Numerical-control machine tool capable of realizing non-rotary curved-surface turning and milling combined machining

A compound processing and CNC machine tool technology, applied in the field of CNC machine tools, can solve the problems of reduced processing efficiency, difficult turning surface turning, high acceleration, etc., and achieve the effect of meeting high acceleration requirements, ensuring surface finish, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

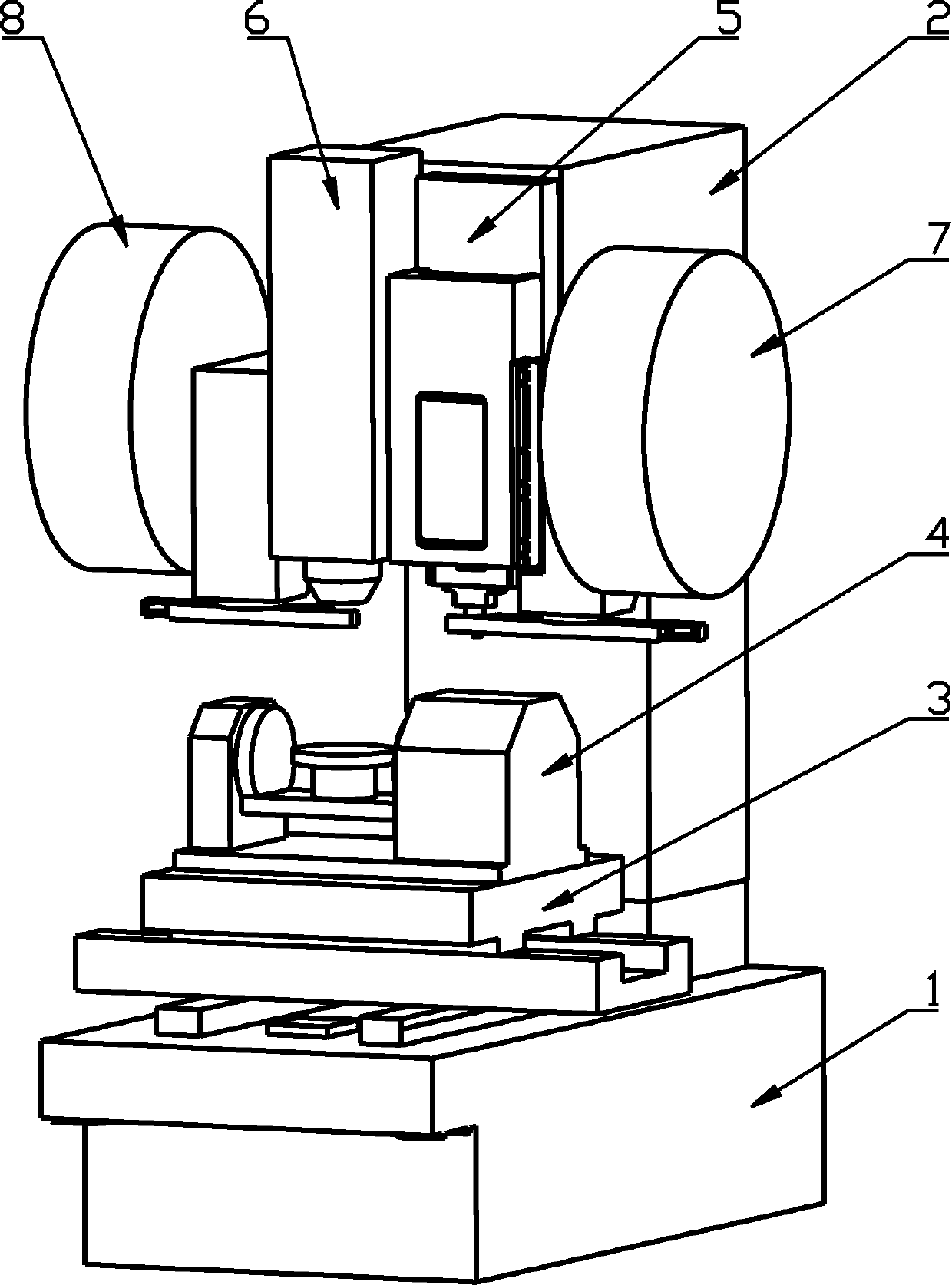

[0016] to combine figure 1 and figure 2 As shown, a kind of numerically controlled machine tool of the present invention that can realize non-revolving curved surface turning and milling composite processing consists of a bed 1, a cantilever column 2, a cross slide table 3, a biaxial rotary table 4, a turning head 5, The milling head 6, the turning tool magazine 7 and the milling cutter magazine 8 are composed.

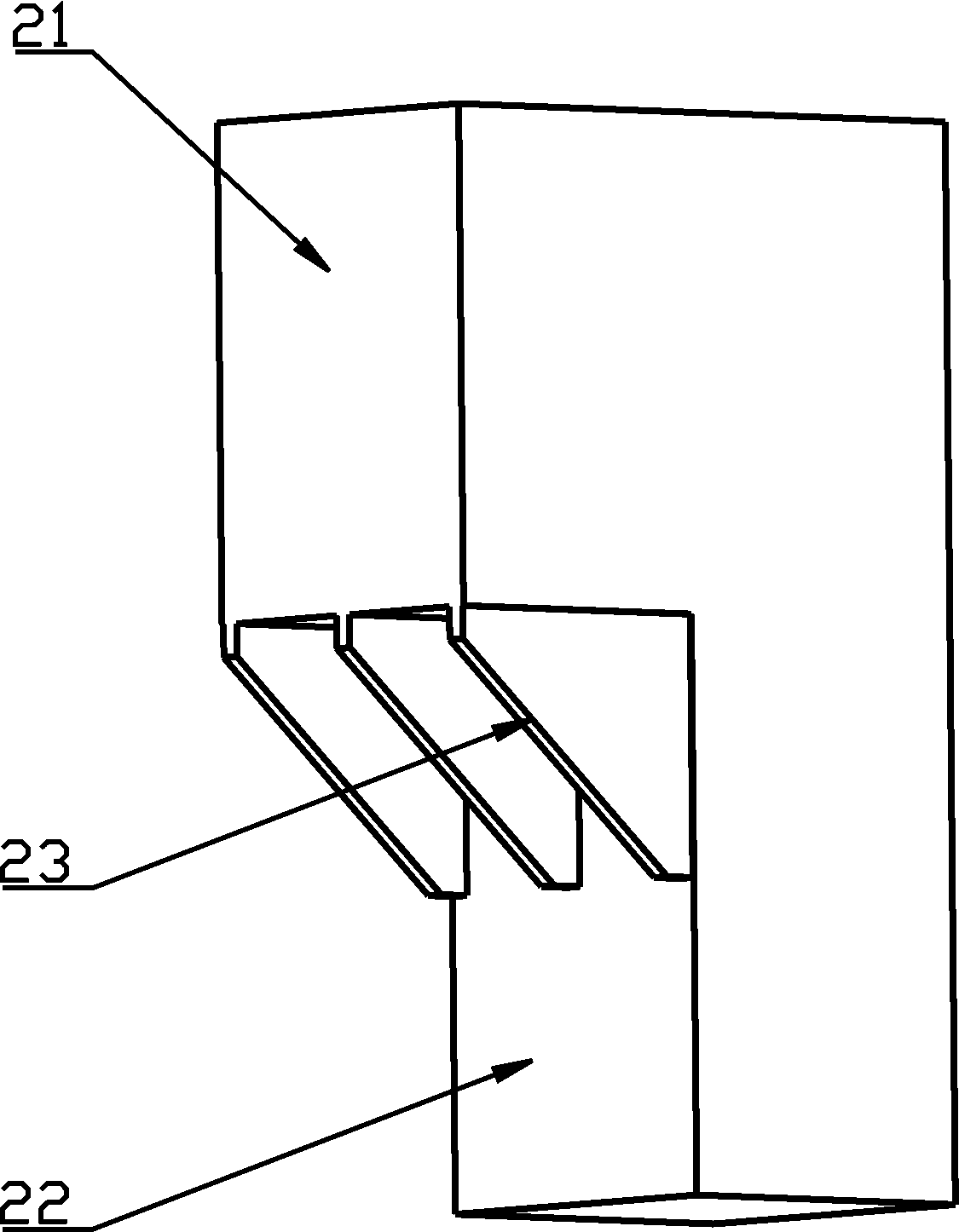

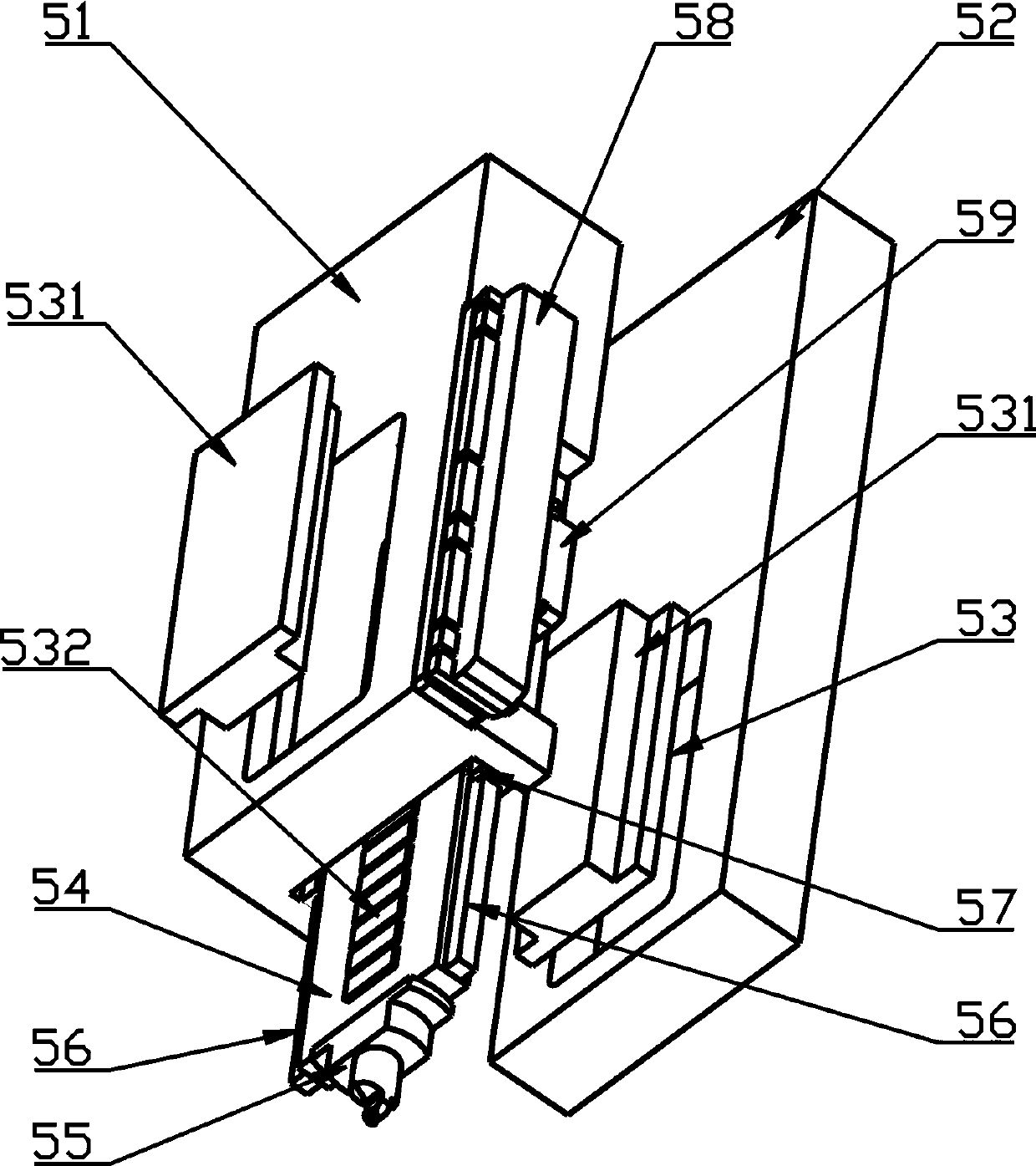

[0017] The cantilever column 2 includes a cantilever end 21 and a column end 22, the cantilever end 21 is located above the column end 22, and forms an inverted L-shaped structure with the column end 22, and the column end 22 is fixed on the bed 1; For rigidity, a reinforcing rib 23 is provided between the cantilever end 21 and the column end 22 . The cross slide table 3 is installed on the bed 1, and the double-axis rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com