Glass substrate ceramic dielectric layer glaze and preparation method thereof

A glass substrate and ceramicization technology, applied in the field of coatings, can solve problems such as easy scratches, poor hydrophilicity, and poor adhesion on glass surfaces, and achieve the effects of preventing shrinkage cavities, reducing surface tension, and optimizing printing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

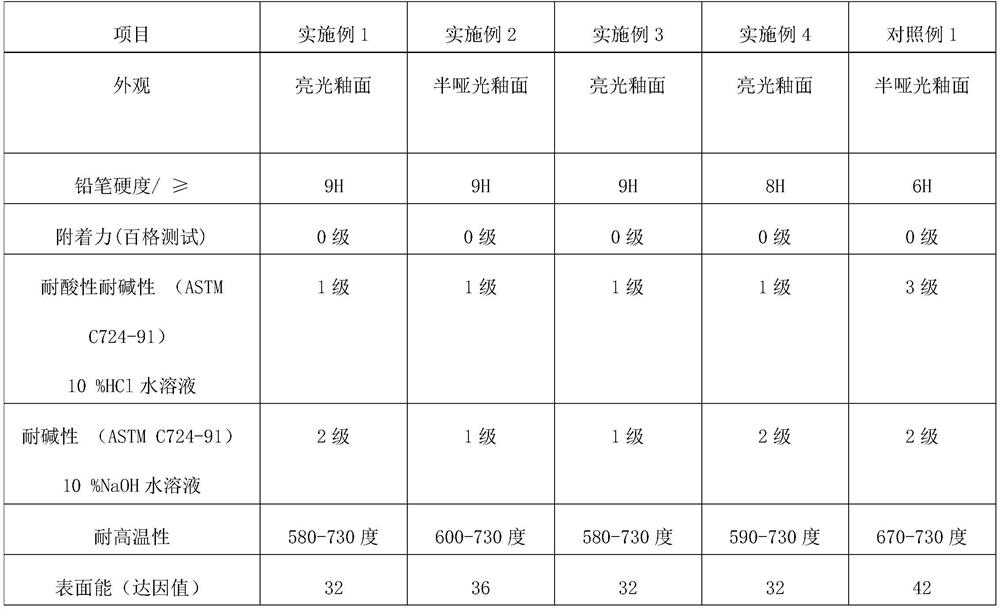

Examples

Embodiment 1

[0028]A ceramicized dielectric layer glaze for a glass substrate, which is made of the following raw materials: 55% by weight of low-melting lead-free dielectric powder, 28% by weight of inorganic metal oxide pigments, 14% by weight of water-soluble environmentally friendly varnish, and 0.75% by weight of dispersant , Antifoaming agent 1.5wt%, leveling agent 0.75wt%.

[0029]The low melting point lead-free dielectric powder is composed of the following proportions by weight: SiO2 9%, TiO2 4%, ZnO3%, Al2O3 2%, Bi2O3 67%, H3BO3 8%, Li2CO3 3%, K2O 4%.

[0030]The water-soluble environmentally friendly ink-changing oil is composed of the following proportions by weight: diethylene glycol butyl ether 40%, diethylene glycol methyl ether 25%, diethylene glycol butyl ether acetate 26%, ethyl fiber 5%, water-based modified acrylic resin 4%.

[0031]The dispersant is SILCO WET D-504 / PEG (wetting and dispersing agent).

[0032]The defoamer is BYK-300 (silicone defoamer).

[0033]The leveling agent is SILCO F...

Embodiment 2

[0041]A ceramicized dielectric layer glaze for a glass substrate, which is made of the following raw materials: low melting point lead-free dielectric powder 50wt%, inorganic metal oxide pigment 30wt%, water-soluble environmentally friendly ink adjustment 18wt%, dispersant 1wt%, and Foaming agent 0.5wt%, leveling agent 0.5wt%.

[0042]The low melting point lead-free dielectric powder is composed of the following proportions by weight: SiO2 14%, TiO2 4%, ZnO3%, Al2O3 2%, Bi2O3 65%, H3BO3 5%, Li2CO3 3%, K2O 4%.

[0043]The water-soluble and environmentally friendly ink adjustment is composed of the following proportions by weight: diethylene glycol butyl ether 40%, diethylene glycol methyl ether 25%, diethylene glycol butyl ether acetate 26%, ethyl cellulose 5%, water-based modified acrylic resin 4%.

[0044]The dispersant is SILCO WET D-504 / PEG (wetting and dispersing agent).

[0045]The defoamer is BYK-300 (silicone defoamer).

[0046]The leveling agent is BYK-358N (polyacrylate surface leveling a...

Embodiment 3

[0054]A ceramicized dielectric layer glaze for a glass substrate, which is made of the following raw materials: low melting point lead-free dielectric powder 60wt%, inorganic metal oxide pigment 22wt%, water-soluble environmentally friendly varnish 17.5wt%, dispersant 0.2wt %, 0.2wt% defoamer, 0.1wt% leveling agent.

[0055]The low melting point lead-free dielectric powder is composed of the following proportions by weight: SiO2 20%, TiO2 4%, ZnO3%, Al2O3 2%, Bi2O3 55%, H3BO3 7%, Li2CO3 5%, K2O 4%.

[0056]The water-soluble environmentally friendly ink-mixing oil is composed of the following proportions by weight: diethylene glycol butyl ether 38%, diethylene glycol methyl ether 28%, diethylene glycol butyl ether acetate 25%, ethyl fiber 6%, water-based modified acrylic resin 3%.

[0057]The dispersant is BYK-306 (silicone surface wetting agent).

[0058]The defoamer is BYK-300 (silicone defoamer).

[0059]The leveling agent is BYK-358N (polyacrylate surface leveling agent).

[0060]The preparation m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com