Limestone machine-made sand dry-mixed mortar and preparation method thereof

A technology for dry-mixed mortar and machine-made sand, applied in the field of building materials, can solve the problems of high mud content, high proportion of coarse particles and fine powder, poor particle gradation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Weigh the raw materials according to the following parts by weight: cement 90kg, fly ash 80kg, machine-made sand 830kg, mortar water-retaining plasticizer 0.8kg, water 135kg;

[0026] (2) Pour the weighed dry raw materials into the blender and dry mix for 180s;

[0027] (3) According to the consistency at the construction site, add mixing water and stir evenly.

[0028] Among them, the cement strength grade is P O42.5, the fly ash is grade II, the limestone machine-made sand particle size is 1.18-3.5mm is the first grade, and the particle size is below 1.18mm is the first grade, and the mixing weight ratio of the two is 0.8:1 ,

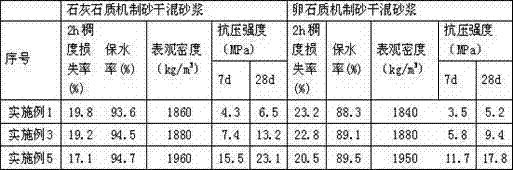

[0029] The resulting mortar mixture has a consistency of 78mm, a 2h consistency loss rate of 19.8%, a water retention rate of 93.6%, and an apparent density of 1860 kg / m 3 , The 7-day strength is 4.3MPa, and the 28-day strength is 6.5MPa. The basic performance of the mortar meets the requirements of the national standard "Ready-mixed Mor...

Embodiment 2

[0031] (1) Weigh the raw materials according to the following parts by weight: cement 105kg, fly ash 80kg, machine-made sand 815kg, mortar water-retaining plasticizer 0.8kg, water 135kg;

[0032] (2) Pour the weighed dry raw materials into the blender and dry mix for 180s;

[0033] (3) According to the consistency at the construction site, add mixing water and stir evenly.

[0034] Among them, the cement strength grade is P O42.5, the fly ash is grade II, the limestone machine-made sand particle size is 1.18-3.5mm is the first grade, and the particle size is below 1.18mm is the first grade, and the mixing weight ratio of the two is 0.8:1 ,

[0035] The resulting mortar mixture has a consistency of 76 mm, a 2-hour consistency loss rate of 20.2%, a water retention rate of 94.9%, and an apparent density of 1860 kg / m 3 , The 7-day strength is 5.5MPa, and the 28-day strength is 8.6MPa. The basic performance of the mortar meets the requirements of the national standard "Ready-mix...

Embodiment 3

[0037] (1) Weigh the raw materials according to the following parts by weight: cement 120kg, fly ash 75kg, machine-made sand 805kg, mortar water-retaining plasticizer 0.8kg, water 138kg;

[0038] (2) Pour the weighed dry raw materials into the blender and dry mix for 180s;

[0039] (3) According to the consistency at the construction site, add mixing water and stir evenly.

[0040] Among them, the cement strength grade is P O42.5, the fly ash is grade II, the limestone machine-made sand particle size is 1.18-3.5mm is the first grade, and the particle size is below 1.18mm is the first grade, and the mixing weight ratio of the two is 0.8:1 ,

[0041] The resulting mortar mixture has a consistency of 77mm, a 2h consistency loss rate of 19.2%, a water retention rate of 94.5%, and an apparent density of 1880 kg / m 3 , The 7-day strength is 7.4MPa, and the 28-day strength is 13.2MPa. The basic performance of the mortar meets the requirements of the national standard "Ready-mixed M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| power level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com