Patents

Literature

97results about How to "Improve drop strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Direction reduction and electric furnace smelting-separation preparation process of vanadium-titanium magnetite cold bound pellet

The cooled agglomerated carbon-contained pellet prepared with vanadium titano magnetite concentrate and opposite direct reduction with former pellet comprises: mixing the concentrate, reducer and bonding agent, drying, grinding, and pelletizing to obtain the cooled agglomerated carbon-contained pellet drying and sieving into the reduction furnace with reducer for reduction atmosphere; loading the reduced pellet into electric furnace to melt and separate the iron liquid, V, Ti and Cr. This invention is fit to the pellet on wide application temperature and low energy consumption, has well efficiency and low running cost, and can also extract V, Ti Fe and Cr from electric furnace with high yield and obvious environmental protection.

Owner:鲜帆 +2

Pelletizing of broad molecular weight polyethylene

InactiveUS6454976B1Increased effect on polymer temperatureLow costFlat articlesPolymer scienceProduct gas

Polyethylene having a broad molecular weight distribution is extruded in pellet form using a pelletizing extruder having one or more zones essentially filled with the polyethylene and two or more zones partially filled with the polyethylene. The polyethylene is fed into the extruder at a temperature sufficient to melt the polyethylene, and a mixture of an inert gas and oxygen is fed into at least one partially filled zone of the extruder with the exception of the feed zone. The mixture contains about 1 to about 21% by volume oxygen based on the volume of the gas mixture.

Owner:UNION CARBIDE CHEM & PLASTICS TECH CORP

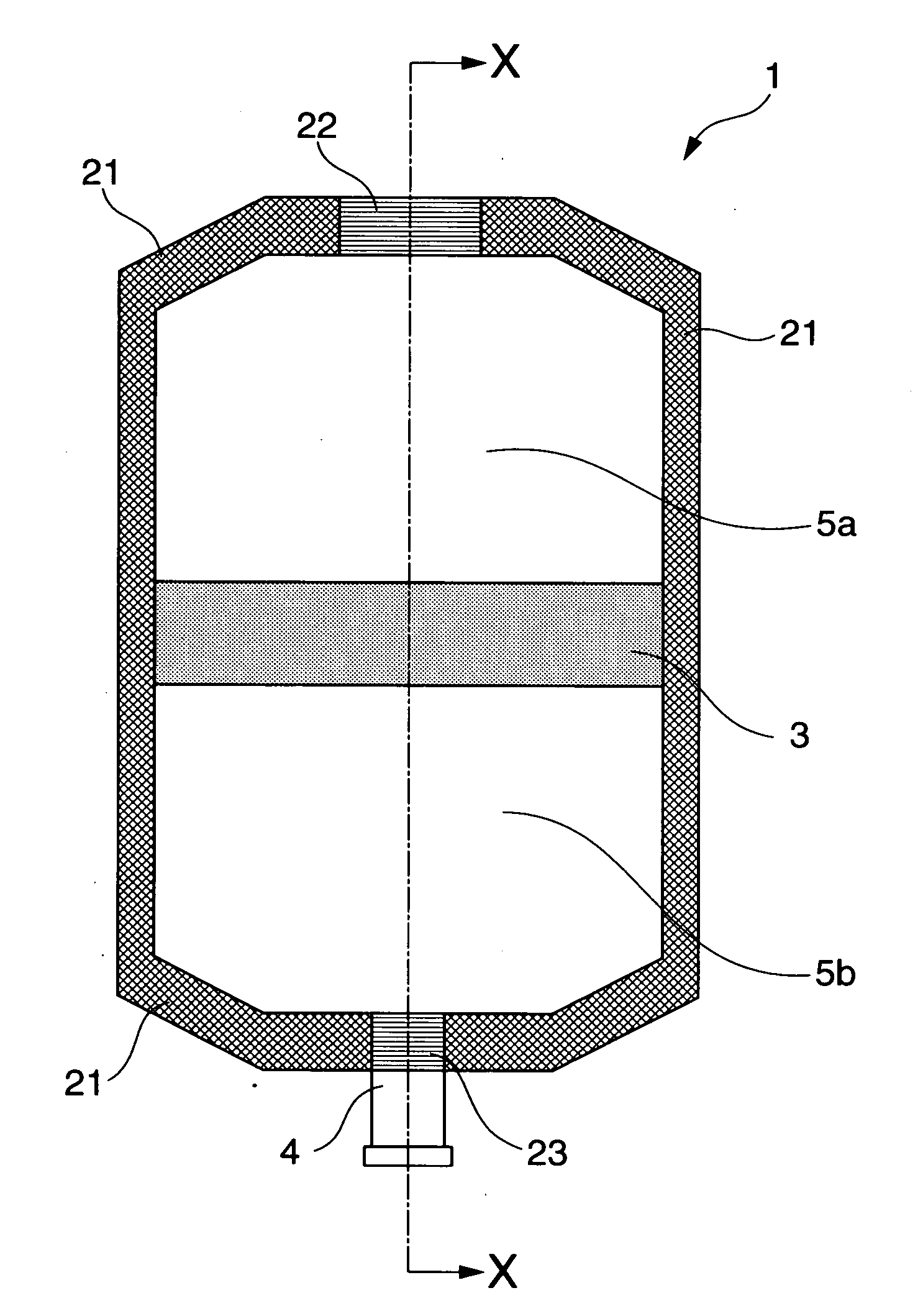

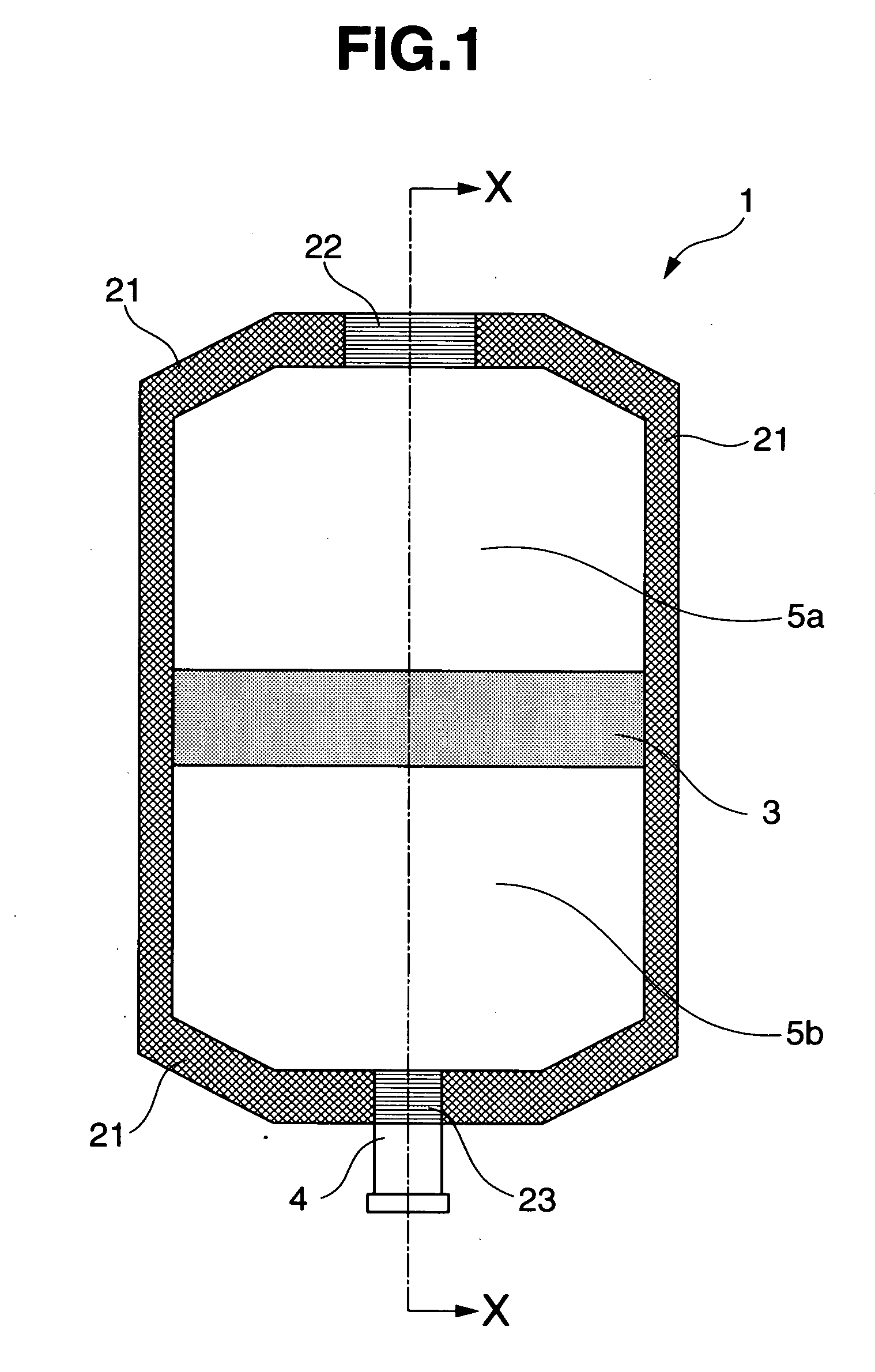

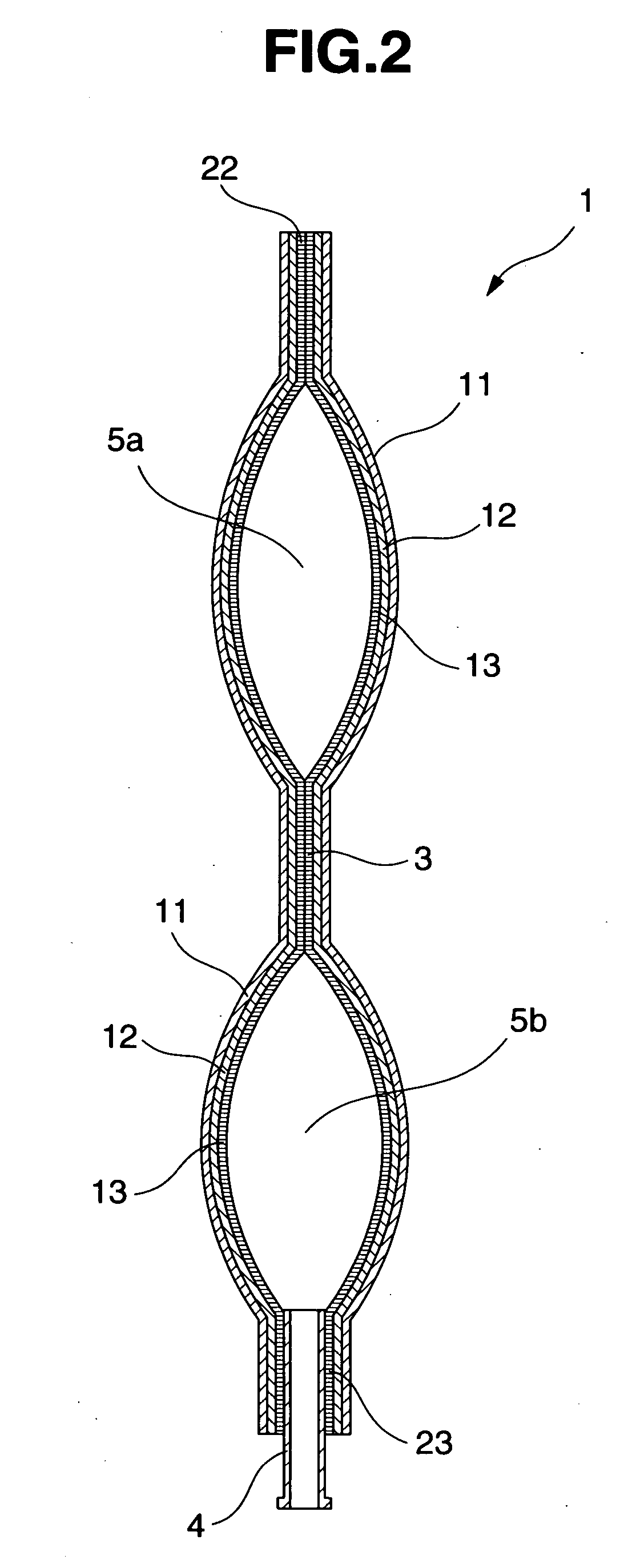

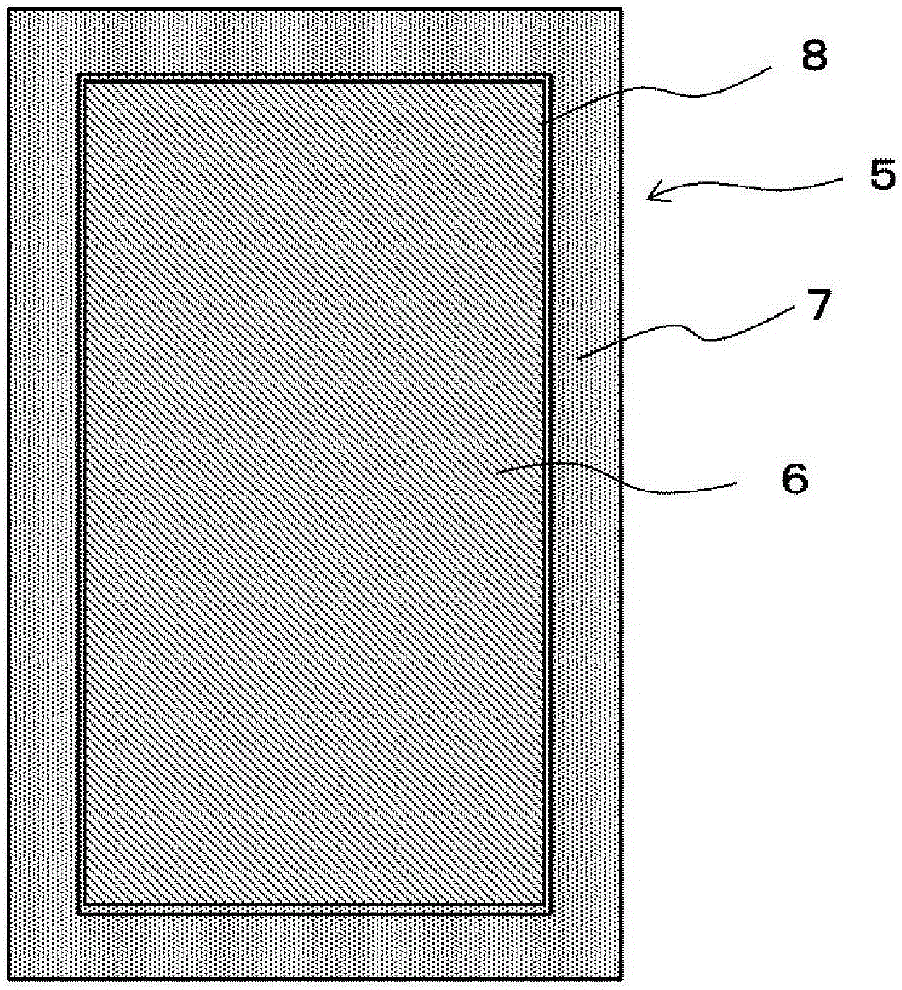

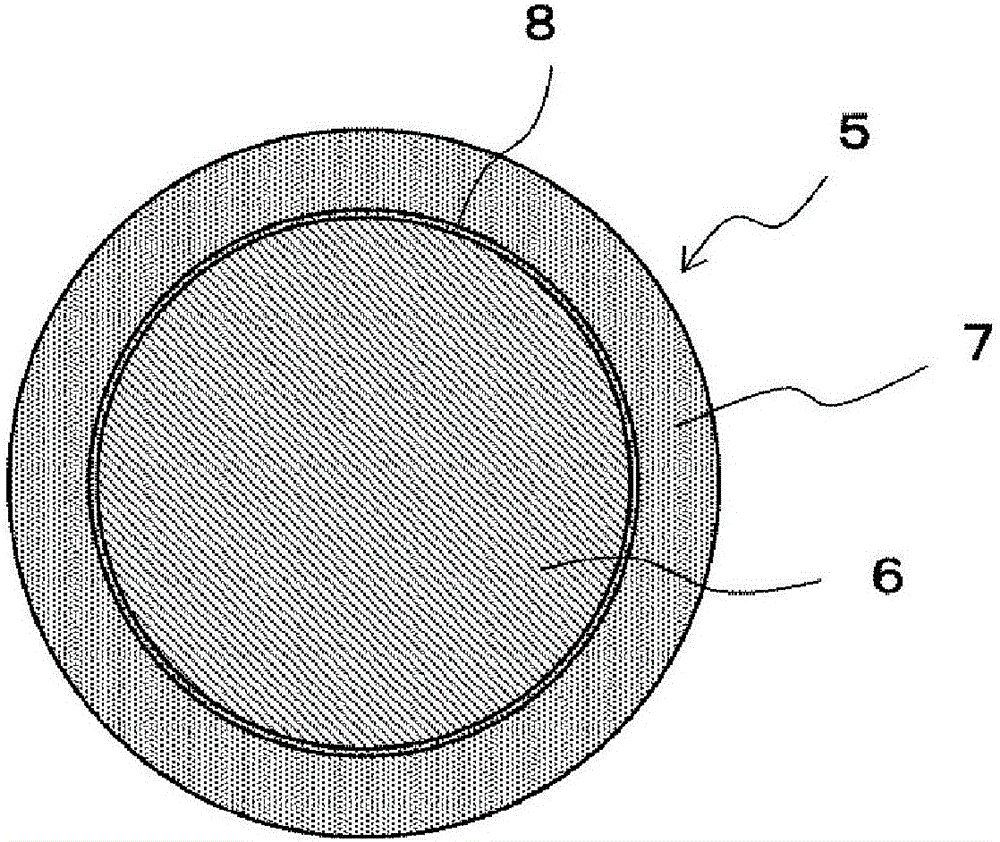

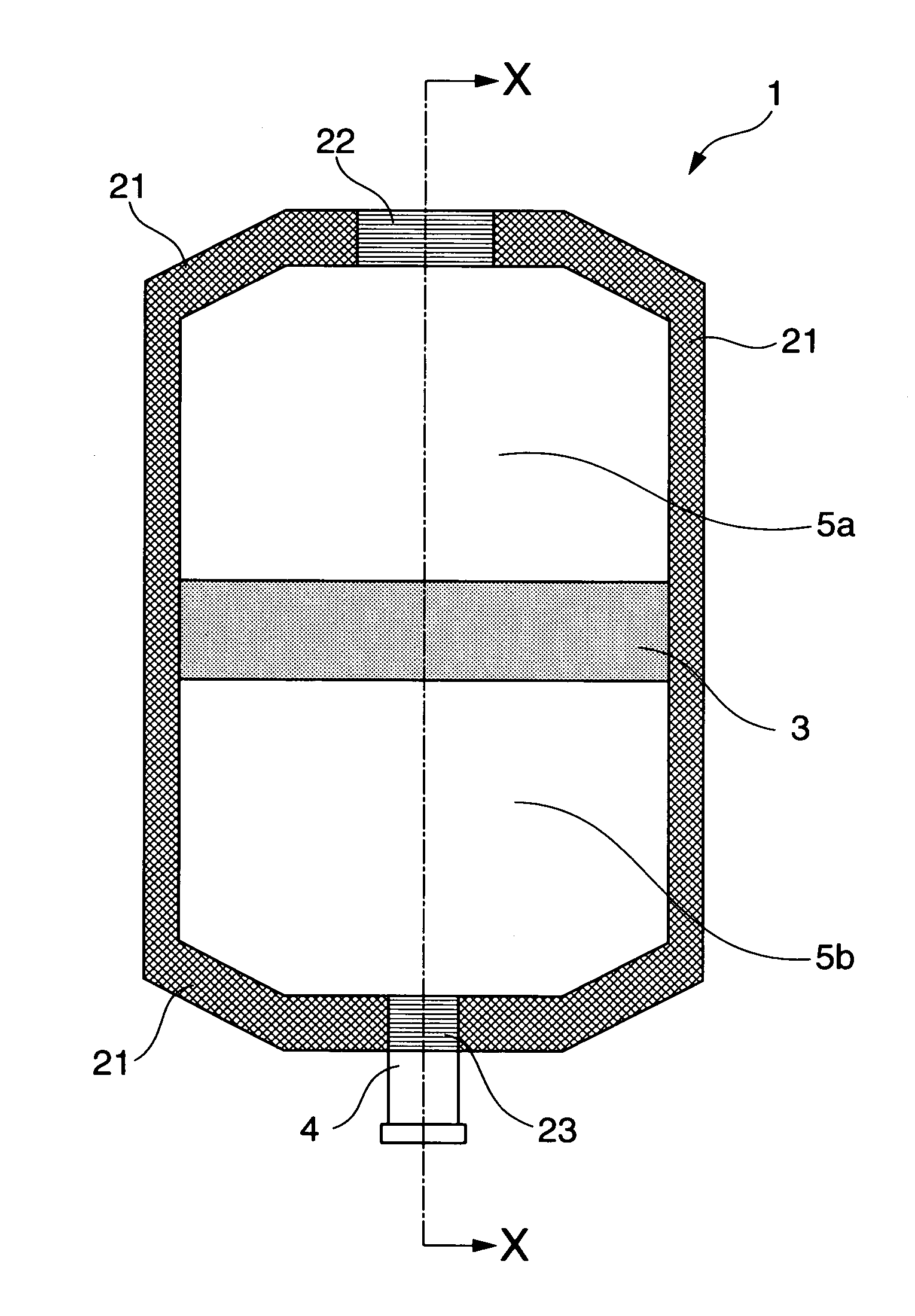

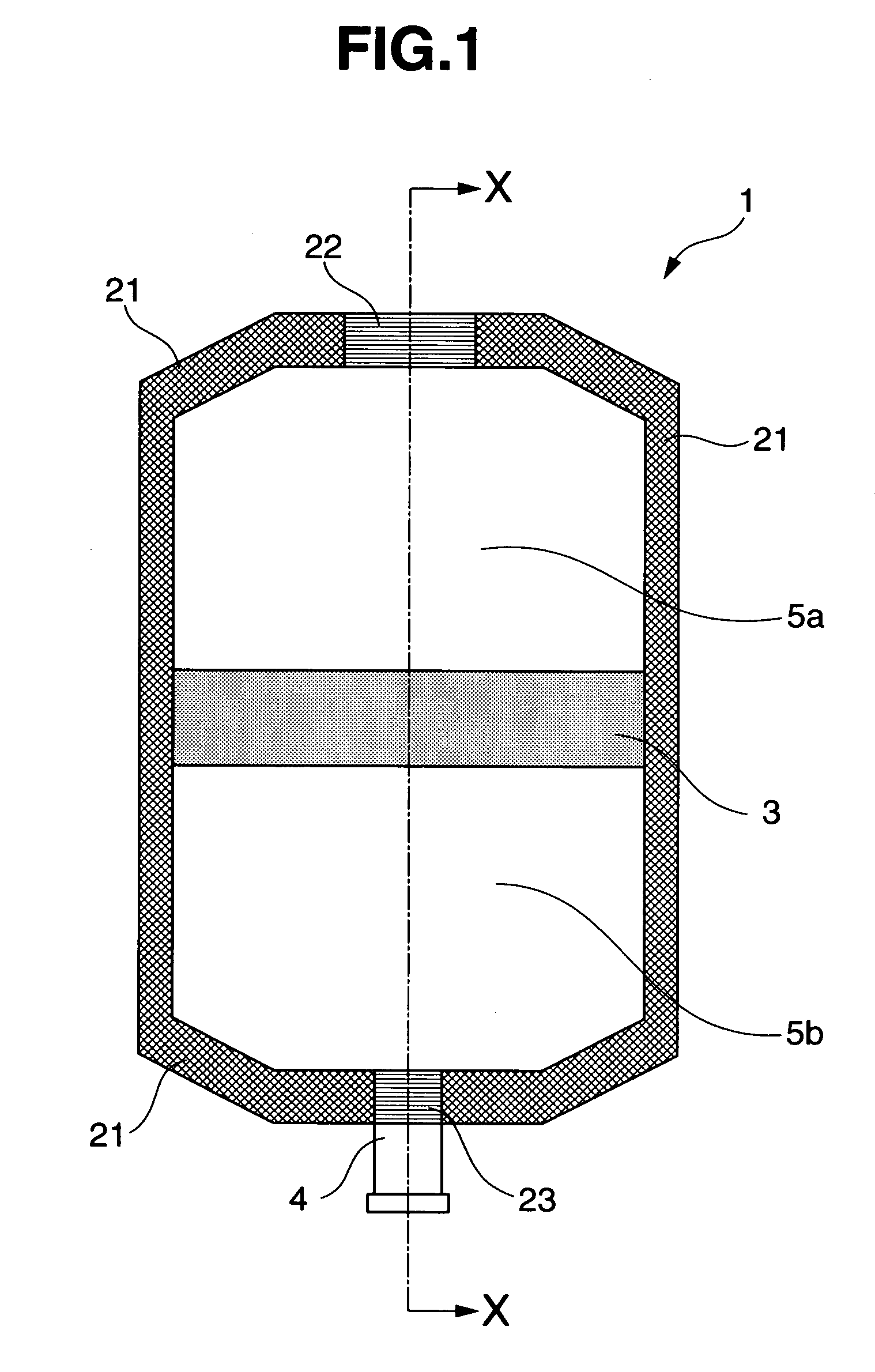

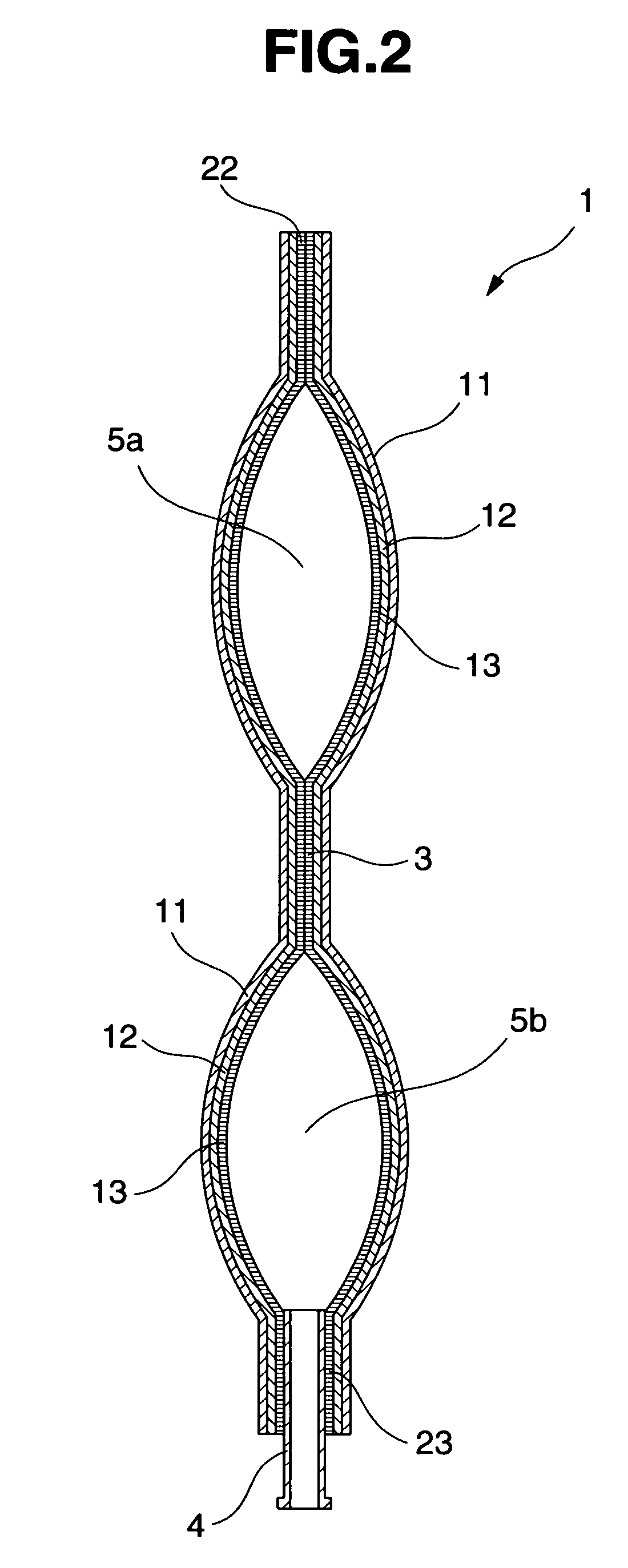

Multi-chamber container

ActiveUS20070114144A1Improve heat resistanceHigh transparencyMedical devicesDomestic containersPolymer scienceAlkene

Multi-chamber container (1) having its interior partitioned by weak seal portions (3) provided through detachable heat sealing so that multiple contents are accommodated separately from each other, wherein use is made of heat seal layers consisting of a composition comprising two types of propylene copolymers components (component A and component B) from propylene and ethylene and / or a C4-C8 α-olefin which have the following elution properties. Thus, a region wherein a change of seal strength by a change of heat seal temperature is small has a wide temperature range to thereby facilitate controlling of the seal strength at the weak seal portions. The proportion (mass %) of, to total solution, elution according to the TREF method (temperature: 0 to 140° C. and solvent: ODCB) is as follows. With respect to component A: 15 to 50 at 0° C., and 5 to less than 15 at 60 to 90° C. With respect to component B: 0 to 25 at 0° C., and 15 to 70 at 60 to 90° C.

Owner:FUJIMORI KOGYO CO LTD

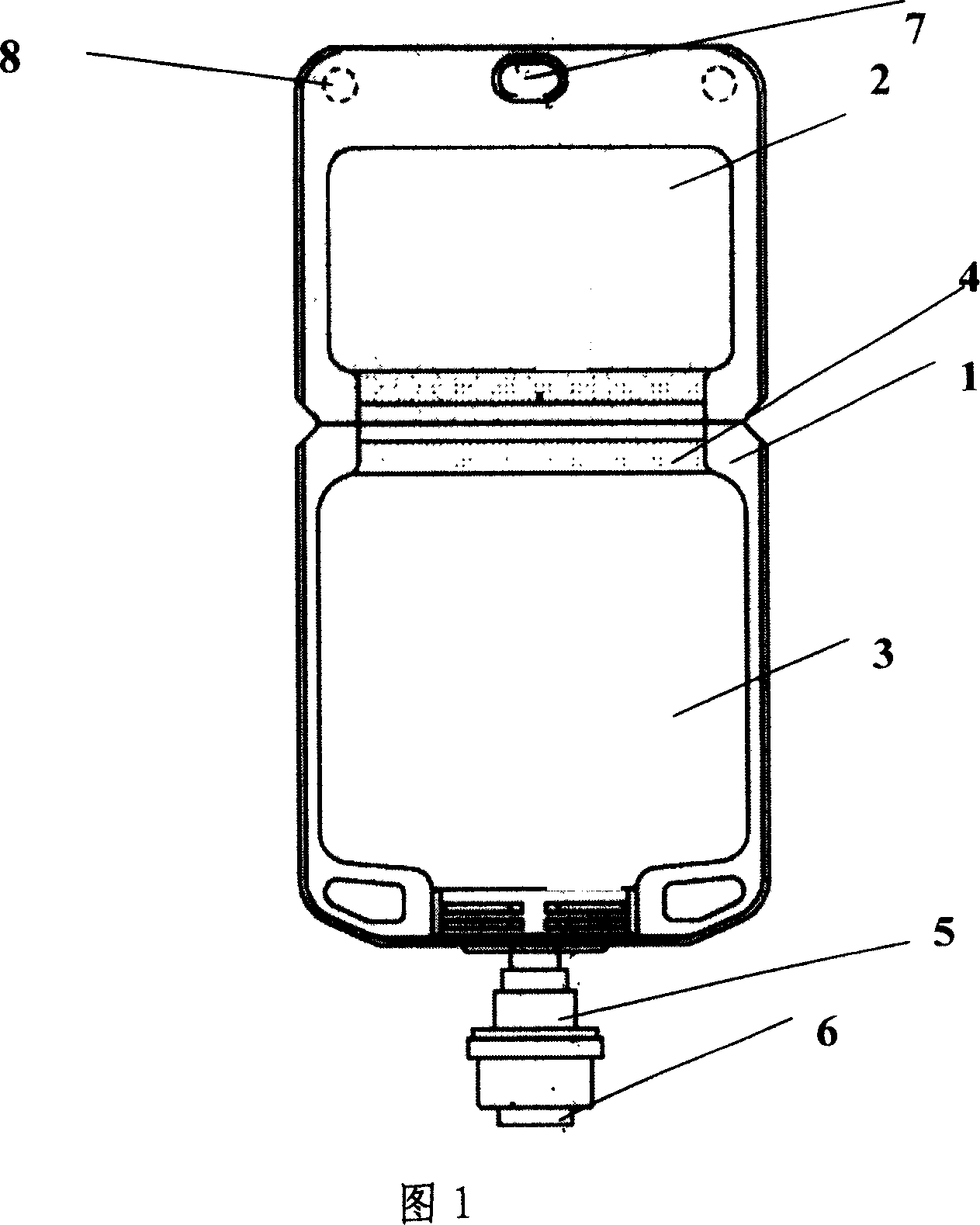

Powder and liquid bag and preparation method thereof

The invention discloses a powder-liquid container and manufacturing method, which is composed of sealed bag with two bag film on the periphery, wherein the bag possesses at least one powder chamber with antibiotics and liquid chamber with aseptic solution, which is separated by separating part, the separating part is connected by bag film through strippable welding structure, two external sides of bag film of powder chamber possesses a layer of baffle film.

Owner:SHANGHAI WUBIN PACKAGING PRODS

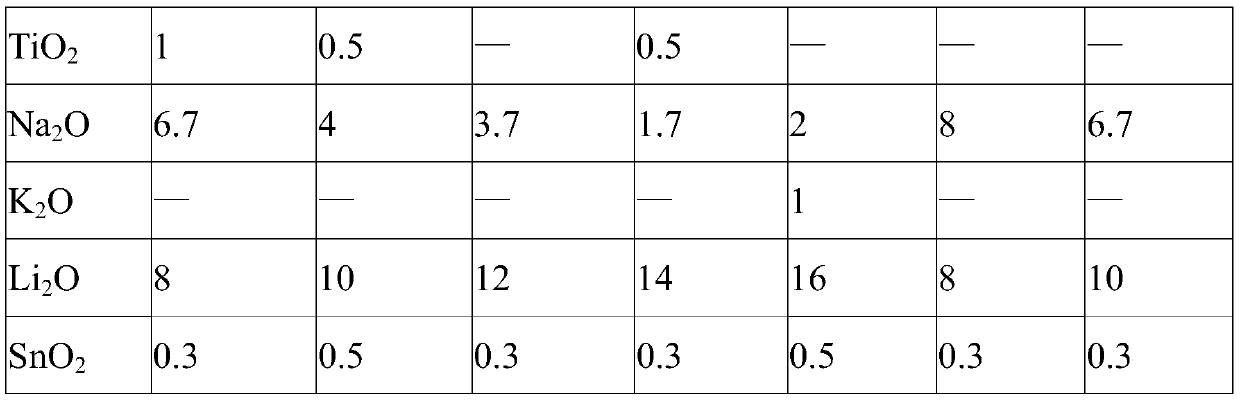

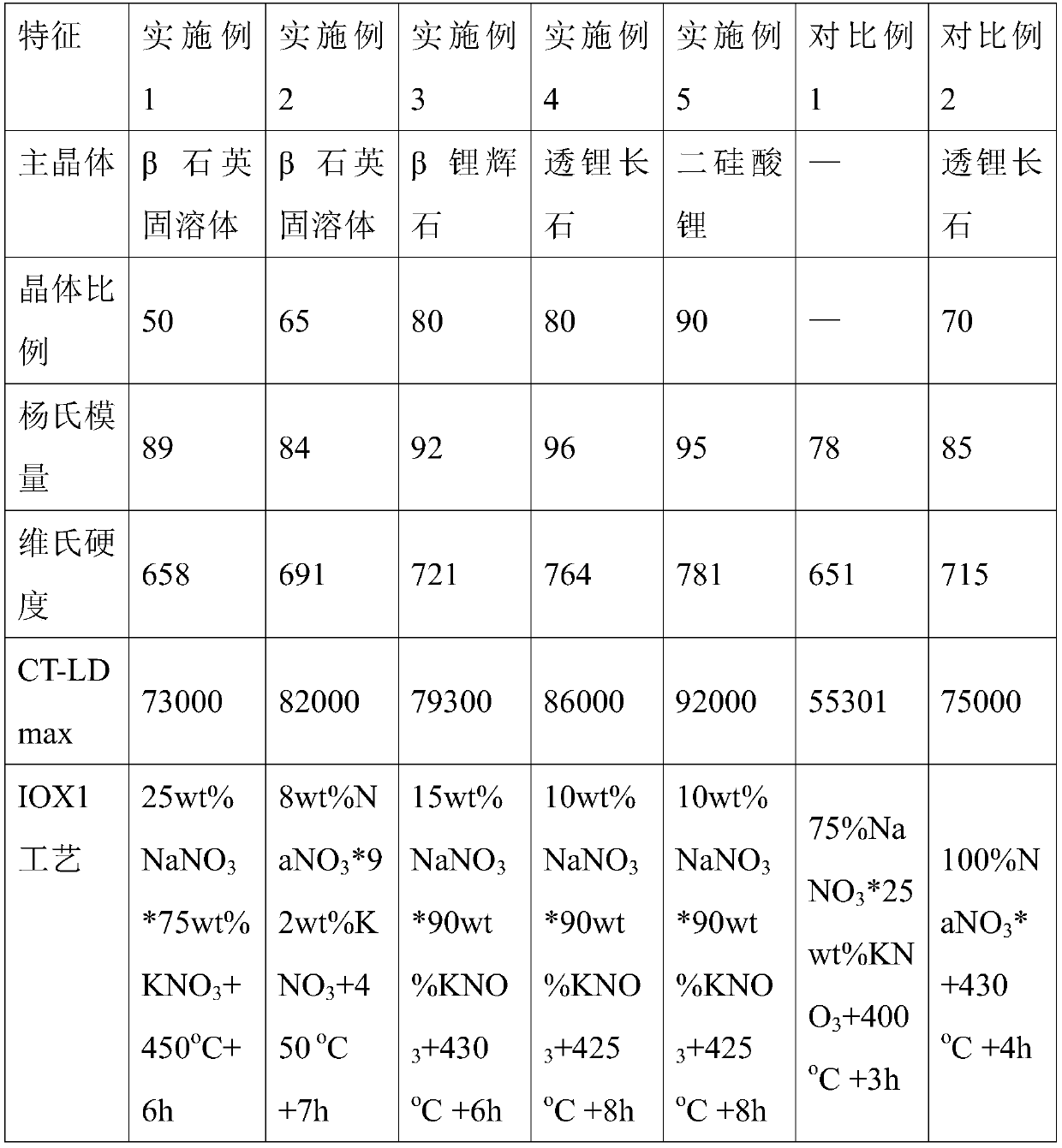

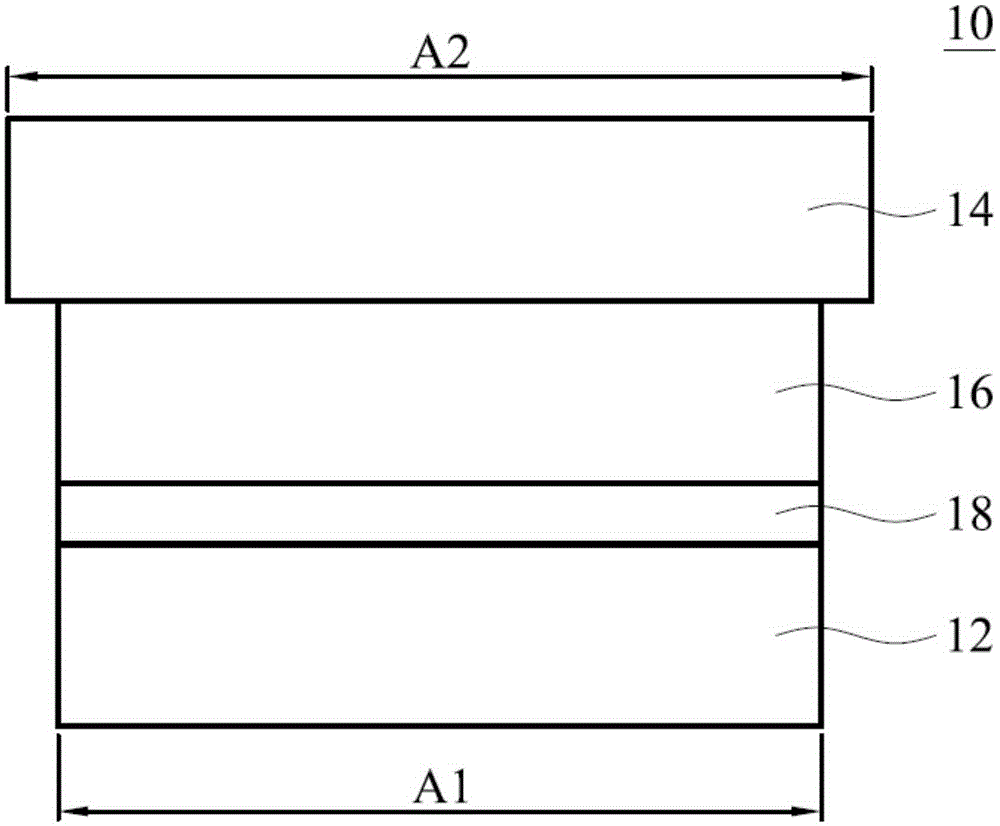

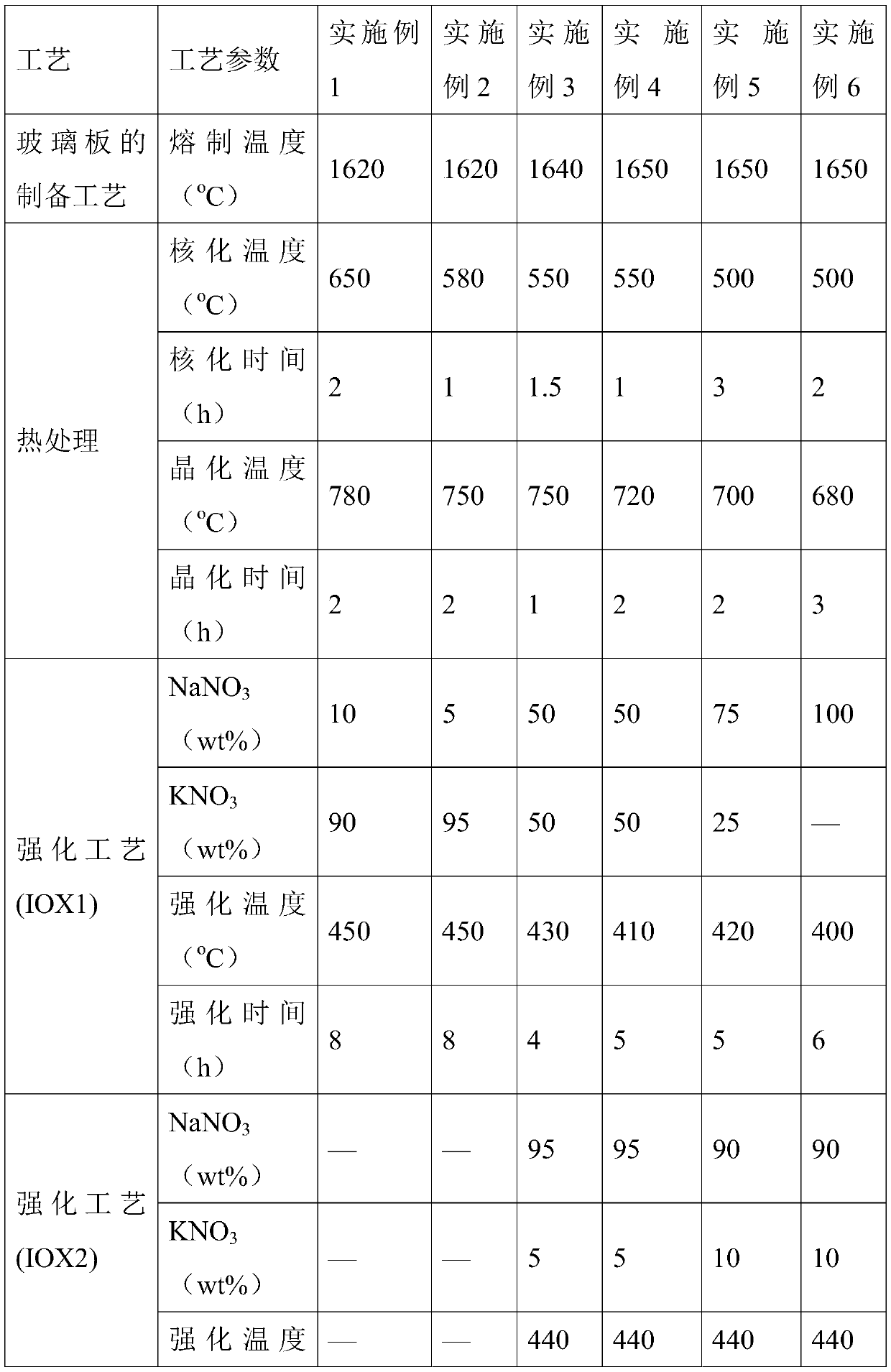

Strengthened microcrystalline glass with high-pressure stress layer depth and preparation method thereof

ActiveCN110845153AImprove structural strengthSufficient surface compressive stressIon exchangeStress relaxation

The invention discloses strengthened microcrystalline glass with high stress layer depth and a preparation method of the strengthened microcrystalline glass. The strengthened microcrystalline glass isformed by carrying out chemical ion exchange on the microcrystalline glass in a salt bath for one time or multiple times; a pressure stress layer and a tensile stress layer corresponding to the pressure stress layer are sequentially formed on the two opposite sides of the strengthened microcrystalline glass from the surface to the interior respectively, and the depth of the single-face pressure stress layer of the strengthened microcrystalline glass is 18%-25% of the total thickness of the strengthened microcrystalline glass. The high crystallinity of the strengthened microcrystalline glass improves the intrinsic network structure strength of the strengthened microcrystalline glass, so that the microcrystalline glass can accommodate higher compressive stress, and the stress relaxation amount at high temperature is small; the exchange depth of the microcrystalline glass can be increased by adopting a lithium-containing salt bath, so that the depth of the pressure stress layer is remarkably increased; the depth of the stress layer of the strengthened microcrystalline glass accounts for more than 18% of the total thickness of the glass, and the strengthened microcrystalline glass hasvery high anti-falling strength; wide field of application.

Owner:CHONGQING XINJING SPECIAL GLASS CO LTD

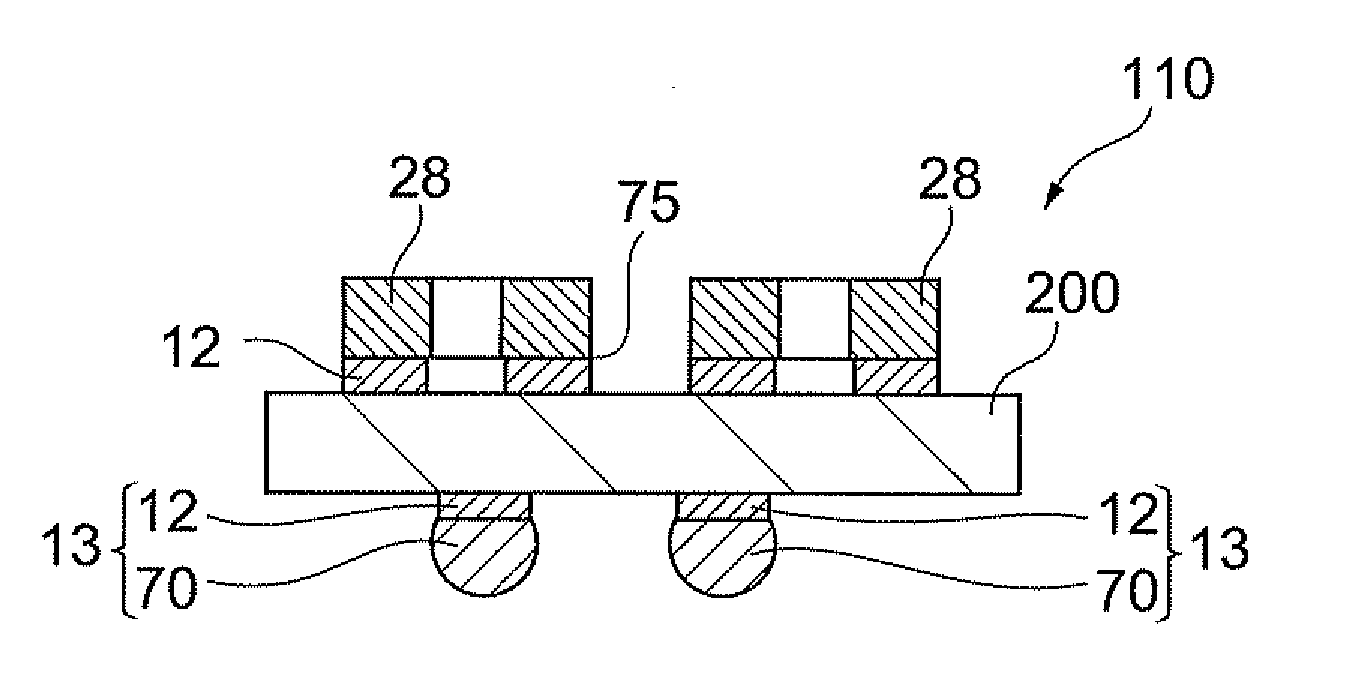

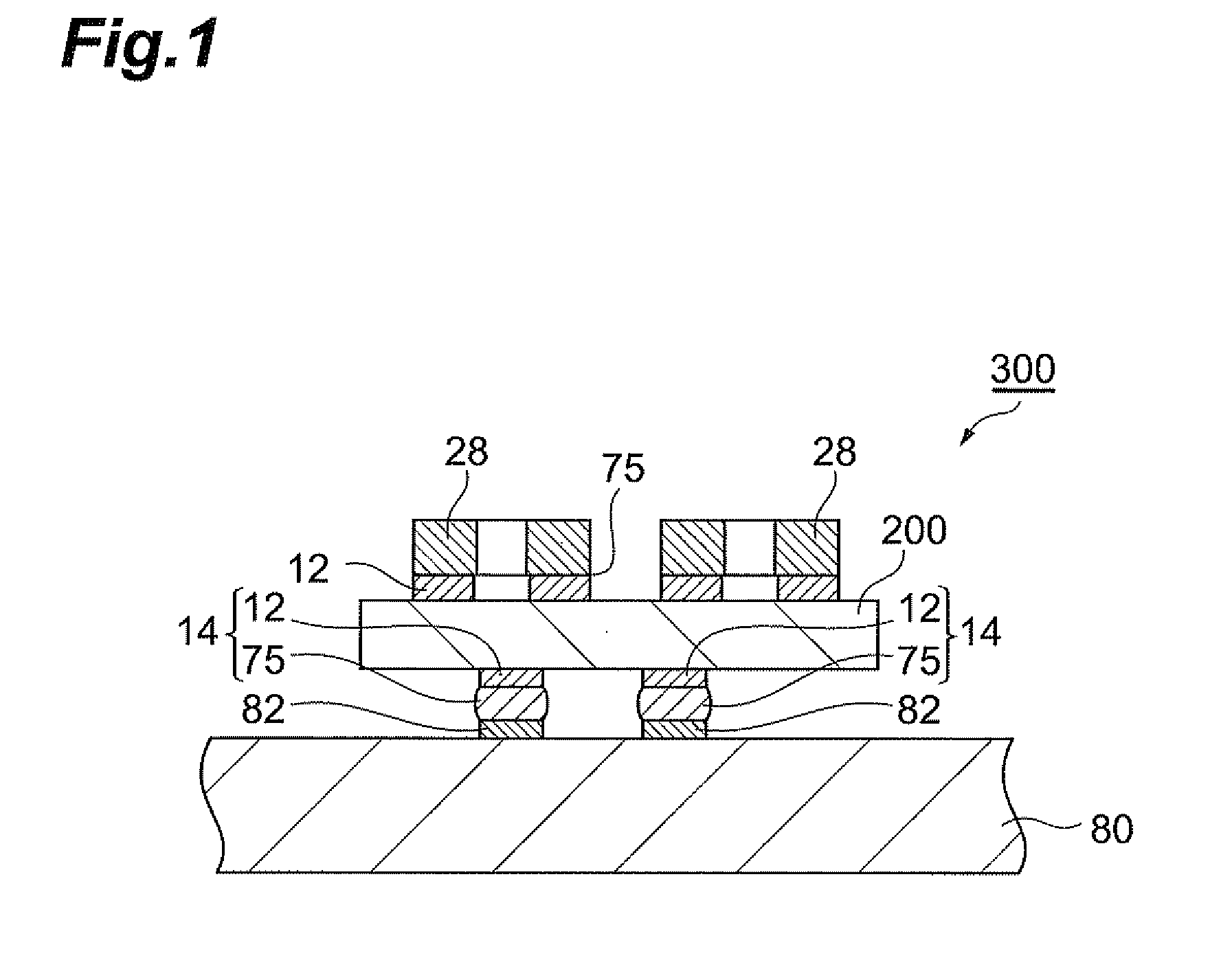

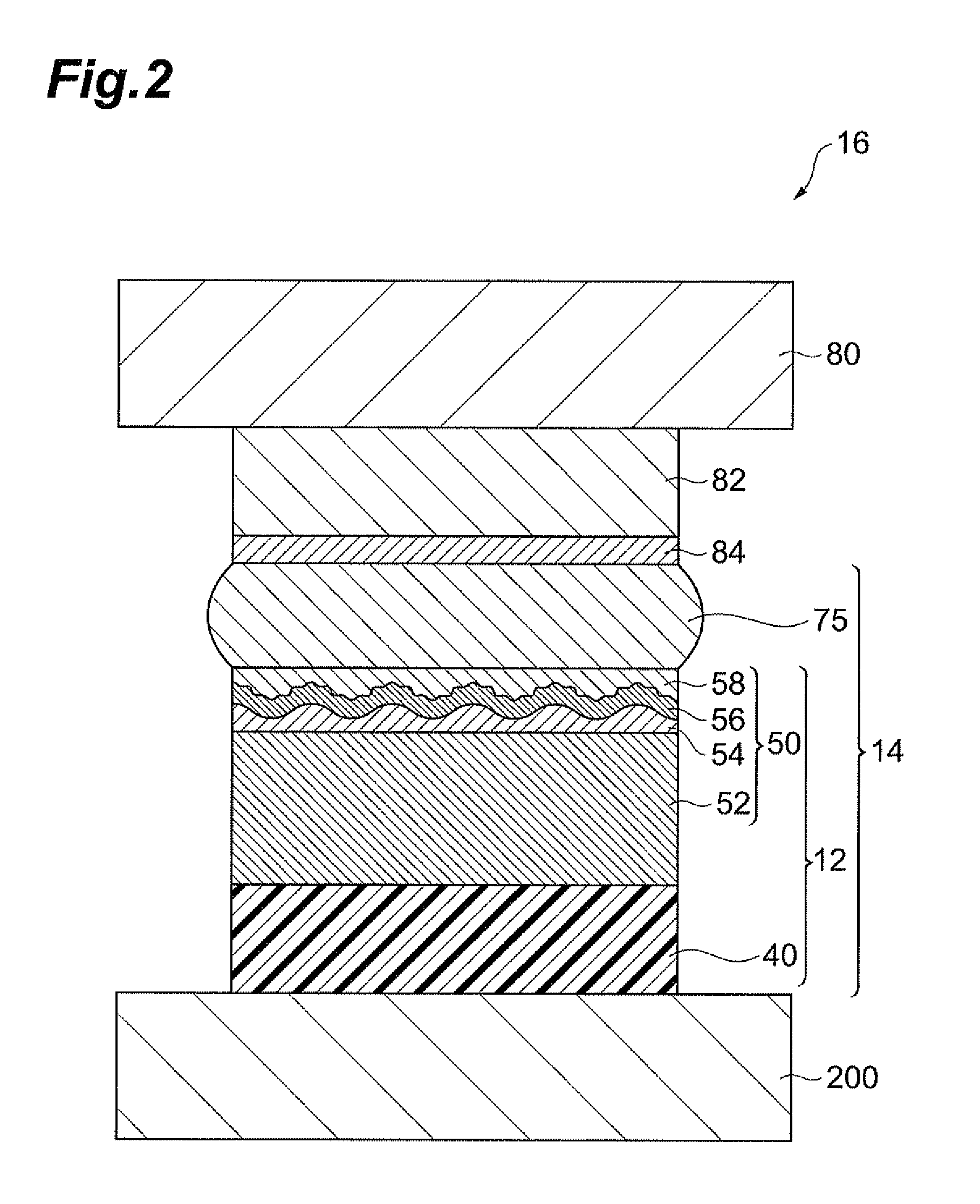

Terminal structure, printed wiring board, module substrate, and electronic device

ActiveUS20120044652A1Improve drop strengthNon-insulated conductorsSolid-state devicesElectrical conductorSurface roughness

The present invention relates to a terminal structure. The terminal structure includes: a terminal having: a conductor layer containing at least one metal selected from gold, silver, and copper; a first layer containing nickel and phosphorus, laid on the conductor layer; a second layer having a smaller atomic ratio of nickel to phosphorus than the first layer and containing Ni3P, laid on the first layer; a third layer containing a first intermetallic compound of an Ni—P—Sn type, laid on the second layer; and a fourth layer containing a second intermetallic compound of an Ni—Cu—Sn type, laid on the third layer; and a solder layer on the fourth layer of the terminal. Ra2 is larger than Ra1, where Ra1 is a surface roughness of the third layer on the second layer side and Ra2 is a surface roughness of the third layer on the fourth layer side.

Owner:TDK CORPARATION

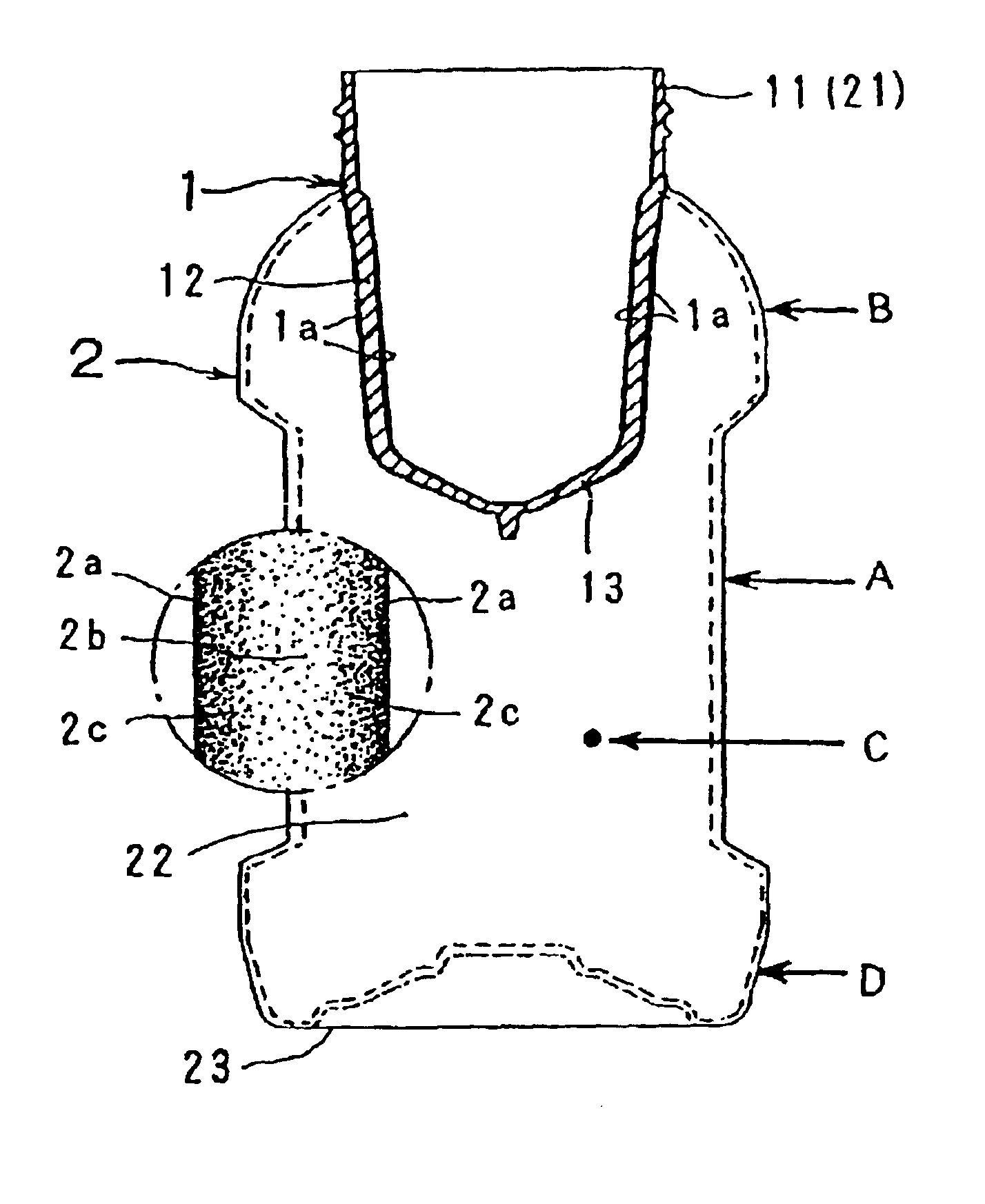

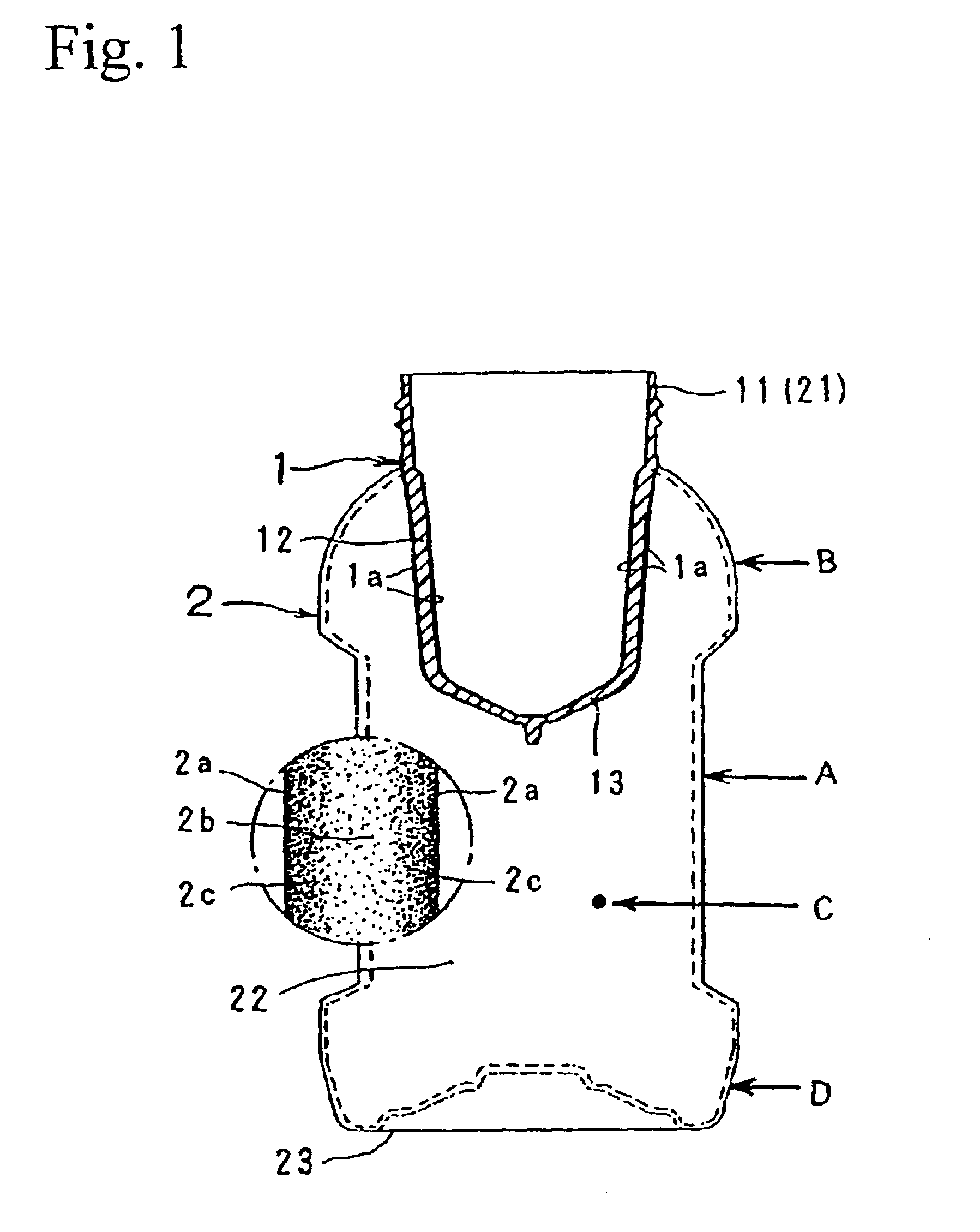

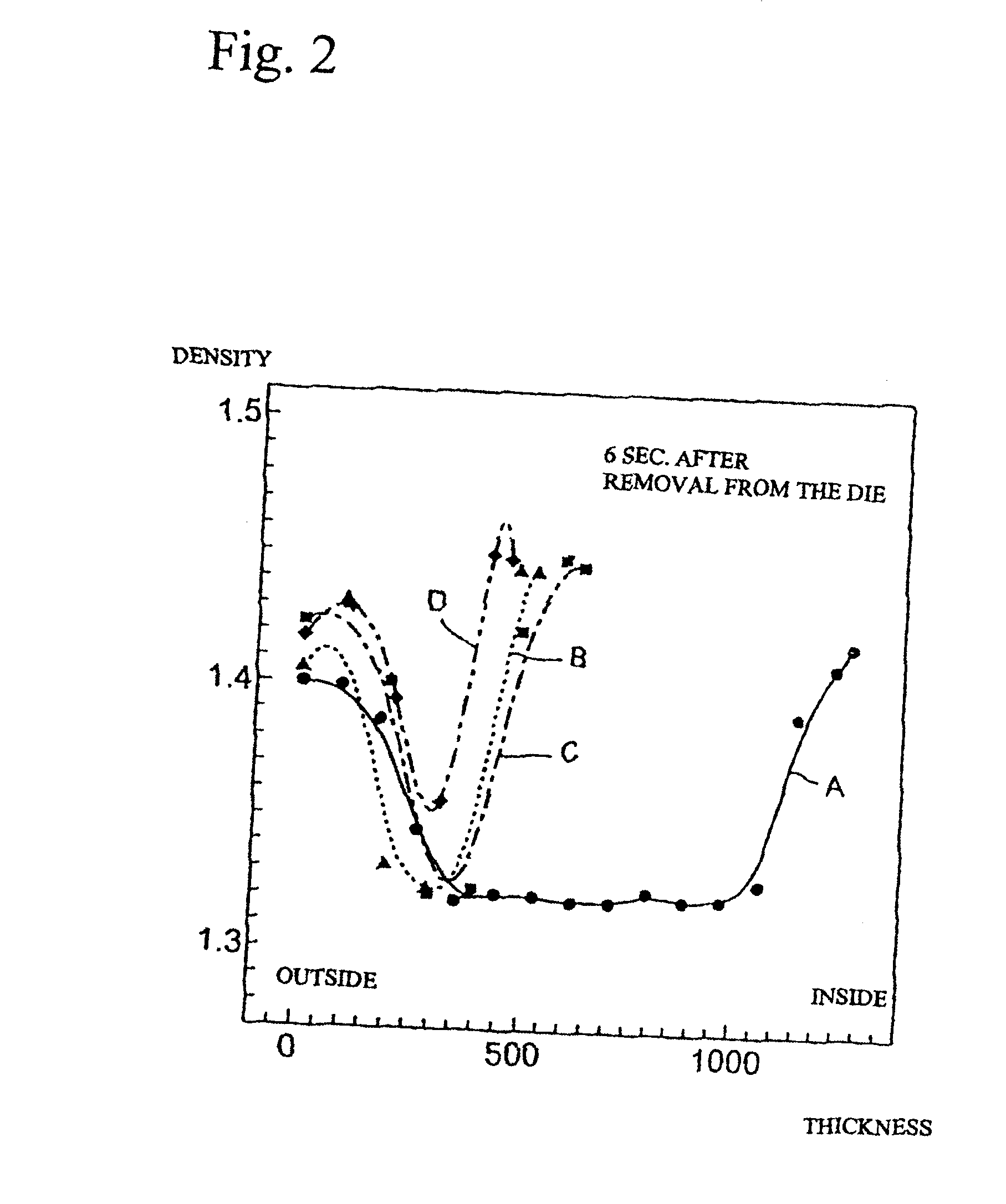

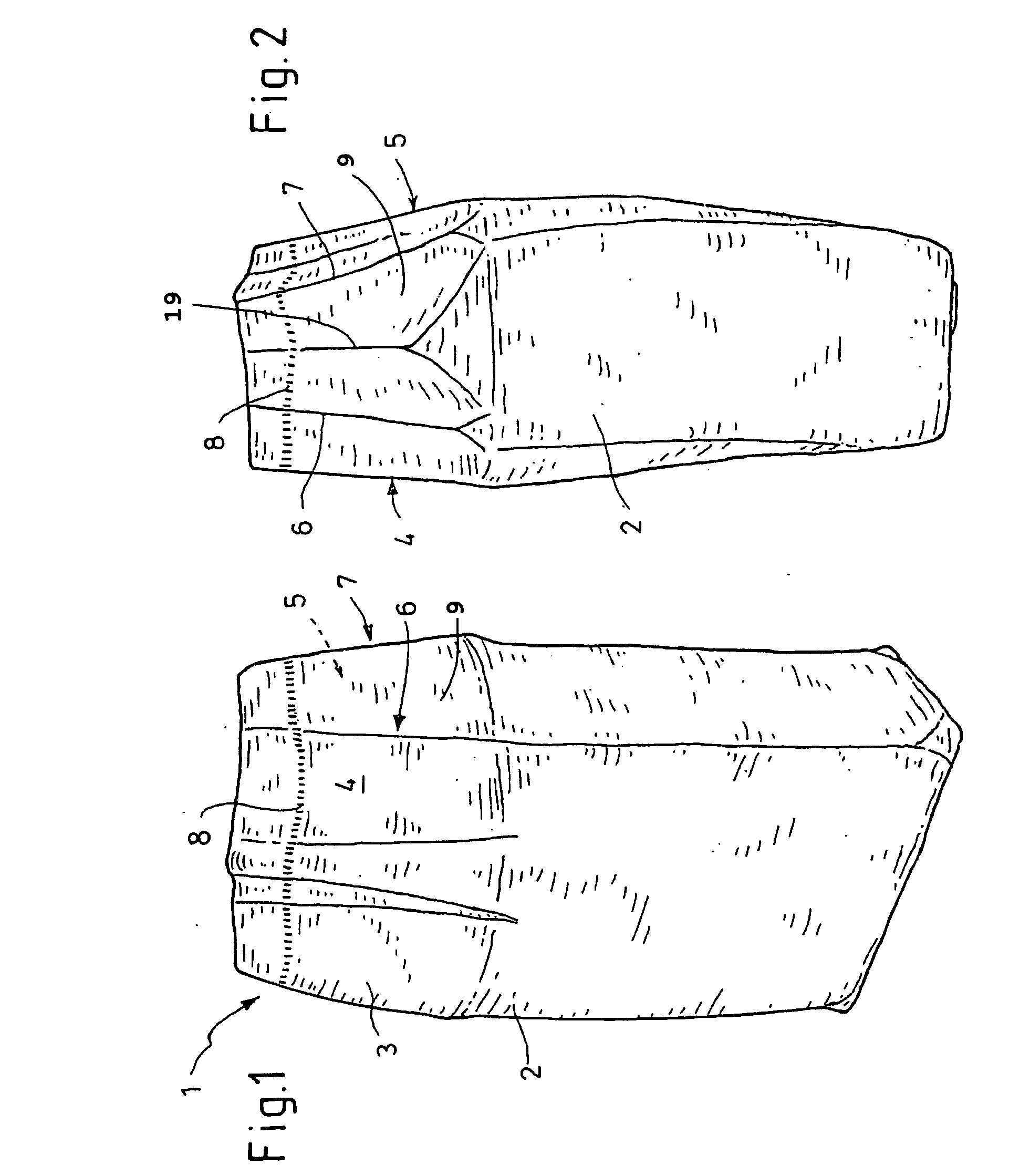

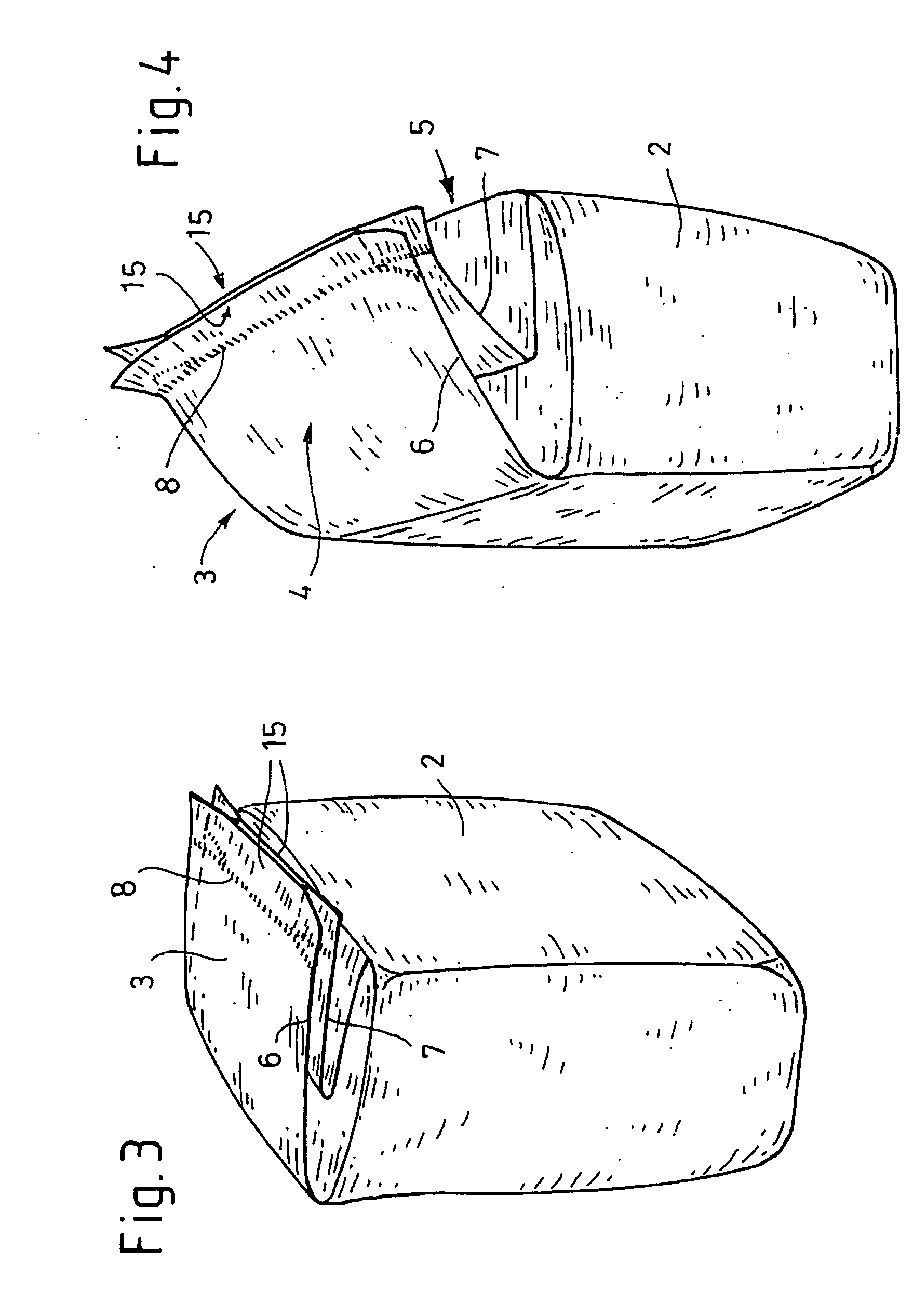

Stretch blow receptacle and molding method of the same

InactiveUS6890621B2FragilityImprove drop strengthBottlesSynthetic resin layered productsHigh densitySurface layer

Improve the strength of the stretch blow receptacle and make the heat resistant treatment easier, by making the receptacle wall cross-section multi-layered in view of crystalline density, and the crystalline density of the surface layer high density. The inventions concerns a thin plastic receptacle 2 molded by stretch blowing of a bottomed preform 1 in the longitudinal and transversal directions. The wall cross-section is composed of inside and outside surface layers 2a whose crystalline density is high by stretching, a core layer 2b presenting a lower density than the surface layers 2a, and an intermediate layer 2c presenting a graduated density between both layers 2a, 2b.

Owner:A K TECH LAB INC

Environmental-friendly solid fuel manufactured by municipal solid waste without manual classification and manufacturing method thereof

ActiveCN101831339AQuality improvementEfficient desulfurizationBiofuelsSolid fuelsBiotechnologySolid fuel

The invention discloses solid fuel manufactured by municipal solid wastes without manual classification. The solid fuel is manufactured by the following components in percentage by weight: 75%-85% of treated municipal solid wastes, 2%-7% of coal dust containing fixed carbon and 10%-20% of mixed additives. The invention aims at overcoming the defects in the prior art and increasing a novel treatment technology taking a biotechnology as a main technology to carry out advanced treatment on the municipal solid wastes, thereby providing the solid fuel which turns wastes into useful things by taking the municipal solid wastes as raw materials, has low production cost and little pollution, is beneficial to the environmental protection and has high combustion efficiency; and in addition, the invention has an other purpose of additionally providing a method which has simple process and environmental protection and is used for producing the solid fuel for changing a biochemical treatment methodof percolate generated in the wastes treatment process, wherein the biochemical treatment method has high production cost.

Owner:茹兆祥 +2

Composite additive for preparing hematite concentrate pellet and application thereof

A composite additive for preparing hematite concentrate pellets comprises the following components: humic acid, calcium peroxide, and paigeite. During application, the composite additive is added which has a mass percent of 0.5%-1.6% of the total mass of the hematite concentrates, and the finished product pellets are obtained by pelletization, preheating, and roasting. Compared with pellets prepared by traditional technology, the hematite pellets prepared by the composite additive of the invention have improved falling strength of the green pellets, and compression strength of the finished product pellets; the preheating temperature and roasting temperature suitable for the pellets are reduced; both the preheating time and roasting time are shortened; the TFe grade is increased by 0.8%-1.2%. The composite additive of the invention has reasonable component ratios, is easy to process and manufacture, has a low using amount and a low residual amount, can significantly improve the pelletability of hematite concentrates which are difficult to be palletized, can improve the green pellet quality, has good heat stability, and can effectively reduce the preheating and roasting temperatures and shorten the preheating and roasting time of hematite concentrates. The composite additive of the invention is applicable to the production of oxidized pellets by hematites, and is especially applicable to the production of oxidized pellets by specularites. The composite additive of the invention is applicable to large-scale industrial production.

Owner:CENT SOUTH UNIV

Method for manufacturing metallurgic composite pellet by using different binders and two-step pelletizing way

The invention provides a method for manufacturing a metallurgic composite pellet by using different binders and a two-step pelletizing way. The method comprises the steps: with an inorganic binder as the binder of a pellet core, preparing the pellet core through disc pelletizing or pressure pelletizing, wherein the diameter of the pellet core is 2-8mm, and the addition amount of the inorganic binder is 0.5-3.5%; with an organic binder as the binder of a pellet shell, attaching an iron-contained raw material onto the pellet core through disc pelletizing or pressure pelletizing to obtain the pellet with the diameter of 8-15mm, wherein the iron-contained raw material contains 0.1-1.0% of organic binder, and the volume ratio of the pellet core to the pellet shell of the obtained pellet is 1:1 to 1:4. Compared with a pellet with the inorganic binder, the pellet prepared by using the method provided by the invention has higher fresh pellet falling strength; in addition, the organic binder at an outer layer burns and decomposes in a roasting process, so that the iron grade of the pellet placed into a furnace is relatively high; compared with a pellet with an organic binder, the pellet prepared by using the method has higher compressive strength. All metallurgical performance indexes of the composite pellet are greatly superior to those of a conventional pellet, so that a relatively considerable economic benefit can be created.

Owner:UNIV OF SCI & TECH BEIJING

Touch panel, touch display device and display device

PendingCN106557188AReduce splashReduce harmElectrical equipmentGlass/slag layered productsTouch SensesWood splinter

The present invention provides a touch panel. The touch panel comprises: a substrate; a cover plate provided on the substrate; an optical glue disposed between the substrate and the cover plate, wherein an elastic modulus of the optical glue is between 1x10<7> Pa and 1x10<10> Pa; and a touch sensing layer disposed an upper surface or a low surface of the substrate or the upper surface and the low surface of the substrate. The present invention further provides a touch display device and a display device. The present invention further provides a touch display device and a display device, which both comprise an optical glue with a relatively great elastic modulus. Therefore, anti-drop strength of products can be effectively improved, the rupture of the edge of the cover plate or the touch panel is reduced so that the splinters are not easy to spread, and damage to the human body is reduced.

Owner:TPK TOUCH SOLUTIONS (XIAMEN) INC

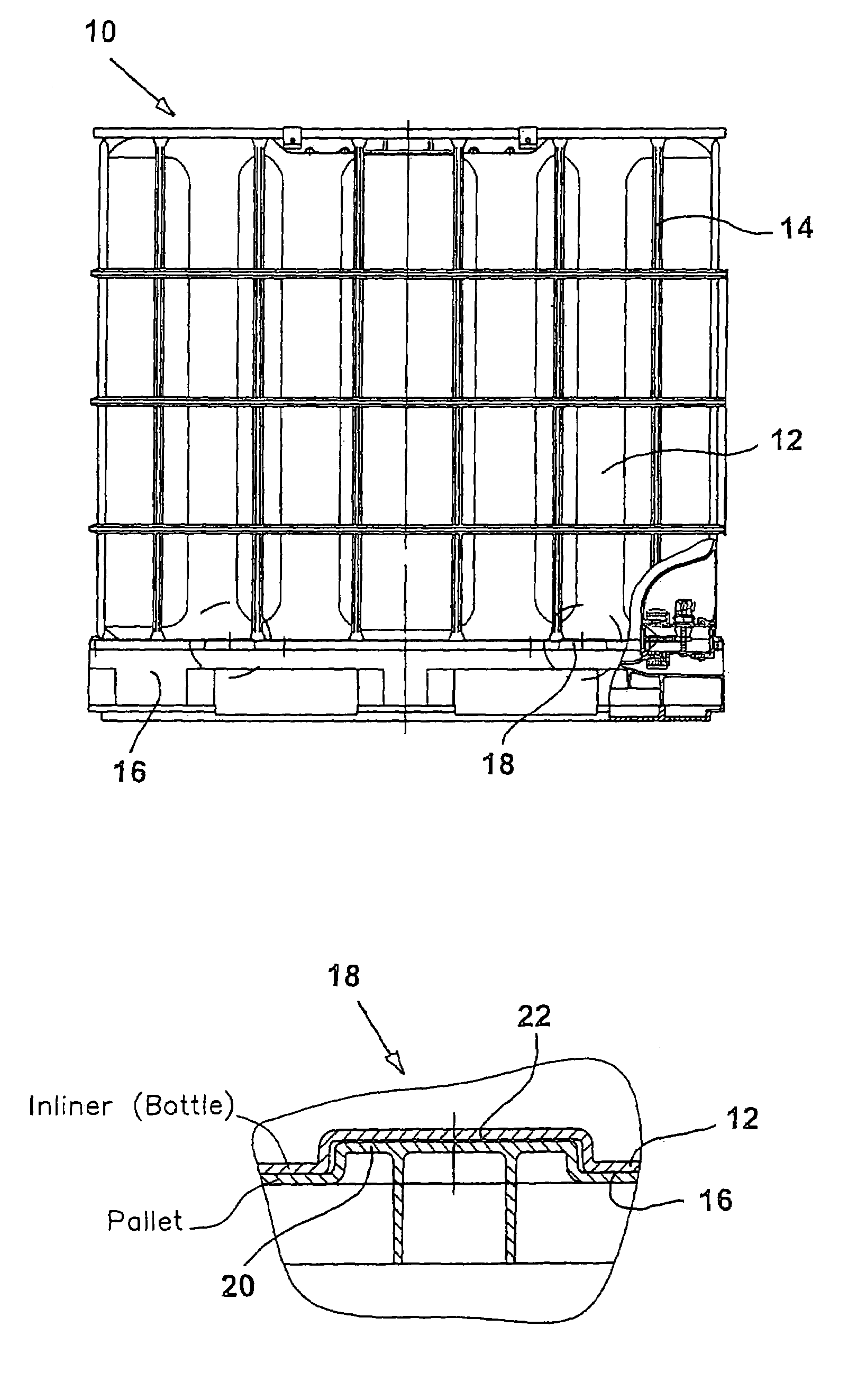

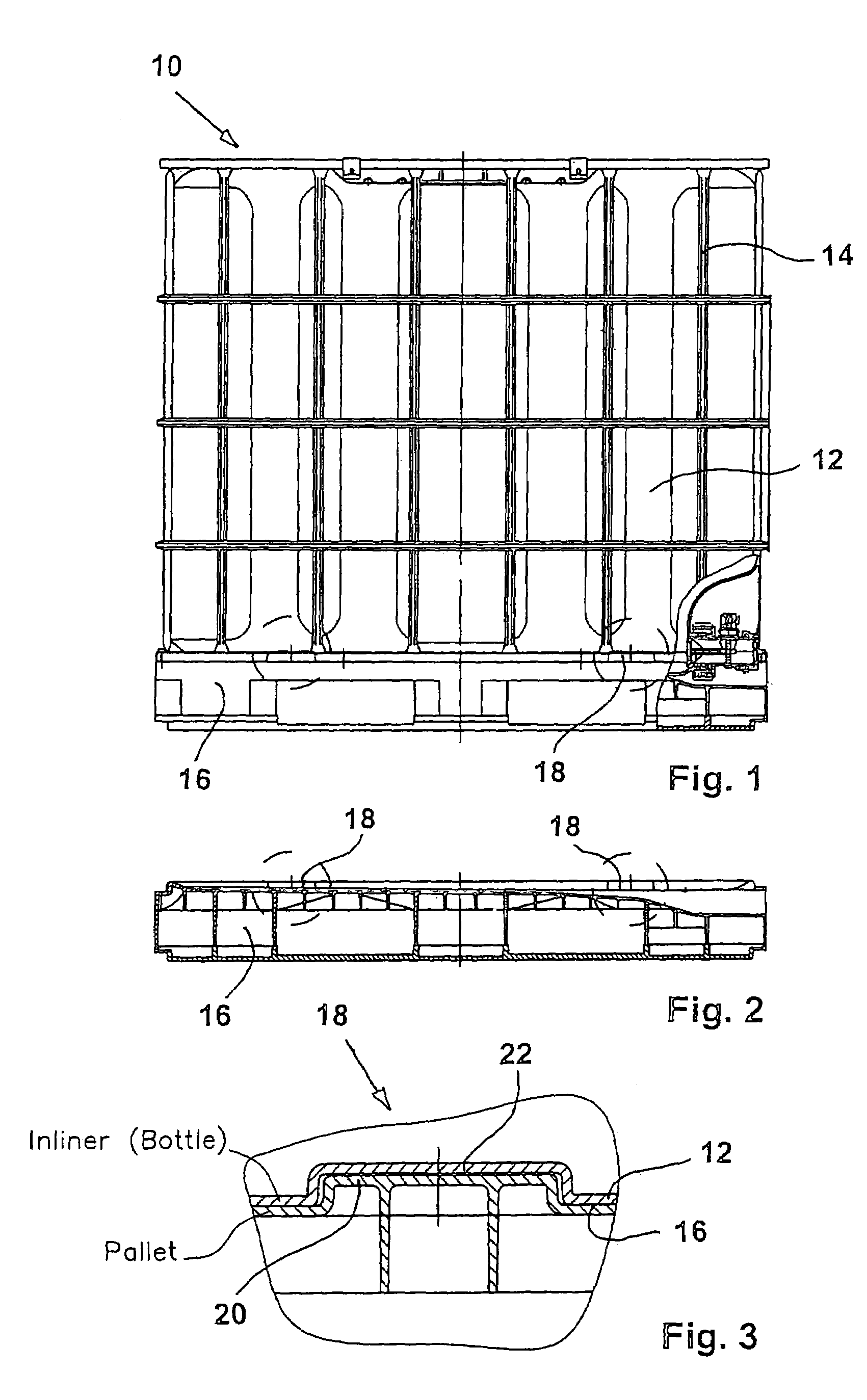

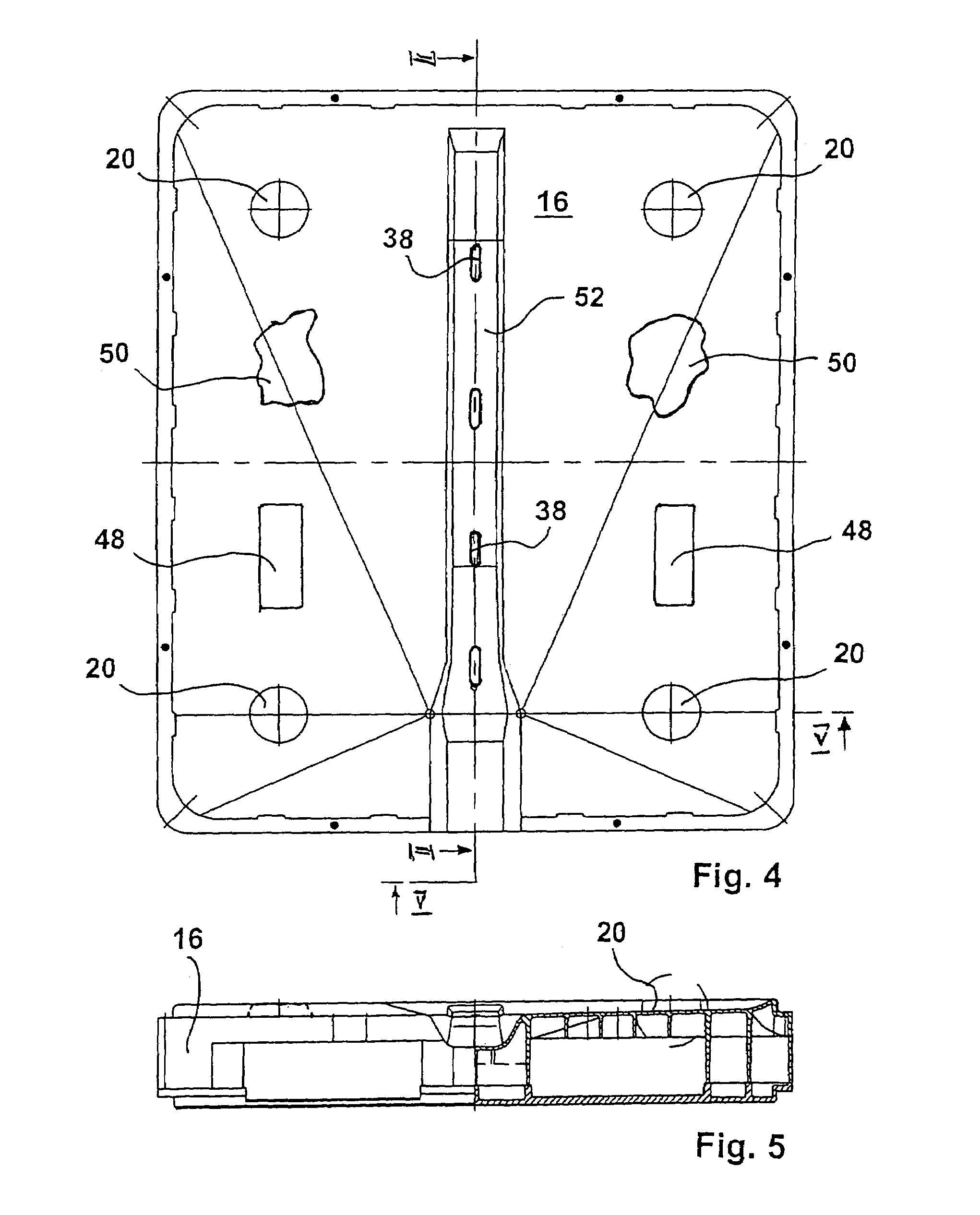

Pallet container

InactiveUS7108133B2Avoid disadvantagesImprove impactOther accessoriesContainer/bottle contructionEngineeringSlip resistance

The invention is directed to a pallet container assembly with a thin-walled rigid inner container of thermoplastic material for the storage and transport of liquid or flowable contents, including a cage-like bar frame closely surrounding as support jacket the inner plastic container, and a bottom pallet for placement of the inner plastic container and secure attachment of the support jacket, wherein there are provided, within the support area of the inner plastic container on the surface of the bottom pallet optionally on the surface of an intermediate plate, respective means (form-fitting means / frictional connection means) which—as viewed in the direction of the horizontal plane—result in a substantial increase of the slip resistance between the downwardly pointing outer surface of the bottom pallet or the intermediate plate.

Owner:MAUSER WERKE GMBH

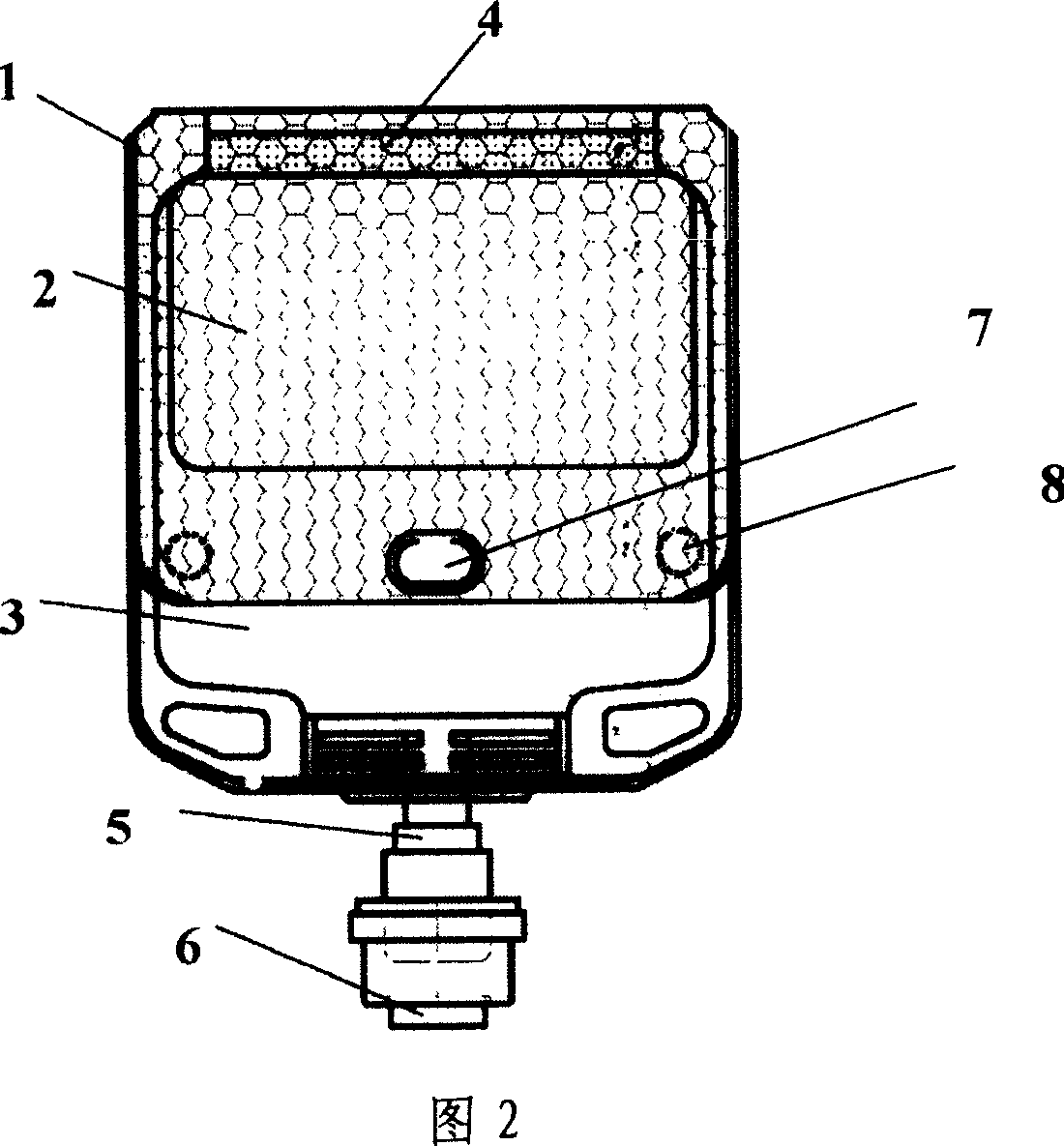

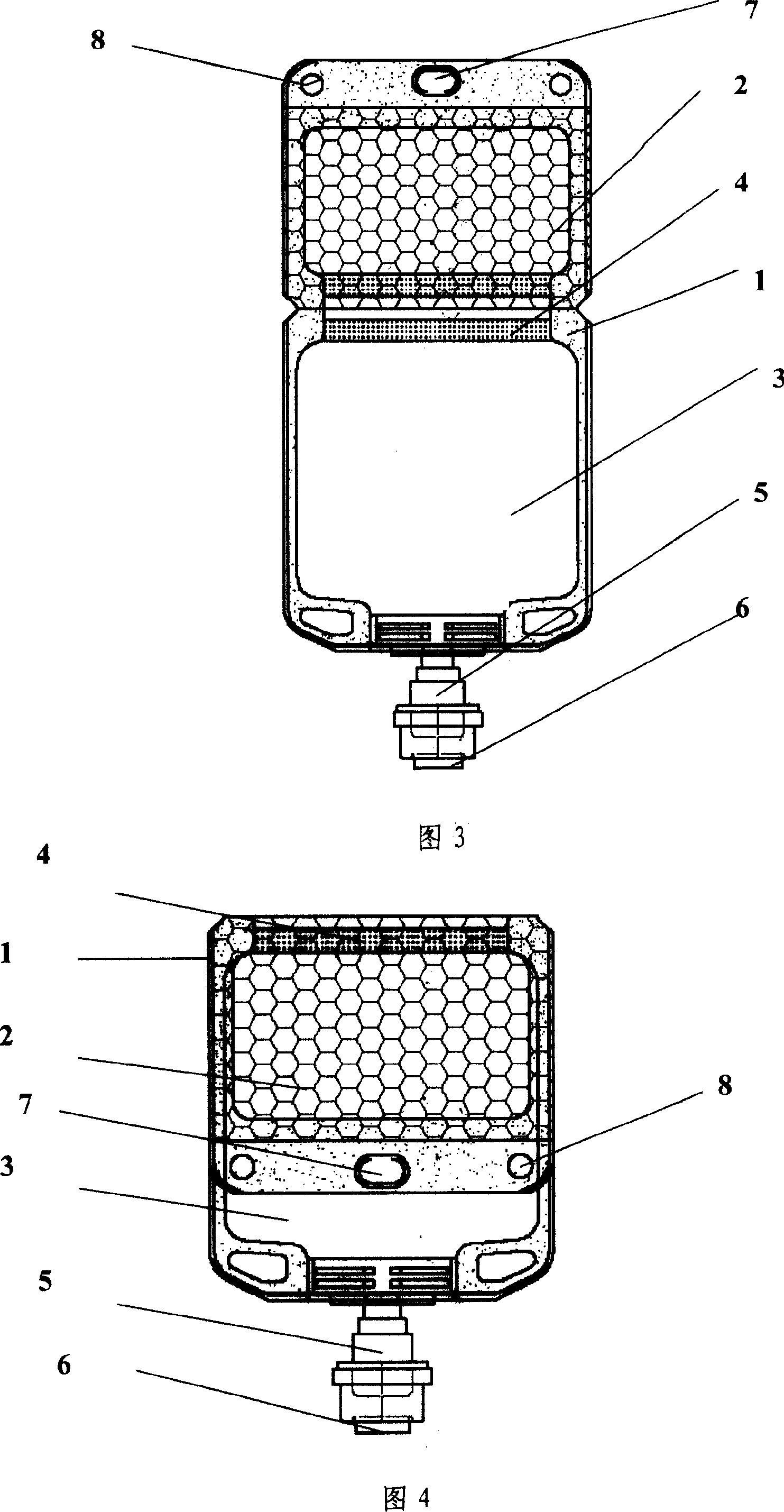

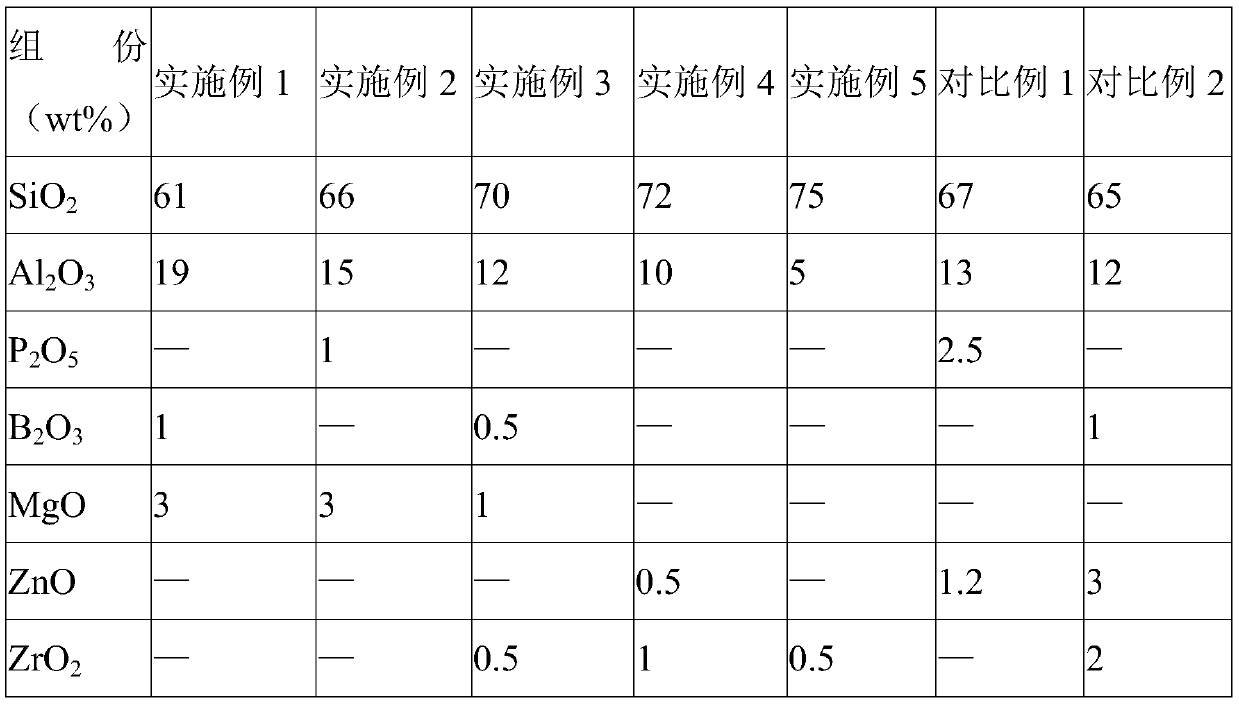

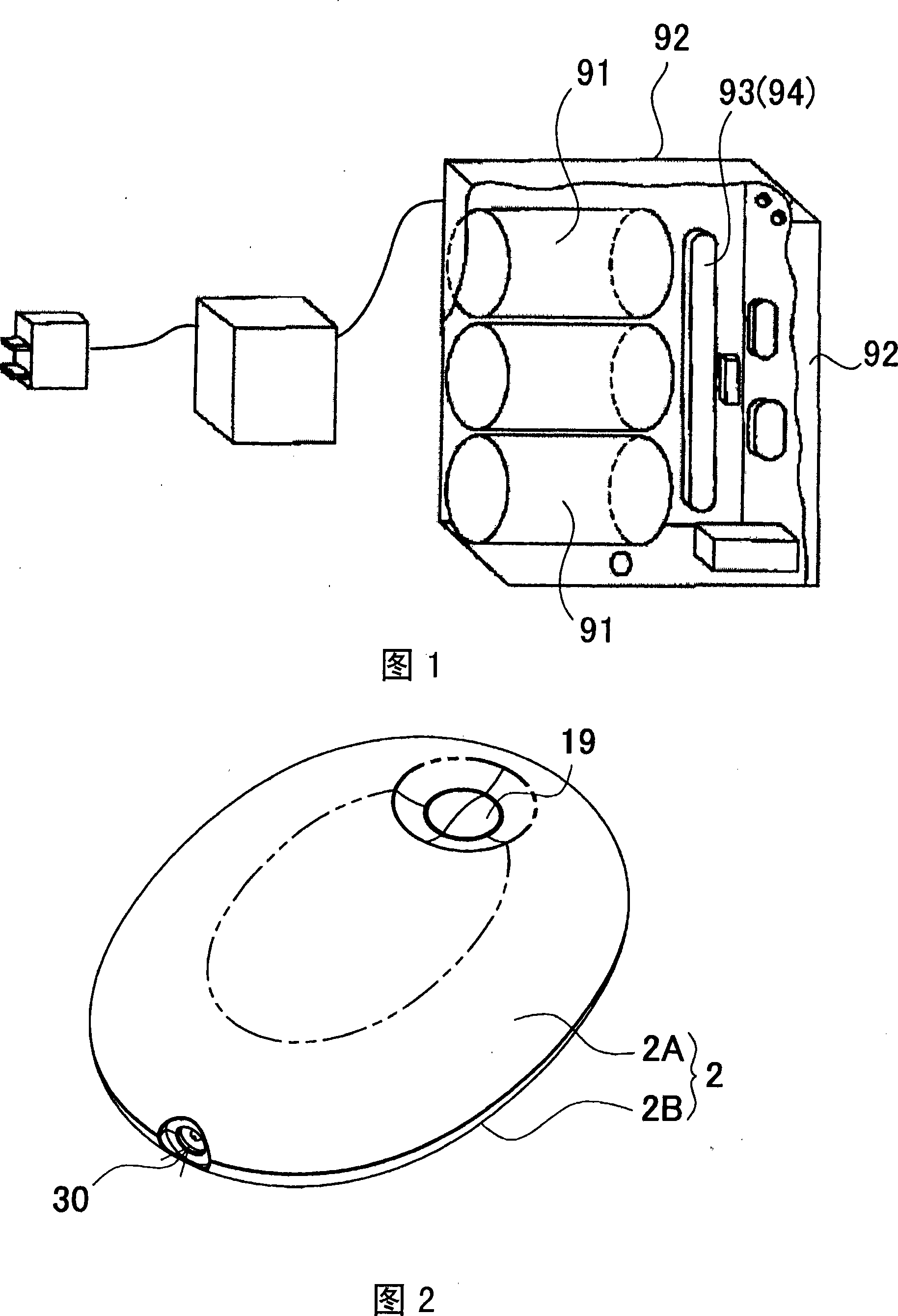

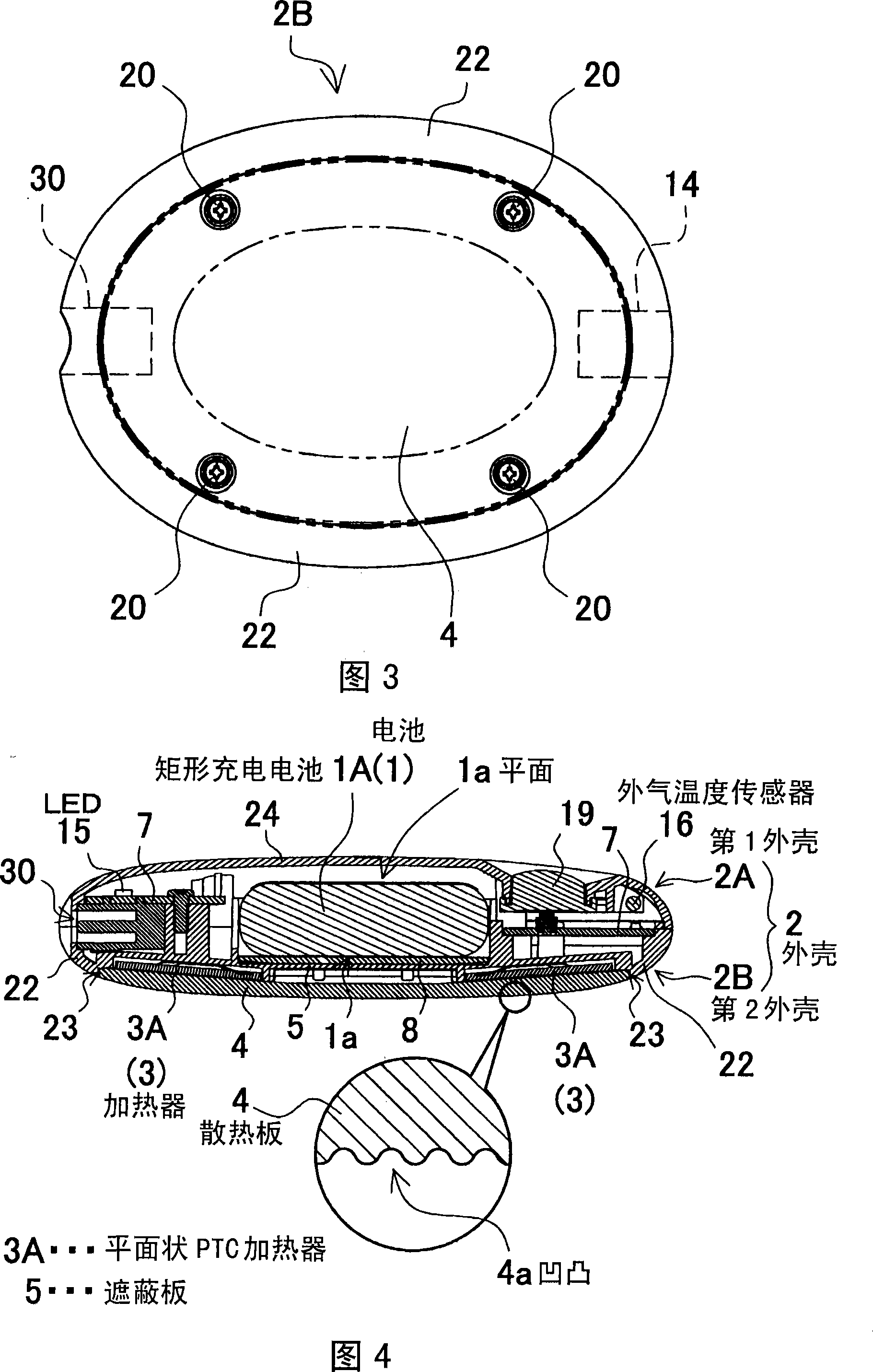

Bosom warmer

InactiveCN101120900ATemperature controlReduce temperature barriersOhmic-resistance heatingTherapeutic coolingHeating timeEngineering

A breast warmer implements heat coupling to a heat radiation board (4) and a heater (3) which is electrified by inner battery (1) through an outer shell (2). The battery (1) is a rectangle charging battery (1A) composed of lithium ion charging battery or lithium polymer battery which constitute rectangle using two opposite surface as plane (1a). The heater (3) is a heating body and opposites to the plane (1a) of the battery (1). Setting a shield board (5) between the heater and the plane (1a) of the battery (1). Setting a heat radiation board (4) after coupling with the heater on the surface of the outer shell (2). The breast warmer is characterized in that the plane (1a) of the rectangle charging battery (1A), the shield board (5), the heater and the heat radiation board (4) form cascade structure, and heats the heat radiation board (4) using the heating body. The breast warmer improves the temperature circumstance of the battery and prolongs heating time, and is minitype as well as light so as to carry easily.

Owner:SANYO ELECTRIC CO LTD

Process for extrusion

InactiveUS20020074682A1Increased effect on polymer temperatureReduce capacityWood working apparatusDomestic articlesPolymer scienceProduct gas

A process for the extrusion of polyethylene having a broad molecular weight distribution wherein the polyethylene is prepared in pellet form, said extrusion taking place in a pelletizing extruder having one or more zones essentially filled with polyethylene and two or more zones partially filled with polyethylene including a feed zone comprising (i) introducing the polyethylene into the extruder at a temperature sufficient to melt the polyethylene; (ii) introducing a mixture of an inert gas and oxygen into at least one partially filled zone with the exception of the feed zone, said mixture containing about 1 to about 21 percent by volume oxygen based on the volume of the gaseous mixture; (iii) passing the molten polyethylene through each zone at melt temperature; and (iv) extruding the polyethylene into pellets and cooling same.

Owner:UNION CARBIDE CHEM & PLASTICS TECH CORP

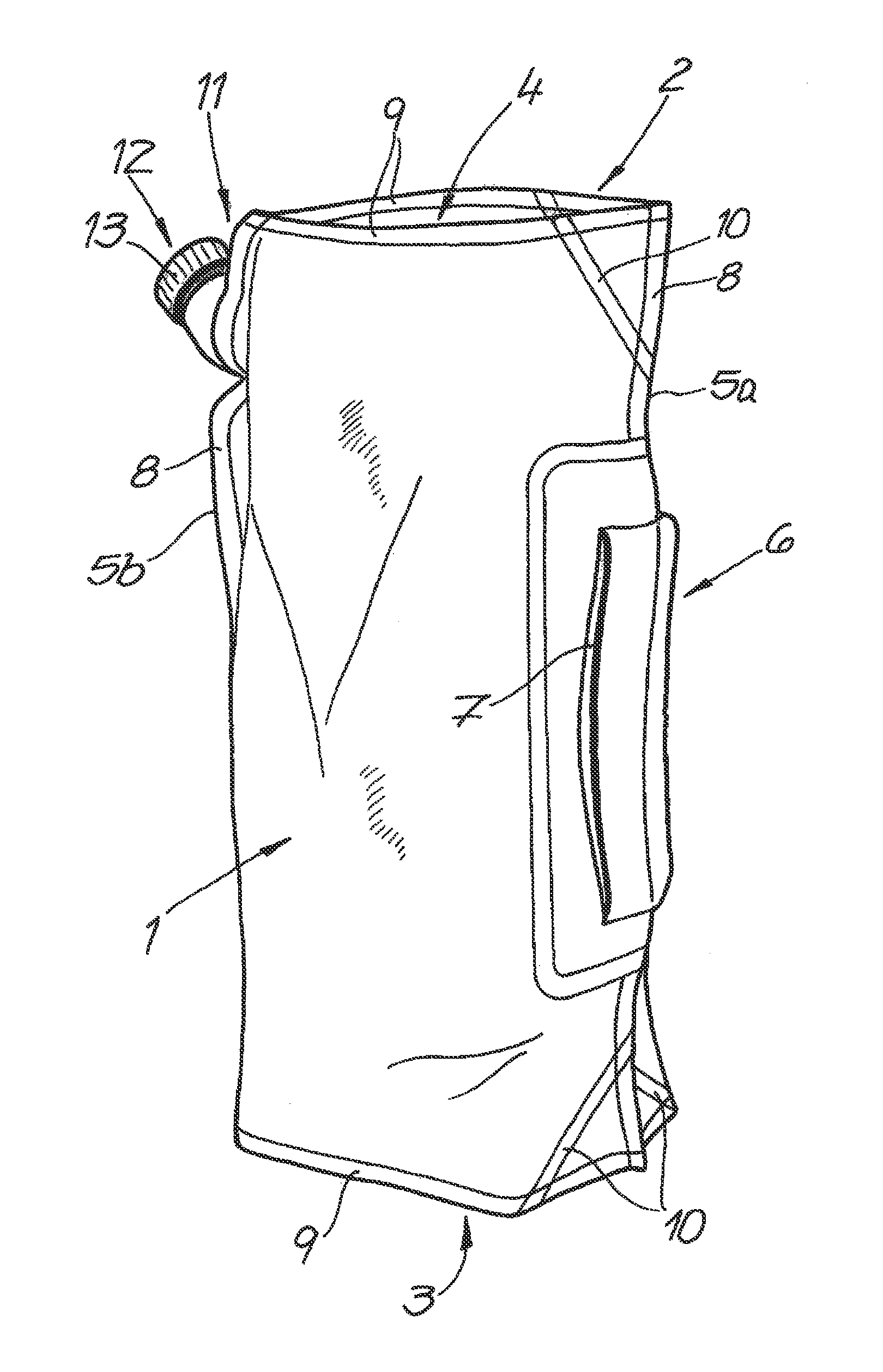

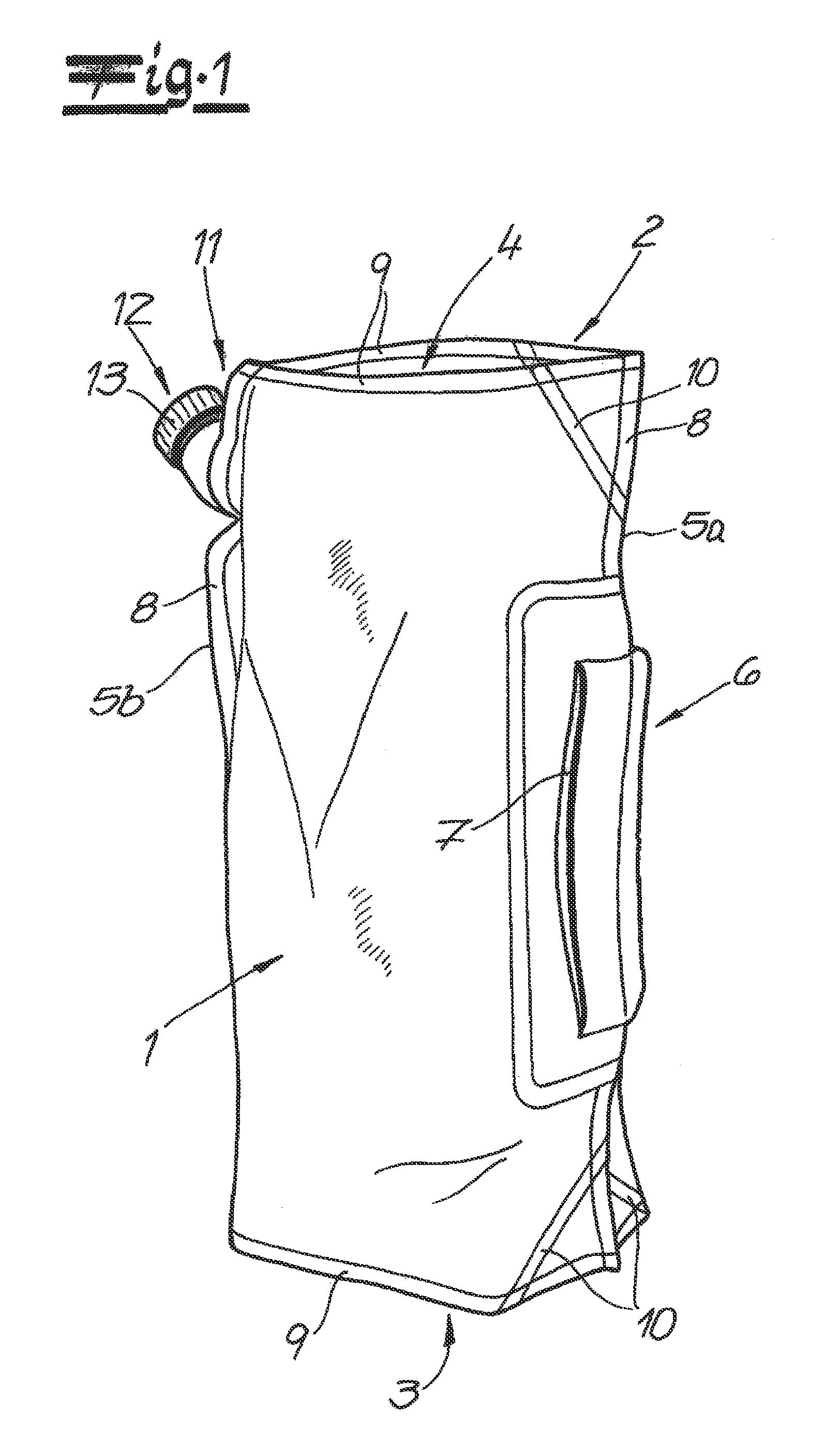

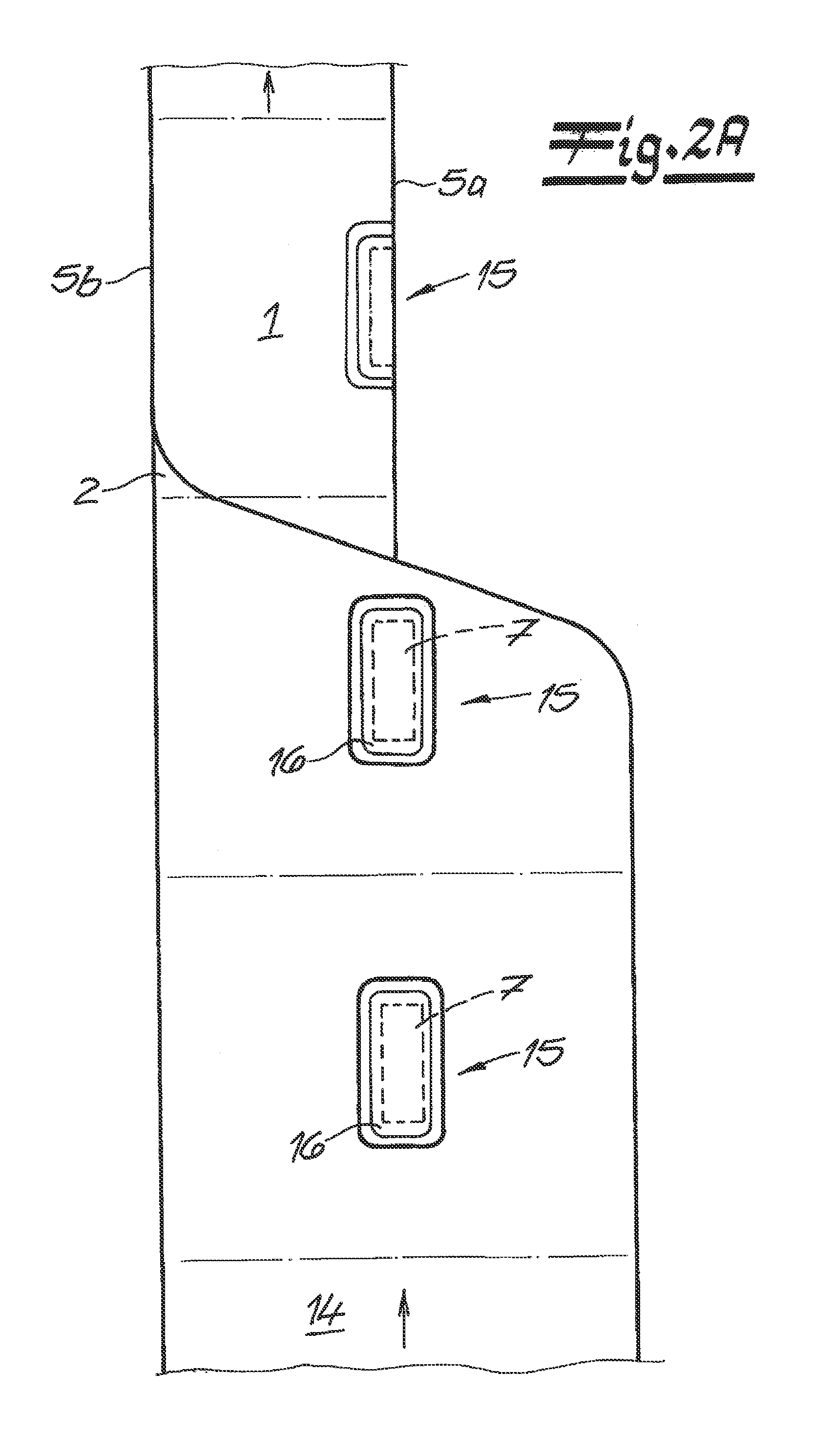

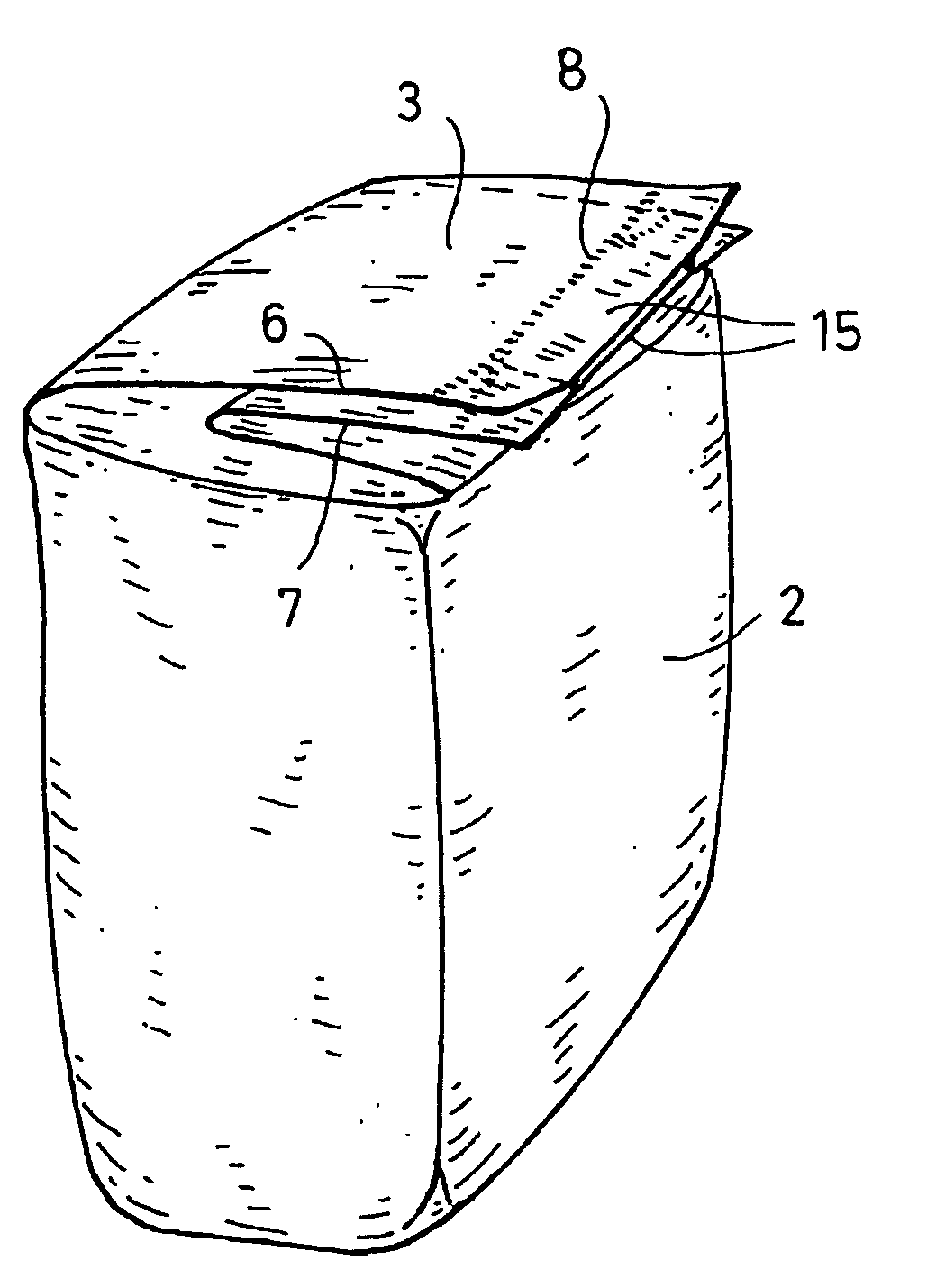

Stand-up bag for pourable goods and method for manufacturing the stand-up bag

ActiveUS20120076441A1Easy to stackEasy to transportEnvelopes/bags making machineryBag making operationsEngineeringMechanical engineering

A stand-up bag for pourable goods includes a front wall, a back wall coupled to the front wall at a first side edge and an opposite second side edge, and a base fold, wherein the front wall, the back wall, and the base fold are manufactured from a film, and wherein the base fold provides a standing base and is coupled to lower edges of the front wall and the back wall. The bag further includes a bag top situated opposite from the base fold, a closure device, wherein the closure device is attached proximate the bag top, and a carrying handle on the first side edge between the base fold and the bag top, the carrying handle positioned a distance from the base fold and the bag top.

Owner:NORDENIA DEUTLAND HALLE

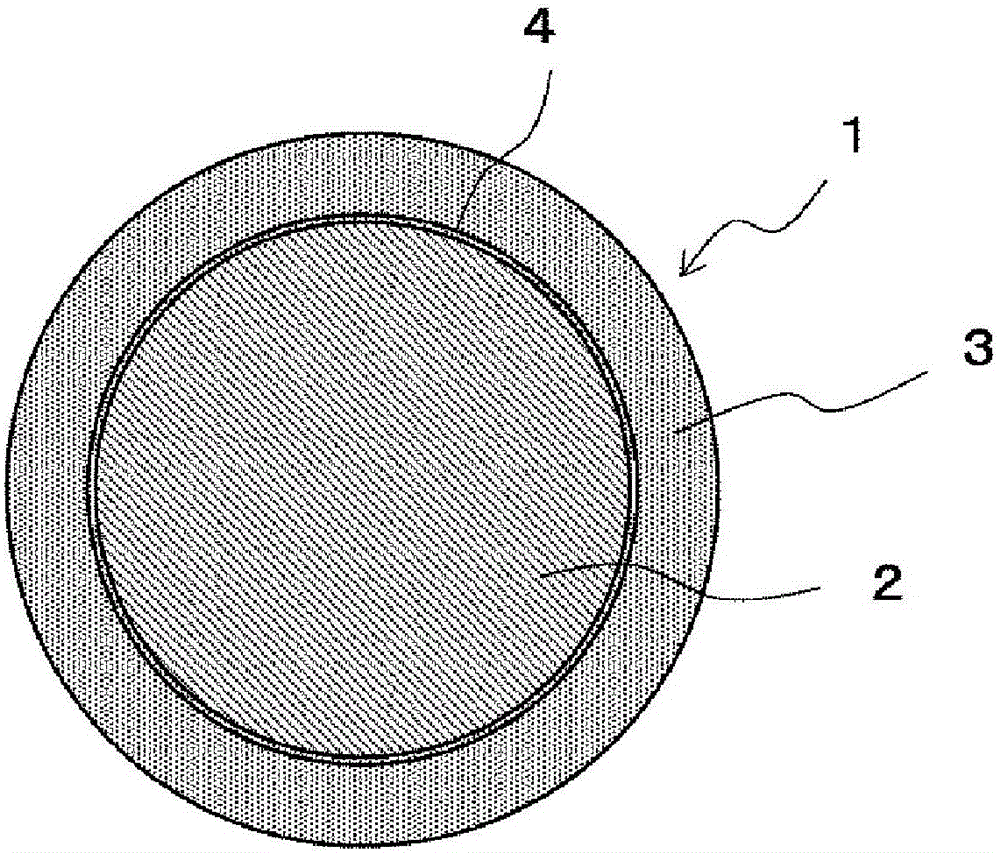

Cu core ball, solder paste, formed solder, cu core column, and solder joint

ActiveCN105873716AHigh strengthImprove drop strengthTransportation and packagingSemiconductor/solid-state device detailsSolder pasteImpurity

Provided are a Cu core ball and a Cu core column making it possible to obtain drop strength and strength in relation to heat cycle. The Cu core ball (1) is provided with: a Cu ball (2) configured from Cu or a Cu alloy; and a solder layer (3) configured from a solder alloy comprising Sn and Cu, the solder layer (3) covering the Cu ball (2). The solder layer (3) contains 0.1-3.0% Cu, the balance being Sn and unavoidable impurities.

Owner:SENJU METAL IND CO LTD

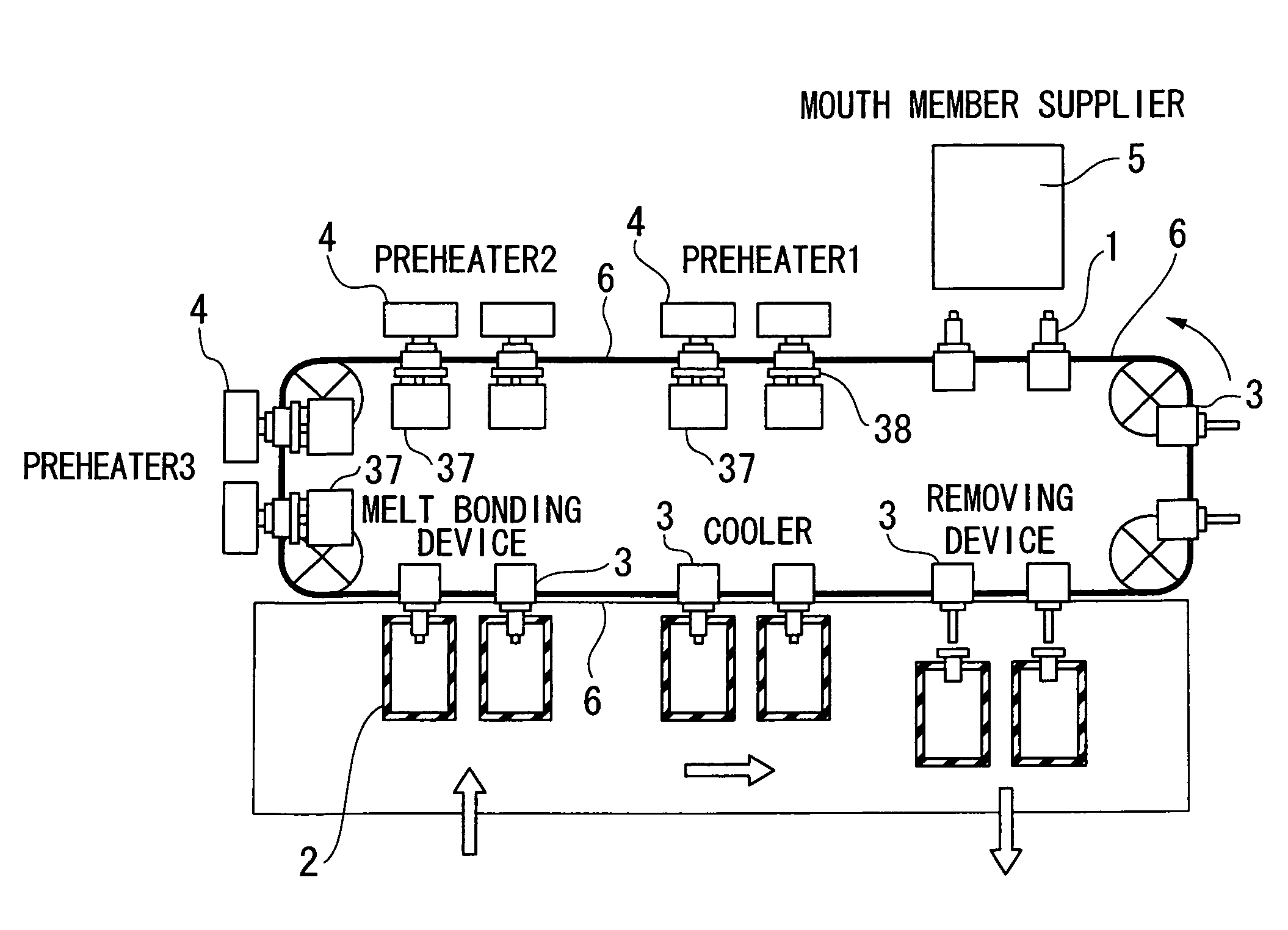

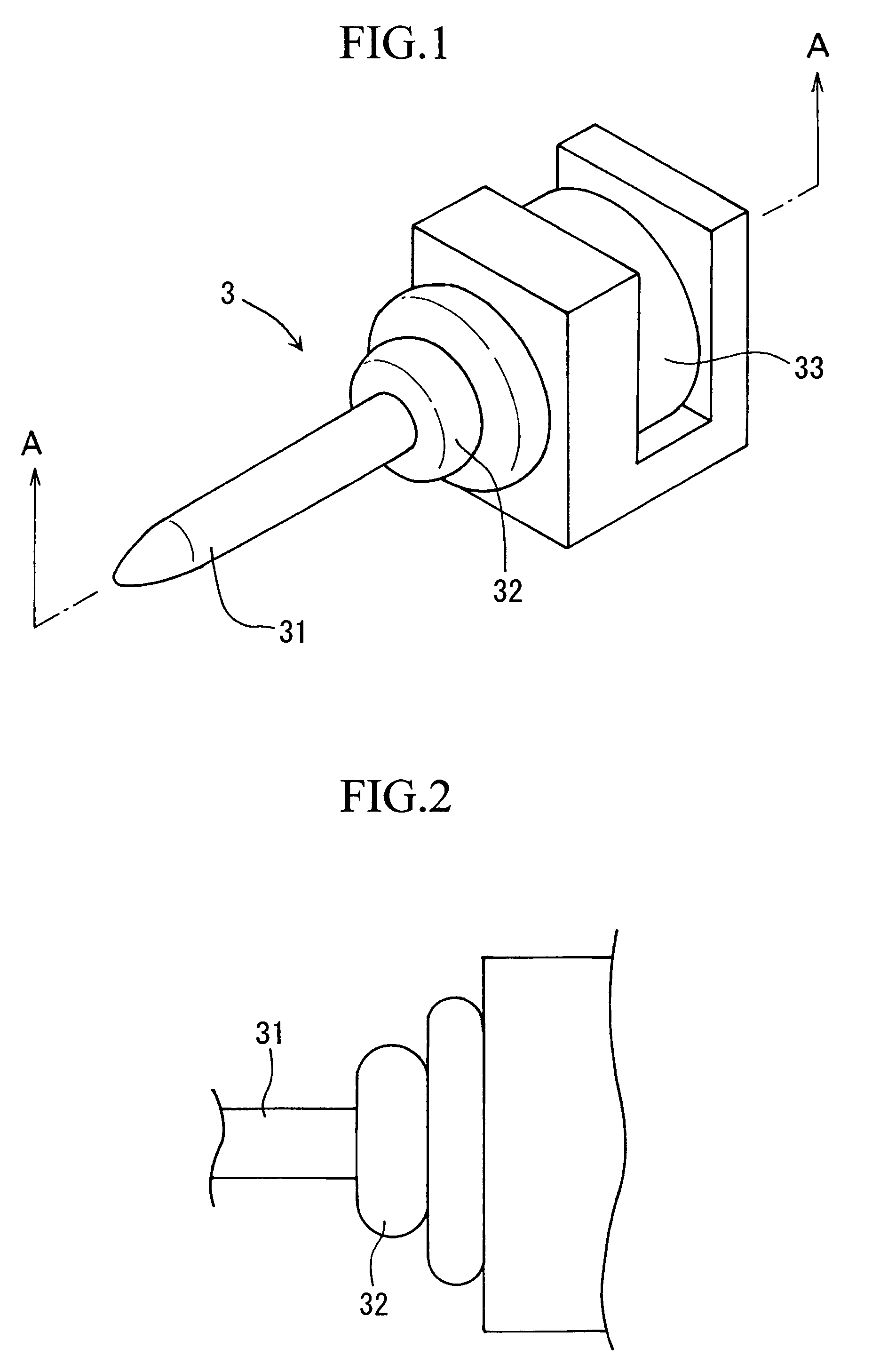

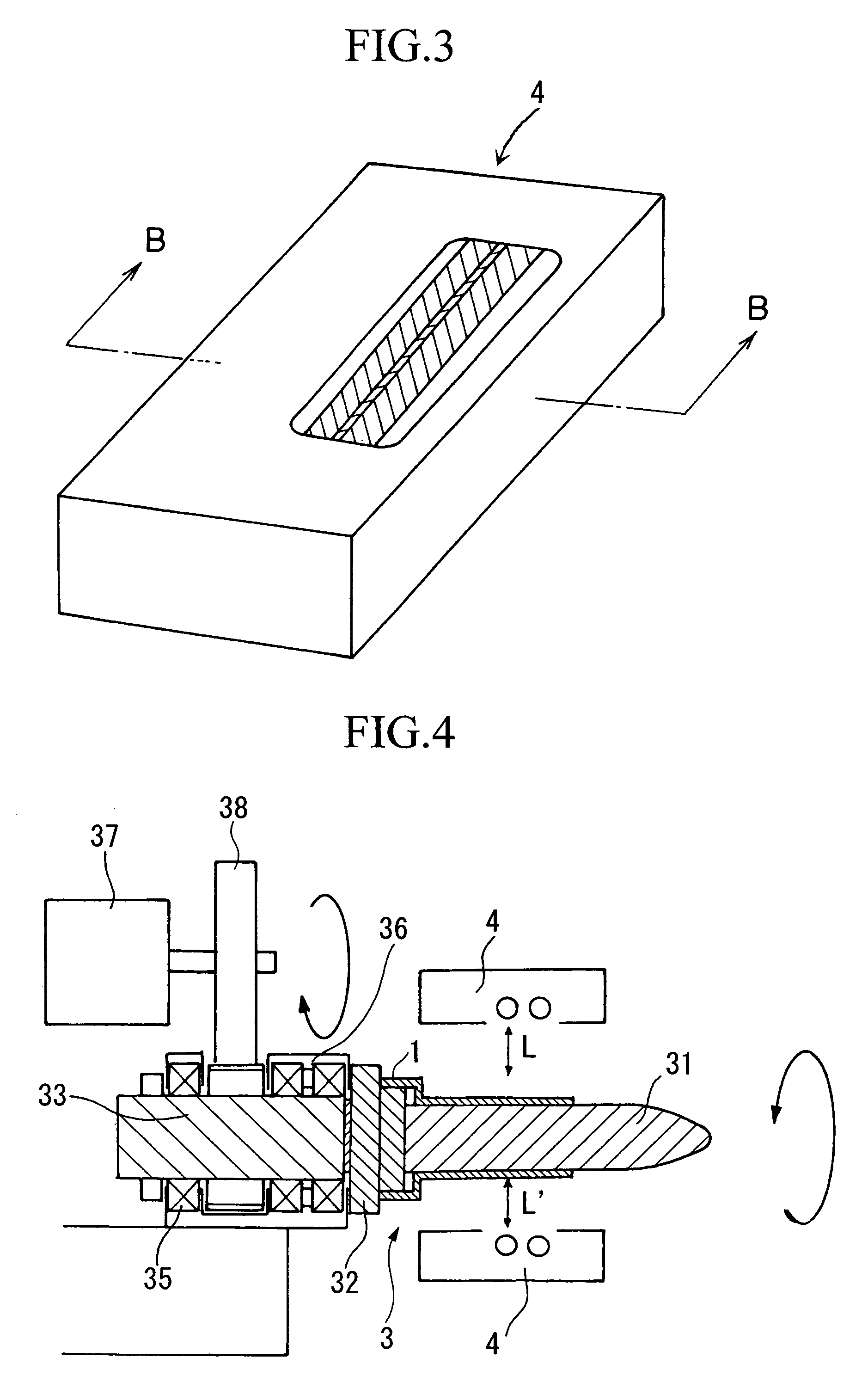

Method and apparatus for producing bag with mouth member

InactiveUS7736288B2Uniform surface temperatureAvoid it happening againEnvelopes/bags making machineryMechanical working/deformationEngineering

A method is provided for producing a bag with a mouth member by liquidtightly melt-bonding a mouth member comprising a thermoplastic resin and a bag unit comprising a relatively soft flexible film, in which uniform surface temperature of the mouth member is realized, generation of an A-shaped gap is prevented, and a bag with a mouth member excellent in the liquidtightness of the melt-bonded part between the mouth member and the bag unit is produced; and also a production apparatus therefor is provided. The method comprises a preheating step of heating a tubular mouth member while rotating it around the cylinder axis thereof, and a melt-bonding step of inserting the heated mouth member into the opening part of a bag unit and pressing, and thereby melt-bonding the mouth member to the opening part of the bag unit.

Owner:HOSOKAWA YOKO CO LTD

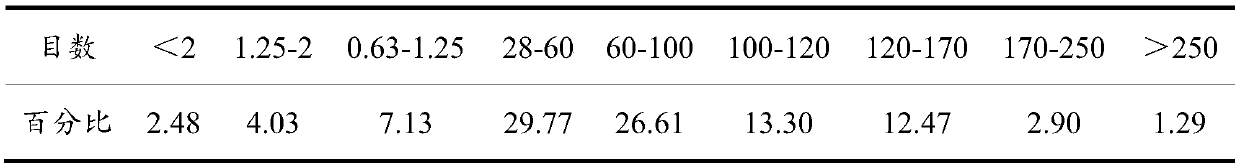

Pelletizing method suitable for heap leaching of gold ores

InactiveCN105506272ALarge granularityHigh strengthProcess efficiency improvementPerformance indexCobalt

The invention belongs to the field of metallurgy and mineral engineering, and discloses a pelletizing method suitable for heap leaching of gold ores. According to the method, certain amount of a binding agent is added into crushed cores and ore fines or gold concentrates which are small in grain size and are not suitable for direct heap leaching, a circular disk pelletizer is used for pelletizing, and the rotation speed, the moisture adding amount, the pelletizing time of the pelletizer are controlled in a pelletizing process, so that block mass with a relatively great grain size and various good performance indexes such as compressive strength, dropping strength, leaching strength and the like is finally prepared. The pelletized ore balls are uniform in grain size, and are relatively good in strength, so that the permeability of a stock heap is greatly improved, a leaching agent solution can be distributed more uniformly, and can be in contact with ores more sufficiently, and therefore, the leaching time is shortened, and the gold leaching rate is increased. According to the current condition that gold demand is increasing fiercely, world high-quality gold resource is increasingly exhausted and low-grade refractory gold ores become main raw materials for gold extraction, the method undoubtedly has a wide application prospect today. The method also can be applied to the field of pelletizing and heap leaching of minerals such as copper, nickel-cobalt, and the like.

Owner:UNIV OF SCI & TECH BEIJING

Binder for lignite upgrading and preparation method and applications thereof

InactiveCN104004561AImprove drop strengthImprove thermal stabilitySolid fuelsPhosphateALUMINUM PHOSPHATE

The invention relates to the technical field of lignite upgrading, and particularly relates to a binder capable of significantly boosting the drop strength and thermal stability of lignite, and a preparation method and applications thereof, which are applicable to lignite formed in the Mesozoic Jurassic period of Inner Mongolia. The binder for lignite upgrading is characterized by being prepared from the following raw materials in percentage by mass: 10-30% of sodium humate, 5-10% of aluminum dihydrogen phosphate, 2-5% of aluminum phosphate, 1-4% of hydroxymethyl cellulose, 3-6% of thermosetting phenolic resin, 25-35% of calcium carbonate and 10-54% of metakaolin. The binder disclosed by the invention is simple in preparation process, wide in material sources, and low in cost; and the binder prepared by using the method can increase the drop strength and thermal stability of lignite.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

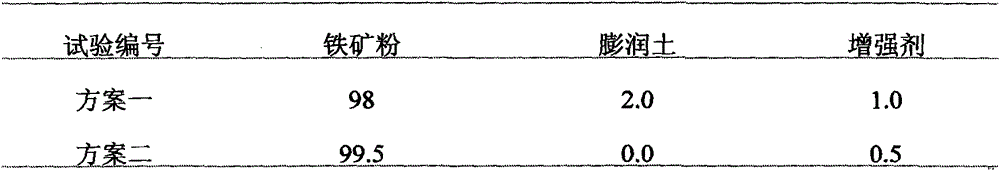

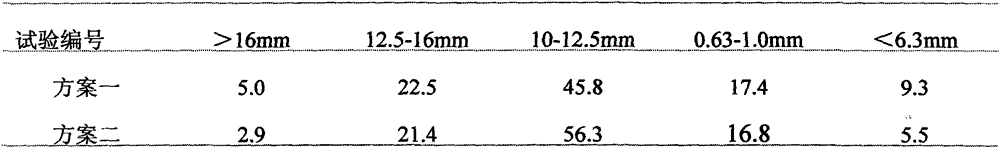

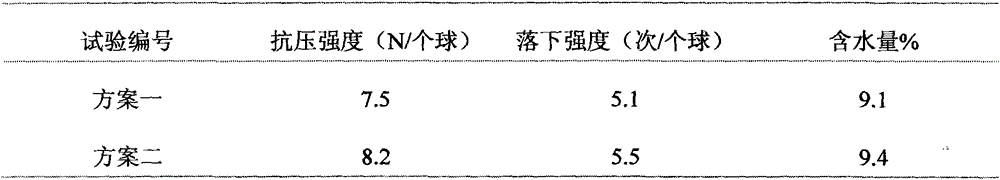

Technique for producing agglomeration by mixing sulfuric acid residue and concentrate

The invention discloses a technique for preparing pellet by mixing the purple ore and the ore concentrate. The purple ore with the iron grade ranging from 30 to 55 percent is mixed with the ore concentrate, the weight percentage of the purple ore ranges from 10 to 18 percent, the weight percentage of the ore concentrate ranges from 82 to 90 percent; the swell soil is added into the mixed ore to mix, the weight of the swell soil occupies 1 to 3.2 percent of the weight of the mixed ore; one part of the mixed ore substance is grinded by a globe mill and is mixed with the remaining part evenly to obtain the mixed ore of purple ore and the ore concentrate as well as the swell soil, the mixed ore is taken as the material for preparing the pellet. The technique can make the best of the industry waste of purple ore, changes waste into valuable and ensures that the purple ore as a resource containing iron ore is used effectively; part of the purple ore replaces the ore concentrate and the ore cost is lowered, thereby lowering the smelting production cost and increasing the competitive force of the enterprise; a slag yard is not necessary to pile up the purple ore, thereby avoiding the environmental pollution of the purple ore and being beneficial to the environment protection.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

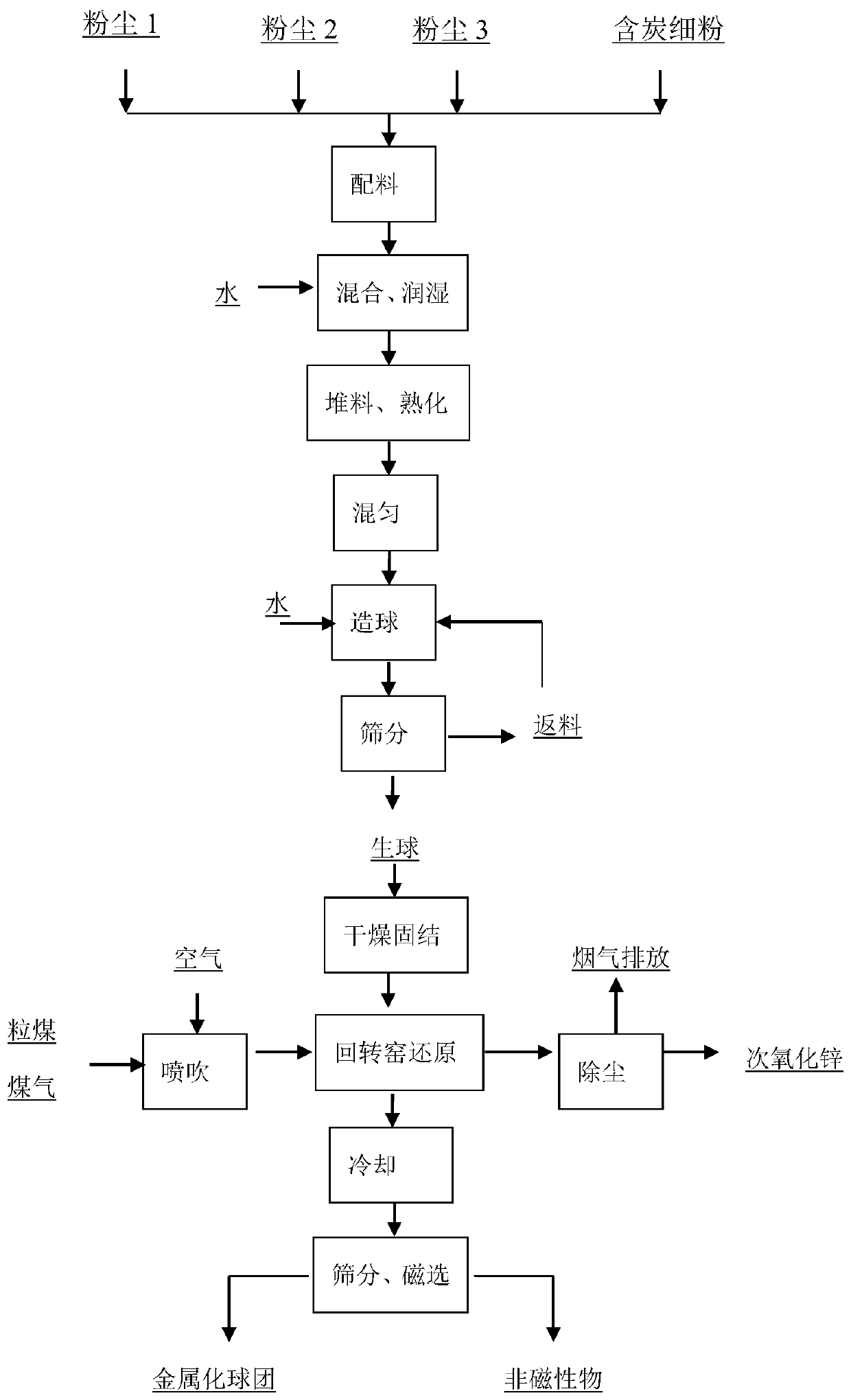

Preparation method of zinc-containing dust pellet

ActiveCN110317949AOvercoming the characteristics of weak ball formationGood ball formingRotary drum furnacesProcess efficiency improvementMixed materialsCompressive strength

The invention provides a preparation method of a zinc-containing dust pellet. The preparation method comprises the following steps of S1, carrying out burdening , mixing the blast furnace cloth bag ash, the steel-making ladle furnace ash, the steel-making converter smoke dust and other zinc-containing dust with the carbon-containing fine powder to obtain a mixture; S2, carrying out pretreatment, adding water into the mixture obtained in the step S1 for wetting, and piling up and curing after wetting; S3, adding a composite binder into the cured mixture, and carrying out uniformly mixing to obtain a uniform mixture; S4, carrying out pelletizing on the uniformly mixed material prepared in the step S3 to obtain a green pellet; and S5, drying the green pellet in the step S4 to obtain the zinc-containing dust dry pellet. The dry pellet has the advantages of high compressive strength and good reducibility, the metallization rate is high in the direct reduction process, the dezincification effect is good, and the preparation method solves the technical problems that an existing zinc-containing dust pellet is easy to break and pulverize in the reduction process.

Owner:CENT SOUTH UNIV

Multi-chamber container

ActiveUS7976917B2Improve heat resistanceHigh transparencyMedical devicesDomestic containersElutionEngineering

Multi-chamber container (1) having its interior partitioned by weak seal portions (3) provided through detachable heat sealing so that multiple contents are accommodated separately from each other, wherein use is made of heat seal layers consisting of a composition comprising two types of propylene copolymers components (component A and component B) from propylene and ethylene and / or a C4-C8 α-olefin which have the following elution properties. Thus, a region wherein a change of seal strength by a change of heat seal temperature is small has a wide temperature range to thereby facilitate controlling of the seal strength at the weak seal portions. The proportion (mass %) of, to total solution, elution according to the TREF method (temperature: 0 to 140° C. and solvent: ODCB) is as follows. With respect to component A: 15 to 50 at 0° C., and 5 to less than 15 at 60 to 90° C. With respect to component B: 0 to 25 at 0° C., and 15 to 70 at 60 to 90° C.

Owner:FUJIMORI KOGYO CO LTD

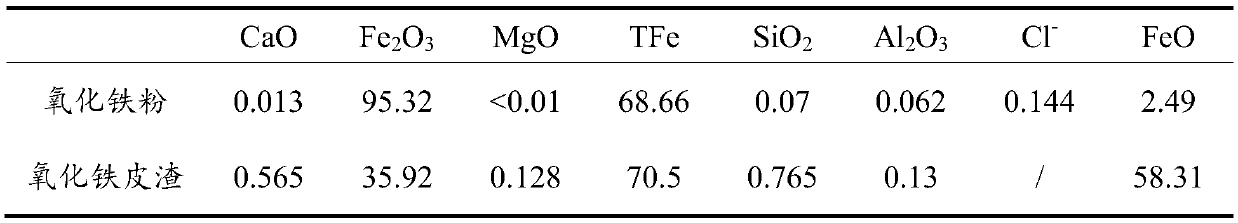

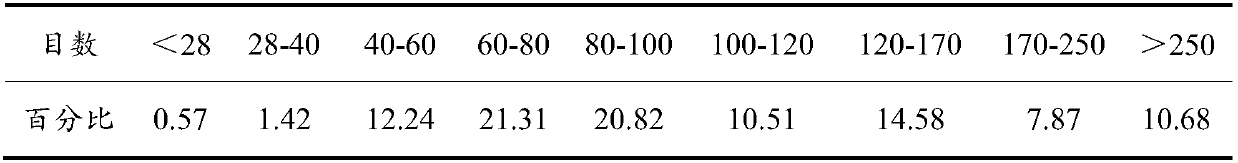

Ferric oxide pellets and preparation method and application thereof

The invention belongs to the technical field of comprehensive utilization of ferrous secondary resources and particularly relates to ferric oxide pellets and a preparation method and application thereof. The preparation method of the ferric oxide pellets comprises the following steps that (a) oxidized scale slag is dried and then mixed with ferric oxide powder; (b) a mixture obtained through mixing in the step (a) and a water-soluble organic bonding agent are subjected to dry blending, and a dry blending mixture is obtained; (c) water is added into the dry blending mixture obtained in the step(b), wet blending is performed, and a wet blending mixture is obtained; and (d) the wet blending mixture obtained in the step (c) is subjected to extrusion forming and drying in sequence, and then the ferric oxide pellets are obtained. The ferric oxide pellets obtained through the method have certain drop strength and can serve as a steelmaking coolant and / or a vanadium extraction coolant, the dust yield is decreased, and environment pollution is reduced.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Production method for brown coal binding and forming

The invention discloses a production method for brown coal binding and forming, and relates to a binding agent suitable for low-order brown coal forming and a preparation method of the coal briquette. The method comprises the following steps: (1) crushing and screening the brown coal block until the size is smaller than or equal to 3 mm; (2) dissolving polyvinyl alcohol, carboxymethyl cellulose and sodium silicate into water according to a certain ratio, and preparing a composite binding agent; (3) adding the binding agent according to a certain proportion to the brown coal raw material, stirring uniformly, and then conducting cold extrusion forming in a coal rod extrusion machine; (4) drying the formed coal rod at the temperature of 60-120 DEG C until the moisture is smaller than 10% so as to obtain the coal briquette product. The production method disclosed by the invention is simple in technology; the binding agent is wide in source, convenient to prepare, and low in cost; the coal briquette product is high in cold intensity and heat intensity both, can substitute lump coal to be supplied to a gas generator, and further can meet the requirements on the granularity and the strength for the synthesis ammonia gas-making section.

Owner:YUNNAN CHEM RES INST

Microcrystalline glass with ultrahigh bifurcation threshold value

ActiveCN110734226AImprove network structure strengthImprove structural strengthTransmittanceUltimate tensile strength

The invention discloses microcrystalline glass with an ultrahigh bifurcation threshold value. The microcrystalline glass contains crystals having an average crystal size of 70 nm or less; the ratio ofthe crystals is 50wt%-90wt%; the thickness of the microcrystalline glass ranges from 0.4 mm to 1.5 mm; the maximum value of the tensile stress linear density of the microcrystalline glass achieved instrengthening process is 70000 Mpa / mm or above; the bifurcation threshold value is more than 50000 Mpa / mm, the average size of the vertical projection of broken particles on a two-dimensional drawingin drop resistance test is more than 10 mm, and the transmittance of the microcrystalline glass with the thickness of 1 mm on a visible spectrum is in a range of 80%-92%. The microcrystalline glass provided by the invention has high network structure strength and high crystal proportion, can greatly improve the structural strength of the glass and improve the bifurcation threshold of the glass, improve the limit of the anti-falling strength of the microcrystalline glass, and ensures the tensile stress safety of the microcrystalline glass on the basis.

Owner:CHONGQING XINJING SPECIAL GLASS CO LTD

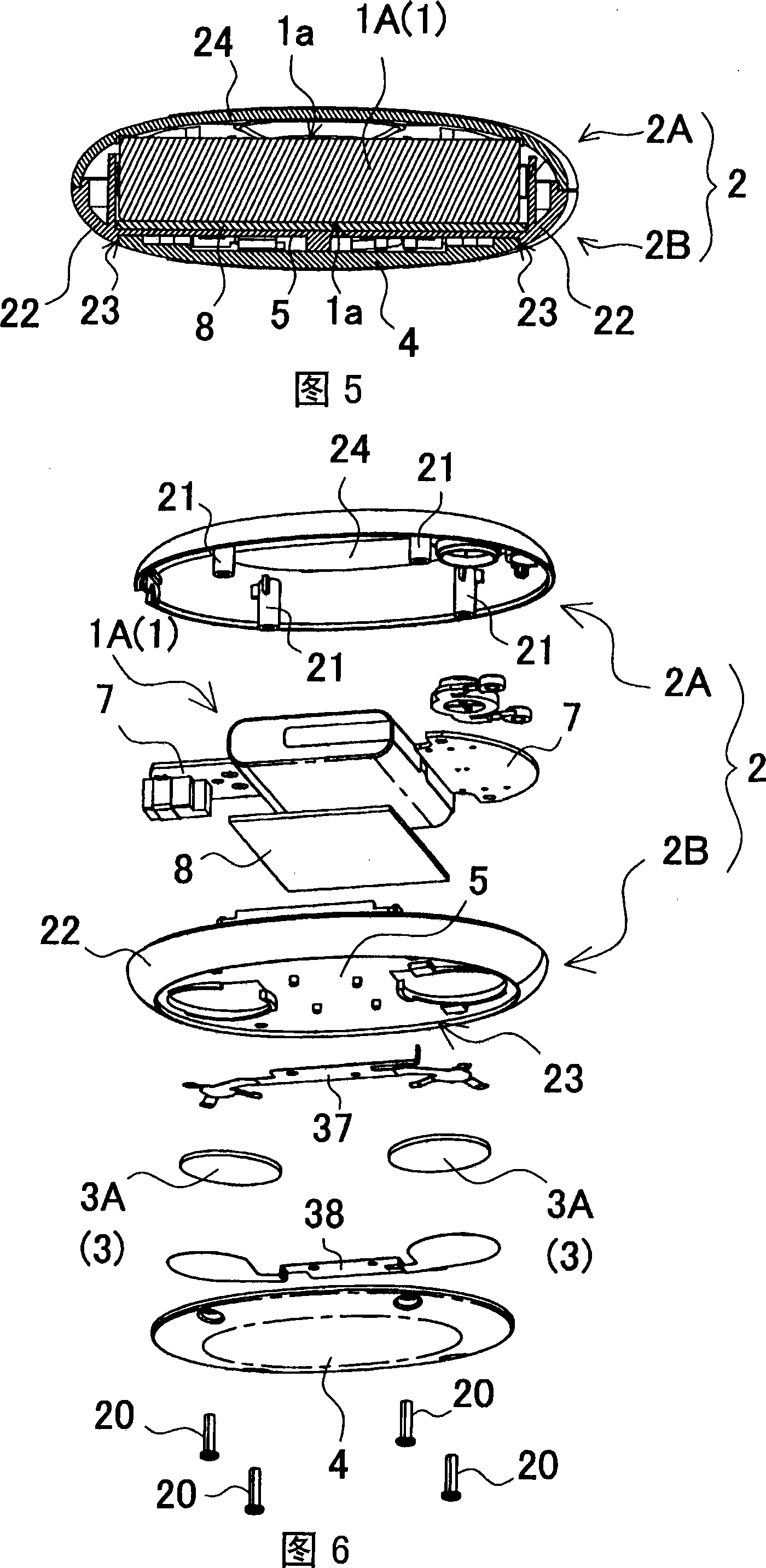

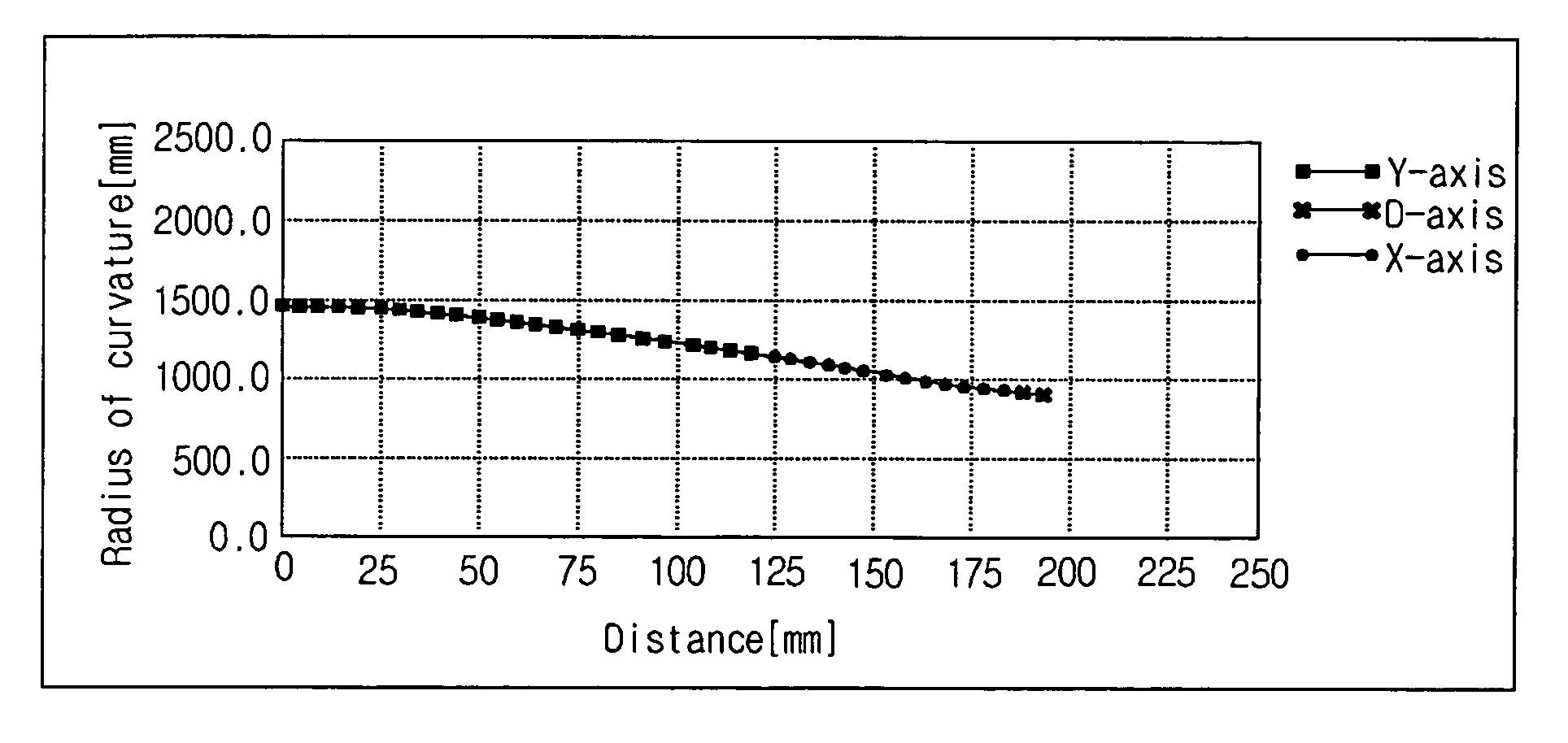

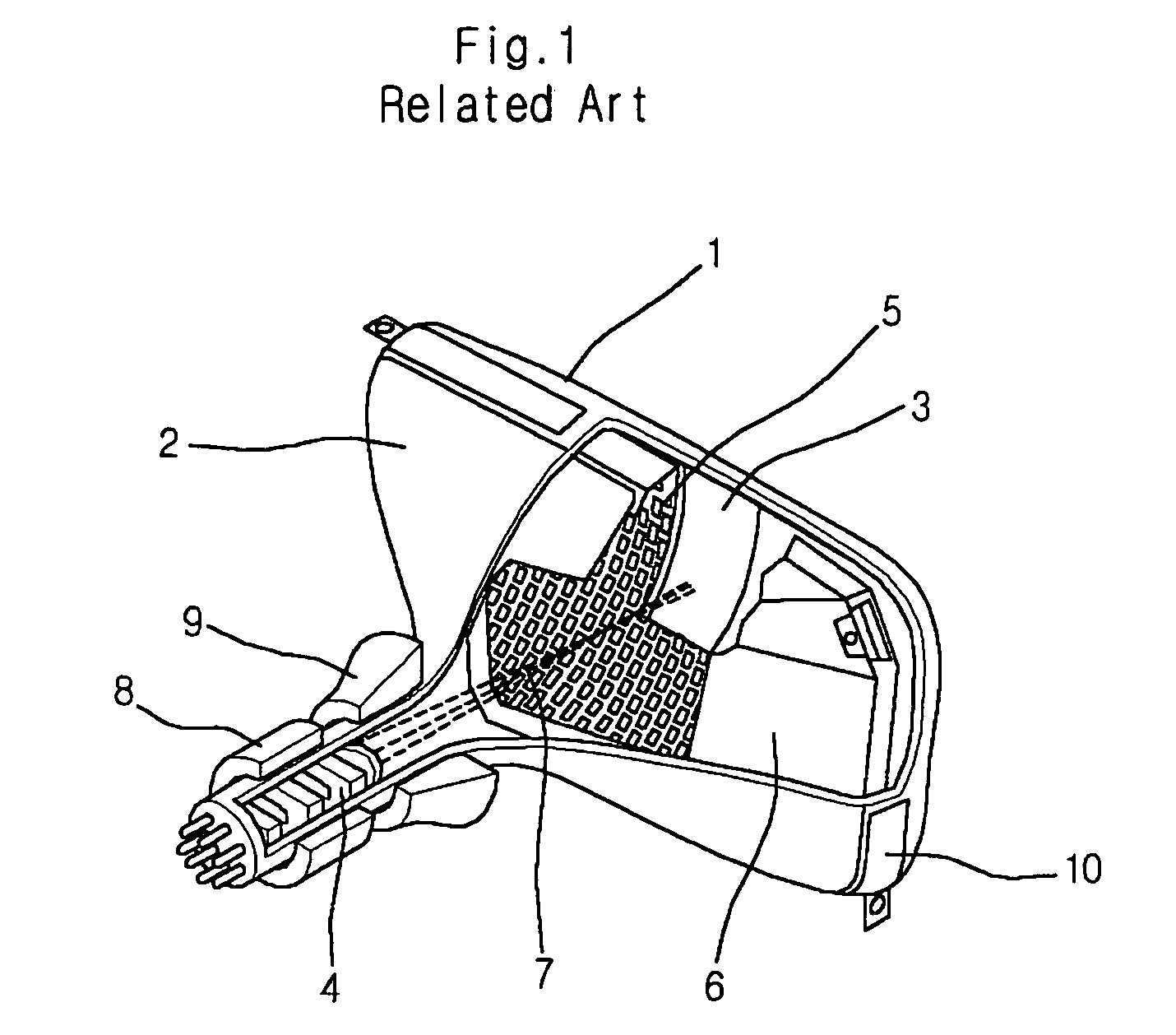

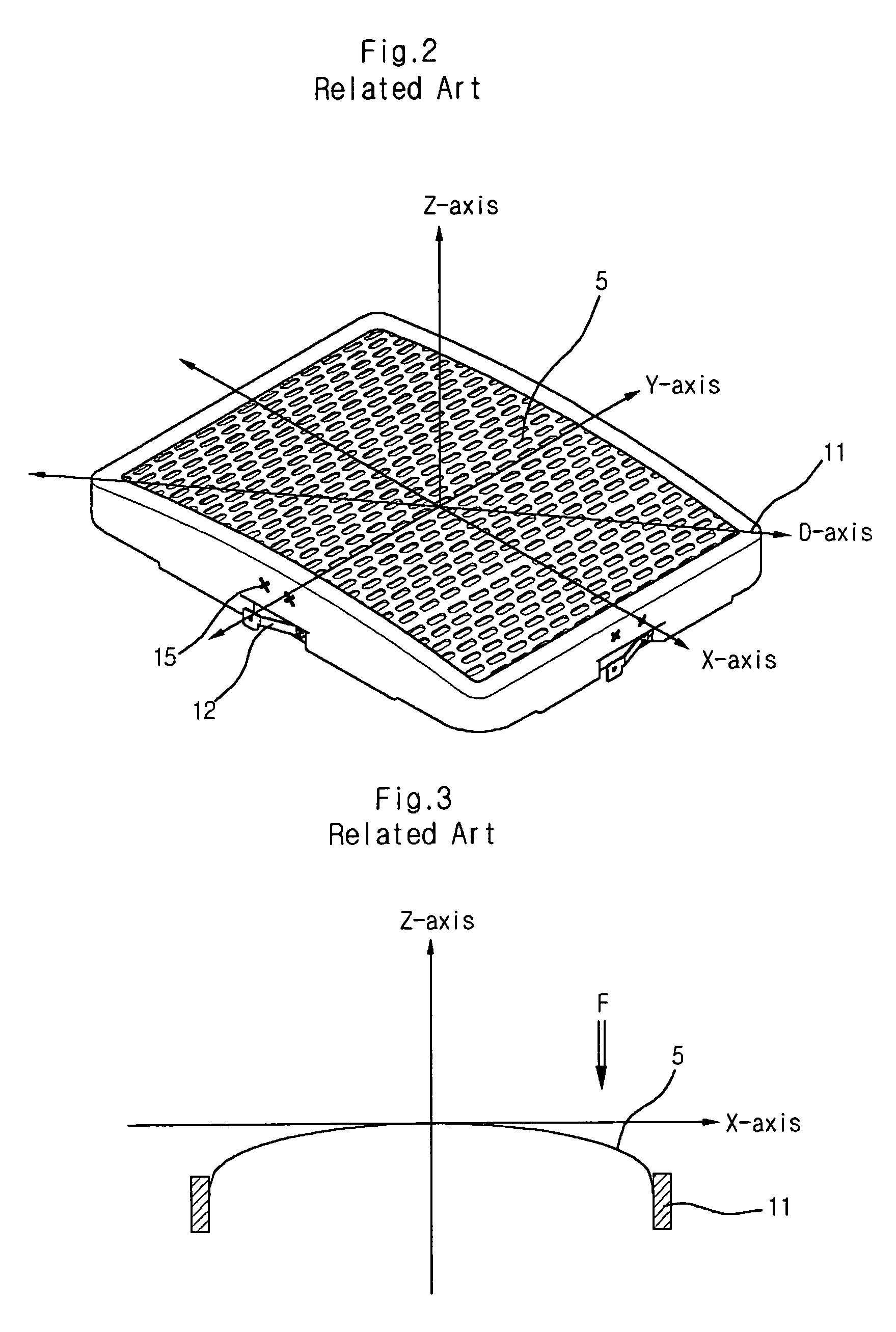

Cathode ray tube having an improved shadow mask

InactiveUS7098582B2Maximized drop strengthSimple structureCathode-ray/electron-beam tube vessels/containersElectrode and associated part arrangementsFluorescenceLong axis

A cathode ray tube comprises a panel having a fluorescent formed on an inner surface thereof; a funnel connected to the panel; an electron gun housed in the funnel emitting electron beams; a deflection yoke for deflecting the electron beams in horizontal and vertical directions; a shadow mask for selecting colors of the electron beams; and a mask frame for supporting the shadow mask, in which an outer surface of the panel is substantially flat and an inner surface has a designated curvature, and a radius of curvature from a center of the shadow mask in a major-axis, minor-axis and diagonal-axis direction is substantially same.

Owner:MERIDIAN SOLAR & DISPLAY

Packaging for free-flowing products, consisting of a heat-sealed bag

Packaging for free-flowing products consisting of a tubular bag composed of a flexible material. One end, which lies flat when the bag is filled, is formed by two broad-face panels lying flat against one another and narrow-face panels that are folded back by center fold lines between the opposite edges of the narrow-face panels, and positioned between the marginal areas of the broad-face panels. A side fold connects each narrow-face panel to one broad-face panel and another side fold connects the narrow-face panel to the other broad-face panel. The fold lines extend substantially parallel to the longitudinal axis of the bag. The end of the bag is closed by a sealing weld that extends in a transverse direction to the longitudinal axis of the bag. The sealing weld is controlled to be weaker than the other welds which connect the panels to form the panels into a bag for containing the product. Preferably the outer surfaces of the panels are treated to prevent their being sealed together when folded back

Owner:HENKEL KGAA

Compound binder for lignite molding and molded coal preparation method

InactiveCN105950245AImprove thermal stabilityImprove drop strengthSolid fuelsHeat stabilityCompressive strength

The invention provides a compound binder for lignite molding. The compound binder comprises two or more components of sodium humate, coal tar pitch and lignin. The compound binder takes a low-cost organic binder as a main component, a few binder is used, a preparation method is simple, components easily producing ash are not used, and the problems that a binder in the prior art contains much ash, the use amount is large, a preparation method is complicated and the cost is higher are solved. The compound binder further enables prepared molded coal to have higher falling strength, cold compressive strength and heat stability on the basis of solving the problems and has broader industrial application prospect.

Owner:SHENWU TECH GRP CO LTD

Pellet additive and preparation method thereof

The invention relates to the technical field of a pelletizing craft process of powdered iron during a pelletizing process, particularly to a pellet additive and a preparation method thereof. The pellet additive mainly consists of hydroxyethyl cellulose, hydroxypropyl cellulose, povidone (PVP), gelatin, gelatinized starch, cationic polyacrylamide, anionic polyacrylamide, high temperature glue, sodium humate, polyvinyl alcohol, sodium bentonite, sodium carbonate and other substances. The pellet additive is prepared through batching, mixing, testing and other steps. The problem that the pelletizing rate of the powered iron during the palletizing process is low is solved. The pellet additive and the preparation method thereof have the advantages that the rate of return mine is reduced, a large amount of cost is saved, the compressive strength and the drop strength of pellets can be significantly improved, pelletized granularity is uniform, pelletized surfaces are smooth, and the compressive strength of finished balls is significantly improved.

Owner:BEIJING YUHANG TONGHUI ENERGY SCI & TECH

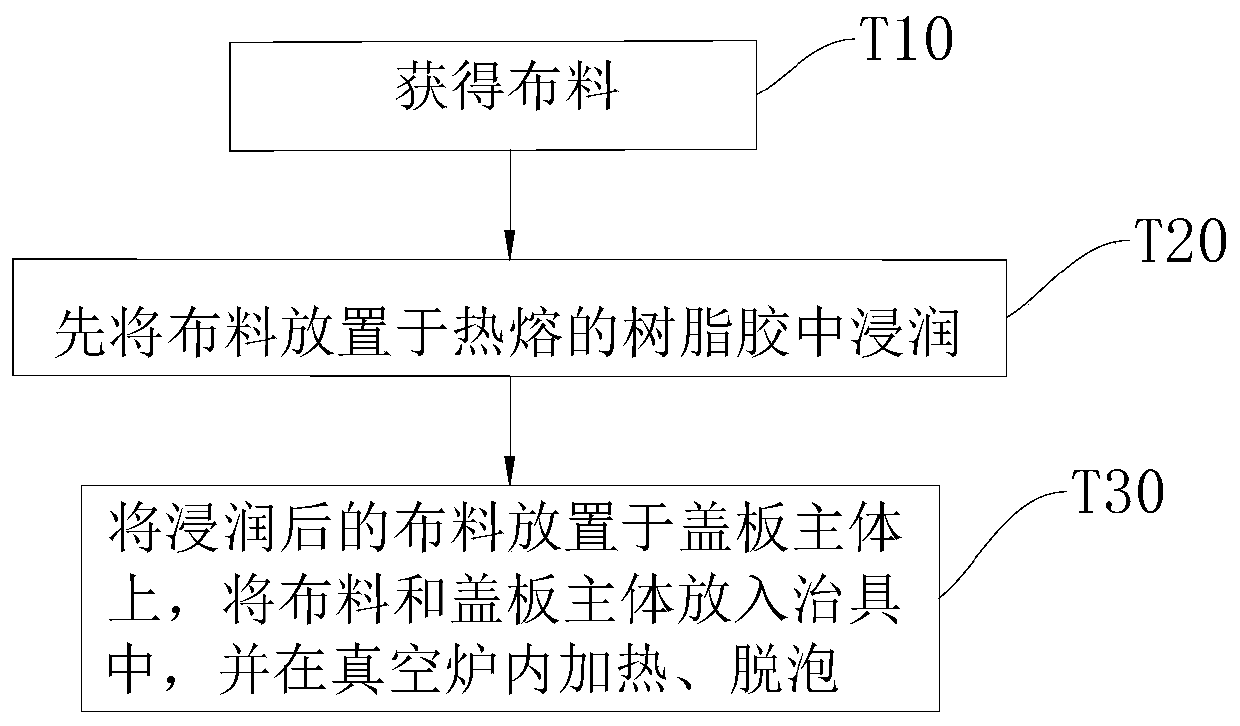

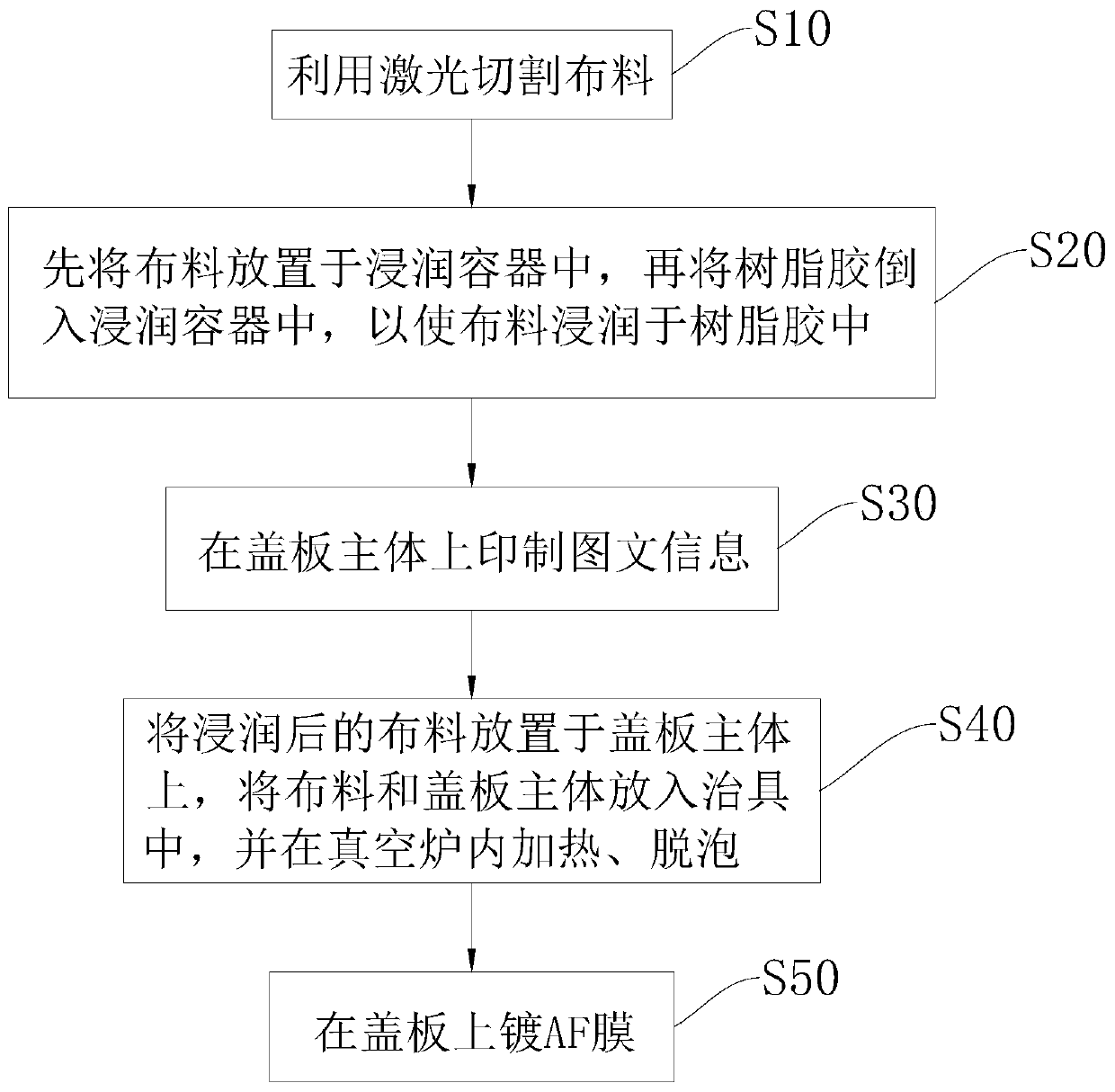

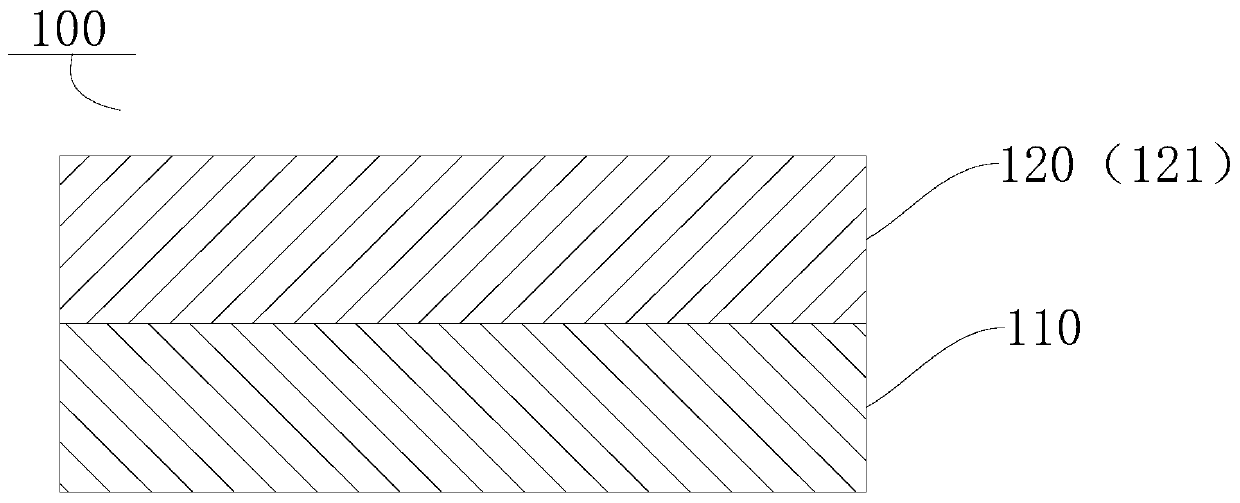

Electronic equipment, glass cover plate and manufacturing method of glass cover plate

The invention discloses electronic equipment, a glass cover plate and a manufacturing method of the glass cover plate. The manufacturing method comprises the steps of obtaining cloth; soaking the cloth in a resin adhesive; and arranging the soaked cloth on the cover plate main body, placing the cloth and the cover plate main body in a jig, and performing heating to defoam. According to the manufacturing method of the glass cover plate of the electronic equipment, the cover plate main body is provided with the cloth soaked with the resin adhesive, so that on one hand, a special texture effect with a stable shape can be conveniently presented on the cover plate main body; and on the other hand, by compounding the cloth on the cover plate main body, the structural strength of the glass can beimproved by utilizing the characteristic of high toughness of the cloth, so that the falling strength of the cover plate main body can be improved, and the usability and the anti-falling performanceof the glass cover plate can be improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com