Integrated adjustable rack

An adjustable, material rack technology, used in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve the problems of inability to load more coils, increase costs, reduce work efficiency, etc., to reduce the number of cart motors and reduce occupation. time, the effect of enhancing the overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

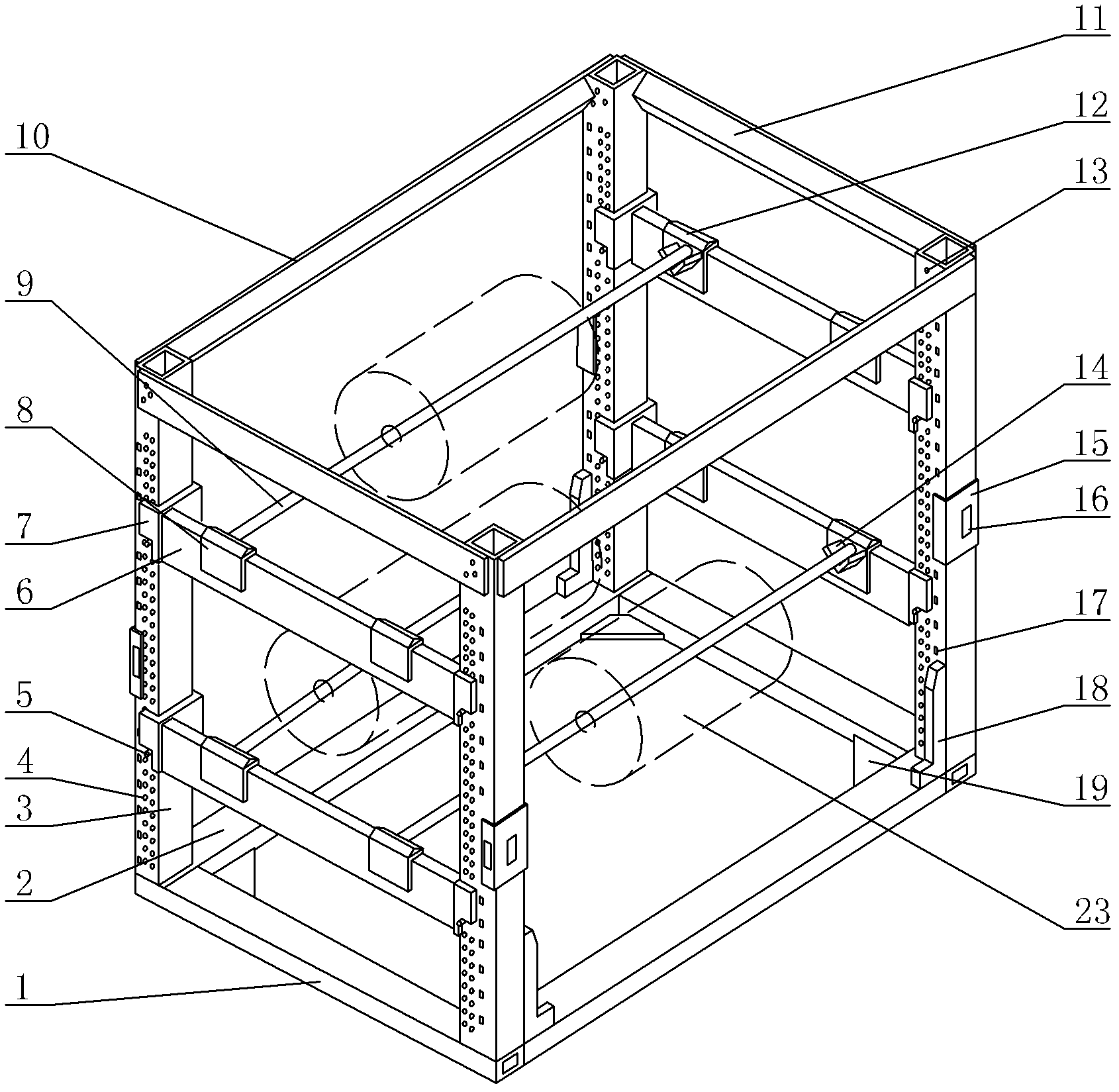

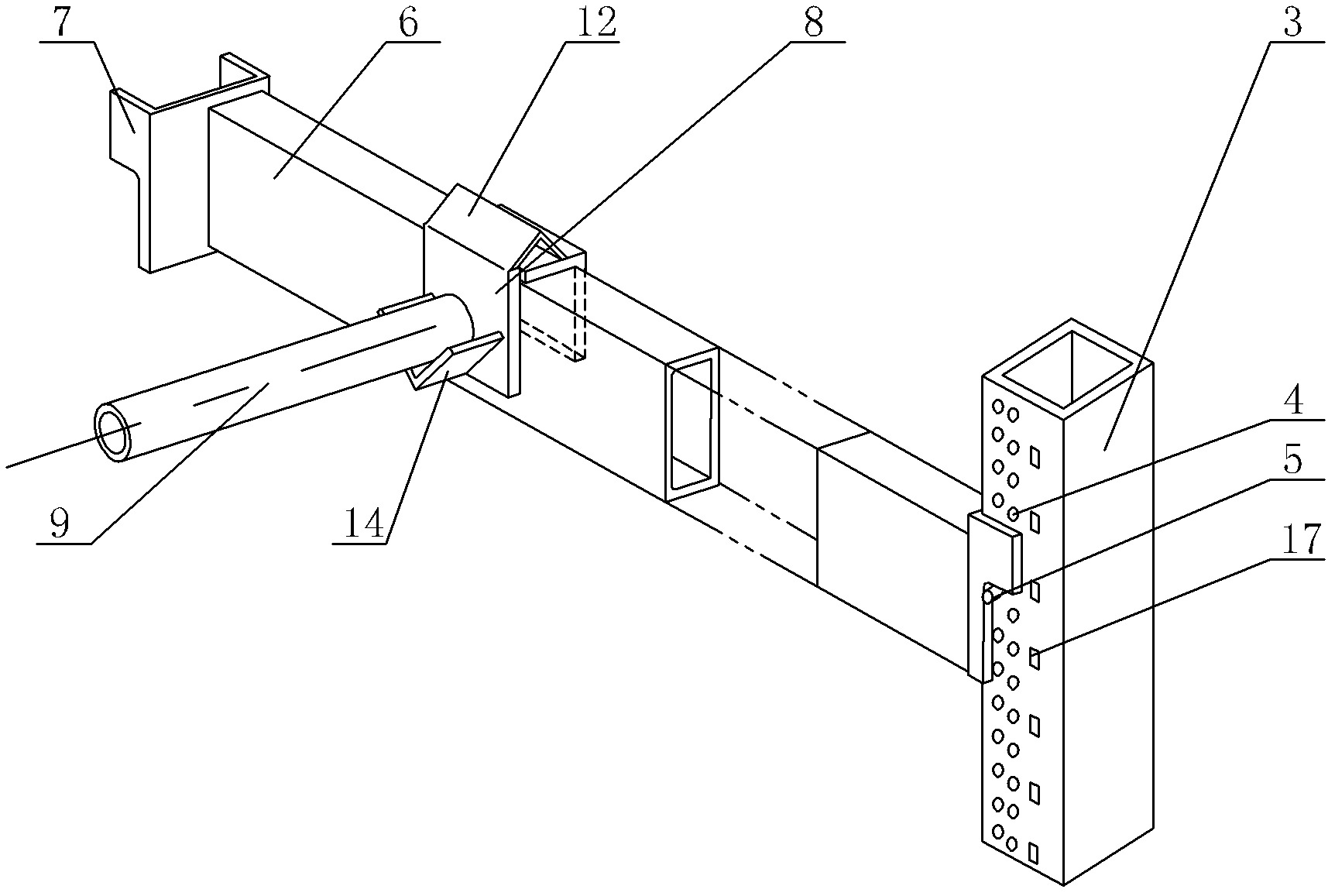

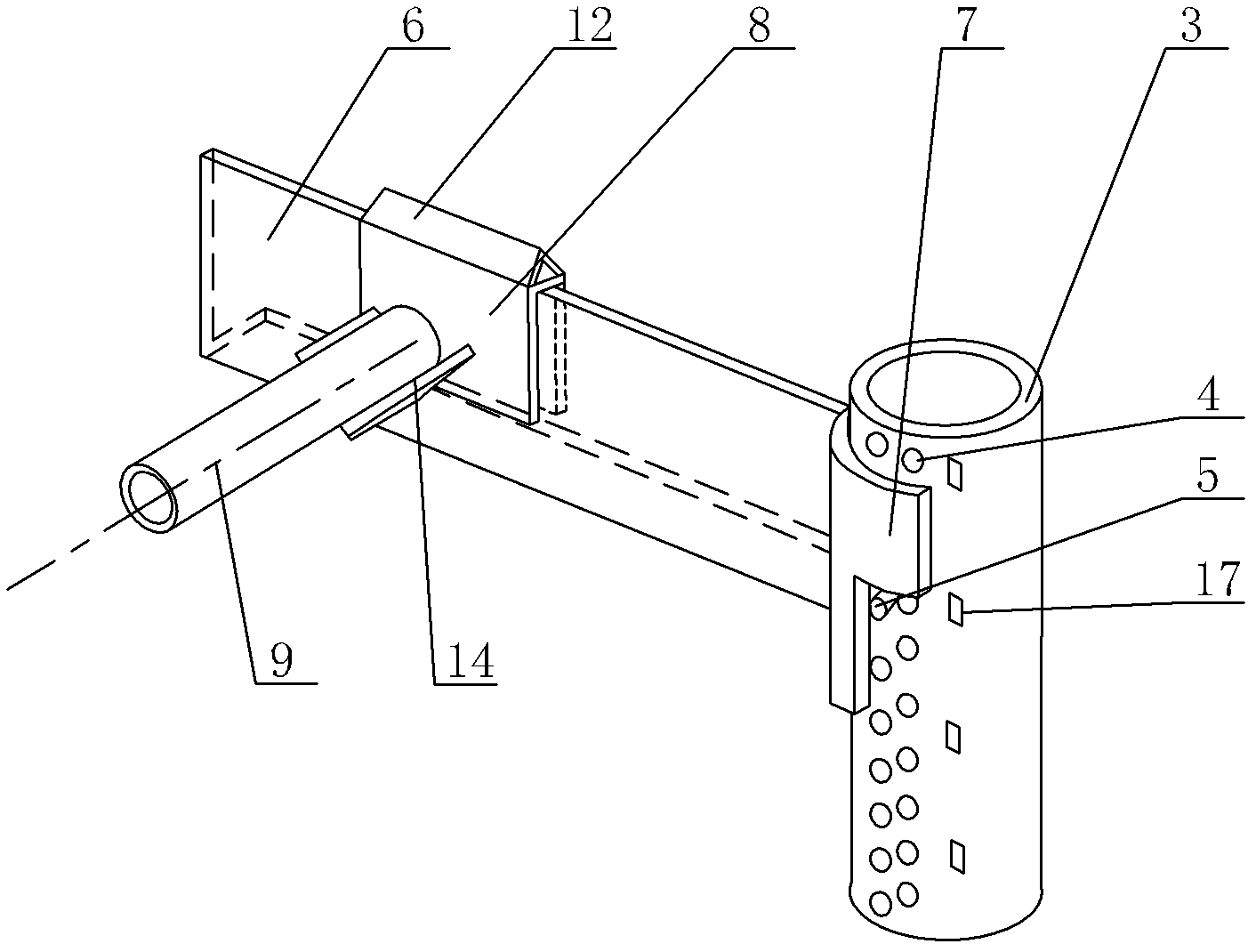

[0039] like Figure 1 to Figure 5 As shown, the integrated adjustable material rack of the present invention includes a rack body, the rack body includes a rectangular chassis, the chassis includes an upper chassis and a lower chassis, and the lower chassis is composed of two parallel beams 1 and two parallel longitudinal beams 2, Four uprights 3 are arranged at the connection between the two beams 1 and the two longitudinal beams 2 , a column angle plate 18 is arranged between the upright column 3 and the longitudinal beam 2 , and a chassis angle plate 19 is arranged on the inner side between the transverse beam 1 and the longitudinal beam 2 . The vertical column 3 is evenly provided with two rows of pin shaft holes 4 that are staggered in the longitudinal direction. The pin shaft holes 4 are through holes. The pin shaft hole 4 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com