Preparation method for carbon fiber electroplating iron-nickel alloy

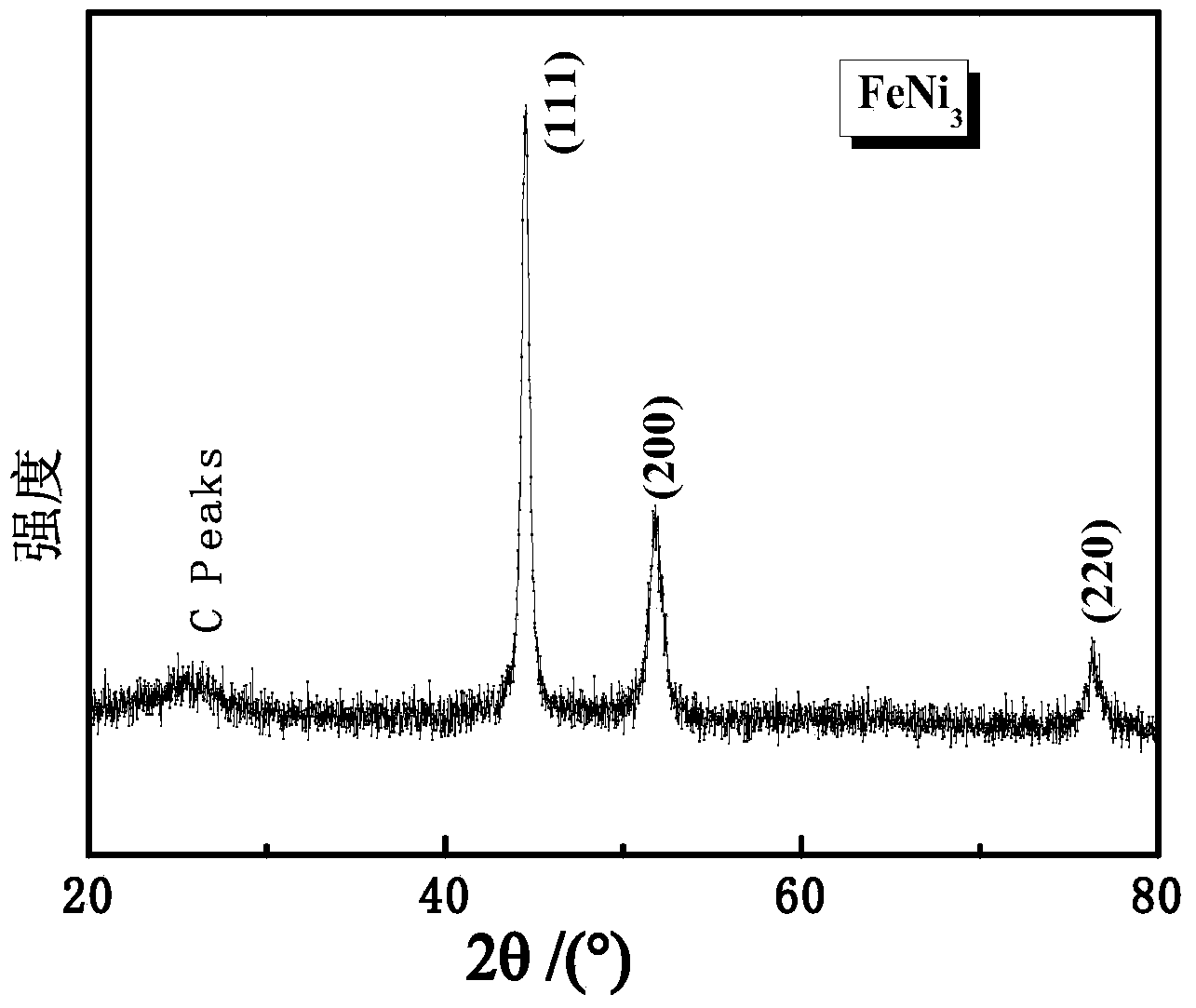

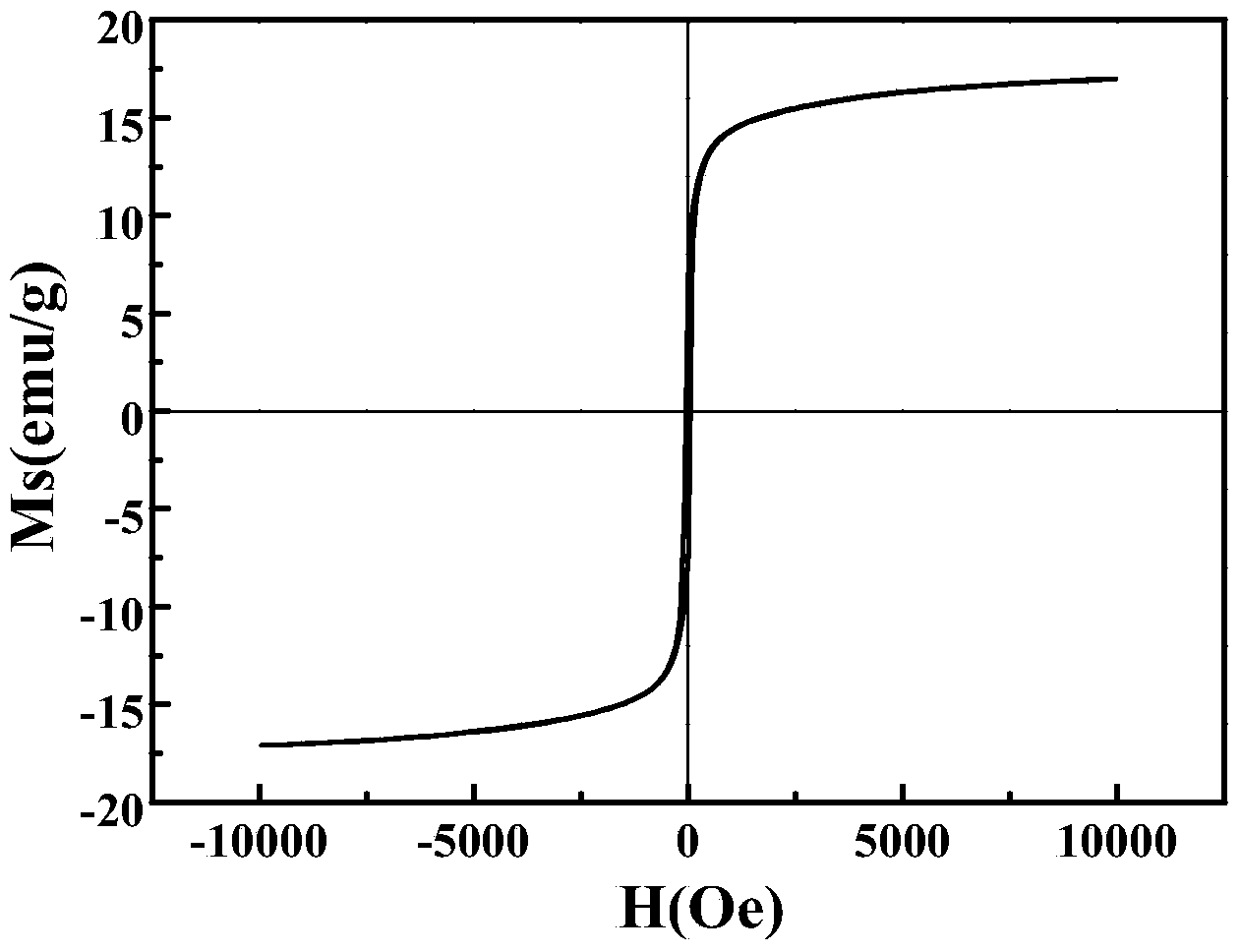

An iron-nickel alloy and carbon fiber technology, which is applied to the preparation field of electroplating iron-nickel alloy on the surface of carbon fiber, can solve the problems of inability to impart magnetism, low coercivity, high magnetic permeability and the like to carbon fiber, and achieves low cost and improved coating adhesion. Powerful and maneuverable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

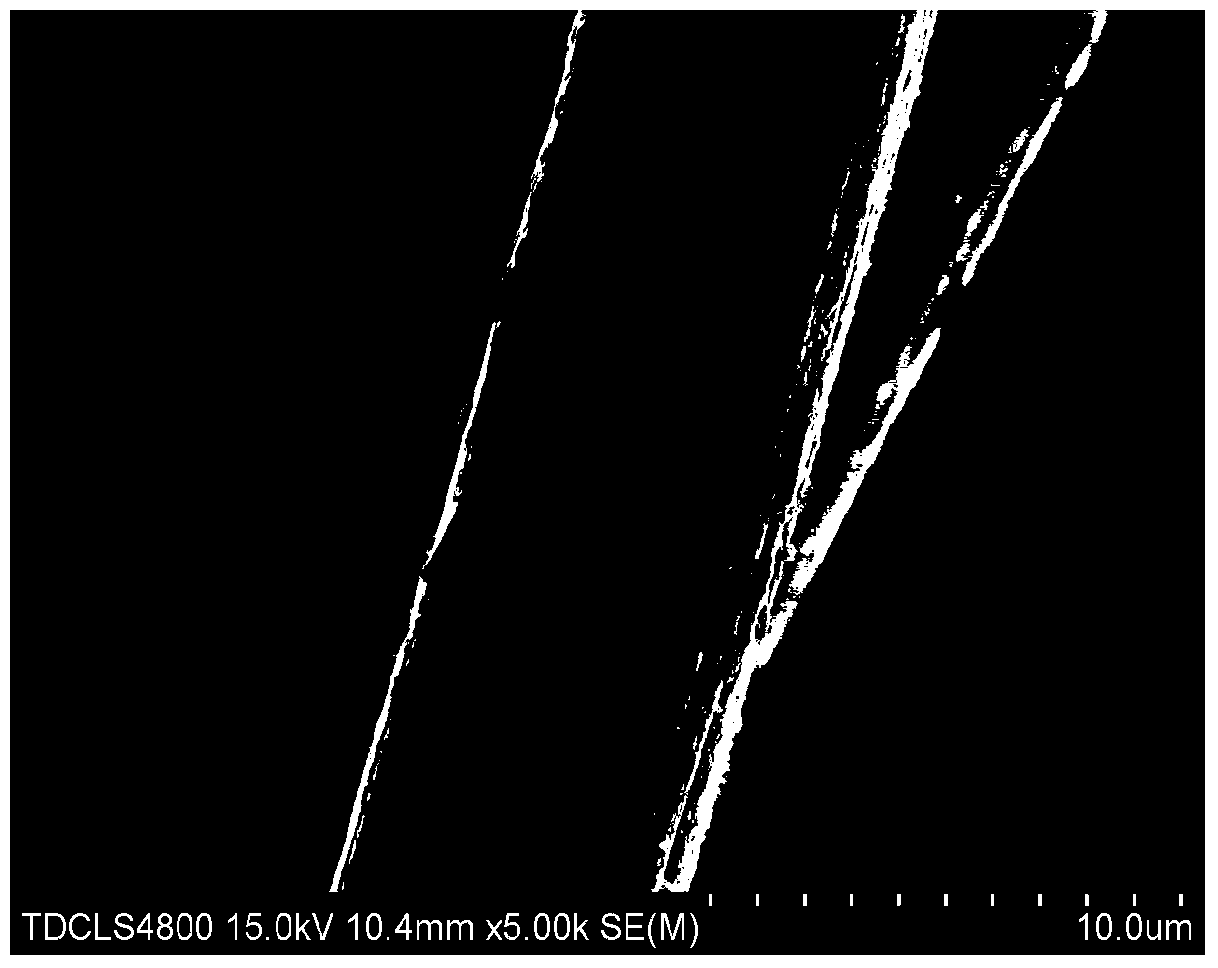

[0021] (1) Degumming and oxidation process 4K carbon fibers with a single filament diameter of 7-8um (a bundle of fibers is 4000 carbon fiber monofilaments) are first soaked in acetone for 24 hours, and then burned in a muffle furnace for degumming and oxidation. Degumming conditions: temperature 400°C, holding time 30min, heating rate 2°C / min, take out after cooling down to room temperature with the furnace after holding.

[0022] (2) The configuration of the electroplating solution is according to the weight ratio, first weigh 90g of NiSO 4 ·6H 2 O, 15g of NiCl 2 ·6H 2 O, 50g of FeSO 4 ·7H 2 O, 17.5g of C 6 h 5 Na 3 o 7 2H 2 O, 1.5g of C 7 h 5 NO 3 S (saccharin) and 20g of H 3 BO 3 Dissolve in 400mL of ultrapure water, stir evenly at room temperature, then weigh 0.2g of C 6 h 5 NaO 2 Dissolve S (sodium benzenesulfinate) in 50mL of ultrapure water, stir evenly with a glass rod, then mix the above two solutions, stir with a glass rod at room temperature for 10...

example 2

[0025] (1) Degumming and oxidation process 4K carbon fibers with a single filament diameter of 7-8um (a bundle of fibers is 4000 carbon fiber monofilaments) are first soaked in acetone for 24 hours, and then burned in a muffle furnace for degumming and oxidation. Conditions for degumming: temperature 400°C, holding time 30 minutes, heating rate 3-4°C / min, and take out with the furnace down to room temperature after holding.

[0026] (2) The configuration of the electroplating solution is according to the weight ratio, first weigh 80g of NiSO 4 ·6H 2 O, 15g of NiCl 2 ·6H 2 O, 40g of FeSO 4 ·7H 2 O, 17.5g of C 6 h 5 Na 3 o 7 2H 2 O, 1.5g of C 7 h 5 NO 3 S (saccharin) and 20g of H 3 BO 3 Dissolve in 400mL ultrapure water, stir evenly at room temperature, then weigh 0.2g of C 6 h 5 NaO 2 Dissolve S (sodium benzenesulfinate) in 50mL of ultrapure water, stir well with a glass rod, then mix the above two solutions, stir with a glass rod at room temperature for 10min,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com