Patents

Literature

147 results about "Reaction field" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

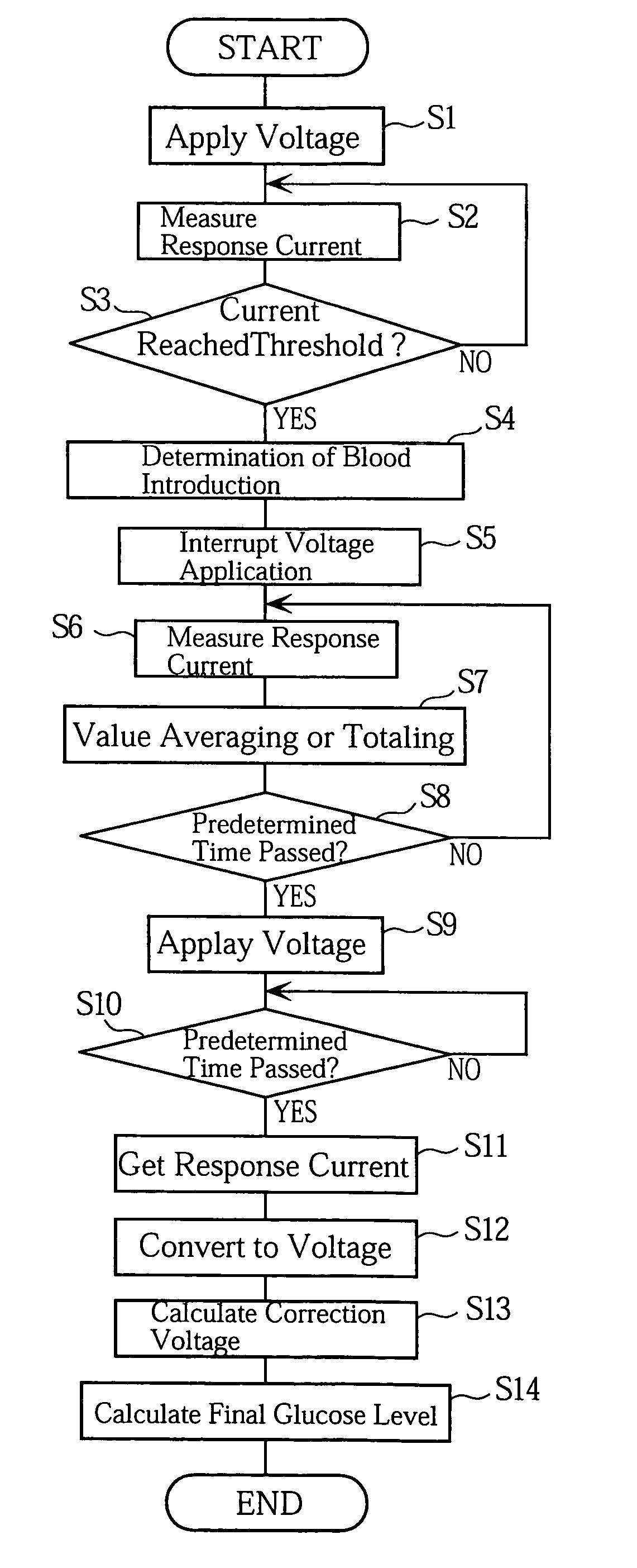

Method and apparatus for measuring specific component

A method for measuring a concentration of a specific component includes the steps of: supplying a sample fluid to a reaction field holding a reagent; obtaining a single or a plurality of leak currents for correction, through a measurement of electric current made once or a plurality of times without applying a voltage to the reaction field; obtaining a single or a plurality of electric currents for calculation, through a measurement of electric current made once or a plurality of times while applying a voltage to the reaction field; and calculating a concentration of a specific component in the sample fluid, based on the single or the plurality of values for correction and the single or the plurality of values for calculation.

Owner:ARKRAY INC

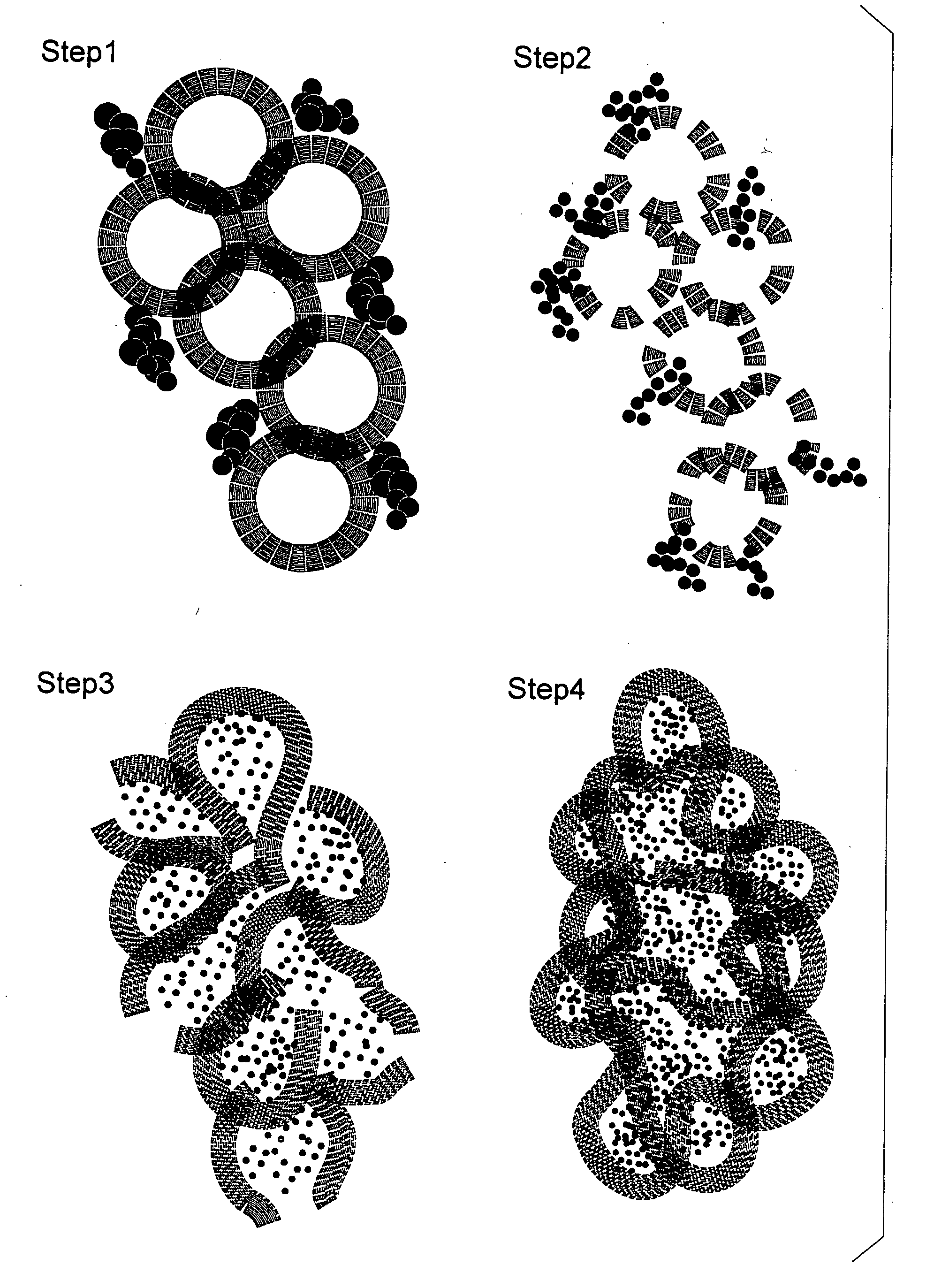

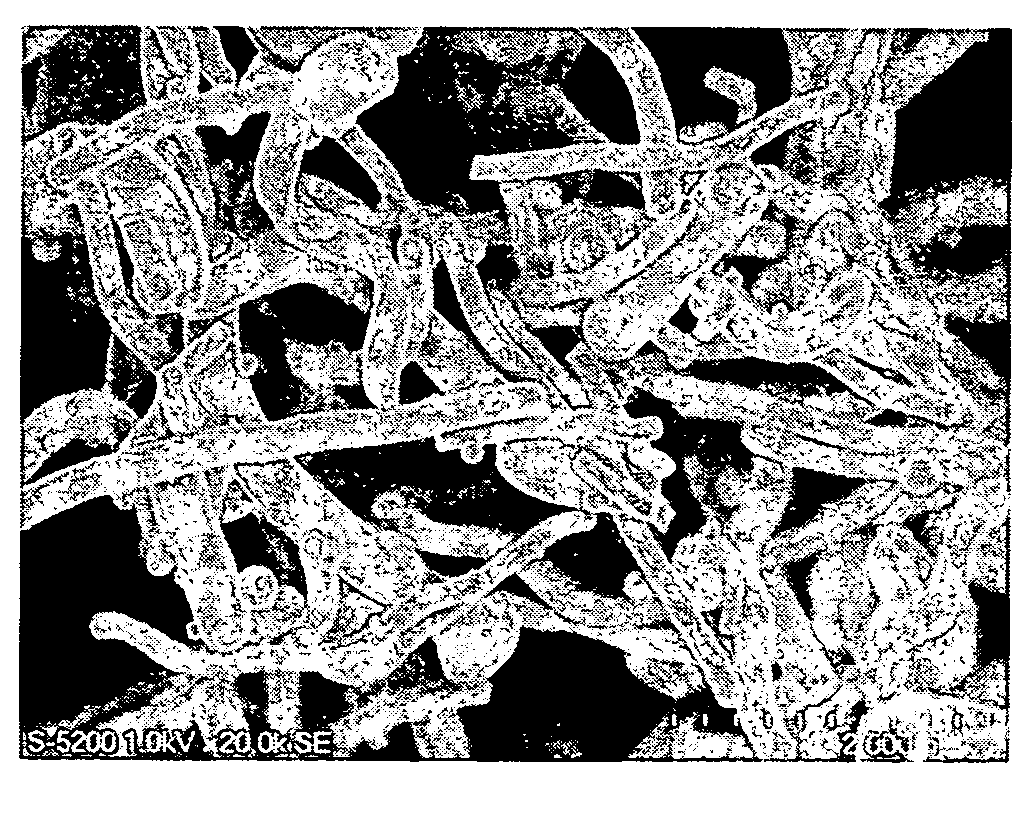

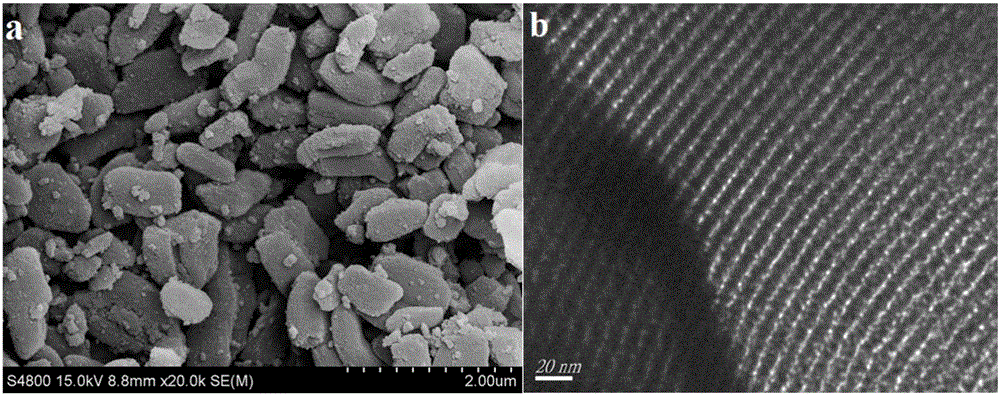

Nanocarbon Composite Structure Having Ruthenium Oxide Trapped Therein

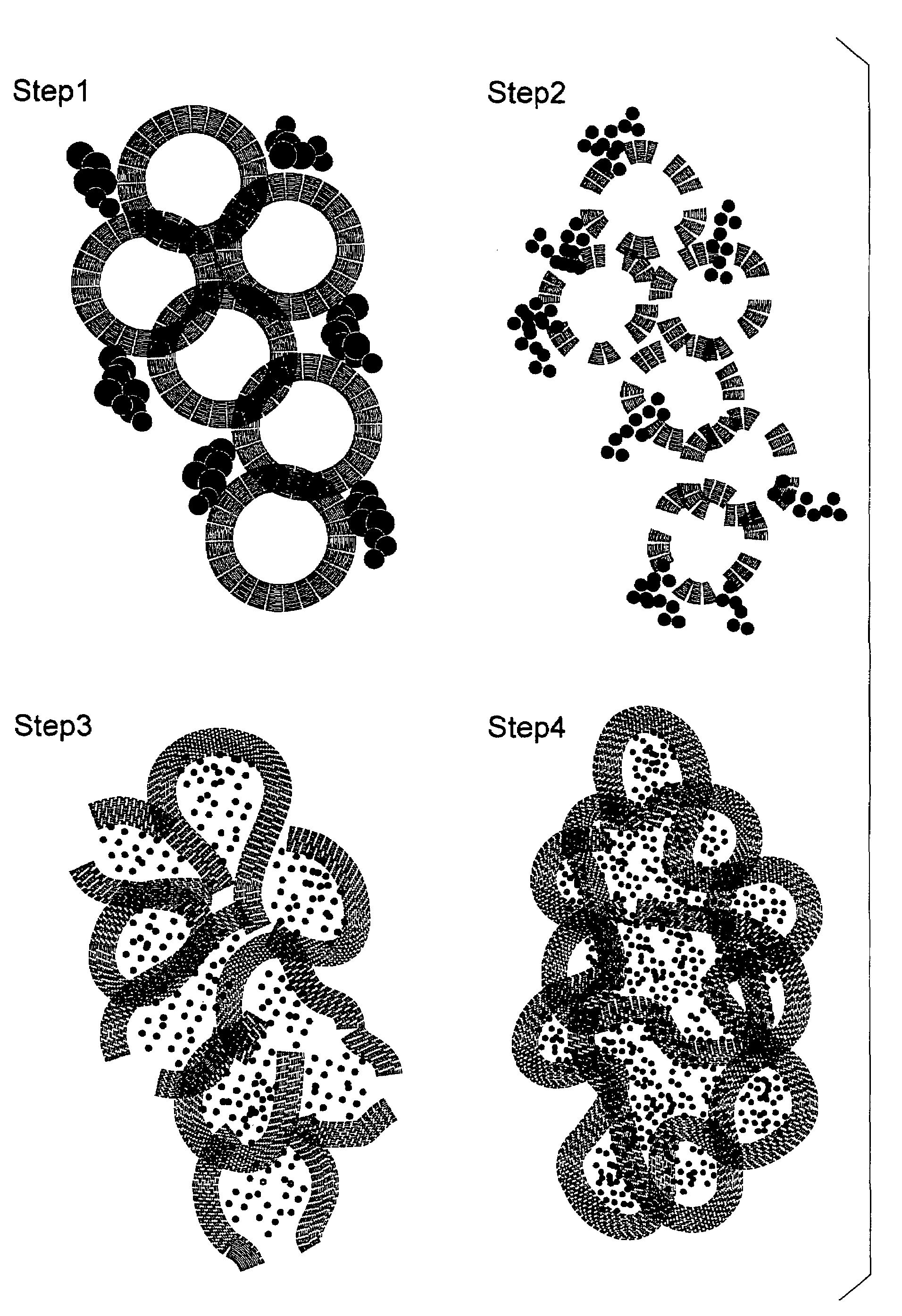

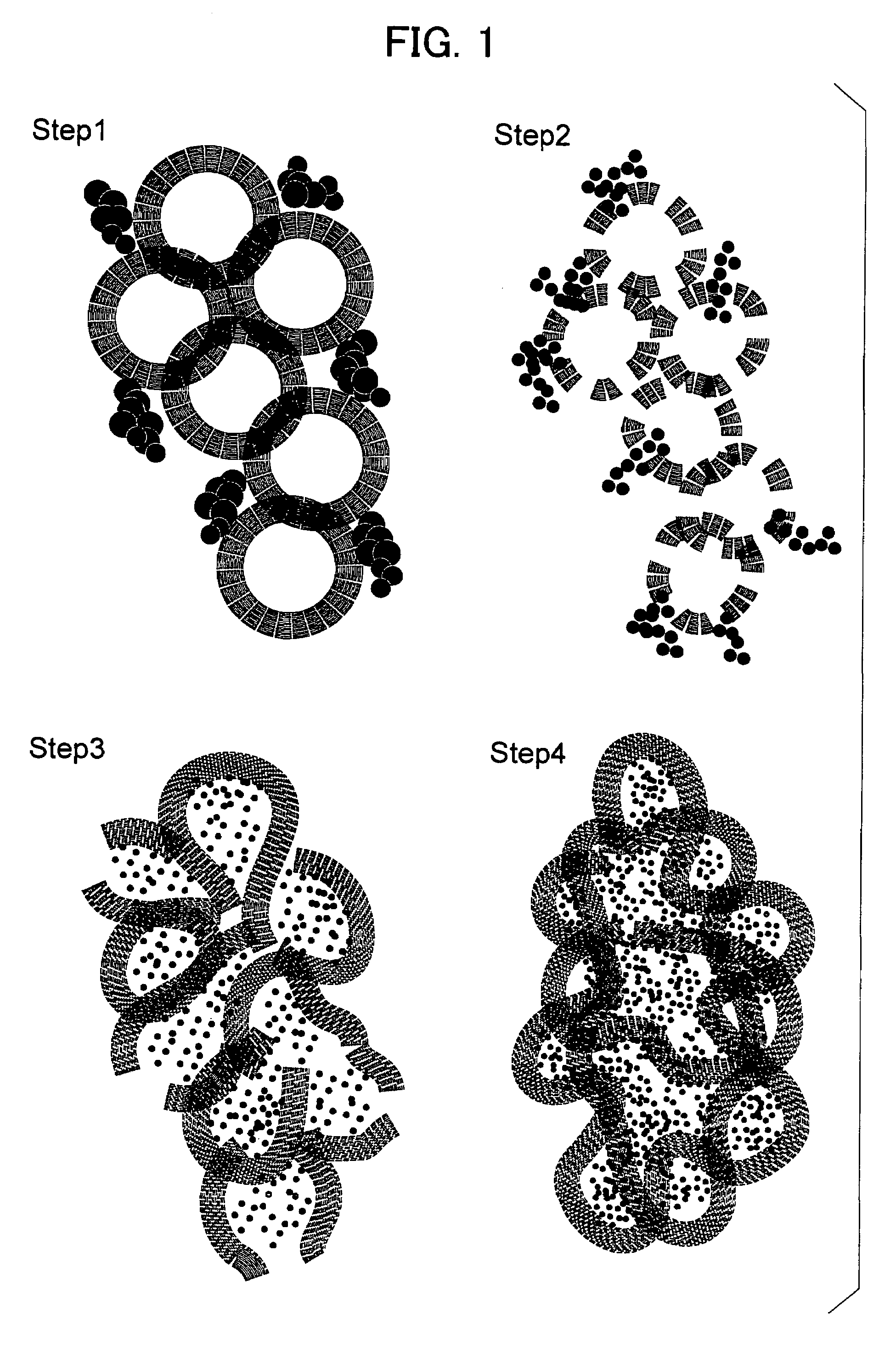

InactiveUS20080048153A1Increase capacitanceImprove electrochemical activityMaterial nanotechnologyCarbon compoundsReaction fieldNanoparticle

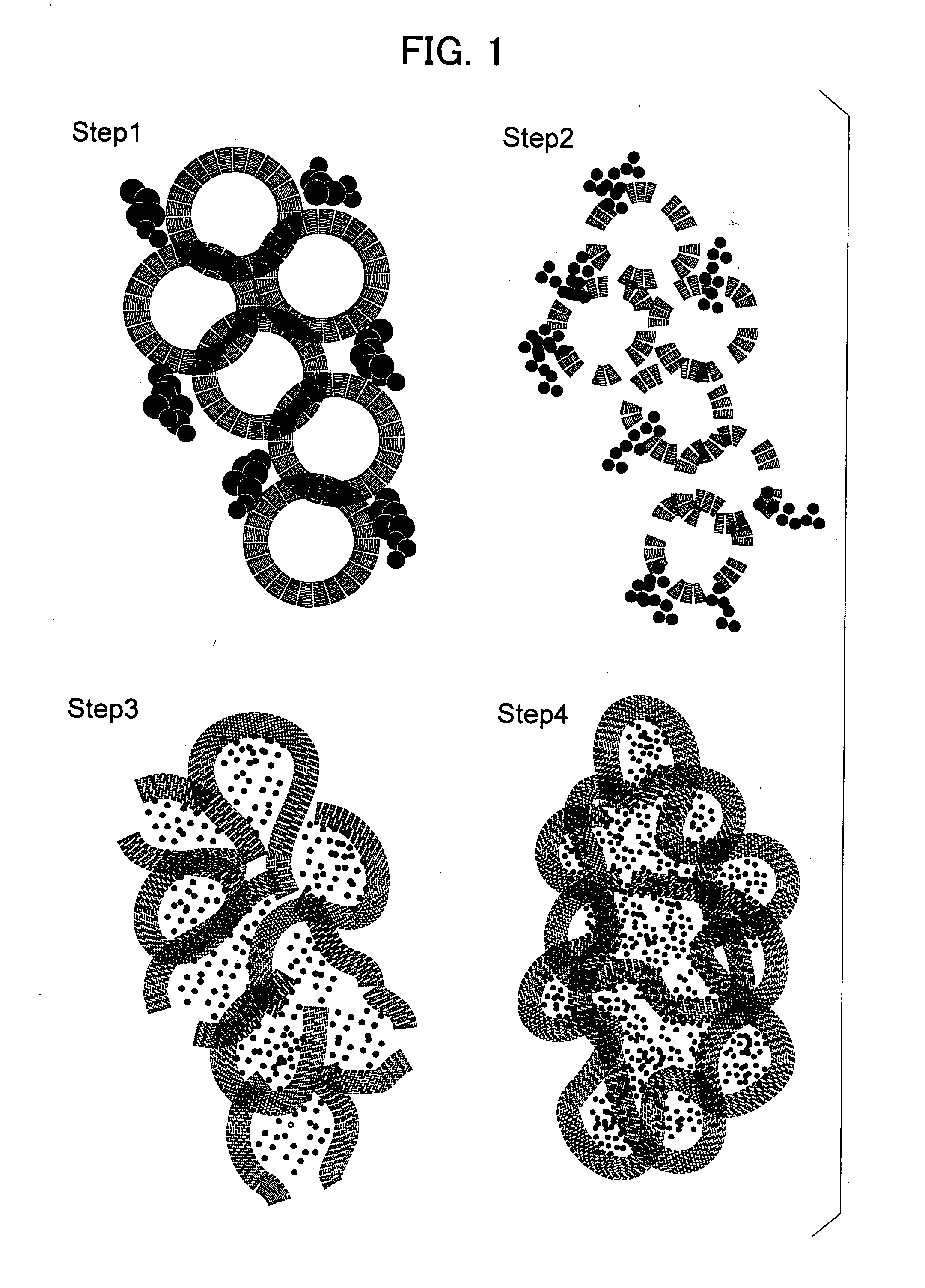

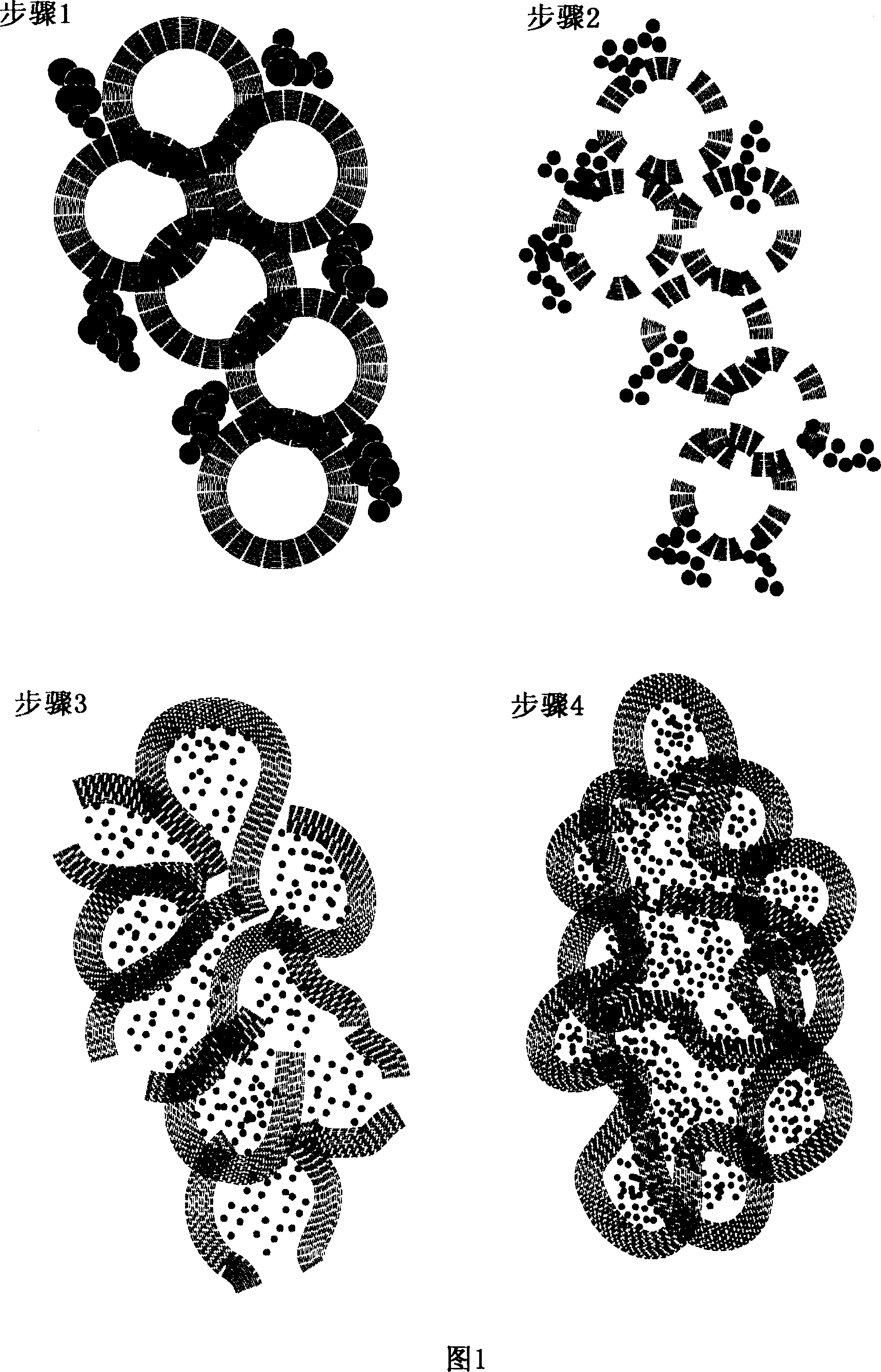

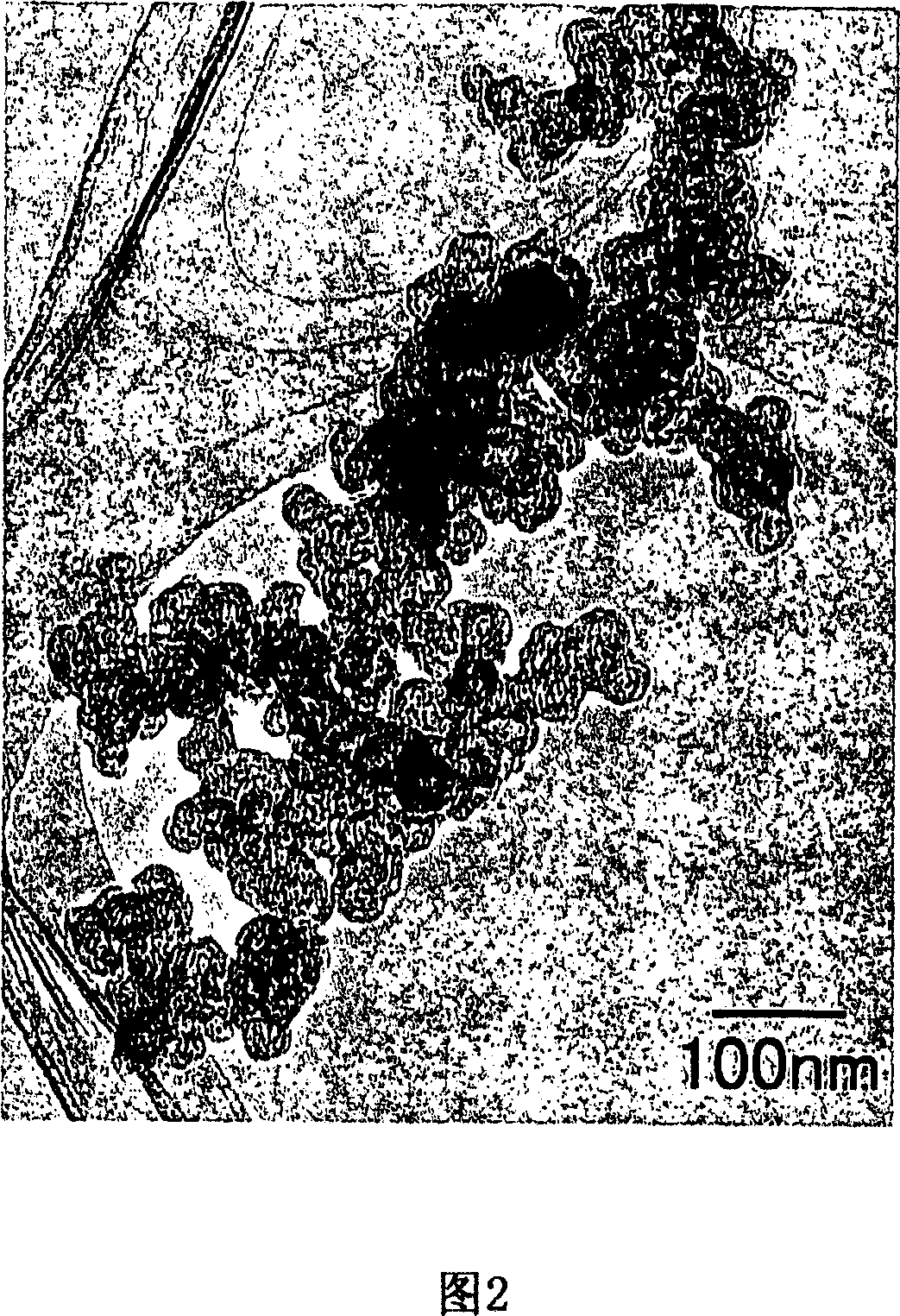

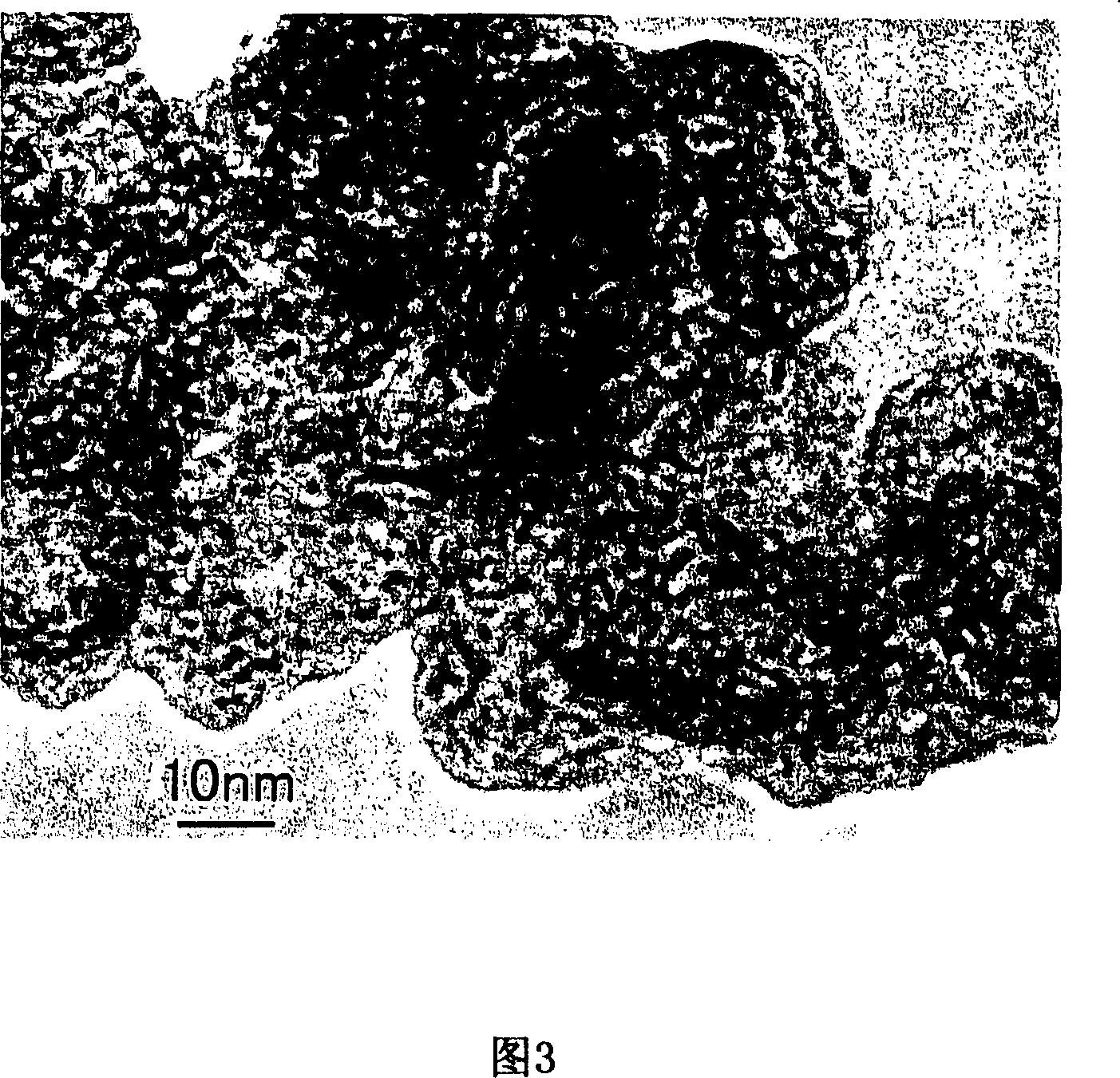

A novel nanocarbon composite structure is provided having trapped ruthenium oxide. By using Ketjen black, and through chemical-mechanical effect utilizing an ultracentrifugal reaction field, both the specific surface area of ruthenium oxide and space of electrode material are expanded to have nanoparticles of ruthenium oxide highly dispersed in a graphene layer. This nanocarbon composite structure having trapped ruthenium oxide exhibits high electrochemical activity and is suitable for use as an electrical energy storing device, such as a large-capacity capacitor.

Owner:NAT UNIV CORP TOKYO UNIV OF AGRI & TECH

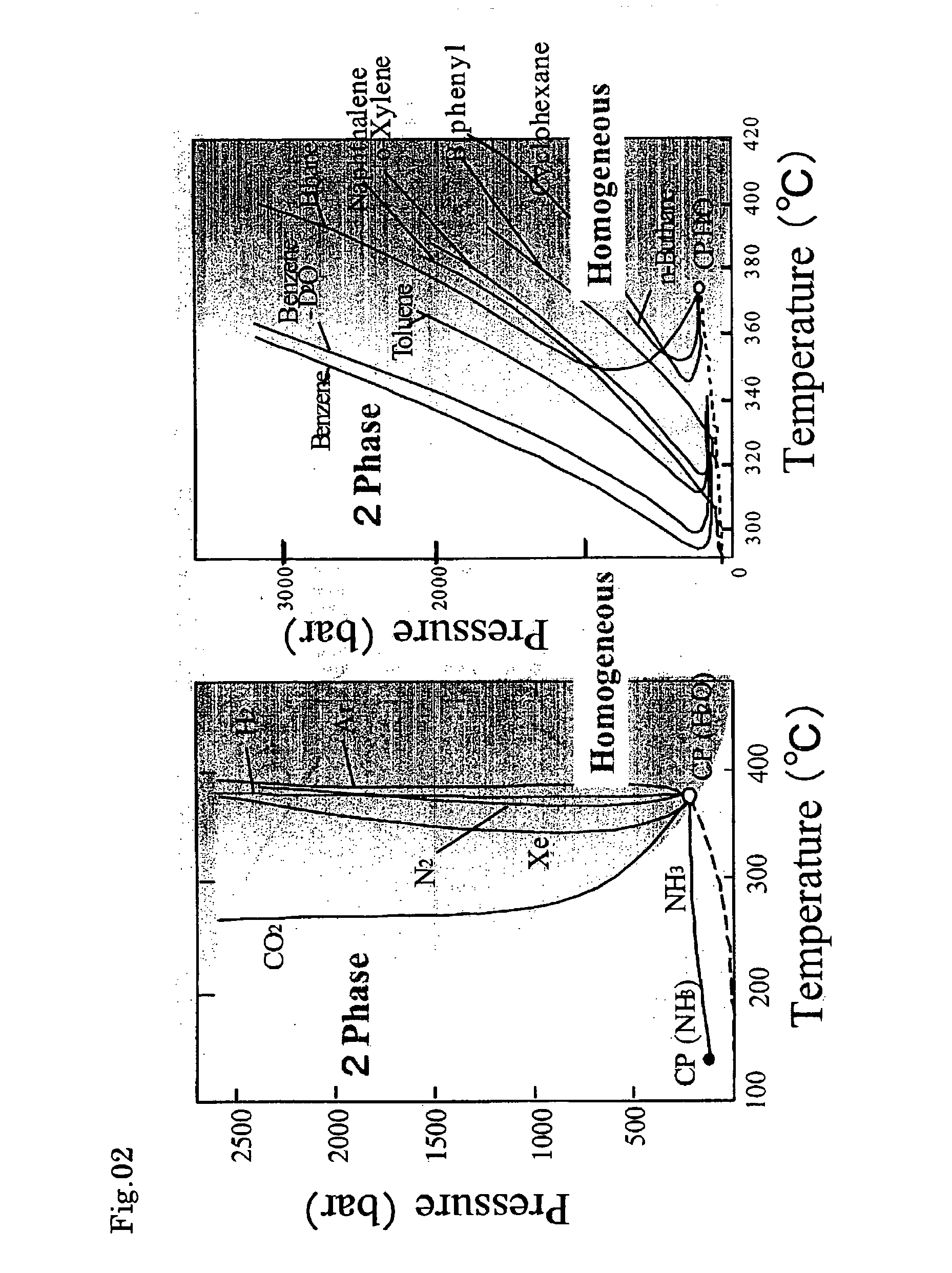

Organically modified fine particles

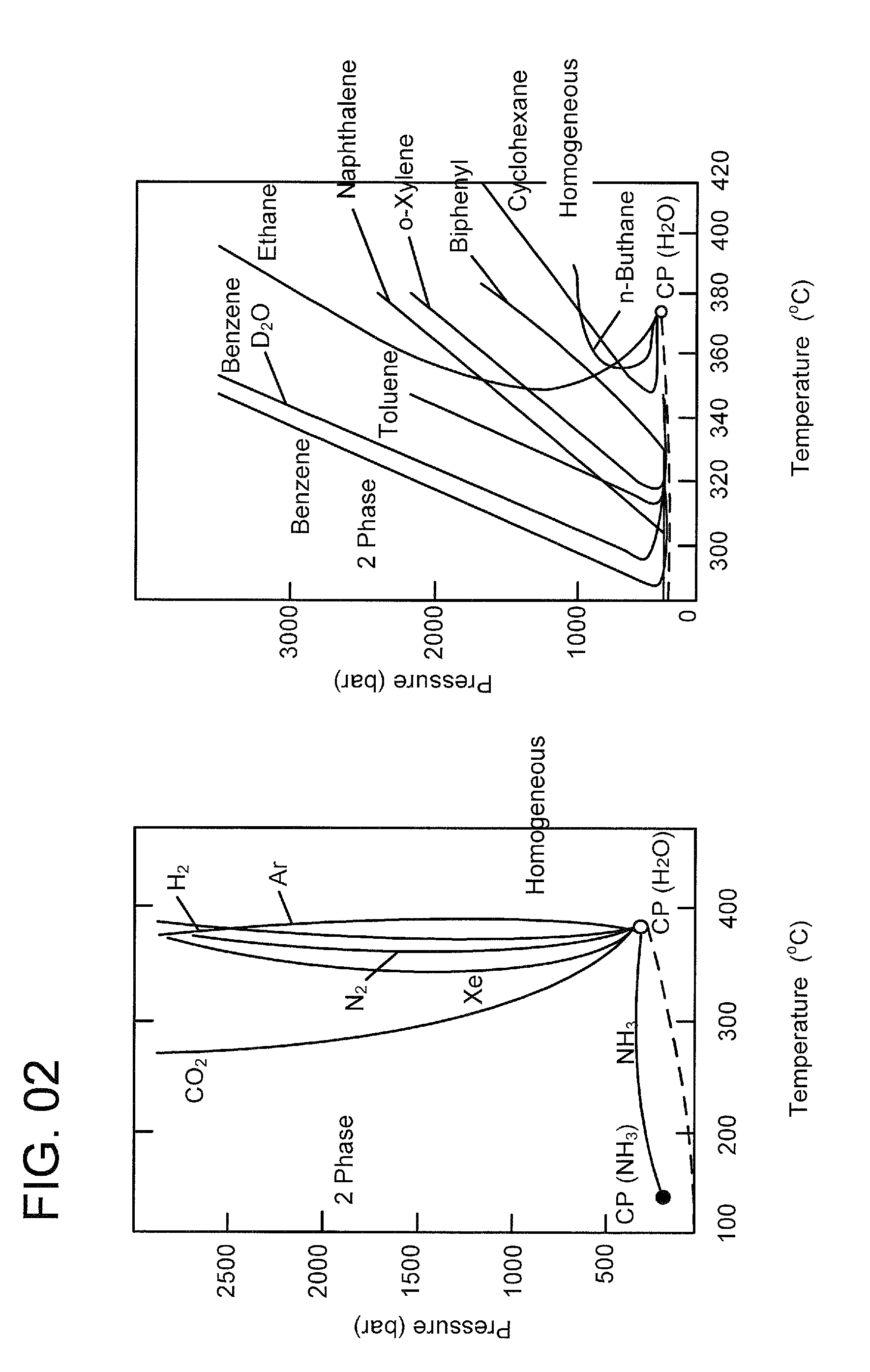

ActiveUS20070003463A1Easy transferManganese oxides/hydroxidesGermanium dioxideReaction fieldNanoparticle

A technique for bonding an organic group with the surface of fine particles such as nanoparticles through strong linkage is provided, whereas such fine particles are attracting attention as materials essential for development of high-tech products because of various unique excellent characteristics and functions thereof. Organically modified metal oxide fine particles can be obtained by adapting high-temperature, high-pressure water as a reaction field to bond an organic matter with the surface of metal oxide fine particles through strong linkage. The use of the same condition enables not only the formation of metal oxide fine particles but also the organic modification of the formed fine particles. The resulting organically modified metal oxide fine particles exhibit excellent properties, characteristics and functions.

Owner:SUPER NANO DESIGN CO LTD

Nanocarbon composite structure having ruthenium oxide trapped therein

InactiveUS7572542B2Increase capacitanceImprove electrochemical activityMaterial nanotechnologyCarbon compoundsReaction fieldNanoparticle

A novel nanocarbon composite structure is provided having trapped ruthenium oxide. By using Ketjen black, and through chemical-mechanical effect utilizing an ultracentrifugal reaction field, both the specific surface area of ruthenium oxide and space of electrode material are expanded to have nanoparticles of ruthenium oxide highly dispersed in a graphene layer. This nanocarbon composite structure having trapped ruthenium oxide exhibits high electrochemical activity and is suitable for use as an electrical energy storing device, such as a large-capacity capacitor.

Owner:NAT UNIV CORP TOKYO UNIV OF AGRI & TECH

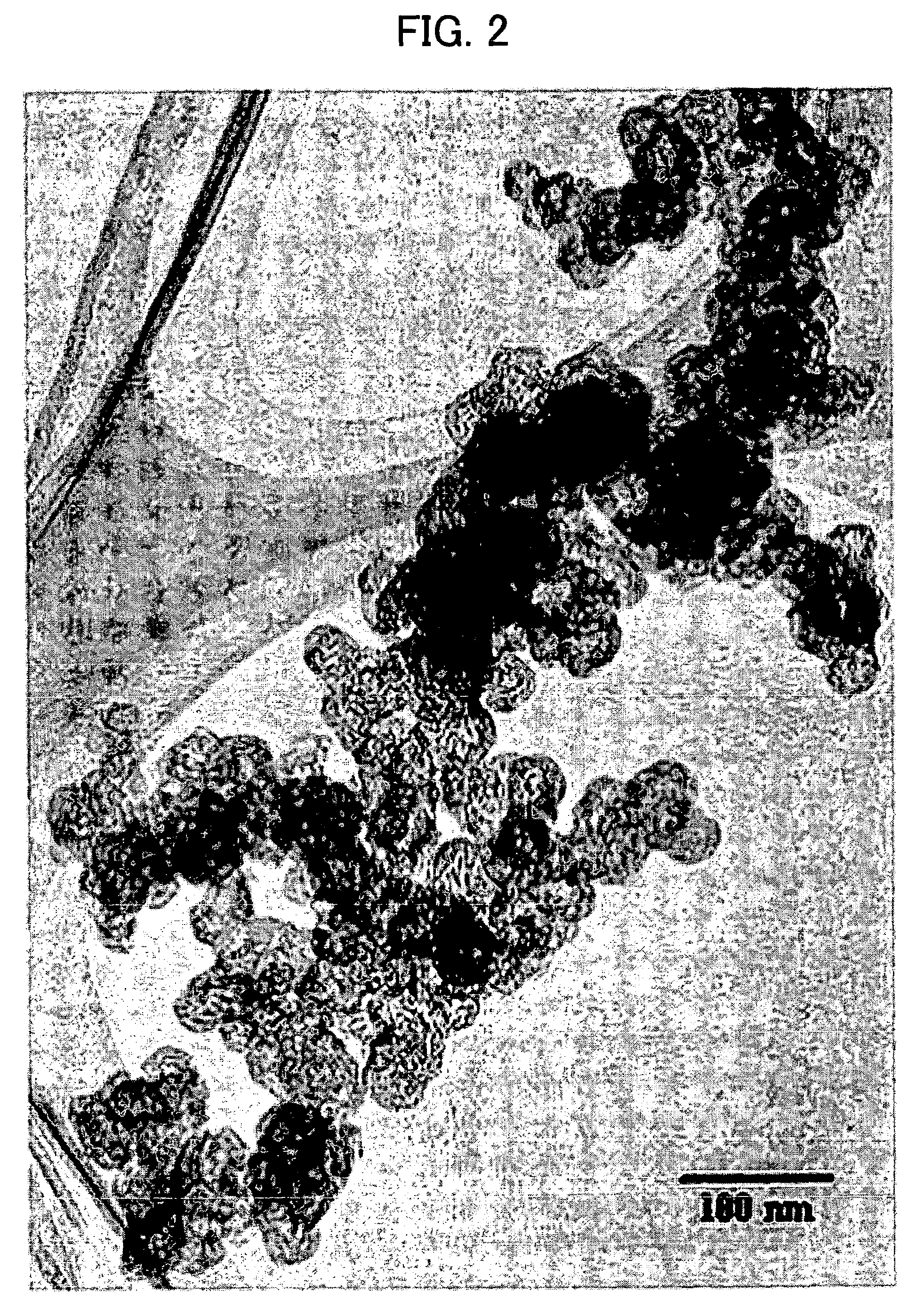

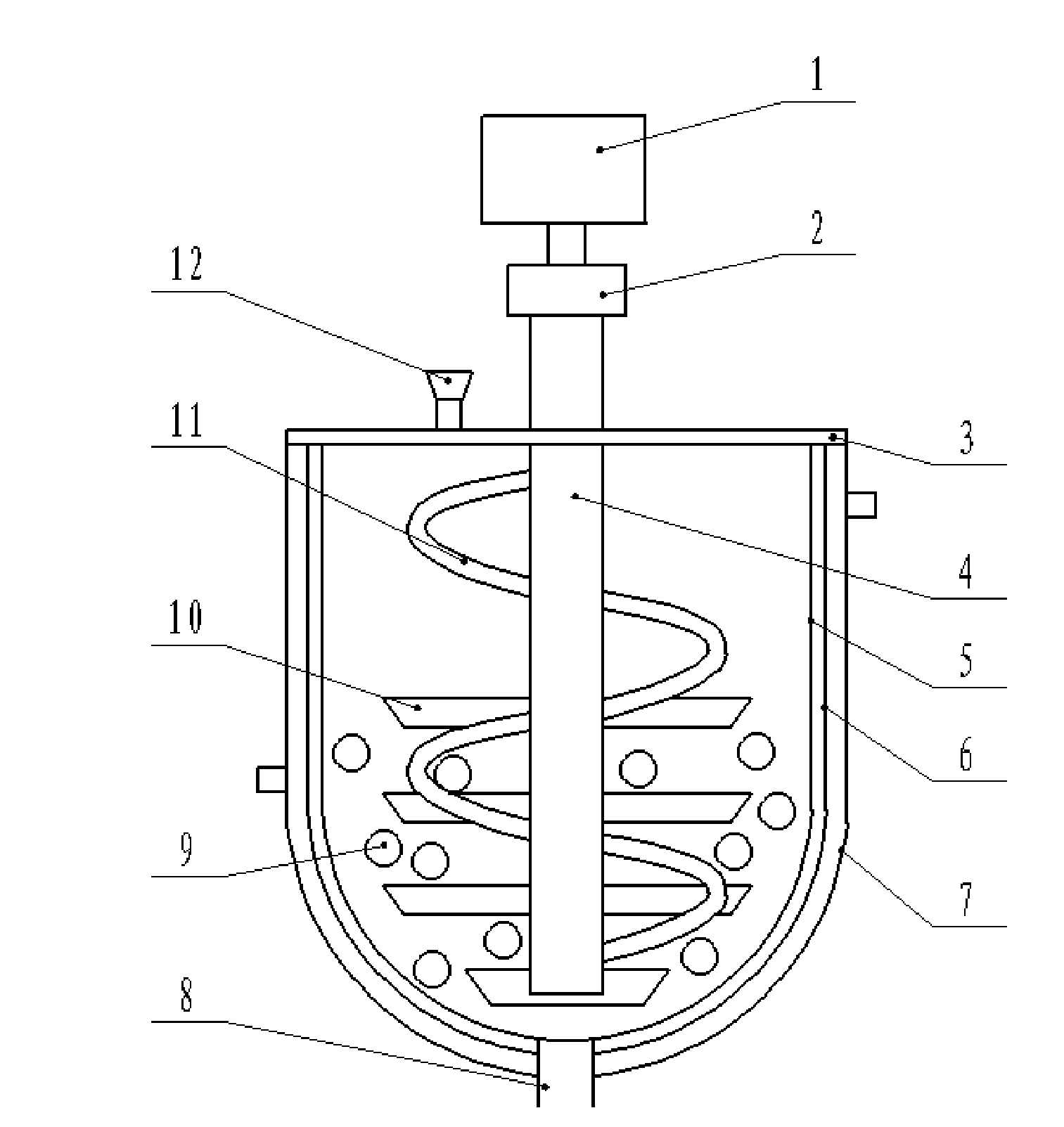

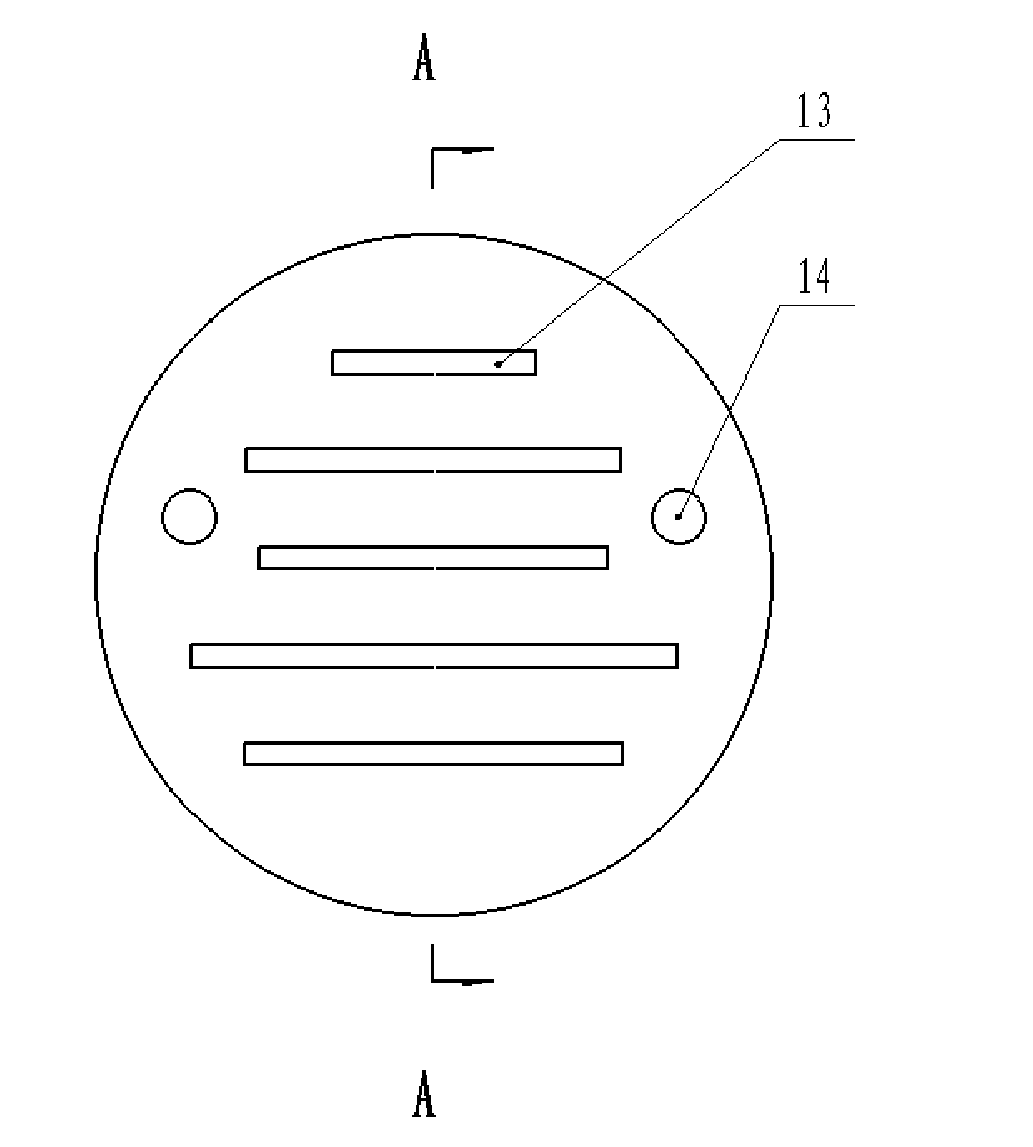

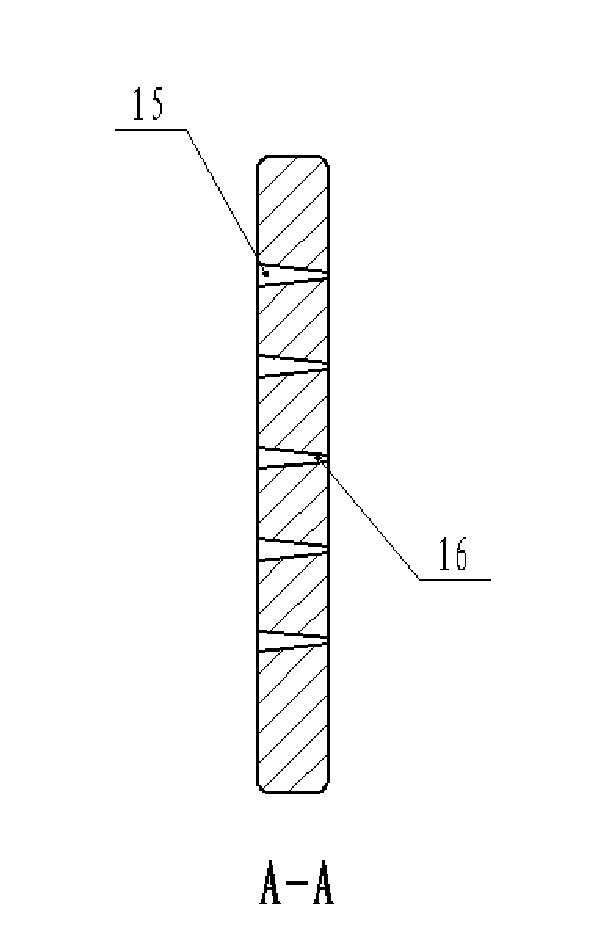

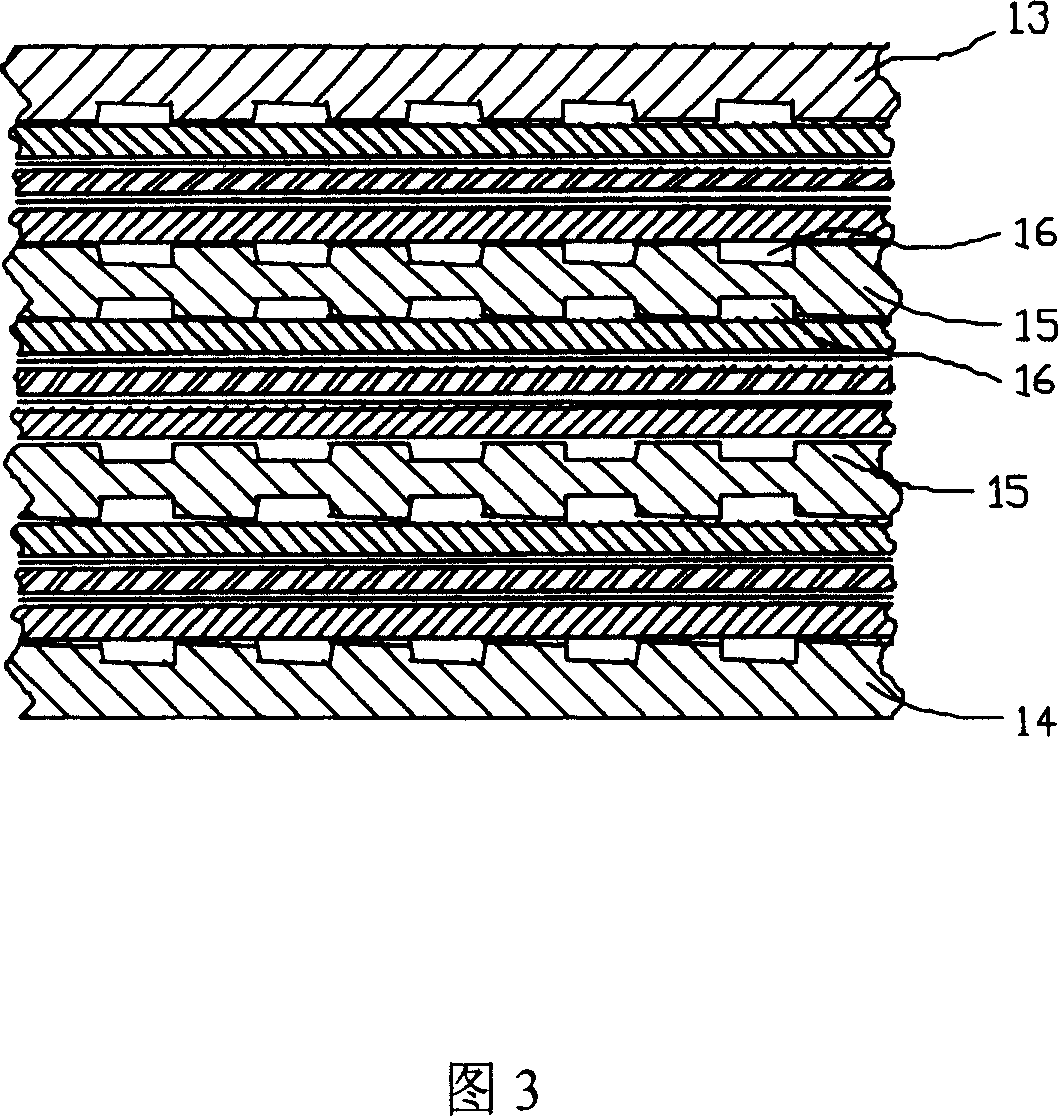

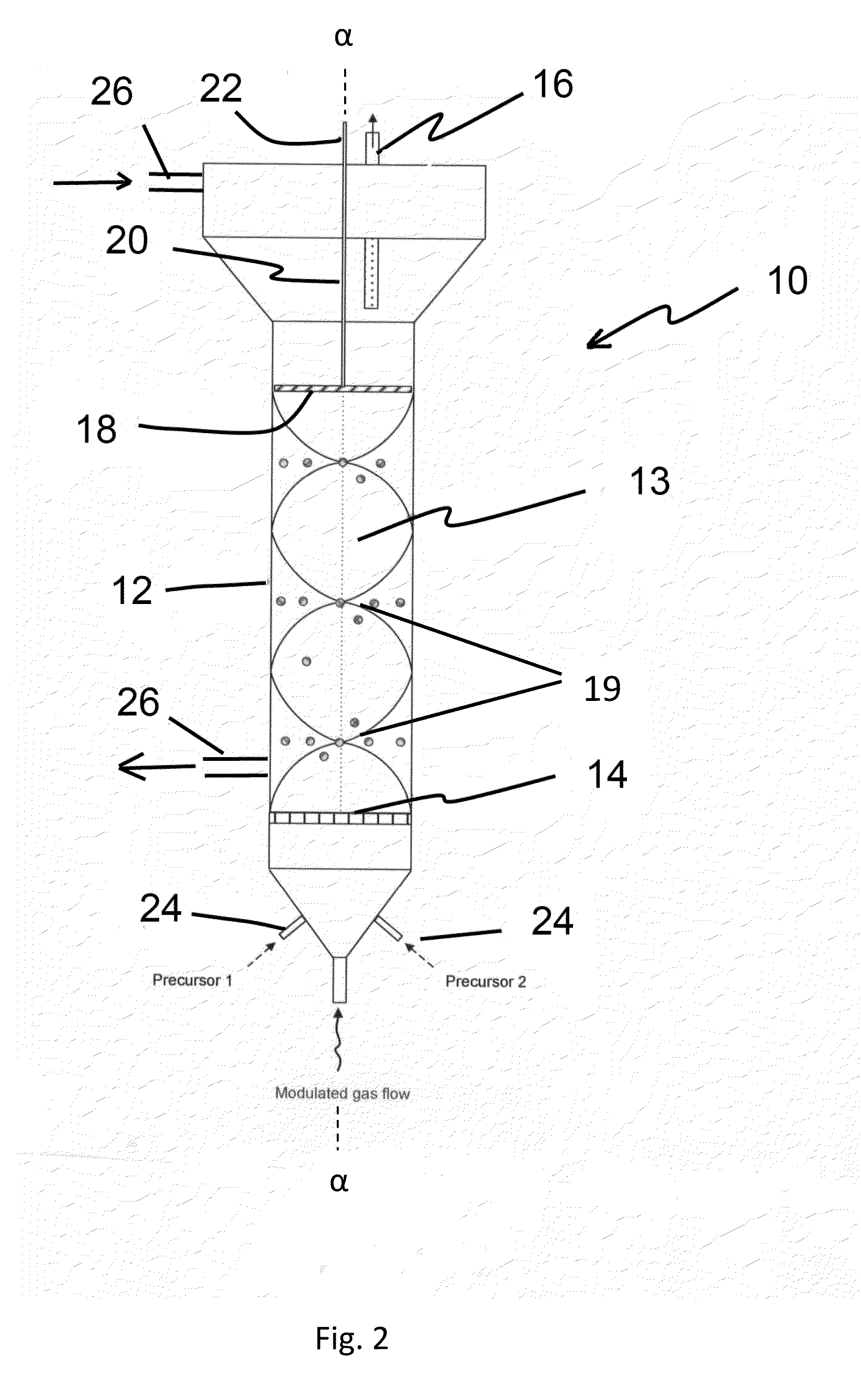

Vertical modified stir ball-milling reactor for reinforcing polysaccharide polymers

ActiveCN102935350AImprove the perturbation effectHigh activityChemical/physical/physico-chemical stationary reactorsGrain treatmentsReaction fieldSpiral blade

The invention relates to a vertical modified stir ball-milling reactor for reinforcing polysaccharide polymers, and a stirring shaft is driven by a drive unit through a coupling. The reactor further comprises a cylinder cover plate, a grinding inner cylinder, a lining plate, a funnel type material feeding port, a material discharging port and grinding balls. A stirring blade set composed of inclined plate blades and an S-shaped spiral blade is mounted on the stirring shaft, the inclined plate blades are mounted on the stirring shaft in parallel, and the S-shaped spiral blade is vertically mounted on the stirring shaft; and a plurality of through holes for grinding balls in the grinding inner cylinder to pass through are arranged on the inclined plate blades. According to the reactor, the stirring blade set is added, so that materials can be mixed evenly, and accordingly, the production efficiency is improved. Simultaneously, the stirring shaft and the S-shaped spiral blade are manufactured into hollow structures, and fed cooling substances are helpful for keeping the temperature to be uniform and the constant-temperature reaction field; and the bottom of grinding inner cylinder is hemispherical, so that grinding dead angles are avoided.

Owner:广西防城港五星环保科技股份有限公司

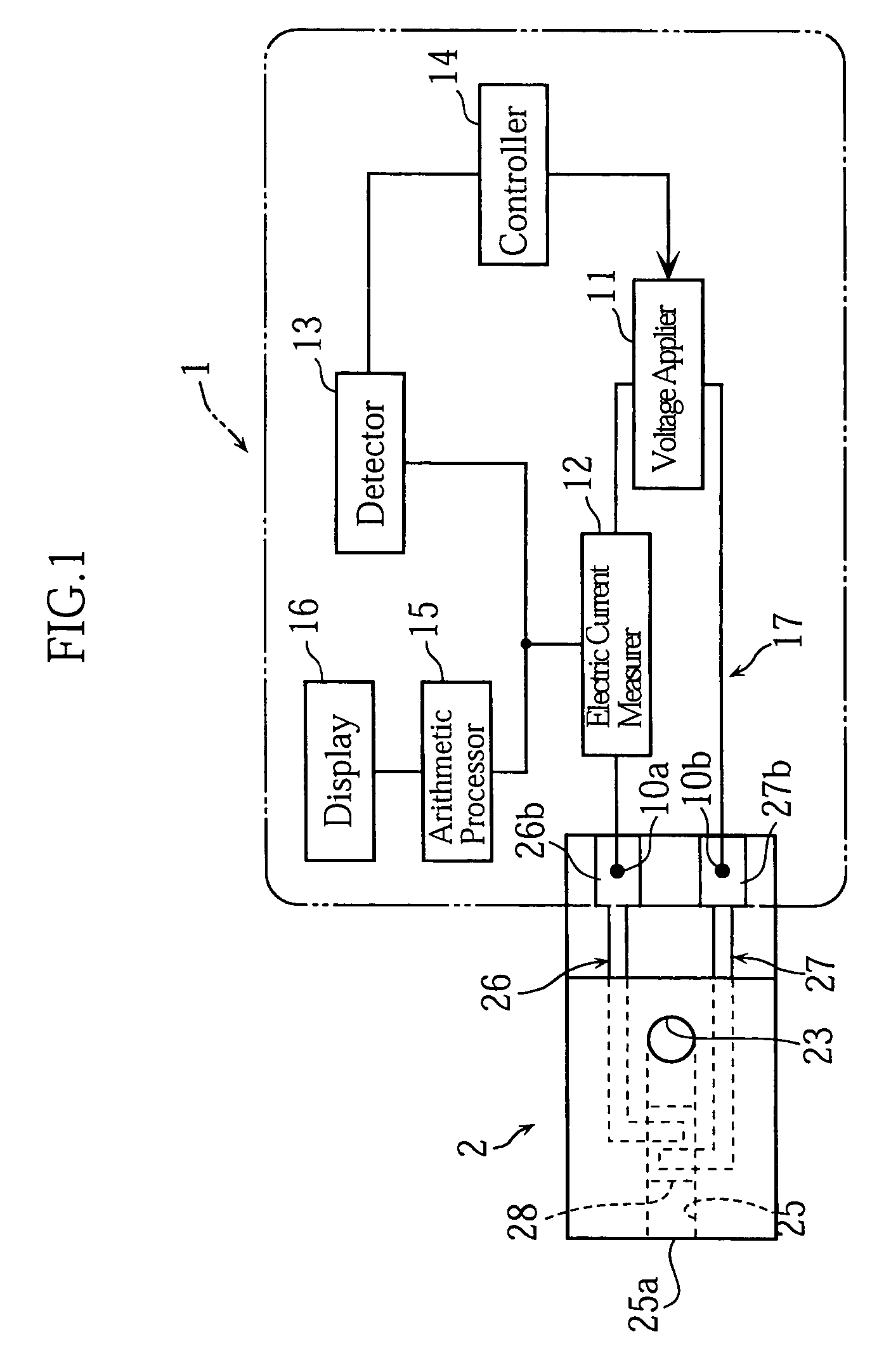

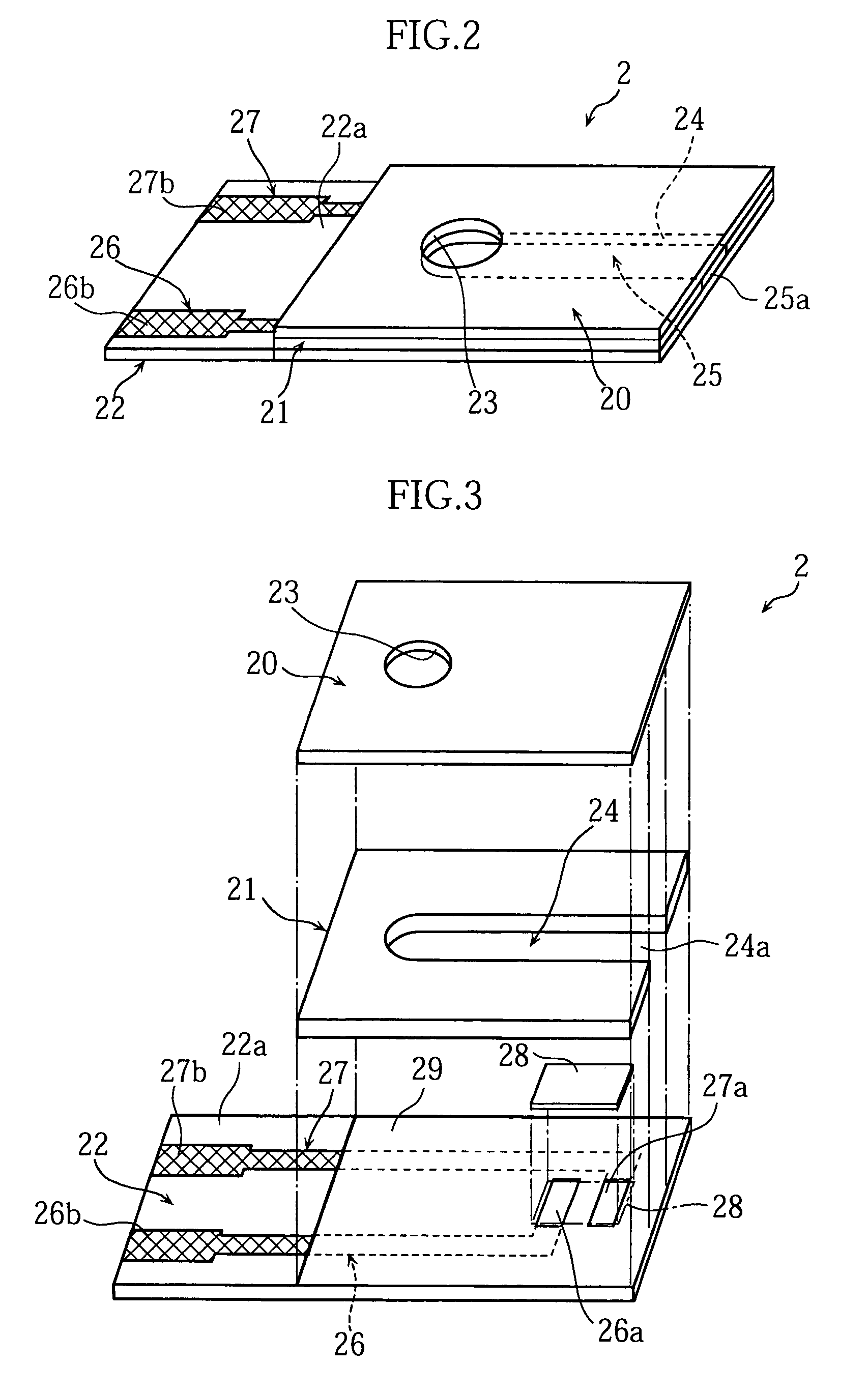

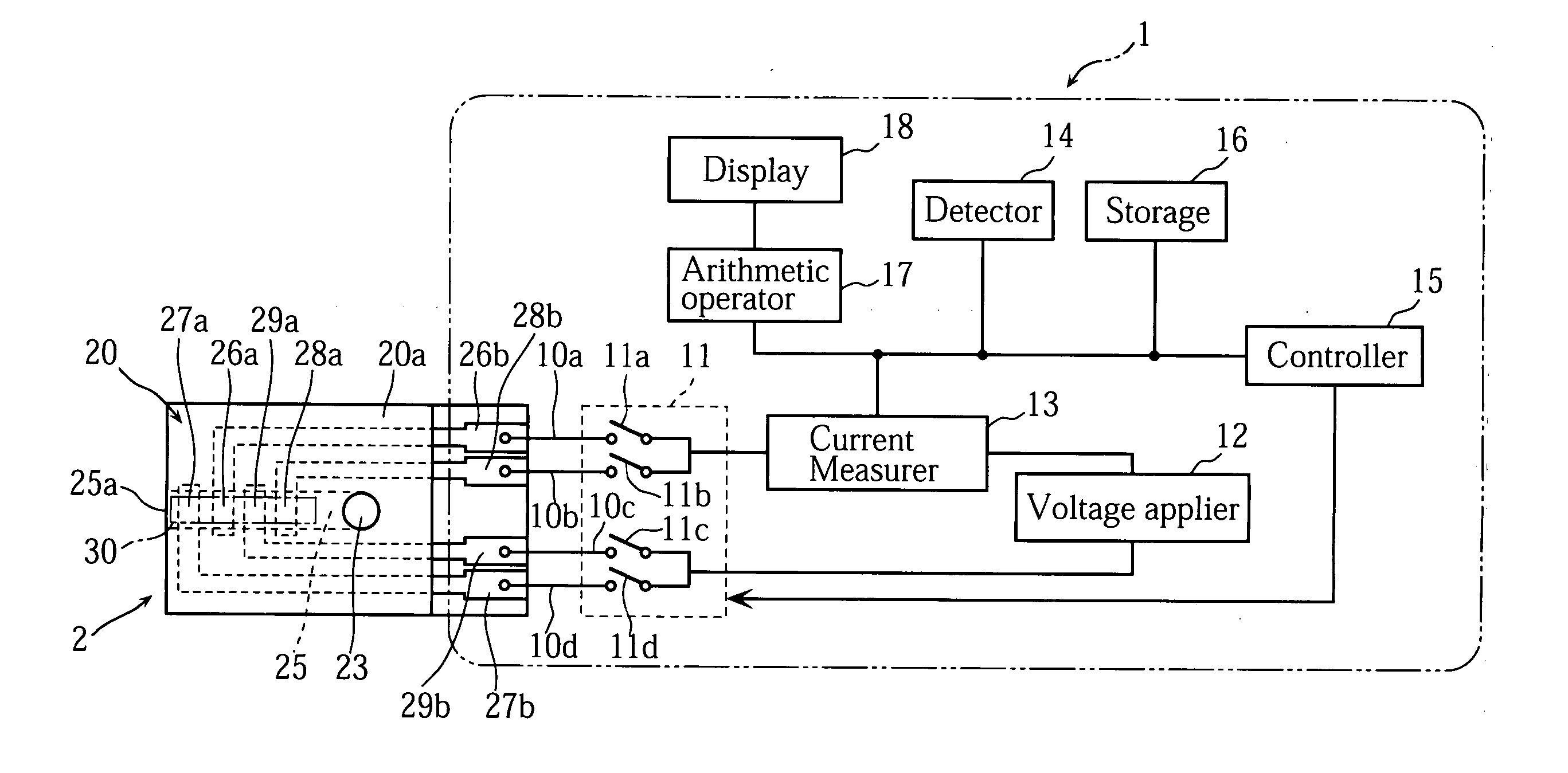

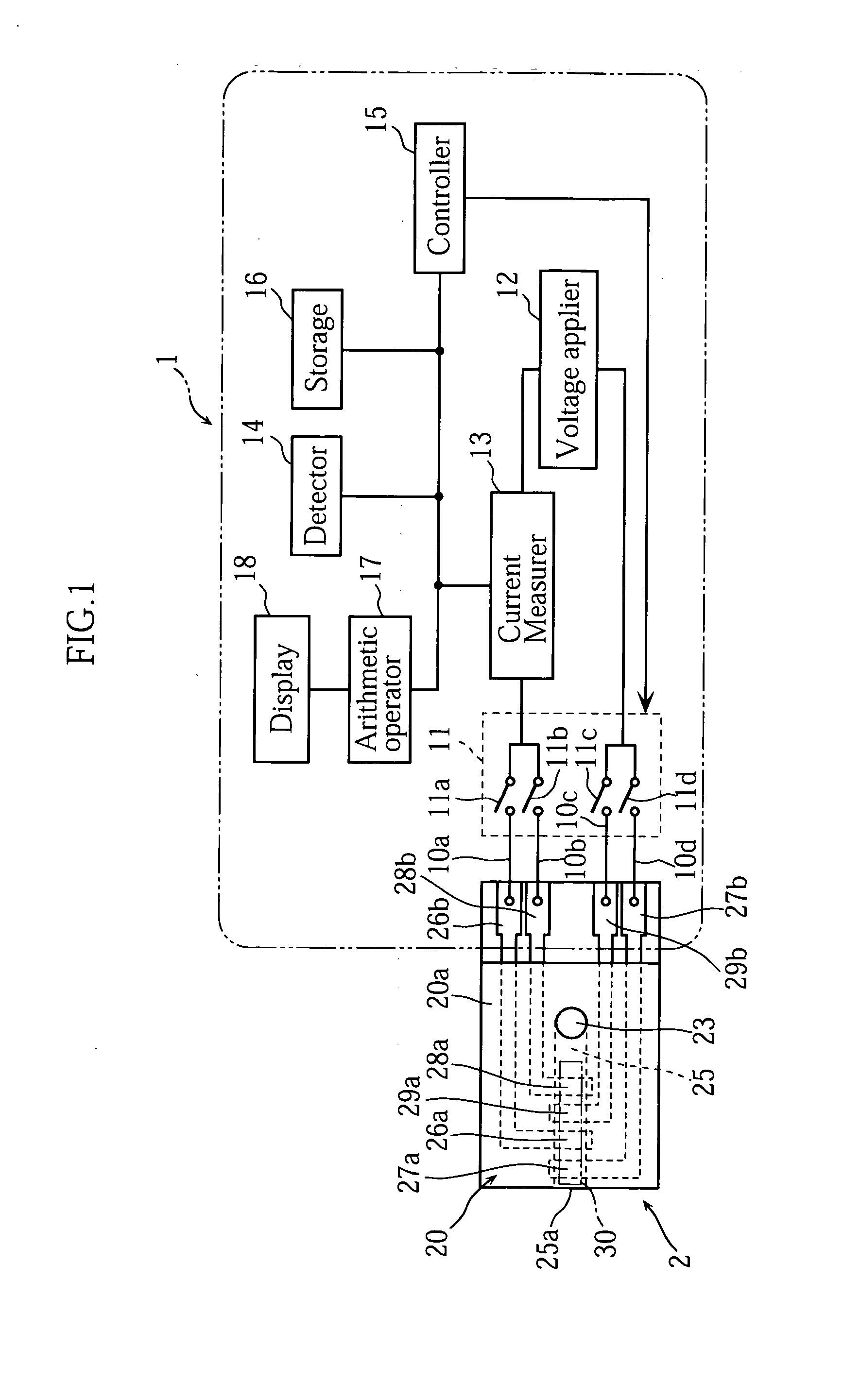

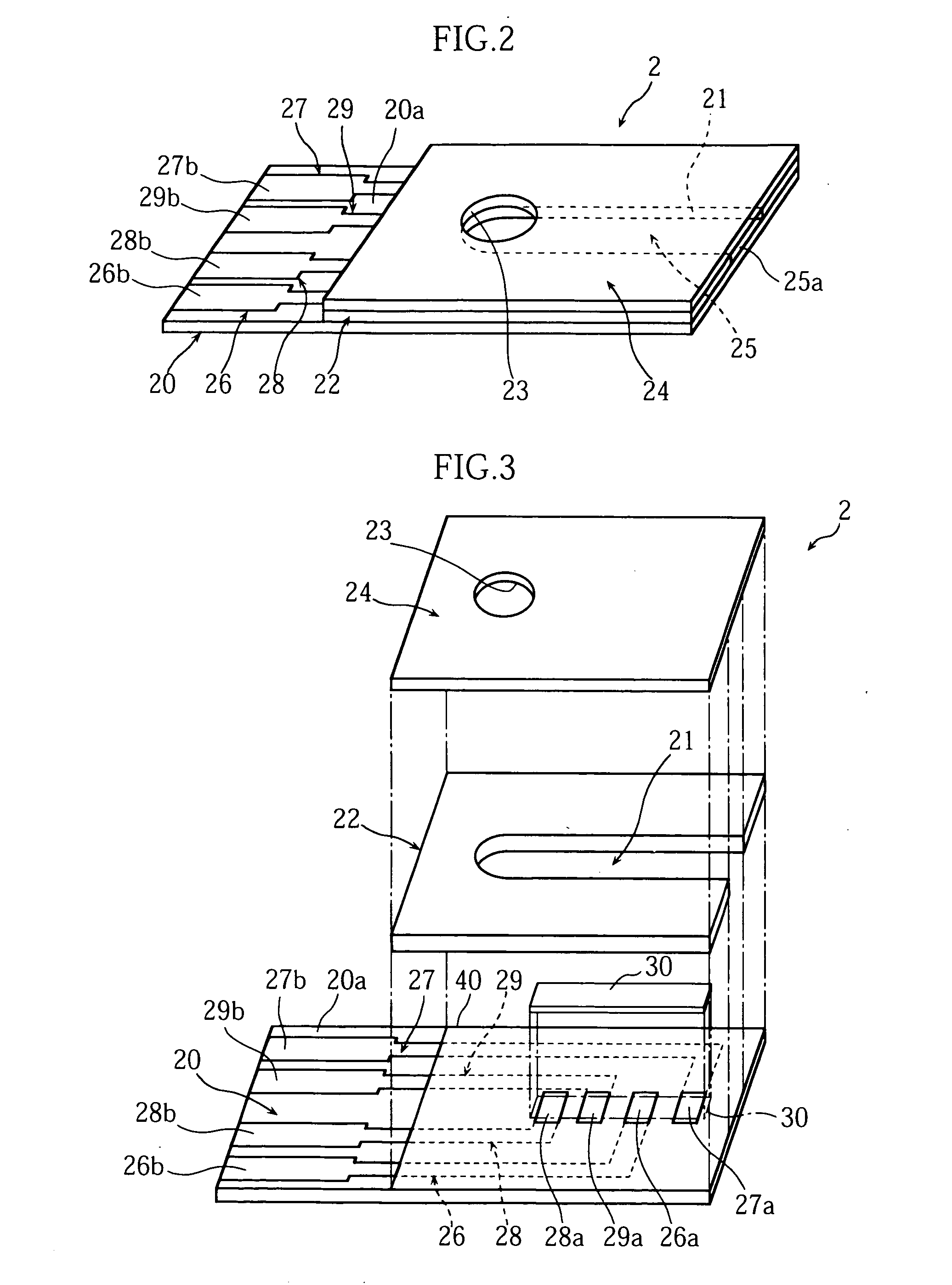

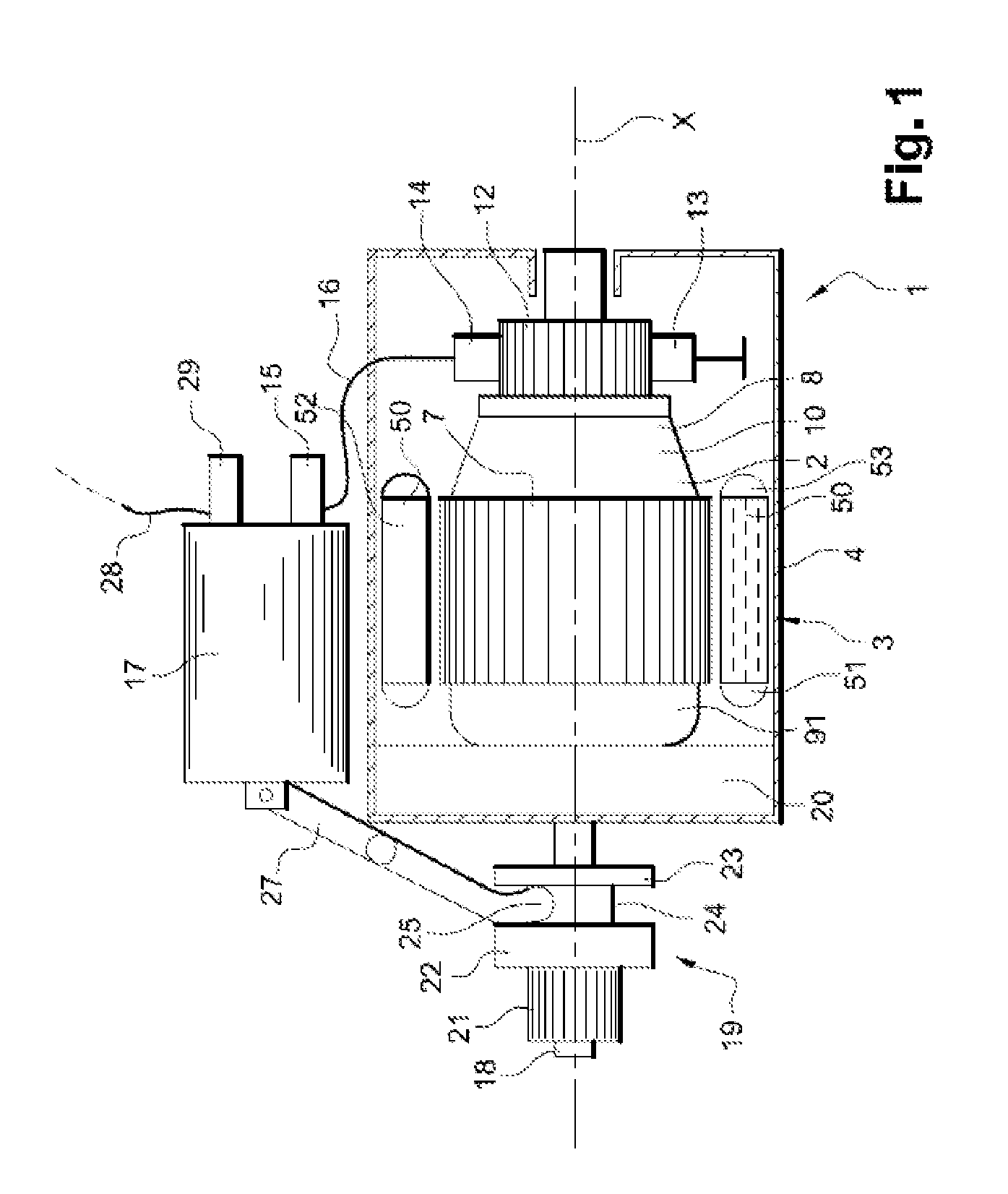

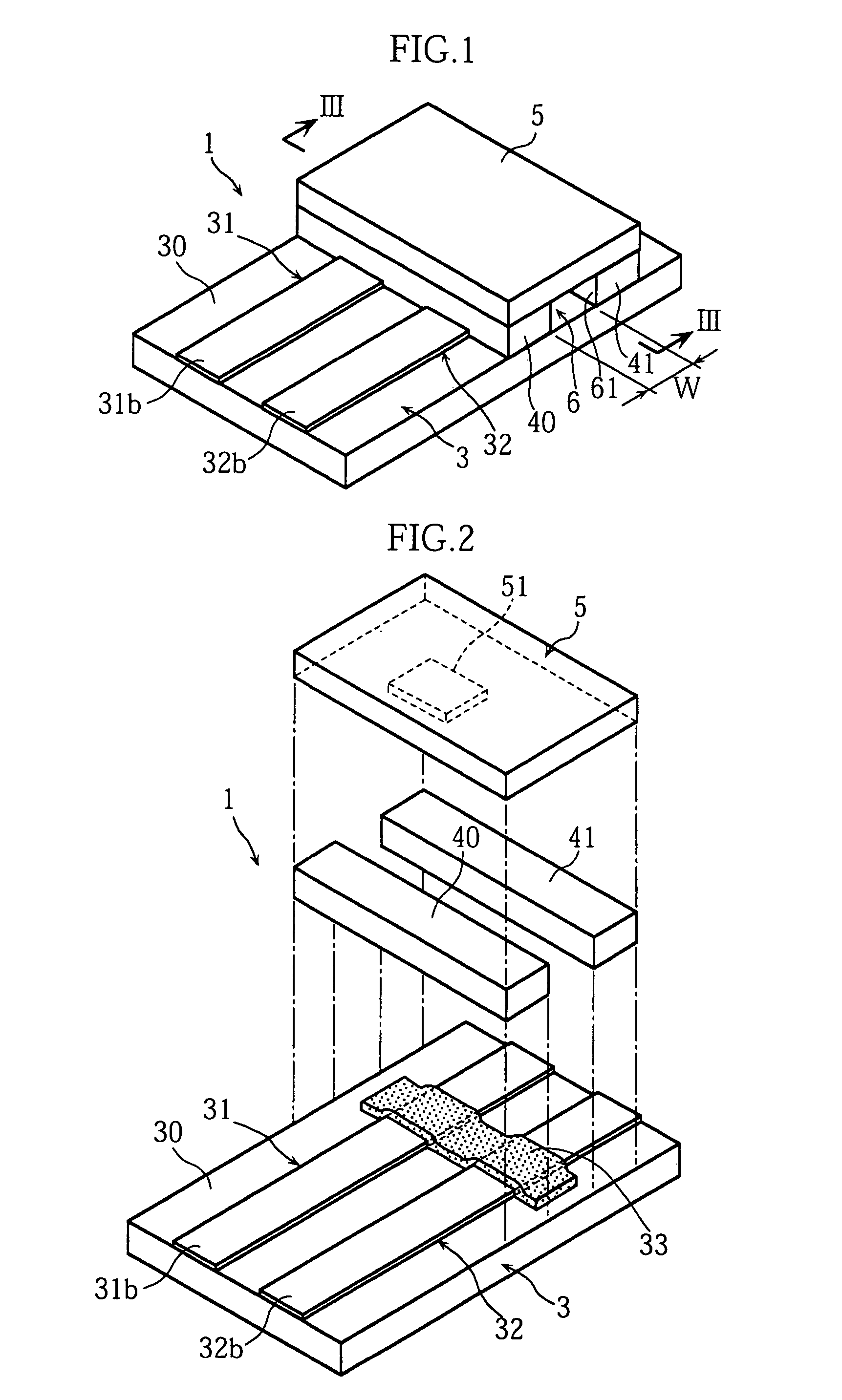

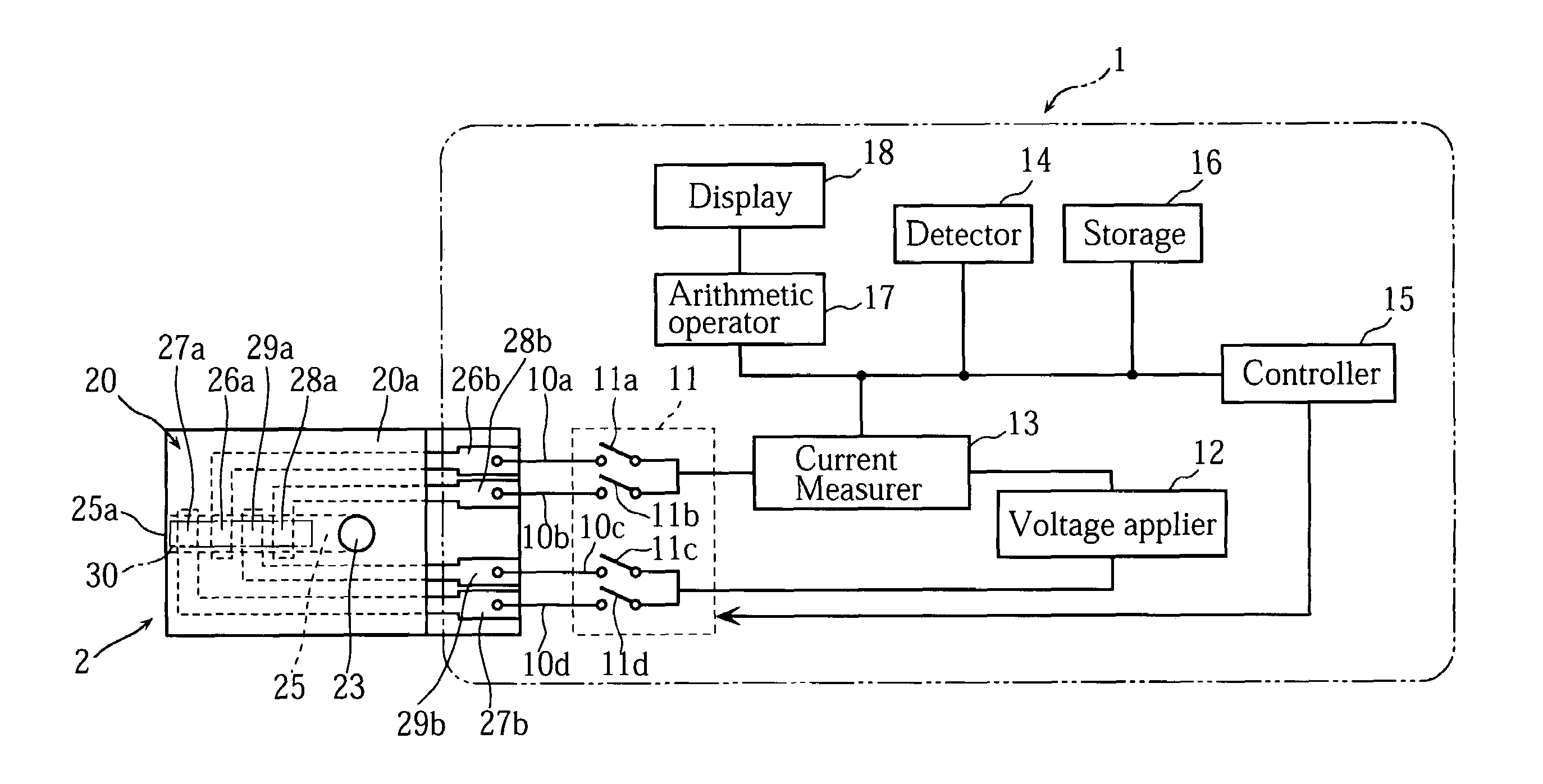

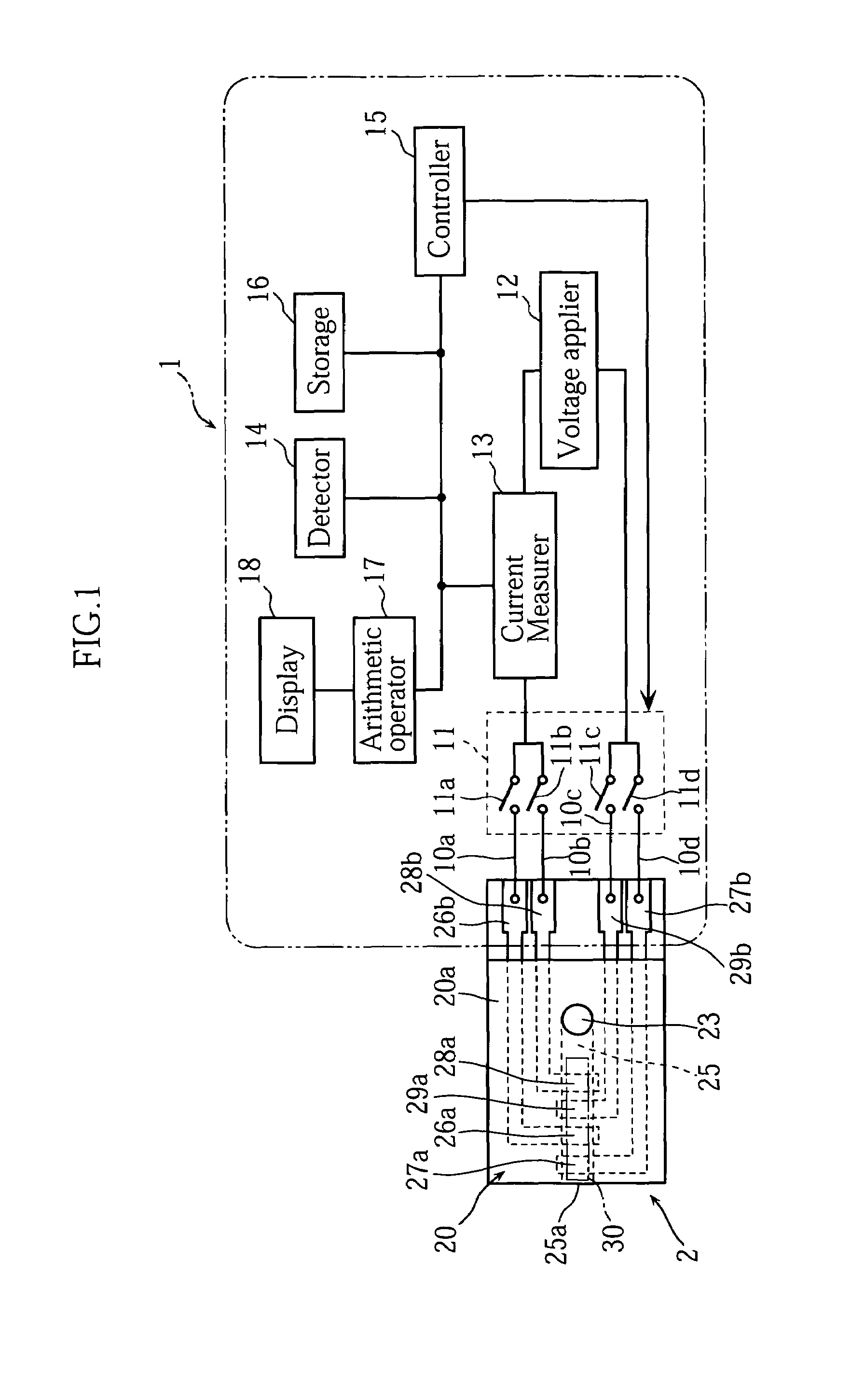

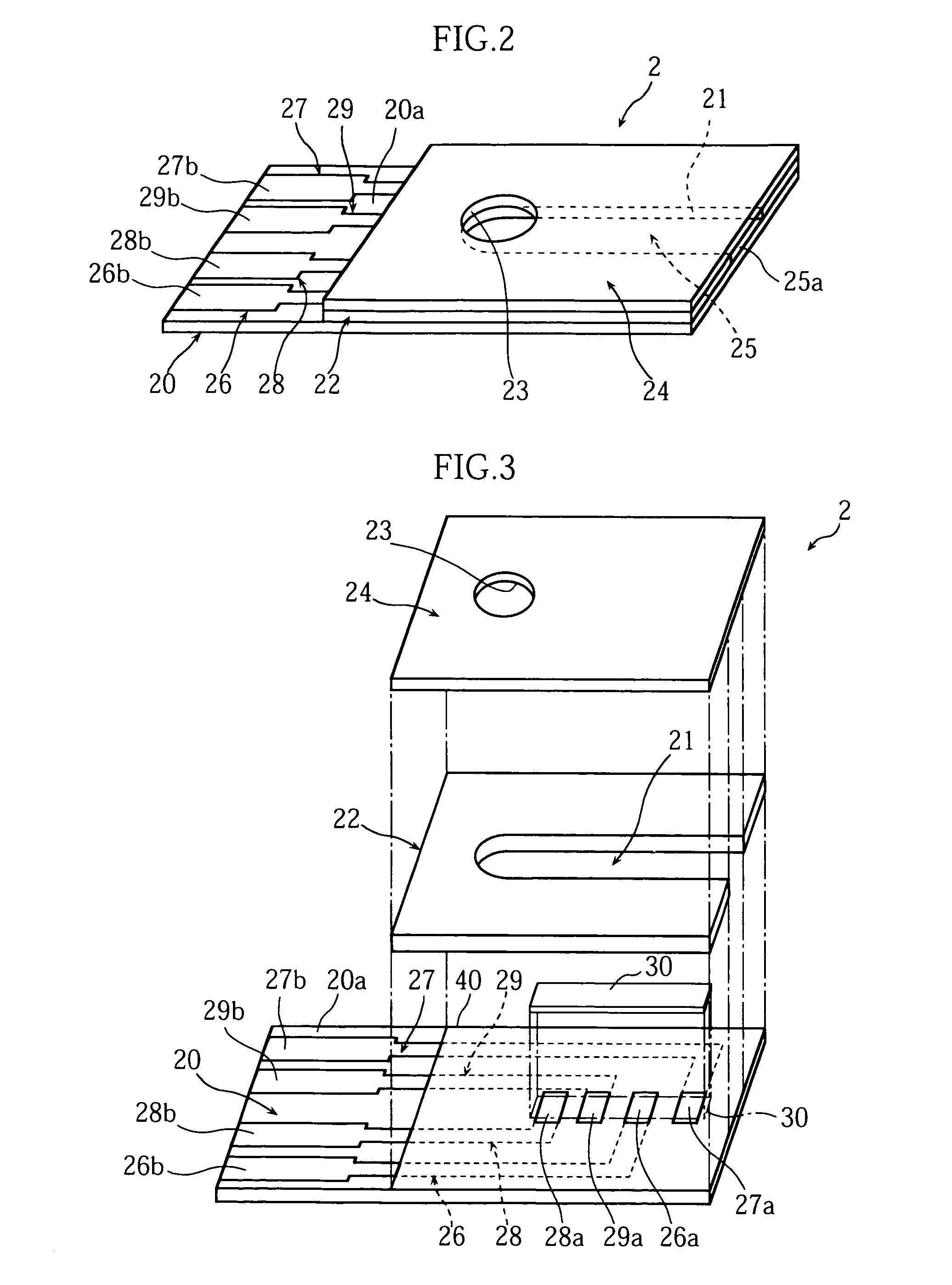

Sample analyzing method and sample analyzing device

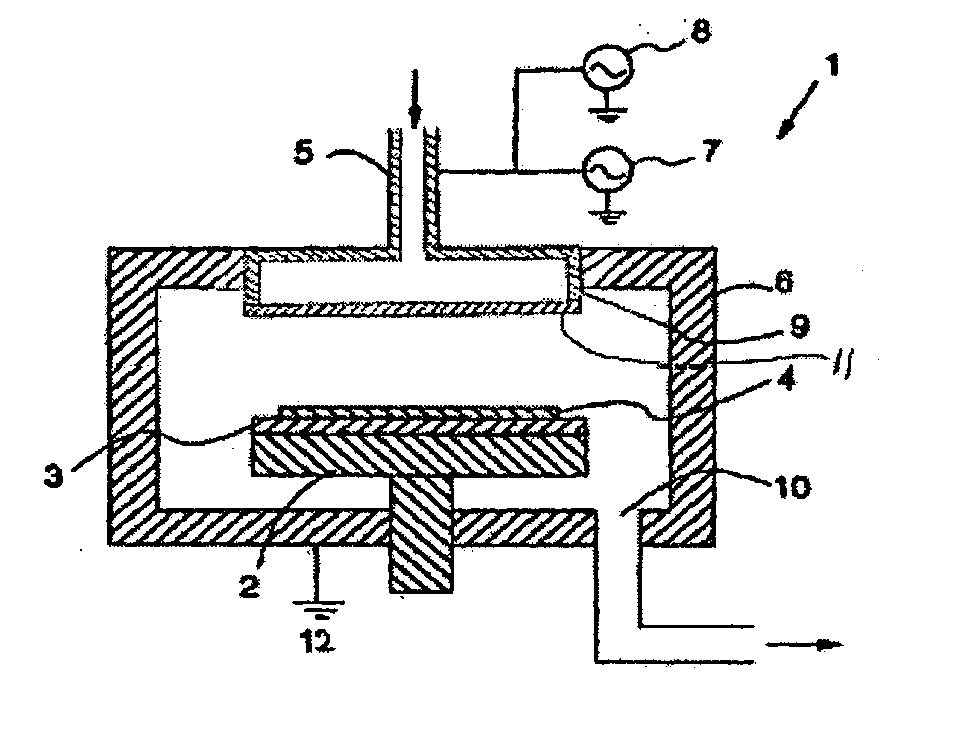

ActiveUS20060224658A1Without sacrificing accuracy of analysisImprove accuracyMicrobiological testing/measurementVolume/mass flow measurementReaction fieldEngineering

This invention relates to a technique for analyzing a sample. A sample analyzer (1) provided by the invention includes: a voltage applier (12) for applying a voltage to a reaction field which includes a sample; a response measurer (13) for measurement of a response to the voltage applied to the reaction field; a selector (11) for selecting a first voltage application state for measurement of a first response for use in calculation necessary for analyzing the sample or a second voltage application state for measurement of a second response for use in determining whether or not the reaction field has been supplied with a target amount of the sample; an arithmetic operator (17) for calculation necessary for analyzing the sample based on the first response; a determiner (17) for determination, based on the second response, on whether or not the reaction field has been supplied with the target amount of sample; and a controller (15) which makes the selector select the second voltage application state after making the selector select the first voltage application state.

Owner:ARKRAY INC

Process for synthesis of polysiloxane

The invention discloses a process for synthesis of polysiloxane which comprises the steps of charging reactant, catalyst and water, agitating at normal temperature, reacting in the microwave reaction field for 60-120 min, and charging terminating substance, the constituents include (by weight portions) reactant 100 parts, catalyst 0.01-0.05 part, water 0.01-0.1 part, and terminating substance 0.01-0.1 part.

Owner:GUANGZHOU GBS HIGH TECH & IND +1

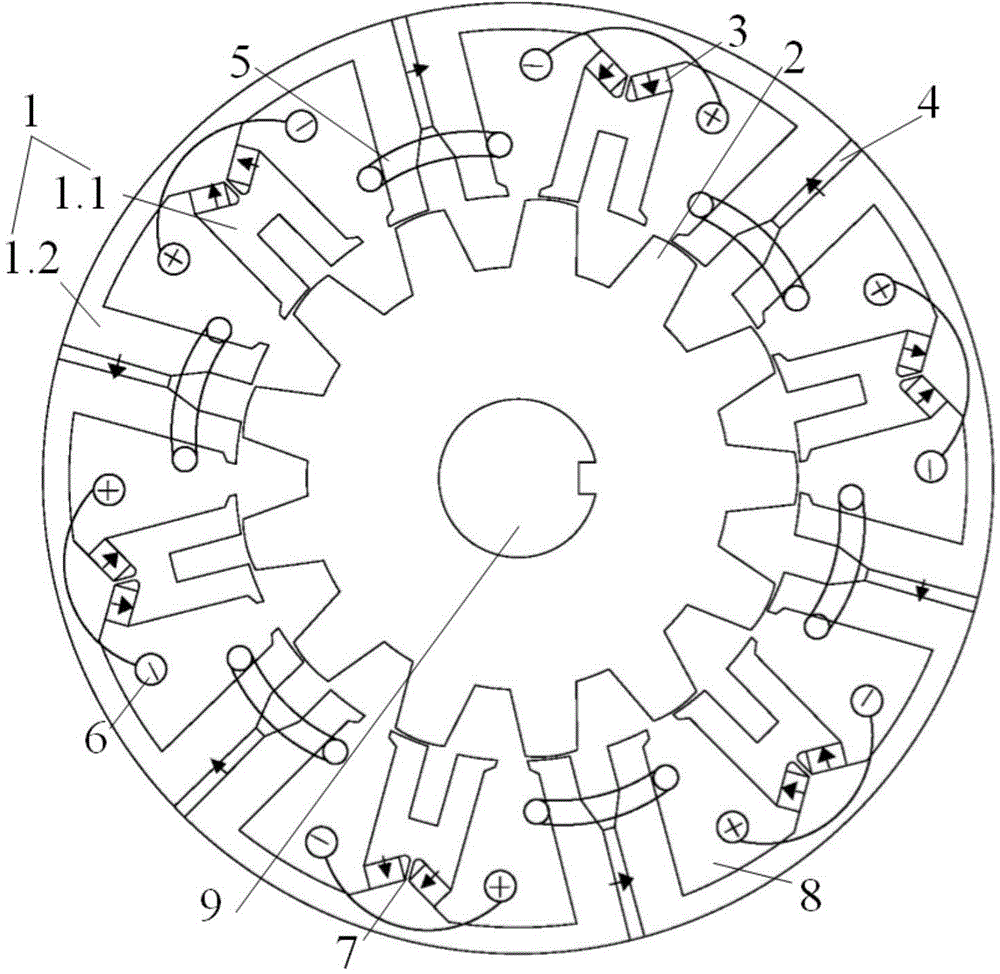

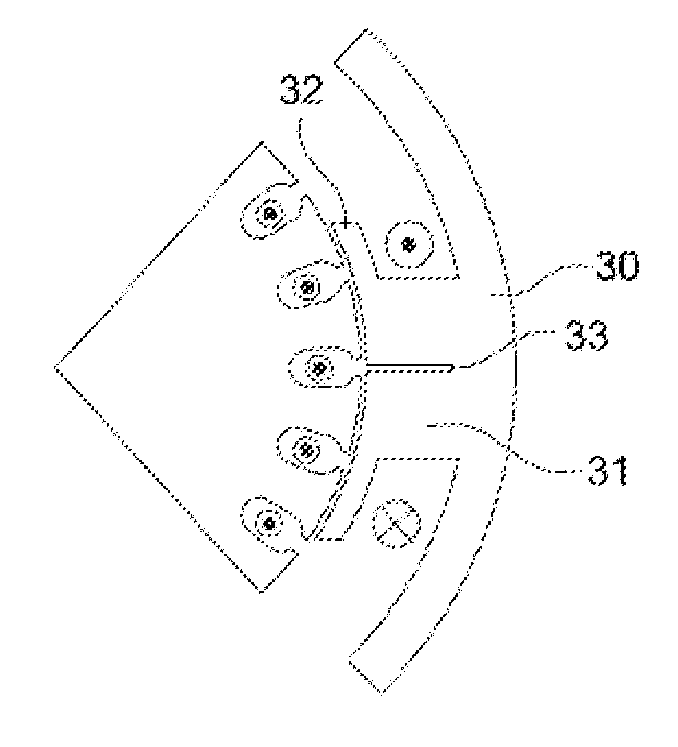

Mixed permanent magnetic pole-alternating and magnetic flux-switching memory motor and winding switching magnetism-weakening control method thereof

ActiveCN104578477ASimple structureImprove space utilizationAC motor controlMagnetic circuit stationary partsLow speedMagnetic poles

The invention discloses a mixed permanent magnetic pole-alternating and magnetic flux-switching memory motor and a winding switching magnetism-weakening control method thereof. The mixed permanent magnetic pole-alternating and magnetic flux-switching memory motor comprises a salient rotor and a stator, wherein the stator contains stator cores, aluminium-nickel-cobalt permanent magnets, neodymium-iron-boron permanent magnets, centralized armature windings and pulsed magnetism-adjusting windings; iron core edges of two adjacent outer U-shaped units and tangentially-magnetized long-stripped neodymium-iron-boron permanent magnets form a first permanent magnetic pole, while the circumferentially-inward (outward) and parallel-magnetized V-shaped embedded aluminium-nickel-cobalt permanent magnets and inner U-shaped units form a second permanent magnetic pole; mixed magnetic poles are in alternating polarity distribution; when the motor runs at a low speed, the pulsed magnetism-adjusting windings are in direct-current pulsed working state, while in a high-speed weak-magnetism area, the pulsed magnetism-adjusting windings are converted into alternating-current armature windings. Requirements on performance in a low-speed area and in the high-speed area can be met at the same time; influence of an armature reaction field on the aluminium-nickel-cobalt permanent magnets with low coercivity is small; the utilization rate of permanent magnetism, the torque density, and the reliability of system operation are high.

Owner:SOUTHEAST UNIV

Organically modified fine particles

A technique for bonding an organic group with the surface of fine particles such as nanoparticles through strong linkage is provided, whereas such fine particles are attracting attention as materials essential for development of high-tech products because of various unique excellent characteristics and functions thereof. Organically modified metal oxide fine particles can be obtained by adapting high-temperature, high-pressure water as a reaction field to bond an organic matter with the surface of metal oxide fine particles through strong linkage. The use of the same condition enables not only the formation of metal oxide fine particles but also the organic modification of the formed fine particles. The resulting organically modified metal oxide fine particles exhibit excellent properties, characteristics and functions.

Owner:SUPER NANO DESIGN CO LTD

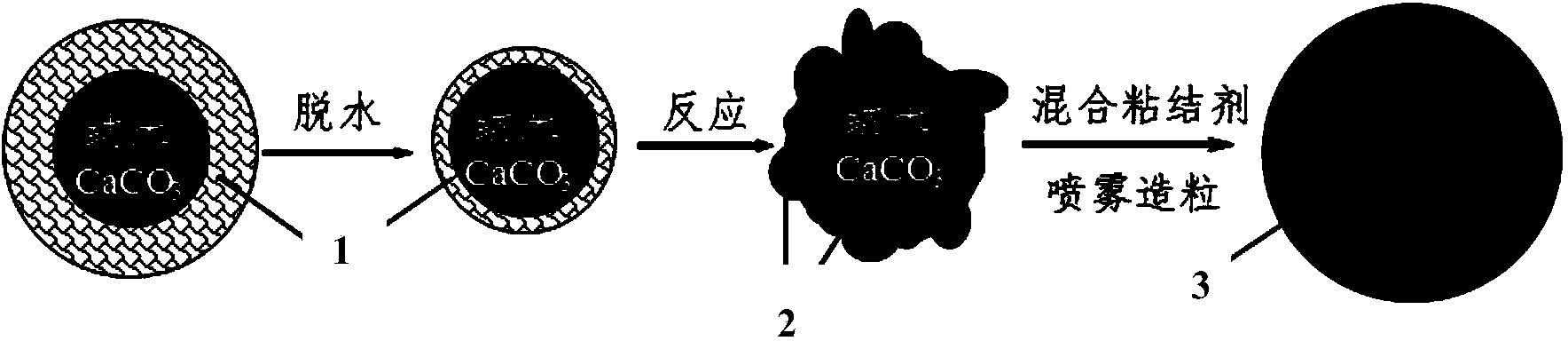

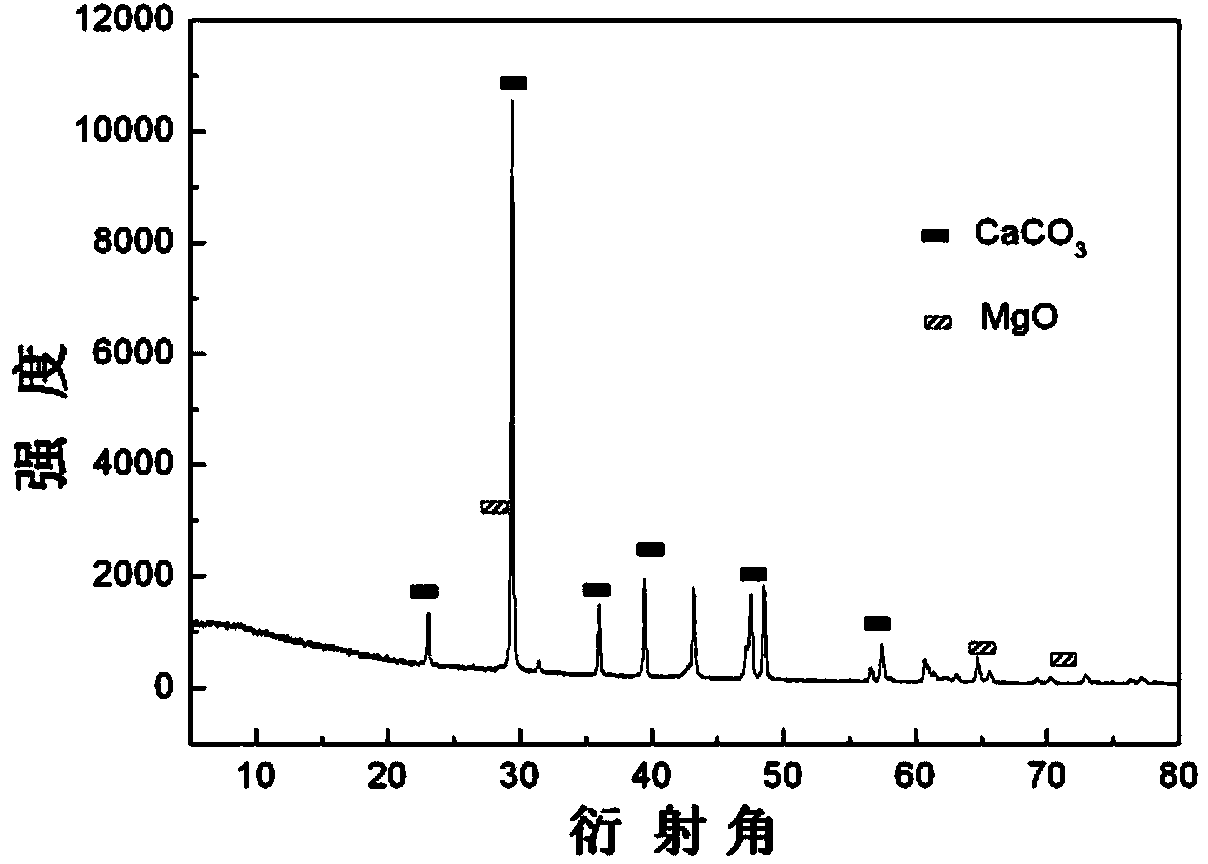

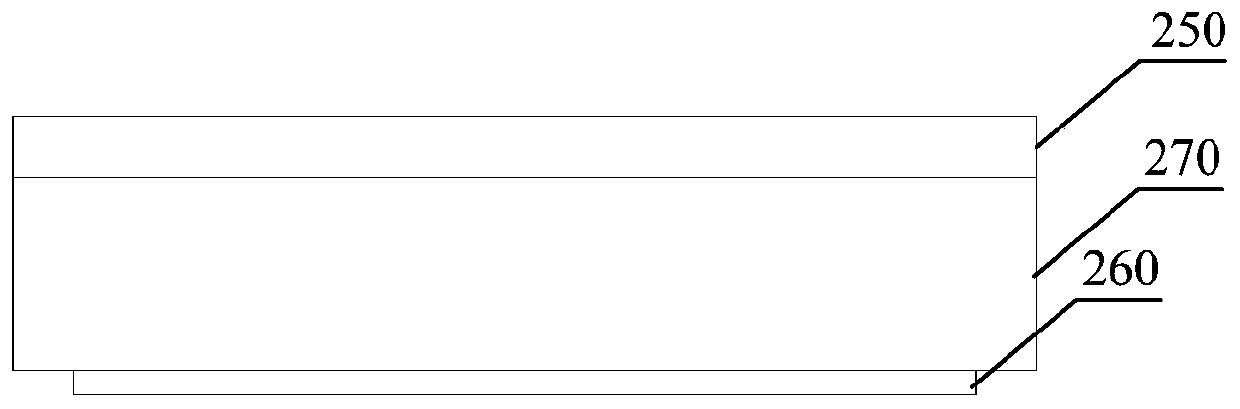

Surface coating modified nano calcium oxide based CO2 adsorbing agent and preparation method thereof

ActiveCN103962087AControl UniformitySimple methodOther chemical processesDispersed particle separationReaction fieldSorbent

The invention discloses a surface coating modified nano calcium oxide based CO2 adsorbing agent which is composed of internal nano calcium oxide and an external surface coating layer; the surface coating layer is prepared from at least one of Al2O3, Ca12Al14O33 and MgO. The invention further discloses a preparation method of the surface coating modified nano calcium oxide based CO2 adsorbing agent. An adsorption phase reaction method is utilized, and thickness and uniformity of the surface coating layer are controlled by controlling a reaction field, the method is simple and regulation and control are facilitated; according to the invention, the prepared surface coating modified nano calcium oxide based CO2 adsorbing agent has high CO2 adsorption capacity and obvious stability in adsorption ability in manifold cycles, can be in long-term recycling, and is an ideal adsorption agent in the adsorption process of high-temperature CO2.

Owner:ZHEJIANG UNIV

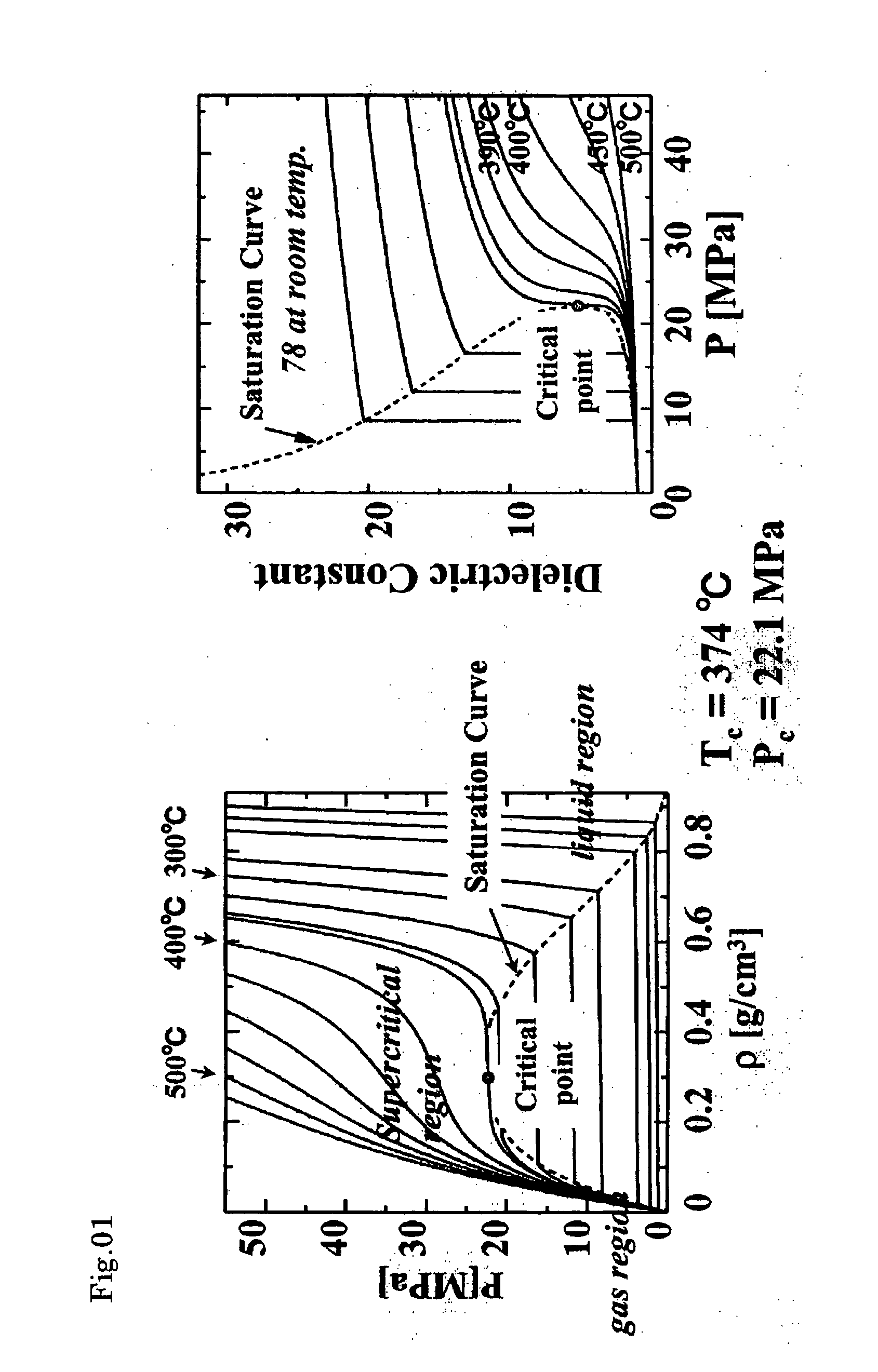

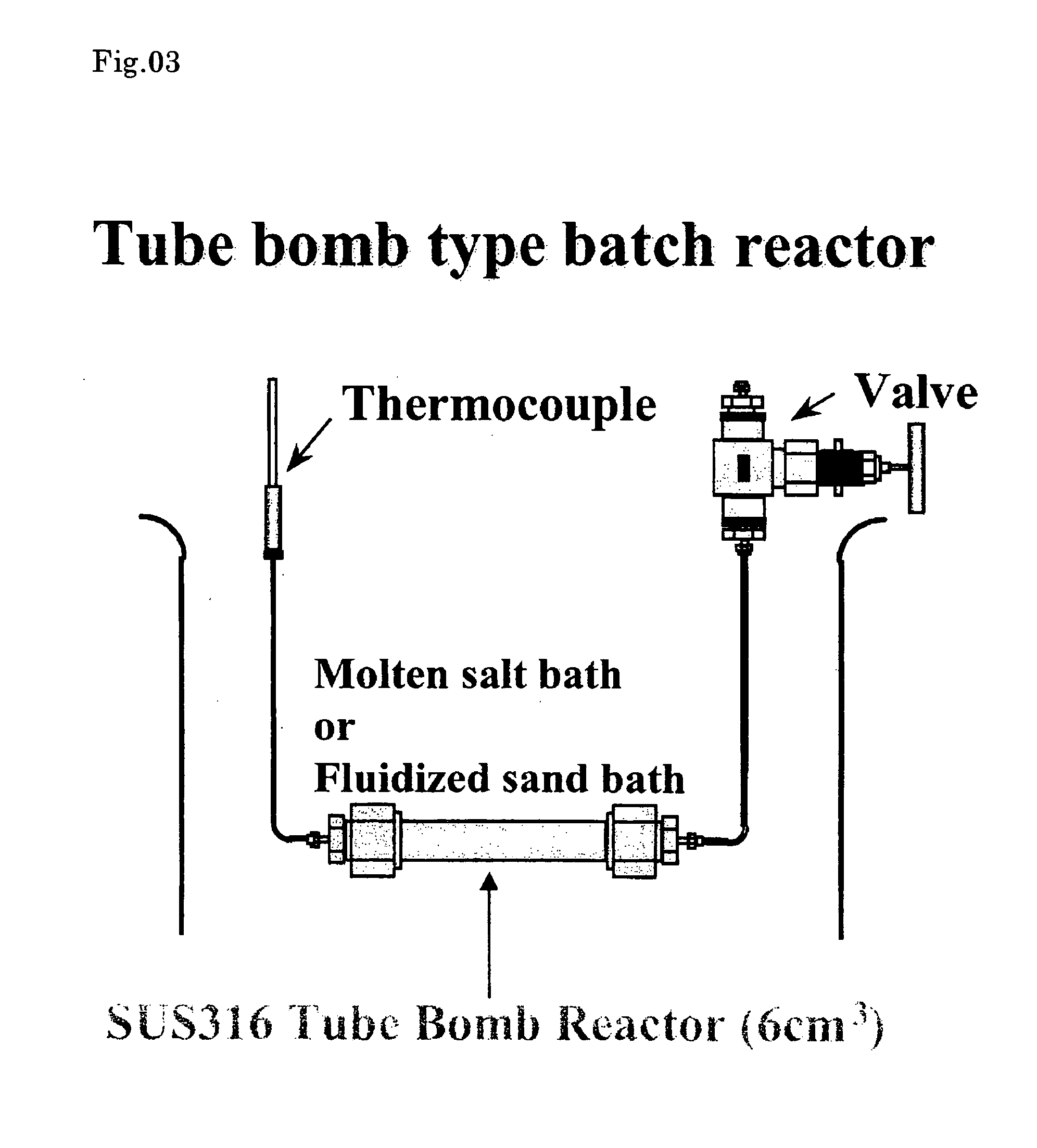

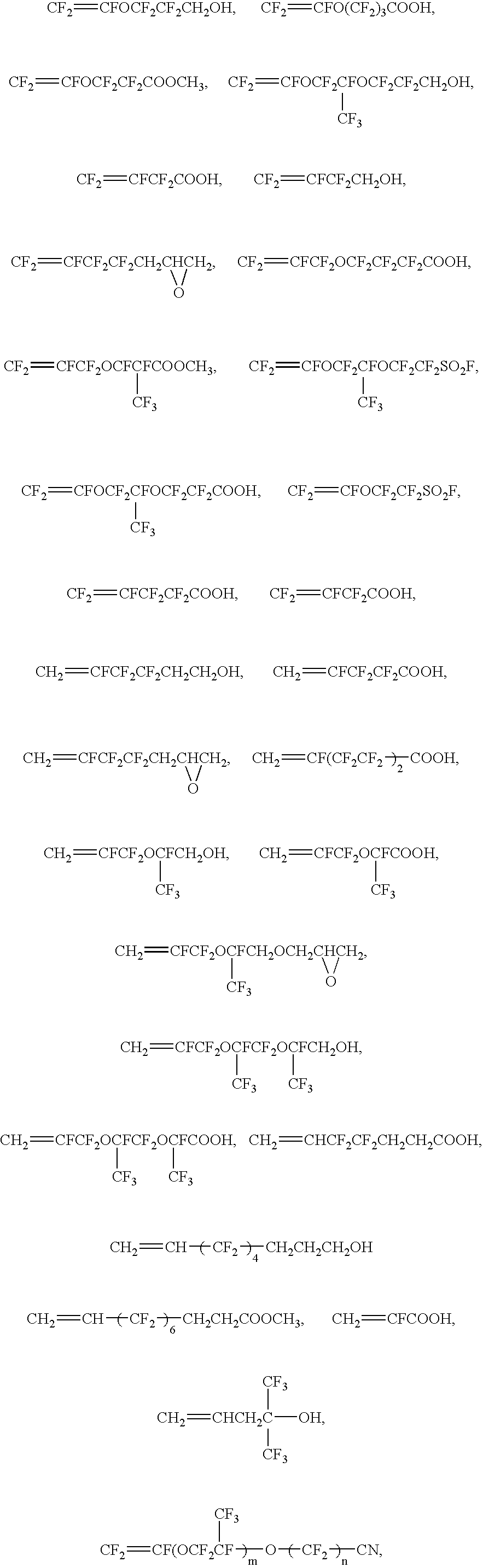

Process for producing fluoropolymer

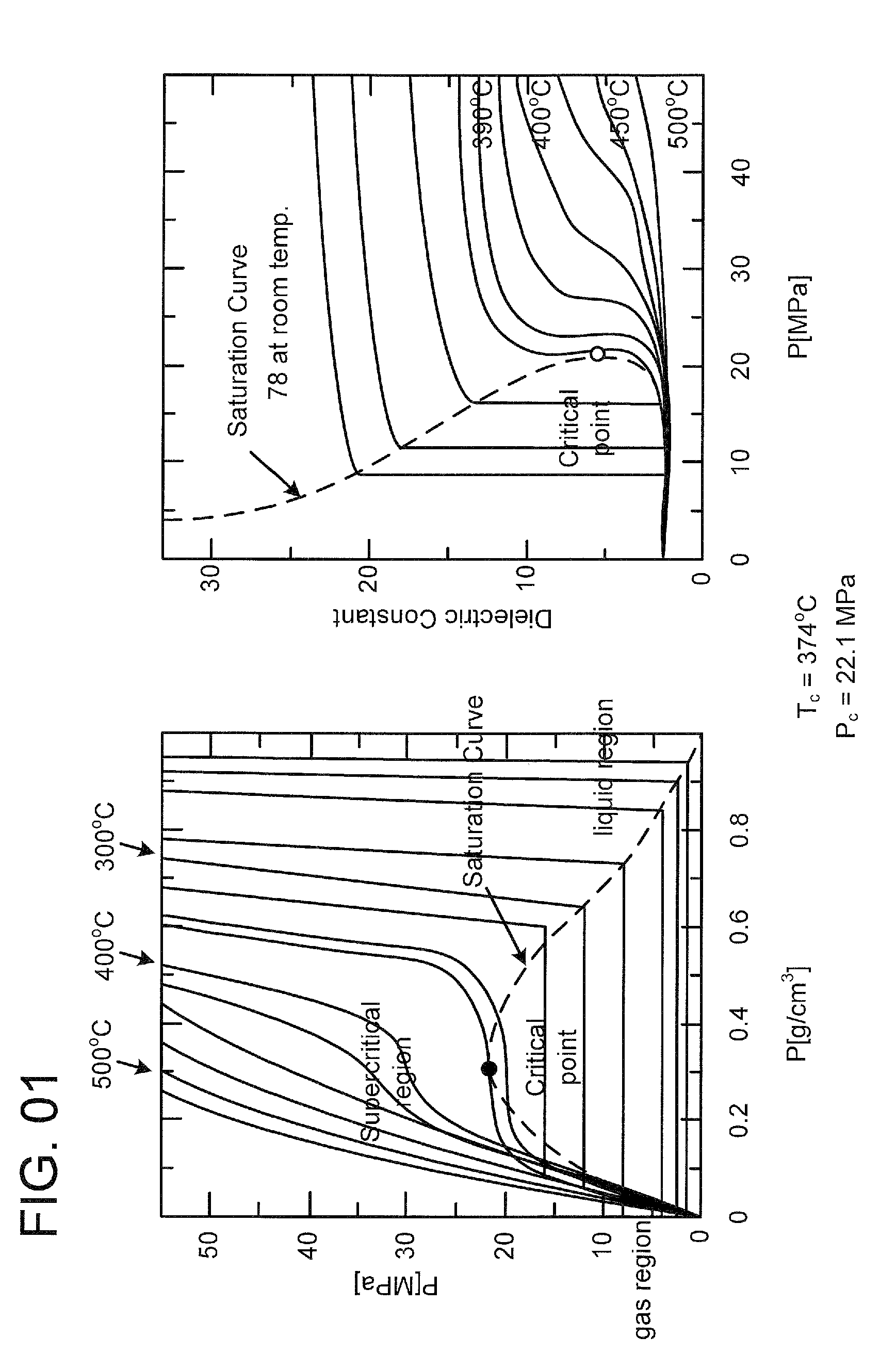

InactiveUS6716942B1Increase polymerization rateImprove energy efficiencyBulk chemical productionSupercritical condition processesReaction fieldPolymer science

A process for preparing a fluoropolymer by polymerizing one or more radically polymerizable monomers comprising at least one fluoroolefin monomer in the presence of a radical polymerization initiator and as case demands, an inactive fluorocarbon and chain transfer agent in a reaction field where at least one of components forming the reaction field is in a supercritical state. According to the preparation process, generation of unstable end groups of the polymer, a decrease in a purity and complicated post-treatment can be eliminated.

Owner:DAIKIN IND LTD

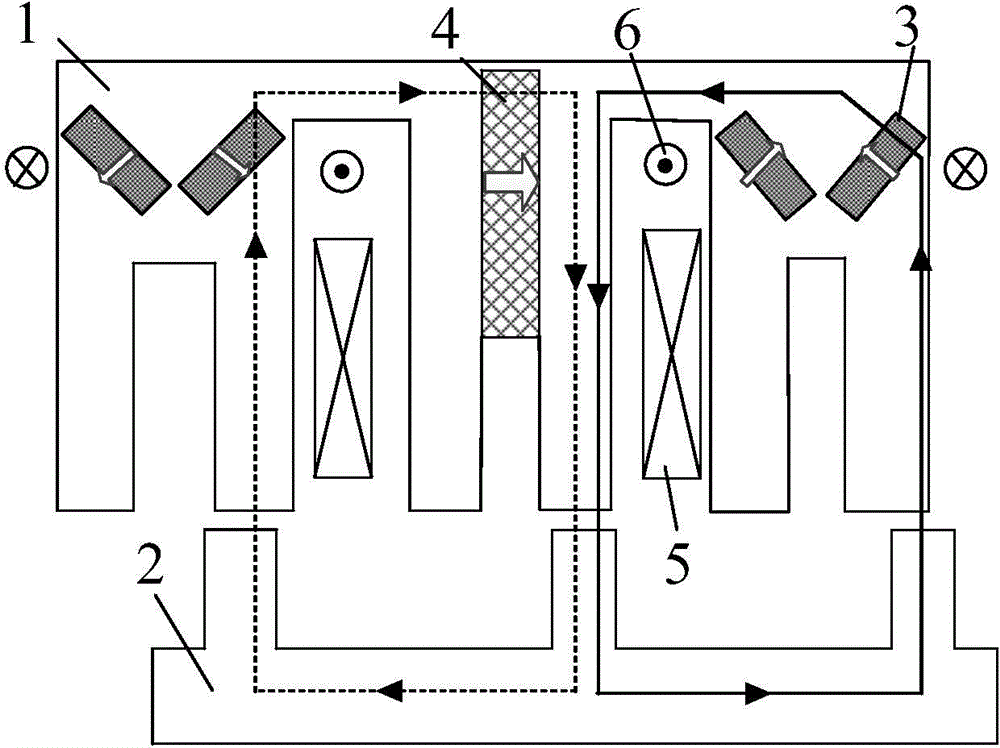

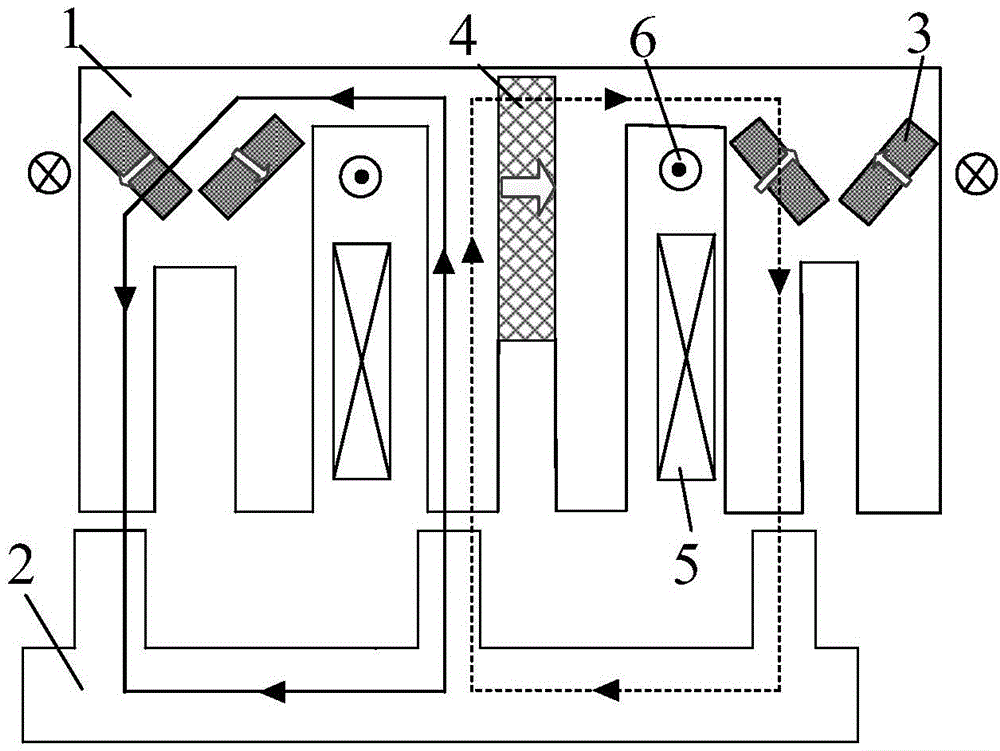

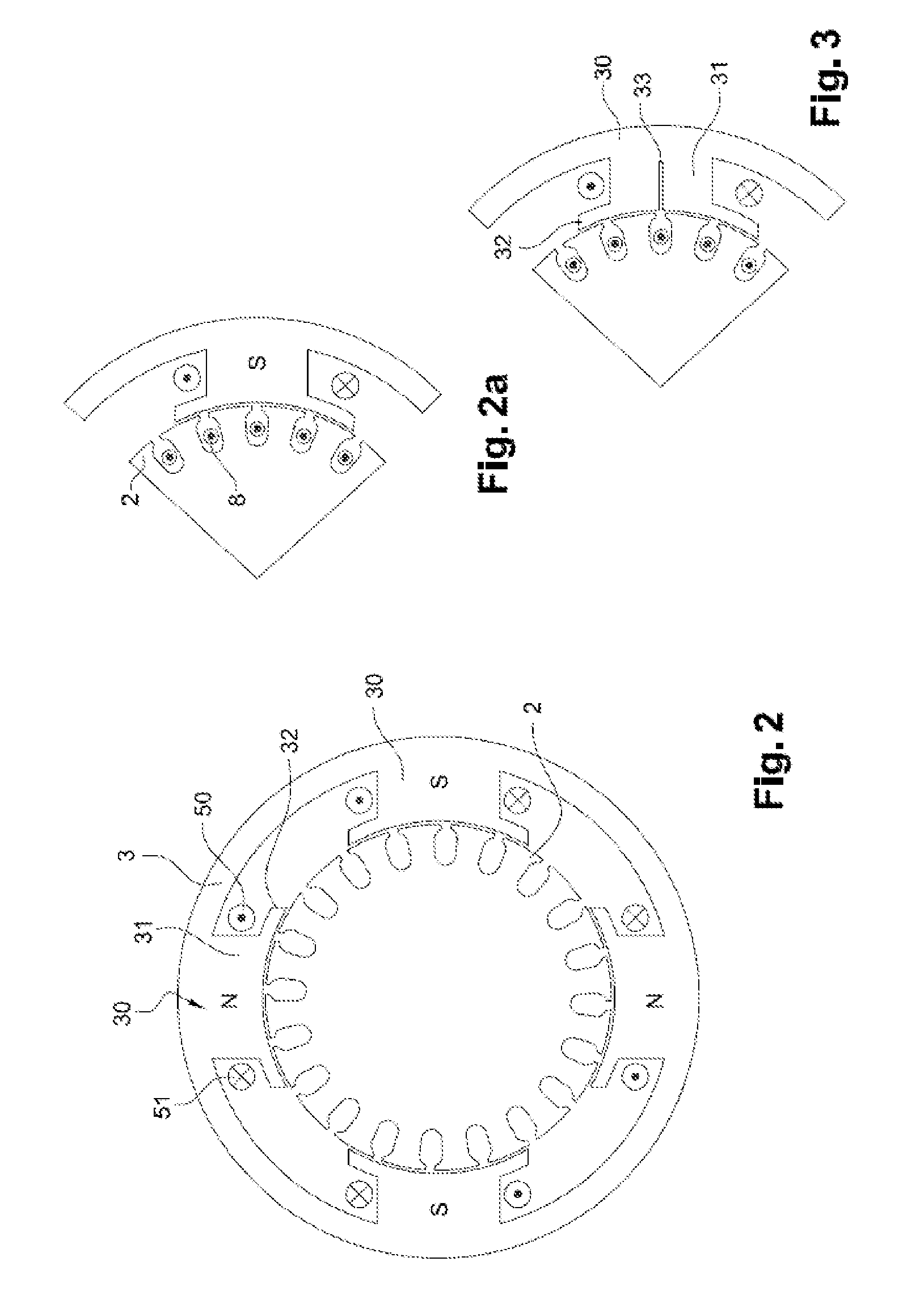

Electric rotating machine with salient poles

InactiveUS20100176677A1Reduce in quantityEliminate the effects ofMagnetic circuit stationary partsElectric motor startersReaction fieldElectrical polarity

A DC electric rotating machine, such as a starter of an automotive vehicle, includes a stator with salient poles having at least four poles distributed uniformly over the circumference of the stator, a rotor disposed inside the stator, a set of brushes adapted for the electric supply of the rotor, and at least two geometrically opposed salient poles. Each pole includes at least one substantially radial slot in a plane parallel to the axis of rotation of the rotor and preferably passes through the axis of the rotor. By minimizing the reaction fields of the armature, utilization of the magnetic material of the parts of the stator is balanced and a harmful armature reaction effect, which increases saturation of the polar parts of the inductor and which leads to reduction in the driving magnetic torque, is mitigated.

Owner:VALEO EQUIP ELECTRIC MOTEUR

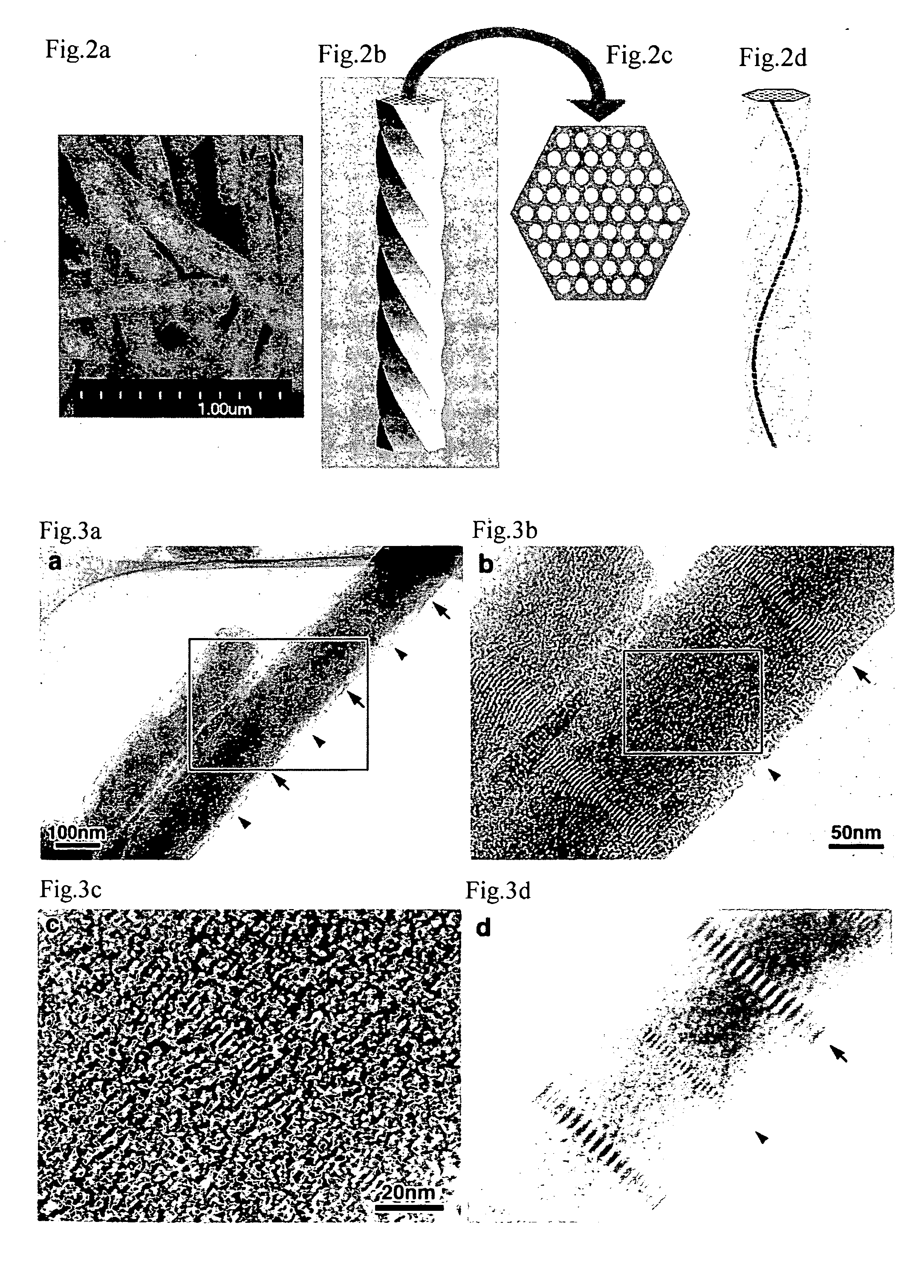

Nanocarbon composite structure having ruthenium oxide trapped therein

InactiveCN1964917AImprove electrochemical activityIncrease capacityMaterial nanotechnologyCarbon compoundsMechanochemistryMaterials science

A novel nanocarbon composite structure having ruthenium oxide trapped therein, wherein using Ketjen black, through a mechanochemical effect utilizing an ultracentrifugal reaction field, both the specific surface area of ruthenium oxide and the space of electrode material have been expanded so as to have nanoparticles of ruthenium oxide highly dispersed in a graphene layer. This nanocarbon composite structure having ruthenium oxide trapped therein exhibits high electrochemical activity, so that it is suitable for use as an electrical energy storing device, such as a large-capacity capacitor.

Owner:NAT UNIV CORP TOKYO UNIV OF AGRI & TECH

Method of forming fluorine-doped low-dielectric-constant insulating film

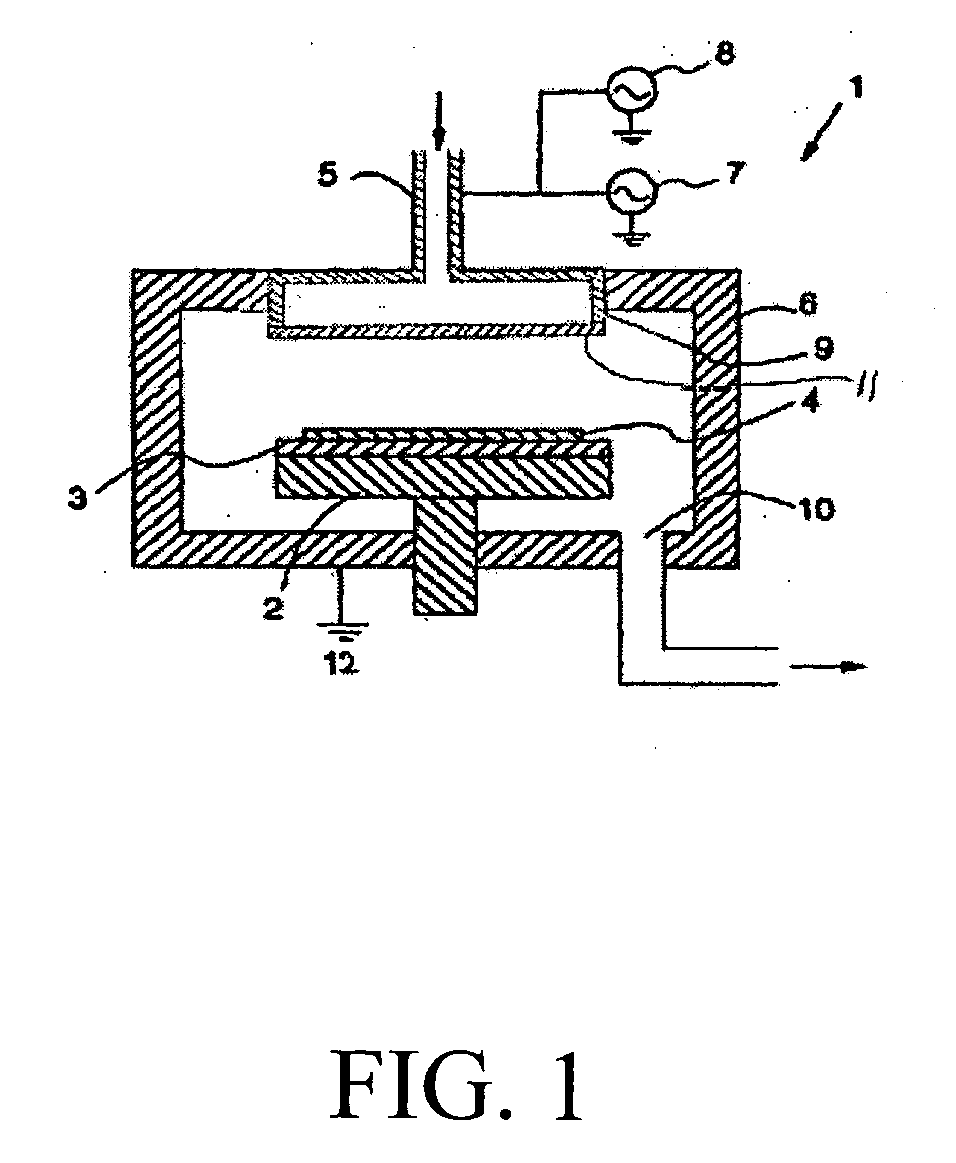

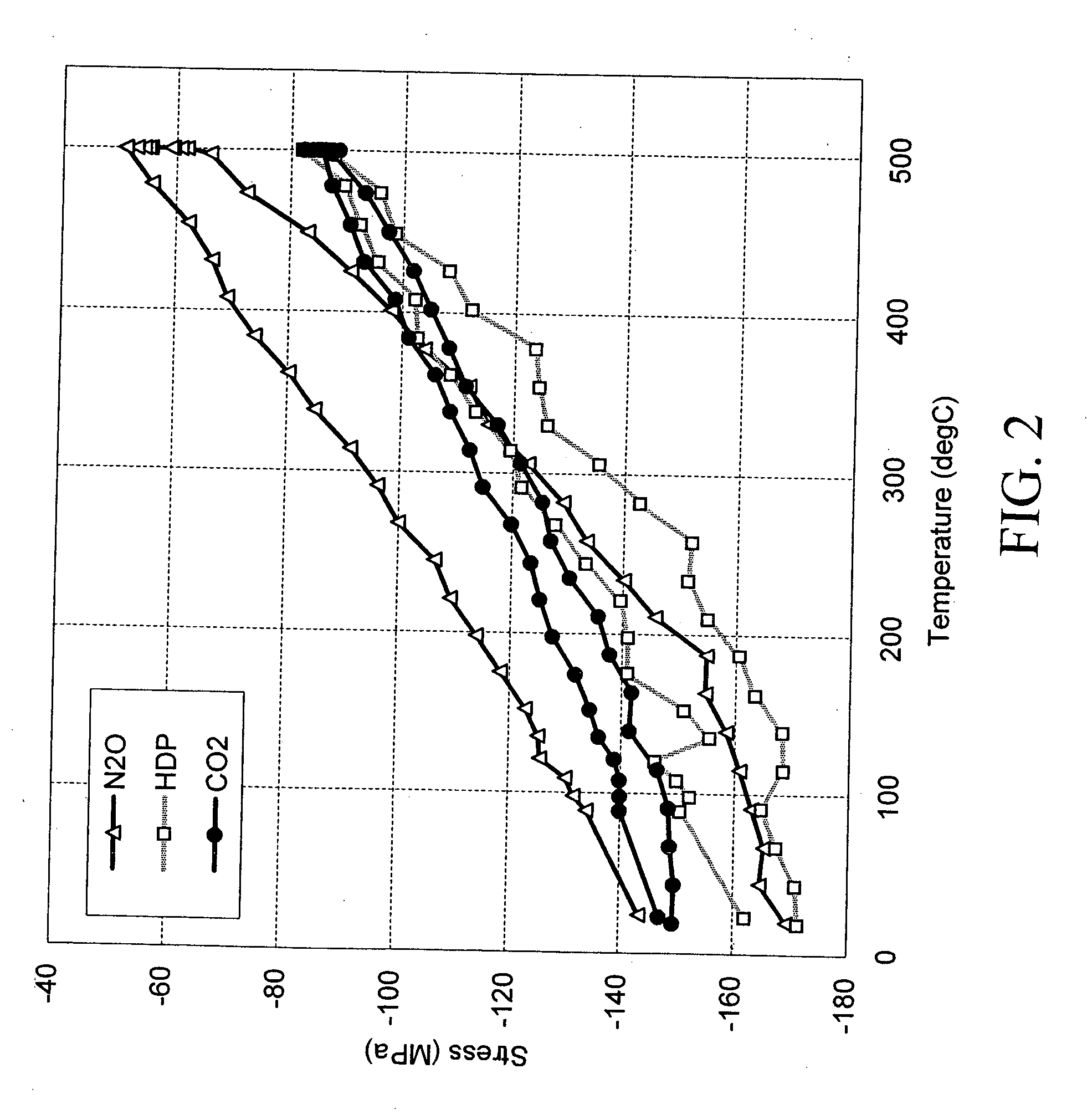

ActiveUS20060046519A1Increase equipment costLow dielectric constantSemiconductor/solid-state device manufacturingChemical vapor deposition coatingCapacitanceReaction field

A method of forming low-dielectric-constant silicon oxide films by capacitive-coupled plasma CVD comprises: introducing a processing gas comprising SiH4 as a silicon source gas, SiF4 as a fluorine source gas, and CO2 as an oxidizing gas to a reaction chamber at a ratio of (SiH4+SiF4) / CO2 in the range of 0.02 to 0.2 and at a total pressure of 250 Pa to 350 Pa; applying first RF power at a frequency of 10 MHz to 30 MHz and second RF power at a frequency of 400 kHz to 500 kHz by overlaying the two RF powers to generate a plasma reaction field within the reaction chamber; and controlling a flow of the respective gases and the respective RF power outputs.

Owner:ASM JAPAN

Resin composition, transparent member obtained from the resin composition, and use of the same

InactiveUS20100256271A1High transparencyHigh refractive indexMaterial nanotechnologyAntimony organic compoundsReaction fieldRefractive index

The present invention provides a resin composition which enables to obtain a transparent member having excellent transparency, high refractive index and high strength and an optical component composed of such a transparent member. A resin composition of the present invention comprises a polymerizable compound or a resin component and an organically modified fine particle produced in the presence of a high-temperature high-pressure water as a reaction field, in which an organic material is bonded to the surface of a metal fine particle.

Owner:MITSUI CHEM INC

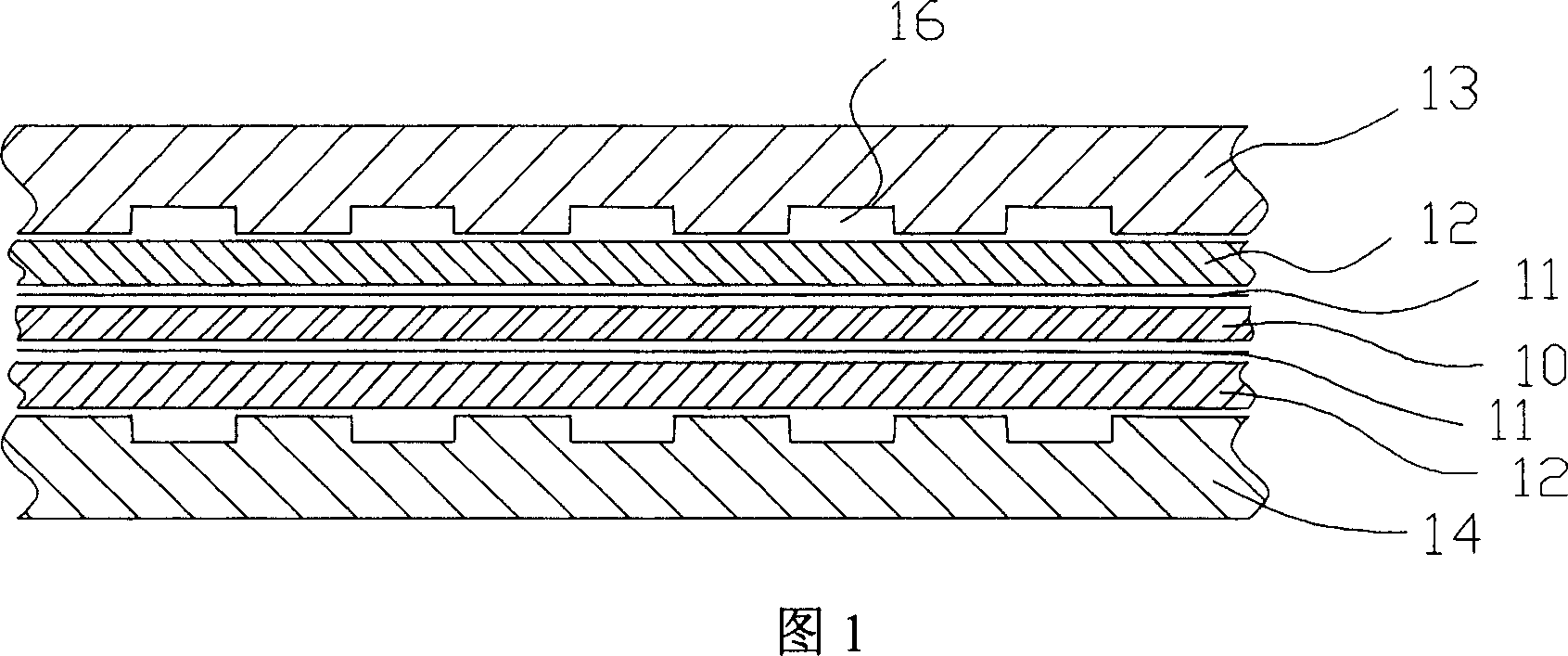

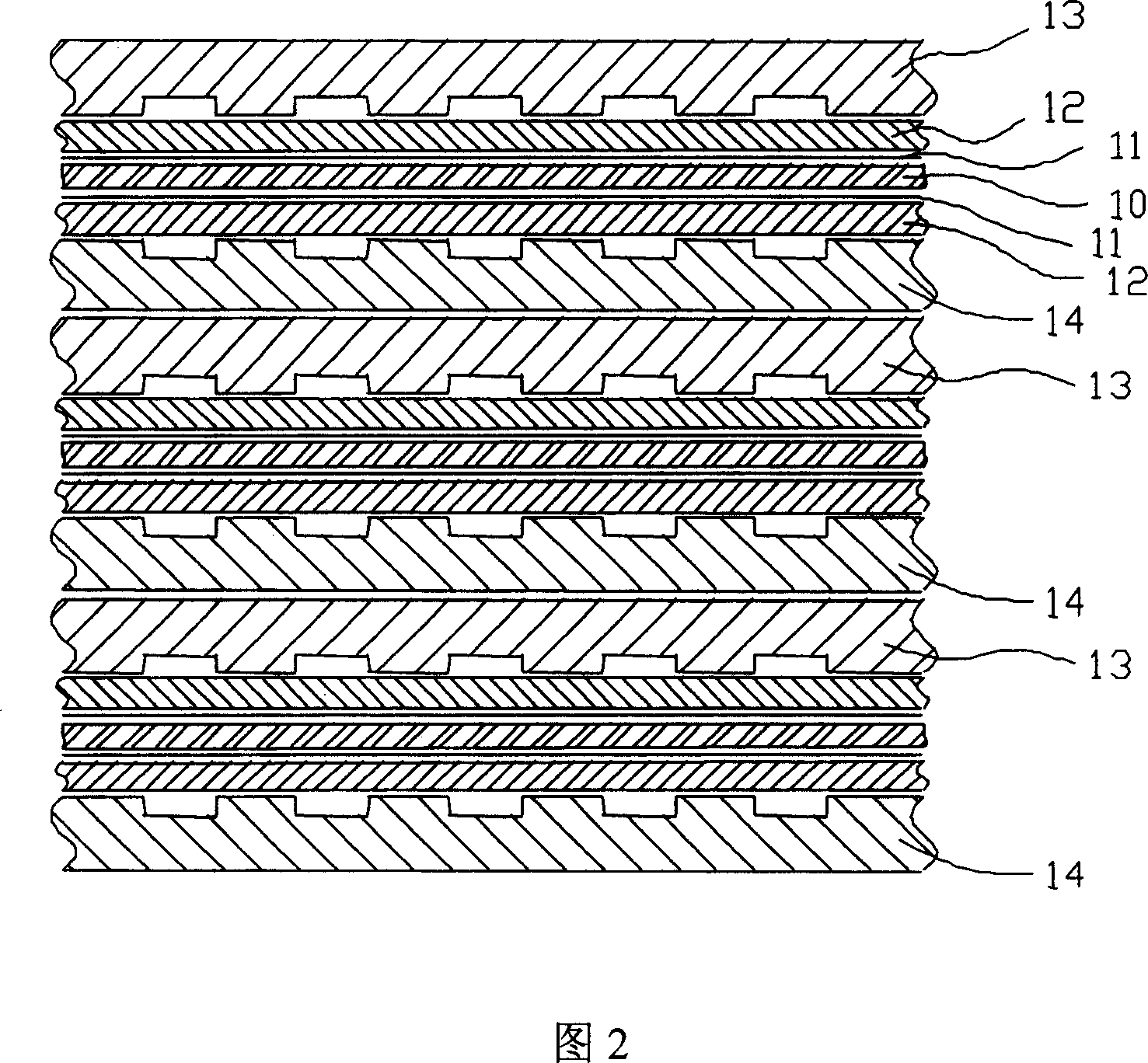

Separated area current detecting system for proton exchange film fuel cell

InactiveCN1945887AAchieving tightnessAchieve insulationElectrical testingSolid electrolyte fuel cellsReaction fieldProton

This invention relates to a regional current test system for proton exchange membrane fuel batteries including an anode collecting board, a membrane electrode and a cathode collecting board, in which, an anode gas flow field is processed on the anode collecting board to provide a flow channel for the anode gas, collect current generated by the membrane electrode and bring out the current, besides, the membrane electrode provides reaction field for anode and cathode reaction gas, and the proton exchange membrane conducts proton and water to finish the reaction, cathode and anode provide reaction field for various gas and convey current to the collecting board. A reaction gas flow field is processed on the cathode collecting board to provide a flow channel for the cathode gas and collect current generated by the membrane electrode to carry it to outside current.

Owner:北京飞驰绿能电源技术有限责任公司

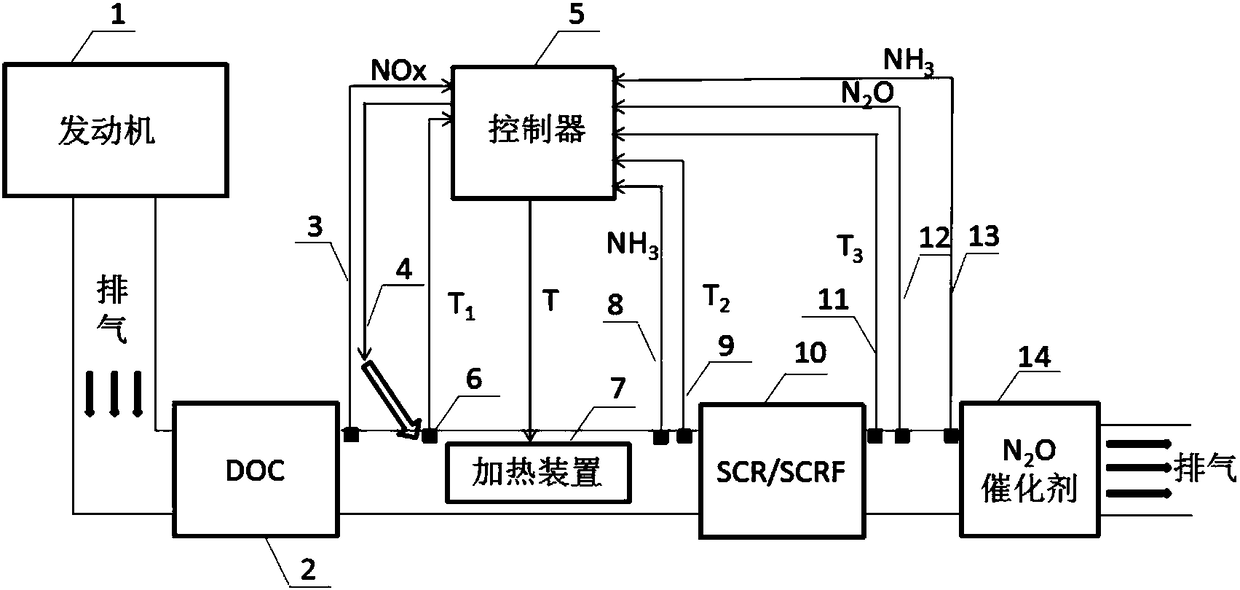

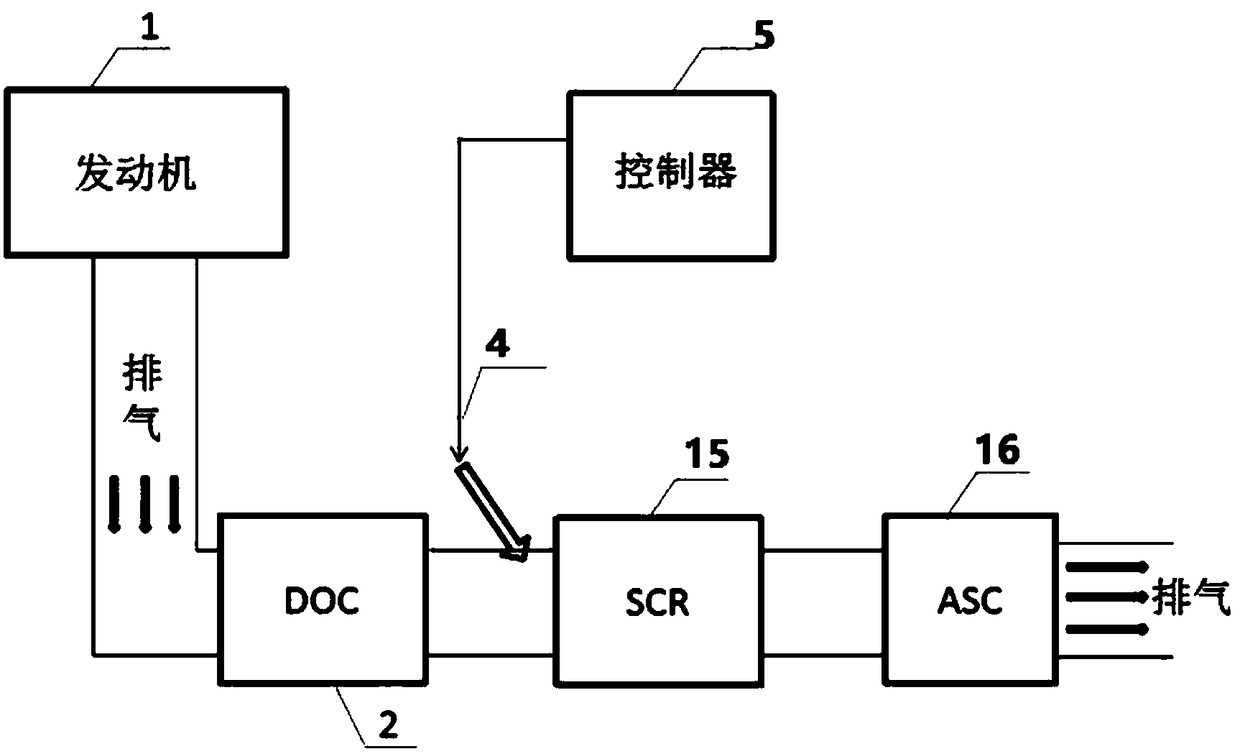

Catalyst system for reducing N2O emission of SCR/SCRF (selective catalytic reduction/self-consistent reaction field) system of diesel engine

InactiveCN108223082AEmission reductionEfficient removalInternal combustion piston enginesExhaust apparatusReaction fieldDiesel engine

The invention discloses a catalyst system for reducing N2O emission of an SCR / SCRF (selective catalytic reduction / self-consistent reaction field) system of a diesel engine. The catalyst system comprises a DOC (diesel oxidation catalyst), a urea injection device, a heating device, a controller, the SCR / SCRF system and an N2O catalyst. The DOC is used for oxidizing NO to obtain NO2 and further improving the NOX conversion efficiency of the SCR / SCRF system; the urea injection device is used for injecting urea into exhaust pipes, and NH3 generated after the urea is decomposed can be used as a reducing agent for SCR and N2O catalytic reduction reaction; the heating device is arranged at the front end of the SCR / SCRF system of the exhaust pipes of the diesel engine and is used for heating exhausted gas; the controller is used for actively controlling catalytic environments according to data measured by sensors; NOX in the exhausted gas can be treated by the SCR / SCRF system; remaining NH3 inthe exhausted gas treated by the SCR / SCRF system is used as a reducing agent for carrying out catalytic reduction on N2O by the N2O catalyst, and accordingly the purpose of removing the N2O can be achieved.

Owner:JIANGSU UNIV

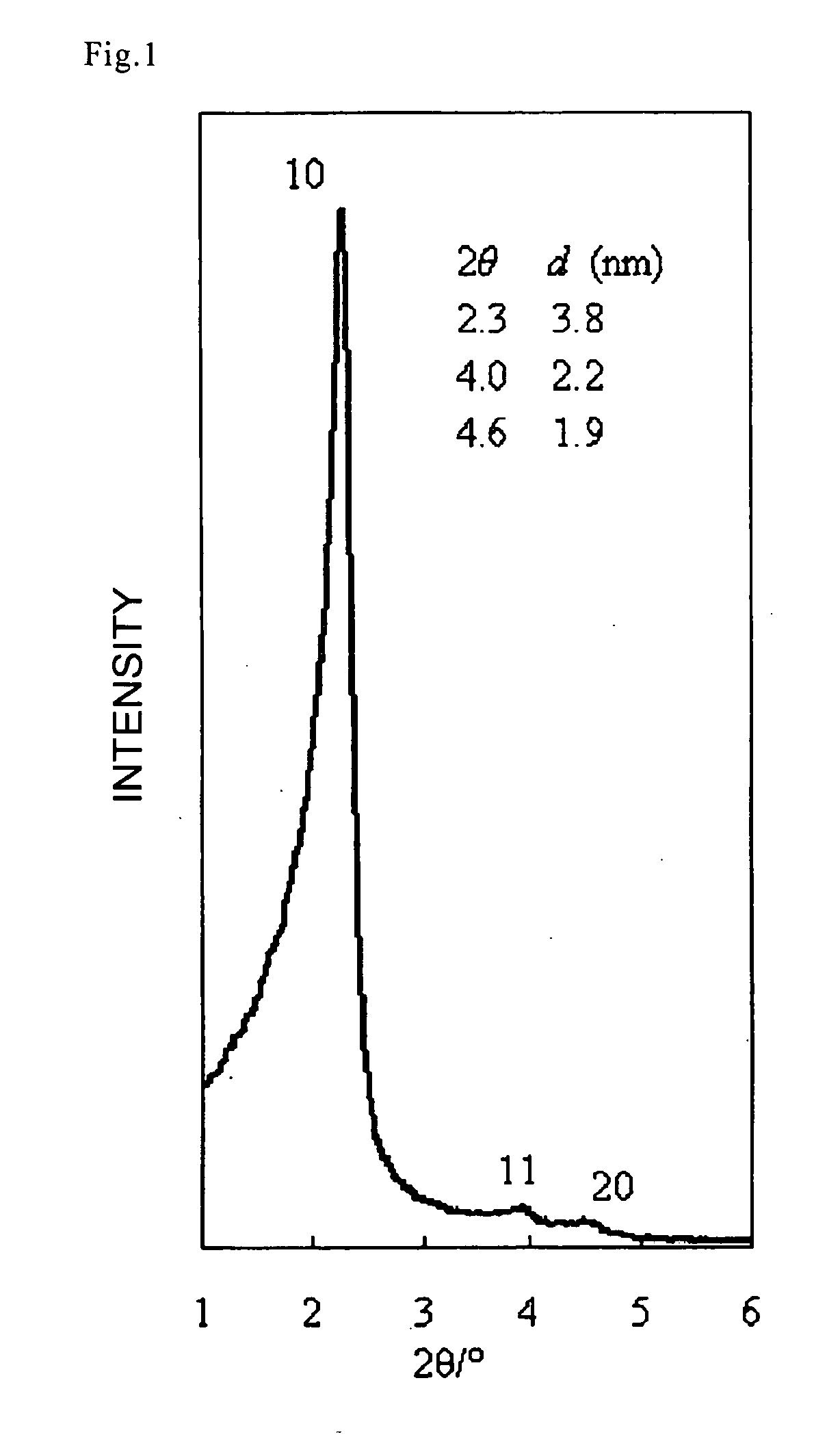

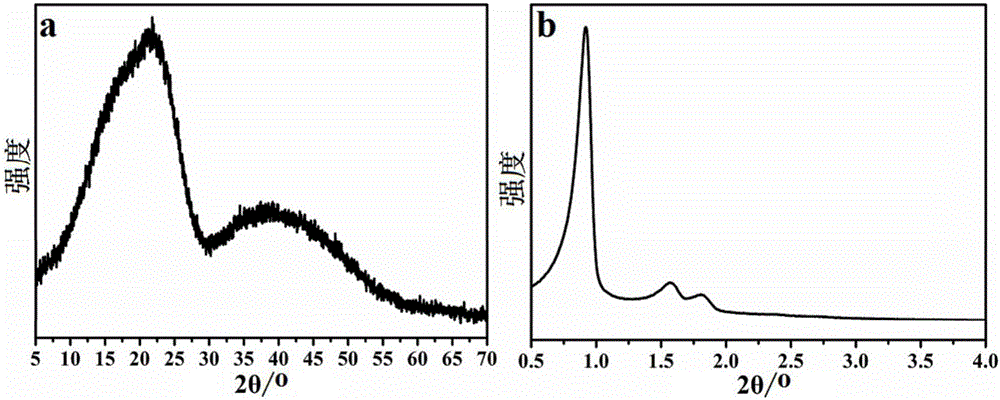

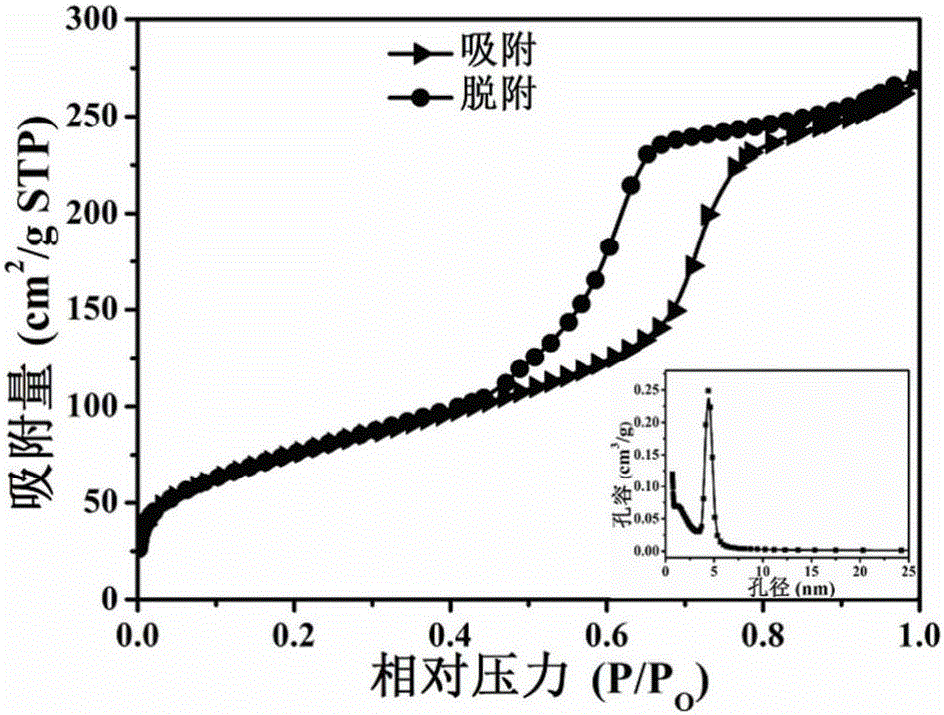

Inorganic mesoporous material having chiral twisted structure and process for producing the same

InactiveUS20090043003A1Easy to useAdjustable sizeMaterial nanotechnologyPolycrystalline material growthReaction fieldEnantioselective synthesis

A chiral inorganic mesoporous material characterized by having a chiral twisted structure and being mesoporous; a process for producing the material; and a method of using the material. The process for inorganic mesoporous material production is a method in which one or more polymerizable inorganic monomers selected from the group consisting of polymerizable inorganic monomers and polymerizable inorganic monomers having a functional group capable of having a charge are polymerized in the presence of a solvent using as a template a self-assembly of a chiral surfactant such as an N-(higher alkanoyl)amino acid salt. Examples of the use of the inorganic mesoporous material include the separation of racemates and reaction fields for asymmetric syntheses.

Owner:JAPAN SCI & TECH CORP

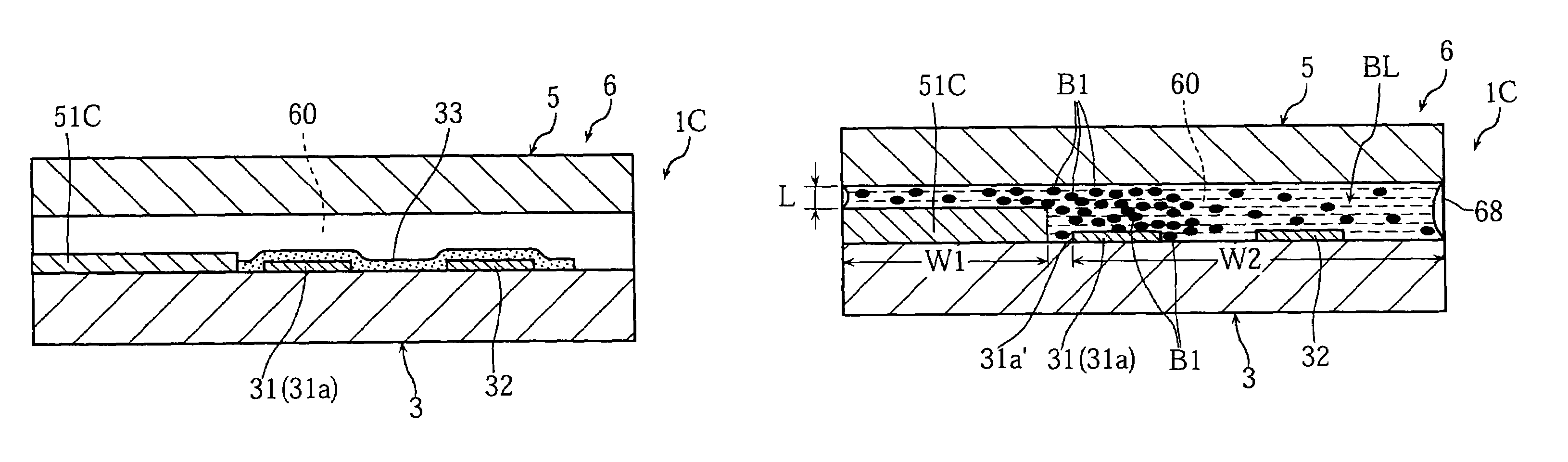

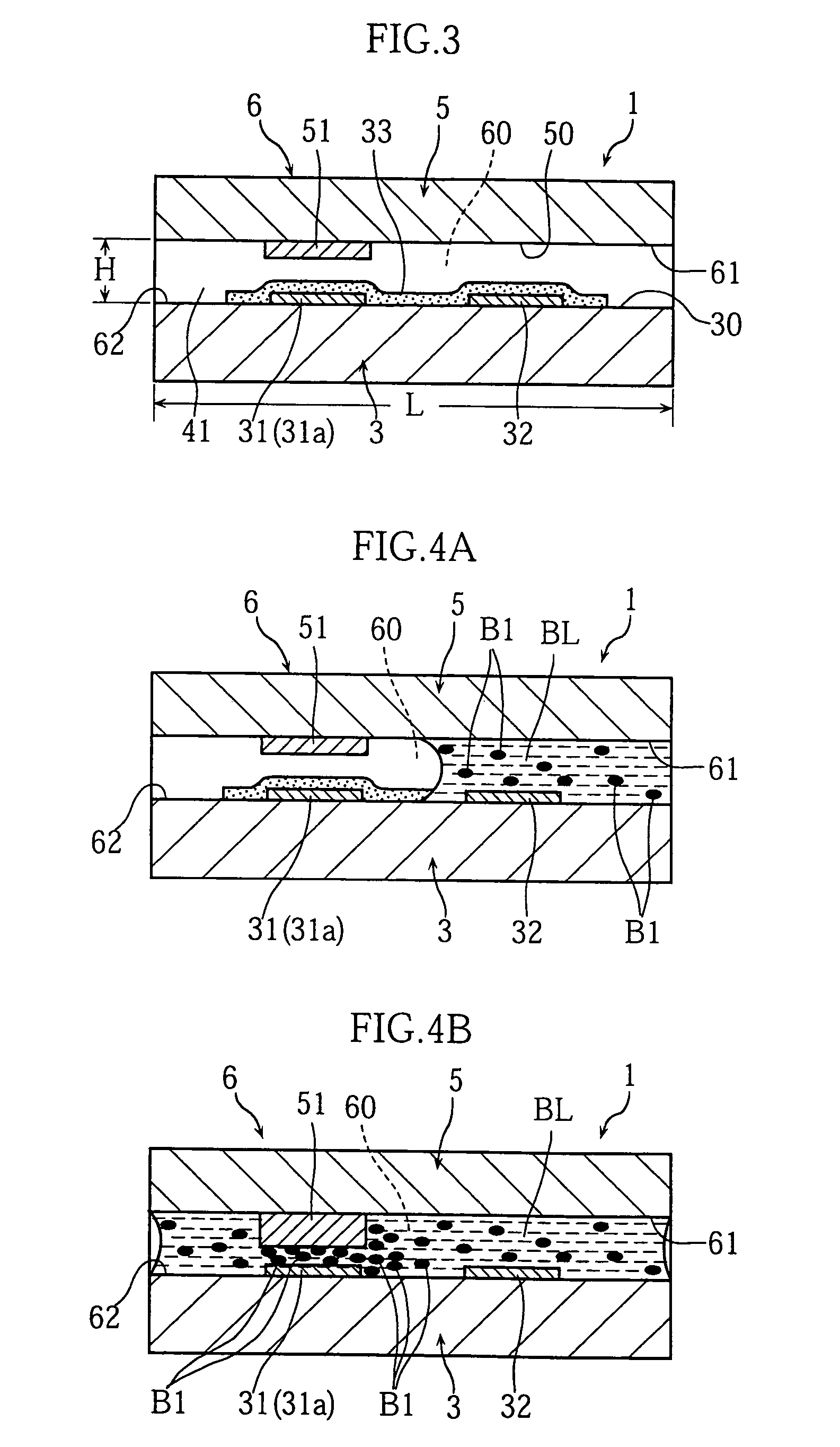

Measuring instrument provided with solid component concentrating means

InactiveUS7201042B2Short measurement timeImprove concentrationImmobilised enzymesBioreactor/fermenter combinationsReaction fieldSolid component

The present invention relates to a measuring instrument (1) comprising a channel (60) for moving a sample liquid (BL) containing a solid component (B1) and providing a liquid reaction field and first and second electrodes (31, 32) which are used to apply voltage to the liquid reaction field. The first electrode (31) has an electron transfer interface (31a) for transferring electrons between it and the liquid reaction field when voltage is applied to the liquid reaction field via the first and second electrodes (31, 32). The measuring instrument (1) comprises concentrating means (51) for increasing the concentration of solid components at portions thereof which contact the electron transfer interface (31a) in the liquid reaction field. The concentrating means (51) preferably comprises a water-absorbing layer containing an absorbent polymer material.

Owner:ARKRAY INC

Method for preparing large surface improved aluminium oxide with high temperature resistant performance

ActiveCN101168125ALarge specific surface areaGood dispersionHydrogenDispersed particle separationPartial oxidationSource material

The invention relates to a method of utilizing co-precipitation method to prepare modified alumina. Firstly, M-source materials and soluble aluminium salts are accurately weighed according to stoichiometric ratio needed by M-Al2O3, then M-source materials and soluble aluminum are dissolved in water, surface active agent is then added into the water with M-source materials and soluble aluminum, the mixed liquid is mixed and then precipitated with the solution of ammonium carbonate with dispersants under the temperature of 40 to 80 DEG C, pH(potential of Hydrogen) value is finally adjusted to 7 to 11, the mixed liquid is then vigorously stirred for 3 to 24 hours, filtered, washed, dried under the temperature of 100 to 120 DEG C, roasted for 4 to 6 hours under the temperature of 500 to 550 DEG C, and is reroasted for 2 to 6 hours under the temperature of 1100 to 1250 DEG C, and finally the produce is prepared. The invention has the advantages of low cost of raw materials, low temperature for synthesizing, simple operation, no pollution, good repeatability and easiness for large scale preparation, thereby being capable of promoting large scale commercial production of the modified alumina. Consequently, the invention can be pushed to be applied in reaction fields such as purifying exhaust gas of automobiles, methane partial oxidation to syngas, catalytic decomposition of propellant used in spacecraft and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

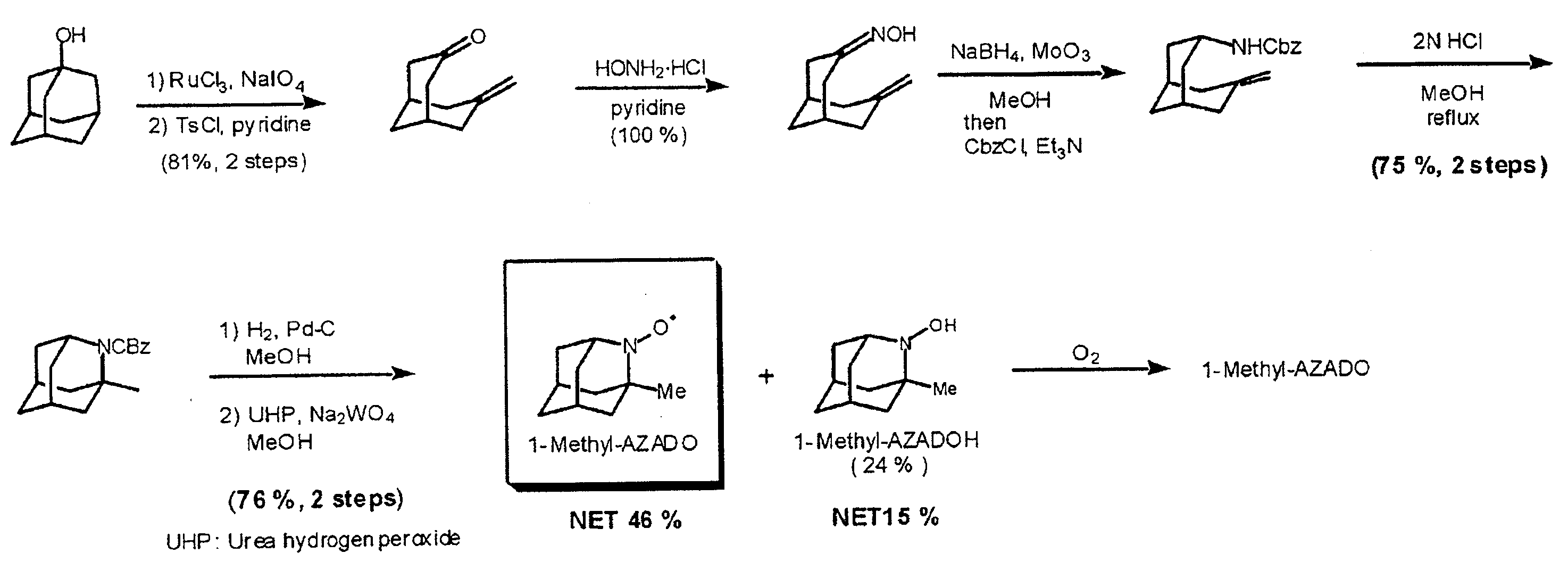

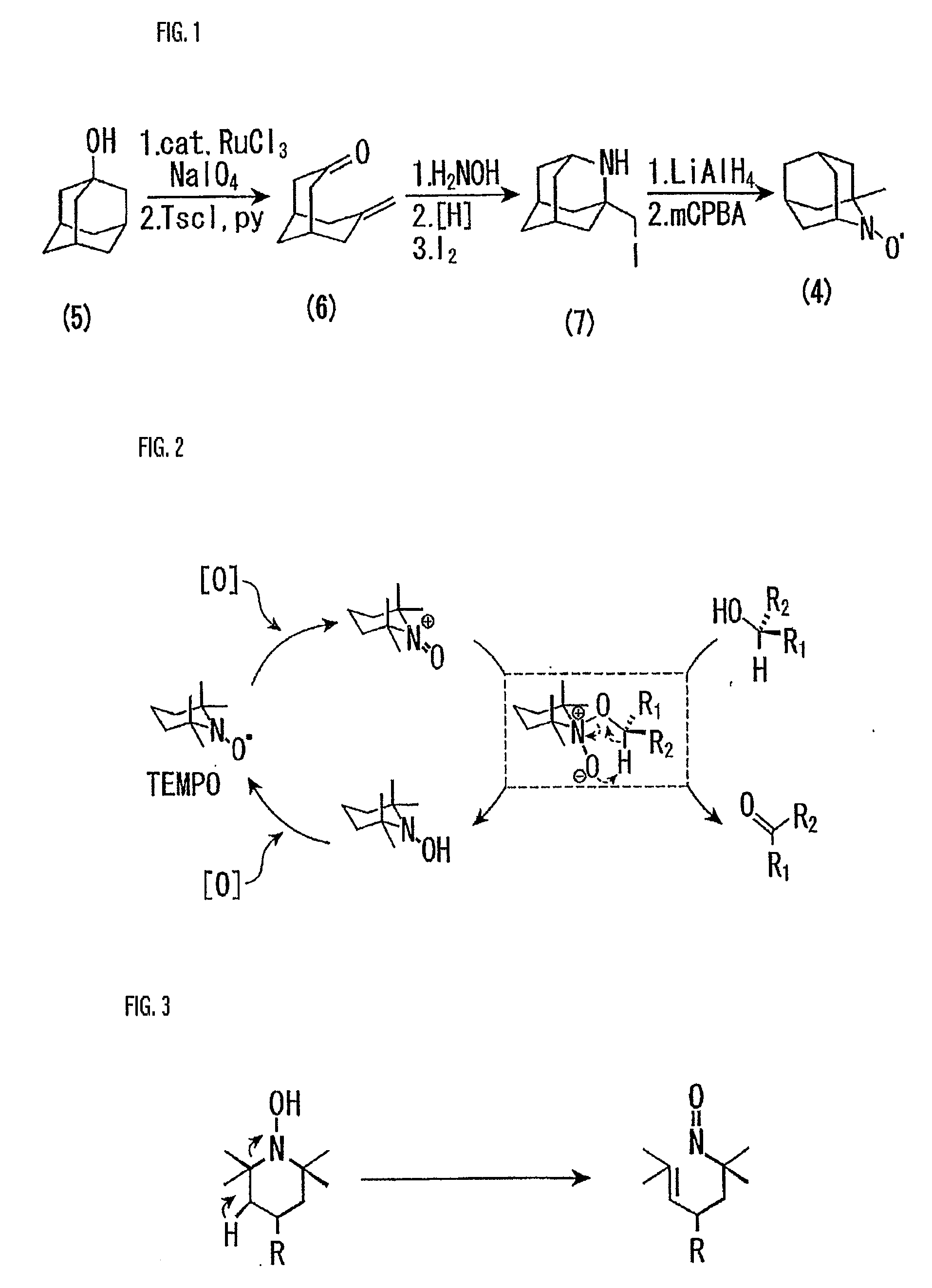

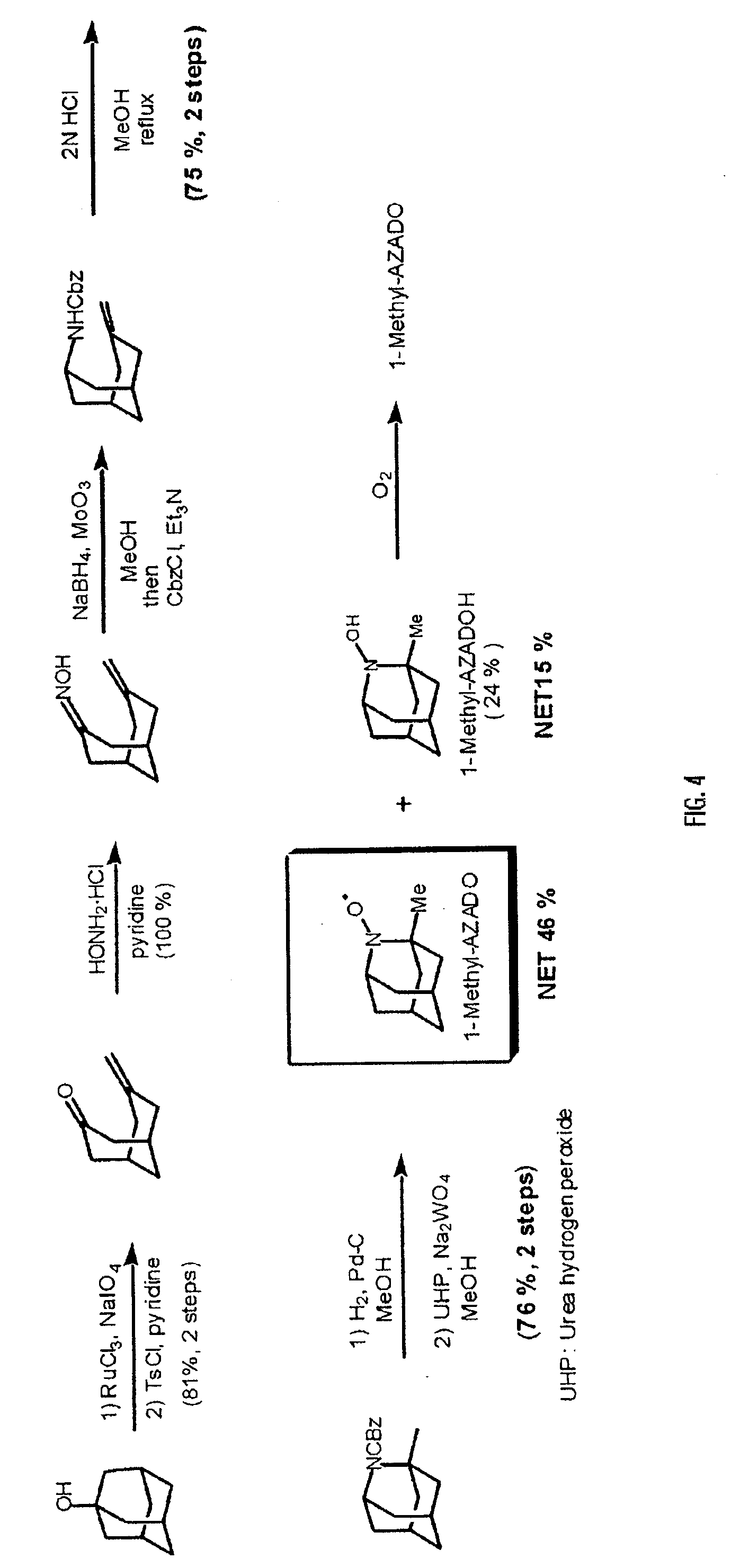

Alcohol Oxidation Catalyst and Method of Synthesizing the Same

InactiveUS20070232838A1Small loadSimple structureOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsReaction fieldHydrogen

An organic oxidation catalyst for alcohols which is environmentally less harmful and with which efficient oxidation can be conducted. The oxidation catalyst for alcohols is a 1-alkyl-2-azadamantan-N-oxyl which has a nitroxyl group incorporated in the adamantane skeleton and was synthesized from as a base material a bicyclic compound obtained by the Grob-type ring-opening reaction of 1,3-adamantanediol. Due to the nitroxyl group on the adamantane skeleton, the α-position hydrogen is stabilized based on Bredt's rule and the stability of the oxoammonium group generated by the oxidation thereof is ensured. Compared to TEMPO, which is a conventional oxidation catalyst, this catalyst is reduced in steric hindrance and is usable in a wide range of reaction fields. Because of this, not only a primary alcohol but a secondary alcohol having a sterically complicated structure, which has been difficult to oxidize with TEMPO, can be oxidized at a high efficiency.

Owner:NISSAN CHEM IND LTD

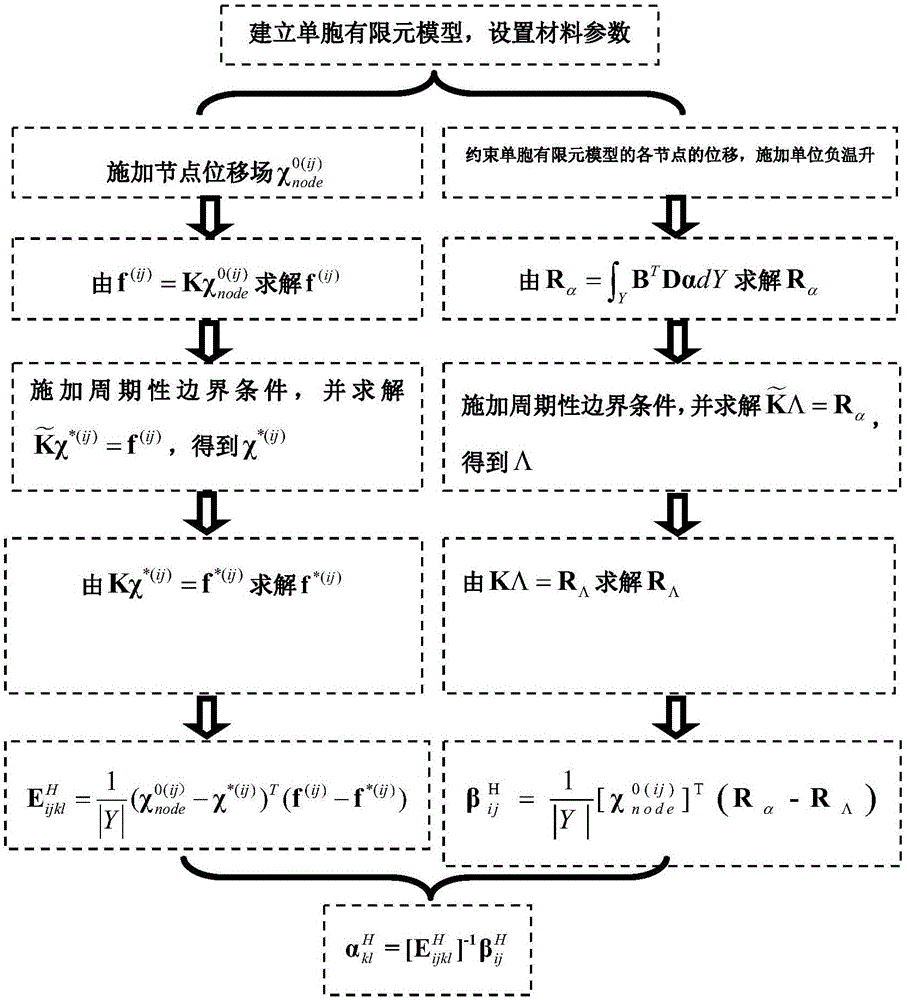

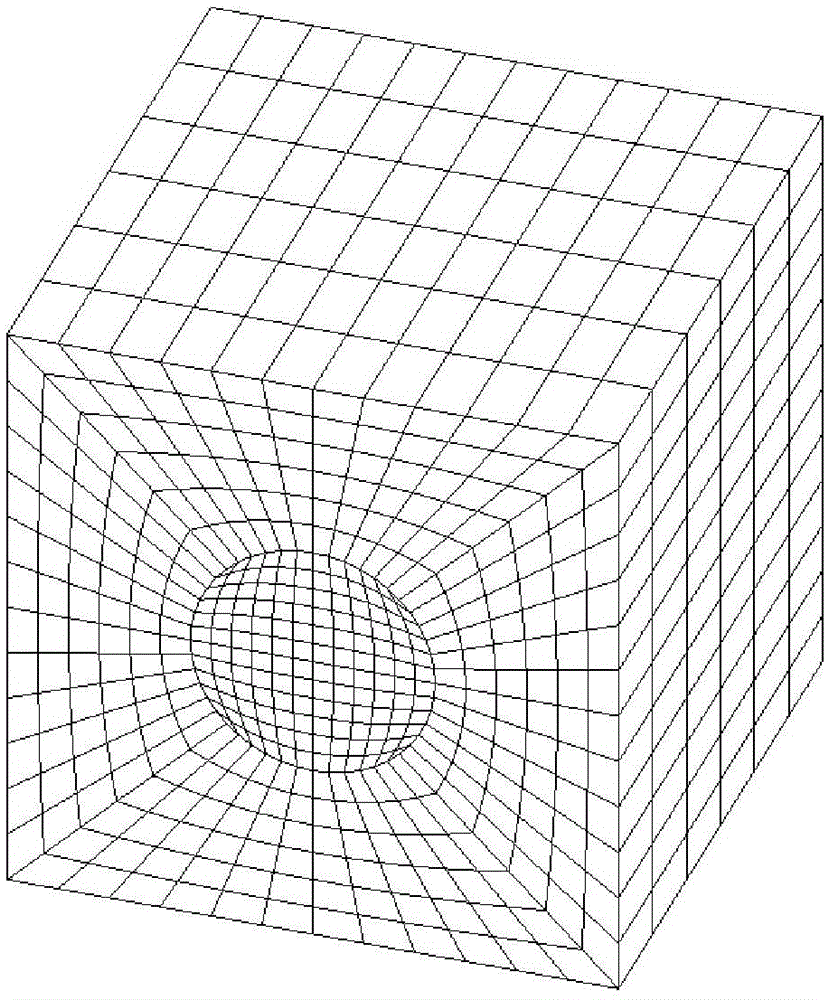

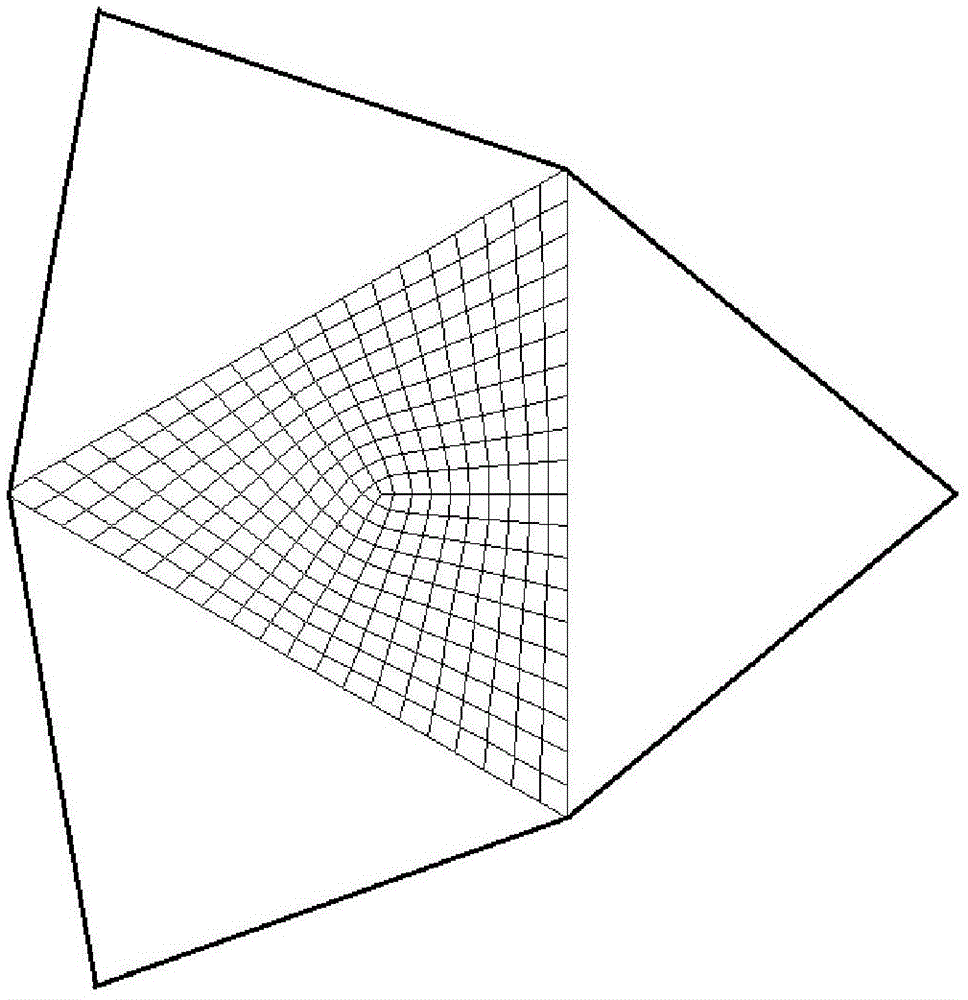

Simple implementation method for performing gradual homogenized prediction on thermal expansion coefficient of periodic composite material

InactiveCN105160085AImproved coefficient of thermal expansionImprove adaptabilitySpecial data processing applicationsReaction fieldElement model

The present invention discloses a simple implementation method for performing gradual homogenized prediction on a thermal expansion coefficient of a periodic composite material. The method comprises the following steps: establishing a single-cell finite element model by means of commercial finite element software, and setting a material parameter in the single-cell finite element model; performing finite element grid division on the single-cell finite element model to obtain nodes and unit information of the single-cell finite element model; determining an initial displacement field according to node coordinate values of the single-cell finite element model; calculating a periodic structure equivalent elastic modulus and a periodic structure equivalent thermoelastic constant; and calculating a thermal expansion coefficient of a periodic composite material. The simple implementation method for performing gradual homogenized prediction on the thermal expansion coefficient of the periodic composite material disclosed by the present invention is convenient to execute, and the method is capable of using the conventional commercial finite element software as a black box to predict the thermal expansion coefficient of the periodic composite material, so that adaptability of a homogenization method is greatly improved; and a process of resolving a strain field in original homogenization and performing integration on each unit is converted to a product of a corresponding displacement field and a node reaction field, which can be obtained in the commercial finite element software, and the process is simplified.

Owner:DALIAN UNIV OF TECH

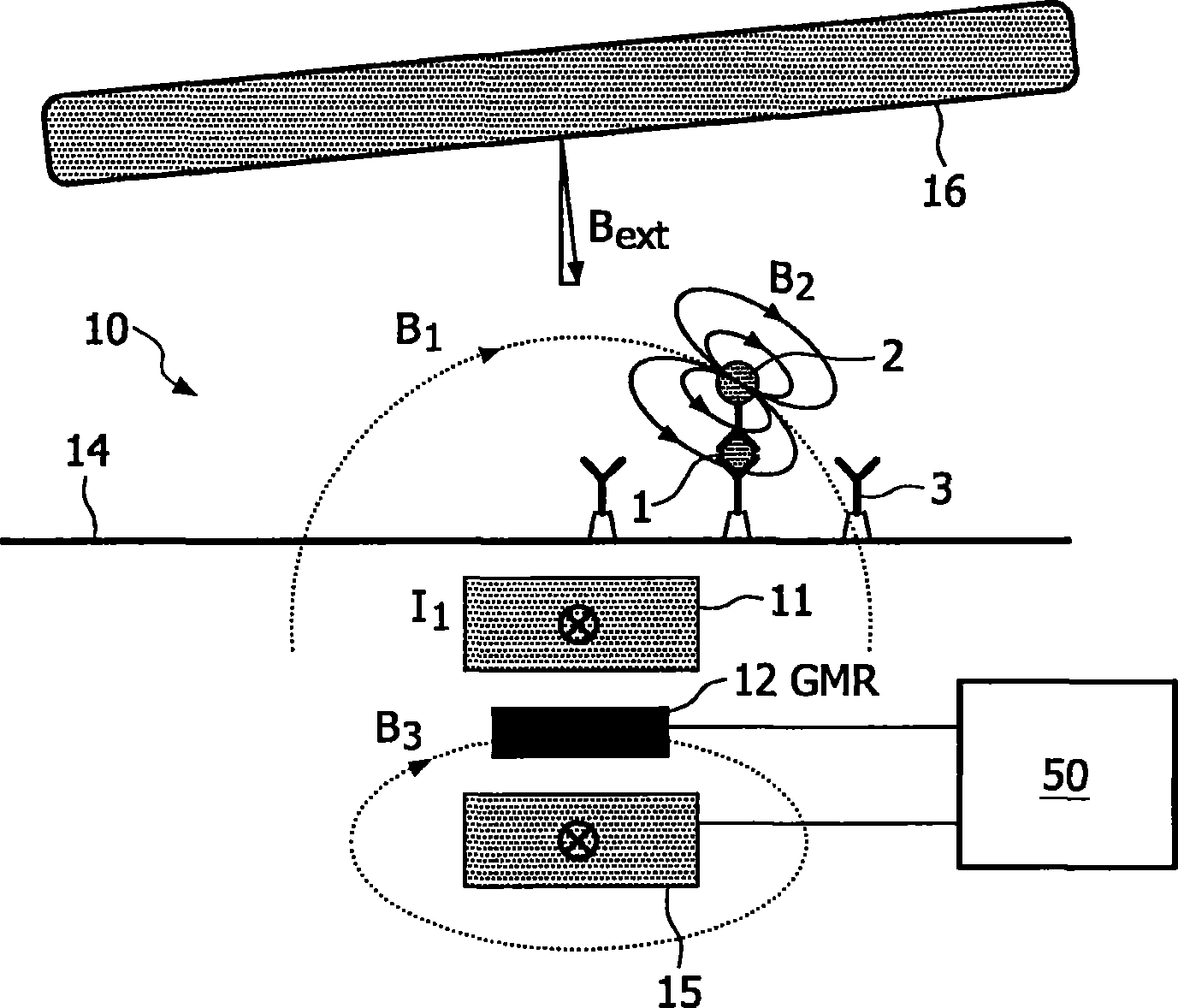

Sensor device with adaptive field compensation

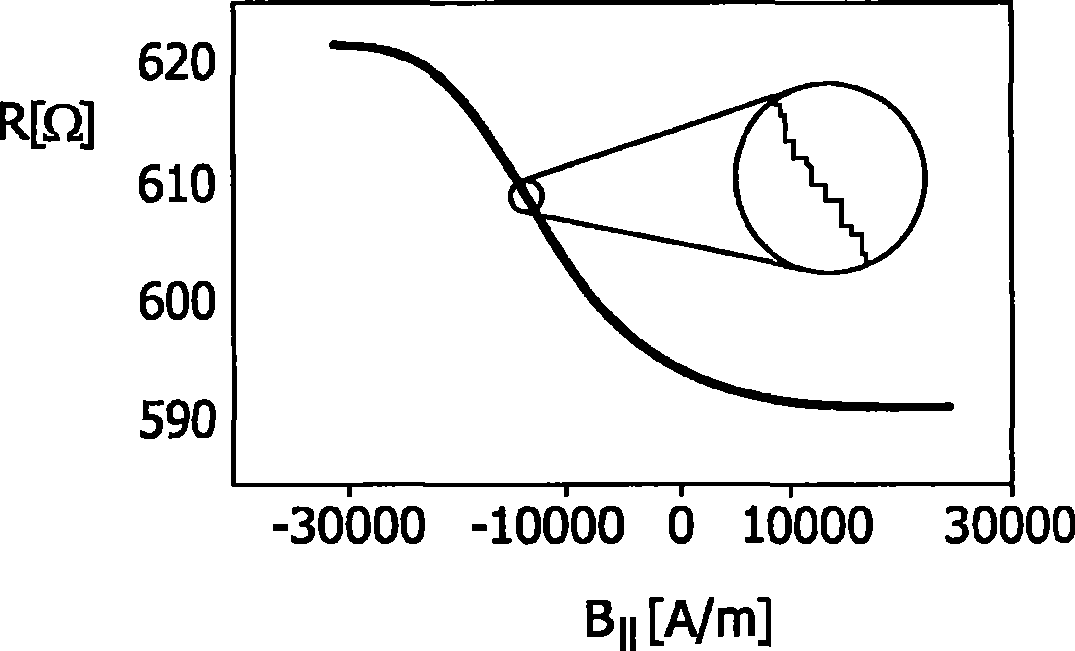

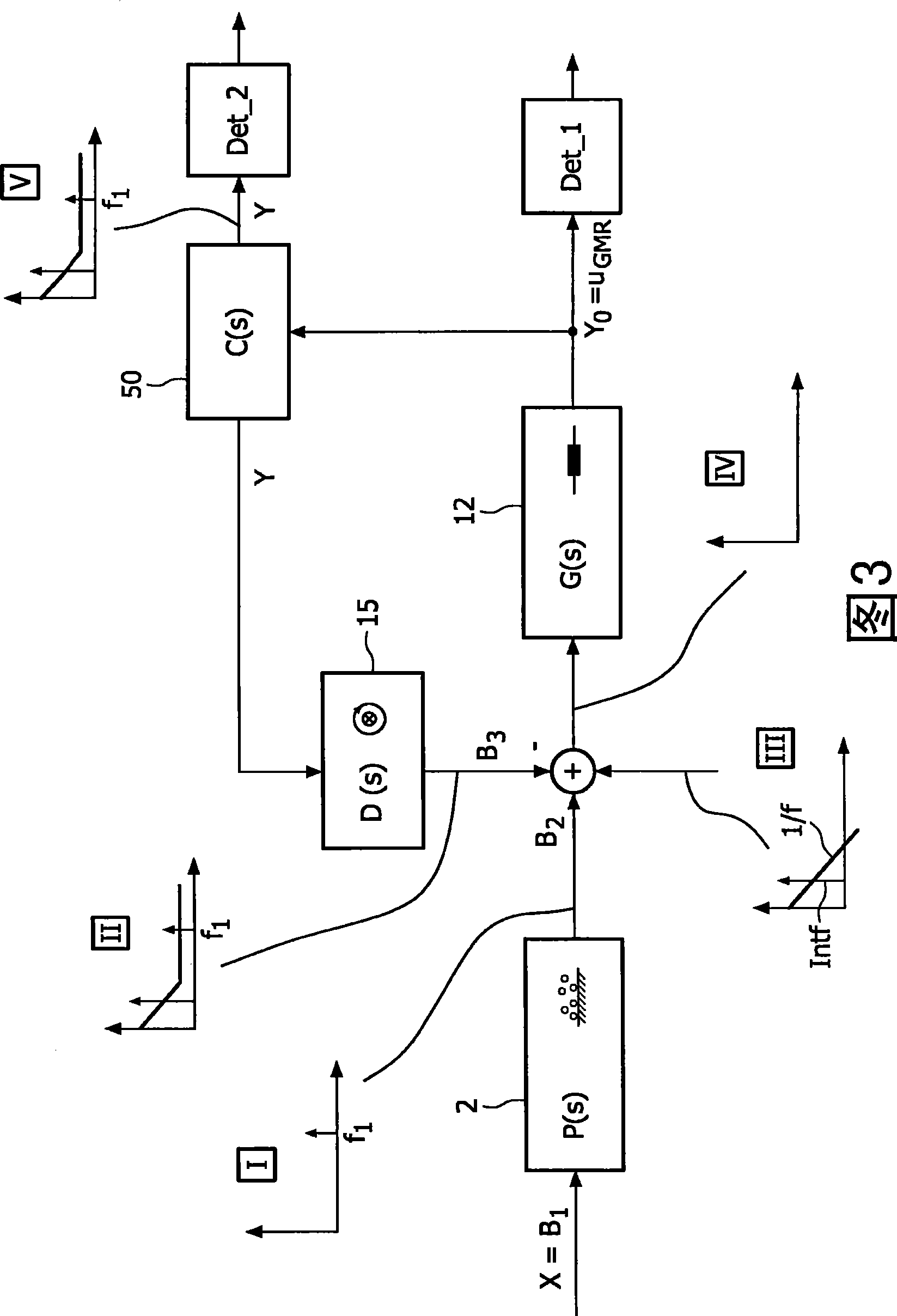

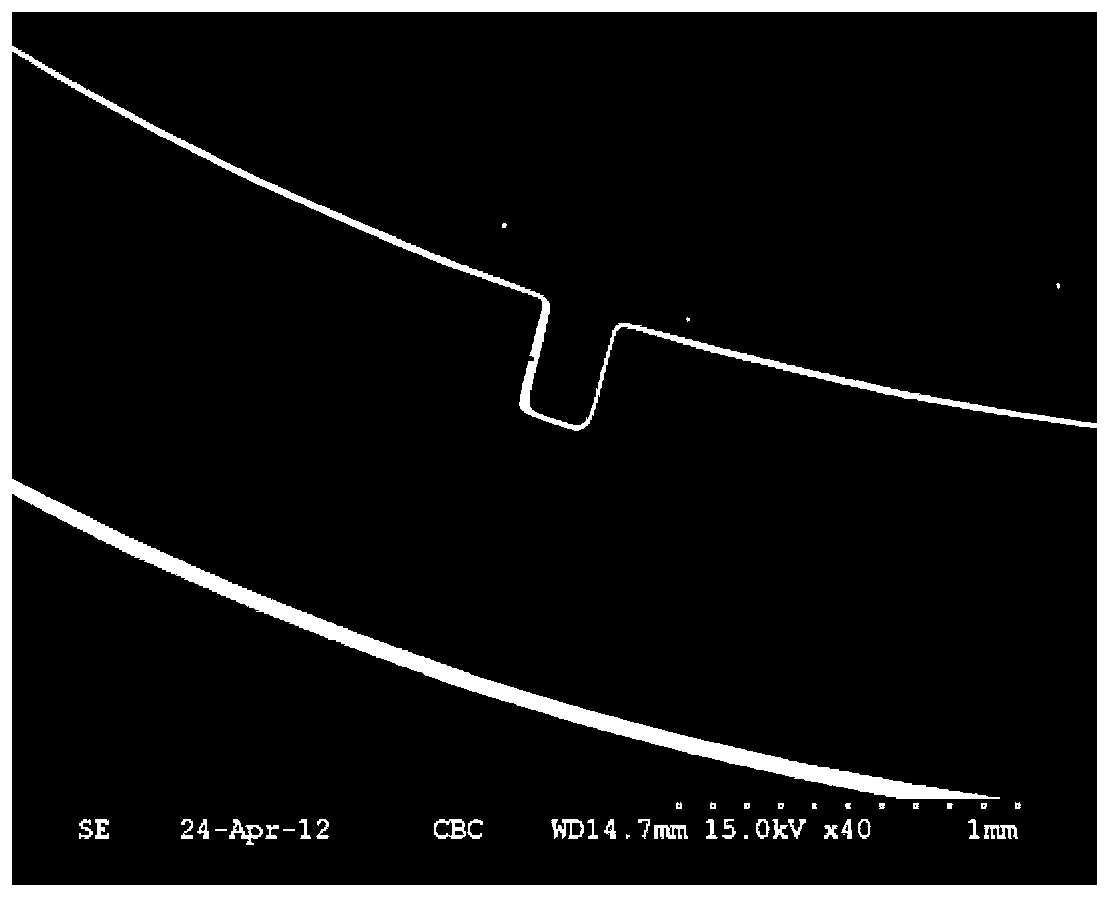

InactiveCN101454683ANanomagnetismMaterial analysis by electric/magnetic meansReaction fieldAtomic physics

The invention relates to a magnetic sensor device comprising an excitation wire for the generation of an alternating magnetic excitation field (Bi) and a GMR sensor (12) for sensing reaction fields (B2) generated by magnetized particles (2) in reaction to the excitation fields. Moreover, it comprises a compensator (15) for the generation of a magnetic compensation field (B3) that adaptively cancels predetermined spectral components of all magnetic fields (B2, B3) which lie in the sensitive direction of the magnetic sensor element (12). Measurements of the GMR sensor (12) are thus made robust against gain variations of the sensor.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

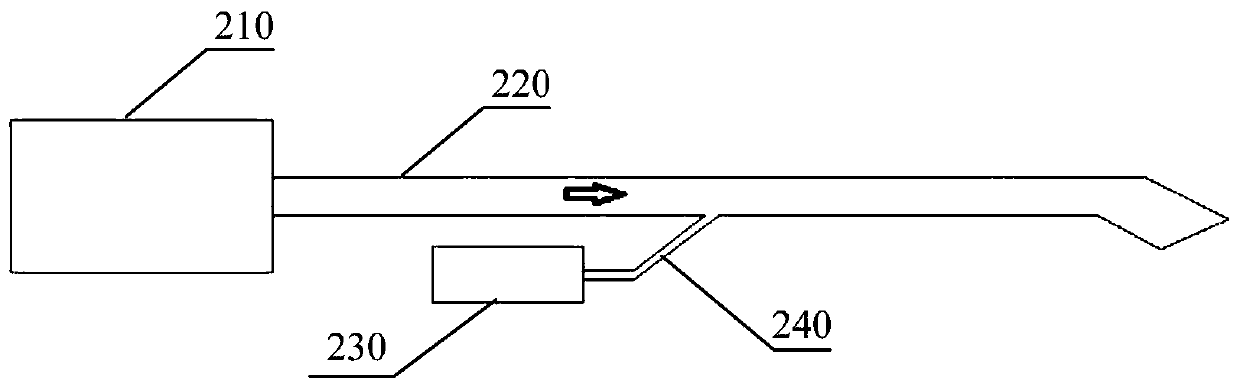

Passive spiral micro-structural mixing unit and application thereof

ActiveCN102974255AEnhanced mixing processImprove the mixing effectNanotechFlow mixersReaction fieldEngineering

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Gas treatment system and method

InactiveCN111068916AEasy to understandInternal combustion piston enginesExhaust apparatusParticulatesReaction field

The invention provides a gas treatment system and method. The gas treatment system comprises a gas dedusting system and a gas ozone purification system. The gas dedusting system comprises a dedustingsystem inlet, a dedusting system outlet and an electric field device. The gas ozone purification system comprises a reaction field for the mixed reaction of an ozone stream and a gas stream. The gas treatment system disclosed by the invention can effectively remove particulate matters in gas and has a better gas purification treatment effect.

Owner:SHANGHAI BIXIUFU ENTERPRISE MANAGEMENT CO LTD

Acid-base bifunctional solid catalyst and preparation method thereof

InactiveCN106311345AHigh specific surface areaImprove thermal stabilityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsMolecular sieveCellulose

The invention belongs to the field of heterogeneous catalysts, and particularly provides an acid-base bifunctional solid catalyst and a preparation method thereof. The method comprises the steps that a silica-based mesoporous molecular sieve SBA-15 is selected as a carrier, ZrO2 / SO4<2-> type solid superacid is loaded, obtained solid superacid is subsequently grafted with an acidic -SO3H group and a basic -NH2 group through a silane coupling reaction, and the acid-base bifunctional solid catalyst is obtained. The defects that in the reaction field of preparing 5-hydroxymethylfurfural (5-HMF) from cellulose, the activity is not high, and the selectivity is poor are overcome, and the preparation method of the acid-base bifunctional heterogeneous solid catalyst with a large specific surface area is provided.

Owner:JIANGSU UNIV

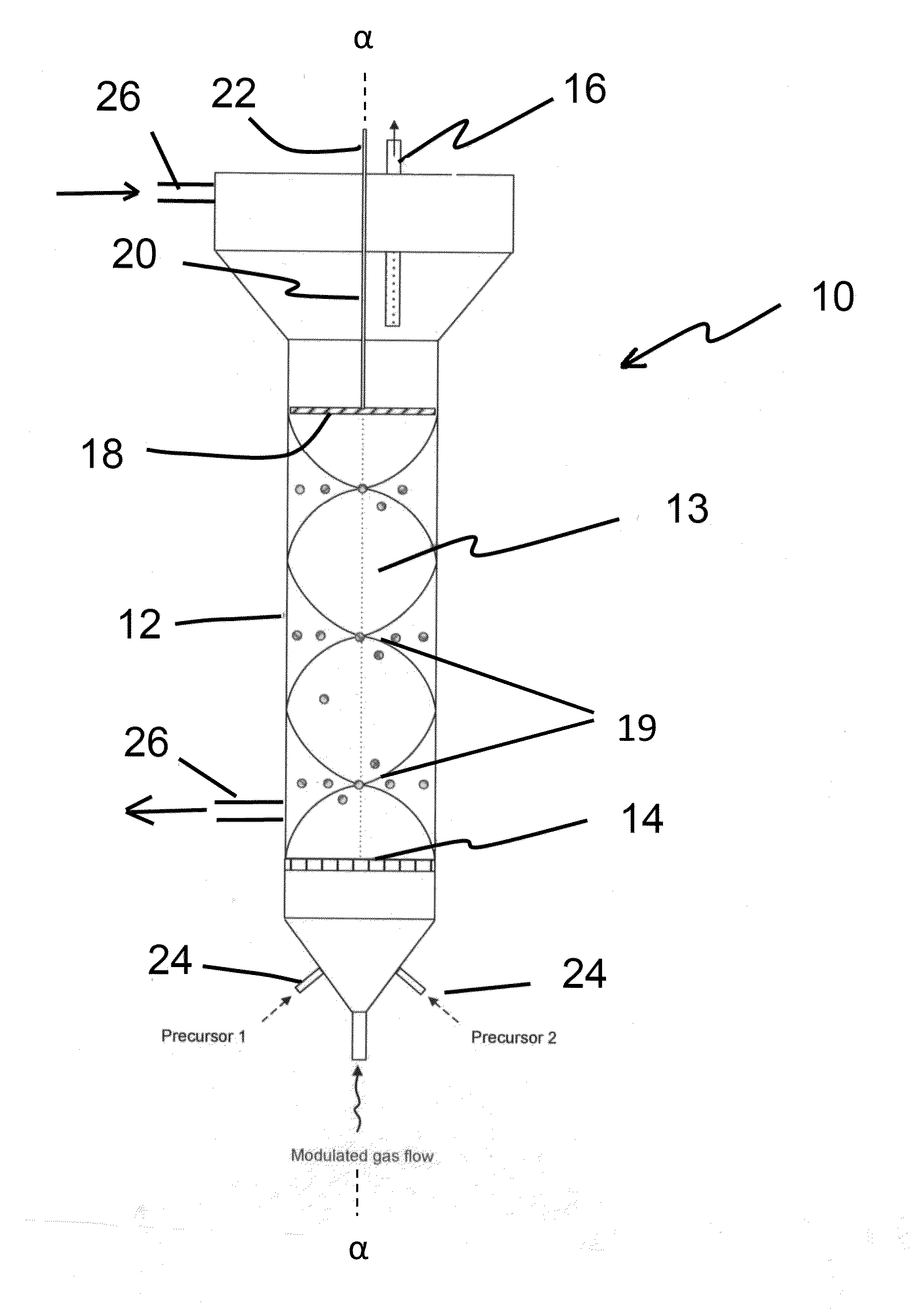

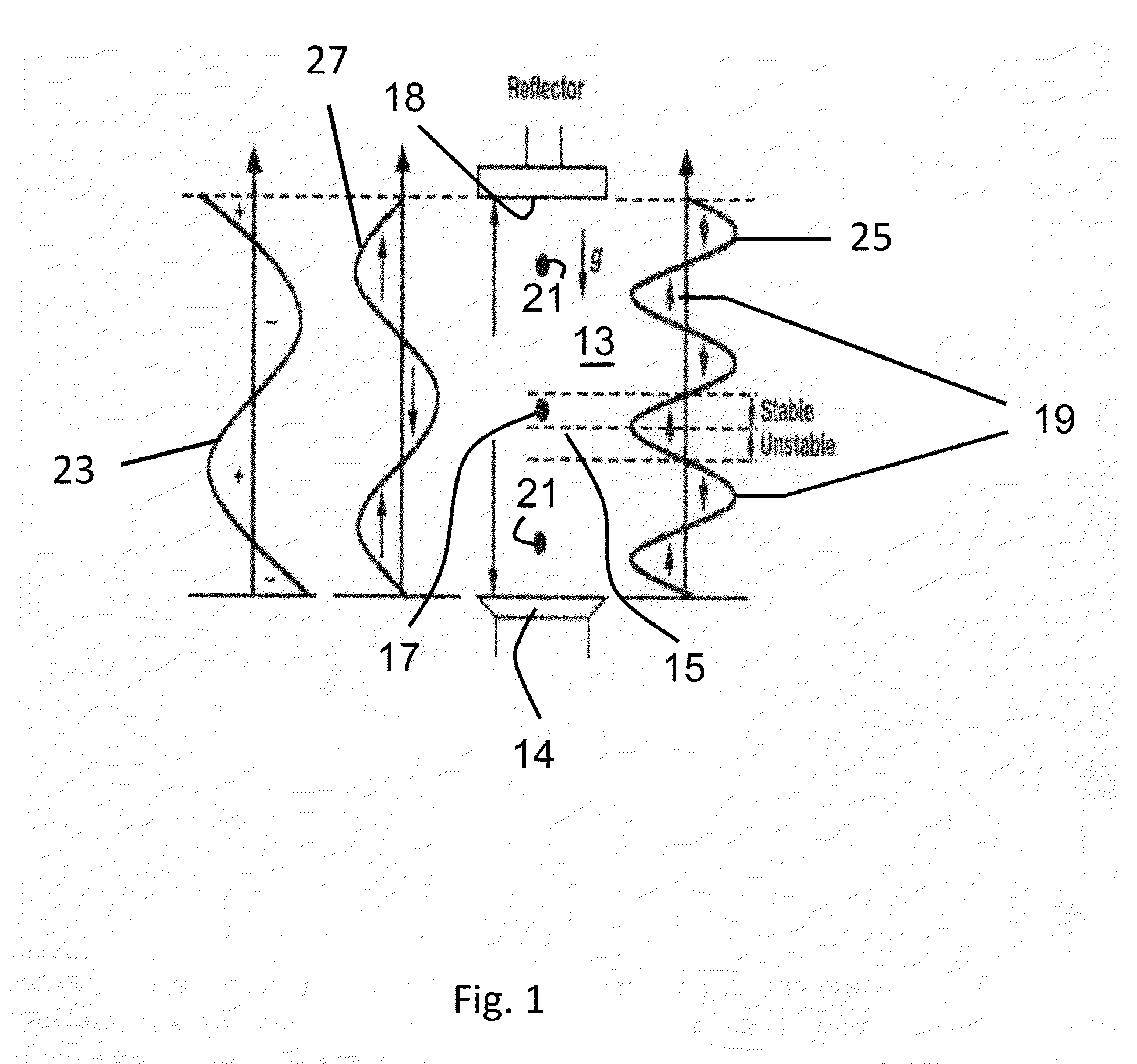

Method for fluidizing and coating ultrafine particles, device for fluidizing and coating ultrafine particles

ActiveUS20130202790A1Prevent unwanted reactionImprove performanceLiquid surface applicatorsGranule coatingReaction fieldPhysical chemistry

The invention provides a method for dispersing particles within a reaction field, the method comprising confining the particles to the reaction field using a standing wave. The invention also provides a system for coating particles, the system comprising a reaction zone; a means for producing fluidized particles within the reaction zone; a fluid to produce a standing wave within the reaction zone; and a means for introducing coating moieties to the reaction zone. The invention also provides a method for coating particles, the method comprising fluidizing the particles, subjecting the particles to a standing wave; and contacting the subjected particles with a coating moiety.

Owner:UCHICAGO ARGONNE LLC

Sample analyzing method and sample analyzing device

ActiveUS7537684B2Improve accuracyImmobilised enzymesBioreactor/fermenter combinationsReaction fieldEngineering

This invention relates to a technique for analyzing a sample. A sample analyzer (1) provided by the invention includes: a voltage applier (12) for applying a voltage to a reaction field which includes a sample; a response measurer (13) for measurement of a response to the voltage applied to the reaction field; a selector (11) for selecting a first voltage application state for measurement of a first response for use in calculation necessary for analyzing the sample or a second voltage application state for measurement of a second response for use in determining whether or not the reaction field has been supplied with a target amount of the sample; an arithmetic operator (17) for calculation necessary for analyzing the sample based on the first response; a determiner (17) for determination, based on the second response, on whether or not the reaction field has been supplied with the target amount of sample; and a controller (15) which makes the selector select the second voltage application state after making the selector select the first voltage application state.

Owner:ARKRAY INC

Catalyst for removing metal carbonyl, process for producing mixed reformed gas containing hydrogen, process for removing metal carbonyl, and fuel cells system

InactiveUS20070281203A1Efficient removalCell electrodesHydrogen/synthetic gas productionIridiumClay minerals

The present invention relates to a catalyst for removing a metal carbonyl which comprises a nickel-containing catalyst component and copper, said copper being present in an amount of 0.001 to 250% by weight in terms of metallic copper on the basis of a weight of the nickel contained in the catalyst component. The catalyst may further contain, if required, zinc oxide, a clay mineral, or a clay mineral supporting at least one element having an average particle diameter of not more than 50 nm which is selected from the group consisting of ruthenium, rhodium, iridium, platinum, gold, silver, palladium, nickel, cobalt, copper, iron, zinc, vanadium and manganese. When using the catalyst, it is possible to produce a mixed reformed gas from hydrocarbons, and remove a metal carbonyl in a reforming reaction field.

Owner:TODA IND

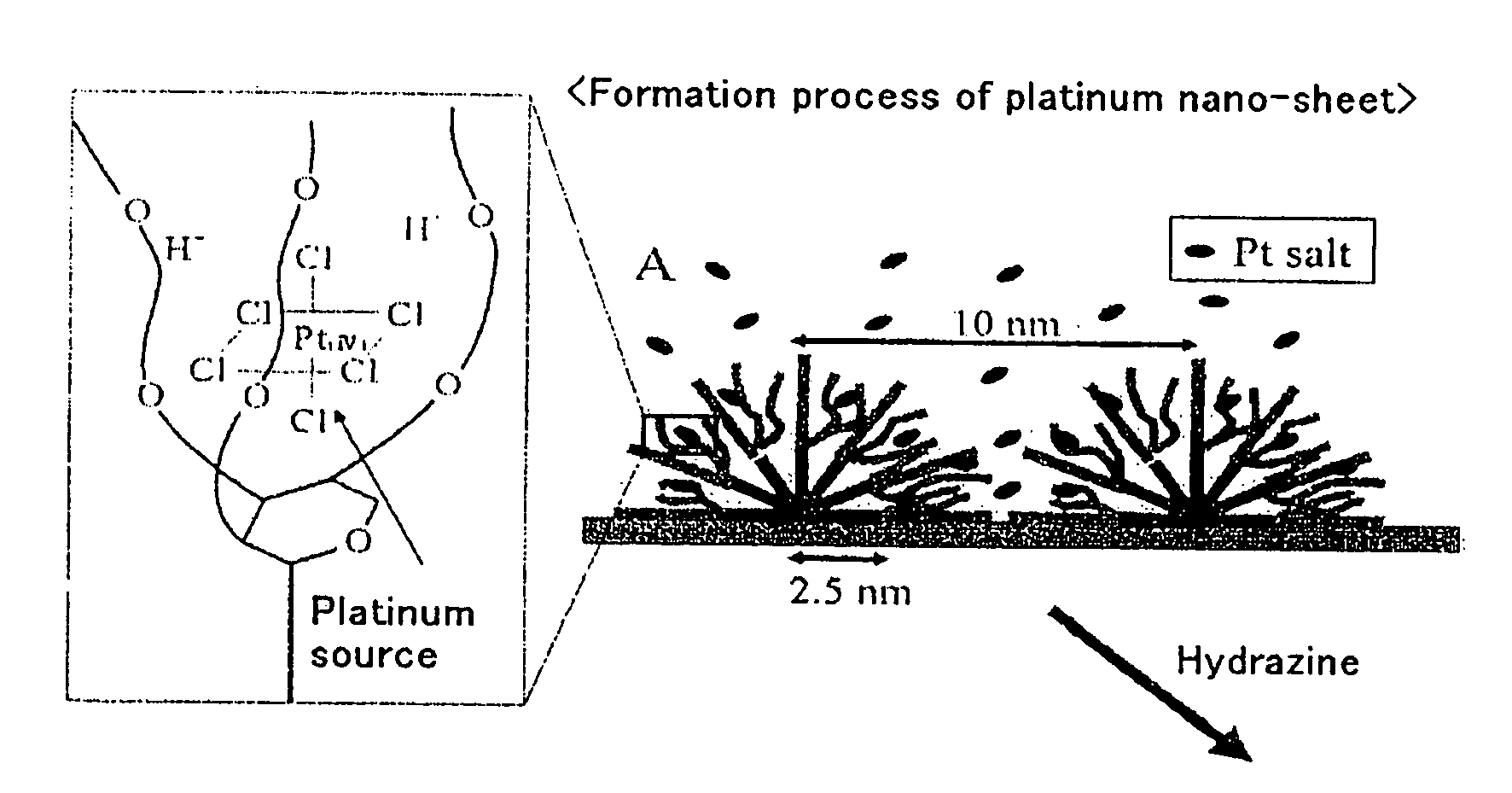

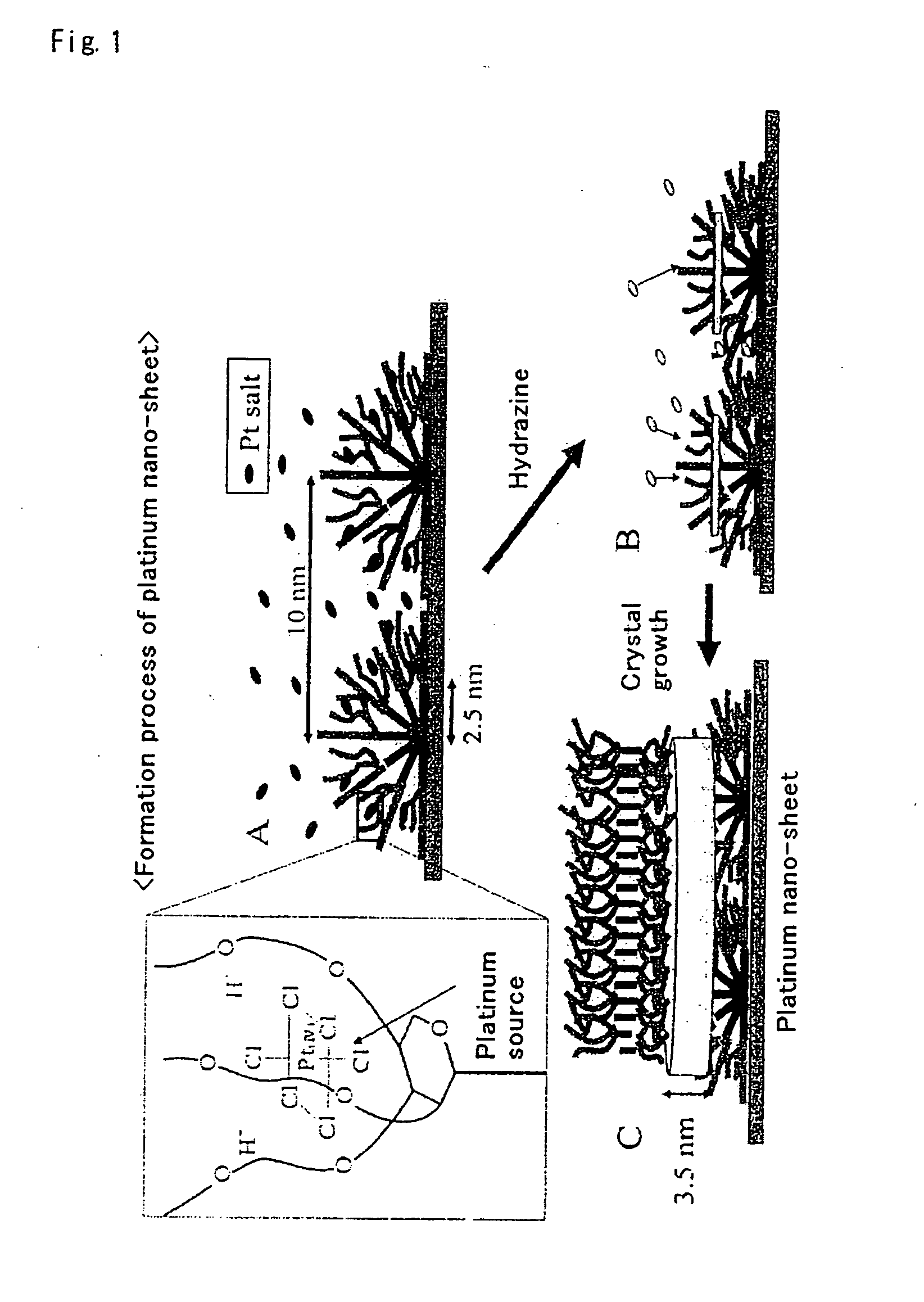

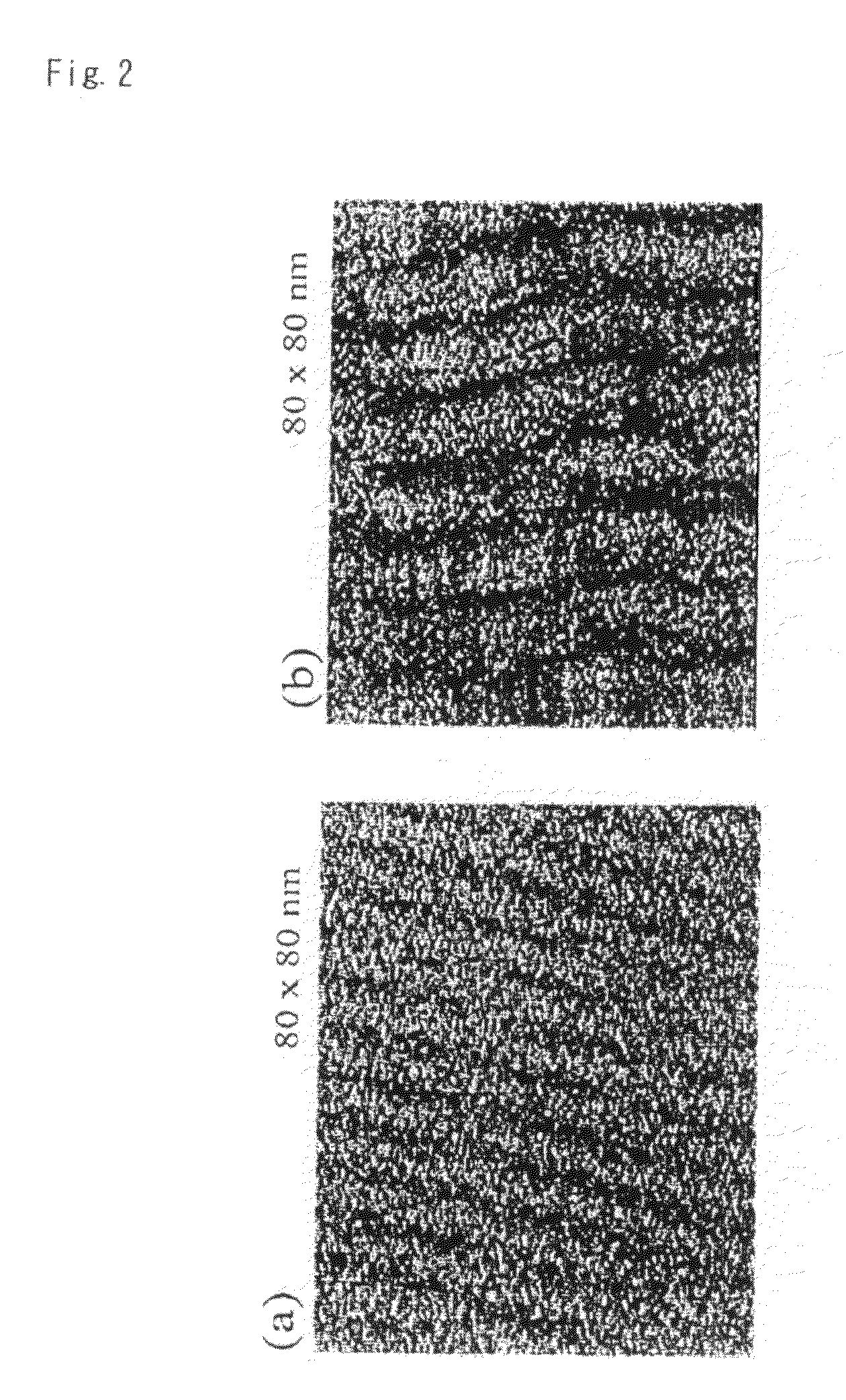

Single Crytalline Noble Metal Ultrathin-Film-Like Nanoparticle Formed in Adsorbed Micelle Film as Reaction Filed Formed at Solid-Liquid Interface, and Production Method Thereof

InactiveUS20080166259A1Small amountMaterial nanotechnologyTransportation and packagingReaction fieldSingle crystal

It is aimed at creating noble metal nanoparticles having novel shapes, sizes, and arrangements usable for catalysts, electrodes, and the like.Micelles made into rod-like shapes having semicylindrical cross-sections are formed on a carrier substrate in a self-creating manner and immobilized thereon; noble metal ions are added and diffused in the micelles to complex the micelles with noble metal ions; and a reducing agent is subsequently caused to act thereon to progress a reductive reaction of noble metal within the immobilized micelles as reaction fields, thereby growing single crystalline noble metal ultrathin-film nanoparticles on the carrier substrate by utilizing the fixed micelles having the shapes as templates, respectively.

Owner:JAPAN SCI & TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com