Hard coating, preparation method thereof, and coated article with the coating

A hard coating and hard technology, which is applied in coatings, chemical instruments and methods, metal material coating technology, etc., can solve the problems of coating mechanical properties decline and cannot meet the high-speed cutting of stainless steel well, and achieve The effect of small internal stress, excellent interfacial bonding, and high melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The "atomic percentage content" referred to in the present invention refers to the atomic number percentage content.

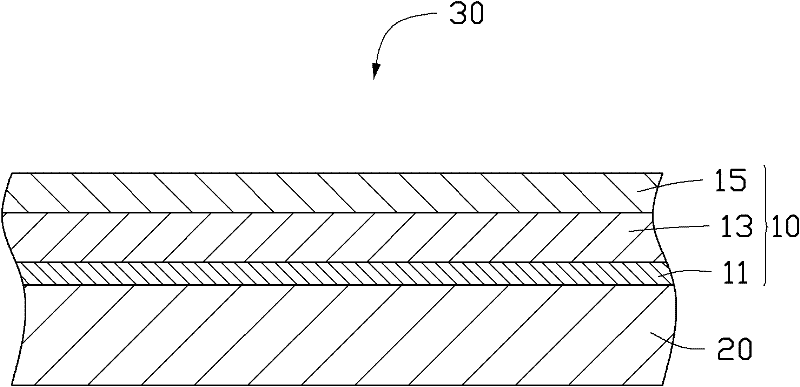

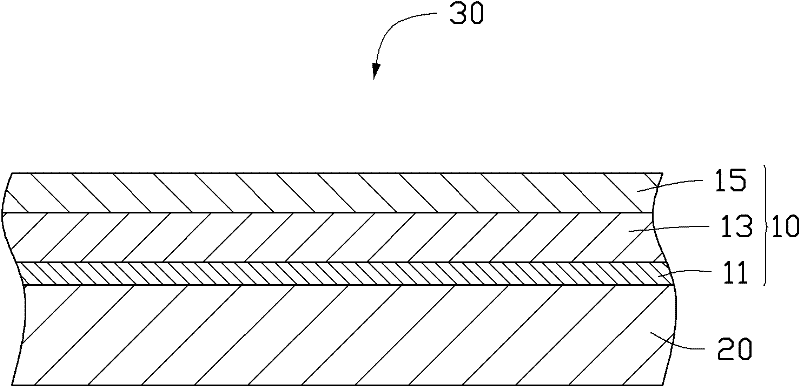

[0024] see figure 1 , the hard coating 10 of the preferred embodiment of the present invention is composed of a transition layer 11 , an intermediate layer 13 and an outermost layer 15 sequentially formed on a hard substrate 20 . The substrate 20 can be high speed steel, hard alloy, cermet and so on.

[0025] The transition layer 11 is directly deposited on the surface of the substrate 20, and the transition layer 11 is composed of Ti-Nb-N tricomponent, wherein the atomic percentage of Ti is about 50-60%, and the atomic percentage of Nb is about 4-6. %, N atomic percentage is about 35-45%. In this embodiment, the atomic percentage of Ti in the transition layer 11 is 55%, the atomic percentage of Nb is 5%, and the atomic percentage of N is 40%.

[0026] The intermediate layer 13 is formed directly on the transition layer 11 . The intermediate layer 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com