Medium low alkali biochemical catalyst

A catalyst, alkali-type technology, applied in the direction of hydrolase, etc., can solve the problems of complex composition, reduced fibril strength, effective length and output rate, poor durability, etc., to achieve high value, unprecedented huge profits and market space, and easy filter effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The catalyst consists of 45% NaOH, 15% lipase (SINCO-T100), 15% anthraquinone, 15% JFC and 10% sodium dodecylbenzenesulfonate.

Embodiment 2

[0028] The catalyst is composed of KOH 45%, lipase (SINCO-T100) 10%, anthraquinone 20%, penetrant 10% and sodium dodecylbenzenesulfonate 15%.

Embodiment 3

[0030] Catalyst consists of NaNO 2 40%, lipase (SINCO-T100) 10%, anthraquinone 20%, penetrant 15% and sodium dodecylbenzenesulfonate 15%.

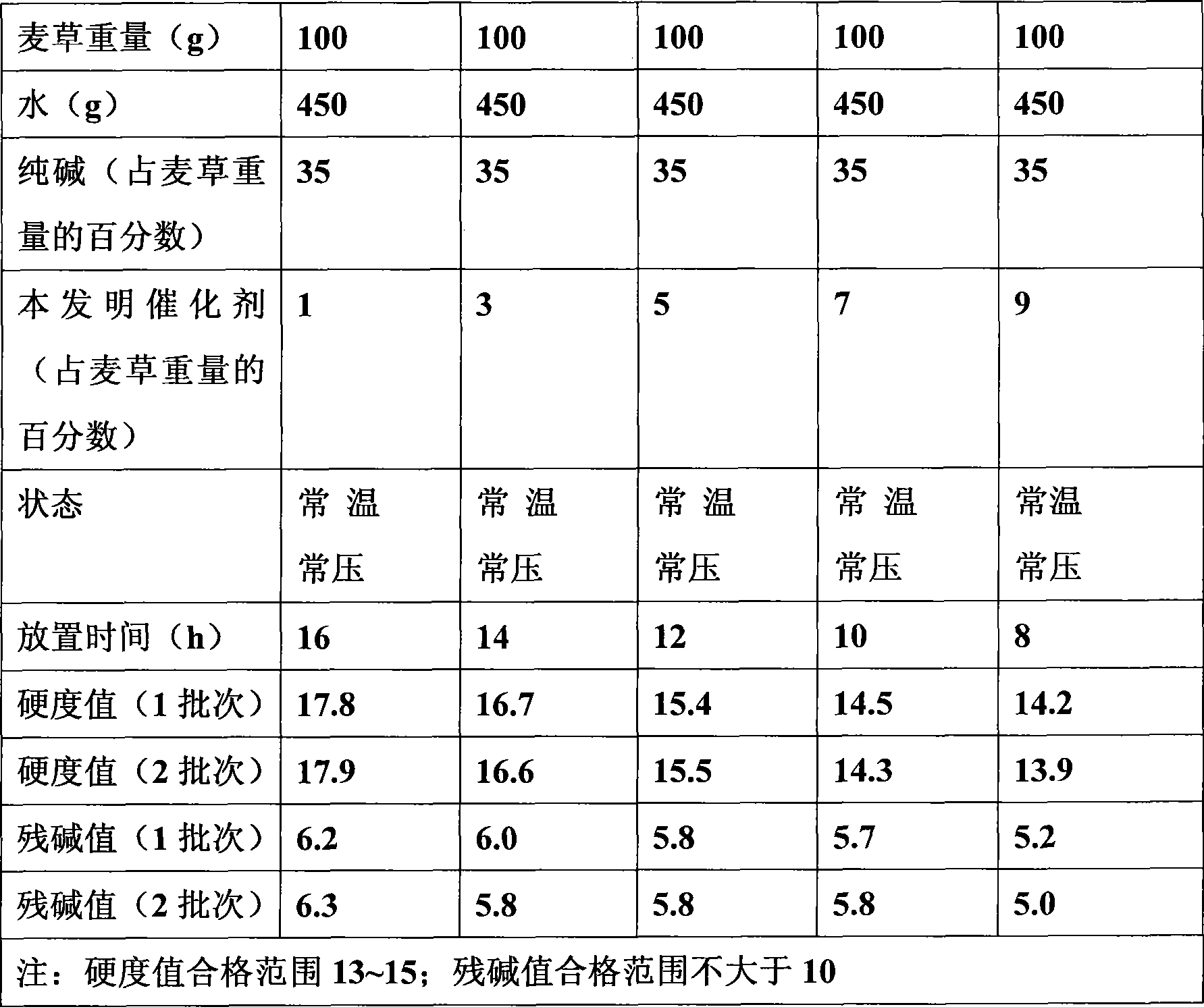

[0031] The following is the relevant data of using the catalyst of the present invention to make fiber from wheat straw. The wheat straw fiber making process is all the same as the prior art except that it is produced under the normal temperature and pressure state.

[0032]

[0033] As can be seen from the data in the above table, at normal temperature, adding an appropriate amount of catalyst (accounting for 7-10% of the weight of wheat straw) can accelerate the delignification speed, increase the fiber yield and reduce the residual alkali value.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com