Patents

Literature

322 results about "Superacid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

According to the classical definition, a superacid is an acid with an acidity greater than that of 100% pure sulfuric acid, which has a Hammett acidity function (H₀) of −12. According to the modern definition, a superacid is a medium in which the chemical potential of the proton is higher than in pure sulfuric acid. Commercially available superacids include trifluoromethanesulfonic acid (CF₃SO₃H), also known as triflic acid, and fluorosulfuric acid (HSO₃F), both of which are about a thousand times stronger (i.e. have more negative H₀ values) than sulfuric acid. Most strong superacids are prepared by the combination of a strong Lewis acid and a strong Brønsted acid. A strong superacid of this kind is fluoroantimonic acid. Another group of superacids, the carborane acid group, contains some of the strongest known acids. Finally, when treated with anhydrous acid, zeolites (microporous aluminosilicate minerals) will contain superacidic sites within its pores. These materials are used on massive scale by the petrochemical industry in the upgrading of hydrocarbons to make fuels.

Method for synthesizing polyoxymethylene dimethyl ether

The invention relates to a method for synthesizing polyoxymethylene dimethyl ether. The invention mainly solves the following problems of the prior art that: in the process of synthesizing polyoxymethylene dimethyl ether, catalyst separation is difficult, the material conversion rate is low, and product selectivity is poor. The method adopts methanol and trioxymethylene as materials, the reactiontemperature is 70 DEG C to 200 DEG C, the reaction pressure is 0.5MPa to 6MPa, the materials react with super solid acidic catalyst by way of contact, so that the polyoxymethylene dimethyl ether CH3O(CH2O)nCH3 is produced, wherein the used catalyst is selected from solid superacids. By weight part, the polyoxymethylene dimethyl ethe comprises the following components: (a) 20 to 70 parts of acid selected from sulfuric acid, hydrochloric acid or peroxosulfuric acid or at least one of salt thereof; (b) 30 to 80 parts of carrier selected from at least one of ZrO2, TiO2, SiO2, Fe2O3, SnO2, WO3 andAl203. The method effectively solves the problems, and can be used in the industrial production of polyoxymethylene dimethyl ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for catalytically decomposing carbon fiber-reinforced thermosetting epoxy resin composite material

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

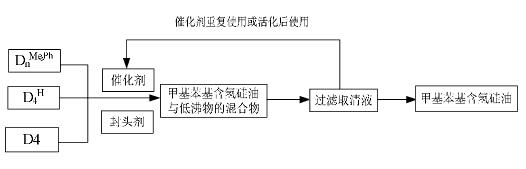

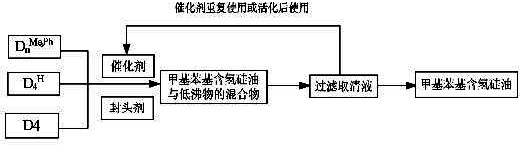

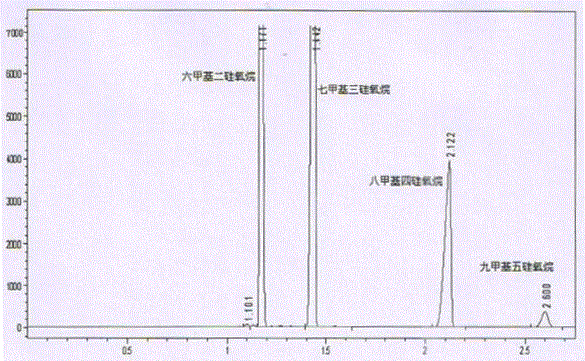

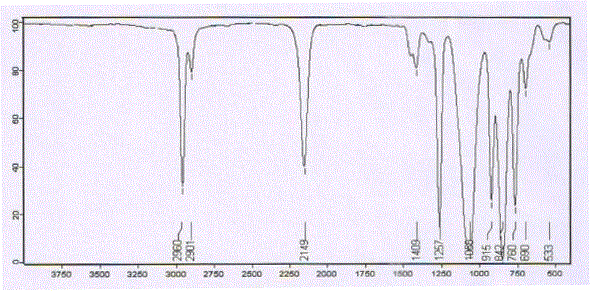

Method for preparing methyl phenyl hydrogen-containing silicone oil by rare earth super acid catalysis

InactiveCN101851333AHigh refractive indexSimple processOther chemical processesAdhesivesPtru catalystMethyl benzene

The invention discloses a method for preparing methyl phenyl hydrogen-containing silicone oil by rare earth super acid catalysis, which comprises the following steps of: taking methyl phenyl cyclosiloxane (DnMe, Ph, wherein n=3, 4, 5, 6), dimethyl cyclosiloxane (Dn, wherein n=3, 4, 5, 6), and methylhydrocyclosiloxane (DnH, wherein n=3, 4, 5, 6) as monomers; adding a blocking agent; and selecting rare earth super acids, controlling the reaction temperature, performing polymerization for a certain period under the protection of N2 gas, gradually raising the temperature to 205 DEG C under -0.9 MPa, and extracting low-boiling substances under reduced pressure to obtain the target product. The method has the advantages that: the catalyst can be separated only by filtering without washing neutralization, and the method has low labor intensity, simple process, simple and convenient operation and no pollution, and is convenient for industrialization. The product prepared by the method has good effects in the LED packaging process.

Owner:HANGZHOU NORMAL UNIVERSITY

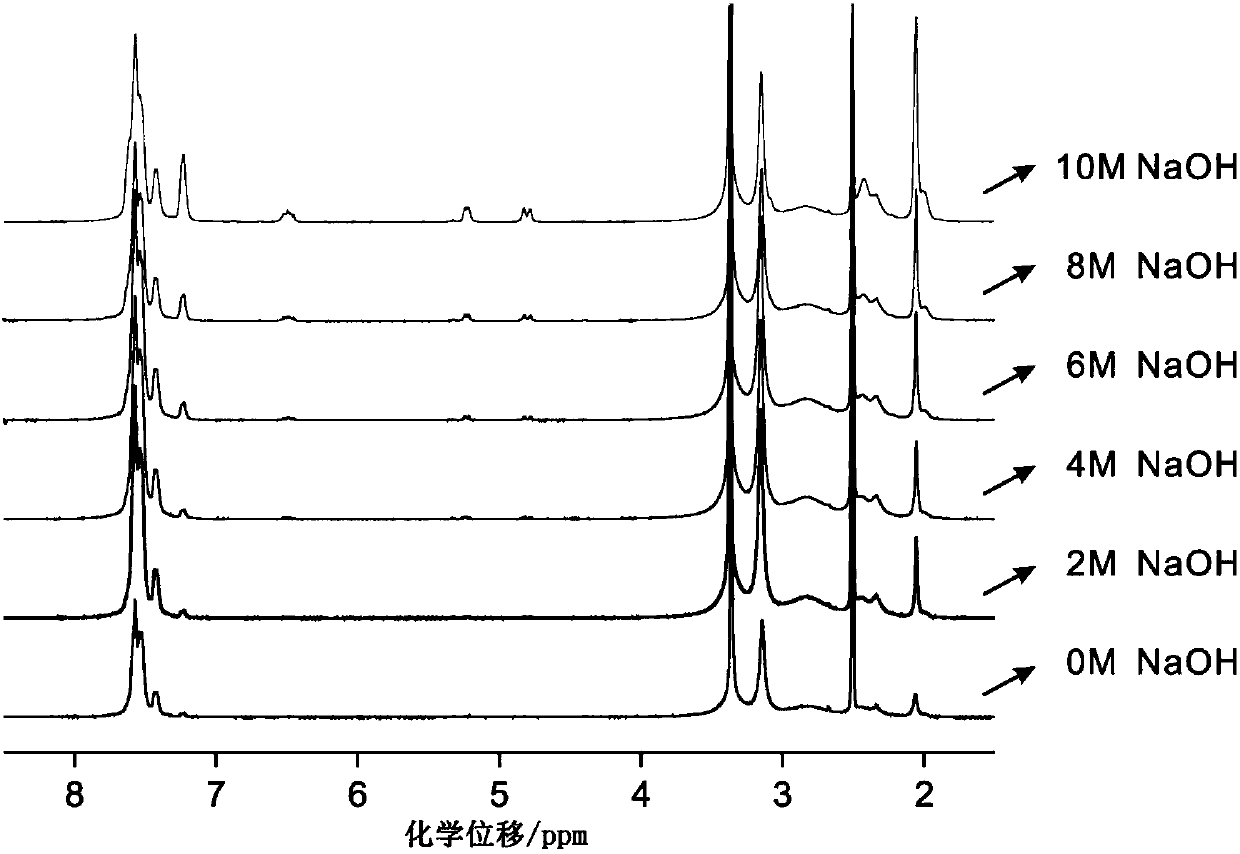

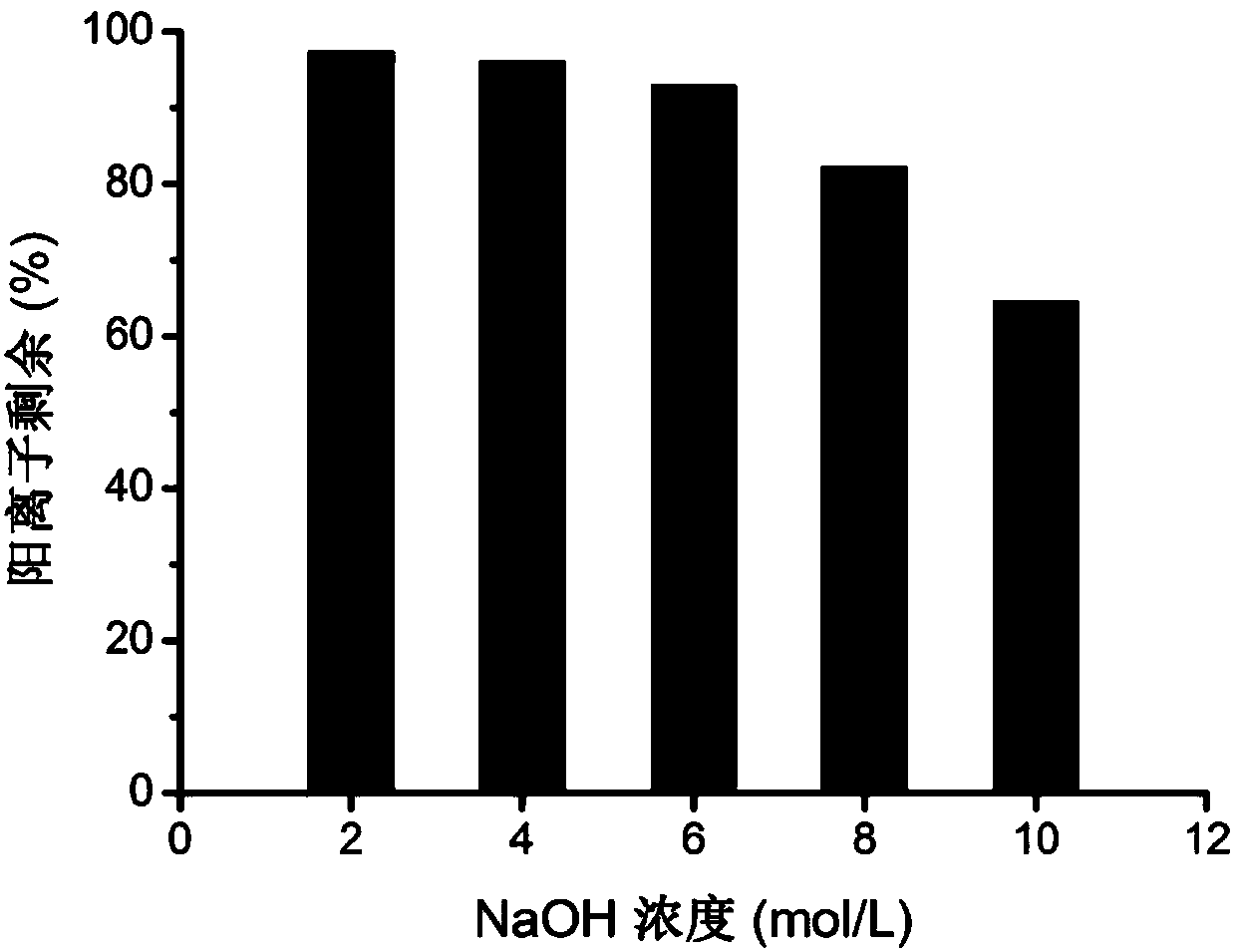

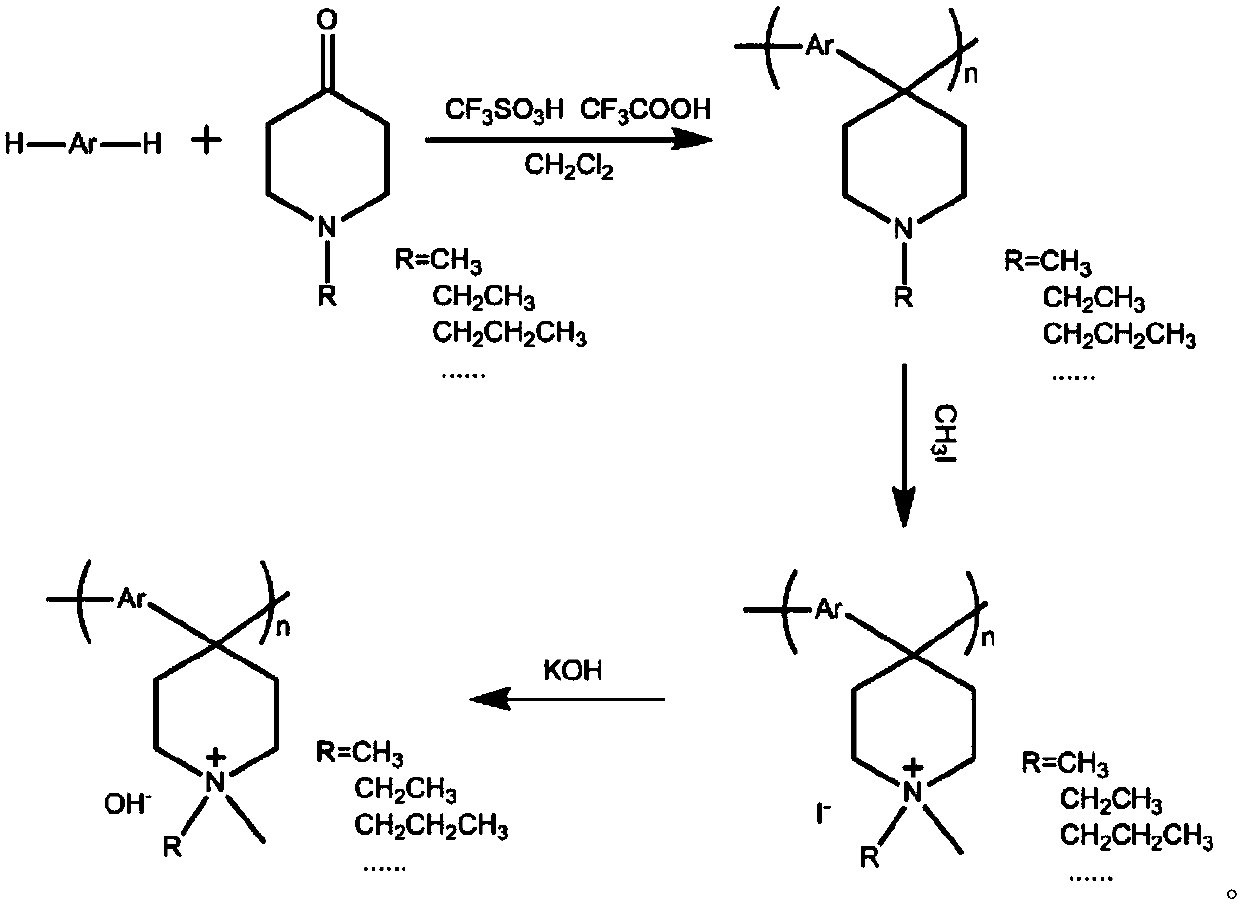

Preparation method of anionic polymer membrane with high chemical stability

The invention discloses a preparation method of an anionic polymer membrane with the high chemical stability, and belongs to the field of ionic polymer membranes. The preparation method comprises thesteps that under catalysis of mixed superacid, an aryl compound and an N-alkyl-4-piperidone compound generate an addition condensation reaction to obtain a linear polymer with high molecular weight and narrow molecular weight distribution; and quaternization modification is conducted on a nitrogen heterocycle on a polymer chain with methyl iodide or alkyl bromide, the obtained quaternized ionic polymer is soaked in a concentrated strong alkaline solution for ion exchange, washing and drying are conducted, and finally the obtained ion polymer is subjected to dissolution casting. According to the preparation method, the experiment process is simple and efficient, and the obtained anionic polymer membrane has the high ionic conductivity and ionic exchange capacity and is very excellent in chemical and heat stability and mechanical strength. The anionic polymer membrane has the very good application prospect and development potential in the alkaline polymer fuel cell field and has the great advantage compared with an anionic polymer membrane applied to a fuel cell at the present stage.

Owner:WUHAN UNIV

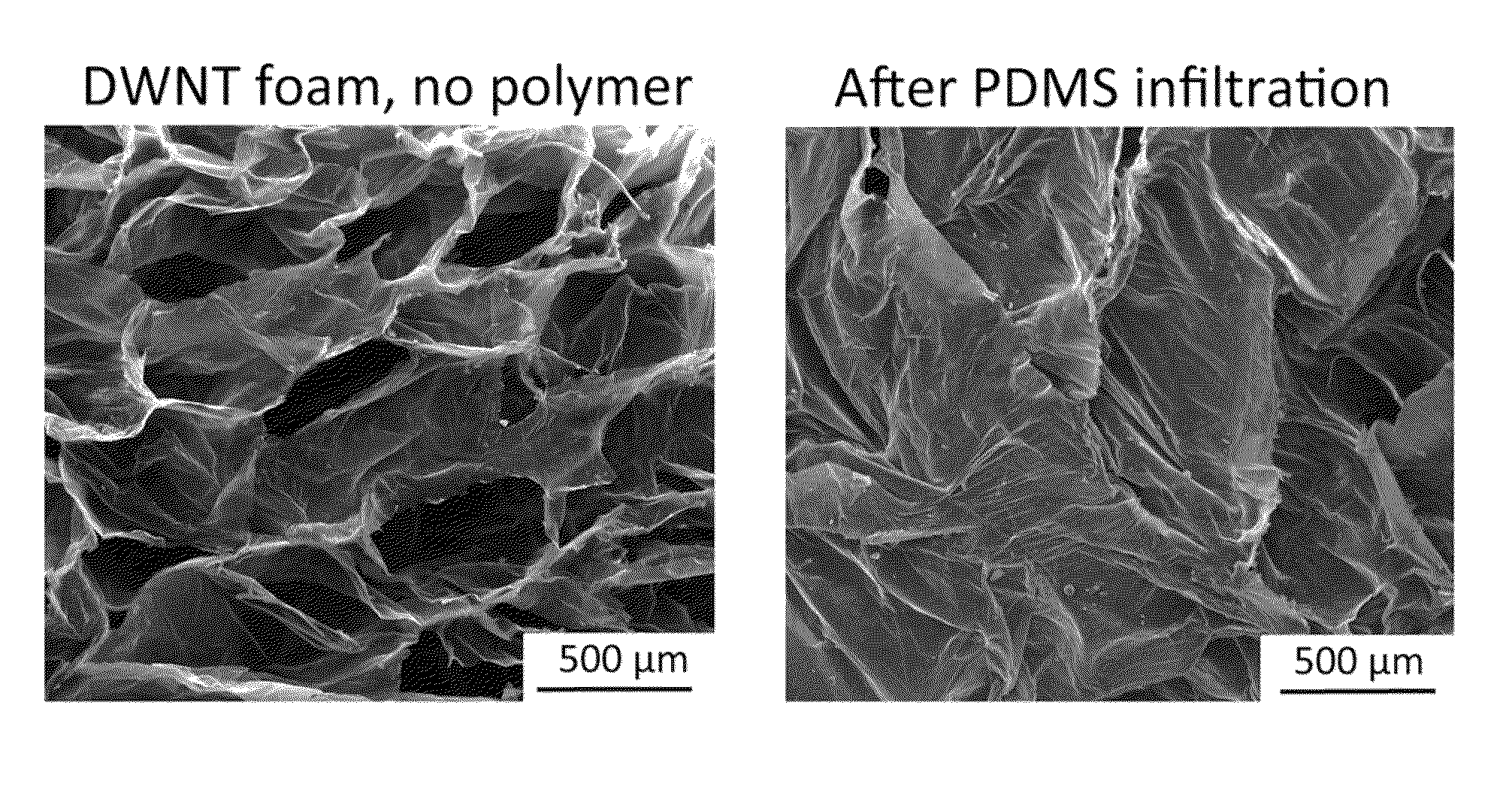

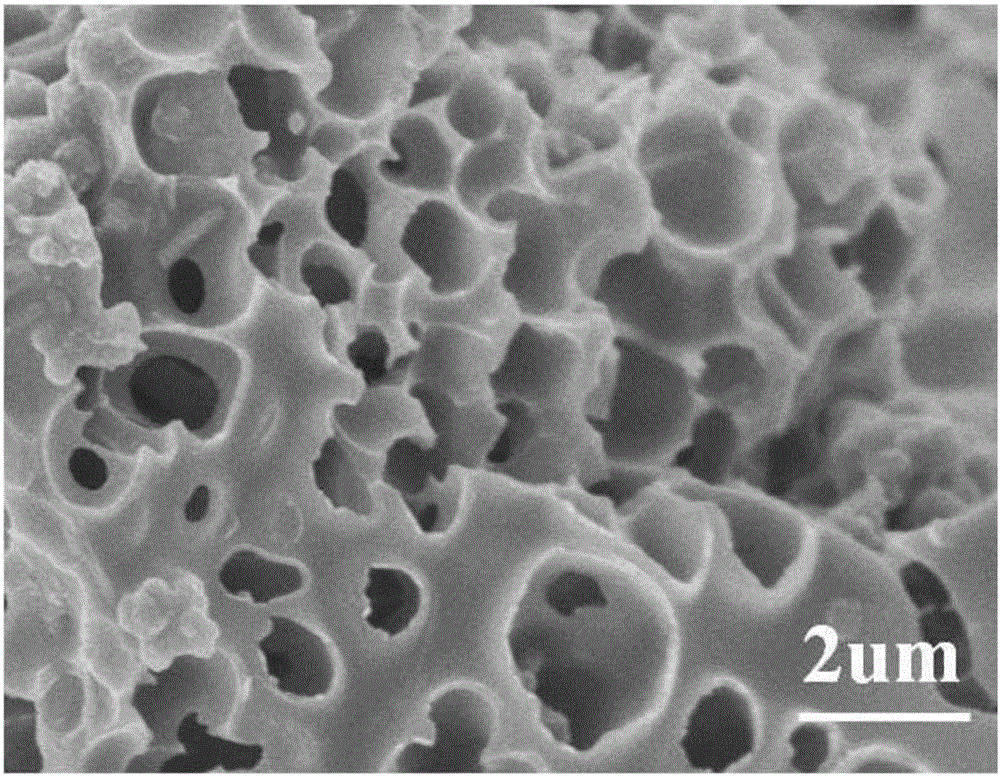

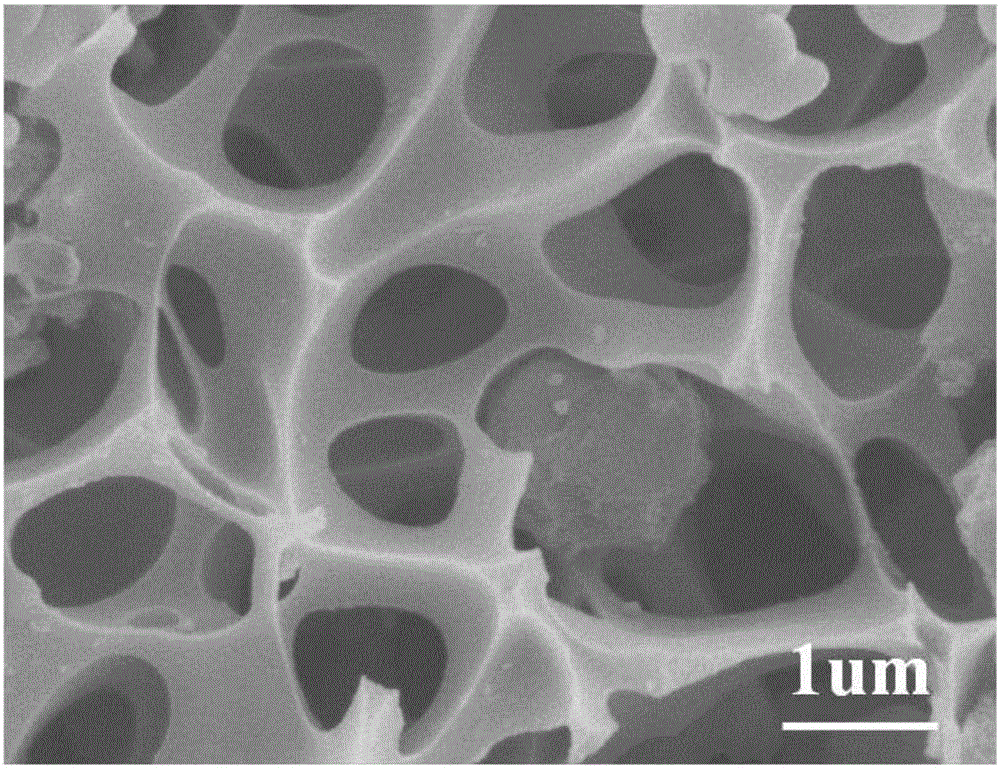

Fabrication of carbon foams through solution processing in superacids

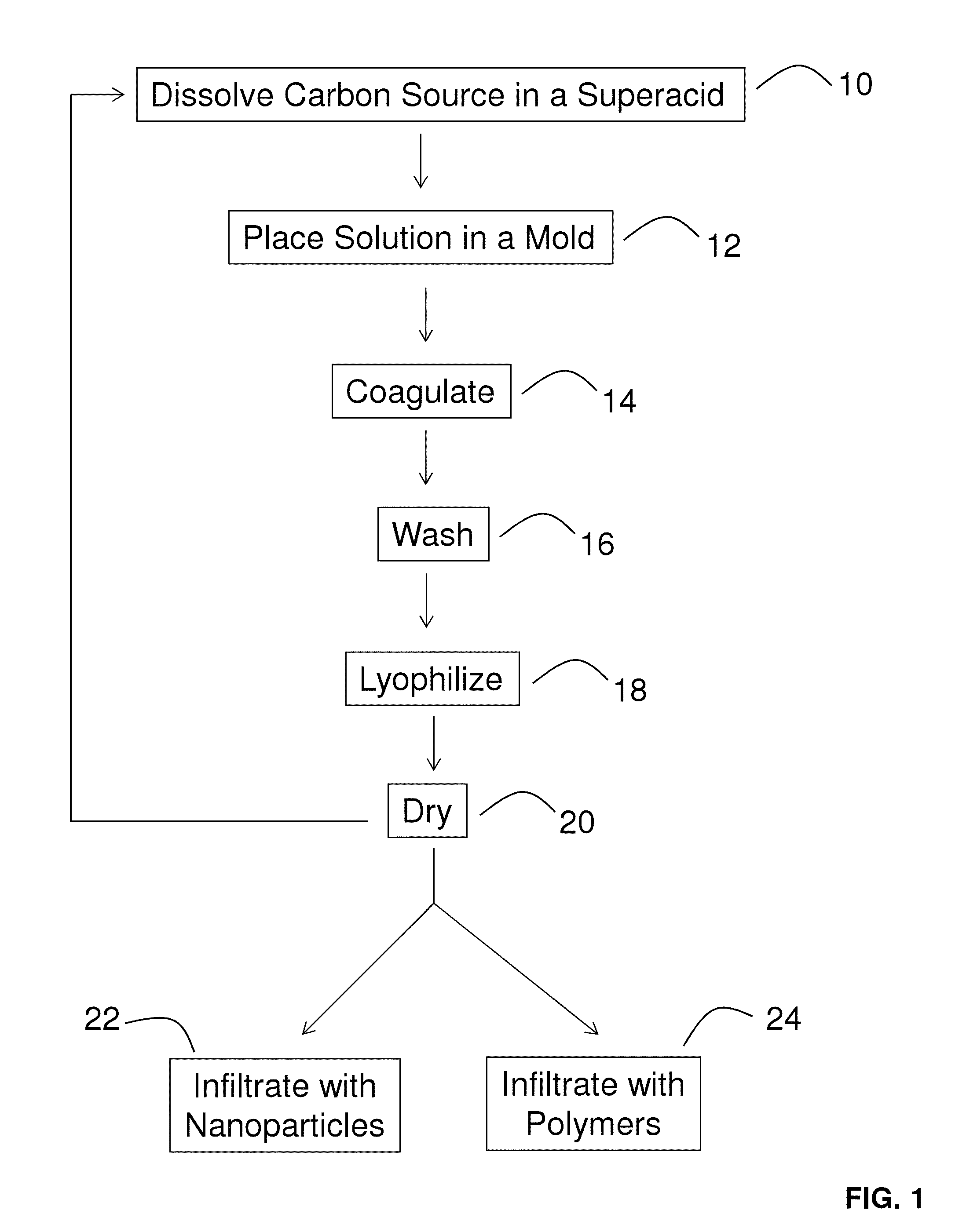

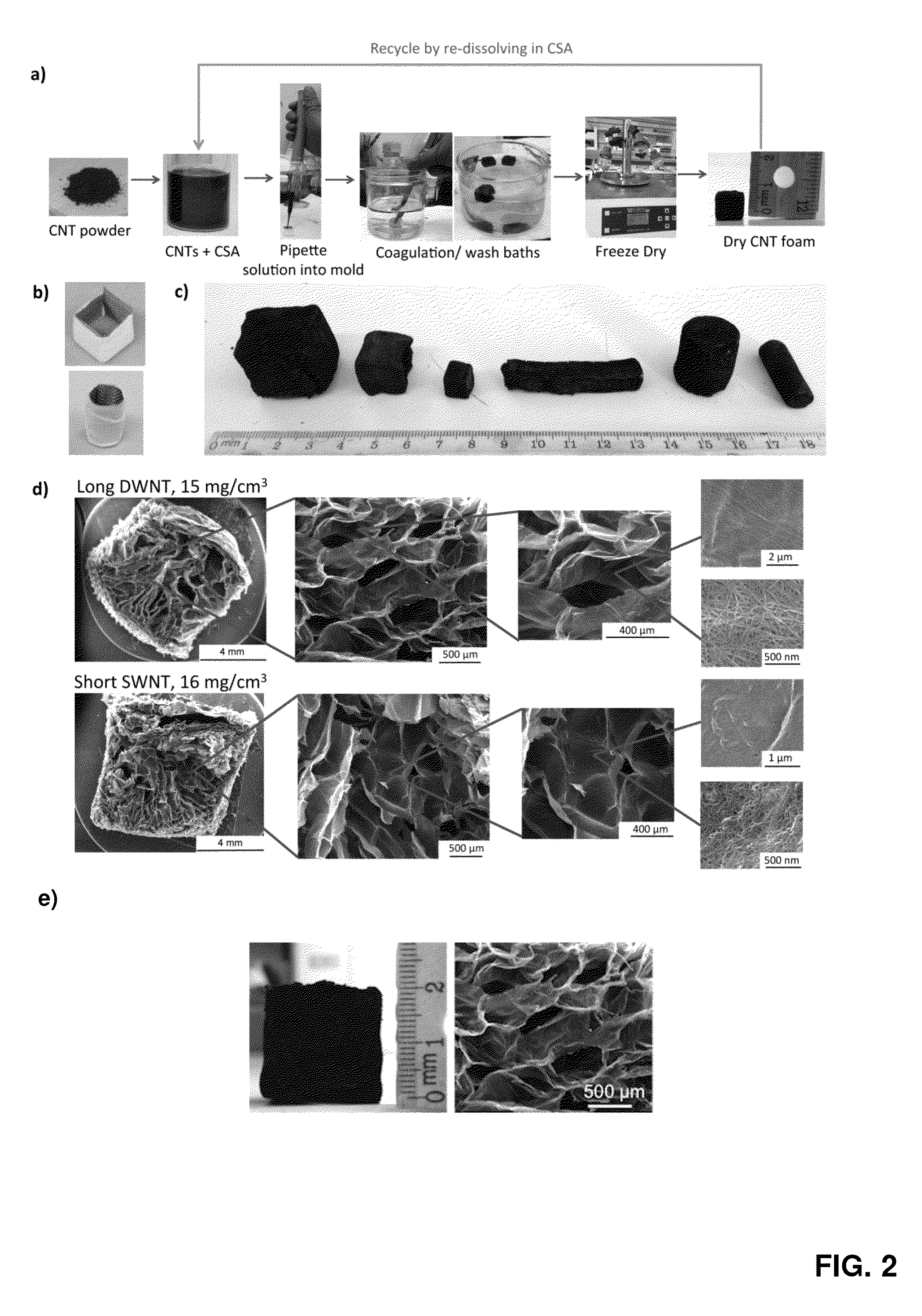

In some embodiments, the present disclosure pertains to methods of making carbon foams. In some embodiments, the methods comprise: (a) dissolving a carbon source in a superacid to form a solution; (b) placing the solution in a mold; and (c) coagulating the carbon source in the mold. In some embodiments, the methods of the present disclosure further comprise a step of washing the coagulated carbon source. In some embodiments, the methods of the present disclosure further comprise a step of lyophilizing the coagulated carbon source. In some embodiments, the methods of the present disclosure further comprise a step of drying the coagulated carbon source. In some embodiments, the methods of the present disclosure also include steps of infiltrating the formed carbon foams with nanoparticles or polymers. Further embodiments of the present disclosure pertain to the carbon foams formed by the aforementioned methods.

Owner:RICE UNIV

Preparation method of methylsilicone oil

The invention discloses a preparation method of methylsilicone oil, and specifically relates to methyl silicone oil with different viscosity (molecular weight) prepared by using supported solid superacid SO4<2-> / ZrO2-ZSM-5 as a catalyst and by adopting inexpensive and commercially available methylsilicone oil (Dn), octamethylcyclotetrasiloxane (D4) and hexamethyldisiloxane (MM), so as to fit various needs. Compared with a conventional catalyst for producing methylsilicone oil, the supported solid superacid catalyst provided by the invention has higher catalytic activity, higher stability, lower cost and the like. More importantly, the supported solid superacid catalyst is in a solid state and can be separated via simple filtration and reused, thereby enabling the production to have the advantages of simple process, convenient operation, no pollutions, no corrosion toward equipment, and the like.

Owner:JIANGNAN UNIV

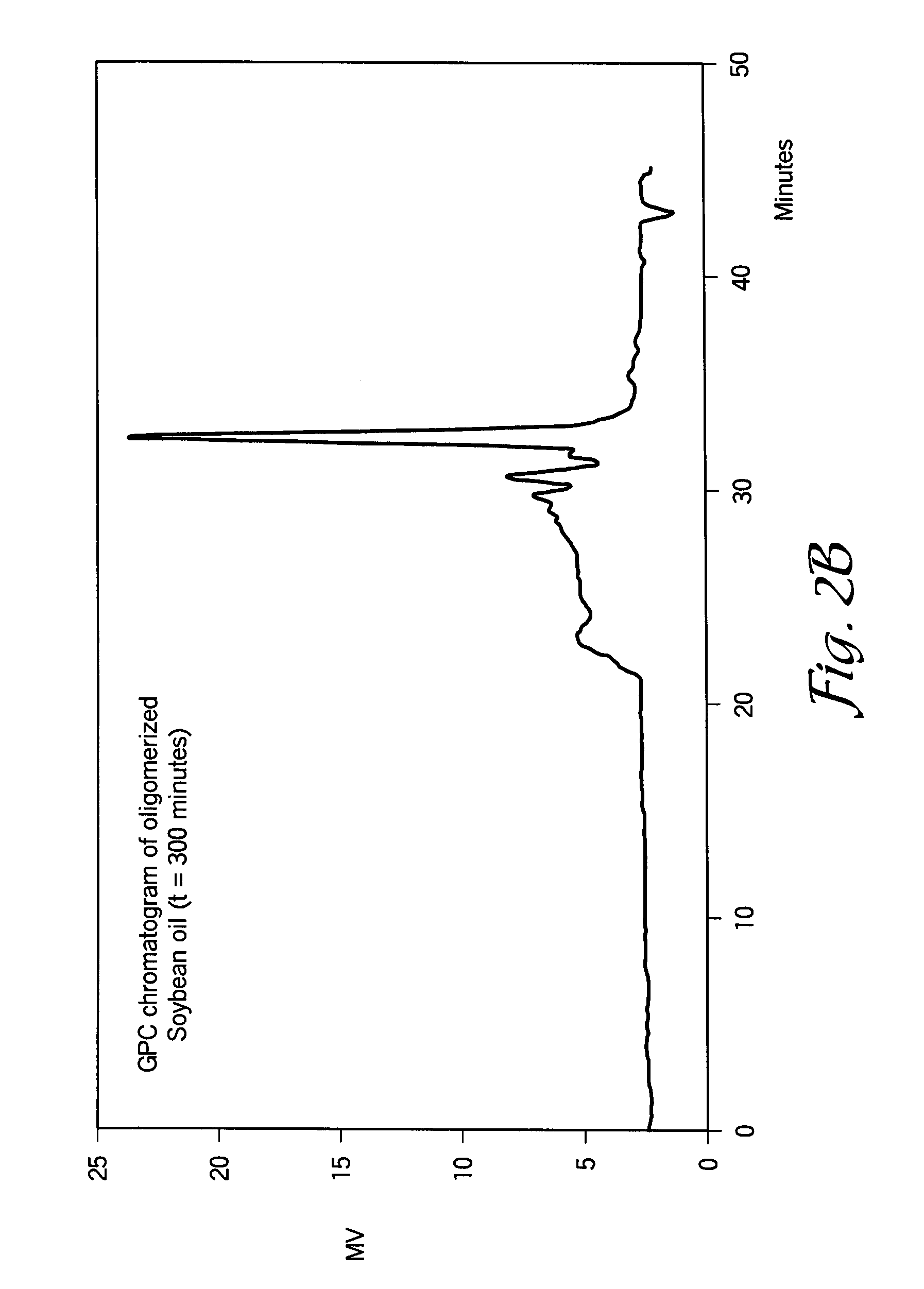

Cationic polymerization of biological oils

ActiveUS20080281071A1High of double bondReduce the numberFatty acid chemical modificationFatty acids production/refiningCationic polymerizationDouble bond

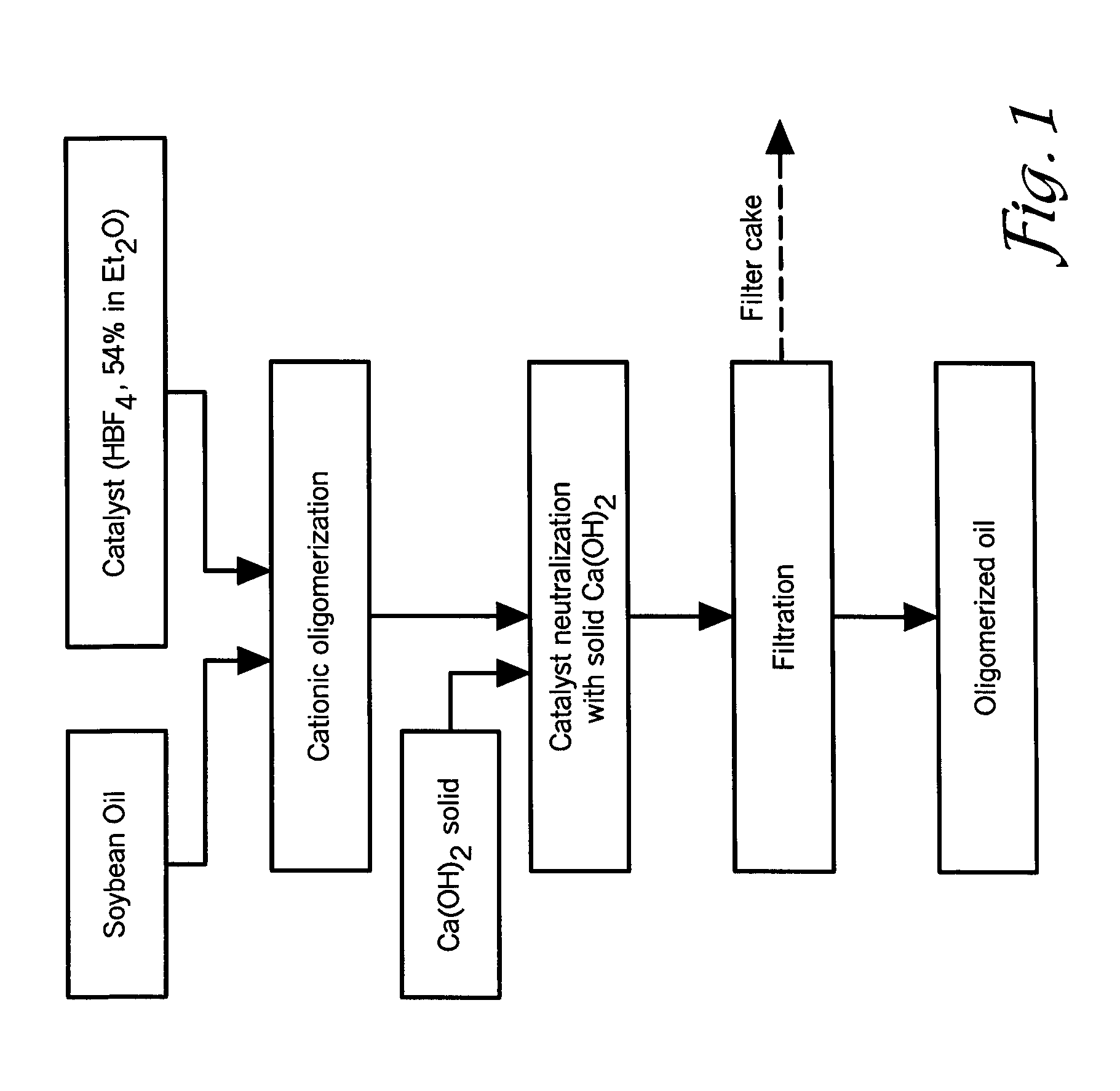

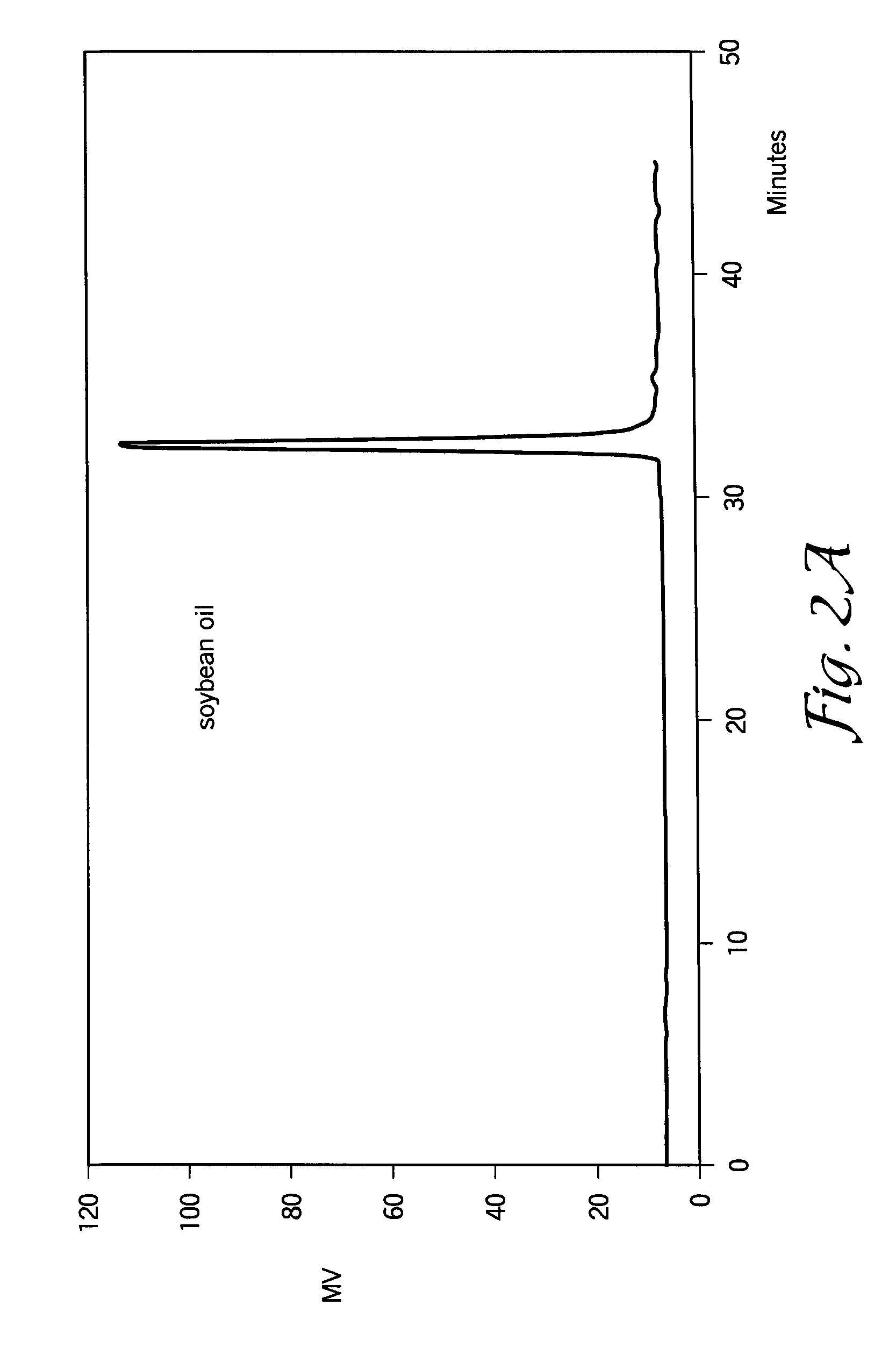

A method for the cationic polymerization of unsaturated biological oils (e.g., vegetable oils and animal oils) based on the cationic reaction of double bonds initiated by superacids is provided. The process occurs under very mild reaction conditions (about 70-110° C. and atmospheric pressure) and with short reaction times. The polymerized oils have a viscosity about 10 to 200 times higher than the initial oil and relatively high unsaturation (only about 10-30% lower than that of initial oils).

Owner:PITTSBURG STATE UNIVERSITY

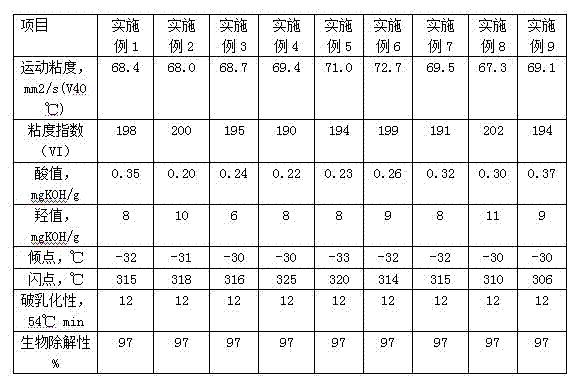

Method for producing pentaerythritol oleate under catalysis of granular solid superacid

InactiveCN102875374ANo pollutionHigh yieldOrganic compound preparationCarboxylic acid esters separation/purificationPentaerythritolAcid catalyzed

The invention discloses a method for producing pentaerythritol oleate under catalysis of granular solid superacid, and relates to a method for synthesizing ester base oil in biodegradable lubricating oil. The method comprises the following steps of: mixing pentaerythritol and oleic acid in a mass ratio of 1:(7.2-9.5), adding the granular solid superacid, and reacting at the temperature of between 140 and 240DEG C for 4 to 10 hours in the vacuum degree of 100-1,000Pa; filtering by using a 200-12,500 mesh filter screen or filter plate; and heating crude grease to the temperature of between 160 and 280DEG C, removing unreacted acid or alcohol, keeping the vacuum degree of the system ranging from 1 to 500Pa, and distilling under reduced pressure for 40 to 120 minutes to obtain the pentaerythritol oleate. The pentaerythritol oleate produced by the method has excellent low temperature fluidity, lubricity, viscosity-temperature characteristics, oxidation safety, cleanness and good biodegradability, and the method is an environment-friendly and high-efficiency production method having advantages of simple treatment, short production period, high esterification rate and high product yield.

Owner:SICHUAN SIPO CHEMICAL CO LTD

Method for preparing oleic acid esters by using solid super acid as catalyst

InactiveCN101229999ALess prone to side effectsGood reaction selectivityPhysical/chemical process catalystsOrganic compound preparationState of artChemical industry

The invention relates to a method for manufacturing oleic acid ester by using solid superacid as catalyst. The invention can overcome problems existing in the prior art that products are impure, yield coefficient is low and the prior art can not achieve the object of replacing sulphuric acid as catalyst. For overcoming the problems existing in the prior art, the technical proposal provided by the invention is that: the method for manufacturing oleic acid ester by using solid superacid as catalyst is characterized in that ZrO2 carrier is added into sulphuric acid accelerator to carry out ultrasonic wave dipping in all the process for preparing the solid superacid; after dipping for 20 to 40 minutes, the obtained substance is filtered and parched; as the catalyst, the dosage of the solid superacid is 0.05 percent to 0.5 percent of the quality of the oleic acid. Comparing with the prior art, the invention has the advantages that: the preparation cycle of the solid superacid is shortened and the activity is enhanced; side effect does not easily occur by using the solid superacid as the catalyst; the production technique is simplified. And the invention has convenient post treatment and low energy consumption, and is safe as well as reliable, which suits for the sustainable development requirement of chemical industry.

Owner:SHAANXI UNIV OF SCI & TECH

Hybrid polyester-polyether polyols

A process for preparing a hybrid polyester-polyether polyol comprises contacting a carboxyl group-containing component and an epoxide, optionally in the presence of one or more of a double metal cyanide catalyst, a superacid catalyst, a metal salt of a superacid catalyst and / or a tertiary amine catalyst, under conditions such that a hybrid polyester-polyether polyol is formed. The hybrid polyester-polyether polyol offers the advantages of both ester and ether functionalities when used in a polyurethane formulation, thus enhancing physical properties. The process results in products having narrow polydispersity, a low acid number and unsaturation, and reduced byproduct formation, particularly when the double metal cyanide catalyst is employed.

Owner:THE DOW CHEM CO

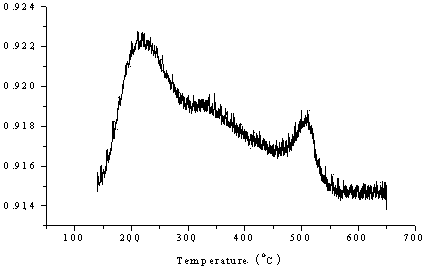

Method for recycling carbon fibers from waste carbon fiber resin matrix composite material

ActiveCN106957451AGuaranteed RecoveryImprove performance indicatorsProductsReagentsCarbon fibersResin matrix

The invention relates to the technical field of recycling of carbon fibers and discloses a method for recycling carbon fibers from a waste carbon fiber resin matrix composite material. The method comprises the following steps: paving a layer of solid superacid SO4<2> / TiO2 powder on the surface of the waste carbon fiber resin matrix composite material; carrying out pyrolysis at 500-700 DEG C for 10-30 minutes in an anaerobic inert environment; and carrying out pyrolysis at 350-450 DEG C for 10-60 minutes in an aerobic environment. According to the method for recycling the carbon fibers by paving solid superacid SO4<2>-TiO2 powder and carrying out two-step pyrolysis treatment, the recycling efficiency is high, the problem that the quality of recycled carbon fibers is lowered is solved, and technical support is provided for cyclic utilization of the carbon fiber resin matrix composite material. The method has the beneficial effects that equipment is simple, the technical process is simple, and the treatment cost is low; and the method has industrial feasibility, and the reutilization convenience of the recycled carbon fibers is greatly improved.

Owner:BEIJING UNIV OF CHEM TECH +1

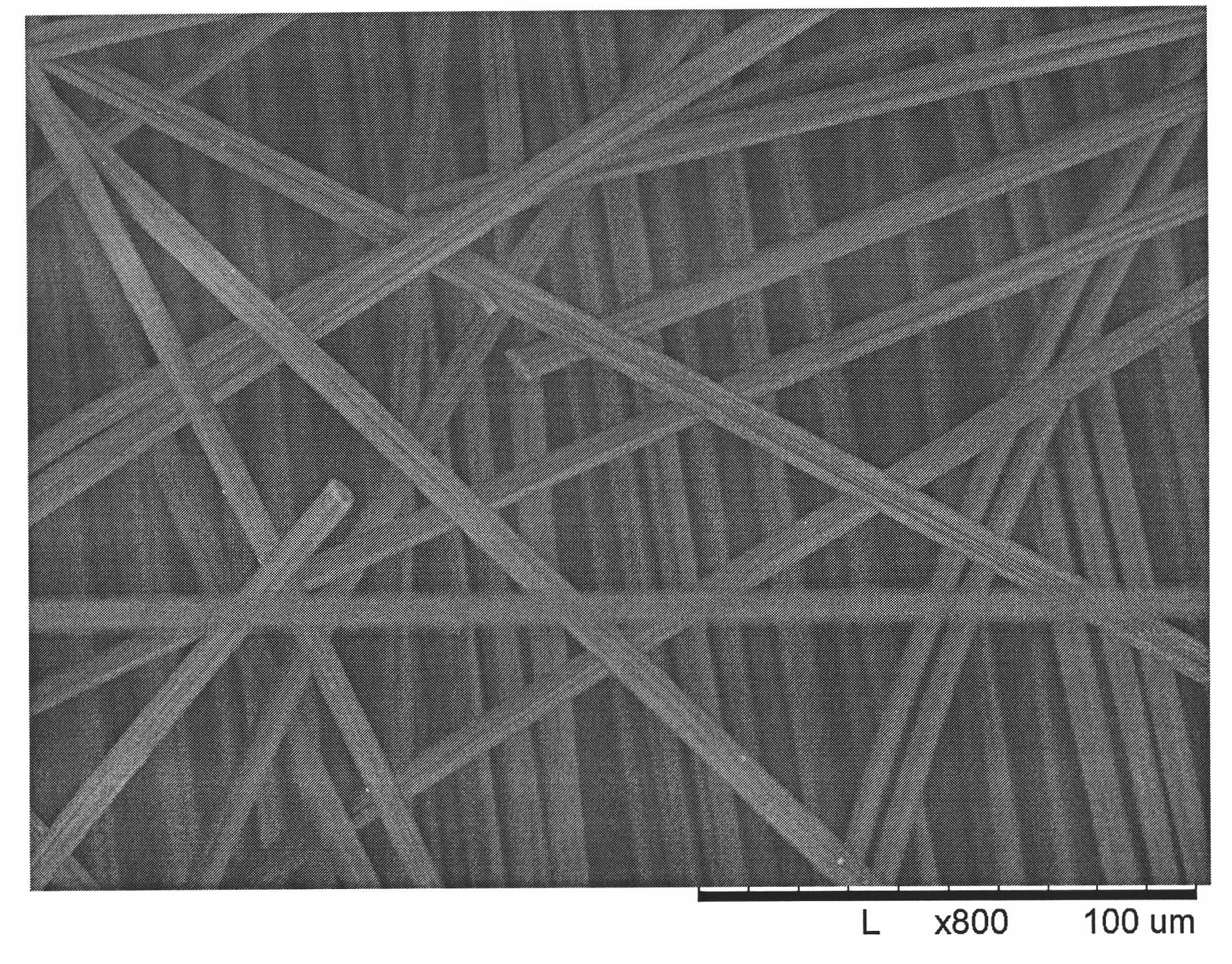

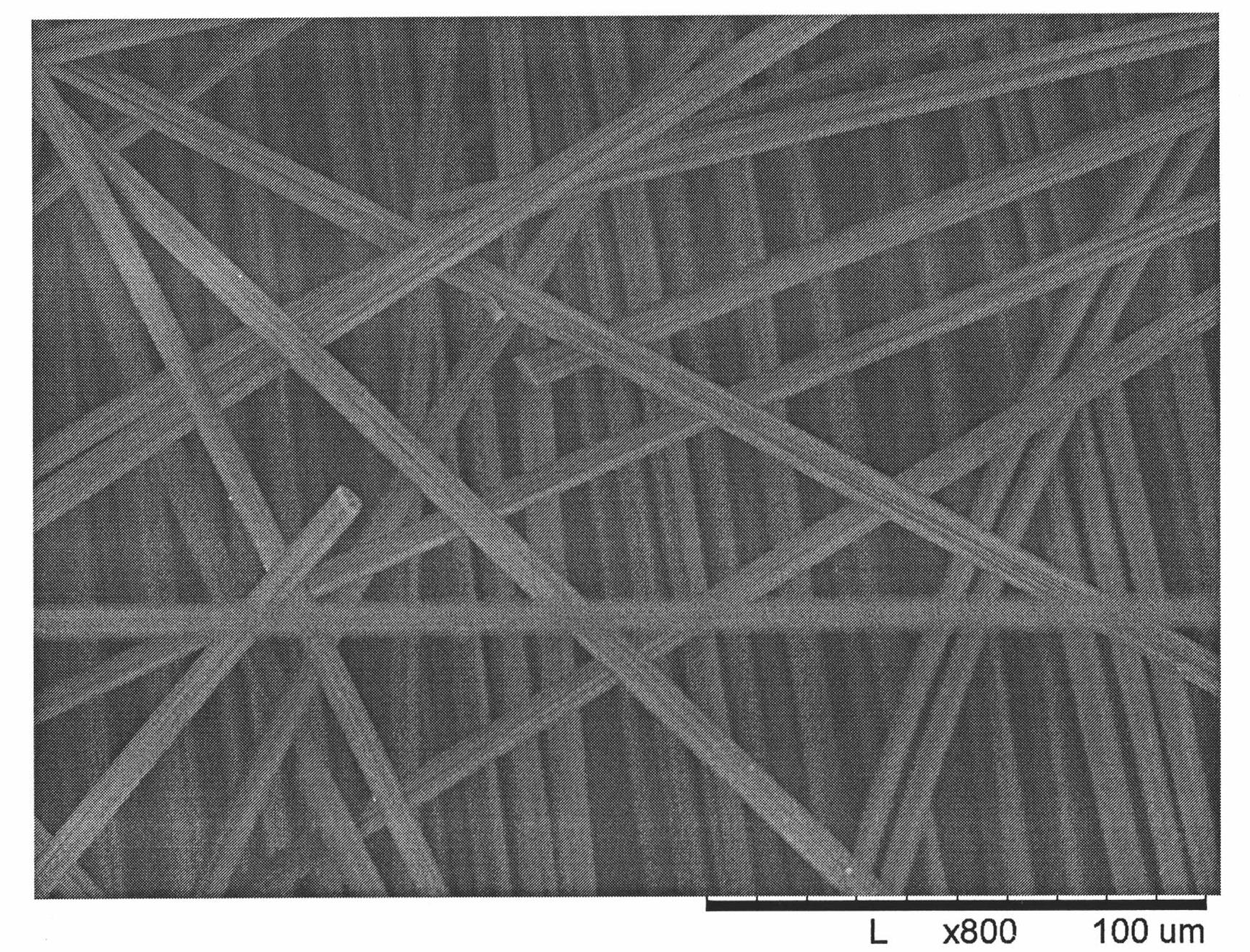

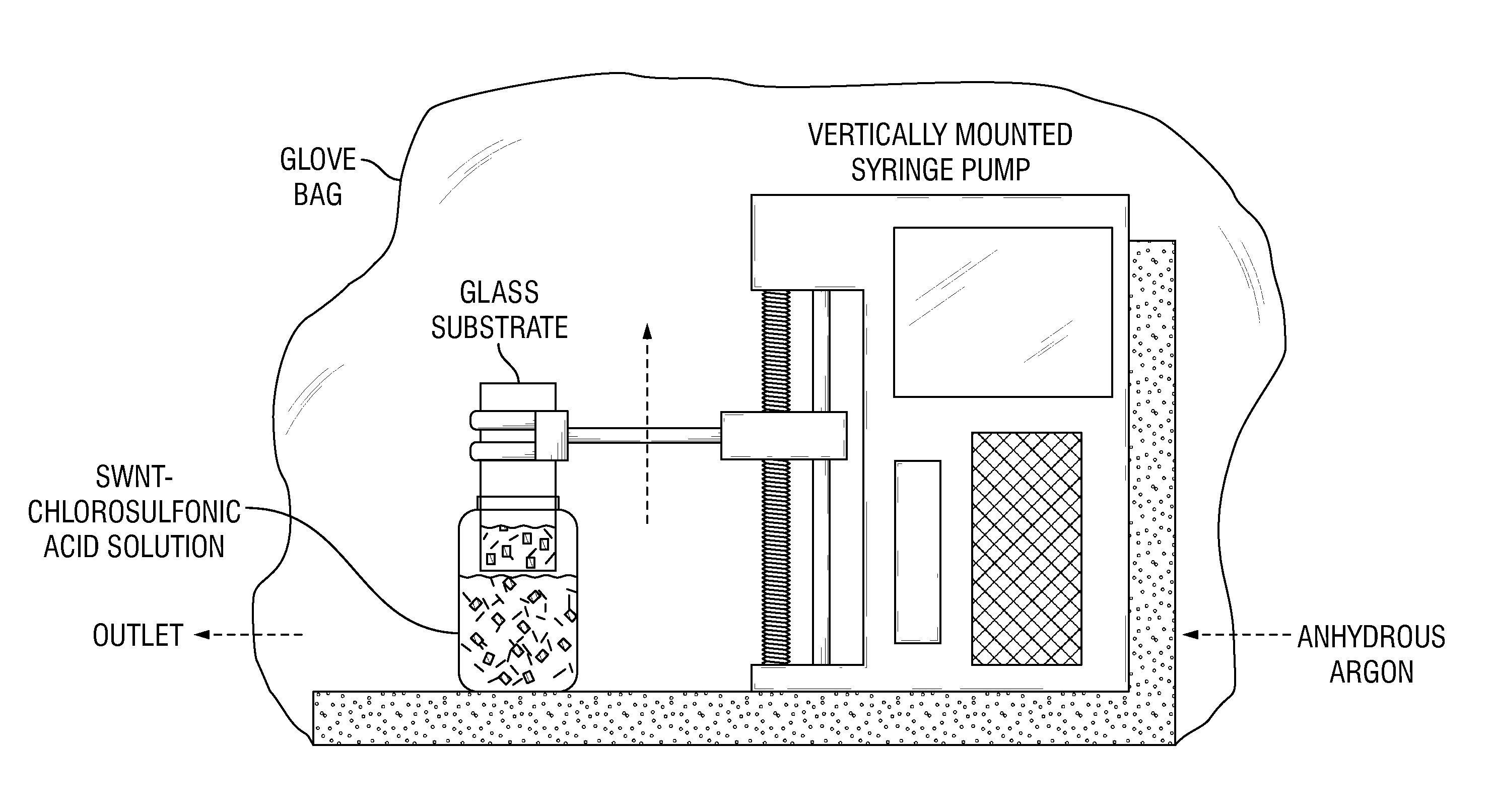

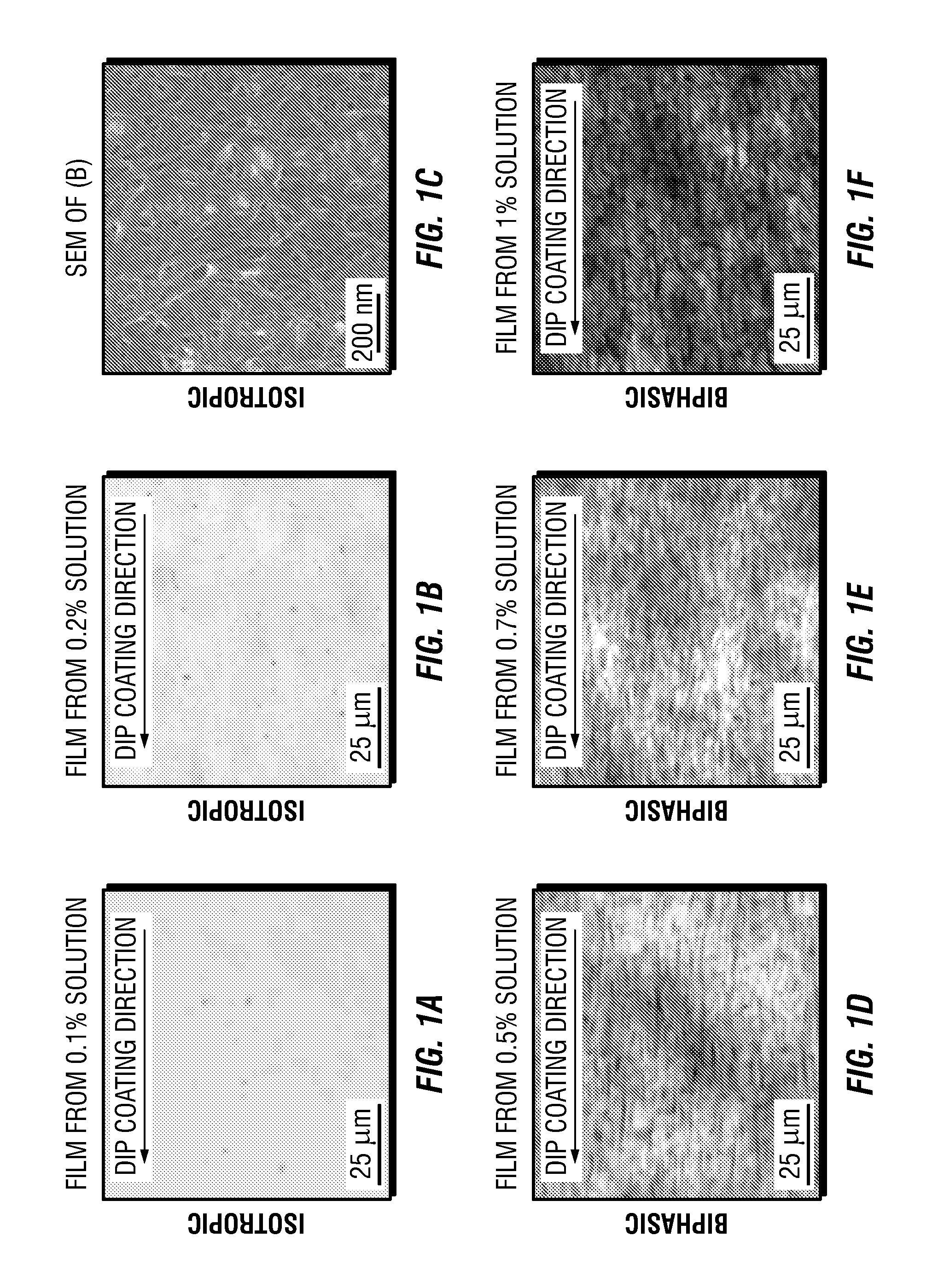

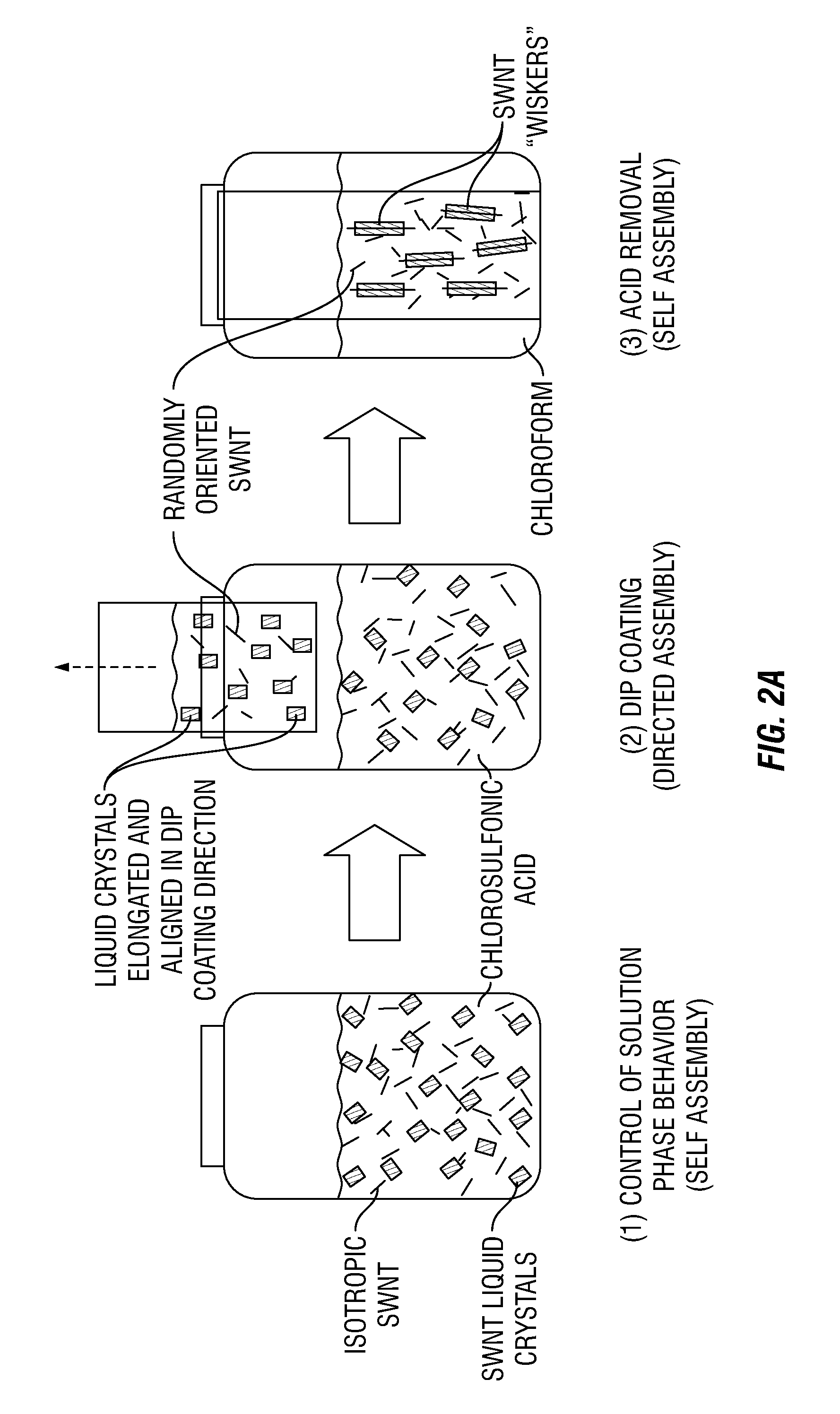

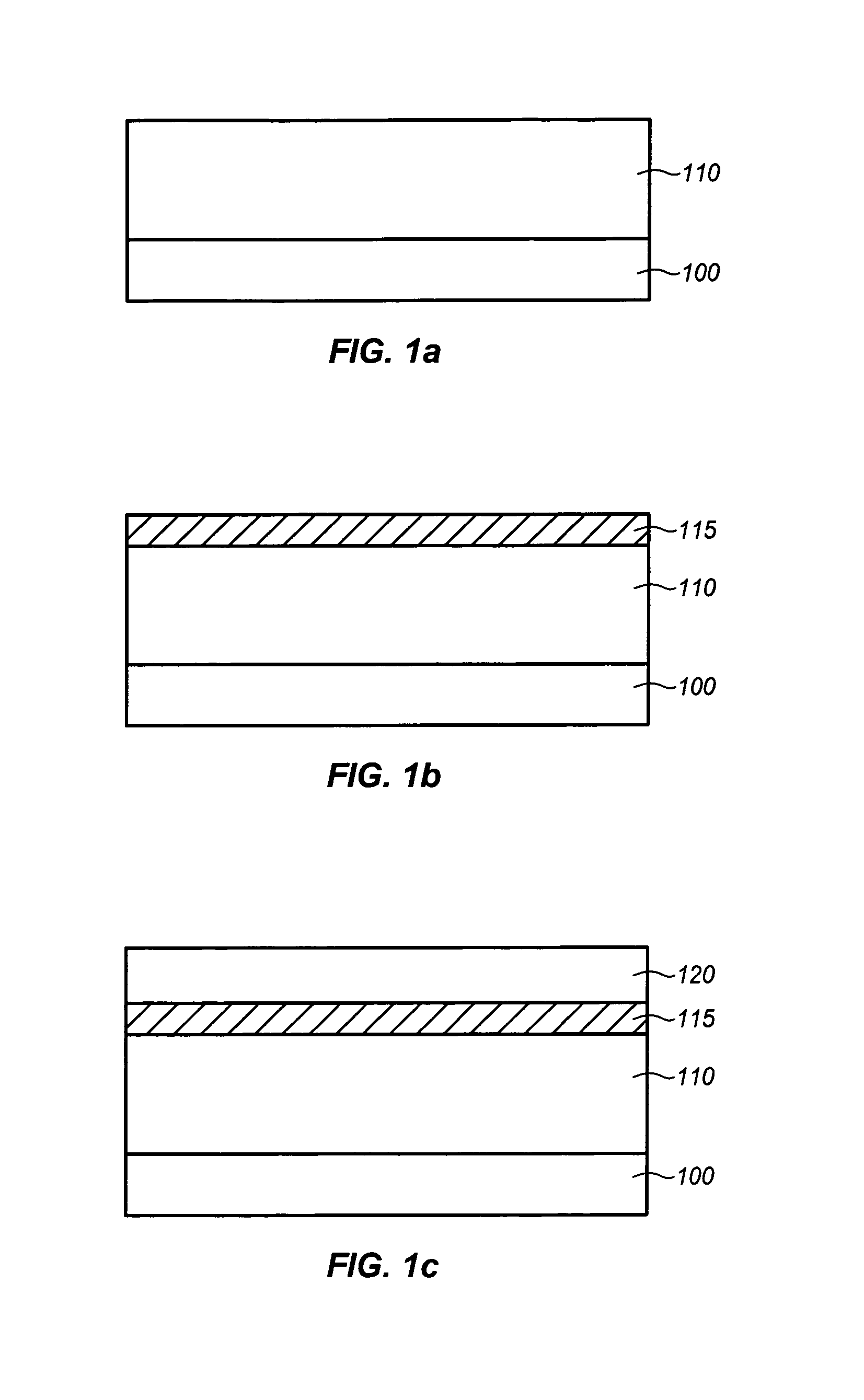

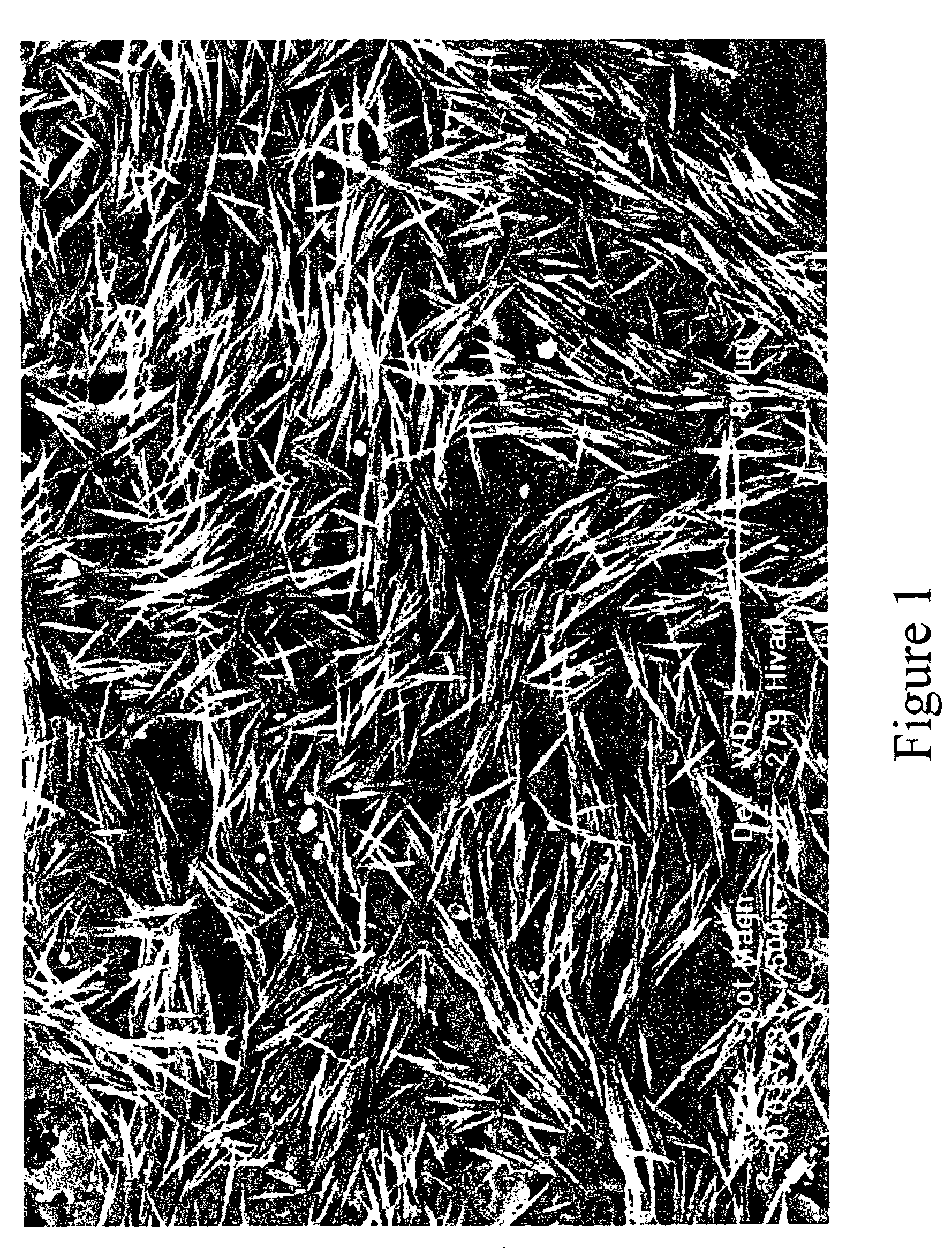

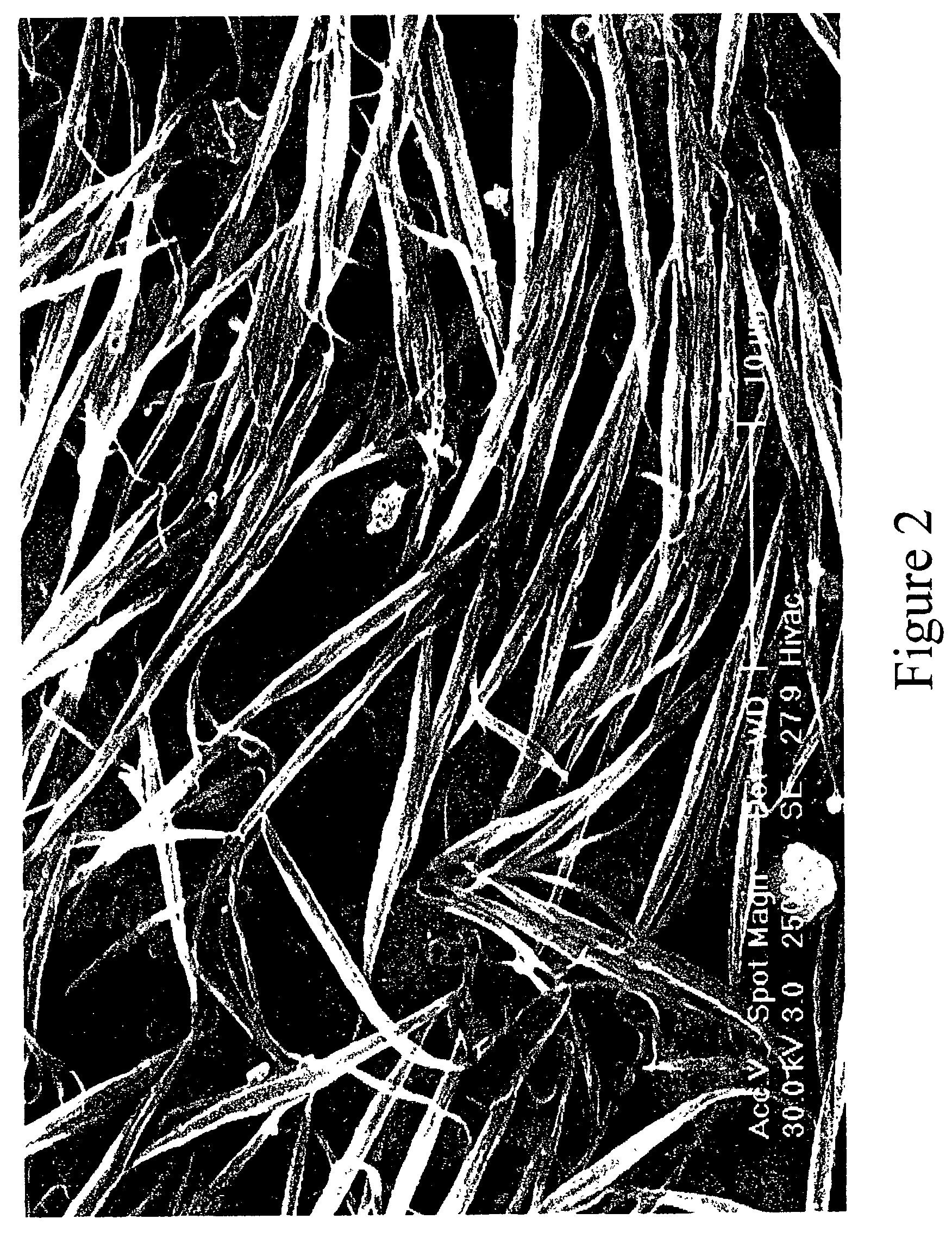

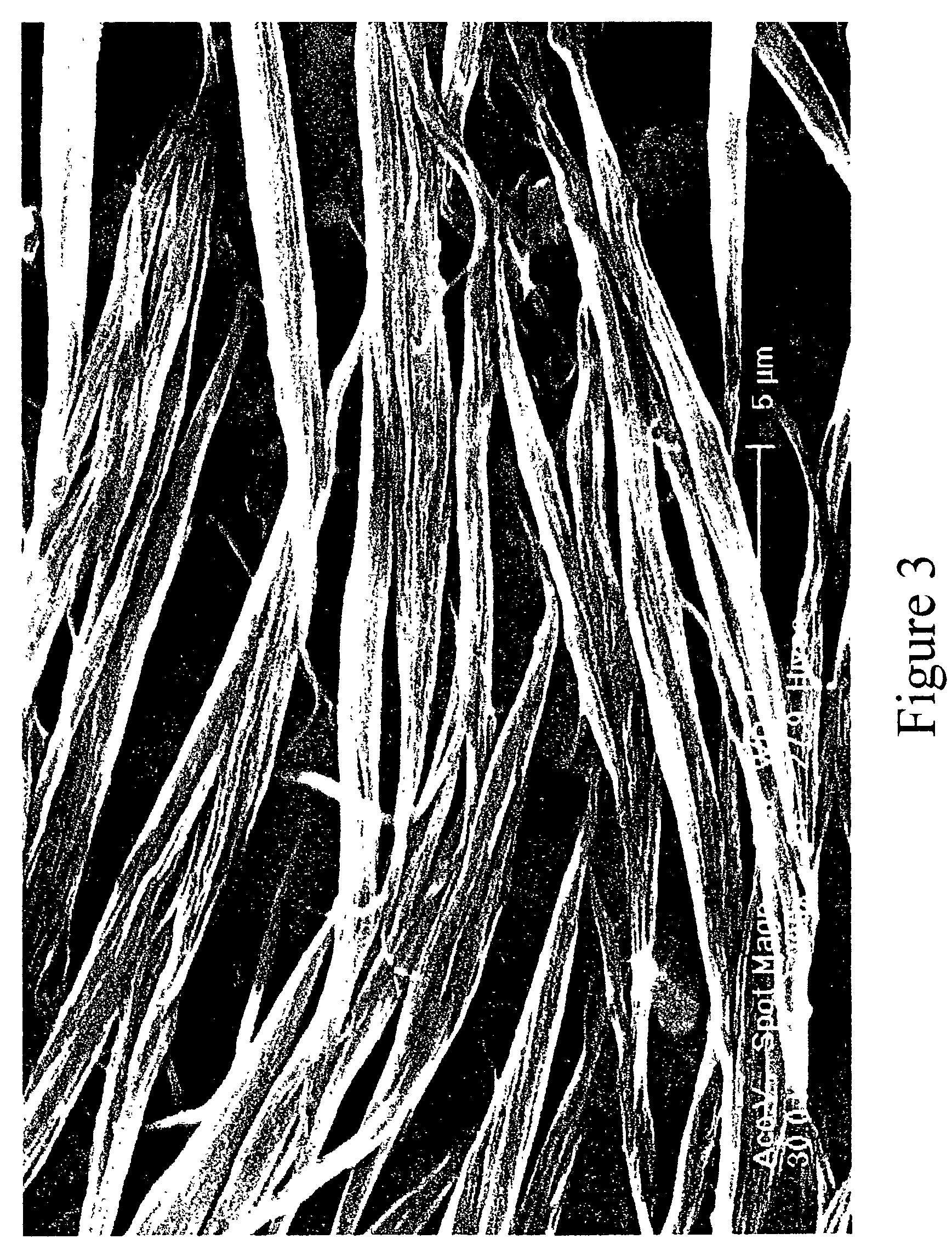

Carbon nanotube films processed from strong acid solutions and methods for production thereof

InactiveUS20150298164A1Material nanotechnologySynthetic resin layered productsStrong acidsCarbon nanotube

In some embodiments, the present disclosure provides methods for fabricating carbon nanotube films. Such methods generally comprise: (i) suspending carbon nanotubes in a superacid (e.g. chloro sulfonic acid) to form a dispersed carbon nanotube-superacid solution, wherein the carbon nanotubes have substantially exposed sidewalls in the carbon nanotube-superacid solution; (ii) applying the dispersed carbon nanotube-superacid solution onto a surface to form a carbon nanotube film; and (iii) removing the superacid. Desirably, such methods occur without the utilization of carbon nanotube wrapping molecules or sonication. Further embodiments of the present disclosure pertain to carbon nanotube films that are fabricated in accordance with the methods of the present disclosure. Such carbon nanotube films comprise a plurality of carbon nanotubes that are dispersed and individualized. Additional embodiments of the present disclosure pertain to macroscopic objects comprising the carbon nanotube films made in accordance with the methods of the present disclosure described supra.

Owner:RICE UNIV

The method for synthesizing polyoxymethylene dimethyl ether

ActiveCN102295734AImprove utilization efficiencyLow selectivityOrganic chemistryOrganic compound preparationMolecular sieveMass ratio

The invention relates to a method for synthesizing polyoxymethylene dimethyl ether, which mainly solves the problems of low reaction efficiency of a solid superacid catalyst, high cost of raw material trioxymethylene and more byproducts after reaction during synthesis of polyoxymethylene dimethyl ether existing in the prior art. In the method, dimethoxymethane and paraformaldehyde are used as rawmaterials, wherein the mass ratio of the dimethoxymethane to the paraformaldehyde is 0.5-10:1; the raw materials are in contact with the catalyst to generate catalytic reaction to prepare the polyoxymethylene dimethyl ether under the conditions of reaction temperature of 70-200 DEG C and reaction pressure of 0.2-6MPa; the amount of the used catalyst is 0.1-5.0 percent; and the used catalyst comprises the following components in percentage by weight: (a) 30-80 parts of molecular sieve carrier; and (b) 20-70 parts of solid superacid. Due to the technical scheme, the problems are solved well; and the method can be used for industrial production of the polyoxymethylene dimethyl ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method for low hydrogen-containing silicon oil

The invention relates to the technical field of chemical engineering, in particular to a preparation method for low hydrogen-containing silicon oil. The preparation method adopts high hydrogen-containing silicon oil (202) and dimethylcyclosiloxane (DMC) as raw materials and hexamethyldisiloxane (MM) as an end-capping agent, under the catalysis of a solid superacid, the temperature is increased to 50-140 DEG C for a telomerization, and the low hydrogen-containing silicon oil is prepared. Compared with the prior art for preparing the low hydrogen-containing silicon oil under the catalysis of vitriol, the preparation method adopts the solid superacid as a catalyst, the catalyst has a good catalysis effect and can be reused, neutralization and washing are not required during the preparation method, and short time is taken by the whole preparation process, continuous method industrial production is likely to be achieved, and the production efficiency is high.

Owner:蓝星安迪苏股份有限公司

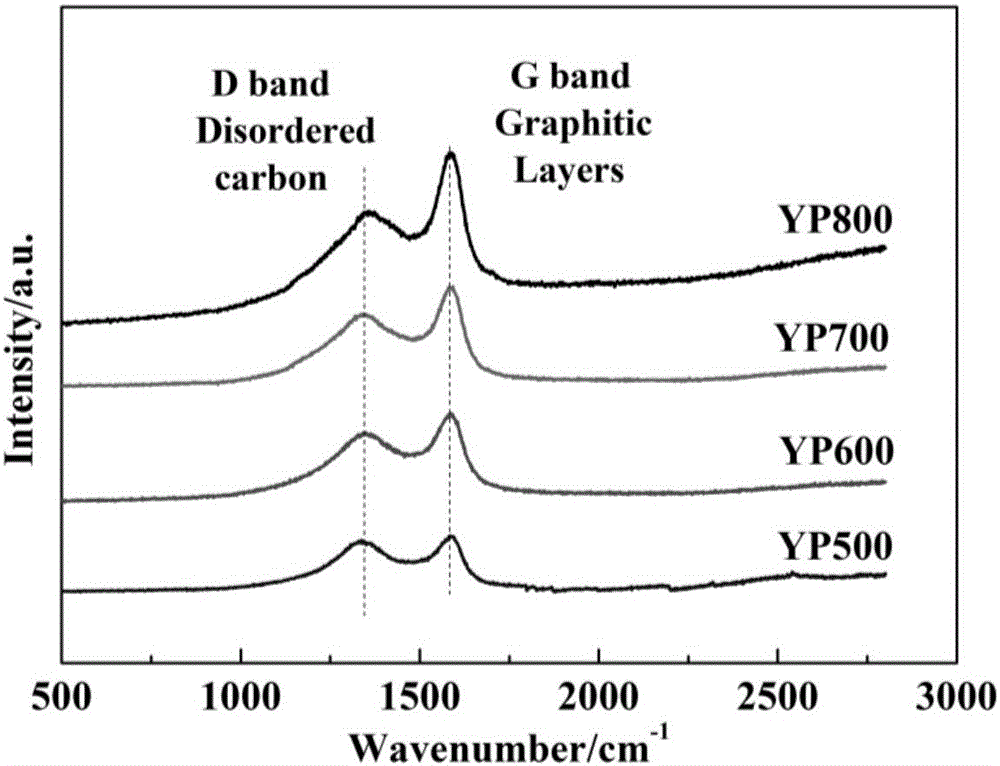

Method for preparing negative electrode material for sodium-ion battery from KOH activated pomelo peel

InactiveCN106207179AReduce pollutionLarge specific surface areaCell electrodesSecondary cellsBiomass carbonCarbonization

The invention discloses a method for preparing a negative electrode material for a sodium-ion battery from KOH activated pomelo peel. The method comprises the following steps of cleaning a biomass prefabricated part, freezing and drying the biomass prefabricated part, and performing hydrothermal reaction after solid superacid and an ethanol solution are added to obtain a biomass precursor; filtering and drying the biomass precursor, uniformly mixing the biomass precursor and KOH solid according to a certain mass proportion, and performing carbonization in a tubular atmosphere furnace to obtain a carbonization product; and washing and filtering the carbonization product, and drying and grinding the carbonization product to obtain the negative electrode material having a three-dimensional porous communication structure for the biomass carbon sodium-ion battery. By such method, the original porous structure and honeycomb characteristic of biomass are inherited, relatively large specific area and relatively low internal impedance are achieved, a condition is provided for rapid transmission of sodium ions, the capacity of the material is expanded, and the electrochemical property of the material can be remarkably improved.

Owner:SHAANXI UNIV OF SCI & TECH

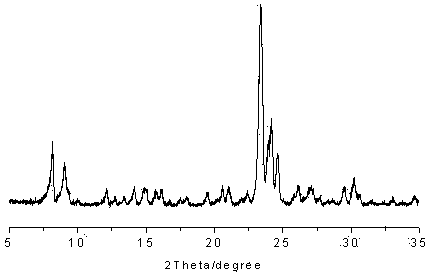

ZSM-5 molecular sieve and preparation method thereof

ActiveCN103880037AWith weak acidityWith strong acidityPentasil aluminosilicate zeoliteStrong acidsSilicon oxide

The invention relates to a ZSM-5 molecular sieve and a preparation method thereof. According to the molecular sieve, the molar ratio of silicon oxide to aluminium oxide is 45-80, the molecular sieve possesses weak acids, strong acids and superacids at the same time, the total acid content is 0.25-0.65 mmol / g, the molar ratio of Bronsted acids to Lewis acids is 1.2-2.1, and the molar ratio of the acid content sum of strong acids and superacids to the acid content of weak acids is 1.2-2. The preparation method comprises: first step, performing crystallization on a mixture containing sodium hydroxide, water, an aluminium source and a silicon source; and second step, adding a proper amount of an aluminium source into the crystallization product of the first step, performing crystallization at a certain temperature, then washing ,drying and roasting to obtain ZSM-5 molecular sieve. The molecular sieve provides an excellent catalytic material for catalytic processes needing relatively more superacid amount or needing different acidity, also the method does not employ any templates, so that the synthetic cost is substantially reduced and the method is green and environment-friendly.

Owner:CHINA PETROLEUM & CHEM CORP +1

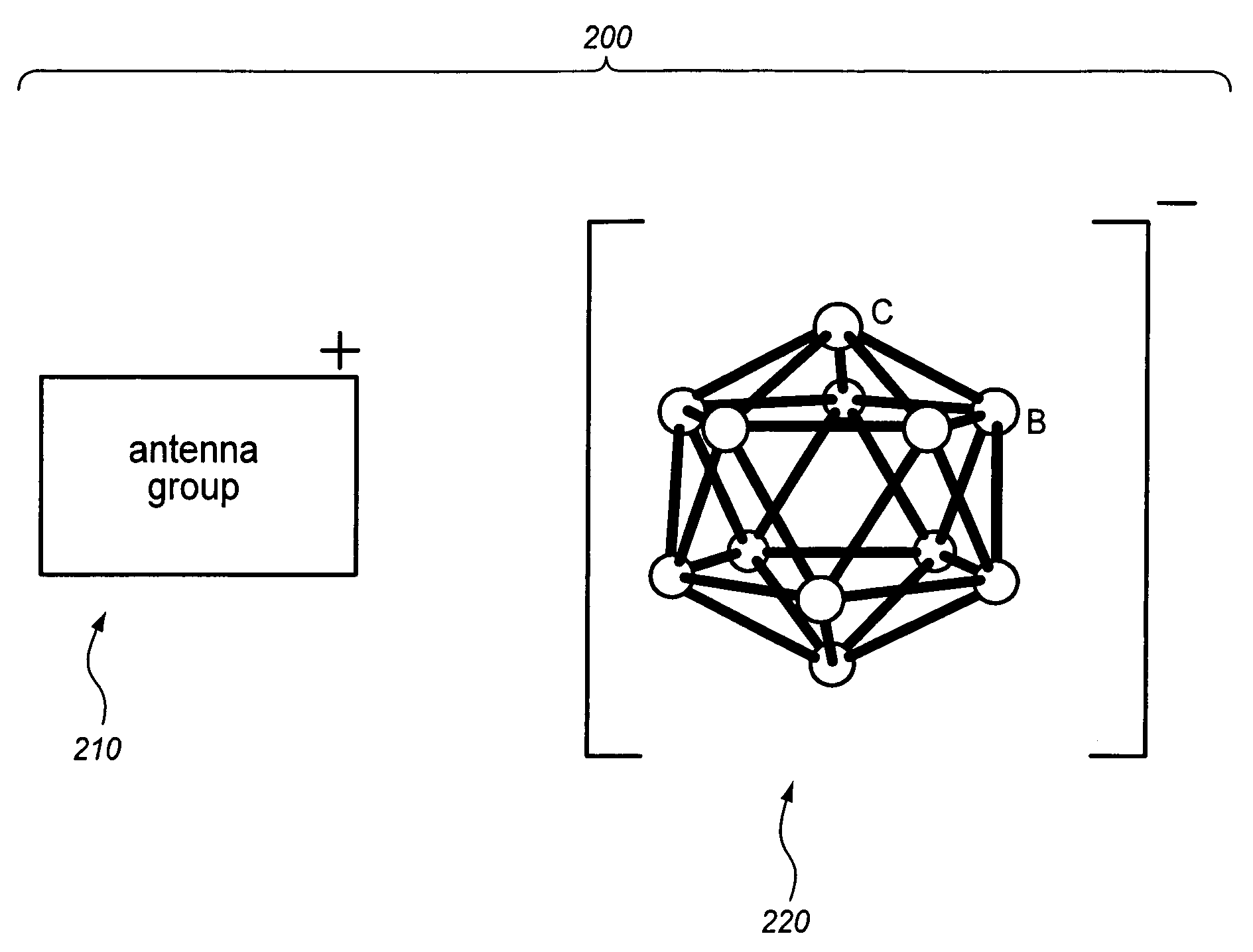

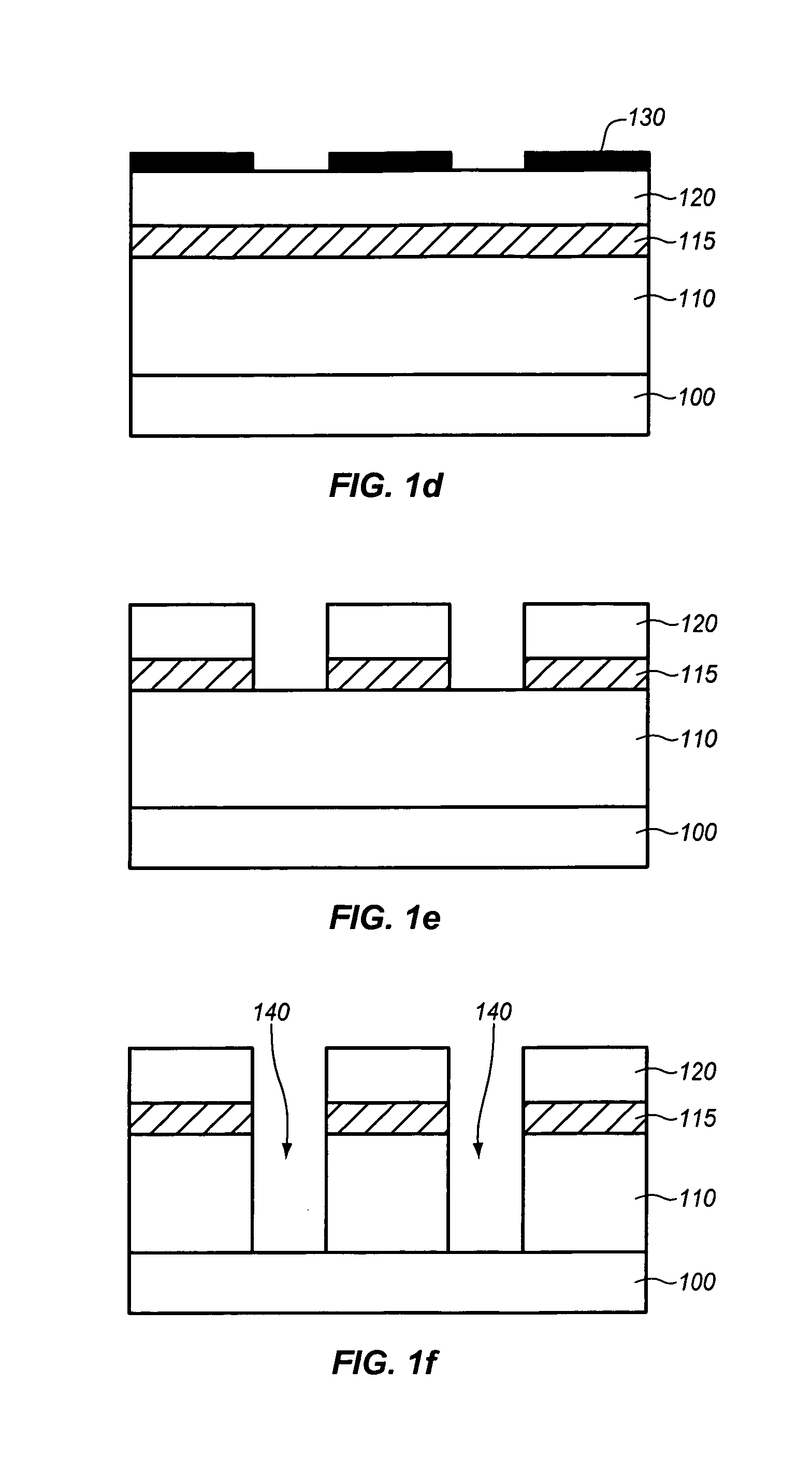

Photoacid generators based on novel superacids

InactiveUS7192686B2Radiation applicationsSemiconductor/solid-state device manufacturingChemical structureImage resolution

Carborane based PAG's are bulky, produce a strong and large superacid, and have polarities that are compatible with the chemically amplified polymers typically used in photoresists. Carborane based PAG's also provide another broad class of bulky PAG's that may be used in photoresist formulations that offer flexibility in acid strength and polarity through changes in chemical structure. These PAG's may be used with EUV wavelengths, 157 nm, or 193 nm. Resolution and critical dimension control may be improved through the use of carborane based PAG's.

Owner:INTEL CORP

Method for preparing ethyl levulinate based on solid superacid catalysis and furfuryl alcohol alcoholysis

InactiveCN103274942ALow costEasy to separateOrganic compound preparationCarboxylic acid esters preparationAlcoholEthyl ester

The invention discloses a method for preparing ethyl levulinate based on solid superacid catalysis and furfuryl alcohol alcoholysis, and relates to ethyl levulinate. The method comprises the steps of adding furfuryl alcohol, a catalyst and a reaction solvent to a reaction kettle, reacting, and obtaining ethyl levulinate. The catalyst is selected from at least one of solid superacid of SO4<2-> / TiO2, SO4<2-> / ZrO2, SO4<2-> / Fe2O3, SO4<2-> / SnO2, and SO4<2-> / Al2O3, or at least one of solid superacid of S2O8<2-> / TiO2, S2O8<2-> / ZrO2, S2O8<2-> / Fe2O3, S2O8<2-> / SnO2, and S2O8<2-> / Al2O3; the reaction solvent is ethyl alcohol; and reaction conditions are that the temperature is 100-150 DEG C, the rotating speed is 300-500 rpm (revolutions per minute), the time is 0.5-2.5h, a mass ratio of furfuryl alcohol to solid superacid is (1-4):1, and a mass ratio of furfuryl alcohol to ethyl alcohol is (0.01-0.2):1.

Owner:XIAMEN UNIV

Single-wall carbon nanotube alewives, process for making, and compositions thereof

InactiveUS7288238B2Good dispersionEasy to incorporatePigmenting treatmentMaterial nanotechnologyCarbon nanotubeCeramic

The present invention involves alewives of highly aligned single-wall carbon nanotubes (SWNT), process for making the same and compositions thereof. The present invention provides a method for effectively making carbon alewives, which are discrete, acicular-shaped aggregates of aligned single-wall carbon nanotubes and resemble the Atlantic fish of the same name. Single-wall carbon nanotube alewives can be conveniently dispersed in materials such as polymers, ceramics, metals, metal oxides and liquids. The process for preparing the alewives comprises mixing single-wall carbon nanotubes with 100% sulfuric acid or a superacid, heating and stirring, and slowly introducing water into the single-wall carbon nanotube / acid mixture to form the alewives. The alewives can be recovered, washed and dried. The properties of the single-wall carbon nanotubes are retained in the alewives.

Owner:RICE UNIV

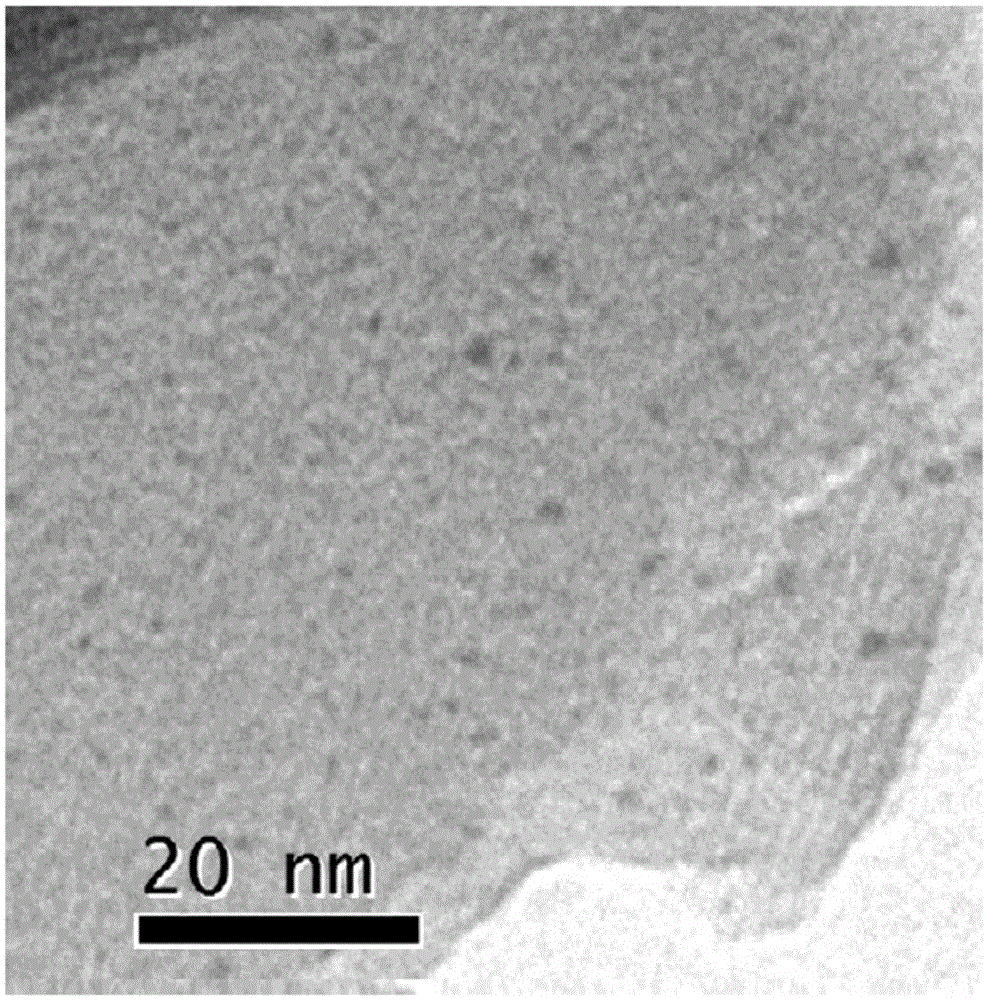

Method for preparing SO4<2->/ZrO2-MxOy solid superacid catalyst and use

InactiveCN101347740ASmall grainLarger than surfaceHydrocarbon by isomerisationPhysical/chemical process catalystsCoprecipitationCamphene

The invention relates to a prepration method of a SO4<2-> / ZrO2-MxOy solid superacid catalyst and the application thereof. The preparation method adopts the coprecipitation method for the preparation, thereby obtaining a precursor of a binary mixed hydroxide containing Zr and M (M is equal to Al or Fe), the precursor is carried out the hydrothermal treatment, dilute sulfuric acid is used for soaking, and the solid superacid catalyst with the larger specific surface area is obtained after the high-temperature calcination. The catalyst can obtain good effect, high conversion rate of Alpha-pinene and high selectivity of target products of camphene and limonene by being applied in the Alpha-pinene isomerization reaction.

Owner:FUDAN UNIV

Method for synthesizing antioxidant 1,3,5-trimethyl-2,4,6-tri(3,5-di-tert-butyl-4-hydroxybenzyl)benzene

InactiveCN101717326AEasy to makeEasy to prepareOrganic chemistryOrganic compound preparationAlkyl transferSuperacid

The invention discloses a method for preparing antioxidant 1,3,5-trimethyl-2,4,6-tri(3,5-di-tert-butyl-4-hydroxybenzyl)benzene by using solid superacid as catalyst, wherein 1,3,5-trihalo methyl-2,4,6-trimethyl benzene and 2,6-do-tert-butylphenol, as raw materials, are subject to alkylation in inert solvent under the action of solid superacid-type catalyst SO42- / MXOY, so as to prepare target products. The method simplifies operating process, achieves mild reaction conditions, has the characteristics of easy separation of products, good reusability of the catalyst, small environmental pollutionand the like, and is suitable for industrial production.

Owner:BOHAI UNIV

Production method of solid superacid catalyst so42-/sb-sno2

InactiveCN102294252ALow reaction temperatureReduce production investment costsFatty-oils/fats refiningCatalyst activation/preparationAcid valueReaction temperature

The invention discloses a production method of a solid super acidic catalyst S04<2-> / Sb-SnO2, which comprises the following steps: (1) preparing Fe3O4 magnetic nanoparticles; (2) preparing an Sb-SnO2 colloid; (3) preparing Fe3O4 / Sb-SnO2 covering powder; and (4) preparing a magnetic solid super acidic catalyst S04<2-> / Sb-SnO2. In the invention, antimony doped tin oxide is used for preparing the magnetic solid super acidic catalyst S04<2-> / Sb-SnO2, a Hammett tracer method is used for carrying out acid strength characterization on solid super acid, the acid strength H0 is less than -13.8, and issuper acid. The magnetic super solid acidic catalyst S04<2-> / Sb-SnO2 disclosed by the invention can be applied in high-acid-value rice bran oil pre-esterification deacidification, so that the original reaction temperature can be reduced to 70 DEG C from more than 200 DEG C before non-strong super acidification, the esterification efficiency can reach over 90%, and the production investment and the management cost can be effectively reduced.

Owner:QIANXINAN HENGLI NEW ENERGY TECH

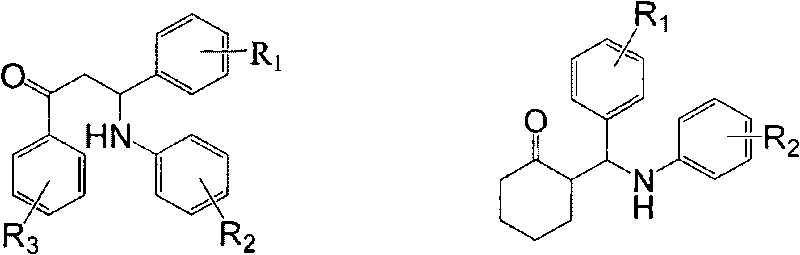

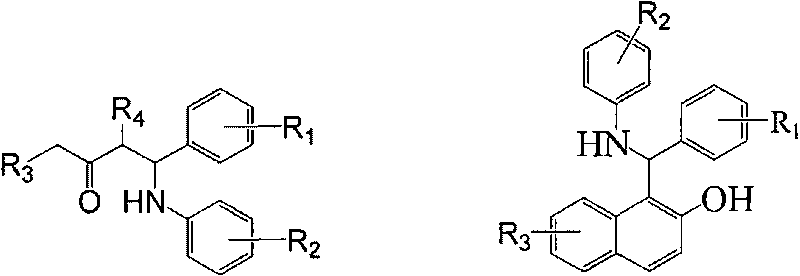

Preparing method of mannich base

InactiveCN101717320ALow costImprove securityOrganic compound preparationAmino group formation/introductionRoom temperatureKetone

The invention provides a preparing method of mannich base. The method takes three components of aldehyde, amine, ketone or naphthol as a raw material, takes water as a solvent, and takes liquid superacid as a catalyst, the raw material, the solvent and the catalyst are reacted at normal pressure and room temperature, and then recrystallized and dried to obtain the product of mannich base. The method has the advantages of mild condition, convenient operation, environment protection, high efficiency, good selectivity, high productivity and easy realization.

Owner:ANYANG NORMAL UNIV

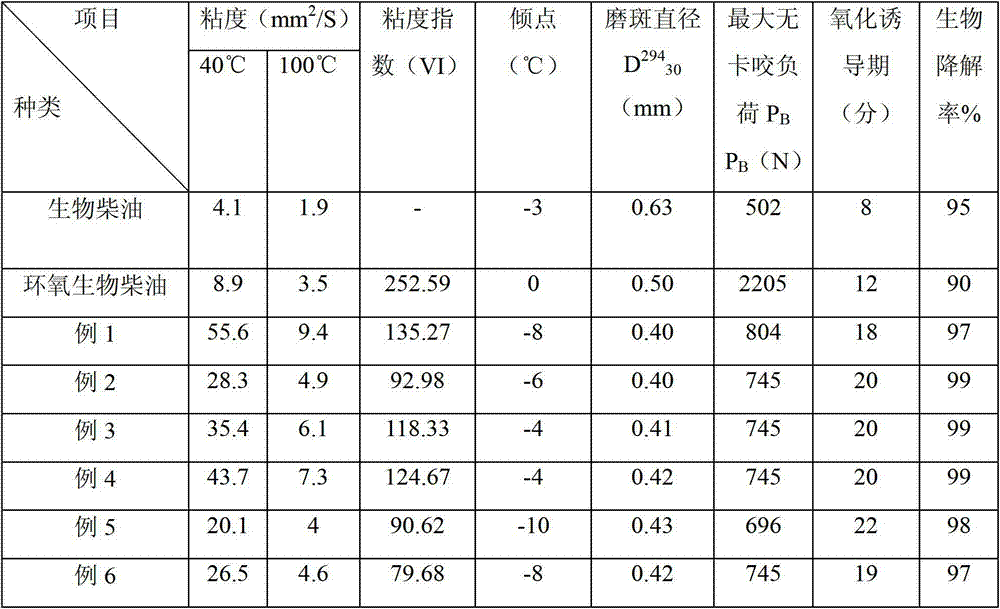

Preparation method of biodegradable lubricating oil

ActiveCN103087797AEmission reductionReduce post-processing difficultyBase-materialsEpoxyIsomerization

The invention belongs to the technical field of a biodiesel modification technology, and particularly relates to a preparation method of alcohol ester type environmentally-friendly lubricant base oil. The method comprises the following steps of: under an ultrasonic-assistedcondition, carrying out chemical modification to epoxy biodiesel (epoxy fatty acid methyl ester) serving as a raw material by solid superacid catalytic isomerization, and opening an unstable epoxy bond in the epoxy biodiesel with fatty acid by adopting an esterification method to form a hydroxy-containing modified biodiesel monoester with a heterogeneous shape. The solid superacid has the characteristics of high catalytic efficiency, good stability, easiness in separation, environment friendliness and the like, and the adoption of ultrasonic reinforcement can greatly shorten the reaction time and reduce the reaction temperature.

Owner:SHANDONG XINGQIANG CHEM IND TECH RES INST CO LTD

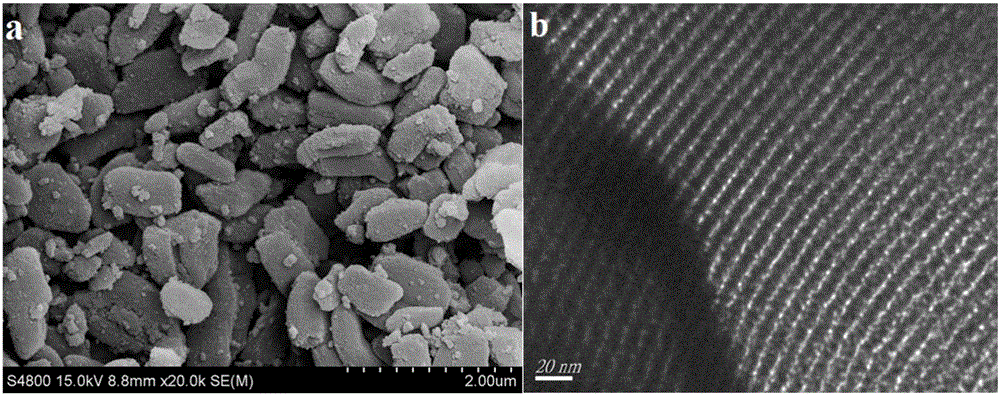

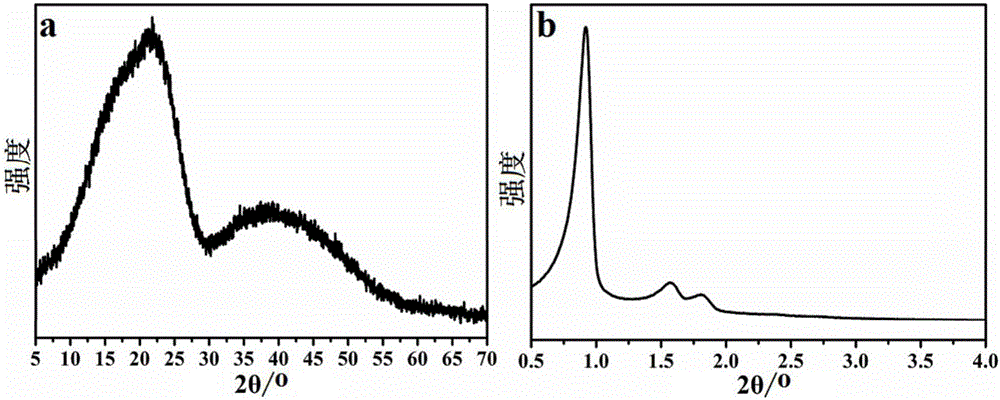

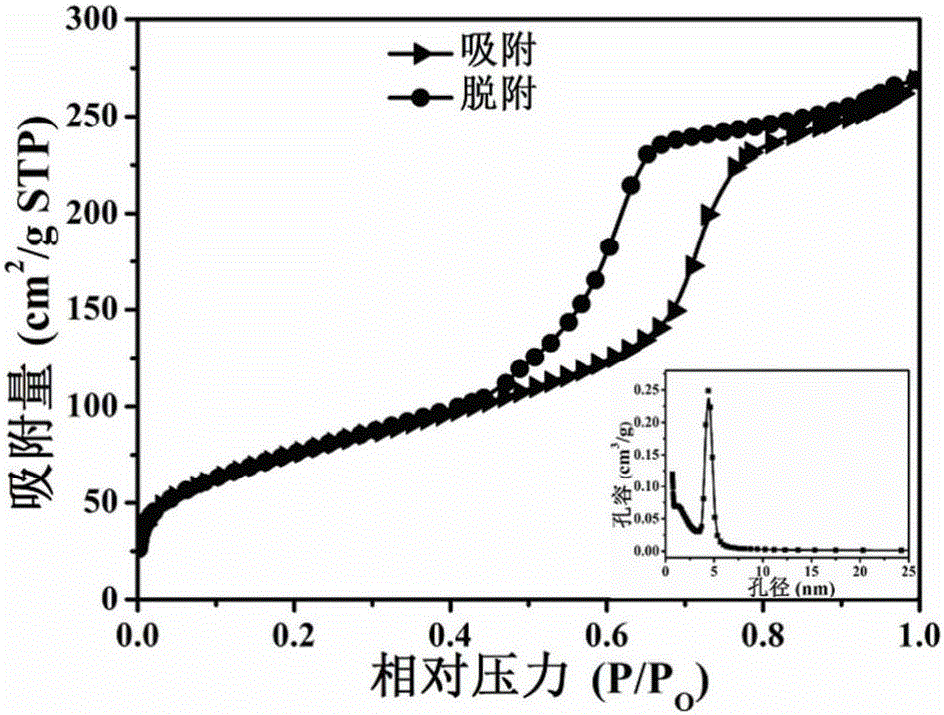

Acid-base bifunctional solid catalyst and preparation method thereof

InactiveCN106311345AHigh specific surface areaImprove thermal stabilityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsMolecular sieveCellulose

The invention belongs to the field of heterogeneous catalysts, and particularly provides an acid-base bifunctional solid catalyst and a preparation method thereof. The method comprises the steps that a silica-based mesoporous molecular sieve SBA-15 is selected as a carrier, ZrO2 / SO4<2-> type solid superacid is loaded, obtained solid superacid is subsequently grafted with an acidic -SO3H group and a basic -NH2 group through a silane coupling reaction, and the acid-base bifunctional solid catalyst is obtained. The defects that in the reaction field of preparing 5-hydroxymethylfurfural (5-HMF) from cellulose, the activity is not high, and the selectivity is poor are overcome, and the preparation method of the acid-base bifunctional heterogeneous solid catalyst with a large specific surface area is provided.

Owner:JIANGSU UNIV

Method for catalytic production of trimethylolpropane oleate by using solid superacid and application of method

InactiveCN102010332AIncrease productivitySolve complexityOrganic compound preparationCarboxylic acid esters preparationFiltrationTrimethylolpropane

The invention relates to a method for catalytic production of trimethylolpropane oleate by using solid superacid and an application of the method. The method comprises the following steps: esterification reaction: mixing trimethylolpropane with oleic acid according to the weight ratio of 1:(2.1-9.5), simultaneously adding the solid superacid, and carrying out reaction under the vacuum degree of 10-1000Pa and the temperature of 120-200 DEG C for 4-10 hours; filtration: using a 10-600 mesh filter mesh or a filter plate to filter reaction products, and removing the solid superacid; and removal of unreacted reactants: heating the reaction products after the filtration to 180-300 DEG C, keeping the vacuum degree of a system at 1-1000Pa, carrying out vacuum distillation for 40-120 minutes, and removing the unreacted reactants to obtain the trimethylolpropane oleate. The method has the advantages of solving the problems of complex product separation, poor product quality, dark color, more side reactions, environmental pollution and the like caused by the use of sulfuric acid during the traditional production processes of the trimethylolpropane and the oleic acid.

Owner:SHENYANG POLYTECHNIC UNIV +1

Method for synthesizing N-methylmorpholine with granular solid superacid as catalyst

InactiveCN101638397AHigh catalytic activityImprove catalytic stabilityOrganic chemistryPhysical/chemical process catalystsDesiccantFixed bed

A method for synthesizing N-methylmorpholine with granular solid superacid as a catalyst comprises the following steps: loading an SO4<2-> / MxOy super acidic catalyst into a fixed bed; heating the fixed bed to the temperature of 260-360 DEG C; pumping nitrogen into the fixed bed to ensure the catalysts under the protection of the nitrogen; introducing N-methyldiethanolamine aqueous solution into the fixed bed; dehydrating the N-methyldiethanolamine aqueous solution in the presence of the catalyst to generate the N-methylmorpholine; collecting mixed gas of the N-methylmorpholine and water, whichis discharged from the discharge hole of the fixed bed and passes through a condensing unit, into a flask, then adding solid NaOH for alkaline separation to separate supernatant; drying the supernatant with NaOH, removing the drying agent and carrying out rectification to collect distillates at a temperature of 104-106 DEG C to obtain the product of N-methylmorpholine. The invention has the effect as follows: the invention is fixed bed catalysis under normal pressure; the catalyst has stability and resistance to carbon deposition, and the method has the advantages of simple catalytic process,high product yield and purity, low cost and the like.

Owner:曲阜市圣泉催化应用科技有限公司

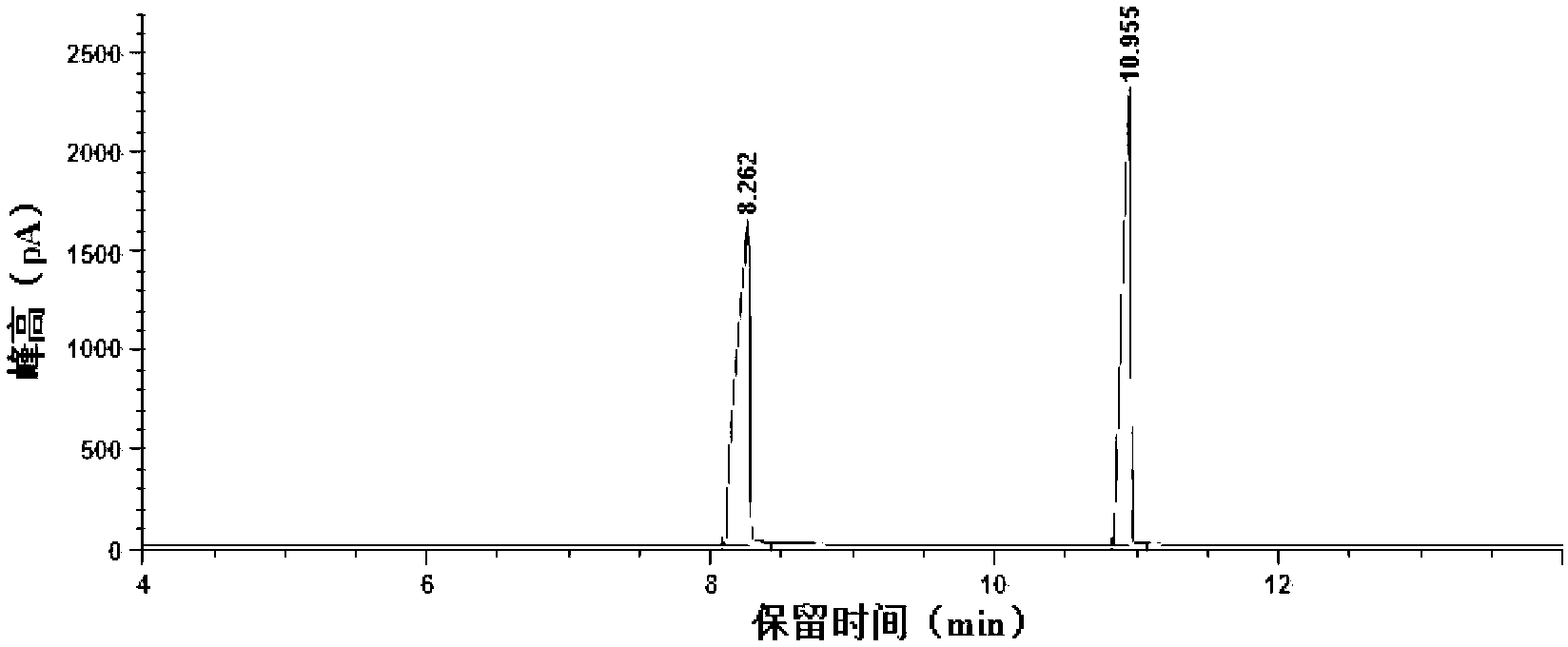

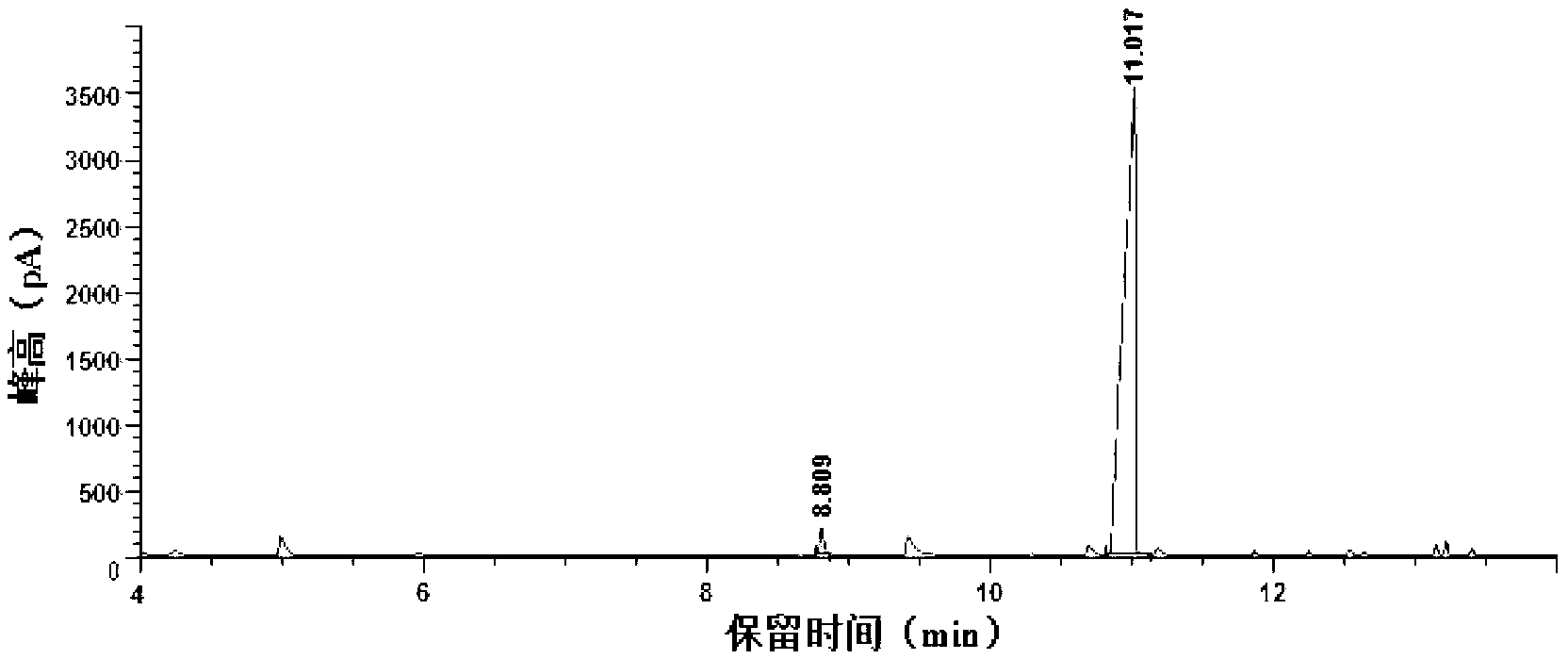

Novel method for preparing 1,1,1,3,5,5,5-heptamethyltrisiloxane by adopting solid superacid

InactiveCN104004010ARich varietyExcellent categorySilicon organic compoundsPhysical/chemical process catalystsMass ratioReaction temperature

The invention relates to a novel method for preparing 1,1,1,3,5,5,5-heptamethyltrisiloxane by adopting solid superacid. The novel method comprises the following steps that: high-hydrogen-content silicone oil and hexamethyldisiloxane with the mass ratio of (3-10):1 are adopted as raw materials; a kettle type reaction is carried out under the catalytic effect of the solid superacid at a reaction temperature of 50 to 90 DEG C, and the reaction time is 5 to 9 hours; the 1,1,1,3,5,5,5-heptamethyltrisiloxane is prepared; and a product obtained after the reaction is rectified, and the product with the purity higher than 99.3 percent is obtained. The novel method provided by the invention has the advantages that the process is simple and continuous; the reaction conditions are mild; corrosion to equipment is avoided; the harm to environment is little; products can be easily separated; the production cost is low; the industrial continuous production can be realized; the catalytic efficiency of catalysts is high; the cost is reduced; and meanwhile, the product purity is improved.

Owner:JIANGXI BLUESTAR XINGHUO SILICONE CO LTD

Synthesis method for zeolite-coated precious metal particles and application of zelite-coated precious metal particles in light paraffin isomerization

ActiveCN105413742AHigh metal dispersionReduce loadMolecular sieve catalystsHydrocarbon oils refiningAlkaneAir atmosphere

The invention provides a synthesis method for zeolite-coated precious metal particles. The synthesis method comprises the steps that 1, a metal salt solution of platinum-containing soluble salt and / or palladium-containing soluble salt is taken to be mixed with a silicon source and / or an aluminum source, a template agent, a pH value regulating agent and water, gel is obtained through stirring, and dry gel is obtained through drying; 2, crystallization is performed by adopting a dry gel steam assisting method; 3, a product obtained through crystallization is calcined for 5-8 hours in an air atmosphere and then reduced for 2-4 hours in a hydrogen atmosphere. According to the method, by learning from the characteristics of synthesizing Silicate-1-coated precious metal through a steam assisting converting method, a precursor of solid superacid is introduced in the synthesizing process of mordenite and Beta zeolite, synthesis of a zeolite molecular sieve of which pore channels contain precious metal is successfully achieved, and the catalytic property of the catalyst in a light paraffin isomerization reaction is further improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

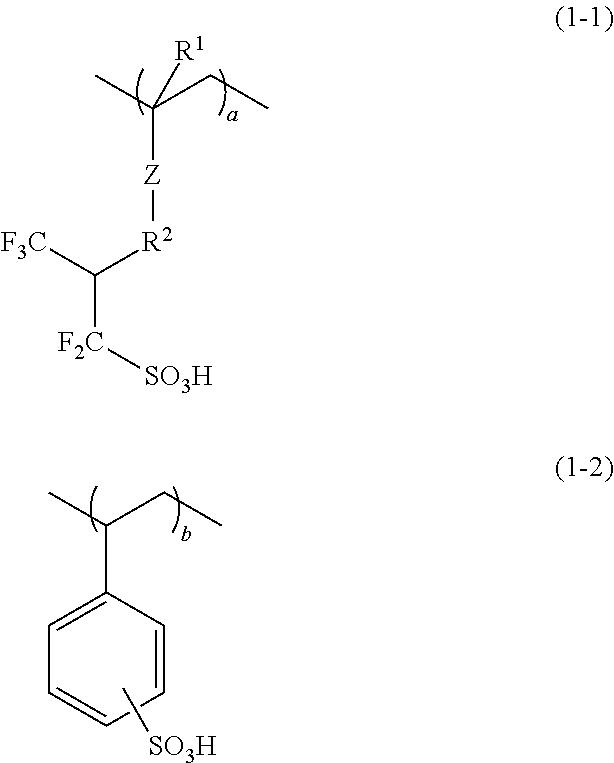

Polymer compound

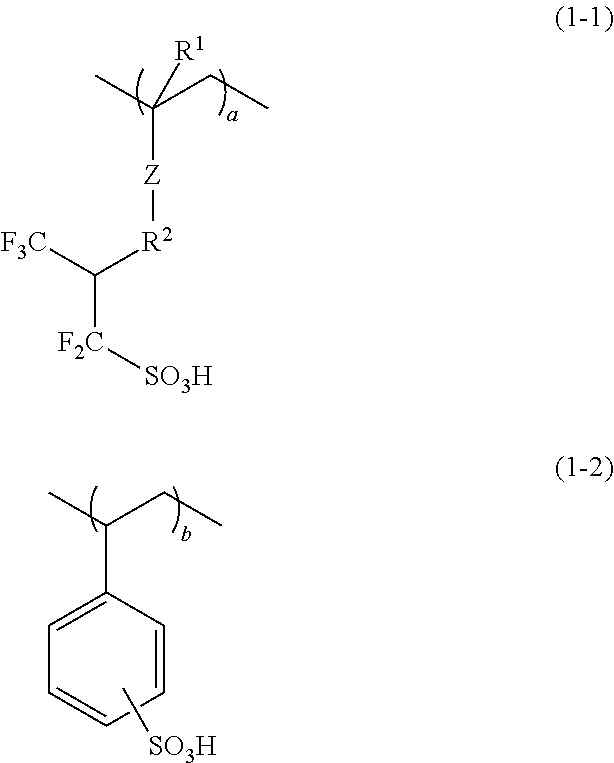

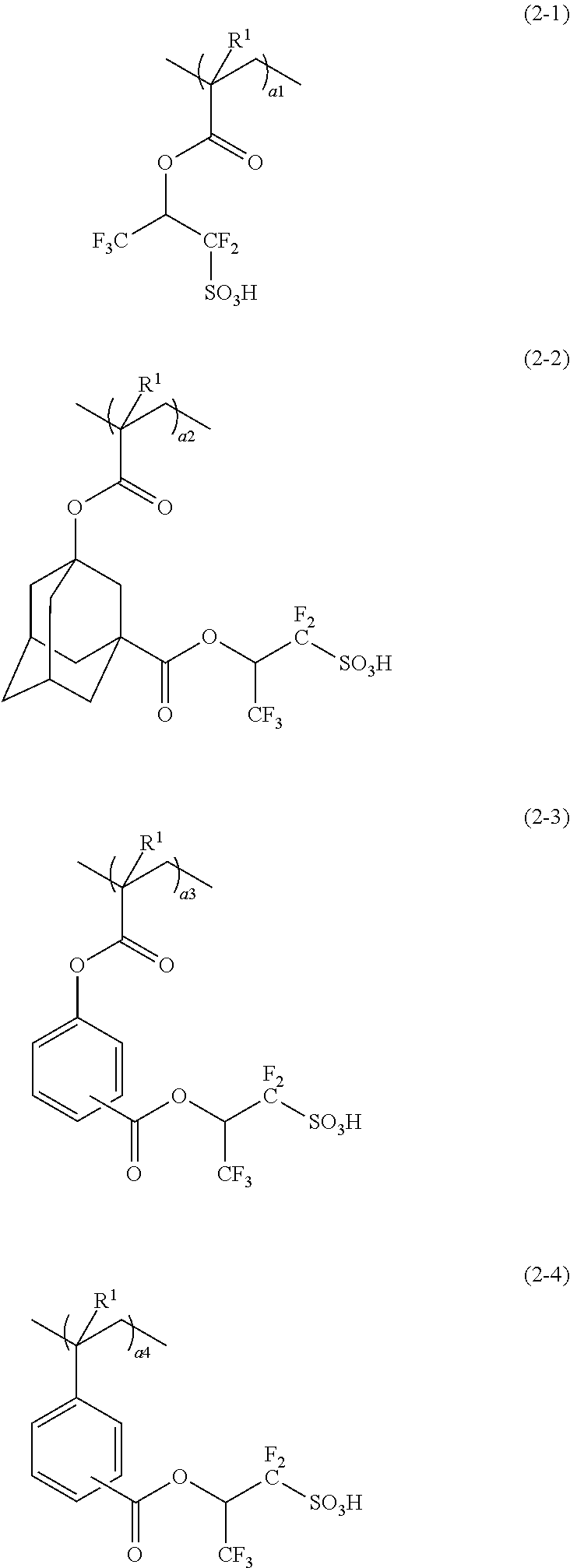

The present invention provides a polymer compound which comprises both repeating unit “a” represented by the following general formula (1-1) and repeating unit “b” represented by the following general formula (1-2), and has a weight average molecular weight in the range of 1,000 to 500,000,wherein R1 represents a hydrogen atom or a methyl group, R2 represents a single bond, an ester group, or a linear, branched, or cyclic hydrocarbon group having 1 to 12 carbon atoms which may have either or both of an ether group and an ester group, Z represents a phenylene group, a naphthylene group, or an ester group, and “a” and “b” satisfy 0<a<1.0 and 0<b<1.0.There can be provided a polymer compound having a specific super strongly acidic sulfo group, which is soluble in an organic solvent, and suitably used for a fuel cell or a dopant for a conductive material.

Owner:SHIN ETSU CHEM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com