Patents

Literature

48results about How to "Improve high temperature deformation resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Asphalt and SBS compatibility evaluation method based on molecular dynamics simulation

PendingCN110489858AImprove high temperature deformation resistanceSolving Segregation ProblemsBuilding insulationsSpecial data processing applicationsSolubilityInteraction energy

The invention relates to an asphalt and SBS compatibility evaluation method based on molecular dynamics simulation, belongs to the technical field of modified asphalt compatibility, and mainly solvesthe problem that no specific and accurate method for evaluating the compatibility of SBS and asphalt exists at present. A molecular dynamics simulation method is used as a basis. The method comprises:using molecular dynamics simulation software, respectively constructing a single asphalt system unit cell model, an SBS block copolymer molecular structure model and an SBS modified asphalt blendingsystem model, respectively carrying out molecular dynamics simulation on the models, calculating to obtain solubility parameters and interaction energy, and characterizing and evaluating the compatibility of SBS and asphalt by taking the solubility parameters and interaction energy as indexes. The compatibility evaluation method disclosed by the invention provides an idea for researching the compatibility mechanism of the SBS and the asphalt. The method provides guidance for the establishment of a modified asphalt compatibility evaluation system and an evaluation system thereof, provides a theoretical basis for the formula of the SBS modifier, and has very important significance for solving the problem of asphalt segregation and improving the stability of the modified asphalt.

Owner:NANJING FORESTRY UNIV

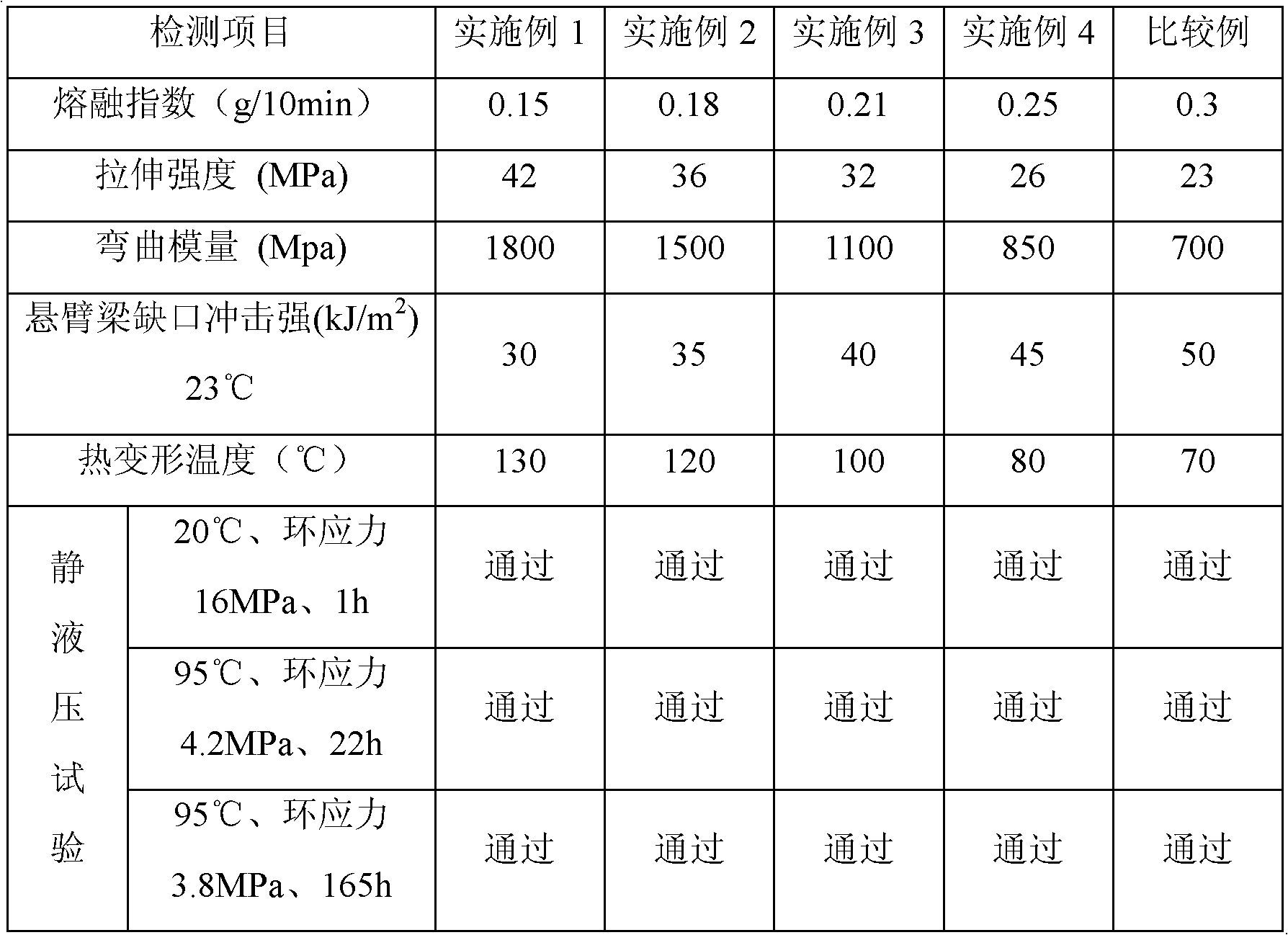

High temperature deformation-resistant modified polypropylene random (PPR) copolymer tube and preparation method thereof

InactiveCN103214743AImprove high temperature deformation resistanceLow costRigid pipesPolymer sciencePolypropylene

The invention relates to a high temperature deformation-resistant modified polypropylene random (PPR) copolymer tube and a preparation method thereof. The high temperature deformation-resistant modified PPR copolymer tube comprises, by weight, 60 to 90 parts of a PPR copolymer special-purpose material, 10 to 40 parts of talcum powder, 0.2 to 0.6 parts of an alpha nucleating agent and 0.3 to 0.6 parts of an anti-oxidant. The alpha nucleating agent and the talcum powder improve high temperature deformation resistance of a PPR tube special-purpose material. The talcum powder reduces a PPR tube cost. The preparation method has simple processes and can be realized easily.

Owner:HEFEI GENIUS NEW MATERIALS

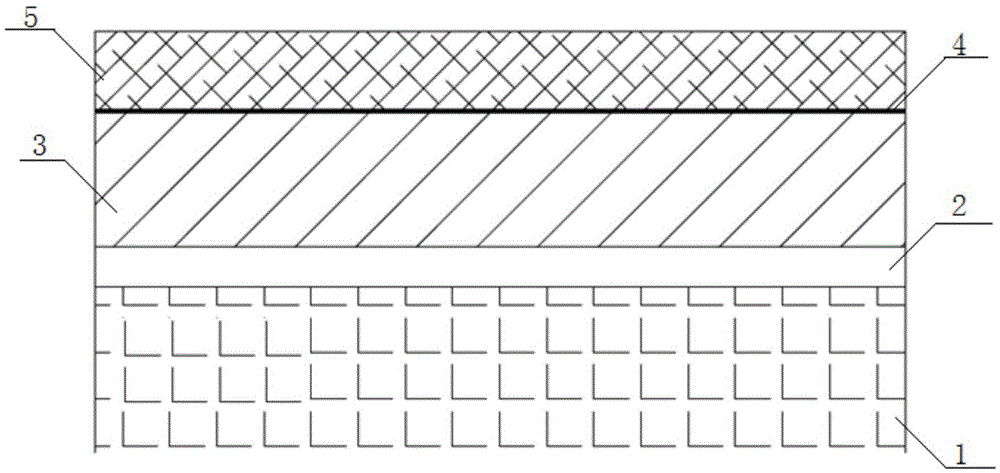

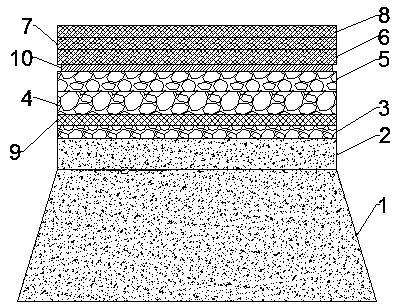

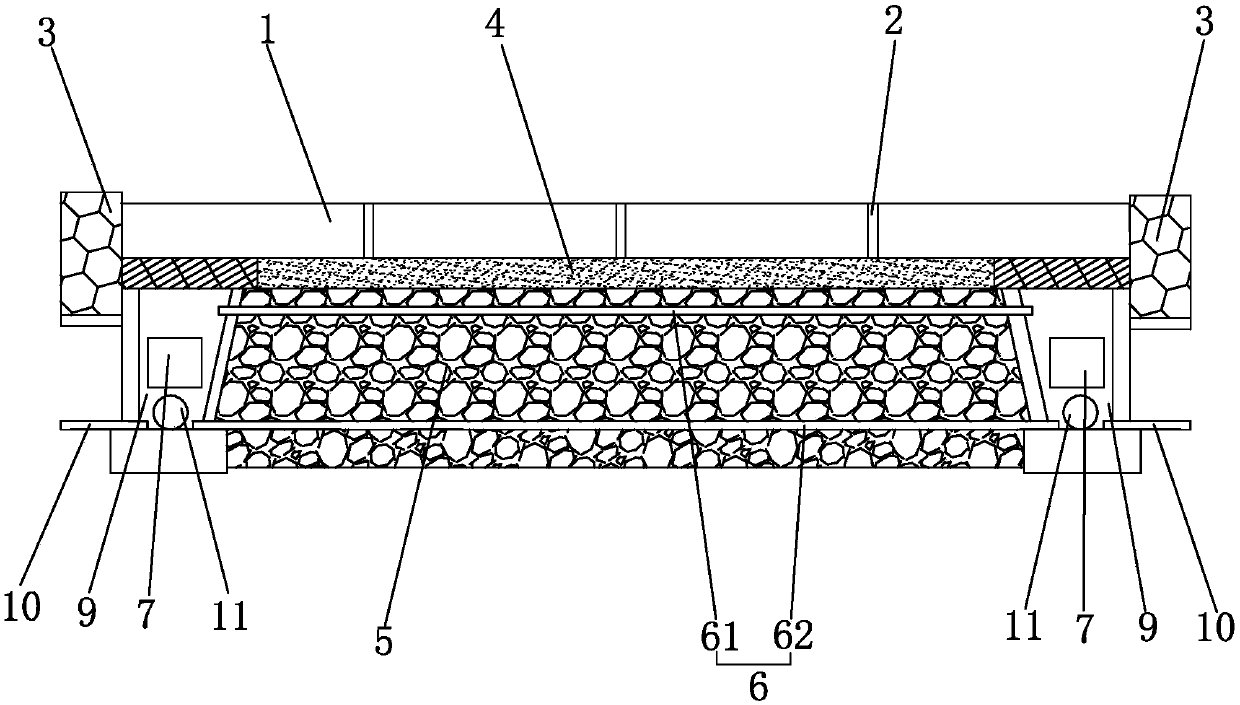

Durable cement concrete bridge deck pavement structure with noise reduction and water drainage functions

InactiveCN105648910AHigh modulusImprove high temperature deformation resistanceBridge structural detailsBridge deckRoad surface

The invention discloses a durable cement concrete bridge deck pavement structure with noise reduction and water drainage functions. A high-performance cold-paved waterproof bonding layer is arranged on the upper surface of a treated concrete bridge deck, the high-performance cold-paved waterproof bonding layer is paved with durable high-modulus asphalt concrete, a waterproof layer is arranged on the upper surface of the durable high-modulus asphalt concrete, and the upper surface of the waterproof layer is paved with an anti-skidding noise reduction and water drainage wear thin layer. The modulus of the asphalt concrete is increased through the durable high-modulus asphalt mixture, deformation of the road surface structure under the effect of vehicle loads is relieved, high-temperature deformation resistance of the road surface is improved, and generation of ruts is delayed. The high-performance waterproof bonding layer material is adopted, attention is paid to treatment of the concrete bridge deck, and bonding durability of the waterproof layer, an asphalt pavement surface layer and a cement concrete board is improved. Noise of the road surface can be lowered to a certain degree through the anti-skidding noise reduction and water drainage wear thin layer, water accumulated on the road surface is eliminated, driving safety is improved, and good social benefits are achieved.

Owner:JSTI GRP CO LTD

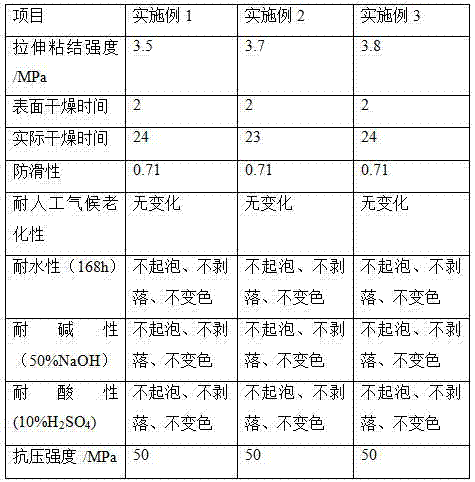

Modified fiber asphalt rubber paste

The invention discloses a modified fiber asphalt rubber paste, which belongs to the technical field of a building material. According to the invention, silicon nitride whiskers and hydrofluoric acid are mixed for immersion, a mixture is filtered, washed, and dried to obtain pretreated silicon nitride whiskers, the pretreated silicon nitride whiskers, secondary sedimentation tank sludge, sucrose, and a sodium alginate solution are mixed and fermented, the mixture is filtered, washed, dried, and carbonized to obtain modified silicon carbide whiskers; the rice husk fiber is pulverized and sievedto obtain fine rice husk fiber, the rice husk fiber, a biogas slurry, a glucose solution, and the water are mixed and fermented, and the mixture is filtered to obtain a pretreatment fiber, the pretreated fiber is mixed with a sodium hydroxide solution for immersion, and the mixture is frozen, sieved, melted, and dried to obtain a modified fiber; asphalt, mixed mineral powder, the modified siliconcarbide whisker, phospholipid, rubber powder, organic silicon resin, the modified fiber and the waste oil are heated, and the materials are stirred to obtain the modified fiber asphalt rubber paste.

Owner:江苏雨梦建设有限公司

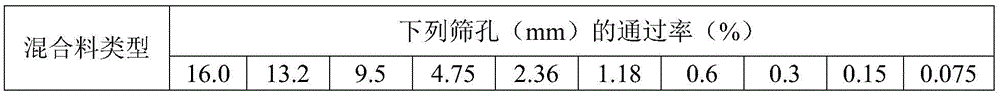

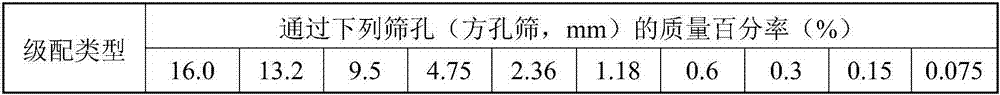

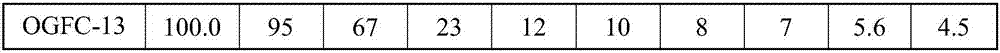

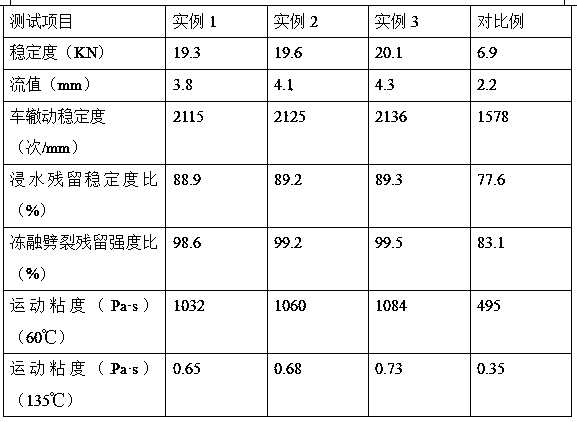

Multifunctional permeable asphalt mixture and preparation method thereof

The invention discloses a multifunctional permeable asphalt mixture and a preparation method thereof. The multifunctional permeable asphalt mixture comprises the following components in parts by mass: 100 parts of mineral aggregate, 4-6 parts of modified asphalt and 0.1-0.5 part of a fiber stabilizer, wherein the mineral aggregate is composed of coarse aggregate, fine aggregate, infiltration materials and mineral powder; the modified asphalt is composed of 100 parts of matrix asphalt, 4-8 parts of SBS, 8-12 parts of waste rubber powder, 0.4-0.9 part of MWCNT (Multi Walled Carbon Nanotubes) and 2-5 parts of a tackifier; and the fiber stabilizer is one of lignin fibers, mineral fibers or polyester fibers. According to the multifunctional permeable asphalt mixture provided by the invention, the mineral aggregate contains the infiltration materials, and the infiltration materials refer to low-cost and readily-available materials such as volcanic, activated carbon, ceramsite, zeolite or crab shell-clam shell powder and the like, so that rainfall runoff pollution can be effectively controlled, the aims of fully utilizing rainwater resources and supplementing groundwater resources are achieved, and the preparation cost can be effectively reduced. The used modified asphalt is compounded by the MWCNT and SBS, so that the shear deformation resistance of the asphalt can be obviously improved.

Owner:南京交科瑞路技术有限公司

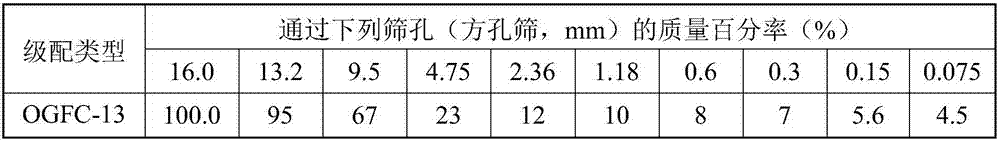

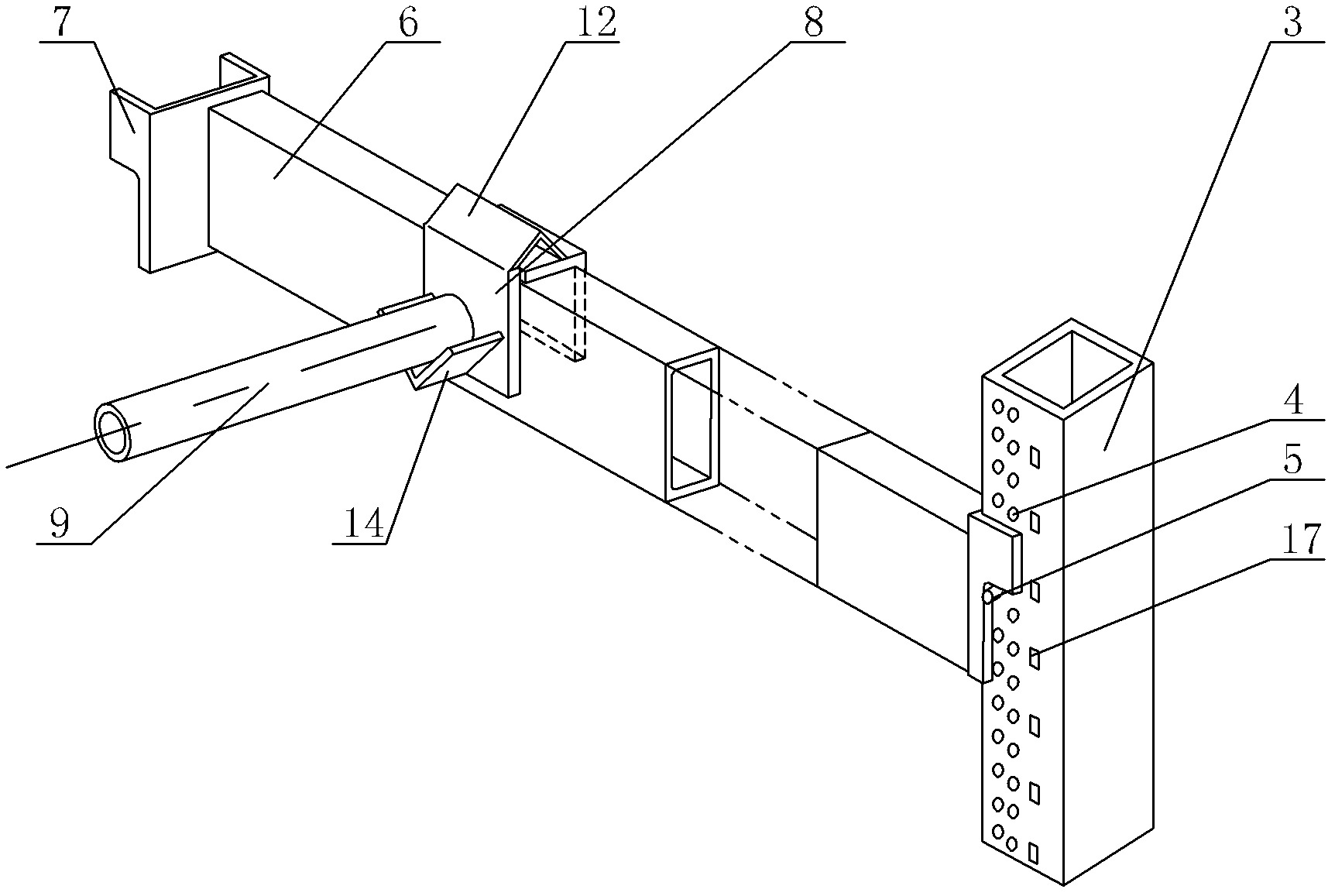

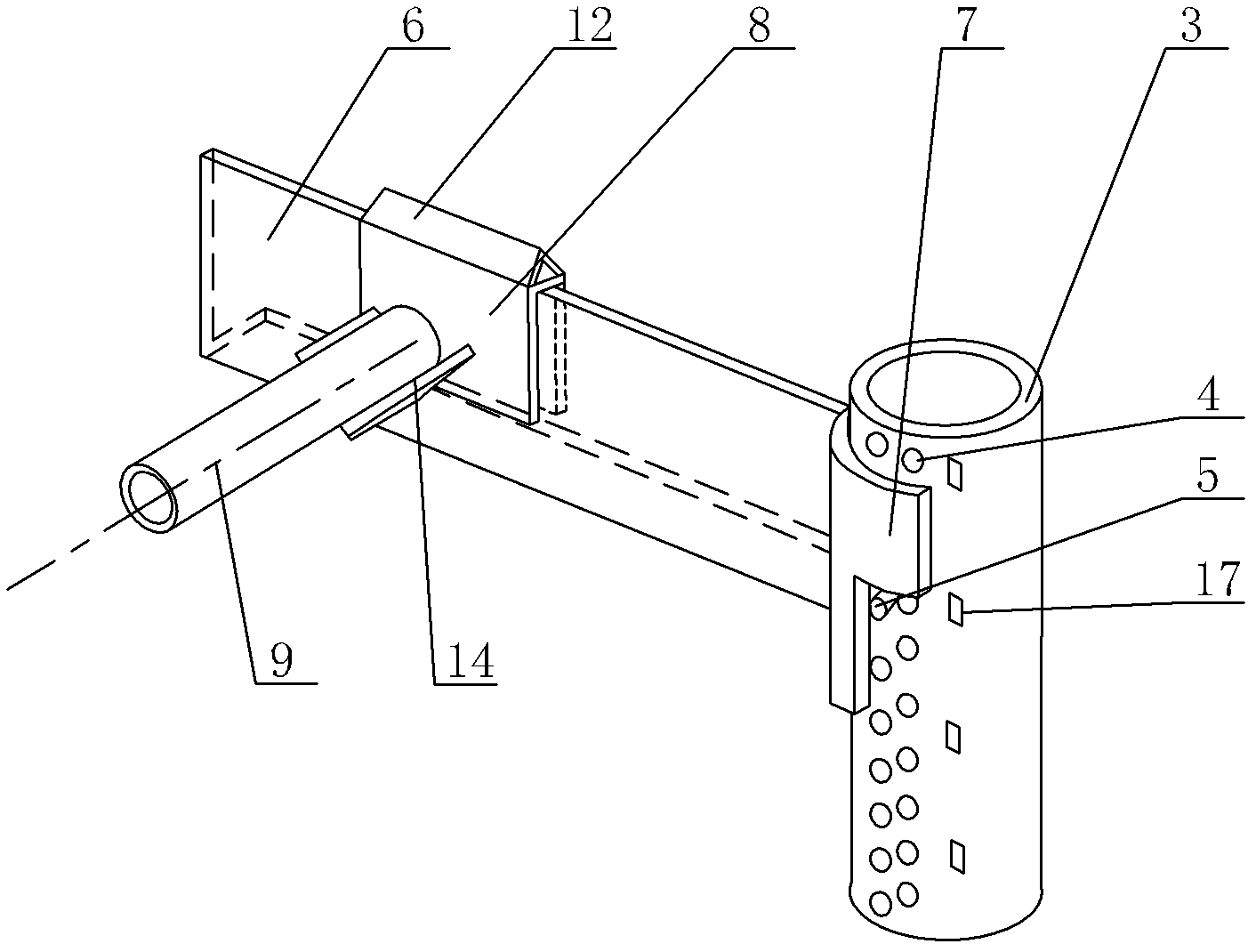

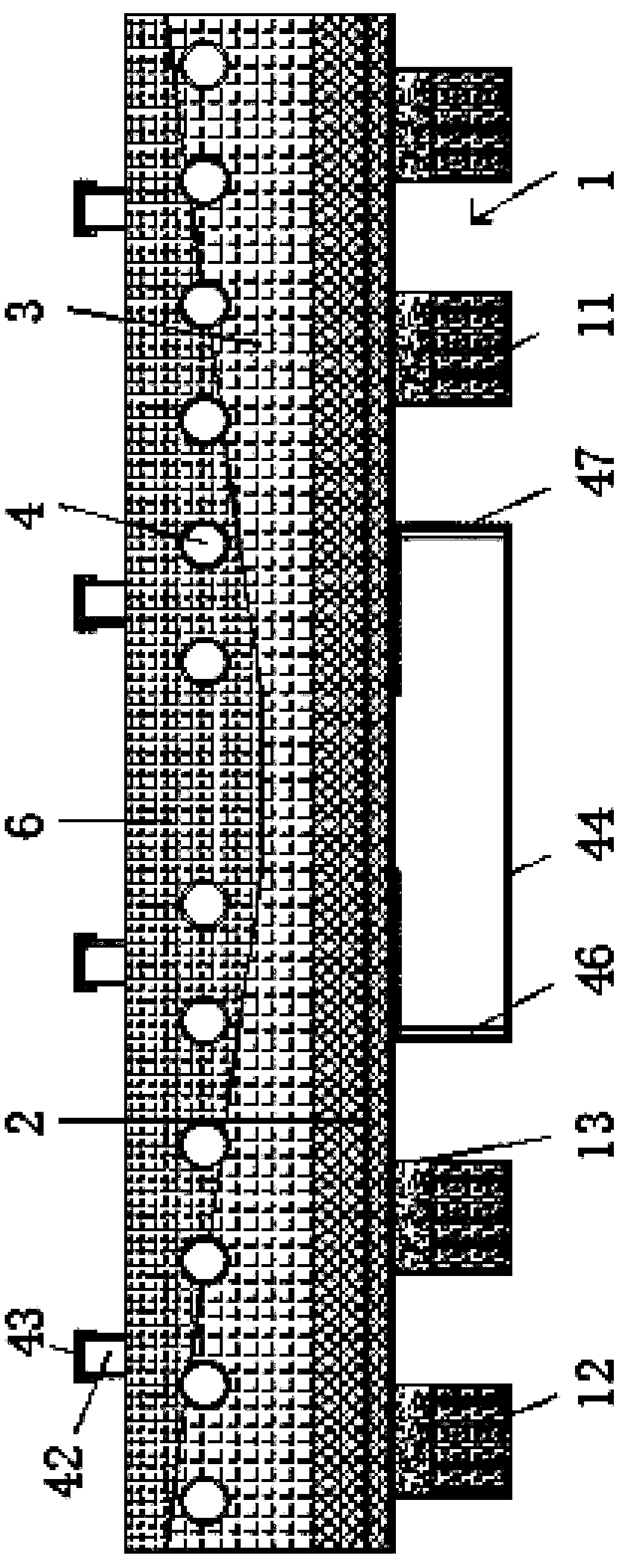

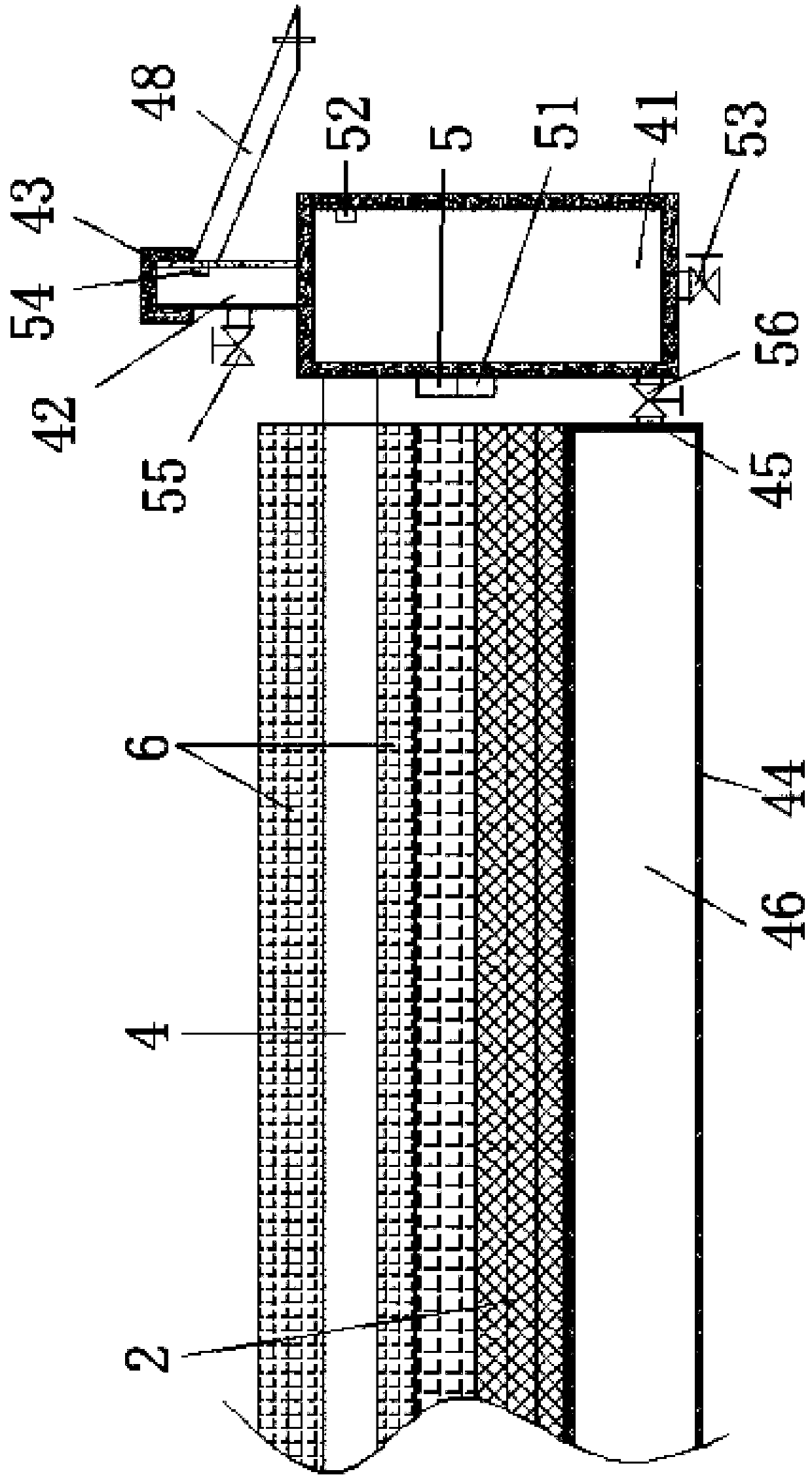

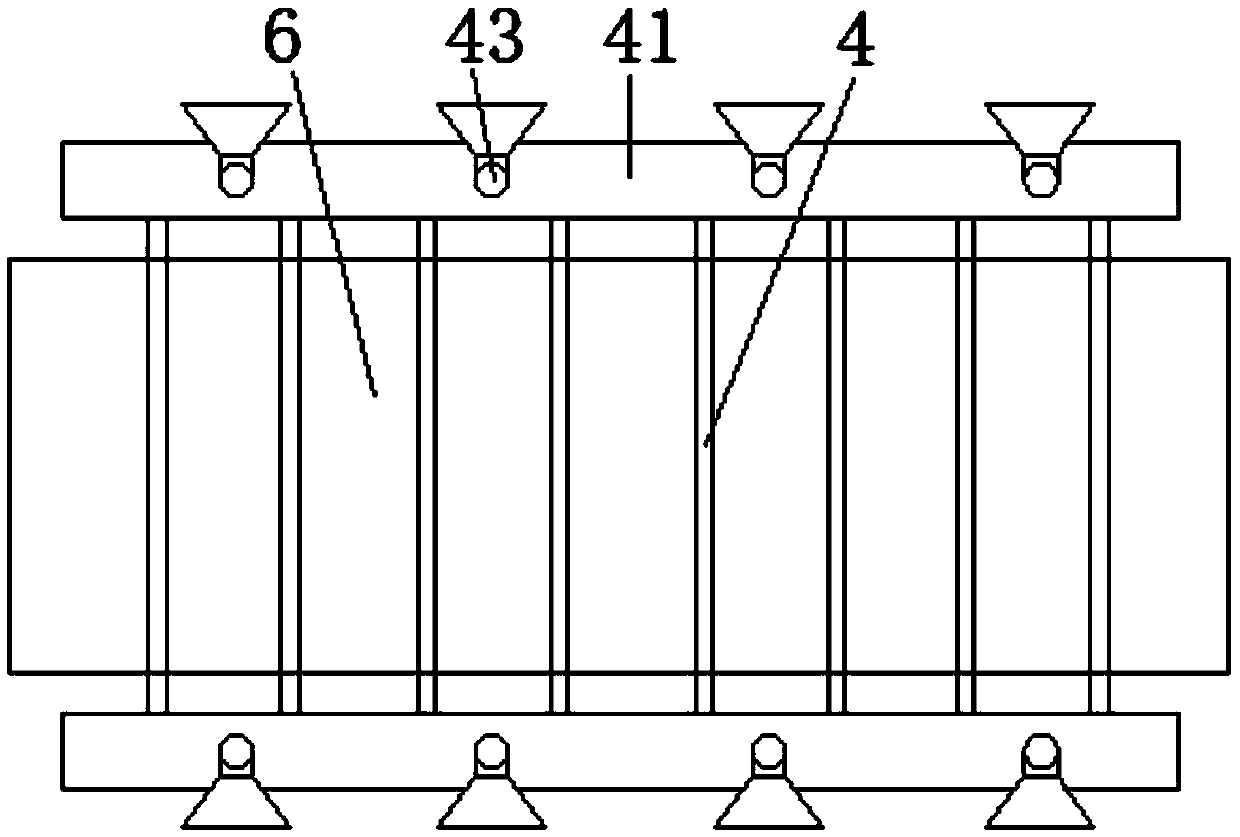

Integrated adjustable rack

InactiveCN102251093AHigh strengthImprove high temperature deformation resistanceFurnace typesHeat treatment furnacesContinuous annealingMechanical engineering

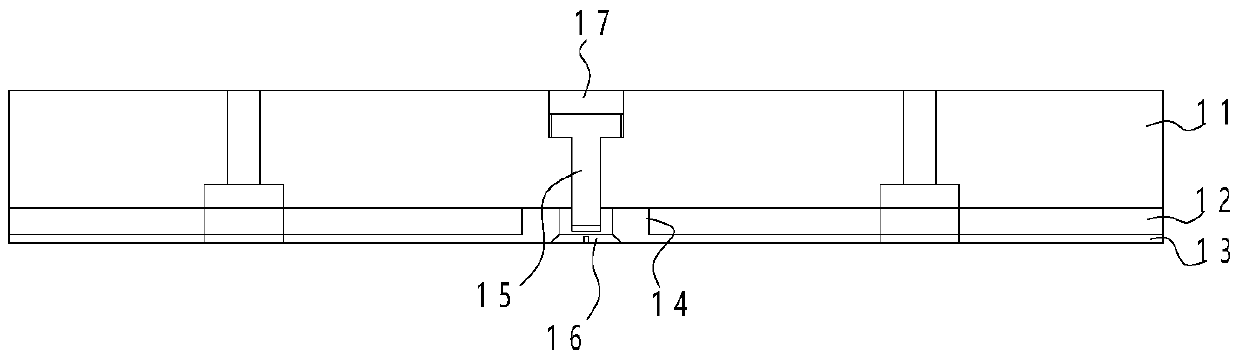

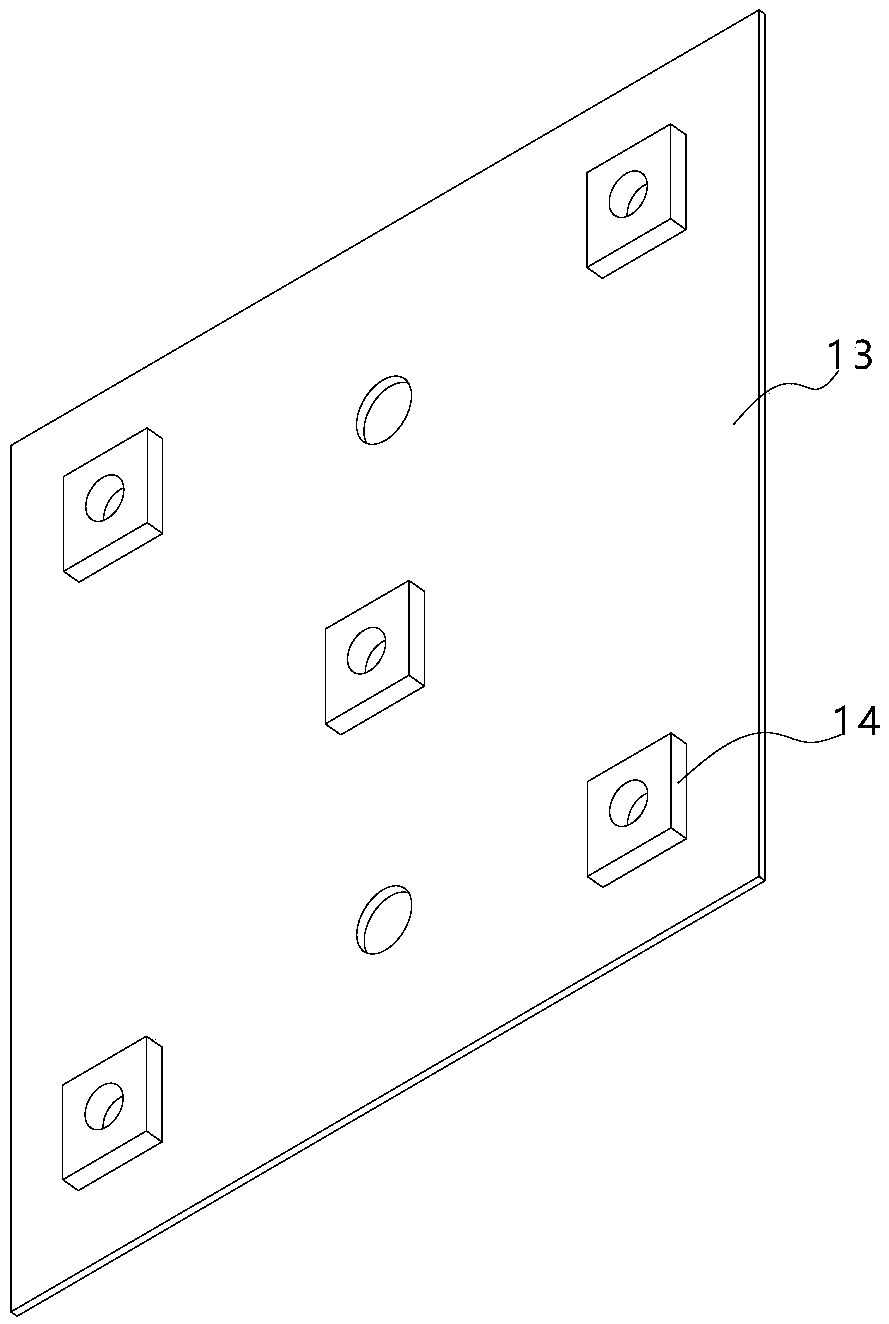

The invention relates to an integrated adjustable rack used for hoisting in a continuous annealing furnace between dense charging and processing of metal plates, belts, foil and other products. The integrated adjustable rack comprises a rack body, wherein the rack body comprises a rectangular underpan; the underpan comprises an upper underpan and a lower underpan; the upper underpan is composed of parallel top cross beams and top longitudinal beams connected with one end of each top cross beam; the lower underpan is composed of parallel cross beams and parallel longitudinal beams which are crossed; the joint of each cross beam and each longitudinal beam between the upper underpan and lower underpan is provided with a column; a top longitudinal beam is arranged between the other ends of every two parallel top cross beams of the upper underpan; a movable cross beam is arranged between every two columns connecting the top cross beams on the left and right sides of the rack body, and positioned between the upper underpan and lower underpan; both ends of the movable cross beam are provided with a U chute which is matched with the column; axis pin holes are distributed on the column; an axis pin which is inserted into the axis pin hole is arranged below the U chute; the movable cross beams on the left and right sides of the rack body are provided with symmetrical slide block seats; and a coil core tube is arranged between the symmetrical slide block seats.

Owner:柳燕明

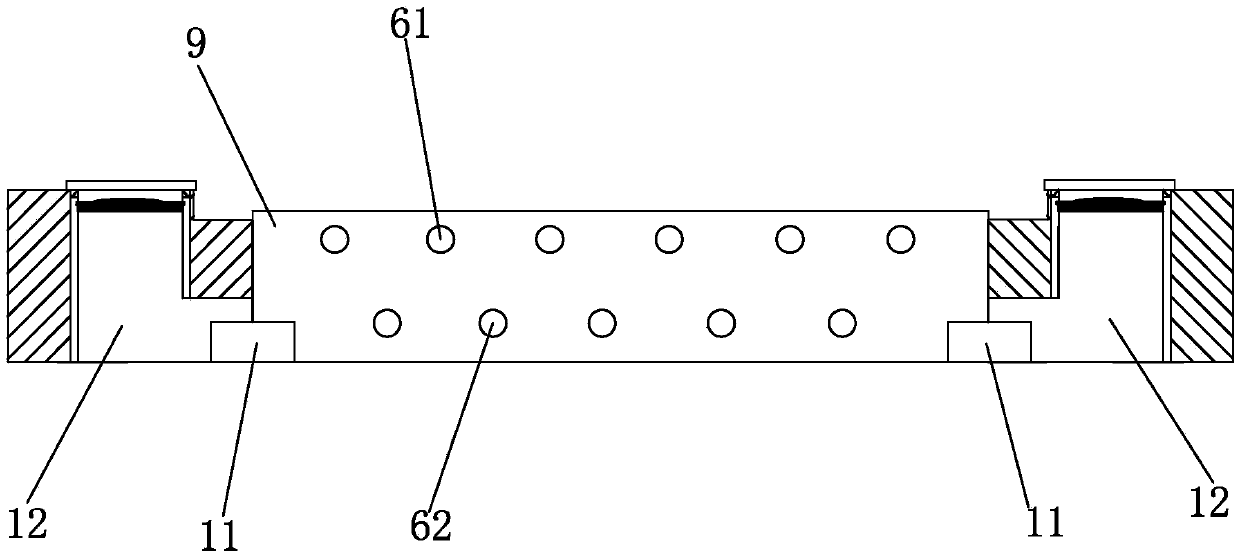

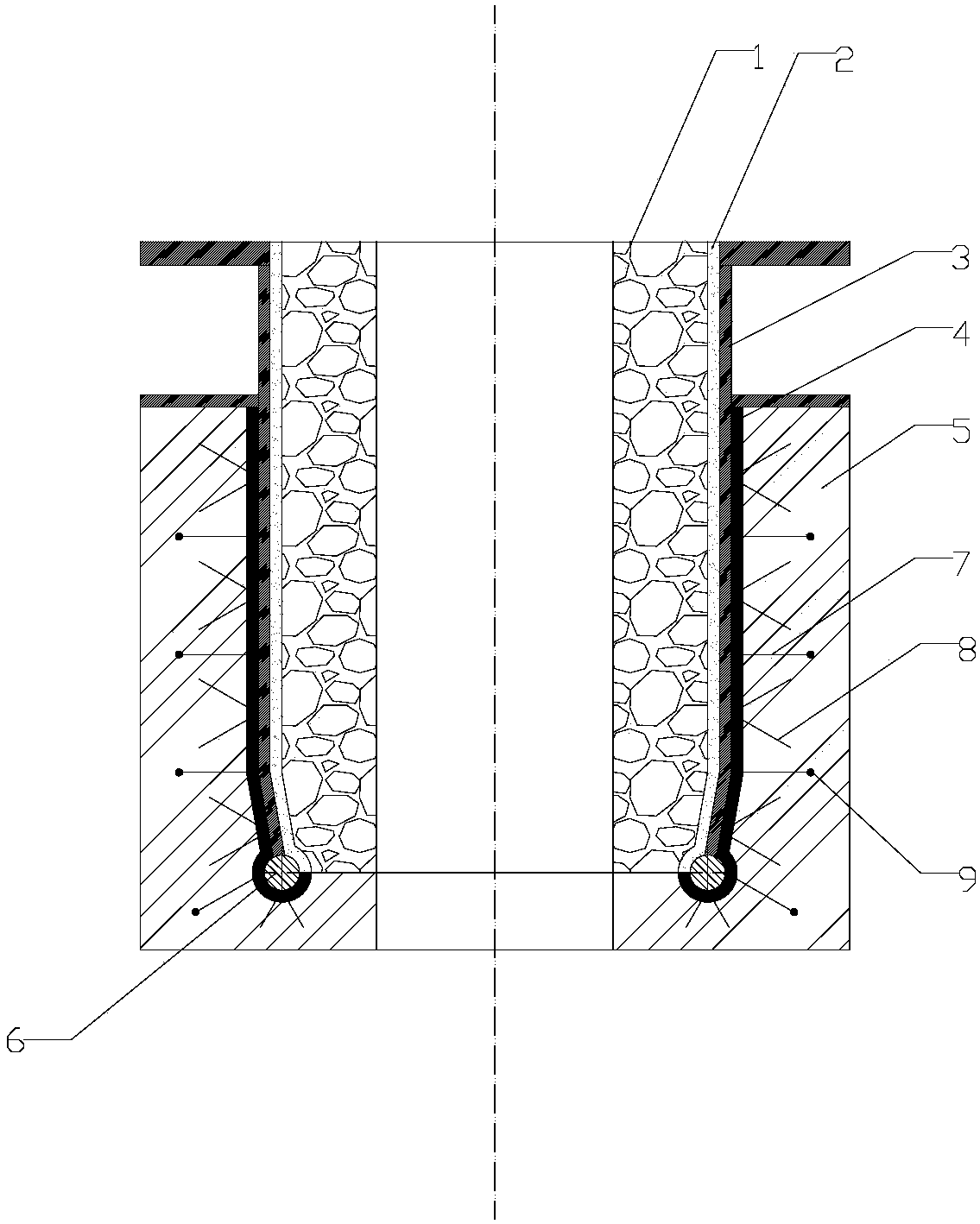

Urban road pavement structure

InactiveCN109594446AEasy to drainRealize water storageIn situ pavingsPaving gutters/kerbsVertical tubeIsosceles trapezoid

The invention discloses an urban road pavement structure which comprises a drainage layer, a support layer, a foundation layer, a drainage degradation layer and a drainage cooling system. The supportlayer is directly paved on an urban road foundation and comprises a plurality of laminated metal perforated plates and gravel arranged between the metal perforated plates in a filling manner; the drainage layer is arranged below the support layer and is inserted into the urban road foundation; the foundation layer is arranged above the support layer and sinks along the middle portion of the uppersurface of a road in the length direction in an inclined downward manner, the longitudinal section of the foundation layer is in an isosceles trapezoid shape with the large upper portion and the smalllower portion; the drainage degradation layer is arranged above the foundation layer, and the upper surface of the drainage degradation layer is horizontal; and the drainage cooling system comprisesa heat exchange tube, a heat exchange main chamber, and a vertical tube, a pipe cap and a water storage tank; the middle portion of the upper portion of the water storage tank is provided with an opening, and the opening is opposite to the sinking position of the upper surface of the foundation layer. The pavement structure has good stability, has good water permeability and water storage performance and has high pavement high temperature deformation resistance.

Owner:HUANGHUAI UNIV

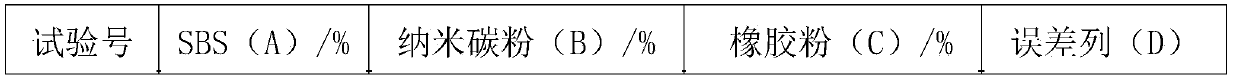

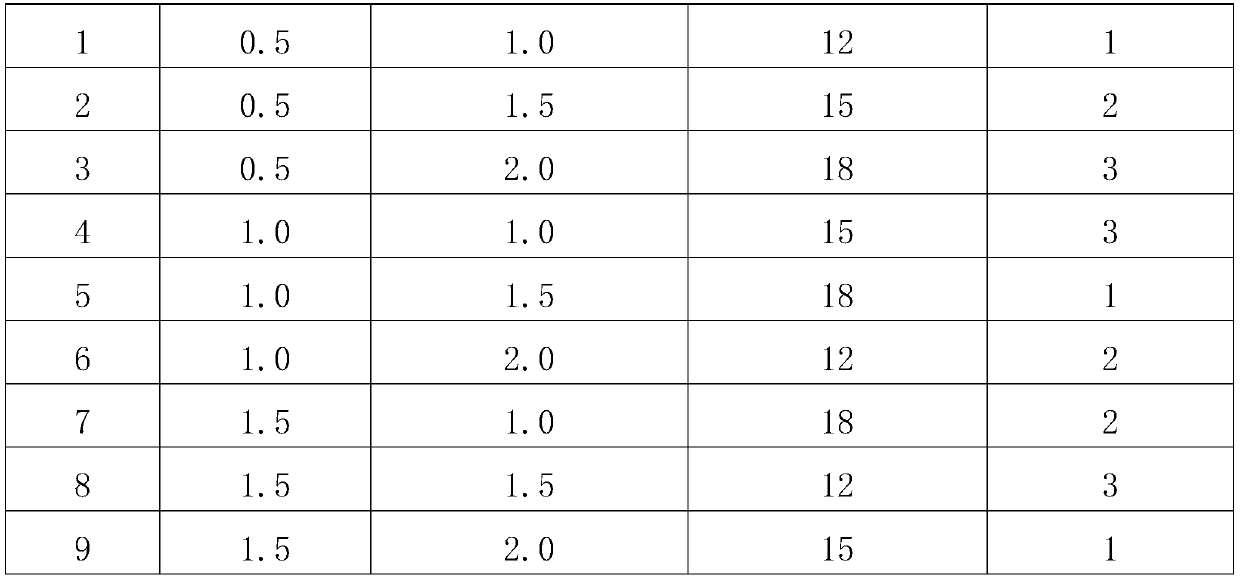

Preparation method of nano carbon powder, SBS and rubber powder composite modified asphalt

InactiveCN111423736AImprove high temperature deformation resistanceImprove low temperature crack resistanceBuilding insulationsSurface modificationBLENDER/MIXER

The invention relates to a preparation method of nano carbon powder, SBS and rubber powder composite modified asphalt. The preparation method comprises the following steps: preparing raw materials such as three groups of nano carbon powder, three groups of rubber powder and three groups of SBS, carrying out surface modification on the nano carbon powder by adopting a titanate coupling agent solution in advance so that an optimal blending ratio is obtained, designing 9 groups of test schemes, carrying out a physical performance test to obtain an optimal blending ratio, giving independent variable factors, taking the modified asphalt at the optimal blending ratio as a research object, and taking a shearing rotation speed, reaction time, a reaction temperature, development time and a development temperature as independent variable control factors, obtaining a test scheme, carrying out an orthogonal test on the parameters, designing 16 groups of test schemes, preparing modified asphalt byutilizing a high-shear emulsifier and a stirrer, carrying out a physical performance test and carrying out grey correlation analysis to obtain a comprehensive score. The preparation method can improvehigh-temperature deformation resistance and the low-temperature crack resistance of the asphalt and reduce the temperature sensitivity.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS +1

Soluble asphalt packing material

InactiveCN101643586AGood compatibilityImprove high temperature deformation resistanceBuilding insulationsRigid containersMelting tankManufacturing technology

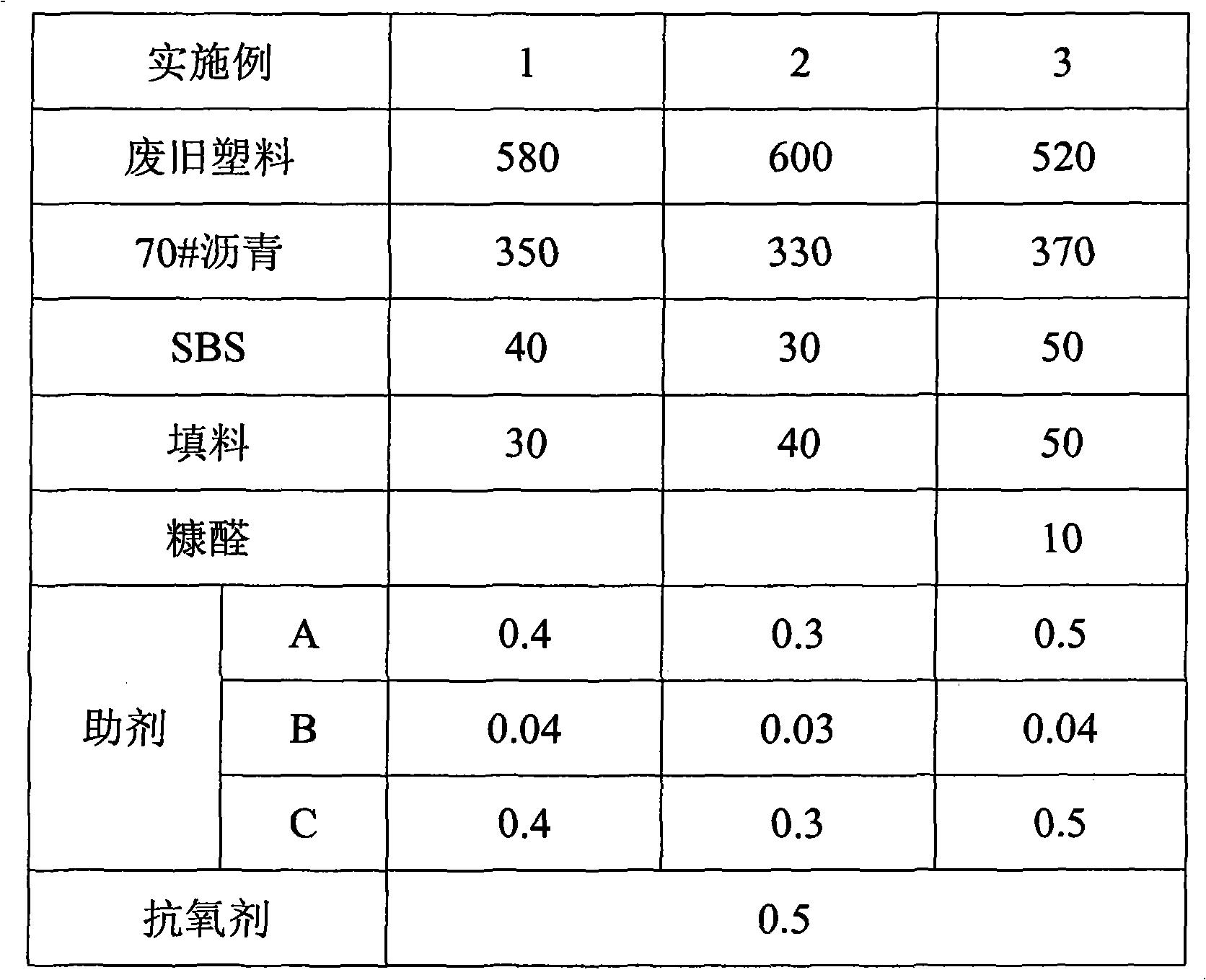

The invention relates to a soluble asphalt packing material, belonging to the field of manufacturing technology of the asphalt packing material. The soluble asphalt packing material comprises the components by weight percent: 1-10% of SBS, 20-60% of waste plastics, 3-15% of filler, 20-50% of asphalt, furfural, 0.03-0.15% of auxiliary agent A, 0.04-0.08% of auxiliary agent B, 0.03-0.15% of auxiliary agent C and 0.02-0.06% of antioxidant, and the sum of the weight percent of the components is 100%. The soluble asphalt packing material has reasonable compound design, realizes one object for dualpurposes, avoids the asphalt from being wasted, and reduces the environmental pollution. A packing box manufactured by the packing material is puncture-resistant and shock-resistant as well as reliable in package, can be put into a melting tank in a whole bag when being applied, is clean and labor-saving, and avoids waste.

Owner:浙江兰亭高科控股有限公司

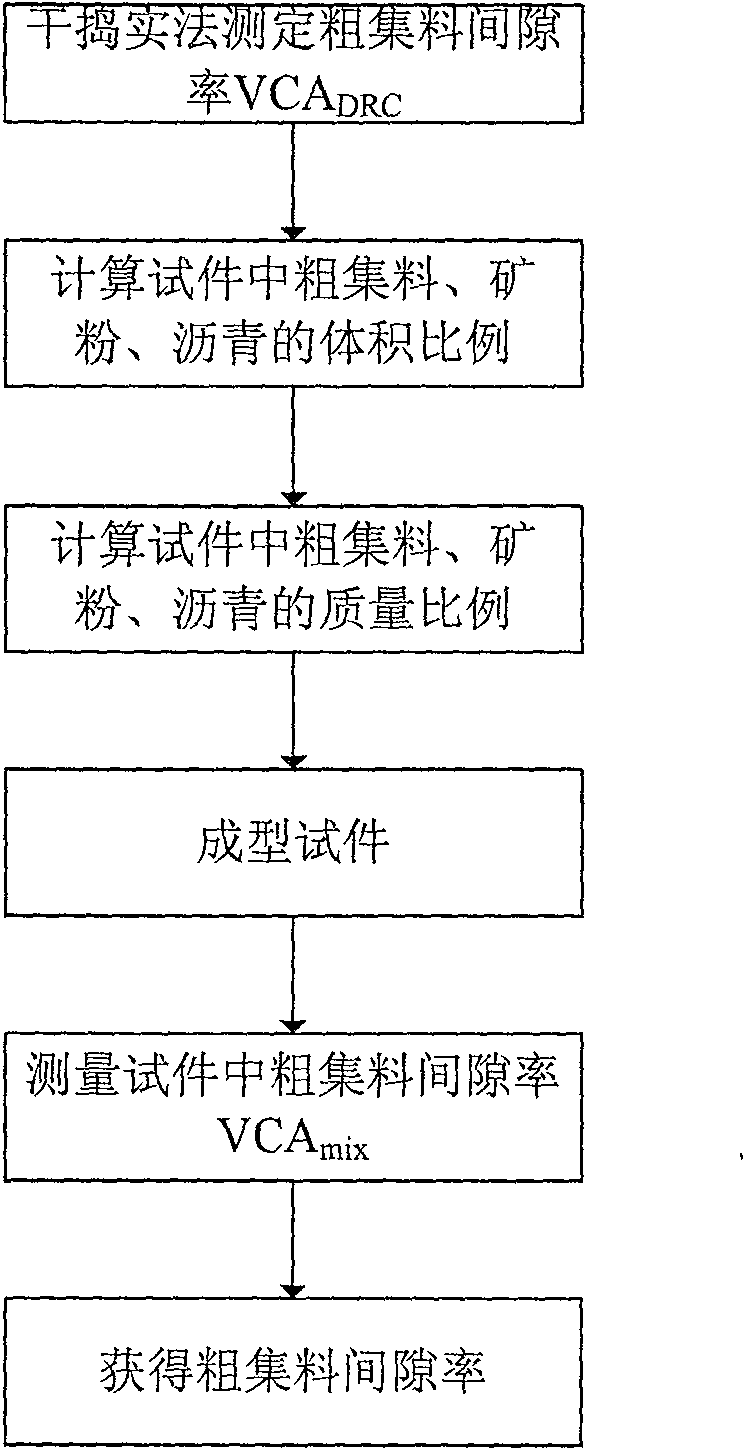

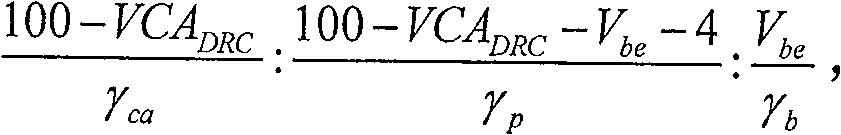

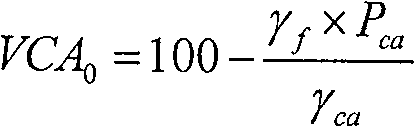

Method for detecting void of coarse aggregate

ActiveCN101614646ACoarse aggregate particle stabilizationParticle stabilizationPreparing sample for investigationSpecific gravity measurementWater volumeAsphalt

The invention discloses a method for detecting a void of coarse aggregate. The technical problem solved by the method is to compare the detection result of the void of the coarse aggregate with the detection result of the void of the coarse aggregate in an asphalt mixture. The method comprises the following steps of: adopting the dry tamping method to detect the void of the coarse aggregate; adding mineral powder and asphalt into the coarse aggregate and mixing the coarse aggregate, the mineral powder and the asphalt; forming a test piece; detecting the relative density of bulk volume, the mass percentage of the coarse aggregate accounting for the total mass and the relative density of synthesis bulk volume of the coarse aggregate accounting for water volume; and calculating the void of the coarse aggregate in the test piece. Compared with the prior art, the mineral powder and the asphalt are added into the coarse aggregate, the detection method is the same as that of the void of the coarse aggregate in the asphalt mixture, and the detection result is comparable, so that the skeleton-compact standard of the coarse aggregate formed by the detection method more scientifically evaluates the skeleton-compact degree of the coarse aggregate in the asphalt mixture.

Owner:SHENZHEN MUNICIPAL ENG +1

Green low-carbon environment-friendly road structure adopting regenerative material

ActiveCN110205895AProtect environmentSave natural resourcesIn situ pavingsClimate change adaptationFoundation engineeringCushion

The invention discloses a green low-carbon environment-friendly road structure adopting regenerative material. The structure comprises a subgrade and a pavement which are sequentially arranged from bottom to top; the subgrade comprises an embankment and a road bed which are sequentially arranged from bottom to top, wherein the embankment is prepared from urban building waste regenerative mixture,and the road bed is prepared from urban building waste regenerative grading mixture; and the pavement comprises a cushion layer, a bottom base layer, a base layer, a lower layer, a middle layer and anupper layer which are sequentially arranged from bottom to top, and the cushion layer is prepared from building waste regenerative grading aggregate. According to the structure, the requirements of the existing traffic development can be guaranteed, the environmental problems left due to the urban development are resolved, and the problem of destructive mining on natural resources due to the foundation engineering construction is solved.

Owner:HENAN PROVINCIAL TRANSPORTATION RES INST

Preparation method of sizing agent of mold core for investment casting

InactiveCN107010933AIncrease crystallization rateImprove high temperature deformation resistanceFoundry mouldsFoundry coresPorosityInvestment casting

The invention discloses a preparation method of a sizing agent of a mold core for investment casting. The preparation method comprises the following steps: (1) putting powder and a mineralizing agent into a ball grinder to carry out mixed grinding for more than 2 hours, taking out and drying so as to cause moisture content to be less than 0.3wt%; and (2) adding 15wt%-wt20% of plasticizer into a stainless steel container with a stirrer, heating to 85-90 DEG C, adding powder and 0.5-1.0wt% of oleic acid under the condition of stirring, and continuously stirring for 4-5 hours to obtain the sizing agent which is used for preparing the core or is cast into ingots for later use. The preparation method has the beneficial effects that a mold core green body made of quartz glass is used; after being heated to above 1100 DEG C, the mold core green body can be sintered; the mineralizing agent can facilitate sintering and has the effects of improving the high-temperature anti-deformation capacity of the mold core, increasing the crystallization rate of quartz glass and the like; and all the performances such as the porosity, bending resistance, volume density and the sintering shrinkage of the mold core are improved by using the use amount of the plasticizer.

Owner:东风精密铸造安徽有限公司

Modified asphalt composite particles and preparation thereof, and modified asphalt and application thereof

ActiveCN114015246AImprove high temperature performanceAvoid crackingSolid waste managementBuilding insulationsPhosphoric Acid EstersPlasticizer

The invention relates to the technical field of modified asphalt, and particularly discloses modified asphalt composite particles and preparation thereof, and modified asphalt and application thereof. The modified asphalt composite particles are prepared from the following raw materials in parts by weight: 20-40 parts of desulfurized waste tire rubber powder, 3-10 parts of rock asphalt, 5-10 parts of a composite solubilizer, 1-8 parts of a plasticizer, 1-6 parts of a composite stabilizer, 1-8 parts of polyphosphoric acid, 3-7 parts of polyphosphate, 2-5 parts of a silane coupling agent, 30-50 parts of petroleum asphalt and 2-10 parts of a tackifier. When the modified asphalt composite particles are added into modified asphalt, the modulus, the high-temperature performance and the water damage resistance of the modified asphalt can be improved, and meanwhile, relatively good low-temperature resistance is obtained. When the modified asphalt is applied to asphalt concrete, asphalt concrete with excellent high and low temperature resistance can be obtained.

Owner:河北交规院瑞志交通技术咨询有限公司

A kind of all-ferrite enamel steel for heat exchanger and its production method

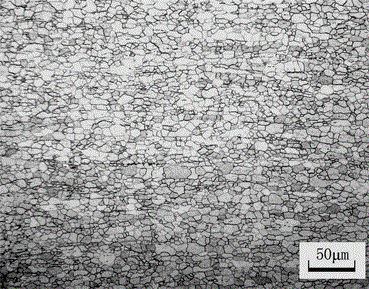

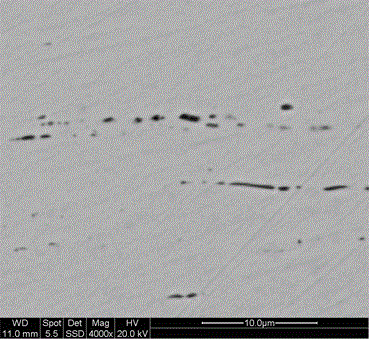

InactiveCN104087828BSimple chemical compositionImprove performanceHydrogen permeationUltimate tensile strength

The invention relates to a full-ferrite enamel steel for a heat exchanger. The full-ferrite enamel steel comprises the following chemical components in percentages by weight: less than or equal to 0.0050% of C, 0.10-0.50% of Mn, less than or equal to 0.010% of Si, less than or equal to 0.020% of P, 0.015-0.045% of S, less than or equal to 0.010% of Als, 0.010-0.055% of Nb, less than or equal to 0.0030% of B and 0.010-0.050% of O; the production method comprises the following steps of pretreating molten iron, smelting, refining and continuously casting by virtue of a converter; heating the cast blank; carrying out hot rolling; coiling and acid pickling; carrying out cold rolling; annealing; finishing for later use. The microstructure of the enamel steel disclosed by the invention is full ferrite, the grain size of ferrite reaches Grade 11, the main inclusions are long-wire-shaped MnS and granular Mn / Nb composite oxides, the precipitated phases are fine NbC / N and BN particles, Rel is 180-240MPa, the tensile strength is 280-360MPa, the elongation is 36-46%, the hydrogen permeation time of the steel plate is equal to or greater than 25min / mm<2>, no scute burst is caused after enamelling, enamel adhesion strength is greater than A1 level and the pinhole rate is less than 10 / m<2>.

Owner:武汉钢铁有限公司

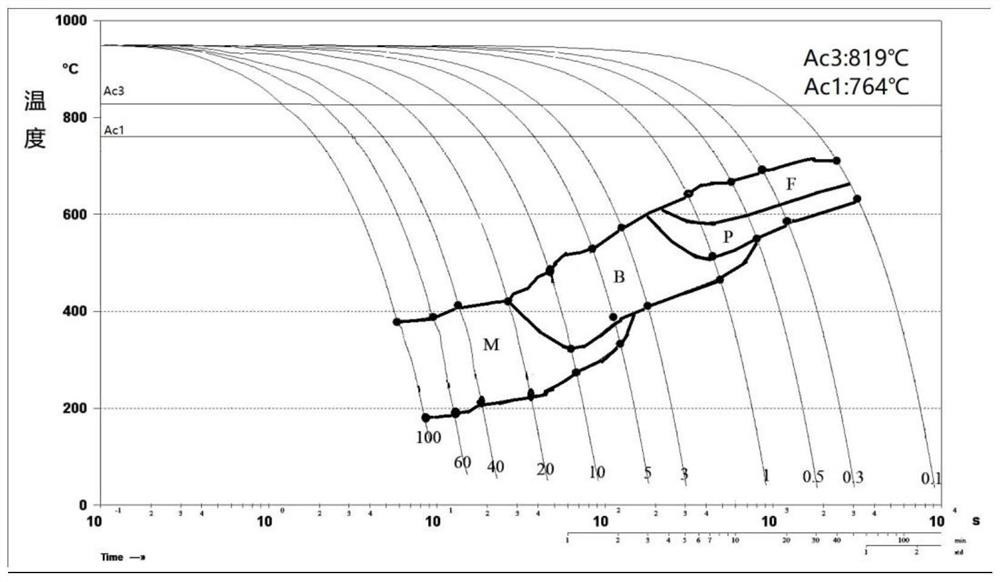

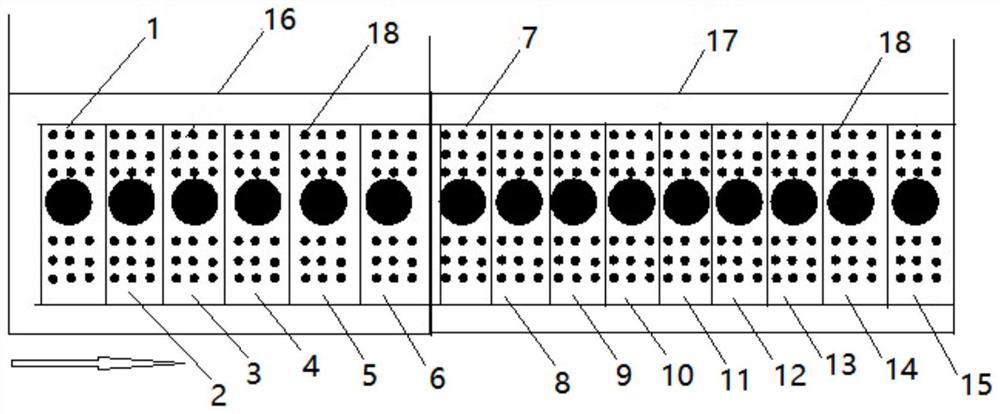

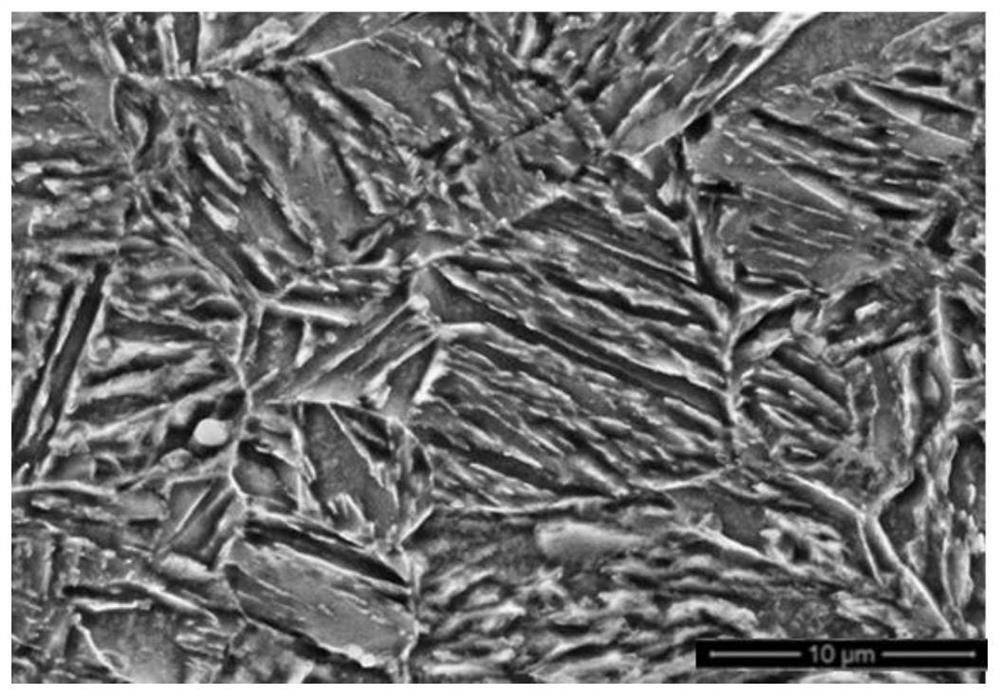

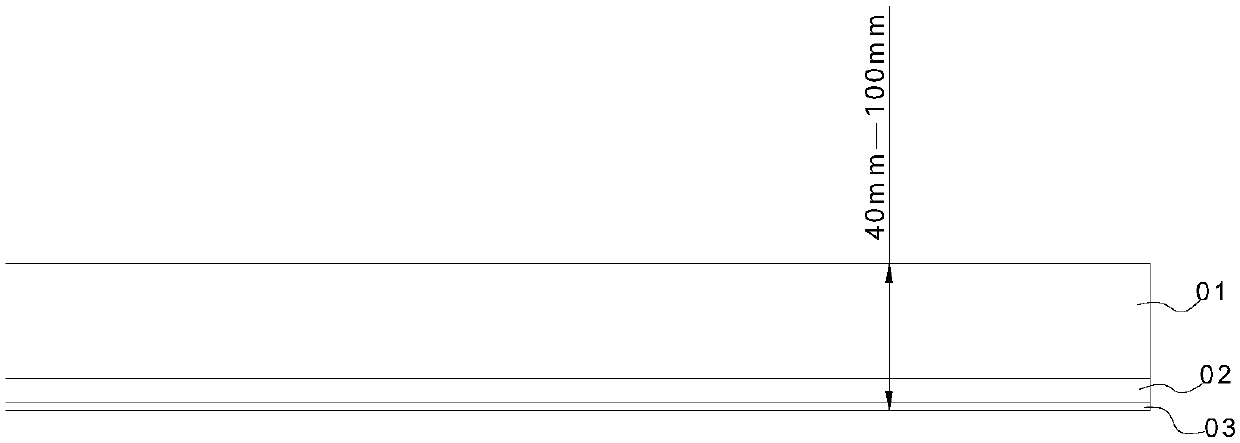

Martensite high-temperature wear-resistant steel and production method thereof

InactiveCN112267064AHigh tensile strengthEnhanced Brinell hardnessFurnace typesHeat treatment process controlMartensiteQuenching

The invention discloses martensite high-temperature wear-resistant steel and a production method thereof. The martensite high-temperature wear-resistant steel comprises the following chemical components in percentage by weight: 0.18%-0.24% of C, 0.1%-0.35% of Si, 0.5%-1.1% of Mn, not greater than 0.013% P, not greater than 0.004% of S, 0.03%-0.06% of Als, 0.025%-0.055% of Nb, 0.02%-0.04% of V, 0.01%-0.025% of Ti, 0.1%-0.35% of Cr, 0.25%-0.45% of Mo, 0.0005%-0.0018% of B, 0.003%-0.0045% of N, not greater than 1.7 ppm of H, 0.002%-0.004% of Ca and the balance of Fe and inevitable impurities. Inthe production method, a temperature-controlled and speed-controlled quenching process and a sub-temperature quenching heating process are adopted; and interval cooling is adopted in the quenching cooling process. The martensite high-temperature wear-resistant steel has good mechanical properties under a high-temperature service condition.

Owner:HANDAN IRON & STEEL GROUP +1

Nano-composite natural rock modified asphalt mixture additive

The invention belongs to the technical field of engineering materials, and particularly relates to a nano-composite natural rock modified asphalt mixture additive. The additive is prepared from natural rock asphalt as a main raw material and waste tire rubber powder, a polymer, nano-diatomite, lignin fibers, nano-zinc oxide and other raw materials as auxiliary materials, so the elasticity, adhesiveness and rigidity of an asphalt mixture are effectively improved, and the high-temperature deformation resistance, the low-temperature crack resistance and the water damage resistance of the compound rock modified asphalt mixture are remarkably improved.

Owner:广西路冠科技投资发展有限责任公司

Carbon fiber thermal insulation cured felt

ActiveCN108673969AImprove high temperature deformation resistanceHigh densityLayered productsCarbon compositesFiber

The invention provides a carbon fiber thermal insulation cured felt. The carbon fiber thermal insulation cured felt comprises an inner felt layer, a middle felt layer and an outer felt layer, whereinthe inner felt layer and the outer felt layer are respectively adhered to the two sides of the middle felt layer; the densities of the inner felt layer, the middle felt layer and the outer felt layerare reduced in sequence; the thicknesses of the inner felt layer, the middle felt layer and the outer felt layer are increased in sequence; the inner felt layer is filled with a carbon / carbon composite material; the middle felt layer is filled with a hard fiber hard felt. The carbon fiber thermal insulation cured felt has the advantages that the inner felt layer, the middle felt layer and the outer felt layer are compounded through resin and a carbon binder, the high temperature deformation resistance capacity of the inner felt layer can be enhanced through the adding of the carbon binder andthe improvement of the density of the inner layer thermal insulation felt, the structure is low in cost, an inner felt layer adopting a separated structure is fixed through a countersunk nut and a hard felt, in order to solve the problem of fixing of a thin carbon plate, the carbon plate is pressed into a local strengthened irregular structure, after a carbon / carbon protective plate loses effectiveness, a protective plate in the innermost layer is only required to be replaced, the structure is beneficial to the reduction of failure rate, and the service life is prolonged.

Owner:浙江星辉新材料科技有限公司

High-strength wear-resisting heat-resisting aluminium alloy material and preparation process thereof

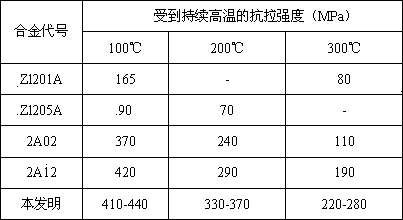

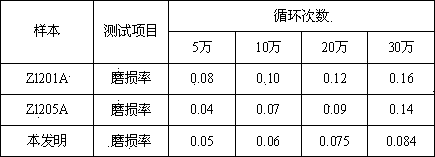

ActiveCN102758109BImprove high temperature deformation resistanceImprove wear resistanceManganeseRare earth

The invention discloses a high-strength wear-resisting heat-resisting aluminium alloy material and a preparation process thereof. The material comprises, by weight, 4.0-6.5% of copper, 0.06-0.4% of titanium, 0.08-0.6% of manganese, 0.03-0.4% of antimony, 0.4-0.6% of nickel, 1.2-1.8% of cobalt, 0.2-0.3% of zirconium, 0.2-1.8% of rare earth and the balance aluminum. During preparation of the material, a special heat treatment process is used. The material has the advantages of being capable of improving the mechanical strength, the abrasive resistance and the high-temperature deformation resistance of an aluminium alloy simultaneously, the material can be used for cast members which are required to bear a certain high temperature and have high mechanical performance requirements, and a new field of application of the aluminium alloy material is developed.

Owner:贵阳华恒机械制造有限公司

Modified polyurethane asphalt material

InactiveCN107286633AImprove heat resistanceImprove high temperature deformation resistanceBuilding insulationsPolyesterCyclohexanone

The invention belongs to the technical field of asphalt materials and particularly relates to a modified polyurethane asphalt material which is composed of a component A and a component B, wherein the component A includes, by weight, 80-90 parts of a modified polyurethane prepolymer, 8-10 parts of anhydrous butyl acetate, 15-20 parts of cyclohexanone, 60-65 parts of dimethylbenzene, 8-10 parts of color paste, 40-50 parts of talcum powder, 10-15 parts of heavy calcium carbonate, 0.3-0.5 parts of N-methyl diethanolamine, 0.3-0.5 parts of monoethanolamine, 0.3-0.5 parts of BYK-320, 0.1-0.6 parts of BYK-052N, and 0.3-0.5 parts of DISPERBYK-2163; the component B includes 50-60 parts of coal tar asphalt and 10-15 parts of polyester. The modified polyurethane asphalt material has high-temperature resistance, waterproofing property and anti-corrosion performance, is wide in range of construction conditions and has wide application range.

Owner:FUZHOU ROYAL FLOOR

Preparation method of high-temperature-rutting-resistant warm mix asphalt mixture

InactiveCN108503257AThickenImprove elastic recovery performance indicatorsClimate change adaptationPitch blendeSmall particle

Owner:吕莉

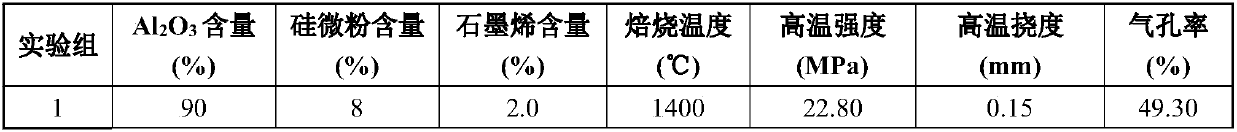

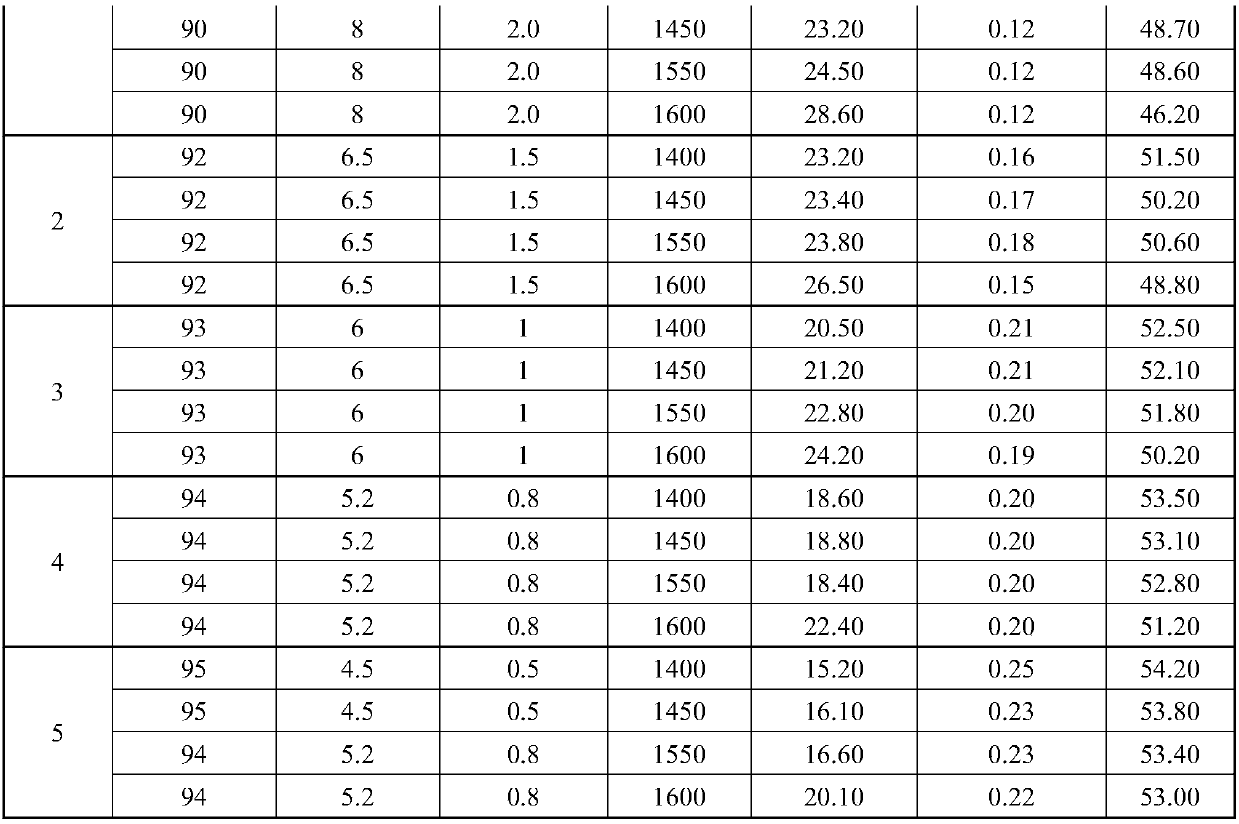

Graphene reinforced alumina-based ceramic bearing for robot

InactiveCN111377716AImprove core removal efficiencyImprove high temperature performanceFoundry mouldsFoundry coresPlasticizerSingle crystal

The invention relates to a graphene reinforced alumina-based ceramic bearing for a robot, which is prepared by the following steps: mixing alumina ceramic powder and graphene powder by using a three-dimensional mixer to obtain uniformly mixed alumina-based ceramic core powder; mixing the ceramic powder and a plasticizer to prepare required ceramic slurry, pressing a wet ceramic core sample by using a hot-press injection molding method, and sintering the obtained wet ceramic core under the protection of an inert atmosphere to obtain the graphene-reinforced alumina-based ceramic core. Accordingto the invention, the graphene material with excellent mechanical properties and thermal properties is innovatively introduced into the alumina-based ceramic core material system, the preparation process of the graphene-reinforced alumina-based ceramic core material is simple and feasible, the operability is strong, and the prepared ceramic core has excellent high-temperature properties and is easy to dissolve. The ceramic core can meet the preparation and use requirements of the single crystal hollow blade, and the size precision and the percent of pass of the blade can be guaranteed.

Owner:GUOREN ROBOT TIANJIN CO LTD

An asphalt pavement structure

ActiveCN107268378BImprove crack resistanceAvoid damageSewerage structuresPaving gutters/kerbsPondingSurface layer

The invention discloses a bituminous pavement structure. The bituminous pavement structure comprises a bituminous pavement layer laid on the ground surface; gaps facilitating rapid leakage of rainwater are formed in the bituminous pavement layer; sand-based water permeable kerbs are arranged on the two sides of the bituminous pavement layer; the bituminous pavement layer is sequentially provided with a laying layer, a water stabilizing layer and a stress absorption layer from top to bottom; a water permeable surface layer is arranged below the bituminous pavement layer; a water permeable base layer is arranged below the water permeable surface layer; a pipe network used for collecting rainwater is embedded into the water permeable base layer; filter ditches are formed in the two sides of the water permeable base layer; the two ends of the pipe network are connected to the filter ditches; the filter ditches are internally provided with a plurality of watering pipes connected with a surrounding green belt; and water guide pipes are arranged at the two ends of the filter ditches and connected to rainwater openings. As the bituminous pavement layer is arranged, the pavement anti-cracking capacity is improved, pavement water damage and rutting are reduced, original waste pavement materials can be fully used, the service life of the pavement is prolonged, the rapid leakage function is achieved for accumulated water, and accumulated water on the pavement can be rapidly drained.

Owner:杭州景睿建设工程有限公司

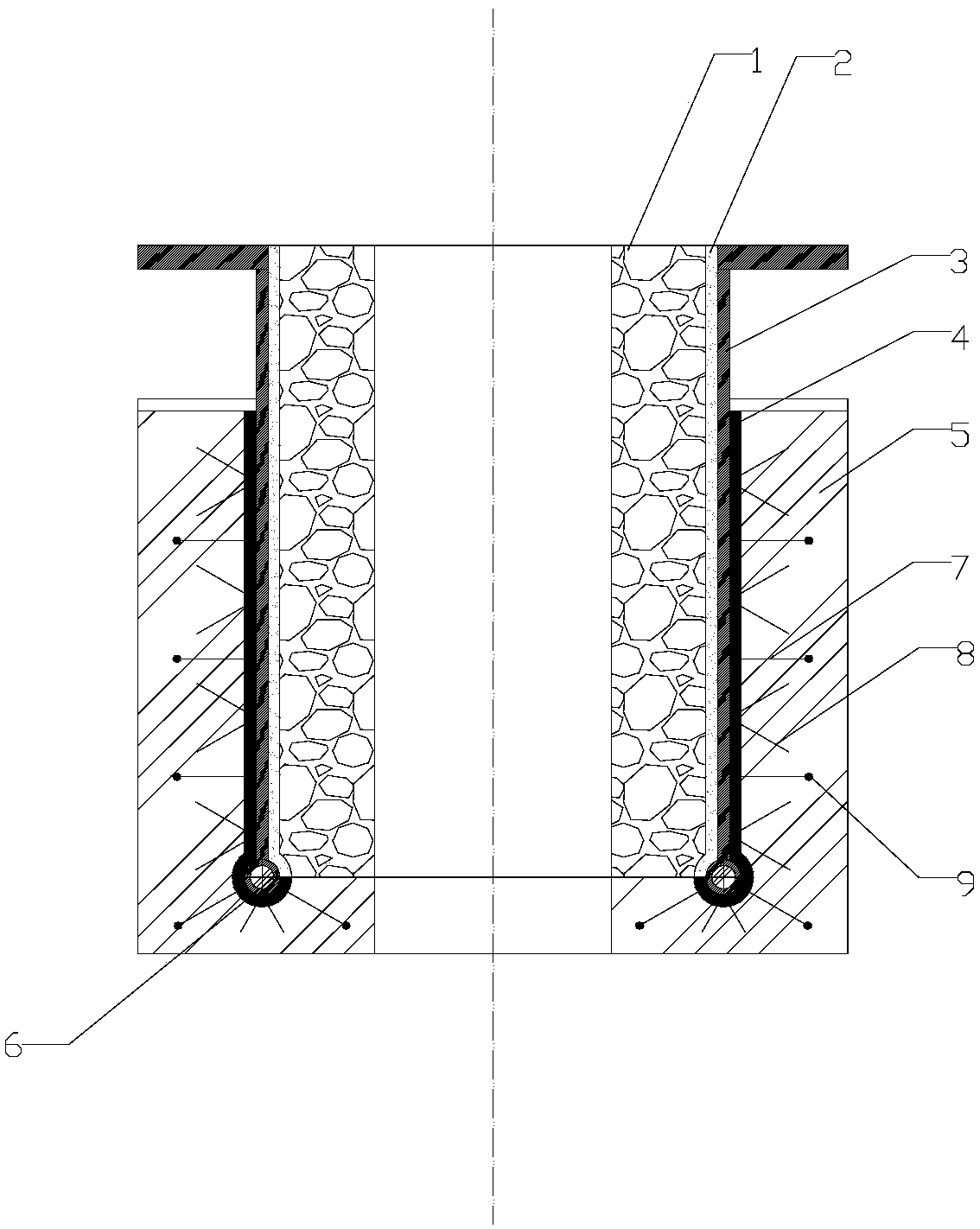

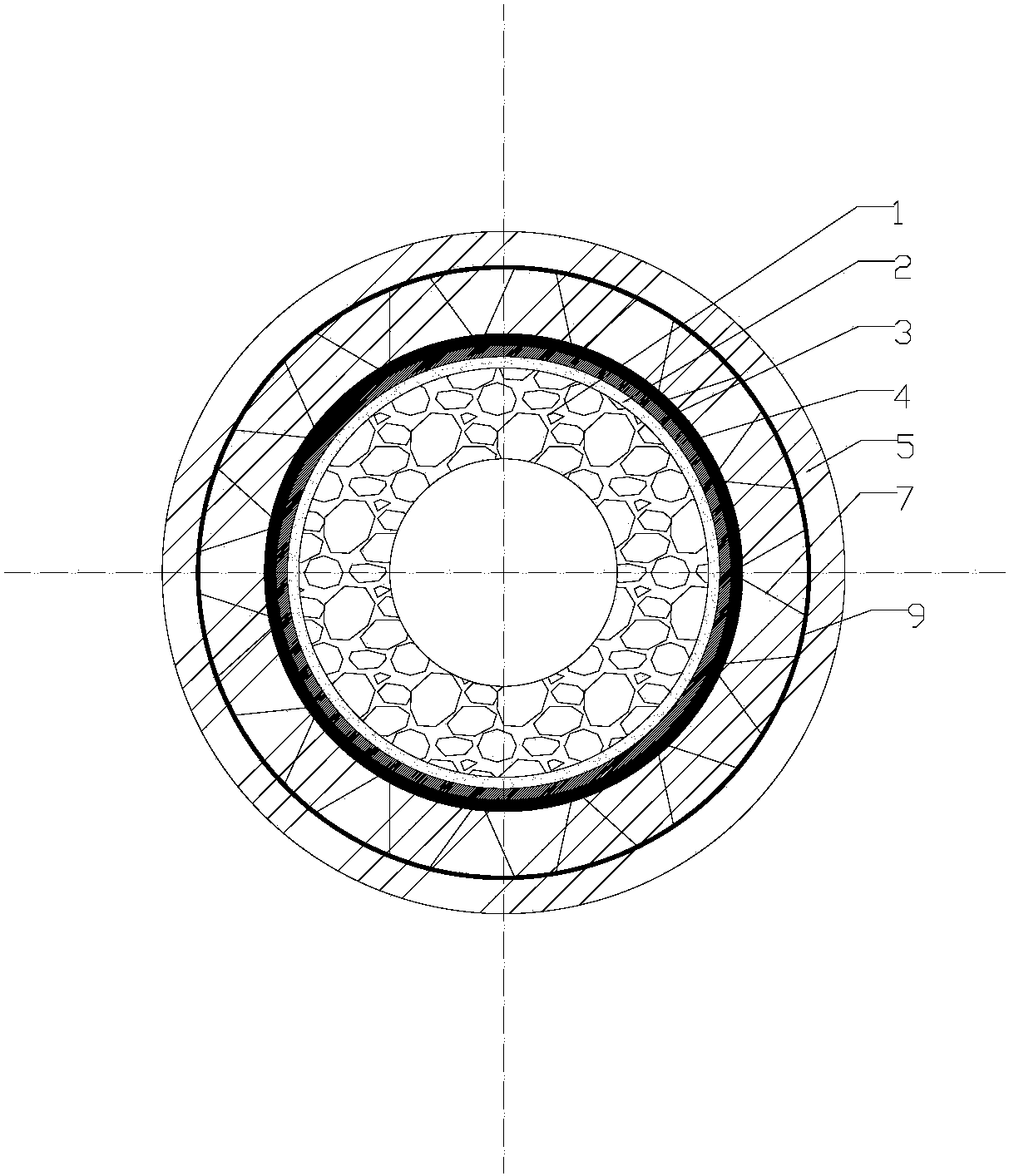

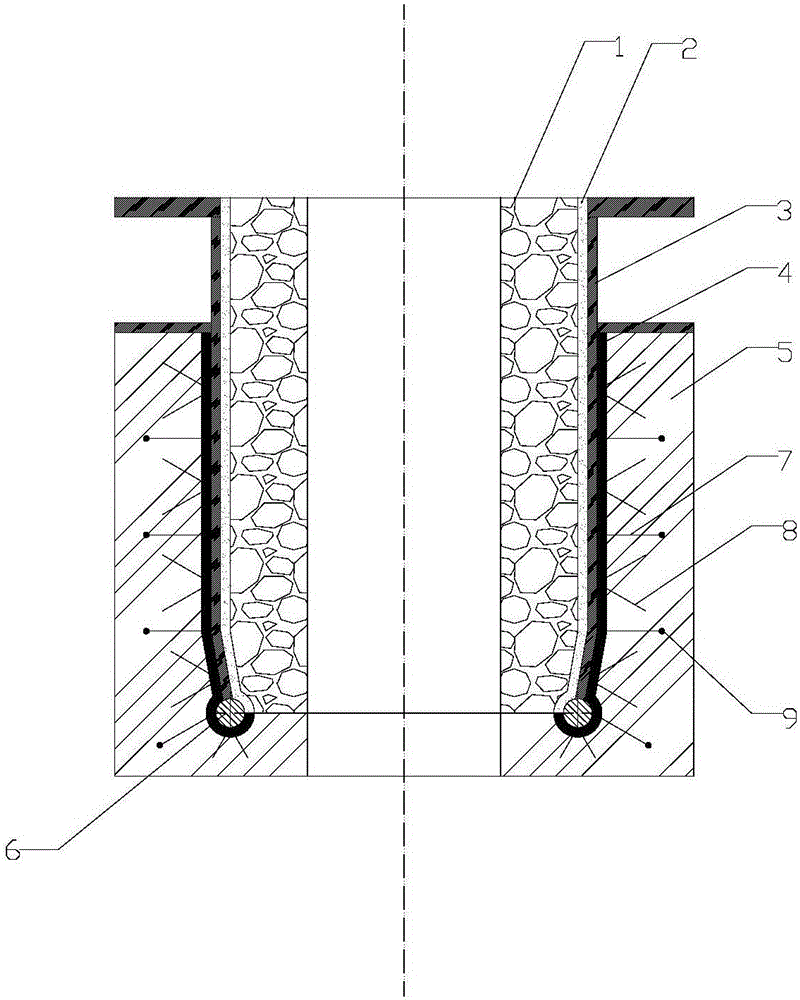

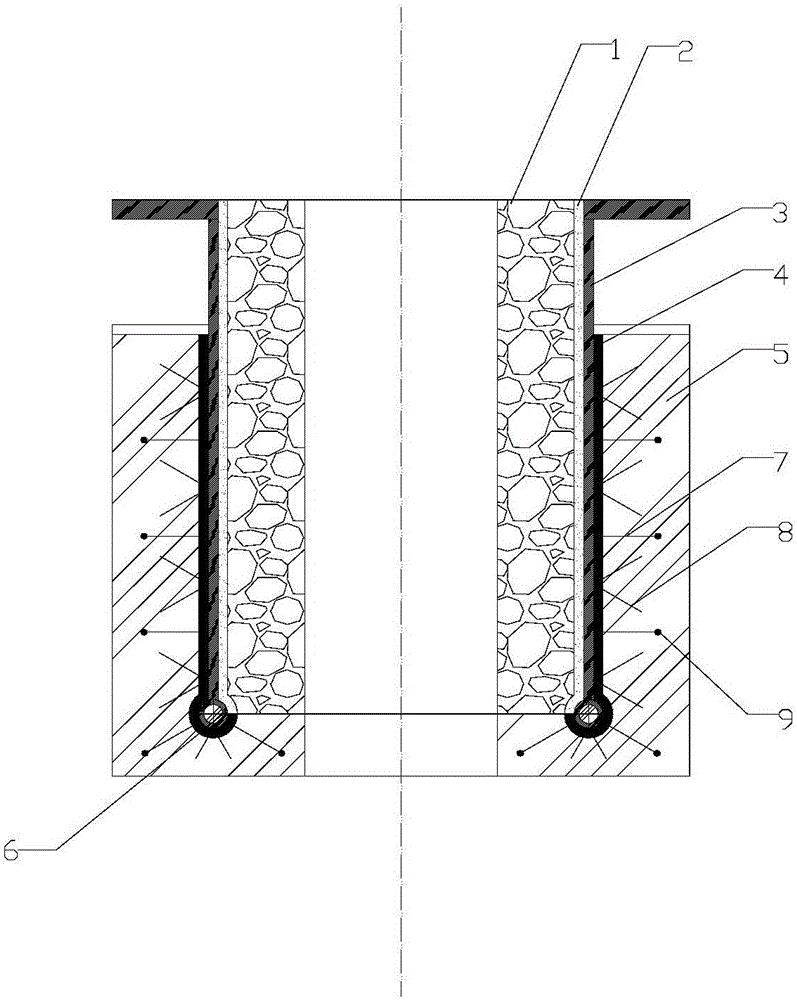

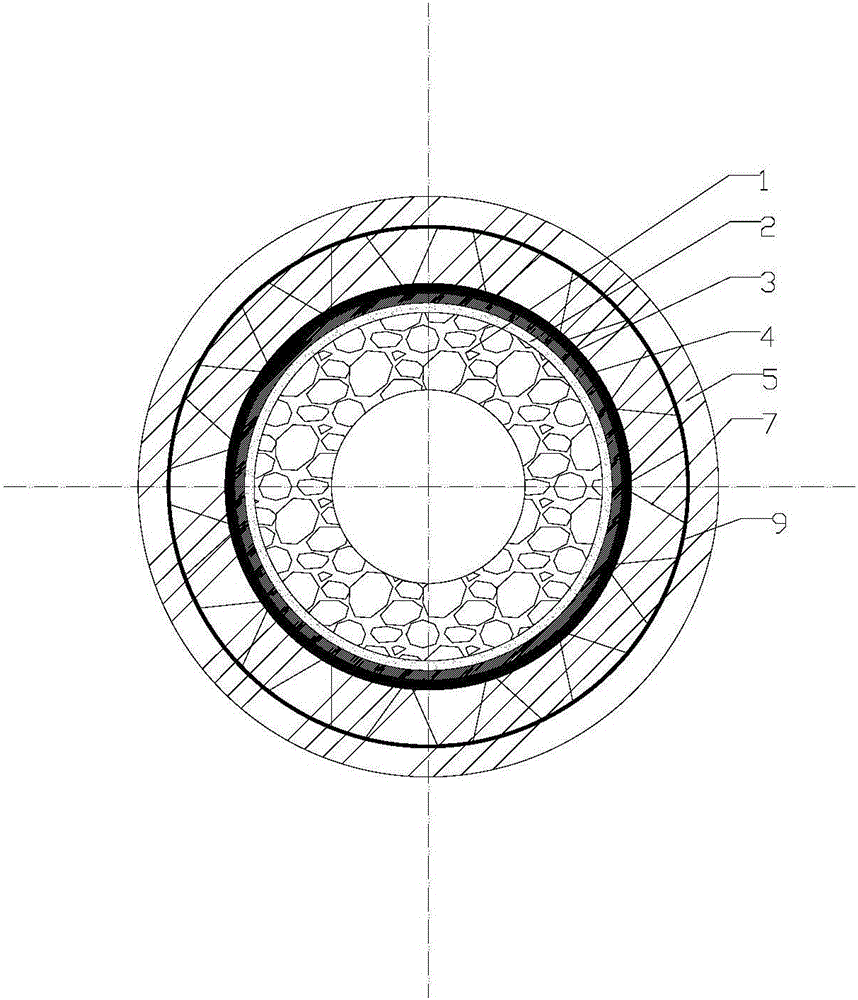

Rh Vacuum Furnace Low Stress Dip Tube

ActiveCN106011389BExtended service lifeImprove high temperature deformation resistanceBrickHeat stress

The invention discloses a low-stress dipping pipe for an RH vacuum furnace. The low-stress dipping pipe sequentially comprises a refractory brick lining, a filling layer and a steel barrel from inside to outside. No hole is formed in the wall surface of the steel barrel. An annular round metal pipe or an annular round metal rod is welded to the bottom surface of the steel barrel. The outer wall of the lower portion of the top of the steel barrel and the outer wall of the annular round metal pipe or the outer wall of the annular round metal rod are each paved with a buffer layer. V-shaped metal anchoring pieces and double-V-shaped metal anchoring pieces are uniformly welded to the outer wall of the steel barrel or the outer wall of the annular round metal rod in the axial spaced layered circumferential direction of the steel barrel and penetrate through the buffer layers. According to the low-stress dipping pipe for the RH vacuum furnace, the problem that damage and deterioration are caused due to the fact that the difference of the material performances of all components in a dipping pipe complex structure is remarkable is effectively solved, and the comprehensive purposes of reducing the structural stress and the heat stress of the dipping pipe, improving the dipping pipe resistance to crack, stripping and damage and the integrality and the structural stability of the dipping pipe, prolonging the service life of the dipping pipe and the like are achieved.

Owner:武汉钢铁有限公司

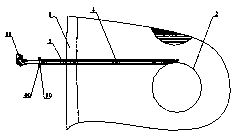

Temperature measurement device for radiant tube of rotary kiln

PendingCN107702814AMeasured temperatureGuaranteed contactThermometer detailsThermometers using electric/magnetic elementsEngineeringThermocouple

The invention provides a temperature measurement device for a radiant tube of a rotary kiln, and belongs to the technical field of temperature measurement. The device comprises a rotary kiln housing,the radiant tube, a temperature measurement conduit and a thermocouple, wherein the radiant tube is located in the rotary kiln housing, and is parallel to the central axis of the rotary kiln housing.The temperature measurement conduit passes through the rotary kiln housing, and the thermocouple is disposed in the temperature measurement conduit, and passes through the temperature measurement conduit along the axis. The temperature measurement conduit and the thermocouple are perpendicular to the radiant tube. The central axis of the temperature measurement conduit is tangent to the outer wallof the radiant tube. A temperature measurement probe of the thermocouple is guided by the temperature measurement conduit to make contact with the radiant tube. The device is simple and practical, and can accurately measure the temperature of the radiant tube in the rotary kiln.

Owner:HENAN DRAGON INTO COAL TECH CO LTD

Low-stress dipping pipe for RH vacuum furnace

ActiveCN106011389AExtended service lifeImprove high temperature deformation resistanceBrickHeat stress

The invention discloses a low-stress dipping pipe for an RH vacuum furnace. The low-stress dipping pipe sequentially comprises a refractory brick lining, a filling layer and a steel barrel from inside to outside. No hole is formed in the wall surface of the steel barrel. An annular round metal pipe or an annular round metal rod is welded to the bottom surface of the steel barrel. The outer wall of the lower portion of the top of the steel barrel and the outer wall of the annular round metal pipe or the outer wall of the annular round metal rod are each paved with a buffer layer. V-shaped metal anchoring pieces and double-V-shaped metal anchoring pieces are uniformly welded to the outer wall of the steel barrel or the outer wall of the annular round metal rod in the axial spaced layered circumferential direction of the steel barrel and penetrate through the buffer layers. According to the low-stress dipping pipe for the RH vacuum furnace, the problem that damage and deterioration are caused due to the fact that the difference of the material performances of all components in a dipping pipe complex structure is remarkable is effectively solved, and the comprehensive purposes of reducing the structural stress and the heat stress of the dipping pipe, improving the dipping pipe resistance to crack, stripping and damage and the integrality and the structural stability of the dipping pipe, prolonging the service life of the dipping pipe and the like are achieved.

Owner:武汉钢铁有限公司

High-modulus asphalt material with excellent durability and preparation method thereof

InactiveCN112574583AHigh modulusImprove fatigue performanceBuilding insulationsLow-density polyethyleneButadiene Dioxide

A high-modulus asphalt material with excellent durability and a preparation method thereof. The high-modulus asphalt material is mainly prepared from the following components in parts by mass: 50-65 parts of low-grade asphalt, 15-25 parts of a high-modulus additive, 5-10 parts of coarse aggregate, 5-10 parts of fine aggregate, 3-5 parts of mineral powder, 1-3 parts of an antioxidant, 1-3 parts ofan anti-ultraviolet agent and 0.3-0.5 part of a cross-linking agent. The high-modulus additive is mainly prepared from the following components in parts by mass: a styrene-butadiene-styrene block copolymer, high-density polyethylene, polyethylene PE, low-density polyethylene, organic silicon modified hydroxyl-terminated hyperbranched polyester resin, polypropylene and linear low-density polyethylene. According to the high-modulus asphalt material with excellent durability and the preparation method of the high-modulus asphalt material, the formula is reasonable, the preparation process is simple, the durability is excellent, the modulus of the asphalt material is improved, the high-temperature deformation resistance of an asphalt pavement is improved, the anti-fatigue performance of the asphalt material is improved, and the application prospect is expanded.

Owner:徐州市融道路桥有限公司

A kind of high modulus asphalt particle and preparation method thereof for road construction

ActiveCN104559257BHigh modulusImprove high temperature deformation resistanceBuilding insulationsSocial benefitsCrack resistance

The invention relates to a high-modulus asphalt particle for road building and a preparation method thereof. The high-modulus asphalt particle comprises the following components in parts by mass: 40-80 parts of modified asphalt and 20-60 parts of filler, wherein the modified asphalt comprises the following raw materials in parts by mass: 10-20 parts of a polymer, 0.1-5 parts of an anti-aging agent, 2-4 parts of a thickener, 2-5 parts of a modifier, 1-3 parts of a crosslinking agent and 50-90 parts of matrix asphalt, wherein the matrix asphalt is one of Shell No. 70, Shell No.90, SK No. 70 and SK No. 90. Compared with the prior art, the preparation method is simple in process and low in cost, the waste utilization is achieved and the asphalt particle is suitable for industrial production; by the prepared high-modulus asphalt particle, the rutting resistance, low-temperature crack resistance, water damage resistance and aging resistance of asphalt concrete can be significantly improved and the service life of the asphalt pavement is prolonged; and the high-modulus asphalt particle is very safe and convenient to store and transport, is energy-saving and environment-friendly and has significant economic and social benefits.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

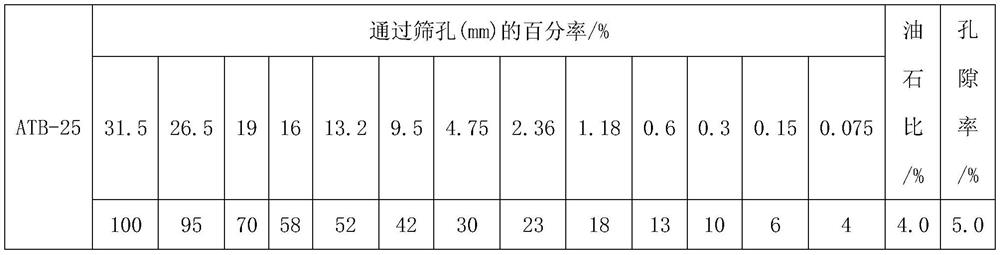

High-modulus asphalt mixture and preparation method thereof

PendingCN112209658AImprove high temperature deformation resistanceImprove project qualityAsphalt pavementRaw material

The invention provides a high-modulus asphalt mixture and a preparation method, the high-modulus asphalt mixture is prepared from the following raw materials by mass fraction: 4.6%-6.6% of matrix asphalt, a high-modulus additive accounting for 4.0%-8.0% of the matrix asphalt, mineral powder accounting for 50% of the matrix asphalt, and the balance of aggregate, and the sum of the mass fractions ofthe raw materials is 100%, or 4.6%-6.6% of matrix asphalt, a high-modulus additive accounting for 4.0%-8.0% of the matrix asphalt, biomass heavy oil accounting for 20% of the matrix asphalt, mineralpowder accounting for 50% of the matrix asphalt and the balance aggregate, and the sum of the mass fractions of the raw materials is 100%. According to the invention, the high-temperature deformationresistance of the asphalt mixture can be improved, the structural track disease of the asphalt pavement is solved, the engineering quality of the asphalt pavement is improved, and the service life ofthe asphalt pavement is prolonged.Biomass heavy oil is added when the high-modulus asphalt mixture is prepared, so that the flexibility and the low-temperature resistance of matrix asphalt are improved, and the high-modulus asphalt mixture has better low-temperature crack resistance.

Owner:CHANGAN UNIV +2

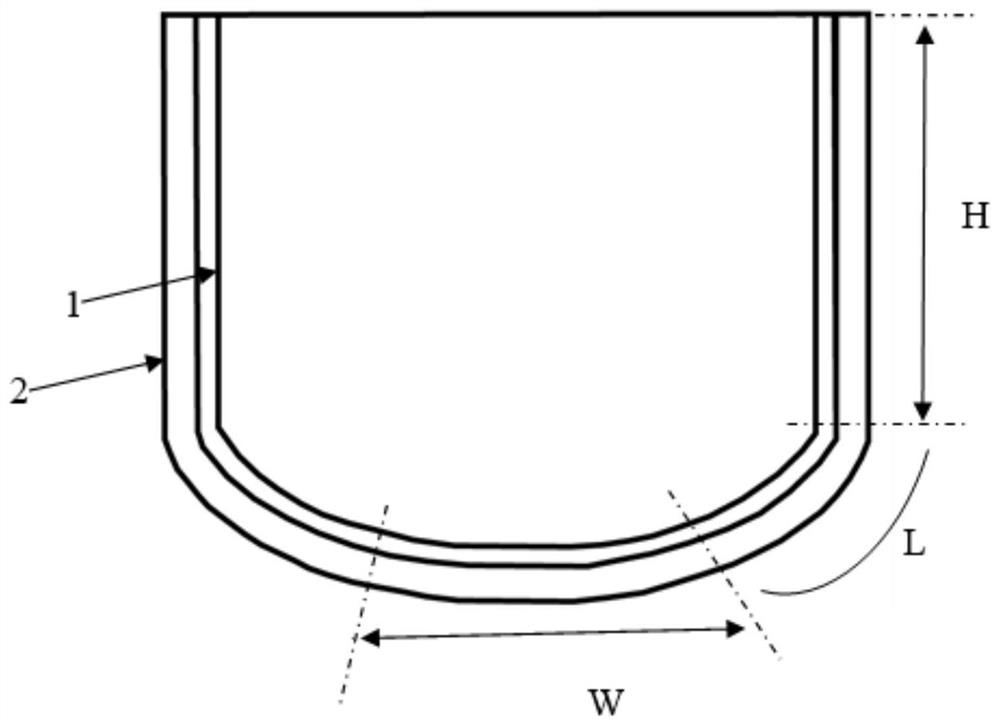

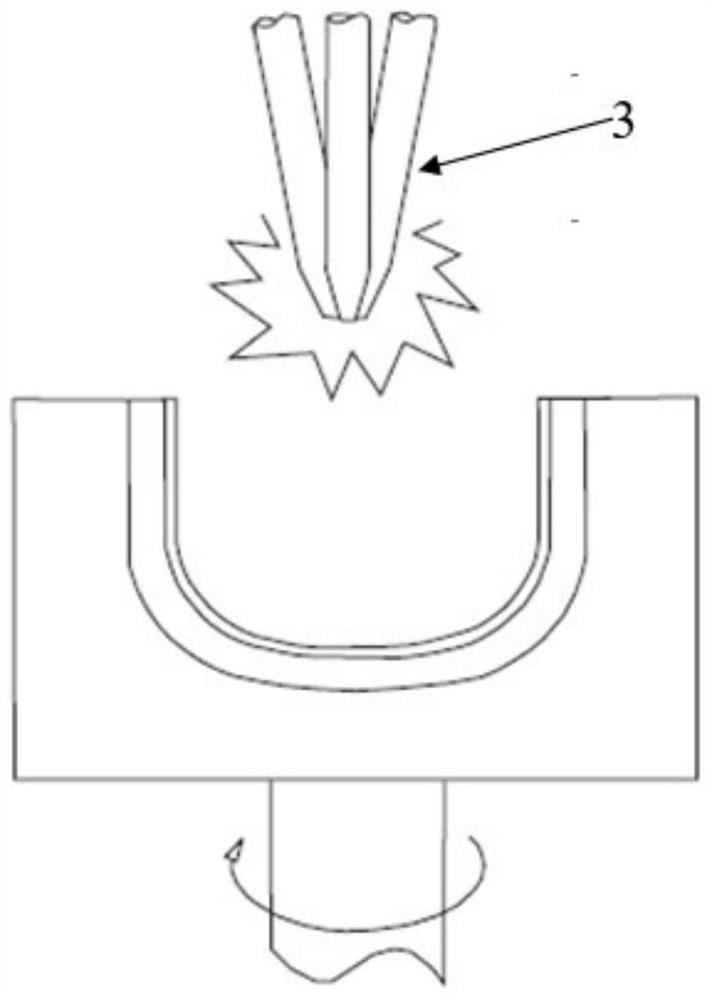

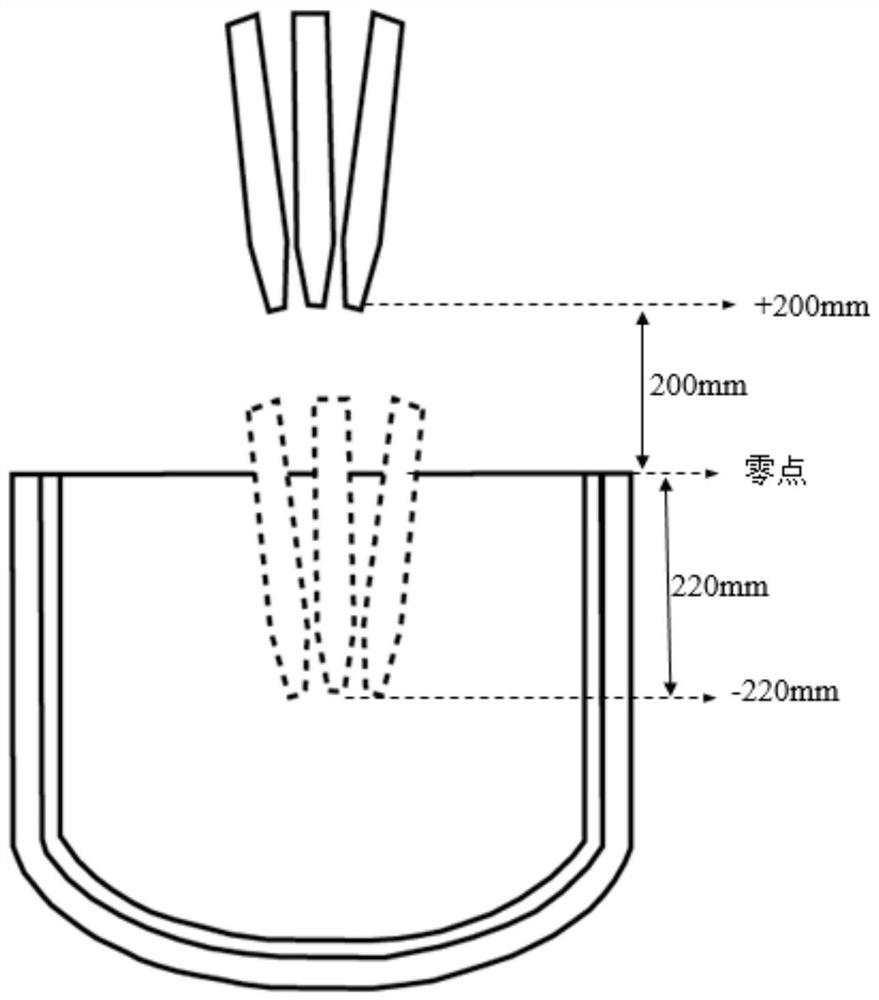

Manufacturing method of high-quality quartz crucible

PendingCN114477736AQuality improvementReduce saggingPolycrystalline material growthBy pulling from meltGraphite electrodeVacuum arc

The invention relates to a manufacturing method of a high-quality quartz crucible, a vacuum arc method is adopted for melting, and the displacement of a graphite electrode and the retention time on each position meet the following conditions: the end face position of an upper opening of a mold is taken as a zero point, the end of the graphite electrode above the zero point is +, and the end of the graphite electrode below the zero point is-; the initial position of the graphite electrode is + 0.10-0.30 times of the outer diameter of the crucible, the retention time is greater than or equal to 2 minutes, then the graphite electrode is sequentially descended according to a step displacement method, the graphite electrode is retained for a period of time every time when the graphite electrode is descended, and the graphite electrode reaches the bottom polishing position after displacement is carried out for at least 3 times; the bottom polishing position is the lowest position where the graphite electrode reaches, enters the crucible blank and is 300-550mm away from the bottom of the crucible; at the position, the graphite electrode stays and performs high-temperature polishing and volatilization impurity removal on the bottom of the crucible; the outer diameter of the crucible is + 0.05-0.07 times of the outer diameter of the crucible, and high-temperature volatilization impurity removal is carried out on the upper portion of the inner wall of the quartz crucible at the tail sweeping station. The method is used for improving the purity of the transparent layer of the crucible, enhancing the high-temperature deformation resistance and the like.

Owner:JINZHOU YOUXIN QUARTZ TECH

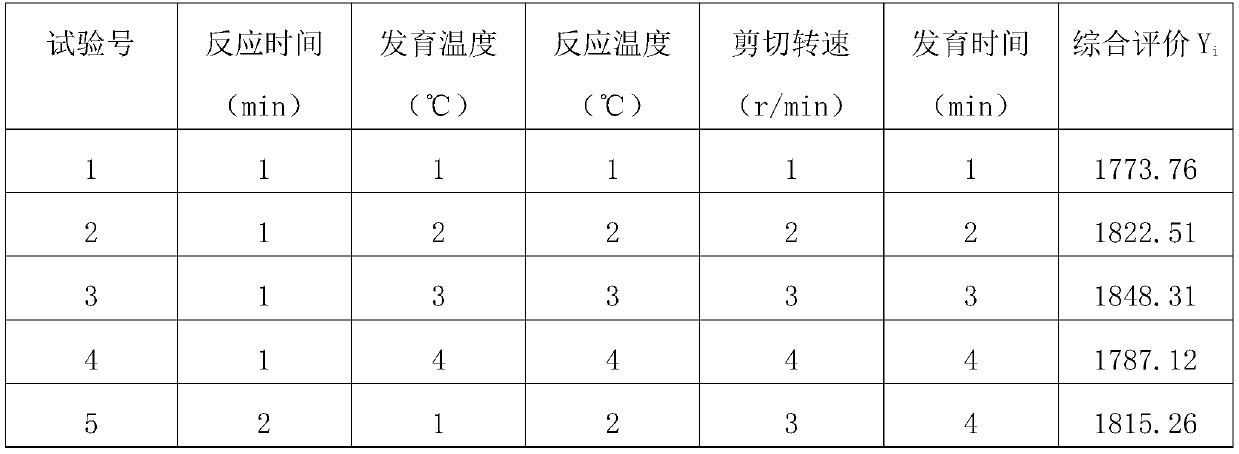

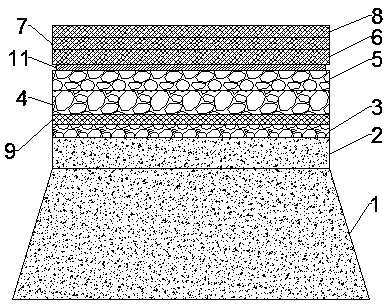

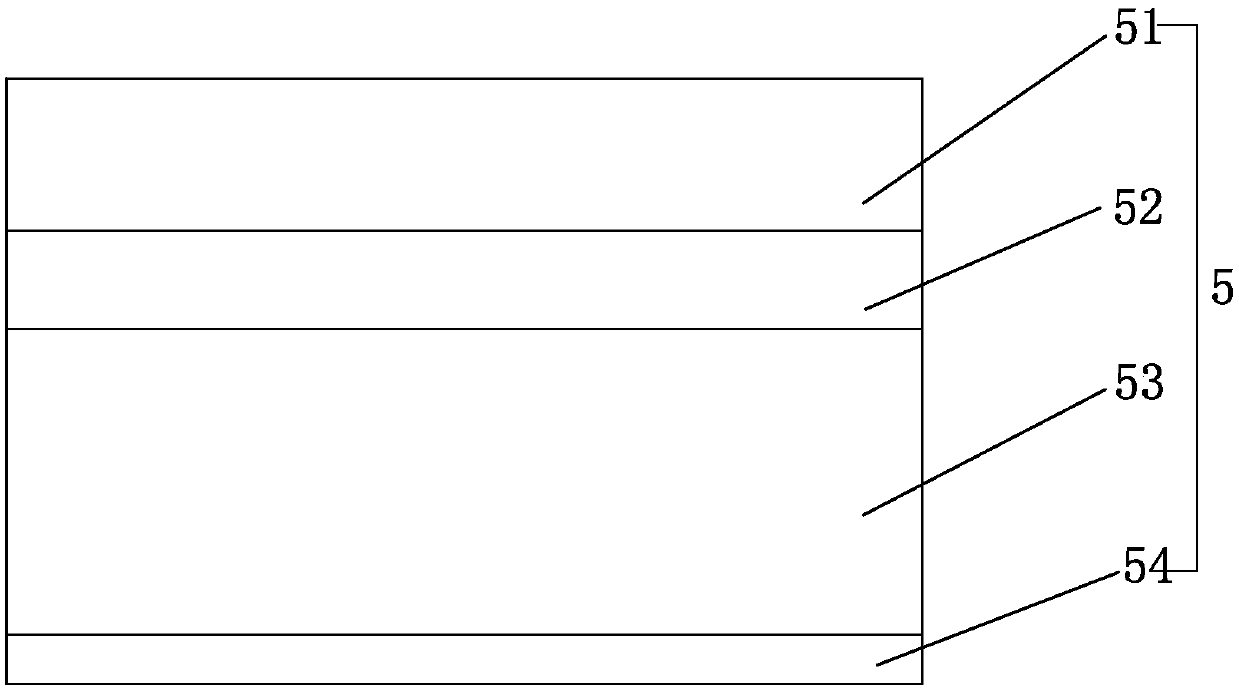

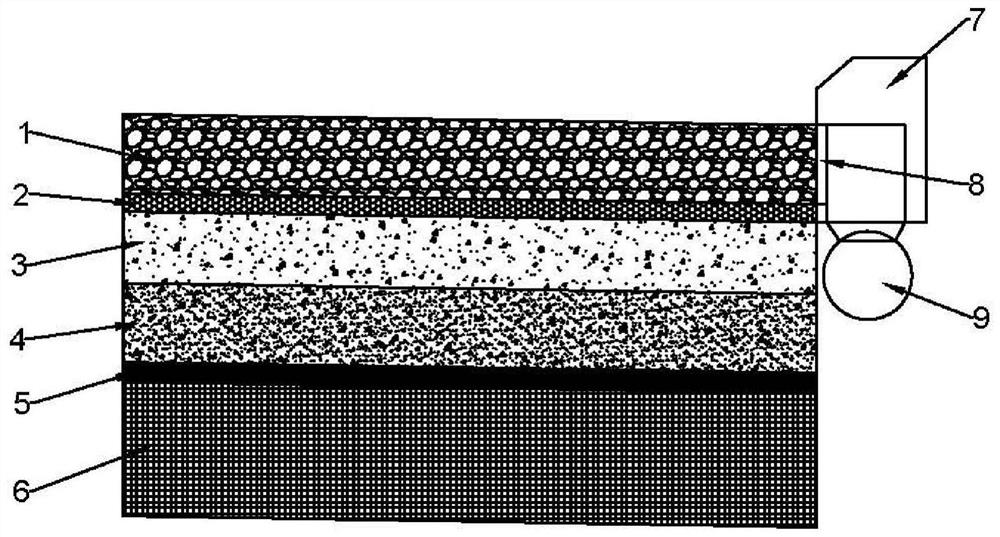

A drainage-retaining pavement structure and construction method for reducing urban heat island effect

ActiveCN109235179BEnsure driving safetyLean structurePaving gutters/kerbsClimate change adaptationPondingCrushed stone

The invention discloses a drainage-retaining pavement structure for reducing the urban heat island effect, and a construction method thereof. The drainage-retaining pavement structure sequentially comprises an asphalt stabilized crushed stone base layer (6), a low water seal layer (5), a water-storing crushed stone layer (4), a macroporous water-retaining concrete layer (3), a water-permeable stress absorbing layer (2) and a macroporous water-permeable asphalt concrete layer (1) arranged from the bottom layer to the top layer thereof. A drainage curb structure (7) is arranged on one side of the macroporous water-permeable asphalt concrete layer (1) near the curb, and a drainage filter screen (8) is arranged on the side of the macroporous water-permeable asphalt concrete layer (1) adjacentto the pavement, and drainage pipes (9) are installed below the drainage curb structure (7); And a drainage curb structure (7) with a drainage filter net (8) is installed on the drainage conduit (9) which is pre-buried at the curb band. On the one hand, the invention ensures no accumulated water on the road surface in rainy season and improves driving safety; on the other hand, the collected watercan gradually absorb heat and evaporate, thus lowering the surface temperature of the road and alleviating the heat island effect of the city.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com