Patents

Literature

289results about How to "Improved coefficient of thermal expansion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

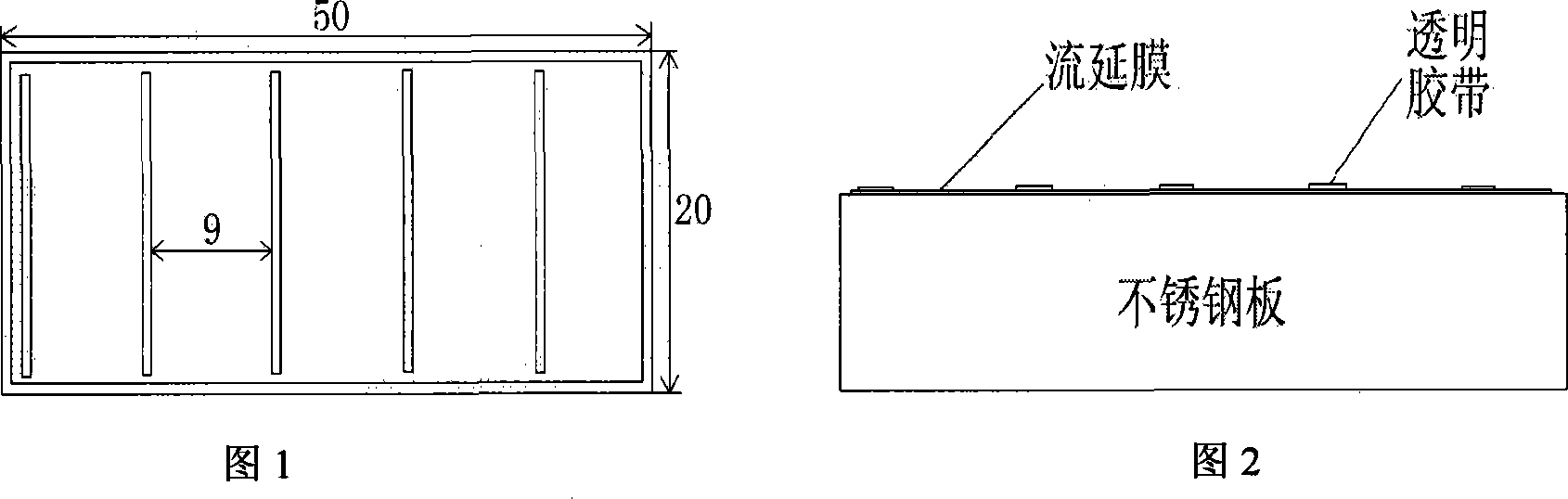

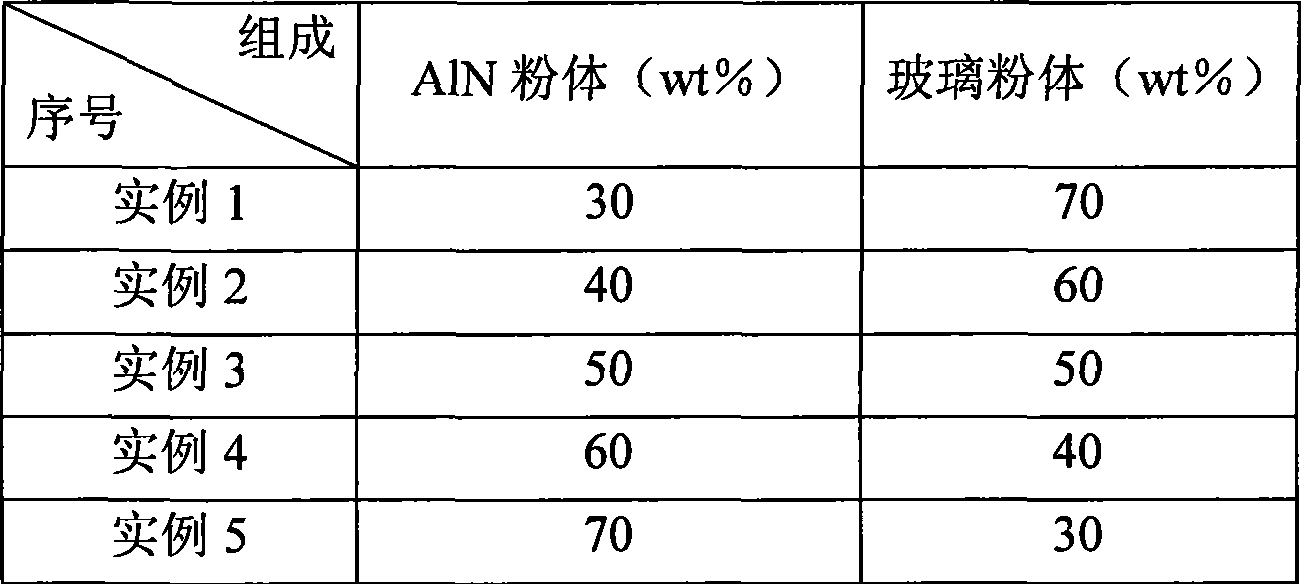

Aluminum nitride/borosilicate glass low-temperature co-fired ceramic substrate material and preparation method thereof

ActiveCN101100367AImprove performanceImprove thermal conductivityCircuit susbtrate materialsCo-fired ceramicProcess conditions

This invention relates to electronic baseplate by low-temperature co-sintering of aluminium nitride / borosilicate glass. This baseplate is composed of: AlN 30-70%; oxides 30-70%. Said oxides are then composed (by mol percentages) of: SiO2 8-12%, B203 18-24%, ZnO 45-60%, Al203 3-8%, Li20 3-8%. This inventive product has excellent comprehensive properties, its heat conductivity is increased from that of prior art product 2-5 W / m.K to 10W / m.K. It can be used in more greater power devices with excellent dielectric property. This invention has also advantages of: easily available raw materials, low cost, simple process.

Owner:TSINGHUA UNIV

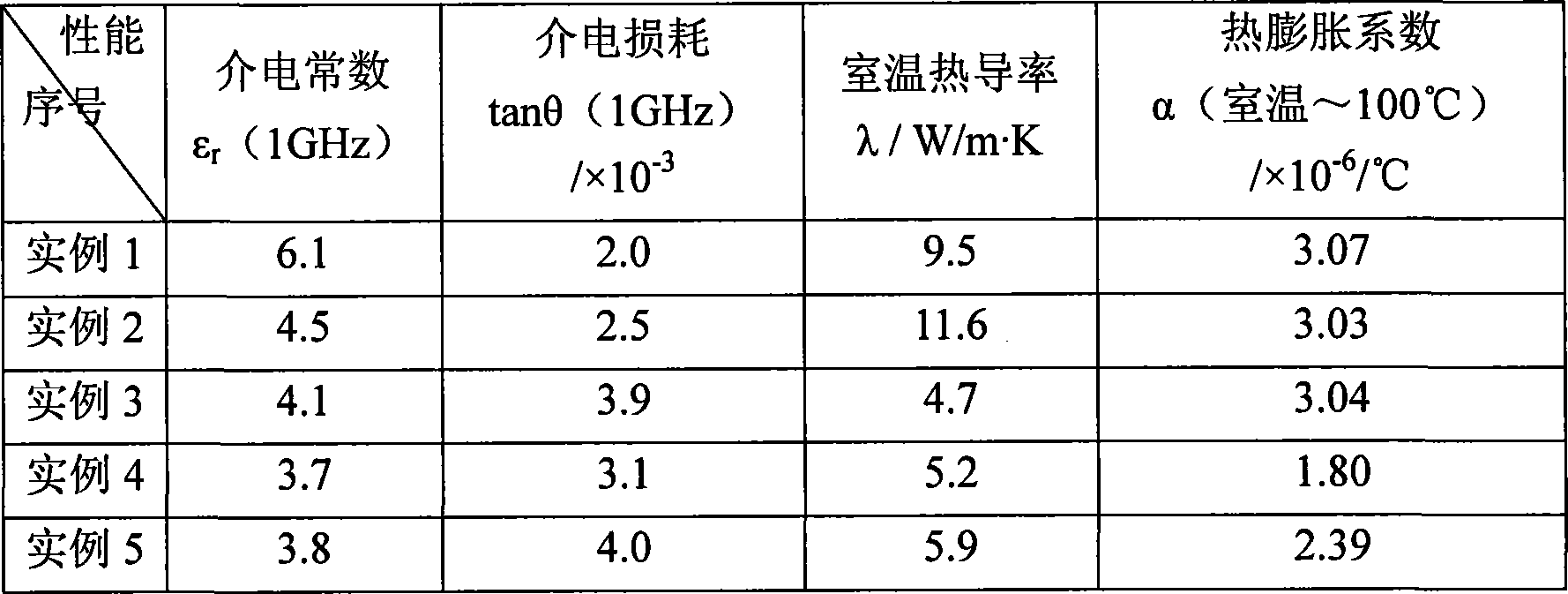

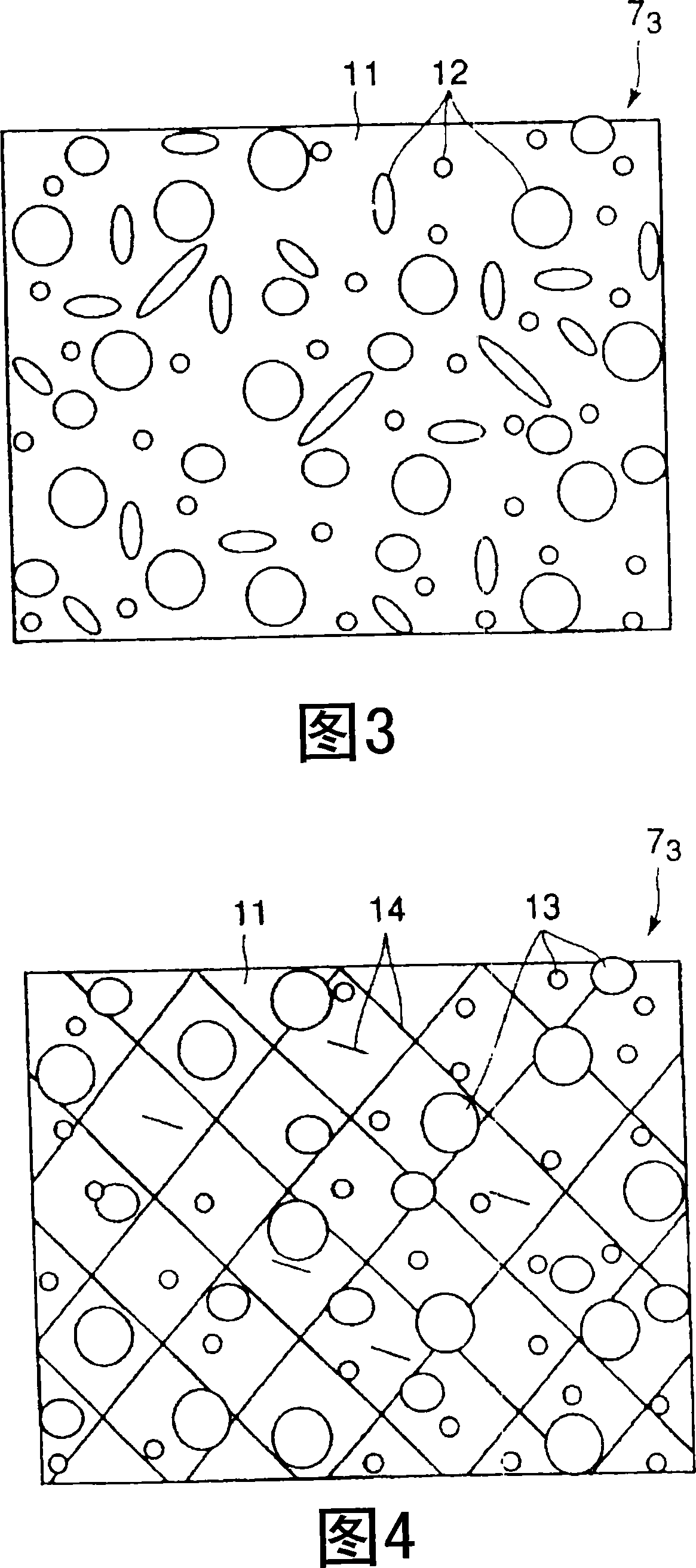

Array-type ultrasonic probe and ultrasonic diagnostic apparatus

InactiveCN101081169ALow decay rateLow machinabilityUltrasonic/sonic/infrasonic diagnosticsMaterial analysis using sonic/ultrasonic/infrasonic wavesHeat resistanceHardness

Disclosed is an array ultrasonic probe, including a plurality of channels arranged with spaces, each channel having a piezoelectric element and a laminated acoustic matching layer structure formed of at least three layers and arranged on the piezoelectric element, a backing on which the piezoelectric element of each channel is mounted and having trenches in which are formed at places corresponding to the spaces, and an acoustic lens formed to cover at least the surface of the uppermost acoustic matching layer of each channel, wherein the uppermost acoustic matching layer comprises a silicone resin-containing mixture having a Shore hardness D not lower than 40 at 25 DEG C., and exhibits an acoustic impedance of 1.8 to 2.5 MRayls at 25 DEG C.

Owner:KK TOSHIBA

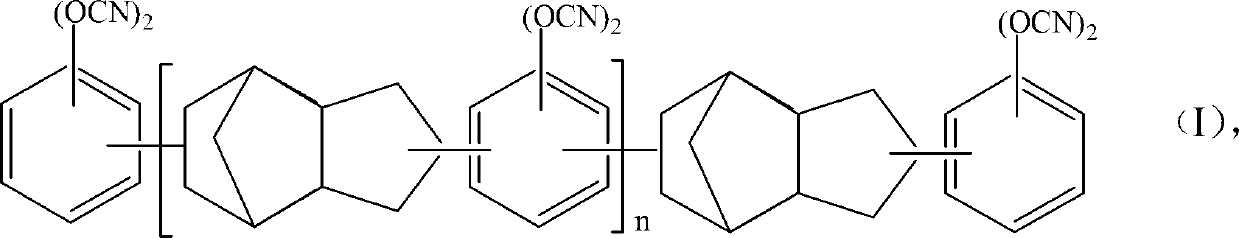

Thermosetting cyanate resin composition and application of thermosetting cyanate resin composition

ActiveCN102942684AOvercome the disadvantage of high water absorptionImprove heat resistanceSynthetic resin layered productsEpoxyCopper coating

The invention relates to a thermosetting cyanate resin composition, which comprises the following components: polyfunctional cyanate, epoxy resin, flame retardant agent and inorganic filler. The thermosetting cyanate resin composition is used for preparing resin substrates, resin compound metal copper foils, prepregs, laminating plates, copper-coating plate laminating plates, printed circuit boards and the like. The thermosetting cyanate resin composition has good heat resistant property, humidity resistant property and flame retardant property and low heat expansion coefficient.

Owner:GUANGDONG SHENGYI SCI TECH

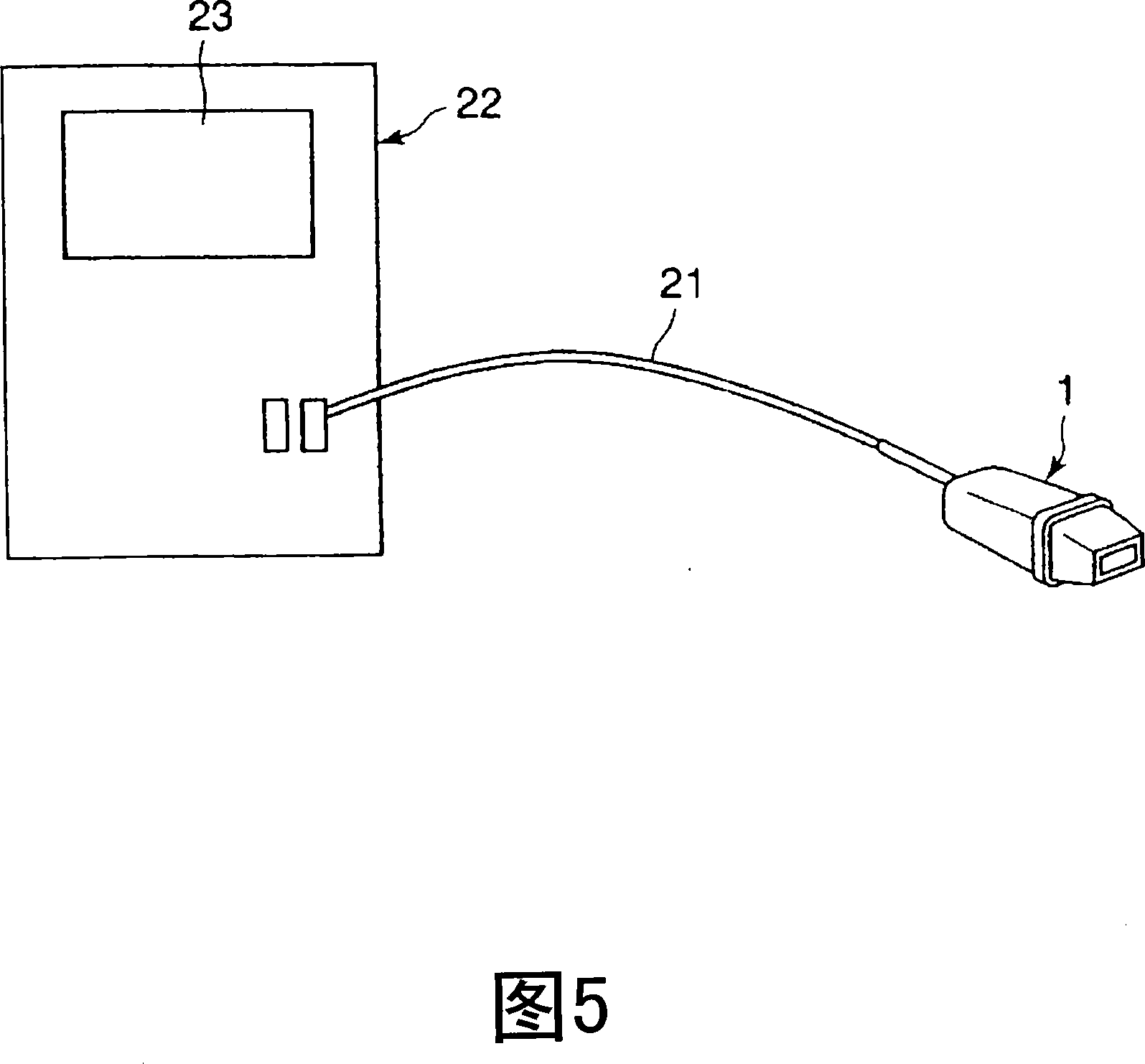

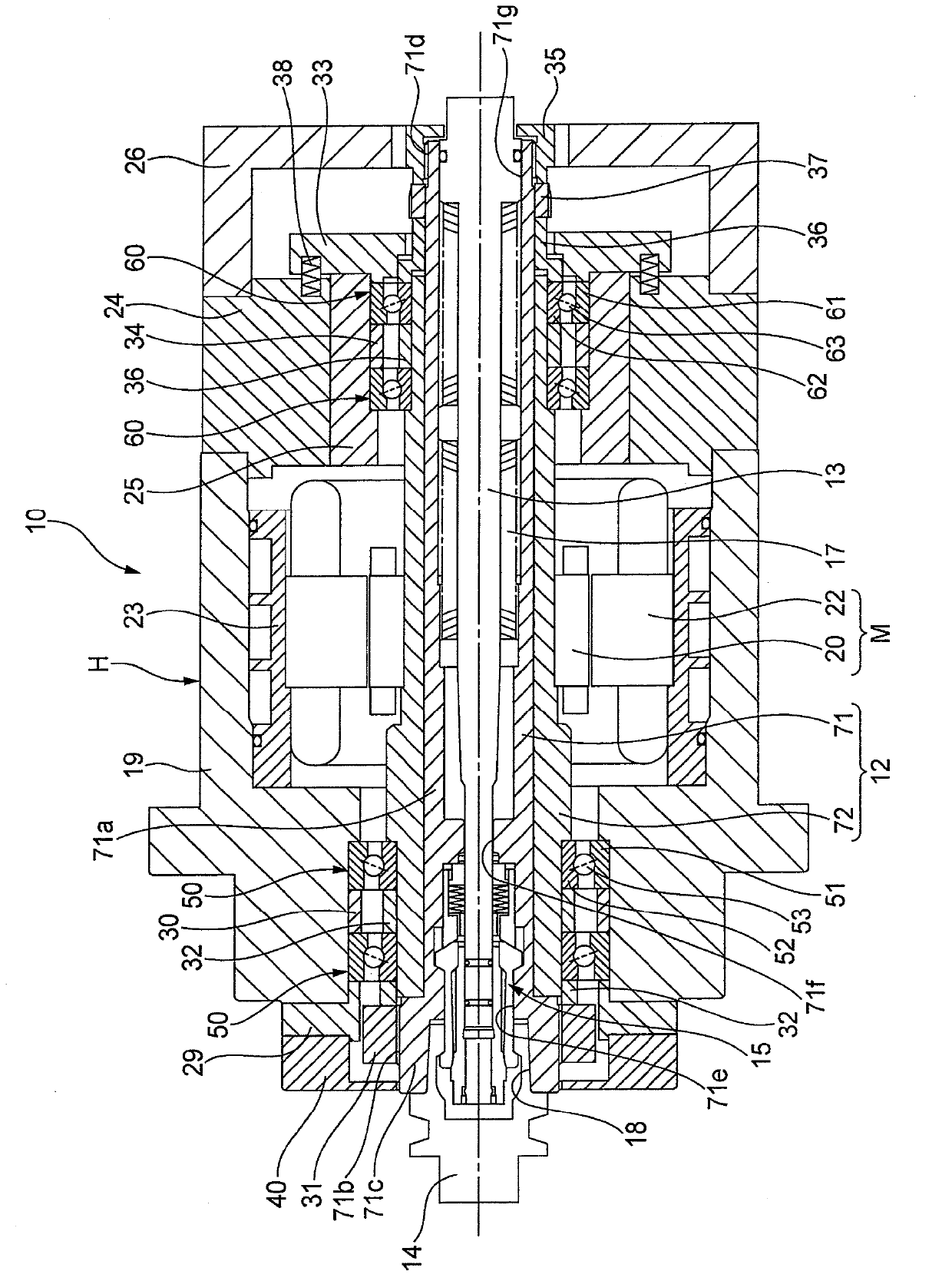

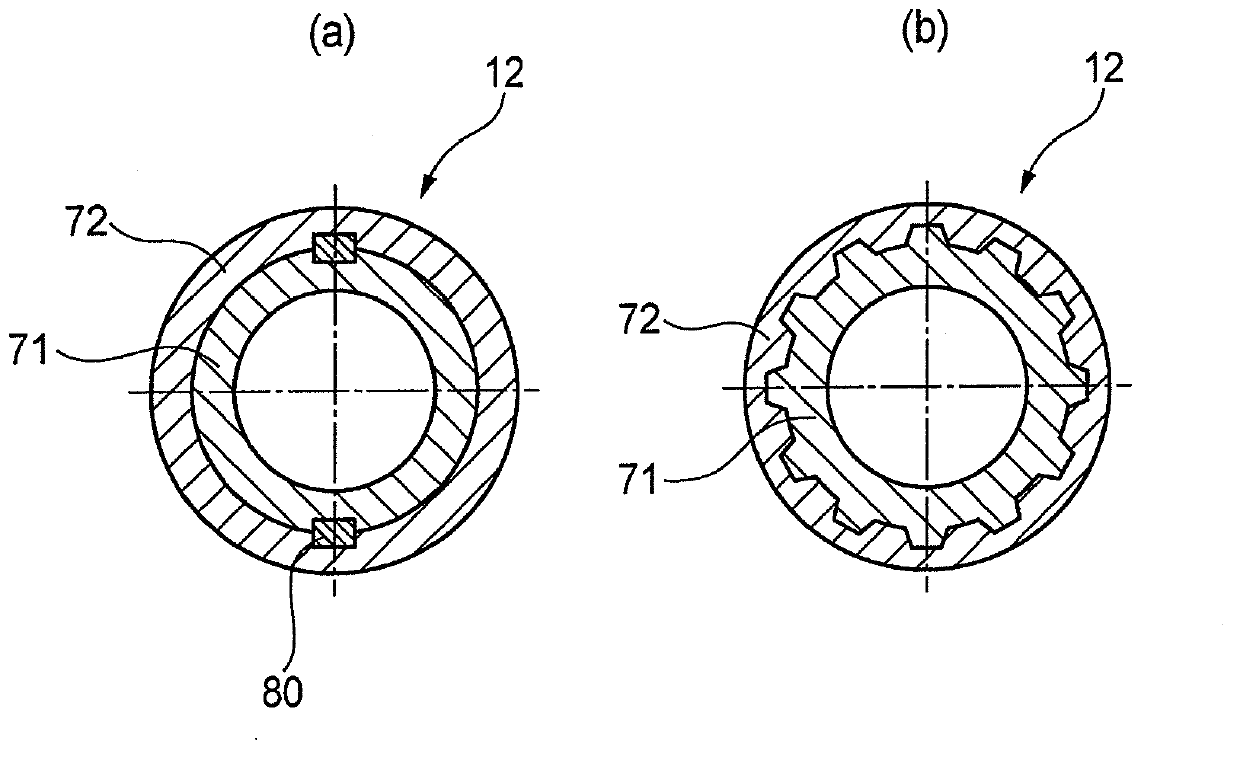

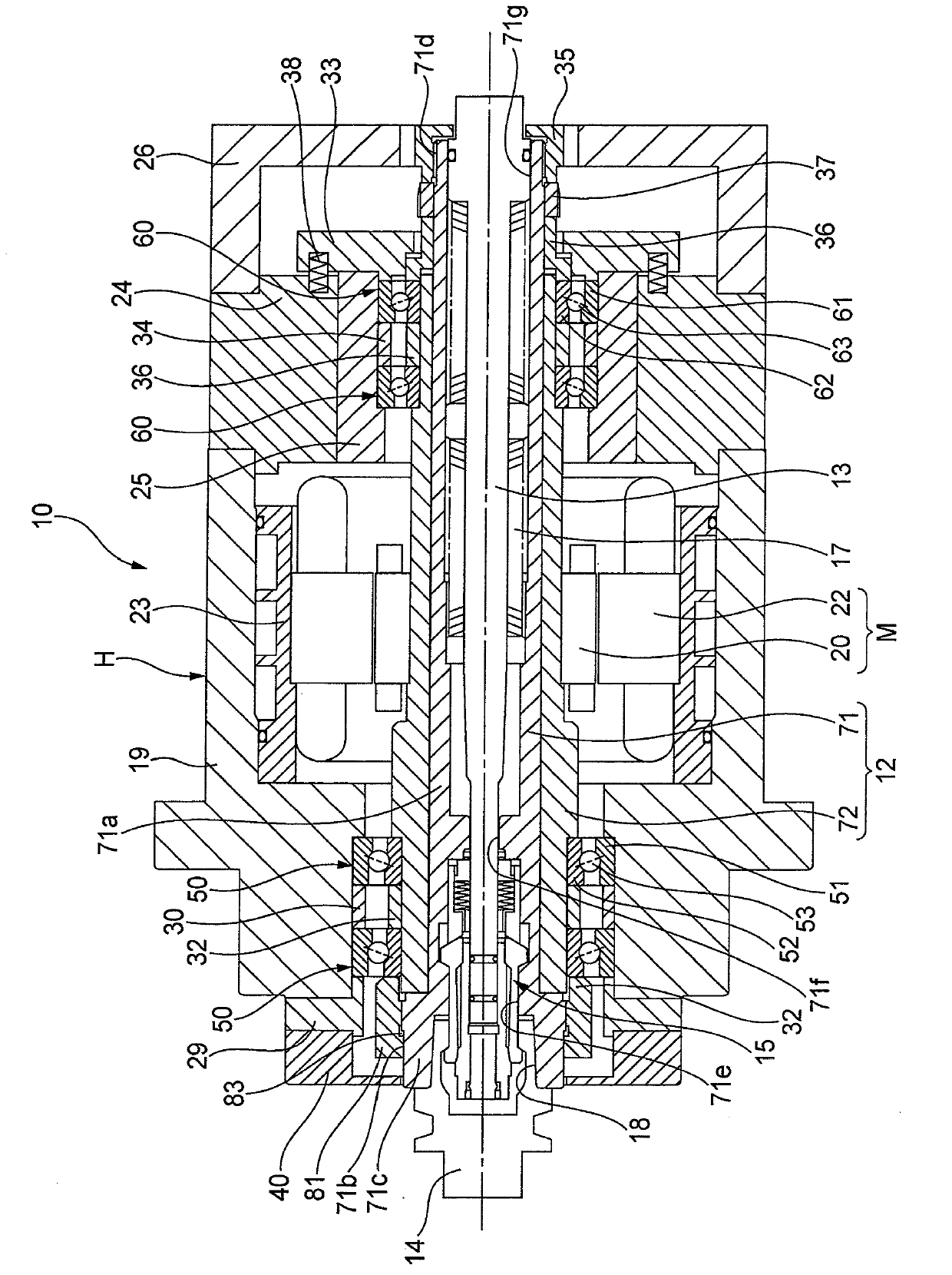

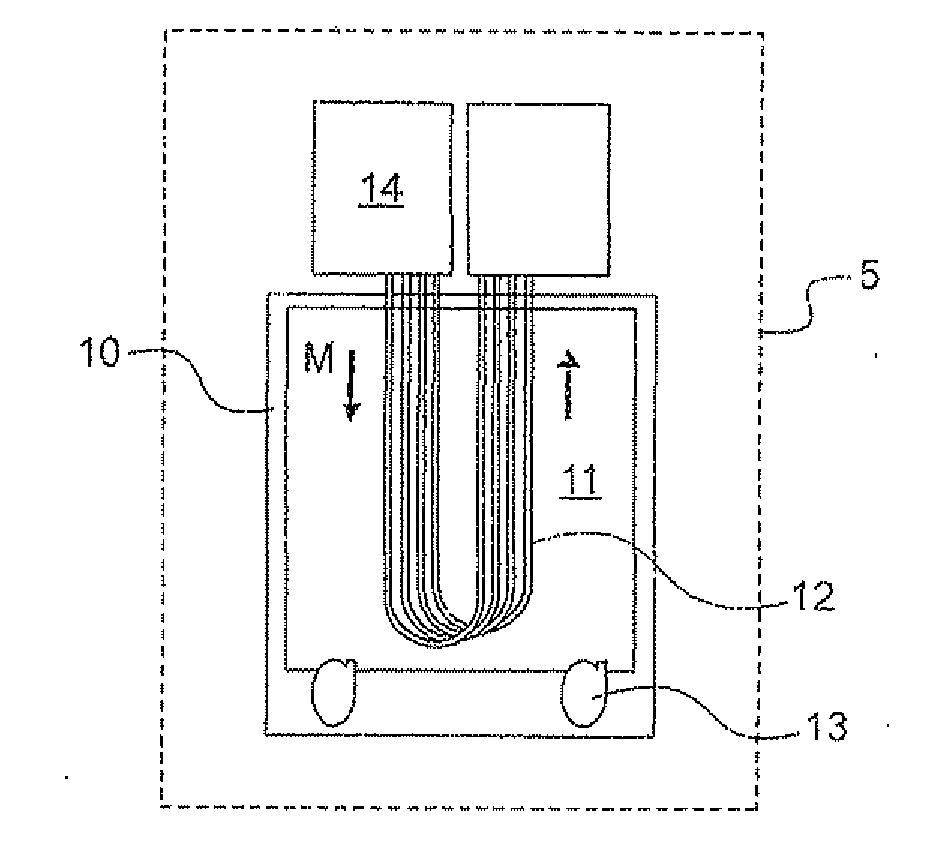

Main shaft apparatus

ActiveCN103003014AIncrease temperatureImprove machining accuracyLarge fixed membersMaintainance and safety accessoriesMetallic materialsEngineering

A main shaft apparatus (10) of a built-in motor system, wherein a rotary shaft (12) is provided with: a first cylindrical component (71) made of metal material; and a second cylindrical component (72) made of carbon fibre composite material, which is positioned on the outer peripheral surface of the first cylindrical component (71) and into the outer peripheral surface of which a rotor (20) fits. By virtue of this, the temperature increase of the rotary shaft and a bearing due to the heat produced by the rotor can be controlled and processing precision can be improved.

Owner:NSK LTD

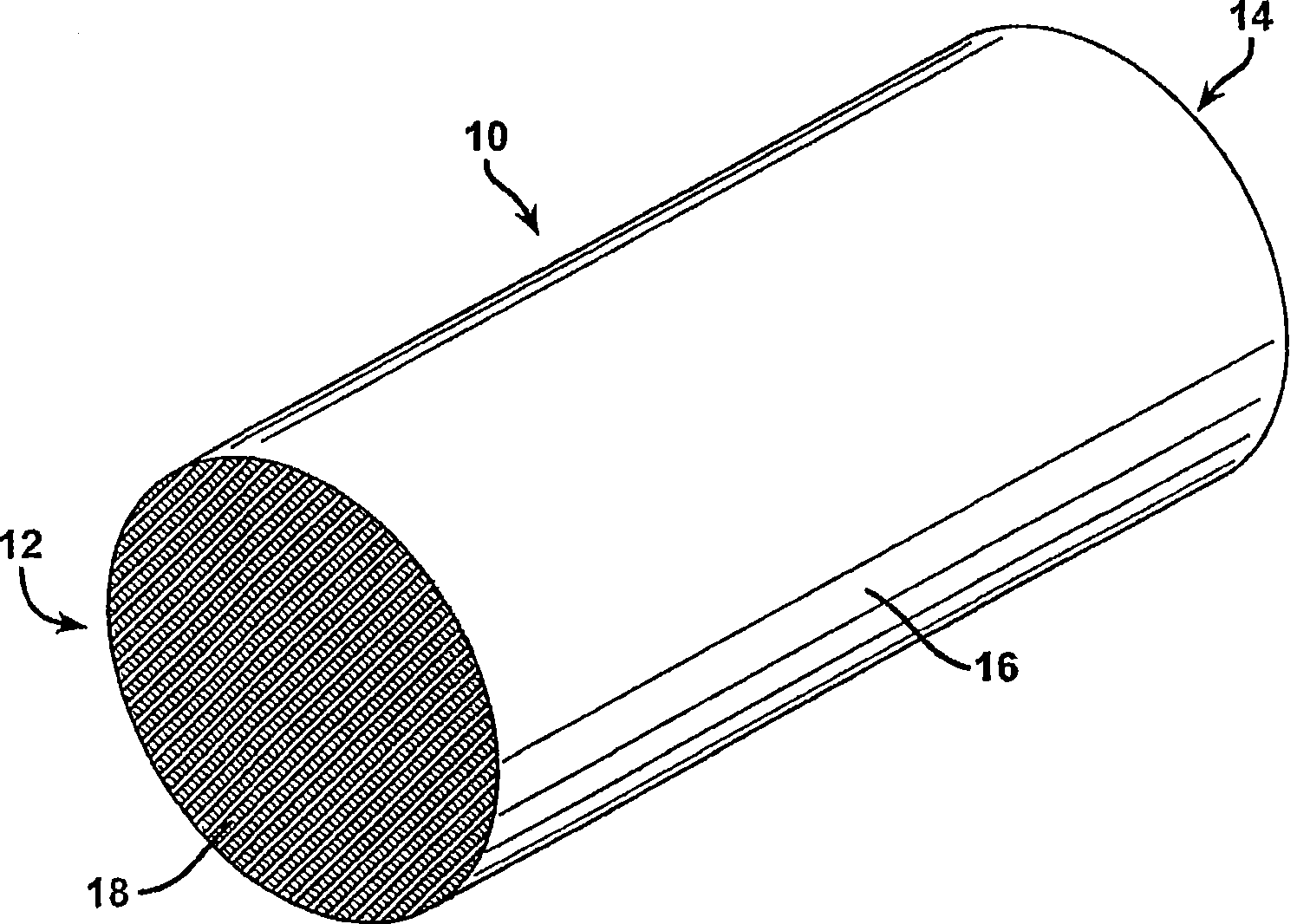

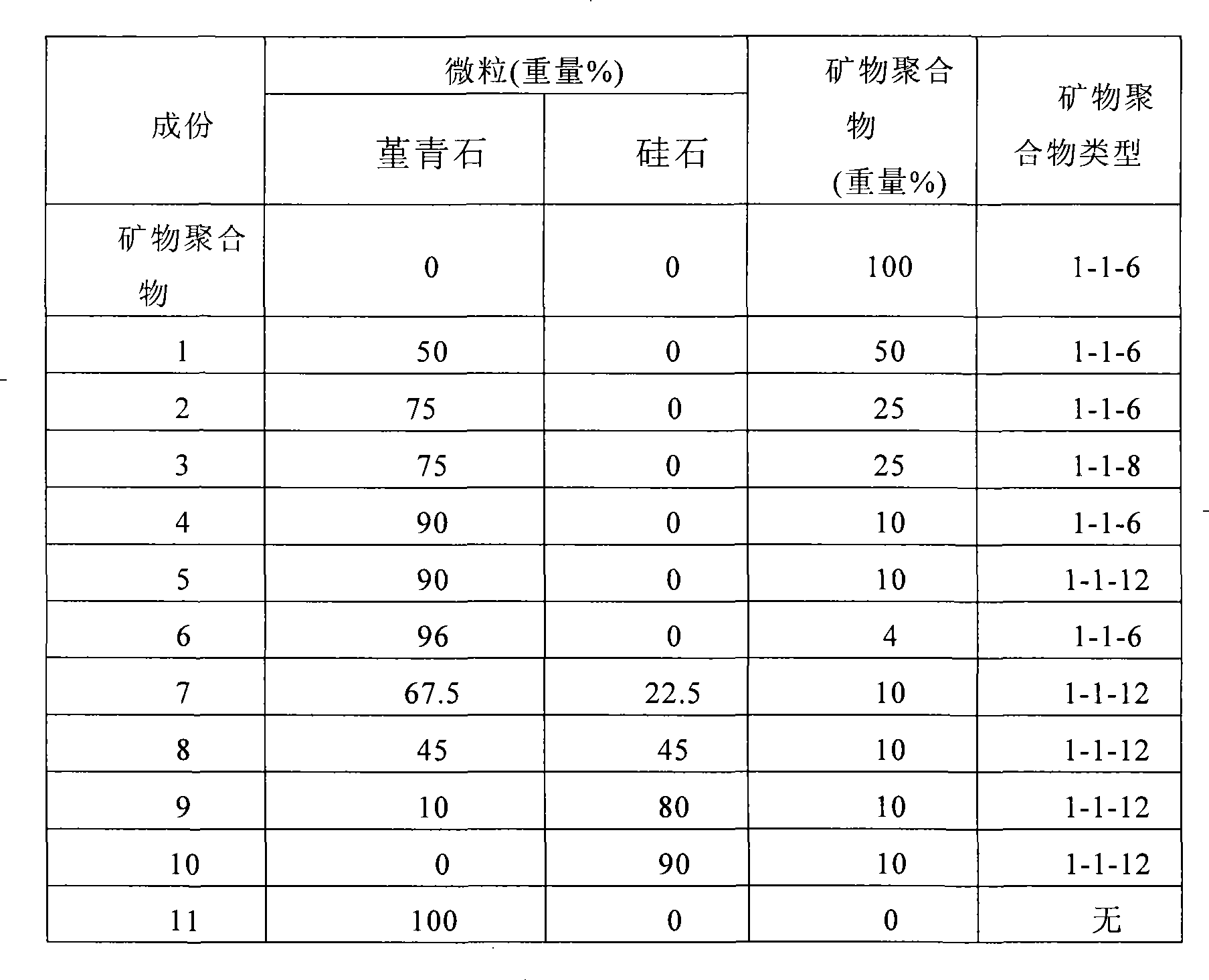

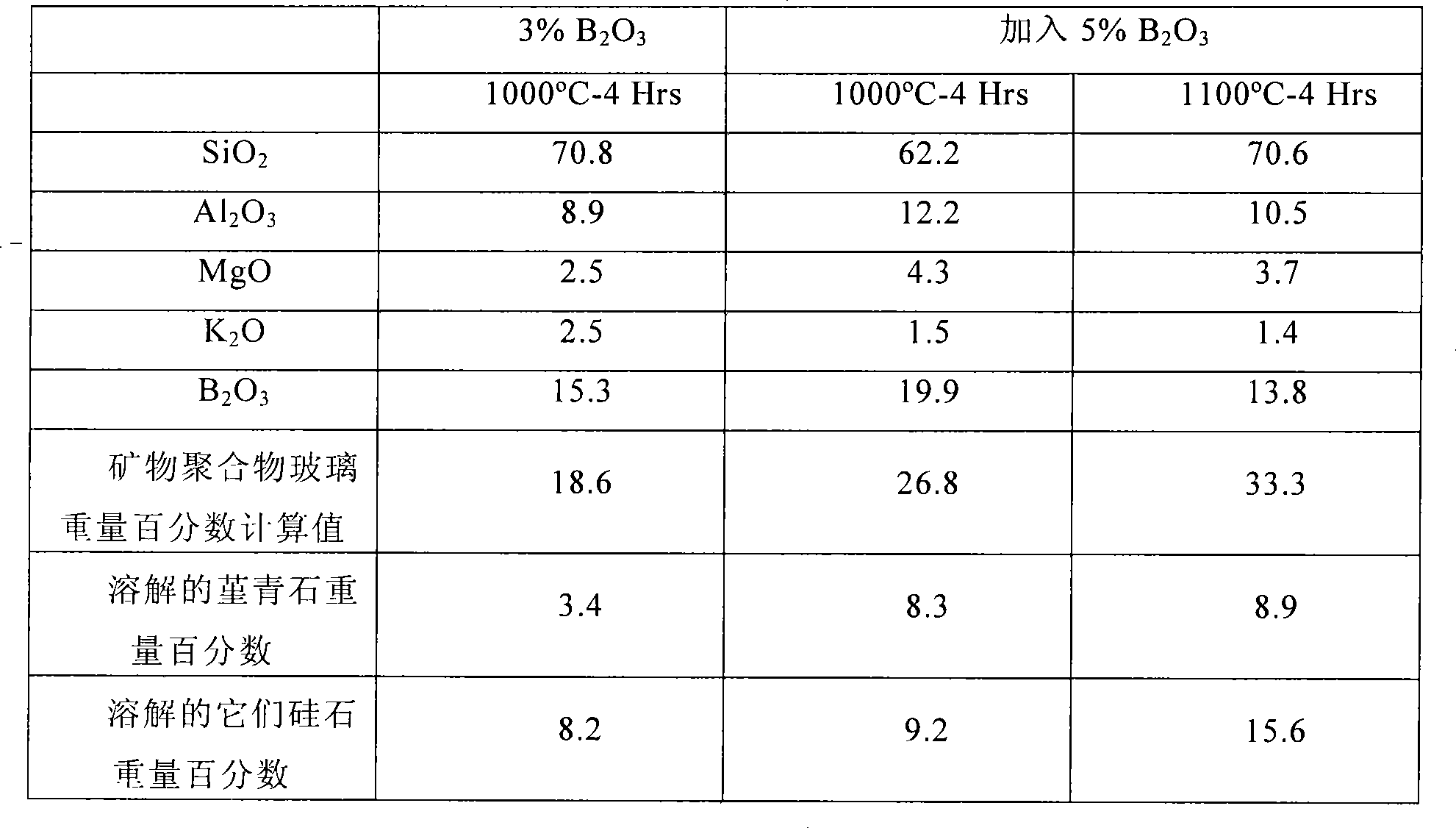

Geopolymer composites and structures formed therefrom

InactiveCN101370748AImproved coefficient of thermal expansionExcellent thermal shock resistanceCement productionLoose filtering material filtersThermal expansionCordierite

Geopolymer composite materials having low coefficient of thermal expansion are disclosed. The materials are useful in high temperature applications due to their low coefficient of thermal expansion and high strength. Also disclosed is a boron modified water glass geopolymer composition that is compatible with ceramic particulate material such as cordierite and fused silica. The geopolymer composite may be extruded to form structures such as honeycomb monoliths, flow filters or used as a plugging or skinning cement and may be fired at temperatures at or below 1100 DEG C. Both the structures and the cement have high green and fired strength, a low coefficient of thermal expansion, and good acid durability. The cost of manufacturing objects using the material of the present invention is substantially reduced, in comparison with typically production methods of cordierite based bodies, due to the substantially shortened firing times.

Owner:CORNING INC

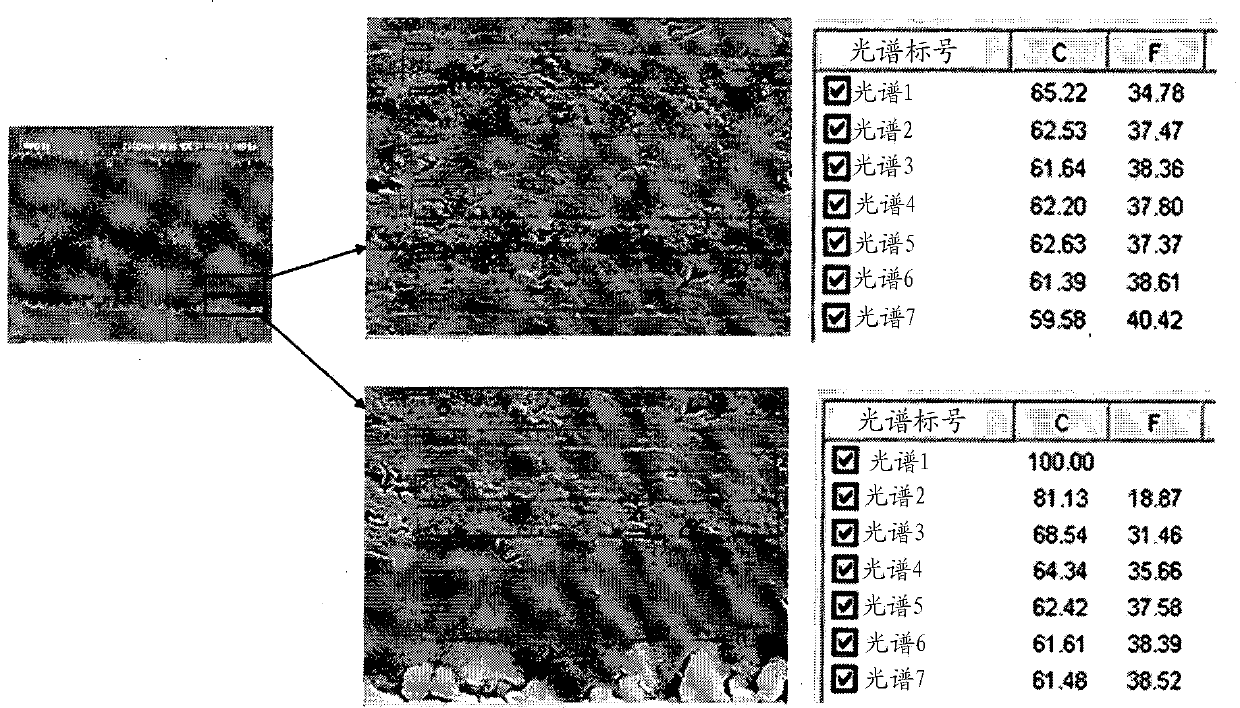

Rare-earth doped leadless and low-melting point sealing glass and its preparation method

InactiveCN101456674AMaintain the ability to formExpand the scope of glass formingRare earthCopper oxide

The invention relates to a method for preparing rare earth doped lead-free sealing glass with low melting point, which comprises the following steps: based on raw materials adopted by a Bi2O3-ZnO-B2O3 glass system, adding proper amount of rare earth oxide into the raw materials, and mixing, melting, annealing, grinding and sieving the mixture to obtain the rare earth doped lead-free sealing glass with the low melting point. The sealing glass comprises the following main components by weight portion: 65.22 to 85.22 portions of bismuth oxide, 4.63 to 11.78 portions of boric acid, 5.76 to 10.76 portions of zinc oxide, 0.80 to 2.80 portions of copper oxide, 0.42 to 2.42 portions of cobalt oxide, 3.32 to 8.47 portions of barium carbonate, 0.4 to 1.8 portions of aluminum oxide, and 0.1 to 6.0 portions of rare earth oxide. The method solves the problems that the sealing glass with the low melting point has low sealing temperature, high sealing strength, stable glass structure and the like under lead-free conditions, and has the advantages of simple process, practicability and reliability; and the prepared rare earth doped lead-free sealing glass with the low melting point is particularly suitable for sealing and closing of stainless steel materials, electrons and electric appliances.

Owner:WUHAN UNIV OF TECH

Ceramic particle reinforced aluminium-based composite material and powder metallurgical process to prepare the material

The present invention belongs to the field of composite material preparation technology. The composite material has the chemical expression of: AlaMgbBcMd, Where a is 50-96, b 1-7, c3-30 and d 0-13; M is one or several of Si, Cu, Ni, Ti, Fe, Cr, La, Mn, Ce, Zn, V and Zr. The preparation process is one combined powder metallurgy and in-situ reaction process and includes mixing material powder, cold pressing the mixture for forming, heating the formed mixture and hot pressing for the material powder to produce chemical reaction at temperature over 950 deg.c. Inside the aluminum alloy base, A1MgB14 ceramic phase particle as reinforcing phase is formed to prepare the composite aluminum alloy material. The ceramic particle reinforced composite aluminum alloy material. The ceramic particle reinforced composite aluminum alloy material has light weight and high strength, integrated functions, and may be used widely in transport industry and national defence industry.

Owner:SHANGHAI JIAO TONG UNIV

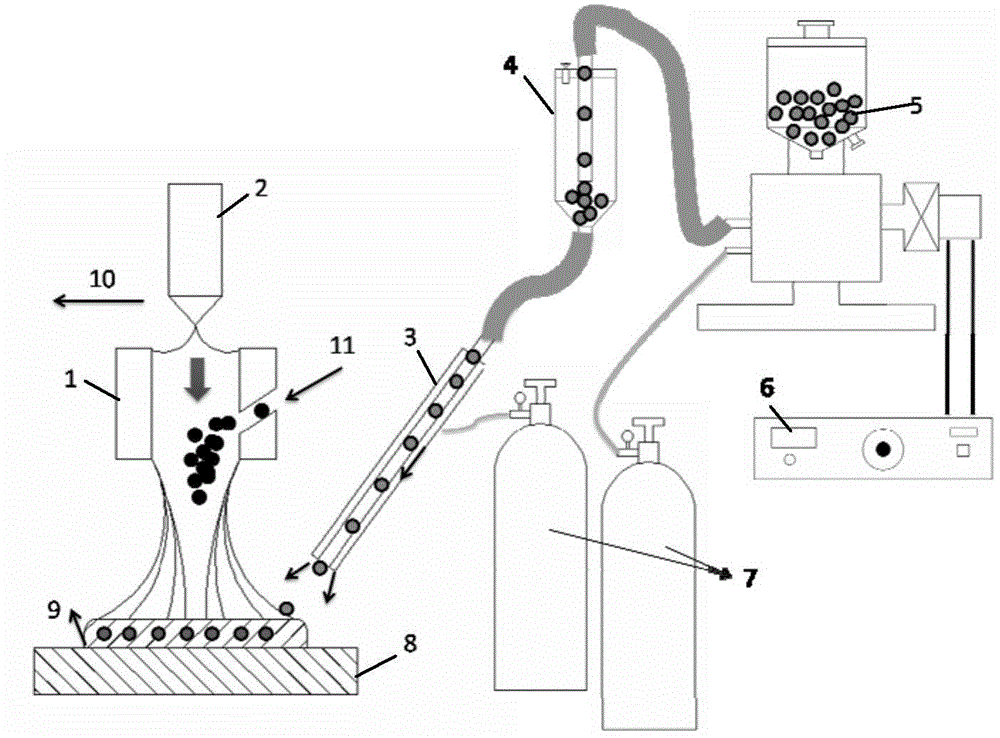

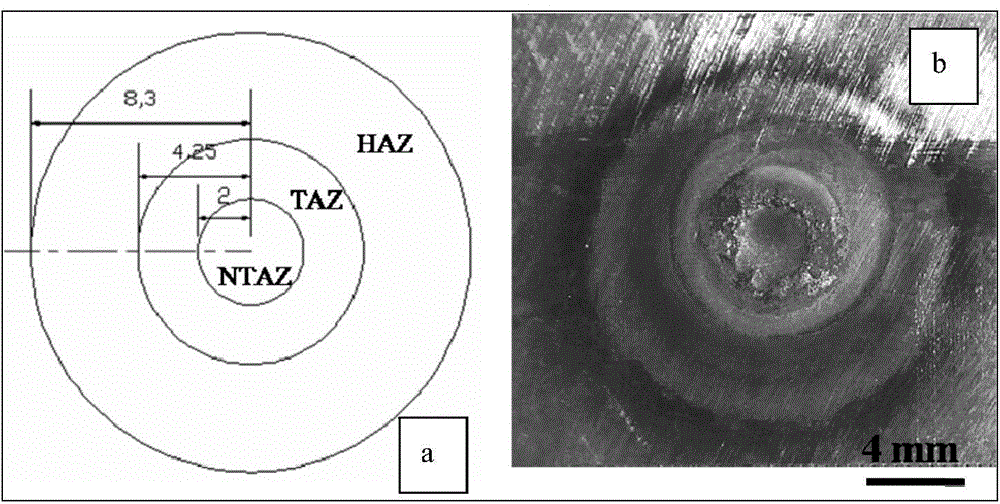

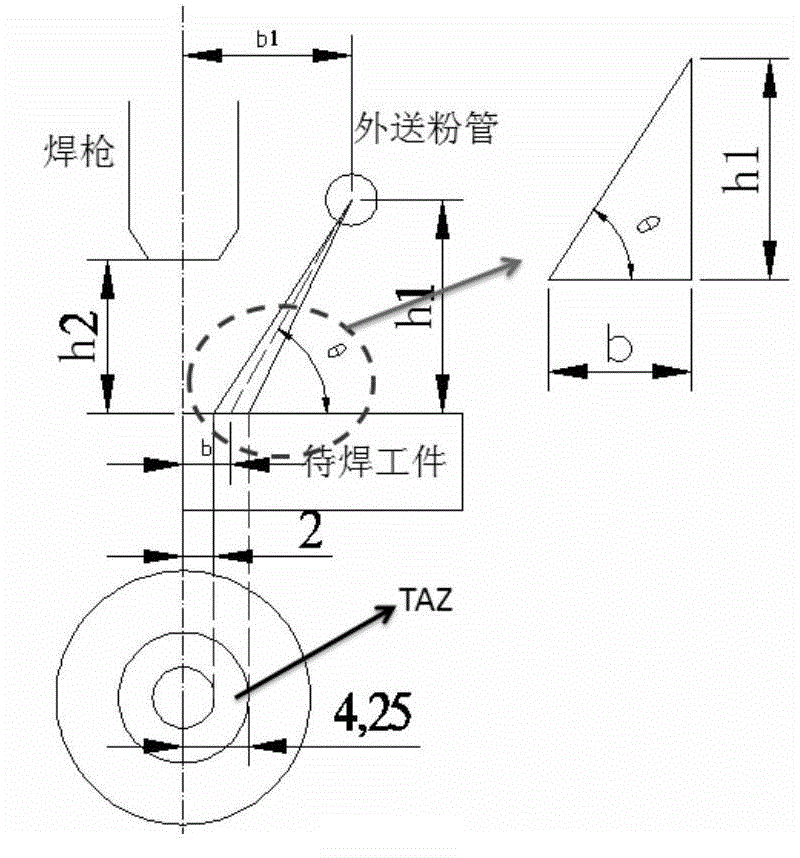

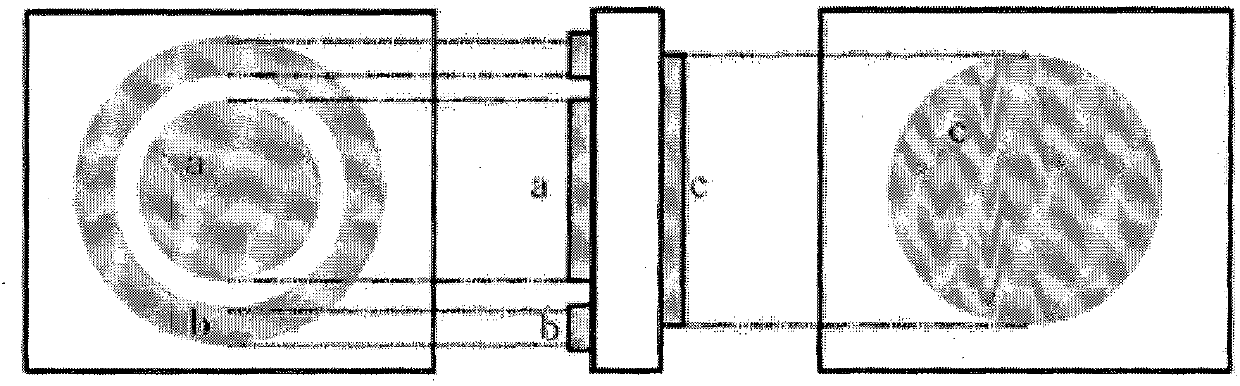

Ceramic reinforced metal matrix composite welding layer plasma overlaying preparation method

InactiveCN104096958AReduce direct burning lossIncrease profitPlasma welding apparatusMelting tankChemical reaction

The invention provides a ceramic reinforced metal matrix composite welding layer plasma overlaying preparation method, which comprises the following steps: 1) pretreatment before overlaying; 2) melting, injecting and feeding of powder outside a gun; 3) performing plasma overlaying to prepare a ceramic reinforced metal matrix composite welding layer. The ceramic reinforced metal matrix composite welding layer plasma overlaying preparation method has the beneficial effects that the utilization ratio of reinforced ceramic in the overlaying process is increased, the chemical reaction rate of the reinforced ceramic and metal molten is lowered due to chemical coating, the trend that the defect is generated in the composite welding layer due to the sharp reaction between the reinforced ceramic and the metal interface is reduced, meanwhile, the composite welding layer prepared by the method has a lot of in situ generated large granular carbides, and thus the mechanical properties (such as strength, hardness and wear resistance) and thermal physical properties (such as thermal expansion coefficient, high temperature oxidation resistance and thermal intensity) of the composite welding layer are significantly improved.

Owner:WUHAN UNIV OF TECH

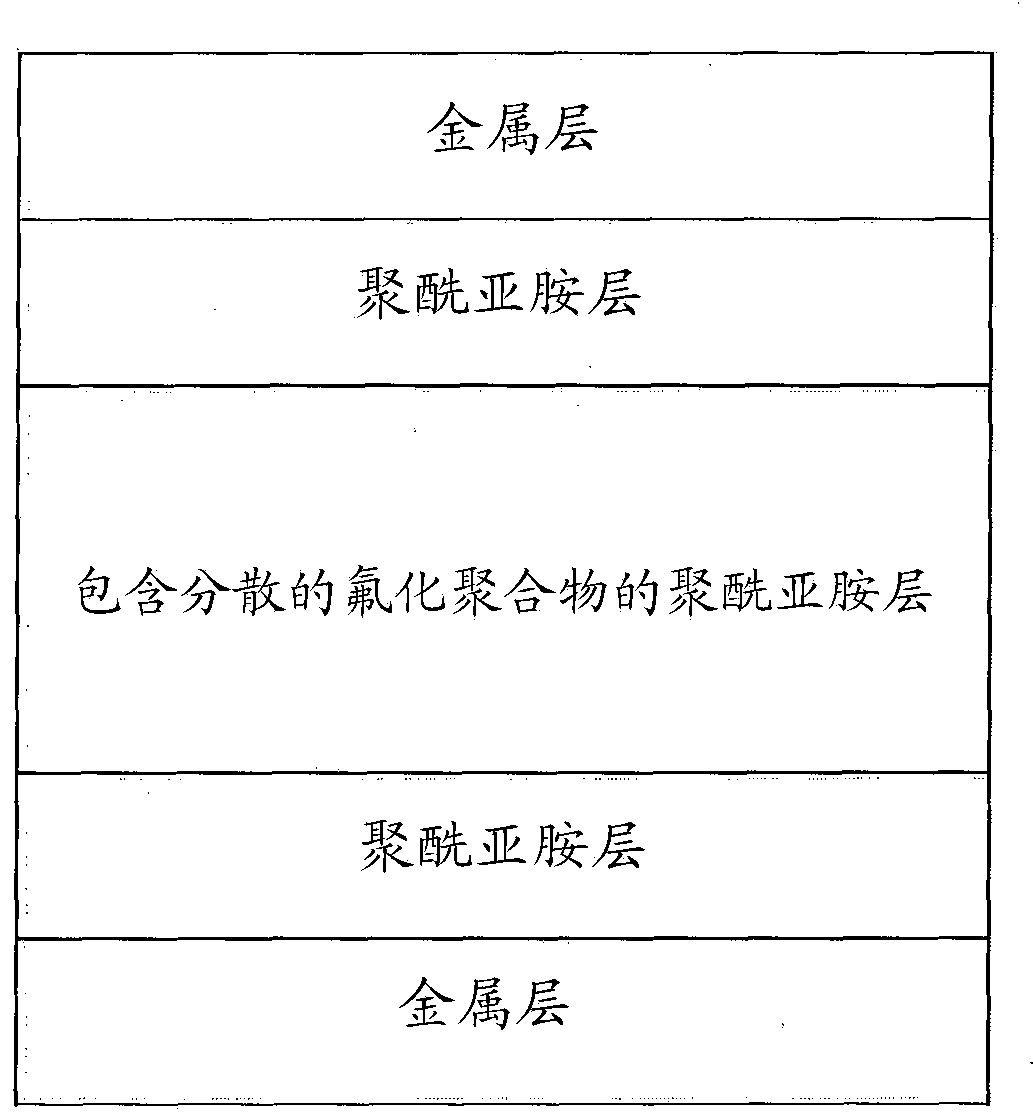

Flexible metal laminate containing fluorocarbon resin

ActiveCN103958188AEvenly dispersedImprove heat resistanceLiquid surface applicatorsSynthetic resin layered productsPermittivityTotal thickness

The present invention relates to a flexible metal laminate having low permittivity, capable of being applied to a soft printed circuit board. According to one aspect of the present invention, the flexible metal laminate comprises: a first metal layer; a first polyimide layer; a polyimide layer in which a fluorocarbon resin, which is formed on the first polyimide layer, is dispersed; and a second polyimide layer formed on the polyimide layer in which a fluorocarbon resin is dispersed, wherein the content per unit volume of the fluorocarbon resin is greater in a depth of 40-60% than in a depth of 5-10% of the total thickness from the surface of the polyimide layer in which a fluorocarbon resin is dispersed.

Owner:GUANGDONG SHENGYI SCI TECH

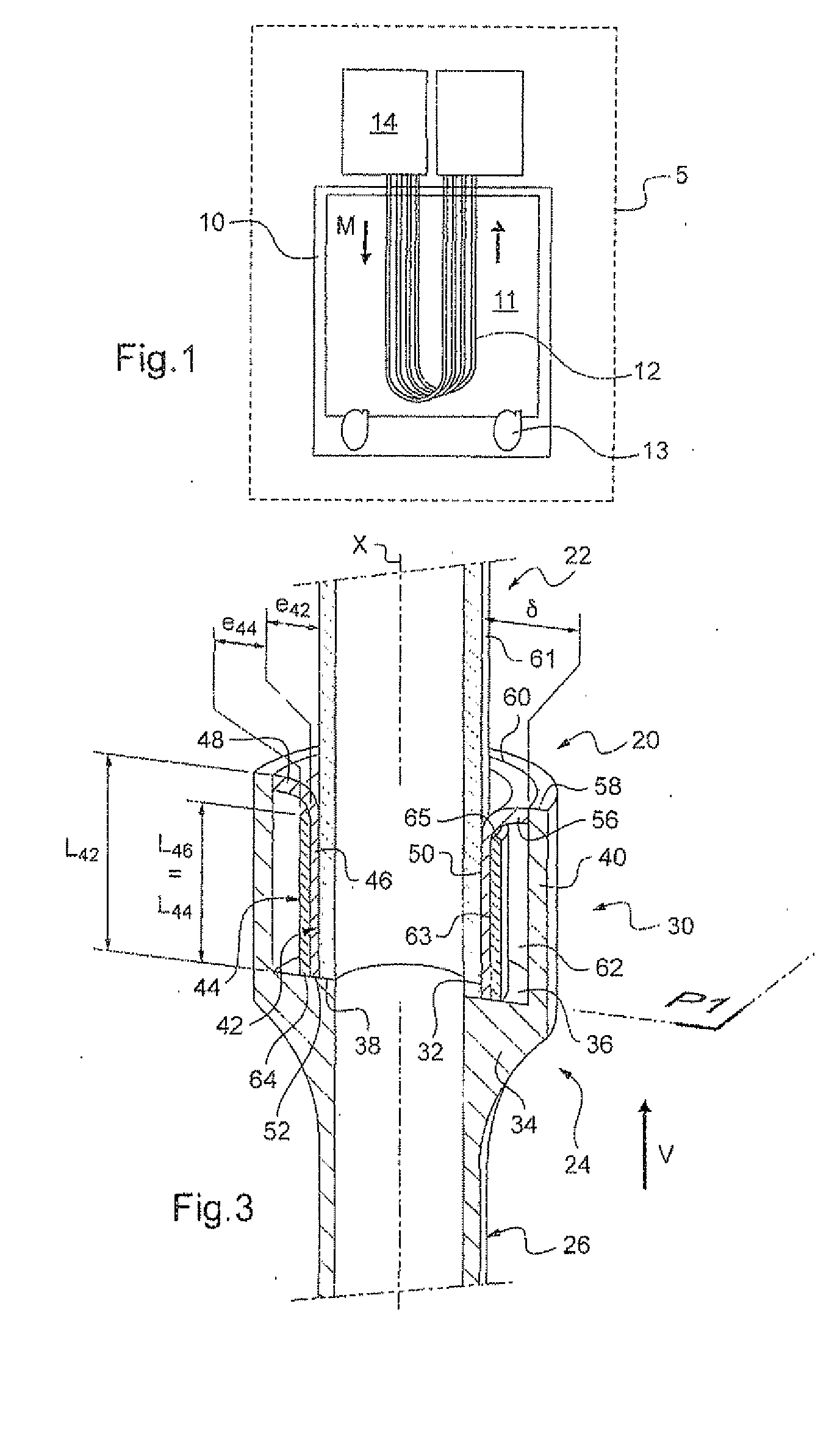

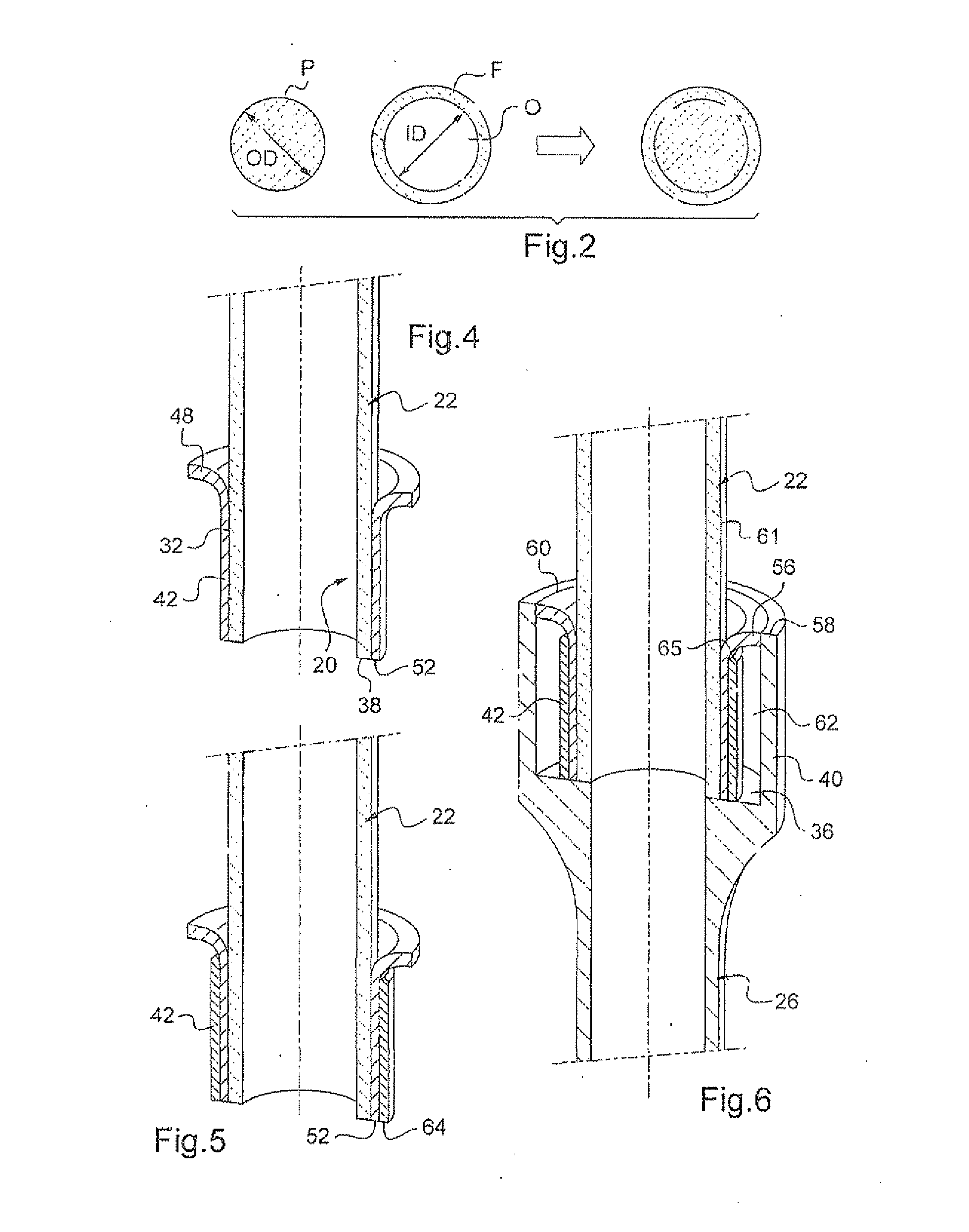

Coated ceramic part

ActiveUS20120003128A1Improve sealingImproved coefficient of thermal expansionThermal non-catalytic crackingLayered productsAlloySilicon dioxide

A device including a first part having a substrate made of a material based on a silicon compound, a coating made of a coating material having a ceramic oxide, a transition layer having silica extending between the substrate and the coating, the transition layer exhibiting a thickness of less than 10 μm, and a first shrink ring and / or a layer made of a compliant material having an alloy with at least two materials selected from silver, gold and palladium, the coating defining at least a portion of the interface between the first part, and the first shrink ring and / or the layer made of a compliant material.

Owner:SAINT GOBAIN CENT DE RES & DEVS & DETUD EUROEN

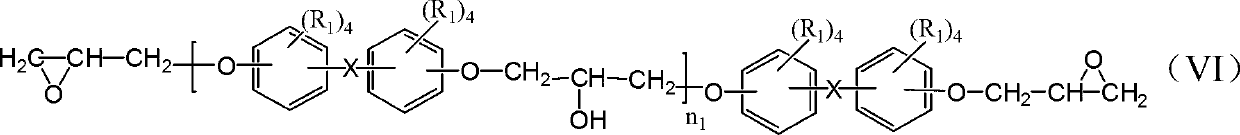

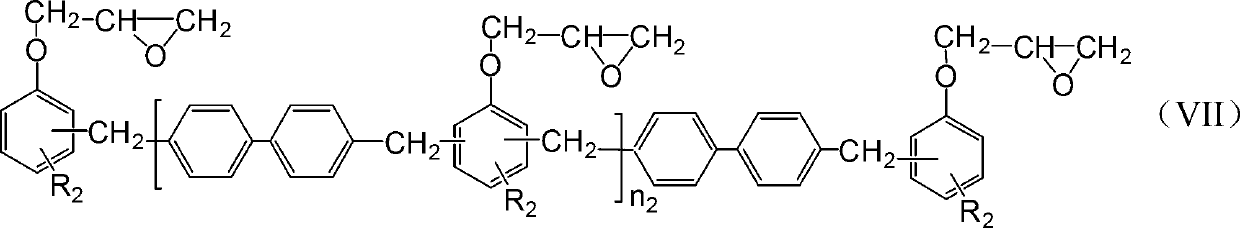

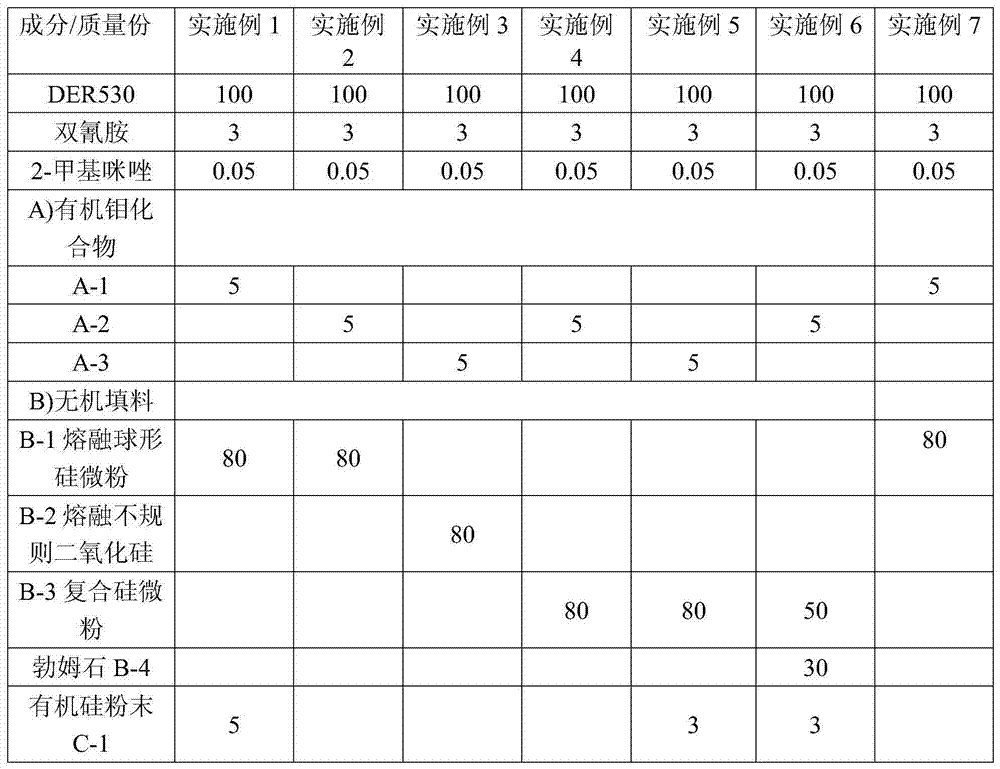

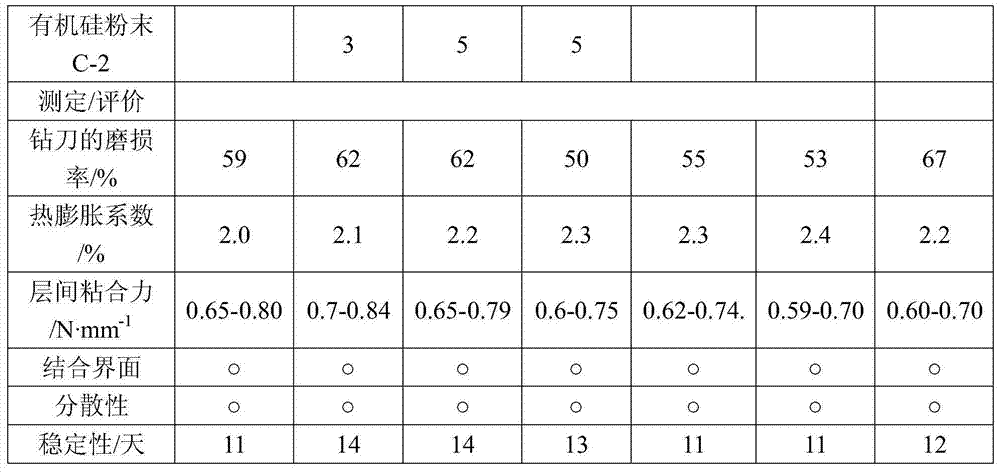

Thermosetting resin composition and use thereof

ActiveCN103497488AImprove drilling processabilityGood compatibilitySynthetic resin layered productsCircuit susbtrate materialsBond interfaceThermal expansion

The invention discloses a thermosetting resin composition. The composition comprises 20wt%-70wt% of thermosetting resin, 1wt%-30wt% of a curing agent, 0wt%-10wt% of an accelerator, an organic molybdenum compound, organic silicon powder and inorganic filler which are prepared into prepreg through an impregnation way or prepared into a coating through a coating way. The composition can be used for remarkably lowering a coefficient of thermal expansion and water absorption of a composite material, improving a bonding interface between the resin and the inorganic filler, improving interlayer adhesiveness of a laminated board and improving drilling processability of the laminated board.

Owner:GUANGDONG SHENGYI SCI TECH

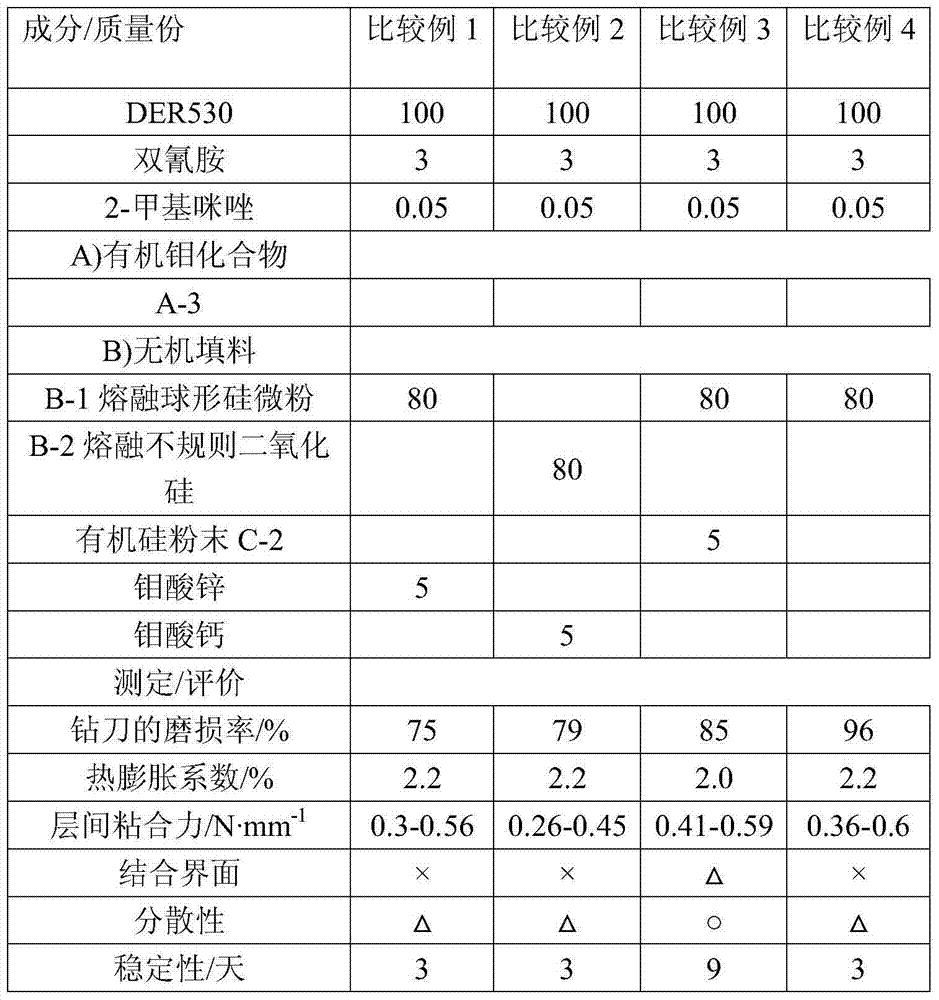

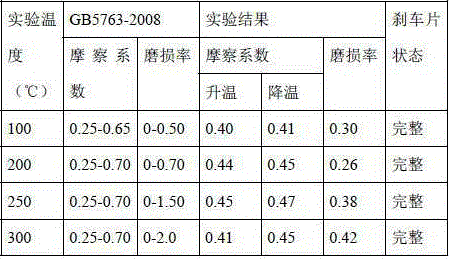

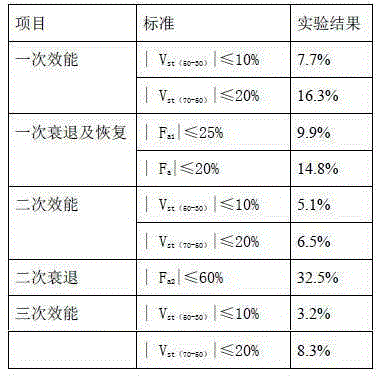

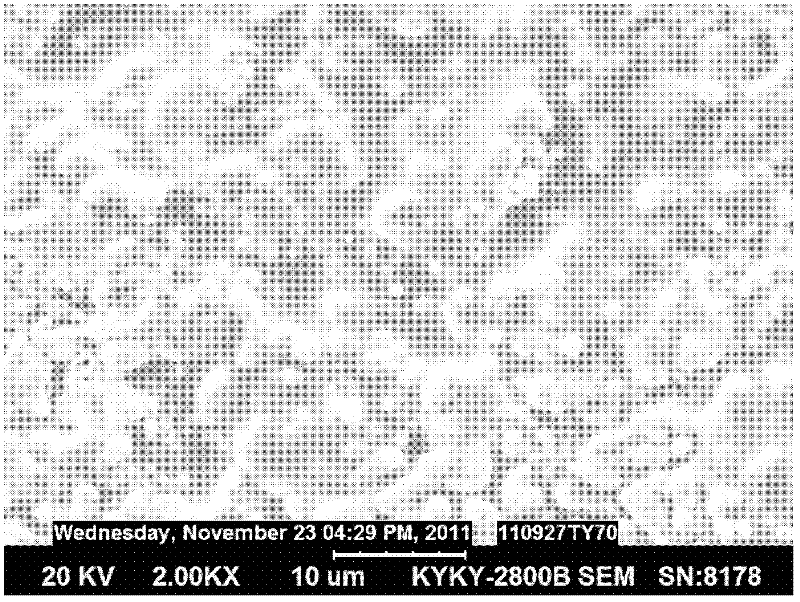

Vanadium-contained semimetallic brake block

ActiveCN105240429ANot easy to produceReduce wear rateOther chemical processesFriction liningAluminum silicateCellulose fiber

The invention discloses a vanadium-contained semimetallic brake block. The vanadium-contained semimetallic brake block includes, by weight, 5-7 parts of red copper fibers, 3-6 parts of potassium hexatitanate whiskers, 4-5 parts of barium sulfate, 15-25 parts of ferrovanadium powder, 4-6 parts of frictional powder, 13-15 parts of short stainless steel fibers, 6-10 parts of graphite, 2-4 parts of cellulosic fibers, 7-9 parts of coke blacking, 1-5 parts of modified resin nitrile fibers, 3-7 parts of chromite ore fine, 1-5 parts of nitrile rubber, 5-9 parts of ceramic adhesive agents and 8-10 parts of spray-bounded aluminum silicate fibers. The brake block obtained by material mixing, steel backing treatment, press molding, heat treatment, packaging and storage is low in wear rate, not prone to being dusty, high in density, good in heat dissipation, small in vibration, low in noise and high in corrosion resistance. The whole manufacturing process is simple, stability is good, cost is low and the cost-performance ratio is high.

Owner:盐城加能汽车部件有限公司

Method for manufacturing extruded bar from magnesium alloy

ActiveCN1695885AImprove mechanical propertiesMeet quality requirementsOther manufacturing equipments/toolsFree coolingIngot

Owner:NORTHEAST LIGHT ALLOY CO LTD

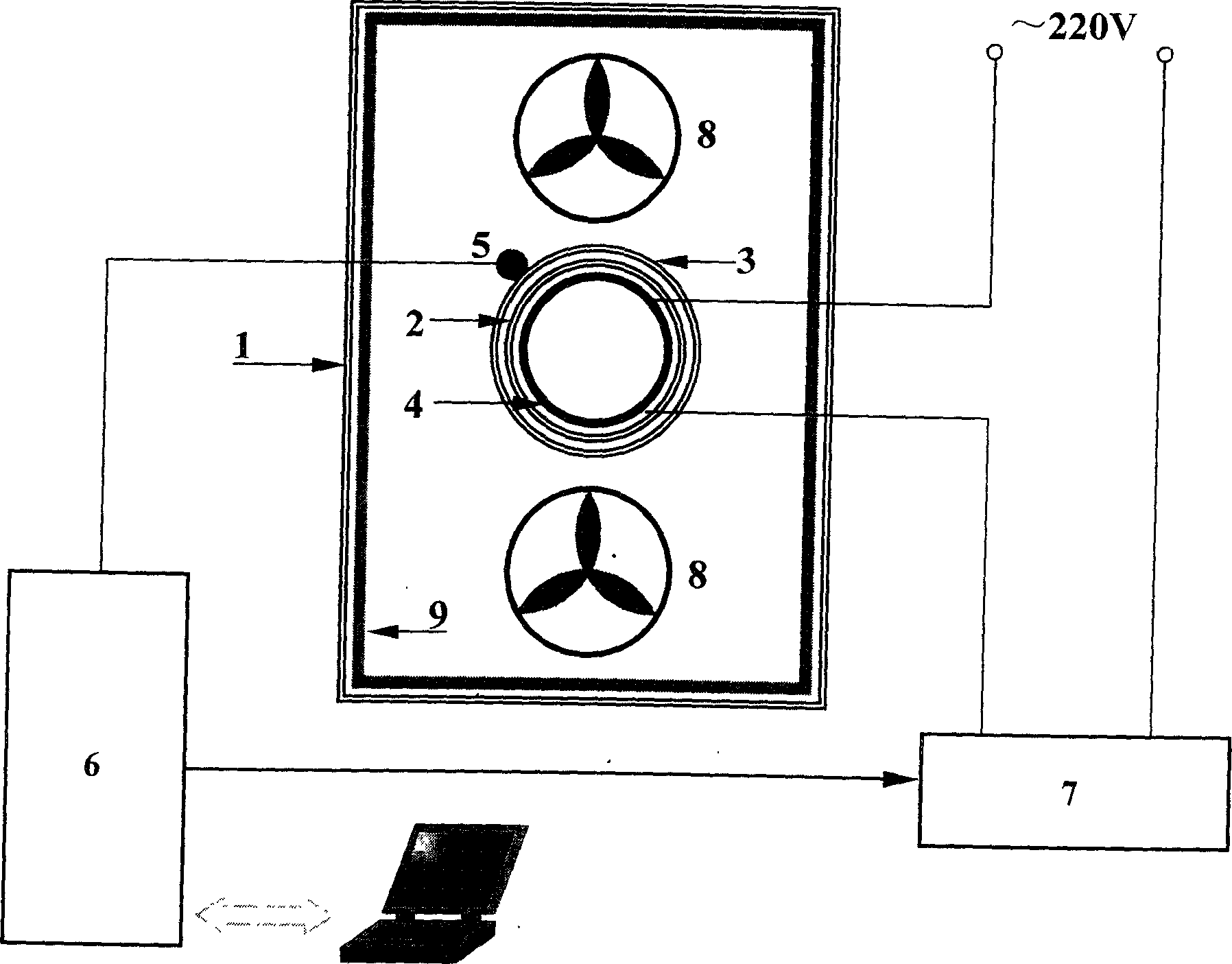

Minisize chromatographic column box with high precision temperature control system

InactiveCN1877319AImprove thermal conductivityImproved coefficient of thermal expansionComponent separationTemperatue controlTemperature controlControl system

The invention discloses a micro chromatographic column tank which comprises a tank body, capillary column heating frame set in the tank, capillary column bound around the frame, a heating device set on the inner wall of the frame, a precise thermo resistor and a temperature control system set out of the tank. The capillary column heating frame employs metal alloy material; the capillary column employs quartz material; the heating device is flexible electrical heating membrane coated on the inner wall of the frame; the temperature control system includes a temperature control module, the precise thermo resistor connects with the signal input terminal of the temperature control module, the output terminal of the temperature control module connects with the insulating single-phase alternative current modulator module of which one end of the output terminal connects with the heating device, and the other end of the output terminal connects with the input power.

Owner:张西咸 +3

Spinel powder with high temperature conductivity and synthesis method and application thereof

InactiveCN106587938AMatch high temperature oxidation resistanceGood high temperature oxidation resistanceFuel cellsSynthesis methodsOxidation resistant

The invention discloses spinel powder with high temperature conductivity and a synthesis method and application thereof, complexing agent citric acid and binder polyvinylpyrrolidone are dissolved in turn in distilled water, then a Cu salt and a Co salt are dissolved into the distilled water, and finally a manganese nitrate solution is added; the obtained mixed solution is stirred magnetically for 2-3h at room temperature, then thermally insulated for 4-6h at 40 DEG C, then thermally insulated for 2-4h at 80 DEG C, and thermally insulated for 2-4h at 100 DEG C to form a colloid; the colloid is heated to 220 DEG C and thermally insulated for 8-15h for volatilization of organic compounds for formation of solid powder. The spinel powder improves the high temperature oxidation resistance and conductive properties of a metal connector in a solid oxide fuel cell in an oxidizing atmosphere, and inhibits cathode poisoning caused by Cr diffusion in a metal matrix, and the spinel powder can be used for the preparation of a metal connector surface used as a corrosion resistant conductive layer.

Owner:JIANGSU UNIV OF SCI & TECH

Production method of large-size graphite electrode

The invention relates to a production method of a large-size graphite electrode which comprises the components in percentage by weight: 76-79 percent of calcined petroleum coke, 21-24 percent of medium-high temperature modified asphalt and the balance of filling material with the diameter of 0.075-2 mm, wherein the calcined petroleum coke comprises the following components in percentage by weight: not more than 4 percent of granules with the diameter of more than 12 mm, 6-10 percent of granules with the diameter of 8-13 mm, 13-17 percent of granules with the diameter of 4-8 mm, 9-13 percent of granules with the diameter of 2-4 mm and 30-32 percent of powder with the diameter of not more than 0.075 mm according to the particle size distribution; and the coking value of the modified asphalt is over 55 percent and the softening point is 95-100 DEG C. After the raw materials are mixed according to the proportion, the large-size graphite electrode is produced by adopting a conventional process, wherein the mixing temperature is 160-165 DEG C and the thicker lumpiness during the die-filling is less than 40 mm. A huge-size electrode with the diameter of over 960 mm can be produced by adopting the production method of the large-size graphite electrode; meanwhile, the electrode has low resistivity and good conduction property and can bear strong current, thereby enabling the unit consumption and the electricity consumption to be greatly lowered and saving the production cost.

Owner:JIEXIU JUYUAN & COALY

Conductive silver paste for ferrite core inductance and method for producing same

ActiveCN102610326AAvoid crackingNot easy to electroplateTransformers/inductances coils/windings/connectionsNon-conductive material with dispersed conductive materialSilver pasteInductance

The invention discloses a conductive silver paste for a ferrite core inductance and a method for producing the same, wherein the method comprises the following steps that: (1) lead-free glass powder is produced and contains an inorganic additive I which occupies 1-4% of the total quantity of the lead-free glass powder; (2) an organic carrier is produced; (3) superfine silver powder, silver flake, the lead-free glass powder and an inorganic additive II are mixed to produce the powder, the powder is uniformly stirred and then added into the organic carrier, after high-speed stirring and dispersion, the powder is rolled by a three-roller mill to the fineness of lower than 10mum, and is screened by a screen of 200 meshes for producing the conductive silver paste for the ferrite core inductance. The ferrite conductive silver paste can effectively solve the defects of the silver paste for the ferrite core inductance on corrosion resistance, adhesive force and electroplating performance, has good quality, is low in cost, and is an ideal substitute product for lead-bearing paste. The adopted technology can ensure the stability and consistency of the silver paste.

Owner:广东羚光新材料股份有限公司

3D printing process method of high-strength aluminum-magnesium alloy

ActiveCN111872386ALow costImprove qualityAdditive manufacturing apparatusTransportation and packaging3D modelingMaterials science

The invention relates to a 3D printing process method of a high-strength aluminum-magnesium alloy, and belongs to the technical field of 3D printing. Firstly, high-strength aluminum-magnesium alloy raw materials are mixed evenly through heating and melting; then high-quality aluminum-magnesium alloy powder is prepared from the high-strength aluminum-magnesium alloy in a molten state through a gasatomization technology, and aluminum-magnesium alloy powder for 3D printing is obtained after drying; and printing parameters are adjusted, 3D printing is carried out according to 3D model data of parts in printing equipment with inert gas introduced, and a 3D printing product with the high-strength aluminum-magnesium alloy as a raw material is obtained. Compared with the prior art, as for the product printed through the process method, the relative density can reach 99% or above, the Vickers hardness can reach 110 HV or above, the tensile strength can reach 430 MPa or above, the elongation can reach 21%, through proper heat treatment, the Vickers hardness of a sample can reach 150 HV or above, the tensile strength can be further increased to 520 MPa or above, and the elongation is maintained at 17% or above.

Owner:TONGJI UNIV

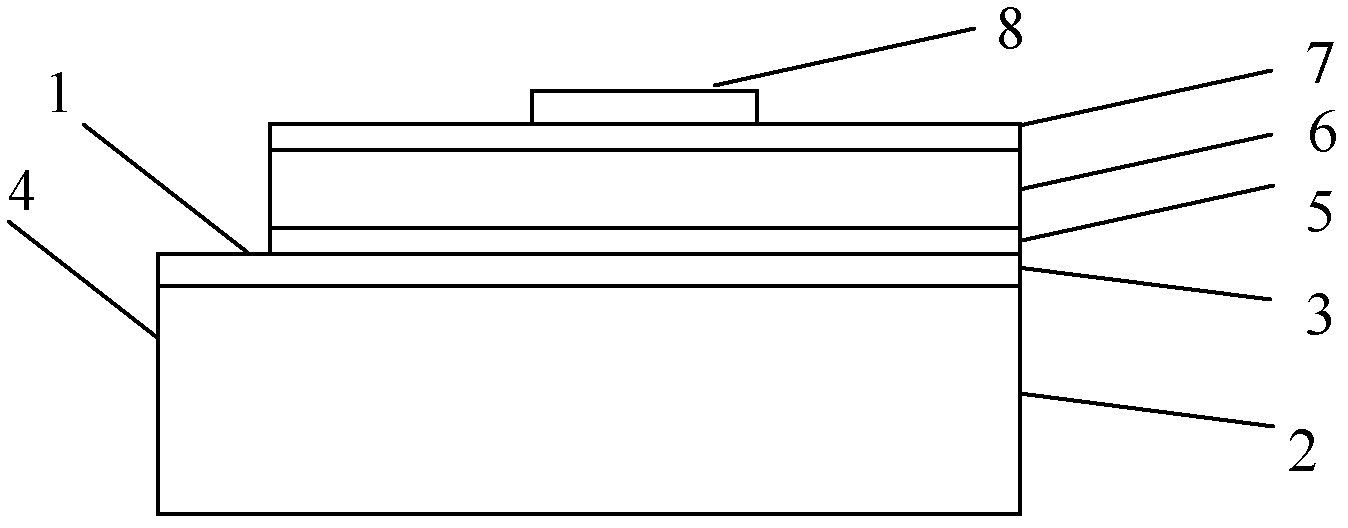

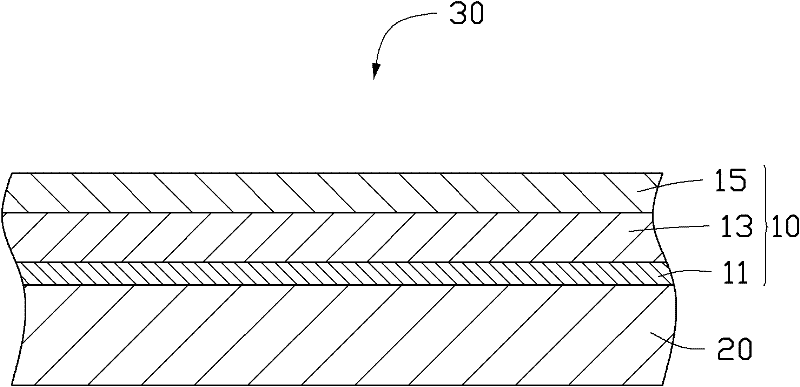

Millimeter wave micro-strip antenna and manufacturing method thereof

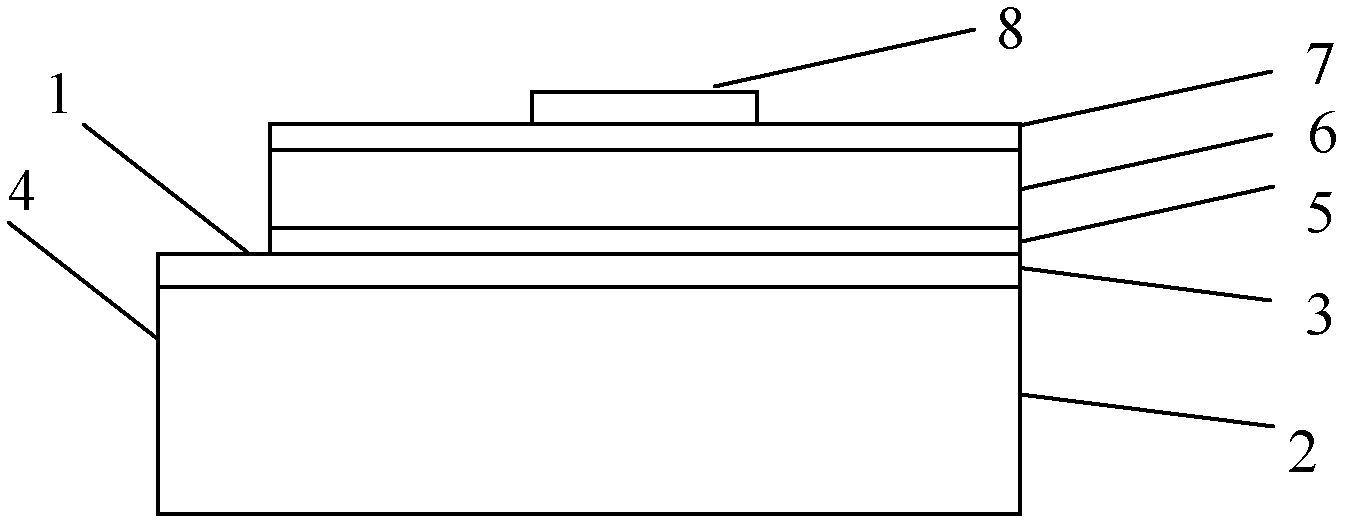

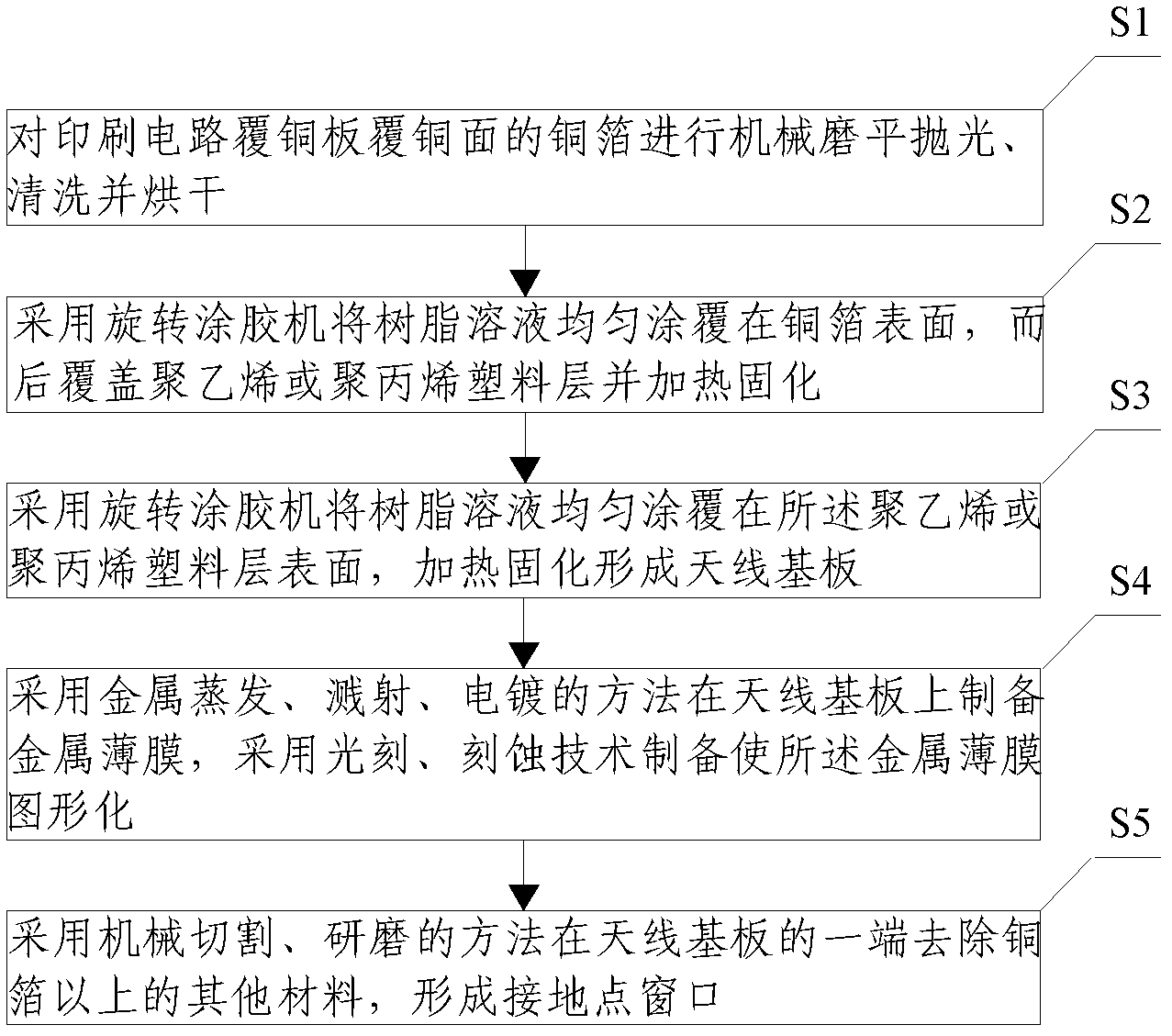

InactiveCN102324619AImprove radiation efficiencyIncrease signal gainRadiating elements structural formsEpoxyRadiance

The invention discloses a millimeter wave micro-strip antenna and a manufacturing method thereof, relating to the technical fields of millimeter wave wireless communication and antennae. The millimeter wave micro-strip antenna comprises an antenna substrate (1) and a graphic metal film (8), wherein the antenna substrate (1) comprises a printed circuit copper-clad plate (4), lower layer epoxy resin (5), a polypropylene or polyethylene plastic layer (6) and upper layer epoxy resin (7) which are arranged from bottom to top; the graphic metal film (8) is positioned on the surface of the lower layer epoxy resin (5); and the printed circuit copper-clad plate (4) comprises an epoxy resin substrate (2) and a copper foil (3). In the invention, the substrate of the millimeter wave micro-strip antenna is manufactured by taking the printed circuit copper-clad plate which consists of the resin substrate and the copper foil on the surface of the resin substrate as well as a layer of common plastic as main bodies, so that the radiance efficiency and signal gain of the micro-strip antenna can be increased, and the cost of the antenna can be lowered.

Owner:TSINGHUA UNIV

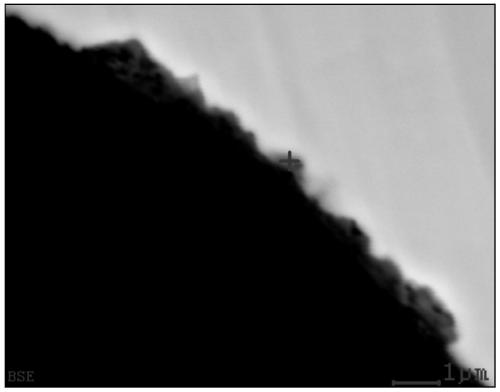

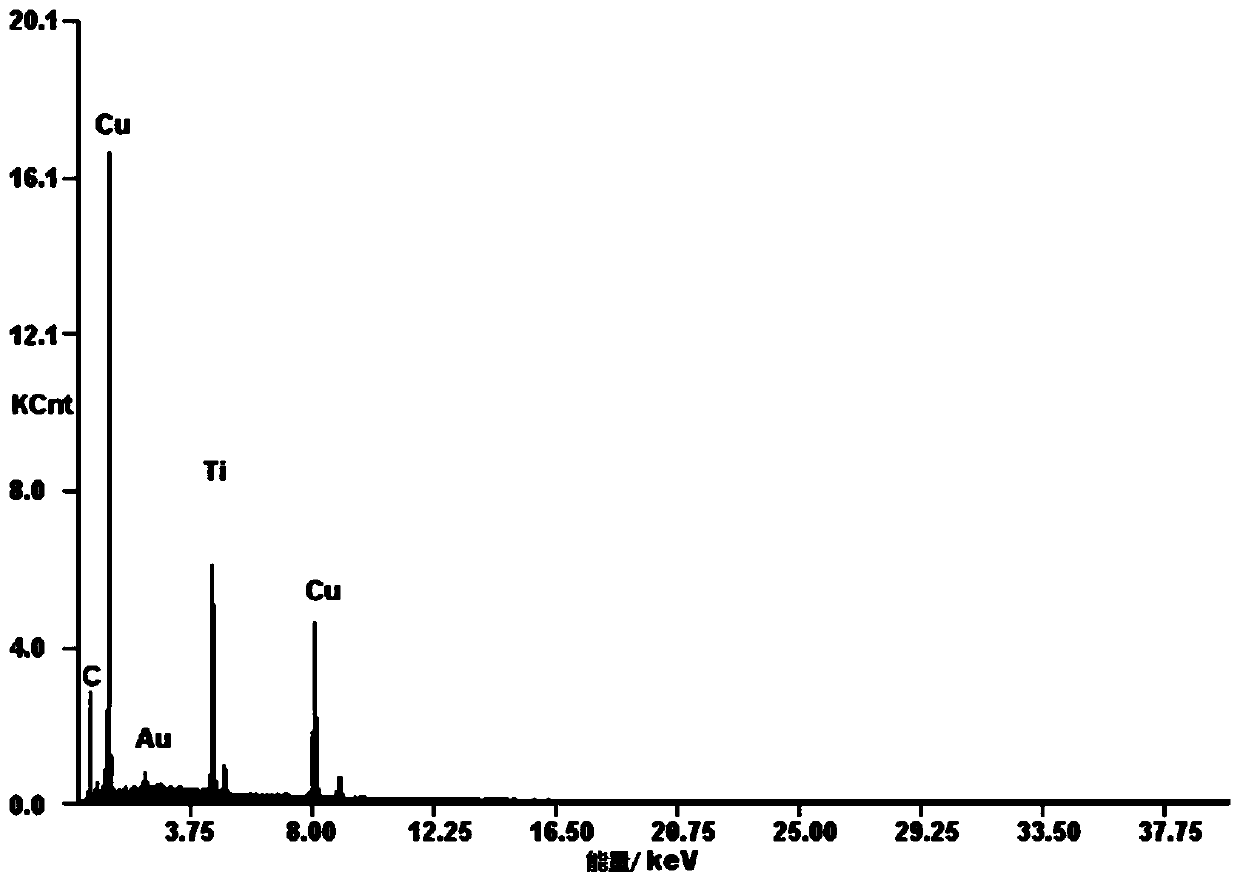

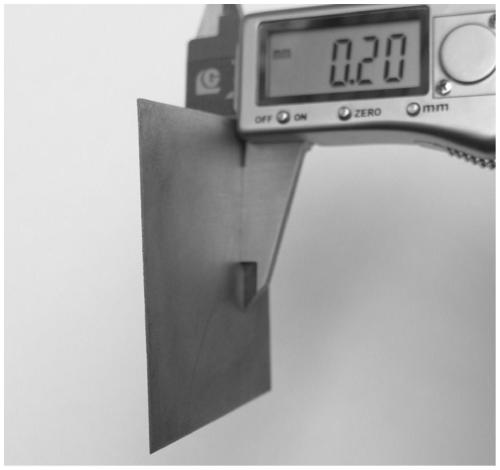

Preparation method for large-size slice-shaped and ultrahigh-heat-conductivity diamond/copper composite material

The invention provides a preparation method for a large-size slice-shaped and ultrahigh-heat-conductivity diamond / copper composite material and relates to the preparation method for the diamond / coppercomposite material. The purpose of the preparation method for the large-size slice-shaped and ultrahigh-heat-conductivity diamond / copper composite material is to solve the problems of the low heat conductivity and the poor interfacial bonding strength of the diamond / copper composite material. The preparation method comprises the steps that diamond particles coated with metal films are filled intoa mold cavity of a graphite mold to obtain a prefabricated body; and the prefabricated body is placed into a crucible, block-shaped pure copper and copper alloy are placed at the upper portion of theprefabricated body inside the crucible to be placed into an air pressure leaching furnace, interfacial layer material tissue form adjusting and control are performed under an argon protective atmosphere, warming copper melting, heat preservation and pressure maintaining leaching are performed, and finally, pressure maintaining stepped cooling is performed. In an obtained composite material component, the diamond volume fraction is 60-85%, the heat conductivity reaches 1500 W / mK, the edge length reaches 60-130 mm, and the thickness reaches 0.2-4 mm. The preparation method for the large-size slice-shaped and ultrahigh-heat-conductivity diamond / copper composite material is suitable for preparing the high-heat-conductivity diamond / copper composite material.

Owner:哈尔滨锦威科技有限公司

Glass substrate ceramic dielectric layer glaze and preparation method thereof

The invention discloses glass substrate ceramic dielectric layer glaze. The dielectric layer glaze is prepared from the following raw materials: 50-60 wt% of low-melting-point lead-free dielectric powder, 20-30 wt% of an inorganic metal oxide pigment, 12-18 wt% of water-soluble environment-friendly varnish and 0.5-3 wt% of an auxiliary agent. The ceramic dielectric layer glaze for the glass substrate is high in adhesive force, good in hydrophilicity, high in hardness, scratch-resistant, high-temperature-resistant and corrosion-resistant.

Owner:厦门翰森达电子科技有限公司

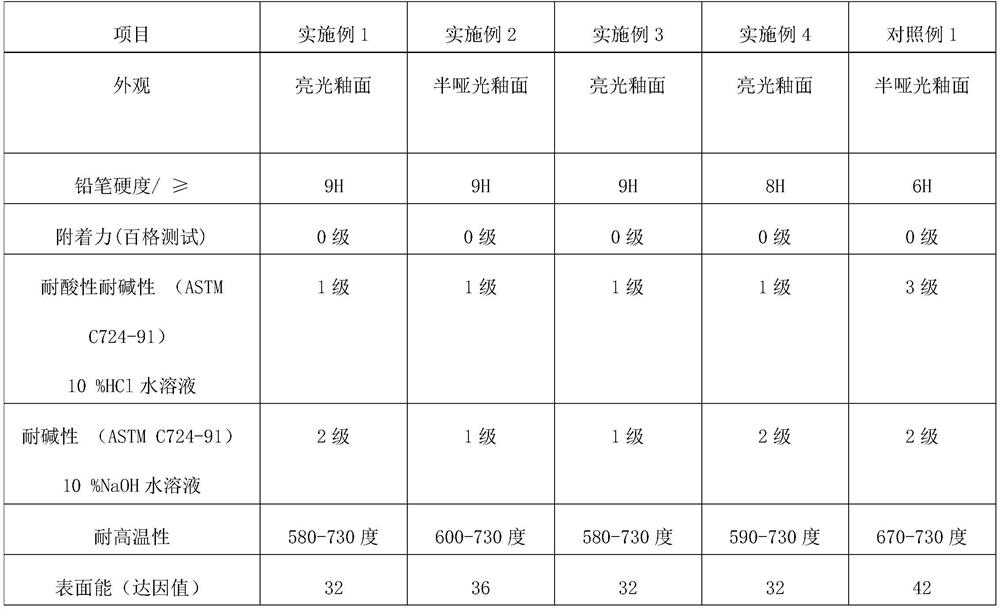

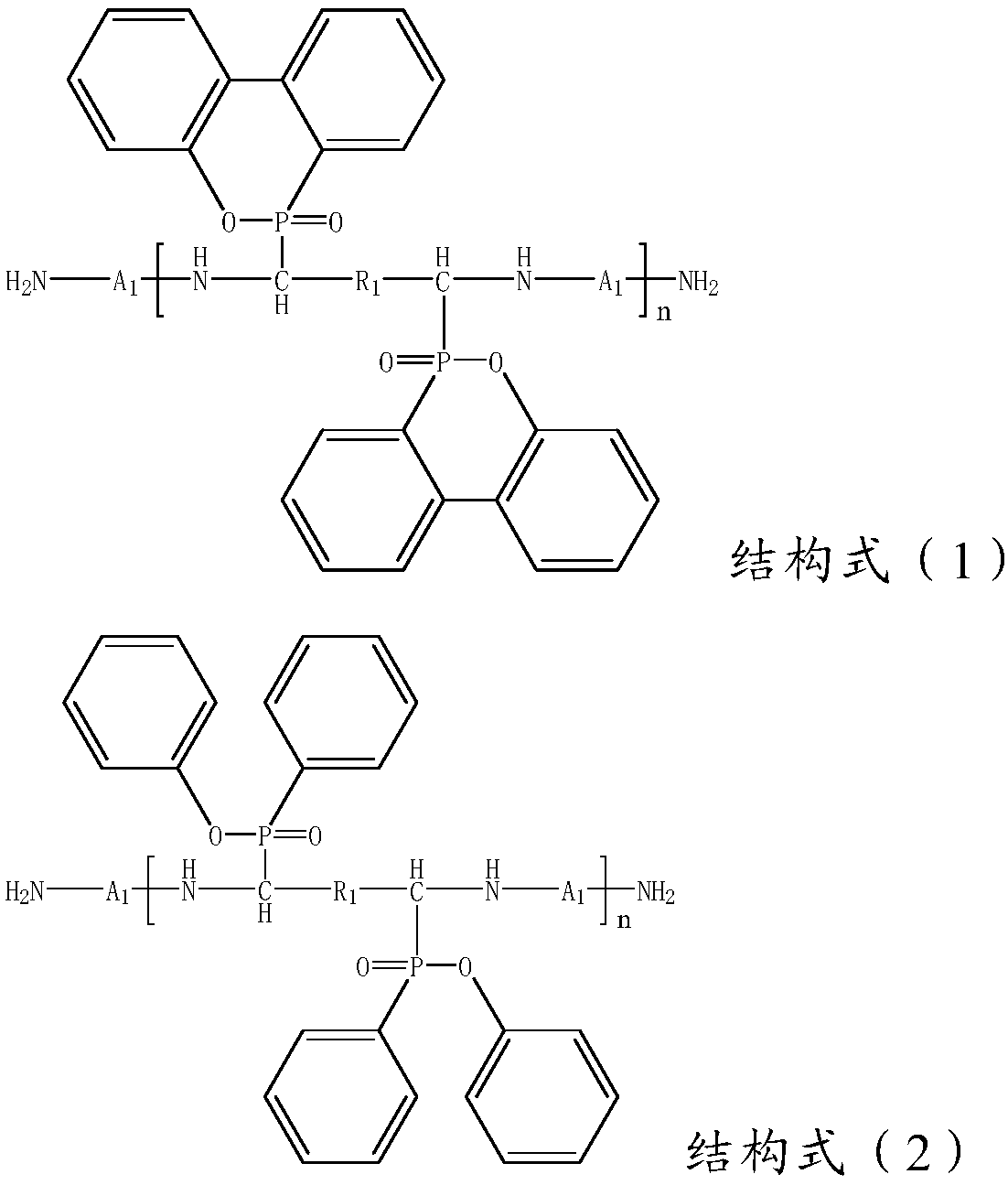

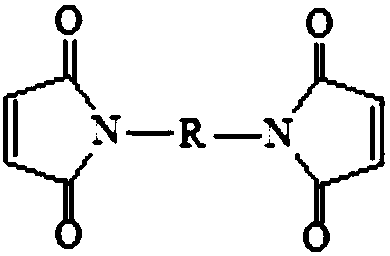

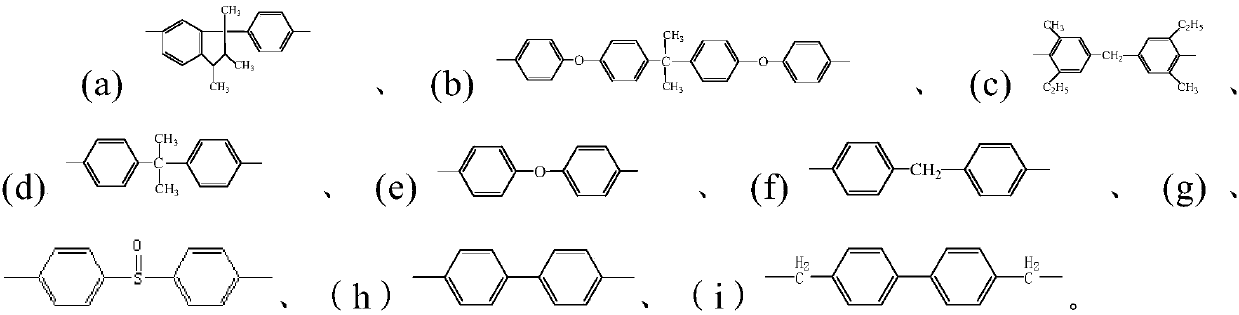

Flame-retardant resin composition and prepreg and laminate prepared using same

ActiveCN109535715AReduced flame retardancyExcellent halogen-free flame retardant performanceSynthetic resin layered productsLaminationEpoxyHydrogen

The invention discloses a flame-retardant resin composition, which comprises the following components by solid weight: 100 parts by weight of a modified bismaleimide prepolymer; 5-30 parts of epoxy resin; 0-20 parts of a curing agent, 0-150 parts of a filler; 0.001-5 parts of a curing accelerator; wherein the modified bismaleimide prepolymer is at least prepolymerized by bismaleimide resin and anamine compound. Compared with the prior art, a DOPO or DPPO-containing amine compound reacts not only with the bismaleimide, but also with the active hydrogen of -NH- in the structure reacts and the epoxy group, so that a small amount of epoxy resin and the curing agent are added to obtain a final cured product having high heat resistance and high modulus, the high-performance print circuit boardrequirements such as HDI multilayer substrates and ultra-thin package substrates can be satisfied, and a small amount of epoxy resin and the curing agent can be added to further improve the adhesion of the resin composition and enhances the anti-stripping intensity of a copper-clad board.

Owner:SHENGYI TECH SUZHOU

Preparation method for engineering ceramic acid and alkali resistant container

ActiveCN103641447AGood acid and alkali resistanceHigh mechanical strengthClaywaresEconomic benefitsPerformance index

The invention discloses a preparation method for an engineering ceramic acid and alkali resistant container. The preparation method comprises steps of batching of blank material raw materials, forming of the blank material, batching of glaze material raw materials, preparation of the glaze material, biscuiting, glaze application and sintering. The engineering ceramic acid and alkali resistant container has advantages of high acid resistance, high alkali resistance, particularly being free from pollution of media, high mechanical strength, high compactness, high dimensional precision, low water absorption, good heat stability, small thermal expansion coefficients, leak resistance and the like. The carcass is compact, the glaze is bright and clean, and there are no defects of pin holes, glaze shrinkage, thin glaze and the like. The defective percentage is lowered, and the production efficiency is raised. Temperature-resistant requirements to a kiln device are eliminated, and the production cost is lowered. The novel engineering ceramic acid and alkali resistant container has good appearance quality and performance indexes, and is an ideal product raising economic benefits.

Owner:江苏省宜兴彩陶工艺厂

3D printing process method of high-strength aluminum manganese alloy

InactiveCN111659889ALow costImprove qualityAdditive manufacturing apparatusTransportation and packagingManganese3D modeling

The invention relates to a 3D printing process method of a high-strength aluminum manganese alloy, and belongs to the technical field of 3D printing. The 3D printing process method comprises the stepsthat firstly, a high-strength aluminum manganese alloy is mixed evenly by heating and melting; then the melted high-strength aluminum manganese alloy is subjected to a gas atomization technology to prepare high-quality aluminum manganese alloy powder, and aluminum manganese alloy powder for 3D printing is obtained after drying; and printing parameters are adjusted, 3D printing is conducted according to three-dimensional model data of parts in printing equipment introduced with inert gas, and a 3D printing product with the high-strength aluminum manganese alloy as a raw material is obtained. Compared with the prior art, according to the product printed by the process method, the relative density can reach more than 99%, the Vickers hardness can reach more than 140 HV, the tensile strengthcan reach more than 440 MPa, the elongation can reach 20%, after proper hear treatment, the hardness of a sample can reach more than 180 HV, the tensile strength can be further increased to more than565 MPa, and the elongation is maintained at or above 19%.

Owner:TONGJI UNIV

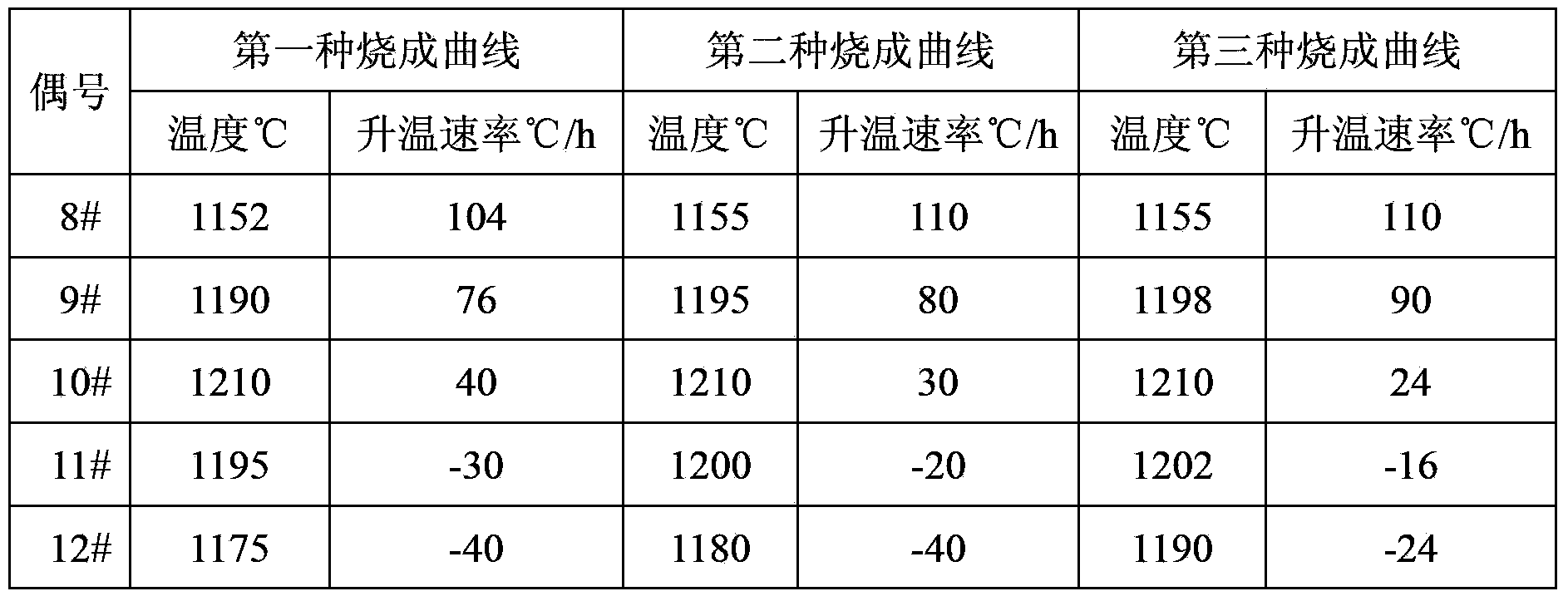

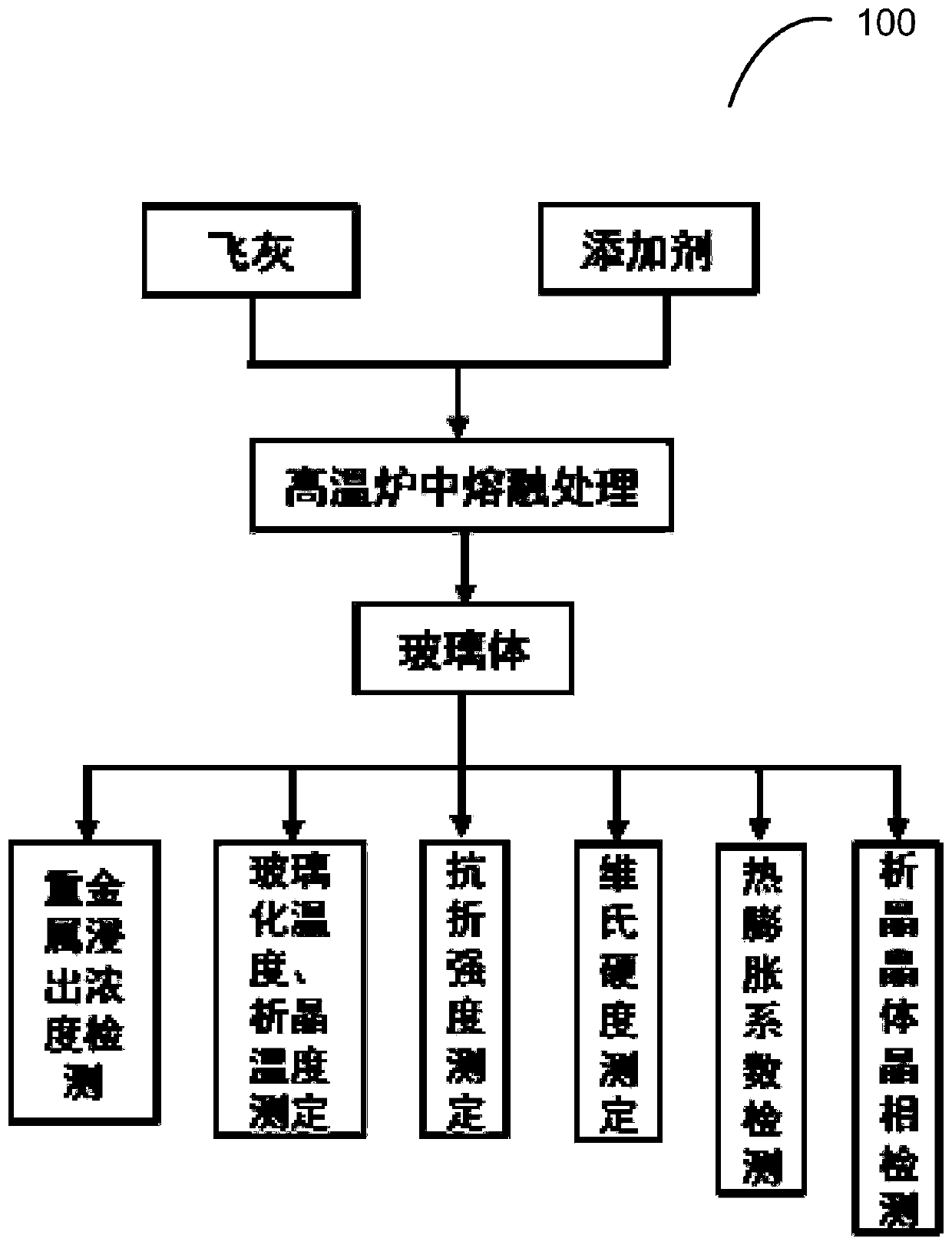

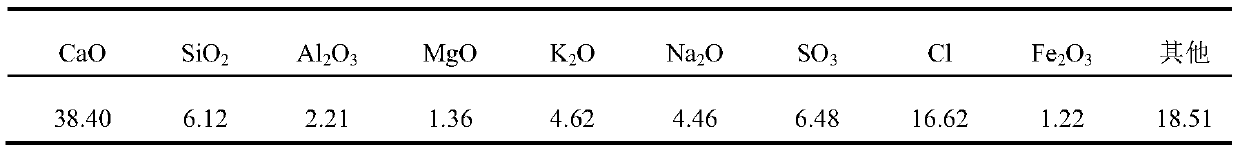

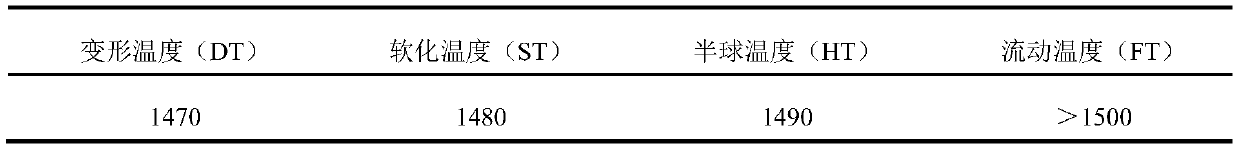

Waste incineration fly ash plasma fusing method

PendingCN110142278ALower melting temperatureReduce leaching concentrationSolid waste disposalTransportation and packagingPhase splittingBoric acid

The invention provides a waste incineration fly ash plasma fusing method. The method at least comprises the following steps that step 1), a fusing additive is added into to-be-fused fly ash so as to obtain a fusing mixture; and step 2), fusion treatment is carried out on the fusing mixture so as to obtain a fusing glass body. The fusing additive comprises quartz sand, Al2O3, ZrO2 and boric acid. SiO2 and Al2O3 in quartz sand serve as a forming body of a network structure of a fusing glass body, ZrO2 serves as a nucleating agent, so that the surface crystallization is converted into the overallcrystallization under the action of an induced phase splitting mechanism of the glass body, and the boric acid is used as a fluxing agent to form a low eutectic point with the to-be-fused fly ash, sothat the fusing temperature of the to-be-fused fly ash is reduced.

Owner:EVERBRIGHT ENVIRONMENTAL TECH EQUIP CHANGZHOU +2

Preparation method of filled-type thermally conductive silicone rubber composite material

ActiveCN101597430AHigh chemical stabilitySmall coefficient of thermal expansionThermal conductivityNanometre

The invention discloses a preparation method of a filled-type thermally conductive silicone rubber composite material. The processing steps of the method are as follows: 1) using alcohol solution to mix carbon-encapsulated copper nanoparticles evenly, and then drying the nanoparticles to prepare dry powder; 2) adding the raw silicone rubber onto a roller, after the raw rubber covers the roller, adding carbon-encapsulated copper nanoparticles dry powder and hydroxy silicone oil in sequence in accordance with the formulation design amounts; mixing the dry powder and the hydroxy silicone oil on the roller repeatedly until being uniform, then adding a vulcanizing agent, and then mixing the mixture uniformly, thin-passing a lower sheet to obtain the silicon rubber compound; 3) putting mixed silicone rubber into a mold, carrying out first vulcanization after cold pressing and mold filling; 4) putting a vulcanization-molded sample on a glass cloth and carrying out post vulcanization on the sample in an air dry oven to obtain finished products. The invention mixes the carbon-encapsulated copper nanoparticles and high-temperature silicone rubber to ensure that the carbon-encapsulated copper nanoparticles are evenly scattered in the silicone rubber substrate to form an integral thermally conductive network chain, thereby improving the thermal conductivity of the silicone rubber.

Owner:GUANGDONG SUNLITE MATERIAL SCI & TECH

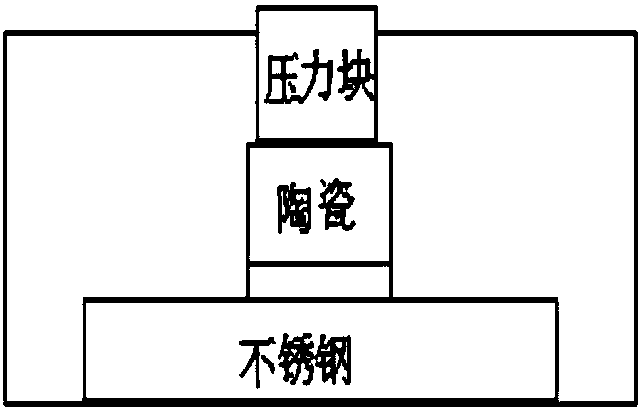

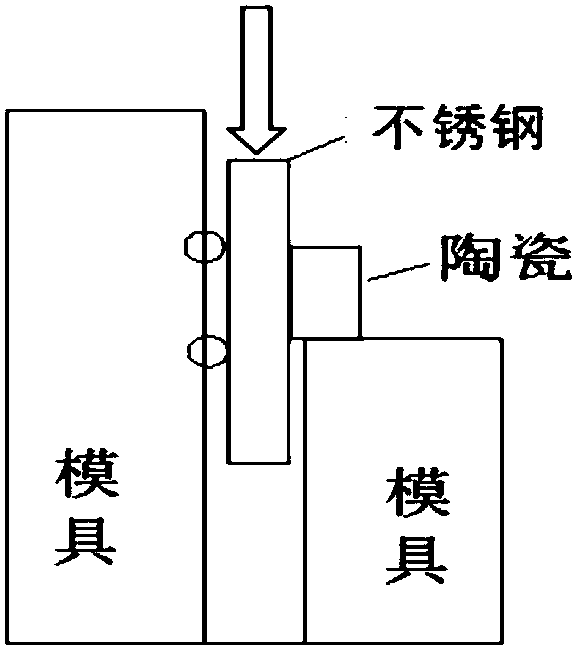

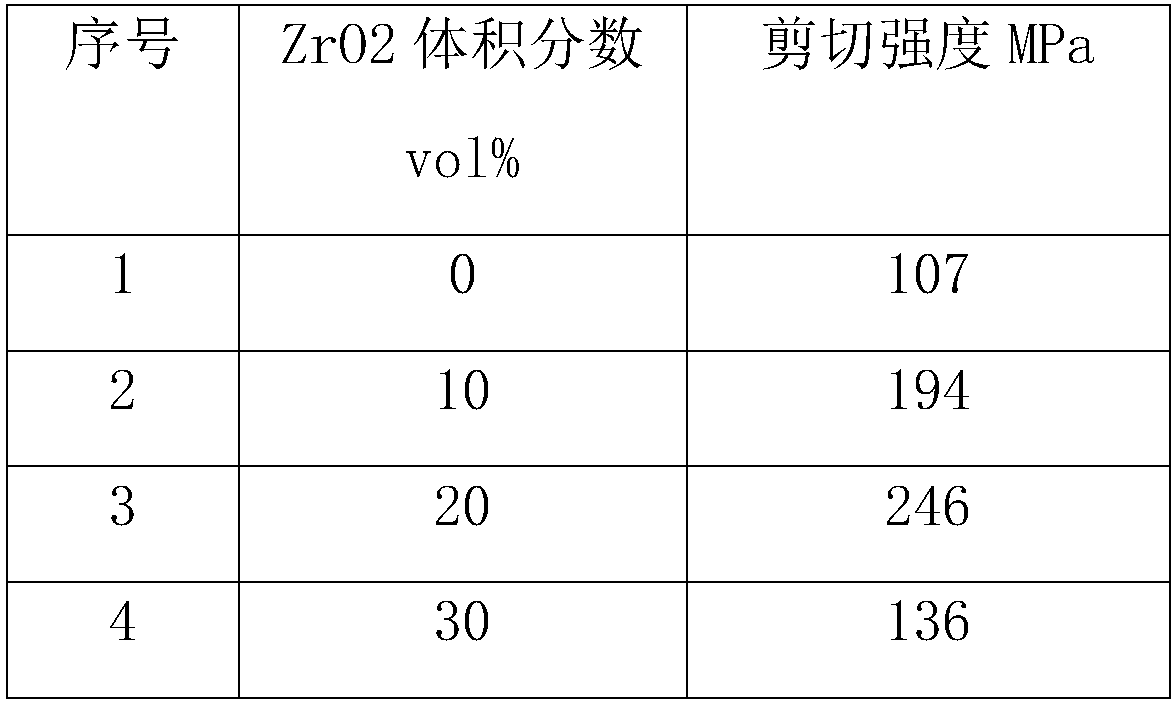

Welding connection method of oxide ceramic and metal

InactiveCN108546095AProne to residual stressSmall difference in coefficient of thermal expansionOxide ceramicComposite ceramic

The invention discloses a welding connection method of oxide ceramic and metal, using brazing filler metal as an interlayer to connect ceramic and stainless steel metal in a vacuum high temperature environment. The method comprises the following steps: step S1: preparing the ceramic; step S2: making a brazing sample; step S3: performing high-temperature high-vacuum brazing on the sample. The invention relates to the field of connection between different materials, in particular to a connection method of the oxide ceramic and the stainless steel metal, integrating performance advantages of bothceramic and metal in application. Particularly a brazing connection method of aluminum oxide ceramic as well as composite ceramic thereof and the stainless steel metal is disclosed; the used interlayer adopts (Ag72-Cu28)96Ti4 brazing filler metal. The toughness, strength, wear resistance and the like can meet the application requirements in fields such as kitchenware, mobile phone cover plates, auto parts and aviation.

Owner:GUANGDONG UNIV OF TECH

Hard coating, preparation method thereof, and coated article with the coating

InactiveCN102294854AImprove toughnessImprove wear resistanceVacuum evaporation coatingSputtering coatingMetallurgyFour component

The invention provides a hard coating. The hard coating is composed of a transition layer, an intermediate layer and an outermost layer orderly formed on a hard substrate; the transition layer is composed of Ti-Nb-N three components, the intermediate layer and the outermost layer are all composed of Ti-Si-Nb-B four components; the percent contents of Ti atoms and Nb atoms in the outermost layer are respectively less than that in the intermediate layer, and the percent content of Si atoms in the outermost layer is more than that in the intermediate layer. The invention further provides a preparation method of the hard coating and a covering element having the hard coating.

Owner:HONGFUJIN PRECISION ELECTRONICS (ZHENGZHOU) CO LTD +1

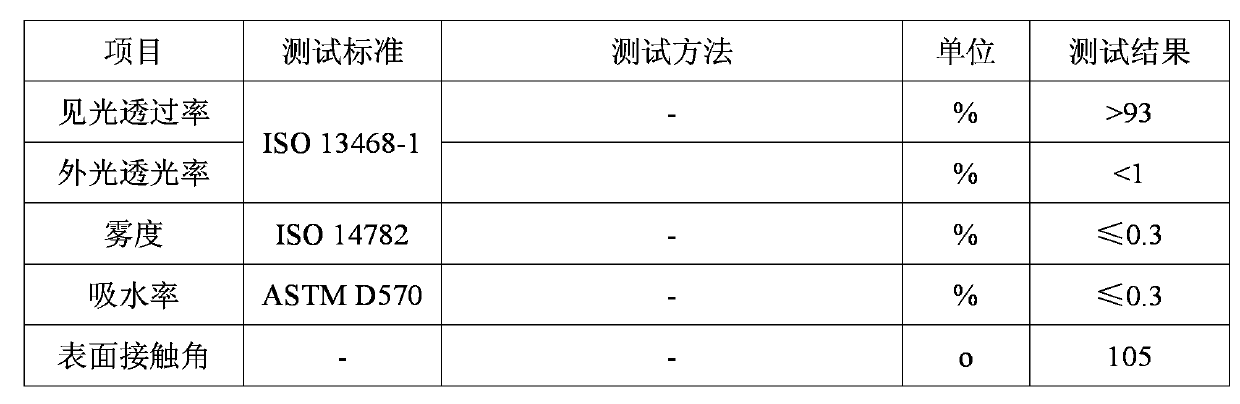

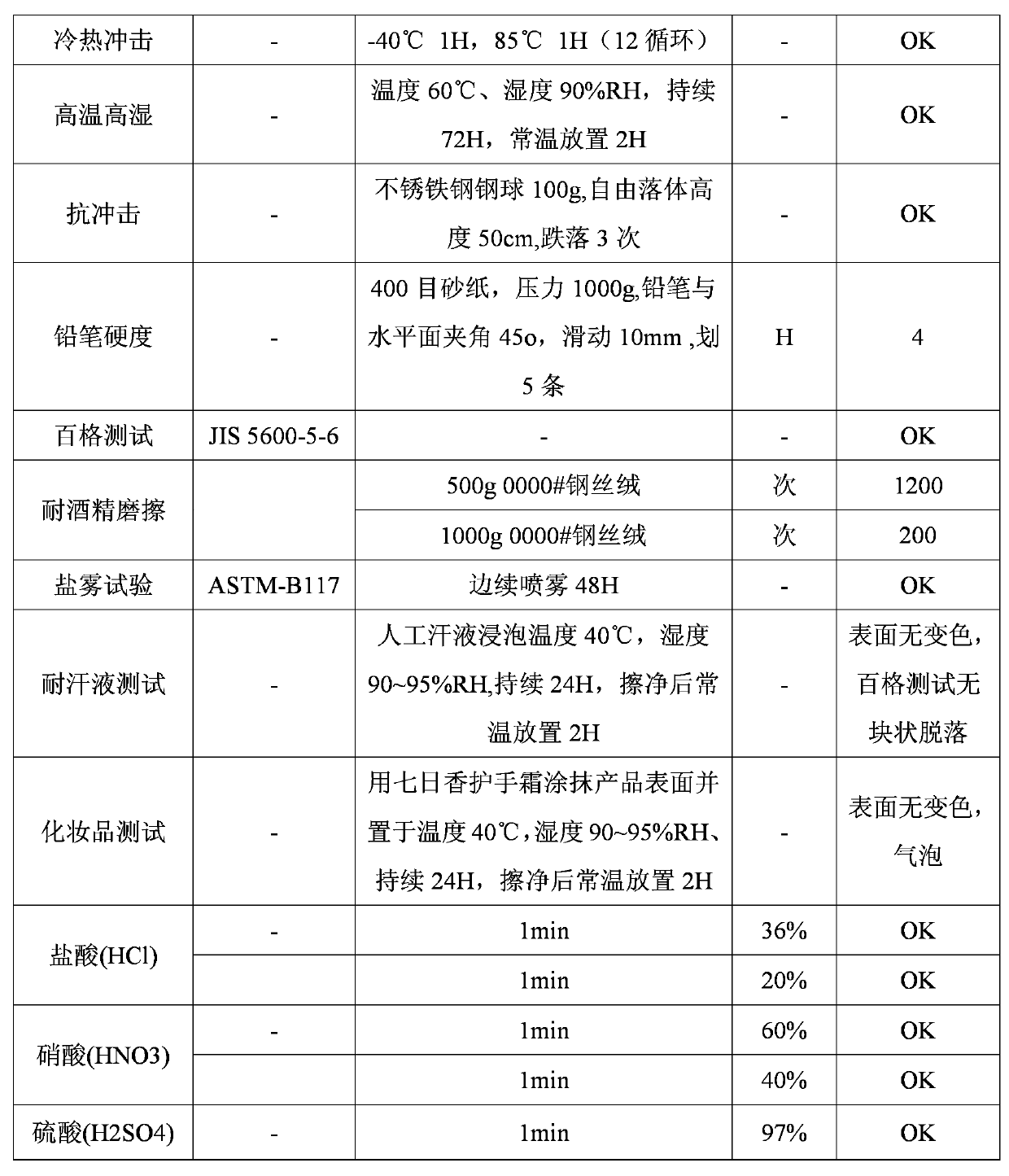

Acrylic-modified organosilicon nano paint and preparation method thereof

ActiveCN102766403AImprove brittlenessImproved coefficient of thermal expansionCoatingsPolycarbonateOrganosilicon

The invention discloses an acrylic-modified organosilicon nano paint and a preparation method thereof. The paint comprises the following components in parts by mass: 0-40 parts of acrylic-modified organosilicon prepolymer, 0-40 parts of tetraalkoxysilane, 0-40 parts of trialkoxysilane, 0-10 parts of dialkoxysilane, 0-40 parts of nano inorganic particle, 5-20 parts of deionized water, 0-5 parts of acid catalyst and 10-40 parts of organic solvent, wherein the tetraalkoxysilane and trialkoxysilane can not be 0 part at the same time. After the paint is applied onto a soft polycarbonate film or sheet and cured, the paint coating has the advantages of high hardness (1000g load, pencil hardness 3-4H), excellent wear resistance (0000# steel wool, 500g load, more than 1200 times), favorable transparency (the visible light transmittance is more than 93%), excellent adhesive force (after stripping with a 3M adhesive tape five times, the 100 / 100 coating does not shed), favorable temperature and water resistance (no change under high temperature (60 DEG C) and high humidity (90%) for 72 hours), and the like.

Owner:许立江

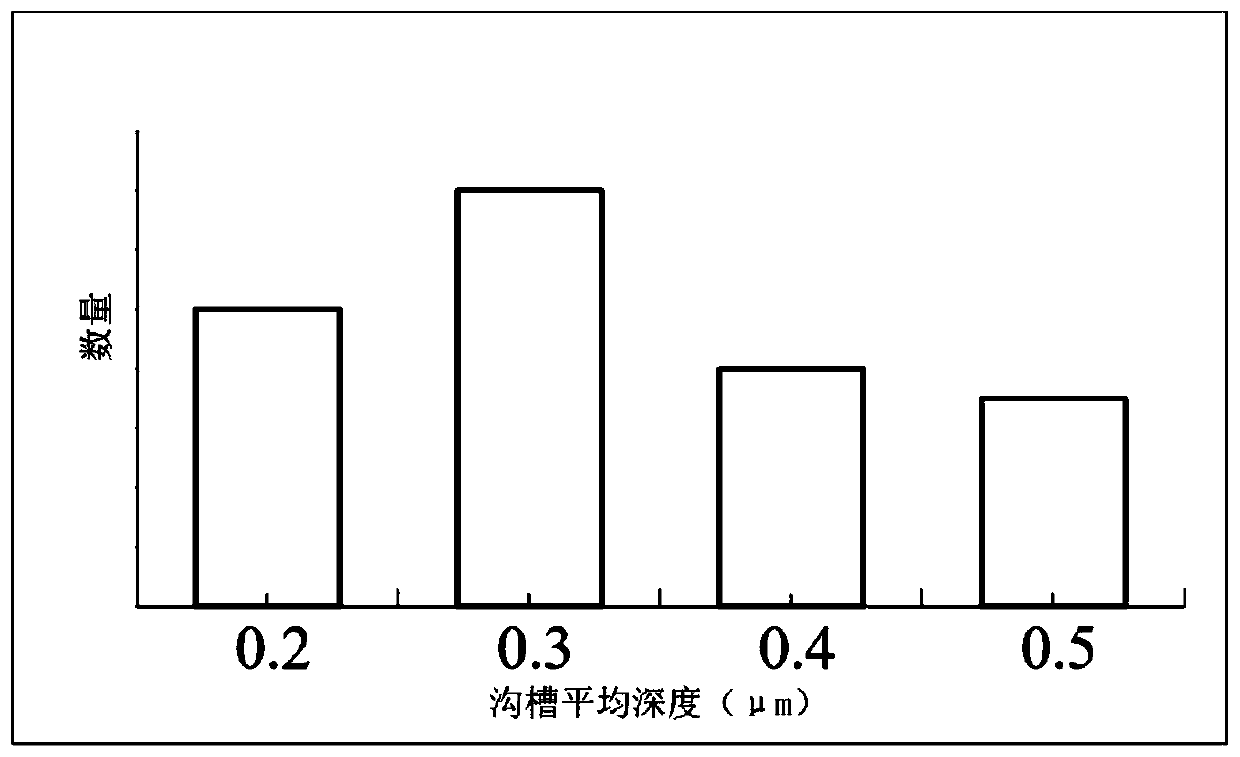

Polyacrylonitrile-based graphite fiber and preparation method thereof

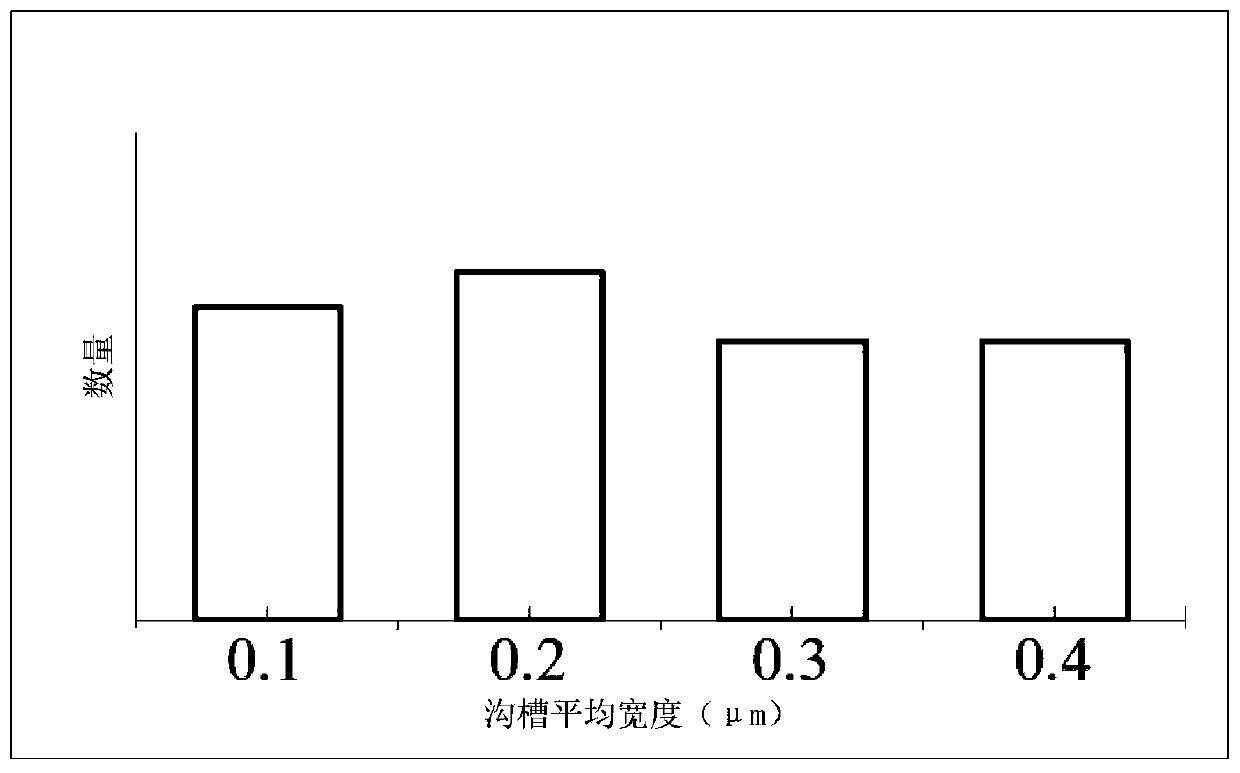

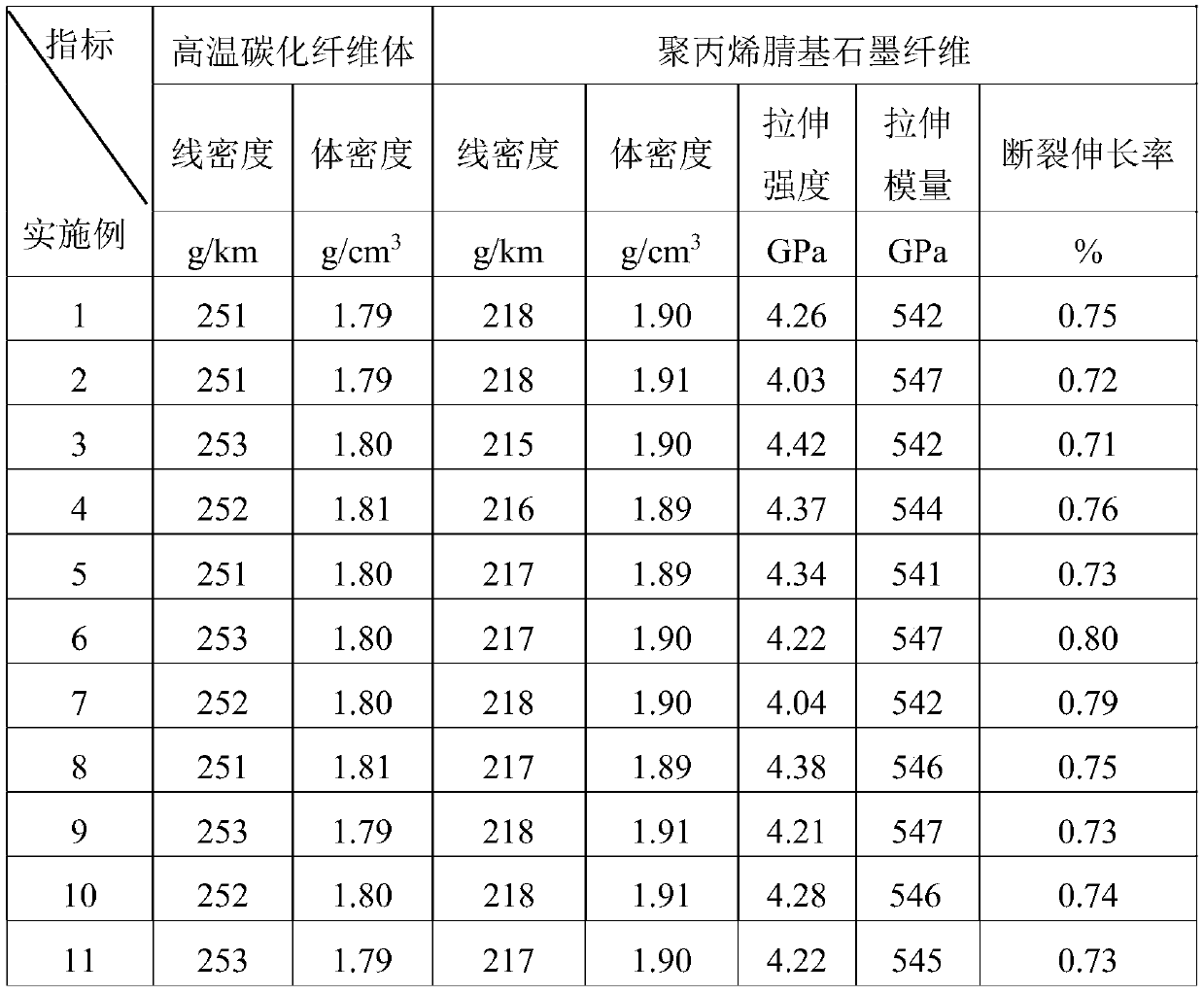

ActiveCN110067044AHigh tensile strengthImprove conductivityFibre chemical featuresGroove widthCarbonization

The invention discloses a polyacrylonitrile-based graphite fiber and a preparation method thereof. According to a main technical scheme, the polyacrylonitrile-based graphite fiber has the tension strength of 4.01-4.46GPa, a tension modus of 541-547PGa and a bulk density of 1.89-1.91g / cm<3>; and the linear density of a 6K polyacrylonitrile-based graphite fiber is 215-218g / km. The preparation methodof the polyacrylonitrile-based graphite fiber comprises the following step: carrying out pre-oxidation, low-temperature carbonization, high-temperature carbonization, graphitization and aftertreatment on protofilaments in sequence, so as to obtain the polyacrylonitrile-based graphite fiber, wherein the protofilaments are polyacrylonitrile fibers; the diameter of a single protofilament is 9-11mu m; the average groove depth of the protofilaments s 0.2-0.5mu m, the average groove width of the protofilaments is 0.1-0.4mu m, and the average surface roughness Ra of the protofilaments is 0.0182-0.0201mu m. The invention mainly aims to prepare the polyacrylonitrile-based graphite fiber which has an excellent mechanical property index such as strength and modi.

Owner:山西钢科碳材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com