Method and apparatus for supercharging water constraint layer based on laser impact technology

A laser shock and constraining layer technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of complicated cleaning, high cost, and the inability to accurately control the thickness uniformity of the water confinement layer, so as to improve the supercharging effect. , the effect of improving the supercharging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

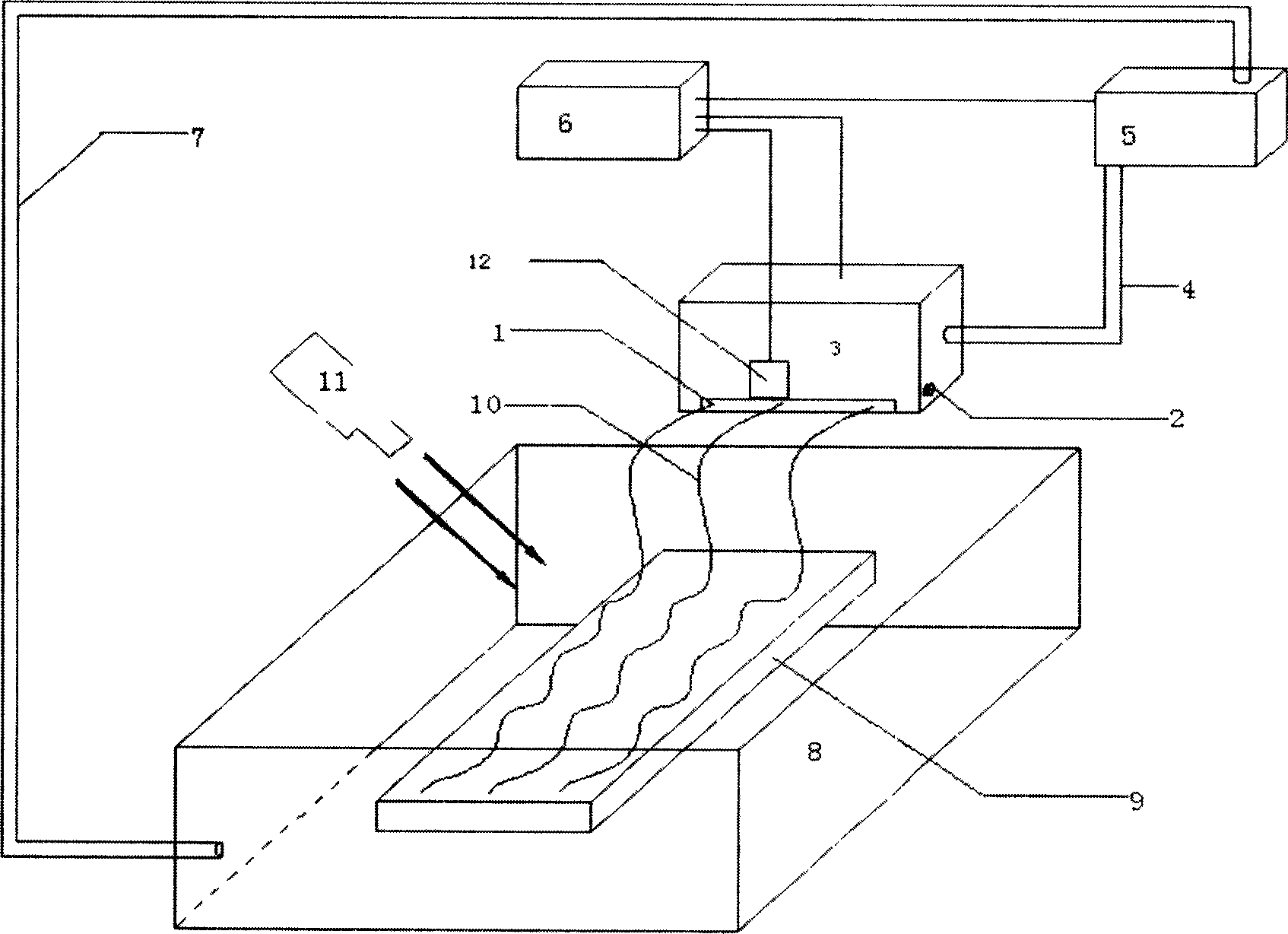

[0019] When a large area, multiple points and multiple impacts are made on the alloy metal surface, the path of the laser spot is first set by the microcomputer controller (6). The faucet (1) is adjusted to follow the laser spot (11), and the water curtain moves continuously with the movement of the laser spot. The adjustment parameters of the device for controlling the faucet to reasonably adjust the water confinement layer by the microcomputer controller (6) are: the speed of the water flow is 8cm / s, water flow pressure 0.3kg / cm 2 , the width of the water flow is 20mm, and the thickness of the water flow on the surface of the workpiece is about 5mm, so as to achieve the ideal constraint layer parameters. During the laser shock process, the water purification device (5) purifies the water flowing into the control water tank (3), thereby reducing impurities in the water flowing through the surface of the workpiece, improving the quality of the water-constrained layer (10), and...

Embodiment 2

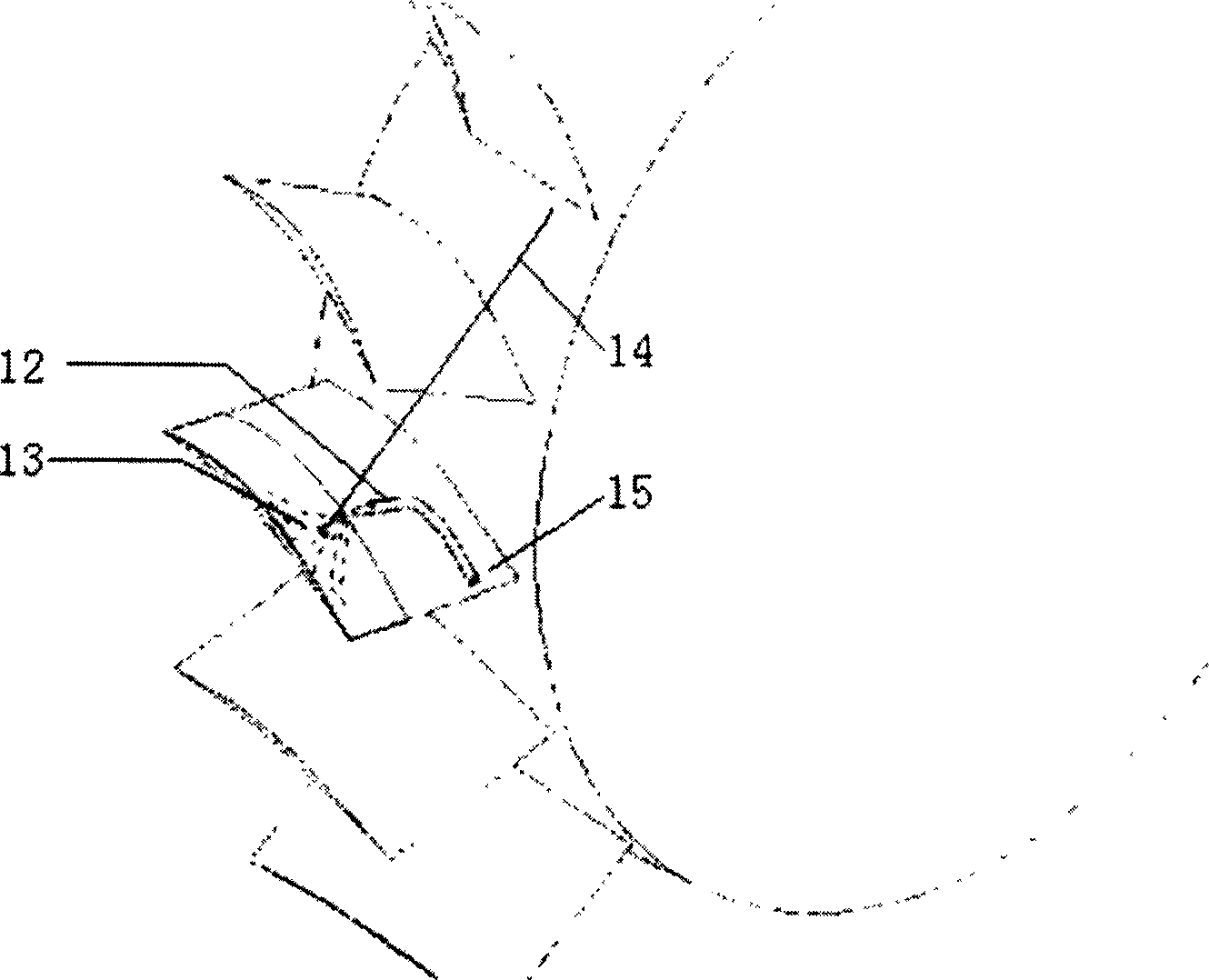

[0021] In the laser shocking of curved aircraft blades, the water confinement layer has been used abroad in laser shocking of the blades of the integral rotary wheel of the aircraft (F119), but because this kind of blade is a curved surface, water directly rushing on the blade cannot guarantee the thickness of the constrained layer Uniformity, and can not guarantee that the horizontal direction is perpendicular to the laser beam. In the present invention, the microcomputer controller (6) controls the adjustable faucet (1) in real time so that the thickness of the water-constrained layer (13) on the vertical plane of the normal line of the curved surface of the aircraft blade is uniform, and the accompanying controller (12) of the faucet can follow the laser spot (14) ) moves along with the movement, which can ensure that the laser is vertically impacted on the surface of the workpiece, so that the laser impact effect is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com