Binder special for coal briquette for Lurgi pressurized gasification

A technology of binder and briquette, which is used in the special binder for briquette for Luqi gasification, the preparation of briquette, and the special binder for gas briquette for Luqi pressurized gasifier, which can solve the problem of Coal binder has problems such as high ash content, low ash melting temperature, and low bonding strength, etc., to achieve the effect of being conducive to continuous operation, high ash melting temperature, and expanding the range of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

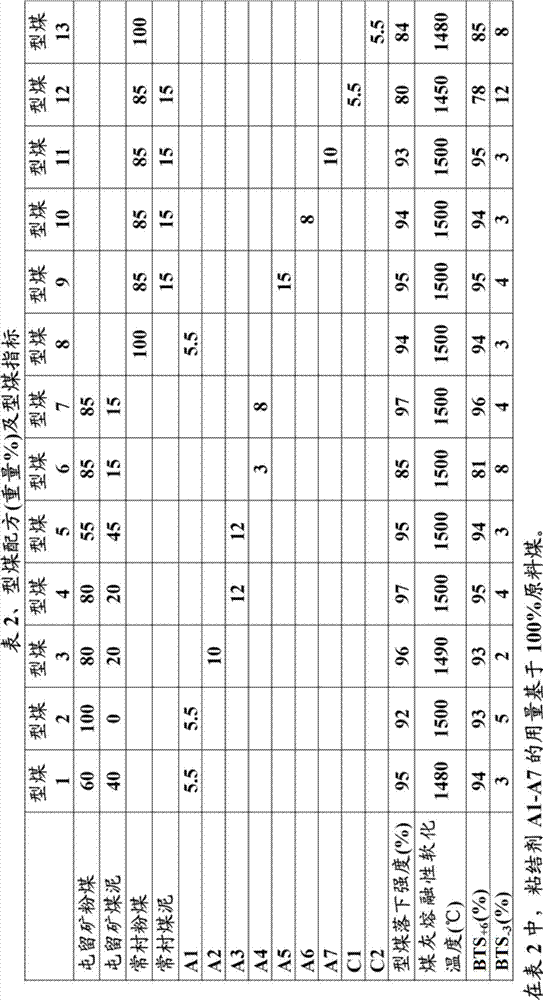

Examples

Embodiment Construction

[0041] Measurement methods

[0042] 1. Measurement method of briquette drop strength

[0043] According to the method stipulated in MT / T925-2004, the main points of the measurement method are: take a certain amount of briquette samples and weigh them, drop them freely from a height of 2m onto a steel plate with a specified thickness, and drop the briquettes with a particle size greater than 13mm from the dropped briquettes. The briquettes were dropped again for a total of 3 times, and the drop strength of the briquettes was represented by the percentage of the mass of the briquettes with a particle size greater than 13 mm after the third drop to the mass of the prototype coal sample.

[0044] 2. Measurement method of thermal stability of briquette

[0045] According to the industry standard MT / T924-2004, the main points of the measurement method are: select a crack-free and basically complete molded coal from the molded coal samples taken according to the regulations of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thermal stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com