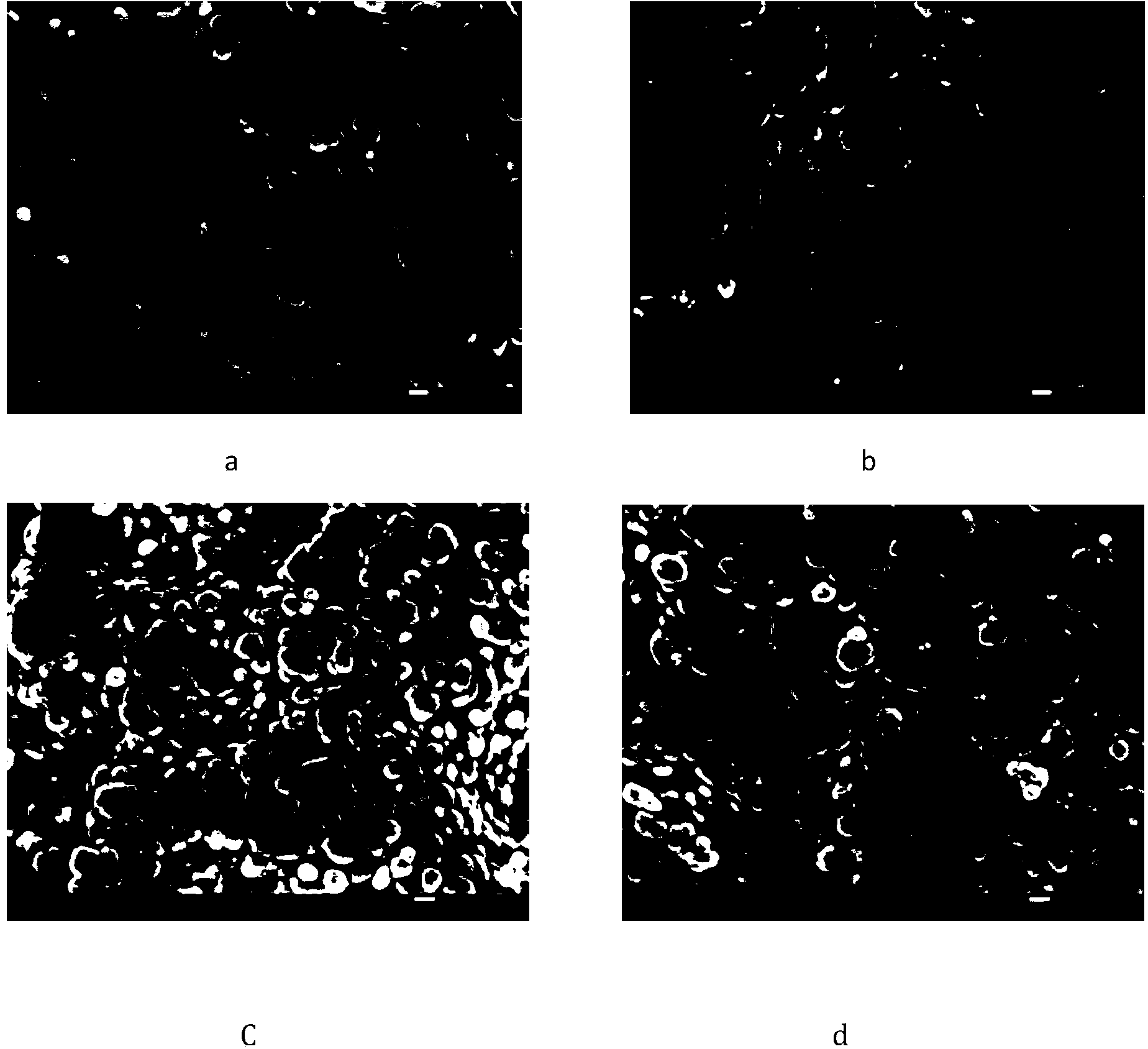

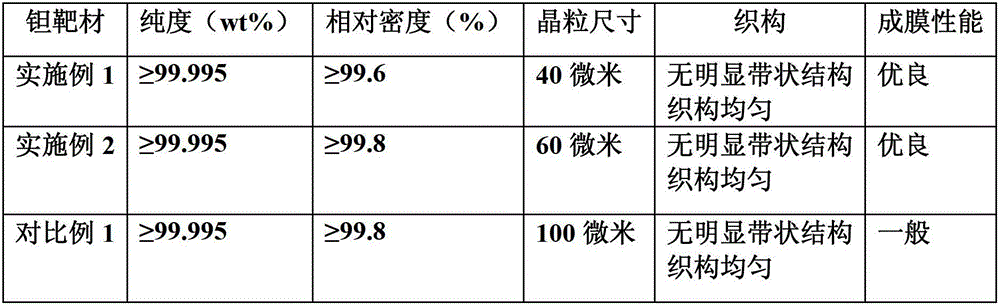

Production method of high-purity tantalum target material

ActiveCN103147050AUniform texture distributionUniform grain size distributionVacuum evaporation coatingSputtering coatingHydrogenProcess conditions

The invention relates to a production method of a high-purity tantalum target material, which comprises the following steps: (1) placing a tantalum block of which the size is 5-10mm*5-10mm in a hydrogenation furnace, and performing hydrogen absorption; and (2) crushing the tantalum subjected to hydrogen absorption into 200-mesh powder, placing in a steel capsule, heating and performing air extraction at certain rates by stages, then placing the steel capsule in a hot isostatic press, sintering under the conditions that the sintering temperature is 1100-1500 DEG C and the atmosphere pressure is 50-200 MPa, and finally machining to cut into a specified shape. According to the invention, a powder metallurgy method is adopted, and specific process conditions are combined, so that the tantalum target material which is uniform in texture distribution, uniform in grain size distribution and small in grain size can be obtained; and the target material has high deposition speed, fine film uniformity and favorable film-forming property, and produces fewer electric arcs and particles. Above all, the method provided by the invention is simple in process and low in cost.

Owner:泰安晶品新材料科技有限公司

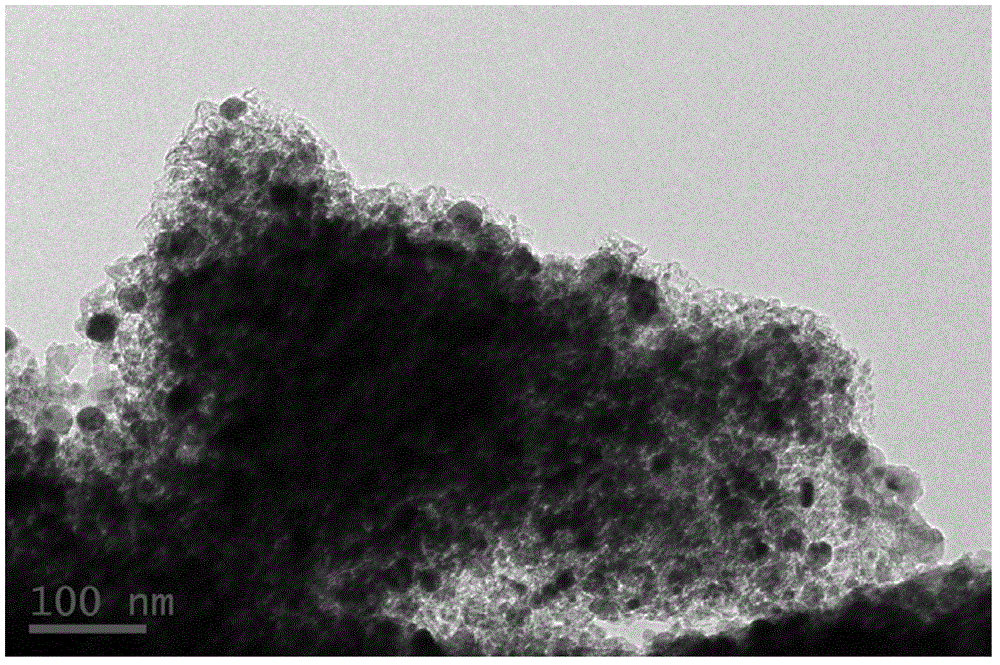

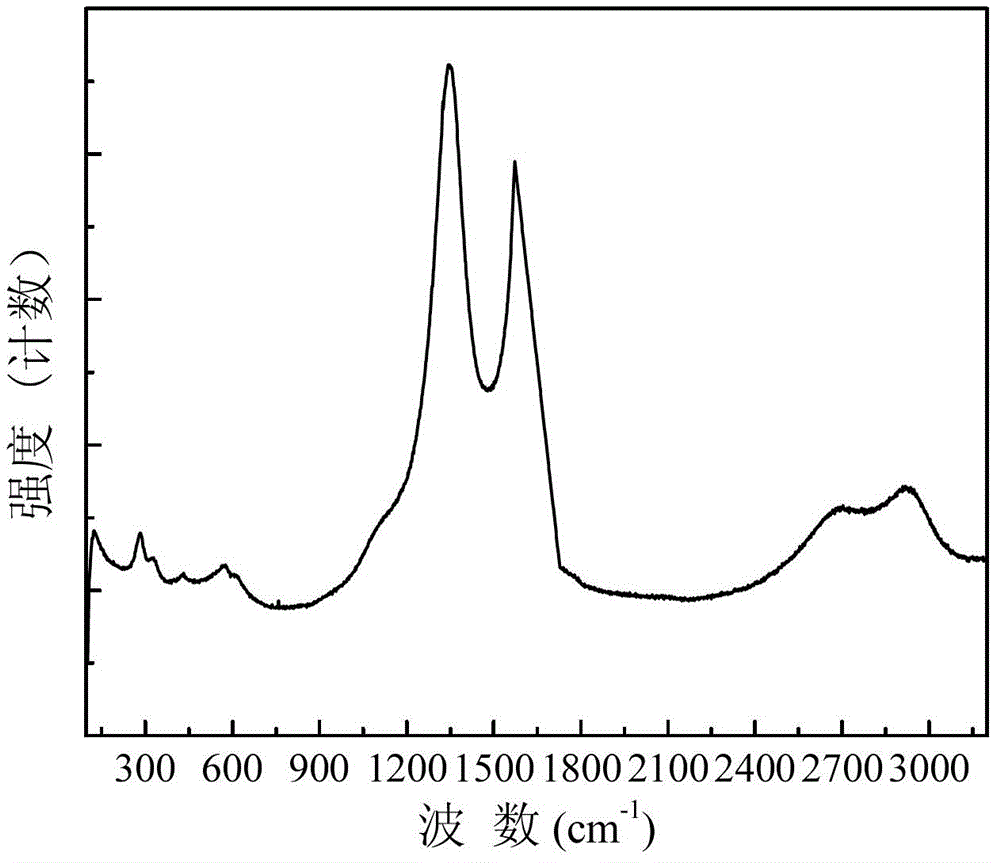

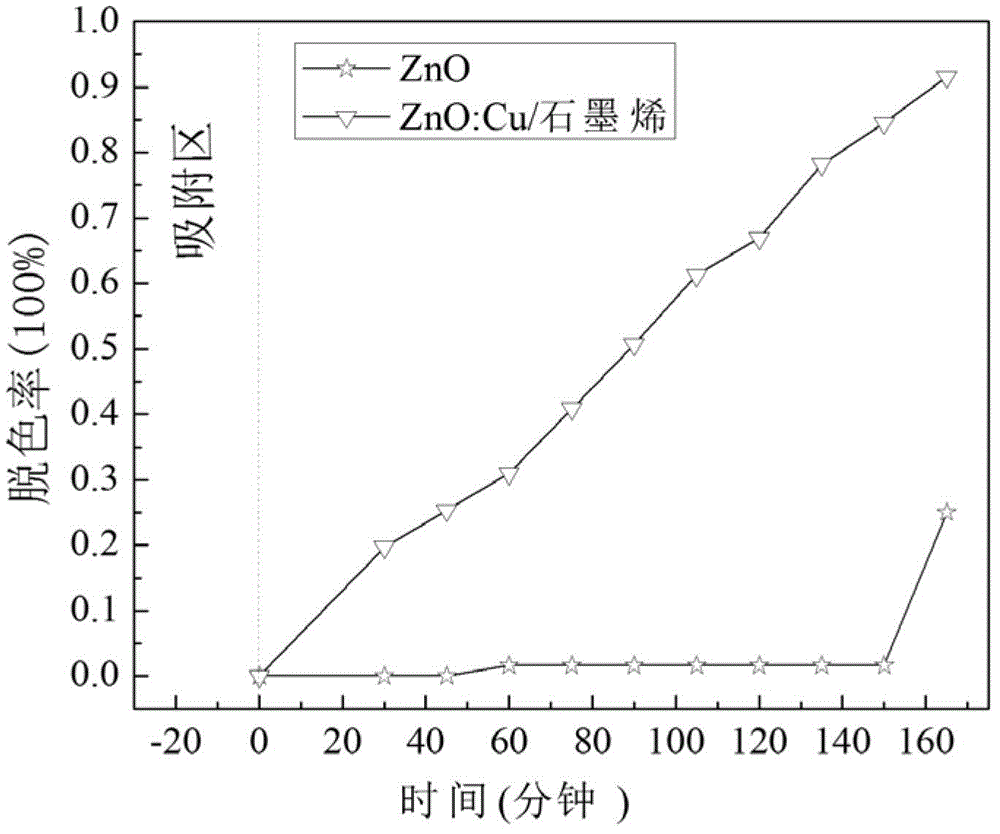

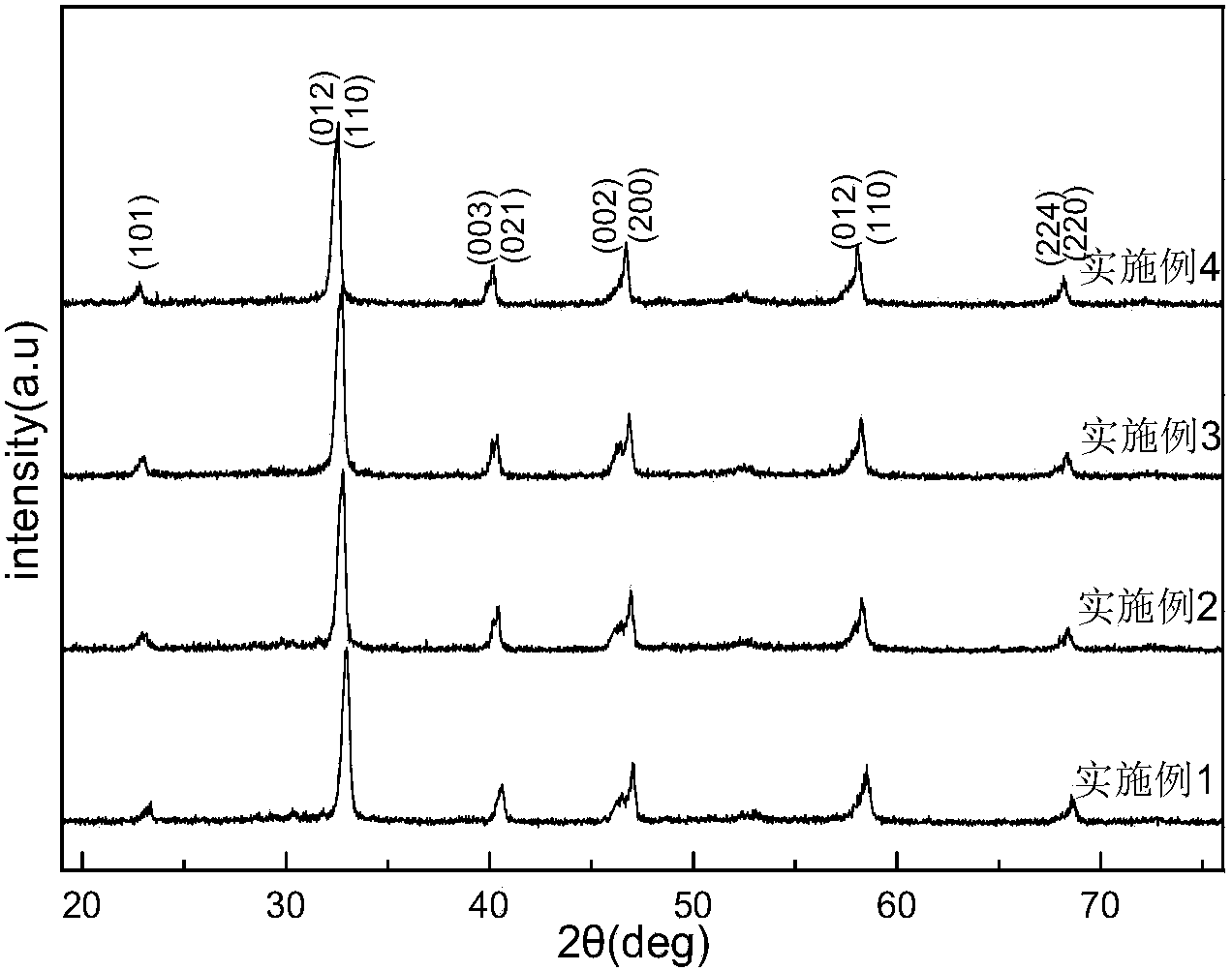

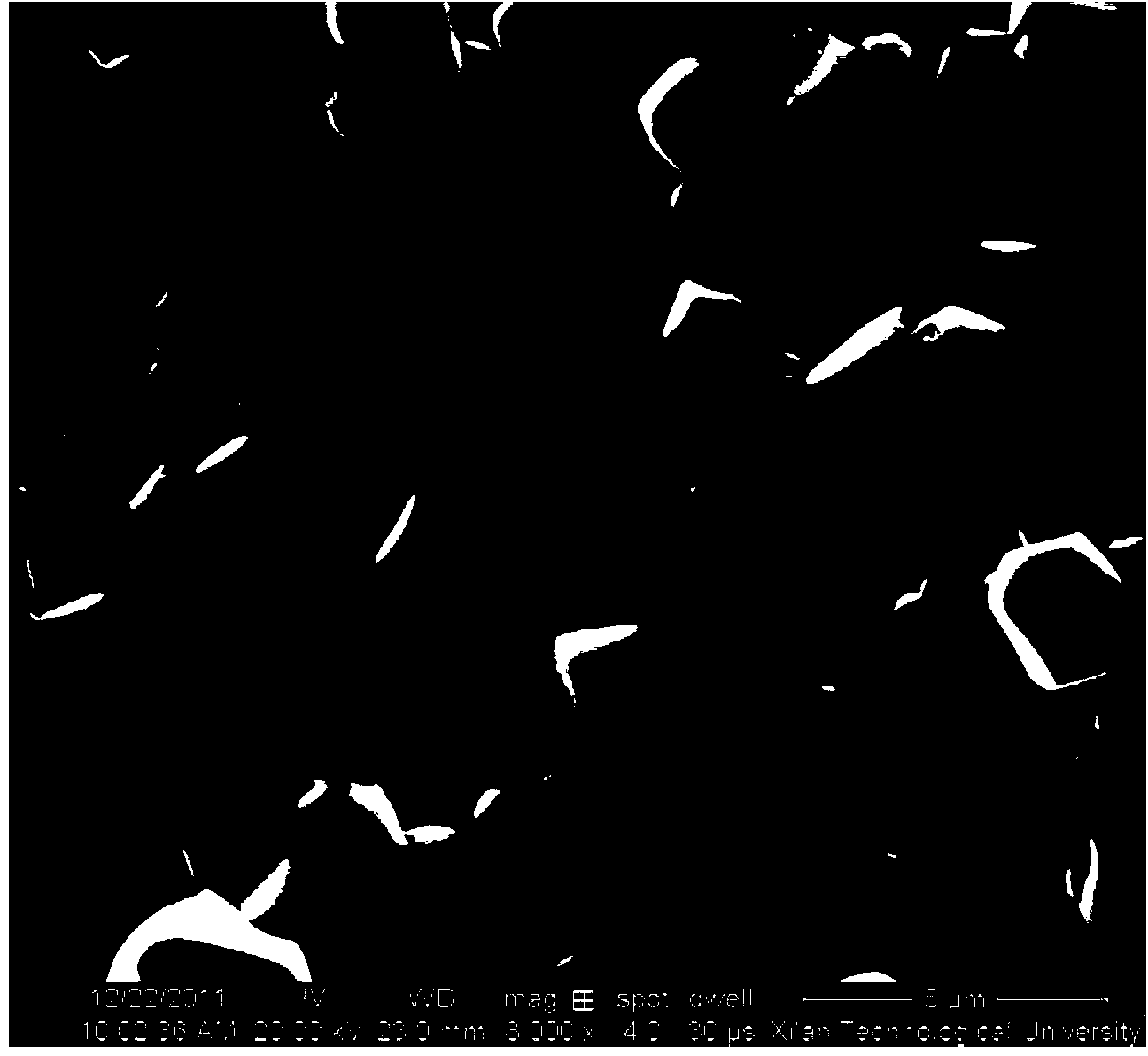

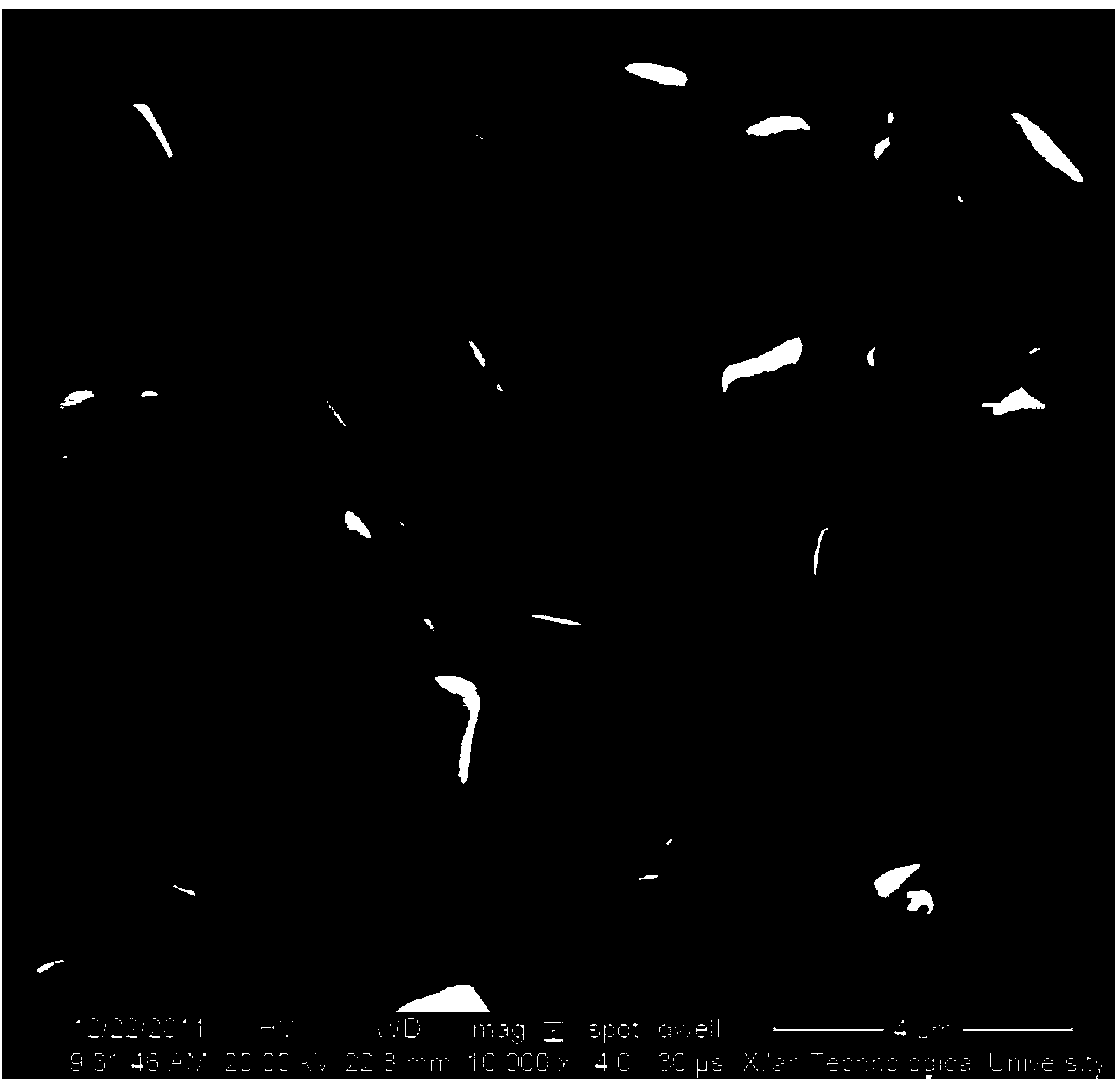

Cu-doped ZnO/graphene composite photocatalyst and preparation method thereof

InactiveCN103182307AUniform grain size distributionImprove adsorption capacityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsFiltrationHexamethylenetetramine

The invention discloses a Cu-doped ZnO / graphene composite photocatalyst and a preparation method thereof. The method comprises the following steps: mixing graphite oxide and a surfactant CTAB (cetyl trimethyl ammonium bromide) in distilled water and carrying out ultrasonic treatment to obtain a first precursor reactant; dissolving zinc acetate and cupric acetate in the distilled water and carrying out ultrasonic treatment to obtain a second precursor reactant; dissolving hexamethylenetetramine and sodium citrate in the distilled water and carrying out ultrasonic treatment to obtain a third precursor reactant; after mixing the first precursor reactant and the second precursor reactant, carrying out ultrasonic treatment, then mixing the obtained product and the third precursor reactant, controlling reaction temperature in the range of 70 DEG C to 120 DEG C and performing reaction; sealing, naturally cooling, standing and carrying out extraction filtration to obtain filter residues; and after drying the filter residues, carrying out annealing treatment. According to the invention, addition of graphene reduces electron-hole compounding possibility; and meanwhile, introduction of Cu ions can be used as an ion trap to temporarily capture a charge carrier and inhibit electron-hole compounding so as to obviously improve photocatalytic efficiency of the product.

Owner:SOUTH CHINA UNIV OF TECH

Production method for samarium cobalt alloy powder

ActiveCN103537684AReduce performanceUniform grain size distributionInorganic material magnetismRare-earth elementHydrogen atmosphere

The invention discloses a production method for samarium cobalt alloy powder. The production method for the samarium cobalt alloy powder comprises weighing samarium, cobalt, iron, copper, zirconium and heavy rare earth element metal salt in proportion, preparing a salt solution and a salt-mixture solution, adding a little acid or alkali to control a PH (Potential of Hydrogen) value to be between 4 and 9, simultaneously adding surface active agent and dispersing agent which account 1 to 5 % of the mass of the metal salt in the metal salt solution, performing spray drying at the temperature between 300 and 350 DEG C to produce composite powder precursor, performing low temperature calcine at the temperature between 200 and 300 DEG C, performing two-step restoring on the precursor under hydrogen atmosphere with the temperature between 400 to 800 DEG C, ball-milling the restored powder to obtain the samarium cobalt alloy powder. The samarium cobalt alloy powder produced through the production method has the advantages of being reasonable in powder size, uniform in crystal grain and component distribution, high in purity and low in oxygen content. The production method has the advantages of being simple in operation, low in energy consumption, high in production efficiency and suitable for continuous production.

Owner:HUNAN AEROSPACE MAGNET & MAGNETO

Solid solution-modified sodium bismuth titanate leadless piezoelectric ceramics and preparation method thereof

ActiveCN103833354AExcellent piezoelectric propertiesHigh electromechanical coupling coefficientElectromechanical coupling coefficientTwo step

The invention provides solid solution-modified sodium bismuth titanate leadless piezoelectric ceramics and a preparation method thereof. The piezoelectric ceramics are represented by chemical composition general formula of (1-x)(0.74Na0.5Bi0.5TiO3-0.26SrTiO3)-xBa(Zr0.05Ti0.95)O3 or (1-y)(0.9Na0.5Bi0.5TiO3-0.1CaTiO3)-yBa(Zr0.05Ti0.95)O3, wherein 0.04<=x<=0.1 and 0.04<=y<=0.1. Solid solution of Ba(Zr0.05Ti0.95)O3 is realized at the morphotropic phase boundary of a 0.74Na0.5Bi0.5TiO3-0.26SrTiO3 and 0.9Na0.5Bi0.5TiO3-0.1CaTiO3 system, and high-density microcrystalline structure ceramics with uniform crystal grain size distribution are obtained by a two-step forming method and a self-bearing pressure sintering process. The piezoelectric property of the material is optimized by the morphotropic phase boundary composition characteristics and the solid solution modification method, and the piezoelectric constant d33 reaches 110-138 PC / N; the electromechanical coupling coefficient of the material is also increased obviously; the preparation process of the material is simple and stable, and the material is an optimal material for manufacturing low-power ultrasonic devices and energy transducers used in fields of gas sensors, industrial nondestructive test, and the like.

Owner:XIAN UNIV OF SCI & TECH

Strontium titanate-based ceramic material with high energy storage density and low dielectric loss and preparation method thereof

The invention discloses a strontium titanate-based ceramic material with high energy storage density and low dielectric loss and a preparation method thereof. The method comprises the following steps: preparing materials according to a chemical formula which is expressed as (1-x)SrTiO[3-x]Bi0.48La0.02Na0.48Li0.02Ti0.98Zr0.02O3, mixing uniformly to obtain raw material powder, uniformly mixing organic solvents and emulsifiers, then adding the raw material powder, adhesives, dispersants and plasticizers, mixing uniformly, carrying out tape casting, then cutting and stacking, then pressurizing, discharging glue and sintering to obtain the strontium titanate-based ceramic material with high energy storage density and low dielectric loss. The ceramic material is simple in preparation process and mature in preparation technique, and is suitable for industrial production; the energy storage density calculated on the basis of ferroelectric hysteresis loop is 1.98-2.59j / cm<3>, the energy storage efficiency is 69-87%, and the electric field intensity is 200kV / cm or more; the ceramic material is excellent in energy storage characteristic and low in dielectric loss.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of low-cost and high-density ITO target material

ActiveCN107130217ALow viscosityUniform and stable dispersionVacuum evaporation coatingSputtering coatingAdhesiveTitanium nitride

The invention discloses a preparation method of a low-cost and high-density ITO target material. The preparation method comprises the following steps that a dispersing agent and an adhesive are added into water and stirred evenly, the pH value is adjusted to be 8-11 with ammonium hydroxide, and a pre-mixed solution is obtained; the weight ratio of the dispersing agent to a mixture of citric acid and polyacrylamide is 1-2:1; ITO powder prepared through a chemical co-precipitation method and a sintering agent are added into the pre-mixed solution, then the pre-mixed solution is subjected to ball milling in a ball mill, mixed slurry is obtained after ball milling and stirred, and bubbles in the slurry are removed through vacuumizing; the sintering agent is composed of rare earth oxide, titanium nitride and nano GeO2; an aluminum mold is installed on a gypsum board, and the obtained slurry is poured into the aluminum mold; demolding and drying are conducted after the slurry is absorbed and molded, and an ITO blank is obtained; and the dried ITO blank is sintered in the normal-pressure pure oxygen atmosphere, and the ITO target material is obtained. Compared with the prior art, the product obtained through the preparation method is high in density, low in cost, low in electrical resistivity and uniform in grain dimension distribution.

Owner:ANHUI TUOJITAI NOVEL CERAMIC TECH

Tin-silver co-doped nano-zinc oxide as photocatalyst and preparation method thereof

InactiveCN106423162AReduce dosageReduce photocatalytic degradation activityWater/sewage treatment by irradiationWater treatment compoundsWater bathsZno nanoparticles

The invention discloses a preparation method of tin-silver co-doped nano-zinc oxide as a photocatalyst. The method comprises the steps that 1, zinc nitrate, tin tetrachloride, a complexing agent and glucose are dissolved in deionized water to form a solution, then acrylamide and methylene bisacrylamide are added in sequence, the solution is stirred to be uniform, heated in a water bath and stirred till white wet gel is formed, and the wet gel is dried, ground into powder and calcined to obtain tin doped nano-zinc oxide; 2, the tin doped nano-zinc oxide, silver nitrate, a complexing agent and glucose are dissolved in deionized water to form a solution, then acrylamide and methylene bisacrylamide are added in sequence, the solution is stirred to be uniform, heated in a water bath and stirred till brown wet gel is formed, and the wet gel is dried, ground into powder and calcined to obtain the tin-silver co-doped nano-zinc oxide. Through the preparation method, production cost is lowered while the photocatalytic activity of nano-zinc oxide is improved.

Owner:SOUTHWEST UNIVERSITY FOR NATIONALITIES

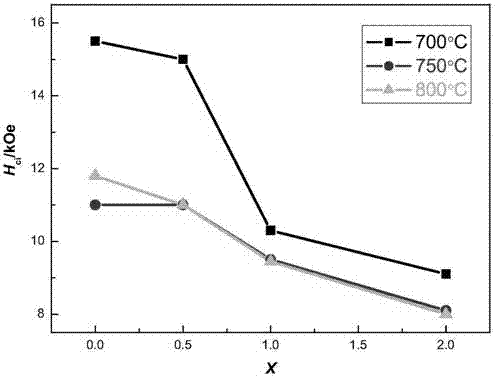

Nanocrystalline rapid quenching rare-earth permanent magnet material, minishing method of grain size of rare-earth permanent magnet material and bonded permanent magnet

InactiveCN106856118AUniform grain size distributionIncreased residual magnetizationInductances/transformers/magnets manufactureMagnetic materialsSmelting processGrain boundary

The invention relates to an nanocrystalline rapid quenching rare-earth permanent magnet material, a minishing method of the grain size of the rare-earth permanent magnet material and a bonded permanent magnet. According to the method, a proper amount of Y, Ho or Gd and the like is added in the alloy smelting process, the feature that the enthalpy generated by (Y, Ho, Gd)-Fe is lower than that generated by Nd-Fe14 is made used of, the grain size of the nanocrystalline rapid quenching rare-earth permanent magnet material is effectively minished, the grain size distribution is more uniform, and the exchange coupling enhancement effect brought by grain size minishing achieves the improvement of residual magnetization; at the same time, since the magnetocrystalline anisotropy field of (Y, Ho, Gd)2Fe14B is larger than 0, coercive force losses caused by the exchange coupling effect can be compensated to a certain extent. Moreover, the uniform grain size distribution and the optimized grain boundary state also contribute to the increase of coercivity.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

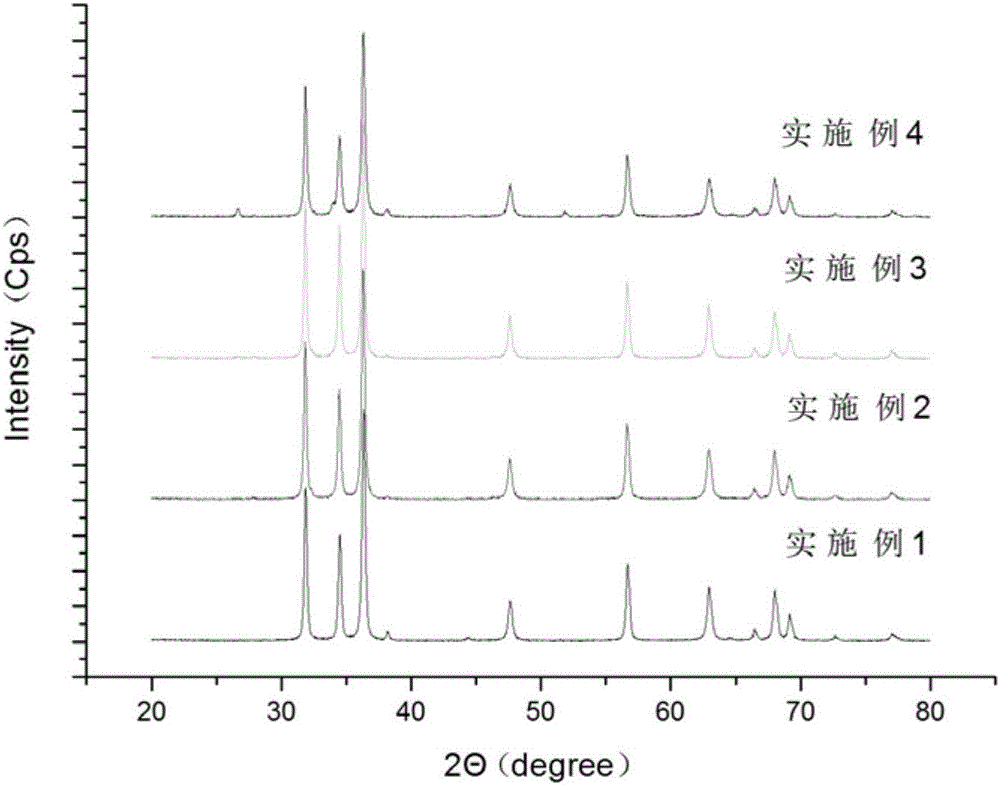

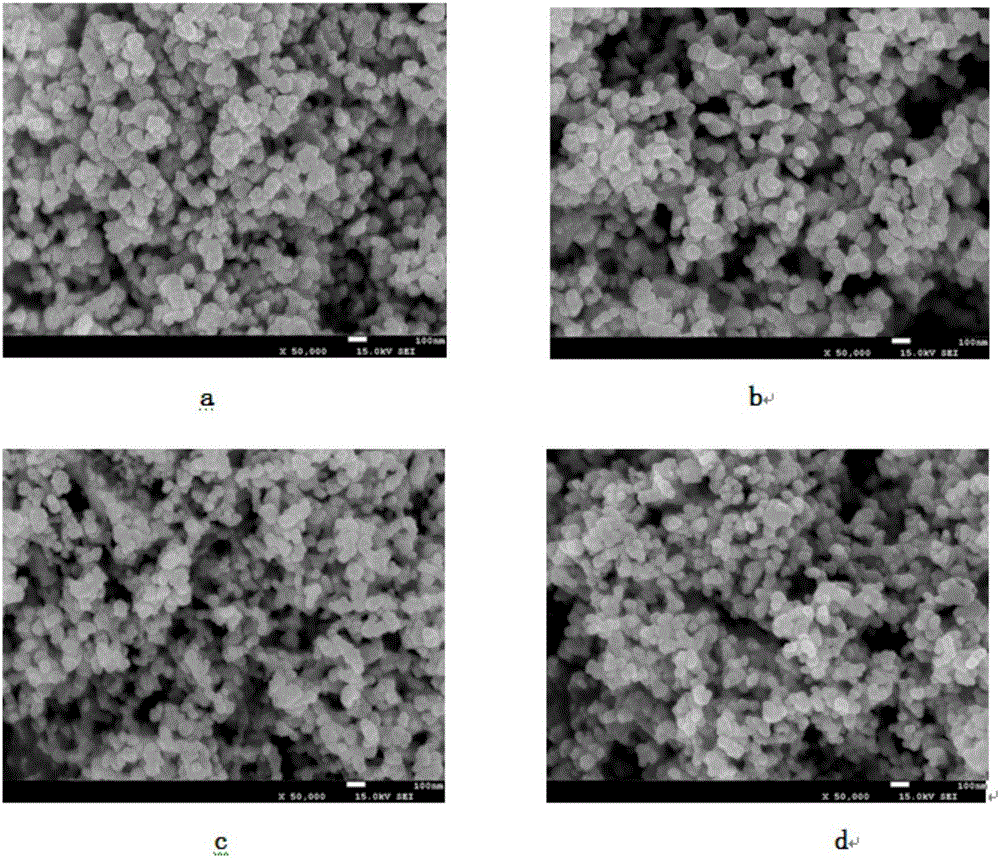

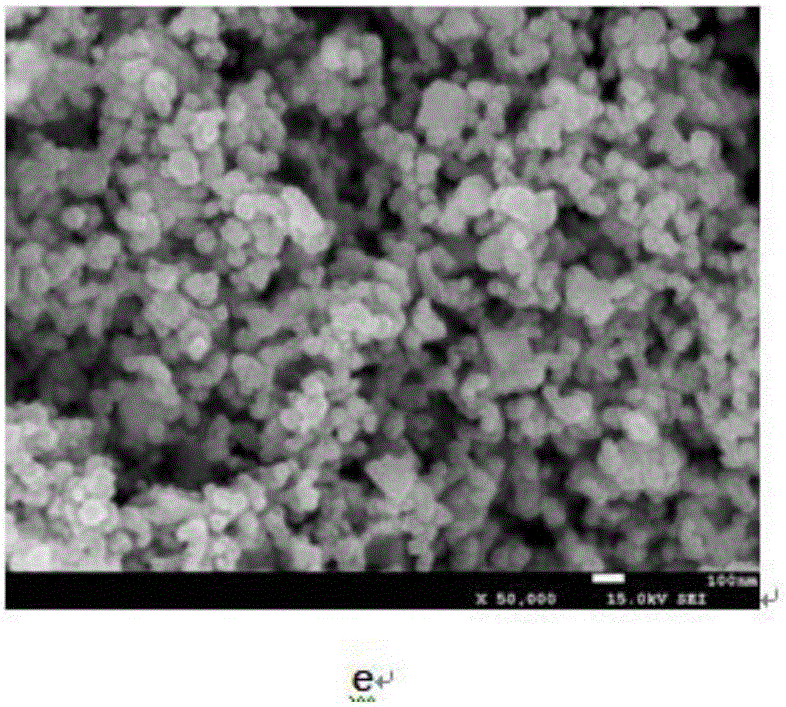

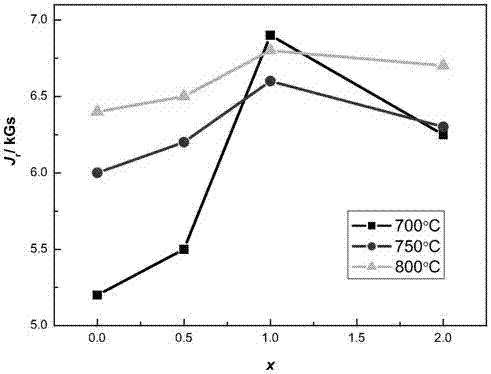

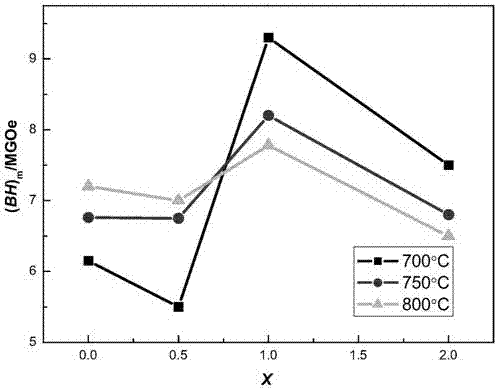

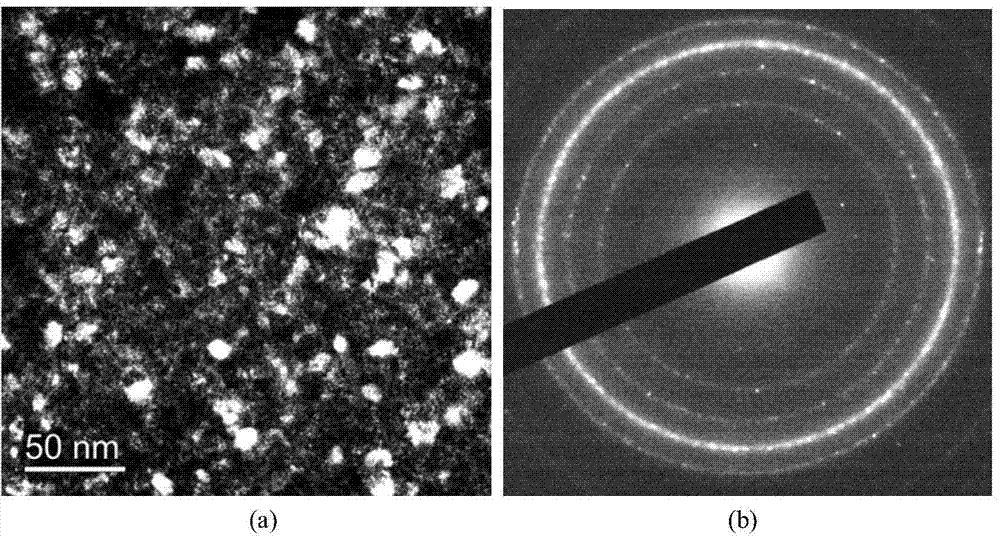

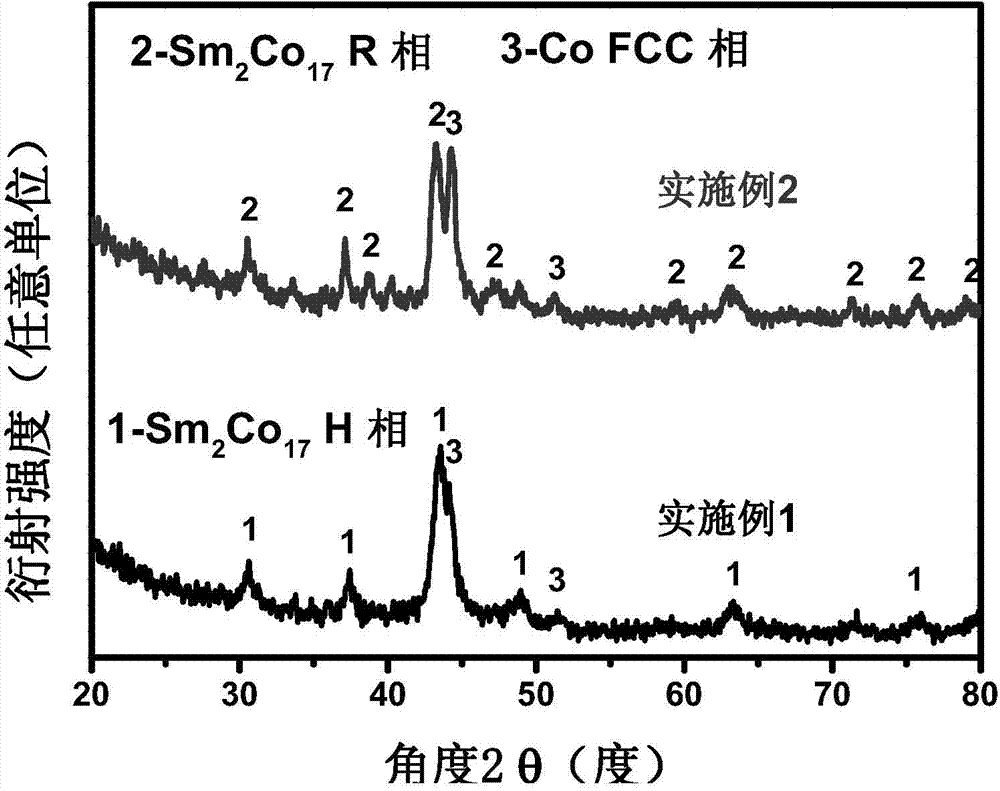

A preparing method of a nanocrystal Sm<2>Co<17>/Co double-phase composite permanent magnetic alloy

The invention provides a preparing method of a nanocrystal Sm<2>Co<17> / Co double-phase composite permanent magnetic alloy, and belongs to the technical field of double-phase composite permanent magnetic alloys. The method includes smelting a pure Sm block, a Co block and an elementary substance of an added element under the protection of argon to obtain a multi-component parent phase alloy; allowing phases and component distribution of the parent phase alloy to be uniform by a plurality of times of remelting and homogenizing annealing; preparing the parent phase alloy into amorphous powder by utilization of high-energy ball milling under the protection of an inert gas; preparing the amorphous powder into an initial nanocrystal alloy block which is a metastable phase alloy by spark plasma sintering; and preparing the nanocrystal Sm<2>Co<17> / Co double-phase composite permanent magnetic alloy by a thermal treatment process. The method has advantages of uniform crystal grain size distribution, controllable crystal grain size, controllable phase composition, controllable phase stability, and the like.

Owner:BEIJING UNIV OF TECH

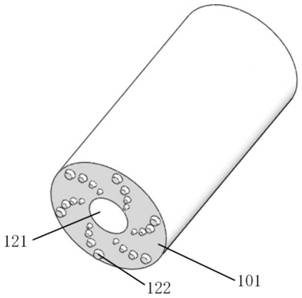

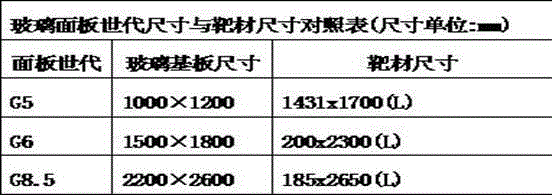

Continuous casting technology of belt material aluminum pipe and aluminum alloy rotating target materials

InactiveCN104907539AImprove microstructureImprove bindingVacuum evaporation coatingSputtering coatingBinding forceSteel tube

The invention discloses a continuous casting technology of a belt material aluminum pipe and aluminum alloy rotating target materials. The method comprises the steps of screened pipe preparing, aluminum or aluminum alloy melting and metal liquid casting and molding. By means of the technology, the micro-structure of the surface of the screened pipe is improved, the binding force between the metal aluminum and a steel pipe is increased, it is guaranteed that the metal aluminum in the liquid phase is combined with the steel pipe completely and firmly in the solidification process, and in the subsequent using process, it is guaranteed that the metal aluminum in the liquid phase is not separated from the steel pipe; all the elements are mixed uniformly, by controlling the atmosphere of a casting furnace body, the pouring speed and the cooling speed, it is guaranteed that the great micro-structure is obtained by the target materials, the combination degree between the target materials and the steel pipe is guaranteed, and air pores are prevented from occurring. The utilization rate of the target materials is improved, and the service lives of the target materials are prolonged; the production cost is reduced, the compactness of the target materials is high, gains are uniform in size and distribution, and the technology is applicable to the manufacturing of connecting membranes of flat display panels.

Owner:GEMCH MATERIAL TECH SUZHOU

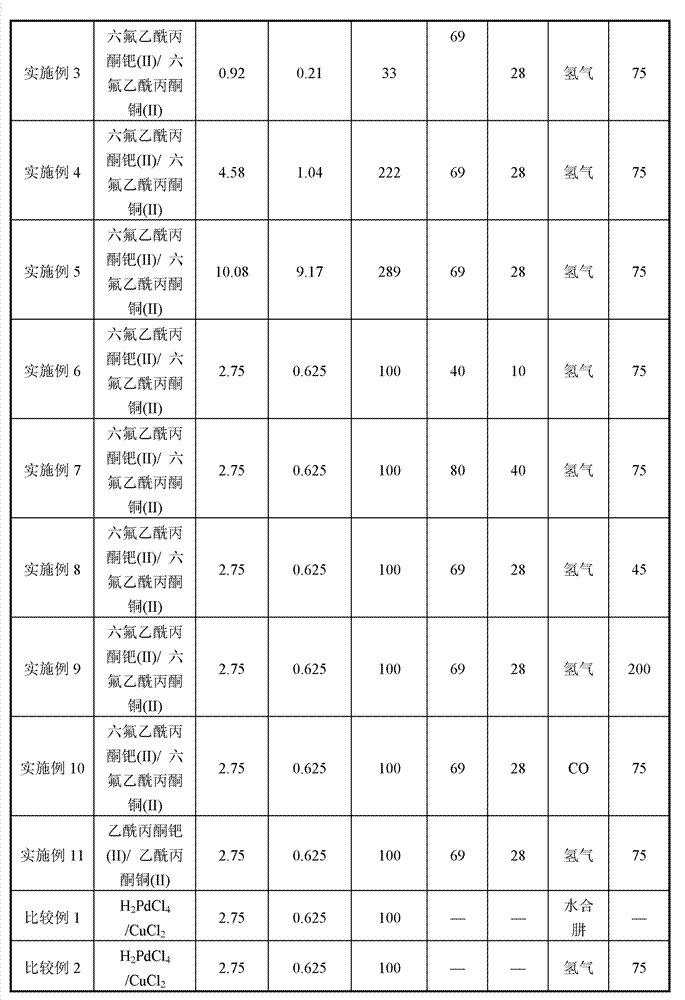

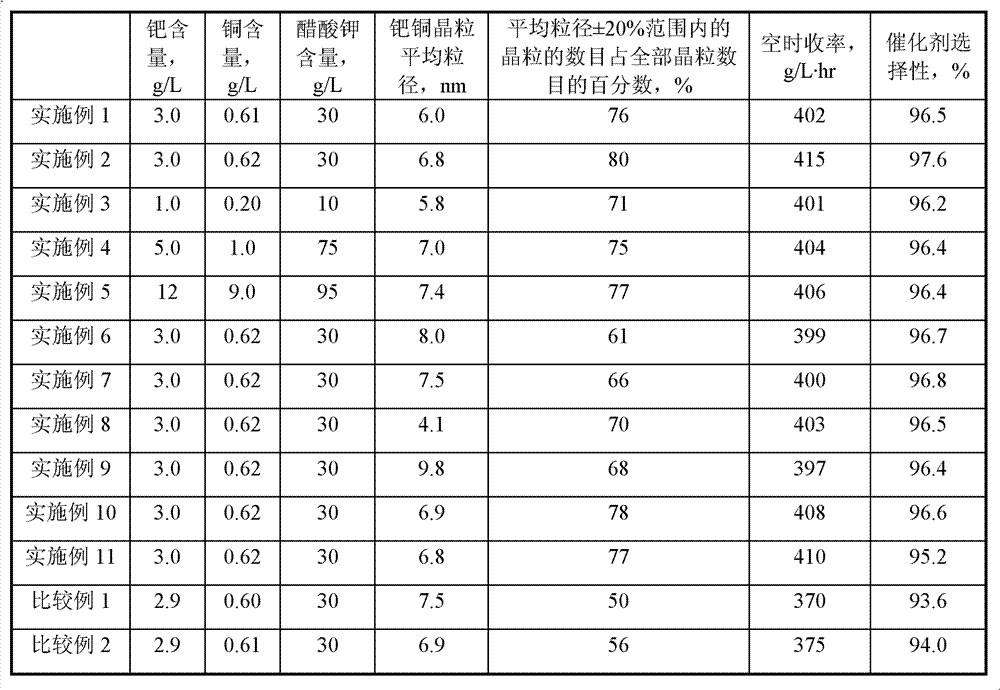

Method for preparing allyl acetate

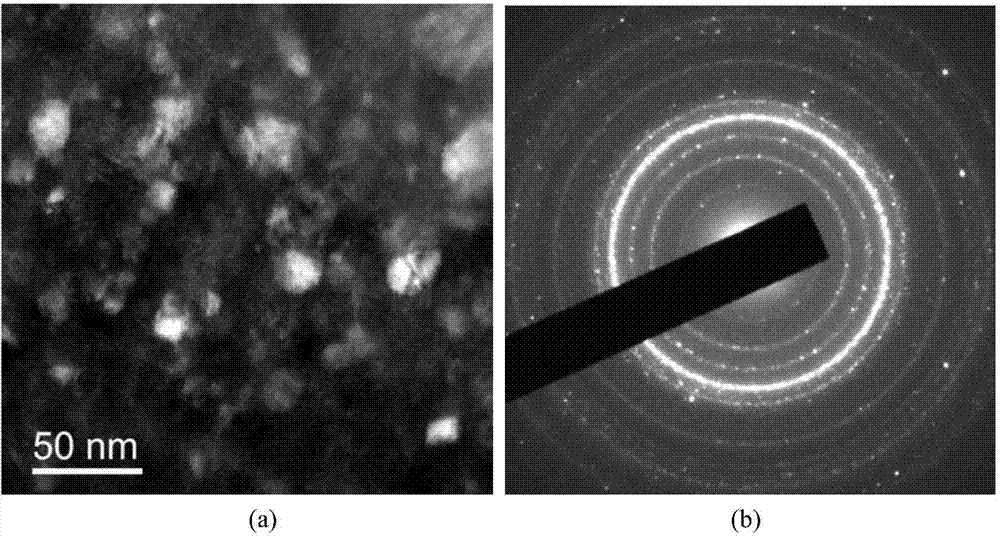

InactiveCN103121955AHigh yieldHigh selectivityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAllyl acetateOxygen

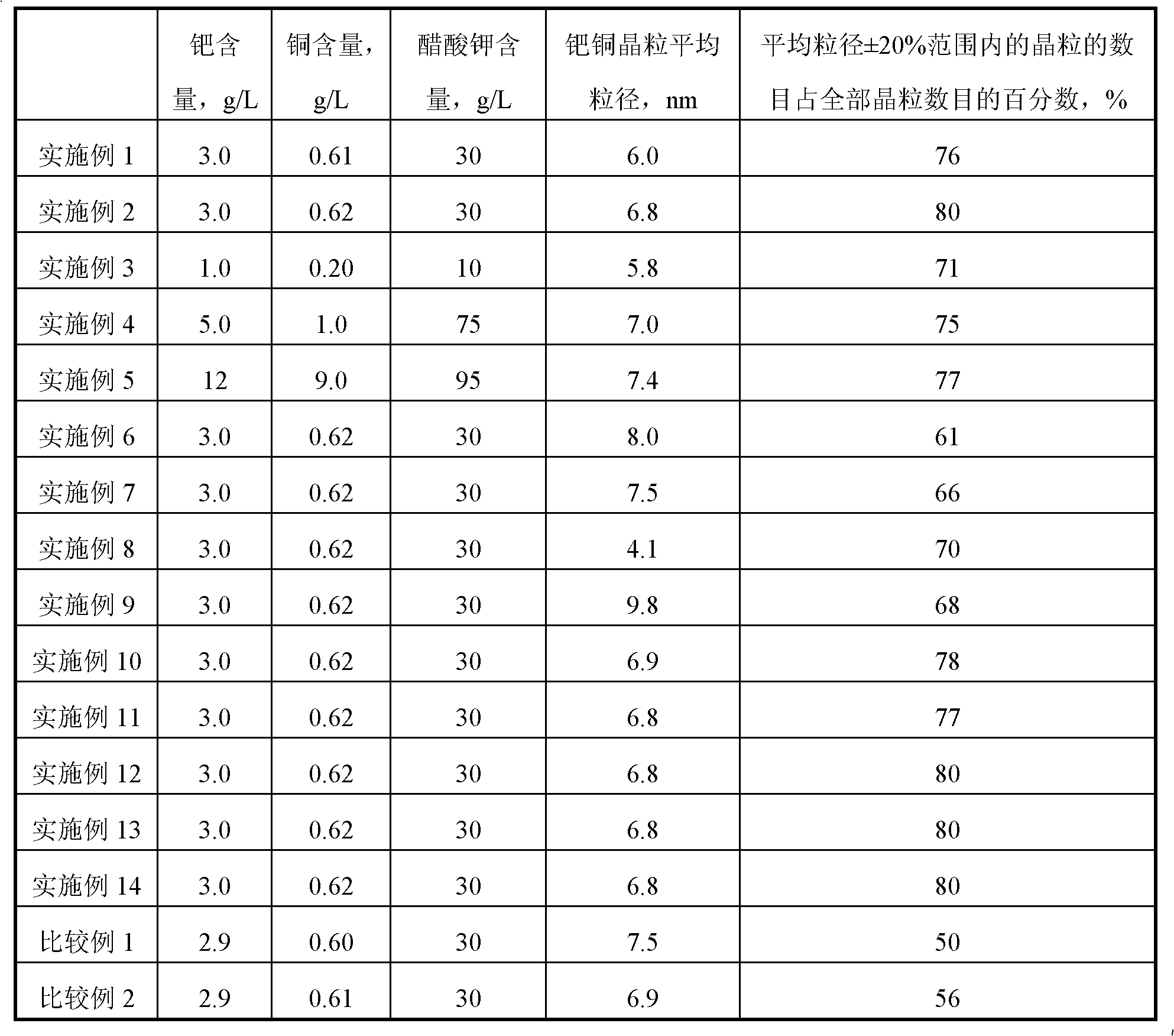

The invention relates to a method for preparing allyl acetate, and the method is mainly used for solving the problems of space time yield and low selectivity of the prior art. The method for preparing allyl acetate is adopted, reaction raw materials which consist of propylene, acetic acid, oxygen and water are contacted with a catalyst so as to obtain a reaction product containing allyl acetate, wherein the catalyst takes SiO2, Al2O3 or a mixture thereof as a carrier, and load active components comprise metal palladium, metal copper and alkali metal acetate; and the catalyst comprises 1-12g / L of palladium, 0.1-10g / L of copper and 10-100g / L of alkali metal acetate, wherein the average crystal grain diameters of palladium and copper are between 4 and 10nm, and crystal grains with the average crystal grain diameters within a scope of plus or minus 20% account for 60-80% of the whole crystal grains. The method can be utilized for better solving the problems and used for allyl acetate industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

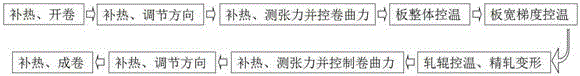

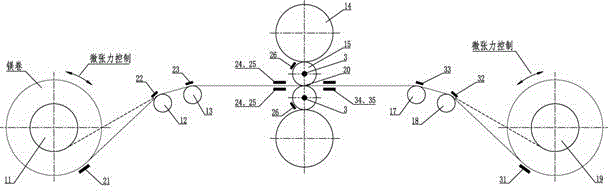

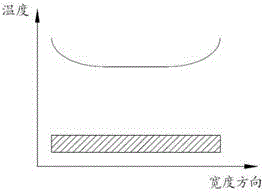

Temperature-controlled rolling technology of magnesium alloy coiled sheet

ActiveCN105834227AAvoid bumpingAvoid featuresTemperature control deviceMetal rolling arrangementsTemperature controlRolling mill

The invention discloses a temperature-controlled rolling technology of magnesium alloy coiled sheets. The steps comprise: (1) performing heating compensation on a magnesium coiled sheet and uncoiling the magnesium coiled sheet; (2) performing sheet heating compensation and adjusting turning directions of the magnesium alloy sheets; (3) measuring tension of the sheet and controlling a crimp force value; (4) performing integrated temperature control on a part which is to bite into the sheet; (5) performing gradient temperature control on the width direction of the part which is to bite into the sheet; (6) through a temperature-controlled roll, performing finishing rolling on the sheet and the sheet deforming; (7) measuring tension of the sheet and controlling a crimp force; (8) performing sheet heating compensation and adjusting turning directions of the magnesium alloy sheets; (9) performing sheet heating compensation and coiling the sheet in rolls; (10) if the thickness of the magnesium plate coil sheet does not reach the thickness (t0) of a target magnesium plate, reversely repeating the steps (1)-(9) on magnesium coiled sheets on a reversible temperature-controlled rolling mill according to the process steps, performing next temperature-controlled finish rolling processing; (11) if the thickness of the magnesium sheet reaches the thickness (t0) of the target magnesium plate, obtaining the magnesium alloy coiled sheet satisfying the thickness requirements.

Owner:BAOSHAN IRON & STEEL CO LTD

Strontium titanate based lead-free high-pressure-resistant ceramic energy storage material and preparation method thereof

ActiveCN107445616ASimple preparation processThe preparation process is matureHysteresisElectrical field strength

The invention discloses a lead-free ceramic material with high energy storage density and energy storage efficiency and a preparation method thereof. The preparation method comprises the following steps of mixing materials according to a chemical formula (1-x)SrTiO3-x(0.93Bi0.5Na0.5TiO3-0.07Ba0.94La0.04Zr0.02Ti0.98O3), uniformly mixing, so as to obtain raw-material powder, uniformly mixing an organic solvent and an emulsifier, then adding the raw-material powder, a binder, a dispersant and a plasticizer, then uniformly mixing, carrying out tape casing, and then cutting, superposing, pressurizing, discharging glue and sintering, so that a strontium titanate based lead-free high-pressure-resistant ceramic energy storage material is obtained. The ceramic material provided by the invention is simple in preparation process, mature in technique, suitable for industrialized production and excellent in energy storage property, and has the energy storage density of 1.80J / cm<3> to 2.83J / cm<3>, the energy storage efficiency of 74 to 87 percent and the electric field intensity of 175kV / cm to 326kV / cm, which are calculated based on an electric hysteresis loop.

Owner:SHAANXI UNIV OF SCI & TECH

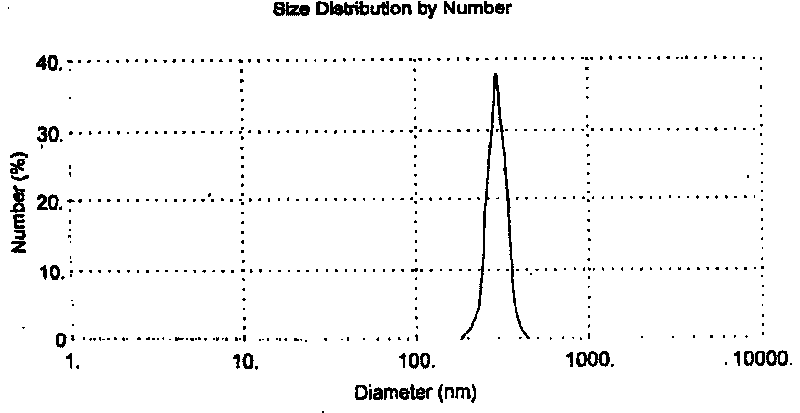

Propenyl ethanoate catalyst and preparation method thereof

ActiveCN103120961BHigh yieldHigh selectivityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsActive componentCopper

The invention relates to a propenyl ethanoate catalyst and a preparation method of the propenyl ethanoate catalyst, in order to mainly solve the problem of low space time yield and selectivity of the catalyst in the prior art. According to the invention, a catalyst for synthesizing propenyl ethanoate is adopted, and SiO2, Al2O3 or the mixture of the SiO2 and Al2O3 are taken as carriers; load active components comprises metal palladium, metal copper and alkali metal acetate; in the catalyst, the content of palladium is 1-12g / L, the content of copper is 0.1-10g / L, and the content of alkali metal acetate is 10-100g / L, wherein the average particle size of palladium copper is 4-10nm, and the number of crystalline grains within the range of -20% to 20% of the average particle size is 60-80% of all the crystalline particles. The technical scheme of the preparation method solves the problem well, and can be used for the industrial production of propenyl ethanoate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for rapidly preparing titanium aluminum carbon ceramic at a room temperature

The invention relates to a method for rapidly preparing a titanium aluminum carbon ceramic at a room temperature. The method comprises: dissolving graphene oxide in deionized water, adding L-ascorbicacid, stirring, controlling the temperature at 80-120 DEG C, carrying out a complete reduction reaction to form a uniform structure graphene hydrogel, and carrying out drying dewatering to obtain a graphene aerogel; uniformly mixing the graphene aerogel, titanium powder and aluminum powder; and pressing the obtained mixed powder into a billet, and carrying out flash sintering treatment by using aplatinum sheet as an electrode and using a graphite column as a pressurizing contact to obtain the compact and uniform titanium aluminum carbon ceramic. Compared with the method in the prior art, themethod for preparing the titanium aluminum carbon ceramic with characteristics of high density, high purity and uniform grain size by using the graphene assisted flash sintering technology in the present invention has characteristics of simple preparation process and high efficiency, and can be completed at a room temperature.

Owner:SHANGHAI JIAO TONG UNIV

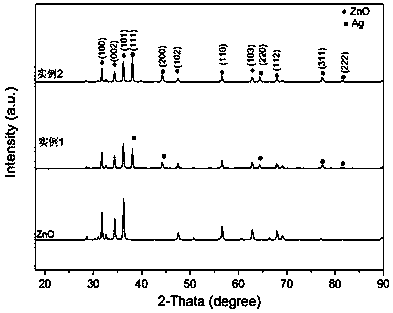

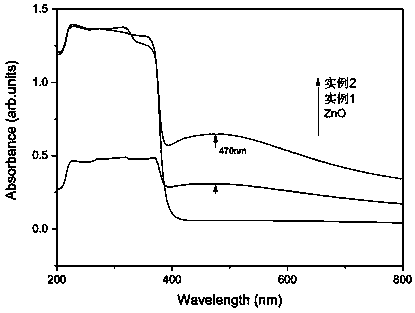

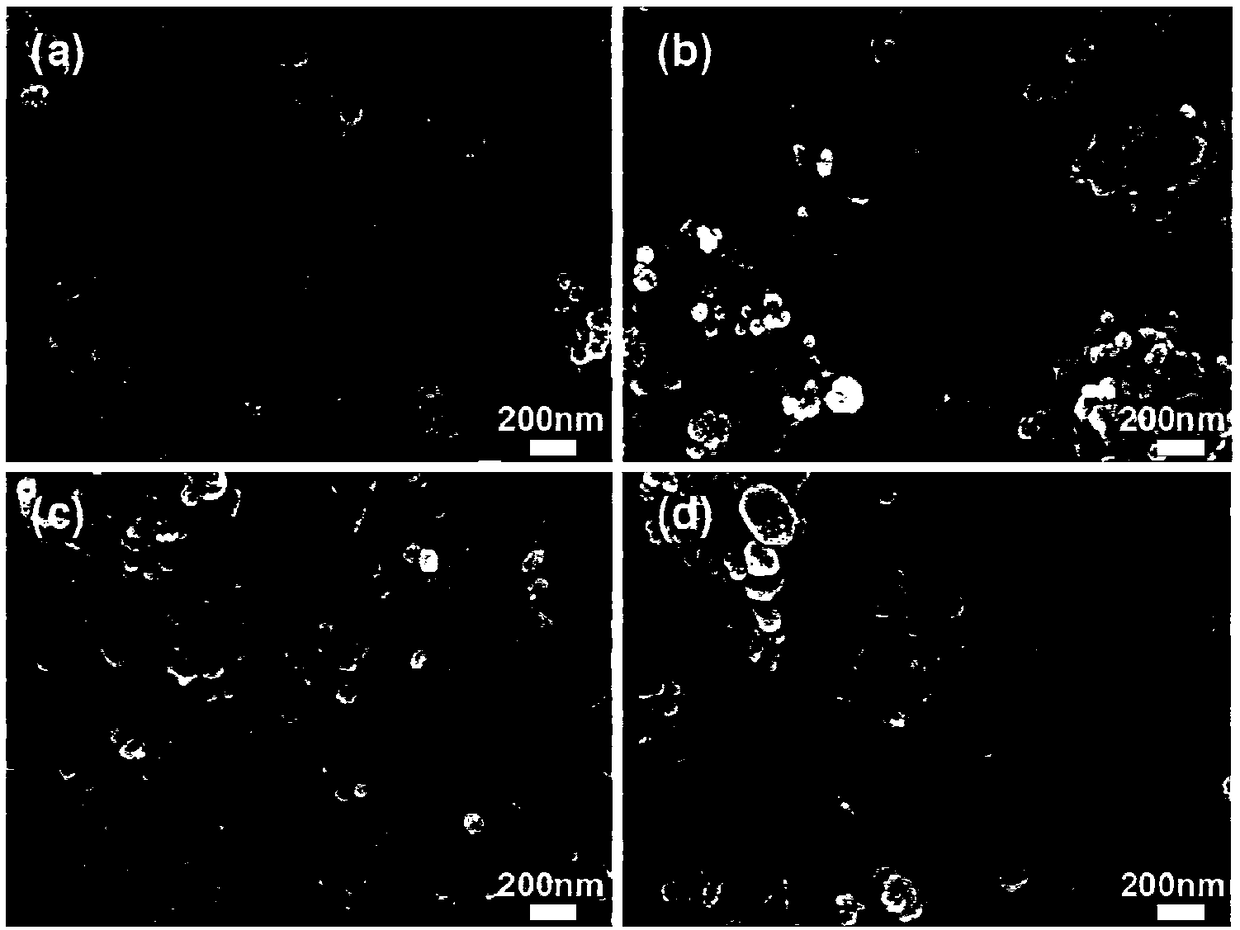

Preparation method of precious metal silver loaded nano-zinc oxide powder

InactiveCN110404533AAvoid hard clumpingReduce hard agglomeratesMaterial nanotechnologyWater/sewage treatment by irradiationDispersityPollution

The invention discloses a preparation method of precious metal silver loaded nano-zinc oxide powder. The preparation method comprises the steps that a water-soluble polymer, zinc nitrate hexahydrate and silver nitrate are taken as raw materials, and through a simple mixing reaction, a gel solution with a certain concentration is prepared; a brown spumescence intermediate is obtained through freezedrying, and finally, calcination is conducted to obtain a silver-zinc oxide target product. Through the entropy effect generated by abundant chain conformations of the water-soluble polymer and strong hydrogen bond association generated by hydrophilic groups on a chain and hydroxyl on the surfaces of particles, dispersion of zinc oxide and silver nanoparticles in a polymer aqueous solution is promoted, and thus nano silver particle loaded zinc oxide with high dispersity is obtained. The preparation technique is simple in process, the prepared powder is good in dispersity, hard agglomeration of the particles is less, the nano silver particle loaded zinc oxide with the high utilization rate and the high dispersity is obtained, the use amount of silver is decreased, raw materials are low incost and easy to obtain, the environment-friendly and pollution-free effects are realized, and the preparation method of the precious metal silver loaded nano-zinc oxide powder is suitable for industrial production.

Owner:BEIJING UNIV OF CHEM TECH

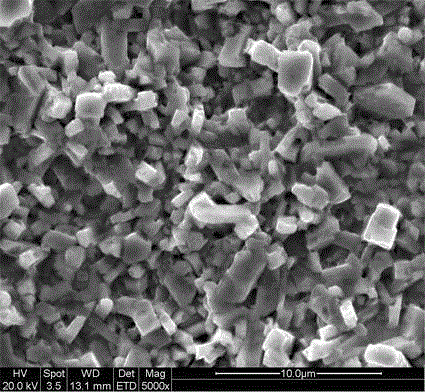

Method for producing iron-zinc alloy coated steel plate with yield strength being equal to or higher than 220 MPa

ActiveCN105274301AFreeze fastCompact structureHot-dipping/immersion processesZinc alloysUltimate tensile strength

The invention discloses a method for producing an iron-zinc alloy coated steel plate with the yield strength being equal to or higher than 220 MPa. The method comprises the steps that molten iron desulphurization, smelting through a converter and continuous casting are conducted, so that a billet is formed; hot rolling is conducted; rolling is conducted; cold rolling is conducted till the billet reaches the required thickness; continuous hot galvanizing is conducted; rapid cooling is conducted; aerial fog is used for cooling after zinc and iron are alloyed; finishing is conducted; oiling treatment is conducted; and sampling, performance testing and subsequence procedure treatment are conducted. According to the method for producing the iron-zinc alloy coated steel plate with the yield strength being equal to or higher than 220 MPa, on the premise that the yield strength ranges from 220 MPa to 260 MPa, the tensile strength ranges from 300 MPa to 380 MPa, and the elongation is equal to or higher than 43%, grains on the surface of a zinc-iron alloy coating are fine and are even in size distribution, the area ratio of holes in the surface of the coating is equal to or smaller than 5%, no microcrack exists on the surface, and the phenomena of pulverization and falling of the coating are unlikely to occur during stamping forming, namely the 90-degree V bending test grade reaches the level 2.

Owner:武汉钢铁有限公司

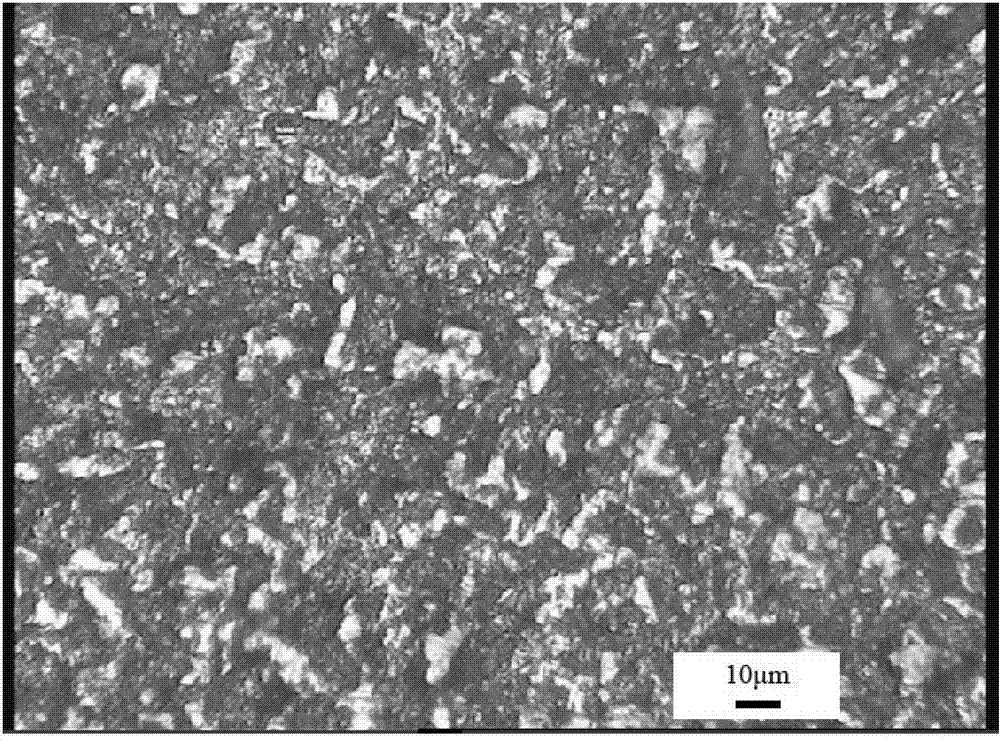

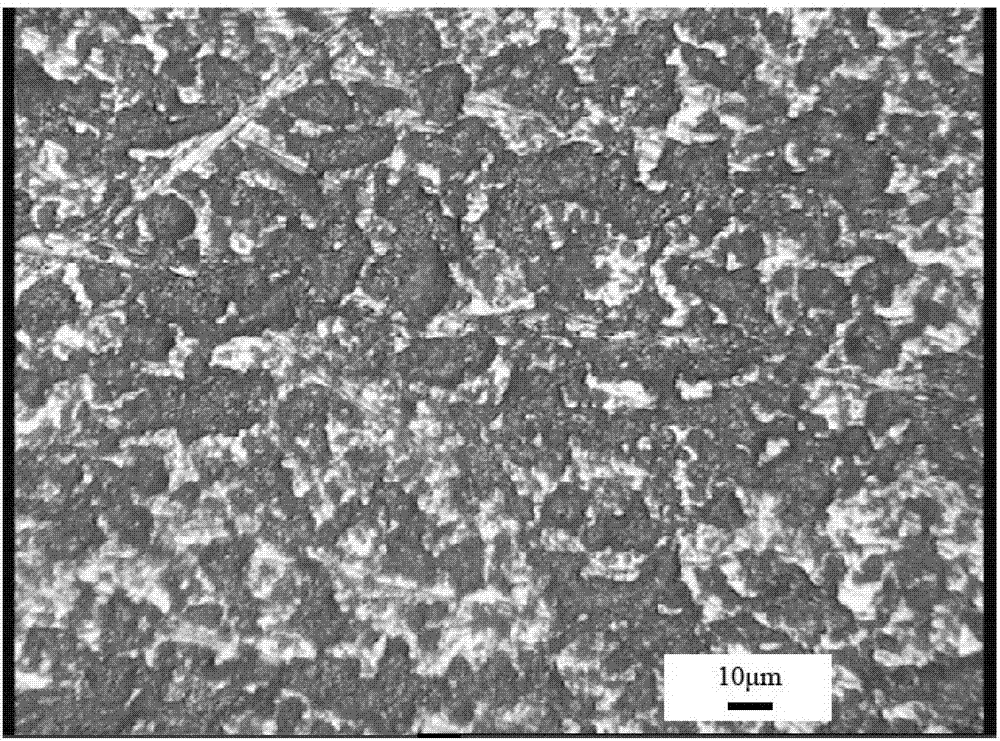

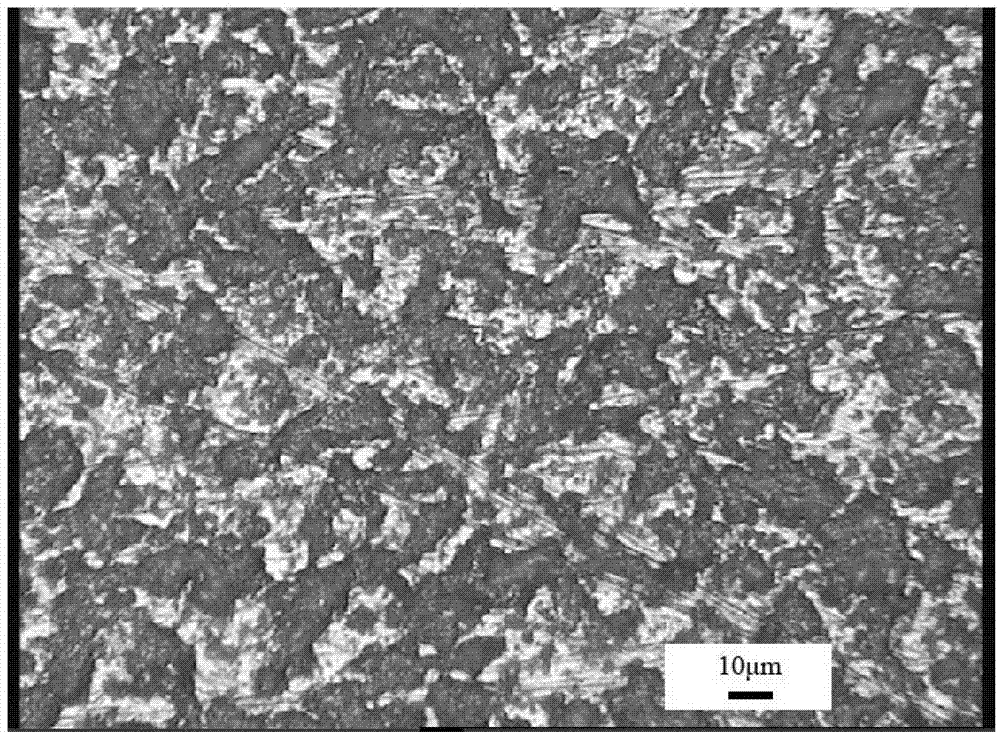

Non-uniform hard alloy prepared by adopting close-packed batching mode and preparation method thereof

The invention discloses a non-uniform hard alloy prepared by adopting a close-packed batching mode, and relates to the technical field of hard alloys. The hard alloy is prepared from the following rawmaterials: coarse-particle tungsten carbide, medium-particle tungsten carbide and nano-particle tungsten carbide powder. The invention further provides a preparation technology process method of thehard alloy. The non-uniform hard alloy has the beneficial effects that the average grain size of the prepared hard alloy is 5-10 microns, the coarse grain size reaches 10-20 microns, the Vickers hardness is 1050 or above, the bending strength TRS is 2200MPa or above, the metallographic structure of alloy grains is thick and large, the heat conductivity is extremely high, the thermal fatigue resistance and the thermal impact resistance are good, and the non-uniform hard alloy can be used for continuous exploitation of soft rock under extreme working conditions and the like.

Owner:江西江钨硬质合金有限公司

Production method of chromium-aluminium alloy target material

ActiveCN103182507BHigh densityUniform grain size distributionVacuum evaporation coatingSputtering coatingAl powderHigh density

The invention relates to a production method of a chromium-aluminum alloy target material, which includes the following steps: (1) placing chromium powder and aluminum powder into a V-shaped mixer for mixing; (2) placing the powder into a cold isostatic pressing sheath, vacuumizing, sealing, suppressing for 10 to 20 minutes, then placing in a vacuum self-propagating high-temperature synthetic furnace, and performing self-propagating reaction to acquire foamed chromium-aluminium alloy; (3) smashing the chromium-aluminium alloy into alloy powder with size of -200 mesh, placing the alloy powder in the cold isostatic pressing sheath for suppressing, so as to obtain a chromium-aluminium alloy blank; (4) placing the alloy blank in a steel sheath for vacuum degassing, then, performing hot isostatic pressing sintering treatment to obtain a chromium-aluminium alloy ingot; and (5) machining the chromium-aluminium alloy ingot to obtain a finished chromium-aluminium alloy target material. According to the invention, after the two raw materials are fully mixed and before the hot isostatic pressing sintering treatment is carried out, the alloying treatment in the step (2) is particularly adopted, so the prepared chromium-aluminum alloy target material has high density, uniform crystallite size distribution and excellent vacuum coating property.

Owner:北京九州新科科技有限公司

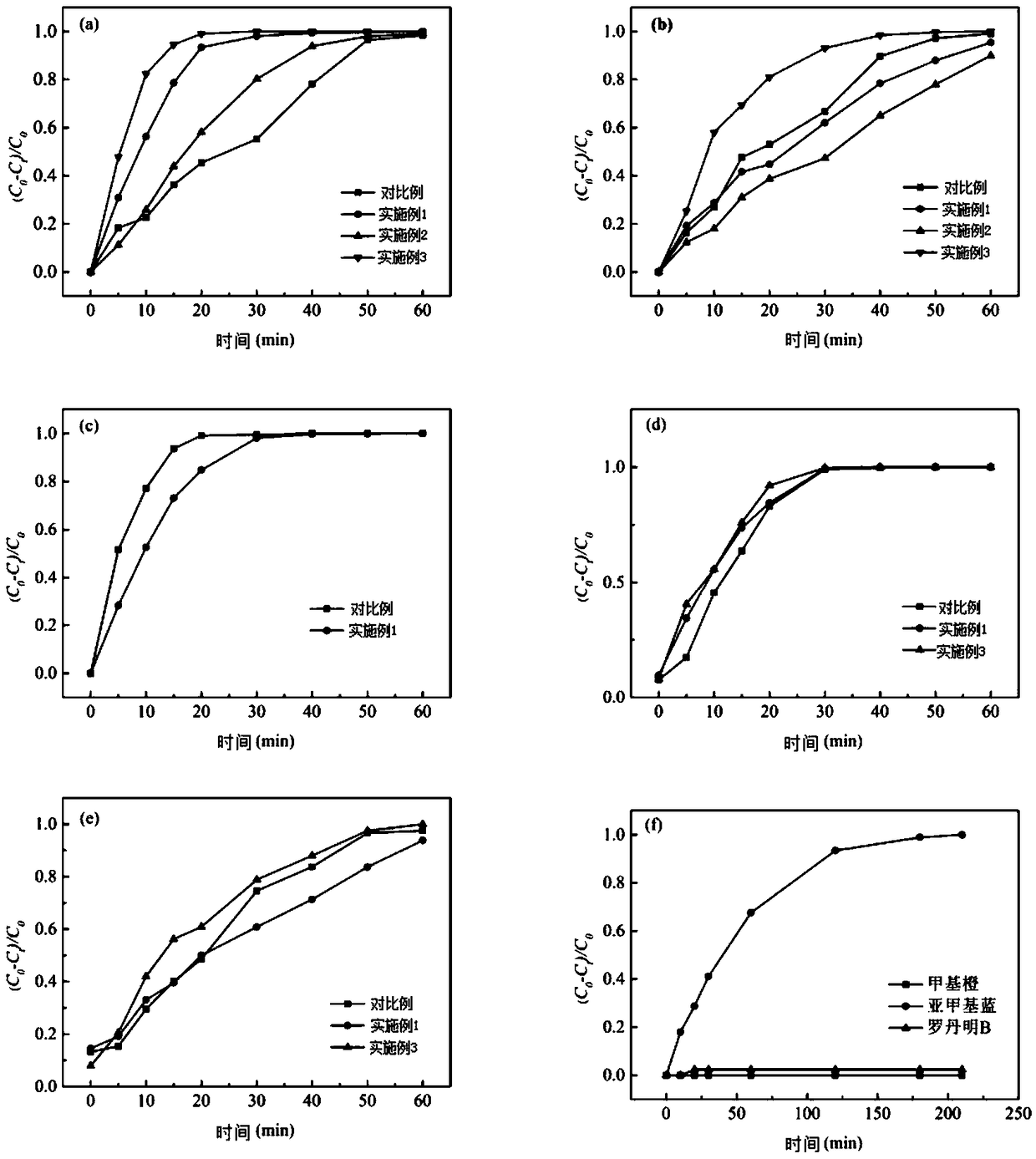

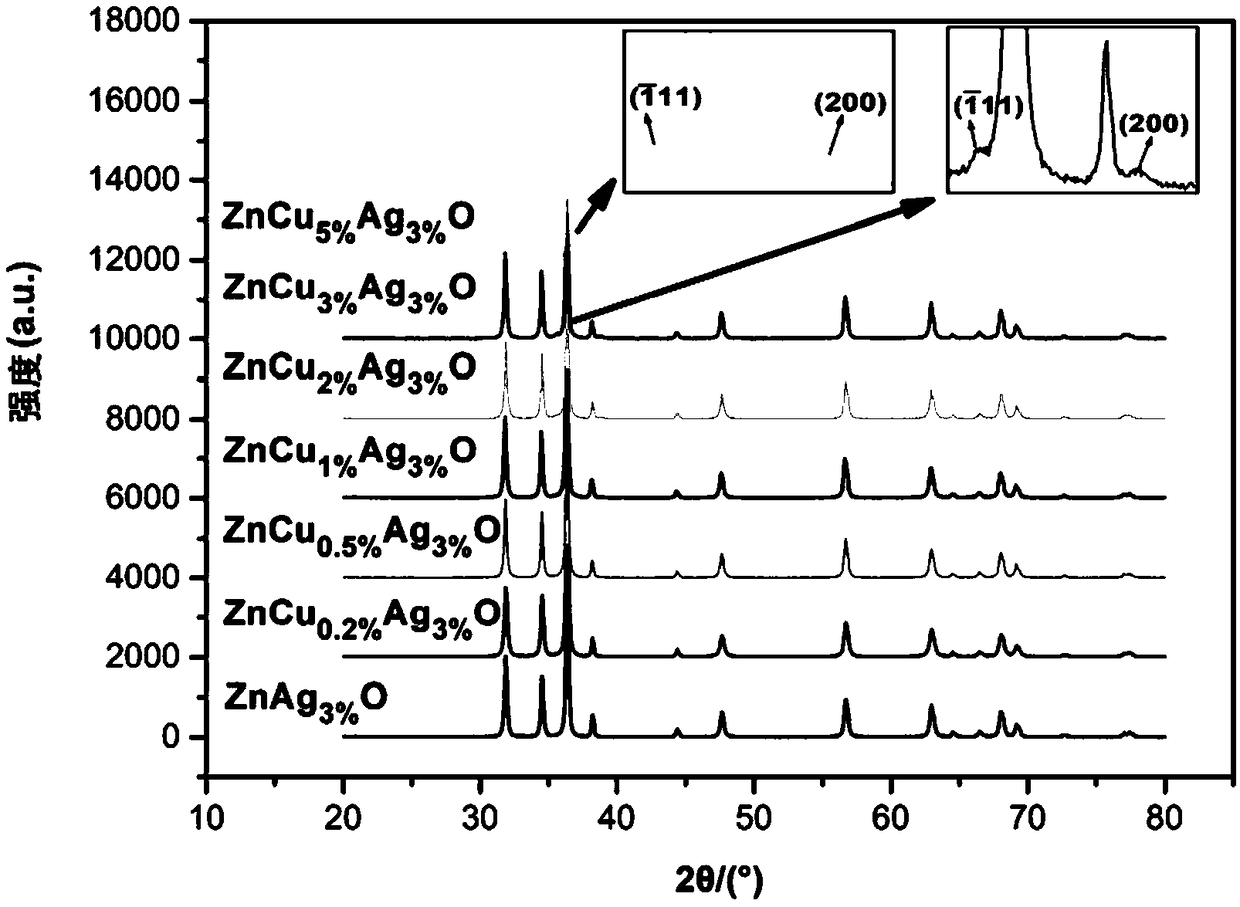

Copper and silver co-doped nano-zinc oxide used as photocatalyst, and preparation method of copper and silver co-doped nano-zinc oxide

InactiveCN109225259AGood crystallinityUniform grain size distributionMetal/metal-oxides/metal-hydroxide catalystsZinc Acetate DihydrateSolvent

The invention discloses copper and silver co-doped nano-zinc oxide used as a photocatalyst, and a preparation method of the copper and silver co-doped nano-zinc oxide. A sol-gel method is adopted, metal alkoxides (copper acetate and zinc acetate) and acid salt (silver nitrate) are used as raw materials and dissolved in a solvent to form gel with a certain spatial structure, finally drying and heattreatment processes are carried out, and thus the copper and silver co-doped nano-zinc oxide uniform in particle size and high in purity can be prepared. Copper and sliver are doped in zinc oxide, sothat the production cost is reduced and industrial production is achieved while the catalytic activity of the nano-zinc oxide is improved.

Owner:SOUTHWEST UNIVERSITY FOR NATIONALITIES

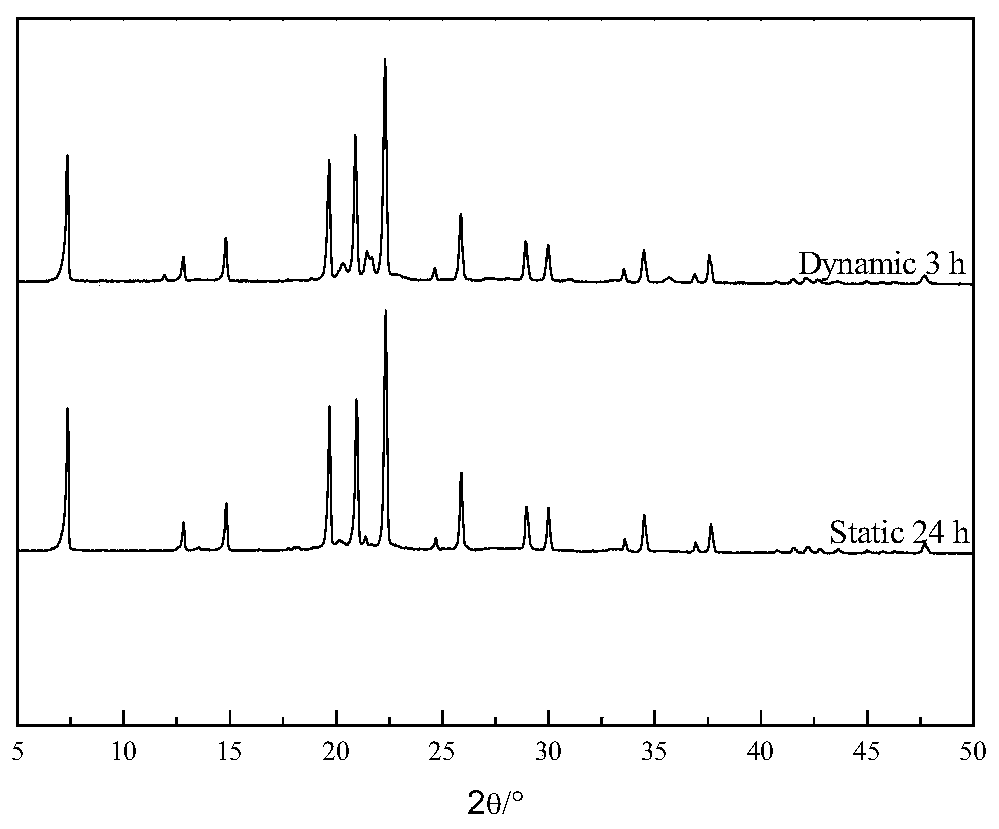

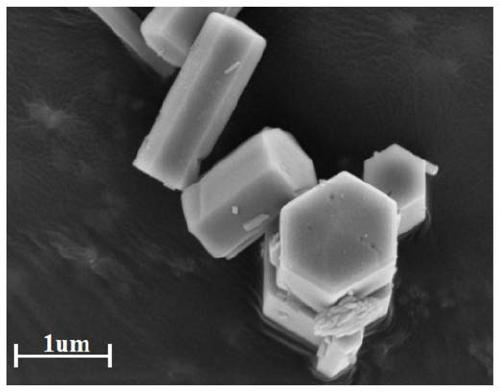

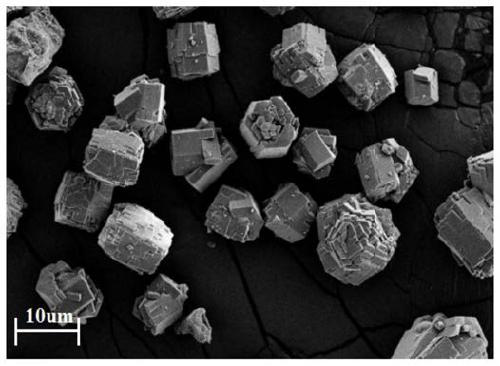

A kind of preparation method of hierarchical porous heteroatom aluminum phosphate molecular sieve for oxidative desulfurization

ActiveCN107777702BHigh crystallinityAvoid reunionRefining with halogen compoundsMolecular-sieve aluminophosphatesMolecular sievePtru catalyst

Owner:CHANGZHOU UNIV

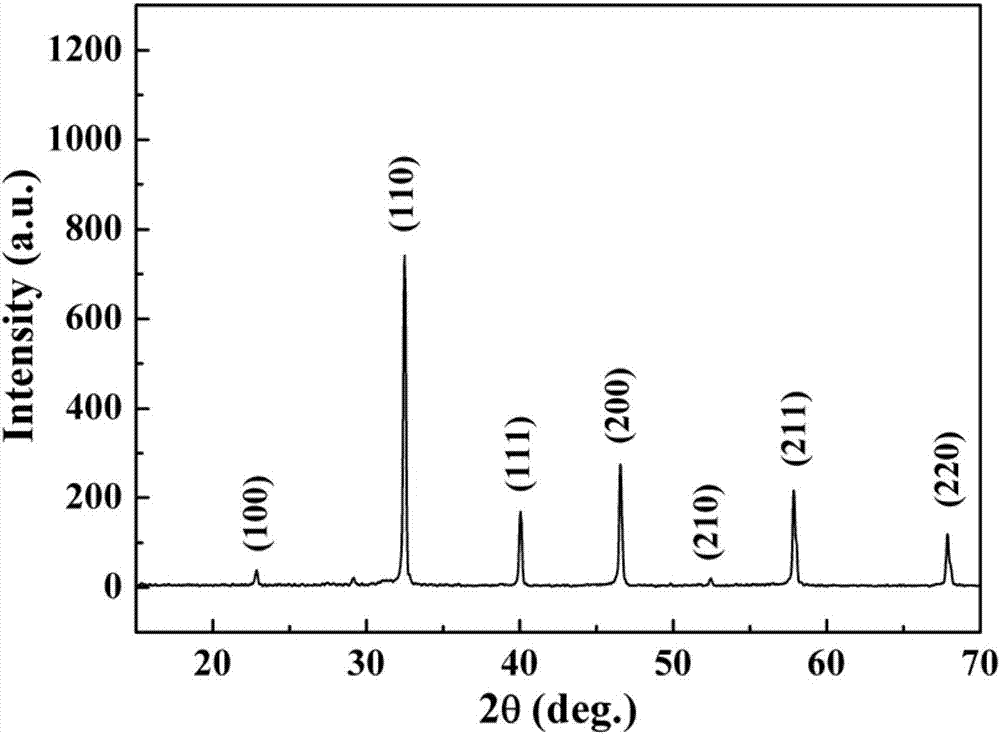

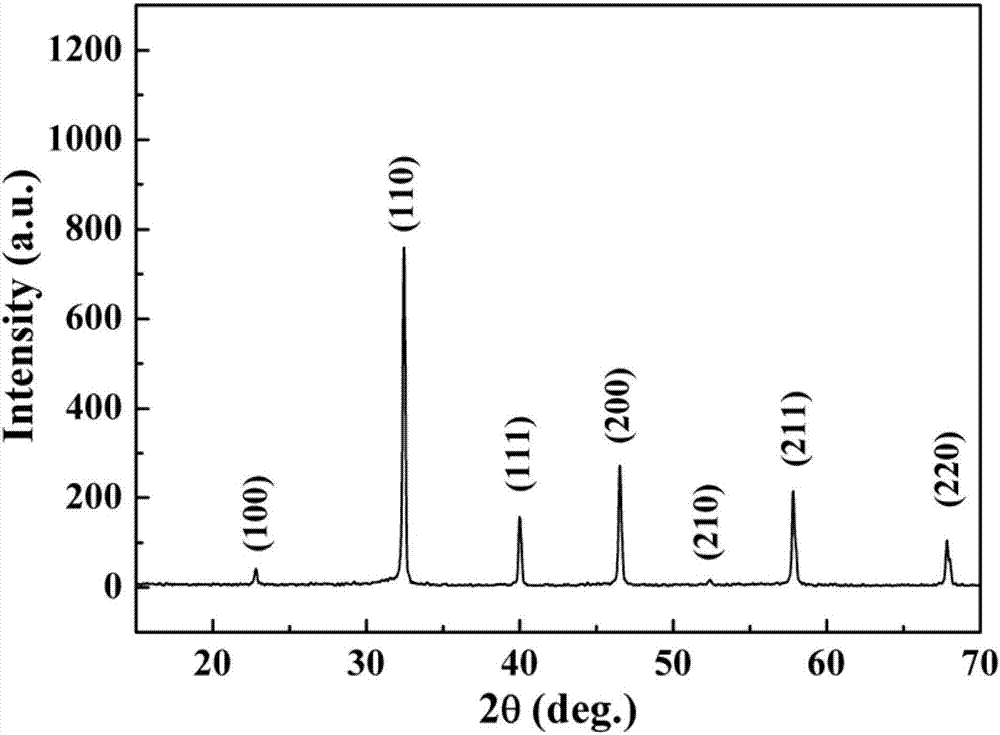

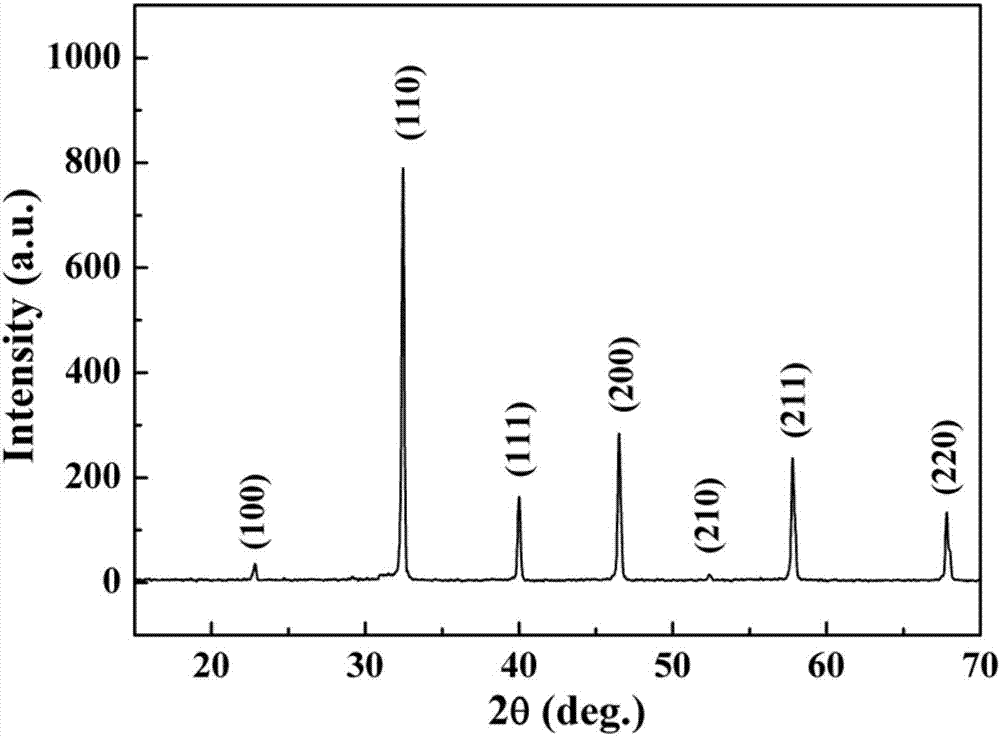

A preparation method of perovskite thin film based on magnetic field control

ActiveCN107482121BImprove performanceEnhanced light absorptionSolid-state devicesSemiconductor/solid-state device manufacturingFilm baseElectrical battery

The invention discloses a method for preparing a perovskite thin film based on magnetic field control, and belongs to the technical field of solar cells. The main steps include: through a film-forming process that is easy to realize industrialization, lead(II) iodide, PbI 2 ) and methylamine iodine (CH 3 NH 3 In the mixed solution of I), a rotating magnetic field of a certain frequency and intensity is introduced during the preparation process, and then heat-treated to obtain a dense, smooth, and uniform perovskite crystal film. The method of the present invention can also prepare smooth and dense perovskite films without using vacuum equipment, glove boxes, etc., and has the advantages of low cost and large-area preparation. The perovskite crystal thin film obtained by this method is used as a light-absorbing material in thin-film solar cells, and the prepared cell device has high efficiency and good stability, which is very important for realizing low-cost preparation and industrialization of high-efficiency perovskite solar cells of great value.

Owner:XIAMEN UNIV

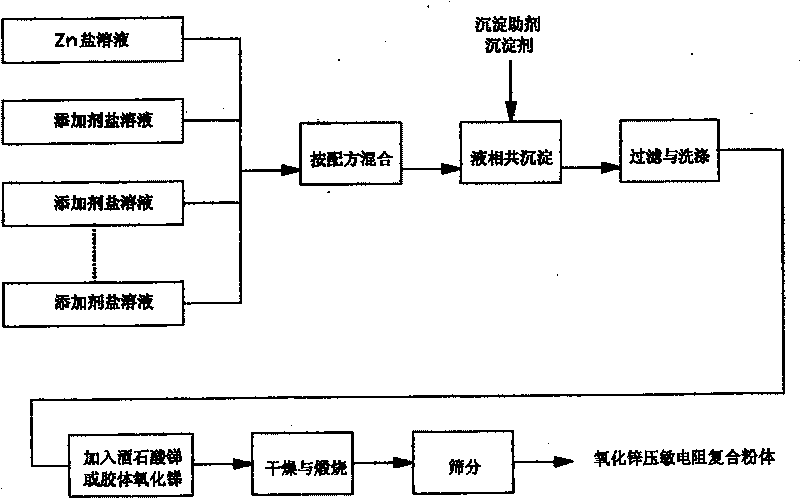

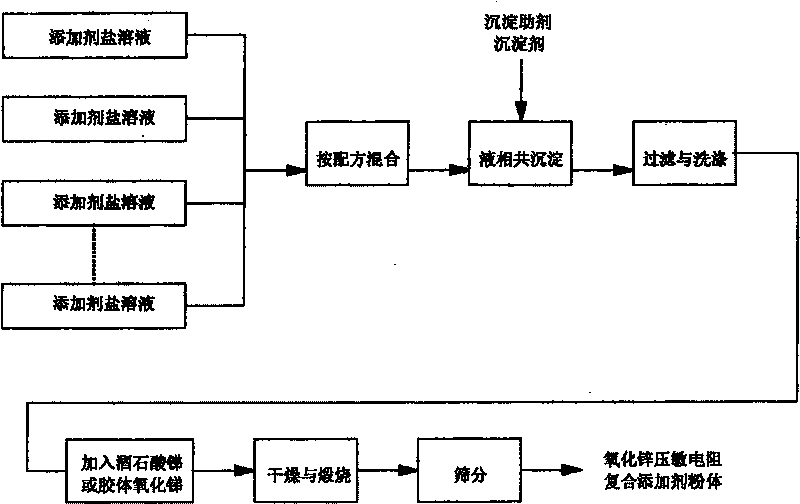

Preparation of zinc oxide piezoresistor composite powder and compound additive agent powder

ActiveCN101246769BUniform compositionNarrow particle size distributionOxide conductorsVaristor coresGranularityCoprecipitation

The invention is a preparing method of a zinc-oxide varistor composite powder and a zinc-oxide varistor composite additive powder, comprising the steps of: (1) mixing according to the formulation, (2)liquid phase coprecipitation, (3) filtering and washing, (4) adding antimony tartrate or colloidal antimony oxide, (5) drying and calcining, and (6) screen separating. In steps (1) and (2), the saltsolutions of the component are uniformly mixed and liquid phase coprecipitated, ensuring the uniformity of the zinc-oxide varistor composite powder. The coprecipitation agent is NaOH or Na2CO3, the coprecipitation promoter is NH4OH. In step (2), the mixed solution of the coprecipitation agent and the coprecipitation promoter is added to a reaction system, so that each component can be combined instantaneously under the same process condition. The method can produce a zinc-oxide varistor composite powder and a zinc-oxide varistor composite additive powder which have a granularity of less than 1mum, narrow granularity distribution scope, uniform components and impurity of no more than 0.01%.

Owner:雷慧绪

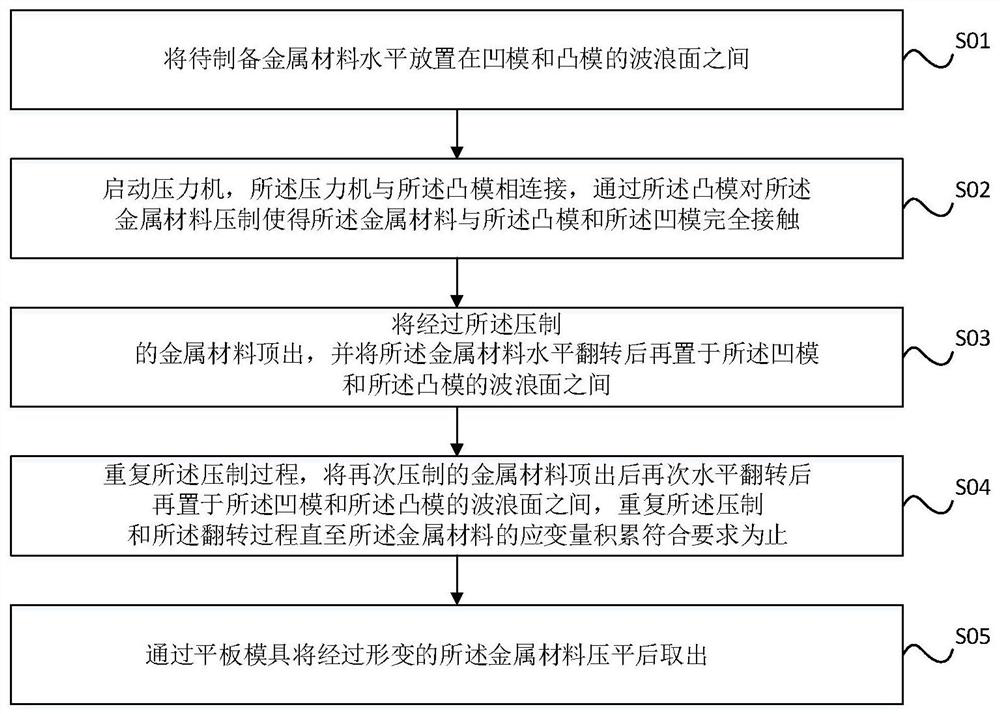

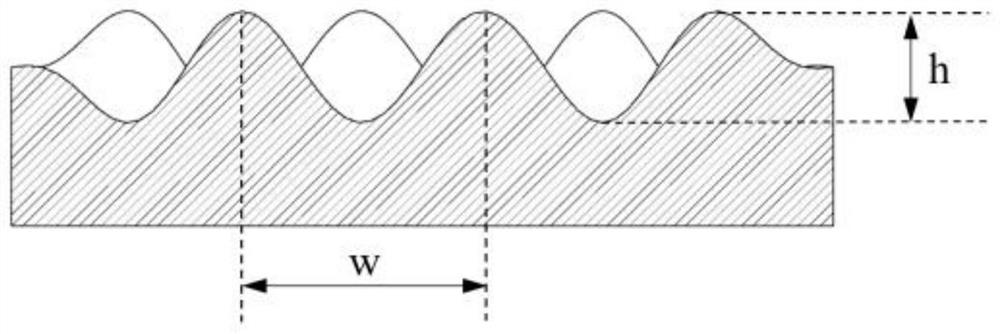

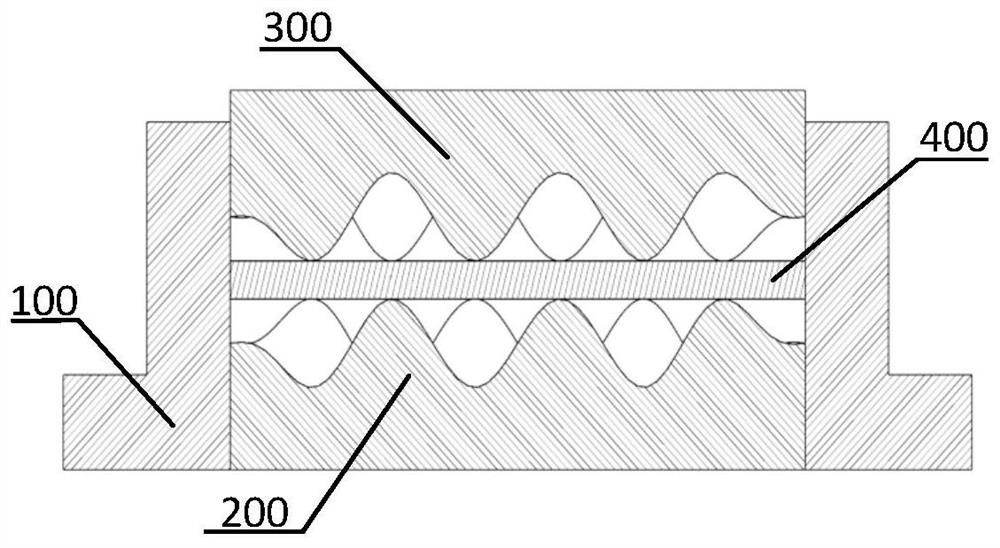

A kind of preparation method of metal material

ActiveCN112588855BUniform grain size distributionStrong refinement abilityExtrusion diesMetallic materialsMetal

Owner:SHANGHAI JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com