Simple implementation method for performing gradual homogenized prediction on thermal expansion coefficient of periodic composite material

A technology of thermal expansion coefficient and composite materials, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as low efficiency, complicated implementation process, poor versatility, etc., and achieve convenient execution, expansion adaptability, and convenient prediction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

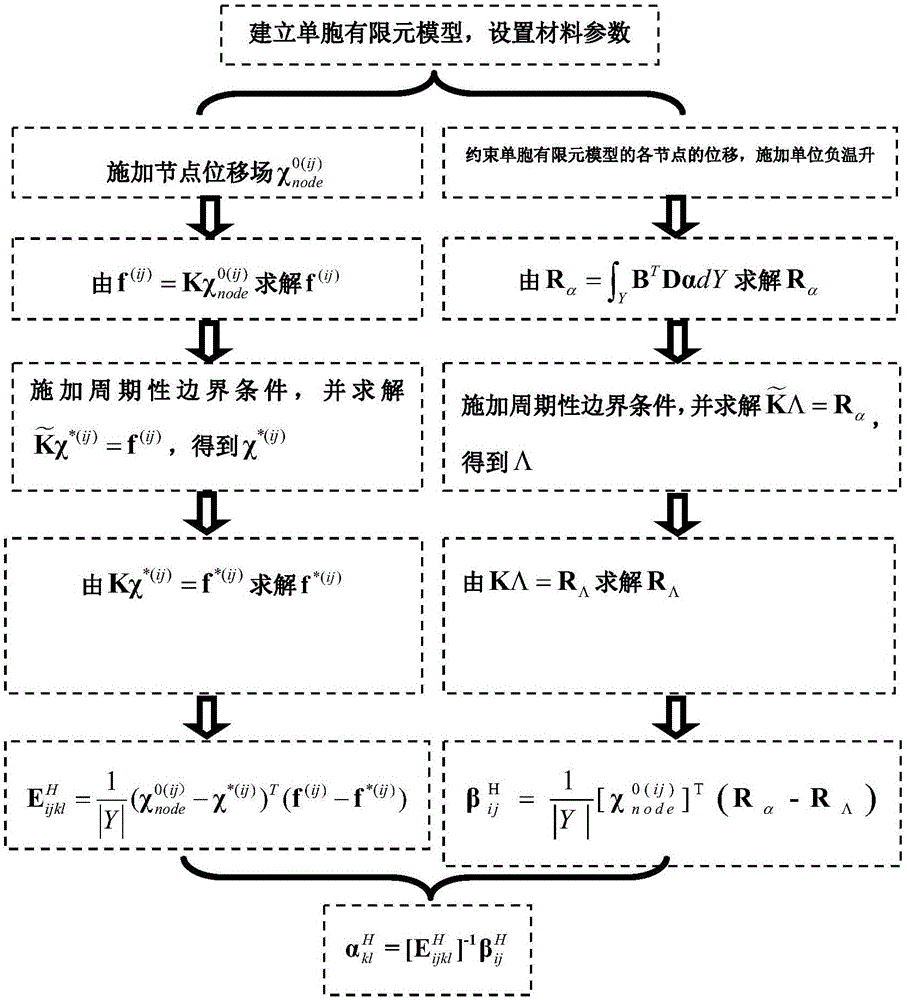

[0105] like figure 1 As shown, the calculation of the expansion coefficient of fiber-reinforced composites has the following steps:

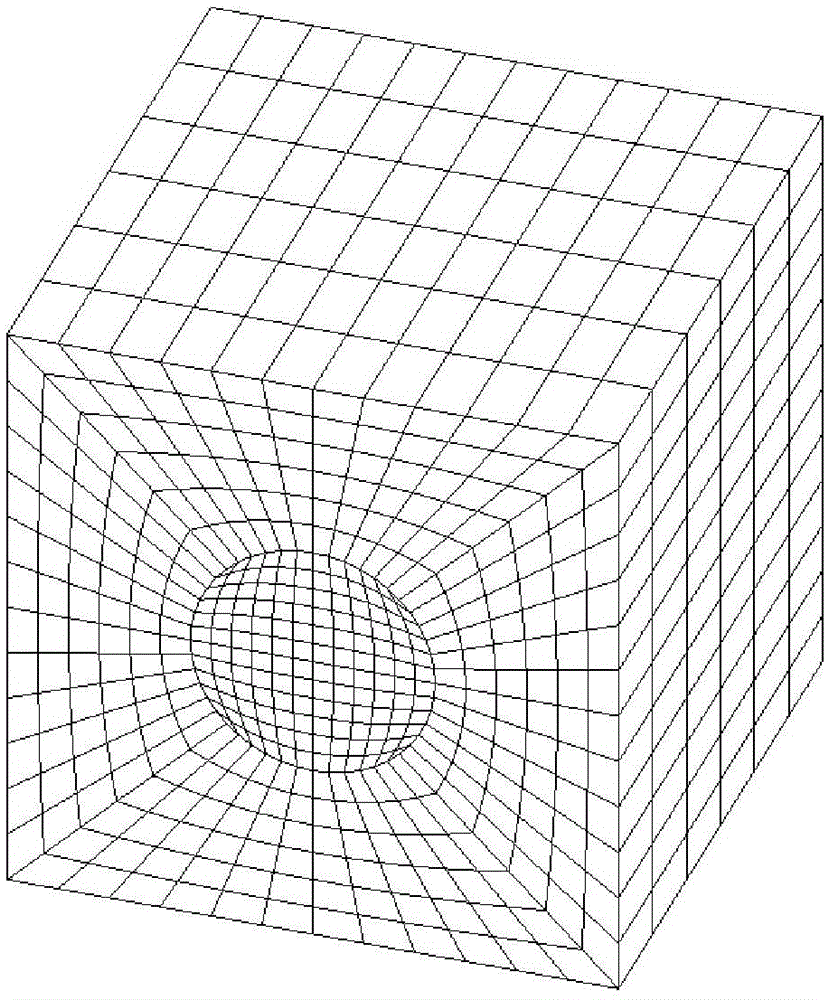

[0106] S1. Establish the unit cell finite element model through commercial finite element software, and set the material parameters in the unit cell finite element model, such as figure 2 shown;

[0107] S2. Dividing the unit cell finite element model into a finite element mesh to obtain node and element information of the unit cell finite element model;

[0108] S3. Determine the initial displacement field from the node coordinate values of the unit cell finite element model for:

[0109] χ n o d e 0 ( 11 ) = { χ 1 0 ...

Embodiment 2

[0158] like figure 1 As shown, the calculation of the expansion coefficient of a two-dimensional zero-expansion structure has the following steps:

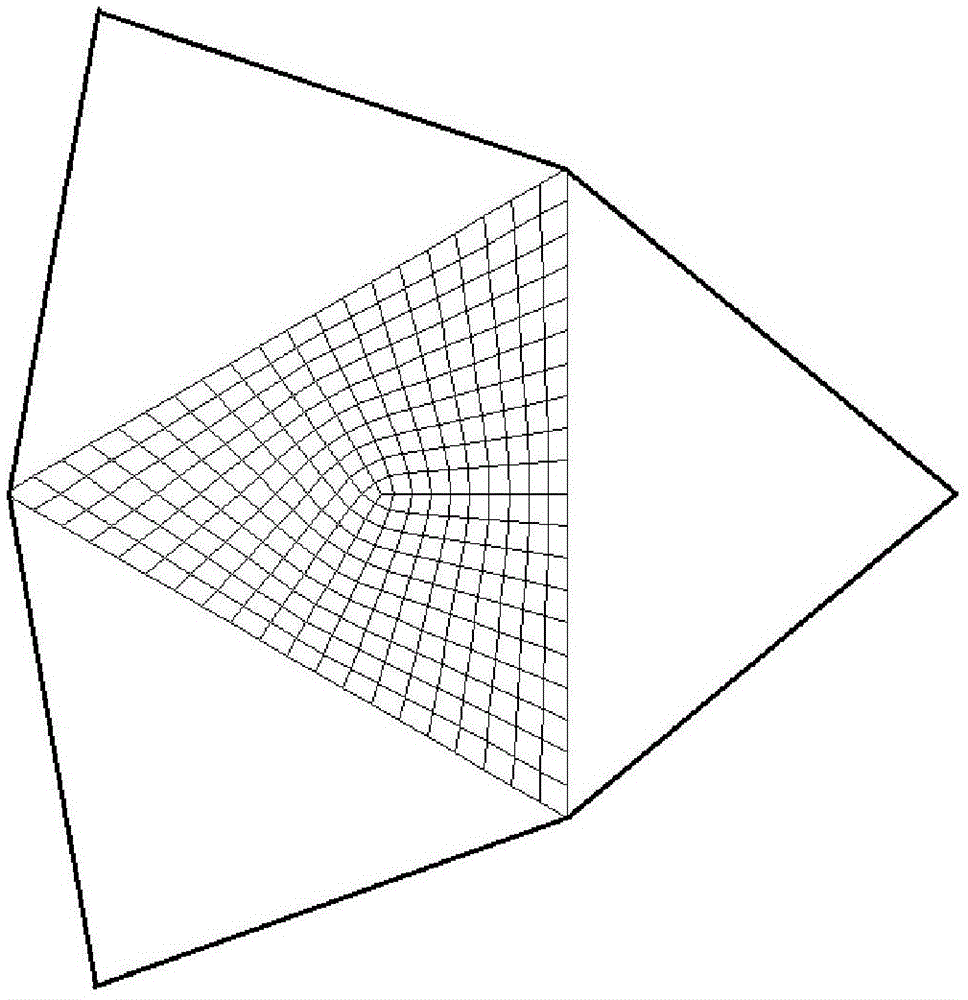

[0159] S1. Establish the unit cell finite element model through commercial finite element software, and set the material parameters in the unit cell finite element model, such as image 3 shown;

[0160] S2. Dividing the unit cell finite element model into a finite element mesh to obtain node and element information of the unit cell finite element model;

[0161] S3. Determine the initial displacement field from the node coordinate values of the unit cell finite element model for:

[0162] χ n o d e 0 ( 11 ) = { χ 1 0 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com