Stamping die structure for circumferential bolts and longitudinal bolts for rail transit

A technology of circumferential bolts and longitudinal bolts, which is applied in the field of mechanical equipment, can solve the problems of increased workload, low production efficiency, and high production costs, and achieve the effects of reliable operation, long service life, and improved product quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

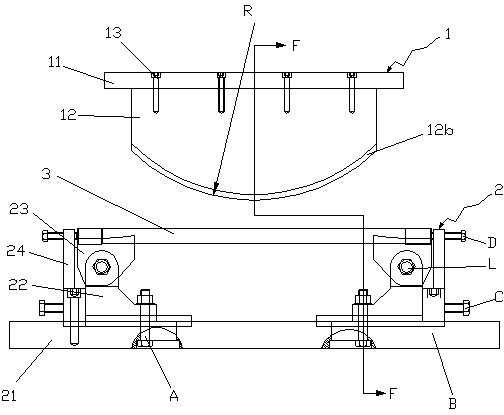

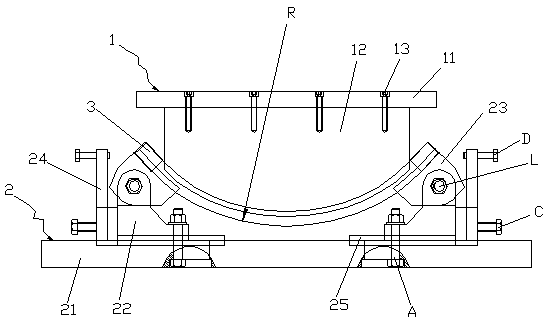

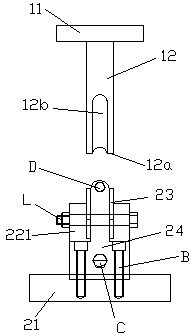

[0024] Figure 1 to Figure 6 Shown is the structural representation of the present invention.

[0025] The reference signs are: bracket fixing bolt A, backing fixing bolt B, bracket adjusting bolt C, upper adjusting bolt D, bracket pin shaft L, upper stamping die 1, upper stamping top plate 11, upper stamping template 12, stamping contact surface 12a, stamping upper groove arc 12b, upper die fixing screw 13, lower stamping die 2, stamping die bottom plate 21, strip-shaped sliding hole 21a, guide positioning groove 21b, backing positioning groove 21c, stamping movable block bracket 22, positioning hole 22a, guide chute 22b, support lug 221, stamping movable block 23, stamping support surface 23a, stamping lower groove arc 23b, backing adjustment plate 24, bracket positioning key 25, stamping product 3.

[0026] Such as Figure 1 to Figure 6 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com