Oxygen electrode slurry of solid oxide electrolytic cell, preparation method of oxygen electrode slurry and solid oxide electrolytic cell

A solid oxide and oxygen electrode technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of not effectively reducing the initial internal resistance of SOEC, fast growth of oxygen electrode impedance, and reducing LSCF, etc., to achieve high initial electrolysis efficiency, The effect of increasing the number of three-phase boundaries and improving mixed conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] 3) Preparation of electrolyte layer: mix YSZ powder and organic binder according to the mass ratio of (1-2): 1, then ball mill for 1-3 hours to mix evenly, and apply to the surface of the hydrogen electrode functional layer with a thickness of 5-2 30μm, fully dried in the air; the particle size of YSZ powder is 60-100nm;

[0063] 4) Sintering of electrolyte and hydrogen electrode part: Sinter the hydrogen electrode support prepared in the above steps-hydrogen electrode functional layer-electrolyte layer at 1200-1600°C for 2-5 hours; after the hydrogen electrode support is sintered and reduced at high temperature The porosity is 25% to 55%, and the porosity of the hydrogen electrode functional layer after high temperature sintering and reduction is 20% to 50%;

[0064] 5) Preparation of SOEC oxygen electrode: use the oxygen electrode material powder as the carrier, load the metal oxide nanoparticles on the oxygen electrode material powder, so that the metal oxide nanopar...

Embodiment 1

[0072] The embodiment of the present application makes the first solid oxide electrolytic cell, and the preparation method is as follows:

[0073]1) First prepare the SOEC hydrogen electrode support body containing NiO and YSZ: mix the NiO and YSZ powder and the graphite pore-forming agent at a ratio of 1:1:0.2 for 10 hours, and put the mixed powder into the mold, and press it Forming to obtain a square sheet-shaped support with a side length of 7 cm and a thickness of 300 μm, and then pre-sintered at 1200 ° C for 2 hours to obtain a hydrogen electrode support, which serves as the support for the entire battery;

[0074] 2) Preparation of hydrogen electrode functional layer: uniformly mix NiO and YSZ powder at a ratio of 1:1, disperse uniformly in isopropanol by ultrasonic, spray on the surface of the support with a thickness of 8 μm, and fully bake in an air atmosphere at 150°C Dry, make the hydrogen electrode functional layer;

[0075] 3) Preparation of the electrolyte laye...

Embodiment 2

[0096] The embodiment of the present application is the electrochemical performance test and scanning electron microscope test of sample 1, sample 2, sample 3 and sample 4:

[0097]

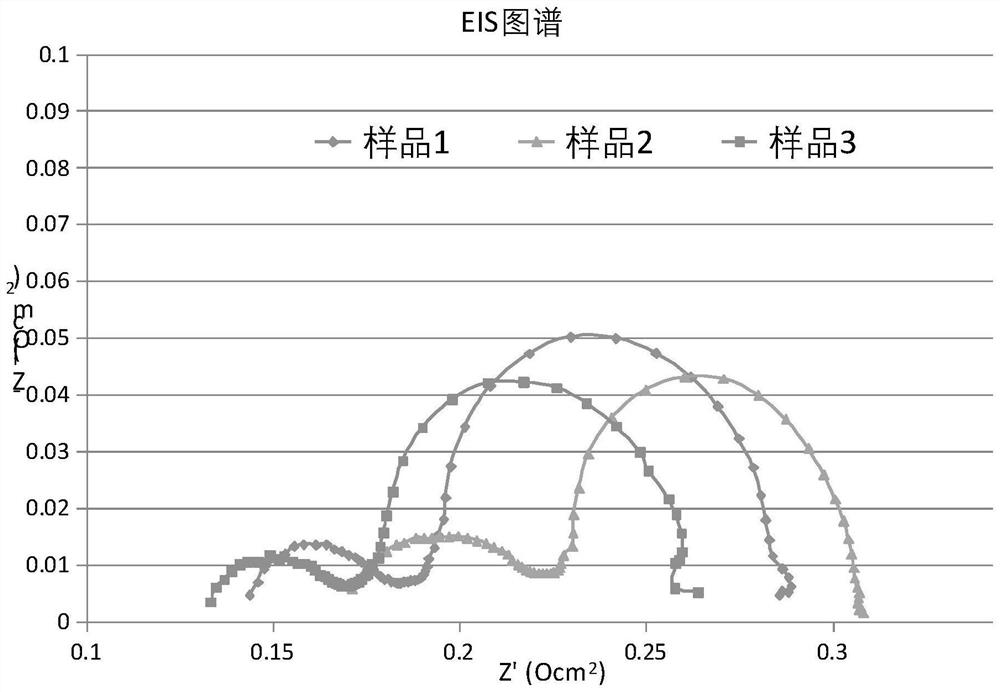

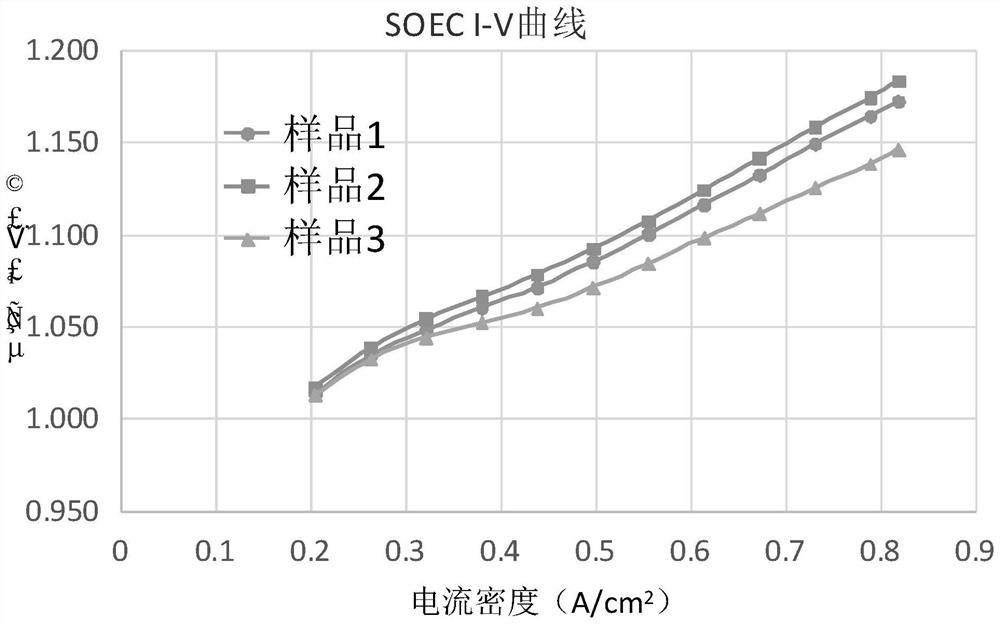

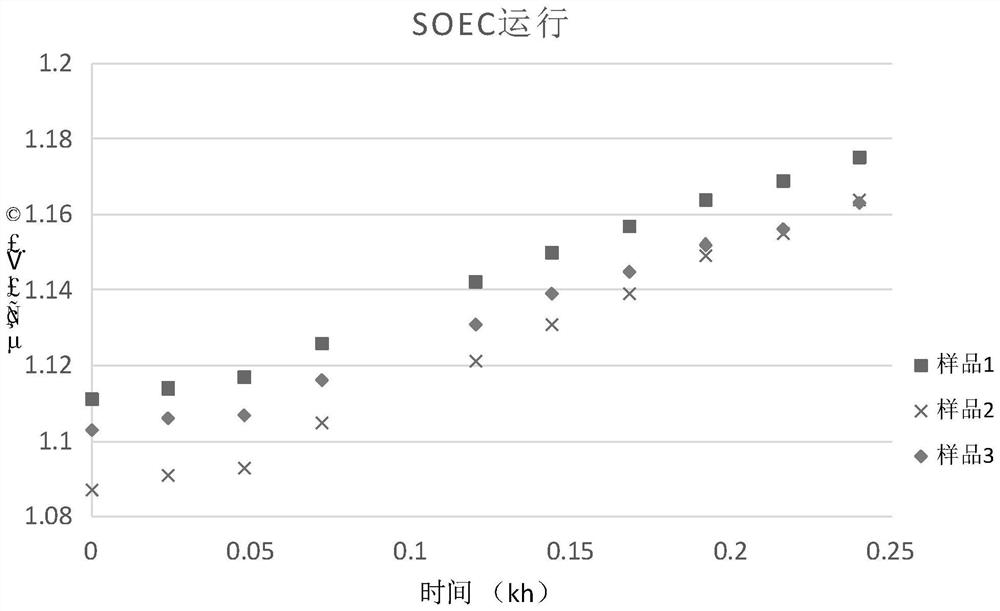

[0098] 1. Measure the internal resistance of sample 1, sample 2 and sample 3, the results are as follows figure 1 shown. figure 1 The graphs of electrochemical impedance spectroscopy results for sample 1, sample 2 and sample 3 provided in the examples of the present application. The internal resistance of several samples was tested by electrochemical impedance spectroscopy (EIS), and the test conditions were 750 ° C, H 2 Humidification 66.6%, open circuit conditions. Such as figure 1 As shown, the impedance spectrum is mainly composed of two semicircles. The intersection of the left side of the semicircle and the real axis corresponds to the ohmic resistance of the electrolytic cell. The diameter of the semicircle in the high frequency area on the left corresponds to the activation polariza...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com