Patents

Literature

529results about How to "Meet the requirements of energy saving and emission reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-carbon dispatching method and device for electric power system based on large-scale wind power grid connection

ActiveCN102170129AImprove economyPromote low carbonSingle network parallel feeding arrangementsFuzzy logic based systemsEcological environmentLow-carbon power

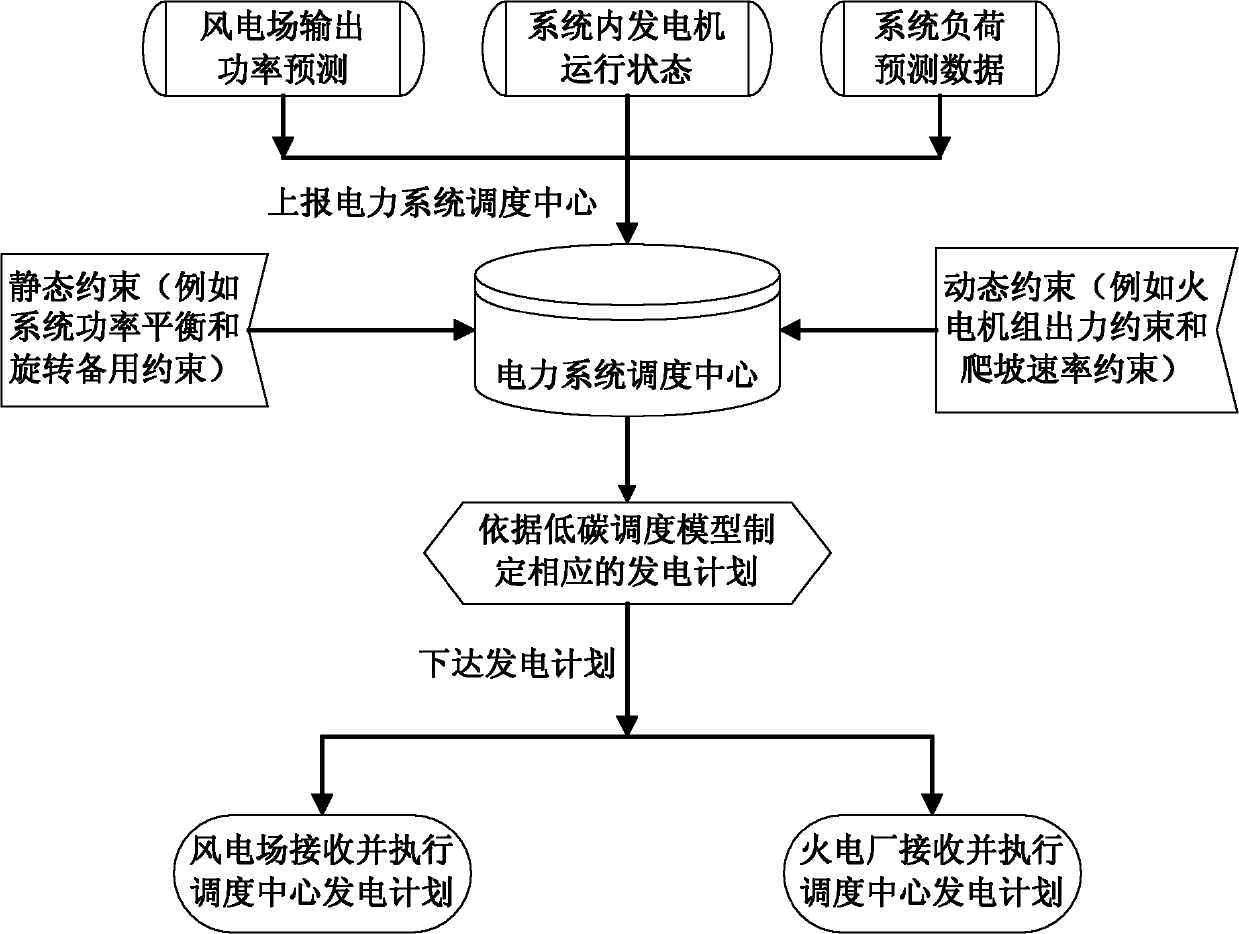

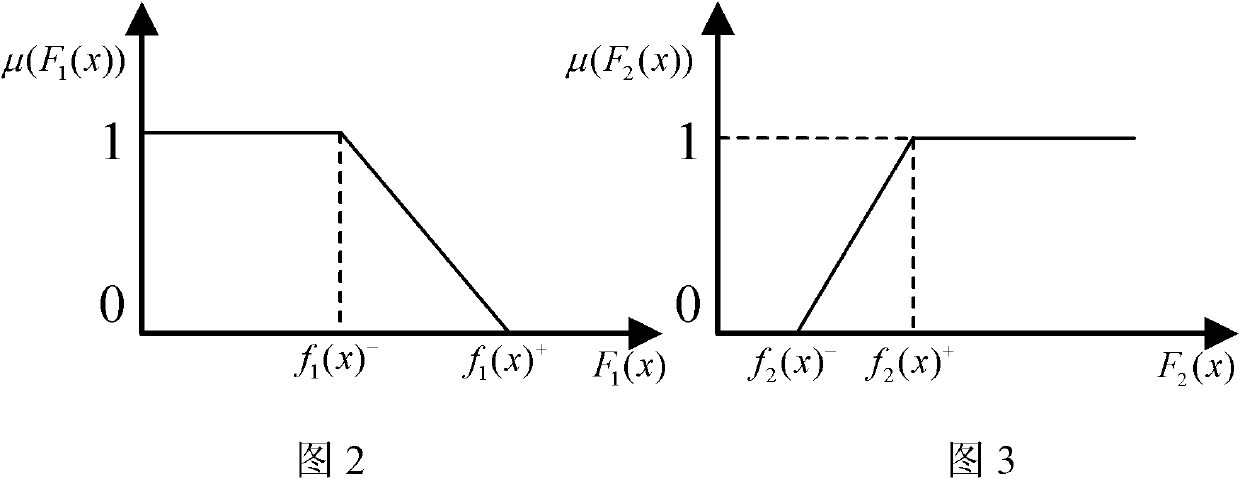

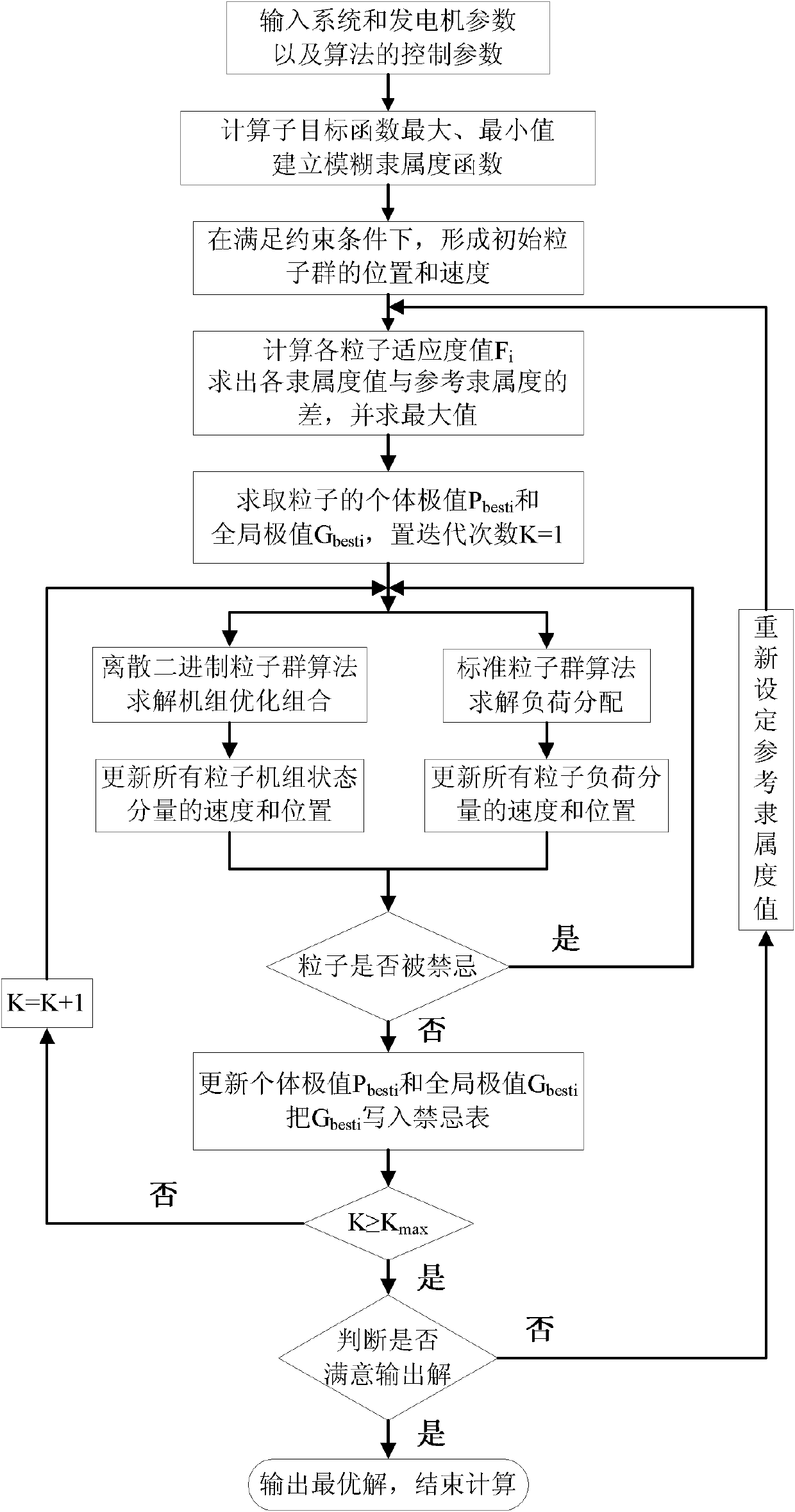

The invention relates to a low-carbon dispatching method and device for an electric power system based on large-scale wind power grid connection. The low-carbon dispatching method comprises the following steps of: (1) collecting power grid data of a given power grid system in the next dispatching cycle by a dispatching system of the electric power system; (2) capturing active load distribution values of a wind power farm and each generator by a low-carbon dispatching system according to the power grid data collected by the dispatching system of the electric power system; (3) making a new power generation executing plan by the dispatching system of the electric power system according to the active load distribution values of the wind power farm and the generators, which are captured by the low-carbon dispatching system; and (4) sending the new power generation executing plan, which is made by the dispatching center of the electric power system, to the wind power farm and a thermal power plant by a power generation executing system so as to execute the plan. The invention has the following advantages that the economy of power production is considered, and moreover, the protection of ecological environment is paid more attention to at the same time; and requirements for energy-saving and emission reduction are met, and low-carbon power production is promoted.

Owner:WUHAN UNIV +1

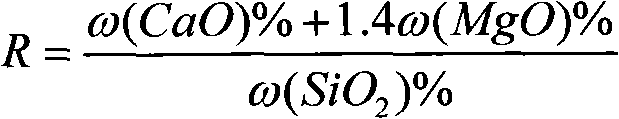

Method for fusing and reducing iron from copper residue by blowing inert gas

InactiveCN101736112AMeet the requirements of energy saving and emission reductionEmission reductionFluidised-bed furnacesMelting tankCombustion

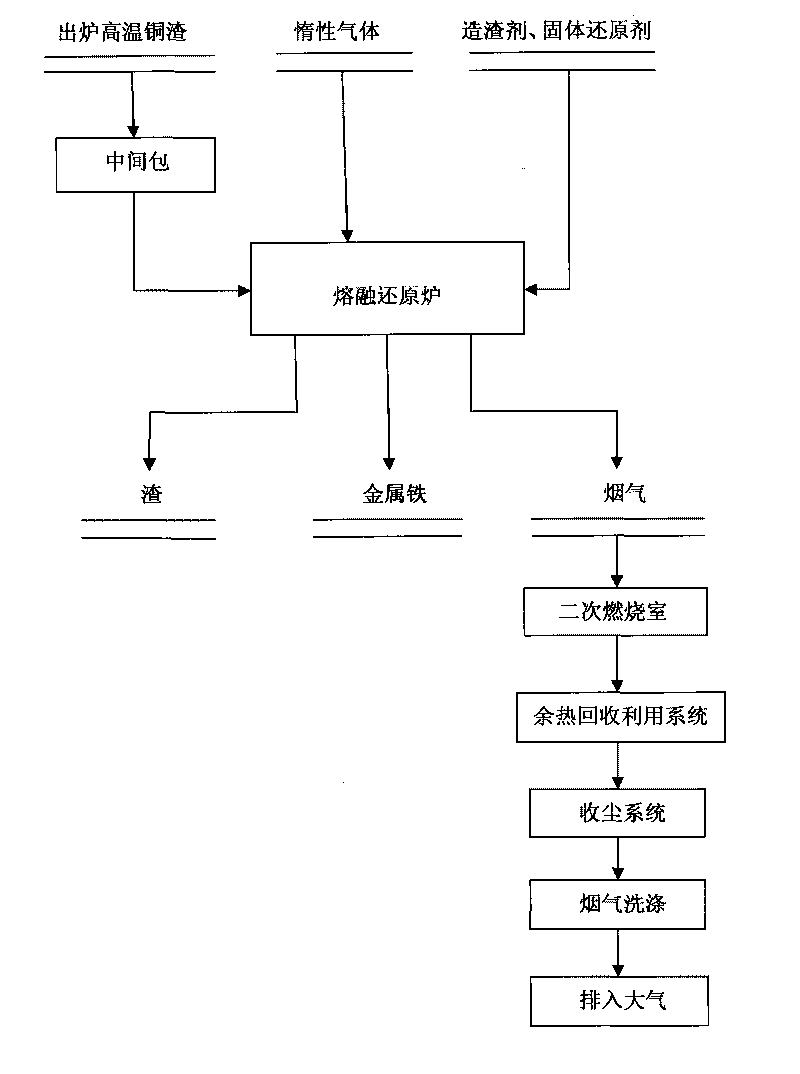

The invention discloses a method for fusing and reducing iron from copper residue by blowing inert gas which comprises the steps of: transferring a high-temperature copper residue from a pouring packet to a high-temperature reduction furnace, adding reducing agent and slagging agent which are crushed into the reduction furnace, performing high-temperature iron reduction reaction, stirring inert gases and blowing into a furnace hearth during the reaction, spraying the inert gases and stirring the fused residue, performing high-temperature smoke secondary combustion, collecting dust and washing after recycling the waste heat, injecting into the atmosphere after emptying, and discharging high-temperature molten iron and slag from an iron outlet and a slag outlet after finishing the reaction. The invention takes full advantages of high-temperature waste heat of the discharged copper residue in order to save energy and reduce emission. The process flow is short; the discharge of contaminant is less, the recovering ratio is high; the applicability is wide; the process flow for recycling iron from copper residue is shortened; the operation in each process flow is simple; and the maintenance cost for furnace is lower.

Owner:KUNMING UNIV OF SCI & TECH

Method for directly restoring and recovering copper iron from smelting copper slag

ActiveCN102952952AMeet the requirements of energy saving and emission reductionEfficient recyclingProcess efficiency improvementGas emission reductionMolten stateOxygen

The invention belongs to the field of metallurgy, and particularly relates to a method for directly restoring and recovering copper iron from smelting copper slag. The method comprises the following steps of: transferring high-temperature molten state copper slag to a high-temperature reducing furnace by a tundish, jetting oxygen to previously desulfurize, adding slagging constituent to keep temperature, jetting natural gas to carry out smelting reduction, slowly cooling to 1096 DEG C at the speed of 1.5-2 DEG C / min, and keeping the temperature for 1h to obtain 7.3at% Cu-Fe copper alloy melt and gamma pig iron, or slowly cooling to 850 DEG C at the speed of 1.5-2 DEG C / min, and keeping the temperature for 1h to obtain 2.7at% Cu-Fe copper alloy melt and gamma pig iron. According to the method provided by the invention, the total recovery use of valuable components, i.e. copper, iron and the like, can be realized, and the alloy melt obtained by the reduction smelting is slowly cooled and separated to obtain copper-rich alloy and low-sulfur gamma pig iron, so that separation of copper and iron is realized and the additional values of products can be improved.

Owner:NORTHEASTERN UNIV

Cationization modification method for nano-crystalline cellulose and preparation method of high-strength cigarette paper

ActiveCN102180979ALess investmentHigh strengthReinforcing agents additionPaper/cardboardFiberReaction temperature

The invention belongs to the field of production of special paper, and in particular relates to a cationization modification method of nano-crystalline cellulose and a method for preparing high-strength cigarette paper from the modified nano-crystalline cellulose. Specific to the characteristic of high specific surface area of nano-crystalline cellulose, KOH and a method for adding an etherification reaction accelerant are adopted, the reaction temperature is lowered below 50 DEG C, cationization modification is performed on the nano-crystalline cellulose, and the modified nano-crystalline cellulose has the characteristics of retention and enhancement, so that the modified nano-crystalline cellulose has a wider application prospect; in the method for preparing cigarette paper, softwood pulp is not used, and higher natural air permeability and higher bonding strength of a product are ensured under the condition of reducing broadleaf wood fiber devillicate and fibrillation, so that energy consumption in the production process of paper, in particular in the pulping process, is remarkably lowered, equipment investment of a paper mill is reduced, high-strength cigarette paper is manufactured, the page quality is improved, higher strength and air permeability of the product are achieved, and the requirements on energy conservation and emission reduction are met.

Owner:MUDANJIANG HENGFENG PAPER CO LTD

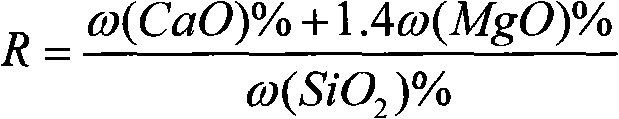

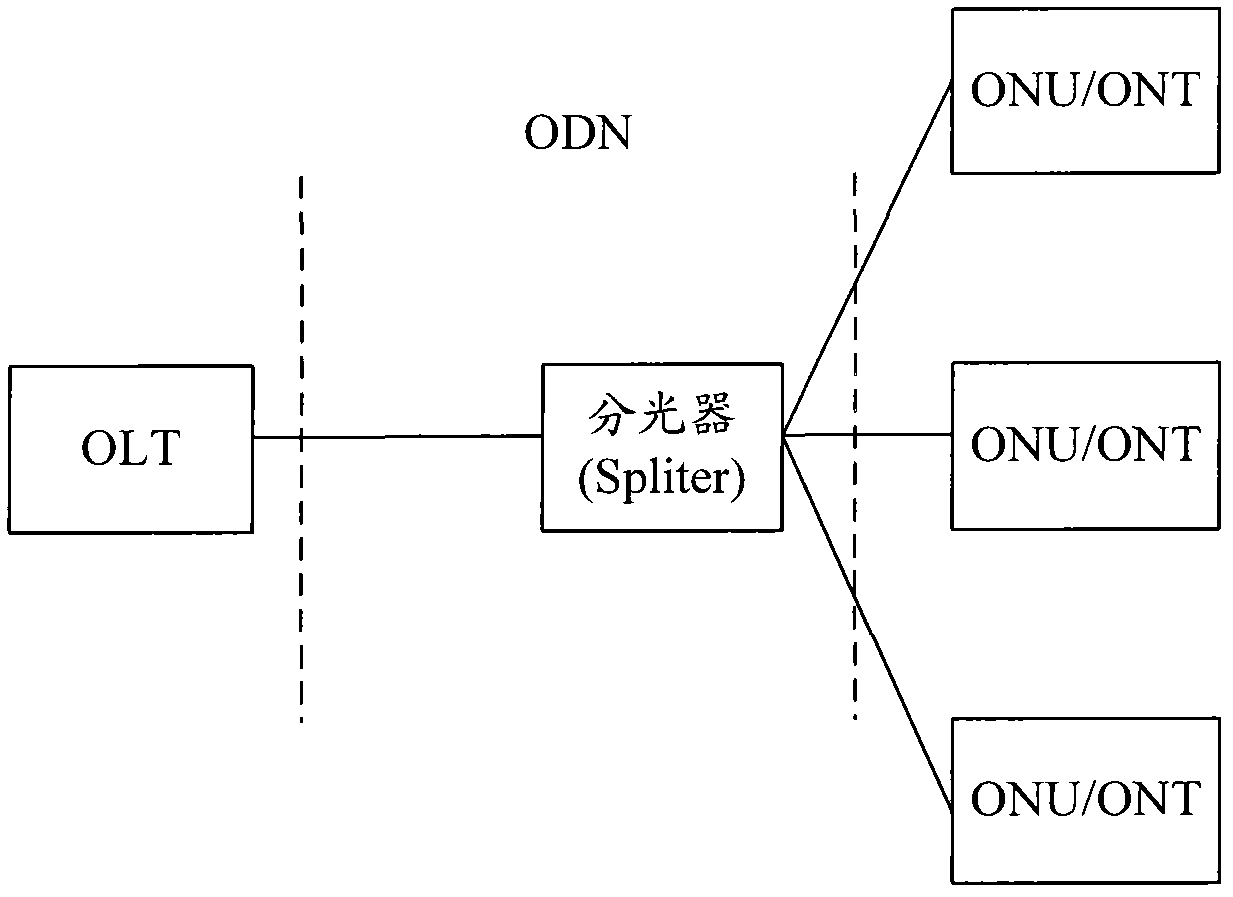

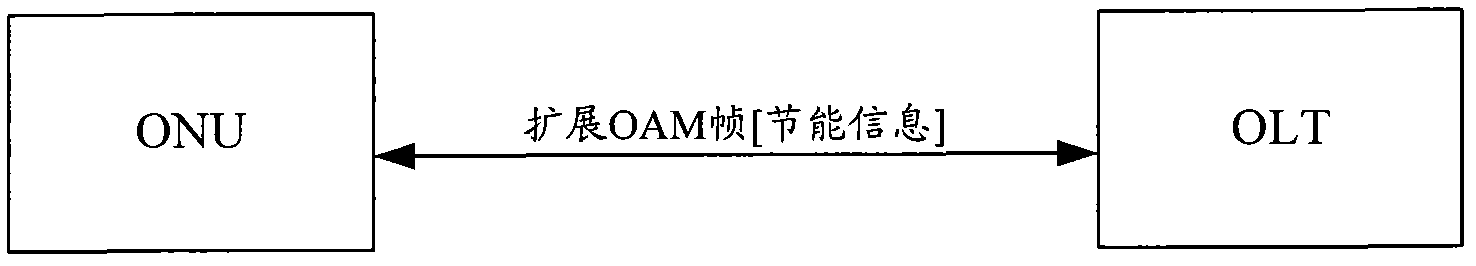

Method and system for realizing energy-saving mechanism management between Optical Network Unit (ONU) and Optical Line Terminal (OLT)

ActiveCN102404047AReduce power consumptionMeet the requirements of energy saving and emission reductionMultiplex system selection arrangementsOptical multiplexOptical ModuleComputer terminal

The invention discloses a method and a system for realizing energy-saving mechanism management between an Optical Network Unit (ONU) and an Optical Line Terminal (OLT). The method comprises the steps of: transferring energy saving information through extended Operation and Maintenance (OAM) frames between the ONU and the OLT; and closing / opening the ONU optical module according to acquired energy saving information. The method disclosed by the invention, when the ONU optical module is not needed to work, closes the optical module in time, thus reducing power consumption of the ONU and meeting the demands on energy saving and emission reduction aspects of interactions between the ONU and the OLT.

Owner:ZTE CORP

A kind of carbon composite refractory material and preparation method thereof

The invention relates to a carbon composite fireproof material and a preparation method thereof. A technical scheme of the method is that: raw materials of the carbon composite fireproof material comprise: 55-75 wt% of oxide particles, 10-20 wt% of oxide fine powder, 5-10 wt% of oxide micropowder, 1-5 wt% of a carbonaceous material, 0.1-3 wt% of graphene, 2-8 wt% of an antioxidant and 3-6 wt% of an organic binding agent. The preparation process for the carbon composite fireproof material comprises: grinding the grapheme, the oxide micropowder and the antioxidant according to the correspondingcontents of the raw materials to obtain precast mixed powder; then uniformly mixing the precast powder, the oxide particles, the oxide fine powder, the carbonaceous material and the organic binding agent, and molding; carrying out heat treatment at a temperature of 180-240 DEG C, then carrying out light burning at the temperature of 700-850 DEG C or carrying out sintering at the temperature of 1100-1400 DEG C to obtain the carbon composite fireproof material. The carbon composite fireproof material provided by the present invention has characteristics of high strength, low thermal conductivity, excellent thermal shock resistance and excellent slag corrosion resistance, and meets the requirement of energy saving and emission reduction.

Owner:WUHAN UNIV OF SCI & TECH

Method for preparing vanadium nitride

InactiveCN101717076AAvoid agglomeration or crystallizationWide variety of sourcesNitrogen-metal/silicon/boron binary compoundsCapacitanceMaterials science

The invention discloses a method for preparing vanadium nitride. In the preparation method, a vanadium-containing compound is mixed with organic nitride, and the mixture is calcinated in nitrogen-containing gas to obtain the vanadium nitride. The vanadium nitride prepared by the method has small grain diameter, and has higher specific capacitance and good cycle performance. The method for preparing the vanadium nitride has the advantages of wide source of raw materials, low production cost, simple operation and low requirement on equipment, meets the requirement of modern industry on energy conservation and emission reduction, and is favorable for industrial production. When the method is used for preparing super capacitors, the super capacitors have high specific capacitance and good cycle performance.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Processing method for recycling aluminum dross

ActiveCN101913634ANo pollutionReduce pollutionAlkaline-earth metal aluminates/aluminium-oxide/aluminium-hydroxide preparationSocial benefitsPtru catalyst

The invention discloses a processing method for recycling aluminum dross, which comprises the following steps: adding crushed limestone and catalyst to aluminum dross, thoroughly homogenizing and mixing the three materials, carrying out catalyzed calcination on the thoroughly homogenized and mixed materials in a calcination reaction furnace, and directly grinding the calcined products or grinding the calcined products after cooling, thus obtaining the calcium aluminate powder product. The processing method has a simple operational process, and can not cause new environmental pollution, thereby according with the policy for industry development. The invention recycles the aluminum dross, simultaneously reduces environmental pollution caused by the aluminum dross, improves the environmental management on surrounding areas, and also provides a reasonable and effective way to recycle waste aluminum dross. Thus, the invention has obvious economic benefits and social benefits.

Owner:HENAN KETAI WATER PURIFYING MATERIALS

Production process of environmental-protection plant energy particle fuel

InactiveCN101892108AReduce pollutionMeet the requirements of energy saving and emission reductionBiofuelsSolid fuelsEnergy particleSolid fuel

The invention relates to a production process of an environmental-protection plant energy particle fuel, which is characterized by collecting combustible plant materials as raw materials and then sequentially processing the raw materials by the following steps of: (1) pulverizing: the raw materials are pulverized into powdery particle materials with the particle size less than 2 mm; (2) drying: the pulverized materials are dried so that the water content of the materials is 12%-20% by drying; and (3) extrusion molding: extrusion molding is carried out to the dried materials so that the materials form a solid particle fuel with the density of 1.0-1.4 g / cm<3> through extrusion molding. The invention can be used for processing various combustible plant materials comprising agricultural or forestall wastes and the like into high-efficiency combustible solid fuel particles, thereby solving the problem of considerably increased agricultural (forestall) wastes at present, also relieving the current situation of increasing energy shortage at present and being beneficial to environmental protection and energy saving.

Owner:福建泰和生物质能源科技有限公司 +2

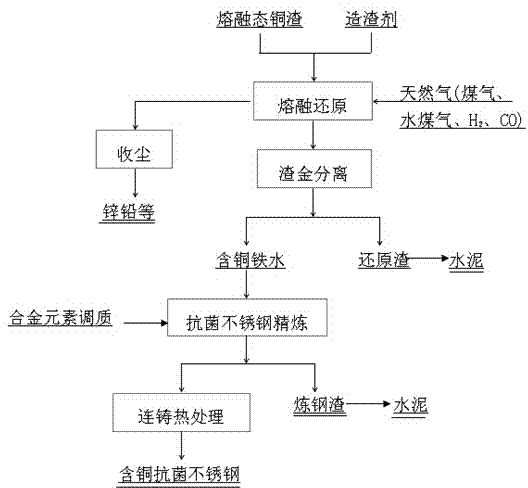

Method for directly smelting copper-bearing antibacterial stainless steel by utilizing copper slag for reducing molten iron

ActiveCN104120351AAchieve high valueRealize slag-free cleaning processSteelmakingRefining (metallurgy)

The invention belongs to the field of metallurgy, and particularly relates to a method for directly smelting copper-bearing antibacterial stainless steel by utilizing copper slag for reducing molten iron. According to the method, high-temperature molten-state copper slag is directly transferred and injected into a high-temperature reduction furnace, oxygen is sprayed and blown into the furnace to perform oxidation impurity removing pretreatment on the molten copper slag, then, slagging constituents are added in the furnace, inert gas and natural gas are sprayed and blown into the furnace for smelting reduction to obtain copper-bearing molten iron, the copper-bearing molten iron is conveyed to the steelmaking process, copper-bearing mother steel liquor is obtained, continuous casting is performed on the molten steel mother liquor obtained by refining to obtain a steel billet, hot rolling and annealing treatment are performed on the steel billet, and the antibacterial stainless steel is obtained. According to the method, the production cost of the antibacterial stainless steel is greatly reduced, and meanwhile the comprehensive utilization added value of valuable elements of the copper slag is greatly improved.

Owner:NORTHEASTERN UNIV

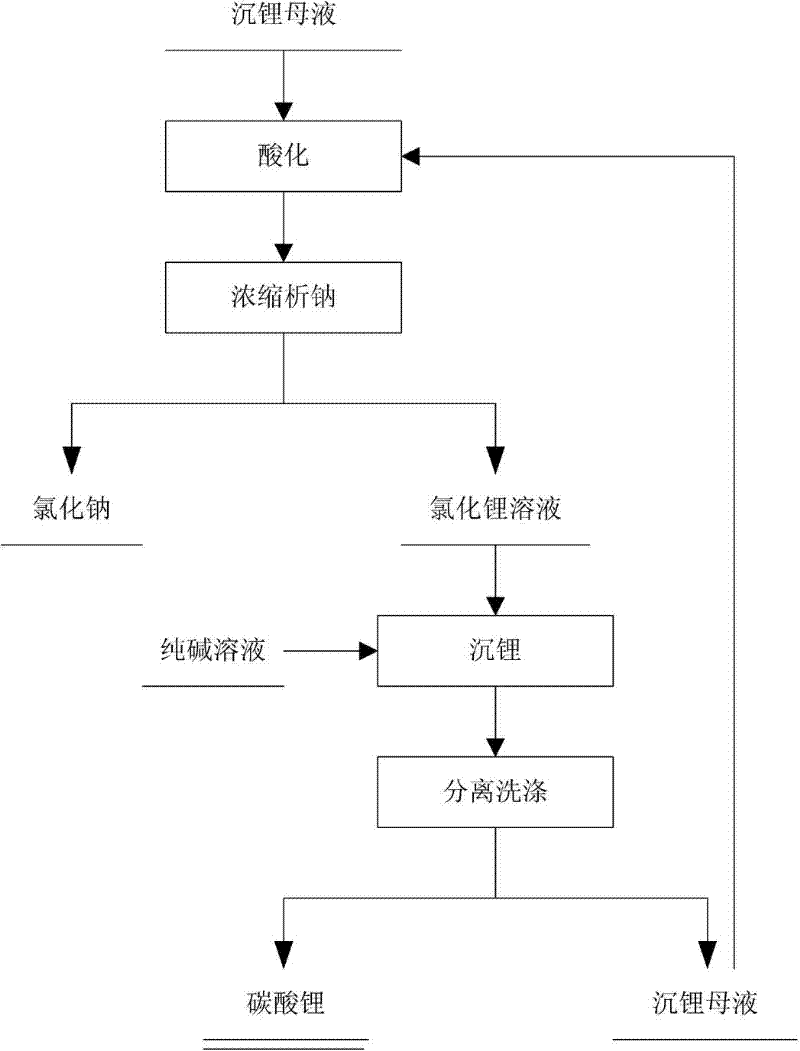

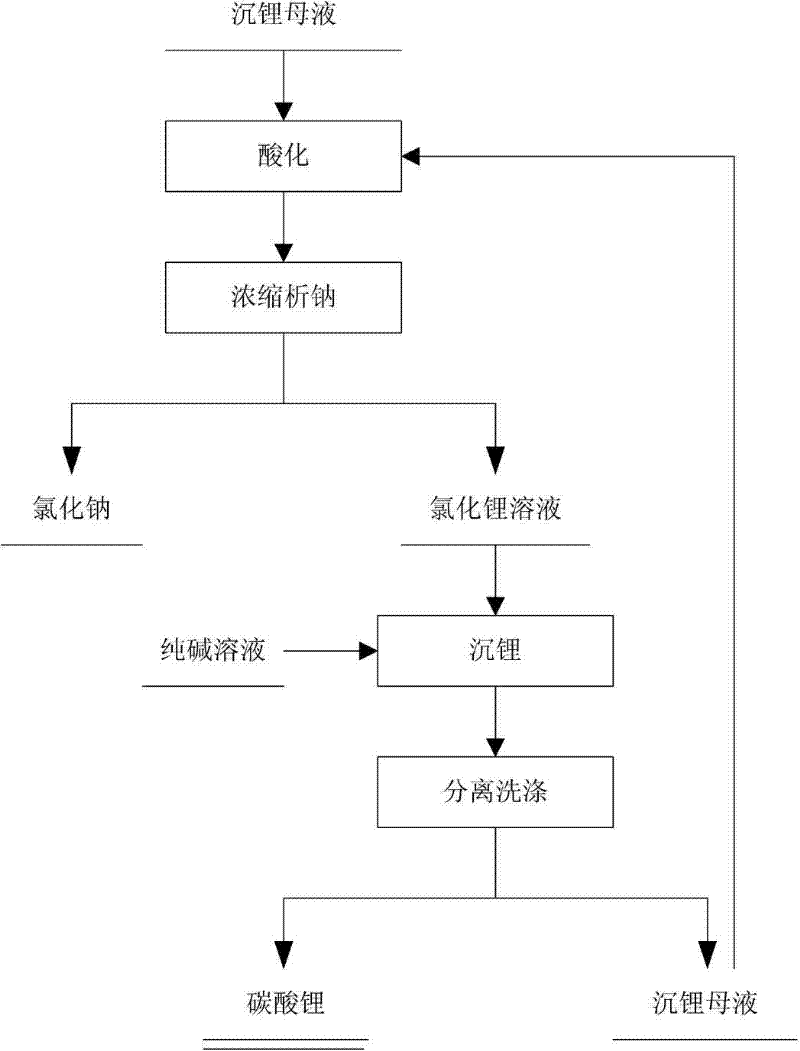

Method for processing battery-level lithium carbonate mother liquor

ActiveCN102249471AIncrease productionHigh recovery rateMultistage water/sewage treatmentAlkali metal chloridesLithium carbonateChemistry

The invention discloses a method for processing battery-level lithium carbonate mother liquor. The processing method comprises the following process follow: A. acidizing lithium deposition mother liquid; B. evaporating, condensing and separating out sodium; C. depositing lithium; and D circulating: circularly carrying out steps from A to C on liquid obtained by dewatering in step B and leaching in the step C and the mother liquor subjected to lithium deposition. By the adoption of the method for processing battery-level lithium carbonate mother liquor, which is disclosed by the invention, the quality of lithium chloride can be guaranteed, and lithium recovery rate can be improved greatly on the basis of the formed sealed circulation. In addition, no the industrial three wastes are discharged, therefore the purpose of clean production is achieved.

Owner:GANFENG LITHIUM CO LTD

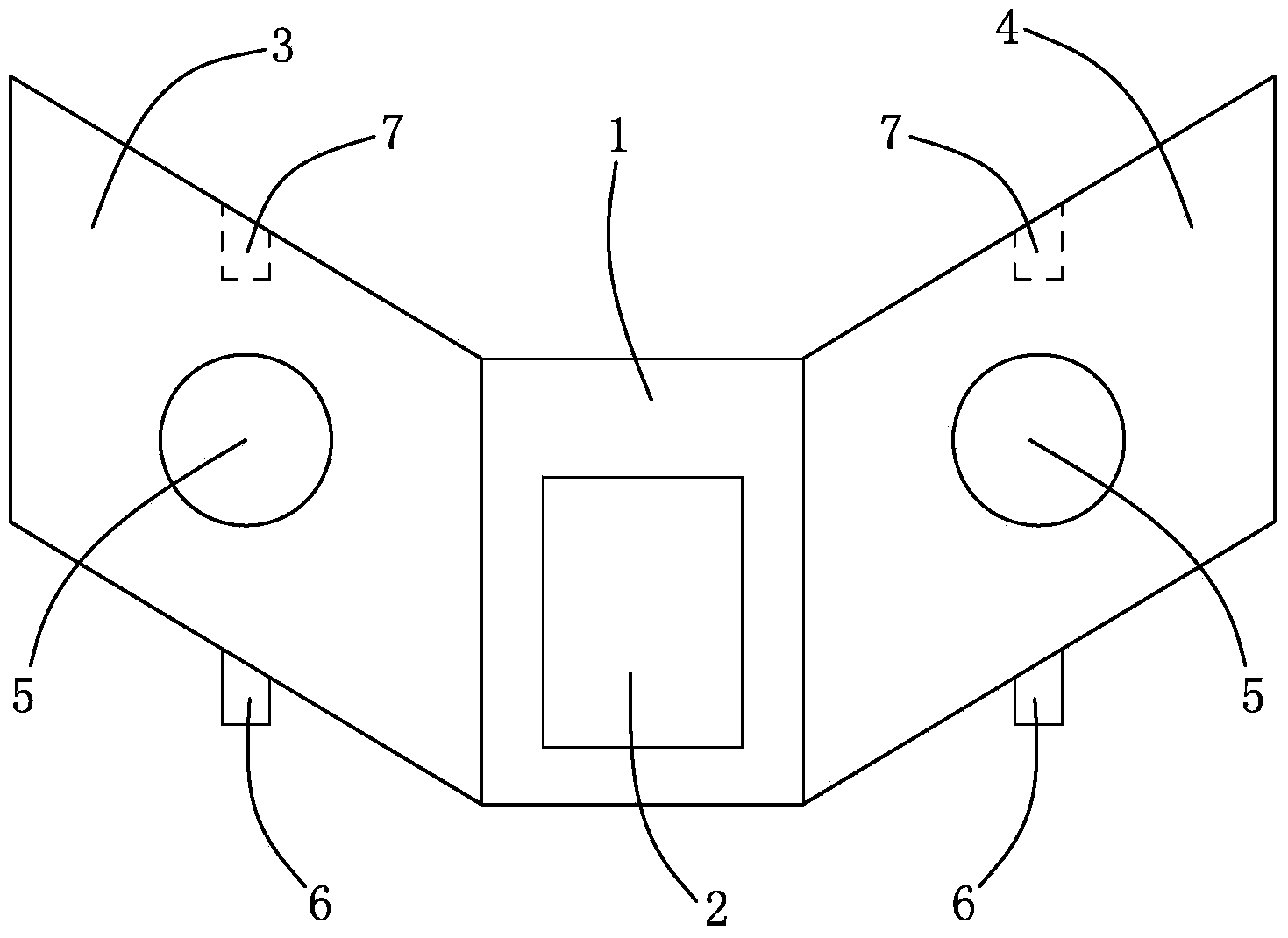

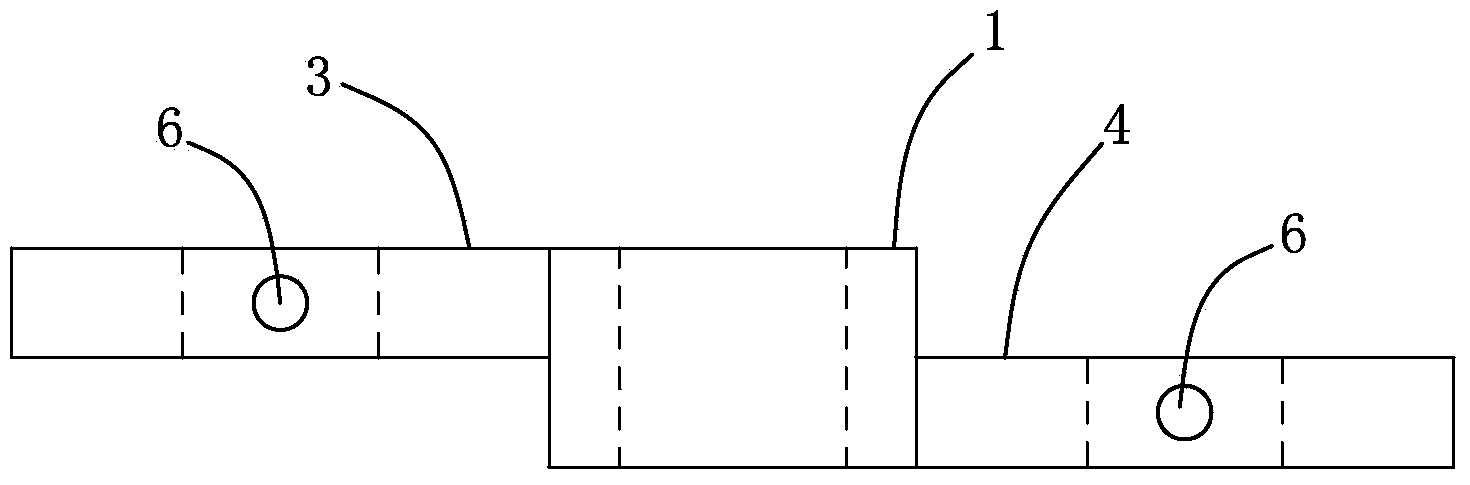

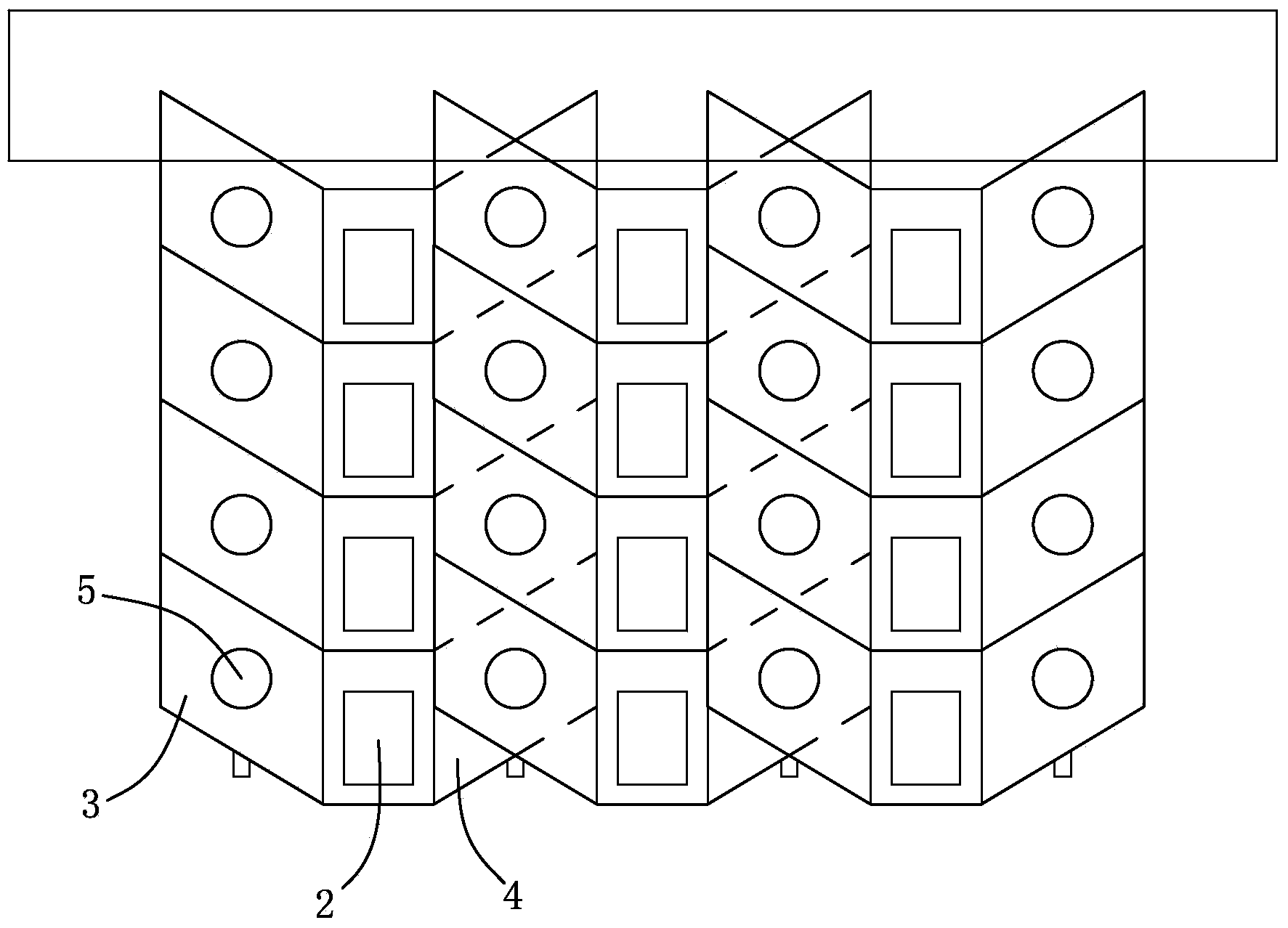

Ecological river interlocking type building blocks and construction method for building protection ridge through building blocks

ActiveCN103758084AImprove frost resistanceGood weather resistanceWater resource protectionCoastlines protectionCrack resistanceArchitectural engineering

The invention discloses ecological river interlocking type building blocks and a construction method for building a protection ridge through the building blocks. Each building block comprises a building block basal body, a first building block connecting body and a second building block connecting body are arranged on the two sides of each building block basal body respectively, and the first building block connecting body and the second building block body are respectively provided with grouting holes. The construction method for building the protection ridge through the building blocks particularly includes the following steps of surveying and setting out, base slot excavation and PVC drain pipe embedment, bottom plate concrete pouring, reinforcing mesh laying and installing, ecological retaining wall installing, steel doweling and grouting, grass planting, earthwork backfilling and geogrid laying. The building blocks have the advantages of being high in strength and crack resistance and few in consumed materials, and therefore the cost for manufacturing the mutually-embedded protection slope building blocks is reduced; bottom plates, retaining walls and earthworks behind the walls form a stable structure, and the structure can resist the load effect and is stable and firm.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

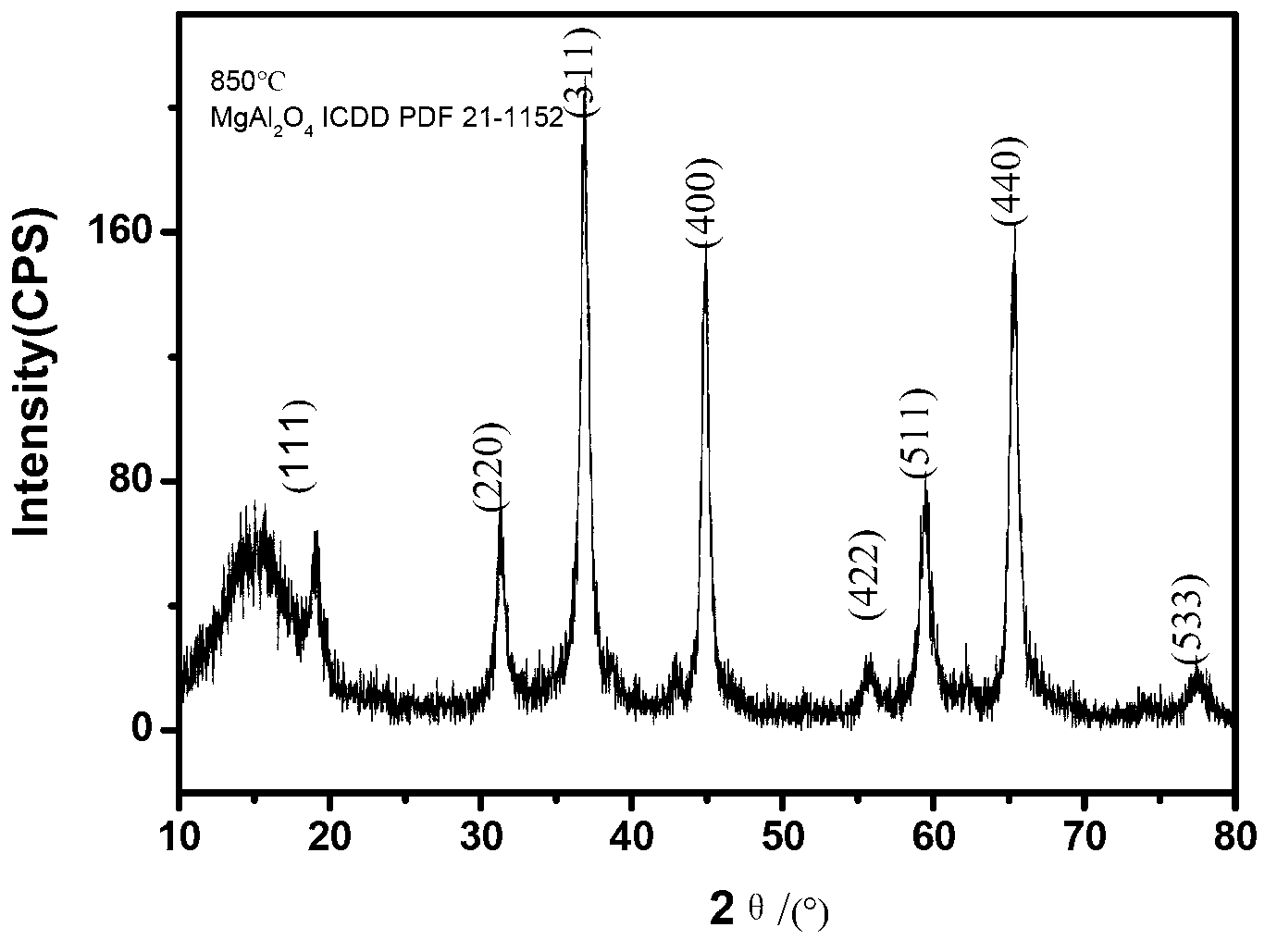

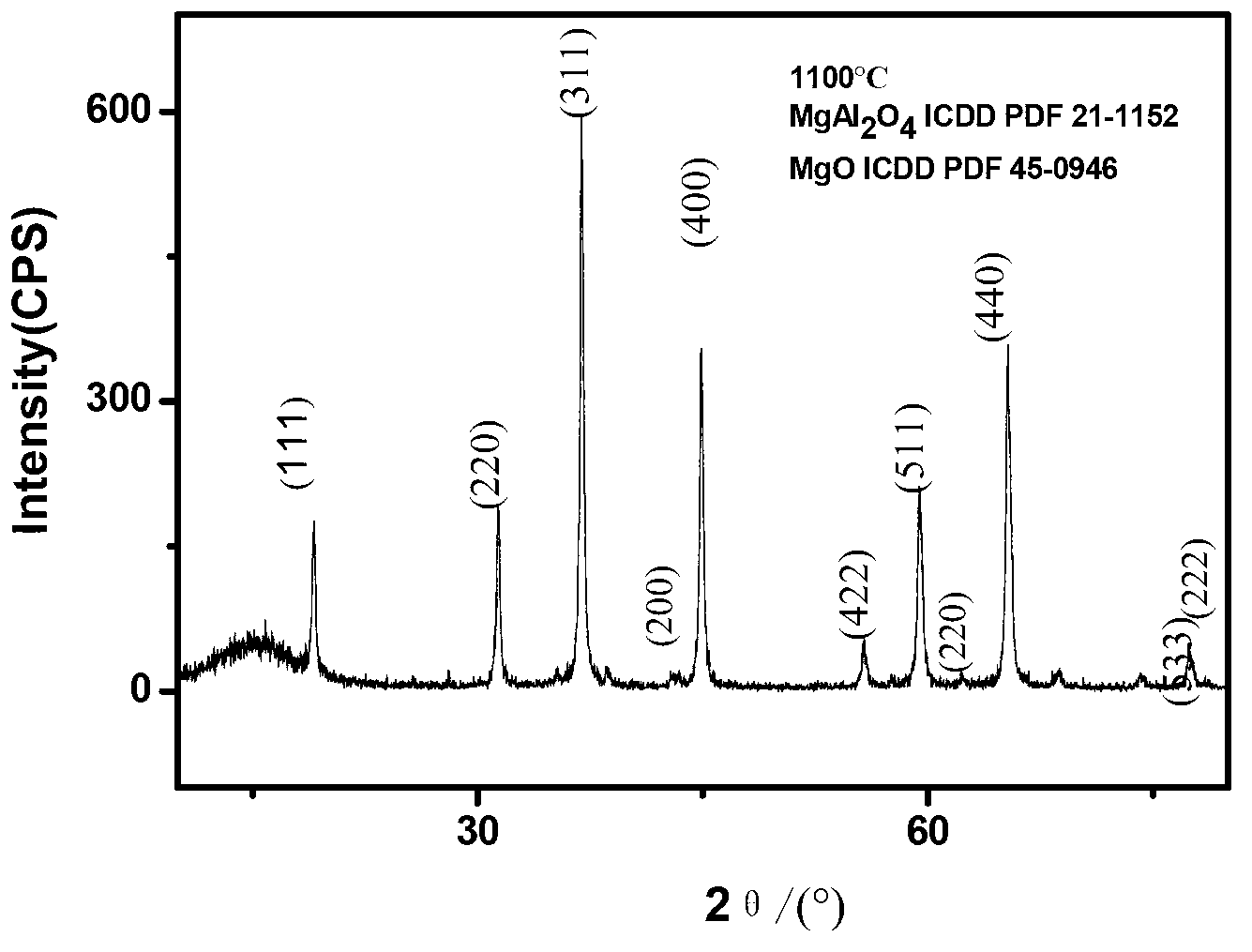

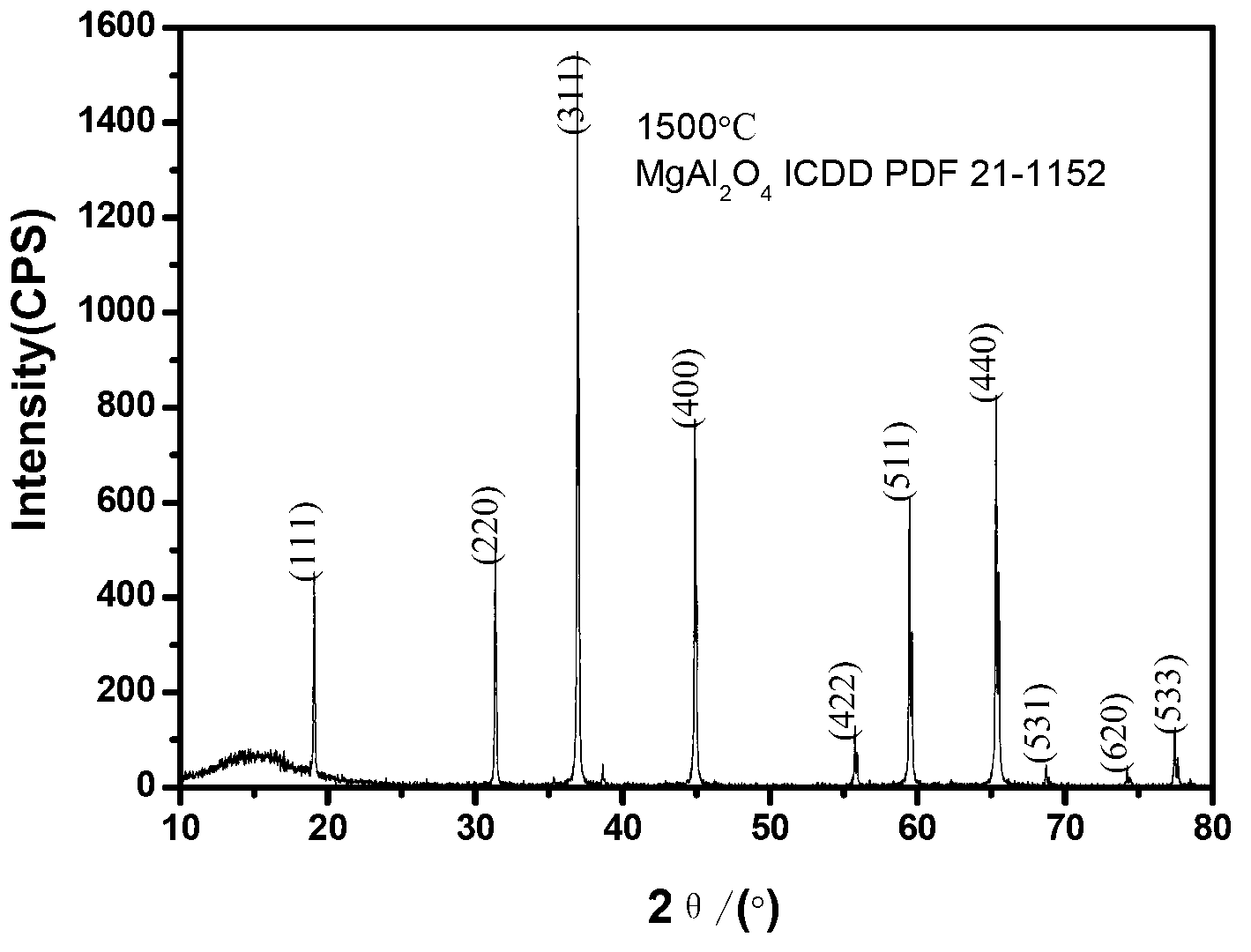

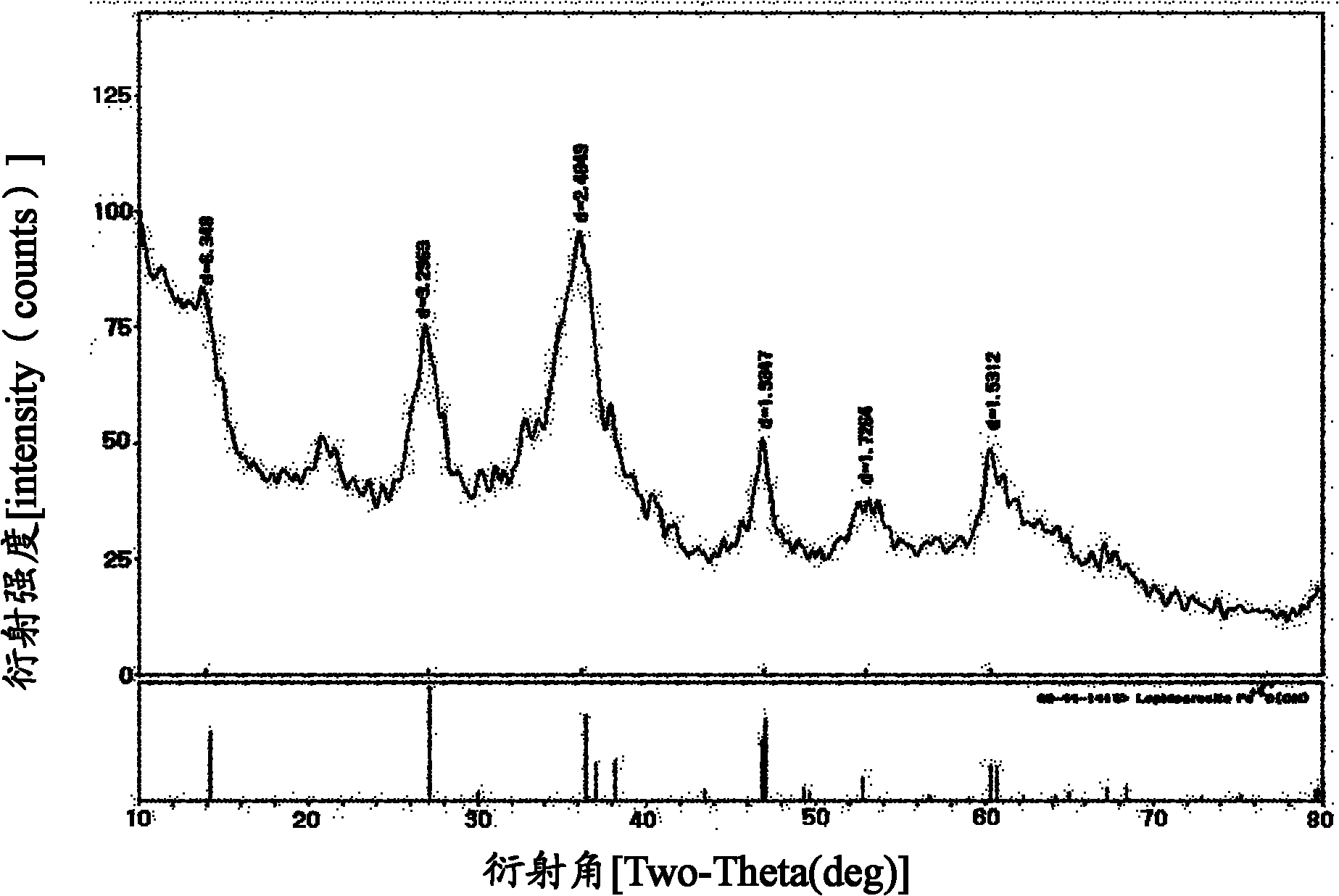

High purity nano-scale magnesium-aluminum spinel synthesis method

InactiveCN102936022ALower sintering temperatureHigh purityAluminium oxides/hydroxidesThermal insulationSpinel

The present invention discloses a high purity nano-scale magnesium-aluminum spinel synthesis method, which comprises the following steps: 1) uniformly mixing light burning magnesium oxide and boehmite according to an amount ratio of MgO to Al2O3 of 1:1, and carrying out ball milling and drying molding to obtain a billet sample sheet; and 2) pre-burning the billet sample sheet for 1 h at a temperature of 500 DEG C, then heating to a temperature of 850-1500 DEG C, carrying out thermal insulation for 2-3 h, and cooling to a room temperature to obtain the high purity nano-scale magnesium-aluminum spinel. According to the present invention, the raw material combination is the light burning magnesium oxide and the boehmite, a sintering reaction activity of the newborn gamma-Al2O3 obtained after boehmite pre-burning is greater than a sintering reaction activity of the general gamma-Al2O3, and the nano-scale material has a huge specific surface area and surface activity so as to reduce a sintering temperature of the magnesium-aluminum spinel, shorten a thermal insulation time, and reduce energy consumption, wherein the sintered spinel content can be up to 97.9%; and the method is applicable for industrial production, and meets requirements of energy saving and emission reduction.

Owner:HENAN UNIV OF SCI & TECH

Pre-processing, polishing and dyeing one-bath process for cotton knitted fabric

InactiveCN102505503ALow dyeabilityImprove dyeing effectBiochemical fibre treatmentDyeing processPectinaseWax

The invention relates to a pre-processing, polishing and dyeing one-bath process for cotton knitted fabric; the pre-processing, polishing and dyeing one-bath process comprises the following steps of: processing the cotton knitted fabric by adopting pectinase, neutral cellulase, a refined penetrating agent and a buffer solution, removing a part of or all pectin, wax, oil stains, ash contents and other impurities affecting the dyeing performance on the knitted fabric, endowing the fabric with good wettability and then carrying out a conventional reactive dye dyeing process. As a method of combining biological enzyme and a chemical assistant is adopted, the fabric is deeply colored and has good hand feeling. The pre-processing, polishing and dyeing one-bath process provided invention has the beneficial effects that as the three procedures, i.e. processing, polishing and dyeing the cotton knitted fabric are combined into one bath, the processing procedure is reduced, the production efficiency is improved, the high-temperature treatment is avoided, and the wastewater discharge quantity is reduced; and moreover, the requirements of energy conservation and emission reduction in the dyeing industry are satisfied.

Owner:ZHEJIANG FURUN DYEING & PRINTING

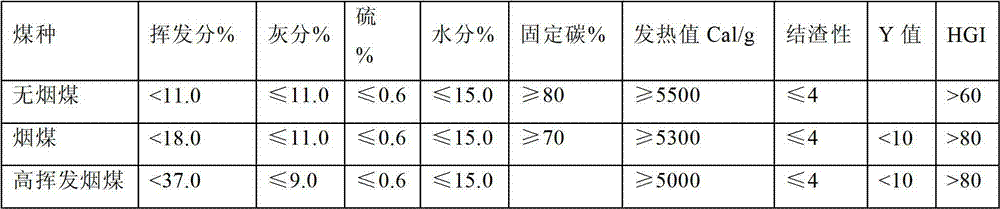

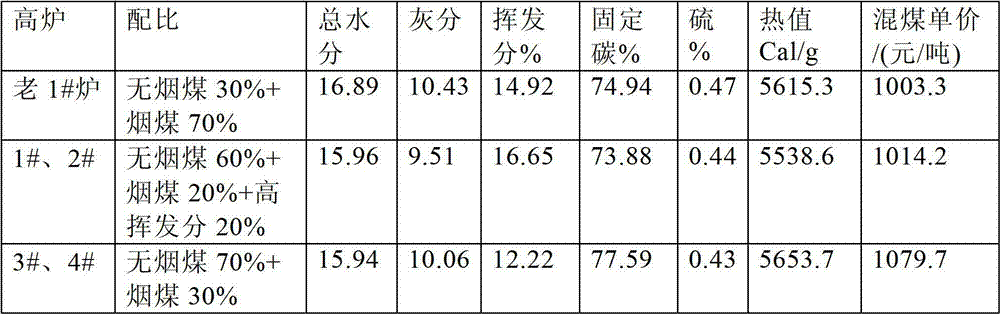

Blast furnace spray-blow coal technology using semi-coke of iron works

InactiveCN102827972ABroaden the scope of industrial applicationsPromote industrial developmentBlast furnace detailsCarbonizationEconomic benefits

The invention provides a blast furnace spray-blow coal technology using semi-coke of iron works. The technology comprises the following steps of: mixing semi-coke, anthracitic coal and bituminous coal based on a ratio; powdering the mixture in a mill, and carrying out spraying and blowing to a blast furnace for one time or multiple times through a blast furnace coal spraying system under a wind temperature of 1200 DEG C. With adoption of the technology, the semi-coke industrial application field can be further expanded; the industrial development can be sped up; the supply situation that the supply of the coking coal and the bituminous coal become tighter can be released through the semi-coke blast furnace spray-blow coal technology; and a benefit is provided to achieve the application and popularization of the coal carbonization technology; the bituminous coal can be replaced via the semi-coke, and the national current requirement on energy conservation and emission reduction can be met; and moreover, the economic benefit of the downstream enterprises can be obviously improved due to the low cost of the semi-coke.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

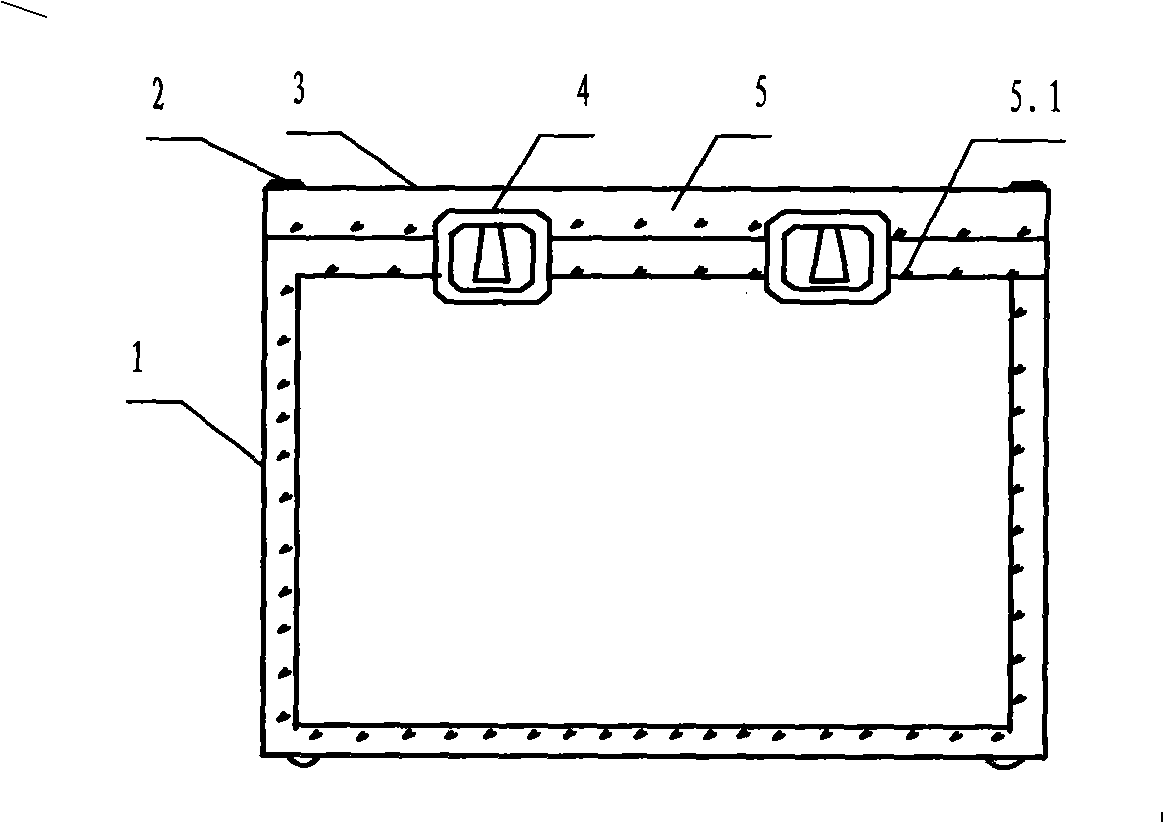

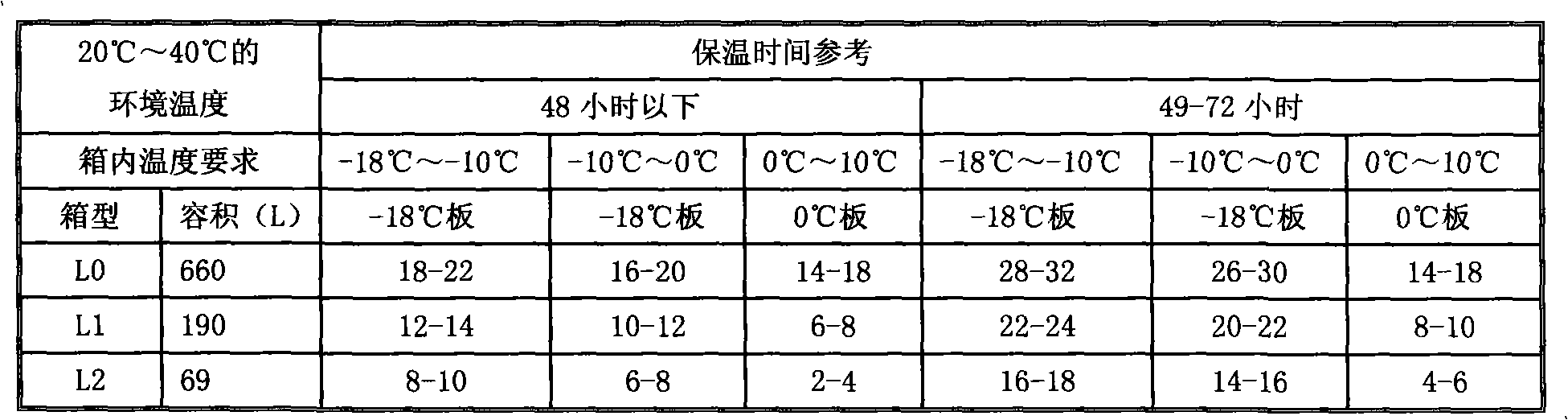

Combined use method for a suit of cold-storage heat-preserving equipment

ActiveCN101256046AGuaranteed accuracyGood cooling effectDomestic cooling apparatusLighting and heating apparatusEnvironmental resistanceService quality

The invention relates to cold accumulation transportation technique field, specially relating to a using method of a set of cold accumulation thermal insulation device. The method comprising following steps: A, preparing for boxing; B, boxing freight, C, measuring temperature and sealing the box; D, opening the box and measuring temperature after the freight reaches the destination; E, cleaning the device. The inventive method is provided with low resource consumption, a low transportation cost, accords with environmental protection requirements, and multi-temperature-segment service is provided. Special requirements for different temperatures and different service quality are satisfied in cold-chain logistic markets, and refrigerated transport service of a small batch and poly batches is provided.

Owner:北京盛世华人供应链管理有限公司

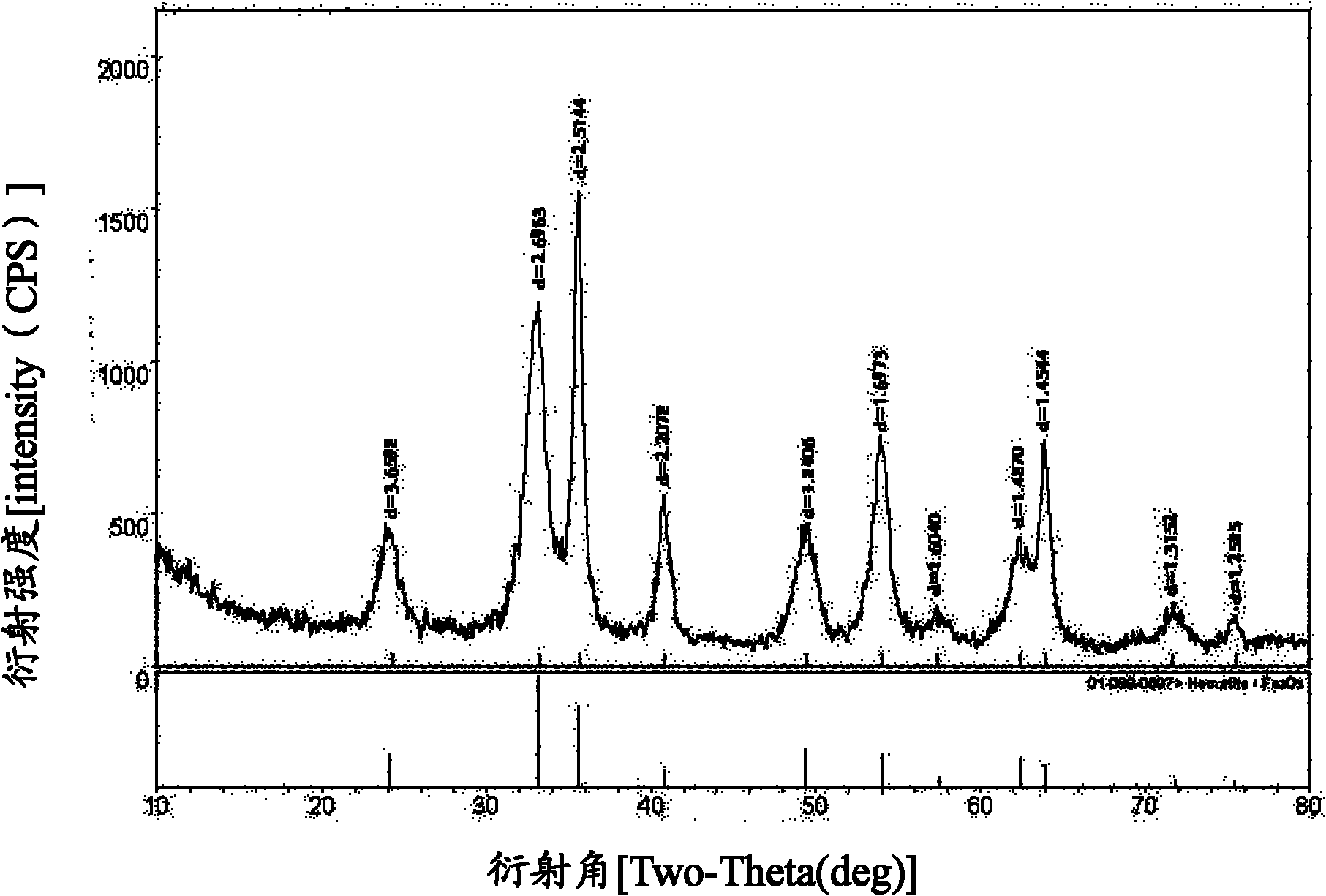

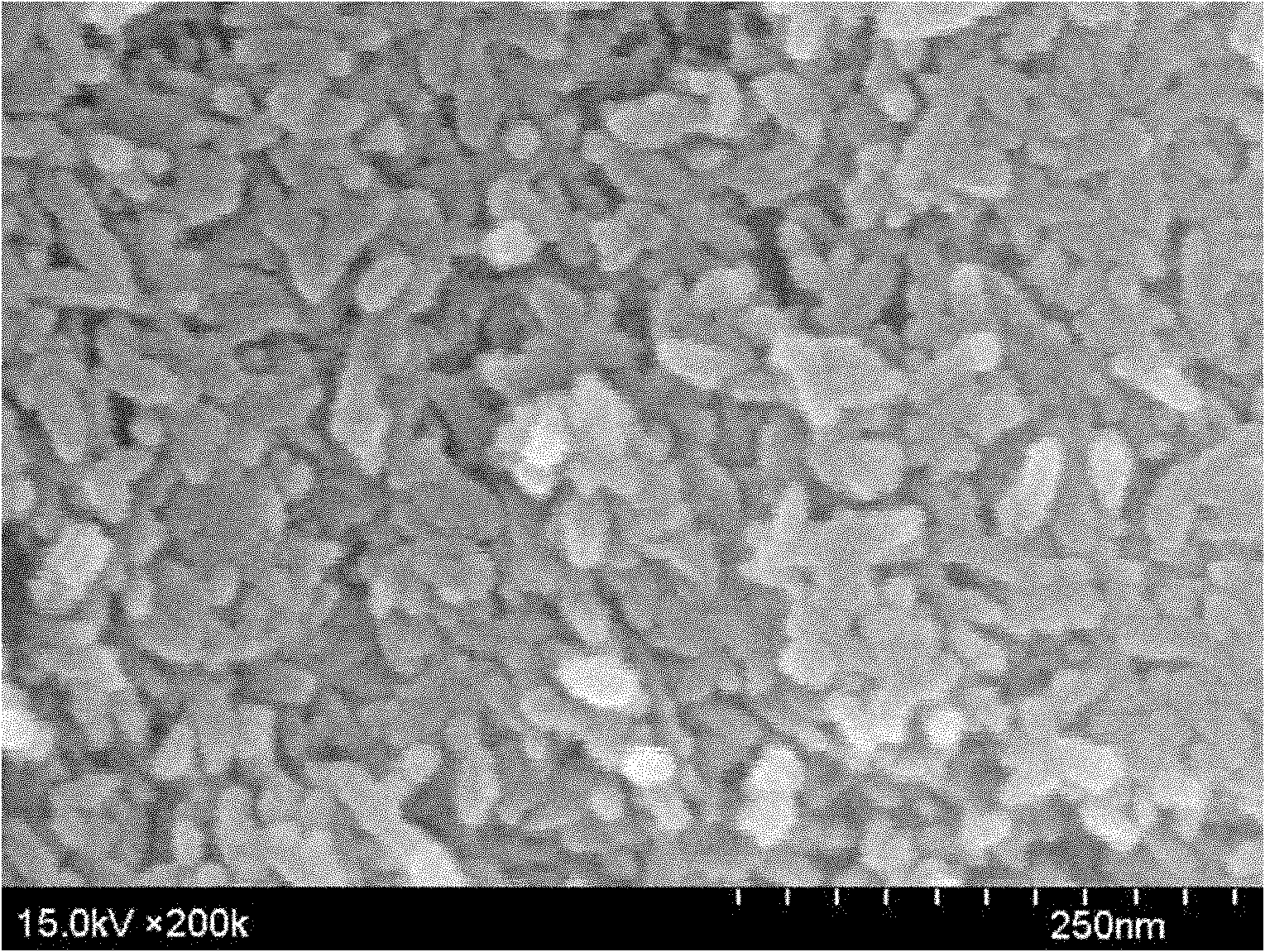

Preparation method of nano iron oxide yellow or nano iron oxide red

InactiveCN102092794AGood crystal formStable performanceNanotechnologyFerric oxidesIonBrown iron oxide

The invention discloses a preparation method of nano iron oxide yellow or nano iron oxide red. The preparation method comprises the following steps: (a) adding a polymerization inhibitor in a ferrite solution with iron ion concentration of 0.05mol / L-1.2mol / L, and dropwise adding a precipitator until the pH value is 3.5-5.0 so as to form a reaction system; (b) continuously reacting for 90-120 minutes to obtain a product after dropwise adding an oxidant in the reaction system; (c) filtering the product obtained from the step (b), washing and drying the obtained filter cake so as to obtain the nano iron oxide yellow; and (d) firing the nano iron oxide yellow obtained from the step (c), cooling the fired nano iron oxide yellow to obtain the nano iron oxide red. By using the method, the particle size of the product can be effectively controlled between 20-100 nanometers, and the nano iron oxide yellow and nano iron oxide red are obtained by subsequent processing; and the method has the characteristics of simple process, small pollution, low energy consumption and short period.

Owner:ZHEJIANG UNIV

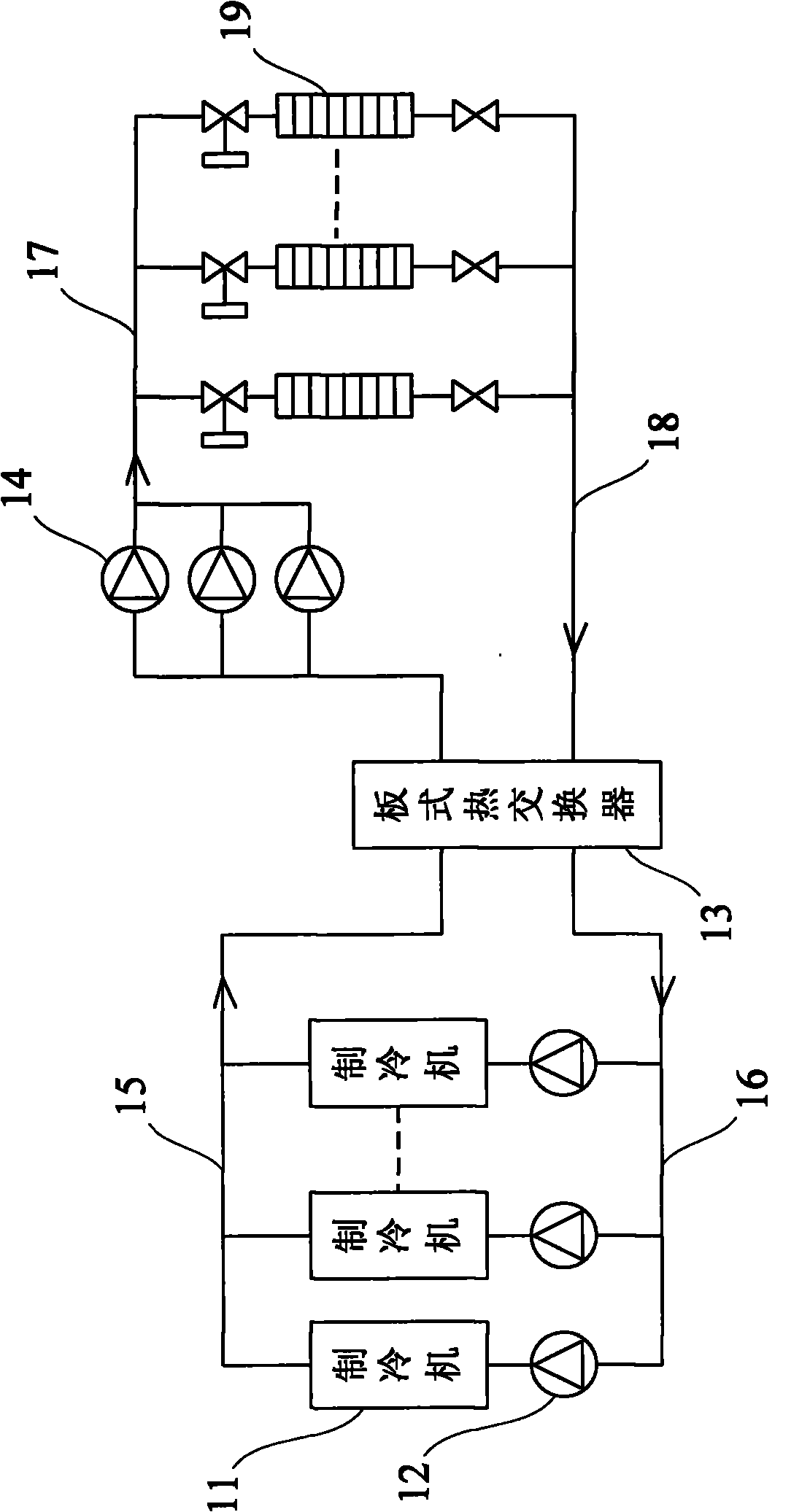

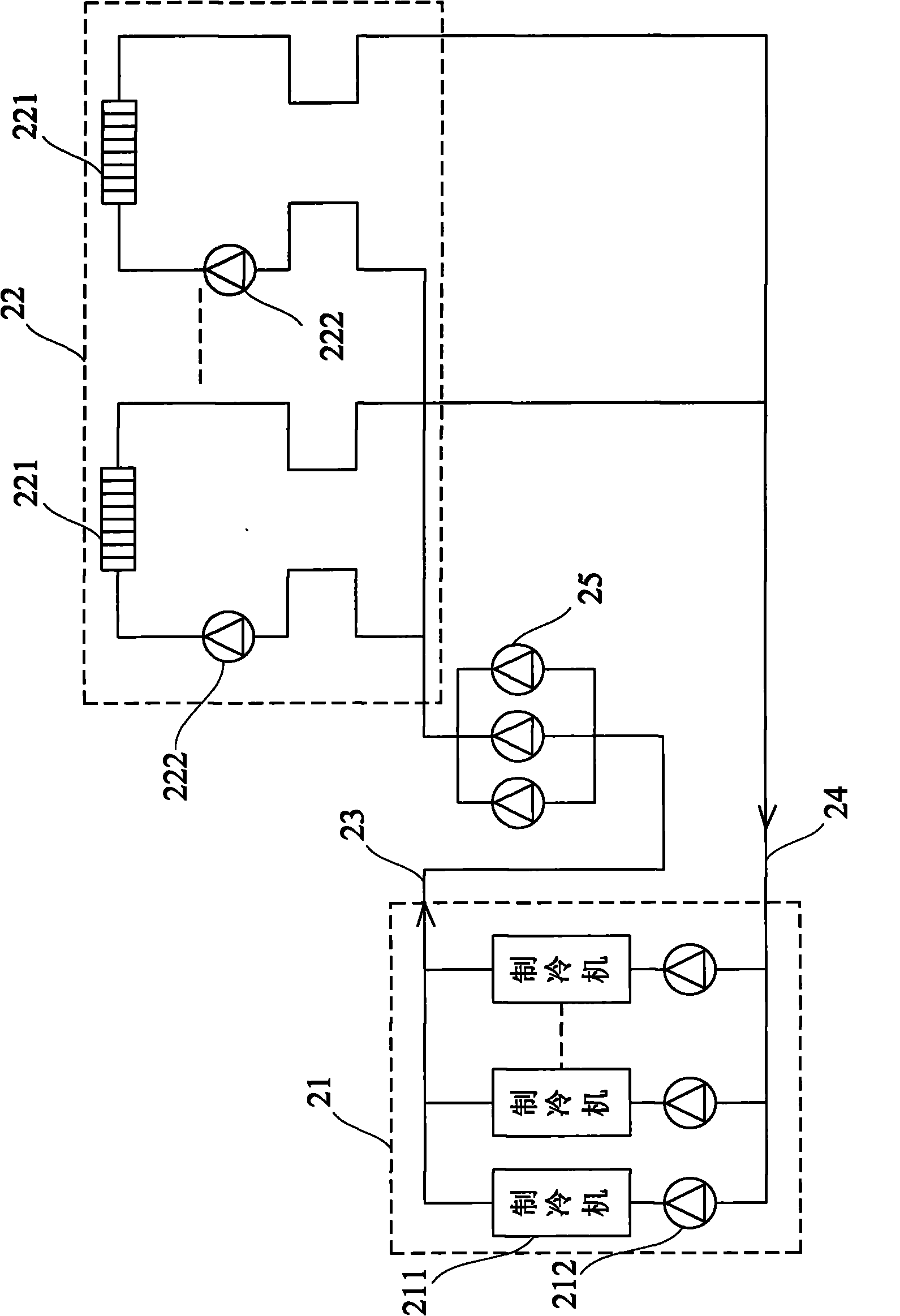

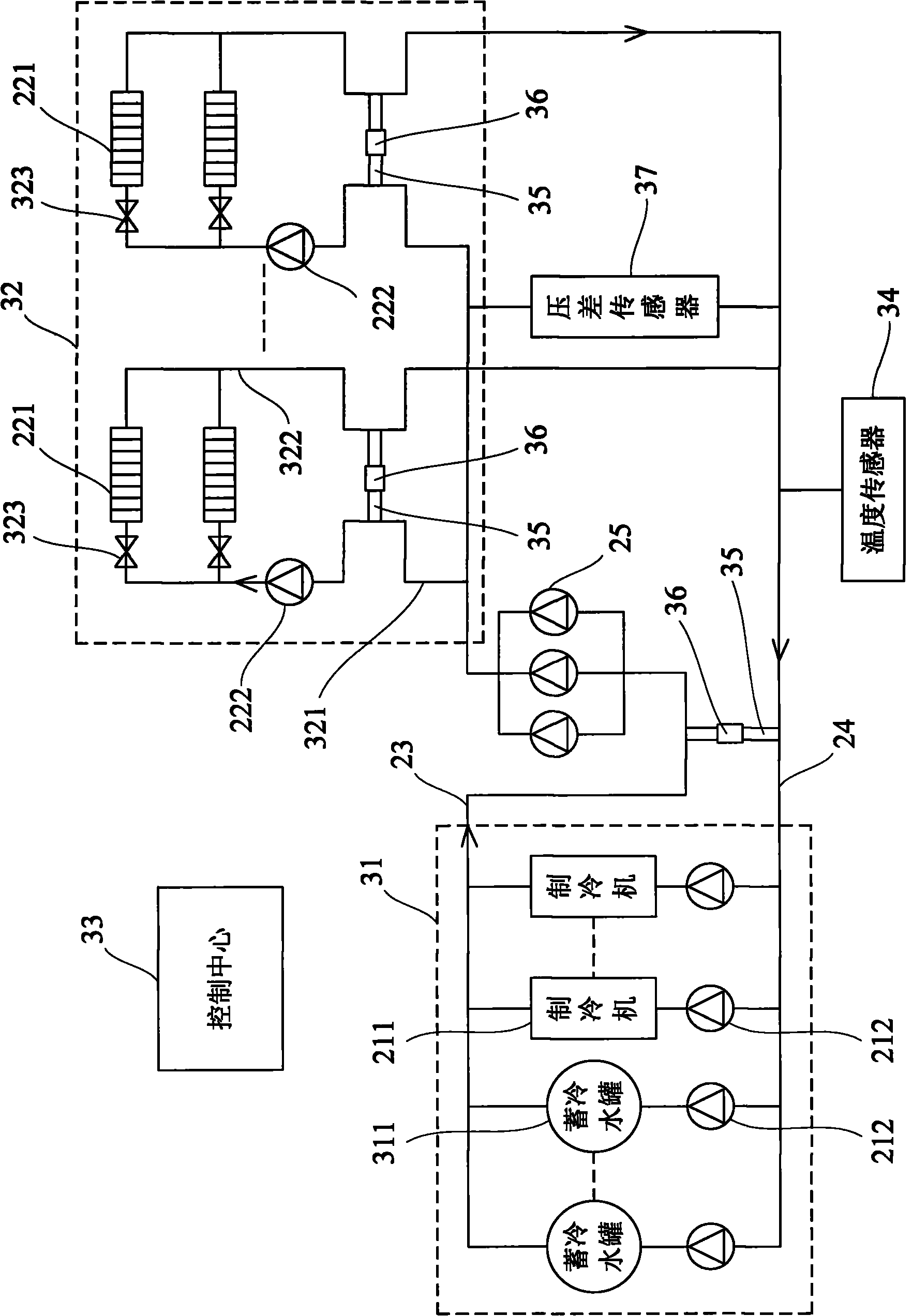

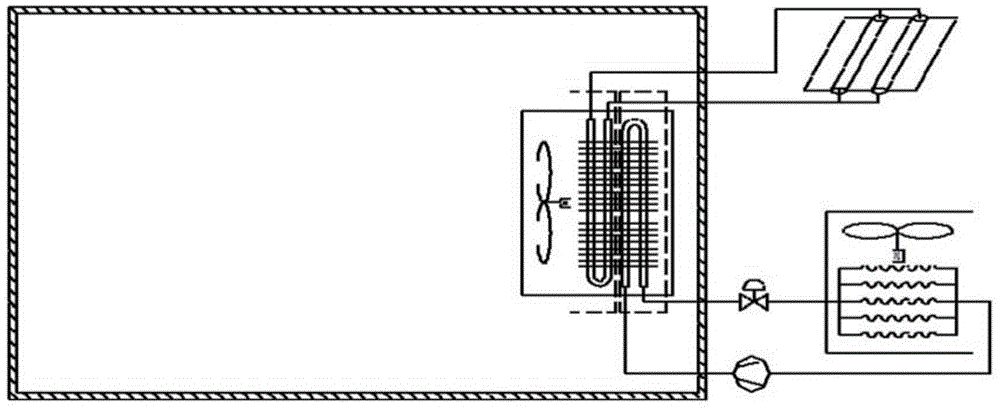

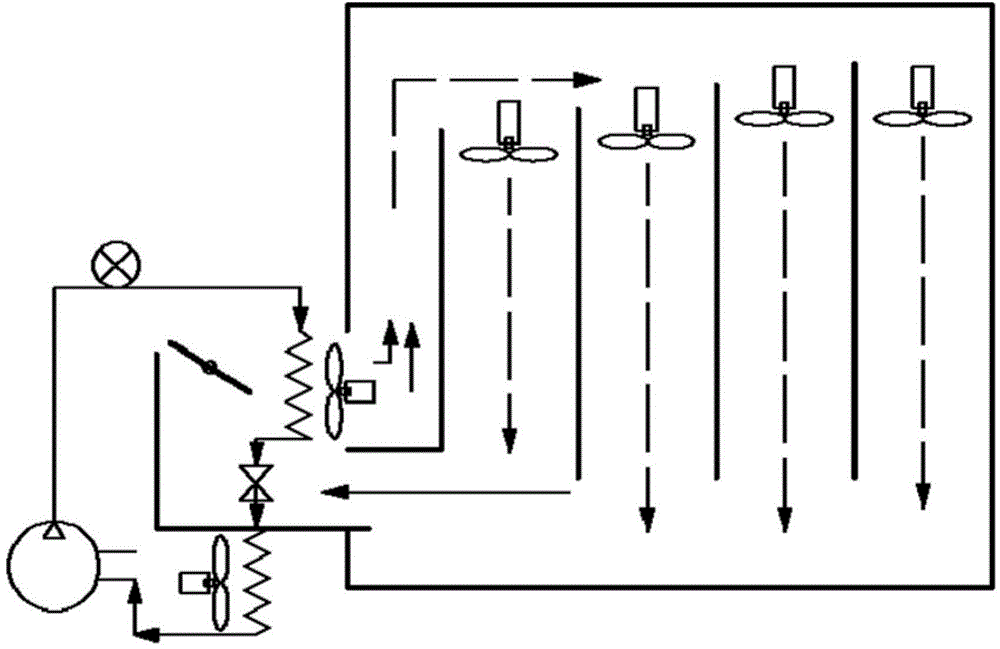

Chilled water direct supply system and method

InactiveCN101865496ALow input costEasy to installSpace heating and ventilation safety systemsLighting and heating apparatusChilled waterCooling capacity

The invention provides a chilled water direct supply system and a method. The system comprises an energy center, a thermal exchange station and at least one secondary pump; wherein the energy center is connected with the thermal exchange station by a master water supply pipe and a master return pipe. The energy source center, which is composed of at least one refrigerator and at least one primary pump, is used for preparing the chilled water; the refrigerator is in series connection with the primary pump and is arranged between the master water supply pipe and the master return pump. The thermal exchange station, which is composed of at least one draught fan and at least one triplex pump, is used for consuming cooling capacity of the chilled water; the draught fan is in series connection with the triplex pump and is arranged between the master water supply pipe and the master return pipe. The secondary pump arranged on the master water supply pipe is used for transmitting the chilled water outputted from the energy center to the thermal exchange station. The invention has the advantages of low cost and energy loss rate as well as small occupied area.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD +1

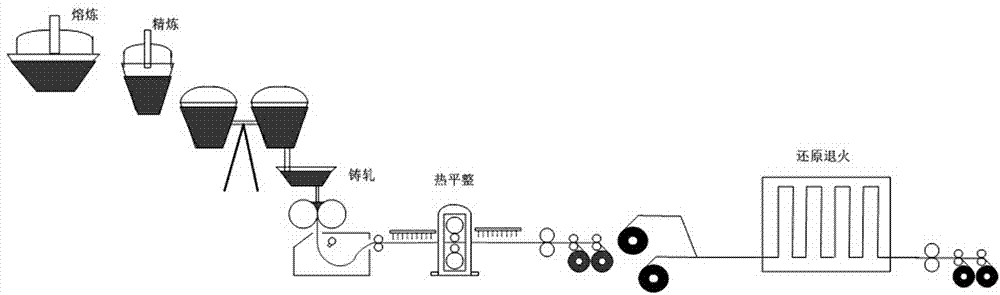

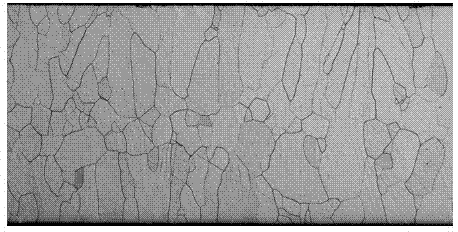

Method for producing hot-rolled pickling-free plate by combining thin-strip continuous casting with reducing annealing

The invention belongs to the technical field of material metallurgy, and particularly relates to a method for producing a hot-rolled pickling-free plate by combining thin-strip continuous casting with reducing annealing. The method specifically includes the steps: obtaining refining molten steel, preparing a cast-rolling strip blank, uncoiling a cast-rolling thin strip after thermal leveling for reducing annealing, removing scale on the surface of the cast-rolling thin strip in a reduction section, and adopting H2 atmosphere condition to protect reduction, wherein reduction temperature is 800-1100 DEG C and reduction time is 10-30min; adopting H2 and N2 atmosphere for protection in a high-temperature annealing section, wherein reduction temperature is 500-1000 DEG C and reduction time is 1-5min, realizing texture and performance control of the thin strip, and obtaining a thin-strip steel product. By the technical scheme, the cast-rolling thin strip is free of pickling and is directly subjected to reducing annealing, so that cold-rolled pickling process is omitted, pre-oxidation process before continuous annealing can be completely abolished, continuity of thin strip production process can be greatly improved, production efficiency is improved, production cost is lowered, discharging of pollutants like waste acid is reduced, and great economic benefit and social benefit are created.

Owner:NORTHEASTERN UNIV LIAONING

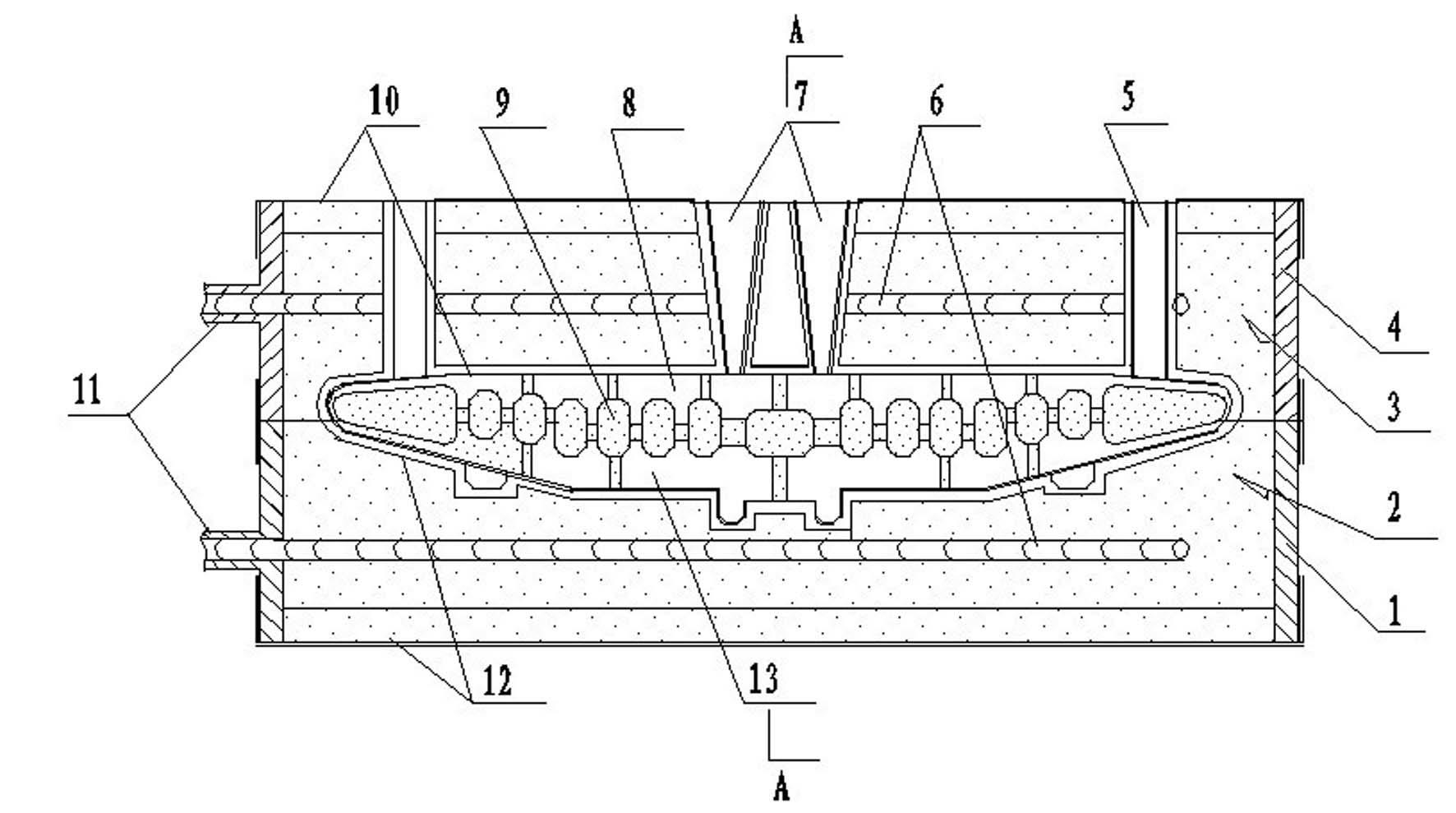

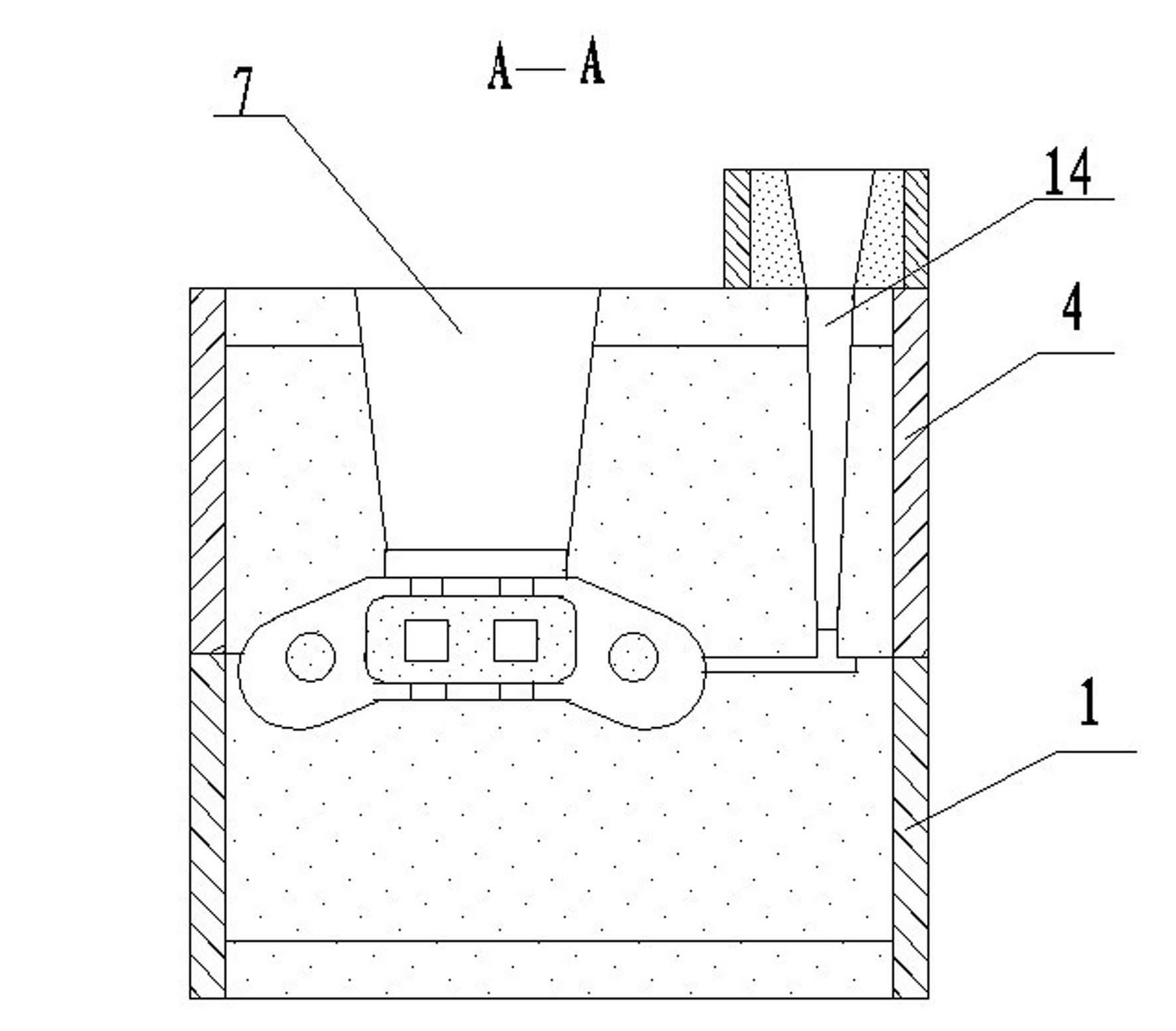

Novel modeling method for casting large-sized and ultra large-sized alloy steel track shoes

InactiveCN102554122AImprove the working environmentExtended service lifeFoundry mouldsFoundry coresPlastic filmAlloy steel

The invention provides a novel modeling method for casting large-sized and ultra large-sized alloy steel track shoes. The method comprises the following steps of: placing a model on a shaping plate with a gas extracting box; covering a heated plastic film on a model form and the shaping plate; attaching the plastic film to each part of the form and the shaping plate through vacuum suction force; brushing a high temperature resistant costing on the model form attached with the plastic film; placing a sand box mounted with a gas extracting device on a model plate; forming a casting head and a gas outlet in an upper casting sand box; filling dry quartz sand into the sand box; ramming the casting sand by using a vibration table; scraping the sand model; covering an upper sealing sand box of the sand model by using a plastic film; pumping loose sand in the sand box to negative pressure so that the sand model is hardened; pulling out the hardened sand model to obtain the model form; making upper and lower sand models; setting a core; and closing the box for casting. Compared with the traditional sand model, the novel modeling method for casting the large-sized and ultra large-sized alloy steel track shoes, provided by the invention, has the following advantages that: the working environment is largely improved, the size accuracy and surface roughness of the cast are improved, long service life of the mold is obtained, the consumption of the casting sand and auxiliary materials is saved, energy is saved and emission is reduced.

Owner:姜玉飞

Method for manufacturing cold plasma modified single board quasi-artificial board

ActiveCN101704256AHigh bonding strengthReduce dosageWood veneer joiningWood dampingEngineeringOxygen

The invention relates to a method for manufacturing cold plasma modified single board quasi-artificial board. The technique thereof is implemented by regulating water content of the single board to 5-8%, placing in a sample chamber of cold plasma modification equipments, vacuum pumping to 2-4Pa, pumping in oxygen, and regulating vacuum degree to 10-30Pa; starting a radio frequency power source, regulating processing power to 100-300W, and modifying the surface of the single board for 1-5min; turning off the oxygen flow control valve, pumping in ammonia, keeping vacuum degree at 50-80Pa, starting the radio frequency power source, regulating processing power to 100-300W, performing graft polymerization on the single board for 3-10min; coating urea resin on the surface of the single board, ageing, assembling and hot-pressing to manufacture into boards. The bonding strength of the product made of single boards modified by cold plasma can be improved by 5-25%, and the release amount of free formaldehyde is decreased by 10-30%. In addition, the method causes no pollution, and is simple in operation and strong in controllability.

Owner:NANJING FORESTRY UNIV

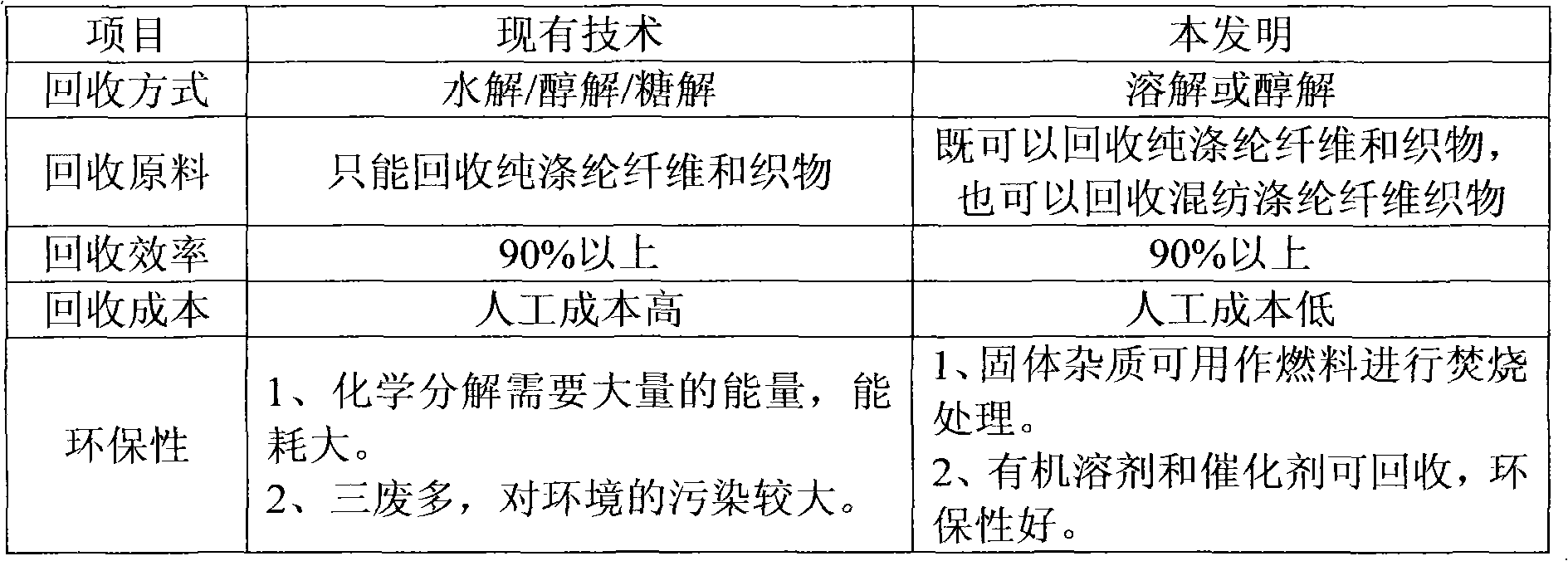

Polyester fiber or polyester fabric waste recycling method

The invention discloses a polyester fiber or polyester fabric waste recycling method, belonging to the technical field of polyester recycling. The method comprises the following steps: placing polyester fiber wastes, polyester fabric wastes, polyester blended fiber wastes and polyester blended fabric wastes thereof in a reaction kettle, adding solvent and catalyst, dissolving or alcoholizing ethylene terephthalate at 25-200 DEG C; filtering the obtained solution, discharging the filtered solution in a distillation kettle; and distilling the solution to recycle organic solvent. Compared with the existing recycling methods of polyester fiber wastes, polyester fabric wastes, polyester blended fiber wastes and polyester blended fabric wastes, the method disclosed by the invention can be used to treat pure polyester fiber and polyester fabric and can also be directly used to treat polyester blended fiber and polyester blended fabric; the method has no requirement on the viscosities of polyester fiber wastes, polyester fabric wastes, polyester blended fiber wastes and polyester blended fabric wastes, thus manual sorting is not required for the clothes prepared from the materials; and the method can not cause serious pollution to the environment and can meet the requirements of energy saving and emission reduction.

Owner:CHINA TEXTILE ACAD JIANGNAN BRANCH

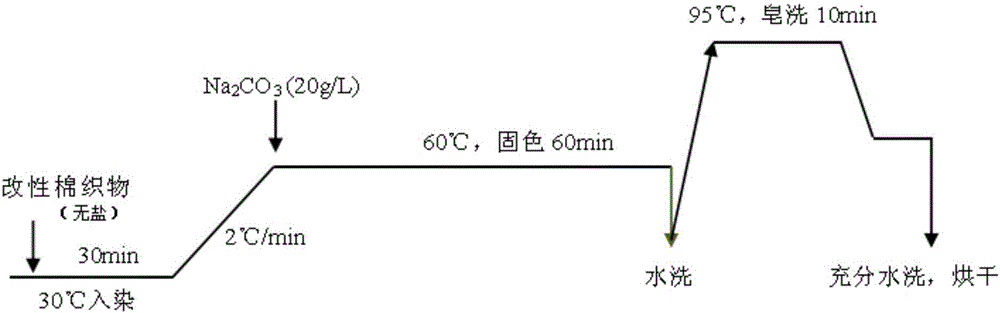

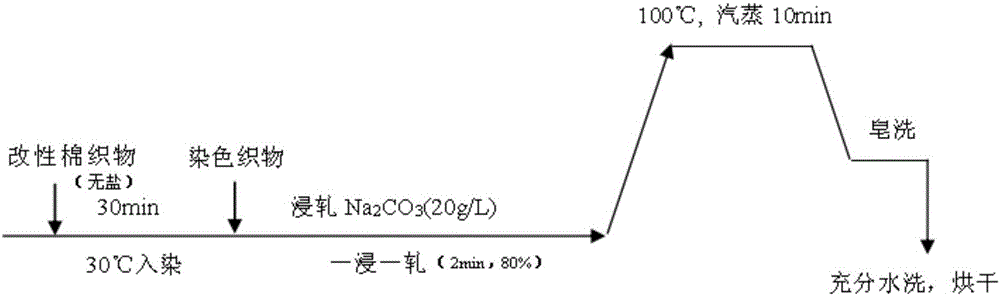

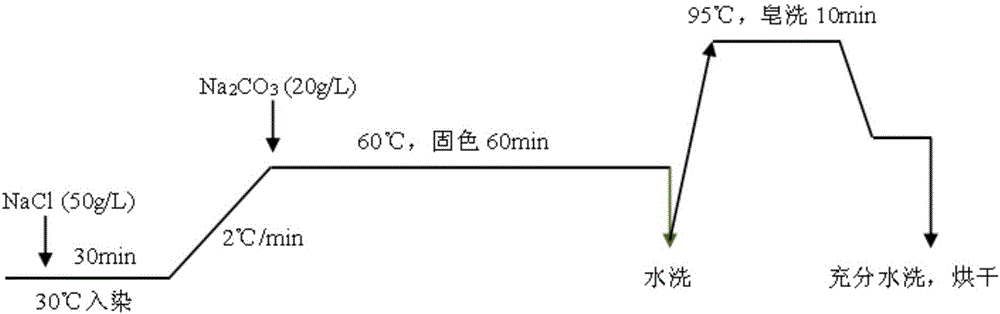

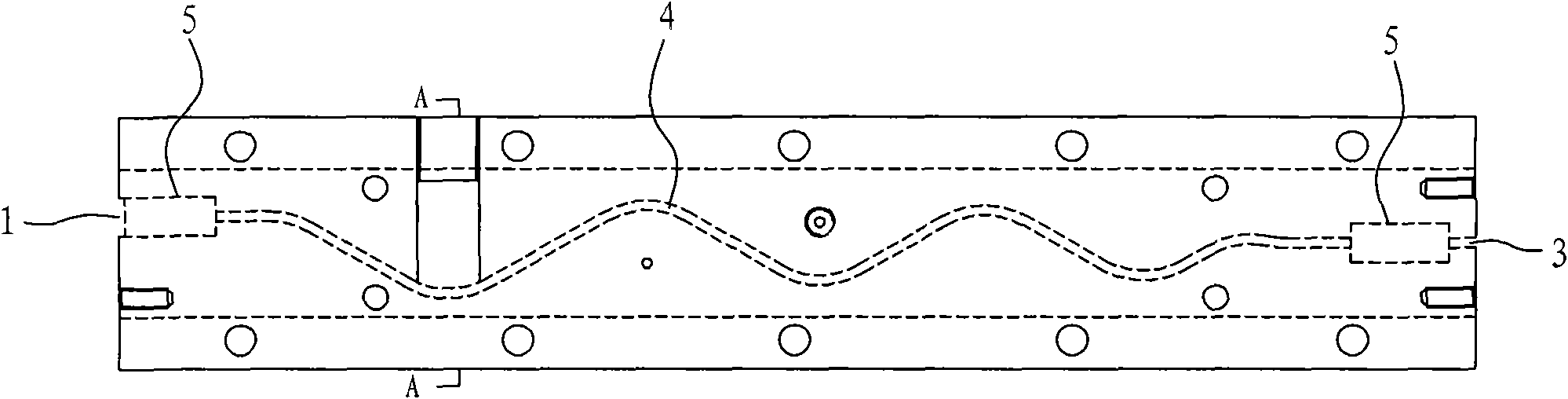

Saltless dyeing method for fabric modified by cationic polymer

ActiveCN106498770AMolecular weight controllableSmall dispersionDyeing processInorganic saltsCooking & baking

The invention relates to a saltless dyeing method for a fabric modified by a cationic polymer. The method comprises the steps that the fabric is placed in a pretreatment solution to be pretreated; pretreatment includes steeping or padding, baking, cold washing and drying are performed to obtain a modified fabric; the modified fabric is placed into a dye bath, and a dip dyeing technology or padding-rolling-steaming technology is adopted for dyeing to obtain the saltless dyeing fabric. The method is easy and convenient to implement and environmentally friendly; meanwhile, a polymer modifier is low in consumption, easy to recycle and capable of meeting the requirements of energy conservation, emission reduction and environmental friendliness of a dyeing and printing enterprise; the traditional salt dyeing effect can be achieved without any inorganic salt or leveling agent, and the requirements for leveling property and color fastness are met.

Owner:DONGHUA UNIV

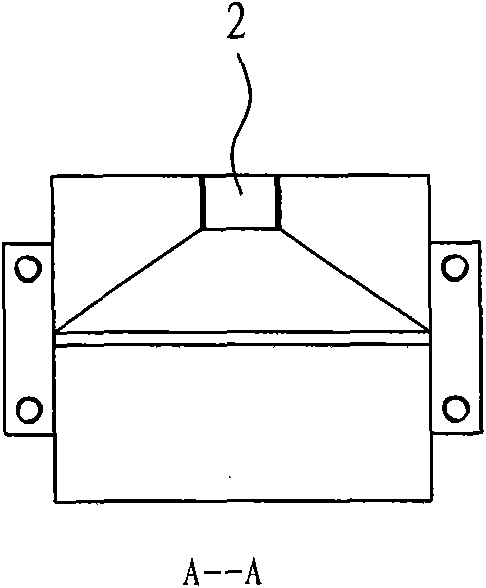

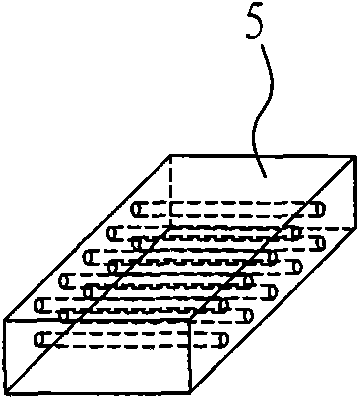

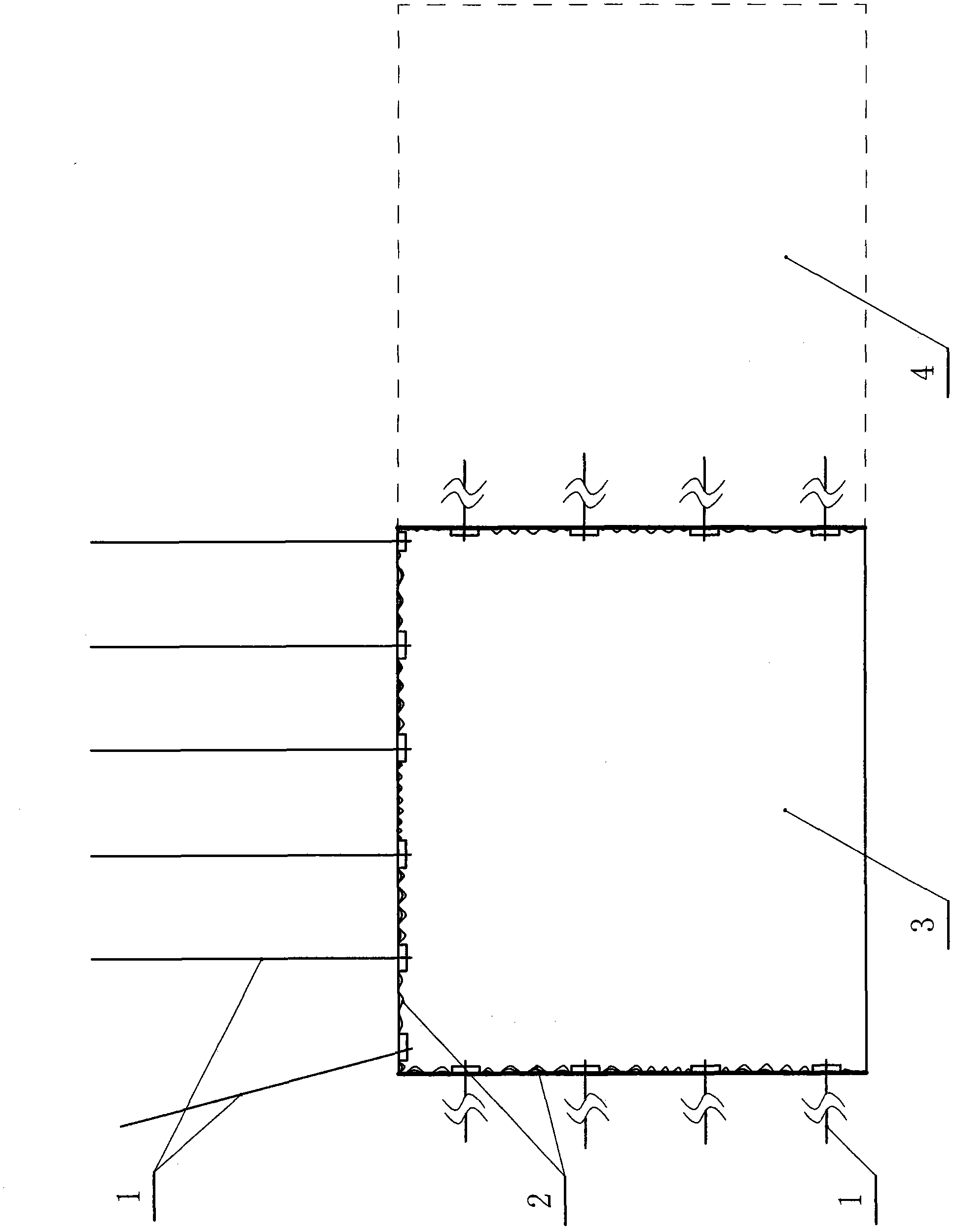

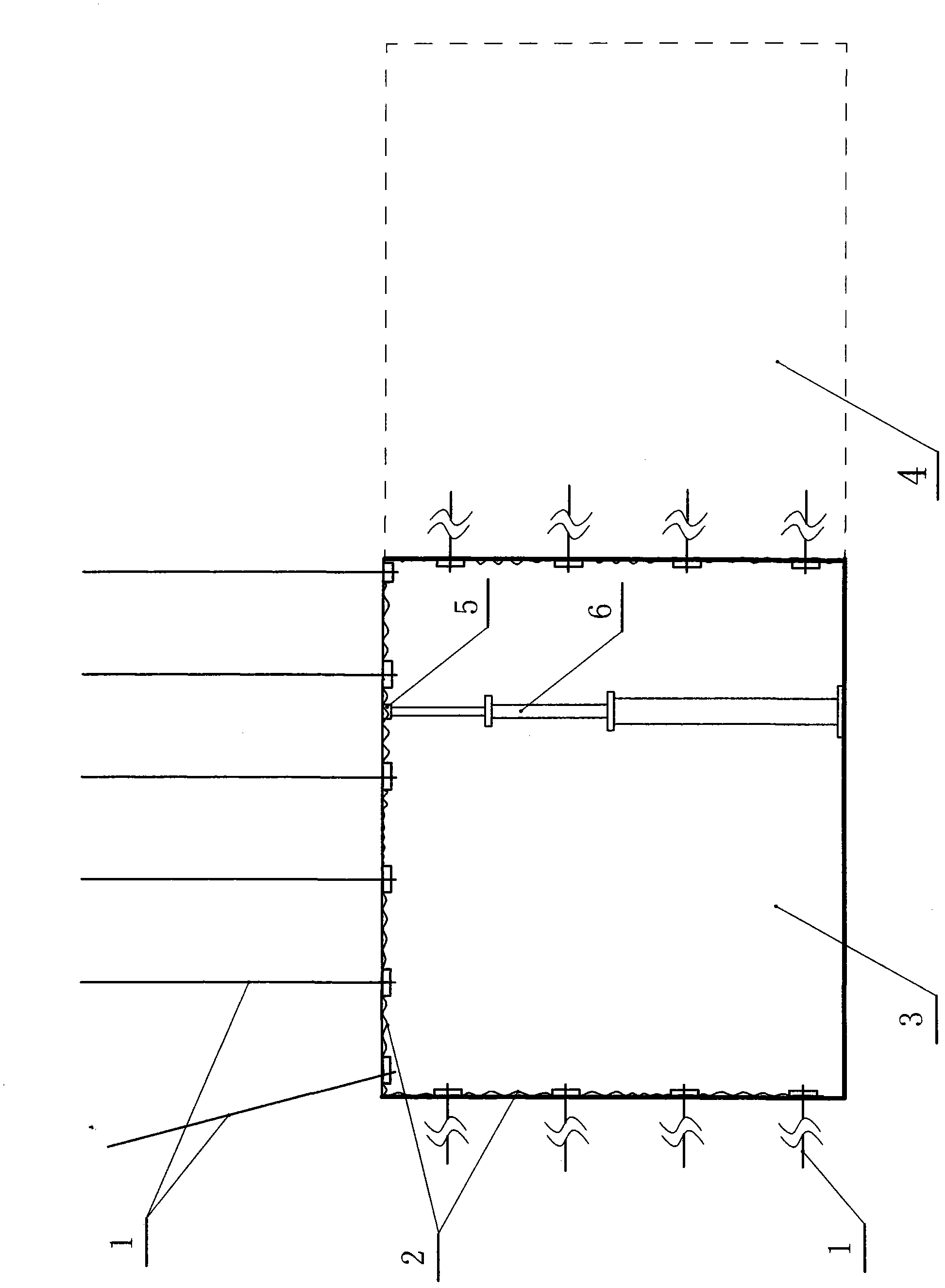

Thermoplastic composite material building template and preparation process thereof and special equipment

InactiveCN101538934AImproved stiffness/mass ratio and creep resistanceImprove stretch resistanceForming/stuttering elementsReuse rateInorganic filler

The invention relates to a thermoplastic composite material building template that comprises 8mm-30mm long glass fiber added in the thermoplastic, and invents a preparation process of the building template as well as special equipment used for implementing the preparation process, thus ensuring that the 8mm-30mm long glass fiber in the thermoplastic composite material building template accounts for 5 percent-60 percent of the weight of the building template. In the building template provided by the invention, the 8mm-30mm long glass fiber accounts for 5 percent-60 percent of the weight of the template, which obviously improves the rigidity / mass ratio and resistance to creep, as well as the stretching, bending and impact properties of the template. Simultaneously, the adoption of thermoplastic leads the building template to be capable of being recovered and renewedly manufactured and processed in damage or in need of other shapes, thus being more environment-friendly and saving more materials. Finally, the addition of inorganic filler can also improve the wearing resistance of the surface of the building template as well as the reuse rate of the template, thus reducing the cost.

Owner:JIANGSU JIATAI TECH MATERIAL

Coal mine roadway supporting method and working face hole-cutting anchor mesh ladder and individual supporting device used by same

InactiveCN102102526AReduce labor intensityReduce supporting costsProps/chocksAnchoring boltsHydraulic pumpEngineering

The invention discloses a coal mine roadway supporting method and a working face hole-cutting anchor mesh ladder and individual supporting device used by the same. The method comprises the following steps of: a, performing hole-cutting construction on one side in advance, and supporting with an anchor mesh ladder; b, after the construction of one side is completed, performing hole-cutting brushing construction to the designed width; before hole-cutting brushing, arranging a hydraulic pump station in a roadway at the end of a cut hole gate; c, supporting a row of individual hydraulic struts for supporting on the coal wall of the brushing side away from one constructed side of a cut hole at the specified position according to the design, supplying liquid to the individual hydraulic struts by adopting a hydraulic pipeline, and supporting a straight hinged top beam at the top of the individuals; and d, after the individuals of the dug side are supported completely, performing hole-cutting brushing, supporting the brushed side by adopting the anchor mesh ladder, and supporting the individuals following a hoeing machine or a development machine. The roadway support comprises an anchor rod, an iron wire mesh and an anchor ladder; the hinged top beam is connected below the iron wire mesh and the anchor ladder in the roadway top support; and a plurality of individuals are connected below the hinged top beam.

Owner:XINAN COAL IND ZAOZHUANG COAL MINING GROUP

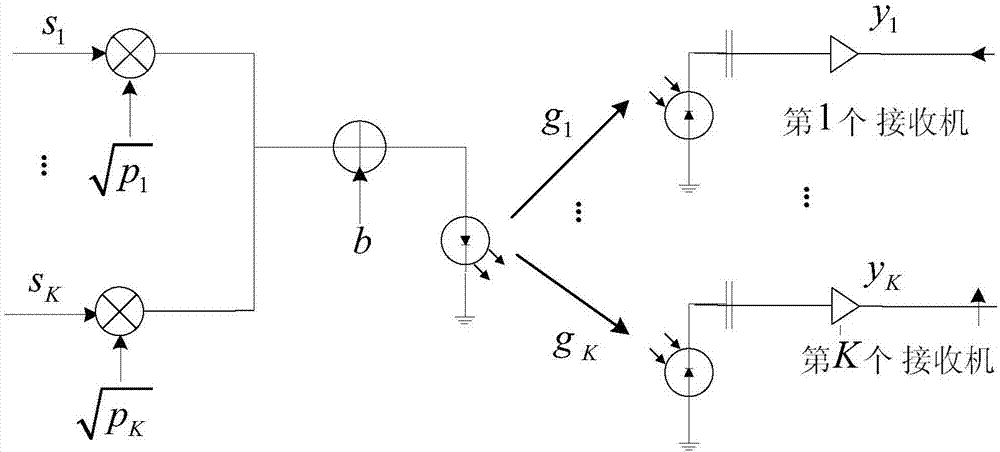

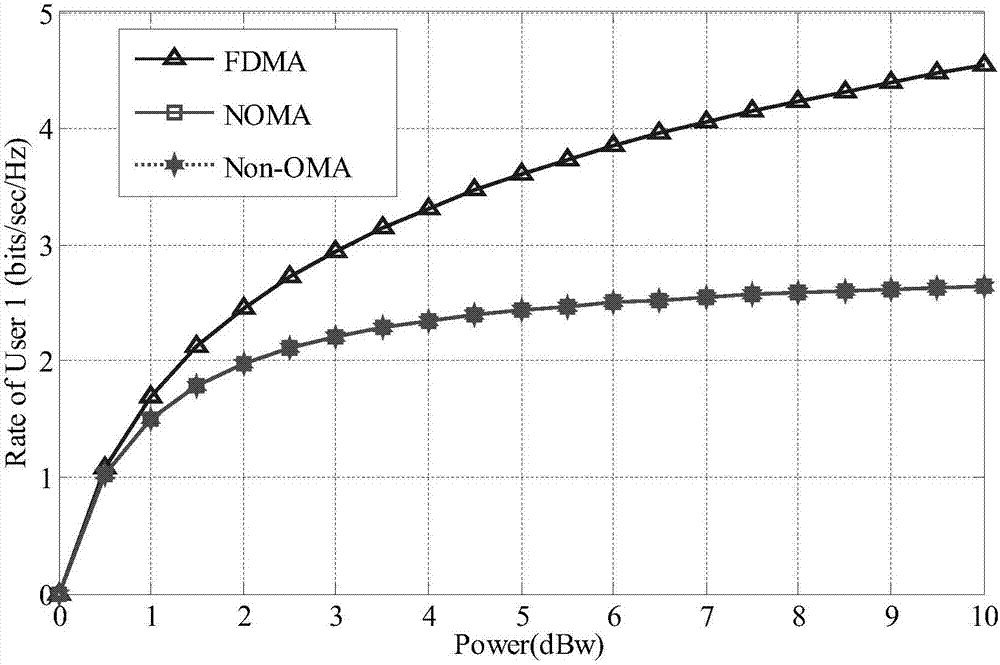

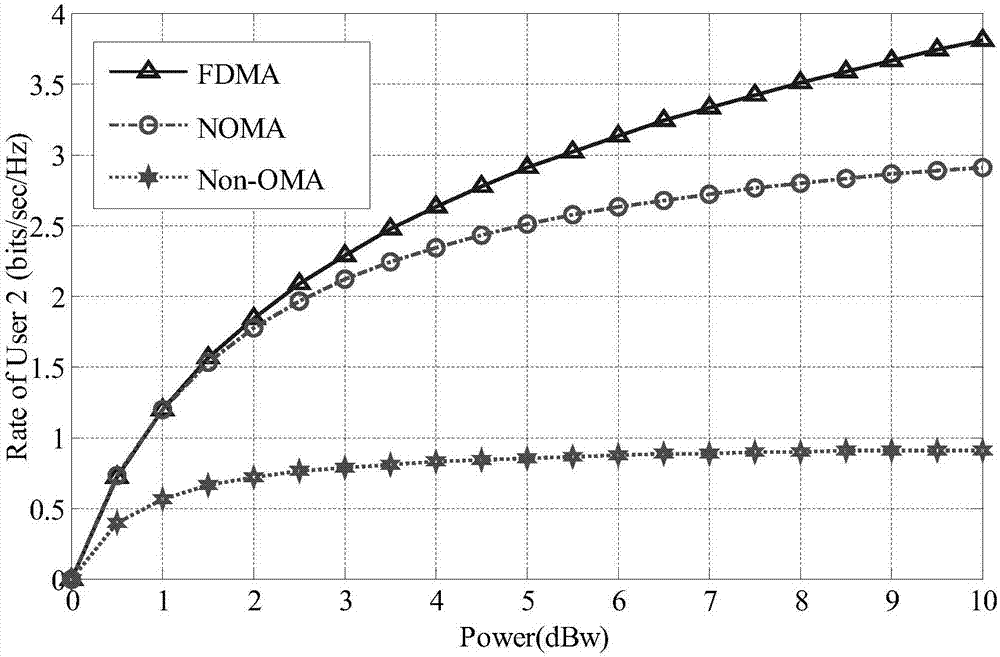

Method for solving downlink NOMA (Non-orthogonal Multiple Access) minimized power of visible light communication system

InactiveCN107342811AIncrease speedGuaranteed service qualityClose-range type systemsQuality of serviceClosed expression

The invention discloses a method for solving downlink NOMA (Non-orthogonal Multiple Access) minimized power of a visible light communication system. According to the method, an NOMA system model is established, a downlink NOMA user rate closed expression in the visible light communication is derived according to features of signals in the visible light communication system, the user quality of service is satisfied, and moreover, the transmitting power is minimized, so energy conservation and emission reduction demands in a mobile communication technology are satisfied. Compared with frequency division multiplexing, the method has the advantages that a user sum rate is maximized, moreover, the consumed transmitting power is minimum, and the user quality of service is ensured.

Owner:CHINA UNIV OF MINING & TECH

Submersed nozzle and preparation method thereof

The invention relates to a submersed nozzle and a preparation method of the submersed nozzle. The technical scheme is that the main raw materials and contents are as follows: 25-50wt% of corundum, 6-20wt% of zircon mullite, 15-32wt% of alpha-Al2O3, 3-8wt% of crystalline flake graphite, 0.5-5wt% of expanded graphite, 1-5wt% of SiC powder, 0.5-5wt% of simple substance Si powder, 0.5-3wt% of B4C powder and 3-8wt% of thermosetting phenolic resin; raw materials and contents of a slag line part are as follows: 70-90wt% of stable zirconia in the calcium oxide part, 3-8wt% of crystalline flake graphite, 0.5-5wt% of expanded graphite, 1-5wt% of SiC powder, 0.5-5wt% of simple substance Si powder, 0.5-3wt% of B4C powder and 3-8wt% of thermosetting phenolic resin. The preparation method comprises thesteps of uniformly mixing the raw materials and pelletizing, moulding, sintering at 1050-1200 DEG C and under a reducing atmosphere, performing surface processing, and drying. The product is featuredwith low carbon content, high strength, excellent thermal shock resistance and slag corrosion resistance.

Owner:WUHAN UNIV OF SCI & TECH

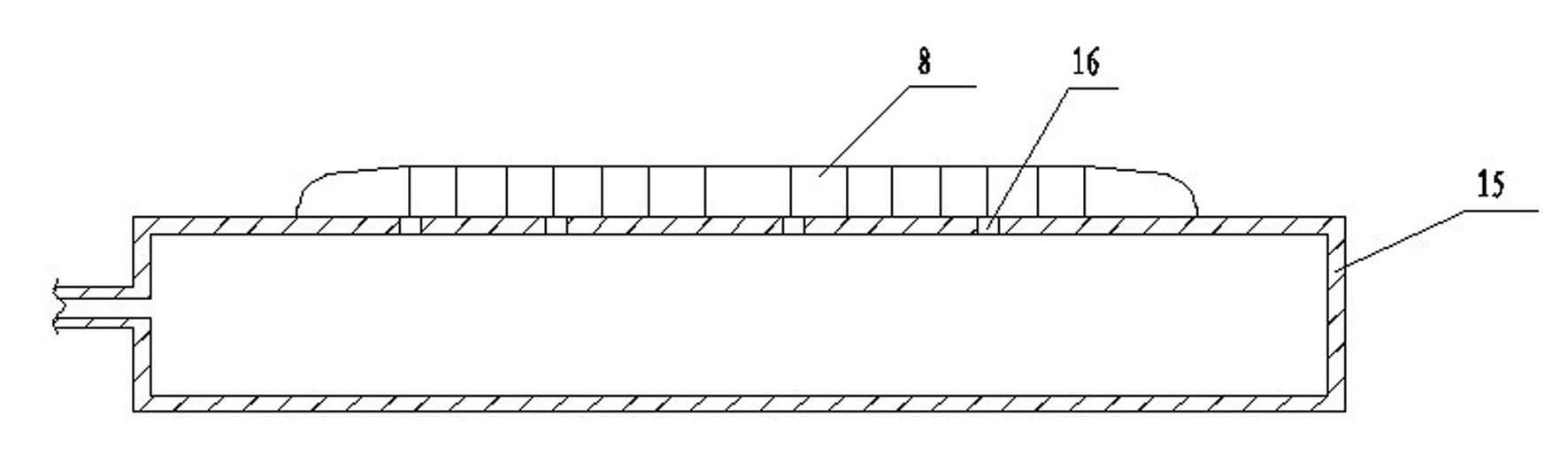

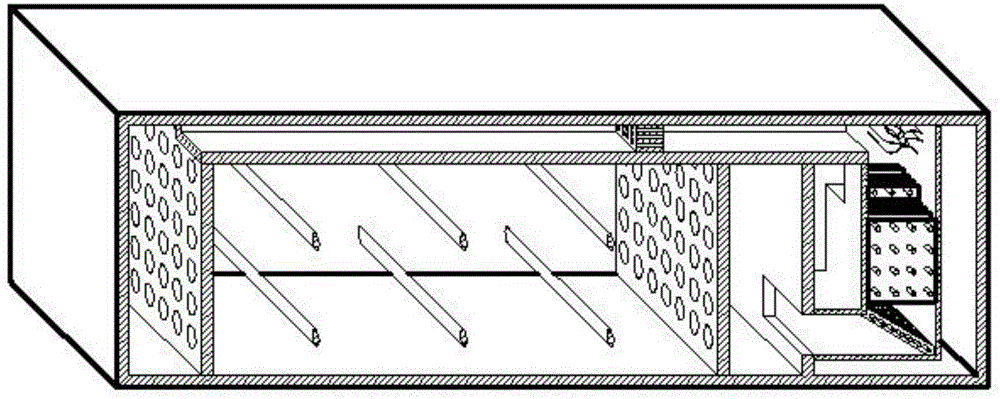

Energy recycling type edible mushroom drying device

ActiveCN104082397AUniform treatmentAchieve recyclabilityFood processingFruits/vegetable preservation by dehydrationAir treatmentFresh air

The invention discloses an energy recycling type edible mushroom drying device. The drying device comprises an external fresh air introducing device, a total heat exchanger, a multistage pressing type airflow-adjustable air hole, an edible mushroom drying device and an induced draft fan, wherein the total heat exchanger is used for recycling the energy; the edible mushroom drying device sequentially comprises a drying room, an air pre-heater, a flow guiding plate, a variable cross-section air flue, an airflow pressure sensor, a blowing pore plate, an air return pore plate, and flow guiding devices arranged on an inlet of the blowing pore plate and an outlet of the air return pore plate, and the blowing pore plate and the air return pore plate are arranged in the drying room in parallel. According to the energy recycling type edible mushroom drying device, by combining a completely-new air supplying drying mode and a direct return-air self-circulation drying mode with a stairstep-energy-supplying air heating manner and the variable cross-section air flue according to different drying conditions of the edible mushroom, the stable distribution of air in the device is guaranteed, meanwhile, the air supplying temperature is decreased, and the drying quality is guaranteed; air is uniformly processed, and the energy consumption is reduced.

Owner:NANJING NORMAL UNIVERSITY

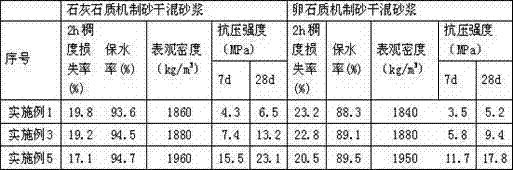

Limestone machine-made sand dry-mixed mortar and preparation method thereof

InactiveCN103922667ASolve the shortage of resourcesAddressing quality degradationCompressive resistanceProcess engineering

The invention relates to a limestone machine-made sand dry-mixed mortar and a preparation method thereof, belonging to the field of building materials. The limestone machine-made sand dry-mixed mortar comprises the following raw materials in parts by weight: 10-25 parts of cement, 5-8 parts of coal ash, 70-85 parts of machine-made sand and 0.06-0.08 part of mortar water-retention plasticizing agents, wherein the machine-made sand is limestone machine-made sand. The limestone machine-made sand dry-mixed mortar disclosed by the invention has the advantages of good cohesiveness, high water-retention rate, high compressive strength, good operability, economy, environmental protection, resource saving and the like, and is a green building material with excellent properties. The preparation method disclosed by the invention is simple and low in cost.

Owner:GUANGXI YUFENG GRP

Wooden sheet dyeing method for performing pretreatment by using cold plasma

InactiveCN102350717AGood light fastnessMeet the requirements of energy saving and emission reductionWood treatment detailsProduct gasEngineering

The invention discloses a wooden sheet dyeing method for performing pretreatment by using cold plasma. The process comprises the following steps of: adjusting the water content of a wooden sheet to be 2-12 percent; placing on a feed conveying belt of a cold plasma treatment system; adjusting a space between two electrode rollers to keep the gap between the surface of the wooden sheet and an electrode at 0.5-1.5mm; starting a power supply; adjusting treatment power to be 1-6kW to produce cold plasma through dielectric barrier discharge of working gas between two electrodes; passing the wooden sheet through four pairs of discharge electrode rollers at a speed of 2-20m / min to simultaneously treat two surfaces of the wooden sheet, wherein the working gas between the two pairs of front electrode rollers is air and the working gas between the two pairs of rear electrode rollers is ammonia gas; and immersing the pretreated wooden sheet in direct dye solution for dyeing, and then washing and drying to obtain a dyed wooden sheet. The wooden sheet pretreated by cold plasma has high dyeing speed, high dye uptake and superior light resistance. In addition, the method has the advantages of energy conservation, environmental friendliness, easiness and convenience in operation, high efficiency and capability of continuous working.

Owner:NANJING FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com