Multifunctional assistant plating additive for hot dip plating process, preparation and use method thereof

A metal technology, multi-functional technology, applied in hot dip plating process, metal material coating process, coating and other directions, can solve the problems of single function, less than ideal effect, and limited application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

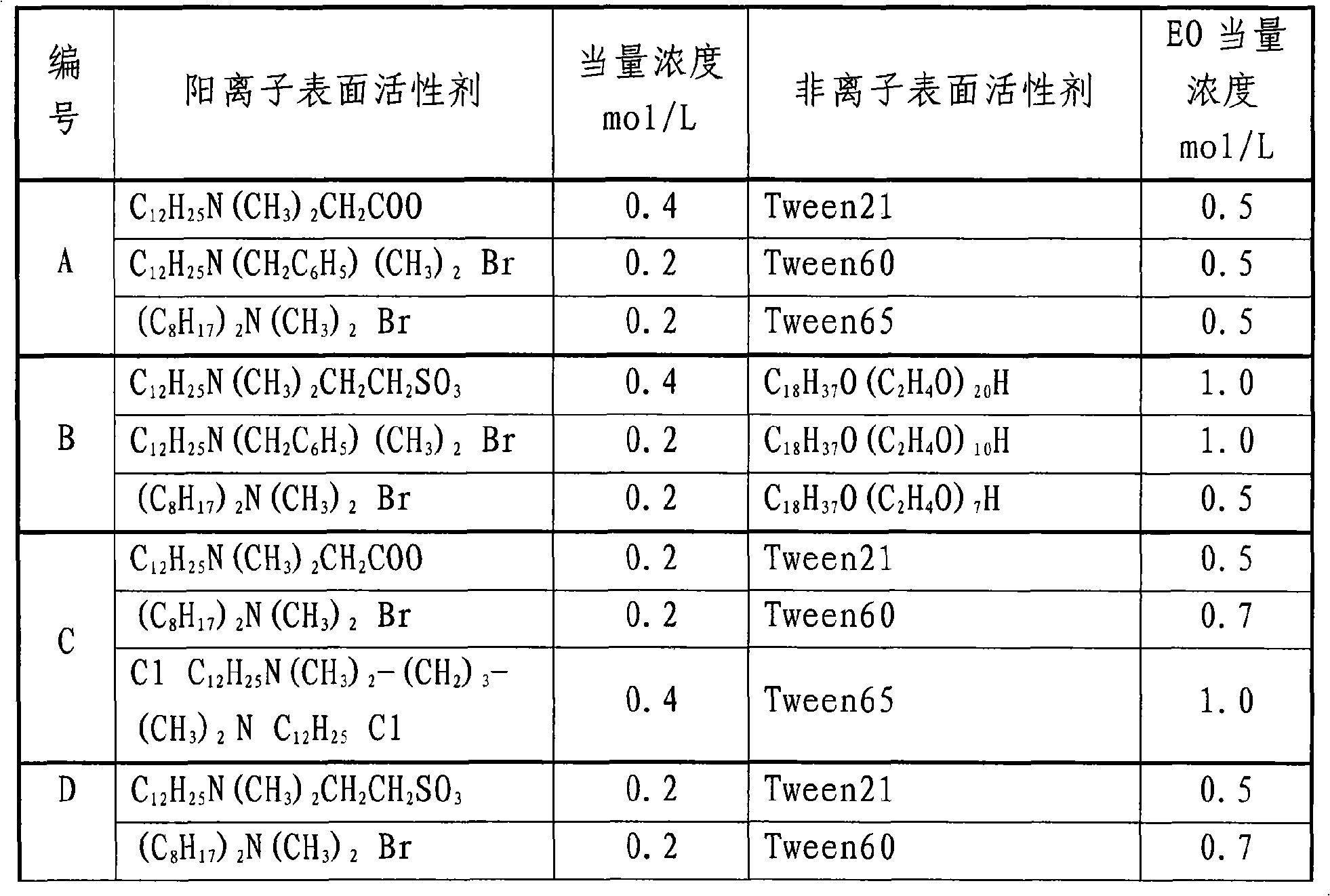

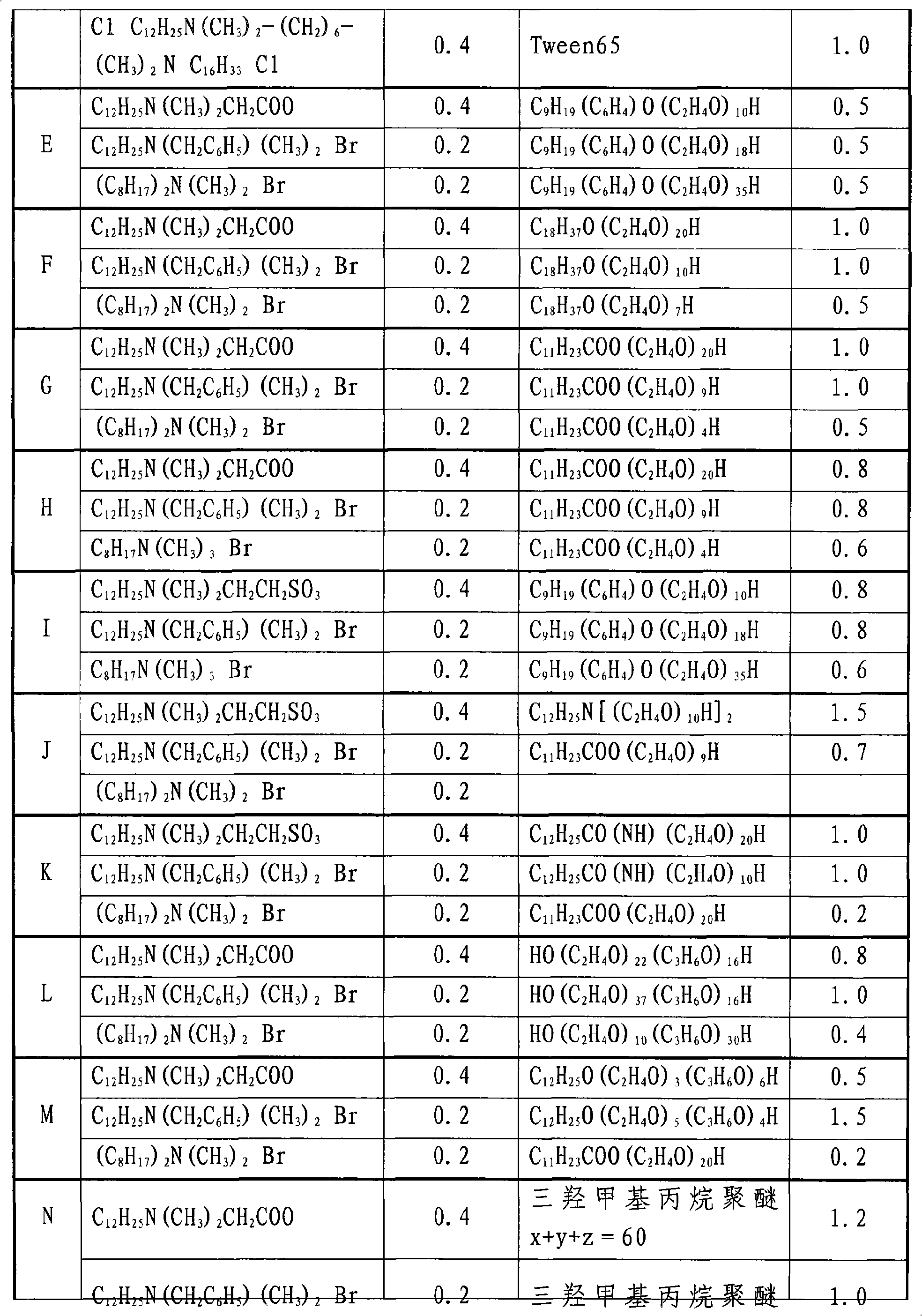

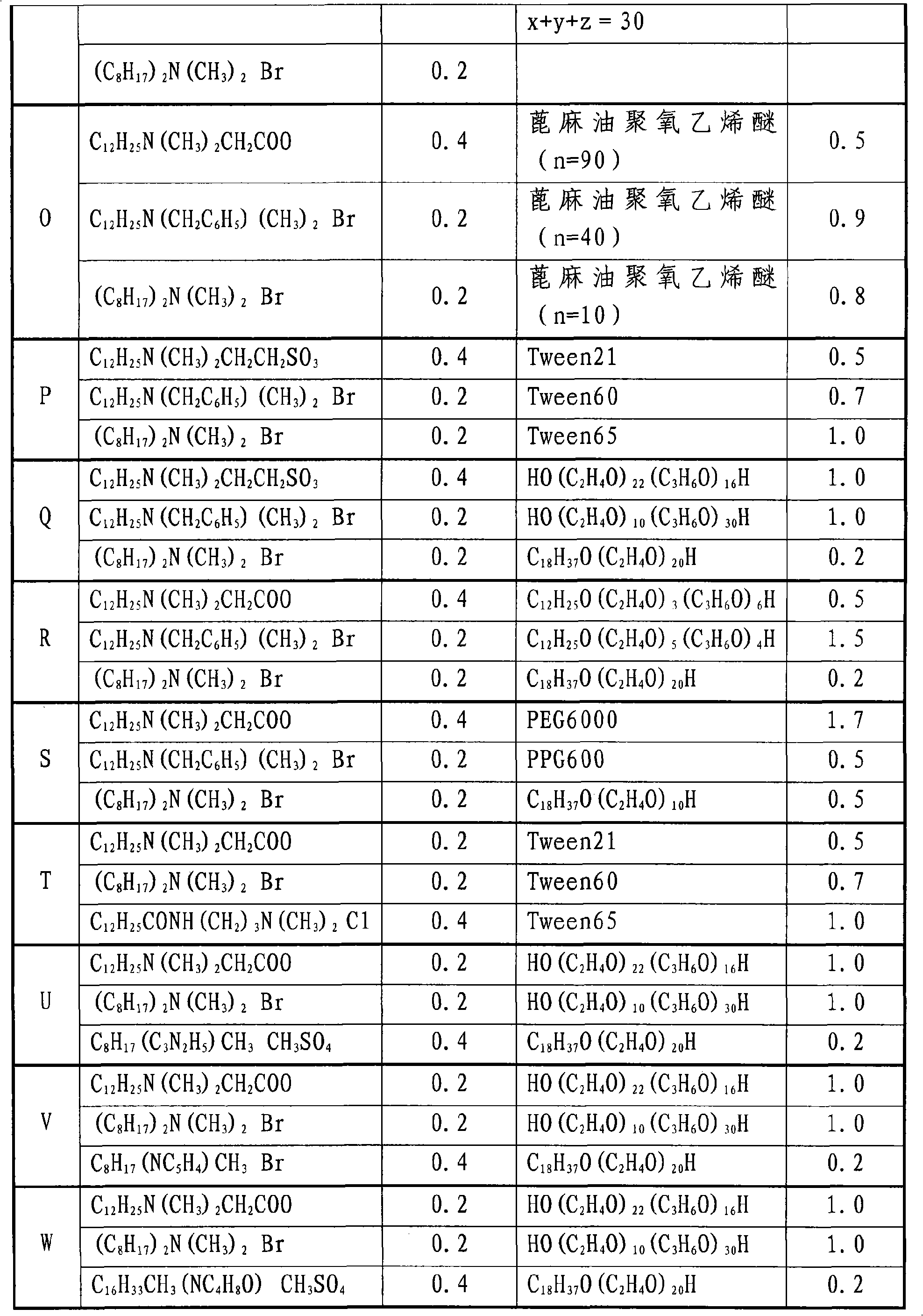

Image

Examples

Embodiment Construction

[0040] The composition of flux solution for hot-dip galvanized aluminum is similar to that of hot-dip galvanized aluminum, and the dipping process of hot-dip galvanized aluminum is the same as that of hot-dip galvanized, so it is suitable for hot-dip galvanized, hot-dip galvanized For three processes, two different flux solutions were prepared for adhesion uniformity experiments, and hot-dip galvanizing and hot-dip aluminum were selected for field experiments. The innovative point of the present invention is reflected through the adhesion uniformity test and the hot-dip galvanizing and hot-dip aluminum field experiments.

[0041] The hot-dip galvanizing flux solution is an aqueous solution of 17.5 wt.% ammonium chloride and 12.5 wt.% zinc chloride. The hot-dip galvanized aluminum and hot-dip aluminum flux solutions are aqueous solutions of 6 wt.% potassium zirconate fluoride, 2 wt.% aluminum fluoride, 4 wt.% potassium fluoride and 4 wt.% sodium chloride. The addition amount o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com