Method for processing high shrinkage superfine denier polyester staple fiber

A technology of ultra-fine denier polyester and processing methods, which can be applied in the direction of short fiber formation, fiber treatment, melt spinning, etc., can solve the problems of low linear density and increased shrinkage, and achieve high water absorption and air permeability, soft and good hand feeling and milled style effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below through specific examples.

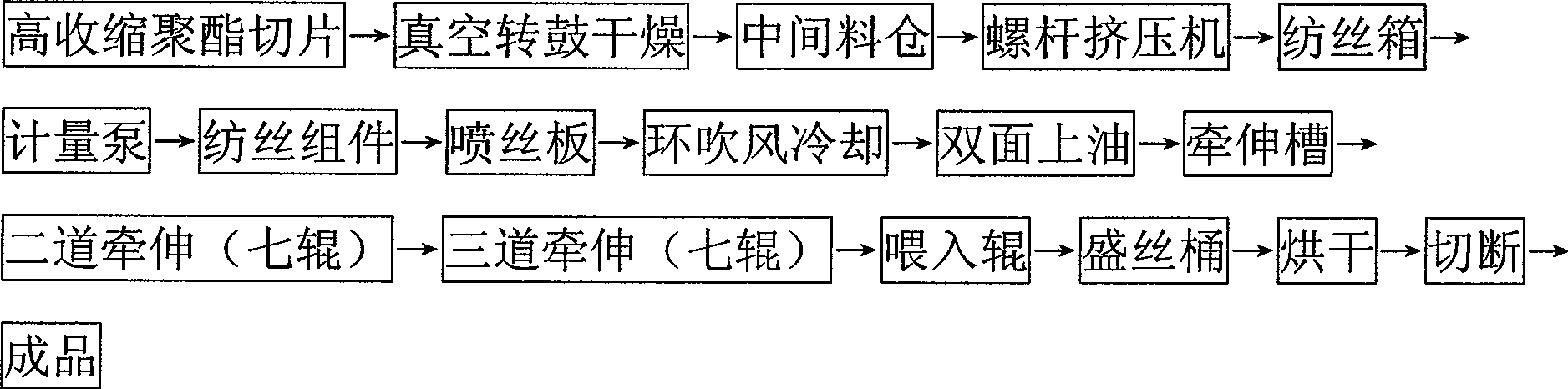

[0014] According to raw material drying, pre-spinning part and post-spinning part respectively:

[0015] (1) slice drying part:

[0016] The high-shrinkage polyester chips are dried by vacuum drum, the drying temperature is 55-60°C, the drying time is 36 hours, and the vacuum degree is -0.2MPa.

[0017] (2) Pre-spinning part:

[0018] 1. The pre-crystallizer temperature of the drying system is 68°C, the temperature of the filling dryer is 32°C, and the fan is turned on to circulate.

[0019] 2. The spinneret adopts 1455 (0.2*0.5), and the assembly is filled with 900 grams of sea sand. The preheating temperature is 260°C and the time is 18 hours. ℃, wind pressure 490Pa.

[0020] 3. The temperature of each zone of the screw: the first zone is 196°C, the second zone is 236°C, the third zone is 248°C, the fourth zone is 270°C, the fifth zone is 275°C, the head is 264°C, and the box is 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com