A kind of underwater concrete containing limestone machine-made sand and its preparation method

A technology of underwater concrete and machine-made sand, which is applied in the field of special concrete and underwater concrete, which can solve the problems of increased difficulty in concrete quality control, increased fluctuation factors of concrete quality, unsatisfactory fluidity and cohesion, etc., to achieve fluidity Unsatisfactory and cohesiveness, good for environmental protection, good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

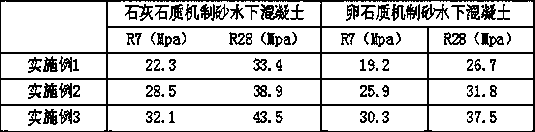

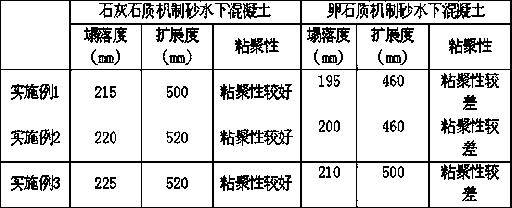

Embodiment 1

[0025] (1) Prepare the above-mentioned limestone-containing machine-made sand underwater concrete 1m 3 , Weigh the raw materials according to the following parts by weight: cement 200kg, mineral powder 60kg, crushed stone 980kg, limestone machine-made sand 950kg, water 165kg, water reducing agent 8.4kg, fly ash 55kg;

[0026] (2) Pour the weighed raw materials into the mixer and stir for 50 seconds.

[0027] Among them, the cement strength is 42.5Mpa, the ore powder is granulated water-quenched blast furnace slag powder, the grade is S75, the crushed stone particle size is 5-31.5mm continuous gradation, and the particle size of limestone machine-made sand is in the range of 75um-5mm Continuous gradation, the fineness modulus distribution is between 2.6 and 3.2, the gradation is in zone 2, the water reducing agent is polycarboxylate high-efficiency water reducing agent, the water reducing rate is 20%, and the fly ash grade is Ⅱ.

[0028] The obtained concrete has a slump of 21...

Embodiment 2

[0030] (1) Prepare the above-mentioned limestone-containing machine-made sand underwater concrete 1m 3 , Weigh the raw materials according to the following parts by weight: cement 210kg, mineral powder 60kg, crushed stone 1000kg, limestone machine-made sand 930kg, water 160kg, water reducing agent 9.0kg, fly ash 55kg;

[0031] (2) Pour the weighed raw materials into the mixer and stir for 50 seconds.

[0032] Among them, the cement strength is 42.5Mpa, the ore powder is granulated water-quenched blast furnace slag powder, the grade is S75, the crushed stone particle size is 5-31.5mm continuous gradation, and the particle size of limestone machine-made sand is in the range of 75um-5mm Continuous gradation, the fineness modulus distribution is between 2.6 and 3.2, the gradation is in zone 2, the water reducing agent is polycarboxylate high-efficiency water reducing agent, the water reducing rate is 20%, and the fly ash grade is Ⅱ.

[0033] The resulting concrete has a slump of ...

Embodiment 3

[0035] (1) Prepare the above-mentioned limestone-containing machine-made sand underwater concrete 1m 3 , Weigh the raw materials according to the following parts by weight: cement 240kg, mineral powder 60kg, crushed stone 1000kg, limestone machine-made sand 900kg, water 160kg, water reducing agent 9.2kg, fly ash 60kg and mix.

[0036] (2) Pour the weighed raw materials into the mixer and stir for 50 seconds.

[0037] Among them, the cement strength is 42.5Mpa, the ore powder is granulated water-quenched blast furnace slag powder, the grade is S75, the crushed stone particle size is 5-31.5mm continuous gradation, and the particle size of limestone machine-made sand is in the range of 75um-5mm Continuous gradation, the fineness modulus distribution is between 2.6 and 3.2, the gradation is in zone 2, the water reducing agent is polycarboxylate high-efficiency water reducing agent, the water reducing rate is 20%, and the fly ash grade is Ⅱ.

[0038] The obtained concrete has a sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| power level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com