Preparation of zinc oxide piezoresistor composite powder and compound additive agent powder

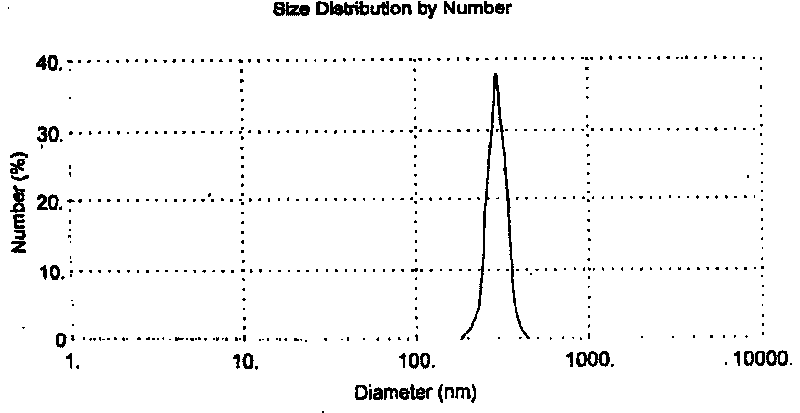

A composite additive, varistor technology, applied in the direction of varistor core, varistor, oxide conductor, etc. The problem of obtaining composite powder, etc., to achieve the effect of narrow particle size distribution, low price and dense structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

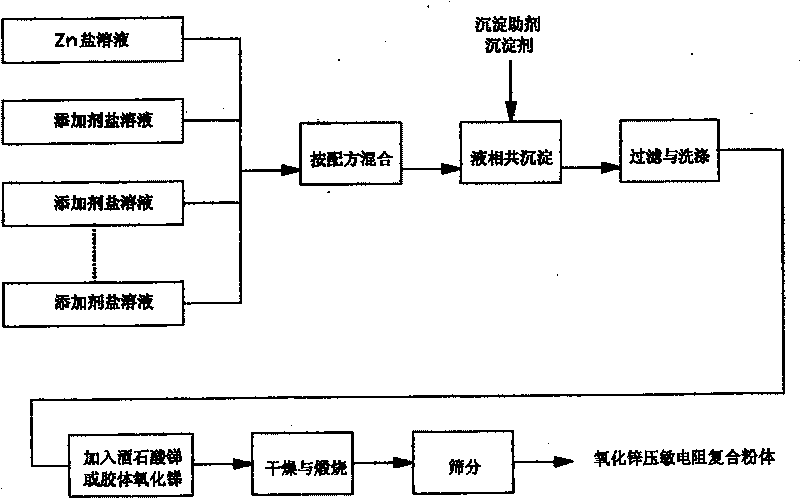

Method used

Image

Examples

Embodiment 1

[0052] This embodiment prepares 1 kg of zinc oxide varistor composite powder, and the formula of the zinc oxide varistor composite powder is:

[0053] ZnO 90.1893%, Bi 2 O 3 3.3929%, Ni 2 O 3 0.7039%, Sb 2 O 3 3.3272%, Co 2 O 3 1.3043%, Cr 2 O 3 0.7012%, MnCO 3 0.3775%, Al(NO 3 ) 3 ·9H 2 O 0.005529%.

[0054] In this example, metal Zn, Bi, Ni, Co, Cr, Mn, Al are used as raw materials and concentrated hydrochloric acid is used as solvent to prepare Zn salt, Bi salt, Ni salt, Co salt, Cr salt, Mn salt and Al salt solution respectively, The concentration of each salt solution is not strictly required, as long as no crystals are precipitated.

[0055] The process steps of preparing zinc oxide varistor composite powder are as follows:

[0056] (1) Mix according to the formula

[0057] Add Zn salt, Bi salt, Ni salt, Co salt, Cr salt, Mn salt and Al salt solution into the reaction vessel according to the amount required by the formula of zinc oxide varistor compo...

Embodiment 2

[0076] The present embodiment prepares 5 kilograms of zinc oxide varistor composite powder, and the formula of the zinc oxide varistor composite powder is:

[0077] ZnO 90.1893%, Bi 2 O 3 3.3929%, Ni 2 O 3 0.7039%, Sb 2 O 3 3.3272%, Co 2 O 3 1.3043%, Cr 2 O 3 0.7012%, MnCO 3 0.3775%, Al(NO 3 ) 3 ·9H 2 O 0.005529%.

[0078] In this example, metals Zn, Bi, Ni, Co, Cr, Mn, Al are used as raw materials, and a nitric acid solution with a mass concentration of 30% is used as a solvent to prepare Zn salt, Bi salt, Ni salt, Co salt, Cr salt, and Mn salt respectively. , Al salt solution, the concentration of each salt solution is not strictly required, as long as there is no crystal precipitation.

[0079] The process steps of preparing zinc oxide varistor composite powder are as follows:

[0080] (1) Mix according to the formula

[0081] Add Zn salt, Bi salt, Ni salt, Co salt, Cr salt, Mn salt and Al salt solution to the reaction vessel according to the amount requ...

Embodiment 3

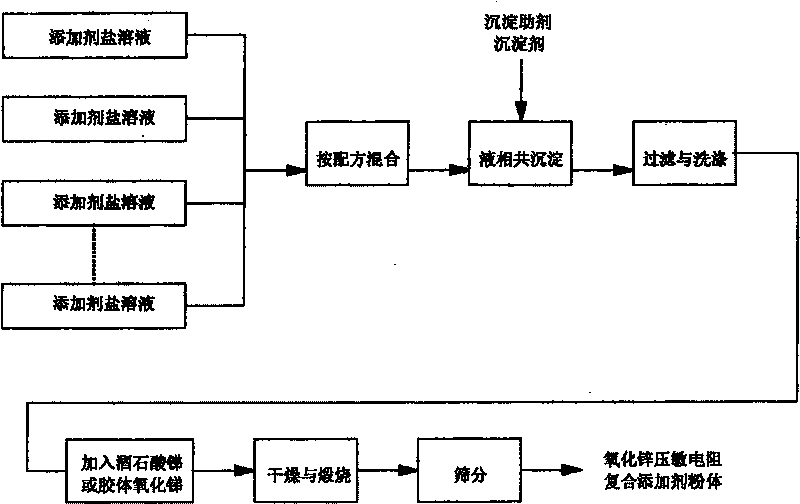

[0099] The present embodiment prepares 1 kg of zinc oxide varistor composite additive powder, and the formula of the zinc oxide varistor composite additive powder is:

[0100] Bi 2 O 3 36.70%, Sb 2 O 3 40.50%, Ni 2 O 3 8.80%, Co 2 O 3 8.60%, MnO 2 4.28%, Y 2 O 3 0.82%, Cr 2 O 3 0.20%, Al 2 O 3 0.10%.

[0101]In this example, metal Bi, Ni, Co, Mn, Y, Cr, and Al are used as raw materials, and concentrated hydrochloric acid is used as solvent to prepare Bi salt, Ni salt, Co salt, Mn salt, Y salt, Cr salt, and Al salt solution respectively. , the concentration of each salt solution is not strictly required, as long as there is no crystal precipitation.

[0102] The process steps of preparing zinc oxide varistor composite additive powder are as follows:

[0103] (1) Mix according to the formula

[0104] Add Bi salt, Ni salt, Co salt, Mn salt, Y salt, Cr salt and Al salt solution into the reaction vessel according to the amount required by the formula of zinc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com