Patents

Literature

42results about How to "Good water absorption and breathability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bio-organic fertilizer

InactiveCN104774054ALow costQuick costBio-organic fraction processingOrganic fertiliser preparationSnow moldMicrobial agent

The invention discloses bio-organic fertilizer, and belongs to the technical field of organic fertilizer. The proportion by weight of all raw materials of the bio-organic fertilizer is dried chicken manure : edible mushroom : compound microbial agent : corn flour or rice bran : functional strain = 110-140 : 390-360 : 0.1-0.5 ; 0.1. The compound microbial agent comprises mould, bacillus, lactic acid bacteria, actinomycetes and saccharomycetes. The strains are efficient viable bacteria. Each gram of the compound microbial agent comprises the number of the mould ranges from 5 hundred million to 8 hundred million, the number of the efficient viable bacteria of bacillus ranges from 12 hundred million to 15 hundred million, and the number of the actinomycetes ranges from 10 hundred million to 12 hundred million and the saccharomycetes of 15 hundred million to 18 million. According to the bio-organic fertilizer, the chicken manure and mushroom dregs serve as main materials, and the high-quality organic fertilizer can be fermented quickly by adding the compound microbial agent and the functional strain.

Owner:YONGZHOU WANXIDENG AGRI DEV

Bio-organic fertilizer with Chinese medicine residue as raw material and production process thereof

ActiveCN103396223AGood water absorption and breathabilityImprove breathabilityBio-organic fraction processingOrganic fertiliser preparationOrganic fertilizerMaceral

The invention provides a bio-organic fertilizer with Chinese medicine residue as a raw material. The formula of the organic fertilizer comprises grass carbon and lignite, and functional bacteria are added. The raw materials comprise the following components in percentage by weight: 30-70 percent of Chinese medicine residue dry product, 0.01-0.5 percent of biological bacteria, 20-40 percent of grass carbon, 10-30 percent of lignite, 1-5 percent of mineral matter fertilizer and 0.1-0.5 percent of functional bacteria. Various nutrients which cannot be effectively absorbed by plants in the soil can be effectively activated, so that the quality and the yield of the crops are improved, and the immune-competence of the crops per se can also be effectively improved.

Owner:FOUR FRIENDS OF CHENGDU CHEM IND

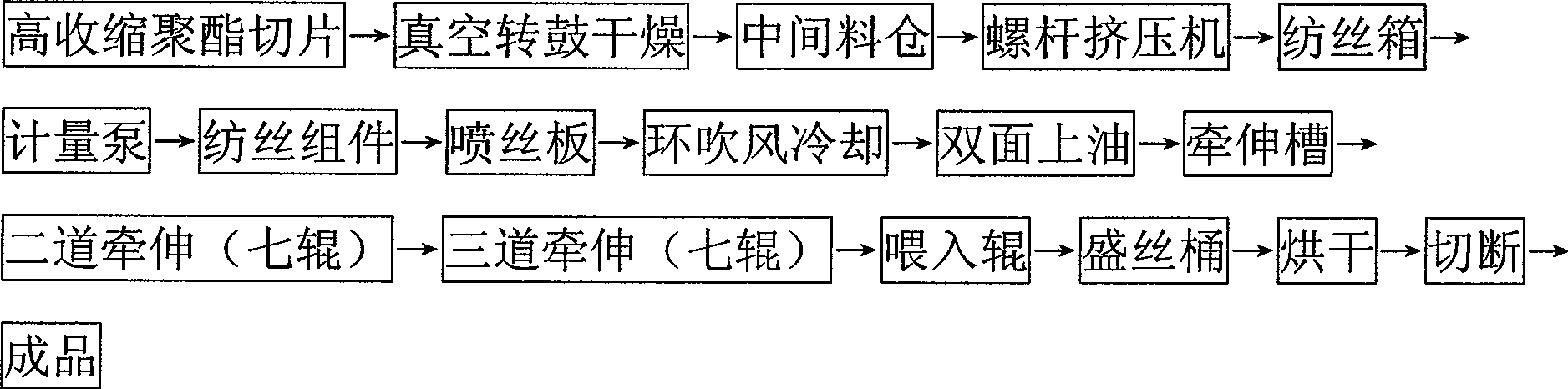

Method for processing high shrinkage superfine denier polyester staple fiber

InactiveCN101503832AFeel goodGood water absorption and breathabilityMelt spinning methodsStaple fibre formationPolyesterYarn

The invention relates to a processing method of high-shrinkage ultrathin polyester short fiber. The process flows of the method comprise: high-shrinkage polyester slicing, vacuum rotary drum drying, intermediate bunker, screw extruder, spinning box, metering pump, spinning component, spinneret plate, circular blowing cooling, double side oiling, drawing groove, second drawing (seven rollers), third drawing (seven rollers), feeding roller, yarn containing drum, drying, cutting and obtaining finished product. The technological parameter of the method is characterized in that slice drying adopts a vacuum rotary drum low-temperature longtime process; spinning temperature and preliminary drawing multiple are properly lowered; low-temperature drawing and unshaped drawing process are adopted; and the spinneret plate adopts a finishing spinneret plate which has 0.2*0.5mm aperture and is matched with a corresponding component. Due to adopting high-shrinkage functional polyester slice as a raw material, the processing method can realize production on common polyester short fiber spinning equipment without changing the prior spinning equipment during production.

Owner:JIANGSU SHENGHONG CHEM FIBRE CO LTD

Fabric with water absorption and air permeability and production method thereof

The invention discloses a fabric with water absorption and air permeability and a production method thereof. The wrap and weft yarns of the fabric at least comprise one kind of dual-component yarn containing common Dacron and cation Dacron, and the dual-component yarn is processed into the finished production through alkali weight reducing finishing. The air permeability of the finished product, tested by JIS (Japanese Industrial Standards) L1907 test method, is above 80cc, joint shift is within 2.5mm under the tension of 9.8N, water absorption performance is good, water absorption diffusing time is within 3S, and the fabric has the function of cool feeling and quick dryness by moisture adsorption, and is an ideal autumn and summer leisure material.

Owner:TORAY SAKAI WEAVING & DYEING NANTONG CO LTD

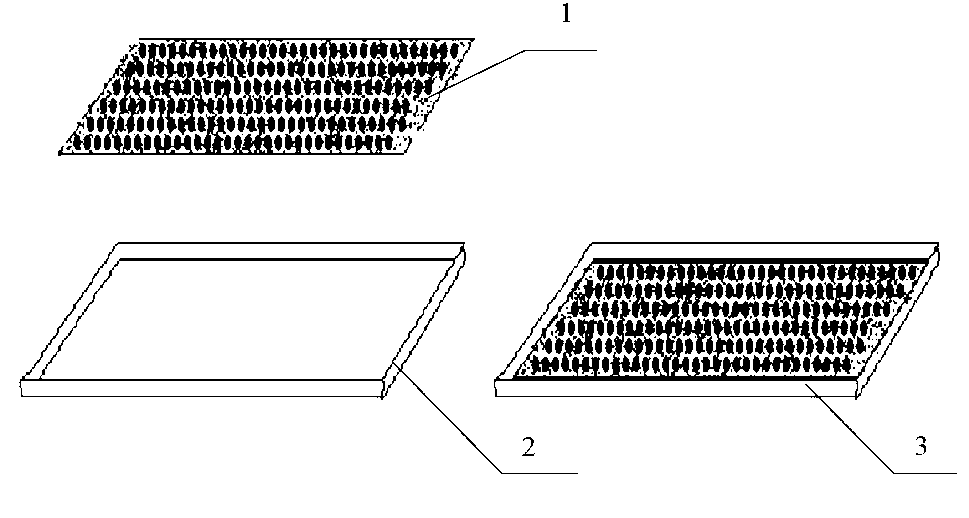

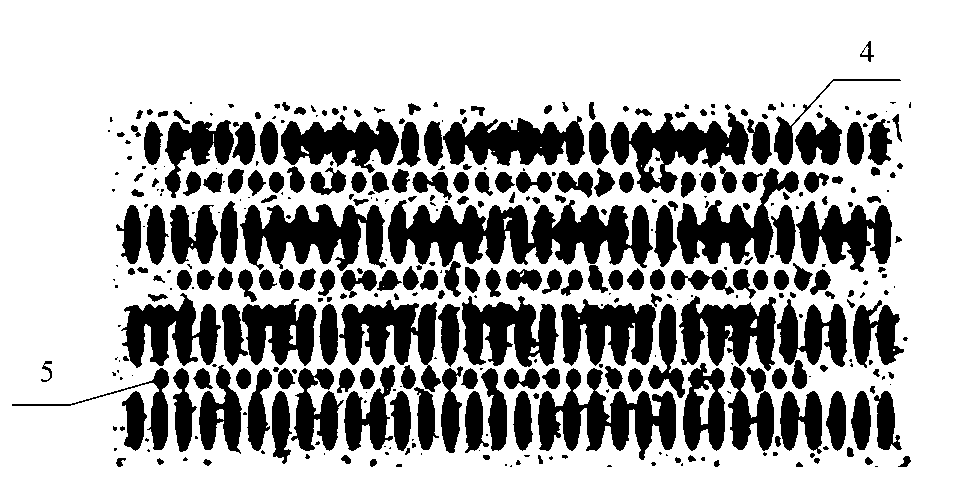

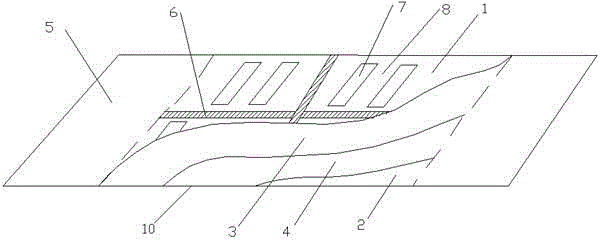

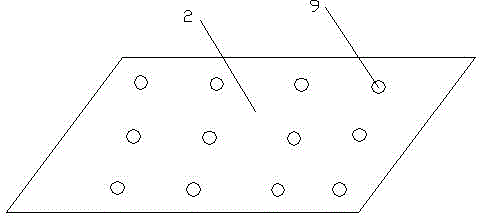

Rice seedling machine seedling planting diaphragm and manufacture method of rice seedling machine seedling planting diaphragm

ActiveCN103070045AGood consolidationPromote growth and developmentCultivating equipmentsNon-woven fabricsMechanical stretchingEconomic benefits

The invention discloses a rice seedling machine seedling planting diaphragm and a manufacture method of the rice seedling machine seedling planting diaphragm. By aiming at the problems that the seedling root winding effect in the rice seedling machine seedling planting is poor, the seedlings can easily get scattered, and the operation is complicated, the invention provides the rice seedling machine seedling planting hemp-base diaphragm, which consists of a hemp fiber diaphragm substrate and rice seeds fixedly carried on the substrate. The hemp fiber raw materials are subjected to loosening, scattering and mechanical stretching to form a net, then, biodegradable bonding agents are adopted for bonding, baking is carried out, the hemp fiber diaphragm substrate is formed, and next, the rice seeds are uniformly scattered and pasted on the hemp fiber diaphragm substrate through the biodegradable bonding agents. When the rice seedling machine seedling planting hemp-base diaphragm provided by the invention is adopted, the seedling culture operation can be greatly simplified, farmers can realize the seedling culture without seeding, in addition, the seedling root system winding effect can be obviously promoted, the winding force is improved, seedlings conforming to the machine seeding requirements are formed, meanwhile, because the seedling quality is improved, the green returning speed of the seedlings after the machine seedling planting is high, the tillering effect is good, the rice yield is obviously improved, and good economic benefits are realized.

Owner:INST OF BAST FIBER CROPS CHINESE ACADEMY OF AGRI SCI

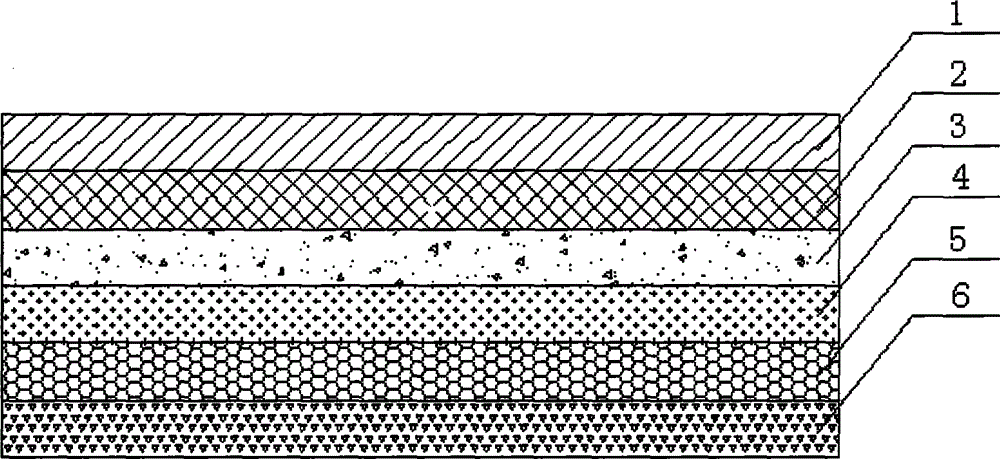

Medical nursing cushion

InactiveCN104800002AGood water absorption and breathabilityFeel comfortable on the skinAbsorbent padsBaby linensFluff pulpWoven fabric

The invention discloses a medical nursing cushion, and belongs to the technical field of nursing materials. The medical nursing cushion comprises an antibacterial layer, a water permeable layer, a water absorption layer, an air ventilation layer, a waterproof layer and a bottom layer in sequence from top to bottom, wherein the antibacterial layer, the water permeable layer, the water absorption layer, the air ventilation layer, the waterproof layer and the bottom layer are extruded and compounded together; the antibacterial layer is provided with pure cotton fabric in which a sterilization material is added; the water permeable layer is a layer which is of a net surface structure; the water absorption layer is provided with fluff pulp, macromolecular absorption resin and cotton; the waterproof layer is provided with a plastic thin film; the bottom layer is made of non-woven fabric. By using the medical nursing cushion, the cleanness, the dryness, the comfortableness and the freshness can be maintained, and the medical nursing cushion has the advantages of being good in water-absorbing capacity and less likely to leak.

Owner:陈亚婷

Sound-absorbing PU synthetic leather and producing method thereof

InactiveCN104479333AImprove comfortImprove the simulation effectTextiles and paperAluminium chlorideGlycerol

Sound-absorbing PU synthetic leather is disclosed. The synthetic leather is prepared from following raw materials by weight: 80-100 parts of polyurethane resin, 80-100 parts of dimethyl formamide, 2-4 parts of vinyl acetate-acrylic emulsion, 1-2 parts of castor oil, 0.1-0.2 part of glycerol monocaprylate, 0.2-0.5 part of lecithin, 4-6 parts of diatomite, 2-4 parts of rice husk, 0.2-0.4 part of tea tree oil, 0.2-0.4 part of nonylphenol polyoxyethylene ether, 5-10 parts of sodium carboxymethyl cellulose, 0.5-1 part of potassium sodium tartrate, 0.5-1 part of aluminium chloride, 4-8 parts of color paste, and 3-5 parts of modification auxiliary agents. The synthetic leather has sound-absorbing and noise-reducing functions, has good water absorption and air permeability performance and emulational texture, and is suitable for applications in indoor decoration.

Owner:HEFEI JINLINGLI CLOTHING

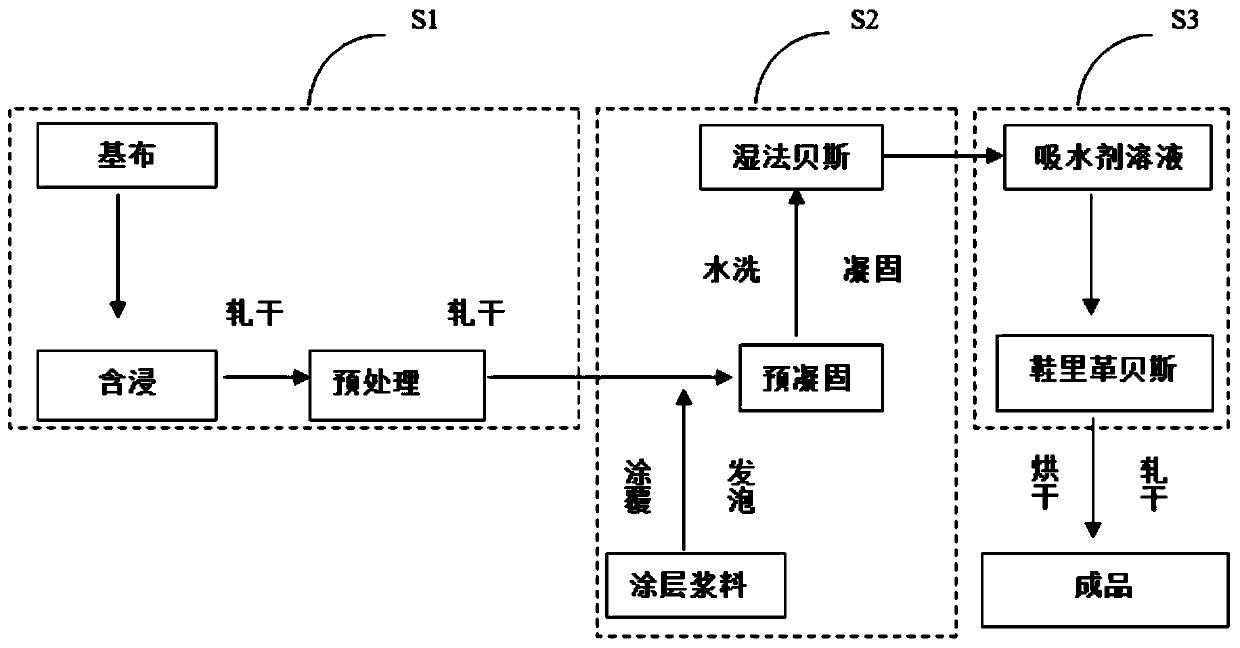

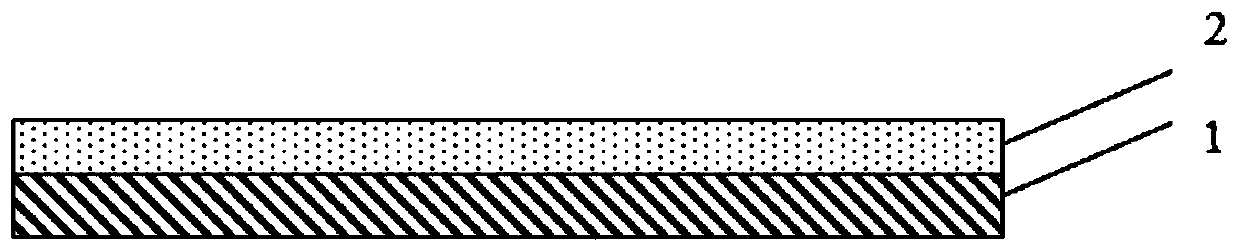

Water-based shoe lining leather bass and preparation method thereof

InactiveCN110318262ASoft touchGood water absorption and breathabilityTextiles and paperFootwearWoven fabricAqueous solution

The invention provides a water-based shoe lining leather bass and a preparation method thereof. The method comprises the following steps of providing a base cloth, coating the base cloth with a coating to obtain a wet bass, and adopting an aqueous solution of a water absorbent for wetting the wet bass to obtain the shoe lining leather bass. The lining leather bass prepared by means of the method has excellent water absorption and air permeability, organic solvents are not used in the whole production and preparation process, a spunlace non-woven fabric is adopted as the base cloth, and the prepared shoe lining leather is soft in hand feeling and high in air permeability.

Owner:LANZHOU KETIAN NEW MATERIAL CO LTD +1

Anti-mildew PU synthetic leather and production method thereof

InactiveCN104594060AImprove comfortImprove the simulation effectSynthetic resin layered productsTextiles and paperAluminium chloridePolylysine

The invention discloses an anti-mildew PU synthetic leather which is produced from the following raw materials in parts by weight: 80-100 parts of polyurethane resin, 80-100 parts of dimethylformamide, 1-2 parts of soluble starch, 1-2 parts of galactomannan, 1-2 parts of peanut oil, 1-2 parts of linseed oil, 1-2 parts of muyu-stone powder, 0.5-1 part of Turkey red oil, 0.1-0.3 part of polylysine, 0.1-0.2 part of sodium lauroyl sarcosinate, 0.2-0.4 part of star anise oil, 5-10 parts of sodium carboxymethylcellulose, 0.5-1 part of aluminum chloride, 4-8 parts of mill base and 6-8 parts of a performance additive. The anti-mildew PU synthetic leather disclosed by the invention has good water absorbing and ventilating properties, simulated appearance, soft hand feel, and mildew preventing property.

Owner:ANHUI YUTANG RAIN GEAR

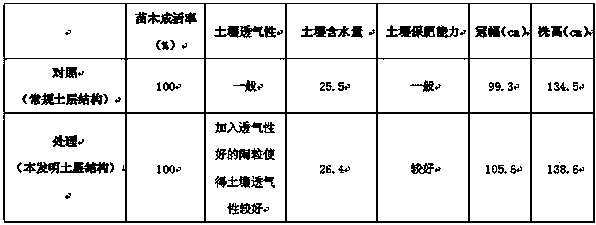

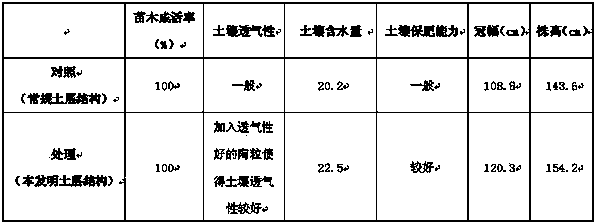

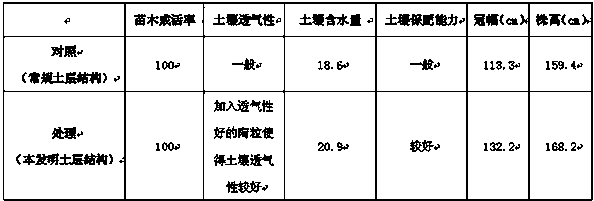

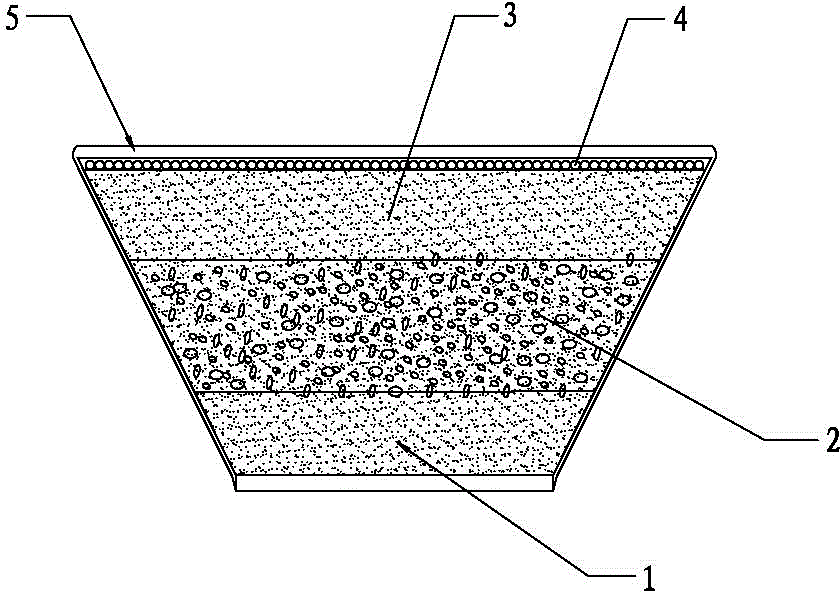

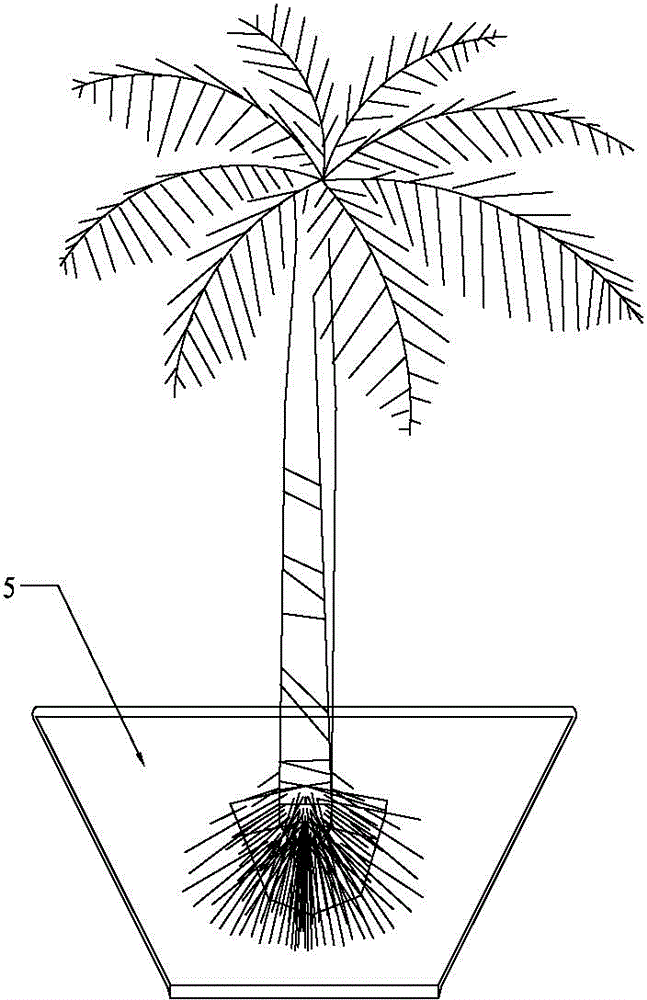

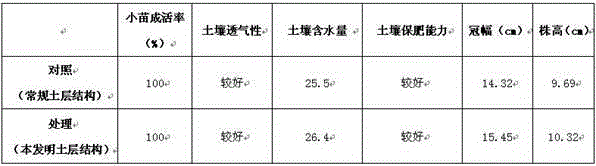

Flower-fruit pot soil structure and preparation method thereof

InactiveCN103461029AImprove water retentionImprove breathabilityCultivating equipmentsFertilizer mixturesFruit treePlant roots

The invention relates to the technical field of plant cultivation, in particular to a flower-fruit pot soil structure and a preparation method thereof. The preparation method includes selecting and preprocessing a cultivation pot for flowers and fruits, laying garden soil mixed with base fertilizer at the bottom of the pot to form a garden soil layer, laying mixed soil made of ceramsites, the garden soil and humus soil on the garden soil layer to form a compound soil layer, laying the humus soil on the compound soil layer to form a humus soil layer, and laying the ceramsites on the humus soil layer to form a ceremsite layer. The compound soil layer is made by mixing of the ceramsites, the garden soil and the humus soil according to an optional proportion. Comprehensive improvements are performed on soil content and soil delamination of pot soil, so that soil layer structures in cultivation pots for the flowers and the fruits and the like can be reasonable, breathability, water retention and manure-keeping performance of soil can be improved, a good water, manure and gas exchanging space is provided to a plant root system, and the flower-fruit pot soil structure is specially applicable to large or slightly large potted flowers and trees or fruit trees.

Owner:DONGGUAN AGRI SCI RES CENT +1

PU (polyurethane) synthetic leather with high comfort level and production method of synthetic leather

InactiveCN106087455AImprove comfortImprove the simulation effectTextiles and paperAluminium chlorideTalc

The invention discloses PU (polyurethane) synthetic leather with the high comfort level and a production method of the synthetic leather. The PU synthetic leather is prepared from raw materials in parts by weight as follows: 80-100 parts of PU resin, 80-100 parts of dimethylformamide, 2-4 parts of tea saponin, 0.5-1 part of soluble soybean polysaccharides, 1-2 parts of liquid rosin resin, 0.1-0.2 parts of squalane, 1-2 parts of talc, 1-2 parts of bamboo charcoal powder, 4-8 parts of color paste, 5-10 parts of sodium carboxymethylcellulose, 0.2-0.4 parts of sodium salicylate, 0.5-1 part of aluminium chloride and 2-4 parts of a modifying aid. According to the synthetic leather, a natural nonionic surfactant, namely, tea saponin, is added, so that the quality and the ageing resistance of the synthetic leather are improved, and the synthetic leather has auxiliary effects of preventing mildewing, resisting bacteria, resisting oxidation and killing and dispelling insects.

Owner:程志刚

Method for processing differential polyester staple fiber

InactiveCN101418473ALow densityFeel goodFilament manufactureMelt spinning methodsPolyesterPore diameter

The invention relates to a method for processing differential polyester staple fibers. The method adopts a technological process as follows: a high-shrinkage polyester chip is dried in a vacuum rotary drum, conveyed into an intermediate bin, a screw extruder, a spinning box, a metering pump, a spinning component and a spinneret plate in turn, subjected to circular blowing-cooling and double-side oiling, conveyed into a drafting groove, subjected to secondary drafting and third drafting and conveyed into a silk holding bucket through a feeding roller, and then silk is dried and cut off so as to obtain finished products. The technological parameters of the method are characterized in that chip drying adopts the vacuum rotary drum and a low-temperature long-time process; spinning temperature and prestretching multiple are appropriately lowered; low-temperature stretching and an indefinite-form drafting process are adopted; and the spinneret plate adopts a finishing spinneret plate with the pore diameter of 0.2x0.5 millimeter, and is used together with corresponding components. As the high-shrinkage functional polyester chip is adopted as a raw material, the prior spinning equipment needs no alteration during production, and the differential polyester staple fibers can be produced on common polyester staple fiber spinning equipment.

Owner:周琴

High-performance PU sofa leather and production method thereof

InactiveCN104594063AImprove comfortImprove the simulation effectTextiles and paperAluminium chlorideMethyl salicylate

The invention discloses a high-performance PU sofa leather which is produced from the following raw materials in parts by weight: 80-100 parts of polyurethane resin, 80-100 parts of dimethylformamide, 0.5-1 part of liquid paraffin, 0.2-0.4 part of cetostearyl alcohol polyether-25, 0.4-0.6 part of lauryl sodium sulfate, 0.2-0.4 part of tween-80, 2-4 parts of gelatin, 5-10 parts of sodium carboxymethylcellulose, 0.5-1 part of aluminum chloride, 0.5-1 part of methyl salicylate, 0.5-1 part of nanometer titania, 4-8 parts of mill base and 6-8 parts of a performance additive. The high-performance PU sofa leather disclosed by the invention has the characteristics of good stretchability, wear resistance, good water absorbing and ventilating properties, simulated appearance, and good hand feel; the comfort and the simulation are effectively improved, and the performance is relatively close to that of natural leather.

Owner:ANHUI YUTANG RAIN GEAR

Imitated PU (polyurethane) synthetic leather and production method thereof

InactiveCN105887504AImprove comfortImprove the simulation effectPolyurea/polyurethane coatingsTextiles and paperCarboxymethyl celluloseChloride

The invention discloses imitated PU (polyurethane) synthetic leather, made from the following materials according to parts by weight: 80-100 parts of polyurethane resin, 80-100 parts of dimethylformamide, 1-2 parts of a soluble starch, 1-2 parts of galactomannan, 1-2 parts of peanut oil, 1-2 parts of flaxseed oil, 1-2 parts of serpeggiante powder, 0.5-1 part of turkey red oil, 0.1-0.3 part of polylysine, 0.1-0.2 part of sodium lauroyl sarcosine, 0.2-0.4 part of star anise oil, 5-10 parts of sodium carboxymethyl cellulose, 0.5-1 part of aluminum chloride, 4-8 parts of color paste, and 6-8 parts of a modifying aid; the synthetic leather has good water absorption and breathability and imitated appearance and handle, comfort and imitation of the PU synthetic leather are improved effectively, and the properties of the synthetic leather are closer to those of natural leather.

Owner:程志刚

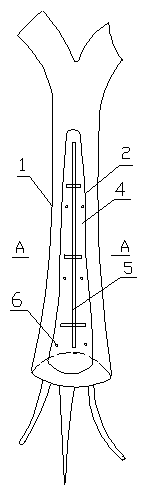

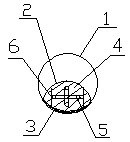

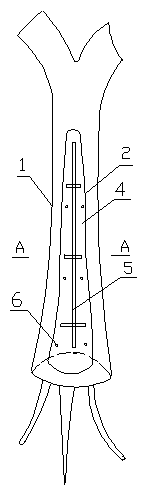

Repair method of decayed tree hole

ActiveCN107509598BReduce weightReduce loadCultivating equipmentsHorticulture methodsForeign matterGibberellin

Owner:欧阳贵明

Tea saponin-containing PU synthetic leather and production method thereof

InactiveCN104594064AImprove comfortImprove the simulation effectLamination ancillary operationsSynthetic resin layered productsSurface-active agentsBamboo charcoal

The invention discloses a tea saponin-containing PU synthetic leather which is produced from the following raw materials in parts by weight: 80-100 parts of polyurethane resin, 80-100 parts of dimethylformamide, 2-4 parts of tea saponin, 0.5-1 part of soluble soybean polysaccharide, 1-2 parts of liquid rosin resin, 0.1-0.2 part of squalane, 1-2 parts of talcum powder, 1-2 parts of bamboo charcoal powder, 4-8 parts of mill base, 5-10 parts of sodium carboxymethylcellulose, 0.2-0.4 part of sodium salicylate, 0.5-1 part of aluminum chloride and 2-4 parts of a performance additive. The synthetic leather disclosed by the invention is added with a natural non-ionic surface active agent tea saponin, the quality and the ageing resistance of the synthetic leather are improved, and the natural non-ionic surface active agent tea saponin also has auxiliary functions of preventing mould and resisting bacteria, resisting oxidation, and killing and expelling insects.

Owner:ANHUI YUTANG RAIN GEAR

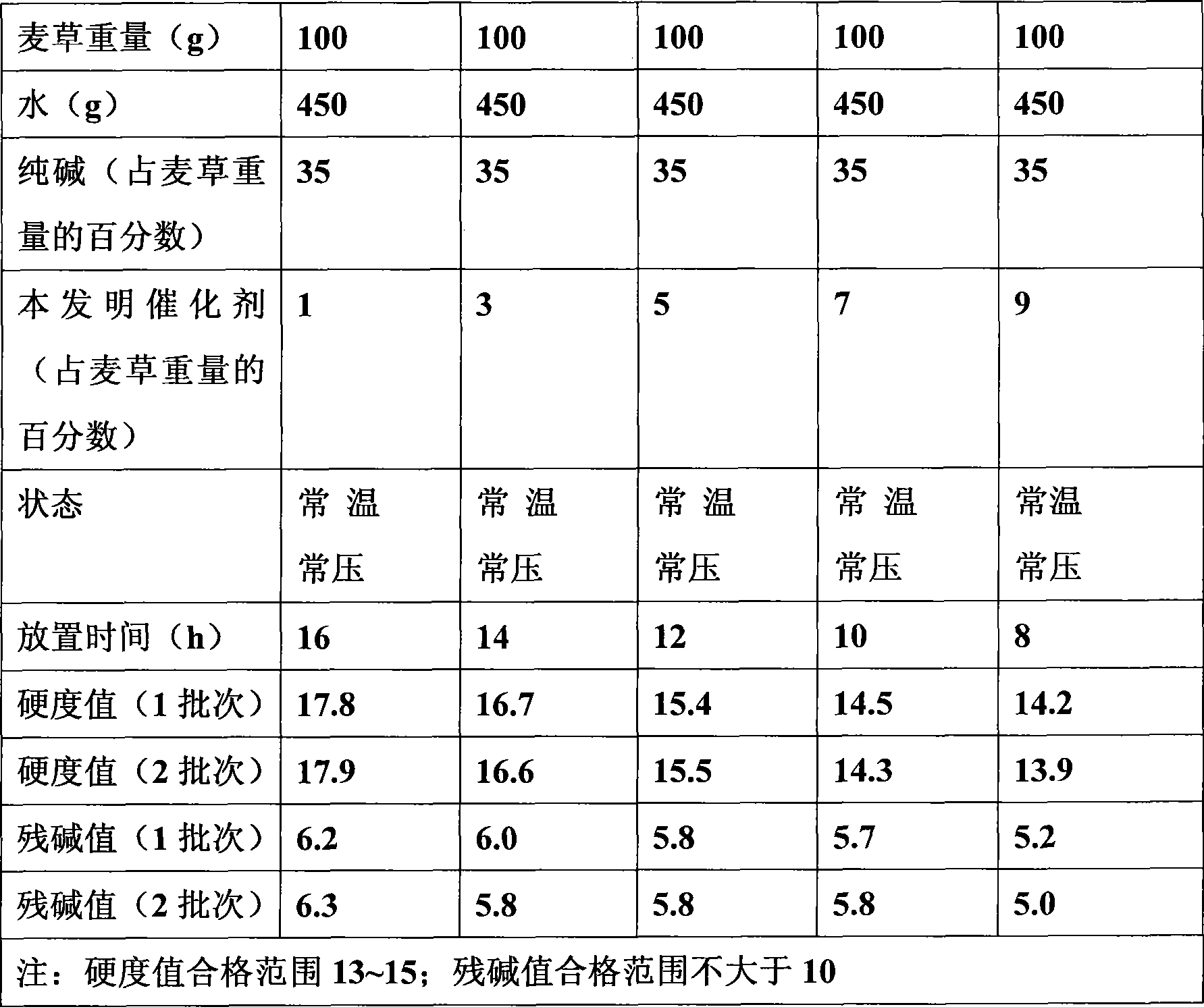

Medium low alkali biochemical catalyst

The invention relates to a medium and low alkali biochemical catalyst which is composed of inorganic alkaline, lipase, anthraquinone, osmotic agent and surface active agent, wherein, the mass percentage of all the components is as follows: inorganic alkaline 35 percent to 45 percent, lipase 10 percent to 15 percent, anthraquinone 15 percent to 20 percent, osmotic agent 10 percent to 15 percent and surface active agent 10 percent to 15 percent. The catalyst is applicable in the dipping and fiber processing of cornstock, cotton stalk, willow timber, reed, Anaphalis yedoensis, straw, pernyi and other plant fiber under normal temperature and normal pressure. The sources of the raw materials are wide and the scope of application is wide. The catalyst can improve the speed of delignify and the fiber yield, and reduce the residual alkali value.

Owner:ZIBO QILONG BIOTECH DEV

Nylon wrap yarn

The invention discloses nylon wrap yarn which is characterized by comprising nylon and compact spun Modal fiber yarn tightly wound outside the nylon. The compact spun Modal fiber yarn is in a spiral shape and is wound anticlockwise in the length direction of spandex, the thickness of the nylon is 25 D, and three or more threads of nylon are arranged and wound in an S shape. The length of knots of the nylon is 15 mm-25 mm. Through the mode, the nylon wrap yarn is high in elasticity and yarn evenness and has the advantages of being smooth like silk, slippery like fibers and high in water absorption and breathing performance, cashmere-like hand feeling is good, the appearance is attractive, the cost for manufacturing cashmere-like fabric is low, and the fabric is comfortable to wear and durable.

Owner:JIANGSU JIADE FIBER TECH

Improved medical nursing cushion

InactiveCN106309017AReasonable structureGood water absorption and breathabilityNursing bedsAbsorbent padsSurface layerBiomedical engineering

The invention relates to a medical nursing cushion, belonging to the field of medical supplies. The adopted technical scheme is as follows: the improved medical nursing cushion comprises a nursing cushion body, wherein the nursing cushion body comprises a surface layer and a bottom layer which are made of a non-woven fabric and are fixed together through connectors, an absorbing layer is arranged between the surface layer and the bottom layer, a ventilation layer is arranged between the bottom layer and the absorbing layer, lengthened folding edges are arranged on the left and right sides of the nursing cushion body, a cross-shaped crease used for folding is pressed on the nursing cushion body, a plurality of strip-shaped bulges distributed in parallel are arranged on the surface layer along the width direction, and flow guide grooves are formed among the adjacent bulges. The medical nursing cushion provided by the invention has the advantages that the structure is reasonable, the water absorption and breathability are good, sliding is seldom caused, the folding is convenient, and thus the medical nursing cushion is suitable for promotion for use.

Owner:蒋满珍

Preparation method of antibacterial deodorized leather

ActiveCN108504793AGood water absorption and breathabilityHas antibacterial propertiesTanning treatmentPre-tanning chemical treatmentDeodorantMixed materials

The invention provides a preparation method of antibacterial deodorized leather. The preparation method comprises the steps that wet blue leather is subjected to degreasing and neutralizing treatmentin sequence and then is subjected to rotation blending with quebracho extract, mimosa extract and a dye leveling agent in a rotary drum to obtain first modified leather; the first modified leather, the quebracho extract and the mimosa extract are subjected to rotation blending and then still standing in the rotary drum; in the dyeing process, titanium dioxide is added so as to improve the antibacterial property, and then fat liquoring softening and solid acid treatment are conducted to obtain primary leather; the obtained primary leather, water, a deodorized resin mixed material, a negative ion deodorant, an interlinking agent, an organic silicon softener and methane acid are subjected to rotation blending in the rotary drum to obtain the antibacterial deodorized leather. The results of the embodiment of the invention show that the prepared antibacterial deodorized leather has the antibacterial deodorization function, and the comfort degree is improved.

Owner:黄方盾

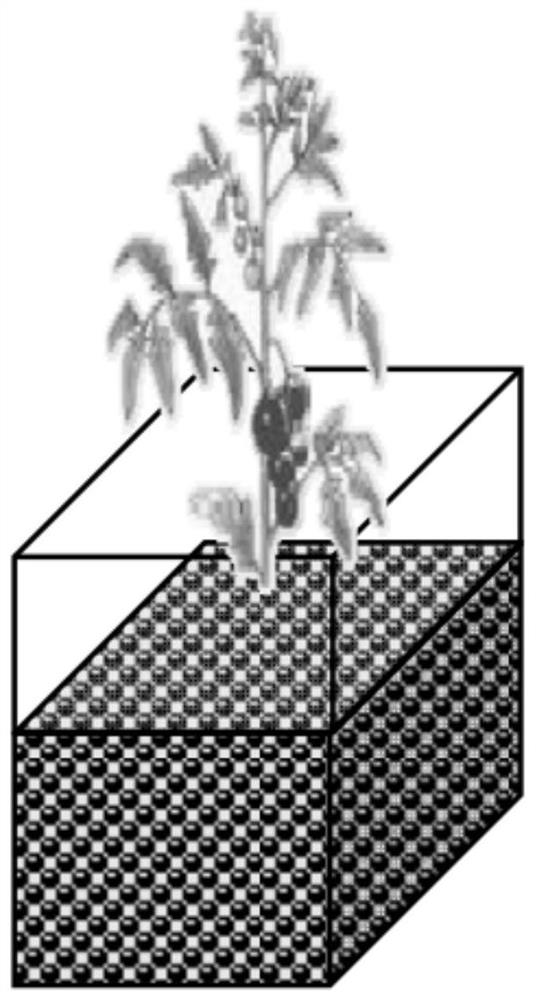

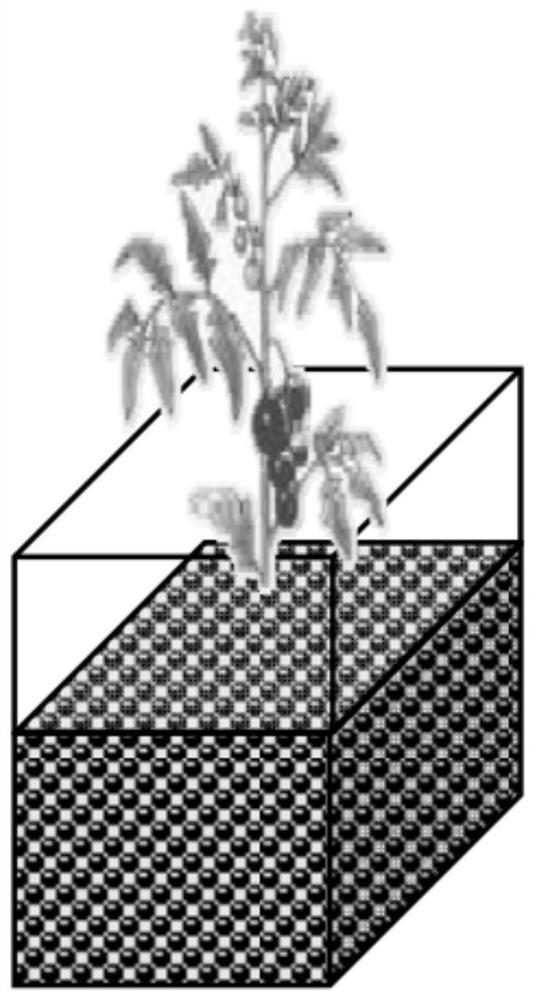

Ceramsite soilless culture substrate as well as preparation method and application thereof

ActiveCN112119864AUnbreakableImprove stabilityGrowth substratesCulture mediaBiotechnologyContinuous cropping

The invention discloses a ceramsite soilless culture substrate and a preparation method and application thereof, and belongs to the technical field of soilless culture. The preparation method comprises the following steps that shells are calcined into powder, and then the powder and fly ash ceramsite are uniformly stirred to obtain a mixture A; chitosan oligosaccharide is loaded on the surface ofa gelatin microcapsule, washing and drying are carried out to obtain a mixture B; spent mushroom composts, perlite and goat manure are crushed correspondingly, bacillus subtilis suspension liquid is added, the mixture A and the mixture B are added after uniform stirring is carried out, and full and uniform mixing is carried out to obtain the ceramsite soilless culture substrate. According to the method, the calcined shell powder, the gelatin / chitosan oligosaccharide mixture and the bacillus subtilis suspension liquid are combined and added into the fly ash ceramsite, a nutrition medium is combined, the synergistic interaction effect is achieved, and the prepared product has the advantages of being environment-protecting, renewable, reusable, high in continuous cropping efficiency, high inantibacterial rate, capable of retaining water, breathable and the like.

Owner:范峪铭

Blended yarn deeply developed from silkworms and spinning process

The invention discloses blended yarn deeply developed from silkworms and a spinning process of the blended yarn. The blended yarn comprises a yarn body, wherein the yarn body is hollow yarn and comprises a hollow inner core layer, a sericin film layer and a winding skin layer which are sequentially arranged from inside to outside, the hollow inner core layer is made of mulberry bark fibers, the mulberry bark fibers are spirally wound outside a hollow core hole of the yarn body, the sericin film layer is formed by coating sericin outside the hollow inner core layer to form a film layer structure, the winding skin layer adopts winding filaments, and the winding filaments are spirally wound outside the sericin film layer to form an outer wrapping structure. According to the blended yarn deeply developed from the silkworms and the spinning process of the blended yarn, the silkworm industry is deeply developed, resources are fully utilized, and the mulberry fibers, the sericin, pupa proteinviscose filaments or spun silk are used for spinning the novel blended yarn; and the blended yarn is low in cost, high in yarn strength, soft and smooth in touch, washable, good in shrink-proof and crease-resistant performance, good in water absorption and air permeability and excellent in comprehensive performance.

Owner:SUZHOU CITY XINGJINGZE FIBER TECH CO LTD

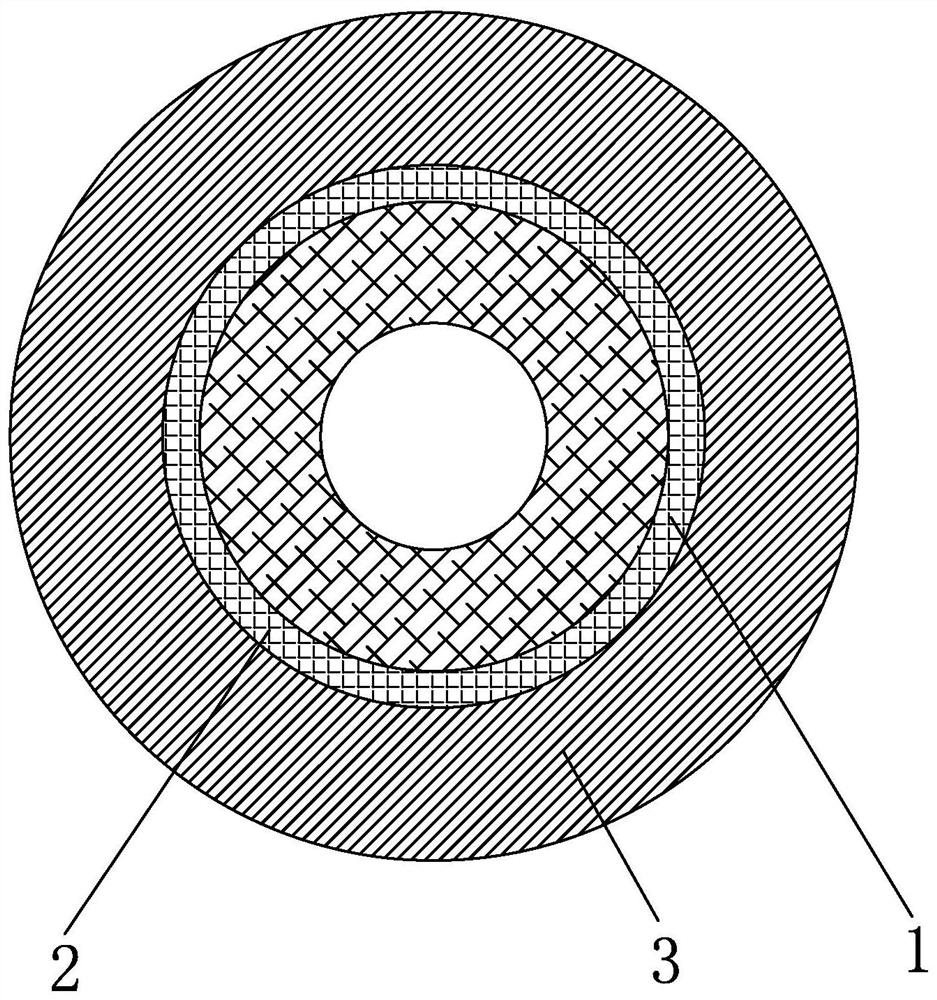

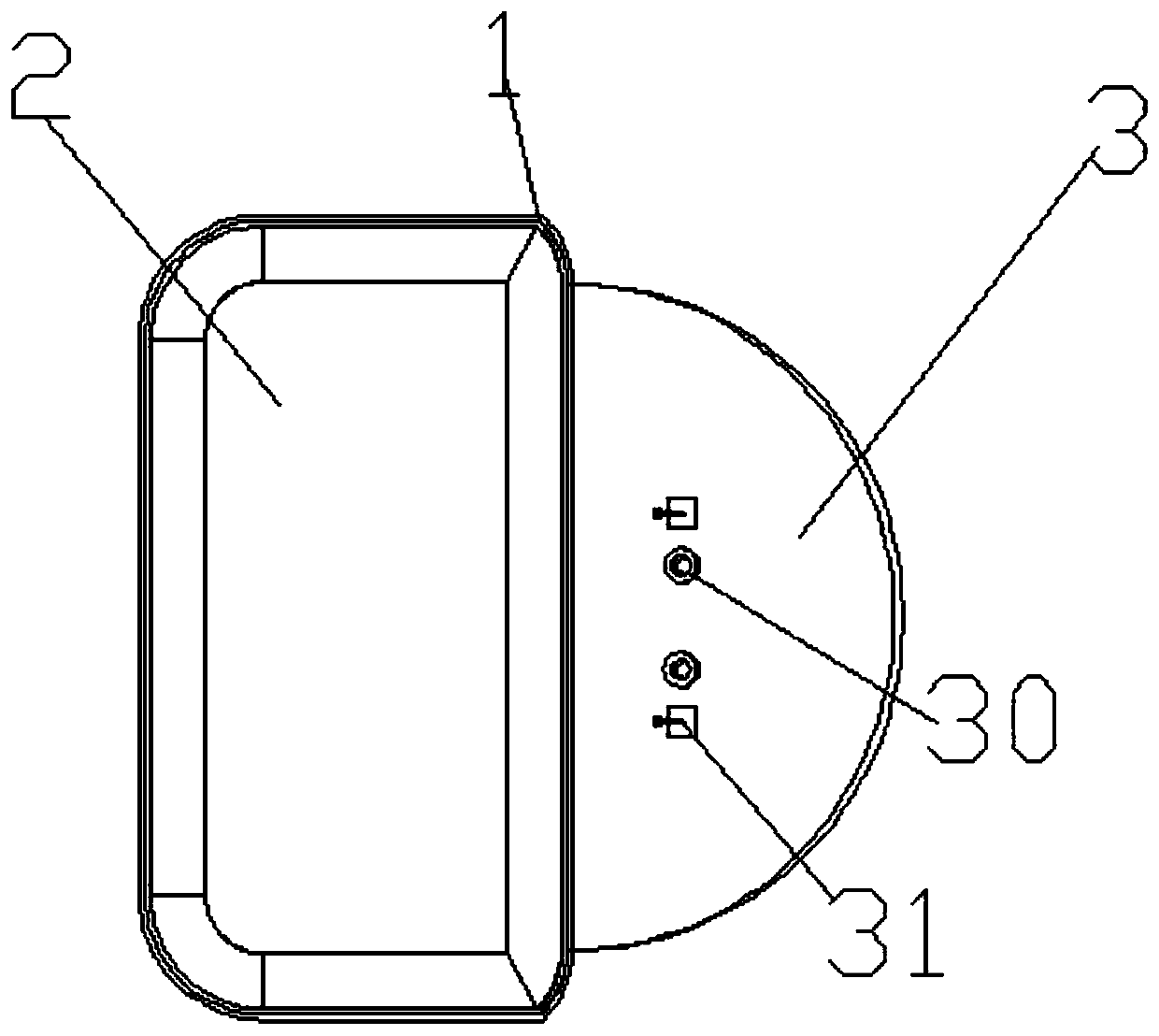

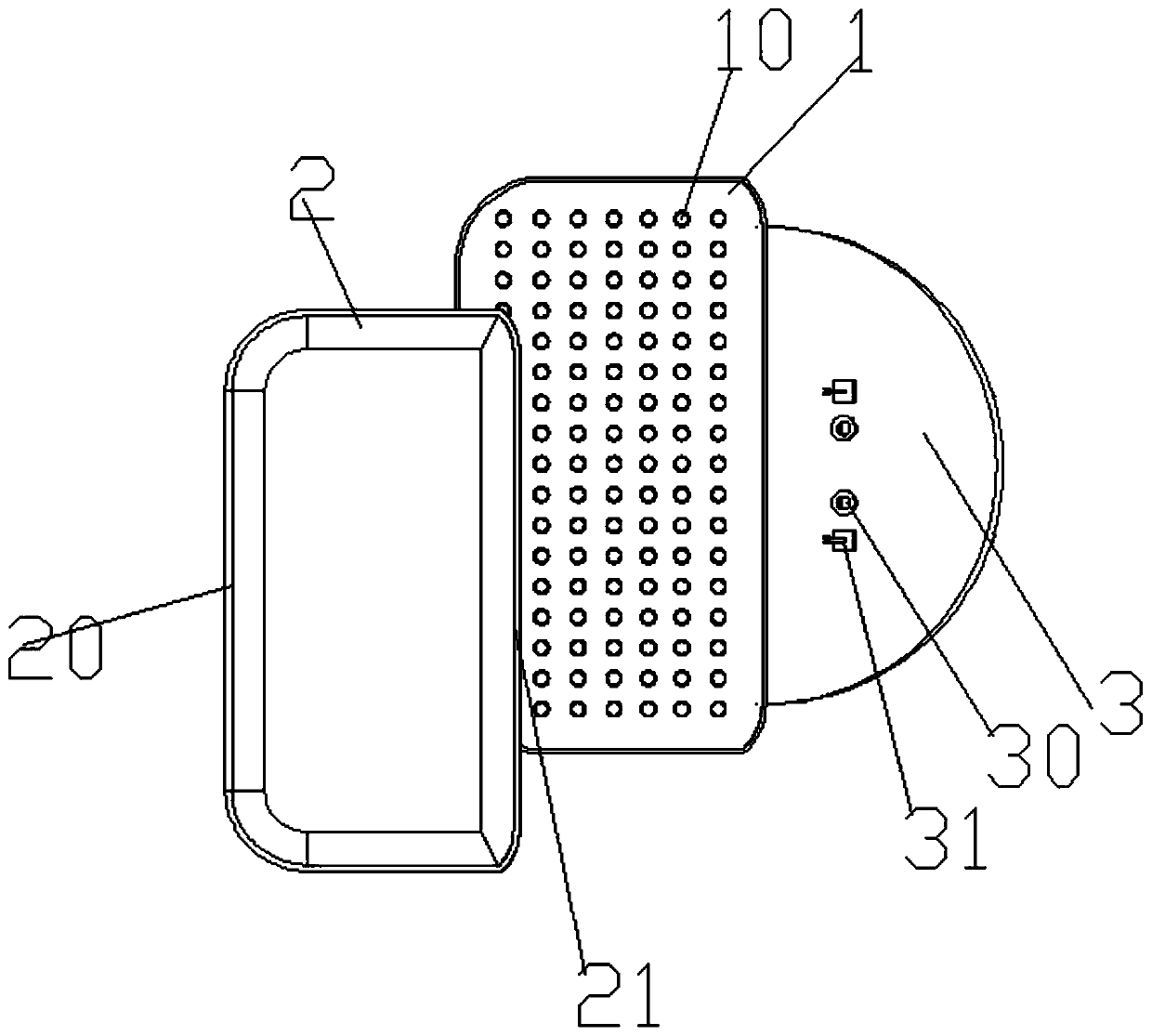

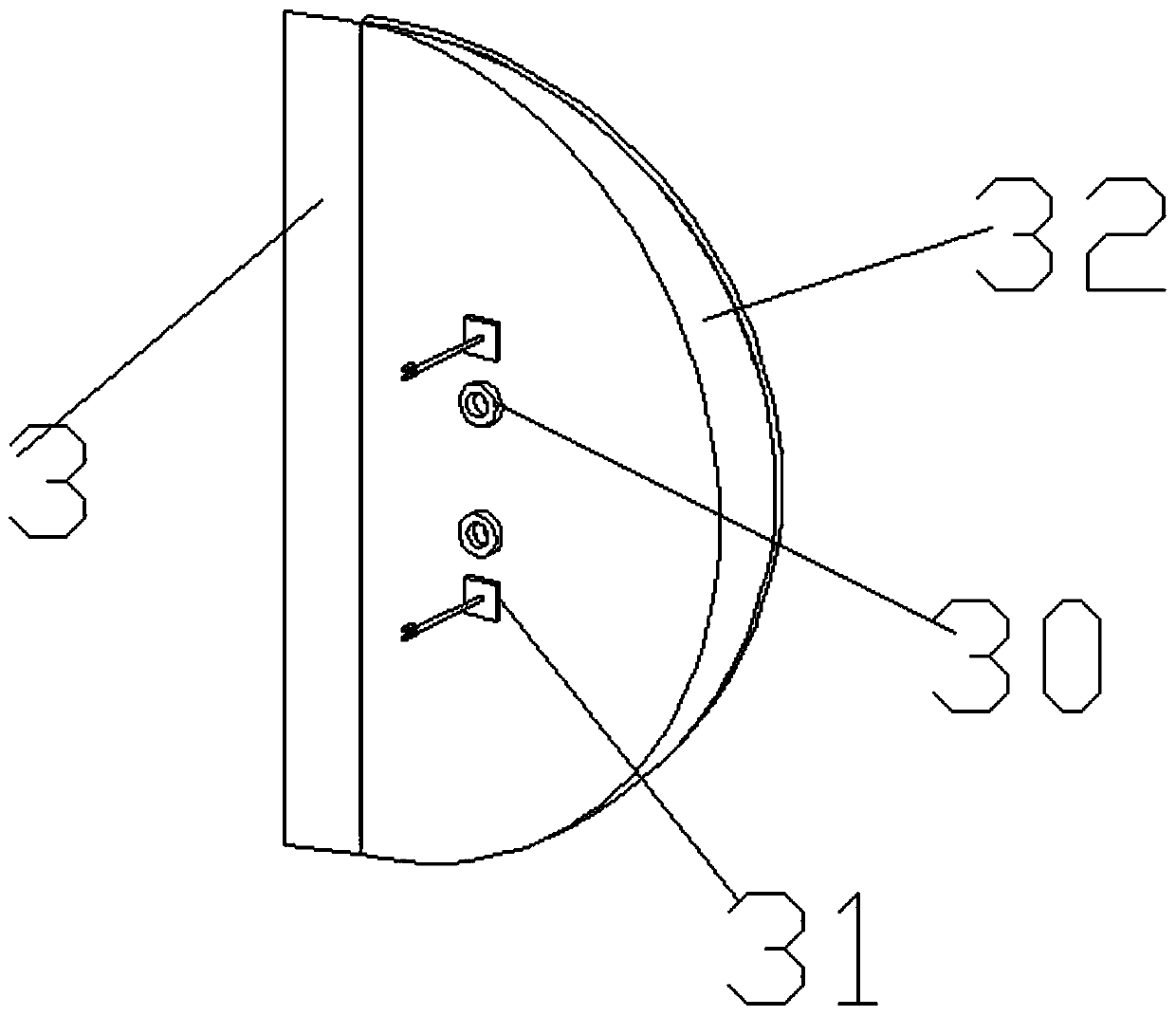

Patch for bladder ostomy

PendingCN110772371APromote absorptionInhibit sheddingPlastersAdhesive dressingsEngineeringBiomedical engineering

The invention discloses a patch for bladder ostomy. The patch comprises a patch body and wound covering cloth, wherein the wound covering cloth is fixedly connected with the edge of the patch body; liquid-permeable holes are formed in the patch body; a soft cover is arranged on the patch body, and is used for covering the liquid-permeable holes into the soft cover; a liquid guide pipe opening is formed in the wound covering cloth and is used for connecting a liquid guide pipe; a pipe clamp is arranged on the wound covering cloth; and a water suction air-permeable layer is arranged in the middle layer of the wound covering cloth. The patch for bladder ostomy has the characteristics that the design is reasonable; convenience is realized; and falling cannot easily occur, and the like.

Owner:刘培

A kind of bio-organic fertilizer using traditional Chinese medicine dregs as raw material and its production process

ActiveCN103396223BGood water absorption and breathabilityImprove breathabilityBio-organic fraction processingOrganic fertiliser preparationOrganic fertilizerBacteria

The invention provides a bio-organic fertilizer with Chinese medicine residue as a raw material. The formula of the organic fertilizer comprises grass carbon and lignite, and functional bacteria are added. The raw materials comprise the following components in percentage by weight: 30-70 percent of Chinese medicine residue dry product, 0.01-0.5 percent of biological bacteria, 20-40 percent of grass carbon, 10-30 percent of lignite, 1-5 percent of mineral matter fertilizer and 0.1-0.5 percent of functional bacteria. Various nutrients which cannot be effectively absorbed by plants in the soil can be effectively activated, so that the quality and the yield of the crops are improved, and the immune-competence of the crops per se can also be effectively improved.

Owner:FOUR FRIENDS OF CHENGDU CHEM IND

Flower-fruit pot soil structure and preparation method thereof

InactiveCN103461029BImprove water retentionImprove breathabilityCultivating equipmentsFertilizer mixturesFruit treePlant roots

The invention relates to the technical field of plant planting, in particular to a flower and fruit pot soil structure and a preparation method thereof. The preparation method is as follows: selecting a flower and fruit cultivation pot, and pretreating the cultivation pot; laying garden soil mixed with base fertilizer on the bottom of the pot , forming a garden soil layer; laying a mixed soil made of ceramsite, garden soil and humus soil on the top of the garden soil layer to form a mixed soil layer; laying humus soil on the top of the mixed soil layer to form a humus soil layer laying ceramsite above the humus layer to form a ceramsite layer; wherein, the mixed soil layer is formed by mixing ceramsite, garden soil and humus in any proportion. The present invention has carried out a comprehensive transformation on the soil composition and soil stratification of the pot soil, which makes the soil layer structure in the planting pots such as flowers and fruits more reasonable, can increase the air permeability and water and fertilizer retention of the soil, and provide better plant roots. Water, fertilizer, and air exchange space are more suitable for large or relatively large potted flowers and trees or fruit trees.

Owner:DONGGUAN AGRI SCI RES CENT +1

Lotus root starch-based water-absorbing breathable PU leather and preparation method thereof

ActiveCN111778731AWide variety of sourcesLow priceTextile/flexible product manufactureTextiles and paperAdhesiveBiology

The invention provides lotus root starch-based water-absorbing breathable PU leather and a preparation method thereof, and belongs to the technical field of synthetic leather. The preparation method comprises the following steps: doping a lotus root starch-based filler into a PU wet resin system to prepare a water-absorbing breathable base, and respectively adhering an adhesive and a dry-method surface material to the surface of the water-absorbing breathable base to obtain the lotus root starch-based water-absorbing breathable PU leather. According to the invention, the water-absorbing breathable base, the dry-method surface material and a dry-method bottom material are ensured to have water-absorbing breathable performance; the prepared lotus root starch-based water-absorbing breathablePU leather has good water-absorbing breathable performance, the moisture permeability of the prepared lotus root starch-based water-absorbing breathable PU leather can reach 1759 g.m<-2>.24h<-1>, andthe water absorption time is 2.4 h.

Owner:浙江旭川树脂有限公司

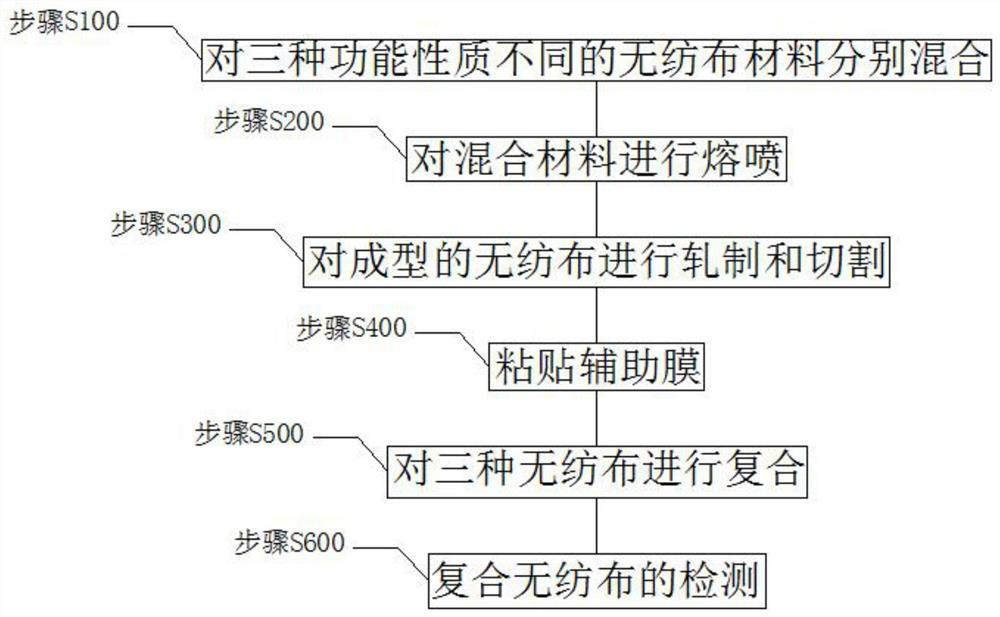

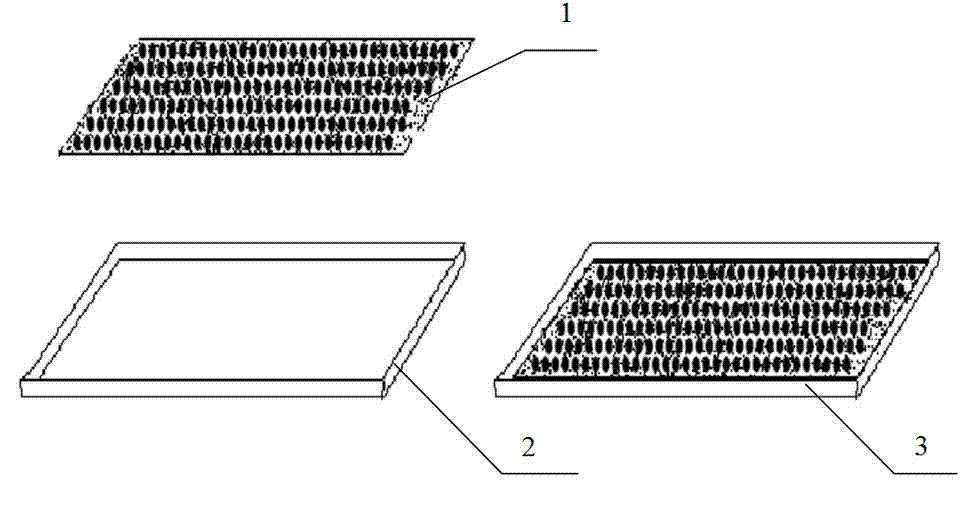

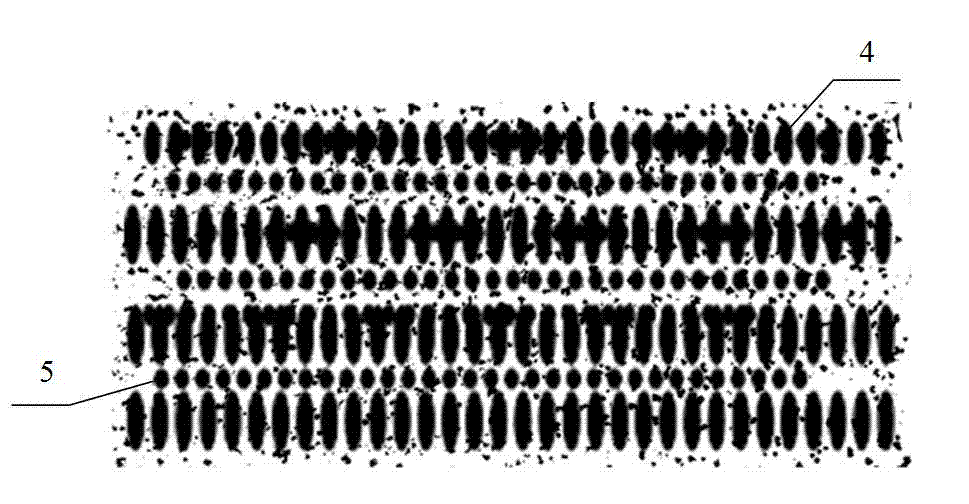

Composite elastic melt-blown non-woven fabric and processing method thereof

ActiveCN112481821AImprove waterproof performanceImprove breathabilityElectroconductive/antistatic filament manufactureSynthetic resin layered productsPolymer scienceDistilled water

The invention is applicable to the technical field of composite elastic non-woven fabric, and provides composite elastic melt-blown non-woven fabric and processing method thereof. The composite elastic melt-blown non-woven fabric comprises the following materials in percentage by weight: 10%-70% of high-fat polypropylene, 10%-70% of low-fat polypropylene, 0.6% of emulsifier, 0.3% of a wetting agent, 0.3% of a spreading agent, 1% of an antistatic agent, 0.2% of polyether silicone oil, 0.4% of graphene, 1% of color master batch and the balance of distilled water. According to the present composite elastic melt-blown non-woven fabric and the processing method thereof, on the premise of ensuring that the external waterproof performance is not reduced, the internal water absorption performanceis improved, the present composite elastic melt-blown non-woven fabric replaces cotton cloth in some fields, and the application field of the non-woven fabric is widened.

Owner:ZHANGJIAGANG JUNMA NON WOVEN CO LTD

A kind of method that utilizes waste plastic bottle to prepare super imitation cotton fabric

ActiveCN104928930BReduce processing loadFeel goodFibre treatmentConjugated synthetic polymer artificial filamentsPotassium persulfateFiber

The invention discloses a production method of super-imitation cotton fabric using waste polyester bottles. The method includes classifying the waste polyester bottles, and subjecting recycled polyester with intrinsic viscosity of less than 0.63g / dl to alcoholysis and esterification to obtain copolyester with a good hydrolytic function; subjecting recycled polyester with intrinsic viscosity of greater than 0.63g / dl and the copolyester to blending, fusion and spinning to obtain blend fibers; spinning the blend fibers to obtain fabric, performing treatment with dilute alkali solution to remove material C before drying, and subjecting the dried fabric in impregnating solution composed of polyethylene glycol monoester maleate and potassium persulfate to immersion treatment to obtain novel polyester fabric with super-imitation-cotton performance. According to the method, the waste plastic bottles are utilized to prepare the novel super-imitation cotton fabric, thus visual pollution can be avoided, resources can be recycled, pollution can be reduced, burden on municipal solid waste disposal can be relieved, land consumption can be saved , and good economic benefits can be achieved.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Rice seedling machine seedling planting diaphragm and manufacture method of rice seedling machine seedling planting diaphragm

ActiveCN103070045BGood consolidationPromote growth and developmentCultivating equipmentsNon-woven fabricsMechanical stretchingEconomic benefits

The invention discloses a rice seedling machine seedling planting diaphragm and a manufacture method of the rice seedling machine seedling planting diaphragm. By aiming at the problems that the seedling root winding effect in the rice seedling machine seedling planting is poor, the seedlings can easily get scattered, and the operation is complicated, the invention provides the rice seedling machine seedling planting hemp-base diaphragm, which consists of a hemp fiber diaphragm substrate and rice seeds fixedly carried on the substrate. The hemp fiber raw materials are subjected to loosening, scattering and mechanical stretching to form a net, then, biodegradable bonding agents are adopted for bonding, baking is carried out, the hemp fiber diaphragm substrate is formed, and next, the rice seeds are uniformly scattered and pasted on the hemp fiber diaphragm substrate through the biodegradable bonding agents. When the rice seedling machine seedling planting hemp-base diaphragm provided by the invention is adopted, the seedling culture operation can be greatly simplified, farmers can realize the seedling culture without seeding, in addition, the seedling root system winding effect can be obviously promoted, the winding force is improved, seedlings conforming to the machine seeding requirements are formed, meanwhile, because the seedling quality is improved, the green returning speed of the seedlings after the machine seedling planting is high, the tillering effect is good, the rice yield is obviously improved, and good economic benefits are realized.

Owner:INST OF BAST FIBER CROPS CHINESE ACADEMY OF AGRI SCI

A kind of ceramsite soilless cultivation substrate and its preparation method and application

ActiveCN112119864BUnbreakableImprove stabilityGrowth substratesCulture mediaBiotechnologyContinuous cropping

The invention relates to a ceramsite soilless cultivation substrate and a preparation method and application thereof, which belong to the technical field of soilless cultivation. The steps are as follows: calcining the shells into powder and then stirring them evenly with fly ash ceramsite to obtain mixture A; loading chitosan oligosaccharide on the surface of gelatin microcapsules, washing and drying to obtain mixture B; separating mushroom slag, perlite and sheep manure Crush, add Bacillus subtilis suspension, stir evenly, add mixture A and mixture B, and mix thoroughly. The method of the present invention combines calcined shell powder, gelatin / oligochitosaccharide mixture and Bacillus subtilis suspension, adds them into fly ash ceramsite, combines with nutrient matrix, plays a synergistic effect, and the prepared product has environmental protection It has the advantages of friendliness, regeneration, reusability, high continuous cropping efficiency, high antibacterial rate, water retention and ventilation.

Owner:范峪铭

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com