Acid-base bifunctional solid catalyst and preparation method thereof

A solid catalyst, acid-base dual function technology, used in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc. The activity needs to be further improved, the yield of 5-HMF is not ideal, etc., to achieve the effect of improving catalytic reaction activity, improving regeneration performance, and enhancing thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Preparation of acid-base bifunctional solid catalyst

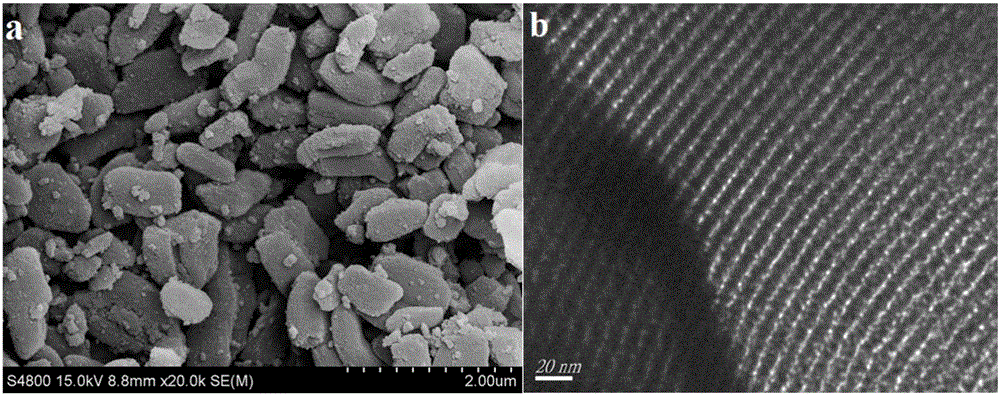

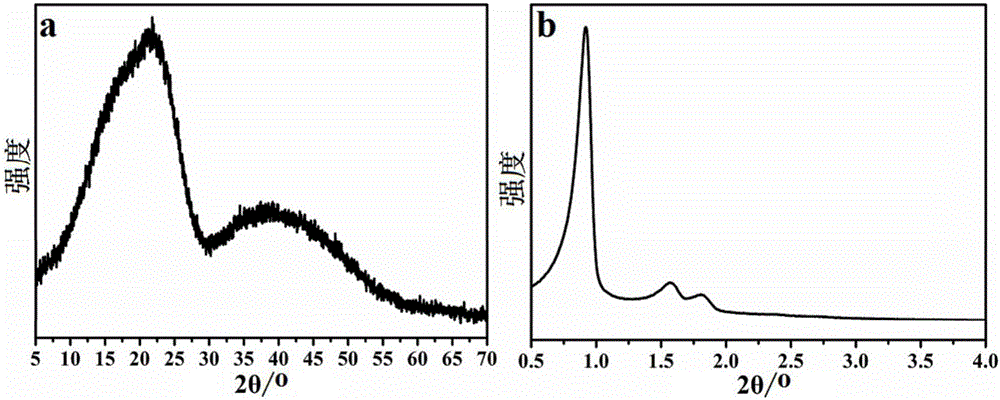

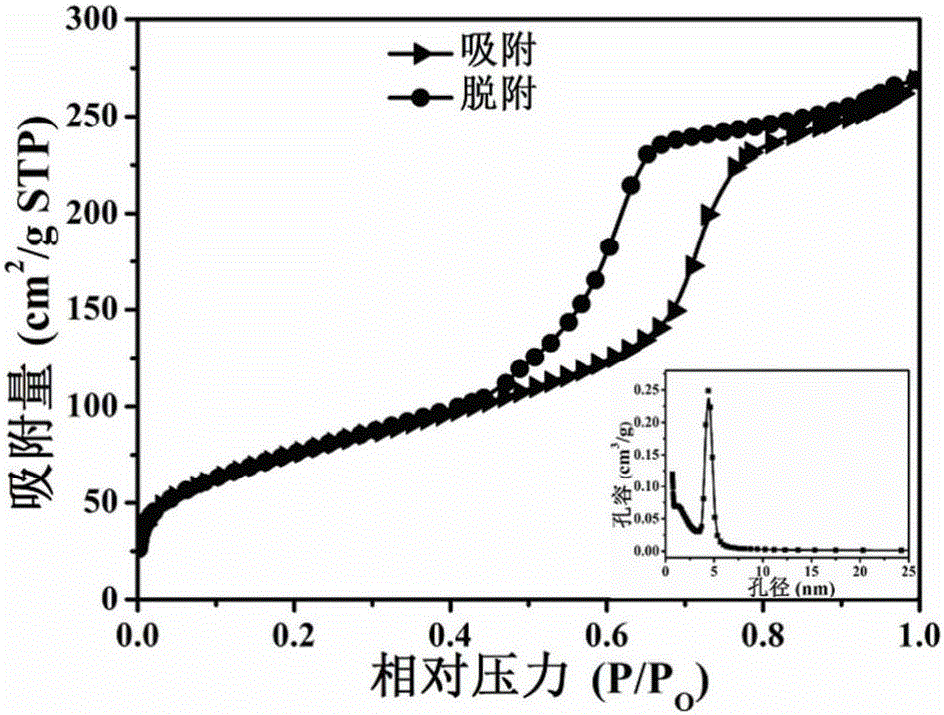

[0035] 0.2 g of dried silicon-based mesoporous molecular sieve SBA-15 was dispersed in 10 mL of n-hexane, and 1.0 g of zirconium n-propoxide was added dropwise to the mixed system under stirring. After the reaction system was hydrolyzed at 50°C for 6h, the resulting product was washed 3-5 times with distilled water, collected by centrifugation and vacuum-dried at 40°C to obtain a single-layer zirconia product (1ML-ZrO 2 @SBA-15).

[0036] 0.2g 1ML-ZrO obtained in the previous step 2 @SBA-15 was redispersed in 10mL of n-hexane, and 0.6g of zirconium n-propoxide was added dropwise to the mixed system under the condition of stirring. After the reaction system was hydrolyzed at 50°C for 6h, the resulting product was washed 3-5 times with distilled water, collected by centrifugation and vacuum-dried at 40°C to obtain a two-layer zirconia product (2ML-ZrO 2 @SBA-15).

[0037] 0.2g of 2ML-ZrO obtained in the previo...

Embodiment 2

[0054] (1) Preparation of acid-base bifunctional solid catalyst

[0055] 5.0 g of dried silicon-based mesoporous molecular sieve SBA-15 was dispersed in 300 mL of n-hexane, and 25 g of zirconium n-propoxide was added dropwise to the mixed system under stirring. After the reaction system was hydrolyzed at 80°C for 30h, the resulting product was washed 3-5 times with distilled water, collected by centrifugation and vacuum-dried at 80°C to obtain a single-layer zirconia product (1ML-ZrO 2 @SBA-15).

[0056] 5.0g 1ML-ZrO obtained in the previous step 2 @SBA-15 was redispersed in 300mL of n-hexane, and 15g of zirconium n-propoxide was added dropwise to the mixed system under stirring conditions. After the reaction system was hydrolyzed at 80°C for 30h, the resulting product was washed 3-5 times with distilled water, collected by centrifugation and vacuum-dried at 80°C to obtain a two-layer zirconia product (2ML-ZrO 2 @SBA-15).

[0057] 1.0g of 2ML-ZrO obtained in the previous s...

Embodiment 3

[0065] (1) Preparation of acid-base bifunctional solid catalyst

[0066] 10 g of dried silicon-based mesoporous molecular sieve SBA-15 was dispersed in 600 mL of n-hexane, and 58.5 g of zirconium n-propoxide was added dropwise to the mixing system under stirring. After the reaction system was hydrolyzed at 120°C for 48h, the resulting product was washed 3-5 times with distilled water, collected by centrifugation and vacuum-dried at 120°C to obtain a single-layer zirconia product (1ML-ZrO 2 @SBA-15).

[0067] 10g of 1ML-ZrO obtained in the previous step 2 @SBA-15 was redispersed in 600mL of n-hexane, and 28.5g of zirconium n-propoxide was added dropwise to the mixed system under the condition of stirring. After the reaction system was hydrolyzed at 120°C for 48h, the resulting product was washed 3-5 times with distilled water, collected by centrifugation and vacuum-dried at 120°C to obtain a SBA-15 loaded two-layer zirconia product (2ML-ZrO 2 @SBA-15).

[0068] 1.8g of 2ML-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com