Preparation method of fibrous iron-nickel alloy powder

An iron-nickel alloy and fibrous technology, which is applied in the field of preparation of fibrous iron-nickel alloy powder, can solve the problems of unreported research and less research on fibrous iron-nickel alloy powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

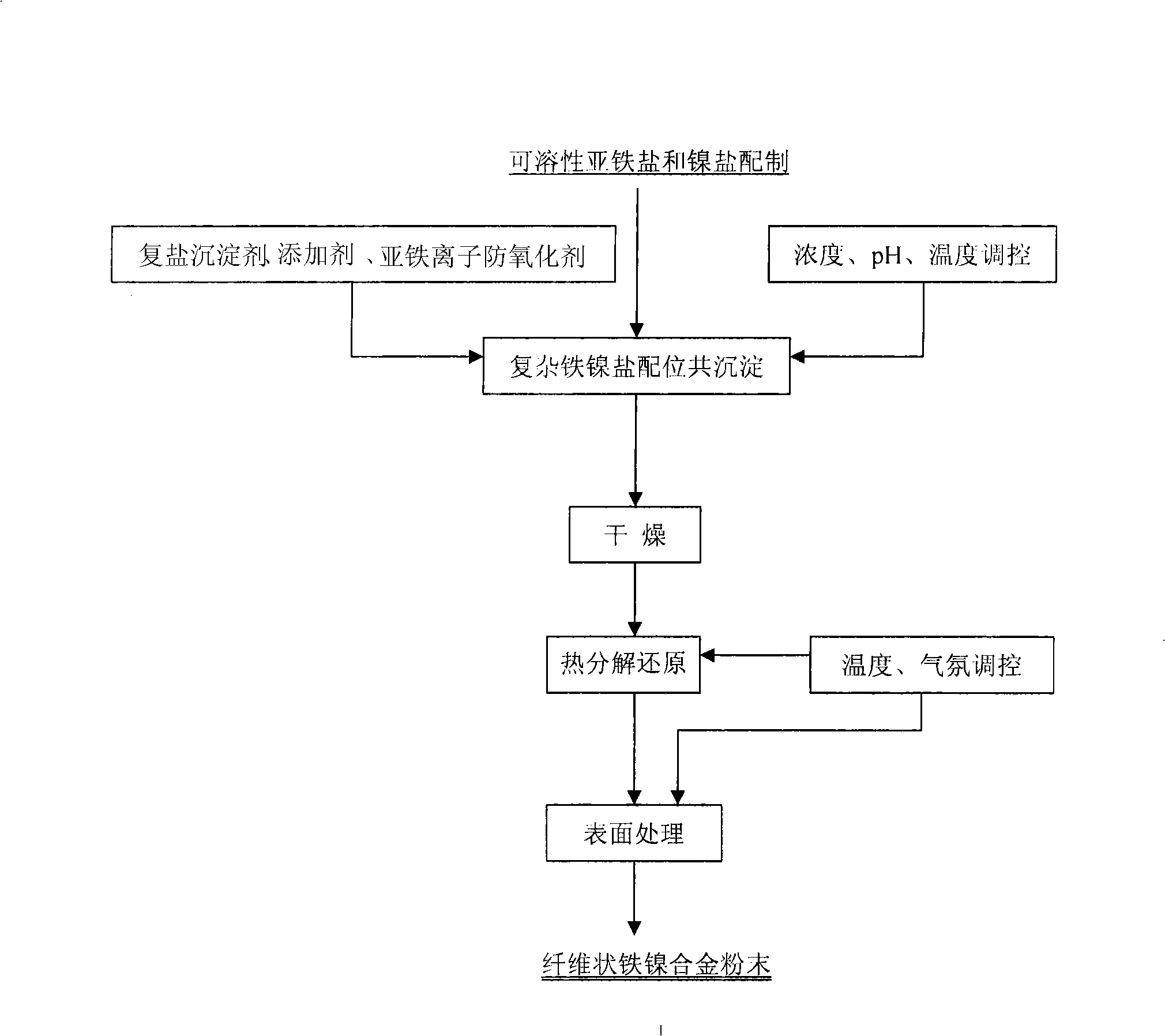

[0021] figure 1 The preparation process of fibrous iron-nickel alloy powder is described:

[0022] ① firstly mix the soluble nickel salt and ferrous salt solution evenly in proportion, then mix the mixed solution with stoichiometric oxalic acid and ethylenediamine, polyvinylpyrrolidone (0.5wt%), citric acid (1wt%) and ascorbic acid (2wt%) %) The compound precipitant solution that constitutes is added in the reactor through feeding device, in Ni 2+ -Fe 2+ -H 2 NCH 2 CH 2 NH 2 -(H 3 NCH 2 CH2 NH 3 ) 2+ -SG n- -C 2 o 4 2- -H 2 Composite precipitation transformation is carried out in the O system, where SG n- Represents Cl - , SO 4 2- , NO 3 - 、CH 3 COO - , the temperature is controlled at 50-60°C, the pH is about 6.1, and the initial total concentration of iron-nickel ions in the feed liquid is 0.4-1.0mol / L

[0023] ② After the reaction is completed, the composite precipitate obtained after washing, filtering and drying is the precursor of the iron-nickel a...

Embodiment 1

[0030] The nickel-iron mol ratio is 1: 1 to be the nickel sulfate solution and the ferrous sulfate solution, and then the mixed solution is mixed with oxalic acid, ethylenediamine, polyvinylpyrrolidone (0.5wt%) (polyvinylpyrrolidone is analytically pure, and The composite precipitant solution that group chemical reagent factory produces), citric acid (1wt%) and ascorbic acid (2wt%) is added in the reactor through feeding device, in Ni 2+ -Fe 2+ -H 2 NCH 2 CH 2 NH 2 -(H 3 NCH 2 CH 2 NH 3 ) 2+ -SO 4 2- -C 2 o 4 2- -H 2 Coordination co-precipitation is carried out in the O system, the temperature is controlled at about 60°C, the pH is adjusted to about 6.1 with ethylenediamine, and the initial Ni in the feed solution 2+ and Fe 2+ The total concentration is 0.6mol / L, C 2 o 4 2- It is 0.72mol / L.

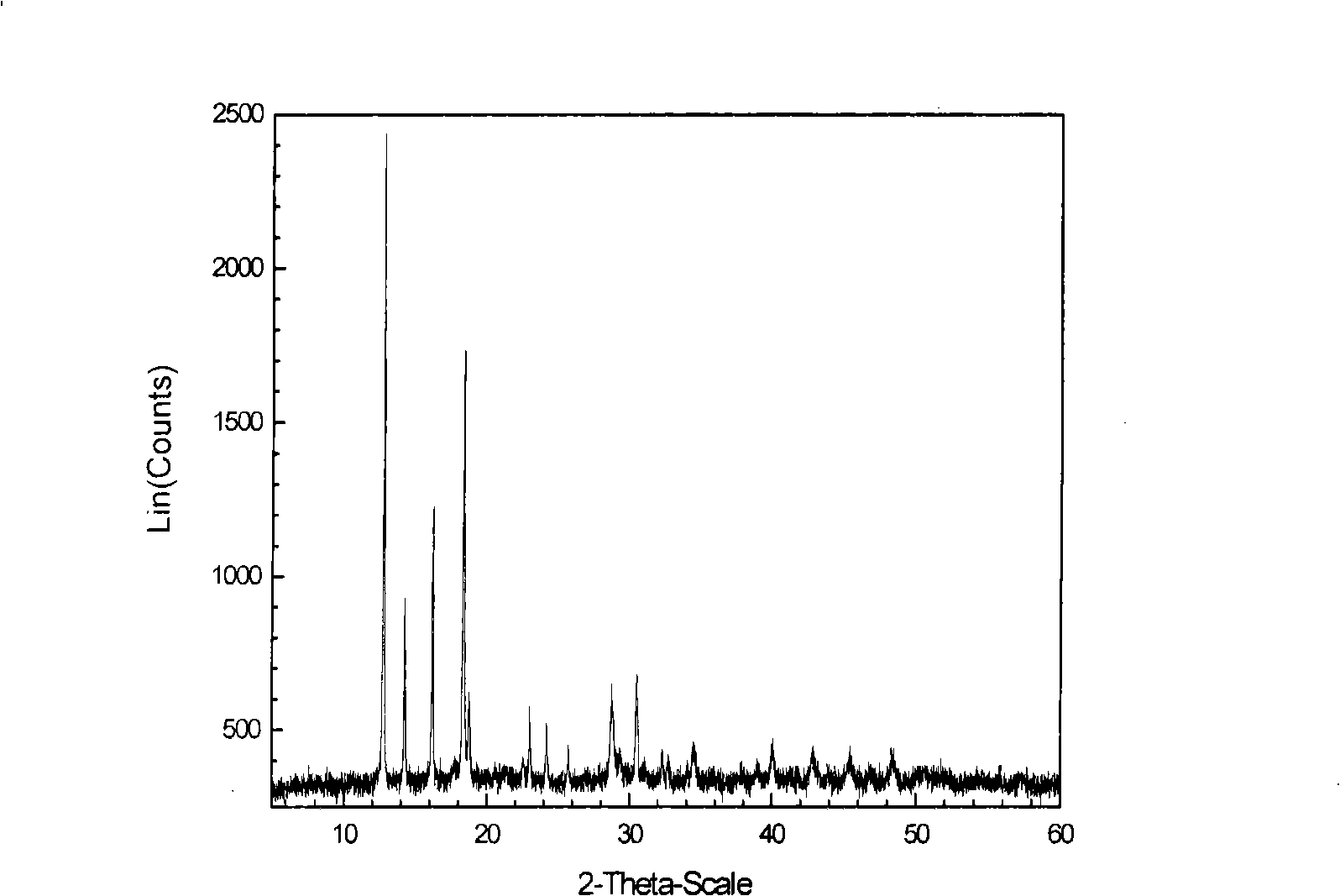

[0031] After the reaction is completed, the obtained composite precipitate is washed, filtered and dried to become the precursor of iron-nickel alloy powder. After tha...

Embodiment 2

[0033] The nickel-iron mol ratio is 7: 3 nickel chloride solution and ferrous chloride are uniformly mixed, then mixed solution is mixed with oxalic acid, ethylenediamine, polyvinylpyrrolidone (0.5wt%), citric acid (1wt%) and ascorbic acid (2wt%) The composite precipitant solution of composition adds in the reactor through feeding device, in Ni 2+ -Fe 2+ -H 2 NCH 2 CH 2 NH 2 -(H 3 NCH 2 CH 2 NH 3 ) 2+ -Cl - -C 2 o 4 2- -H 2 Coordination co-precipitation is carried out in the O system, the temperature is controlled at about 55°C, the pH is adjusted to about 6.1 with ethylenediamine, and the initial Ni in the feed solution 2+ and Fe 2+ The total concentration is 0.8mol / L, C 2 o 4 2- It is 0.88mol / L.

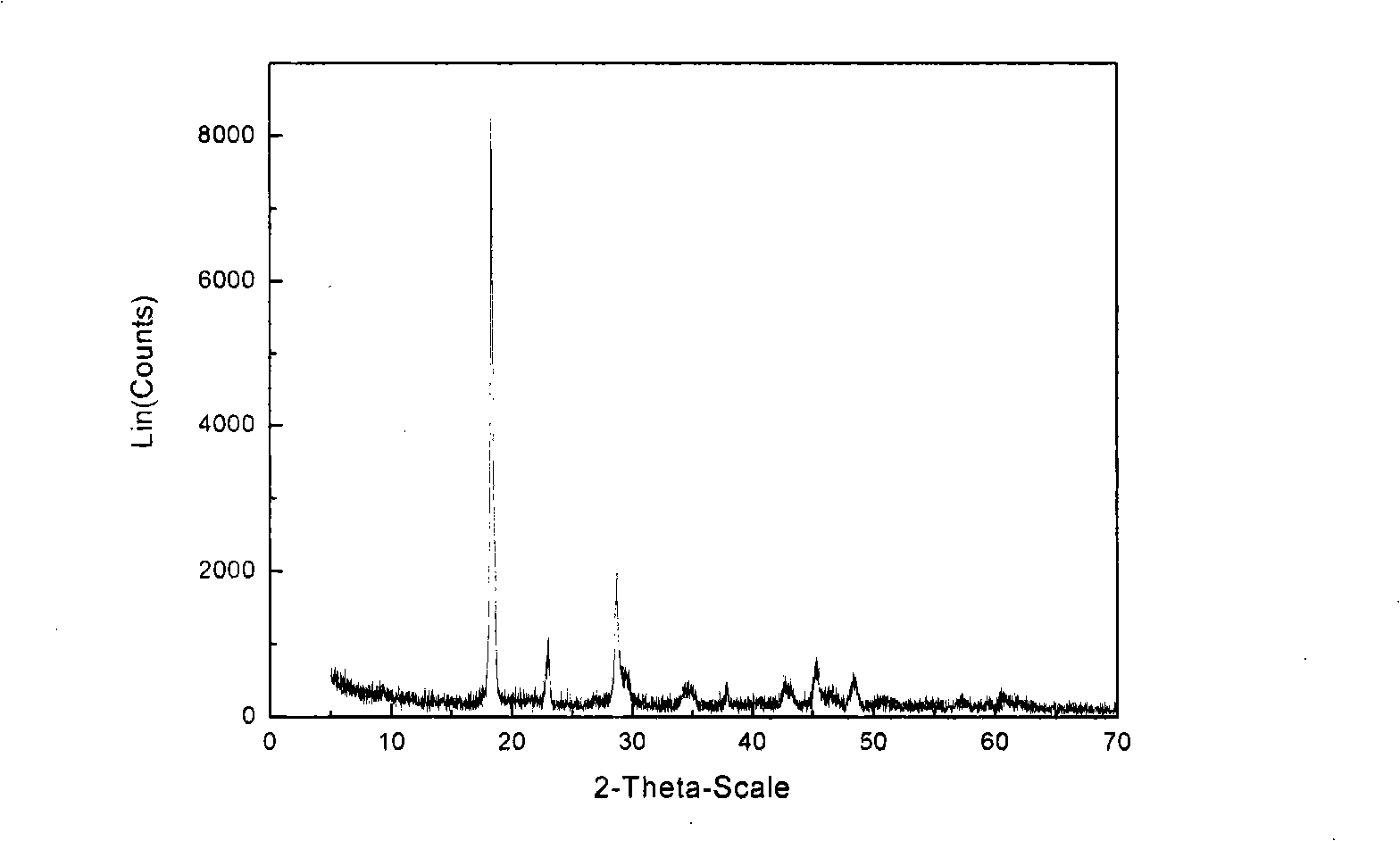

[0034] After the reaction is completed, the obtained composite precipitate is washed, filtered and dried to become the precursor of iron-nickel alloy powder. After that, the precursor is put into a burning boat and placed in a PID-regulated electric furnace. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com