Method for preparing fine-grained magnesium alloy with superplastic deformability

A magnesium alloy and superplastic technology, which is applied in the field of rolling and preparation of fine-grained magnesium alloys with superplastic deformation ability, and can solve the problems of difficulty in obtaining superplastic deformation characteristics, disadvantage of sheet strength stamping and forming, and difficulty in preparing large-sized materials. , to achieve the effect of easy operation, improve forming ability and reduce cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

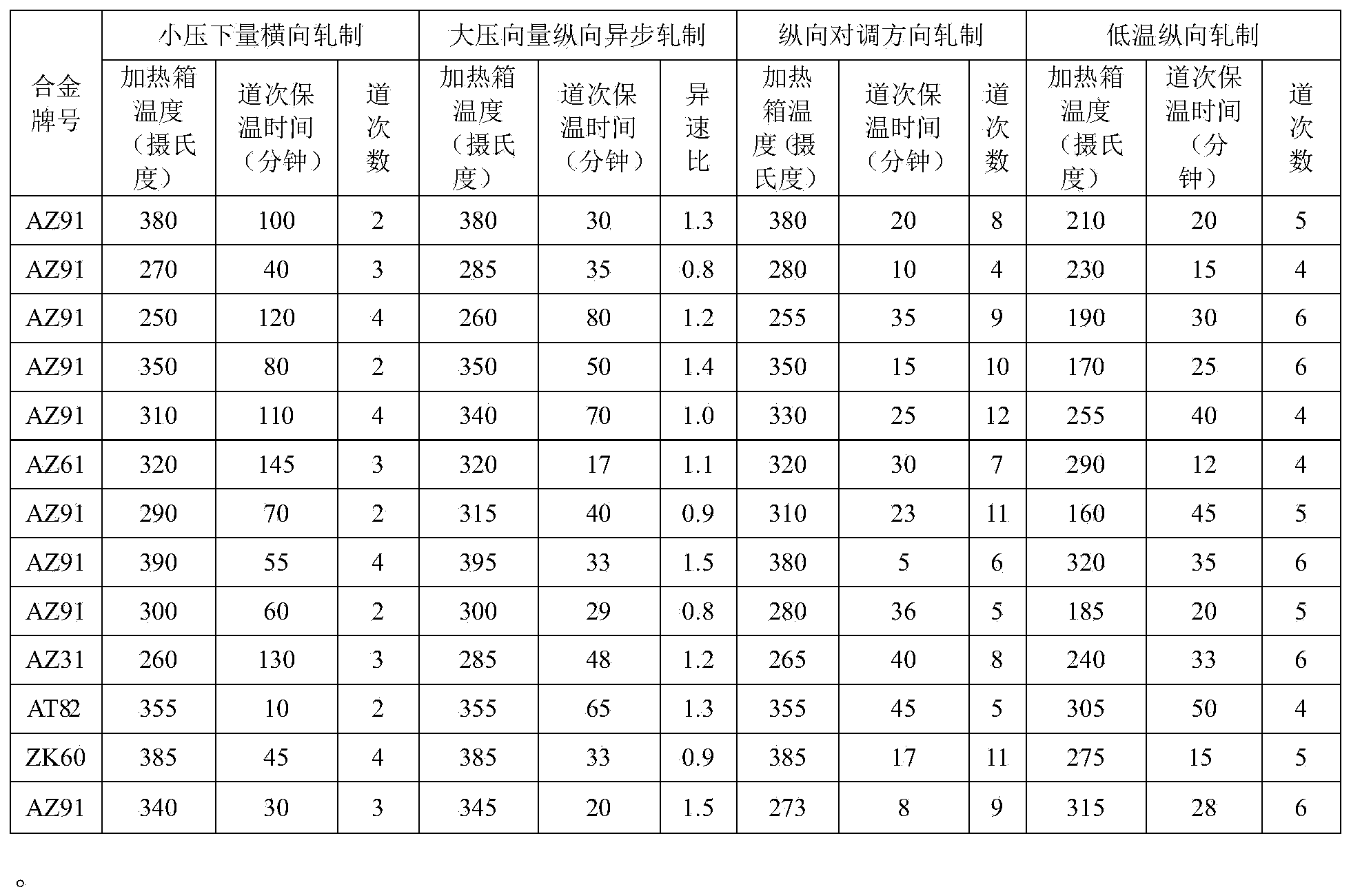

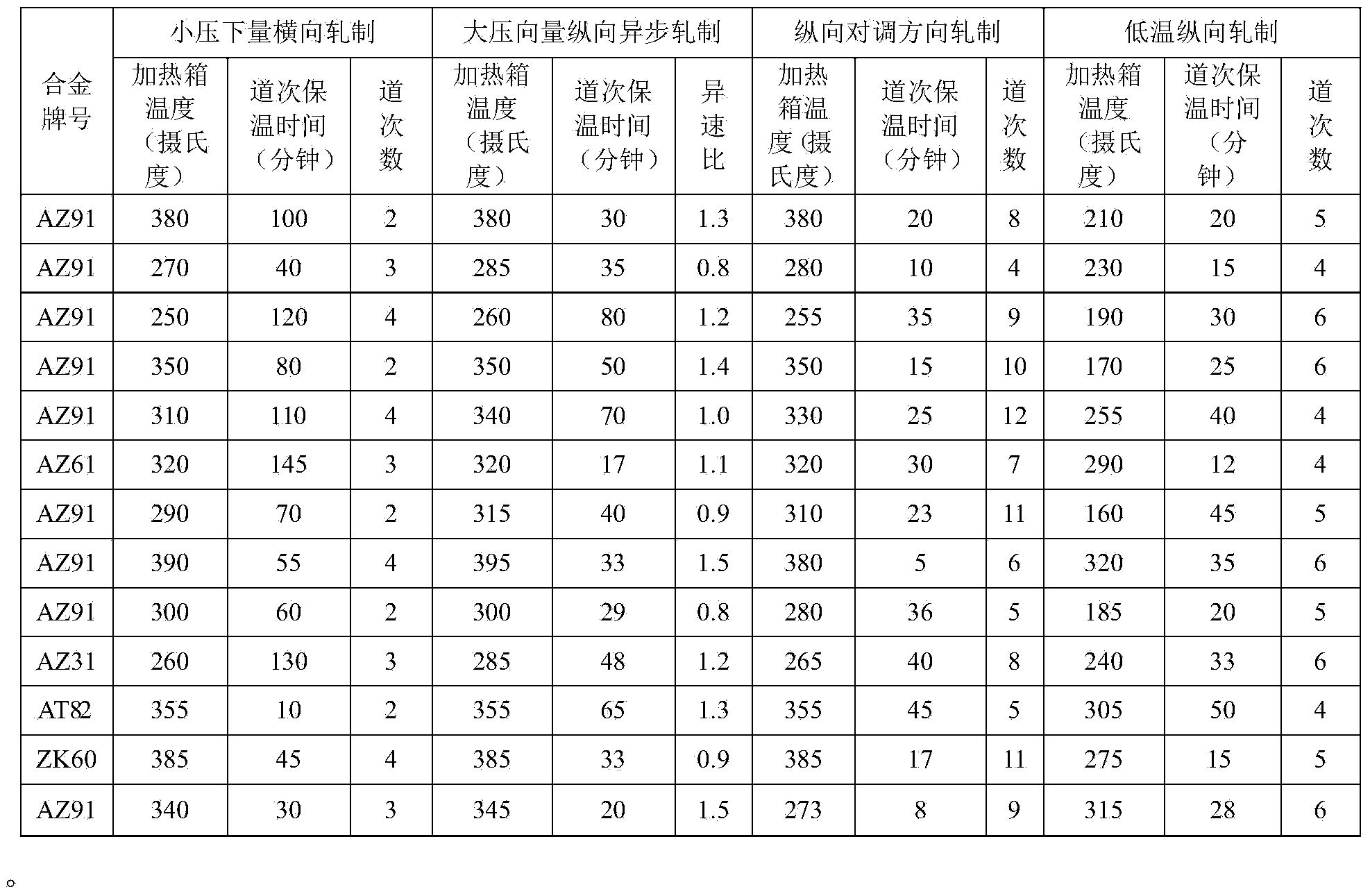

[0021] (1) Put the commercial AZ91 magnesium alloy billet into a heating box for heating. After the temperature rises to 380 degrees Celsius, let it stand for 100 minutes and then push the magnesium alloy billet horizontally to the roll entrance for two passes and a single pass. The vectors are horizontal rolling with small reductions of 8% and 6% respectively;

[0022] (2) Put the sample rolled in the above step (1) into the heating box again, let it stand for 30 minutes and keep it warm for one pass. The upper and lower rolls have an allometric ratio of 1.3 and a single pass reduction of 35%. Reduction in longitudinal asynchronous rolling;

[0023] (3) Put the sample after rolling in the above step (2) into the heating box again, let it stand for 20 minutes, and then carry out 8 passes of rolling, and after each rolling, perform a 180-degree longitudinal direction change;

[0024] (4) Reduce the temperature of the heating box to 210 degrees Celsius, put the sample rolled in the ab...

Embodiment 2

[0027] (1) Put the commercial AZ91 magnesium alloy extruded billet into a heating box for heating. After the temperature is raised to 350 degrees Celsius, let it stand for 80 minutes and then push the magnesium alloy billet horizontally to the roll entrance for 2 passes and single pass Lateral rolling with small reductions of 7% and 6% respectively;

[0028] (2) Put the sample rolled in the above step (1) into the heating box again, let it stand for 50 minutes and keep it warm for one pass. The upper and lower rolls have a different speed ratio of 1.4 and a single pass reduction of 38%. Reduction in longitudinal asynchronous rolling;

[0029] (3) Put the sample after rolling in the above step (2) into the heating box again, leave it to stand for 15 minutes, and then perform 10 passes of rolling, and after each rolling, perform a 180-degree longitudinal direction change;

[0030] (4) Lower the temperature of the heating box to 170 degrees Celsius, put the sample rolled in the above s...

Embodiment 3

[0033] (1) Put the commercial AZ61 magnesium alloy billet into a heating box for heating. After the temperature is raised to 320 degrees Celsius, let it stand for 145 minutes and then push the magnesium alloy billet horizontally to the roll entrance for 3 passes and a single pass. Horizontal rolling with small reductions of 6%, 7%, and 6% respectively;

[0034] (2) Put the sample rolled in the above step (1) into the heating box again, let it stand for 17 minutes, and perform one pass, the upper and lower rolls have an allometric ratio of 1.1, and a single pass reduction of 29%. Reduction in longitudinal asynchronous rolling;

[0035] (3) Put the sample after rolling in the above step (2) into the heating box again, let it stand for 30 minutes and keep it warm for 30 minutes, then perform 7 passes of rolling, and after each rolling, perform a 180-degree longitudinal direction change;

[0036] (4) Lower the temperature of the heating box to 290 degrees Celsius, put the sample rolled ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com