Touch panel, touch display device and display device

A touch panel and touch display technology, used in instruments, electrical digital data processing, electronic equipment, etc., can solve problems such as easy breakage, human injury, glass splash, etc., to reduce splinter splash, reduce damage, and improve anti-fall The effect of drop strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] In the following, the touch display device of the present invention is compared with the drop test of the traditional touch display device. In order to ensure the reliability of the test results, the traditional touch display device uses ordinary optical glue, while the touch display device of the present invention uses this The optical glue of the invention has the same structure as other components. Among them, sample 1 and sample 2 are touch display devices of the present invention, and sample 3 and sample 4 are traditional touch display devices.

[0053] Table 2

[0054] Ball height sample 1 sample 2 sample 3 Sample 4 30cm unbroken unbroken unbroken unbroken 50cm unbroken unbroken rupture rupture 100cm unbroken unbroken rupture rupture

[0055] The test results in Table 2 show that when the height of the falling ball is 30cm, neither the traditional touch display device nor the touch display device of the...

Embodiment 2

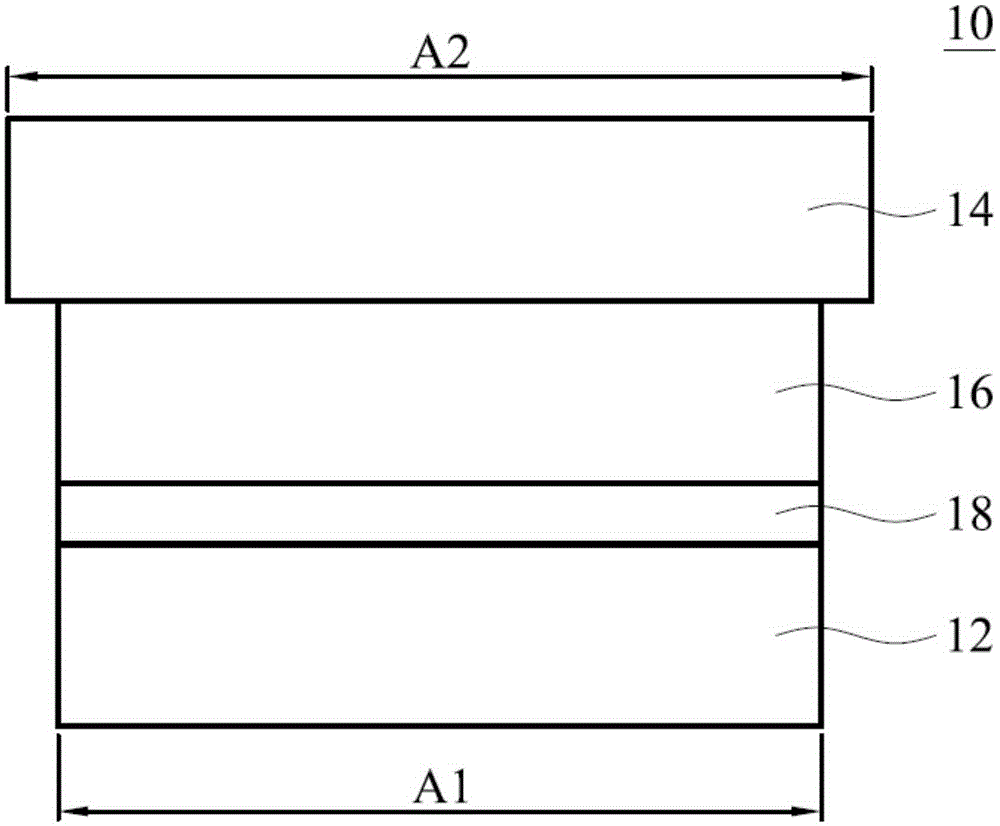

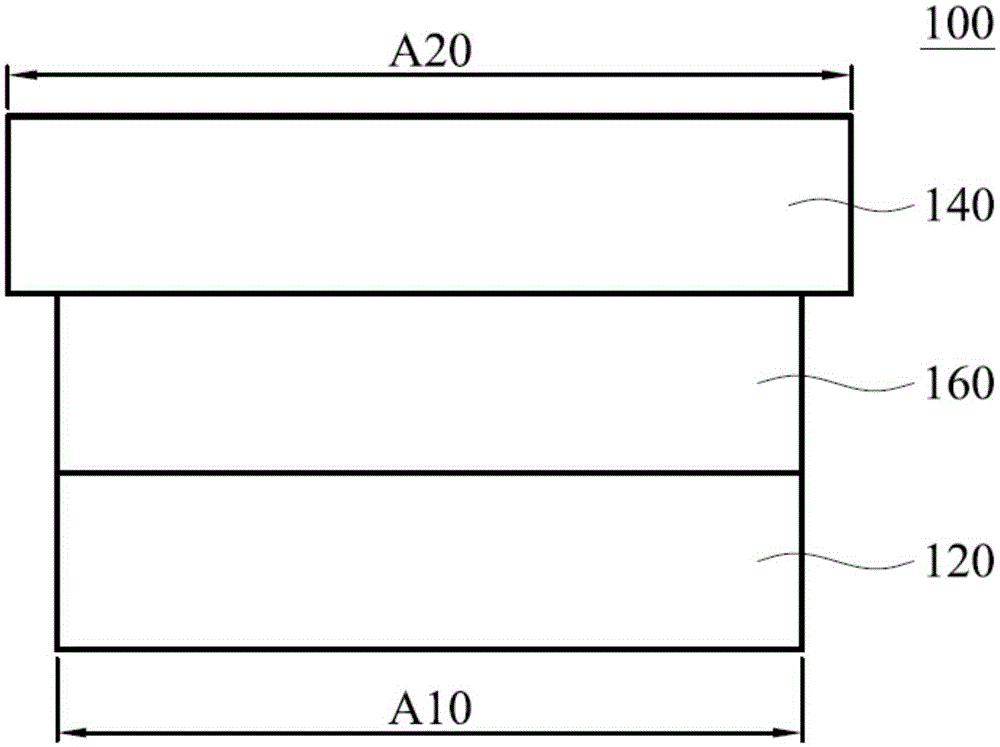

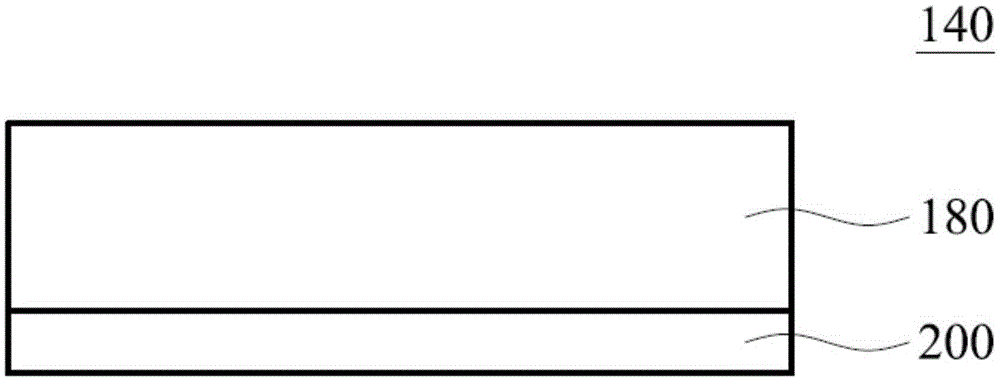

[0057] A comparison of the drop test of the traditional touch display device and the touch display device of the present invention, wherein the structure of the traditional touch display device is: a single-chip touch panel, a hard coating film, a traditional optical glue, and a liquid crystal display module stacked in sequence Plus, the touch display device of the present invention uses figure 2 The touch display device 100 corresponding to the embodiment is a test sample, wherein the touch panel is image 3 The single-chip touch panel 140 of the embodiment is taken as an example. The traditional touch display device (sample 4, sample 5) and the touch display device of the present invention (sample 1, sample 2, sample 3) were dropped and dropped with different steel ball weights (100g, 130g, 150g) respectively (ball height :100cm). The test results are shown in Table 3 below.

[0058] table 3

[0059]

[0060]According to the results in Table 3, when a steel ball with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com