Micro-alloyed high-strength anti-oxidization iron-nickel alloy gas valve steel material and preparation method

A micro-alloying and high-strength technology, applied in the field of materials, can solve the problems of high Ni content, high cost and short life, and achieve the effects of widening the rolling temperature zone, improving the yield and good plasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

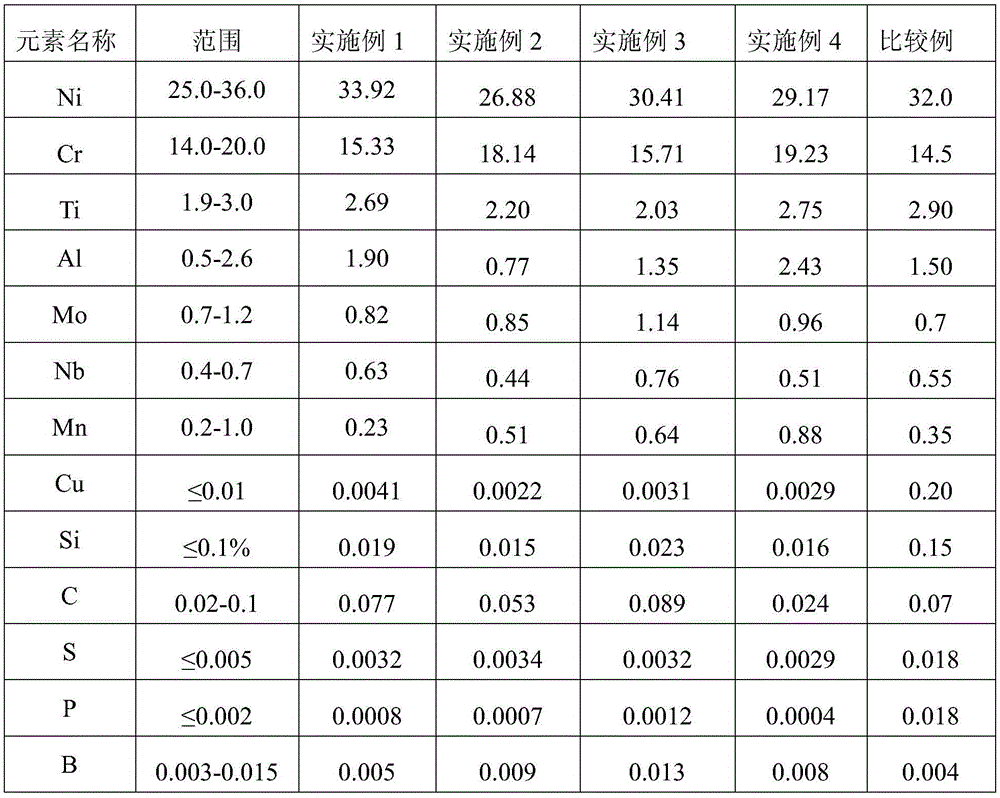

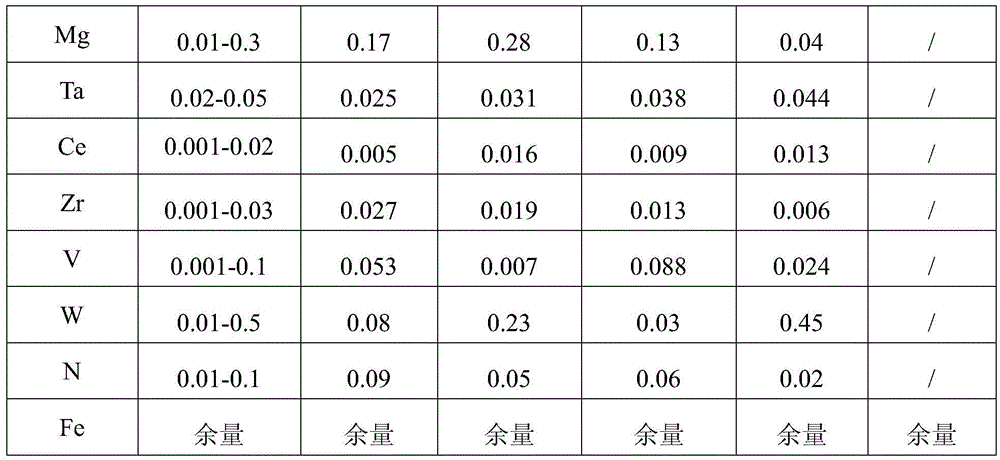

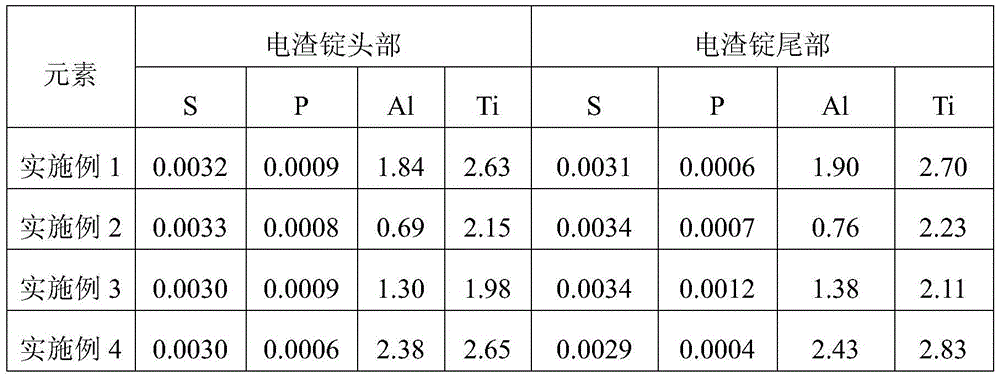

[0057] According to the proportioning described in table 1, get each component described in the present invention, prepare the material shown in the present invention as follows:

[0058] Table 1 chemical composition list (wt%)

[0059]

[0060]

[0061] Note: The comparative example is Ni30, a commercially available valve steel alloy material.

[0062] 1) Preparation of electrode rod

[0063] Take the above-mentioned components according to the ratio in Table 1, and dry them at 200°C for 4 hours to preheat and dry the water vapor. Ni, Cr, Fe, Nb, Ta, W, C are loaded into the crucible of the furnace as large materials, vacuumed to transmit power, and the power transmission power is slowly increased as the vacuum degree continues to increase. When the vacuum degree is better than 20Pa, the power is increased to 650kw until all the large materials are melted, and then the first refining is carried out, the refining power is 500kw, the refining time is 60min, and the vacu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com