Preparation method of low-cost and high-density ITO target material

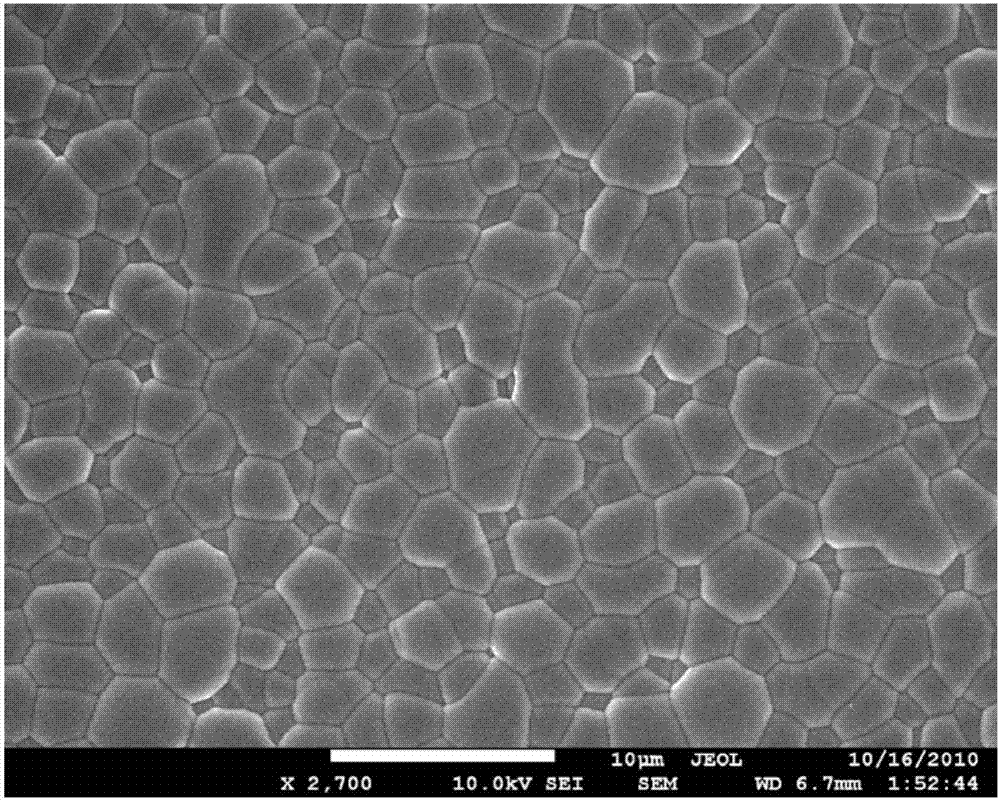

A high-density, low-cost technology, applied in metal material coating process, ion implantation plating, coating, etc., can solve the problems of high cost and unfavorable mass production, and achieve high density and uniform grain size distribution , the effect of low resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment provides a low-cost, high-density ITO target preparation method, including the following steps:

[0024] (1) Preparation of premixed liquid: add dispersant and adhesive into water, stir evenly, adjust the pH to 10 with ammonia water to obtain premixed liquid; the added amount of dispersant is 0.25% of the mass of ITO powder, The addition amount is 1% of the mass of the ITO powder, and the addition amount of water is 15% of the mass of the ITO powder; the dispersant is a mixture of citric acid and polyacrylamide in a weight ratio of 1-2:1;

[0025] (2) Preparation of suspension slurry: add ITO powder prepared by chemical co-precipitation method and sintering agent to the premix, and then ball mill in a ball mill. After ball milling, the mixed slurry is obtained, stirred and vacuumed to remove the slurry. The bubbles; the sintering agent consists of rare earth oxides, titanium nitride and nano-GeO 2 Composition; the rare earth oxide is CeO 2 , Y 2 O 3 Or Dy 2 O...

Embodiment 2

[0032] This embodiment provides a low-cost, high-density ITO target preparation method, including the following steps:

[0033] (1) Preparation of premixed liquid: add dispersant and adhesive into water, stir evenly, adjust pH to 8 with ammonia water to obtain premixed liquid; the added amount of dispersant is 0.3% of the mass of ITO powder, The addition amount is 0.3% of the mass of the ITO powder, and the addition amount of water is 20% of the mass of the ITO powder; the dispersant is a mixture of citric acid and polyacrylamide in a weight ratio of 1-2:1;

[0034] (2) Preparation of suspension slurry: add ITO powder prepared by chemical co-precipitation method and sintering agent to the premix, and then ball mill in a ball mill. After ball milling, the mixed slurry is obtained, stirred and vacuumed to remove the slurry. The bubbles; the sintering agent consists of rare earth oxides, titanium nitride and nano-GeO 2 Composition; the rare earth oxide is CeO 2 , Y 2 O 3 Or Dy 2 O 3 T...

Embodiment 3

[0041] This embodiment provides a low-cost, high-density ITO target preparation method, including the following steps:

[0042] (1) Preparation of premixed liquid: add dispersant and adhesive into water, stir evenly, adjust the pH to 11 with ammonia water to obtain premixed liquid; the added amount of dispersant is 0.2% of the mass of ITO powder, The addition amount is 2% of the mass of the ITO powder, and the addition amount of water is 10% of the mass of the ITO powder; the dispersant is a mixture of citric acid and polyacrylamide in a weight ratio of 1-2:1;

[0043] (2) Preparation of suspension slurry: add ITO powder prepared by chemical co-precipitation method and sintering agent to the premix, and then ball mill in a ball mill. After ball milling, the mixed slurry is obtained, stirred and vacuumed to remove the slurry. The bubbles; the sintering agent consists of rare earth oxides, titanium nitride and nano-GeO 2 Composition; the rare earth oxide is CeO 2 , Y 2 O 3 Or Dy 2 O ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com