Patents

Literature

356 results about "Iron–nickel alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An iron–nickel alloy or nickel–iron alloy, abbreviated FeNi or NiFe, is a group of alloys consisting primarily of the elements nickel (Ni) and iron (Fe). It is the main constituent of the "iron" planetary cores and iron meteorites. The acronym NiFe refers to various chemical reactions that involve an iron–nickel catalyst or component, or in geology, to the general composition of planetary cores (including Earth's).

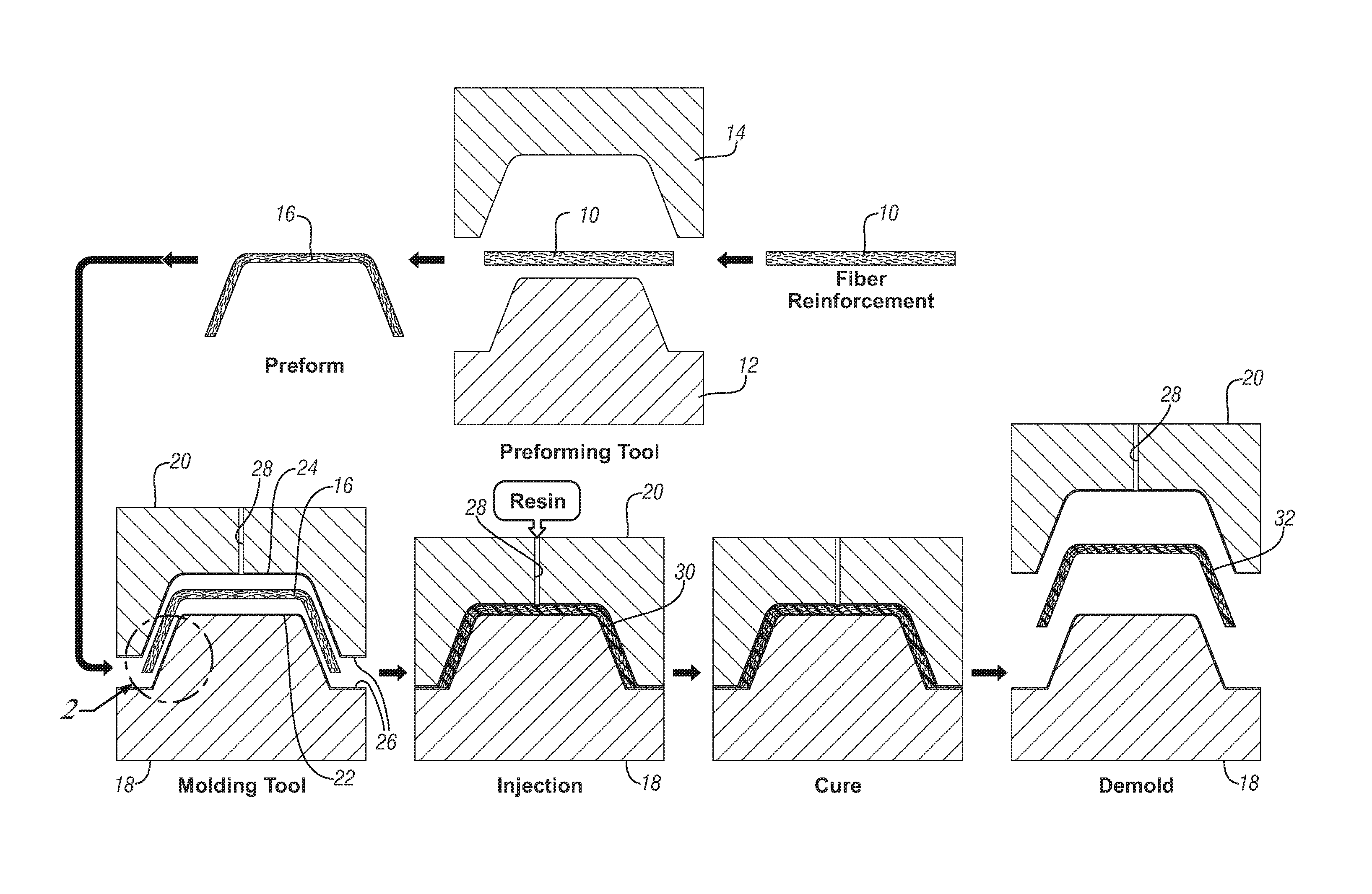

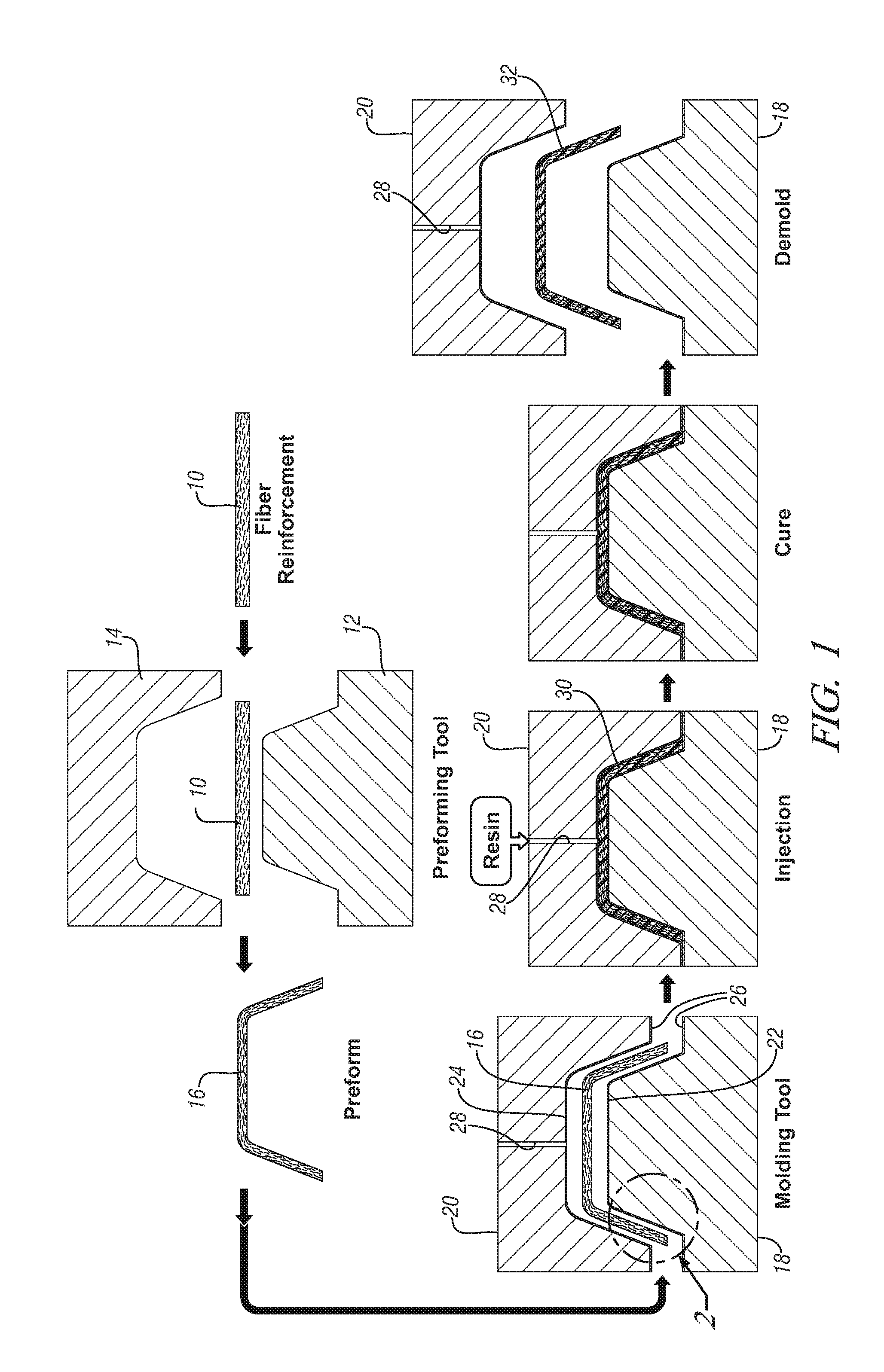

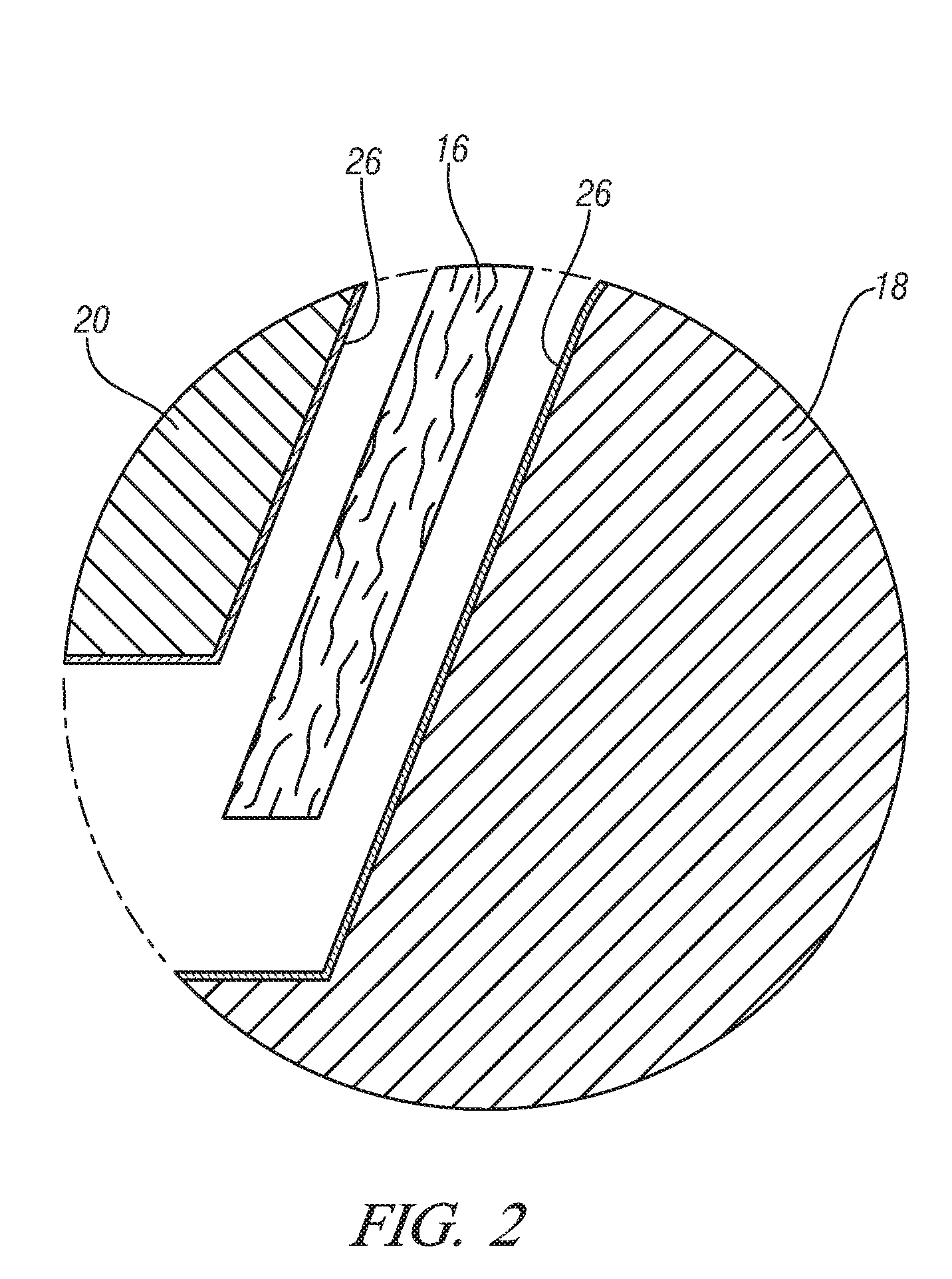

Durable tool for molding of polymer composites

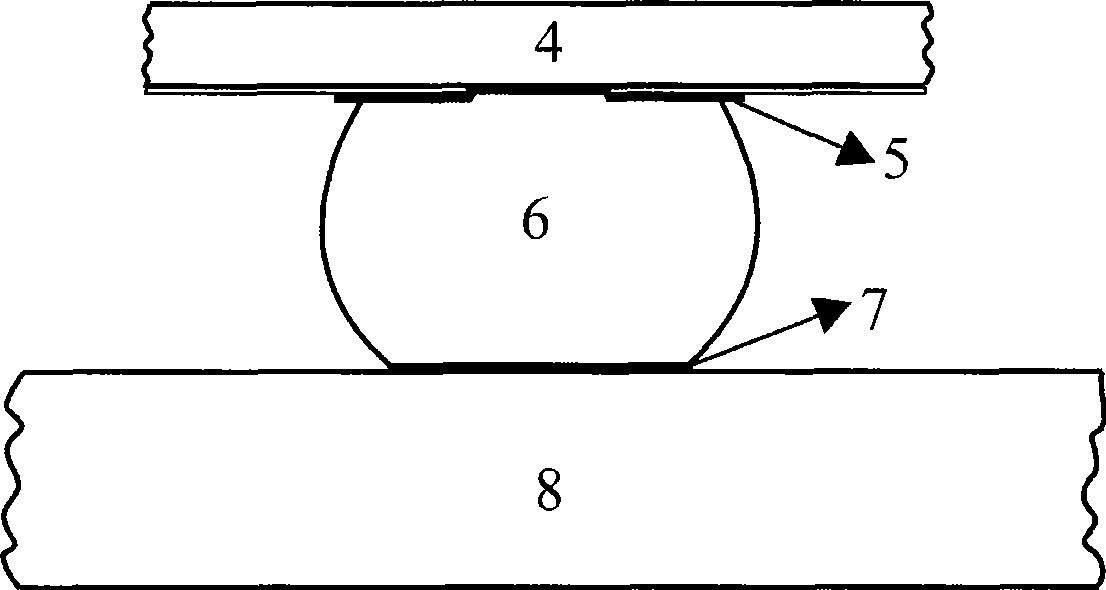

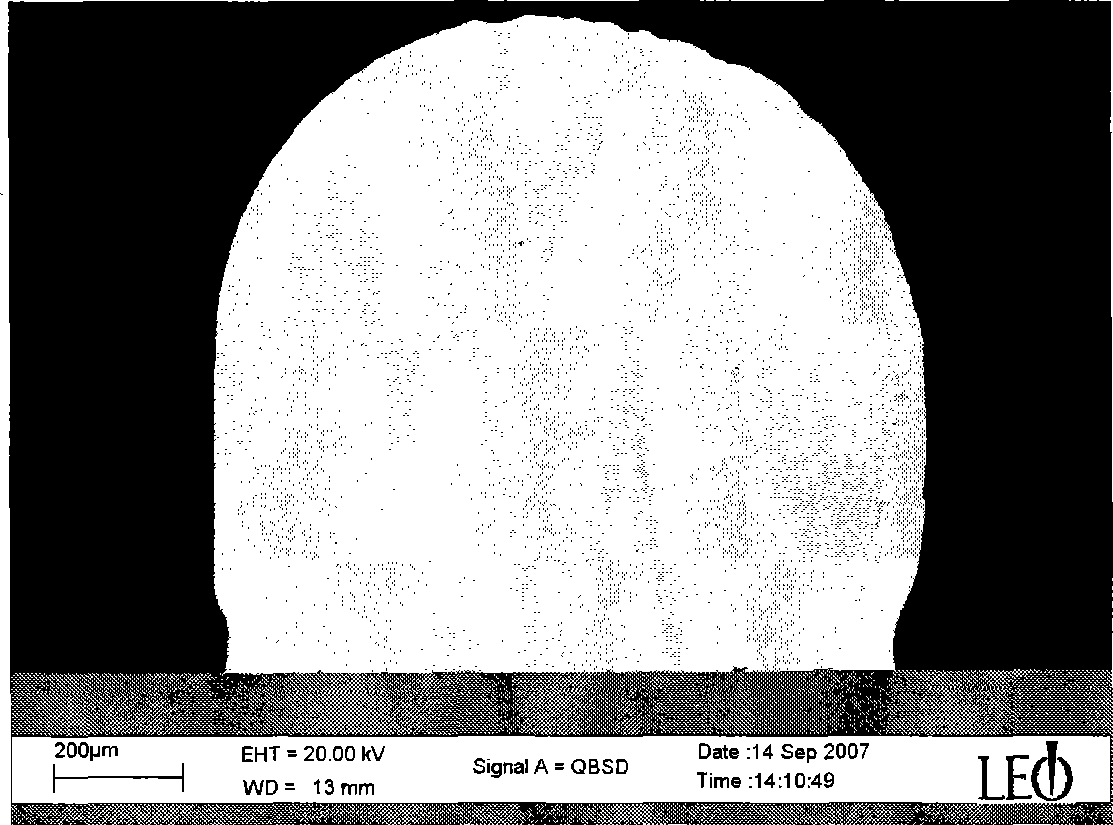

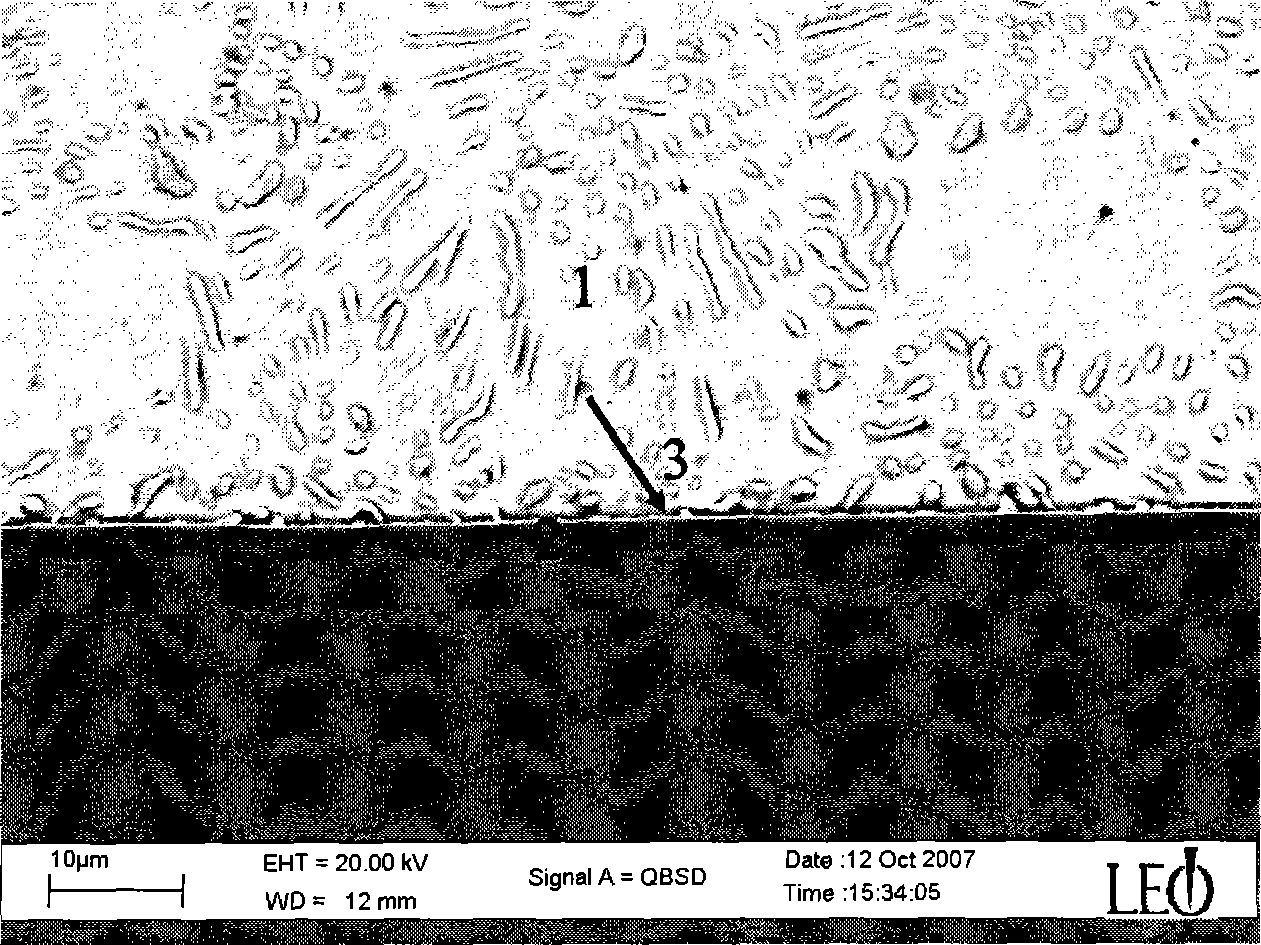

ActiveUS20080241296A1High dimensional accuracyMore durableConfectioneryLaminationCarbon compositesFiber

Mold tooling formed of suitable iron-nickel alloys and provided with a hard electroless nickel coating on the mold cavity surface are useful for high volume production of carbon fiber reinforced, polymer matrix, composites. The iron and nickel alloy provides thermal expansion properties for the molding of dimensionally accurate parts. The nickel alloy coating provides a durable surface, without adversely affecting the expansion properties of the mold, and remains adherent to the base metal during the repeated thermal cycling encountered in high volume production of substantially identical molded carbon composite parts.

Owner:GM GLOBAL TECH OPERATIONS LLC

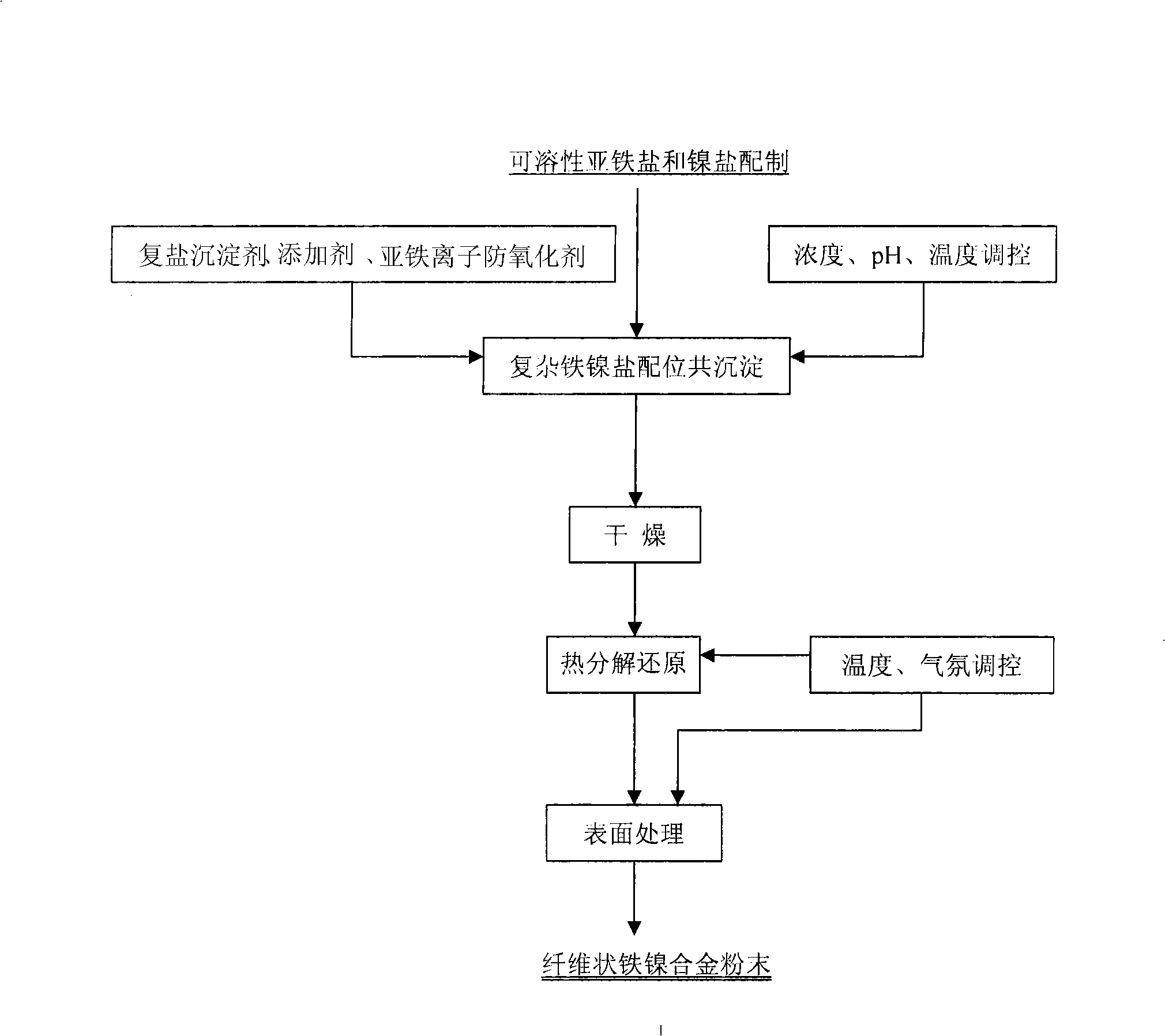

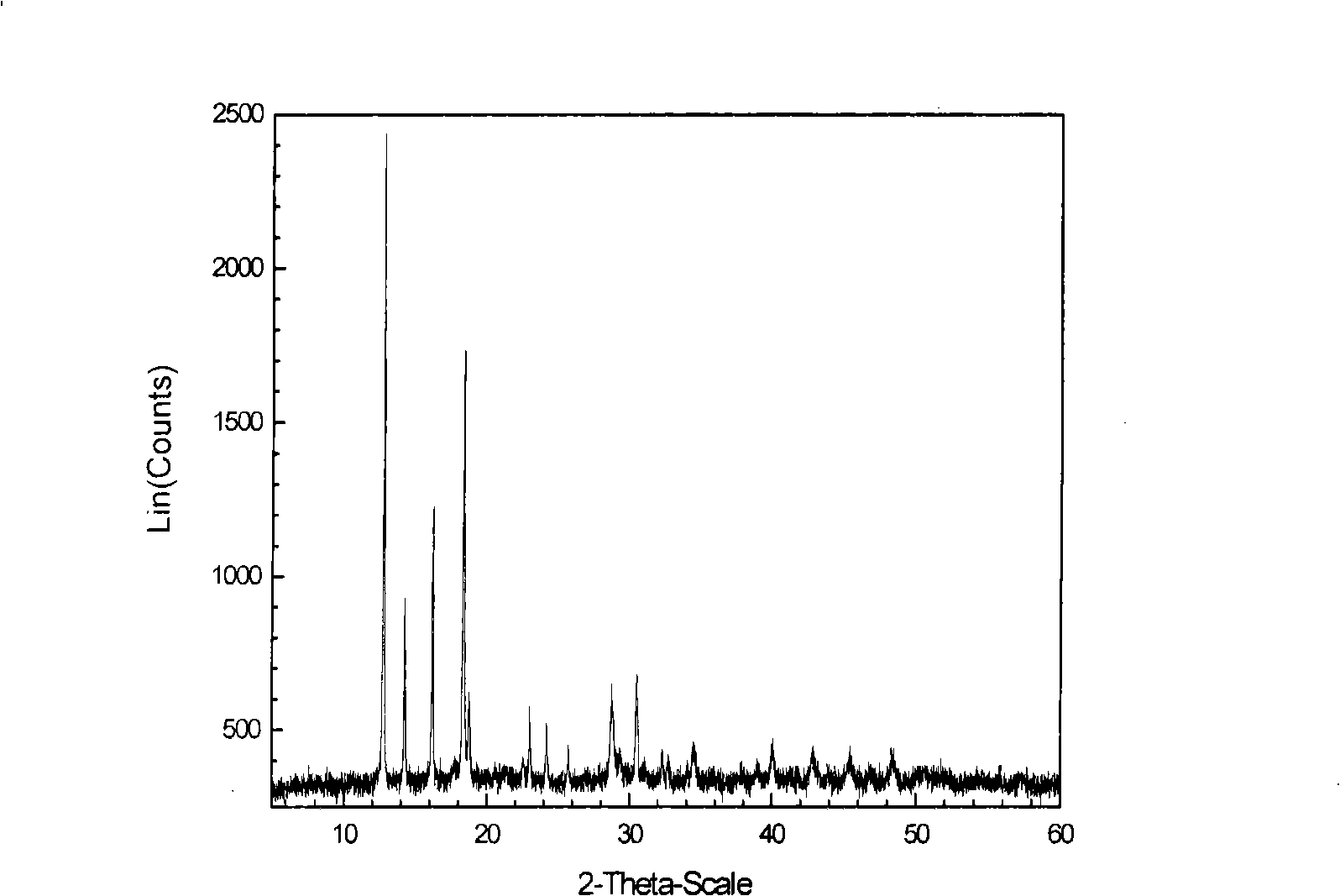

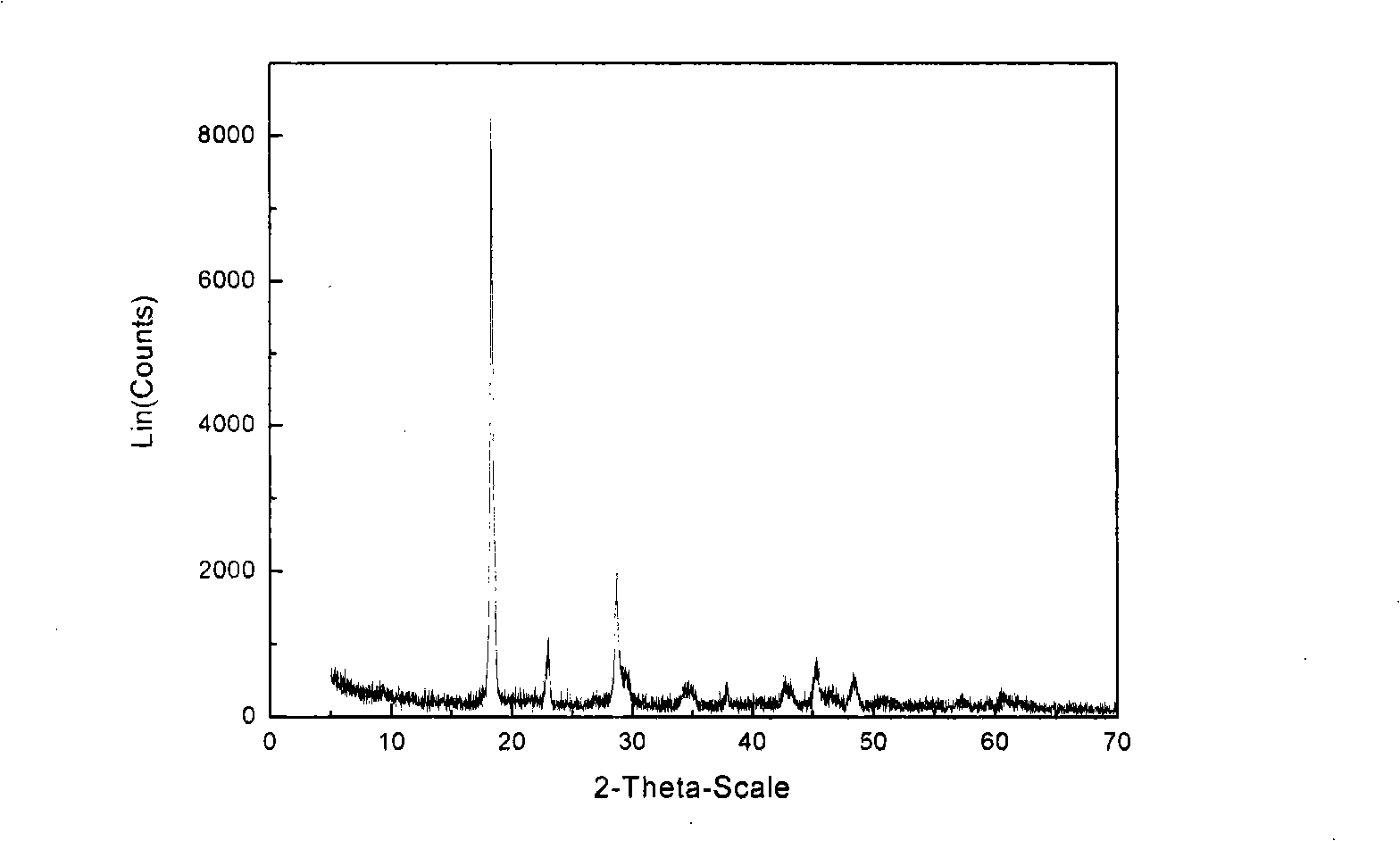

Preparation method of fibrous iron-nickel alloy powder

The invention relates to a preparation technology of a powder functional material, in particular to a preparation method of fibrous iron-nickel alloy powder. A coordinated coprecipitation-thermal decomposition-reduction process is adopted to synthesize a precursor coprecipitate product of the fibrous iron-nickel alloy powder in a Ni<2+>-Fe<2+>-H2NCH2CH2NH2-(H3NCH2CH2NH3)<2+>-SG<n->-C2O4<2->-H2O system at the normal temperature and pressure (SG<n-> stands for Cl<->, SO4<2->, NO3<-> and CH3COO<->), and the precursor is thermally decomposed and reduced under an weak reducing atmosphere to obtain the fibrous iron-nickel alloy powder; anti-oxidation treatment of surface of the fibrous iron-nickel alloy powder is carried out in the same device under the regulation and control of the temperature and atmosphere. The whole preparation process is safe, reliable, nontoxic and pollution-free. The iron-nickel alloy powder produced by the preparation method is fibrous and porous, and has small particle size, large specific surface area; and the iron-nickel alloy powder has strong oxidation resistance, and can meet requirements of a plurality of purposes.

Owner:CENT SOUTH UNIV

Composite electromagnetic screen film material and mfg. method thereof

InactiveCN1787114AMeet the needs of normal workLow costMagnetic/electric field screeningScreening apparatusComposite filmElectromagnetic shielding

The invention belongs to the field of magnetic material, relating to an electromagnetic shielding material and the making method thereof. The invention is a composite metallic film formed on a conductive substrate by multiple deposition in the water solution, and the obtained composite metallic film is 1-100 mum thick, and each layer of the composite metallic film is 1.1-99.9 mum thick, and the combination between the layers of the composite film is by chemical bond, and each layer is layered. The substrate can be stainless steel, copper plate, Ti plate, Al plate or one of the corrosion-resistant alloy plates, and also made of conductive glass, conductive plastics, polymer high molecular material, or other material; the composite metallic film comprises two or above different metallic film layers; each metallic film layer can be of copper, iron, iron-nickel alloy, nickel-cobalt alloy, iron-cobalt alloy or iron-cobalt-nickel alloy. The invention can shield the frequencies between 50Hz and 100 Hz and the shielding efficacy reaches above 70dB.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

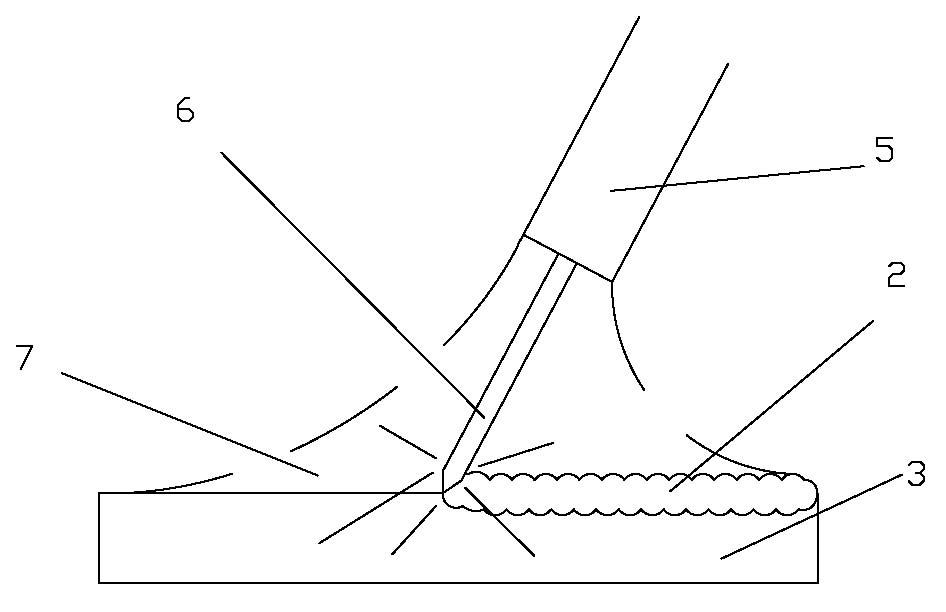

Method for enhancing blade surface of metal hydraulic turbine runner by combining electrical sparkle deposition and plasma cladding

InactiveCN103834893AImprove wear resistanceHigh hardnessMolten spray coatingWear resistantShock resistance

The invention relates to a method for enhancing blade surface of a metal hydraulic turbine runner by combining electrical sparkle deposition and plasma cladding. The method can be used for effectively solving the problems of poor surface hardness, wear resistance, corrosion resistance, shock resistance and the like of a blade of the hydraulic turbine runner and prolonging of the service life of the metal hydraulic turbine runner. The method comprises the following steps: cladding the blade surface of the hydraulic turbine runner with alloy powder by using inoxidizability plasma beams so as to form an alloy coating, and then depositing WC (Wolfram Carbide) ceramic hard alloy by using electrical sparkles on the basis of the plasma cladding coating so as to form an electrical sparkle deposition and plasma cladding combined composite coating. The method is simple and practicable; the formed electrical sparkle deposition and plasma cladding combined composite coating is firmly bonded with a matrix and is large in thickness; a bade is high in hardness, good in compactness and wear-resisting property and long in service life; the composite coating gives play to the advantages of low cost, good wear-resistant anti-corrosion performance, high hardness and strength and excellent wear resistance of iron-nickel alloy.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

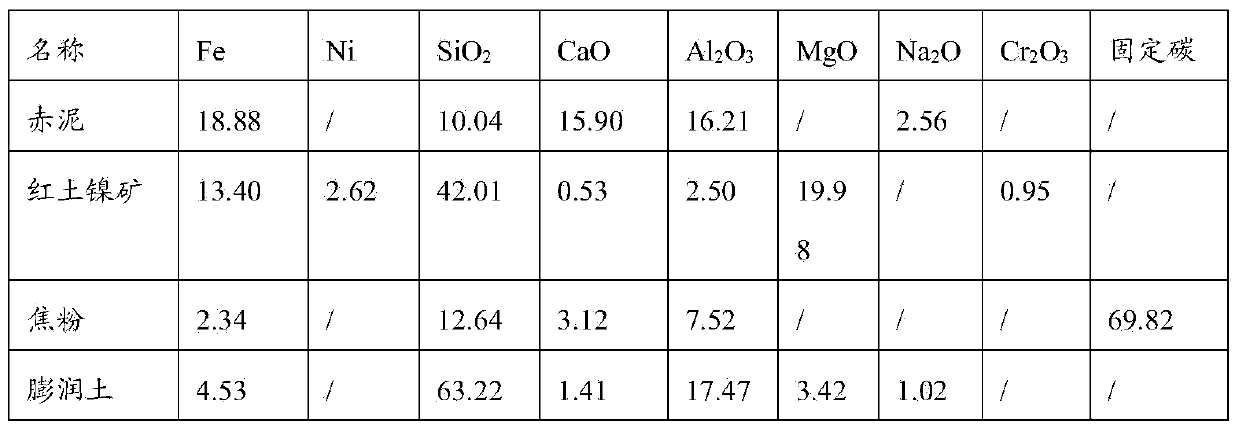

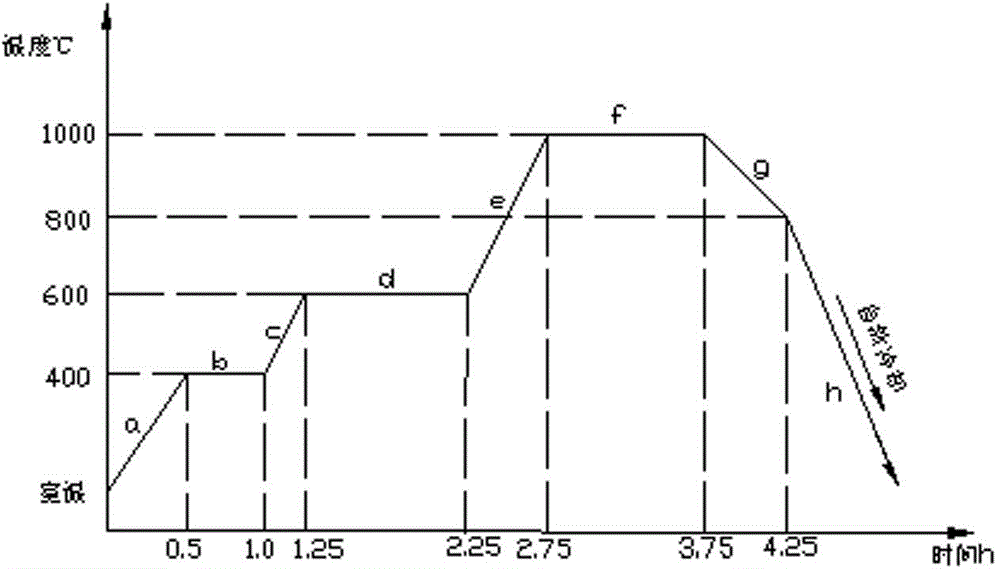

Method for preparing ferronickel by using red mud and laterite-nickel ore

ActiveCN104178624ARich in beneficial chemical ingredientsRealize secondary recyclingFluidised-bed furnacesRed mudLaterite

The invention provides a method for preparing ferronickel by using red mud and laterite-nickel ore. Meanwhile, a novel method is provided for recovery of iron in red mud and production of ferronickel from the red mud and the laterite-nickel ore. According to the method, iron-nickel reduction products in the red mud and the laterite-nickel ore are directly utilized, and low-cost ferronickel can be provided for stainless steel smelting production, ferroalloy casting and alloy steel production. The laterite-nickel ore also contains a little of chromium, and in the production method disclosed by the invention, chromium enters the iron-nickel alloy, so that beneficial chemical components of the iron-nickel alloy are enriched. The contained iron-nickel alloy produced by the method disclosed by the invention is iron-nickel alloy with low P and S content.

Owner:GUANGXI UNIV

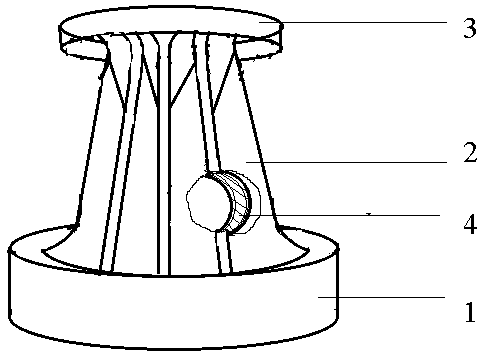

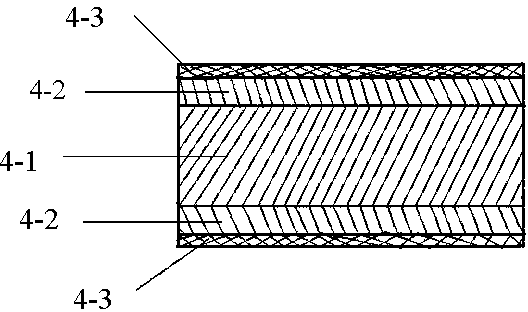

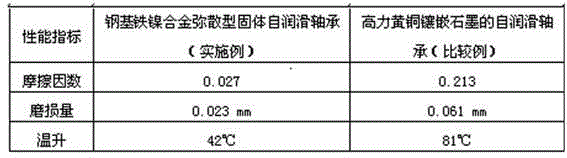

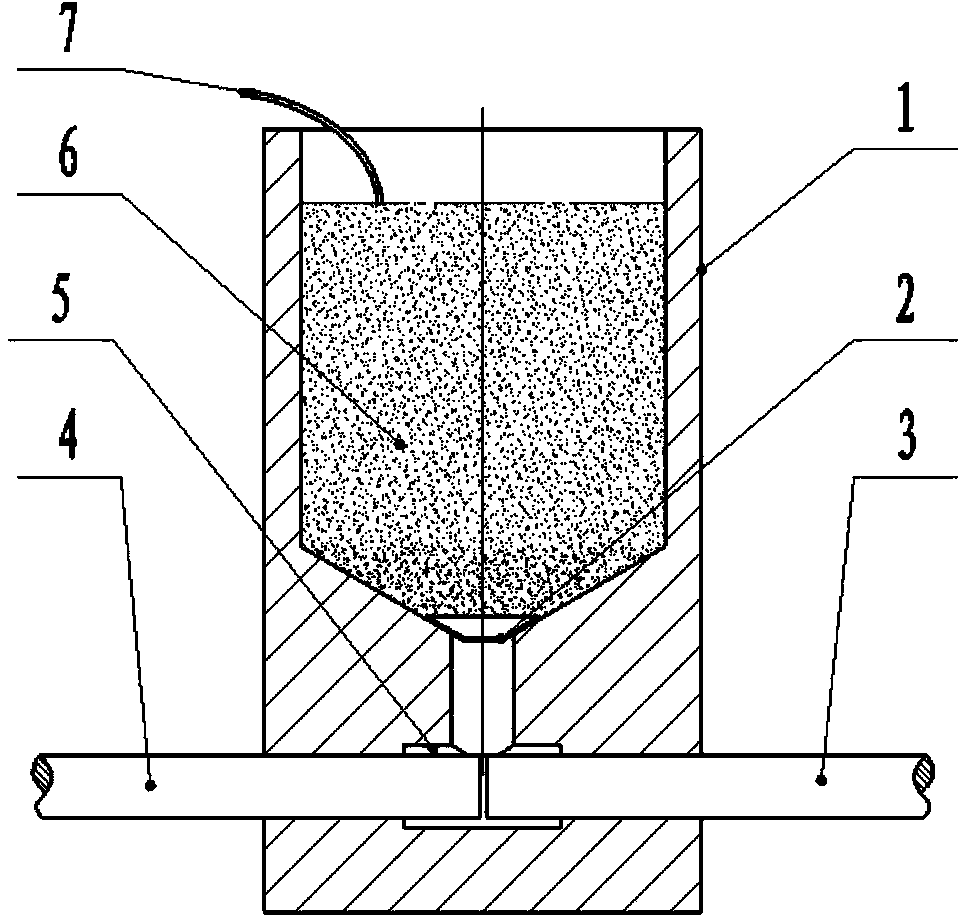

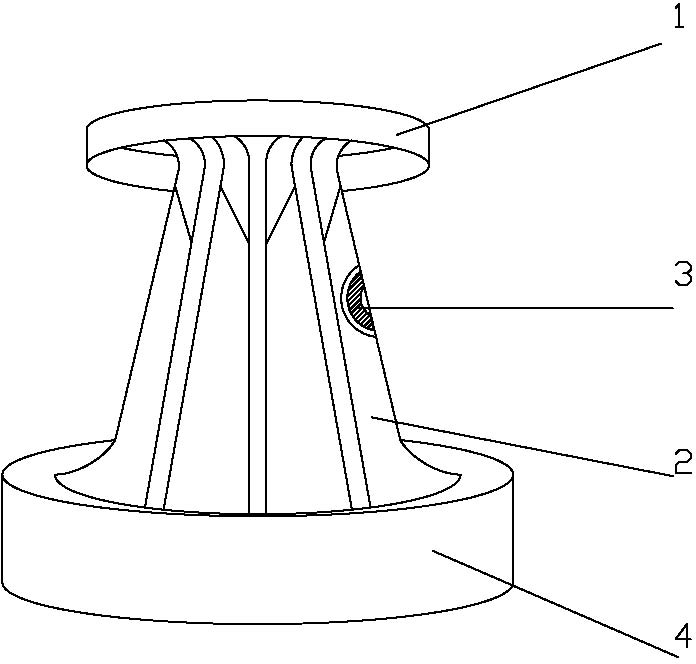

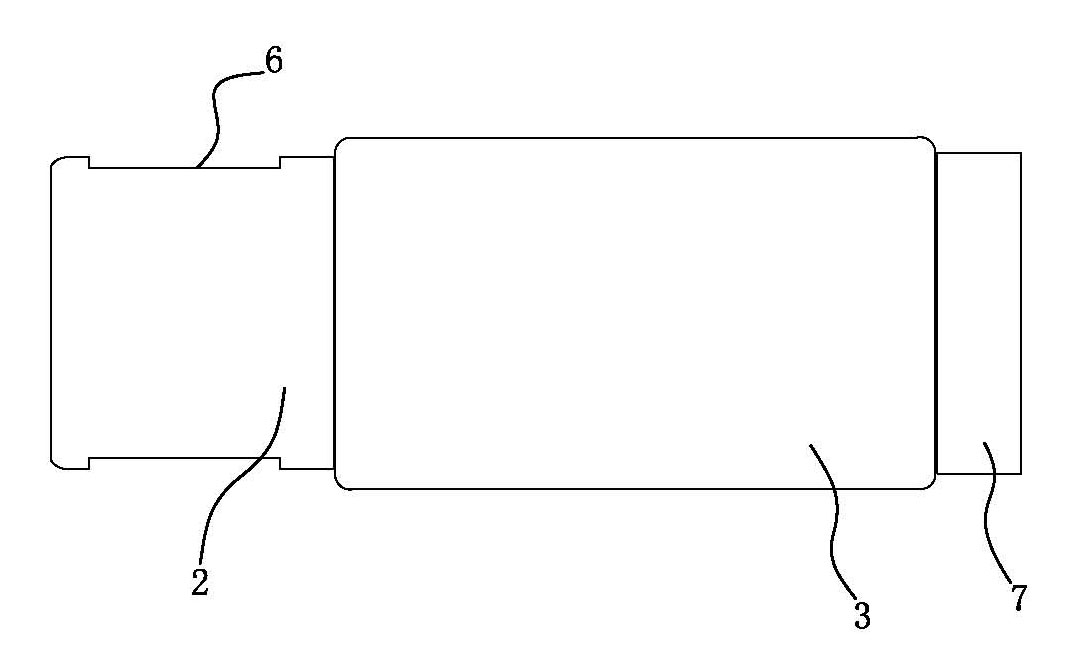

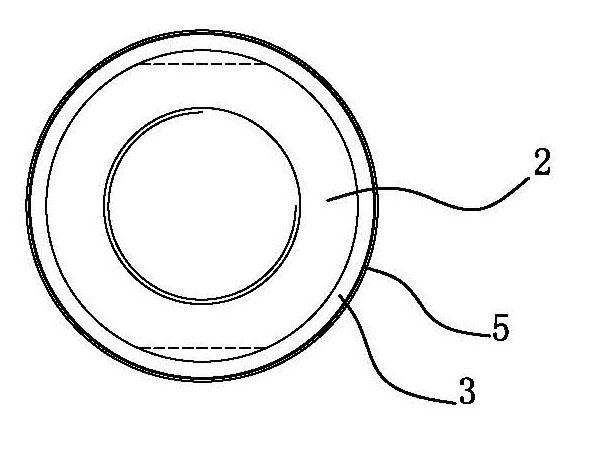

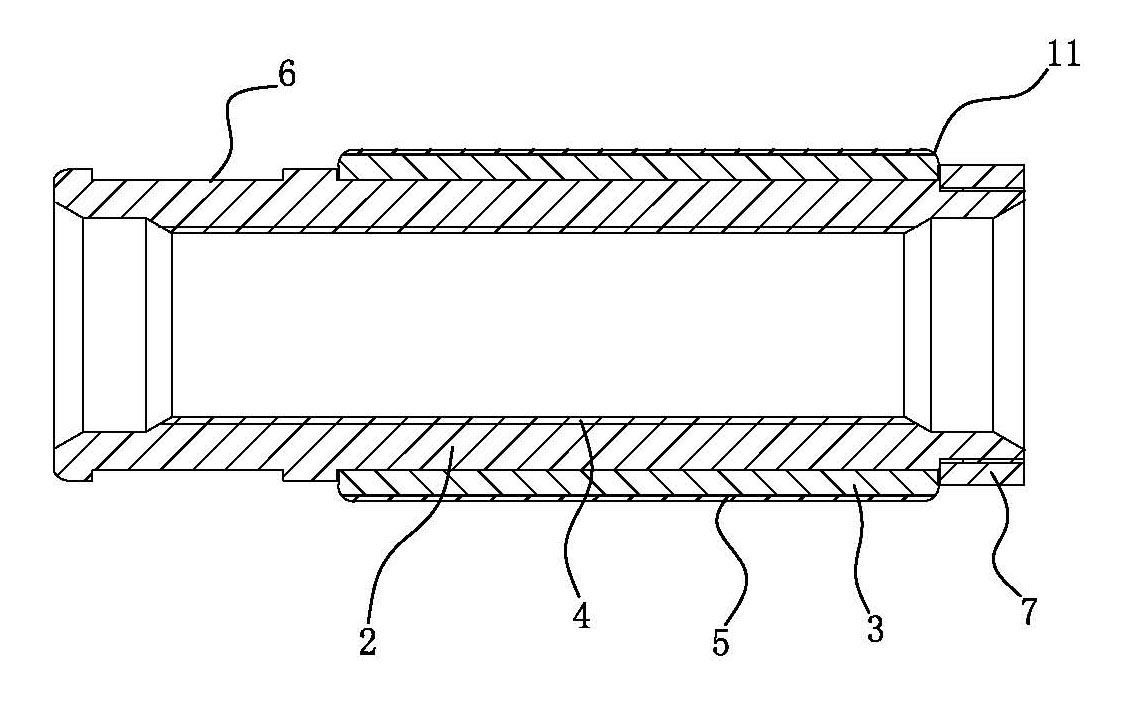

Steel-based iron-nickel alloy diffused-type solid self-lubricating bearing and manufacturing method thereof

The invention discloses a steel-based iron-nickel alloy diffused-type solid self-lubricating bearing and a manufacturing method thereof. The steel-based iron-nickel alloy diffused-type solid self-lubricating bearing is shaft sleeve-shaped; the exterior of the shaft sleeve is a steel jacket; and the inner wall of the shaft sleeve is a wear-resistant layer formed by compacting and sintering iron-nickel alloy mixed powder. The steel-based iron-nickel alloy diffused-type solid self-lubricating bearing is characterized in that the iron-nickel alloy mixed powder comprises 15-20% of nickel, 35-40% of iron, 5-8% of tin, 0.5-1.0% of titanium powder, 1-4% of molybdenum sulfide, 1-3% of aluminum oxide, 1-4% of graphite, 1-2% of zinc stearate and the balance of copper by weight. The manufacturing method of the self-lubricating bearing comprises the following steps of: manufacturing a wear-resistant blank, i.e. blending and stirring the raw materials and carrying out compression molding; manufacturing the steel jacket; and manufacturing the steel-based iron-nickel alloy diffused-type solid self-lubricating bearing, i.e. placing the wear-resistant blank in the steel jacket for vacuum sintering, and carrying out vacuum oil absorption, fine manufacturing and secondary vacuum oil absorption to obtain a finished product. The steel-based iron-nickel alloy diffused-type solid self-lubricating bearing has the characteristics of strong impact resistance, high carrying capacity, wear resistance, low friction coefficients, corrosion resistance and self-lubrication.

Owner:ZHEJIANG CHANGSHENG SLIDING BEARINGS

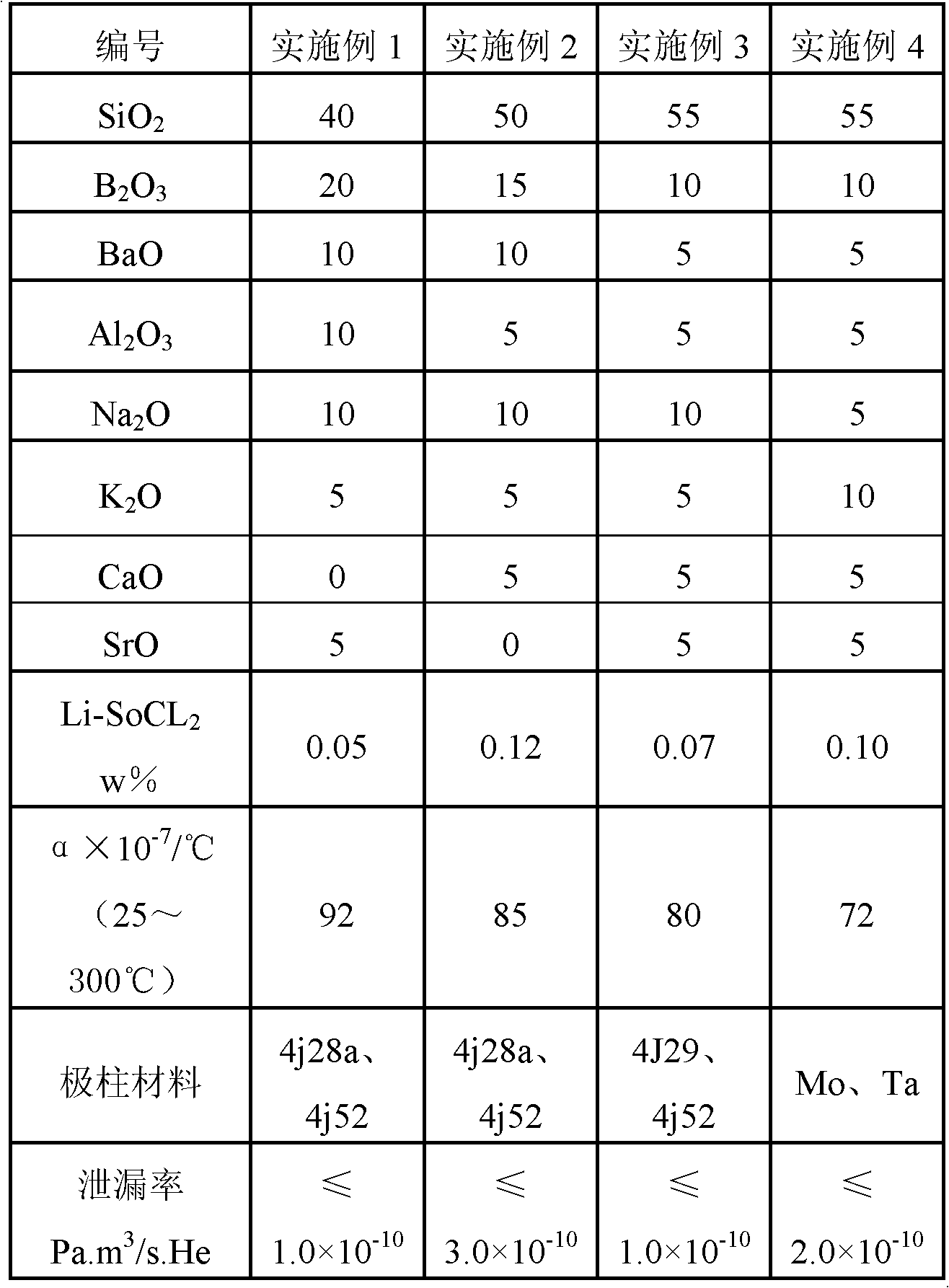

Corrosion-resistant sealing glass material for primary lithium battery and preparation method thereof

The invention discloses a corrosion-resistant sealing glass material for a primary lithium battery and a preparation method thereof. The corrosion-resistant sealing glass material comprises the following components in percentage by mole: 40-60 percent of SiO2, 10-30 percent of B2O3, 5-10 percent of BaO, 5-10 percent of K2O, 5-10 percent of Na2O, 5-10 percent of Al2O3, 0-5 percent of CaO, and 0-5 percent of SrO. The sealing glass material disclosed by the invention resists the corrosion of lithium and electrolyte, has good air tightness and insulativity and is applicable to sealing of the primary lithium battery. The sealing temperature of the glass is 940 DEG C-1010 DEG C. The thermal expansion coefficient is in the range of 65-95*10-7 / DEG C, more metal pole columns can be selected, the corrosion-resistant sealing glass material can be matched and sealed with molybdenum pole columns and iron-nickel alloy wires such as 4J52 and the like with excellent welding performance, the leakage caused by internal stress explosion of the glass is prevented, and the air tightness of a sealing device is ensured.

Owner:西安华泰有色金属实业有限责任公司

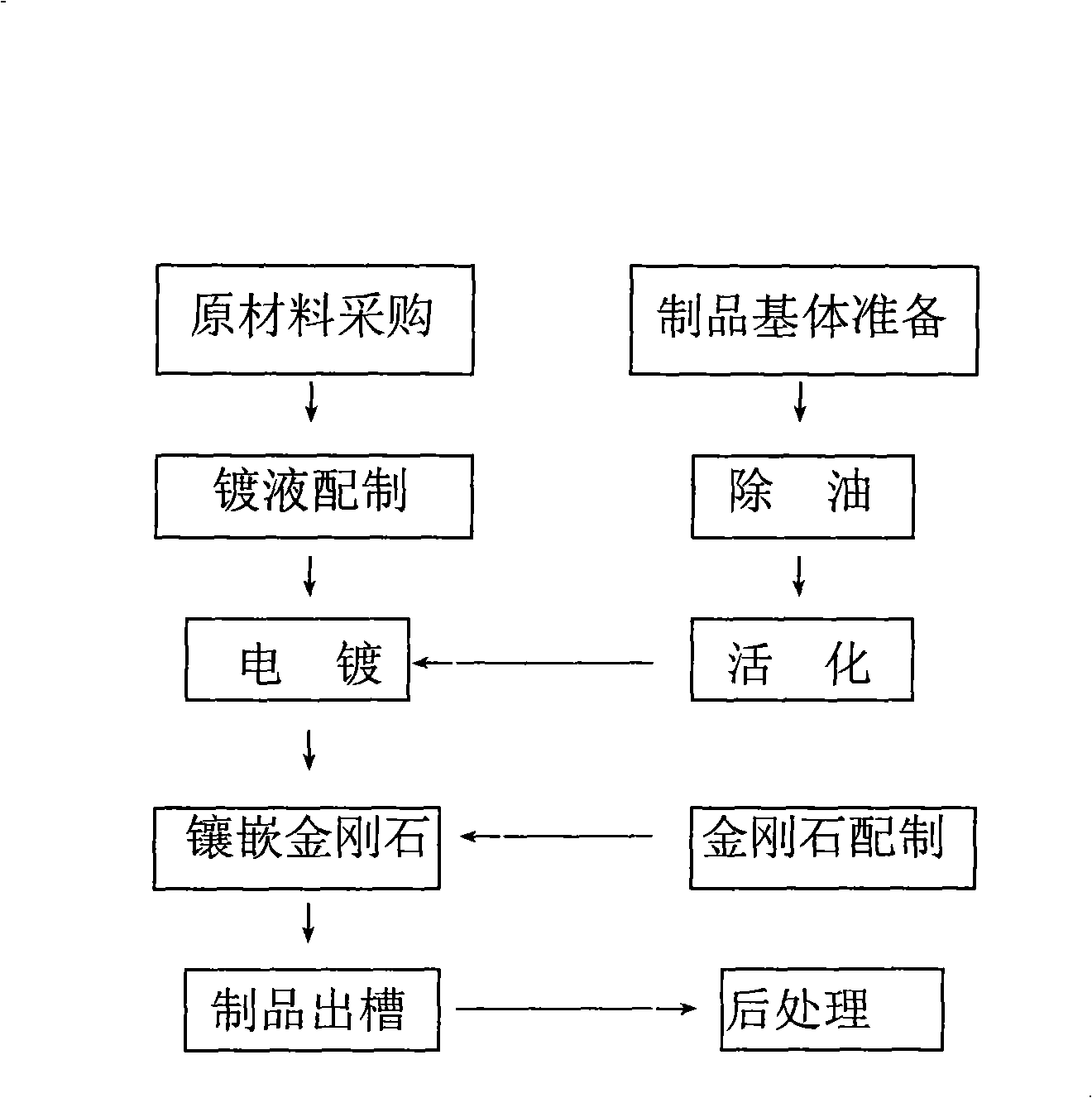

Matrix for electroplating diamond products and electroplating process thereof

The invention relates to a matrix of a diamond product and a plating process thereof. The matrix is characterized in that the matrix consists of electroplated iron or iron-nickel alloy. Electroplating solution adopted by the plating process comprises ferrous sulfate and other sulphates, ferrous chloride and other chlorides, or nickel sulfate, the ferrous sulfate and the chloride. The matrix has the beneficial effects that all of the electroplated iron, the iron-nickel alloy containing 30 to 60 percent of iron and other ferroalloy have higher hardness (HRC35-50) and good bezel setting property for the diamond. Though the matrix is worse than electroplated nickel in wear-resisting property, the matrix is in favor of the exposure of the diamond product and improves the sharpness of the diamond product. Therefore, the matrix is especially suitable for manufacturing the drill pit and the sharper of the diamond. As the cheap iron replaces the expensive nickel, the manufacturing cost of the electroplated diamond product is greatly reduced.

Owner:兰桥昌

Ultra-thin continuous winding wave-absorbing material

The invention discloses an ultra-thin continuous winding wave-absorbing material. The wave-absorbing material is prepared by the following steps: A, preparing an absorbent: carrying out annealing treatment on an alloy material, wherein the alloy material is one or more of an iron-nickel alloy flake powder, an iron-cobalt alloy flake powder, an iron-silicon-aluminum alloy flake powder or a carbonyl iron flake powder; B, selecting one or more of rubber, plastics or a thermoplastic elastomer polymer material as a base material; C, mixing: mixing according to the 1-9 mass ratio of the absorbent to the polymer base material to obtain a mixed compound; D, preforming: pressing the mixed compound into sheets with the thickness less than 0.5 mm; E, rolling and winding: successively and continuously putting the sheets obtained in step D in a calender to obtain the wave-absorbing material with the thickness less than 0.3 mm. The wave-absorbing material has a high-permeability real part and a low-permeability imaginary part at the frequency point of 13.56 MHz, is simple in manufacturing technique and easy to cut and use, and is mainly applied to high-frequency metal-resistant electronic tags and mobile payment.

Owner:JINAN ZHONGZHENG NEW MATERIAL

Iron-nickel alloy

Owner:OUTOKUMPU VDM GMBH

Nickel-iron alloy-based anodes for aluminium electrowinning cells

InactiveUS6562224B2Eliminate pollutionProlong lifeMachining electrodesElectrical-based machining electrodesNickel substrateOxygen ions

Owner:MOLTECH INVENT

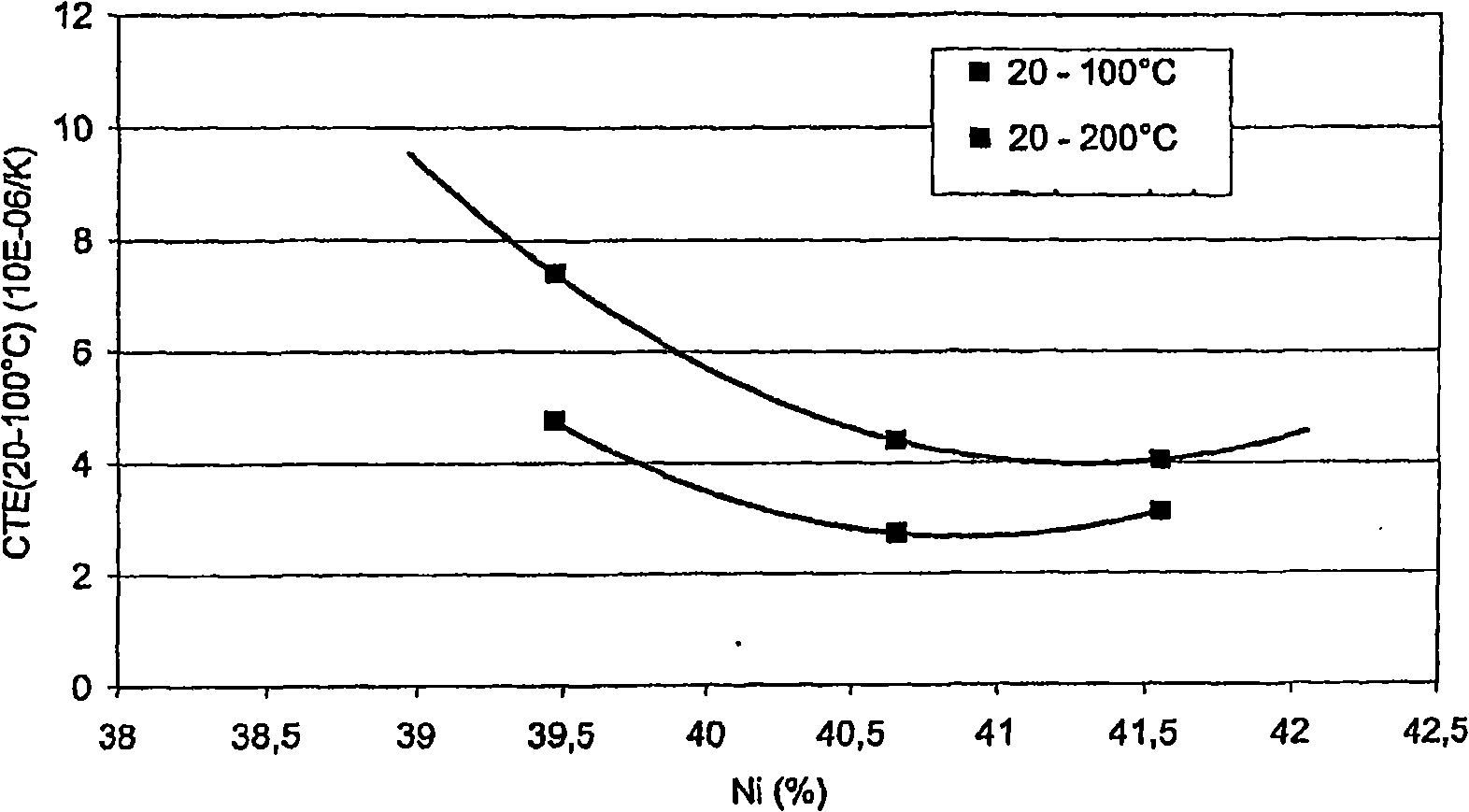

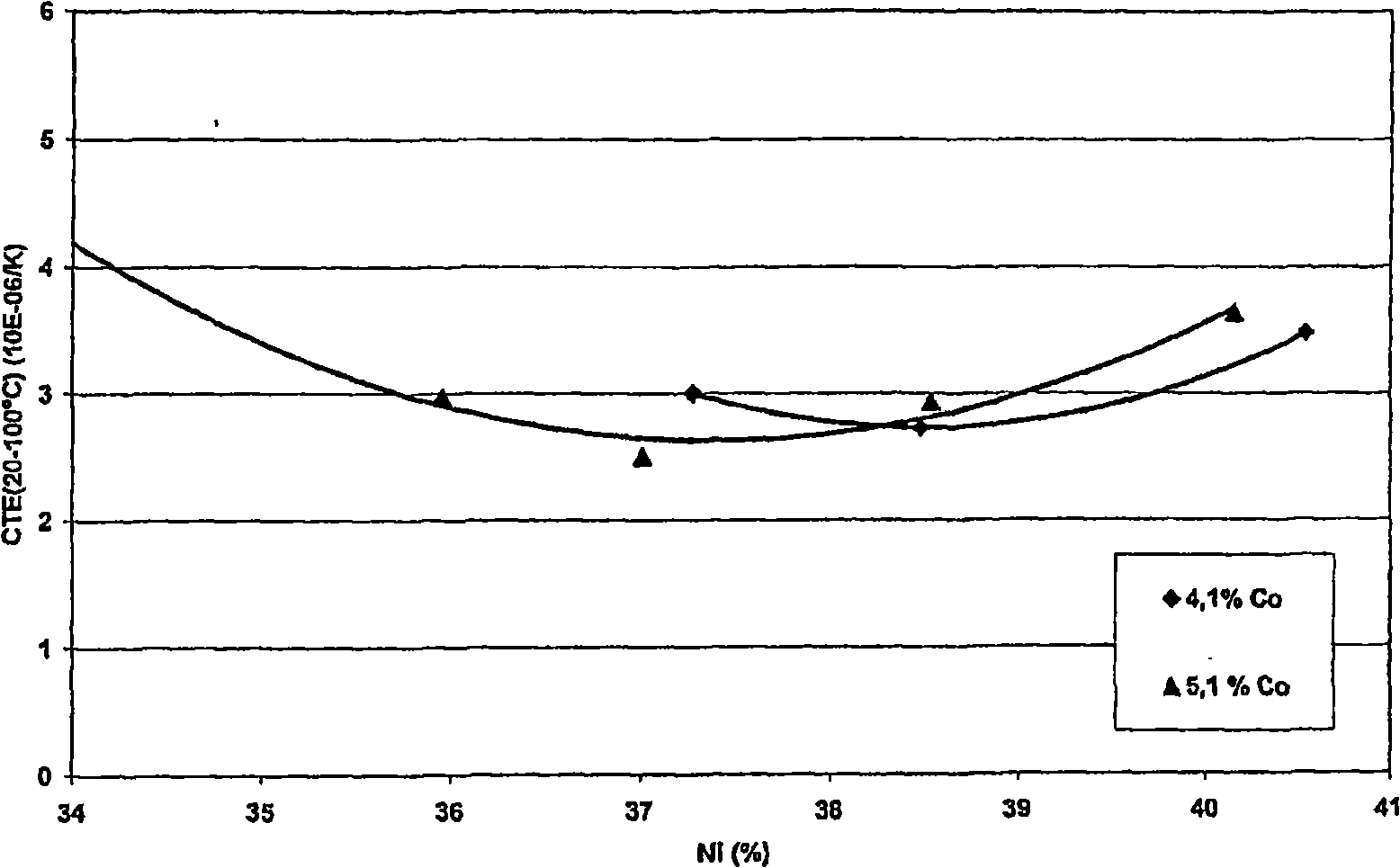

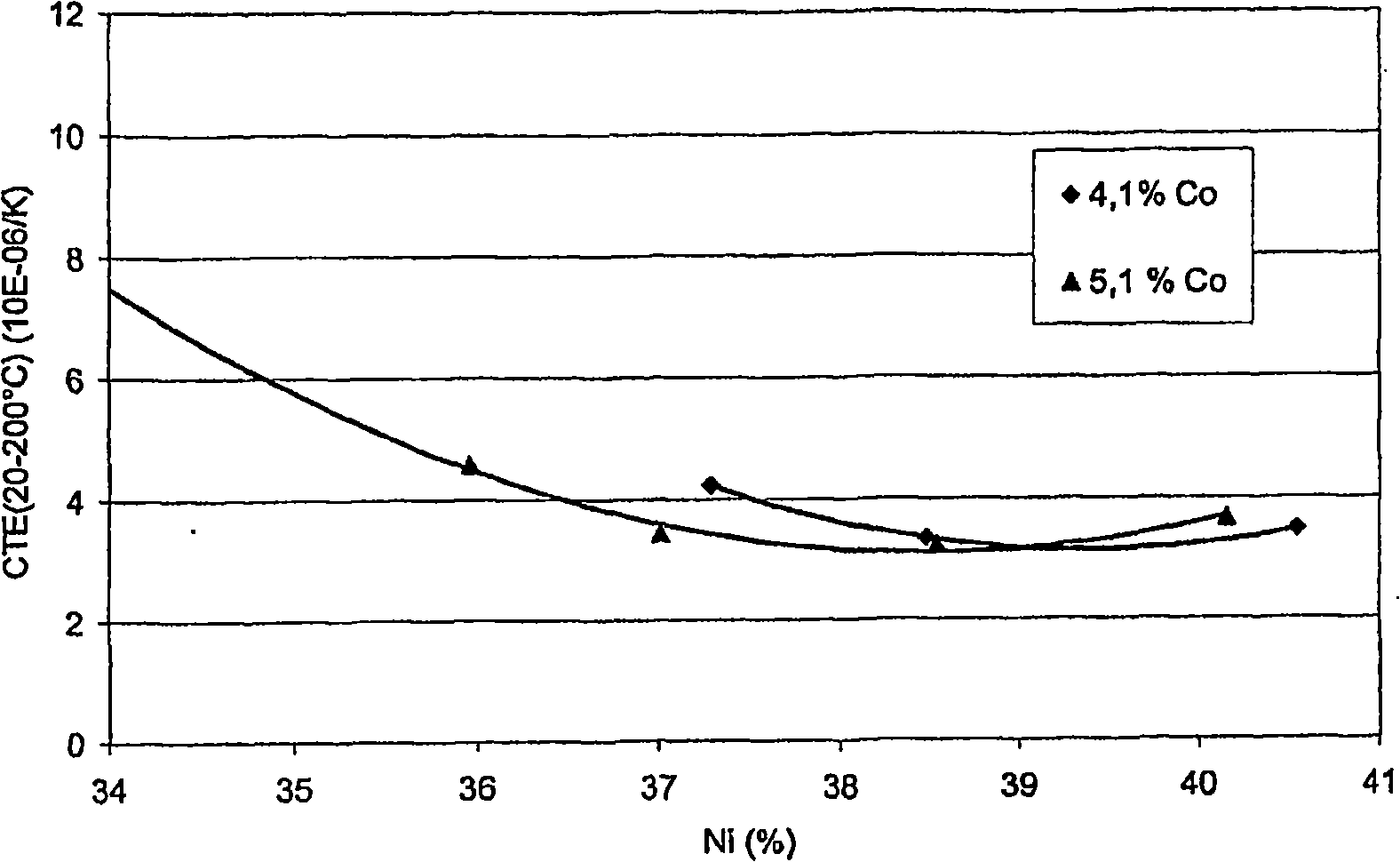

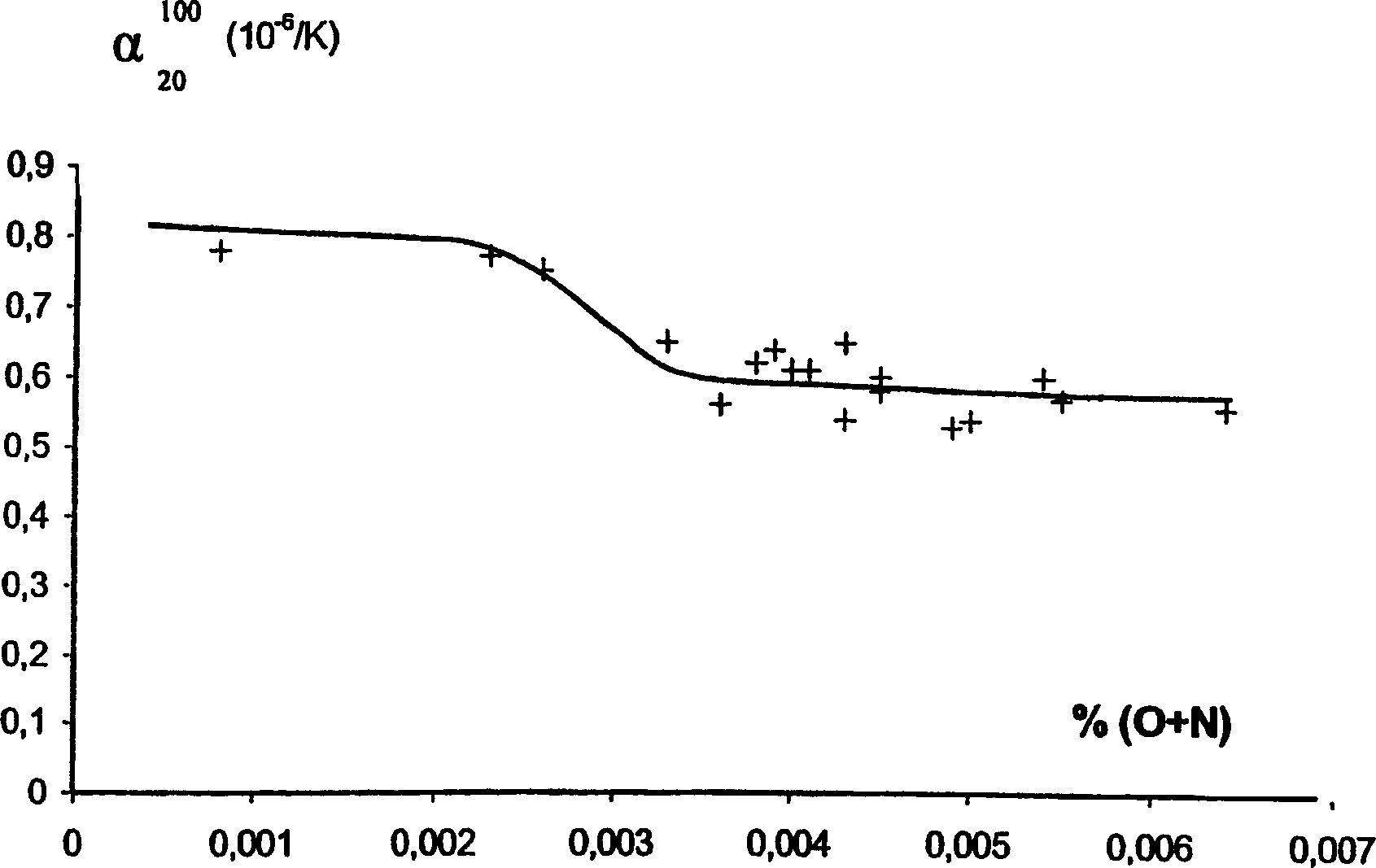

Iron-nickel alloy with low coefficient of thermal expansion for making shade masks

InactiveCN1742107AControl electrodesCathode ray tubes/electron beam tubesChemical compositionThermal expansion

An iron-nickel alloy has the following chemical composition (by wt %): (a) 35 at most Ni at most 37; (b) 0.001 at most C at most 0.05; (c) Mn at most 0.10; (d) Si at most 0.15; (e) Co at most 0.5; (f) S less than 0.002; (g) P less than 0.006; (h) B at most 0.0005; (i) Al+Mo+Cu+Cr at most 0.15; (j) 0.15 at most 2(V+Ti)+Nb+Zr+Ta+Hf at most 0.2; (k) 0.0025 at most N+O at most 0.015; (l) possibly some calcium and / or magnesium with a total content between 0.0001 and 0.005; (m) a balance of iron and inevitable production impurities. An Independent claim is also included for the fabrication of a strip of the above alloy by hot rolling.

Owner:伊菲合金公司

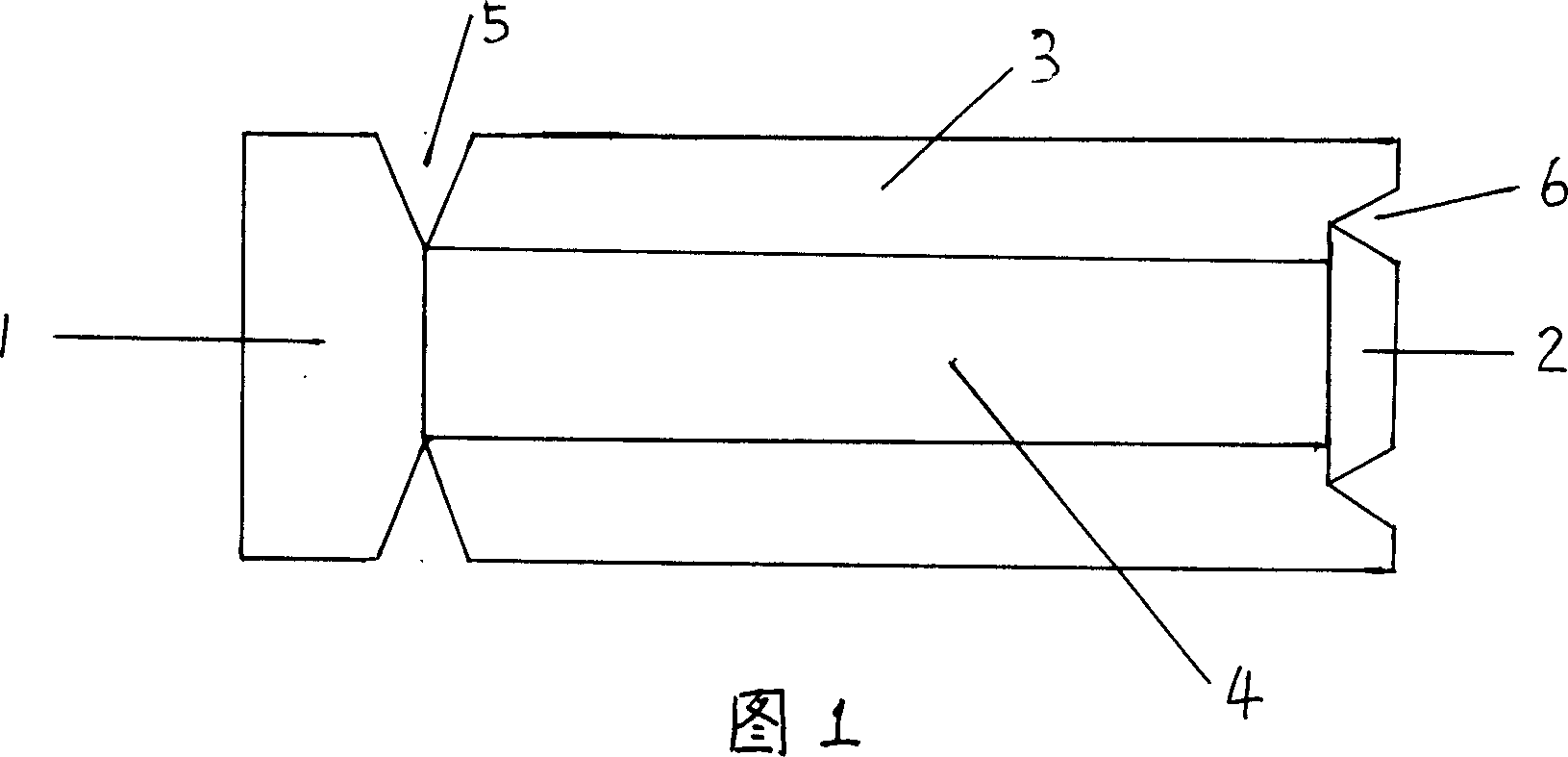

Preparaton method of iron nickel alloy/copper composite wire material

A composite FeNi alloy / Cu wire 4J50 / Cu is made of the copper rod cored FeNI alloy ingot through vacuum high-temp treating, squeezing at 900-950 deg.C, cold drawing and heat treating. Its advantages are high electric and thermal conductivities, better weldability, and good sealing performance to glass and ceramics.

Owner:SINO PLATINUM METALS CO LTD

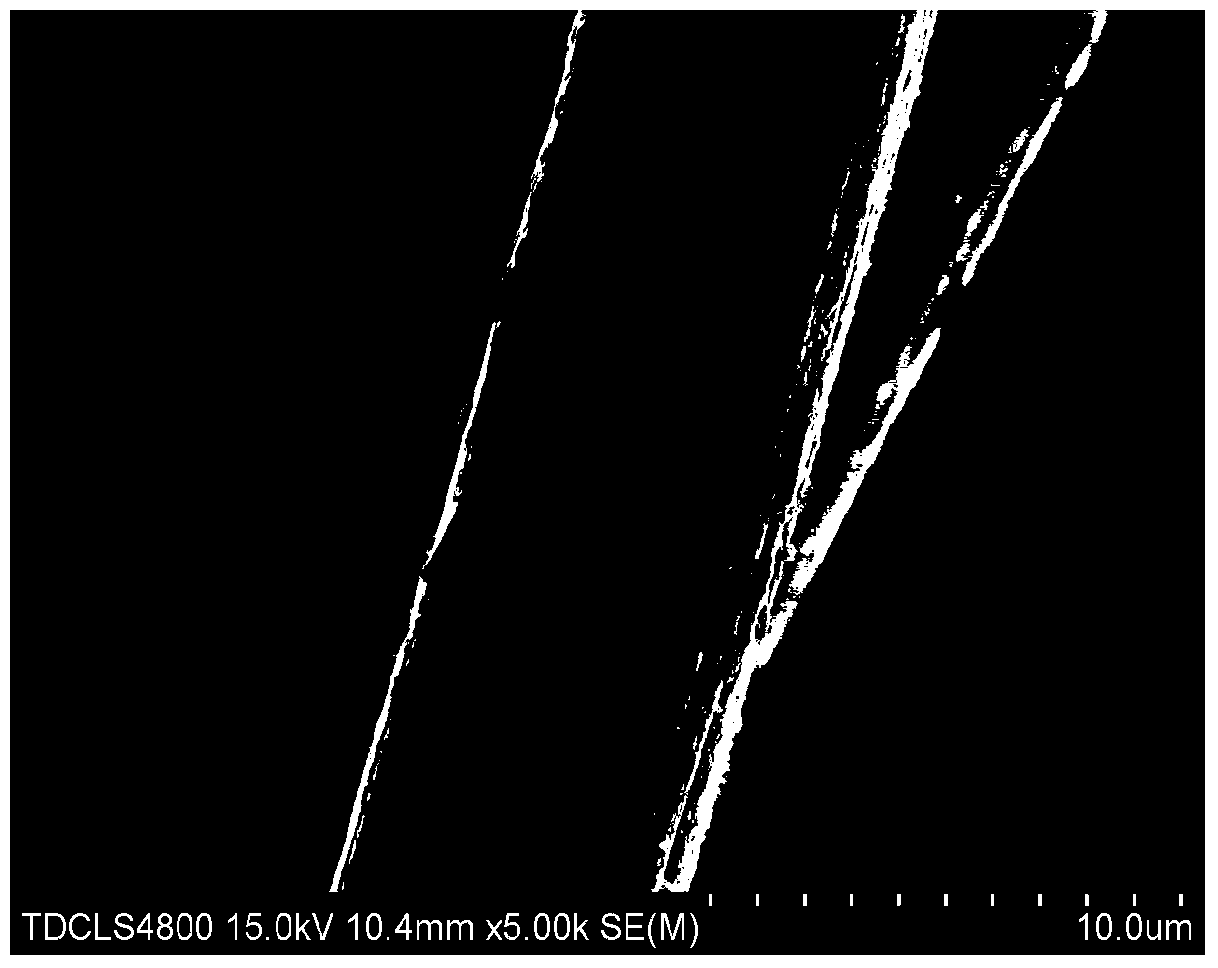

Preparation method for carbon fiber electroplating iron-nickel alloy

The invention belongs to the technical field of electroplating, and relates to a preparation method for a carbon fiber electroplating iron-nickel alloy. The preparation method comprises the following steps of performing degumming oxidation treatment on a carbon fiber bundle; preparing an electroplating solution, namely weighing 60 to 90 parts by weight of NiSO4.6H2O, 10 to 30 parts by weight of NiCl2.6H2O, 60 to 80 parts by weight of FeSO4.7HO, 15 to 20 parts by weight of C6H5Na3O7.2H2O, 1 to 3 parts by weight of C7H5NO3S and 10 to 30 parts by weight of H3BO3 respectively, dissolving the components in a proper amount of ultrapure water, weighing 0.1 to 0.3 part by weight of C6H5NaO2S, dissolving C6H5NaO2S in a small amount of ultrapure water, uniformly mixing the two solutions, and controlling the pH value to be 3 to 4.5; performing electroplating treatment on the surfaces of carbon fibers. According to the method, the magnetism of the electroplated carbon fibers can be improved by controlling the magnetism.

Owner:TIANJIN UNIV

Process for synthesizing iron-nickel alloy nano particle catalyst for selective hydrogenation

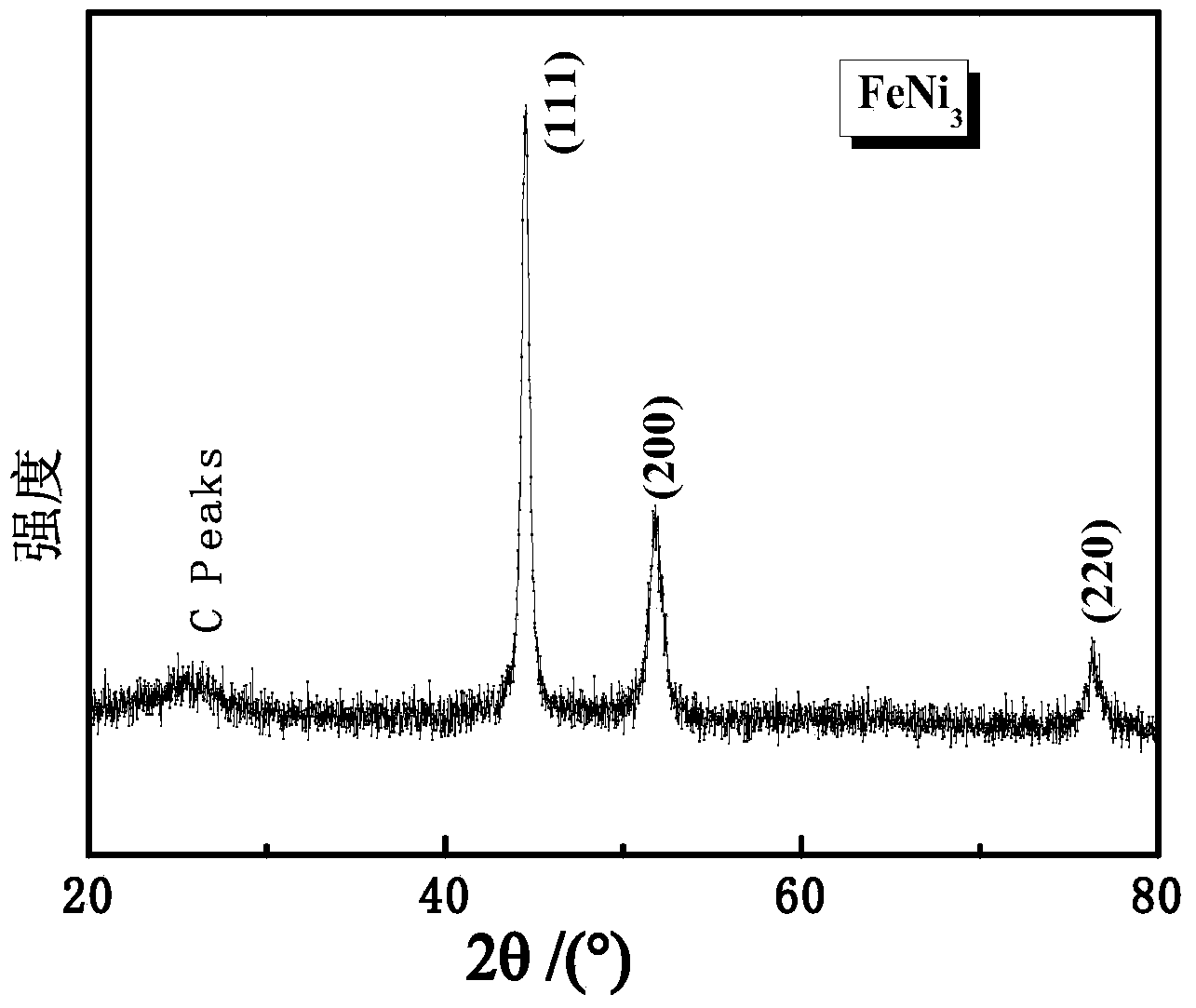

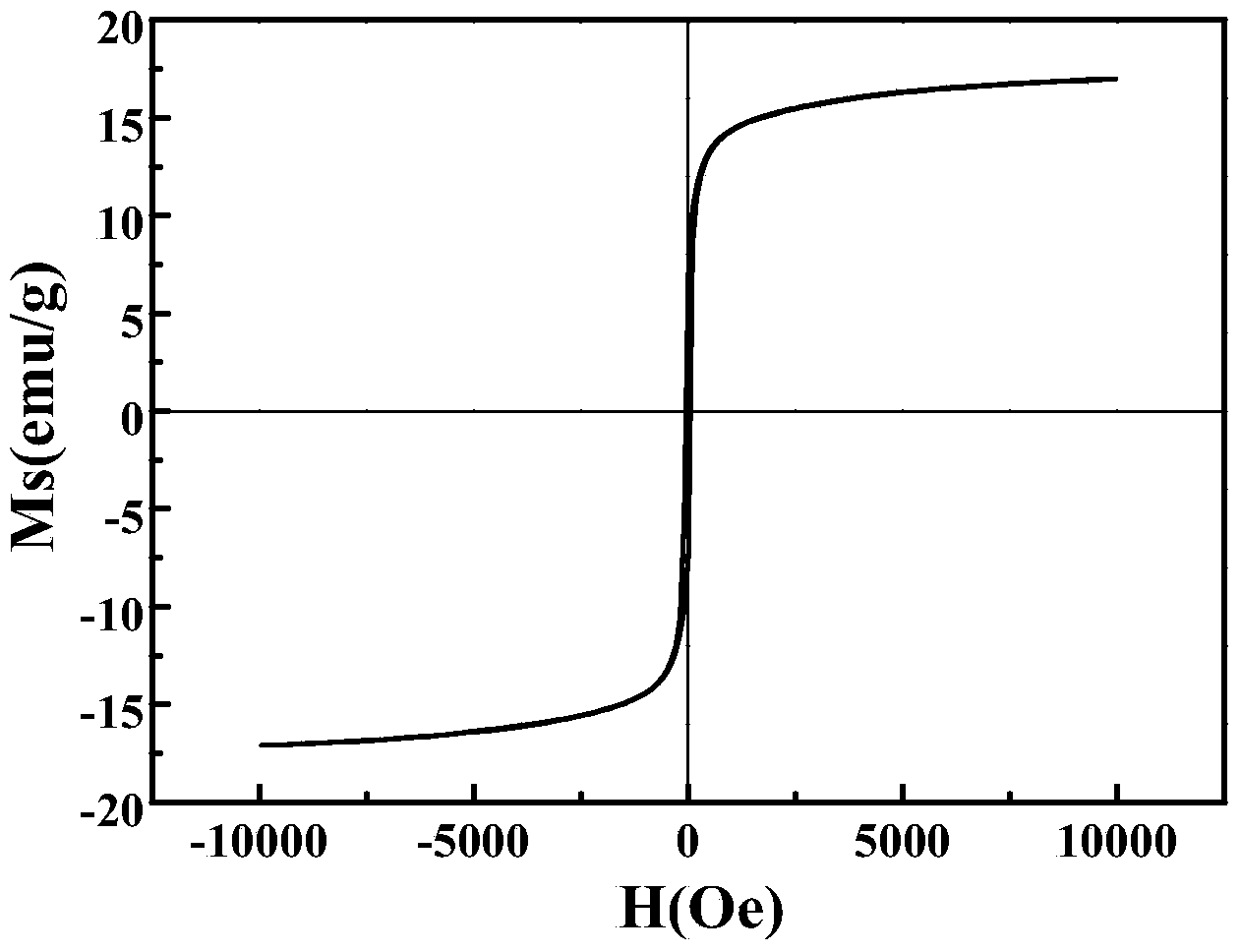

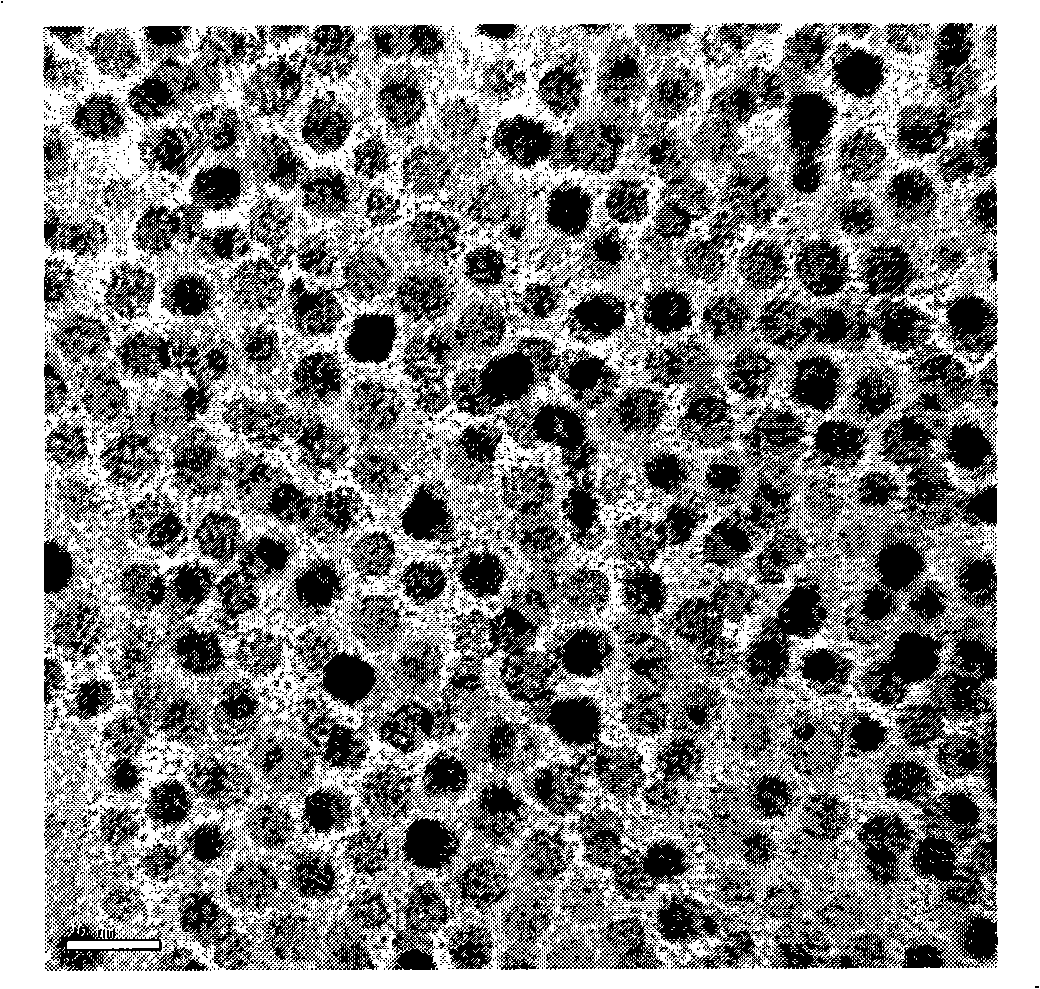

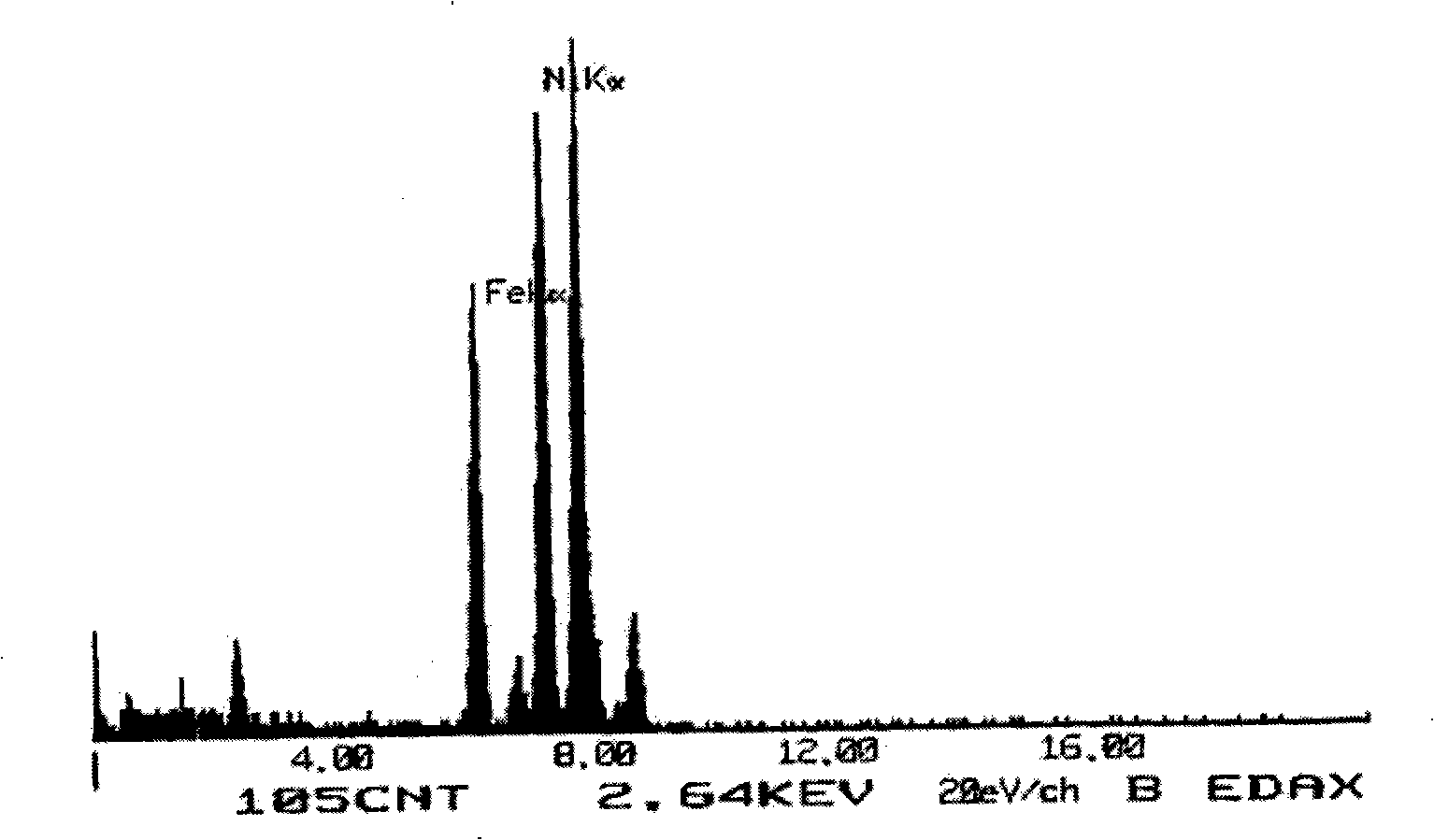

InactiveCN101352684AOrganic reductionMetal/metal-oxides/metal-hydroxide catalystsSuperparamagnetismSolvent

The invention relates to a method for preparing and separating monodisperse superparamagnetism iron-nickel alloy nano-particle catalyst used for selective hydrogenation. In the method, Ferric acetylacetonate and Nickel acetylacetonate are taken as raw materials, liquid paraffin is taken as reaction medium, trioctyl-phosphine and oleyl amine are taken as stabilizer (also called protecting agent or surface modifier) and polyol is taken as morphology modifier. The product obtained is iron-nickel alloy nano-particle. The method adding magnetic field to assist solvent extraction can separate the iron-nickel alloy nano-particle from the reaction system. The iron-nickel alloy nano-particle can be dispersed into organic solvents again such as chloroform, petroleum ether, and the like, without the generation of precipitation. The nano-particle is used as the catalyst for the selectively hydrogenation of chloro-nitrobenzene, the convention rate of reactants can reach 70 percent and the selectivity thereof is 98 percent.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

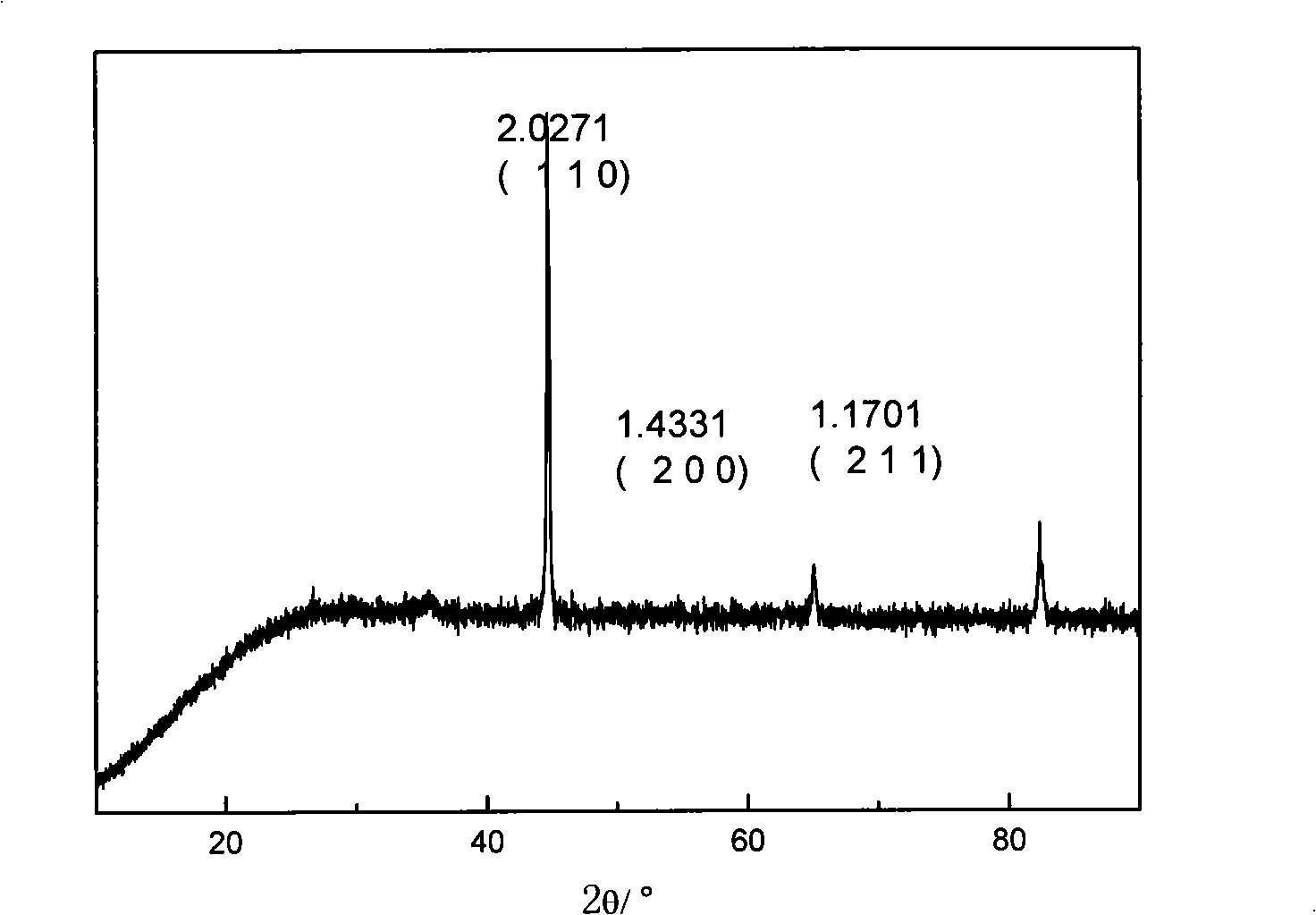

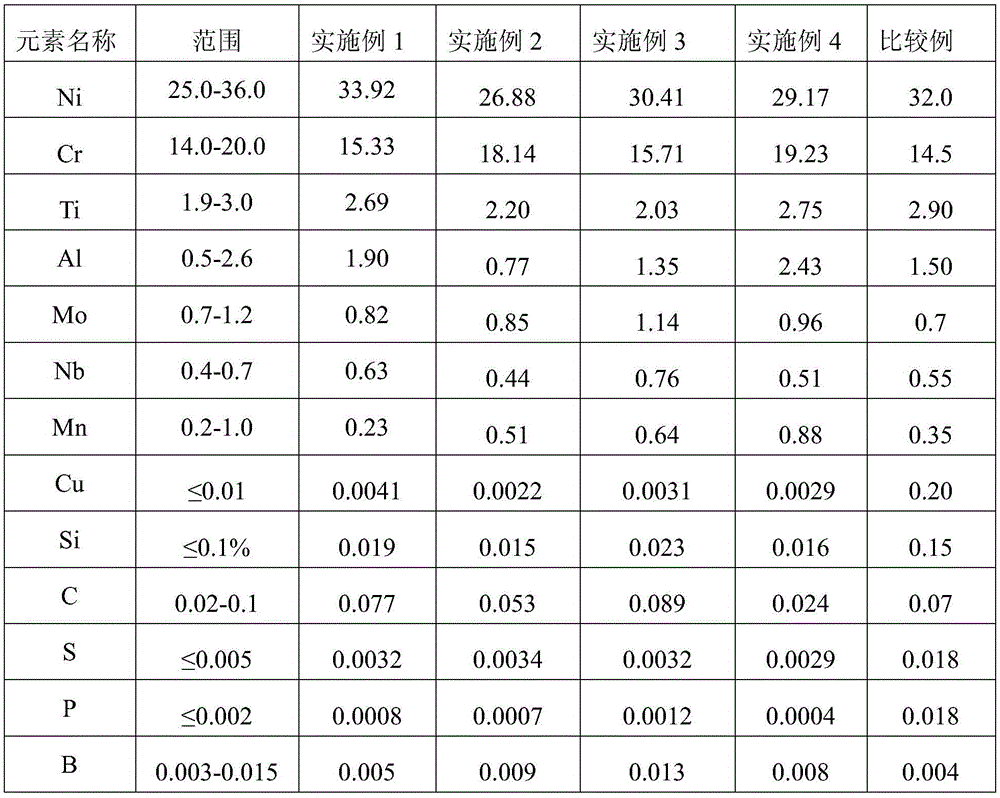

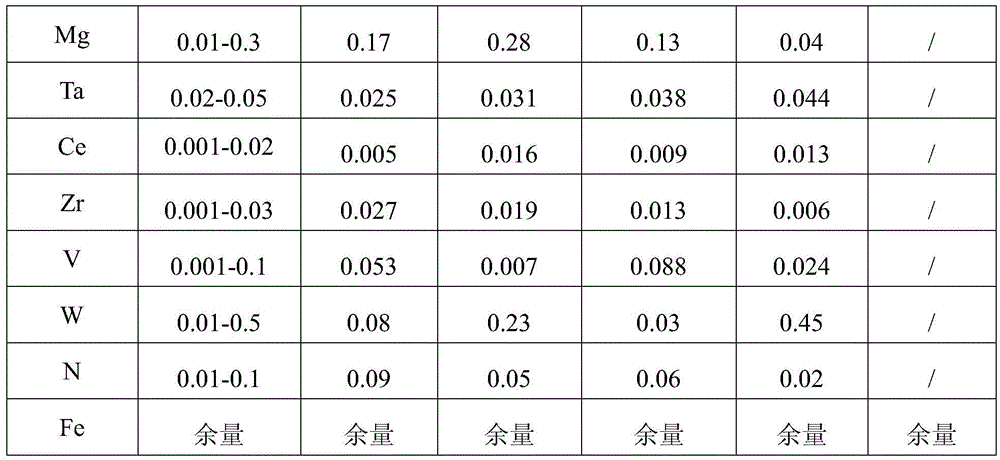

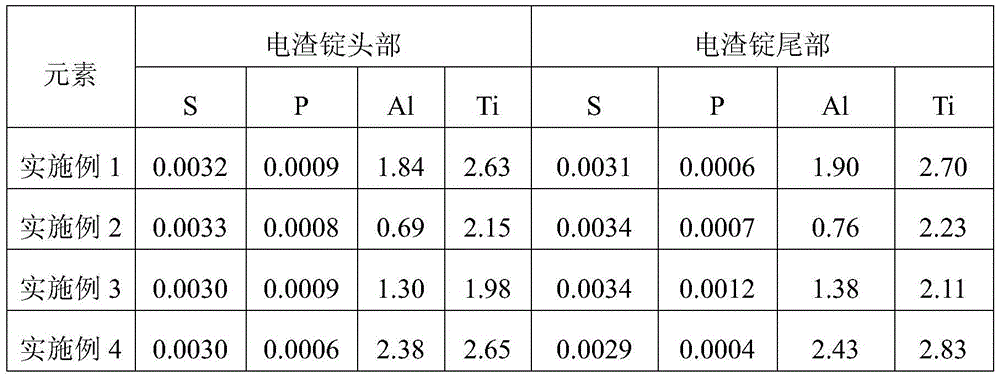

Micro-alloyed high-strength anti-oxidization iron-nickel alloy gas valve steel material and preparation method

The invention relates to a micro-alloyed high-strength anti-oxidization iron-nickel alloy gas valve steel material and a preparation method. The material comprises elements such as Ni, Cr, Ti, Al, Mo, Nb, Mn, C, B, Mg, Ta, Ce, Zr, V, W, N, Fe and the like. The material can be used in a working environment with a high temperature, high load, strong oxidization and strong corrosion, is low in nickel content, has good tensile strength, good endurance strength, good fatigue strength and excellent oxidization resistance, good corrosion resistance and good resistance to fuel gas, and can be used for preparing a gas inlet valve and a gas outlet valve of a medium-high-load engine.

Owner:CHONGQING MATERIALS RES INST

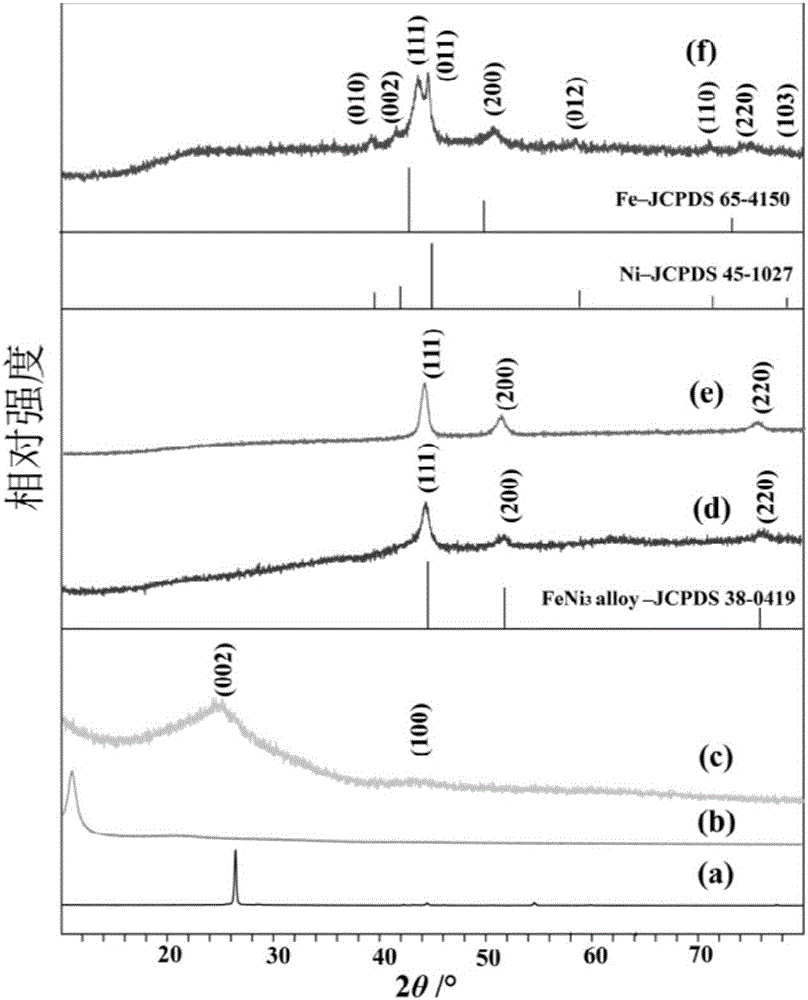

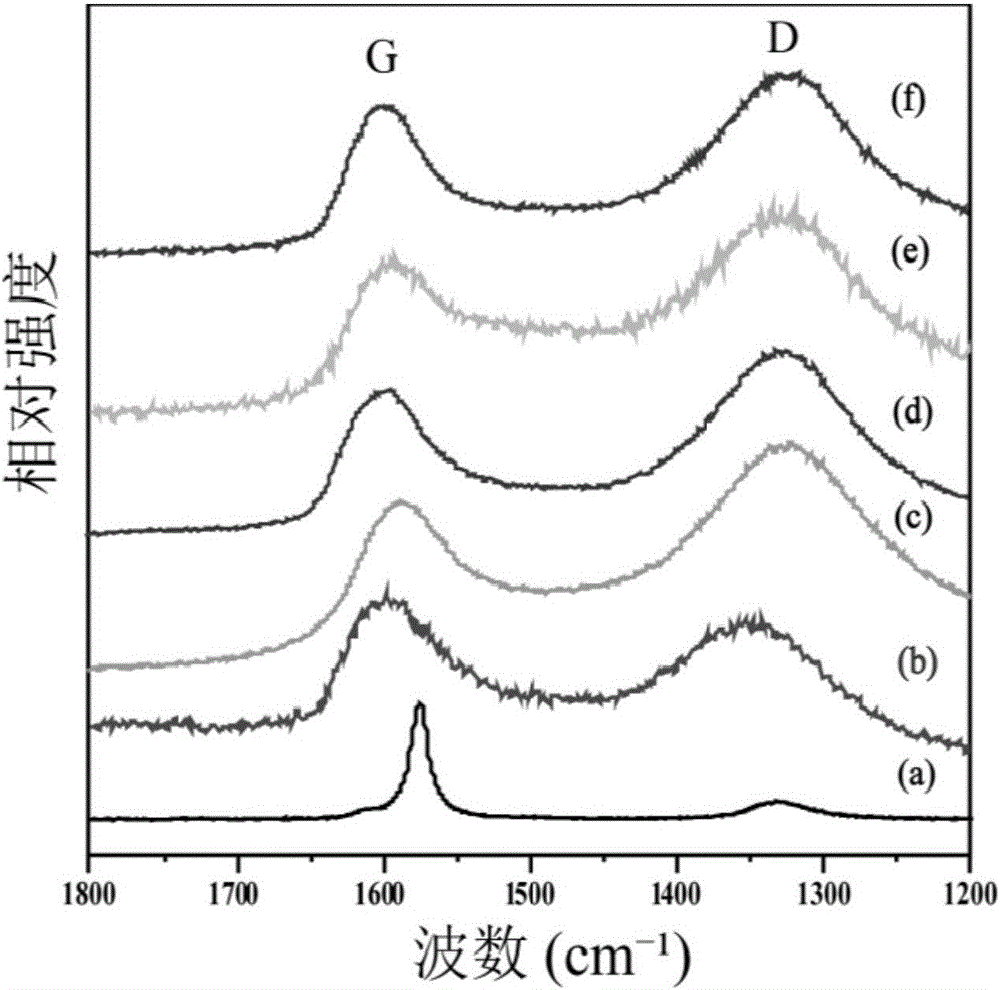

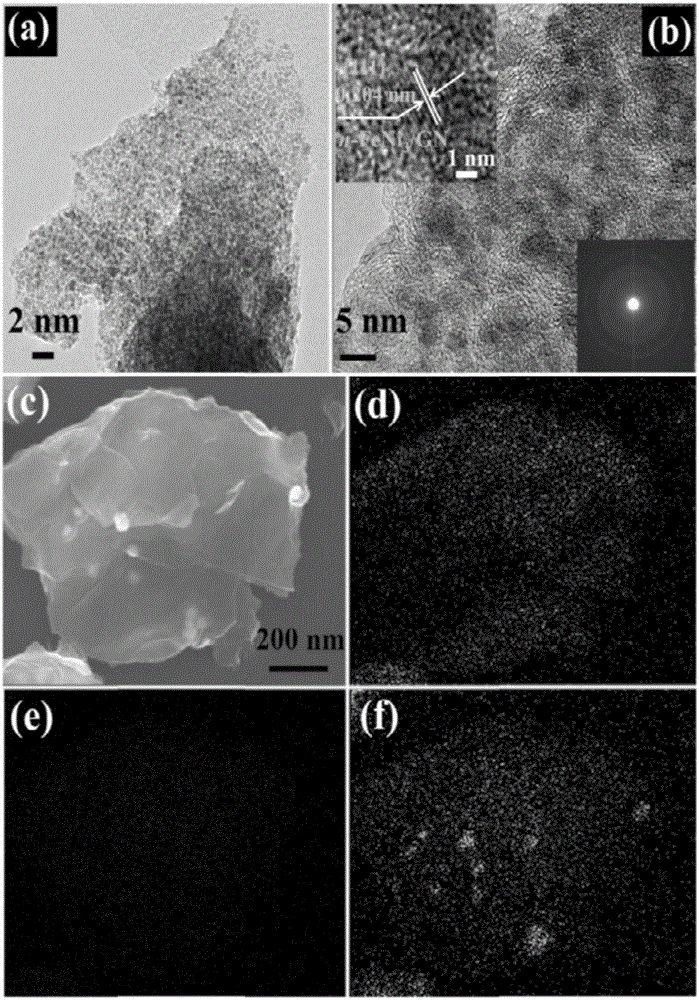

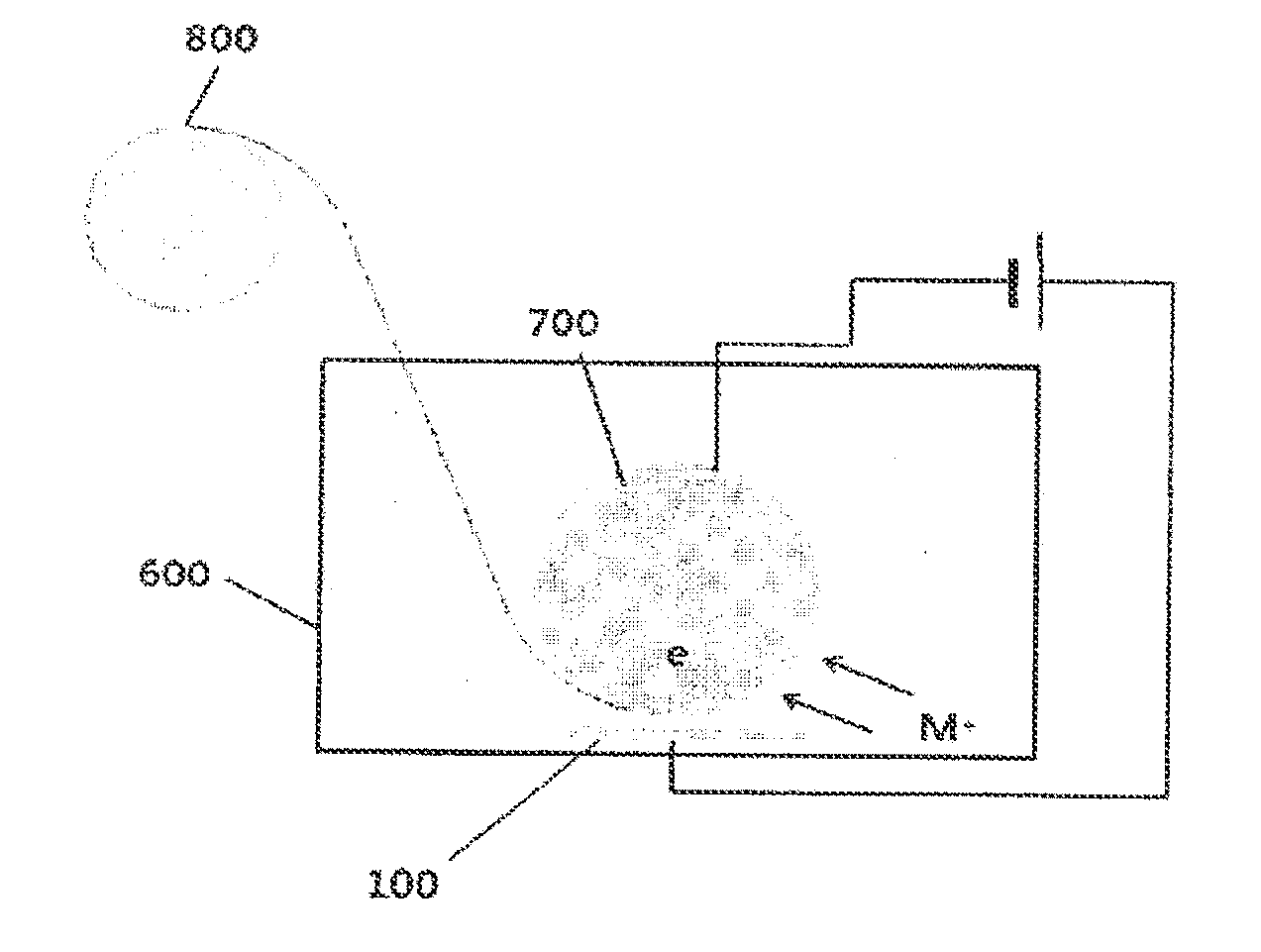

Iron-nickel alloy nanocluster-graphene composite material and preparation method and application thereof

InactiveCN105817648AImprove absorbing performanceOther chemical processesTransportation and packagingOrganic solventThermal decomposition method

The embodiment of the invention discloses a method for preparing an iron-nickel alloy nanocluster-graphene composite material. The method includes the following steps that (1), graphite oxide is added into a first organic solvent to be dispersed; (2), ferric acetylacetonate, nickel acetylacetonate and octadecylamine are added, the mixture is heated to 100 DEG C to 150 DEG C in inertia protective gas, the temperature is kept for 20 min to 50 min, and then the temperature rises till a solution is boiled and flows back, and is kept for 1 h to 5 h; and (3), a second organic solvent is added to suddenly stop the reaction, and reaction products are separated out, washed and dried. The invention further discloses the iron-nickel alloy nanocluster-graphene composite material prepared through the method, and application of the composite material to electromagnetic wave absorption. According to the method, the iron-nickel alloy nanocluster-graphene composite material and the application, graphene is used as a substrate, the iron-nickel alloy nanocluster-graphene composite material is obtained through one-step reduction of a thermal decomposition method, and therefore iron-nickel alloy nanoparticles are protected and dispersed, and the nanometer composite material good in wave absorbing property is obtained.

Owner:BEIJING NORMAL UNIVERSITY +1

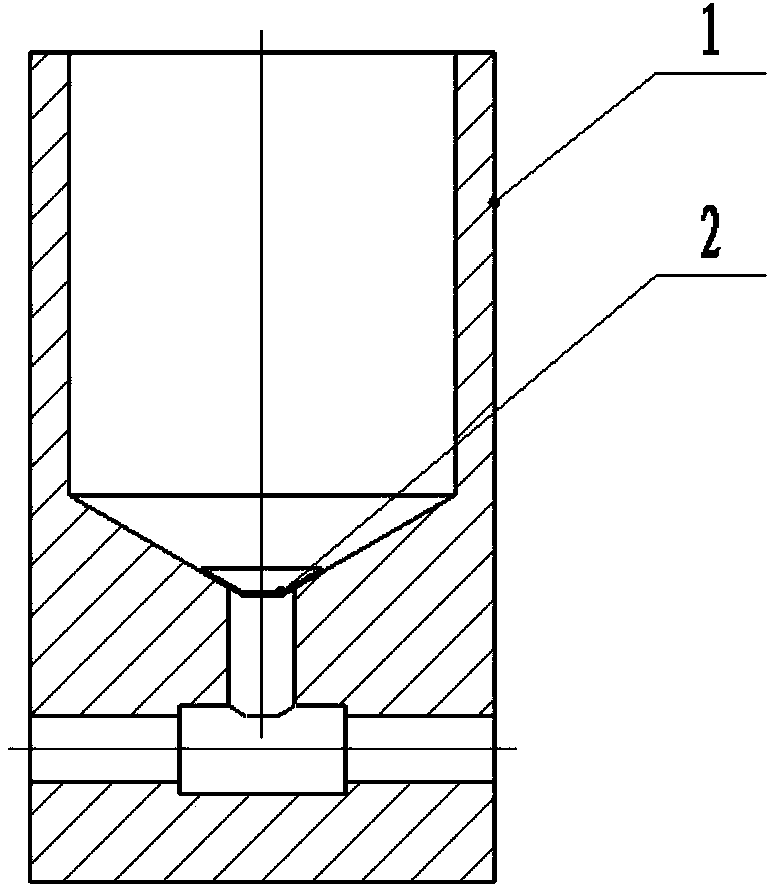

Substrate material of iron-nickel alloy metal foil for cigs solar cells

ActiveUS20140345677A1The process system is simpleFinal product manufacturePhotovoltaic energy generationMetal foilAlloy substrate

The present invention relates to an exclusive alloy substrate material for CIGS solar cells. Particularly, the present invention provides a substrate material having a thermal expansion coefficient similar to that of a CIGS layer. The substrate material according to the present invention may prevent damage such as interlayer separation due to differing thermal expansion coefficients from occurring because the substrate material has a thermal expansion coefficient similar to that of the CIGS layer.

Owner:KOREA INST OF IND TECH

Iron-based nonelectric welding device

ActiveCN103506755ARealize the purpose of weldingReduce the extent of galvanic corrosionWelding/cutting media/materialsSoldering mediaElectrode potentialMetallic aluminum

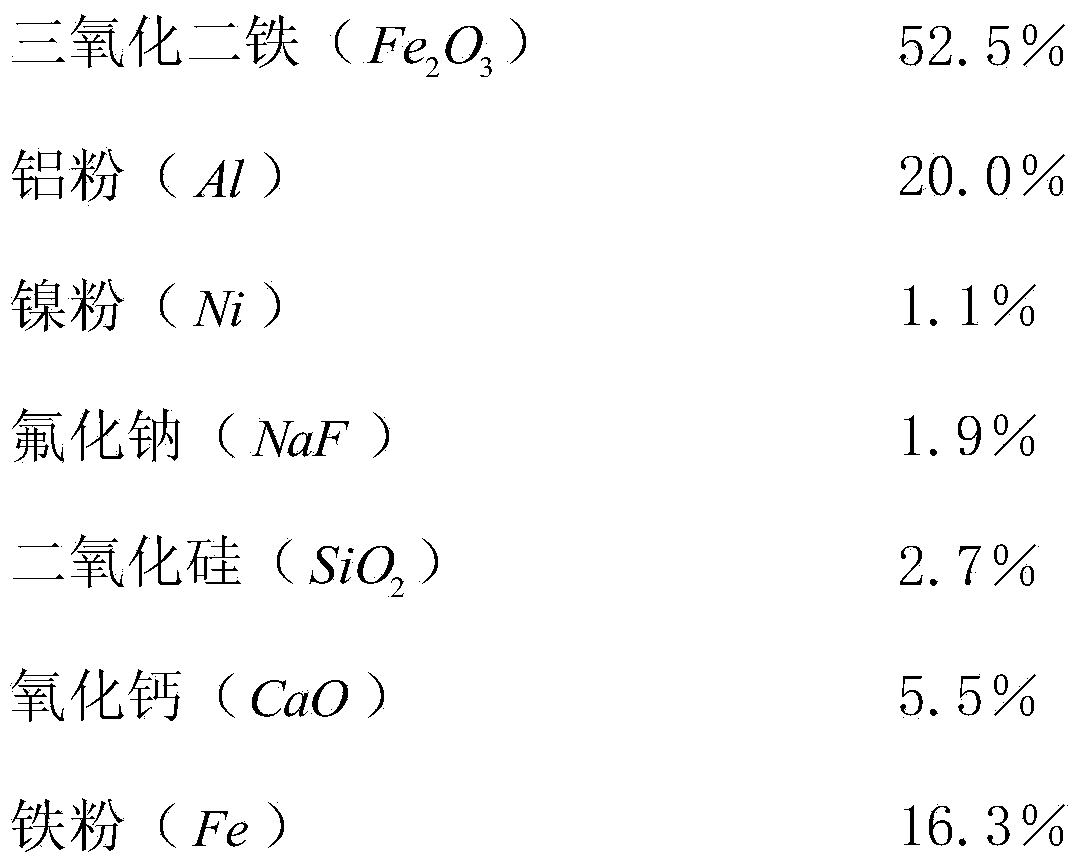

Provided is an iron-based nonelectric welding device. The body of the iron-based nonelectric welding device is a disposable die filled with iron-based soldering flux, wherein the iron-based soldering flux contains 48%-57% of ferric oxide powder, 15%-25% of metallic aluminum powder, 0.2%-2.8% of metallic nickel powder, 0.5%-4% of fluorite powder, 1%-6% of silicon dioxide powder, 3.1%-8.2% of calcium oxide powder and 12%-21% of metallic iron powder. The disposable die is formed through single-pressing and stoving after rick fat oil is mixed with standard sand. The soldering flux mainly comprises ferric oxide, ferrous powder and a little of nickel powder, and iron-nickel alloy is produced on soldering points through self-propagating reaction after ignition; the iron-nickel alloy is approximately equal to parent metal steel of a grounding device in electrode potential, and galvanic corrosion of parent metal cannot caused. The die is good in thermal insulation effect and low in price, links of cleaning, die sinking, die filling and the like are reduced through one-time use, time is saved, and scalding risks of staff are reduced. The reaction speed of soldering flux ranges from 45 seconds to 60 seconds and longer than common self-propagation by 20 seconds, the possibility of splashing of reaction products is reduced, evacuation is facilitated, and safety is good.

Owner:武汉长威电气有限责任公司

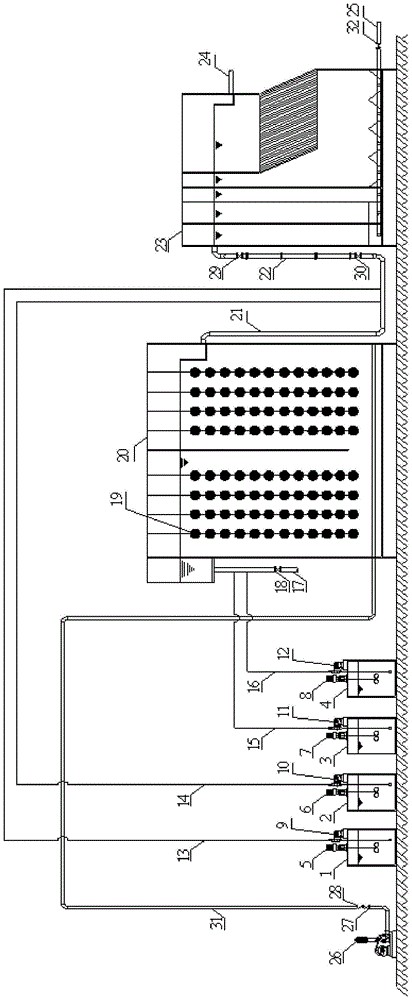

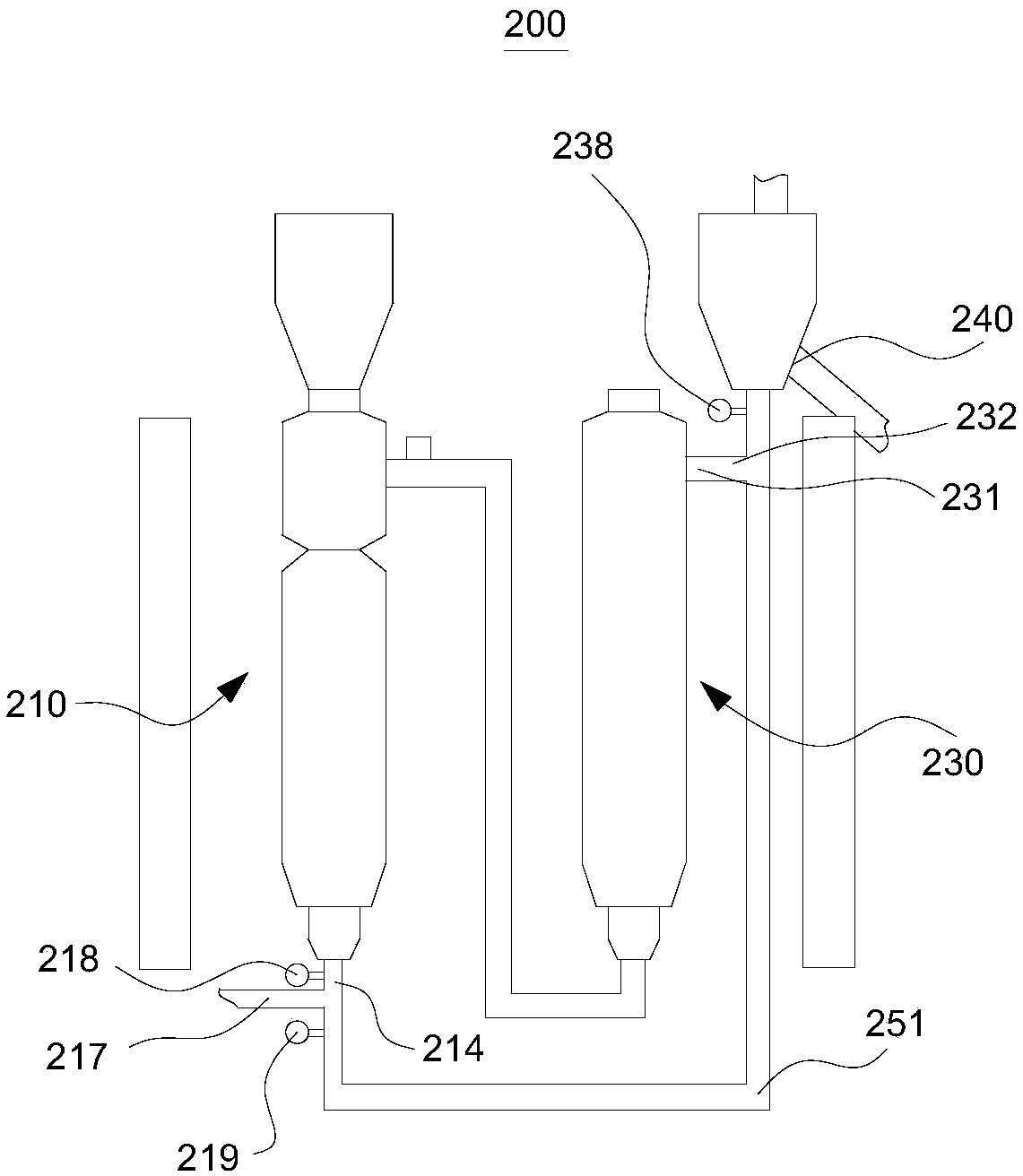

Multi-component composite catalytic zero-valent iron Fenton treatment method and device for industrial wastewater

ActiveCN105540931AReduce outputLow costWater treatment compoundsMultistage water/sewage treatmentSludgeWastewater

The invention relates to a multi-component composite catalytic zero-valent iron Fenton treatment method and device for industrial wastewater. The method comprises the following steps: adding an acid and H2O2 into the industrial wastewater to adjust the pH value to be 4.5-6.0, and allowing the industrial wastewater of which the pH value is adjusted to enter a Fenton-like reaction tank, wherein the Fenton-like reaction tank is filled with a multi-component composite catalytic filling pack which comprises iron-nickel alloy particles, iron-copper alloy particles, manganese-iron alloy particles, zeolite and hematite; after a 3.0-4.0 hours' reaction of the wastewater in the Fenton-like reaction tank, adding an alkali to adjust the pH value to be 7.8-8.0, adding a coagulant aid, allowing the mixture to enter a coagulating-sedimentation integrated tank, discharging water after finishing solid-liquid separation, and performing efflux disposal on iron-containing sludge. The method and the device have the advantages that raw materials are easy to obtain, the assembly is convenient and the cost is low.

Owner:DONGHUA UNIV

Cobalt-tungsten-iron-nickel alloy electroplating liquid

InactiveCN101532152AGood corrosion resistance and friction resistanceHarm reductionSimple componentIron–nickel alloy

The invention discloses cobalt-tungsten-iron-nickel alloy electroplating liquid and belongs to the field of material surface treatment. A formula of the electroplating liquid comprises: 1 to 5 grams / litre of cobalt sulfate, 20 to 60 grams / litre of sodium tungstate, 10 to 50 grams / litre of ferrous sulfate, 20 to 60 grams / litre of nickel sulfate, 10 milliliters / litre of 28 percent oxalic acid, 5 to 15 grams / litre of ammonia sulfate, 20 to 40 grams / litre of a complexing agent, 1 to 8 grams / litre of a stabilizing agent, 2 to 5 milliliters / litre of a brightness additive and 1,000 milliliters of deionized water. The surface of an electroplating layer obtained by using the cobalt-tungsten-iron-nickel alloy electroplating liquid has no microcrack and has good corrosion and friction resistance; each chemical reagent of the electroplating liquid has small harm to the environment; the process is stable; the electroplating liquid has simple components, is convenient to operate and can be stored for a long time after being prepared; and in addition, the electroplating liquid emits no acid mist in the working process and has high current efficiency.

Owner:乔瀚文

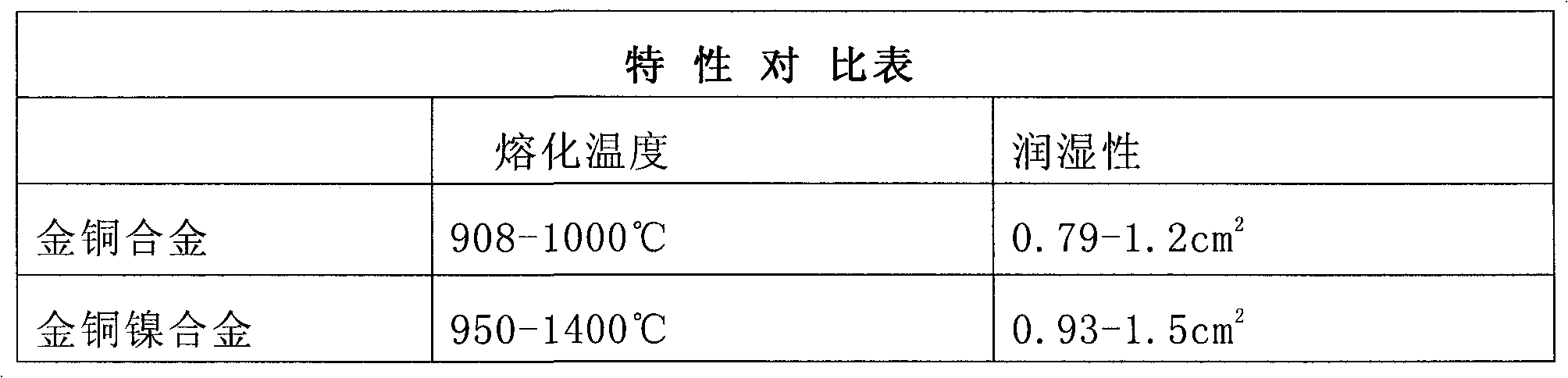

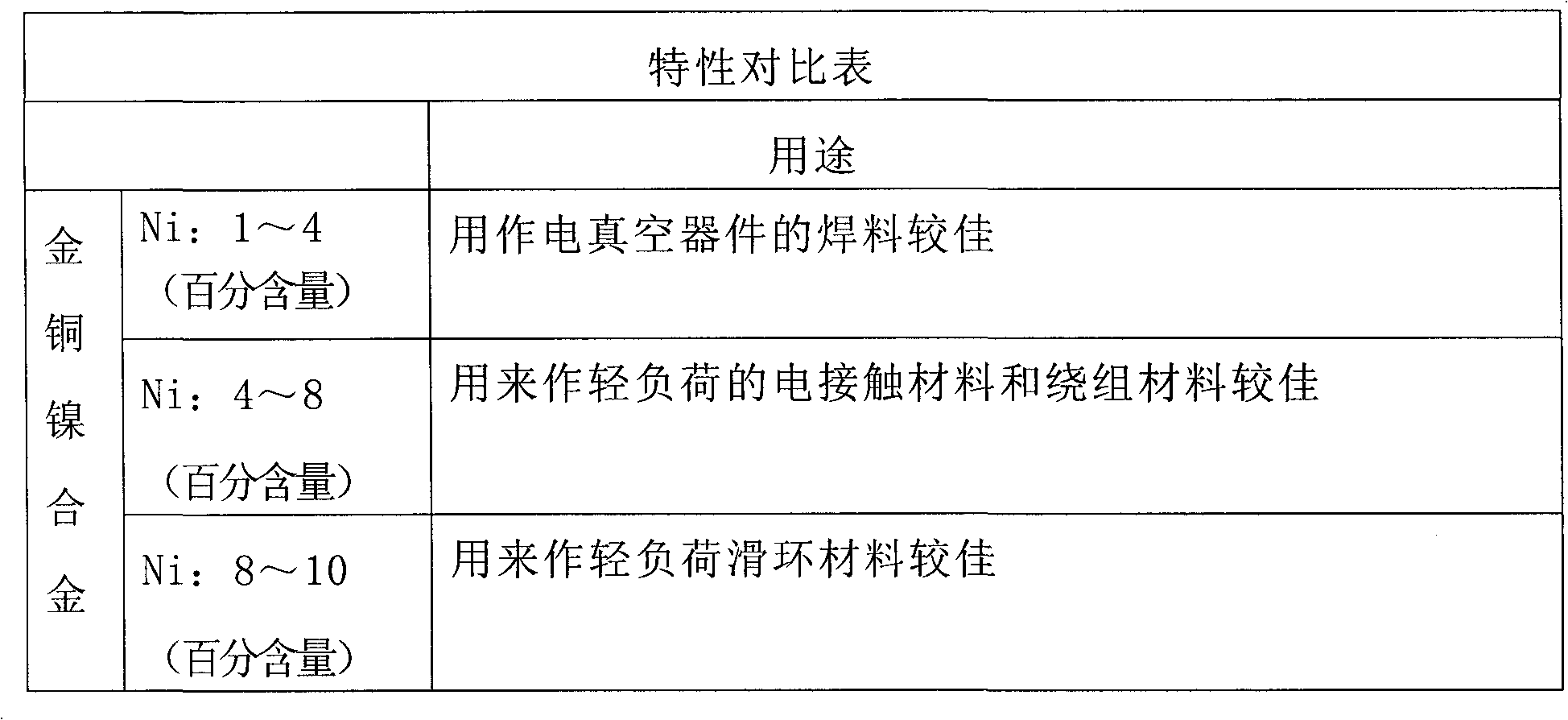

Gold-copper-nickel alloy, preparation method and application thereof

The invention discloses a gold-copper-nickel alloy, a preparation method and applications thereof. The gold-copper-nickel alloy consists of, by weight, 15-60% of Cu, 1-5% of Ni, with the balance being Au. The preparation method comprises the following steps: in accordance with the above-mentioned weight percentage ranges, the high-purity gold, oxygen-free copper and high-purity nickel materials are weighed up; the raw materials are put in a graphite crucible in a vacuum continuous casting machine in order; the continuous casting machine is vacuumized, heated and filled with argon when all materials are melted, then the materials begin to be operated by drawing casting; the obtained wires by drawing casting have a diameter of 8mm; and the size of the finished product is achieved by further drawing operation. The gold-copper-nickel alloy in the invention is widely used as solder for an electric vacuum device, and can be used as light-load electrical contact material, winding material and slidding-ring material. Compared with the gold-copper alloy, nickel element is added in the gold-copper-nickel alloy in the invention, which avoids ordered phase transformation, enables the material to be easy to process, and raises the welding quality when the alloy used as solder.

Owner:BEIJING INST OF NONFERROUS METALS & RARE EARTH

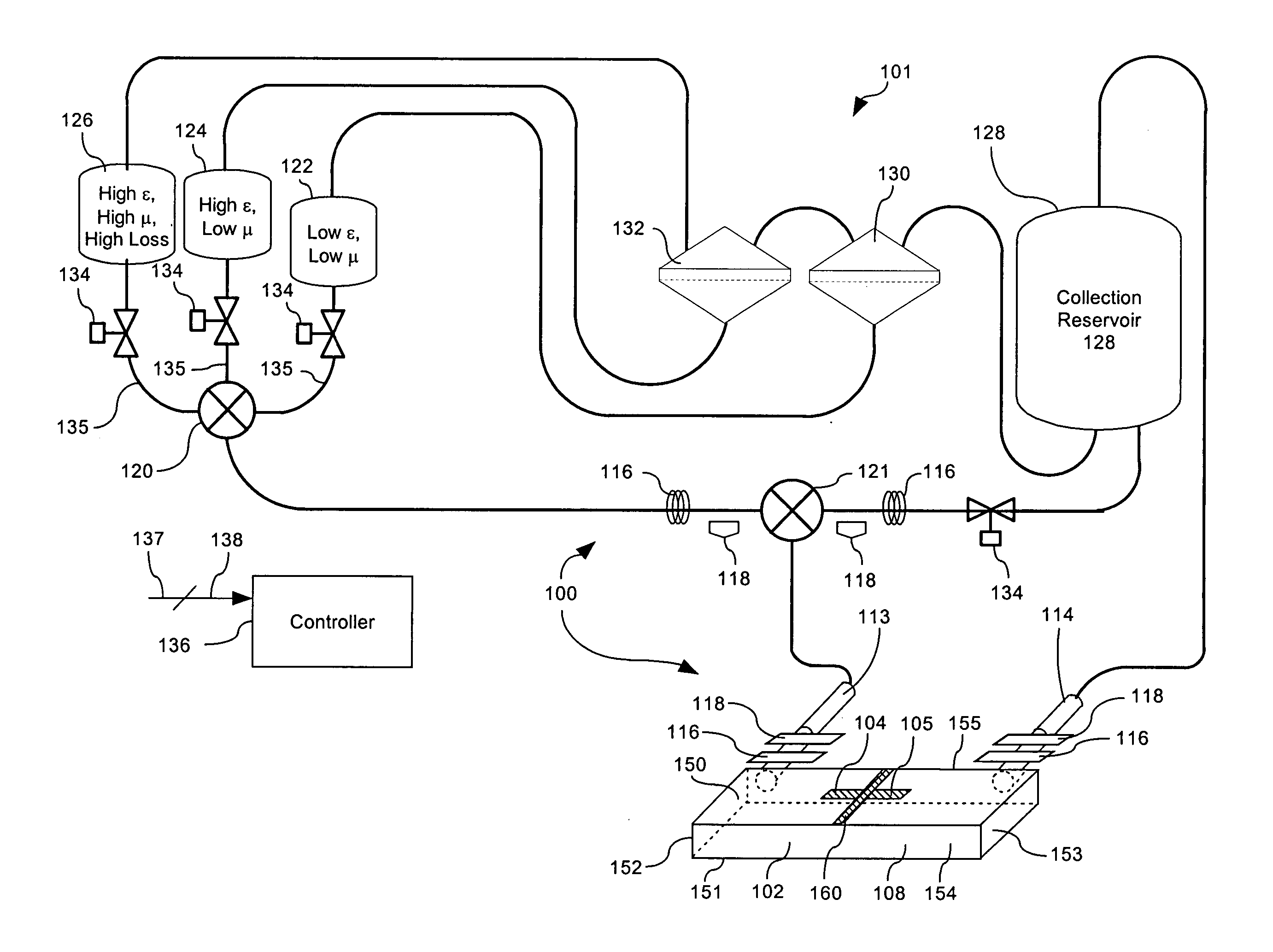

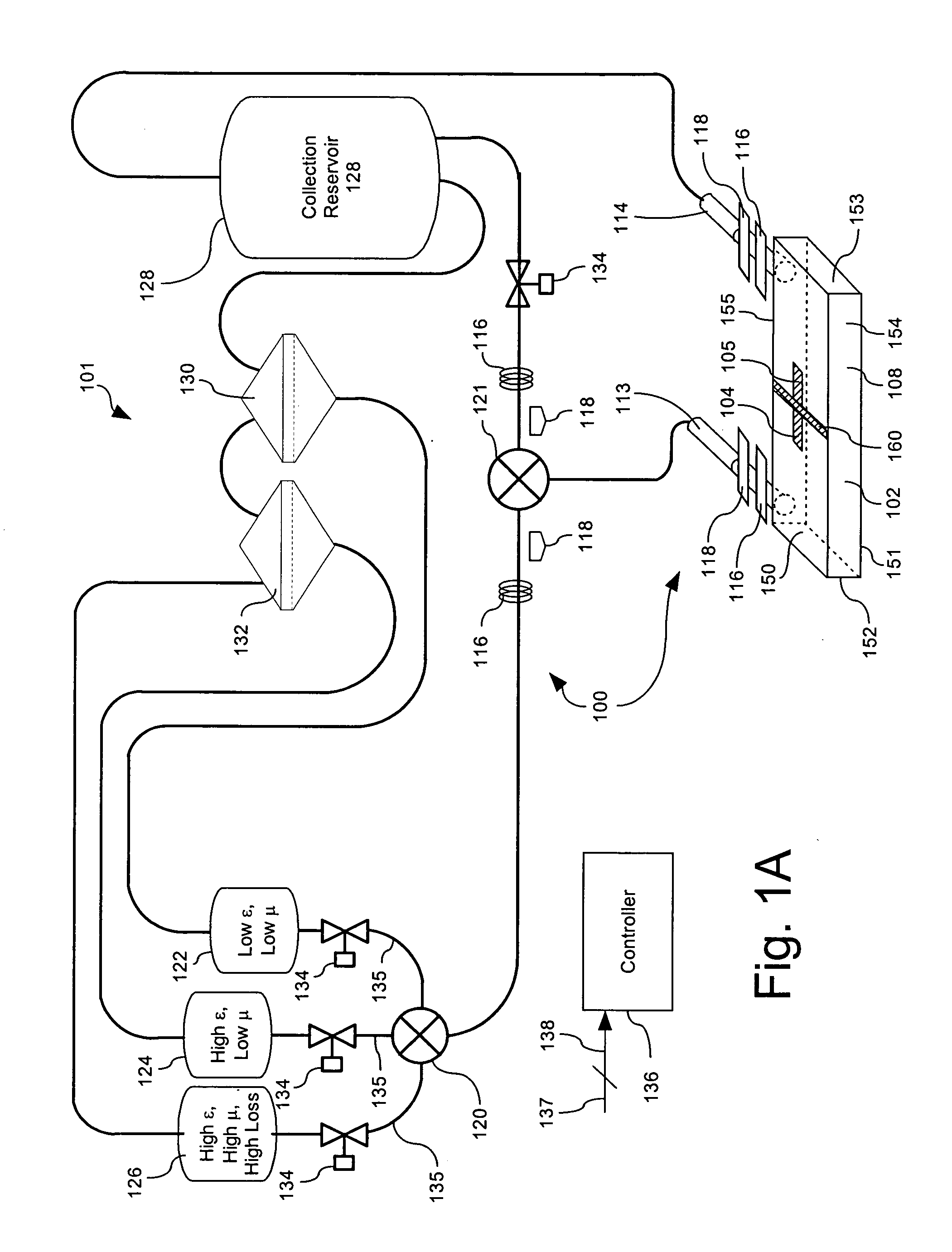

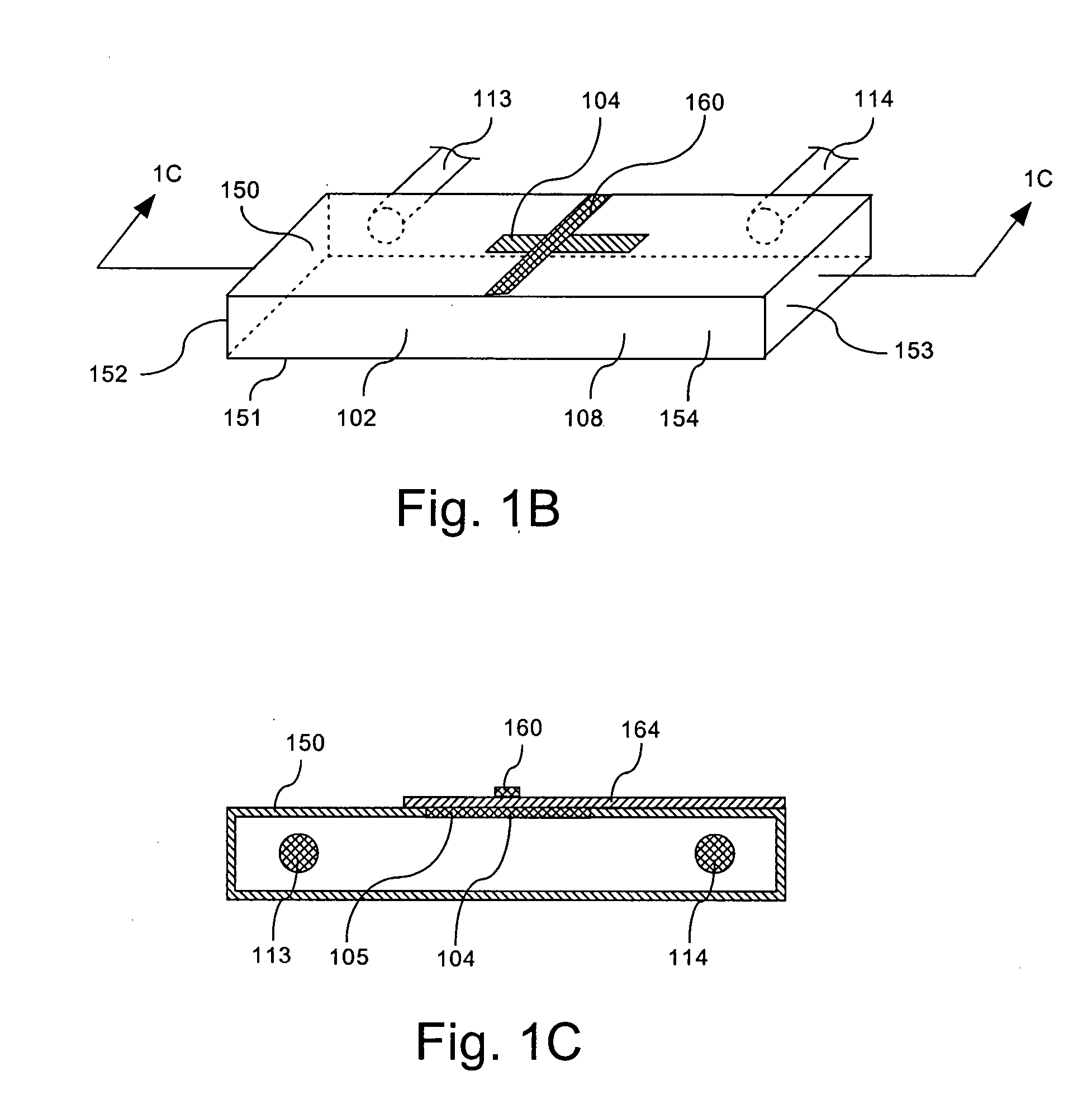

Continuously tunable resonant cavity

InactiveUS20050030133A1Modified dynamicallyHigh dielectric constantResonatorsDielectricResonant cavity

A tunable resonant system comprising a resonant cavity apparatus including at least one cavity wall (150, 151, 152, 153, 154, 155) made of a conductive material and arranged to form a resonant cavity (102), and a method for varying the resonant characteristics of the tuned resonant cavity (102). The conductive material can be steel, brass, copper, ferrite and / or Iron-nickel alloy. At least one slot (104) can be provided in a wall (150, 151, 152, 153, 154, 155) of the resonant cavity for coupling energy in and out of the resonant cavity. A fluidic dielectric (108) is disposed within the resonant cavity (102). A fluid control system (101) can be provided for selectively varying a composition of the fluidic dielectric (108) to dynamically modify a frequency response of the resonant cavity (102).

Owner:HARRIS CORP

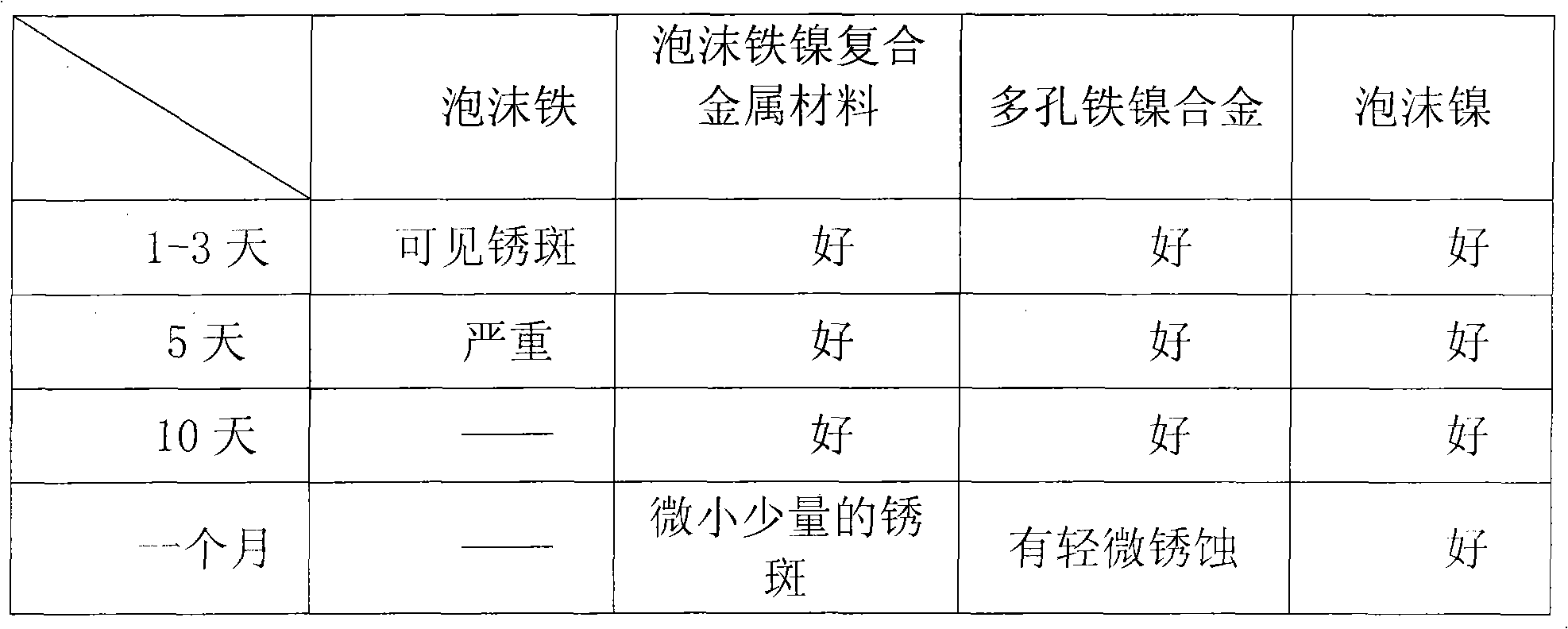

Foam iron-nickel composite metal material and preparation method thereof

ActiveCN101265549AReduce usageReduce manufacturing costVacuum evaporation coatingSputtering coatingPorous substrateFiltration

The invention discloses a foam iron-nickel composite metallic material and a preparation method thereof. The foam iron-nickel composite metallic material has a three-dimensional or two-dimensional network structure; and comprises a base layer composed of iron-nickel alloy and a nickel layer above the alloy base layer as a protective layer, wherein the composite metallic material comprises (wt%) nickel 5-29 and iron in balance. The preparation method comprises electroplating iron-nickel alloy on a conducting porous substrate to obtain the iron-nickel alloy base layer, coating nickel layer above the base layer, and performing high-temperature heat treatment to form the protective layer. The inventive foam iron-nickel composite metallic material has reduced nickel consumption, so as to effectively reduce cost; and can replace porous nickel material to be used in battery substrate, electromagnetic shielding, noise absorption, filtration and other fields.

Owner:先进储能材料国家工程研究中心有限责任公司

Solder convex point connected metal layer in microelectronic package and use thereof

InactiveCN101425489AImprove wettabilityInterface response is slowSemiconductor/solid-state device detailsSolid-state devicesOxidation resistantEngineering

The invention relates to the micro-interconnecting technology in the field of microelectronic encapsulation, in particular to an iron-nickel coating layer with good weldability taken as a solder ball bump connecting metalizing (transition) layer in the microelectronic encapsulation and the application thereof. The invention can be widely applied to the industry of microelectronic encapsulation, is particularly suitable for the BGA and other types of high-density micro-interconnecting technology, and in particular can be taken as a base plate or a bonding pad metalizing layer on a printing circuit board and a ball bump lower metal layer in the flip chip interconnection, and the like. The invention plates an iron-nickel alloy layer on a copper (or a nickel) layer by adopting the plating method; the weight percentage of iron is 5 to 80 percent; and the thickness of the coating layer and the content of an iron element can be adjusted according to the requirements. The coating layer has good weldability, antioxygenic property and very slow reaction rate in the liquid reaction of a solder ball bump. Under the condition of higher temperature, a very thin and smooth compound layer is generated between the coating layer and a solder; and the connecting interface of the coating layer and the solder ball bump has better mechanic reliability.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

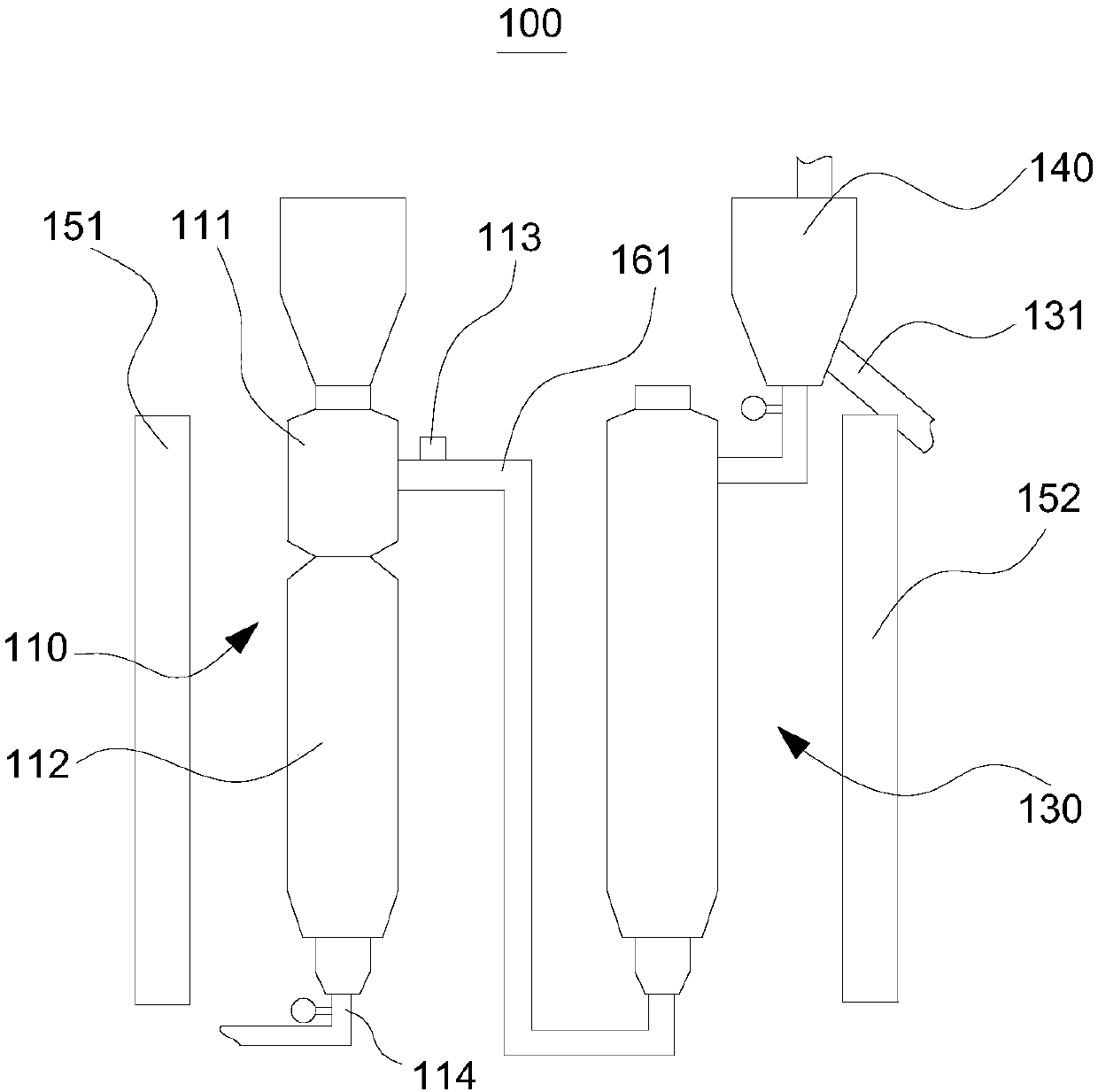

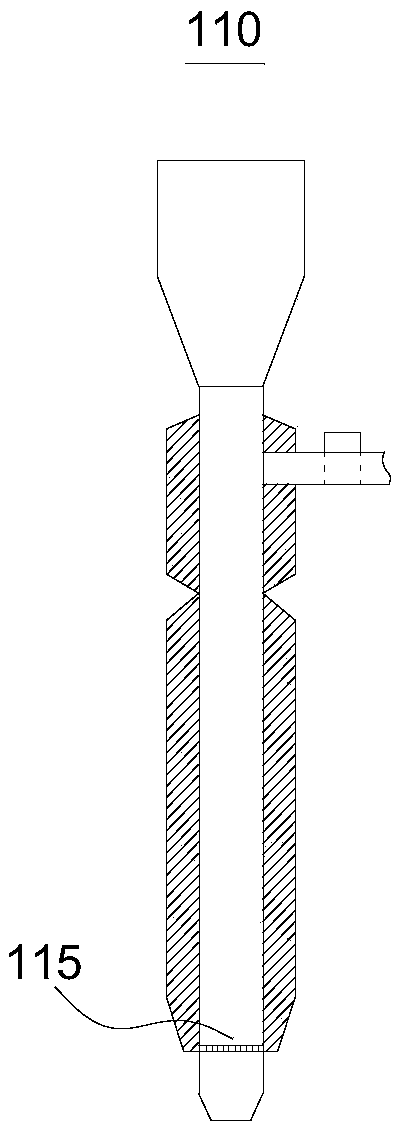

Method and device for preparing carbon nanotubes

PendingCN107720725AImprove qualityHigh magnetizationCarbon compoundsCatalyst activation/preparationFluidized bedCarbon nanotube

The invention relates to the technical field of preparation of carbon nanotubes, and provides a method for preparing the carbon nanotubes. The method comprises the following preparation steps: addingpentacarbonyl iron and tetracarbonyl nickel into a multistage serial fluidized bed, decomposing to obtain a catalyst, and discharging produced carbon monoxide; adding carbon source and inert gas intothe multistage serial fluidized bed, and reacting for 40-90 minutes while heating at 600-800 DEG C, wherein the ratio of the mass of carbon in the carbon source to the mass of the catalyst is 5-7 to 3-5. The composite carbon nanotubes prepared by the method are good in quality, and because of a relatively good mass ratio of the carbon in the produced composite carbon nanotubes to iron-nickel alloy, a method for synthesizing the iron-nickel alloy into the pentacarbonyl iron and the tetracarbonyl nickel can be subsequently used for purifying the composite carbon nanotubes. The invention furtherprovides a device for preparing the carbon nanotubes. The device is used for implementing the method.

Owner:JIANGXI YUEAN SUPERFINE METAL

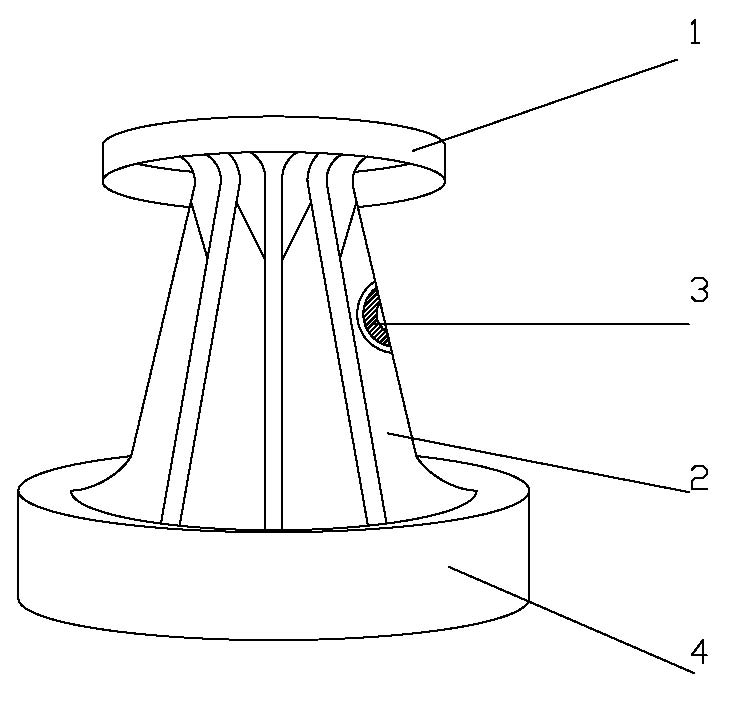

Surface plasma cladding method of metal turbine runner

InactiveCN102230176ALow priceHigh hardnessMetallic material coating processesMolten stateCarbide coating

The invention relates to a surface plasma cladding method of a metal turbine runner. The problems of turbine runner blades such as surface hardness, wear resistance, corrosion resistance, shock resistance and prolonged service life can be effectively solved. The surface plasma cladding method comprises the following steps: a worktable of plasma cladding wear-resistant equipment is started to run so that a plasma torch moves to the position above cladding positions of the turbine runner blades; protective argon and a power supply for the plasma torch are started for arc striking to enter a plasma beam cladding process; under a direct current (DC) plasma beam at high temperature of 10,000-16,000 DEG C, iron-nickel alloy powder is synchronously transferred into the plasma beam of the plasma torch, and then the powder is rapidly heated into a molten or semi-molten state so as to perform mixed diffusion reaction with metal in a molten pool; as the plasma beam moves, the alloy molten pool is rapidly frozen into hard alloy coatings with thickness of 1-10mm; and after completion of cladding operation, grinding or polishing the hard alloy coatings on the surfaces of the blades. The surface plasma cladding method is simple; and by utilizing the method, the blades have the advantages of high hardness, high compactness, wear resistance and long service life.

Owner:王建升

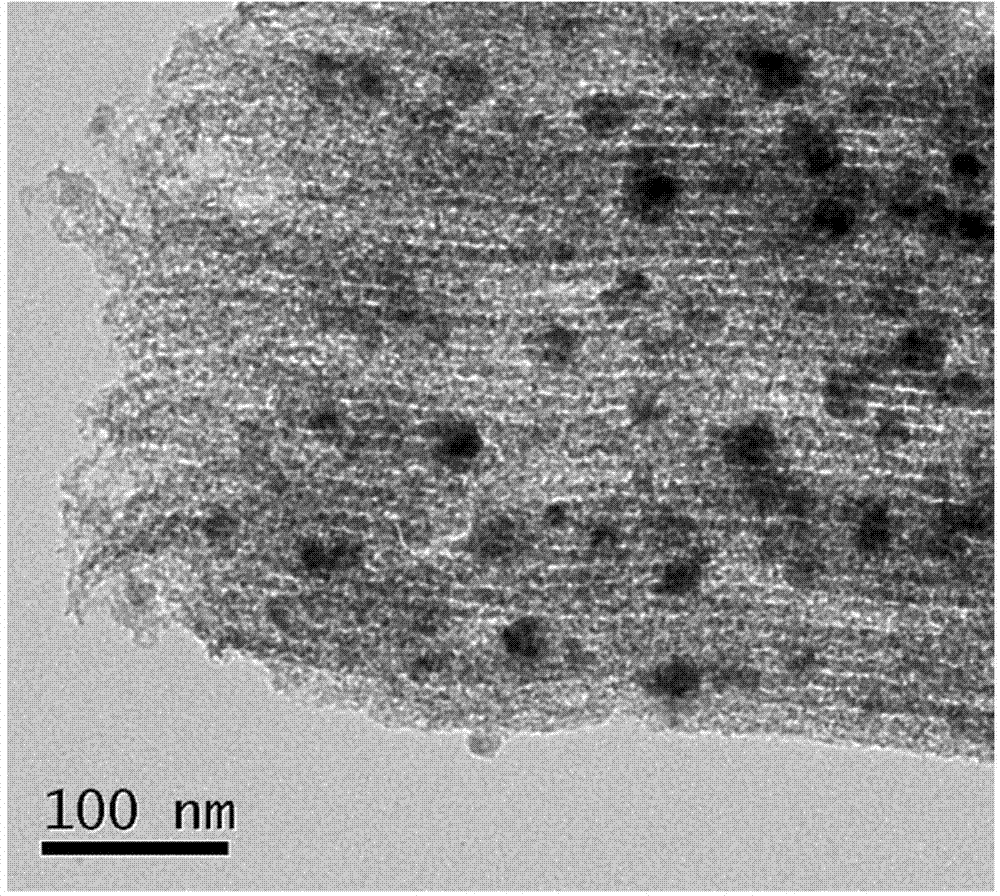

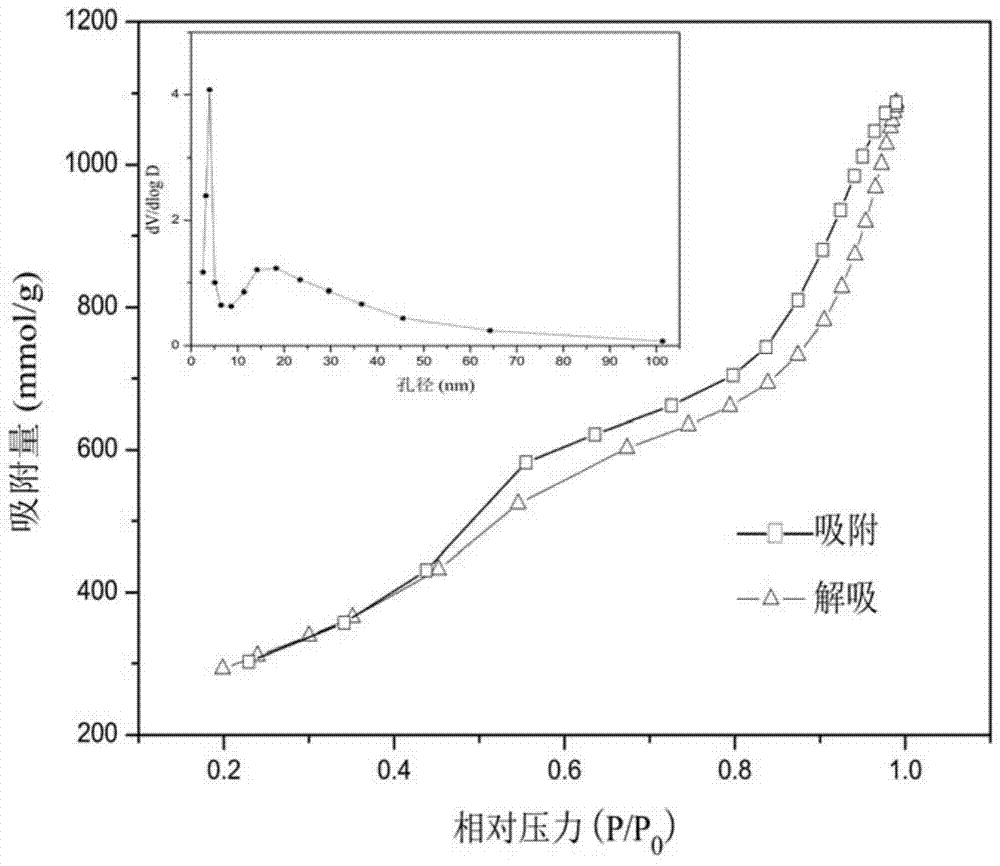

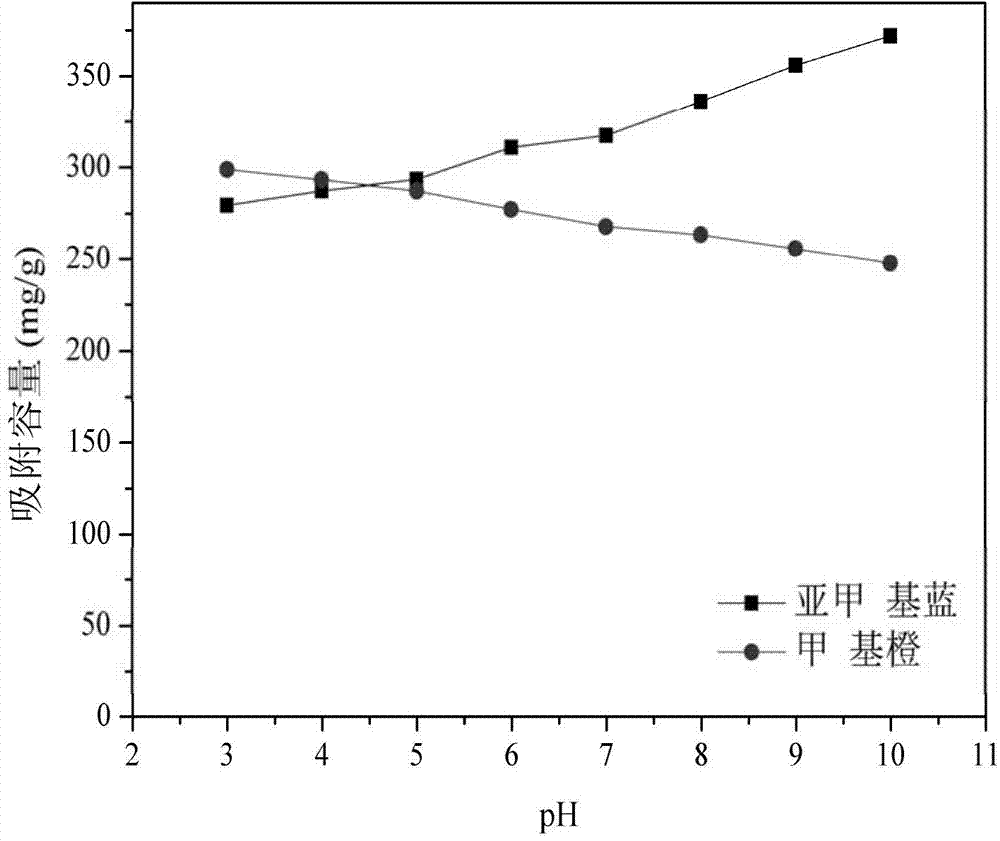

Magnetic two-peak mesoporous carbon containing iron-nickel double metals, preparation method and application thereof

InactiveCN104324690AImprove magnetic propertiesEvenly distributedOther chemical processesAlkali metal oxides/hydroxidesIncipient wetness impregnationMesoporous carbon

The invention discloses magnetic two-peak mesoporous carbon containing iron-nickel double metals, a preparation method and an application thereof. The magnetic two-peak mesoporous carbon adopts magnetic two-peak mesoporous carbon as a carrier, iron-nickle alloy nano particles are dispersed in the magnetic two-peak mesoporous carbon to form an ordered two-peak mesoporous structure with the hole diameters being 4nm-5nm and 15nm-20nm. The preparation method comprises the steps of preparing a mesoporous silicon template, preparing a compound, preparing the magnetic two-peak mesoporous carbon containing the iron-nickel double metals and the like. The invention adopts an initial-wetting impregnation method to prepare the magnetic two-peak mesoporous carbon containing the iron-nickel double metals; the prepared magnetic two-peak mesoporous carbon containing the iron-nickel double metals is large in specific surface area, uniform in distribution of iron-nickle alloy nano particles, difficult in aggregation, excellent in magnetic performance and stable in physicochemical property, can be applied to removal of dyestuff pollutants in water bodies, and has the advantages of large adsorption capacity, high removing efficiency, wide application range, simplicity and convenience in operation, strong practicability and the like.

Owner:HUNAN UNIV

Lubricating and cooling emulsified oil of iron-nickel alloy wire fine drawing and its production

InactiveCN101029269AImprove adsorption capacityReduce wearAdditivesBase-materialsSurface finishParaffin oils

A fine pulling lube cooling emulsified oil of iron-nickel alloy consists of motor oil 56-60wt%, oleic acid 8-12wt%, mersolates 18-22wt%, Turkey red oil 8-12wt%, triethanolamine 4-6wt%, chlorinated paraffin 20-30wt% and bactericide 0.15-0.3wt%. The process is carried out by adding motor oil and chlorinated paraffin into reactor successively, agitating at 600-650 / min while heating to 70-80degree, agitating for 1-2hrs, lowering temperature to 40-50degree, adding mersolates and oleic acid into mixed liquid, agitating at 200-300 / min for 1-2hrs, lowering to normal temperature, adding triethanolamine, Turkey red oil and bactericide into mixed liquid, and agitating at 200-300 / min for 1-2hrs. It can prevent pulling metal from overheat and oxidation coloring and have better finish degree and brightness.

Owner:DALIAN SANDAAOKE CHEM

Columnar coupling compound sucker rod centralizer

InactiveCN102071884AGood and stable self-fluxingImprove the lubrication effectDrilling rodsDrilling casingsCouplingWorking temperature

The invention provides a columnar coupling compound sucker rod centralizer. The centralizer comprises a core rod and a sliding sleeve, wherein the core rod is a hollow cylinder and is provided with an axial via hole in the middle; the via hole is provided with an internal thread suitable for being matched with an external thread of a sucker rod; the sliding sleeve comprises a steel body and a self-lubricating alloy coating; the self-lubricating alloy coating is formed by uniformly mixing 2-6wt% of solid lubrication particles and 94-98wt% of iron-nickel alloy powder; the solid lubrication particles are formed by uniformly mixing MoS2 and WS2; and the iron-nickel alloy powder is prepared from the following components by weight: 0.5-1.1% of carbon, 10-20% of chromium, 1.5-5.5% of silicon, 1.0-4.5% of boron, 25-55% of iron and the balance of nickel. The centralizer has the following advantages: the centralizer has excellent corrosion resistance, wear resistance and self-lubricating property; the use amount of nickel and the cost can be obviously reduced; the service life and the allowable working temperature are substantially improved; the centralizer can well centralize and protect the sucker rods for a long time; and the wear of the oil pipes is reduced.

Owner:黄锦滨 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com