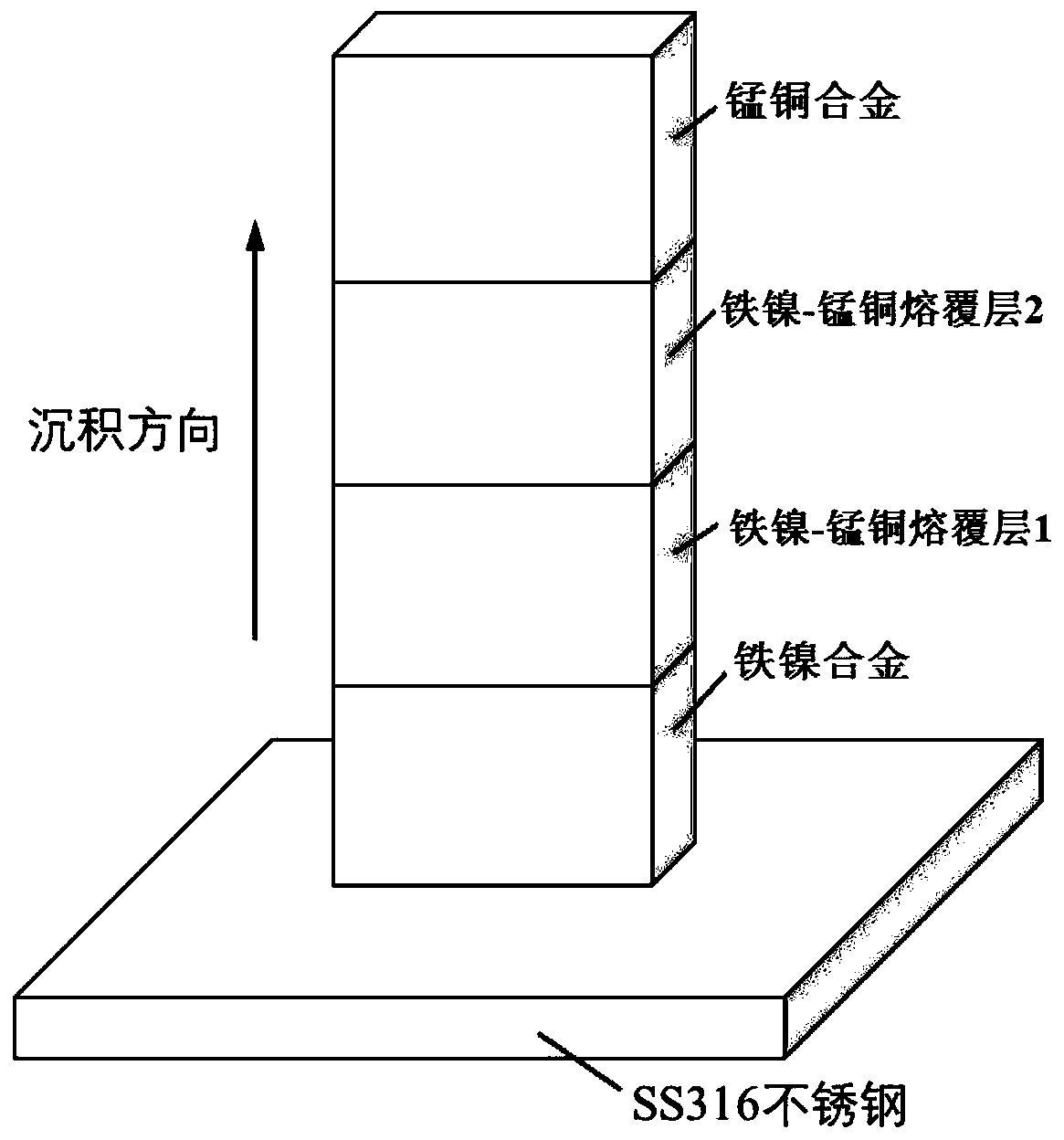

Laser additive manufacturing method for iron nickel-manganese copper dissimilar material metal part

A technology of laser additive and manufacturing methods, which is applied in the direction of additive manufacturing, additive processing, and improvement of process efficiency. It can solve problems such as large thermal stress and complex melting behavior, and avoid cracks, cracks, and insoluble Particles, the effect of reducing the germination tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

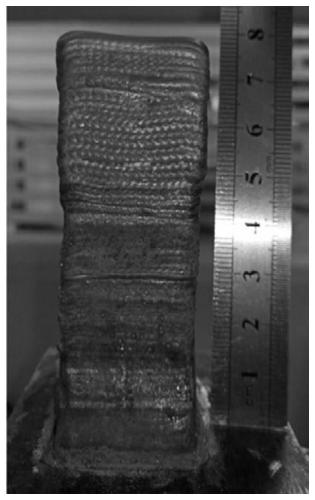

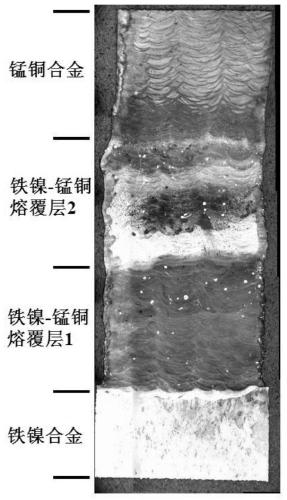

Embodiment 1

[0039] This embodiment includes the following steps:

[0040] Step 1. Using Invar36 iron-nickel alloy powder as raw material, the iron-nickel alloy is deposited on the SS316 stainless steel substrate in an argon atmosphere by laser selective melting method; the Invar36 iron-nickel alloy powder is spherical and has a particle size of 15 μm to 53 μm. Invar36 iron-nickel alloy powder was pre-vacuum-dried at 120°C for 3 hours, and the SS316 stainless steel substrate was pre-cleaned with ethanol and air-dried; the deposition parameters were: laser power 120W-150W, scanning speed 700mm / s-900mm / s, The scanning distance is 70μm~90μm, the layer thickness is 20μm, and the spot diameter is 100μm;

[0041] Step 2: Accurately weigh and mix Invar36 iron-nickel alloy powder and manganese-copper alloy powder whose nominal composition is MnCu48Zn2Al1.8, then put them into a ball mill jar, ball mill and mix them on a planetary ball mill for 3 hours, and then place them in a vacuum environment a...

Embodiment 2

[0066] This embodiment includes the following steps:

[0067] Step 1. Using Invar36 iron-nickel alloy powder as raw material, the iron-nickel alloy is deposited on the SS316 stainless steel substrate in an argon atmosphere by laser selective melting method; the Invar36 iron-nickel alloy powder is spherical and has a particle size of 15 μm to 53 μm. Invar36 iron-nickel alloy powder was pre-vacuum-dried at 120°C for 3 hours, and the SS316 stainless steel substrate was pre-cleaned with ethanol and air-dried; the deposition parameters were: laser power 150W, scanning speed 900mm / s, scanning distance 80μm, layer thickness 20μm, spot diameter 100μm;

[0068] Step 2: Accurately weigh and mix Invar36 iron-nickel alloy powder and manganese-copper alloy powder whose nominal composition is MnCu48Zn2Al1.8, then put them into a ball mill jar, ball mill and mix them on a planetary ball mill for 3 hours, and then place them in a vacuum environment at 120°C Drying for 3h under the hood, resp...

Embodiment 3

[0072] This embodiment includes the following steps:

[0073] Step 1. Using Invar36 iron-nickel alloy powder as raw material, the iron-nickel alloy is deposited on the SS316 stainless steel substrate in an argon atmosphere by laser selective melting method; the Invar36 iron-nickel alloy powder is spherical and has a particle size of 15 μm to 53 μm. Invar36 iron-nickel alloy powder was pre-vacuum-dried at 120°C for 3 hours, and the SS316 stainless steel substrate was pre-cleaned with ethanol and air-dried; the deposition parameters were: laser power 150W, scanning speed 900mm / s, scanning distance 80μm, layer thickness 20μm, spot diameter 100μm;

[0074] Step 2: Accurately weigh and mix Invar36 iron-nickel alloy powder and manganese-copper alloy powder whose nominal composition is MnCu48Zn2Al1.8, then put them into a ball mill jar, ball mill and mix them on a planetary ball mill for 3 hours, and then place them in a vacuum environment at 120°C Drying for 3h under the hood, resp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com