Preparaton method of iron nickel alloy/copper composite wire material

A technology of iron-nickel alloy and composite wire, which is applied in the field of preparation of iron-nickel alloy/copper composite wire, which can solve the problems of high cost, poor air tightness, difficult processing, etc., achieve good electrical conductivity, improve air tightness and output Excellent power and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Taking the 4J50 / CuΦ1.6mm product as an example, the process flow and process parameters adopted in the present invention:

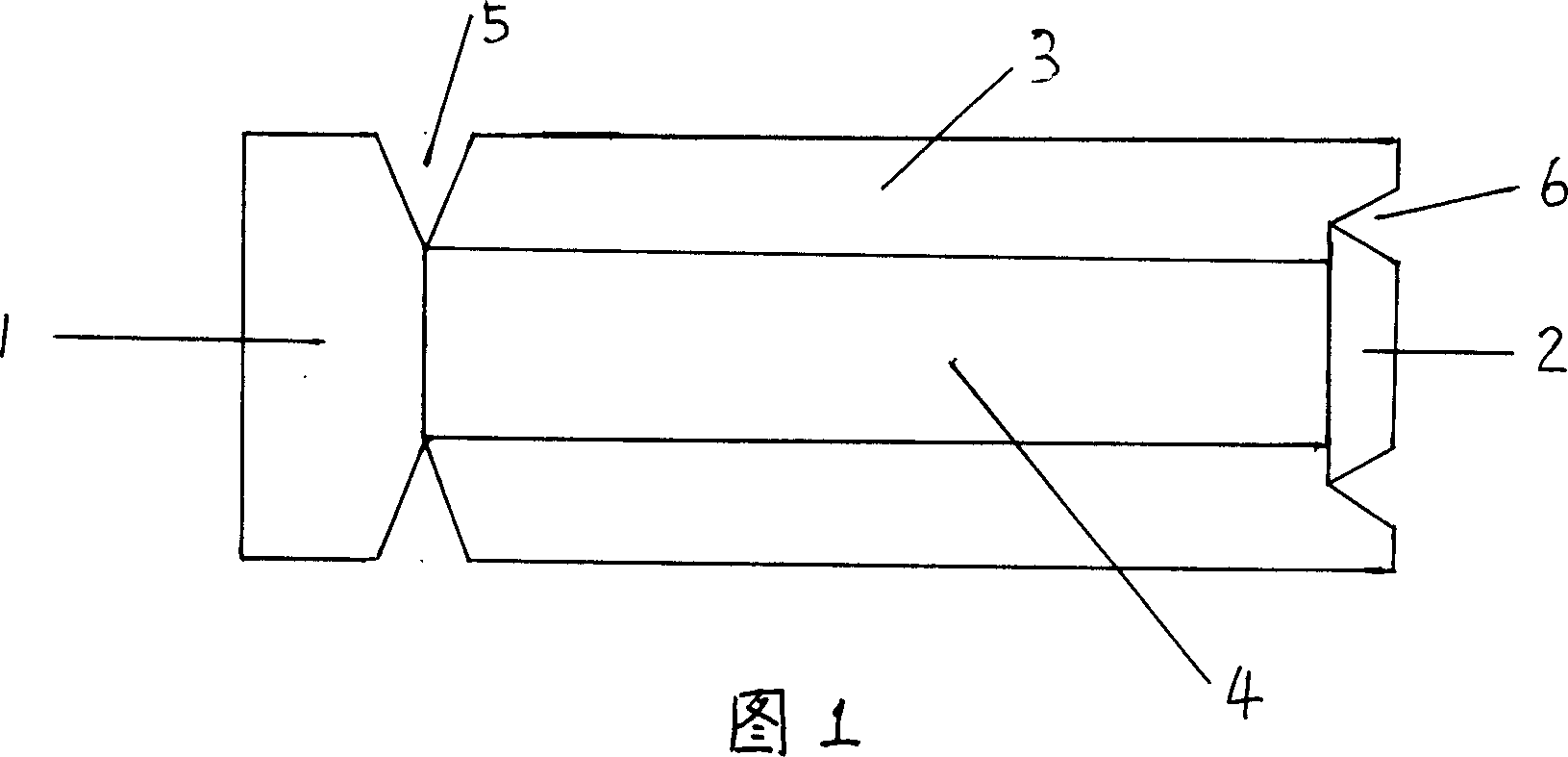

[0023] 1. Billet production: purchased Φ85mm4J50 rods, the size of the wagon is Φ after punching 外 79×Φ 内 32.03×200mm, the copper core is turned to Φ32mm, the size of the front head is Φ76×30mm, the size of the bottom of the conical platform of the rear head is Φ36×10mm, and the welding part is turned into a V-shaped mouth for welding. After pretreatment, cleaning and drying, the oxygen-free copper core is embedded in the expansion alloy cylinder with a hydraulic press or a jack, and then welded with the front and rear heads to form a composite ingot.

[0024] 2. Thermal diffusion treatment: use a vacuum furnace to conduct thermal diffusion treatment at a temperature of 940°C-970°C for 2.5 to 3 hours, and then cool slowly with the furnace to below 400°C.

[0025] 3. Hot extrusion: use a 500T extruder to extrude the billet, use a cone die and a co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com