Patents

Literature

135 results about "Low temperature long time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for brewing blueberry wine

ActiveCN103666922AMicroorganism based processesAlcoholic beverage preparationBiotechnologyOenococcus oeni

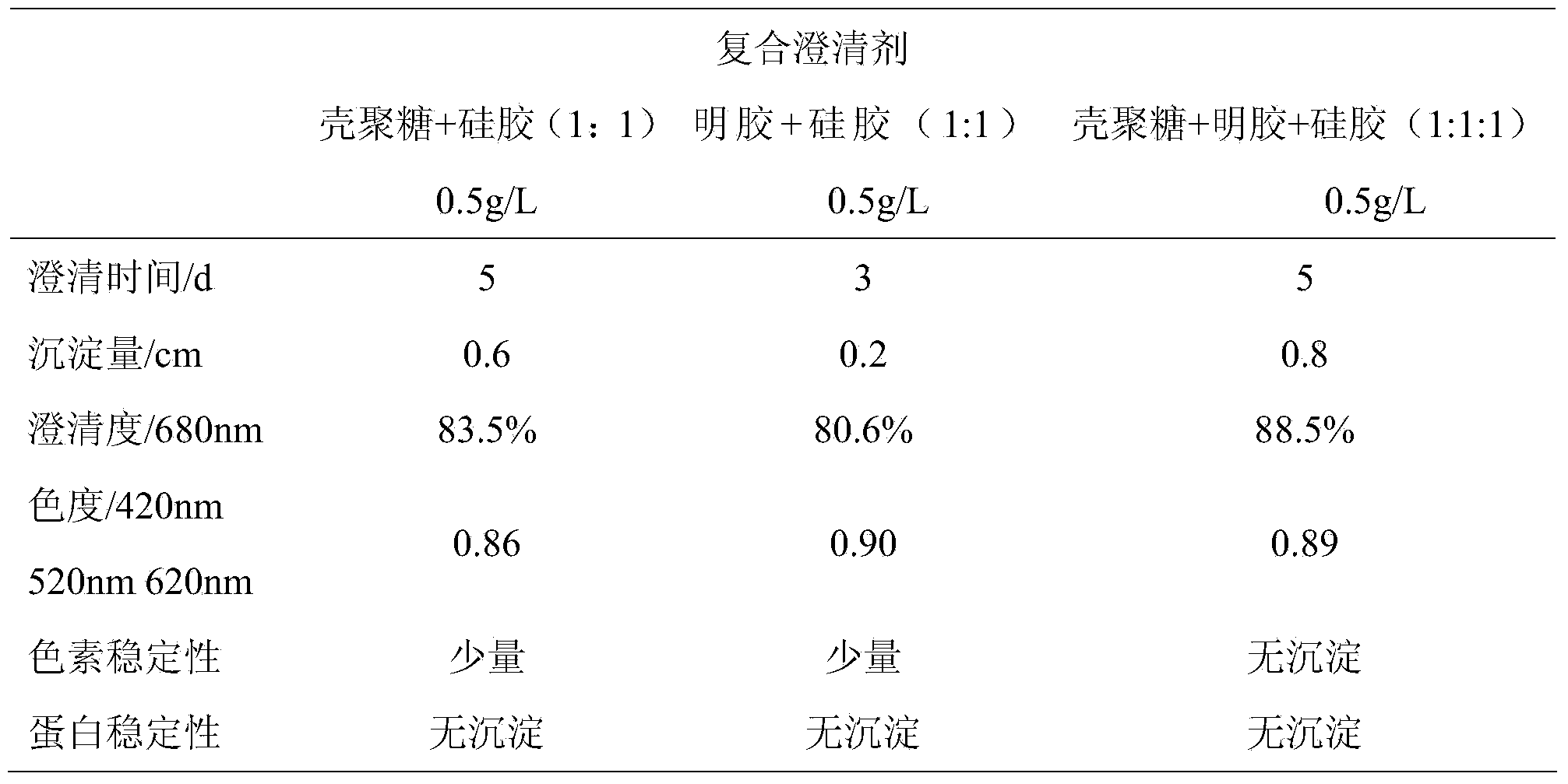

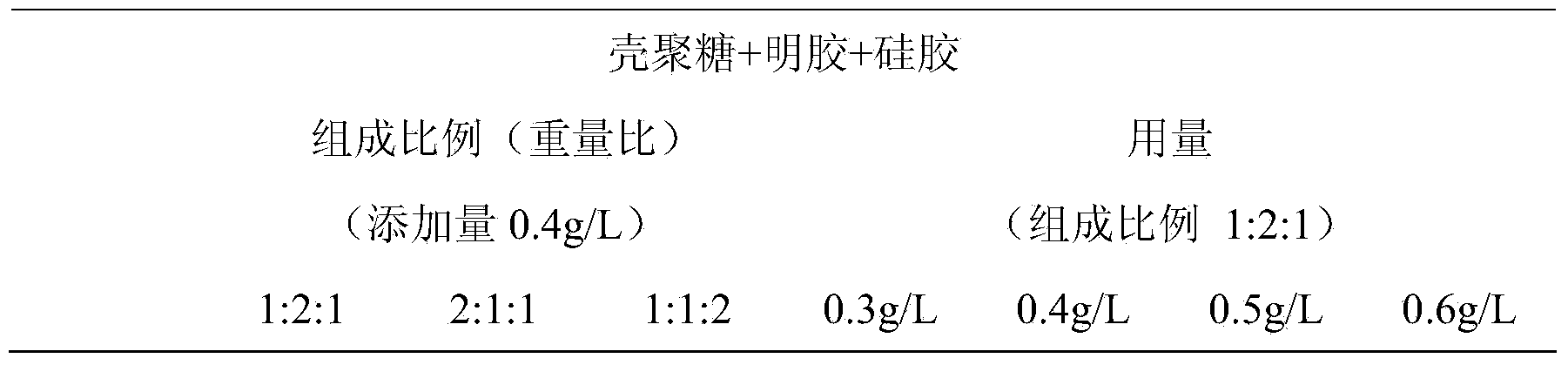

The invention discloses a method for brewing a blueberry wine. The method comprises the steps of selecting raw materials, selecting strains, fermenting with ethanol, carrying out malo-lactic fermentation, ageing, clarifying, stabilizing and the like. According to the method, optimized blueberries Huangshan 1# serve as the raw materials; high-temperature enzymolysis, high-temperature start-up and low-temperature long-time fermentation are carried out by using saccharomycetes RC212 as the fermentation strains; the malo-lactic fermentation is carried out by using oenococcus oeni SD-2 with high glucosidase activity; micro-aerobic ageing is utilized, so as to accelerate wine ageing and improve the quality of the wine; the blueberry wine can keep a clarified and stable state in long term by the technical means of natural clarification, cellaring, cold treatment, heat treatment, stabilizer adding, microfiltration and the like. In accordance with the method, a high-quality blueberry wine with good color, smell and taste can be obtained, and the obtained product meets the requirements of the national wine product quality standard GB2758-81.

Owner:JURONG WANSHANHONGBIAN BIOTECH

Method for processing black tea produced from ancient tea trees

InactiveCN104605041ASweet tasteFresh and sweet tastePre-extraction tea treatmentCooking & bakingPhenolic content in tea

The invention provides a method for processing a black tea produced from ancient tea trees. The tea is prepared from tender leaves of the wild or cultivated ancient tea trees older than 100 years in the Fanjingshan mountain area as a raw material and is prepared by adopting the following steps: picking the fresh tea leaves; naturally withering; rocking; rolling; deblocking; fermenting; drying; and charcoal baking. In the method disclosed by the invention, on the basis of a traditional process, the step of rocking for three times is added after the step of naturally withering, and in combination with a rocking process of oolong, the tea leaves are rubbed with one another in the process of rocking, so that border cells of the leaves are disrupted, the oxidation reaction of substances such as polyphenol is accelerated, and the transformation of aromatic substances in the tea leaves is promoted; and charcoal baking is performed after drying, so that in a long-term low temperature environment, sweeter and mellower taste characteristics of the black tea are formed, and therefore, compared with traditional black tea, the black tea prepared from the raw materials and by adopting the processing method disclosed by the invention is stronger in flower and fruit flavors, richer in flavor type, and fresher, sweeter and mellower in taste.

Owner:TONGREN TEA IND ASSOC

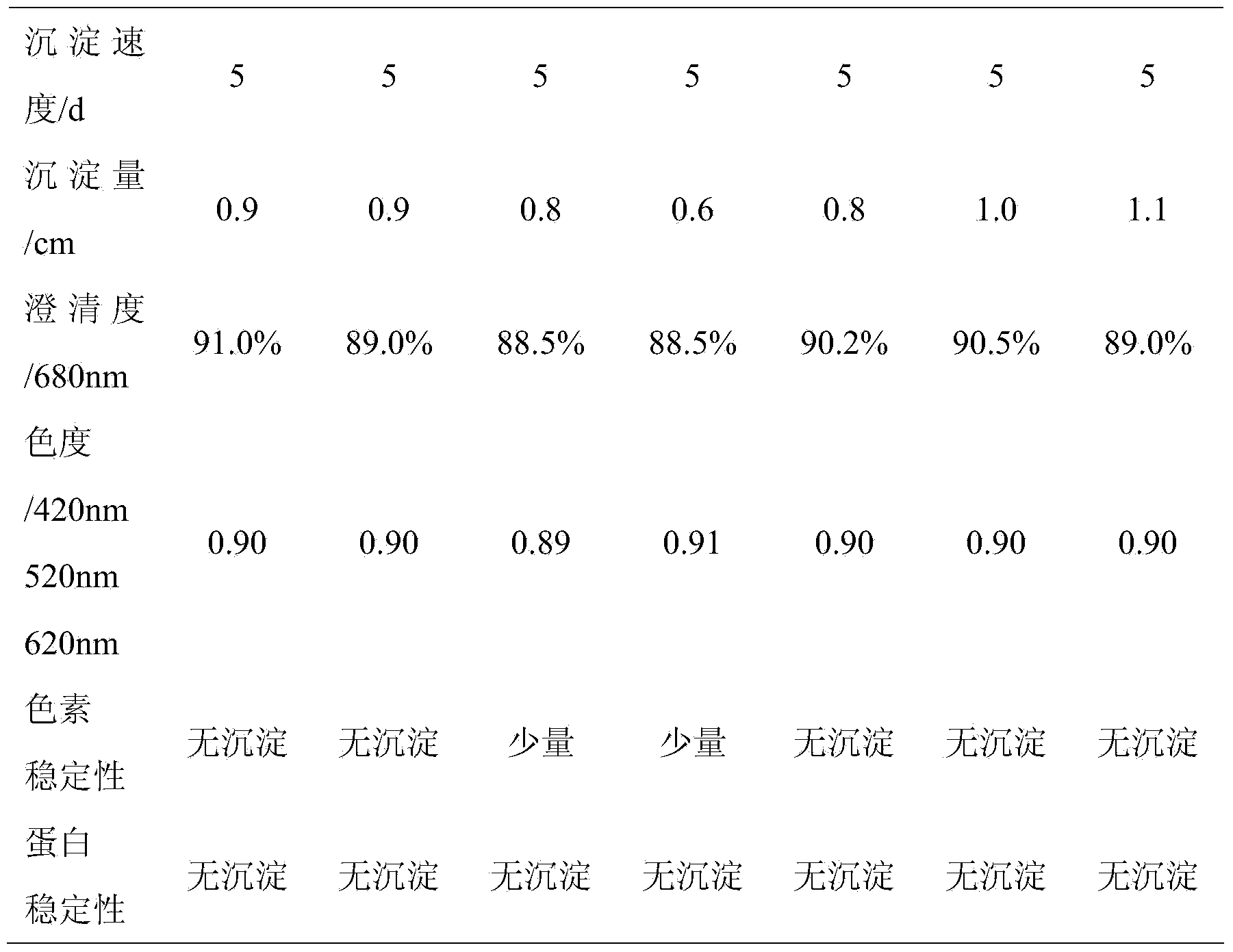

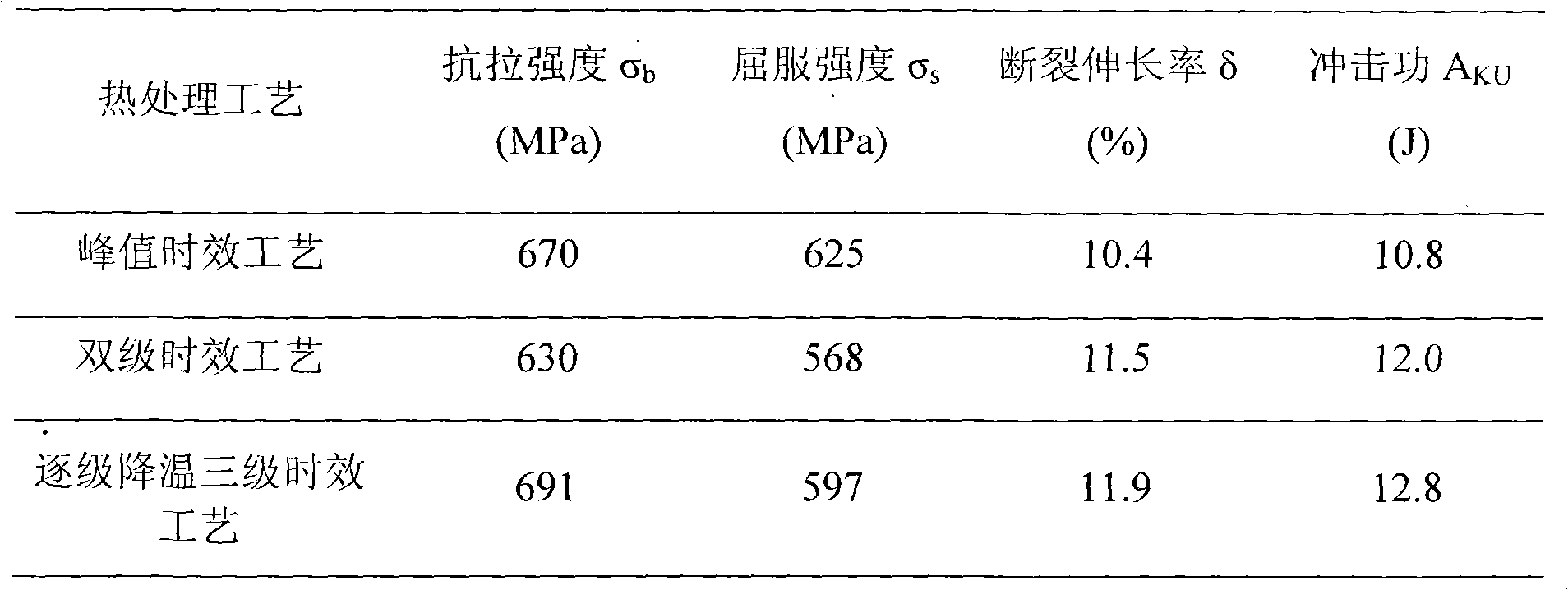

Heat treatment technology of high strength aluminium alloy

InactiveCN101956151AImprove mechanical propertiesImprove heat treatment processSolution treatmentQuenching

The invention relates to a heat treatment technology of high strength aluminium alloy. The technology performs solution treatment, primary quenching treatment, high temperature short time aging treatment, secondary quenching treatment, intermediate temperate short time aging treatment and low temperature long time aging treatment to high strength aluminium alloy in sequence. The technology improves the comprehensive mechanical property of alloy, increases the corrosion resistance and expands the application range of high strength aluminium alloy.

Owner:SICHUAN CITY TRACK TRAFFIC MATERIAL +1

Heat treatment method for improving obdurability of 7-series high strength aluminium alloy

InactiveCN101994072AImprove fracture toughnessIncrease supersaturationSolution treatmentRoom temperature

The invention relates to a heat treatment method for improving the obdurability of a 7-series high strength aluminium alloy, comprising the following steps: firstly carrying out double-stage forced solution treatment on the hot-processing 7***-series high strength aluminium alloy, namely, performing primary solution treatment for 2-4 hours at the temperature of 420-450 DEG C, and performing secondary reinforced solution treatment for 2-4 hours at the temperature of 450-490 DEG C; then quenching and cooling to room temperature, wherein the quenching medium is room temperature water; prestretching within 1-4 hours after quenching, wherein the prestretching distortion is 1-3%; performing high-temperature short-time ageing treatment, wherein the aging temperature is 120-180 DEG C and the aging time is 60-180min; quenching and cooling to room temperature after high-temperature short-time aging treatment, wherein the quenching medium is room temperature water; and finally carrying out low-temperature long-time aging treatment, wherein the aging temperature is 60-120 DEG C, and the aging time is 18-48 hours. The heat treatment method for improving the obdurability of a 7-series high strength aluminium alloy of the invention further improves the fracture toughness property of alloys and broadens the applied range of the aluminium alloys on the basis of maintaining the superhigh alloy strength.

Owner:苏州有色金属研究院有限公司

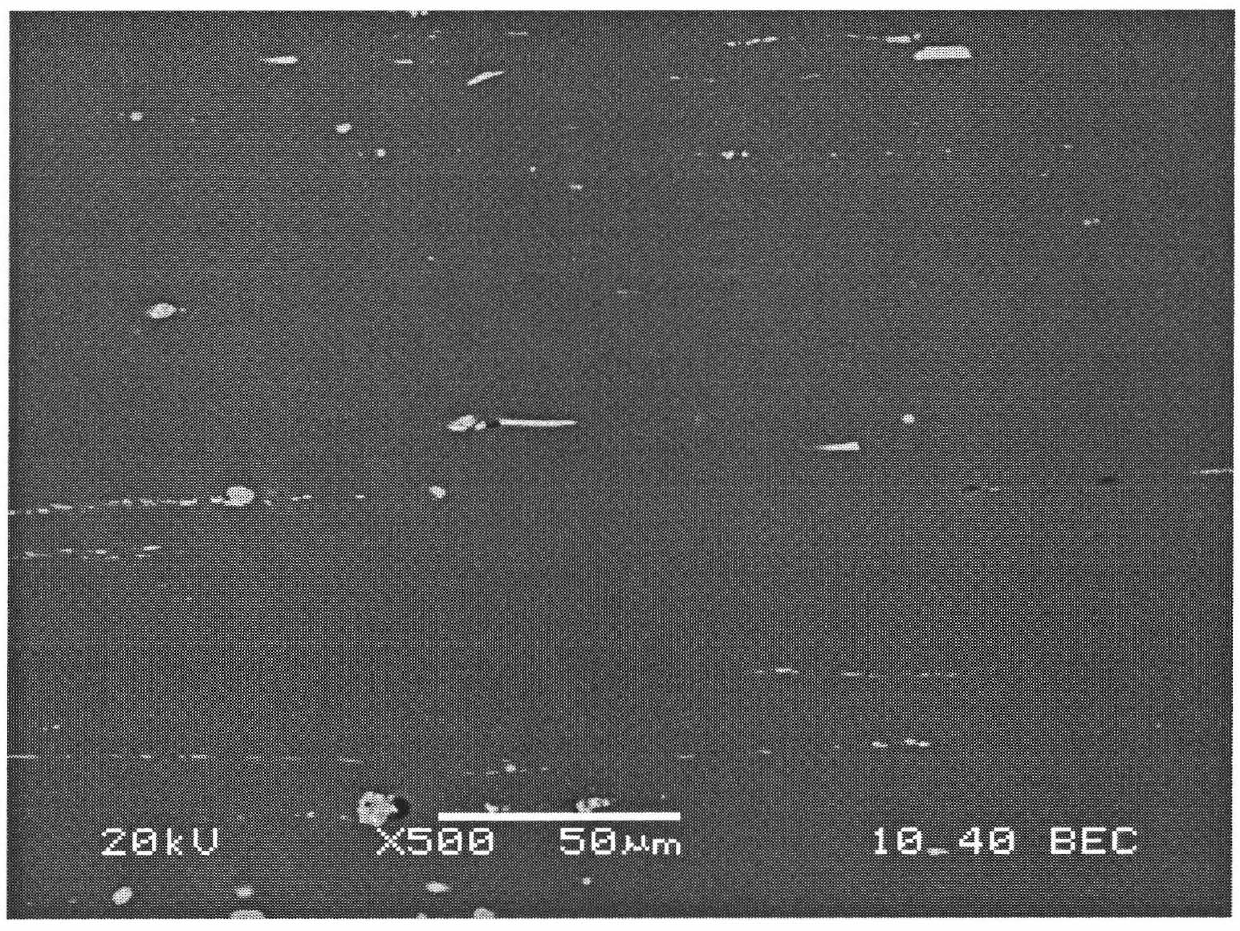

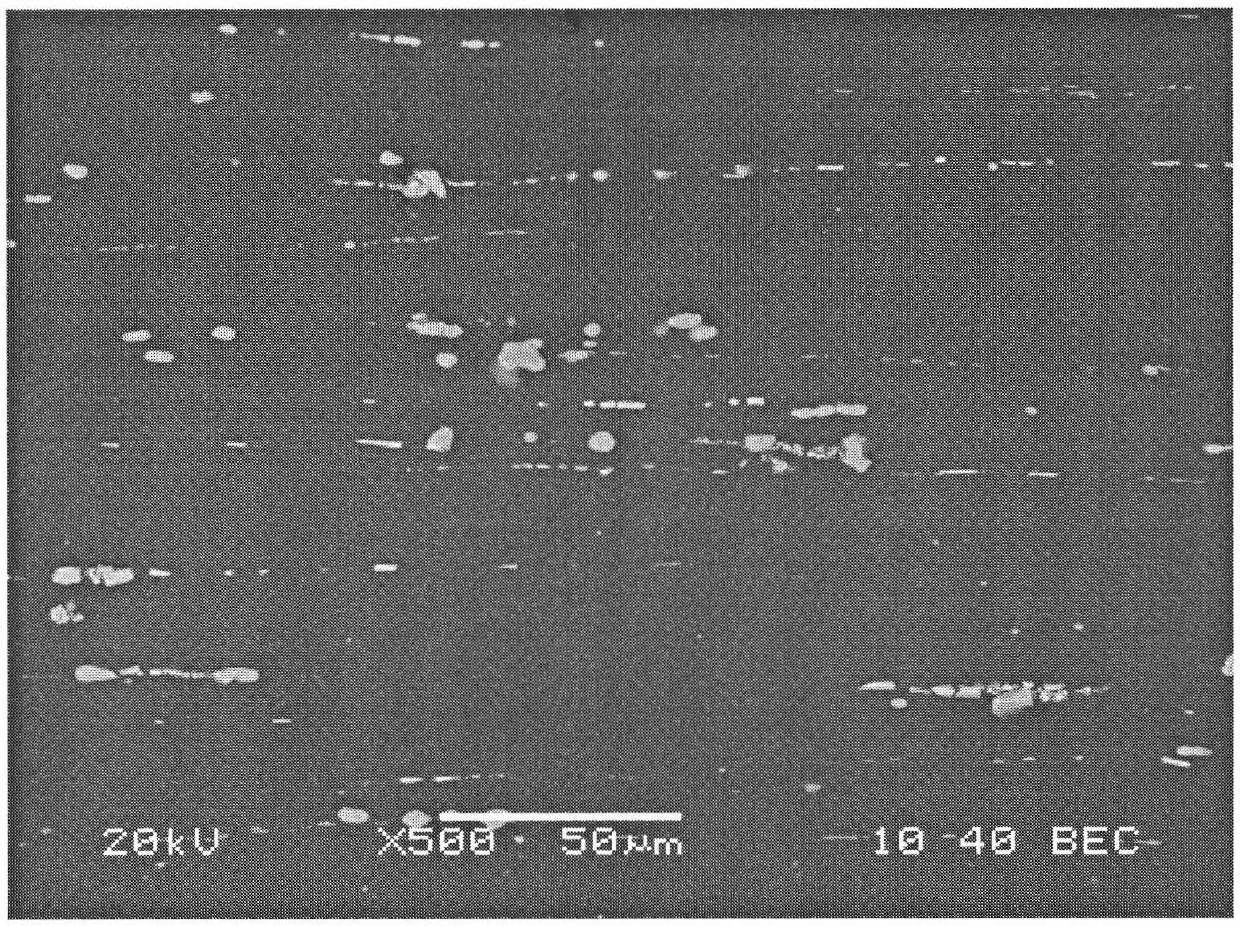

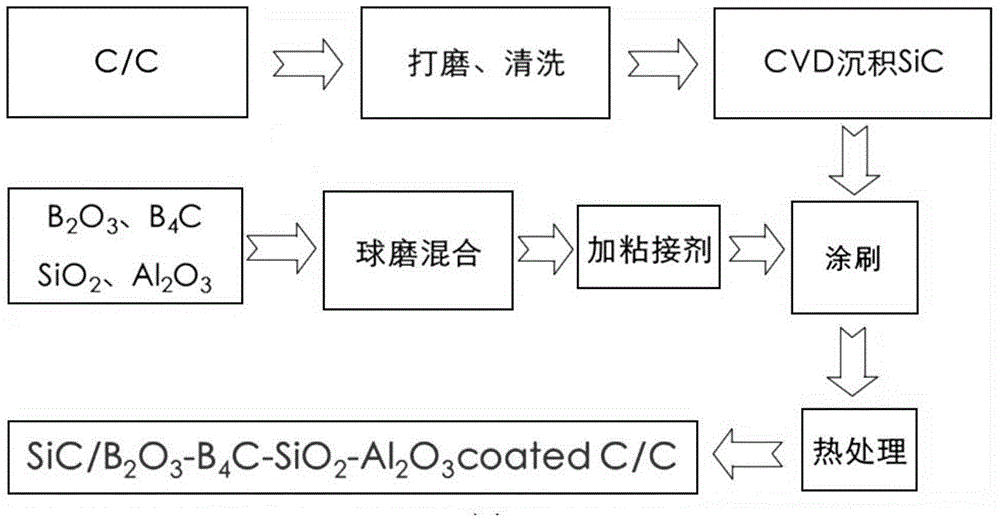

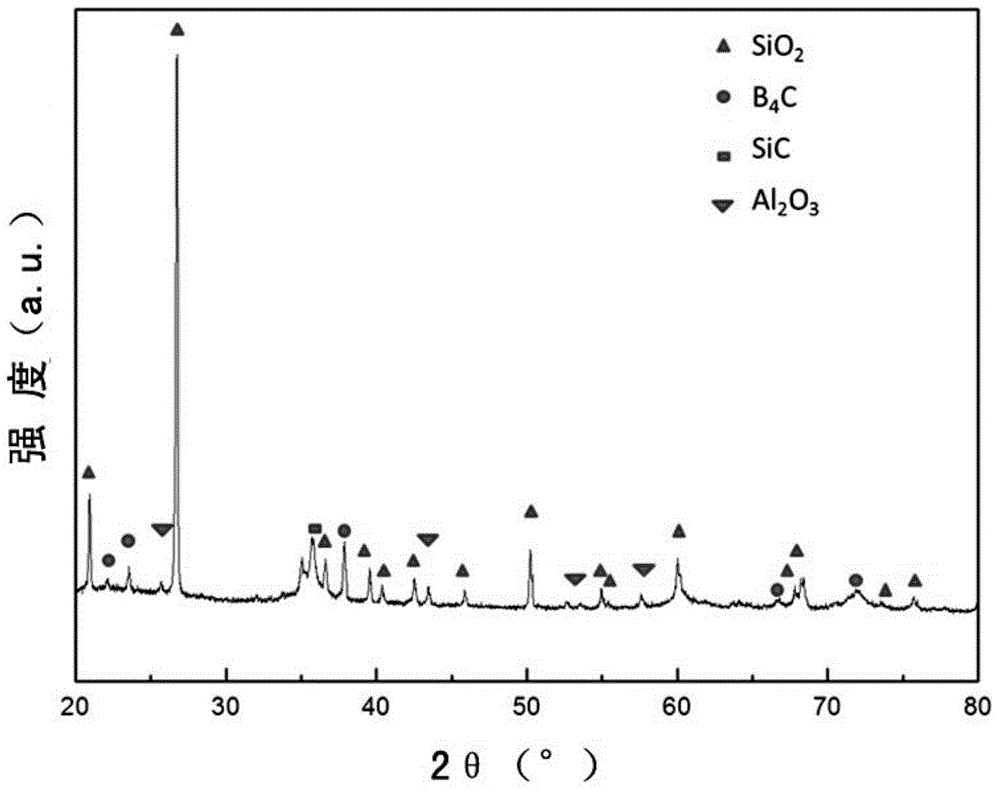

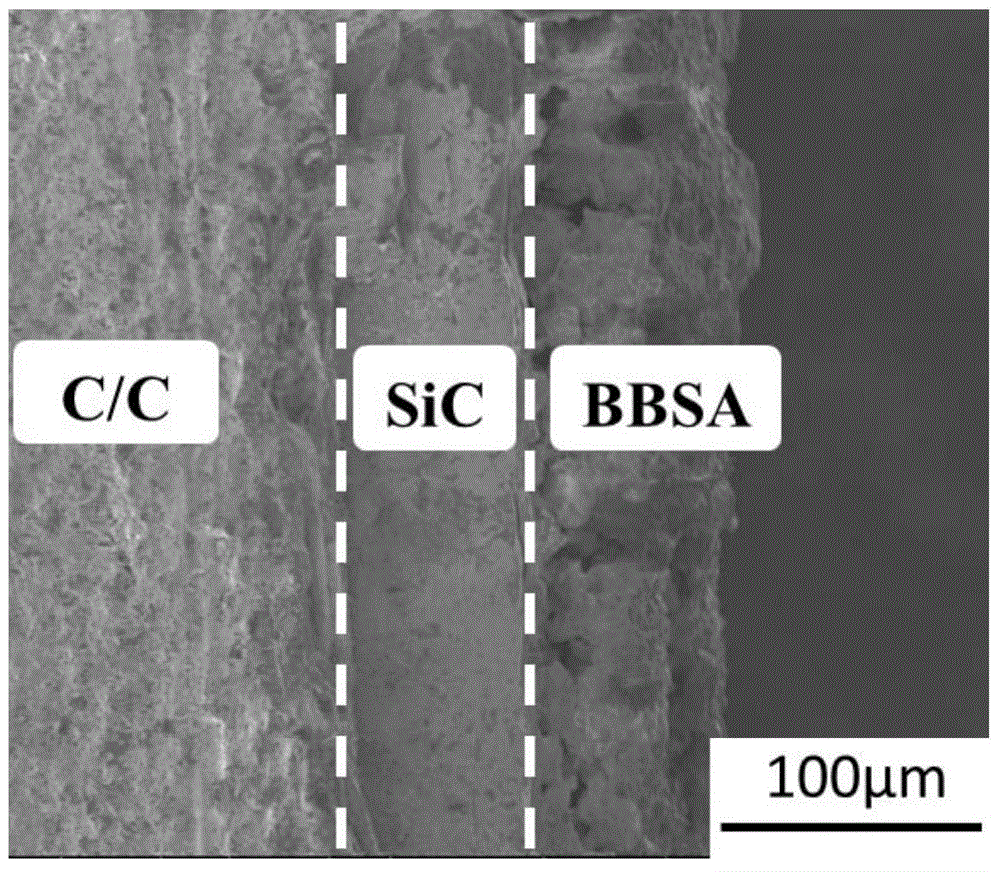

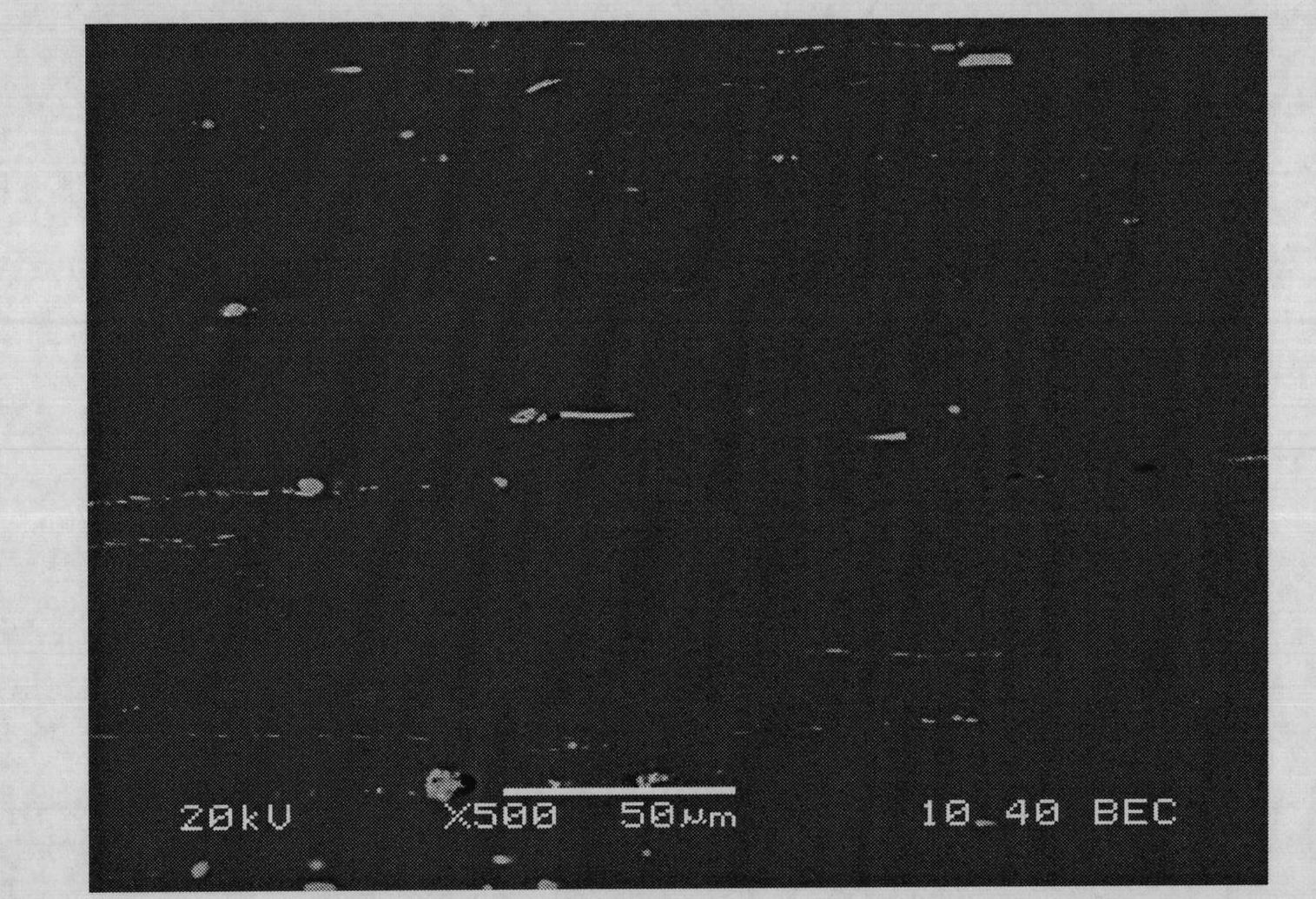

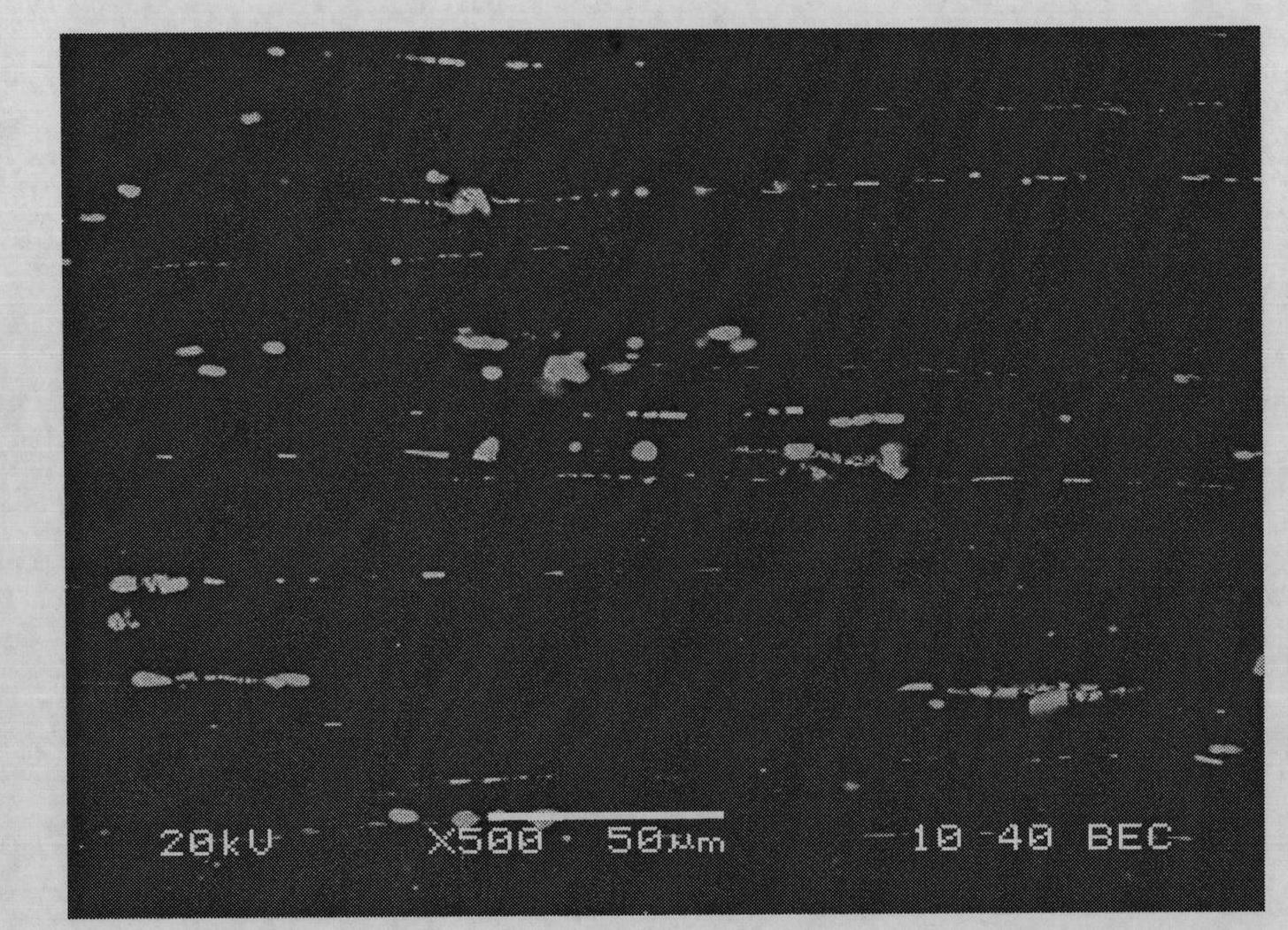

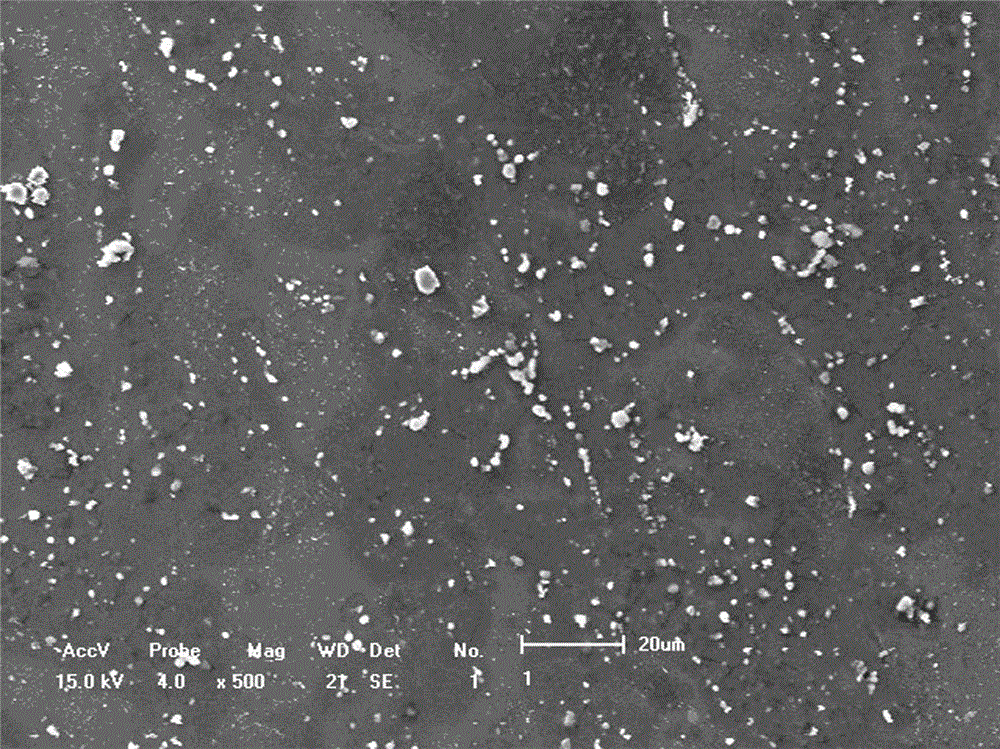

Preparation method of low-temperature long-time oxidation-resistant coating layer on carbon/carbon composite material surfaces

ActiveCN105646007ALong-term anti-oxidation achievedOxidation weight loss rate is smallCarbon compositesAdhesive

The invention discloses a preparation method of a low-temperature long-time oxidation-resistant coating layer on carbon / carbon composite material surfaces, and belongs to the technical field of carbon / carbon composite material antioxidation. The preparation method comprises following steps: firstly, chemical vapor deposition is adopted so as to realize precipitation of high crystallinity silicon carbide on the carbon / carbon composite material surfaces as a transitional inner coating layer; boron oxide, boron carbide, silicon dioxide, and aluminium oxide are taken as coating layer raw materials, silica sol is taken as an adhesives, and painting-sintering technology is adopted so as to obtain a B4C-B2O3-SiO2-Al2O3 outer layer on the silicon carbide inner layer; and finally the SiC / B4C-B2O3-SiO2-Al2O3 composite oxidation-resistant coating layer is formed on the carbon / carbon composite material surfaces. The low-temperature long-time oxidation-resistant coating layer is capable of realizing long-term antioxidation of the carbon / carbon composite material at 600 to 1000 DEG C, and oxidation weight loss ratio is smaller than 1%. It is observed via observation using scanning electron microscopes, the low-temperature long-time oxidation-resistant coating layer is capable of forming compact glass phase at usage environment spontaneously, and realizing oxidation protection.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Pomegranate fermented lactic acid drink

The present invention discloses a pomegranate fermented lactic acid drink. The pomegranate fermented lactic acid drink is made from the following raw materials: pomegranates, skim milk, pomegranate peels, pomegranate flowers, pomegranate barks, pomegranate leaves, sophora japonica leaves, calyx kaki, picrasma quassioides, isomaltitol, gentiooligosaccharide, lactic acid bacteria, compound enzymes, and antioxidants of bamboo leaves. The drink is sour and sweet in mouthfeel, moderate in concentration, stable in state, and rich in nutrition, can promote metabolism, enhance immunity, dispel toxins and beautify feature, and prevent oxidation, aging, and tumors. The pomegranates are rich in organic selenium, help absorption and utilization, and promote the body function; each of the organs of the pomegranate is fully used and scientifically matched with other traditional Chinese medicines, the effects are complementary to each other, the raw materials are extensive, the price is low and cheap, and the costs are saved; a first lactic acid bacterium high-temperature fermentation is conducted, the lactic acid bacterium growth is promoted, and the pollution is avoided, at a second time, the gentiooligosaccharide is added, the activities of the lactic acid bacteria are enhanced, and a low-temperature long-time fermentation is conducted, which is conductive to the produce of flavor substances; and the fermented lactic acid drink is filled, and the filled lactic acid drink is subjected to low-temperature cold storage, which can maintain the activities of the lactic acid bacteria in the drink, so that the pomegranate fermented lactic acid drink promotes gastrointestinal functions.

Owner:阜阳市颍州区金湖丰种植农民专业合作社

High-permeability resin type timber enhancing modifier and efficient immersion treatment control method

InactiveCN105563579AFull penetrationImprove performanceWood treatment detailsPressure impregnationSolubilityPermeation

The invention belongs to a high-permeability resin type timber enhancing modifier and an efficient immersion treatment control method. The method includes: preparing materials according to mole ratio of melamine to formaldehyde to methanol to urea being 1:2-2.5:0.5-1.0:0.2-1.0, wherein the adding amount of flexibilizer is 10-30% of the amount of the melamine. Modified melamine urea resin with good water solubility, high permeability and low molecular weight and used for immersion is prepared by adjusting raw material proportion, using a low-temperature long-time multistage synthesizing process and adding alcohol flexibilizer, polymerization inhibitor and the like. The permeation channels of timber hard in immersion are opened through a multi-time alternating breathing type immersion treatment process, the timber can be permeated evenly, and timber performance is improved greatly. The high-permeability resin type timber enhancing modifier and the efficient immersion treatment control method have the advantages that the timber hard in immersion can be permeated sufficiently, and various performance of the timber can be improved evidently; the fast-growing timber, modified by the method, of a man-made forest is high in density, high in strength, good in toughness, stable in size, flame retardant, capable of preventing mildew and corrosion, good in processing performance, environmental friendly in production, good in use effect, high in additional value, and the like.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

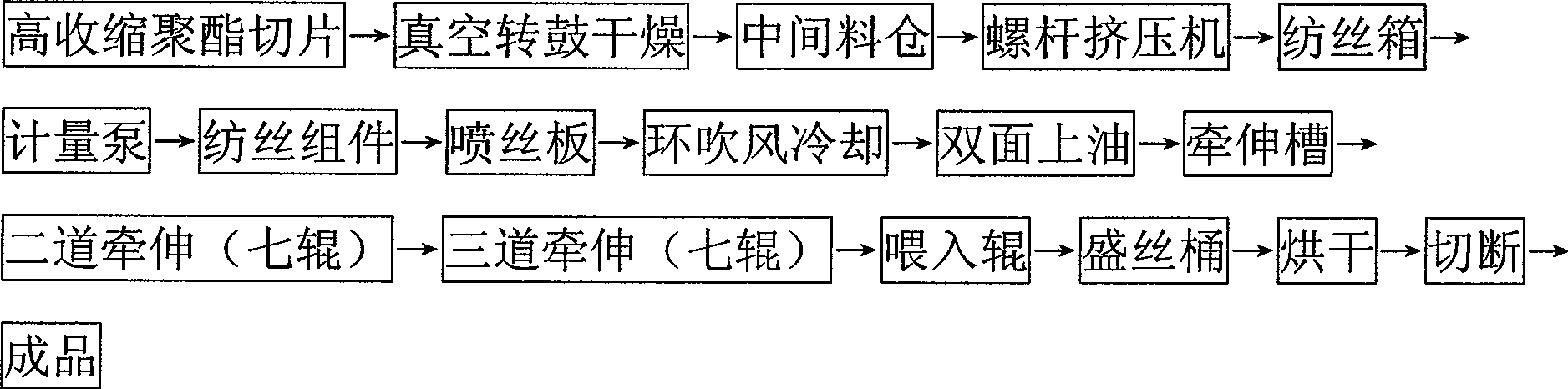

Method for processing high shrinkage superfine denier polyester staple fiber

InactiveCN101503832AFeel goodGood water absorption and breathabilityMelt spinning methodsStaple fibre formationPolyesterYarn

The invention relates to a processing method of high-shrinkage ultrathin polyester short fiber. The process flows of the method comprise: high-shrinkage polyester slicing, vacuum rotary drum drying, intermediate bunker, screw extruder, spinning box, metering pump, spinning component, spinneret plate, circular blowing cooling, double side oiling, drawing groove, second drawing (seven rollers), third drawing (seven rollers), feeding roller, yarn containing drum, drying, cutting and obtaining finished product. The technological parameter of the method is characterized in that slice drying adopts a vacuum rotary drum low-temperature longtime process; spinning temperature and preliminary drawing multiple are properly lowered; low-temperature drawing and unshaped drawing process are adopted; and the spinneret plate adopts a finishing spinneret plate which has 0.2*0.5mm aperture and is matched with a corresponding component. Due to adopting high-shrinkage functional polyester slice as a raw material, the processing method can realize production on common polyester short fiber spinning equipment without changing the prior spinning equipment during production.

Owner:JIANGSU SHENGHONG CHEM FIBRE CO LTD

Method for preparing black tea by using wild ancient tea trees

InactiveCN104757158ATight and thin shapeOily colorPre-extraction tea treatmentFlavorTemperature control

trees. The preparation method comprises the following operation steps that 1, tea leaves are picked according to the standard of one bud and one leaf; 2, the deterioration mode is temperature control deterioration; 3, rolling is performed; 4, the fermentation mode is oxygen introducing fermentation, and the fermentation time is 2-3 hours; 5, the primary drying temperature is 110-120 DEG C, and the dryness of the tea leaves is 70%-80%; 6, the secondary drying temperature is 80-90 DEG C, and the dryness of the tea leaves is 90%-95%; and 7, the flavor raising mode is low-temperature long-time flavor raising, the temperature is 50-60 DEG C, and the time is 5-10 hours. The wild ancient tea tree black tea prepared with the method is tight and thin in trabes in appearance, the color is oily and moisture, the fragrance is sweet, and the taste is sweet and mellow.

Owner:GUIZHOU XINJING ECOLOGICAL TEA IND CO LTD

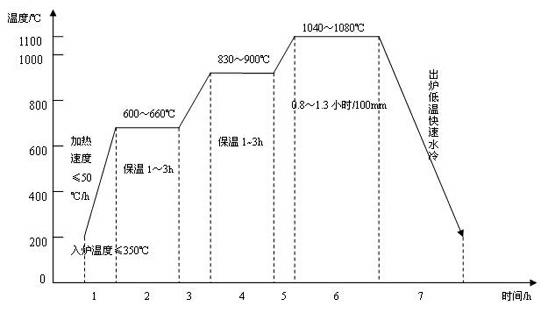

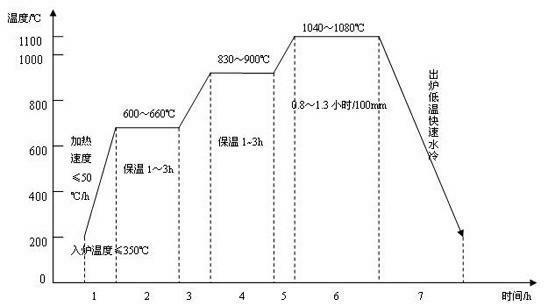

Thermal treatment method for improving low-temperature impact toughness of austenite-ferrite stainless steel

ActiveCN102676766AReduce plasticityReduce toughnessHeat treatment process controlFragilityPerformance index

The invention belongs to the technical field of production of duplex stainless steel products used at low temperature and particularly relates to a thermal treatment method for improving low-temperature impact toughness of austenite-ferrite stainless steel with high requirements for performance indexes. The thermal treatment method comprises the steps: feeding forged austenite-ferrite stainless steel into a furnace at the feeding temperature of not greater than 350 DEG C and performing twice preheating; performing solution treatment; performing cooling, feeding the austenite-ferrite stainless steel into clear water with the initial temperature smaller than 10 DEG C, and retaining the austenite-ferrite stainless steel for 20 minutes at the cooling speed of 4-6 seconds / mm. An austenite-ferrite stainless steel solution treatment process comprises the steps of (1) heating, namely controlling heating speed, preheating temperature, solid solution temperature and retaining time at a low-temperature section, reducing thermal stress and simultaneously obtaining good duplex structural proportion and (2) cooling, namely adopting a quick low-temperature long-time water-cooling mode to prevent precipitation due to fragility phase and remarkably reducing the plasticity and the toughness of the steel.

Owner:HENAN ZHONGYUAN HEAVY FORGING

Heat treatment method suitable for high-strength aluminum alloy thick plates

The invention relates to a heat treatment method suitable for high-strength aluminum alloy thick plates, which comprises the following steps of: performing twin-stage enforced solution treatment on 7xxx series high-strength aluminum alloy subjected to hot working, namely performing first-stage solution treatment at the temperature of between 400 and 450 DEG C for 4 to 6 hours, and performing second-stage enforced solution treatment at the temperature of between 450 and 500 DEG C for 4 to 6 hours; performing quenching treatment and cooling to room temperature, wherein a quenching medium is room temperature water; prestretching in 1 to 4 hours after quenching treatment, wherein the prestretching deformation is 1 to 3 percent; performing high-temperature short-time ageing treatment, wherein the ageing temperature is 120 to 190 DEG C and the ageing time is 30 to 150 minutes; performing quenching treatment and cooling to room temperature, wherein the quenching medium is room temperature water; and performing low-temperature long-time ageing treatment, wherein the ageing temperature is 60 to 120 DEG C and the ageing time is 18 to 48 hours. On the basis of controlling the structural homogeneity of the thick plates and keeping the strength of the super-high strength alloy, the fracture toughness of the alloy is further improved and the application range of the aluminum alloy is widened.

Owner:苏州有色金属研究院有限公司

A method for improving magnetic properties of rare earth NdFeB

ActiveCN109102976AEvenly distributedImprove coercive forceInductances/transformers/magnets manufactureMagnetic materialsRemanenceHydrogen

The invention relates to the technical field of magnetic materials, in particular to a method for improving the magnetic properties of rare earth NdFeB, comprising the following steps: mixing a grainboundary auxiliary alloy RTM casting sheet and a rare earth Nd-Fe-B main alloy, and performing hydrogen crushing, powder preparation, molding, and low-temperature long-time sintering and heat treatment to obtain a high-performance rare earth Nd-Fe-B magnet. Double alloy, grain refining and lwo-temperature long sintering are adopted, so that the influence of the remanence reduction caused by the replacement of Nd in the main phase Nd2Fe14B by the heavy rare earth in the traditional process is avoided; the heavy rare earth in the grain boundary auxiliary alloy RTM casting can be distributed uniformly in the grain boundary, so the coercivity of the magnet can be improved. The method is simple and efficient, and has no special requirements on equipment. The method is suitable for industrial production of high-performance rare earth Nd-Fe-B magnet.

Owner:ZHEJIANG DONGYANG DMEGC RARE EARTH MAGNET CO LTD

Low temperature sintered alumina black ceramic, and preparation method thereof

The invention provides a low temperature sintered alumina black ceramic, and a preparation method thereof. The preparation method comprises following steps: weighing, wherein by a certain mass ratio,alpha-Al2O3, powdered steatile, clay, SiO2, a composite modifying agent, and a colouring agent are weighed; ball milling, wherein the weighed raw materials are introduced into a ball milling machine for material mixing ball milling so as to obtain a premix; granulation, wherein the premix is mixed with a PVA binding agent solution for granulation so as to obtain black ceramic particles; pressing moulding, wherein the black ceramic particles are introduced into a mould for pressing moulding so as to obtain a black ceramic blank; and low temperature sintering, wherein the ceramic blank is introduced into a low temperature sintering furnace for low temperature long time graduate heating sintering so as to obtain low temperature sintered black ceramic. The alumina black ceramic prepared through low temperature sintering is simple in sintering technology, compact in ceramic body, high in mechanical strength, and excellent in dielectric properties and thermal shock resistance.

Owner:新化县顺达电子陶瓷有限公司

Method for brewing fresh litchee juice wine

ActiveCN101671616AIncrease Natural BrixHigh alcohol contentAlcoholic beverage preparationMicroorganism based processesYeastFruit juice

The invention discloses a method for brewing fresh litchee juice wine. The method includes that litchi raw material is subject to pretreatment, then super high temperature sterilization and freeze concentration and then ultralow temperature long fermentation, ageing, juice alcoholization, formulation, clarification and filtering, thus obtaining the fresh litchee juice wine. The ultralow temperature long fermentation includes that active dried yeast growing at low temperature and food grade sulfinic acid solution containing SO2 are added into juice after sterilization, the content of the activedried yeast in juice after sterilization is 200-400mg / L; and fermentation is carried out for 20-35 days at 2-12 DEG C. the invention adopts freeze concentration method to improve natural sugar degreeof litchee juice, brewing cost of litchee wine is low, alcoholic strength is high, mouthfeel is full, no exogenous saccharides is required to be added, and natural nutrients and flavor of fresh litchee juice are kept and fine, smooth and elegant litchee wine mouthfeel while stable and permanent litchee fruity can be obtained.

Owner:广东帝浓酒业有限公司

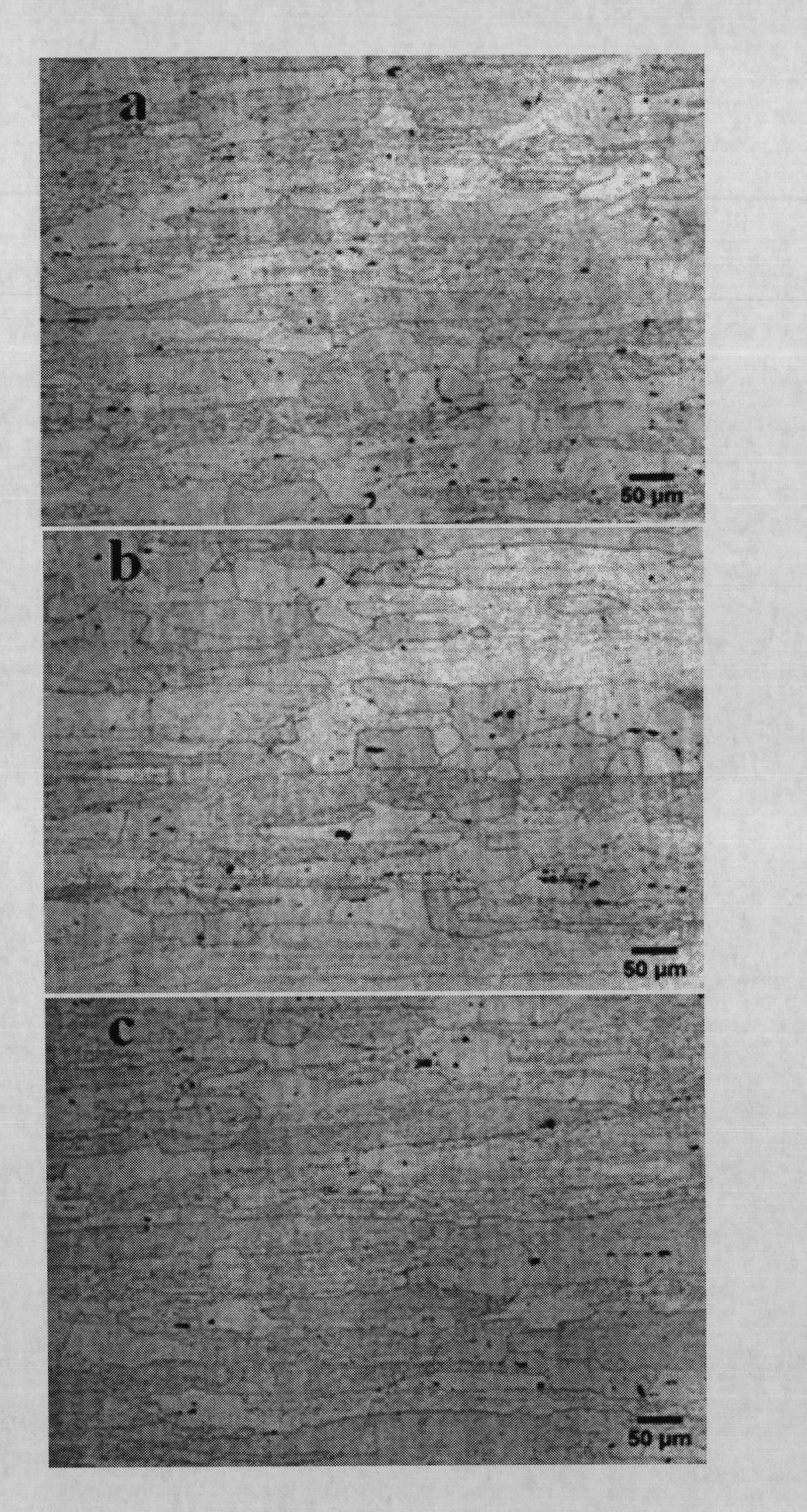

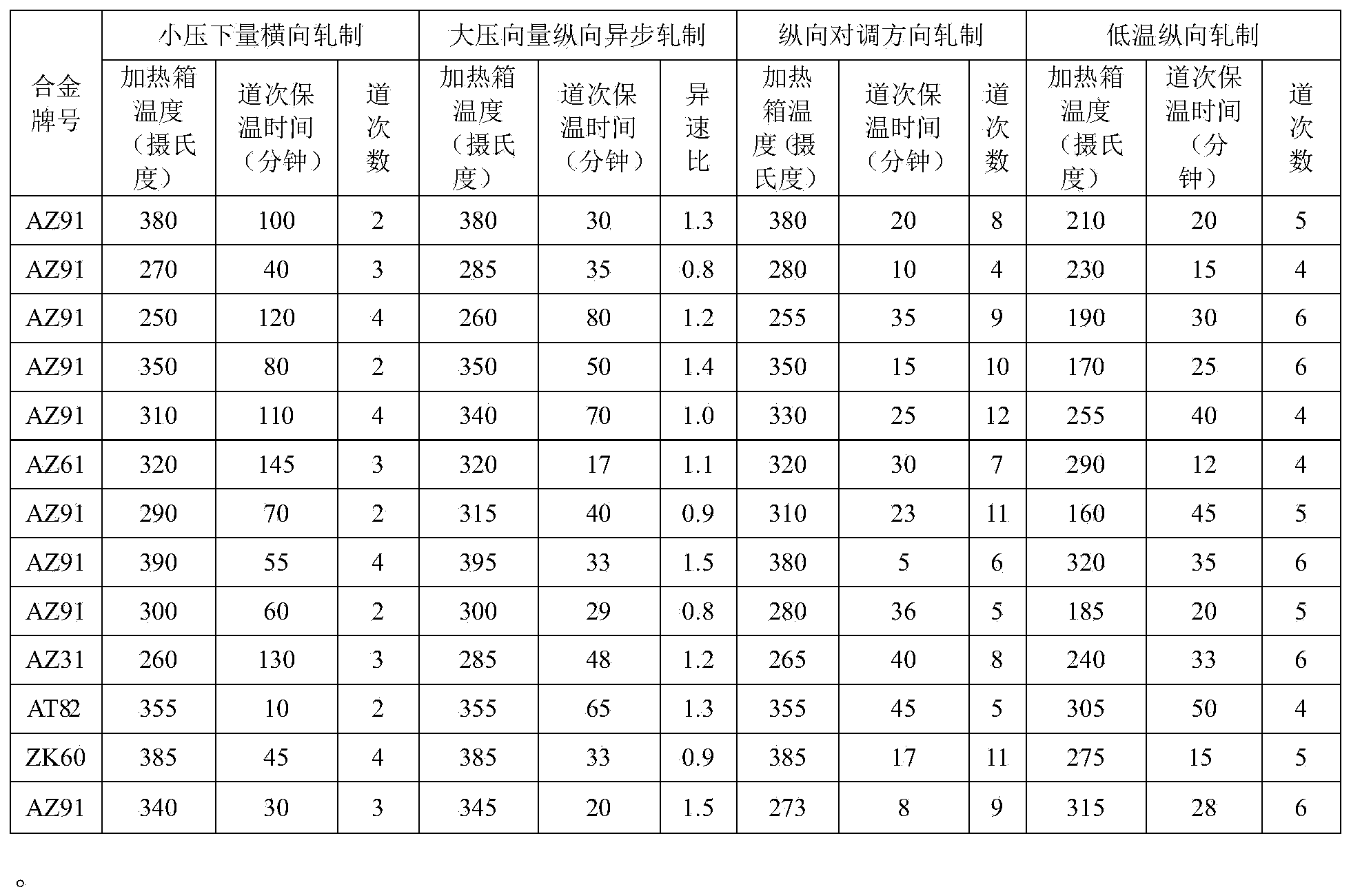

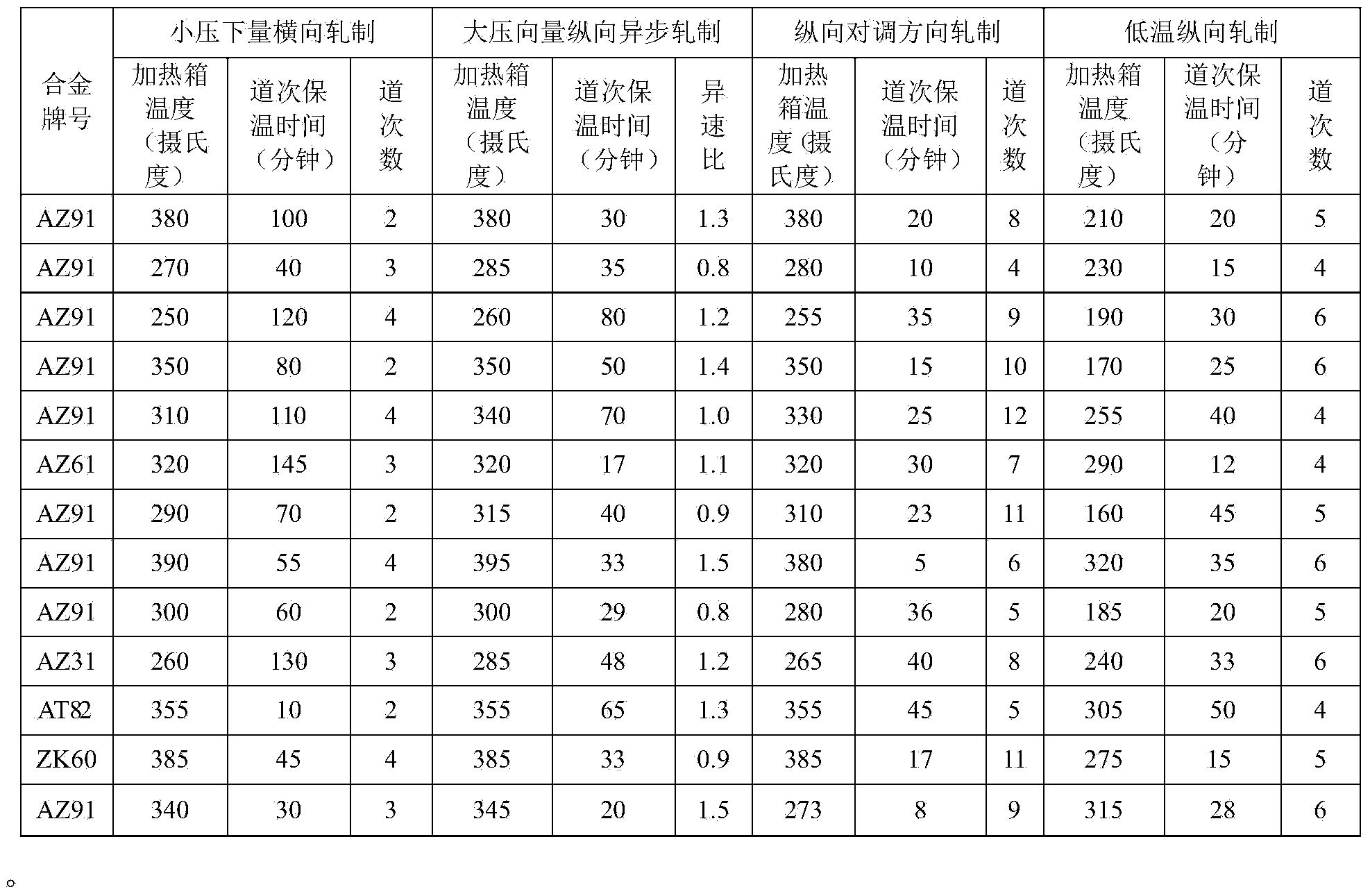

Method for preparing fine-grained magnesium alloy with superplastic deformability

The invention relates to a method for rolling fine-grained magnesium alloy with superplastic deformability. The method comprises the steps of low-rolling-reduction transverse rolling, high-rolling-reduction longitudinal asynchronous rolling, longitudinal reversed-direction rolling, low-temperature longitudinal rolling and annealing, and comprises the specific steps of heating a commercial magnesium alloy blank in a heating box, standing to preserve heat for a period of time after heating to a preset temperature, firstly pushing the magnesium alloy blank to an entrance of a rolling roller along the transverse direction, carrying out transverse rolling firstly, then, carrying out high-rolling-reduction longitudinal asynchronous rolling, then, carrying out longitudinal 180-degree-reversed rolling, then, carrying out low-temperature longitudinal rolling, and finally, carrying out low-temperature long-time annealing treatment or high-temperature short-time annealing treatment. According to the method, cracking during the rolling of the magnesium alloy can be reduced, the crystal grain of the magnesium alloy is refined, the texture is weakened, and the high-temperature plasticity of the magnesium alloy is improved; moreover, the process is simple and easy to operate, large-sized wide-width sheet materials can be prepared, and the formability of the magnesium alloy is improved remarkably, so that the method is applicable to the mass production of superplastic magnesium alloy and is prone to popularization and application.

Owner:JILIN UNIV

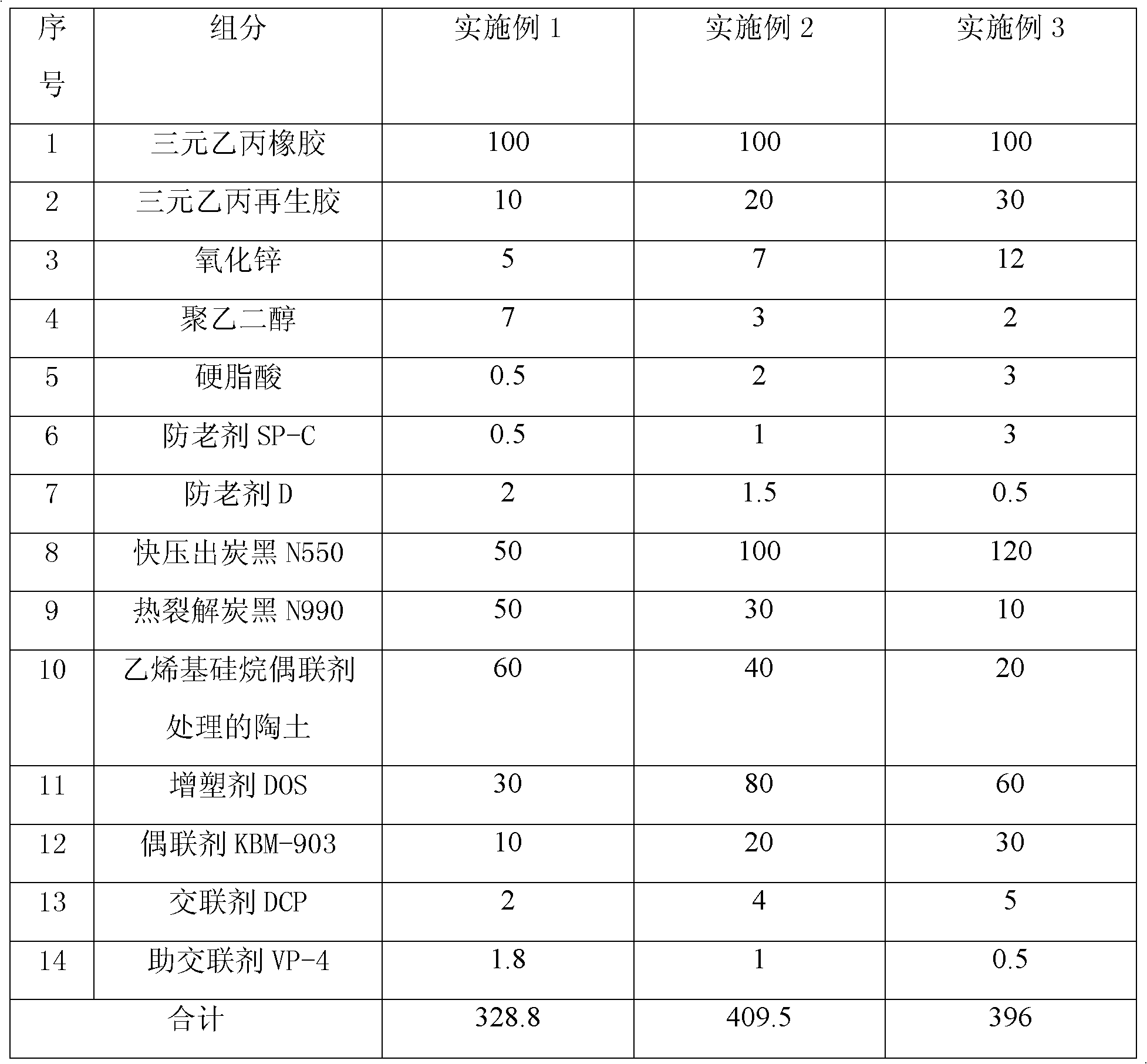

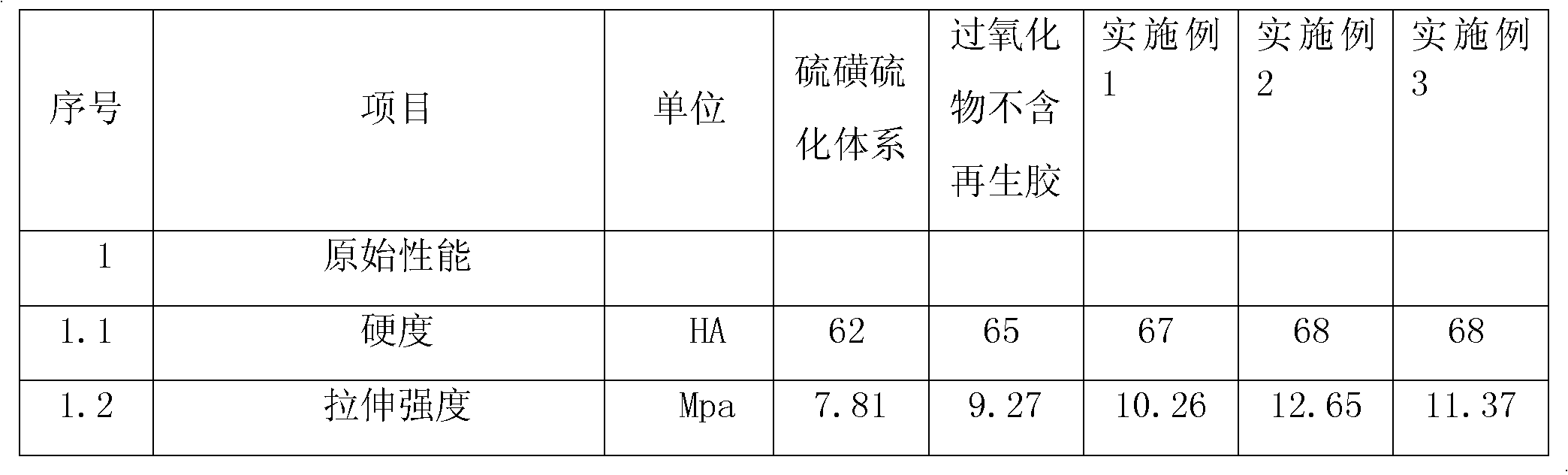

Cold-resistant rubber tube using both peroxide ternary ethylene-propylene rubber and reclaimed rubber

ActiveCN102093638AExcellent ozone resistanceImprove cold resistanceFlexible pipesThermal ageingCross-link

The invention relates to a cold-resistant rubber tube using both peroxide ternary ethylene-propylene rubber and a reclaimed rubber. The cold-resistant rubber tube comprises the following components: ternary ethylene-propylene rubber, ternary ethylene-propylene reclaimed rubber, zinc oxide, polyethylene glycol, stearic acid, an age resister SP-C, an age resister D, fast extruding carbon black N550, thermal cracking carbon black N990, china clay processed by a vinyl silane coupling agent, a plasticizer DOS, a coupling agent KBM-903, a cross-linking agent DCP and an auxiliary cross-linking agent VP-4. Compared with a sulfur vulcanizing system and a peroxide system which do not contain a reclaimed rubber tube, the formula of the cold-resistant rubber tube using both the peroxide ternary ethylene-propylene rubber and the reclaimed rubber has higher cold resistance, cooled liquid resistance, electric property resistance, ozone resistance and thermal ageing resistance, lower compression set, higher elongation, breaking strength and tearing strength and can better meet the requirements of a cooling system circulating water pipe and a connecting hose pipe which are used for a long time at a low temperature.

Owner:TIANJIN PENGYI GRP CO LTD

High-efficiency non-oriented silicon steel and preparation method thereof

InactiveCN110042310AReduce iron lossReduce the risk of belt breakageIncreasing energy efficiencySteelmakingChemical composition

The invention discloses high-efficiency non-oriented silicon steel and a preparation method thereof. The high-efficiency non-oriented silicon steel comprises the chemical components in percentage by mass of at most 0.005% of C, 1.0-2.0% of Si, 0.2-0.8% of Als, 0.25-0.8% of Mn, 0.01-0.05% of Sn, at most 0.02% of P, at most 0.0040% of S, at most 0.0020% of N, at most 0.0020% of Nb, at most 0.0020% of V, at most 0.0020% of Ti and the rest of Fe and unavoidable impurities. The high-efficiency non-oriented silicon steel and the preparation method have the advantages that by the strict component control in steelmaking, the impurity elements meeting the target requirement is ensured; by hot skin rolling, high temperature normalizing, induction heating before cold rolling, annealing and rapid warming and a low temperature long-time insulation process, the high-efficiency non-oriented silicon steel is obtained; and the iron loss of a finished product is P1.5 / 50<=3.2W / kg, and magnetic inductionis B50>=1.73T.

Owner:ZHANGJIAGANG YANGTZE RIVER COLD ROLLED PLATE CO LTD +2

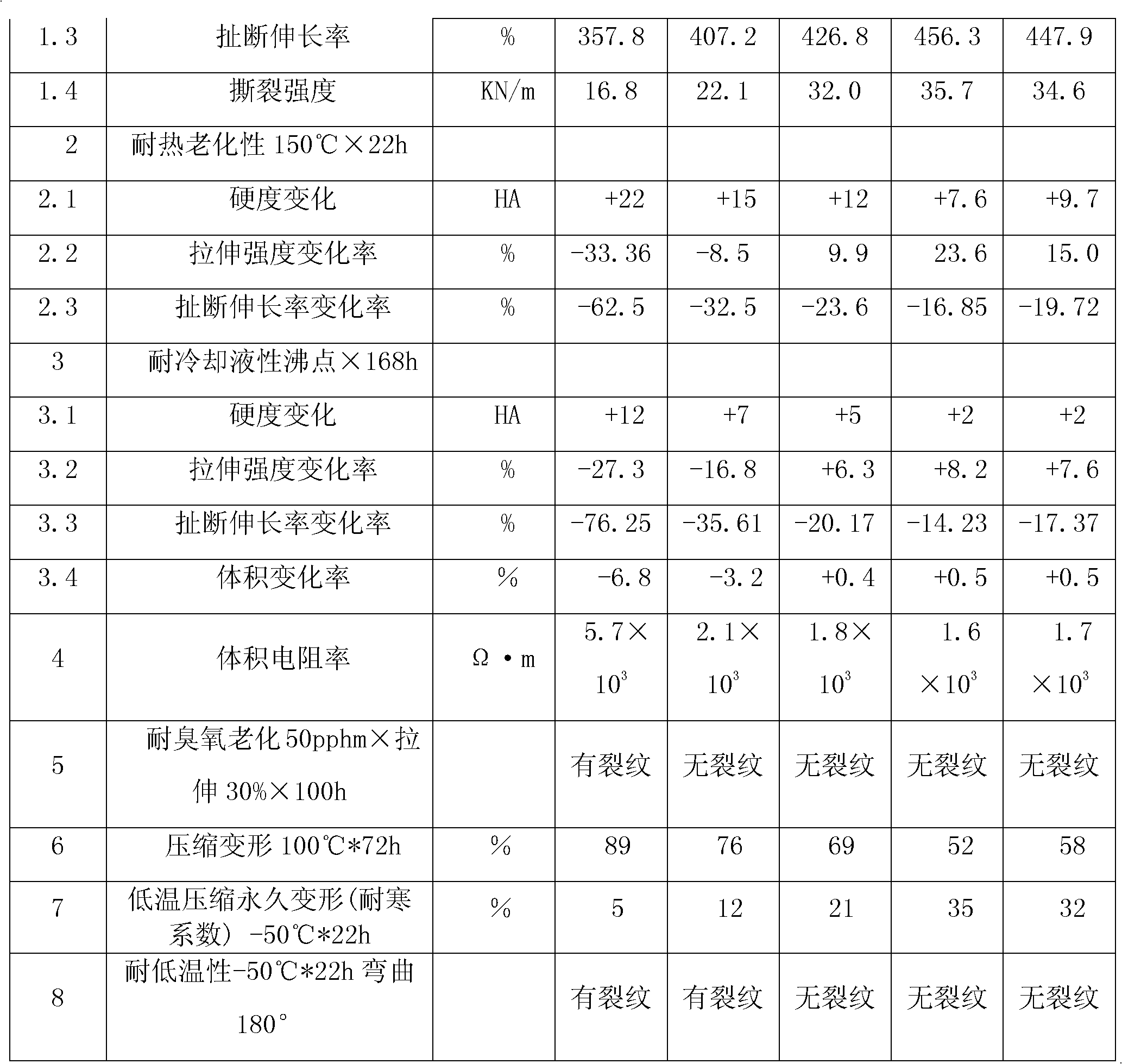

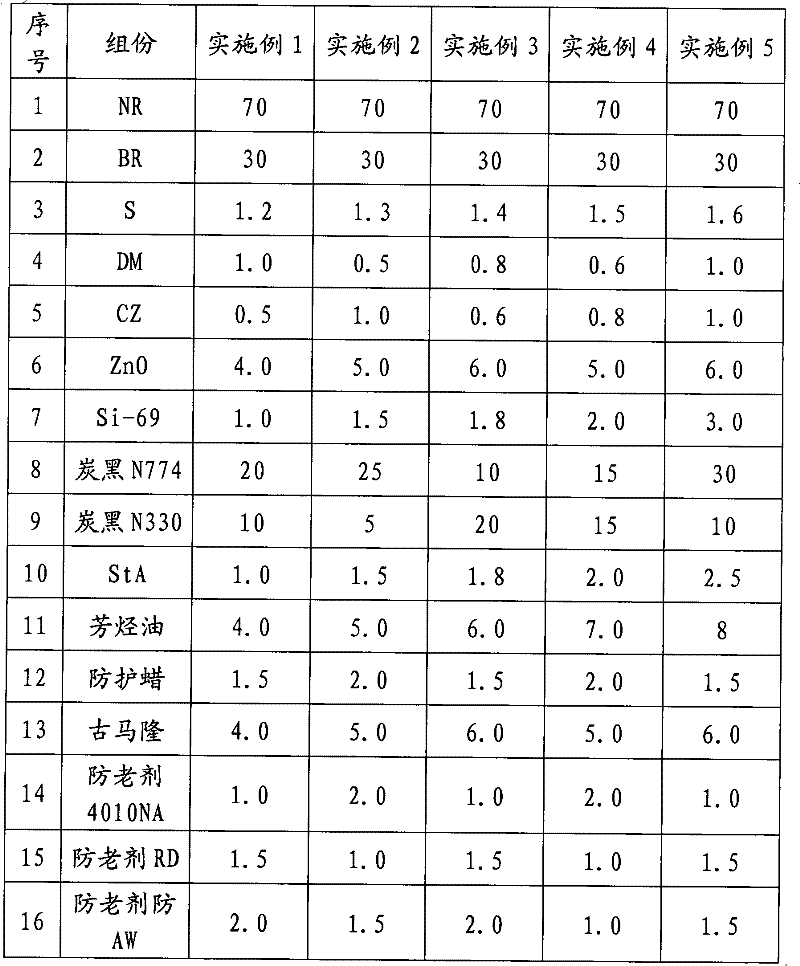

Rubber used for building shock-isolation support and manufacture method thereof

The invention relates to a manufacture method of rubber used for a building shock-isolation support, which is performed by carrying out internal mixing, open mixing, sheet adding and sheet vulcanizing processes on natural rubber (NR), butadiene rubber (BR), S, an accelerator DM (2,2'-dibenzothiazole disulfide), an accelerator CZ (N-cyclohexyl-2-benzothiazole sulfenamide), ZnO, a coupling agent Si-69, carbon black N774 and N330, stearic acid (StA), an aromatic oil, protective wax, coumarone, an antiageing agent 4010NA (N-isopropyl-N'-phenyl-p-phenylenediamine), an antiageing agent RD (poly(1,2-dihydro-2,2,4-trimethyl-quinoline)) and an antiageing agent AW (6-ethoxyl-2,2,4-trimethyl-1,2-dihydroquinoline). According to the manufacture method, the use of a semi-efficient vulcanization system can well balance the performance of the rubber support during the low-temperature long-time vulcanization process; the combined use of the accelerators DM and CZ can well balance the relationship between the vulcanization characteristics and physical properties; and the appropriate combined use of natural rubber and butadiene rubber can improve anti-reversion properties and heat aging performance of the rubber.

Owner:TIANJIN RUBBER IND RES INST

Malt preparation lowering beta-dextran in malt

The invention provides a malt preparation method which can lower the content of beta-hyskon in malt. The method mainly comprises the following steps: A. malt immersion: a small amount of NaOH can be added to lower active levels of microbes, and gibberellic acid is added to treat barley, which can further speed up the related enzymic reaction, and the ventilation and the oxygen supply must be paid attention in the process of the malt immersion and the germination, which facilitates the generation of beta-dextranase, endopeptidase and alfa-amylase; B. germinating: firstly intermediate temperature air, secondly high temperature air and thirdly low temperature air are continuously transferred to supply fresh air; and C. drying: the low temperature long-time moisture expelling method adopted can continuously exert effects of the beta-dextranase and other enzymes. In the invention, three steps of preparing the malt are organically combined, all indexes of the malt are in a proper range, so that the high quality malt which has the advantages of lower content of beta-hyskon and good indexes of leaching rate, ammonia nitrogen and glycation rate, etc. can be prepared.

Owner:HUBEI JINWEI MALT

Radial ply tyre carcass tyre facing stepwise molding sulfuration process

InactiveCN101077632ASmall outer diameterSimplify the manufacturing processTyresEngineeringRubber sheet

The stepped forming and vulcanizing process of producing radial tyre carcass tread for large engineering machine includes the following steps: 1. forming radial tyre carcass without rubber tread conventionally and vulcanizing in no pattern molds; 2. forming 4-40 rubber tread blocks in a hydraulic plate vulcanizing machine and pre-vulcanizing; 3. adhering buffering rubber sheets to the carcass crown; 4. adhering the rubber tread blocks based on the required pattern; and 5. vulcanizing the tyre in a vulcanizing tank at low temperature for long time for combining the tread with the carcass tightly. The present invention has relaxed requirement on the vulcanizing apparatus, simple making process, short production period, high product performance and other advantages.

Owner:HAOHUA SOUTH CHINAGUILIN RUBBER

Production method of low-alcohol cider

The invention relates to a production method of low-alcohol cider. According to the invention, process steps such as original fruit puree impregnation, high-temperature enzymolysis, high-temperature initiation, low-temperature long-time fermentation, and the like are adopted. The obtained cider has the advantages of golden color, clear wine body, good sour and sweet taste, soft and harmonious taste, rich and long-lasting aroma, and sufficient aftertaste. With the method, apple deep processing industrial chain in our nation is prolonged, apple added value is increased, and a defect of insufficient taste of cider in our nation is overcome. With the method, a firm basis is made for expanding consumer groups of the cider in our nation, and the cider is provided with competitiveness in domestic and international markets.

Owner:NORTHWEST A & F UNIV

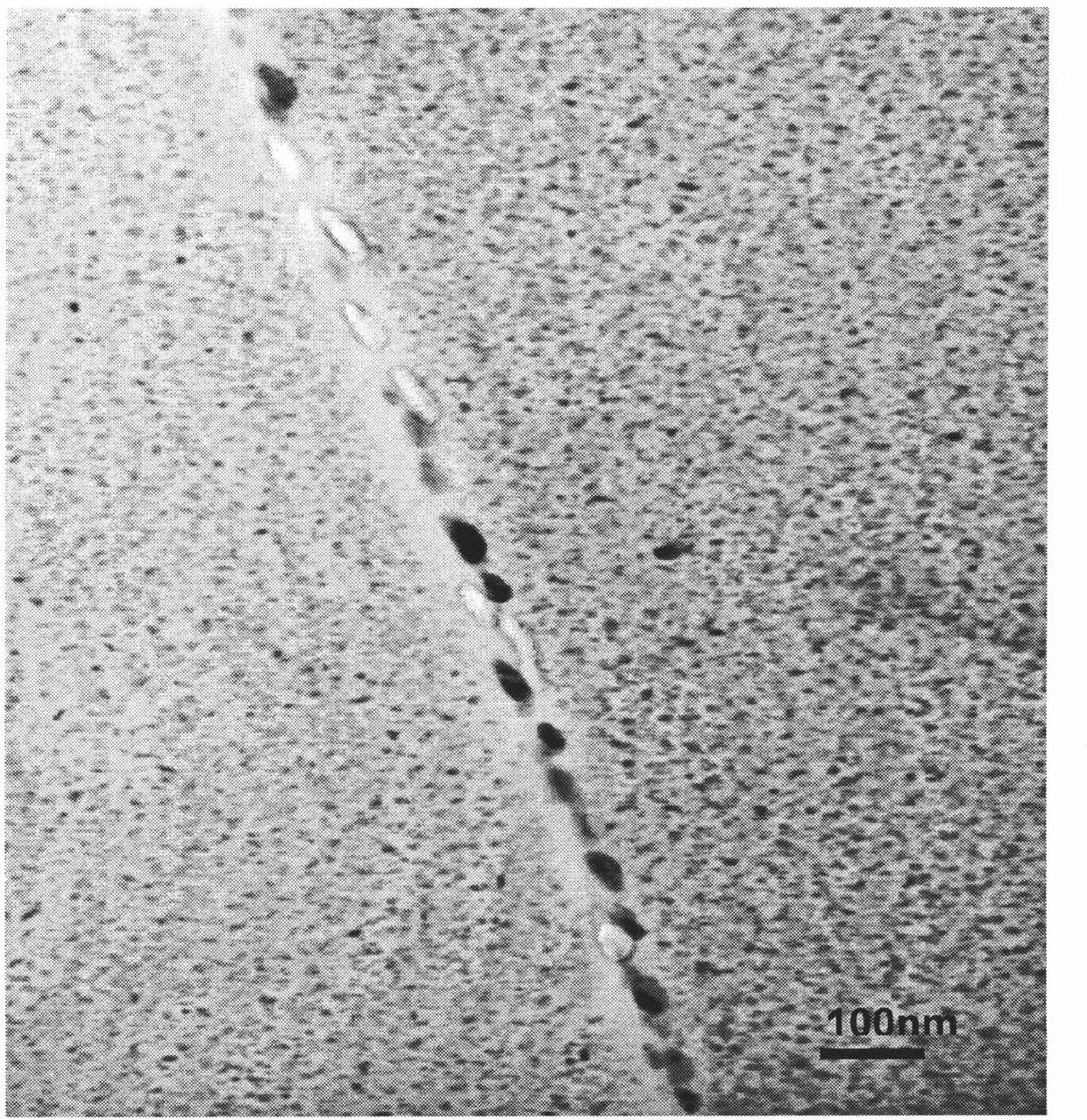

Magnesium alloy etching agent and using method thereof

ActiveCN101058884AGuaranteed viscosityGuaranteed brightnessPreparing sample for investigationAcetic acidRare earth

The invention discloses an etching agent of magnesium alloy and using method, which uses rare earth magnesium alloy disposed by heat to etch sample in the gold phase; displaying microscopic tissue structure. The composition is (a) at least one ethandiol or diethylene glycol ether, (b) acetic acid as basic oxidizing acid, (c) concentrated nitric acid as auxiliary oxidizer and polishing agent, (d) oxidizing typed brightener.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Preparation method of Cap antigen for detecting porcine circovirus 2 type antibody

A preparation method of the Cap antigen of testing pig cirque virus two type antibody, the method includes steps as follow: (1)PCR clone coding gene of PCV2 ORF2; (2)designing and reforming the expression vector rCap; (3)in the culture medium of improved LB liquid, 37deg induction orderly and low temperature long-playing induction rCap expression; (4) sublimating rCap protein; of which the culture medium of improved LB liquid containing 6-9g / L peptone,6-9g / L sodium chloride and 2-4g / L yeast extract; taking the inductor IPTG to induce rCap expression, the finally thickness of it is 0.05-0.2 mol / L; the first inductive temperature of inducing the rCap expression is 37deg, the second inductive temperature of inducing the rCap expression is 16-20deg; the first inducing time is 3-6 hours for induction rCap expression, the first inducing time is 12-20 hours. The method accelerates rCap to bring solubility rCap proteinin the Escherichia coli, reducing the form of occlusion body, avoiding the process of the complicated denaturation and renaturation, at the same time, the biology activity of solubility rCap protein which gets by separating and sublimating is close to PCV2 virus native protein.

Owner:LANZHOU INST OF VETERINARY SCI CHINESE ACAD OF AGRI SCI

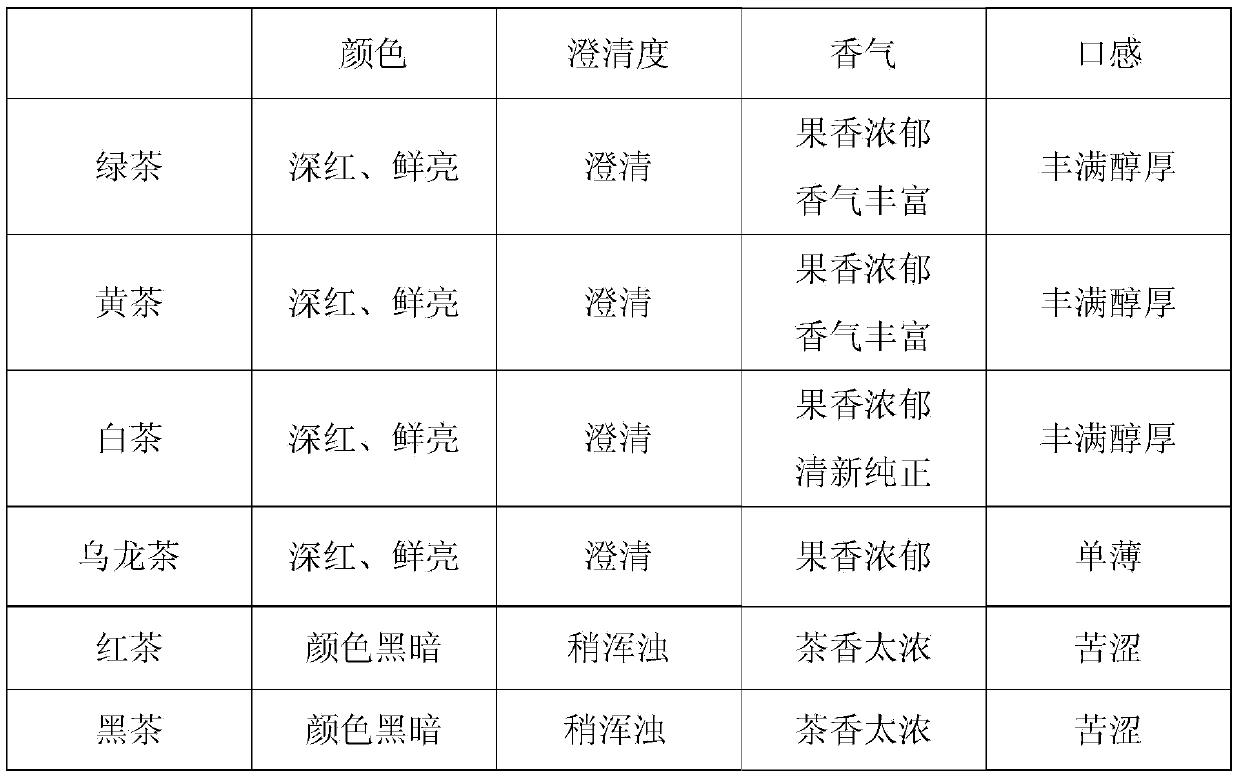

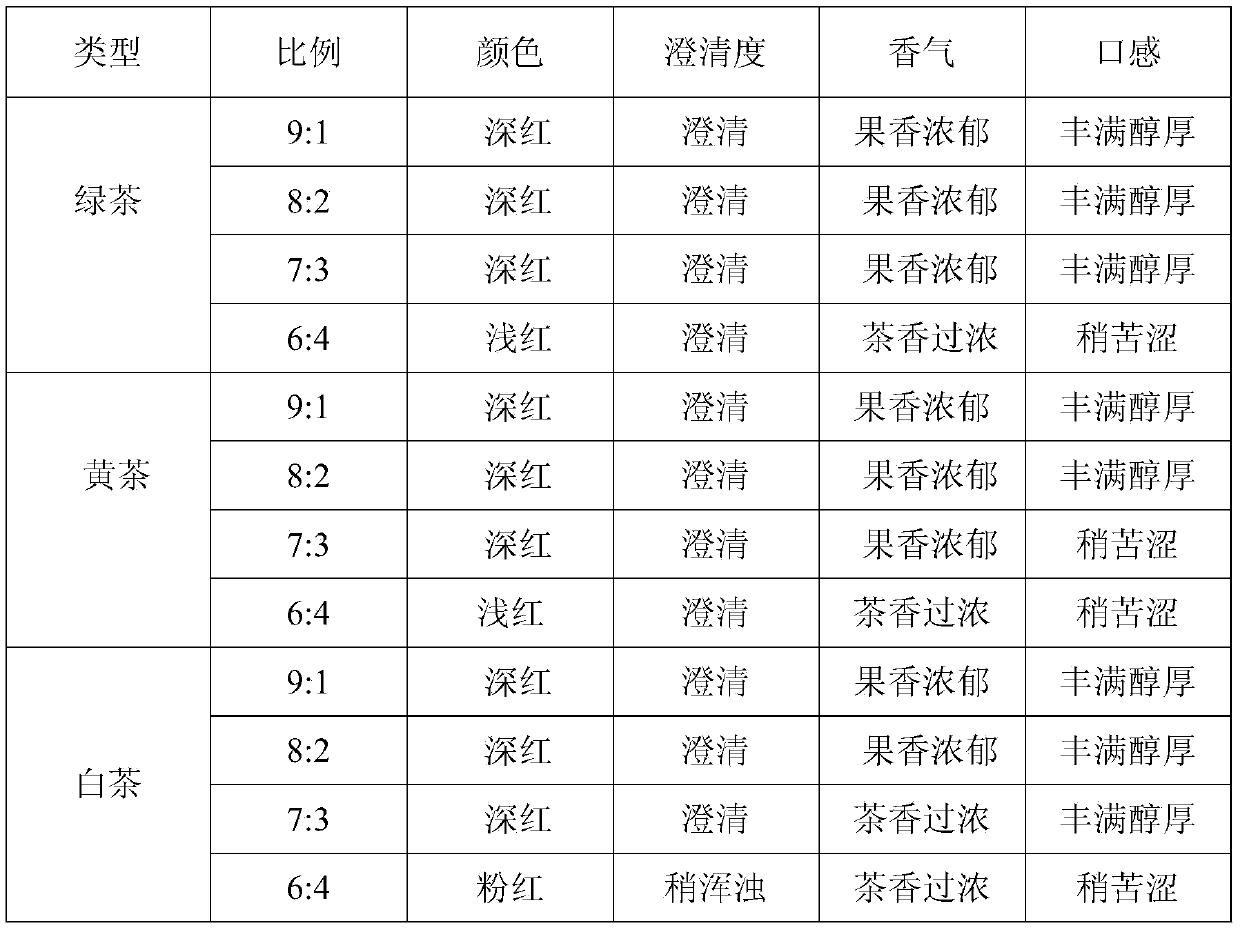

Brewing method of lower-alcohol blueberry health-care wine

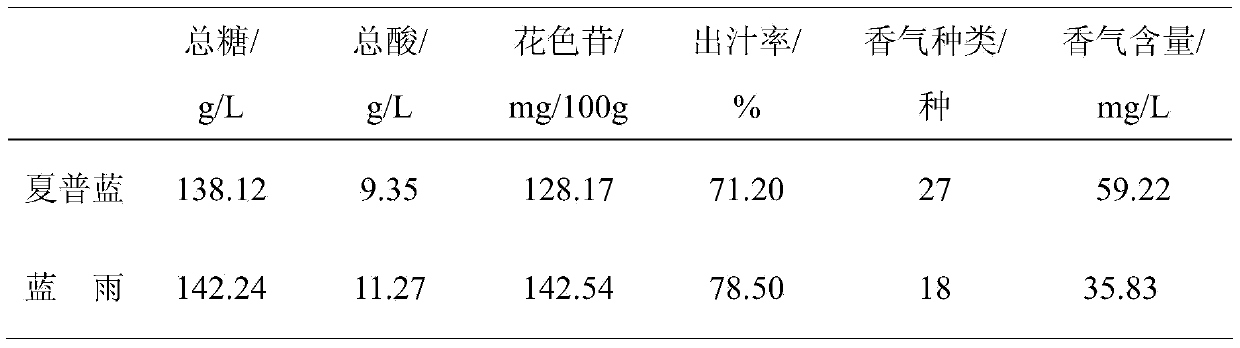

ActiveCN105368631ADeep colorStrong aromaAlcoholic beverage preparationMicroorganism based processesFruit wineStable state

The invention discloses a brewing method of lower-alcohol blueberry health-care wine. The method comprises the steps of blueberry selection and processing, tea preprocessing, raw material blending, ethanol fermentation, ageing, clarification stabilizing processing and the like. The method uses an optimized blue rain variety of blueberries as raw materials, and meanwhile tea leaching liquid, prebiotics and soluble dietary fibers are added; the lower-alcohol blueberry wine is obtained through raw pulp steeping, high-temperature enzymolysis, high-temperature start, mixed-bacteria synergy and low-temperature long-time fermentation; low-temperature ageing is assisted by microwaves to accelerate wine body mature, and the quality of the fruit wine is improved; a wine body is higher in clarity and is kept in a stable state for a long period of time through clarification stabilizing processing; the taste of the wine is improved and meanwhile a health-care function is increased for the wine by adding a functional sweetener. By the adoption of the process, the high-quality lower-alcohol blueberry wine having good color, fragrance and taste and integrating nutrition and health care can be obtained.

Owner:HUANGSHAN BLUEBERRY ECOLOGICAL PARK CO LTD

Gamma-Fe2o3-based benzene gas sensing device and its making process

InactiveCN1487286AImprove thermal stabilityHigh temperature resistanceMaterial resistanceDistillationGas detector

The present invention is one kind of gas-sensitive MOS sensor and its making technology. The gamma-Fe2O3 based benzene gas sensing device has the die surface sensing material comprising fine Y-containing gamma-Fe2O3 powder, SnSO4, SnO, SnC13, AuC13 and pickled asbestos. The fine Y-containing gamma-Fe2O3 powder is prepared through dissolving Fe(NO3)3.9H2O in glycol, refluxing with Y2O3 crystal, distillation, drying to obtain dry gel, and heat treatment. The gas ensing device is made with the said components and through grinding, painting, drying in the air and low temperature long time sintering. The said gas sensing device has high sensitiity, high resolution and high stability.

Owner:SHANDONG NORMAL UNIV

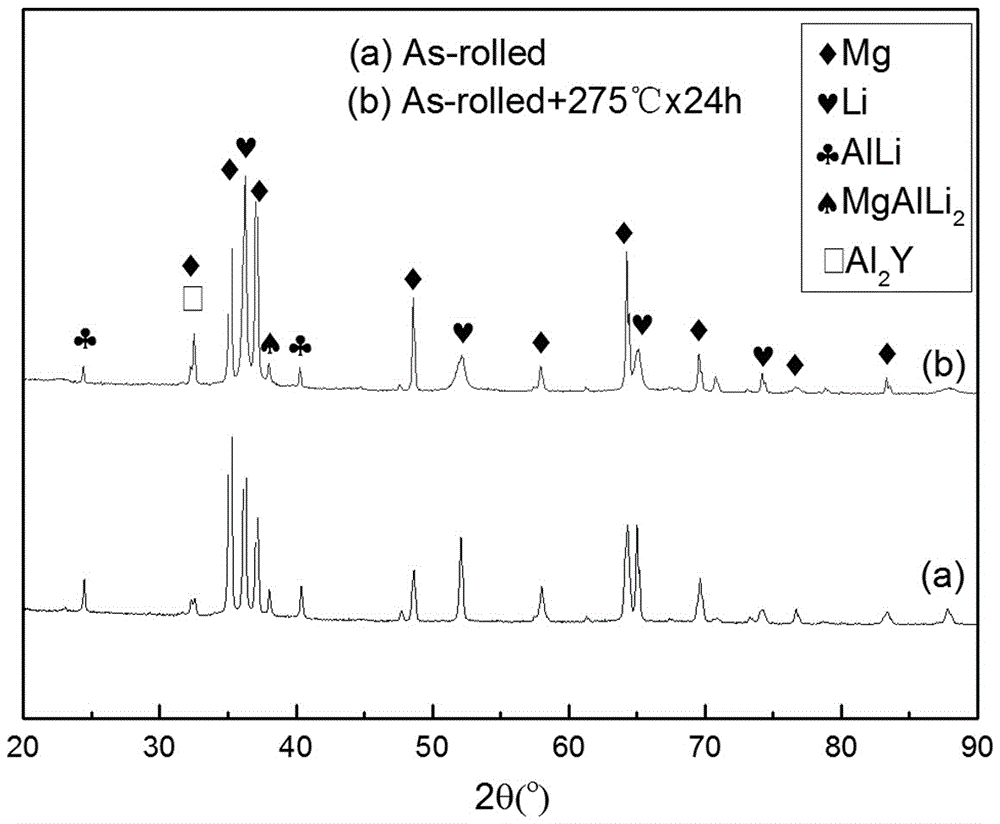

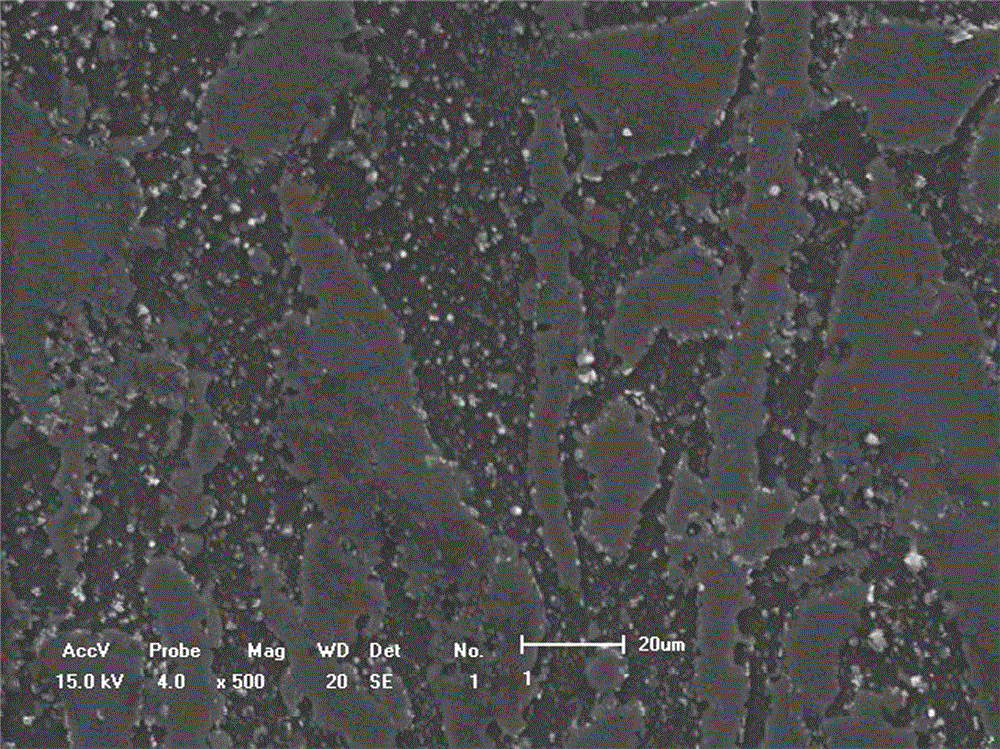

High-strength ultra-light two-phase structure magnesium-lithium alloy plate and preparation method thereof

The invention relates to a high-strength ultra-light two-phase structure magnesium-lithium alloy plate and a preparation method thereof, and belongs to the technical field of material metallurgy, wherein the plate comprises, by mass, 5.7-10.0% of Li, 2.5-3.5% of Al, 1.2-2.0% of Zn, 0.1-0.3% of Y, and the balance of Mg and impurities, has the density of 1.50-1.60 g / cm<3>, and has the tensile strength of more than or equal to 270 MPa. The preparation method comprises: (1) preparing raw materials; (2) carrying out drying treatment on the raw materials, and melting metal magnesium; (3) adding an Mg-Y interalloy, aluminum and zinc, spraying a covering agent, controlling the temperature, and stirring; (4) cooling, pressing metal lithium into the obtained material, spraying a covering agent, stirring, adding a refining agent, and carrying out stirring refining; (5) standing, and then casting; (6) carrying out homogenization treatment; (7) carrying out milling surface processing, and carrying out constant temperature reciprocating warm rolling; and (8) carrying out low temperature long time solution treatment, carrying out air cooling, and carrying out room temperature stretching leveling treatment. With the method of the present invention, the strength of the magnesium-lithium alloy is substantially improved, and the magnesium-lithium alloy plate with characteristics of low density and good plasticity is obtained.

Owner:D MAG KUNSHAN NEW MATERIAL TECH CO LTD +1

Oil composition, preparation method thereof and foodstuffs

ActiveCN105795000AFast crystallization rateShorten production timeDough treatmentCocoaOil and greaseChemical composition

The invention relates to an oil composition, a preparation method thereof and foodstuffs. The oil composition is characterized in that the oil composition comprises triglyceride whose weight is not less than 30% of the total weight as shown in the following general formula (1); in the general formula (1), definitions of R1, R2, and R3 are shown in the specification. The composition does not contain trans-fatty acids, crystallization rate is higher, long time cooling and solidification for shaping at low temperature are not needed, production time is reduced, the composition has a cool mouthfeel without pasty mouthfeel, and the composition melts fast.

Owner:嘉里特种油脂(上海)有限公司

Sweet litchi wine and production method thereof

InactiveCN101735920AIncrease Natural BrixIncrease acidityAlcoholic beverage preparationMicroorganism based processesFruit juiceFiltration

The invention belongs to the field of food fermentation, and relates to a sweet litchi wine and a production method thereof. The production method comprises the following steps: juicing pulp of litchi at the temperature of between 0 and 10 DEG C, adding biological enzyme for hydrolysis and clarification, performing ultra-filtration and concentration on the juice, and adjusting the sugar degree of the concentrated juice to between 270 and 350g / kg and the total acid to between 4 and 7g / kg; and adding Saccharomyces cerevisiae seed liquid into the juice, fermenting at low temperature until the alcoholic strength is between 10 and 14 percent, clarifying, filtering, and fine filtering to remove bacteria to obtain the finished product wine. Under the condition of not adding exogenous sugar and acid, the method adopts low-temperature long-time fermentation, so the brewed litchi wine has high alcoholic strength, maintains high nutrient content simultaneously, and has the advantages of moderate sweetness and acidness, fine and mellow mouthfeel, elegant litchi aroma, attractive color and lustre, and limpidity.

Owner:HAINAN UNIVERSITY

Preparation method of malt

InactiveCN107760503AInhibition of acidic substancesHigh substance contentMalt preparationMaillard reactionAnaerobic respiration

The invention provides a preparation method of malt. The preparation method comprises the following steps: selecting malt; cleaning the malt and removing impurities; soaking the malt; carrying out germination; carrying out drying; carrying out kilning; and removing roots and carrying out packaging. By taking barley which is high in quality and pure in taste as a raw material of high malt-flavoredmalt, ventilation of a large blast capacity is continuously carried out in the malt soaking process, so that acidic substances generated under the anaerobic respiration of the malt are inhibited effectively to provide a proper pH condition for Maillard reaction, and the content of malt-flavored substances is increased. The germinating process is a low-temperature long-time germinating process, sothat the enzymic activity of an enzyme system such as amylase and protease are improved remarkably to form a lot of revertose and amino acids, thereby providing sufficient substrates for Maillard reaction. Under the condition of the most proper water activity, pH and the like of the Maillard reaction, a gradient kilning process is carried out to enrich Maillard reaction products quickly, so that the content of malt-flavored substances is improved, and the malt flavor is obviously better than that of common malt and scorch-flavored malt.

Owner:江苏钰丰麦芽制造有限公司

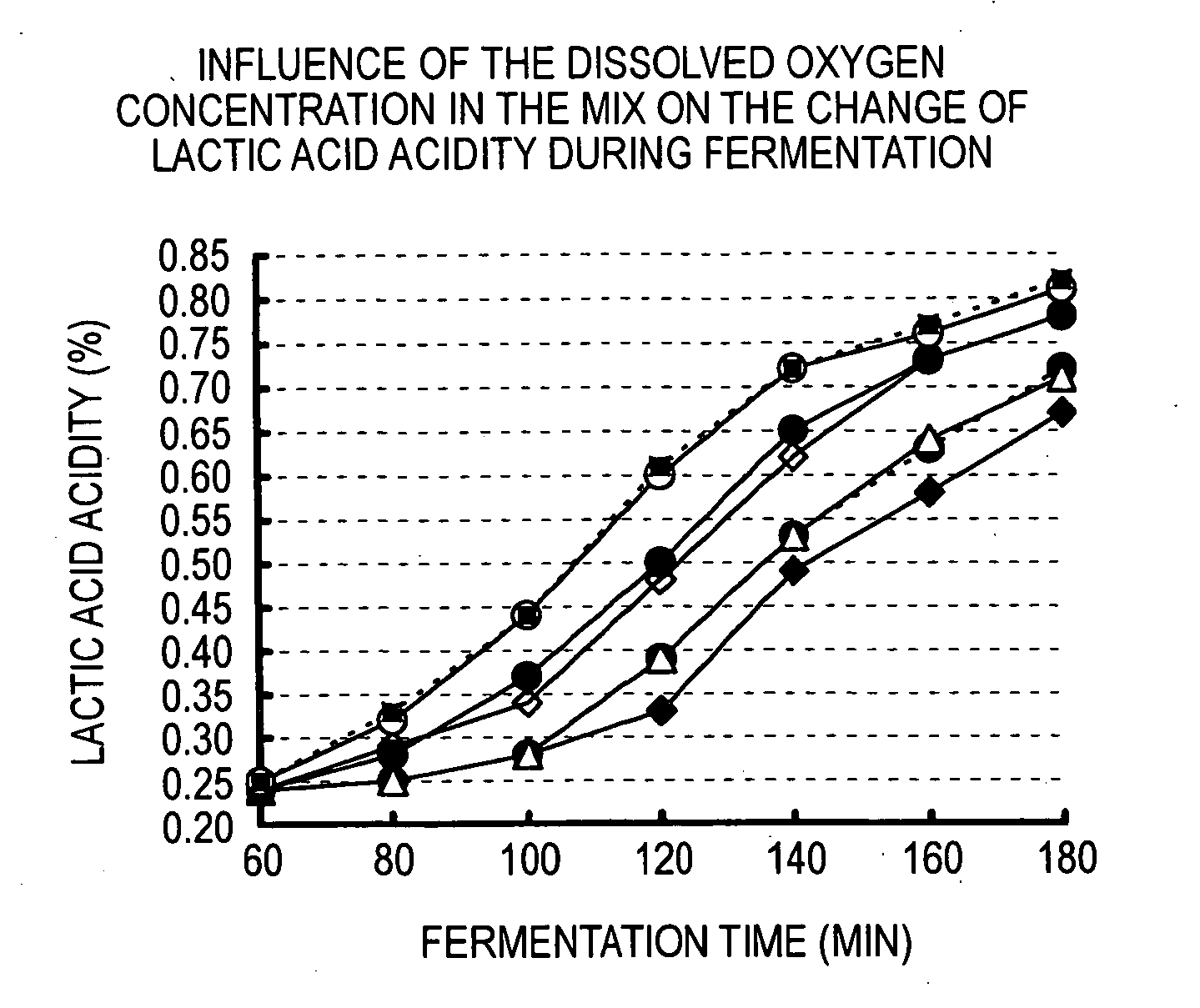

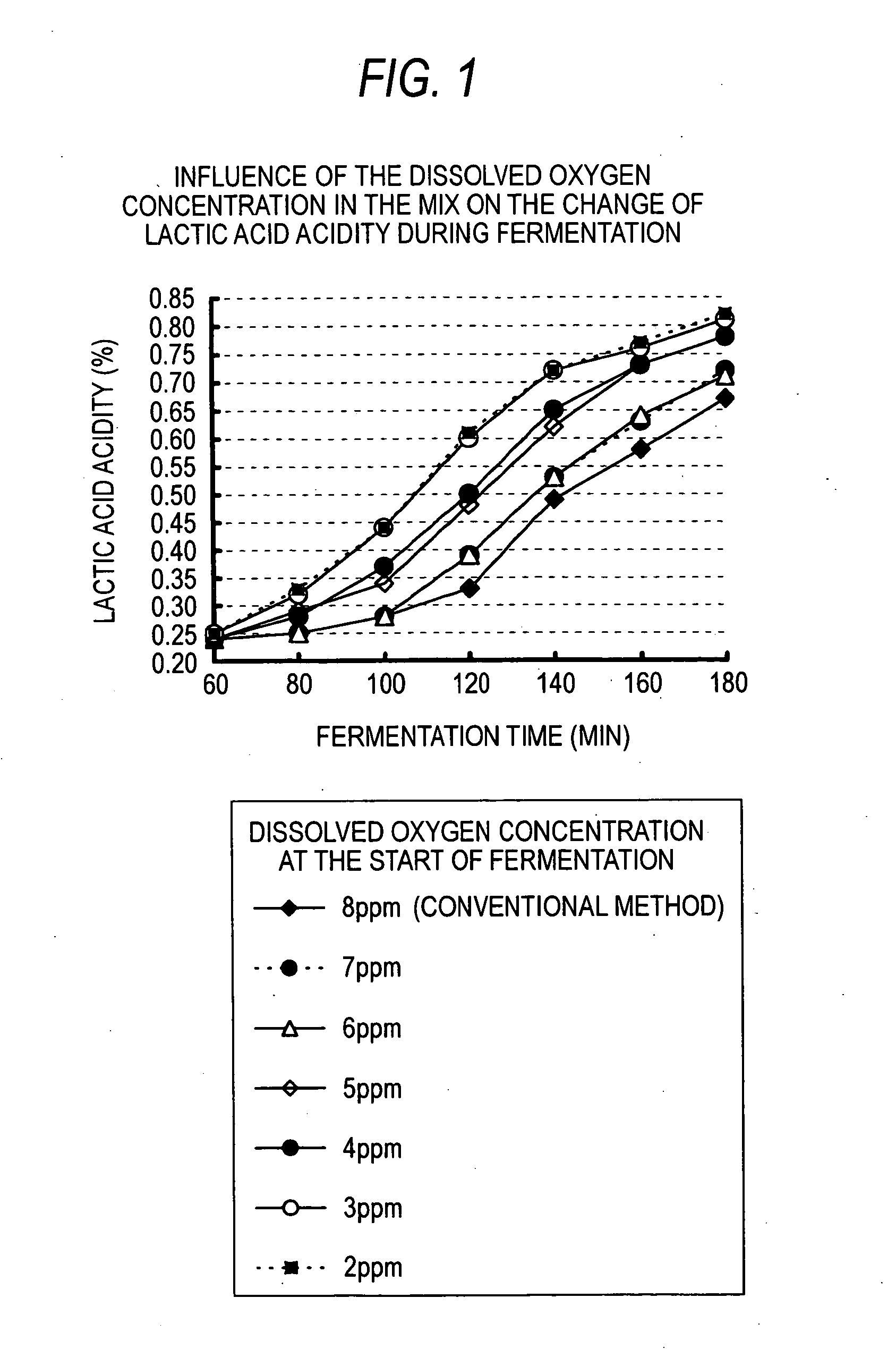

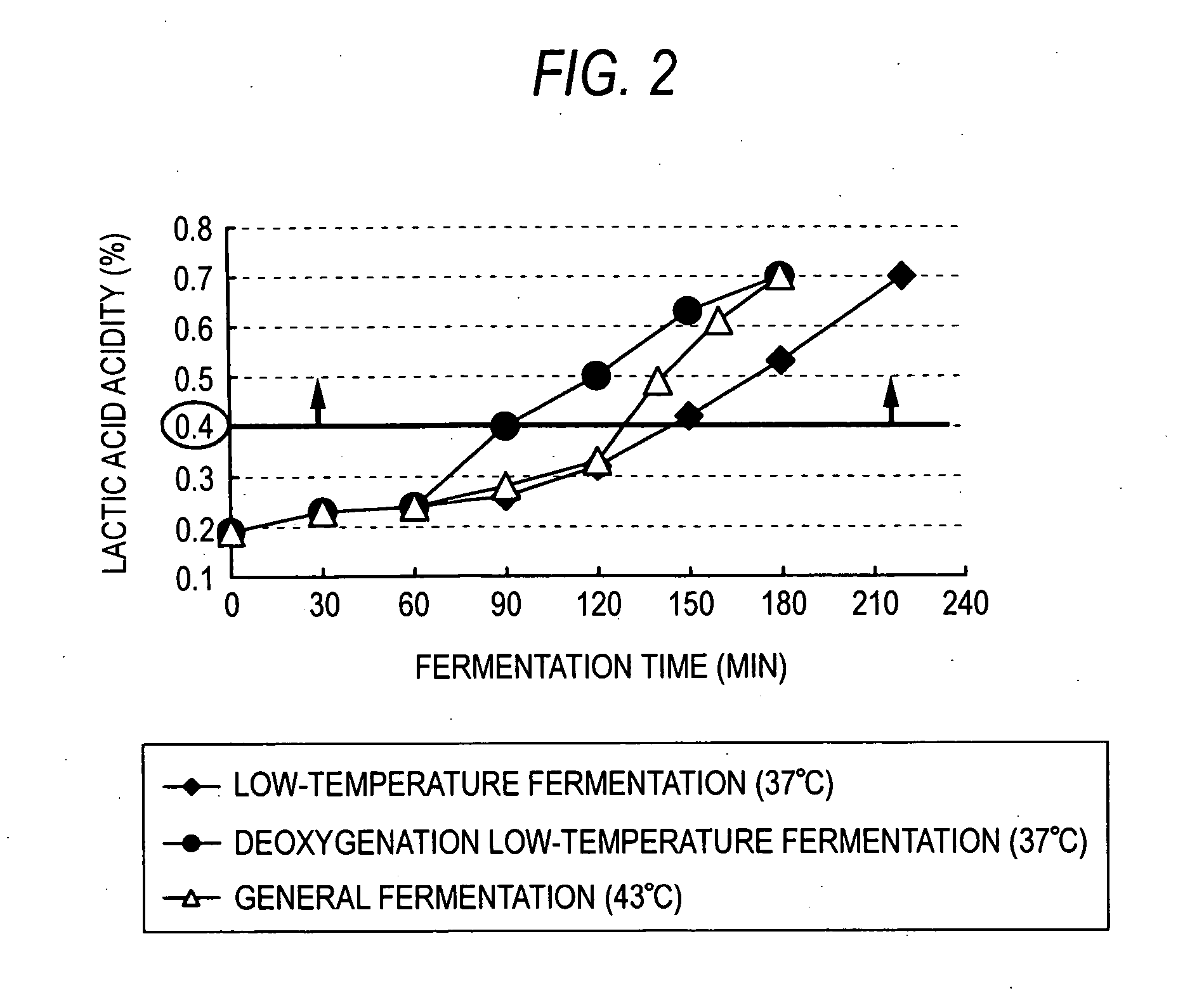

Process for producing fermented milk and fermanted milk

ActiveUS20060040016A1Improve filtration efficiencyShorten fermentation timeMilk preparationOther dairy technologyProduction rateFood flavor

It is an object of the present invention to provide a method for producing fermented milk by promoting fermentation without adding any fermentation-promoting substance, and to provide novel fermented milk with a thick and smooth mouth feel and a mild flavor which has not been obtained conventionally and additionally with a hard texture not degrading during distribution state, as obtained by the method. As a consequence of investigations, it is found out that fermentation efficiency can be promoted by reducing the dissolved oxygen in a mix of raw materials for fermented milk at the start of fermentation through substitution with inert gases. It is also found out that the method including fermentation at general temperature in the above condition can shorten fermentation time to improve productivity, and that the method including fermentation at a fermentation temperature lower than a usual method for general fermentation time can produce novel fermented milk with a thicker and smoother mouth feel and a milder flavor than the mild flavor of fermented milk obtained by conventional low-temperature fermentation for a long period and with a hard texture never degrading during distribution stage, which has not been obtained conventionally, in addition that the fermented milk is obtained by the above method. As a consequence, the invention has been achieved.

Owner:MEIJI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com