Welding connection method of oxide ceramic and metal

An oxide ceramic and metal welding technology, applied in the field of ceramic and metal welding, can solve the problems of difficult processing cost, the inability to widely produce and apply ceramic back shell mobile phones, etc., and achieve small residual stress, small difference in thermal expansion coefficient, and good toughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

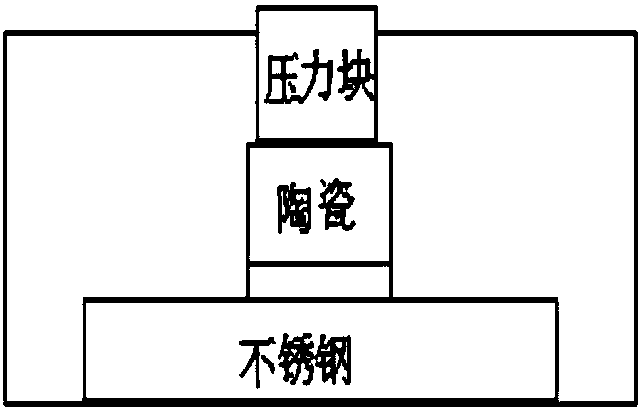

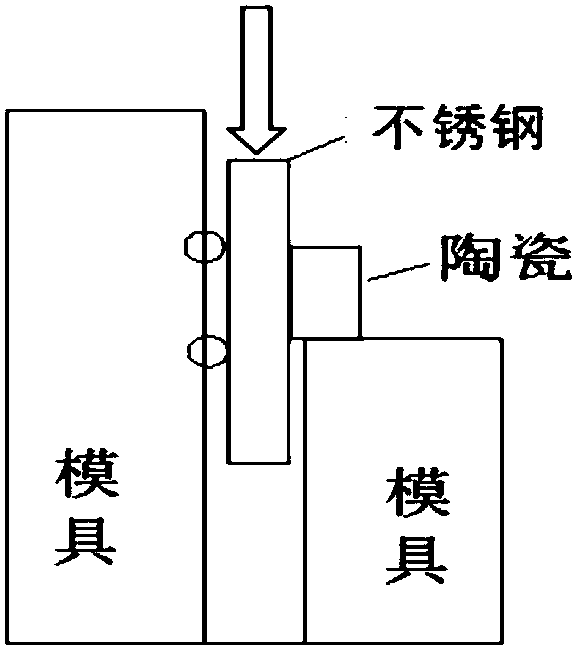

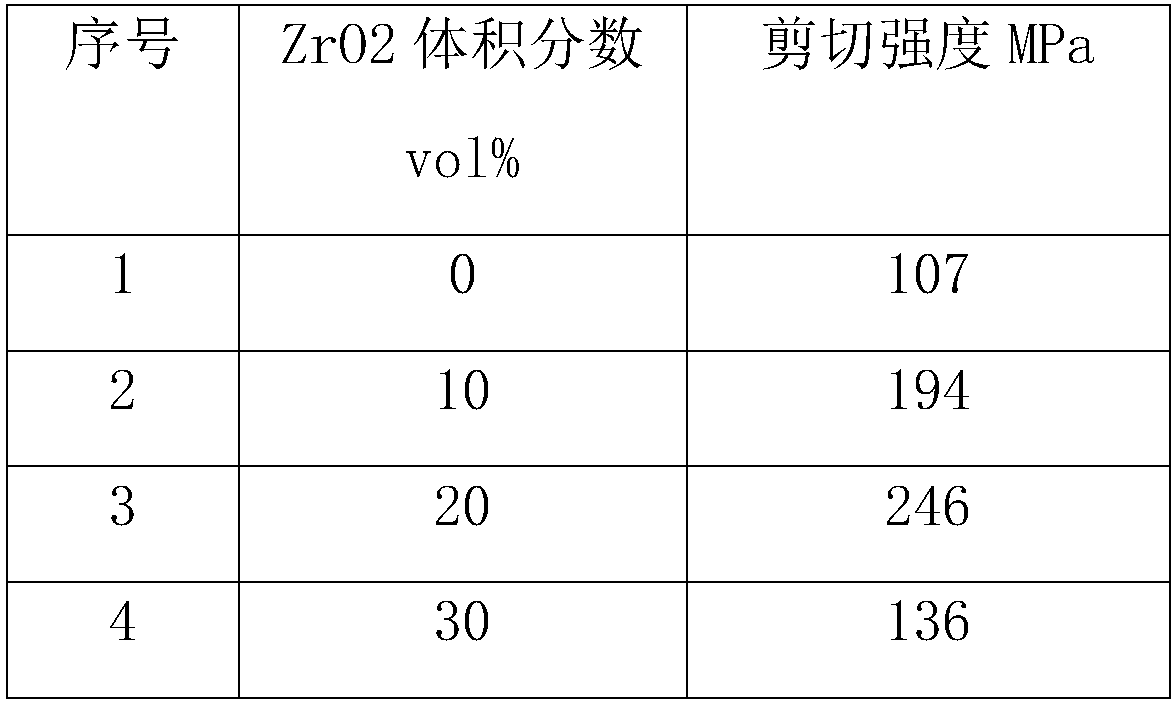

[0032] The preparation of ceramics is sintered according to the following process: powder preparation—mixing and ball milling—drying and sieving—dry pressing molding—isostatic pressing—normal pressure sintering.

[0033]The specific steps are as follows: Weigh a certain amount of alumina ceramic powder with weighing paper, mix it with absolute ethanol and pour it into the ball milling tank, add a certain amount of zirconia grinding balls, put it on the ball mill for 2 hours, and then filter out the grinding balls, Pour the uniformly mixed ceramic powder solution into an eggplant-shaped bottle, put it into a rotary evaporator to evaporate and dry to obtain a dry ceramic powder, weigh 30g of the mixed ceramic powder, and put it in a 50×50mm stainless steel mold. Dry press molding, and then vacuum packaging for isostatic pressing to further reduce the voids in the green body; put the pressed green body into a muffle furnace for air sintering.

[0034] The temperature setting of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com