Method for producing pentaerythritol oleate under catalysis of granular solid superacid

A technology of pentaerythritol oleate and solid superacid, which is applied in chemical instruments and methods, separation/purification of carboxylate, preparation of carboxylate, etc. It can solve the problems of complicated product separation, poor product quality and many side reactions , to achieve the effect of good product color, short production cycle and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

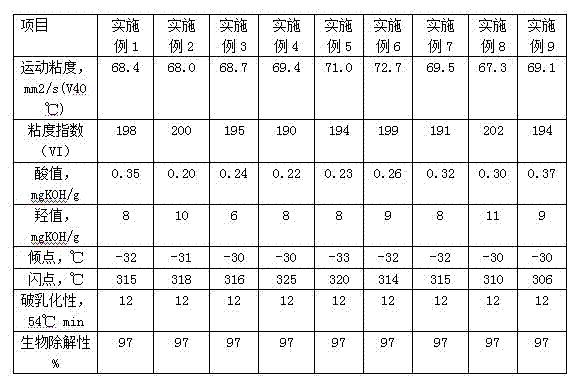

[0017] Get pentaerythritol 100kg, oleic acid 820 kg mixes, granular solid superacid is SO 4 2- / ZrO 2 -MCM-41, weighing 9.2kg, replaced with nitrogen three times, filled with nitrogen, kept at 800Pa vacuum, reacted at 180°C for 6 hours, then reacted at 200°C for 1 hour, cooled to 80°C, first passed through 600 Purpose filter cloth, and then pass through a 12500-mesh insurance filter to filter out the solid superacid, then distill the unreacted acid, alcohol or monoester through molecular distillation, and distill under reduced pressure at 180°C and 20Pa vacuum for 60 minutes to obtain pentaerythritol Oleate. Its performance index see figure 1 .

Embodiment 2

[0019] Get pentaerythritol 100kg, oleic acid 800 kg mixes, granular solid superacid is SO 4 2- / SnO 2 -MCM-41, weighing 9.0kg, replaced with nitrogen three times, filled with nitrogen, kept at 800Pa vacuum, reacted at 180°C for 6 hours, then reacted at 200°C for 1 hour, cooled to 80°C, first passed through 600 Purpose filter cloth, and then pass through a 12500-mesh insurance filter to filter out the solid superacid, then distill the unreacted acid, alcohol or monoester through molecular distillation, and distill under reduced pressure at 180°C and 20Pa vacuum for 60 minutes to obtain pentaerythritol Oleate. Its performance index see figure 1 .

Embodiment 3

[0021] Get pentaerythritol 100kg, oleic acid 850 kg mixes, granular solid superacid is SO 4 2- / TiO 2 -MCM-41, weighing 10.0kg, replaced with nitrogen three times, filled with nitrogen, kept at 800Pa vacuum, reacted at 180°C for 6 hours, then reacted at 200°C for 1 hour, cooled to 80°C, and passed through 600 Purpose filter cloth, and then pass through a 12500-mesh insurance filter to filter out the solid superacid, then distill the unreacted acid, alcohol or monoester through molecular distillation, and distill under reduced pressure at 180°C and 20Pa vacuum for 60 minutes to obtain pentaerythritol Oleate. Its performance index see figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com