Patents

Literature

68results about How to "Good interface wettability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

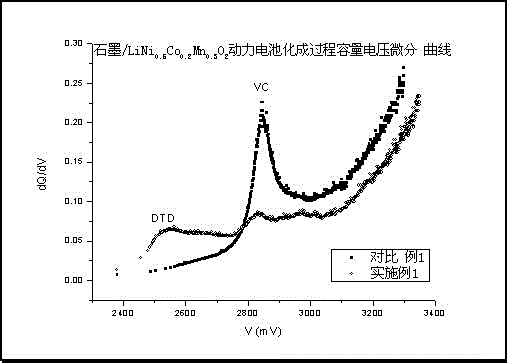

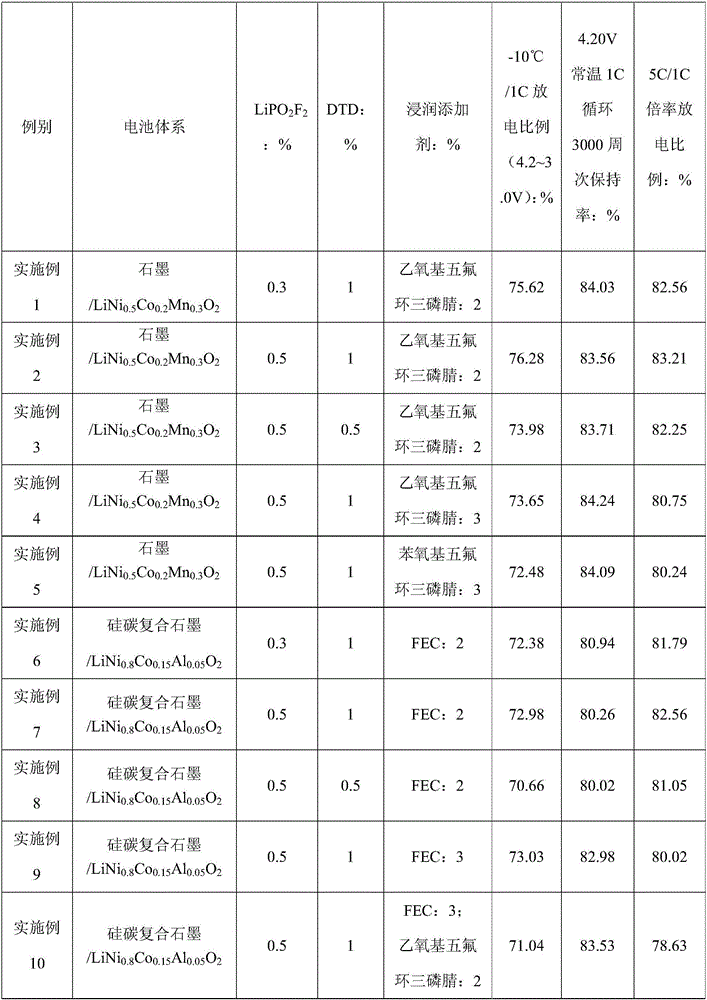

High-nickel ternary lithium ion power battery electrolyte and high-nickel ternary lithium ion power battery

InactiveCN106058316AImprove transmission characteristicsImprove dynamic propertiesSecondary cellsBatteriesDifluorophosphatePower battery

The invention discloses a high-nickel ternary lithium ion power battery electrolyte and a high-nickel ternary lithium ion power battery. The electrolyte includes a non-aqueous organic solvent, a lithium salt, a conductive additive, a film forming additive and an infiltration additive, wherein the conductive additive is lithium difluorophosphate, the film forming additive is ethylene sulfate, and the infiltration additive is at least one of fluorophosphazene and fluoroethylene carbonate; and synergism and mutual promotion of the three additives makes an excellent SEI film be formed on the surface of an electrode and effectively promotes all dynamic processes in the lithium ion battery. The power battery electrolyte has the advantages of good lithium ion transmission characteristic, good oxidation resistance, guaranteeing of high power characteristic and good cycle performances of the power battery, and high safety.

Owner:GUANGZHOU TINCI MATERIALS TECH

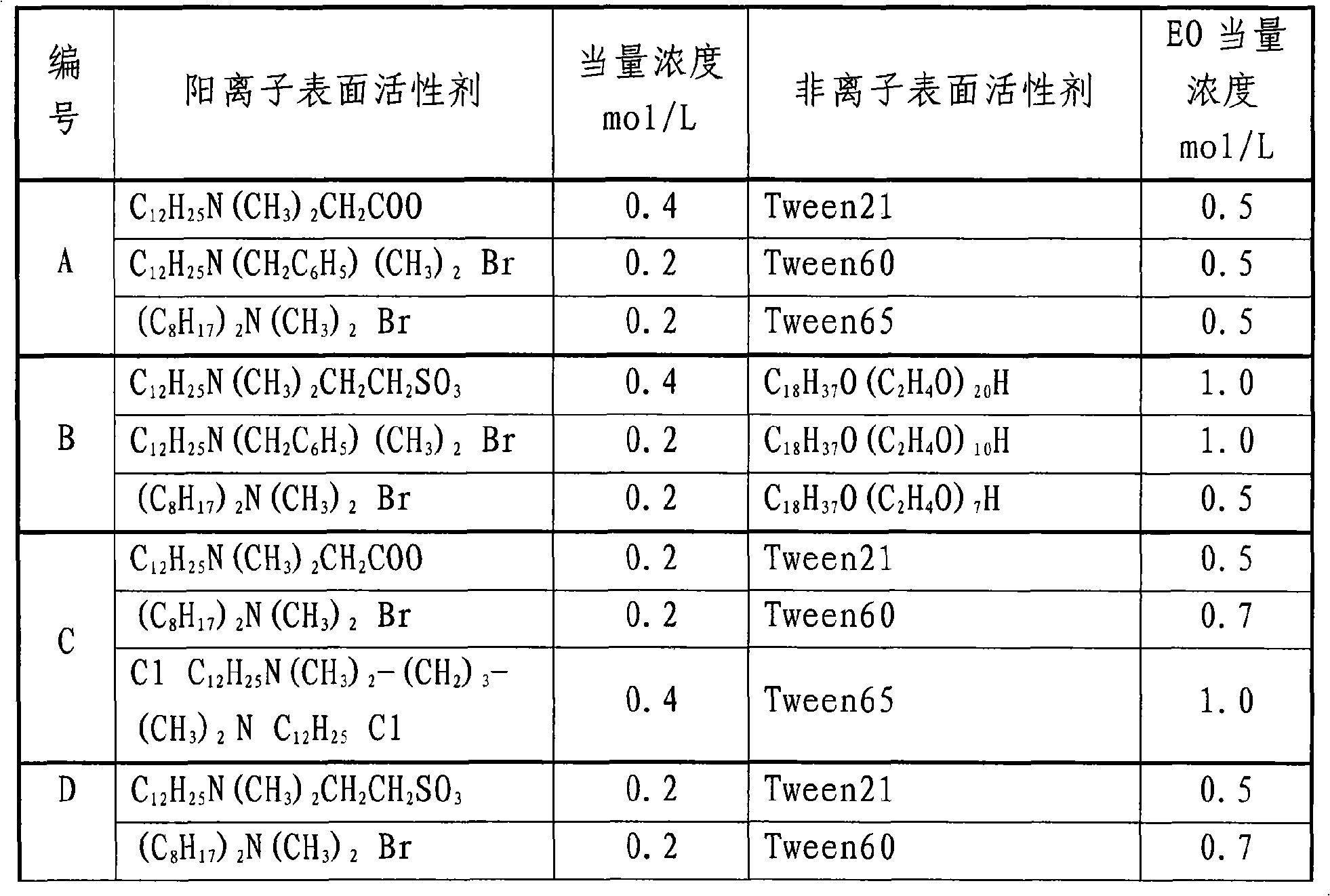

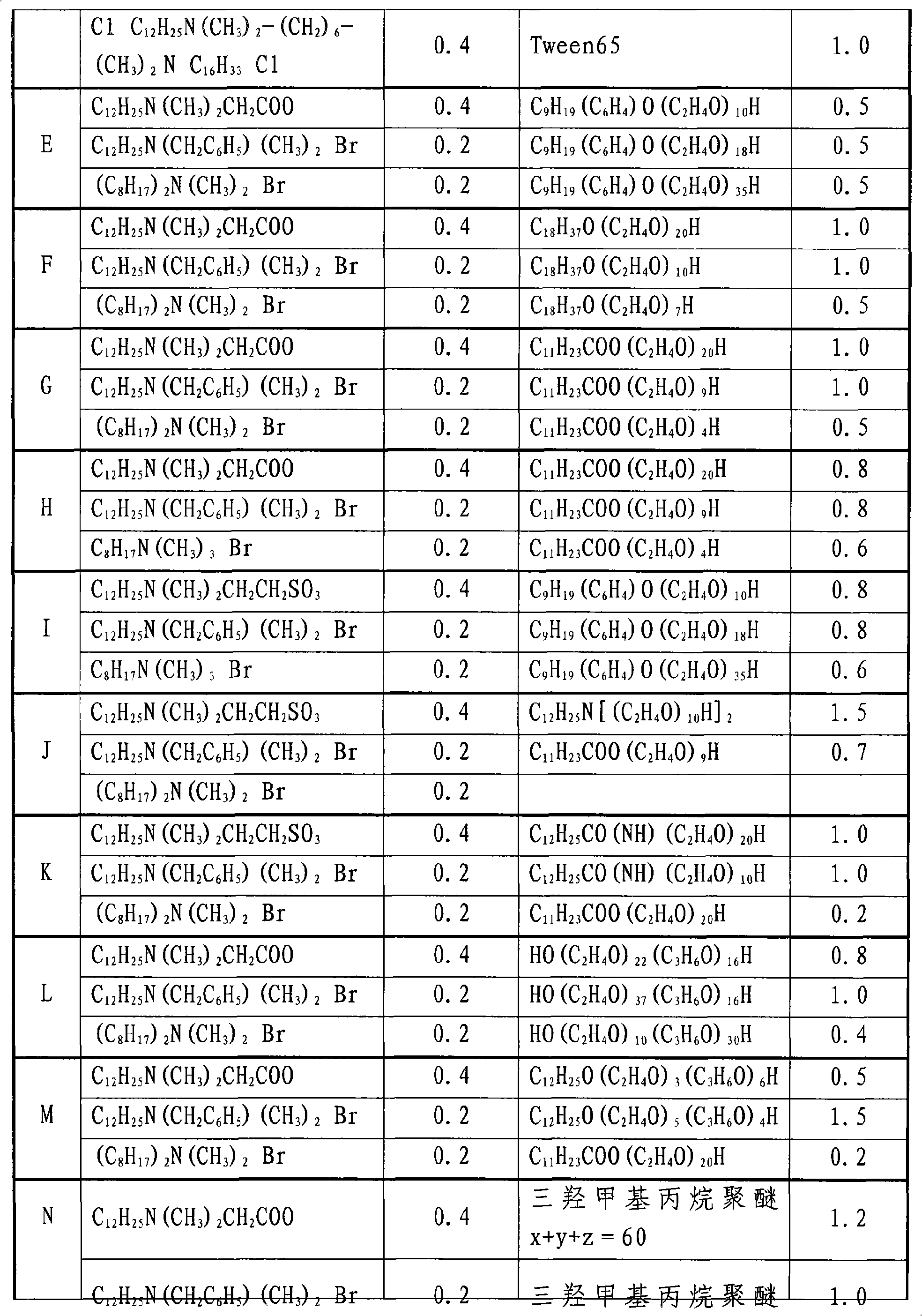

Multifunctional assistant plating additive for hot dip plating process, preparation and use method thereof

ActiveCN101328568AReduce lossImprove stabilityHot-dipping/immersion processesDissolutionLiquid metal

The invention relates to a multifunctional plating assisting additive for a hot dipping metallization process and a preparation and application method thereof, and belongs to the metal material anticorrosive technical field for providing multiple plating assisting efficacy. The technical proposal of the invention comprises that: a plurality of cations or an amphoteric surfactant ( an equivalent concentration of a quaternary ammonium group is between 0.1 and 2 mol / L) and nonionics (an equivalent concentration of a polyoxyethylene group is between 0.5 and 5 mol / L) are dissolved in deionized water. The method can improve the wetting quality between a liquid-state metal and a workpiece, and the adhesive uniformity and continuity of the plating assisting additive, reduces the drying time, prevents the liquid-state metal from falling and splashing, shortens the dipping and plating time, saves raw materials, improves a residue form, reduces an ash content, increases an ash discharge speed, isolates air, stops oxidation, disperses residual dirt and is suitable for a plurality of processes of hot galvanizing, hot plating zinc-aluminum alloy, hot plating aluminum, etc. The preparation steps comprise dissolution, cubage determination, cooling, keeping stand and filling; when the multifunctional plating assisting additive is used, the multifunctional plating assisting additive is directly added into a plating assisting additive solution and is evenly stirred.

Owner:JIANGSU FEITUO INTERFACE ENG TECH CO LTD

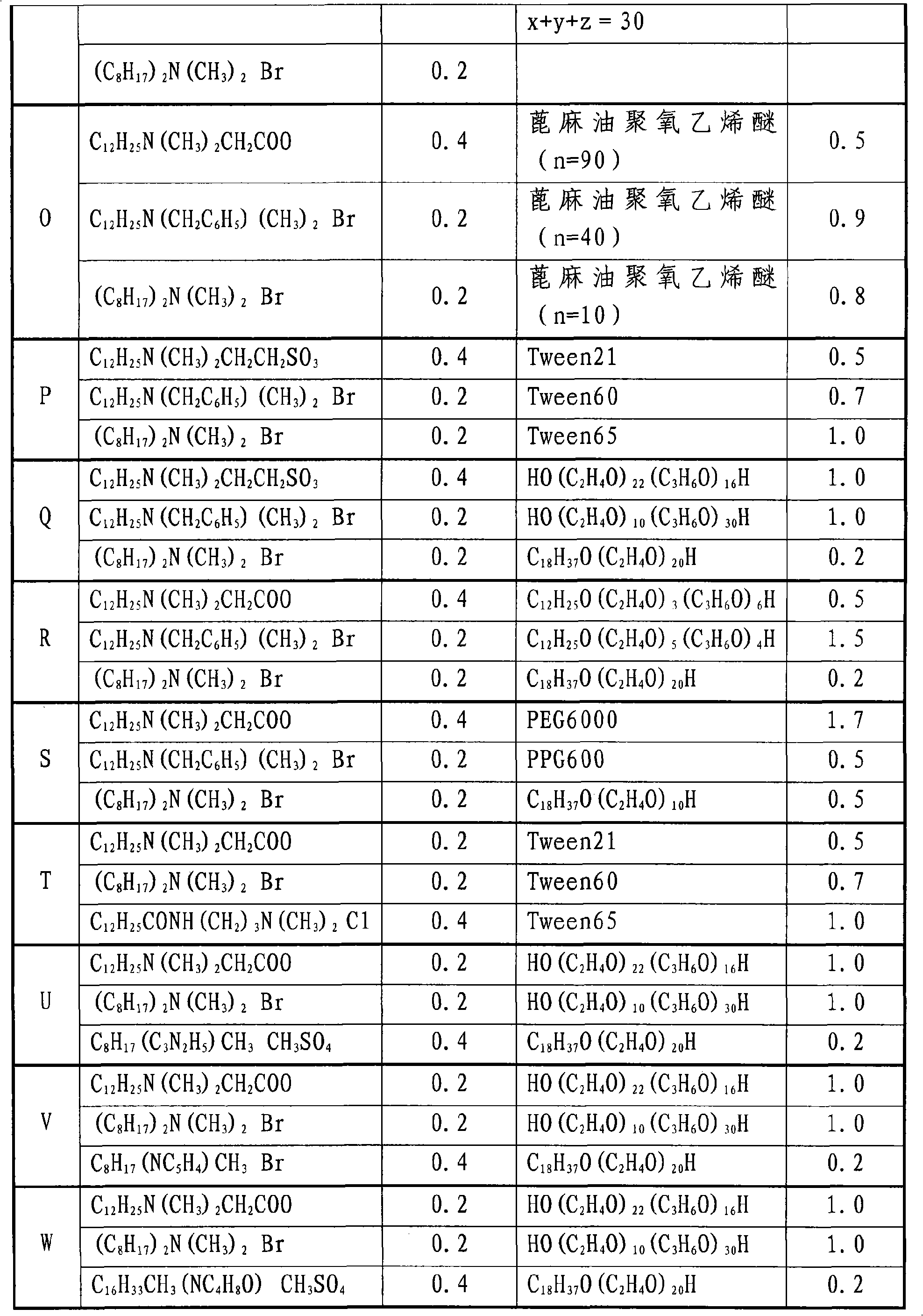

Wind driven generator blade

InactiveCN102465844AHigh tensile strengthIncreased shear strengthSynthetic resin layered productsWind energy generationGlass fiberWind driven

The invention provides a wind driven generator blade. The wind driven generator blade is made of composite material, and the composite material comprises multiple fiber layers and a base material attached to the multiple fiber layers; and the fiber layers comprise carbon fibers and glass fibers, and the volume ratio of the carbon fibers to the glass fibers is 1:4-4:1. The fiber layers in the wind driven generator blade comprise at least two kinds of fibers, namely the carbon fibers and the glass fibers, wherein the carbon fibers have the advantages of high strength and light weight; and the glass fibers have the advantage of good toughness, and have good interface wetness with resin. The glass fibers and the carbon fibers are made into the fiber layers and the fiber layers are superposed to form the wind driven generator blade, so that the wind driven generator blade has good tensile strength, and the toughness of the wind driven generator blade can be improved; and because the multiple fiber layers contain the glass fibers, the fiber layers can achieve a better wetting effect with the resin, and the shearing strength of the wind driven generator blade is improved.

Owner:SANY ELECTRIC CO LTD

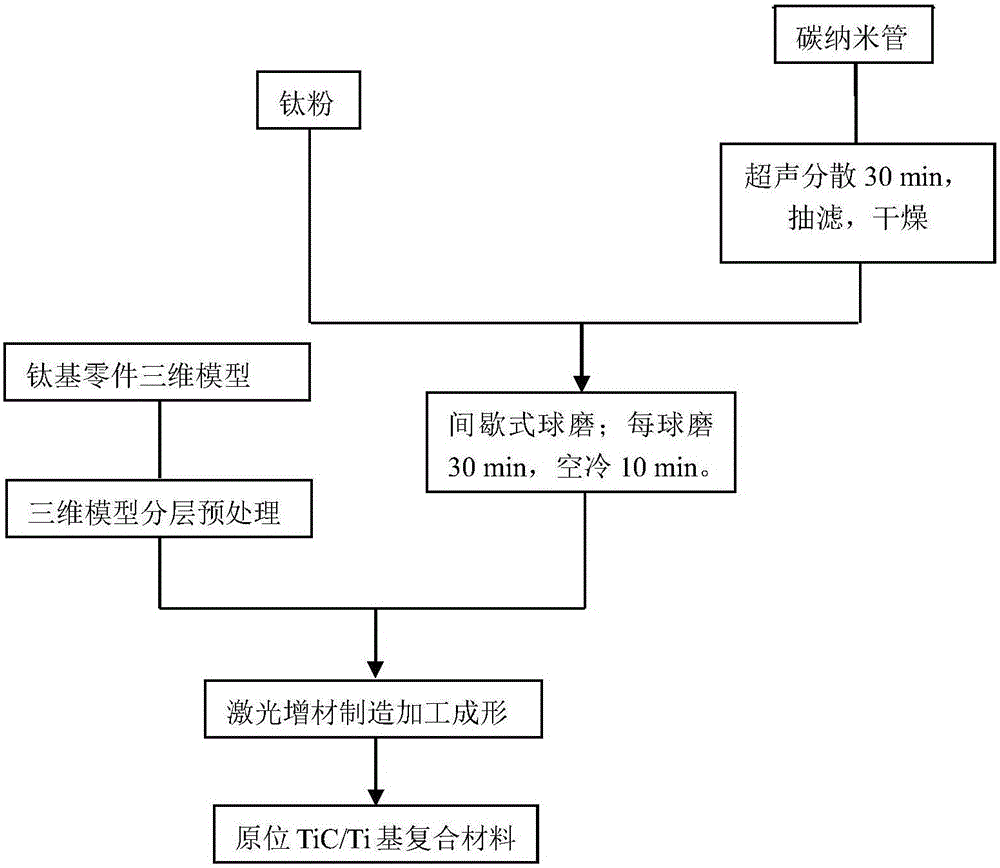

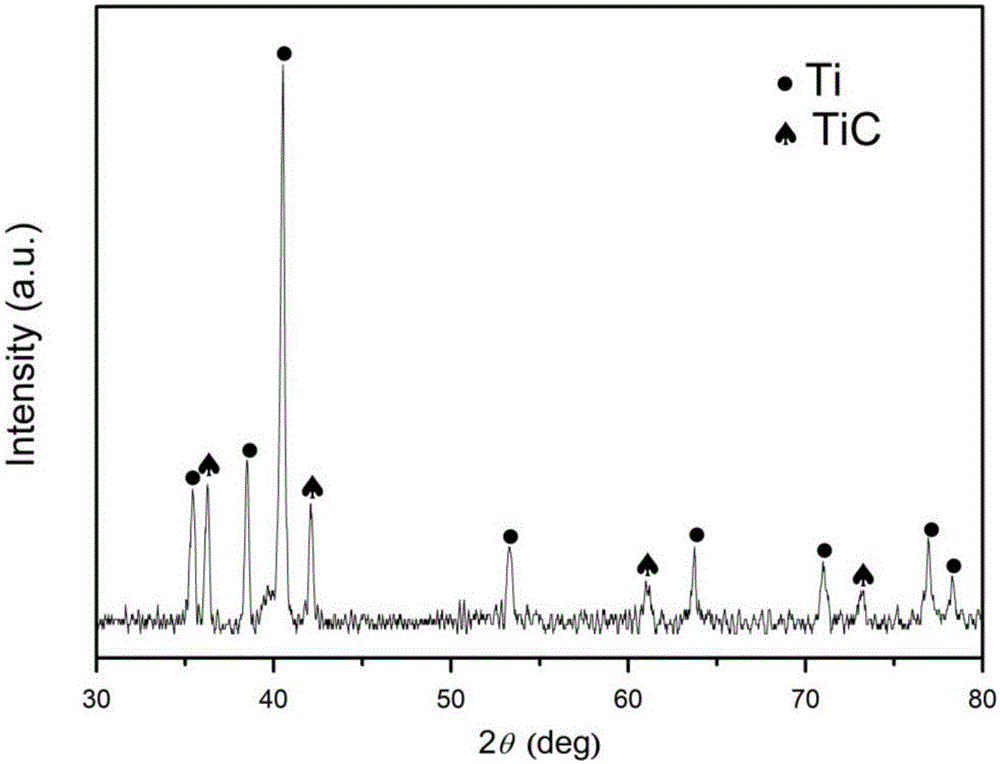

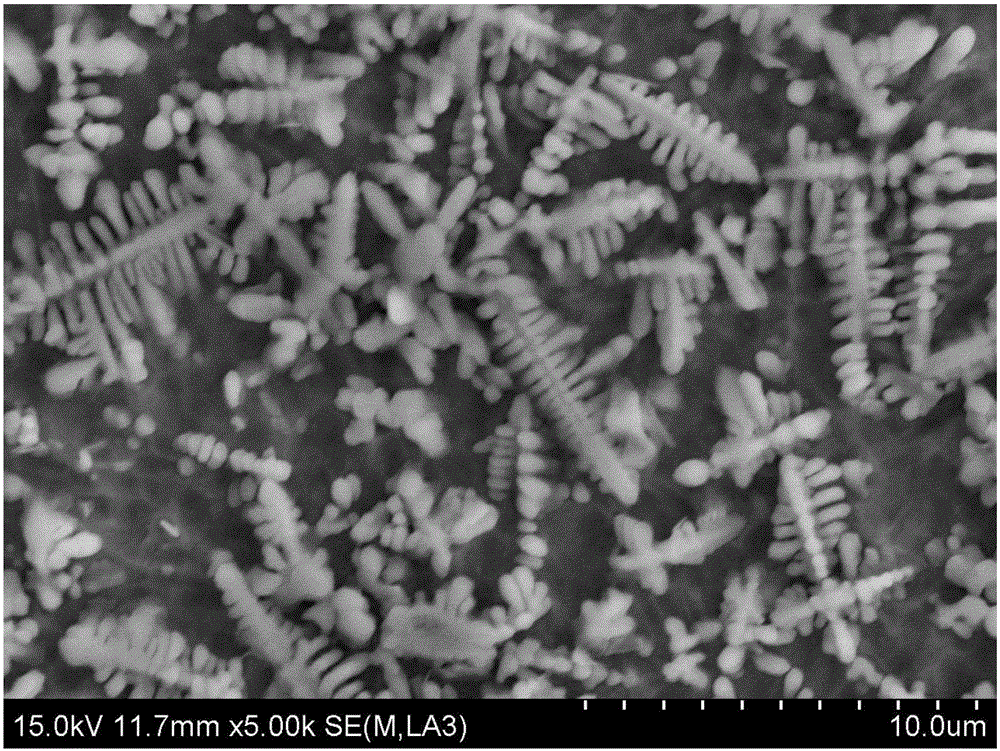

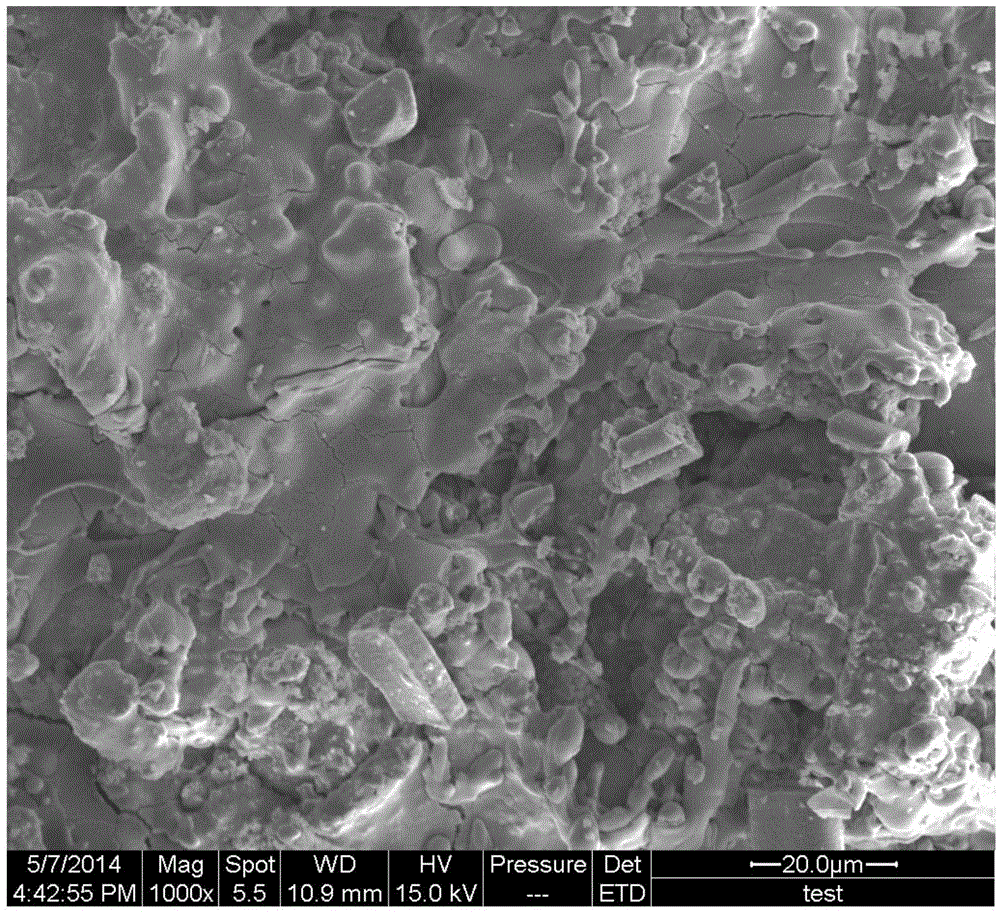

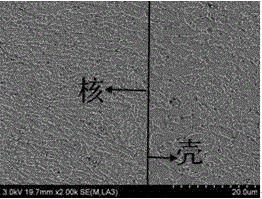

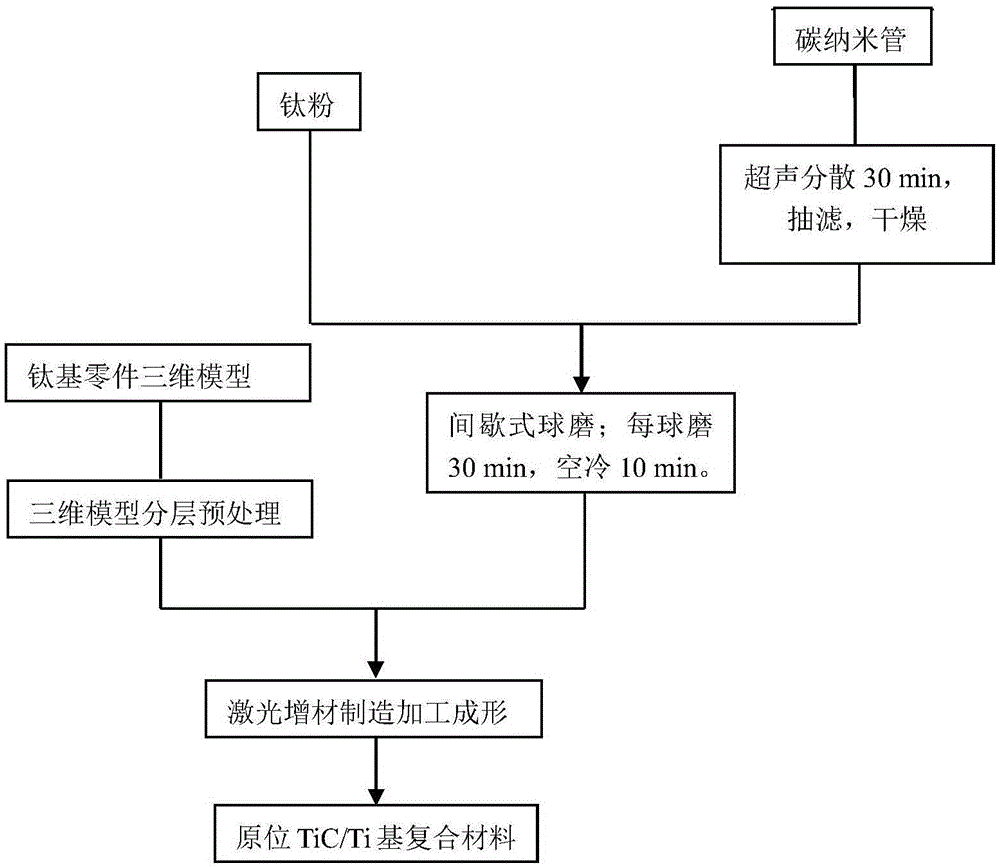

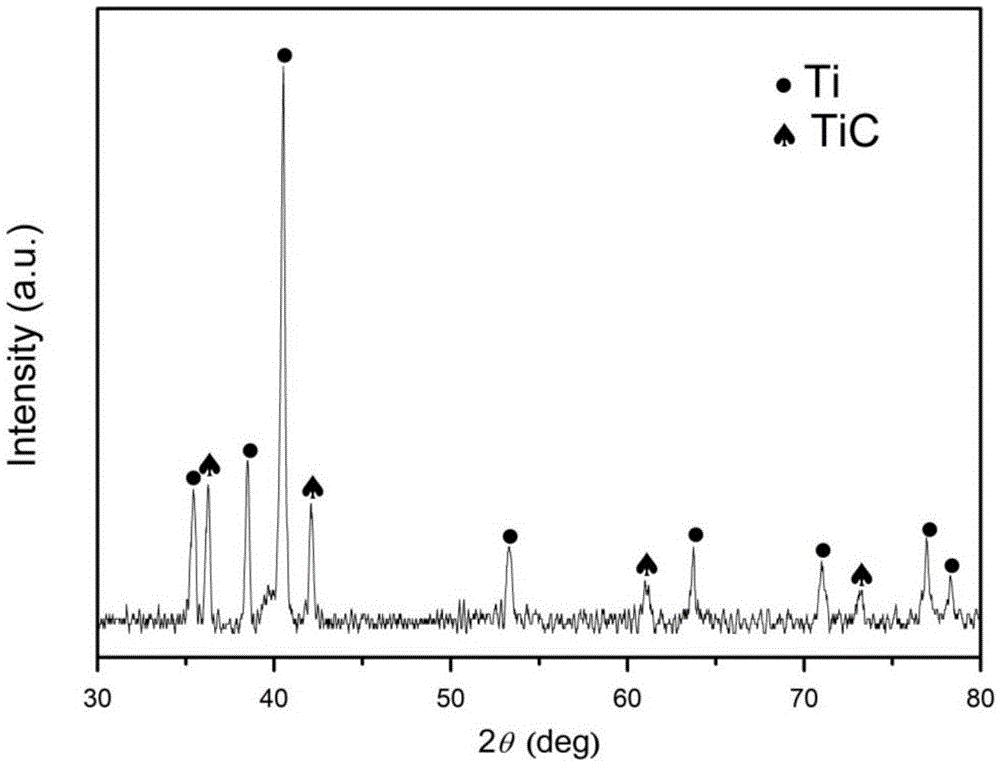

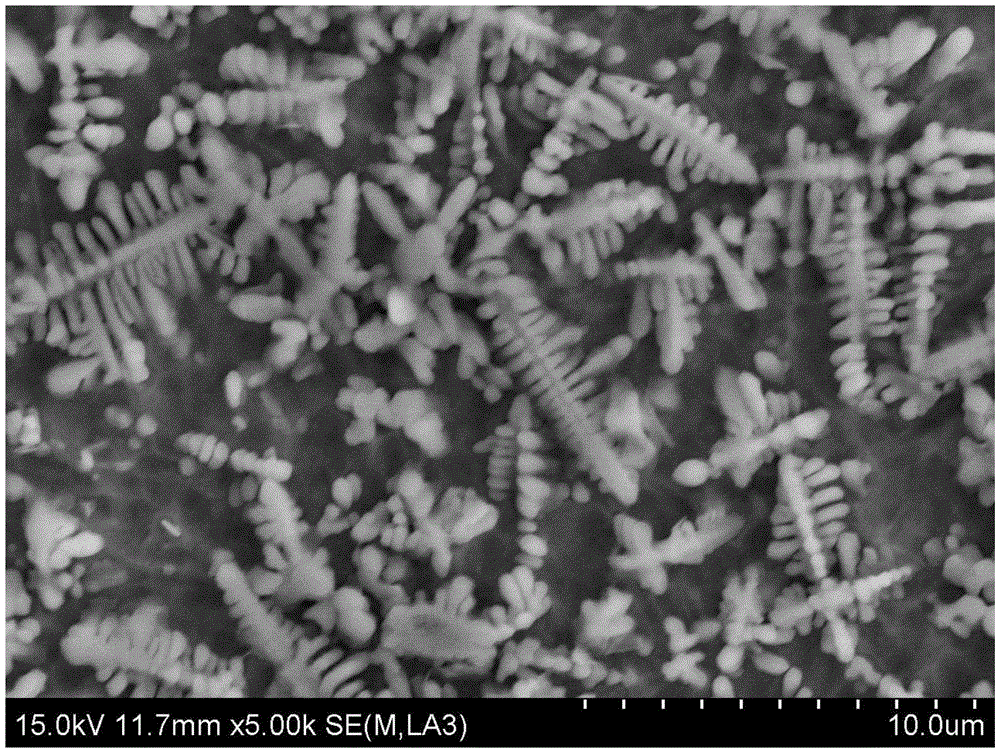

Method for manufacturing high-performance in-situ TiC reinforced titanium-based composite workpiece on basis of CNTs and laser additive manufacturing and processing technology

ActiveCN105033254AGood interface wettabilityTightly boundAdditive manufacturing apparatusIncreasing energy efficiencyTitanium matrix compositesCarbon nanotube

The invention discloses a method for manufacturing a high-performance in-situ TiC reinforced titanium-based composite workpiece on the basis of CNTs and a laser additive manufacturing and processing technology. The method includes the following steps that (1) the carbon nano tubes are subjected to preliminary ultrasonic dispersion treatment; (2) pure titanium powder with the average particle size of 45-75 microns is mixed with the carbon nano tubes to obtain a mixture, and CNTs / Ti mixed powder is obtained by ball-milling the mixture through a ball mill under the protection of argon; and (3) the ball-milled CNTs / Ti mixed powder is shaped through a laser additive manufacturing and processing method so as to obtain a high-performance in-situ TiC reinforced titanium-based composite body. The method has the advantages that in-situ TiC reinforcement phases are formed on the basis of a CNTs in-situ reaction and evenly distributed in a titanium substrate, and the interface bonding strength is high; grains of a composite are refined remarkably; net forming or near-net forming of a test piece can be achieved; any complex heterogeneous part can be formed.

Owner:南京瑞德增域三维技术发展有限公司

Composite material layer melted and coated on surface of titanium alloy through laser

InactiveCN1600891AGood interface wettabilityHigh bonding strengthMetallic material coating processesDispersityChemical reaction

This invention relates to a laser melt-deposition coating on titanium alloy surface. This coating material complex comprises NiCrBSi powder and B4C powder in the weight percentages of 2-10 of the above-said NiCrBSi powder. This invention material compared with prior art material has advantages of: the reinforcement phase formed in situ has excellent interface infiltration, high combination strength, excellent dispersity and thermalstability, due to the chemical reaction taking-place during the coating-prepn. procedure.

Owner:HARBIN INST OF TECH

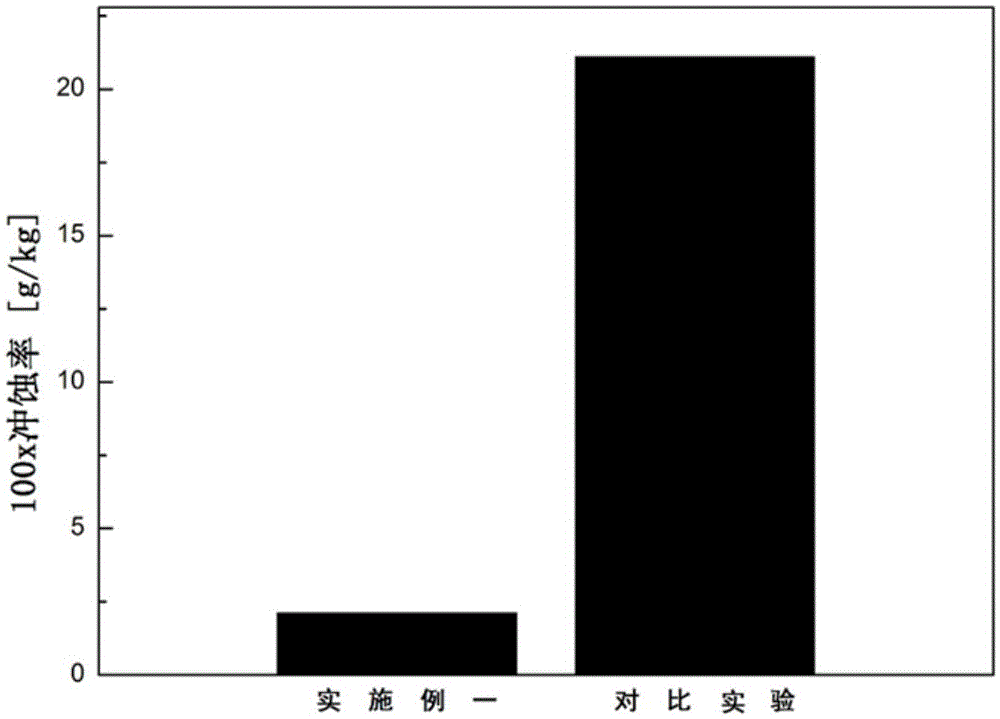

Preparation method of thermal barrier coating of lanthanum zirconate fiber doped lanthanum zirconate

ActiveCN105483597AReduce erosion rateStrong erosion resistanceMolten spray coatingEfficient propulsion technologiesFiberWear resistance

The invention discloses a preparation method of a thermal barrier coating of lanthanum zirconate fiber doped lanthanum zirconate, and relates to a preparation method of a thermal barrier coating. The technical problems that a novel lanthanum zirconate thermal carrier coating is poor in erosive wear resistance and is likely to lose efficacy when impacted by external particles are solved. The preparation method comprises the steps that a composite lanthanum zirconate ceramic layer spraying powder material is prepared; a bonding layer spraying material is sprayed to the surface of preprocessed matrix metal; a layer of composite lanthanum zirconate ceramic layer spraying material is sprayed to a bonding layer. Compared with a traditional thermal barrier coating which is not reinforced by fiber, the erosive wear resistance of the thermal barrier coating system is higher. The preparation method is applied to the field of composite materials.

Owner:HARBIN ENG UNIV

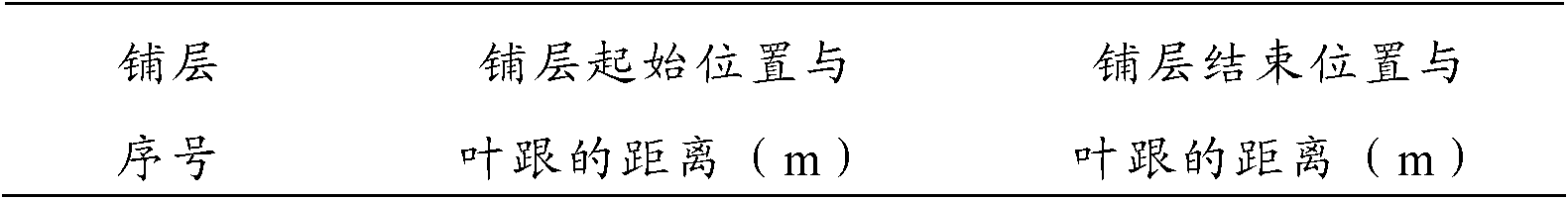

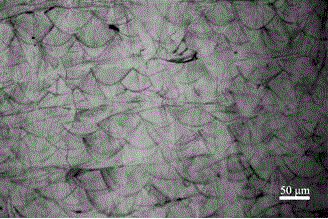

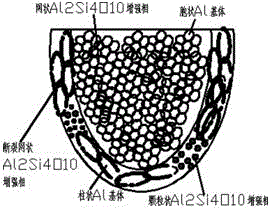

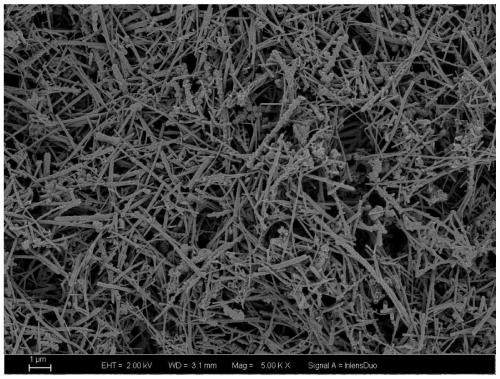

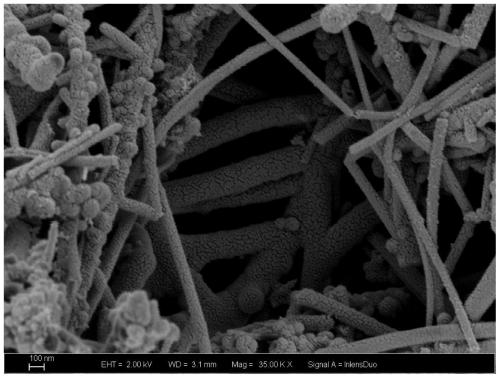

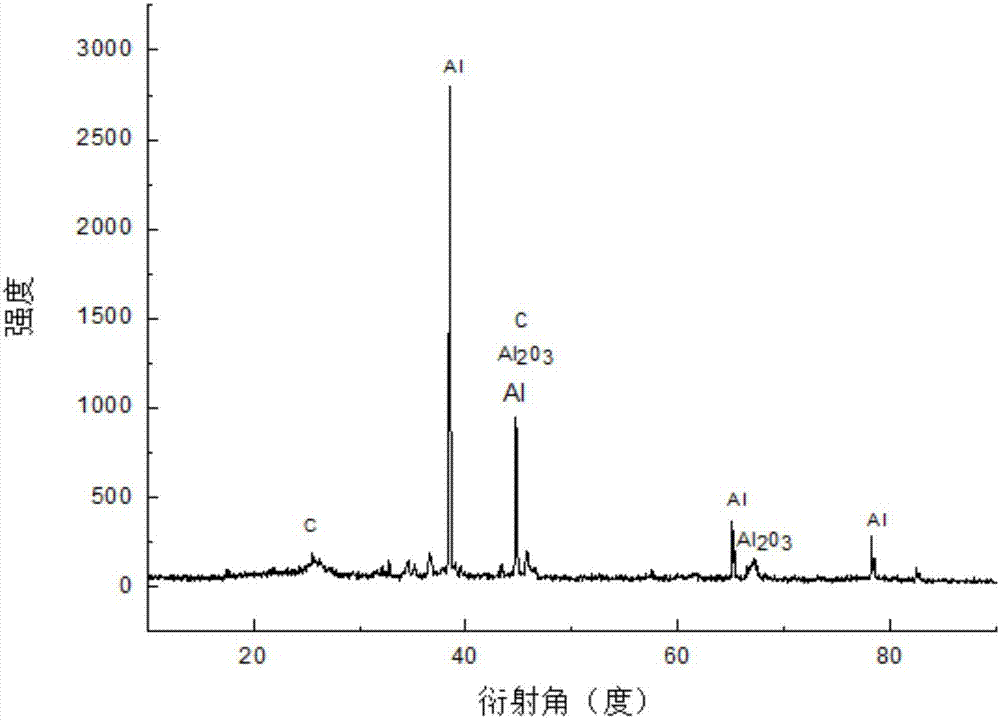

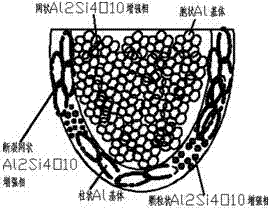

Aluminum-based in-situ composite material formed based on laser 3D printing and preparation method of aluminum-based in-situ composite material

ActiveCN105328186AGood comprehensive mechanical propertiesImprove the overall mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencyLaser printingAluminium

The invention belongs to the technical field of particle-reinforced aluminum-based in-situ composite materials and discloses an aluminum-based in-situ composite material formed based on laser 3D printing and a preparation method of the aluminum-based in-situ composite material. The preparation method includes the steps that a mixture of Al-Si-Mg alloy powder and Al2O3 powder is prepared; the mixture is ball-milled through an intermittent ball-milling process; a three-dimensional CAD model established through a workpiece is subjected to layered slicing treatment; laser beams are adopted for scanning the laid powder line by line to form a two-dimensional section of the workpiece; and the steps are repeated till the workpiece is machined, and the aluminum-based in-situ composite material with an Al2Si4O10 reinforced element scattered on an Al matrix is formed. The operation method is easy and convenient to carry out, Al-Si-Mg alloy and Al2O3 generate the Al2Si4O10 reinforced phase in situ under the effect of high-energy lasers in the laser forming process, the interface wettability is improved, and then the interface strength of the composite material is enhanced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method for preparing carbon fiber surface zinc coat

A method for preparing zinc coating of carbon fiber surface belongs to the material technology field, the method adopts zinc sulfate as main salt, ammonium chloride as electric salt, aluminum sulfate and boric acid as buffering agent, dextrin as dispersing agent and H2O as solvent preparation acidic electroplating solution, the components and the percentage by weight of the electroplating solution are that: the zinc sulfate is 10%-40%, the ammonium chloride is 0.5%-40%, the aluminum sulfate is 1%-5%, the boric acid is 0.5%-3%, the dextrin is 0.5%-3%, the other is H2O. The method comprises the following steps: soaking the treated carbon fiber by the obtained acidic electroplating solution, then electrifying and electroplating the carbon fiber and forming the zinc coating, the thickness of the prepared coating is 2-7mu.m, the coating is plane, homogeneous and uneasy to be peeled off, the carbon fiber of the invention keeps the directionality and configuration as one aspect, simultaneously, the invention improves the soakage of the carbon fiber with basal body in composite material as the other aspect.

Owner:SHANGHAI JIAO TONG UNIV

Plating assistant agent additive for preventing plating leakage of steel wire hot galvanizing

ActiveCN101597732AGood interface wettabilityGood compatibilityHot-dipping/immersion processesAlcoholEther

The invention discloses a plating assistant agent additive for preventing plating leakage of steel wire hot galvanizing which comprises the following components in percentage by weight: 20-25% of fatty alcohol-polyoxyethylene ether, 20-26% of dodecyl phenyl polyoxyethyleneether, 8-14% of polyoxyethylene octylphenol ether, 3-6% of triethanolamine, 0.8-1.5% of carbamide and 30-36% of methyl alcohol. The method comprises the following steps: weighing the raw materials according to the proportioning of the additive, mixing and stirring the raw materials evenly to form the additive of the invention, adding the stock solution of the plating assistant agent additive of the invention into a slot according to a proportion that the amount of the added stock solution of the plating assistant agent additive accounts for 0.1-0.2% of the plating assistant agent bath solution, stirring evenly, and being able to use at the temperature of 70-75 DEG C. By adding the additive of the invention into the plating assistant agent, the wettability and the infiltrative of the plating assistant agent can be effectively enhanced, the plating effect on the surface of the steel wire is improved, and the plating leakage of the steel wire zinc plating is avoided.

Owner:巩义市恒星金属制品有限公司

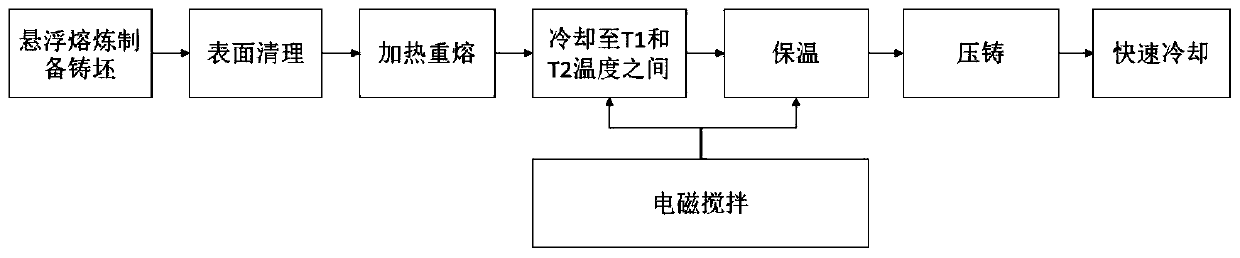

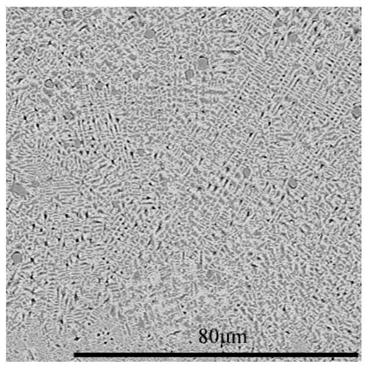

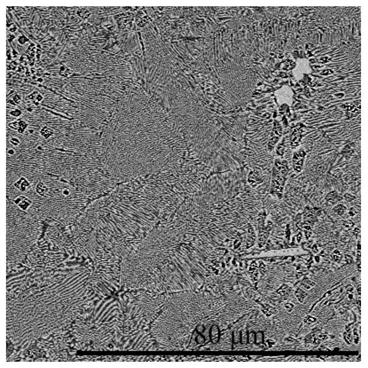

Refractory high-entropy alloy and forming method thereof

The invention relates to a refractory high-entropy alloy and a forming method thereof. The forming method comprises the steps of preparation of a refractory high-entropy alloy raw material, electromagnetic induction suspension smelting, high-frequency electromagnetic stirring of semi-solid slurry and die-casting forming. According to the method, suspension smelting, electromagnetic stirring and semi-solid forming are combined, the problem of serious component segregation commonly existing in high-entropy alloy is avoided, and a product with a fine and uniform microstructure and high density can be obtained.

Owner:苏州天峰动立合金科技有限公司

Method for performing surface modification on metal by ultrasonic nano-welding

ActiveCN102500912ATake full advantage of enhancementsGood interface wettabilityNon-electric welding apparatusMechanical bondMetal substrate

The invention relates to a method for performing surface modification on a metal by ultrasonic nano-welding and belongs to the technical field of nanomaterials. The method comprises the following steps: cleaning a to-be-treated region of the surface of the metal, coating a nanopowder material on the metal surface after cleaning, and performing ultrasonic nano-welding process on the nanopowder material on the metal surface to obtain a modified metal surface. The method is simple to operate and has controllable welding parameters. The nanomaterial and the welding region of the metal substrate form a local miscible body, leading to good interface infiltration, which enhances mechanical bonding effect and gives full play to reinforcement function of the nanomaterial. The nanomaterial is distributed densely and uniformly on the metal surface, and the surface is smooth and clean and has no cracks or air hole.

Owner:SHANGHAI JIAO TONG UNIV

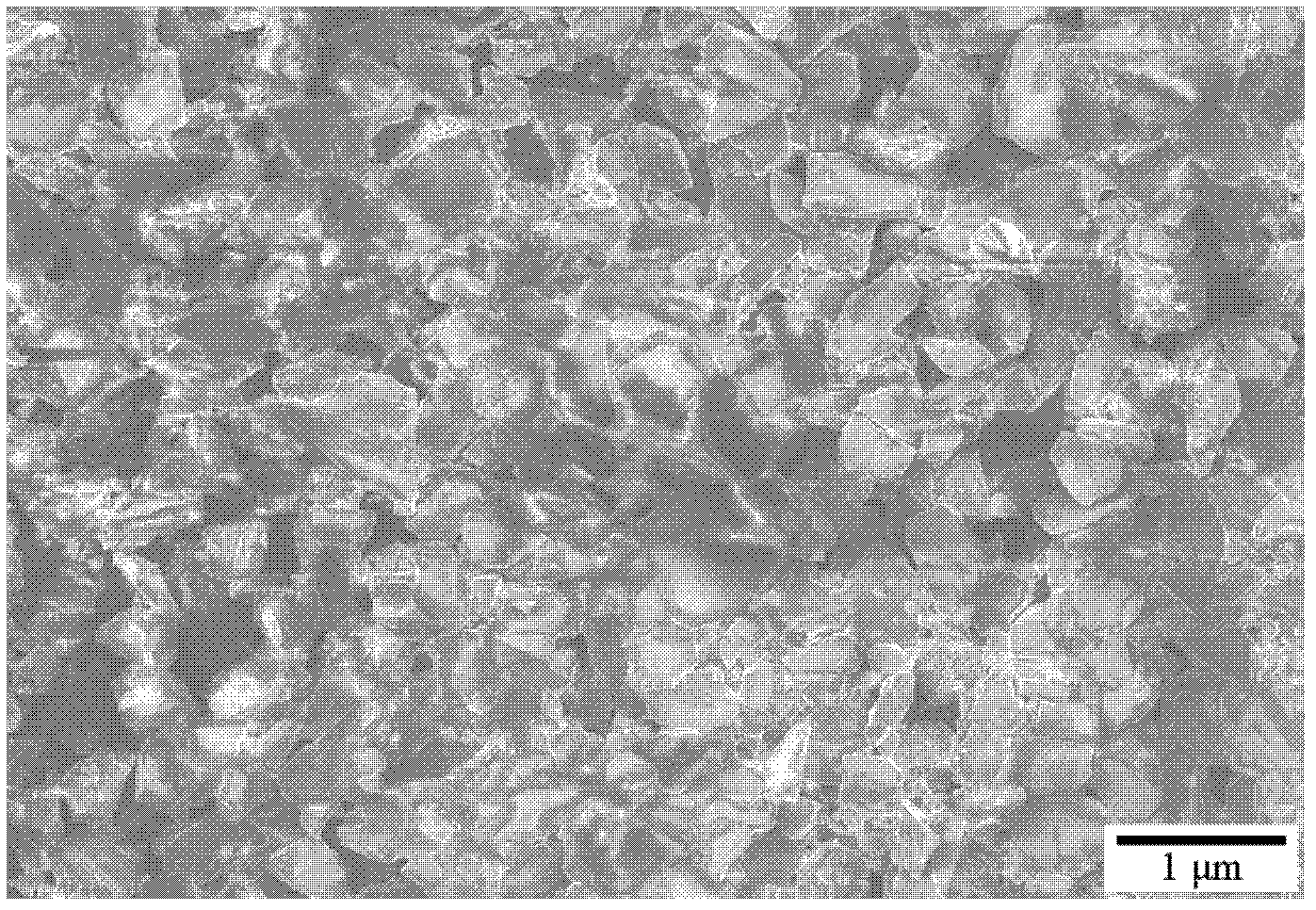

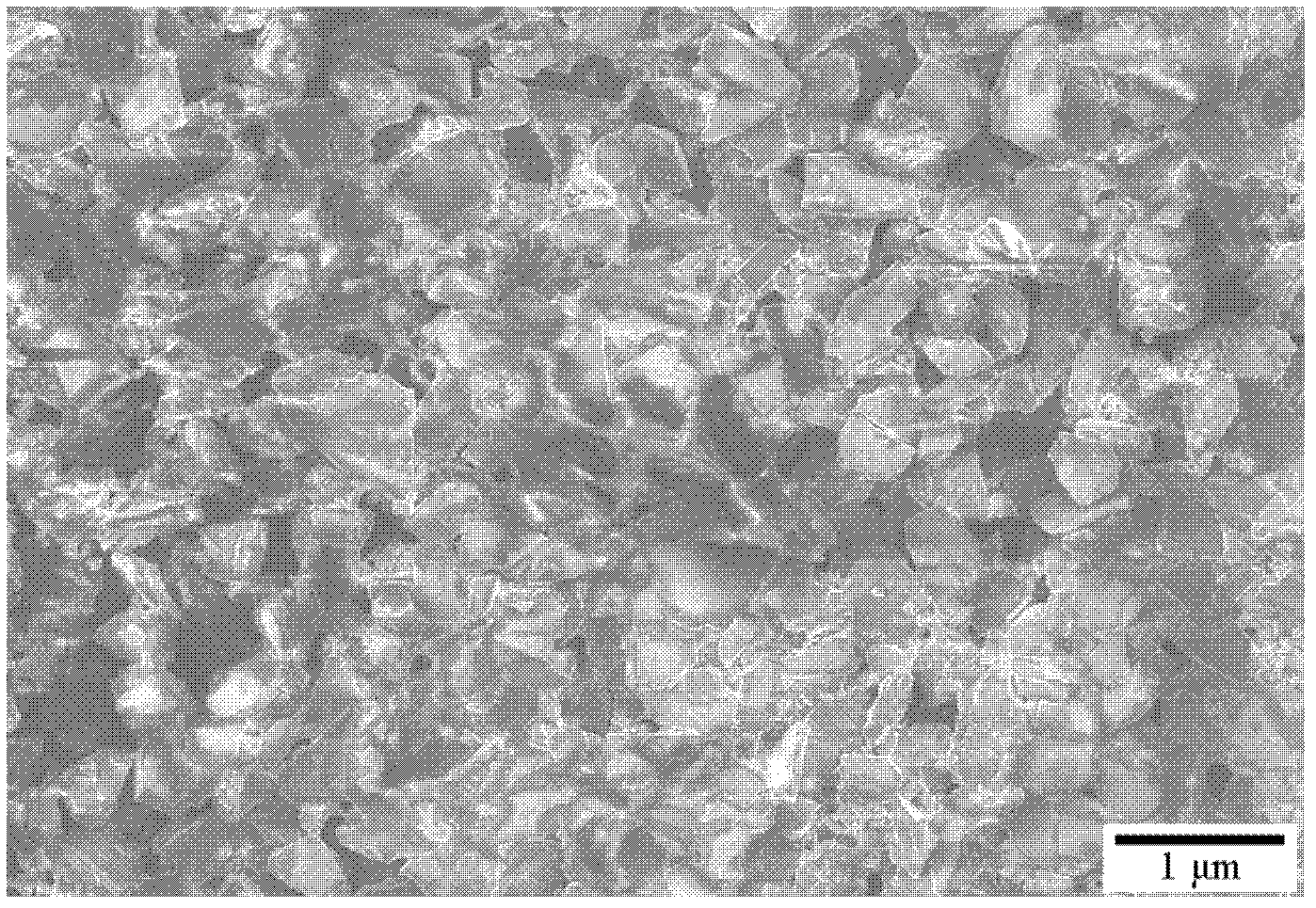

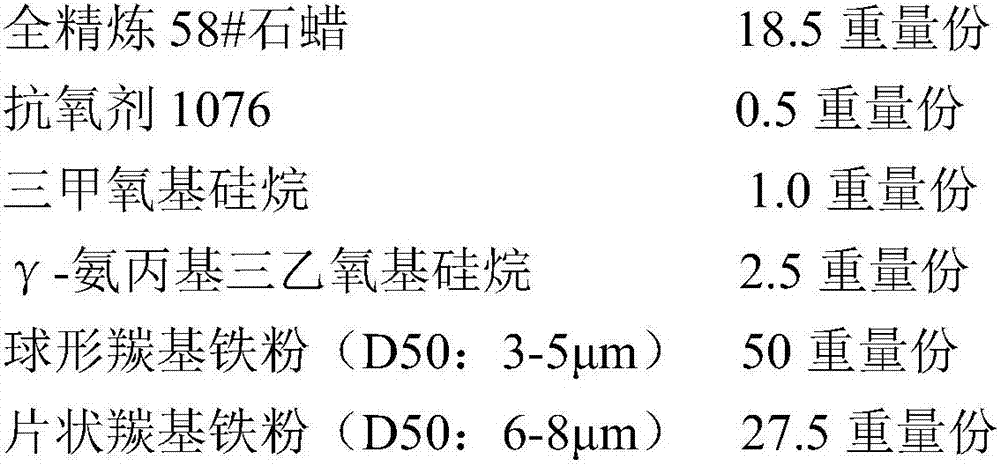

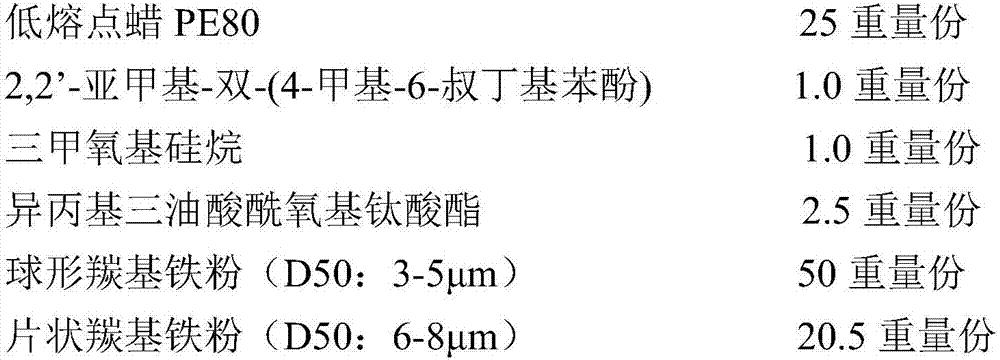

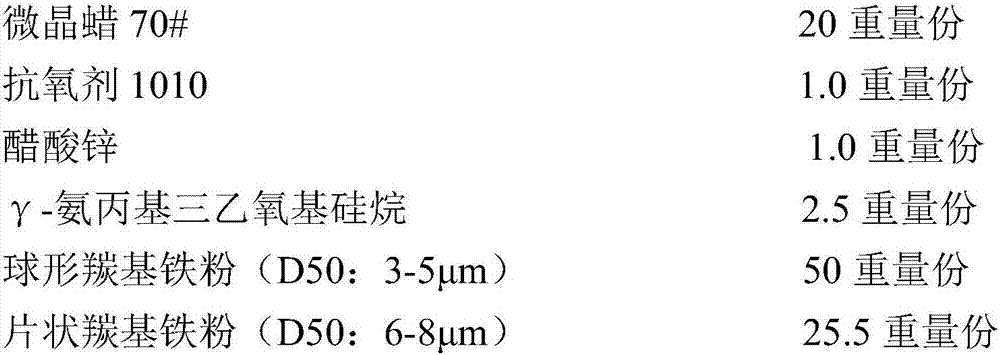

Phase change wave-absorption and heat-conducting material as well as preparation method and application thereof

InactiveCN108003841AExcellent interface wetting abilityGood interface wettabilityMagnetic/electric field screeningHeat-exchange elementsAntioxidantPhase-change material

The invention provides a phase change wave-absorption and heat-conducting material and a preparation method thereof. The phase change wave-absorption and heat-conducting material is prepared from thefollowing components in parts by weight: 15 to 25 parts of a basic phase change material, 0.1 to 5 parts of an antioxidant, 0.1 to 5 parts of a crosslinking agent, 0.1 to 5 parts of a coupling agent and 60 to 85 parts of wave-absorption and heat-conducting particles, wherein the solid-liquid phase transformation point of the basic phase change material is 40 to 80 DEG C. The phase change wave-absorption and heat-conducting material can be used for dissipating heat of electronic equipment.

Owner:HEFEI LCFC INFORMATION TECH

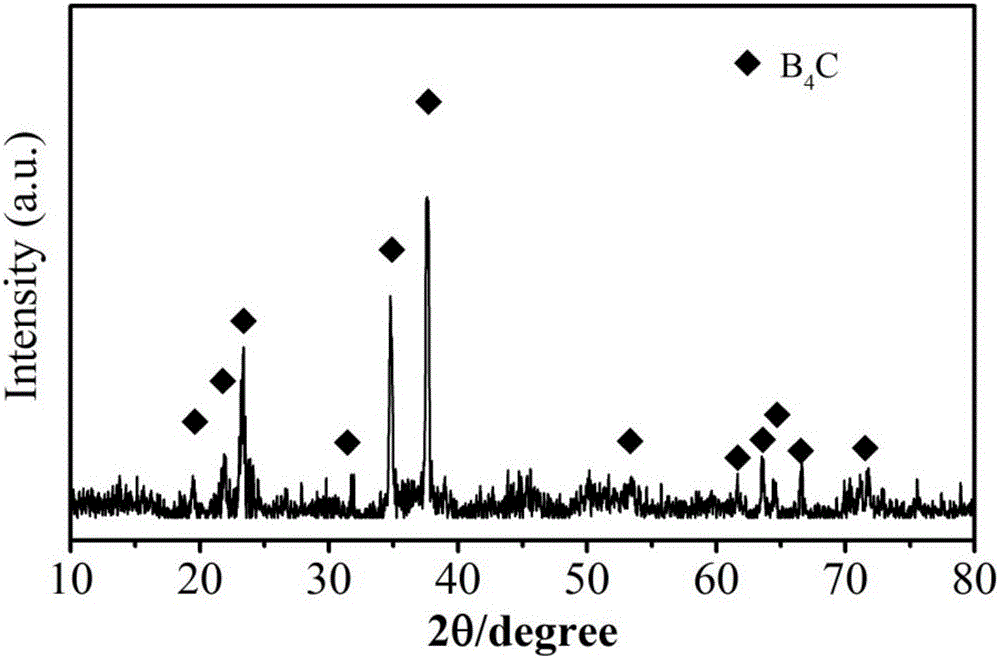

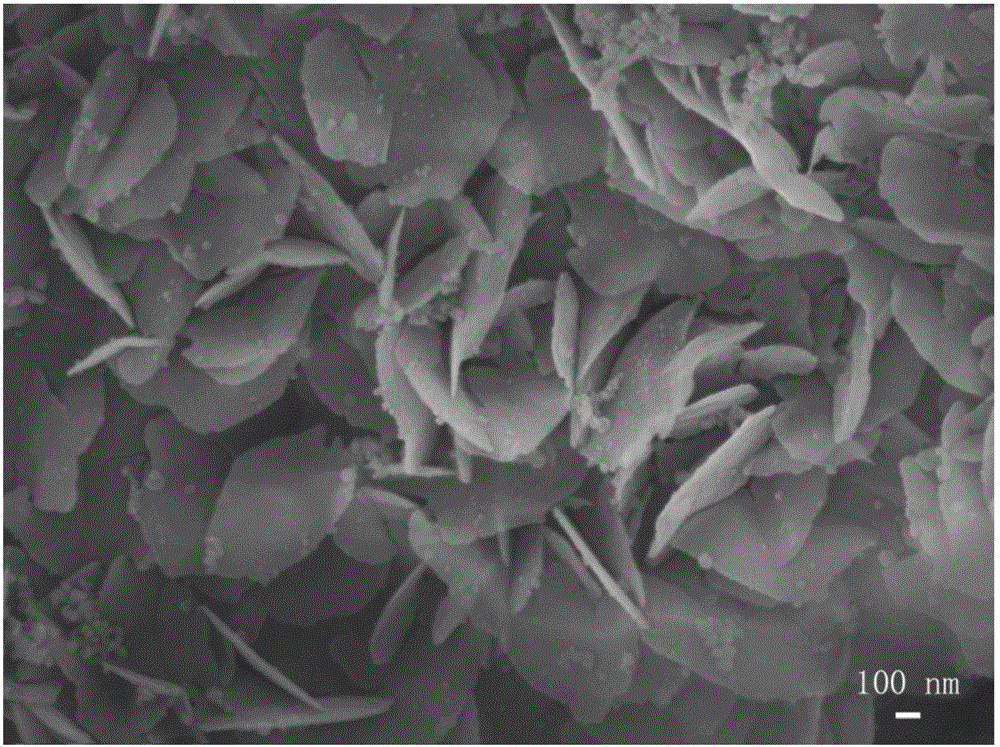

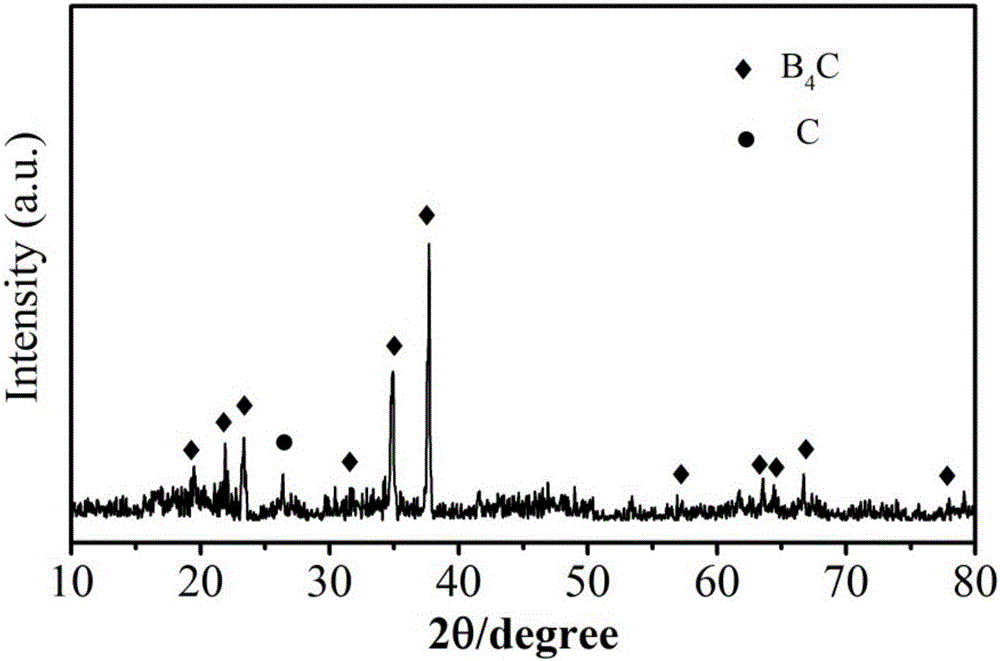

Preparation method of B4C nanosheet and B4C nanosheet

ActiveCN106082228ALarge specific surface areaImprove electrochemical performanceNanotechnologySodium bicarbonatePlasma effect

The invention discloses a preparation method of a B4C nanosheet and the B4C nanosheet. The preparation method comprises: 1) taking boric acid, coal dust and sodium carbonate or sodium bicarbonate to conduct ball-milling to obtain mixed powder, wherein the adding mass of sodium carbonate or sodium bicarbonate accounts for 3%-10% of the total mass of boric acid and coal dust; 2) subjecting the obtained mixed powder to pre-press molding, and then performing cold isostatic pressing to obtain flake object; and 3) imbedding the obtained flake object into quartz sand to conduct microwave sintering, thus obtaining the B4C nanosheet. According to the method, boric acid, coal dust and sodium carbonate or sodium bicarbonate are subjected to ball-milling mixing, pre-press molding and cold isostatic pressing are carried out, then the product is subjected to microwave sintering, by utilizing the excellent wave-absorbing properties of carbon and the plasma effect of gas during microwave sintering, the method realizes rapid synthesis of B4C nanosheet. The obtained B4C nanosheet has good crystallinity, small thickness, and high yield and purity; the sintering time is short, the sintering temperature is low, and a lot of energy is saved. The process is simple, is convenient to operate, and is suitable for industrial rapid production, thus having broad application prospects.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

Preparation method of graphene/flat cocoon toughened carbon fiber composite material

The invention relates to the technical field of composite material preparation, and discloses a preparation method of a graphene / flat cocoon toughened carbon fiber composite material, which comprises the following steps: 1) enabling silkworms to spin in a two-dimensional plane to prepare flat cocoons with different areas and thicknesses, the size and the thickness of the flat cocoons being adjusted by changing the number of matured silkworms and the spinning time. According to the preparation method of the graphene / flat cocoon toughened carbon fiber composite material, flat cocoons with a natural cocoon shell structure are prepared by utilizing the spinning instinct of silkworms, the size and the thickness of the flat cocoons can be adjusted by changing the number of matured silkworms and the spinning time, and the flat cocoons are fluffy and soft in structure and can be freely cut; graphene / flat cocoon prepregs and graphene / carbon fiber prepregs are prepared by using a method of doping epoxy resin into graphene nanosheets, are alternately laid in a certain arrangement mode and proportion, and are hot-pressed and cured to obtain the carbon fiber composite material with an excellent toughening effect.

Owner:SOUTHWEST UNIVERSITY

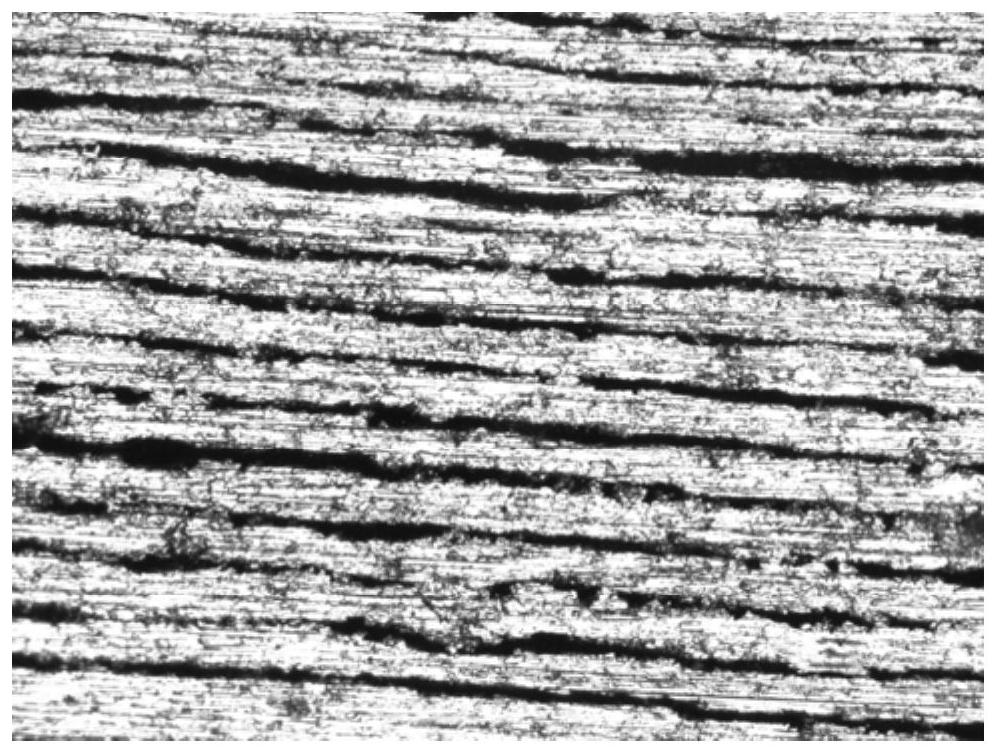

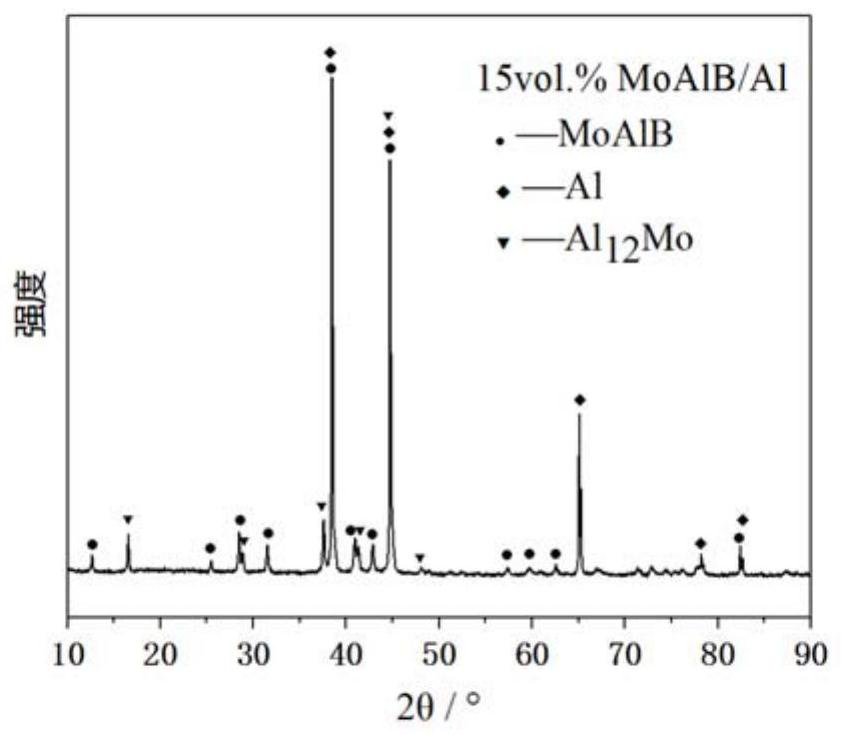

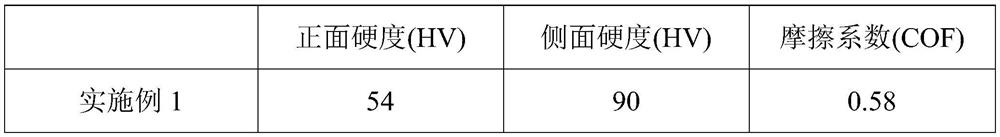

MAB phase ceramic-metal layered composite material as well as preparation method and application thereof

ActiveCN111873570AImprove antioxidant capacityThere will be no shortened lifespanLaminationLamination apparatusSlurryCeramic metal

The invention provides an MAB phase ceramic metal layered composite material and a preparation method and application thereof. The composite material comprises metal layers and MAB phase layers whichare alternately stacked, wherein the MAB phase layers are attached to the metal layers; the preparation method of the composite material comprises the following steps: preparing MAB phase slurry; coating the MAB phase slurry on the surface of a metal substrate; drying and curing the metal base material coated with the MAB phase slurry, and then performing lamination to obtain a laminated blank; preprocessing the laminated blank to obtain a pre-product; and sintering the pre-product, and cooling the sintered product along with the furnace to obtain the MAB-phase ceramic metal layered compositematerial. The composite material has the advantages of high interface strength, light weight, high strength, wear resistance and corrosion resistance, and can meet the application requirements in thefields of carrying tools, power transmission and transformation or military materials.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for preparing copper / graphite conductive slide plate material

The invention relates to a method for preparing a copper / graphite conductive slide plate material, and belongs to the technical field of electric locomotive contact slide materials. The method adopts a technology combining ball-milling of mixed powder, powder forming and sintering, molding machining and reshaping to prepare the copper / graphite conductive slide plate material. The method can utilize existing production equipment, is less in investment, low in production cost, can sufficiently improve the interface wetting property of graphite and a copper substrate, and thus the copper-based slide plate material which is excellent in self lubricity and electric conductivity is obtained.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method of botanical herbicide water aqua

InactiveCN108991025ASimple processing technologyLow equipment requirementsBiocideAnimal repellantsSoil treatmentRoot growth

The invention relates to a preparation method of a botanical herbicide water aqua, and belongs to the field of botanical pesticides. The botanical herbicide water aqua disclosed by the invention is composed of the following components by mass: 5-40% of an effective component, which is an herbicide active component obtained through column chromatography of an extract of sapindus mukorossi exotesta,1-5% of an anti-freezing agent, 2-6% of a surfactant and the balance of water, wherein the total amount of the components is 100%. The herbicide disclosed by the invention can be used for soil treatment after seeding is carried out and before seedlings grow out, root growth of weeds can be effectively inhibited, and prevention and removal of field weeds can be realized. Compared with the prior art, the botanical herbicide disclosed by the invention has the advantages of safety, high efficiency, low toxicity, no pollution, environment friendliness, no easy generation of herbicide resistance, and the like, and has a wide application prospect.

Owner:INT CENT FOR BAMBOO & RATTAN

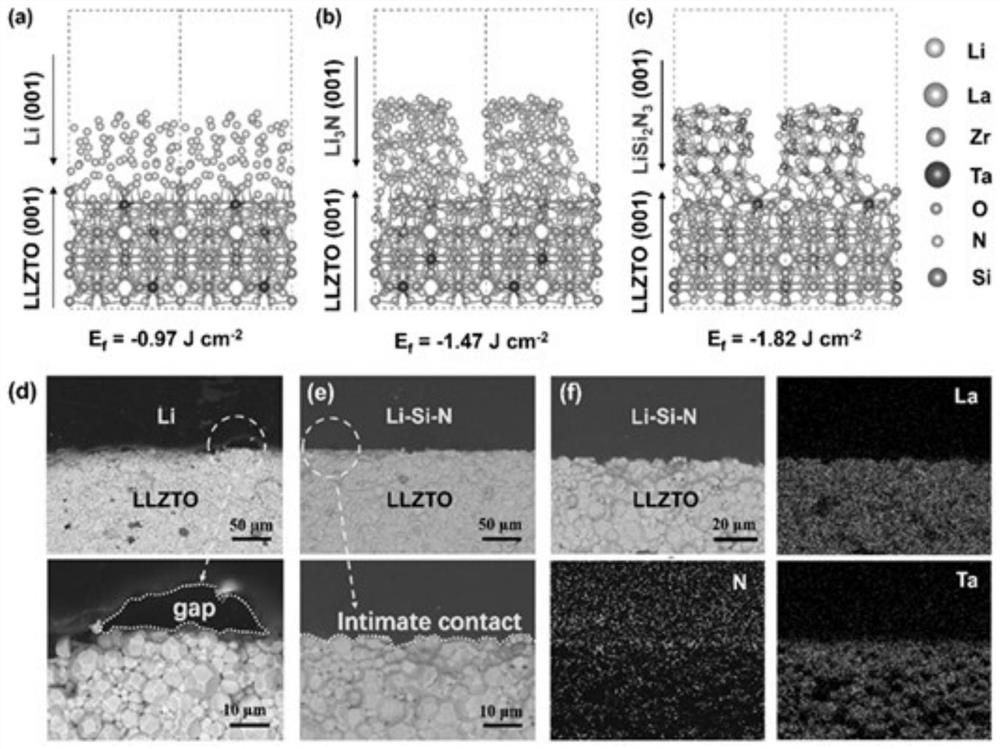

Molten lithium battery negative electrode material, preparation method and all-solid-state lithium battery

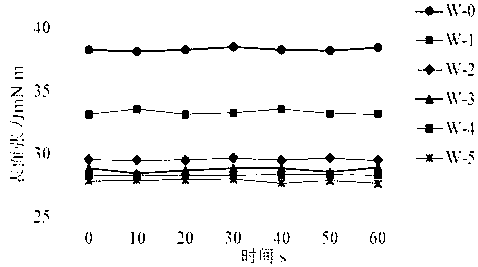

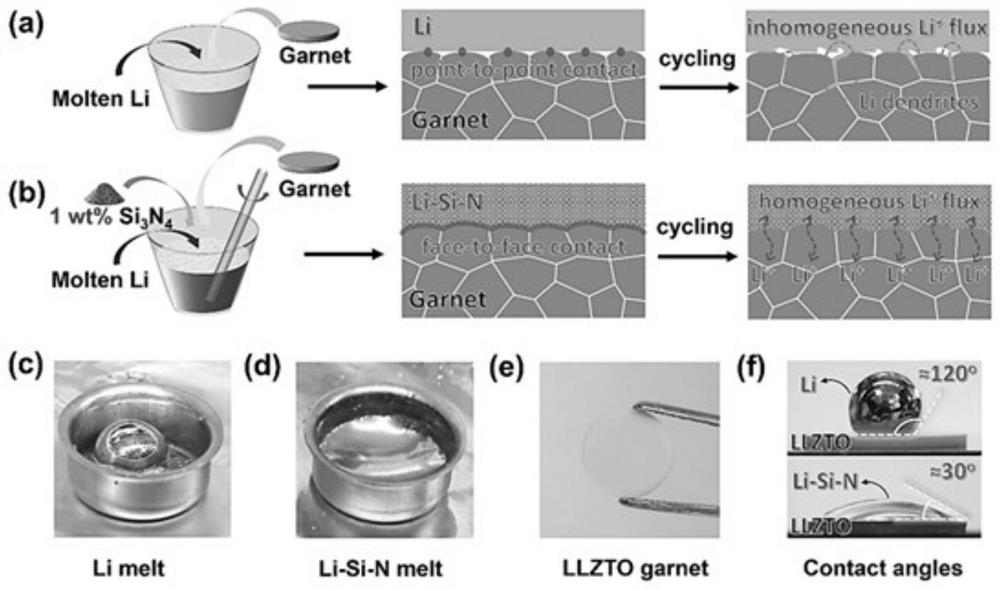

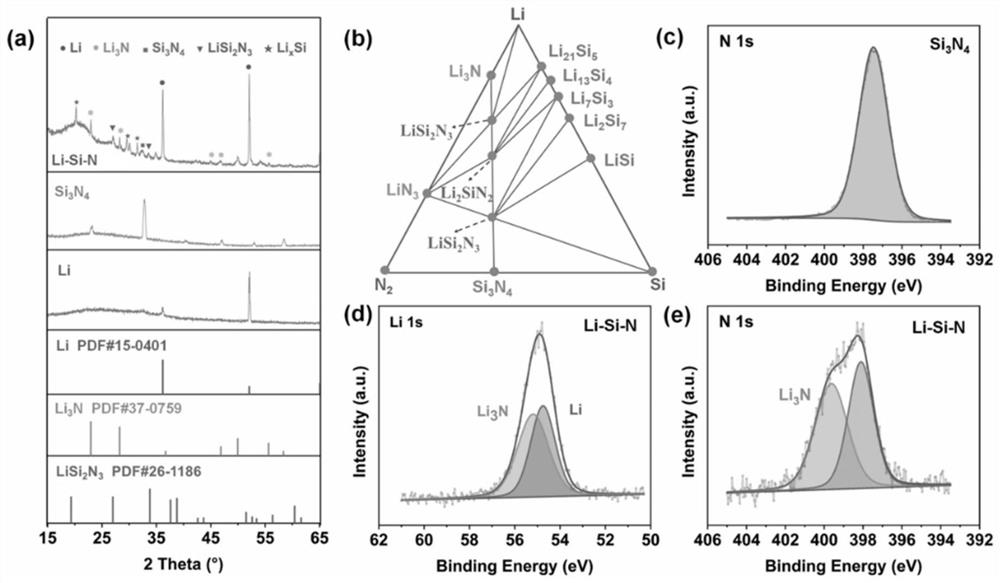

InactiveCN113258048AReserved useGood interface wettabilityNegative electrodesLi-accumulatorsMetallic lithiumAll solid state

The invention provides a molten lithium battery negative electrode material, a preparation method and an all-solid-state lithium battery. A small amount of Si3N4 is added into molten Li to adjust the surface tension of the molten Li, and the molten Li-Si-N after reaction can change point contact of lithium and a garnet interface into surface contact, so that the wettability of a garnet electrolyte and metal lithium is improved, the interface impedance of the two is reduced, and a uniform electric field is provided for lithium deposition and stripping processes. After being assembled into a symmetrical battery, the material shows excellent cycling stability (stably cycling for 1500 hours under the current density of 0.2 mA cm <-2 > and stably cycling for 1000 hours under the current density of 0.4 mA cm <-2 >) and relatively high critical current density (1.8 mA cm <-2 >). The first specific discharge capacity of the assembled all-solid-state battery under the current density of 2C reaches up to 145mA h g <-1 >, and the capacity is kept at 97% after 100 cycles under the current density of 1C.

Owner:NANJING UNIV OF TECH

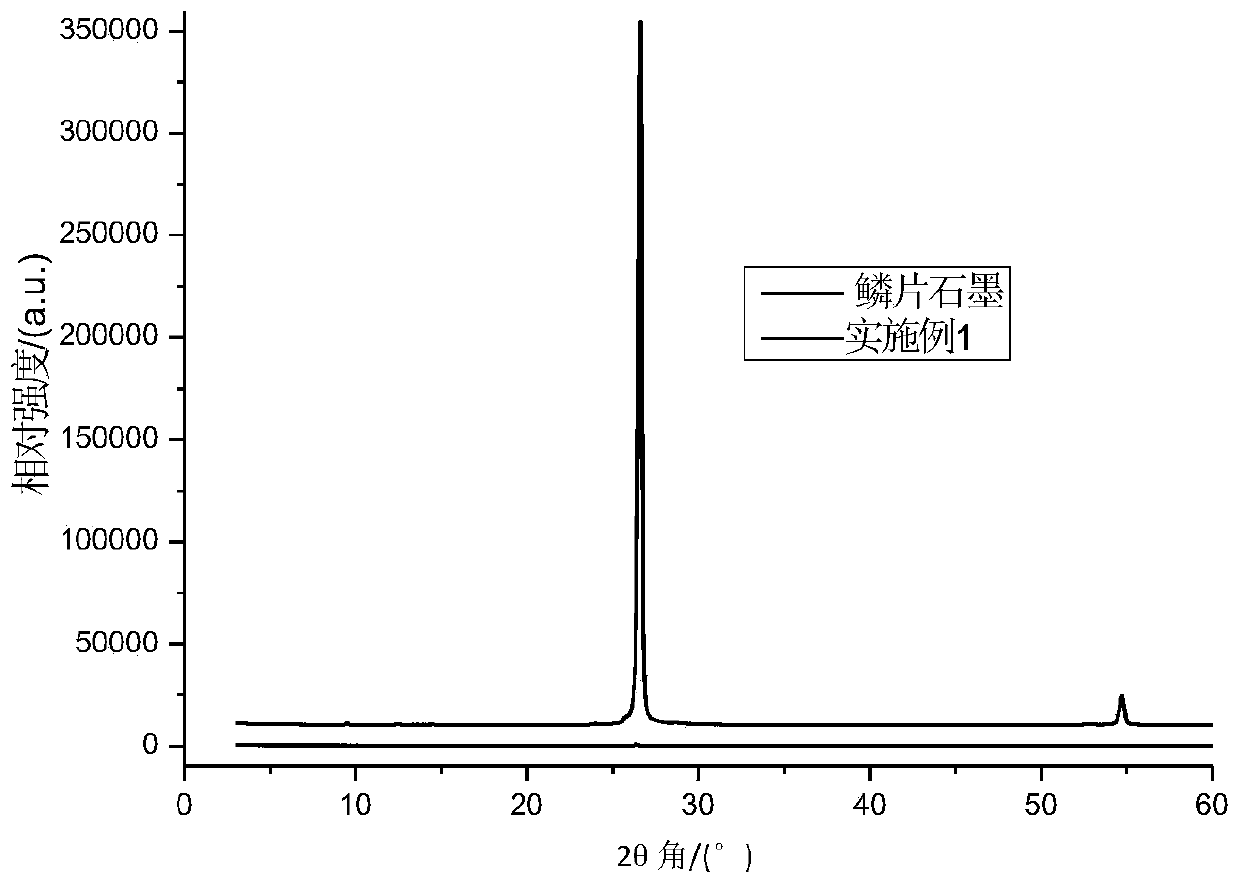

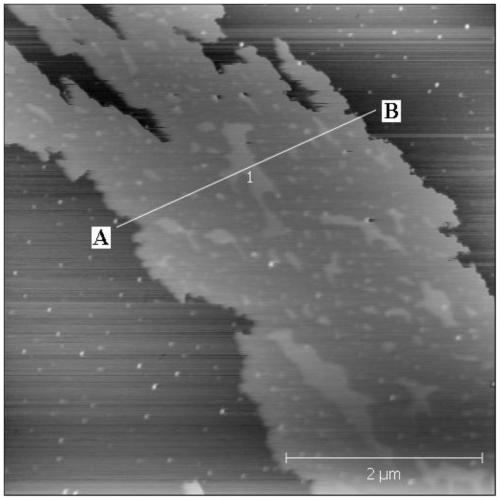

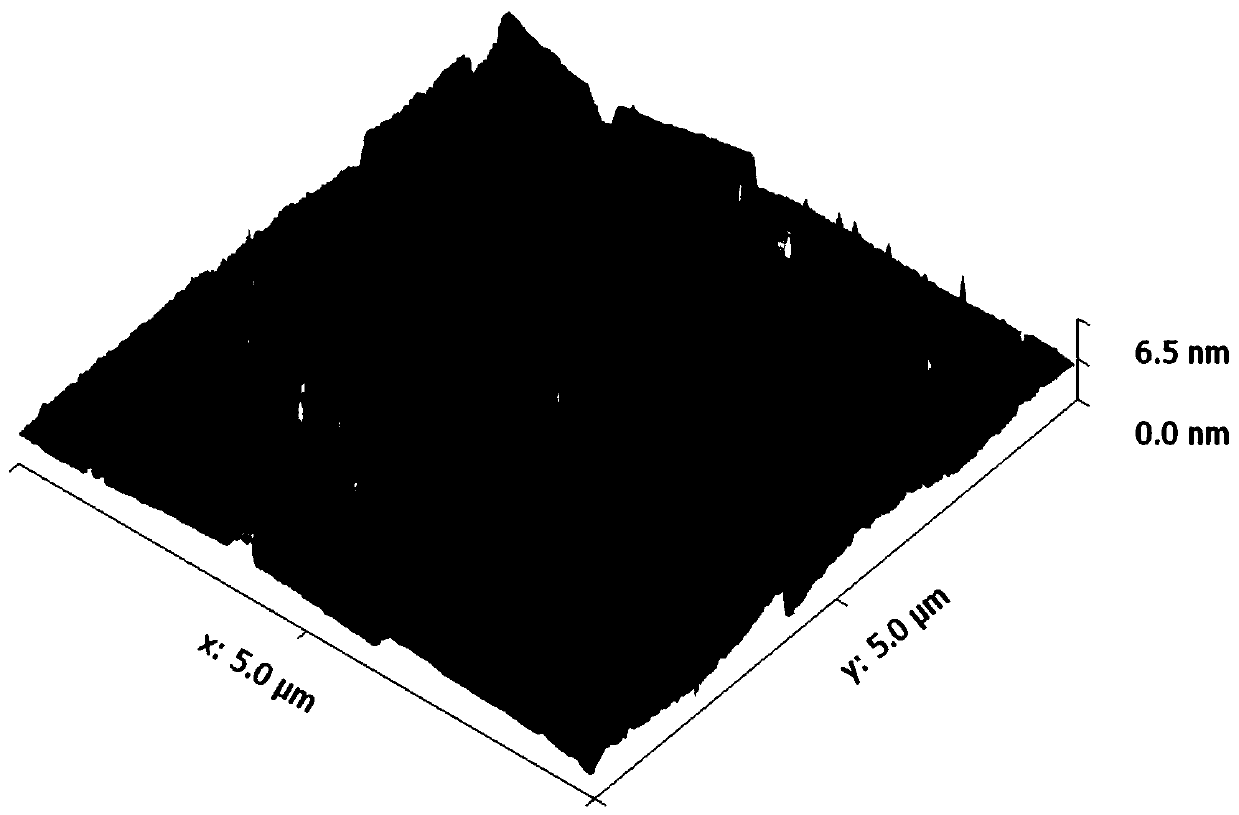

Method for preparing graphene by stripping flake graphite with liquid rubbers

The invention relates to a method for preparing graphene by stripping flake graphite with liquid rubbers. According to the method, different kinds of liquid rubbers are mixed with the flake graphite, through the mechanical shear force of grinding equipment such as a disc mill, a colloid mill, a stripper and a vibration mill and by combining with wetting agent which can strengthen and wet the surface of the flake graphite, the flake graphite can be rapidly stripped into graphene rubber latex in a single-layer or few-layer structure. The method can help obtain graphene compounded latex blocks containing higher than 30% of graphene, and during application, strong acids, strong bases, strong oxidants and toxic substances are avoided, so that the demands on green and healthful development of environment and economy can be met.

Owner:HEBEI UNIV OF TECH

Plating assistant agent additive for preventing plating leakage of steel wire hot galvanizing

ActiveCN101597732BGood interface wettabilityGood compatibilityHot-dipping/immersion processesAlcoholAlkylphenol

Owner:巩义市恒星金属制品有限公司

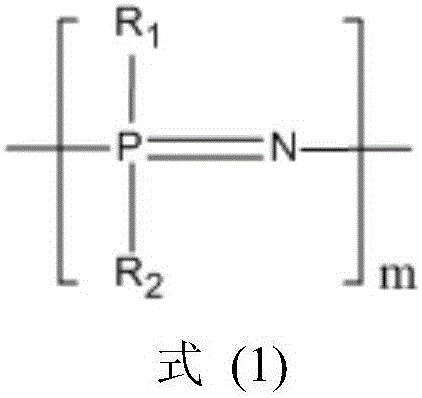

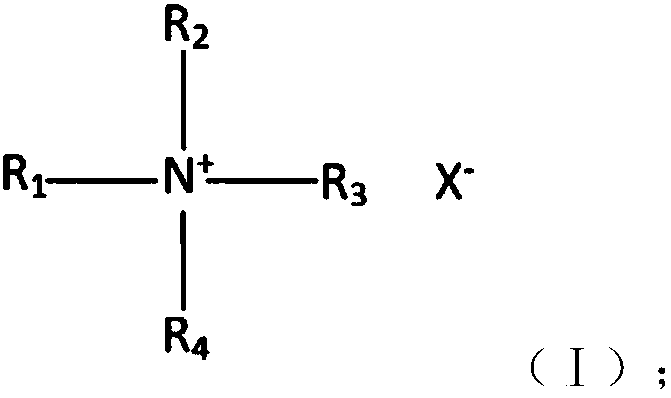

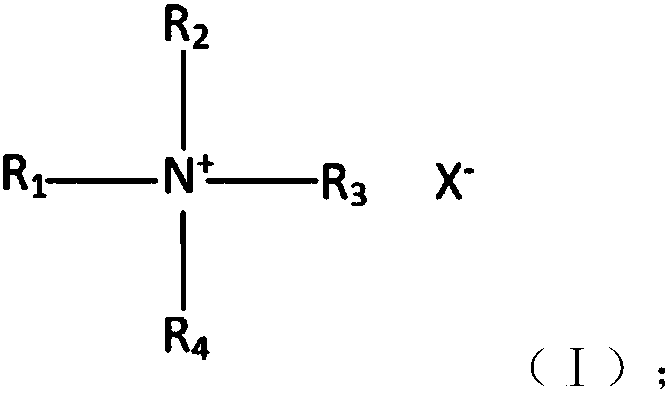

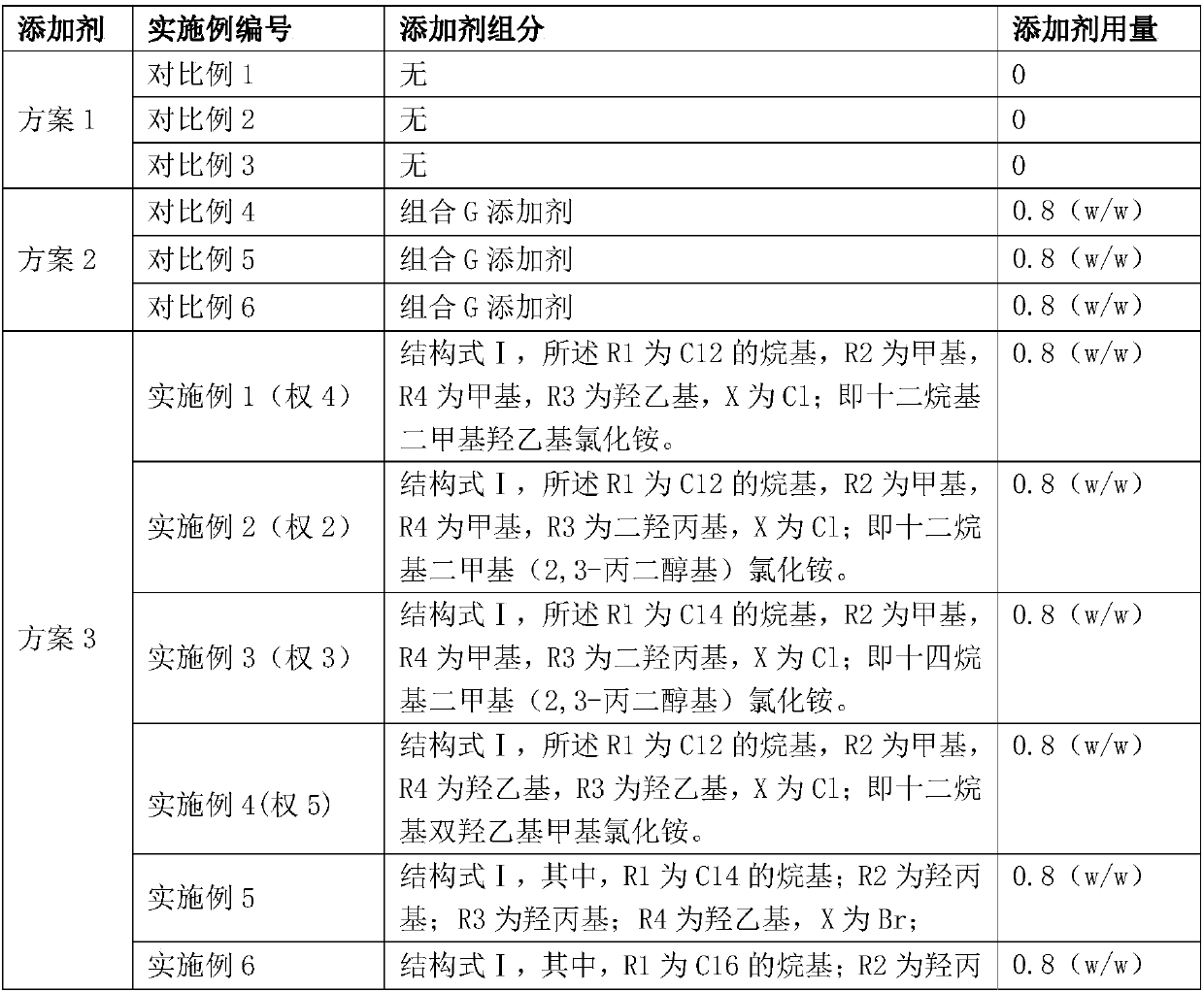

Additive for plating assisting, plating assisting solution and hot-dip plating method

ActiveCN107699833AReduce the amount of adhesionGood interface wettabilityHot-dipping/immersion processesOrganic chemistryMaterial consumptionMethyl group

The invention relates to an additive for plating assisting, a plating assisting solution and a hot-dip plating method in the technical field of chemical engineering. The additive for plating assistingcomprises a chemical compound which is as shown in the formula I (Please see the formula I in the specification.), wherein R1 represents C12-16 alkyl radical, R2 represents methyl or hydroxypropyl, R3 represents one of hydroxyethyl, hydroxypropyl and dihydroxy propyl, R4 represents one of methyl, hydroxyethyl and dihydroxy propyl, and X represents one of Cl, Br and I. According to the additive, better interface wettability between molten coated metal and workpieces can be achieved, and skip plating is prevented; and meanwhile, the adhesion amount of a plating assisting agent is reduced, the drying process is accelerated, the risk of accidents such as scalds is reduced, the dip plating time is shortened, and material consumption is reduced.

Owner:JIANGSU FEITUO INTERFACE ENG TECH CO LTD

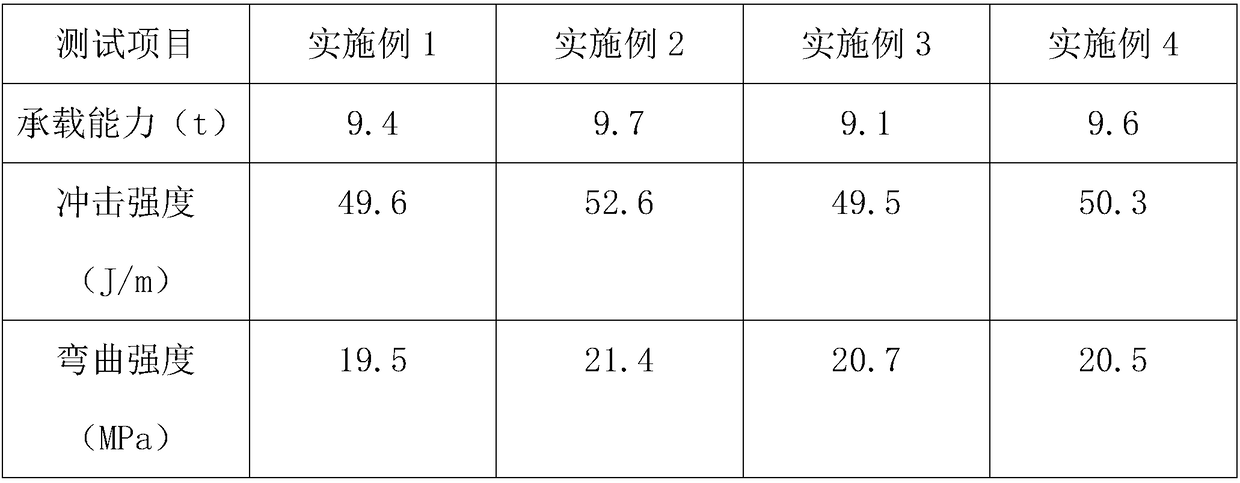

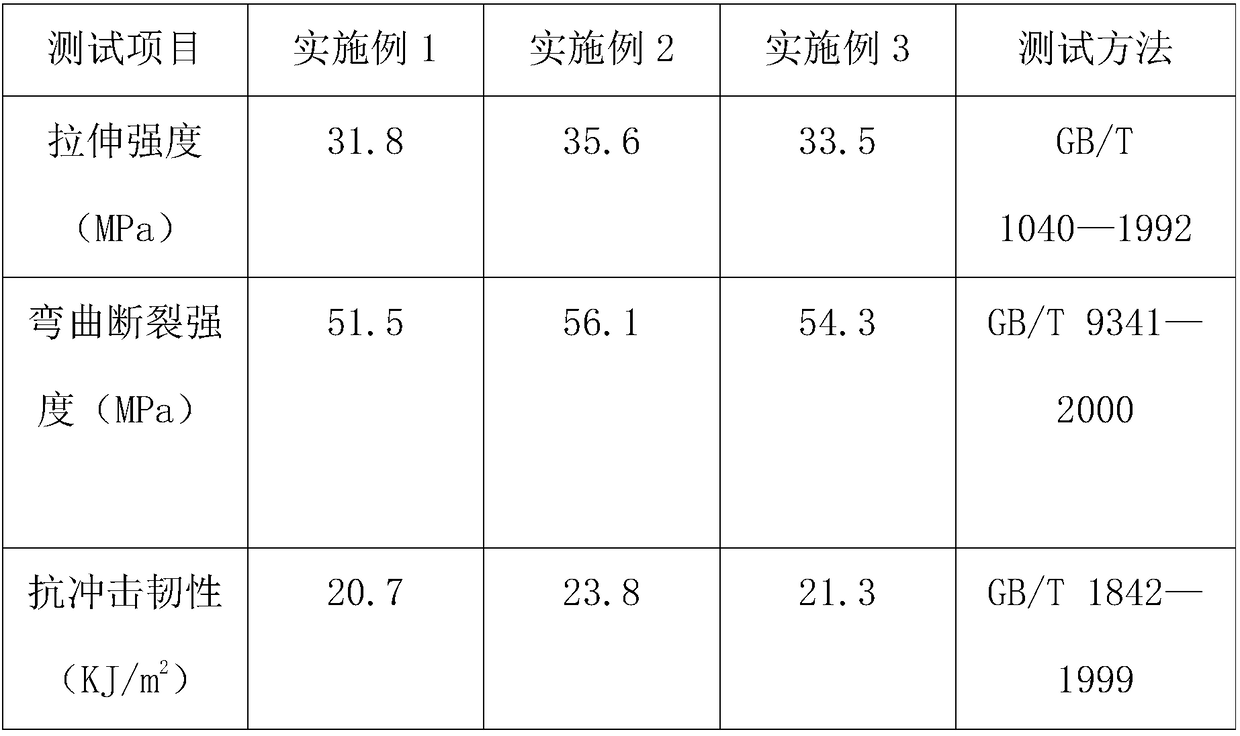

A high-strength wood-plastic tray

The invention relates to the technical field of plastic product production, and particularly discloses a high-strength wood-plastic tray. The tray is prepared from, by weight, 60-80 parts of modifiedcotton stalk powder, 50-70 parts of regenerated polypropylene, 1-5 parts of maleic anhydride grafted polypropylene, 0.5-2 parts of phthalic acid, 1-2 parts of zinc stearate, 1-2 parts of polypropylenewax, 0.2-1 part of diphenylamine, 0.2-1 part of an antioxidant 1010, 0.5-1 part of azobisformamide, 3-7 parts of muscovite, 1-10 parts of nanometer calcium carbonate, 2-8 parts of glass fibers and 2-8 parts of carbon fibers. The tray is prepared by utilizing the agricultural waste cotton stalks and the regenerated polypropylene so that ecologic benefit and economic benefit are high, and the prepared tray is high in strength.

Owner:WUHU ASIA PACIFIC GENERAL TRAY PACKING CO LTD

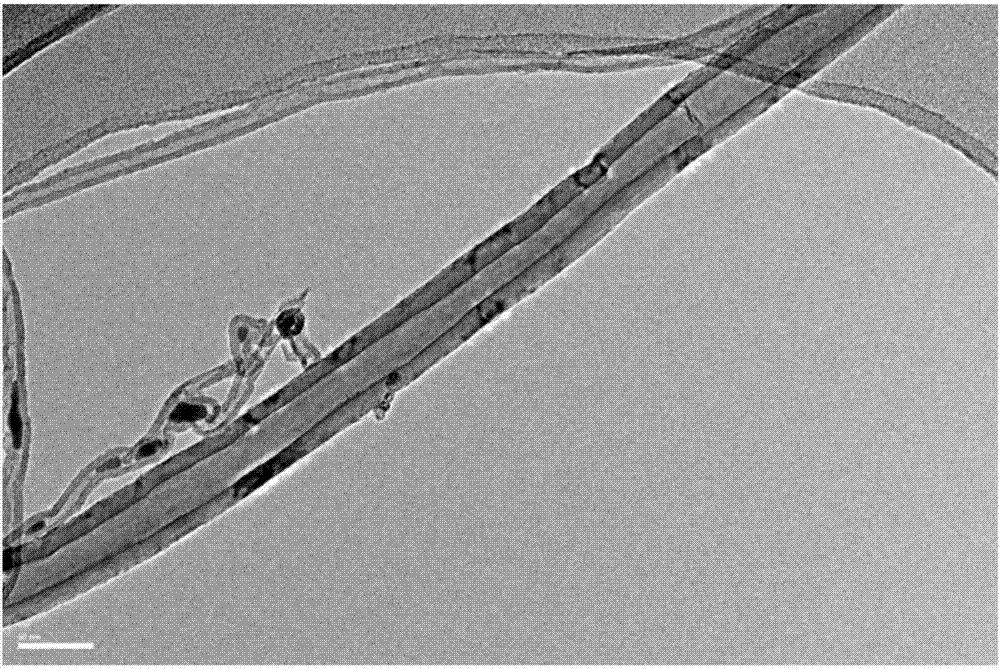

Boron carbide coated carbon nanotube and preparation method and application thereof

The invention relates to a boron carbide coated carbon nanotube and a preparation method and application thereof, and belongs to the technical field of functional materials. The preparation method ofthe boron carbide coated carbon nanotube includes the following steps that S1, a solution A of boric acid and trihydroxypropane is prepared; S2, carbon nanotube slurry B is prepared; S3, the carbon nanotube slurry B is added into the solution A, stirring and heating in a water bath are carried out after ultrasonic treatment, and uniformly mixed paste C of carbon nanotube, boric acid and trihydroxypropane is obtained; S4, the paste C is placed an inert gas atmosphere and heated to dehydrate the boric acid, trihydroxypropane is carbonized simultaneously, and the boron oxide / amorphous carbon coated carbon nanotube powder is obtained; and S5, the boron oxide / amorphous carbon coated carbon nanotube powder is loosely packed in a high-pressure reactor, vacuumzing is carried out, inert gas is introduced and then heating is carried out to 1400-1500 DEG C, heat is preserved for 1-5 hours, and then cooling is carried out naturally, that is, the carbon boron oxide coated carbon nanotube powder isobtained. According to the boron carbide coated carbon nanotube and the preparation method and application thereof, the interface binding ability of the carbon nanotube and aluminum alloy materials isimproved by synthesizing a boron carbide coating on the surface of a carbon nanotube.

Owner:SUZHOU FIRST ELEMENT NANO TECH

Polyurethane elastic fiber with thermal insulation performance and preparation method thereof

ActiveCN104153034BEvenly dispersedReduce lossMonocomponent synthetic polymer artificial filamentPigment physical treatmentFiberThermal insulation

A polyurethane elastic fiber with thermal insulation performance and a preparation method thereof. A ceramic powder of nanometer level as an insulation additive is mixed with polyurethane fiber, wherein the dosage of ceramic powder is 0.1-10% of the weight of polyurethane fiber. The barrier and reflection effects of ceramic powder on heat radiation are utilized to reduce heat loss; a low temperature plasma irradiation technology is used for modification treatment on the powder surface, so that the ceramic powder shows good dispersion effect and interface combination effect in polyurethane. The polyurethane prepared by the method has excellent thermal insulation performance, is especially suitable for weaving fabrics for winter underwear, and elastic fabrics such as knee pads, wrister and waistband, etc.

Owner:ZHEJIANG HUAFENG SPANDEX

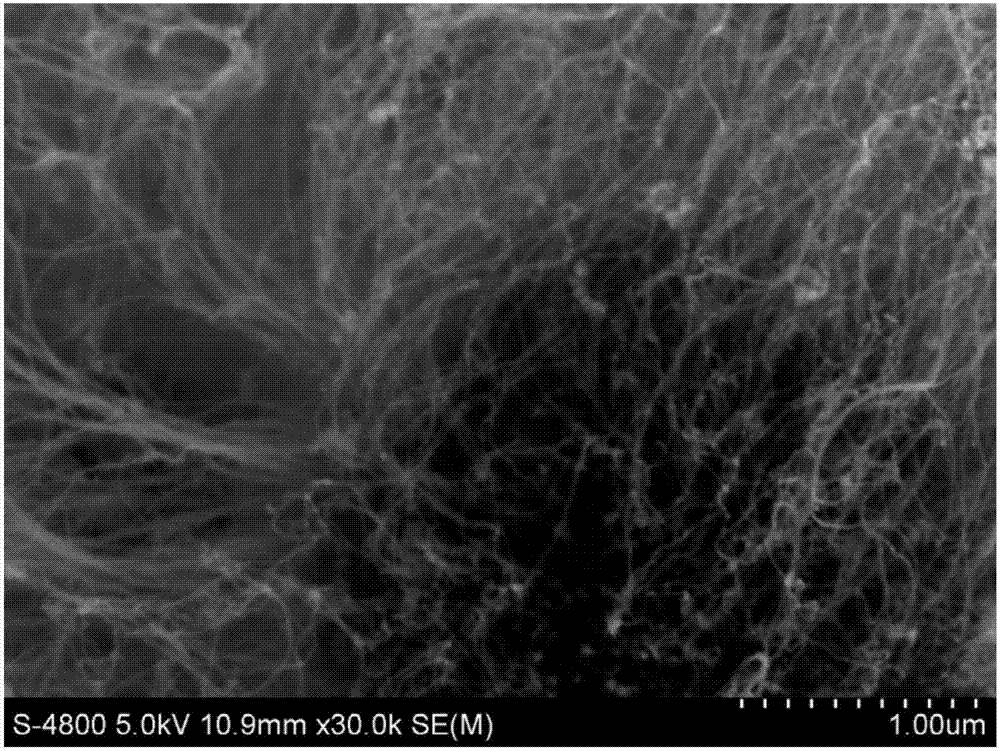

Preparation method of carbon nanotube-alumina hybrid reinforced magnesium-aluminum alloy composite material

InactiveCN106498225BSuppresses structural damageEvenly dispersedMaterial nanotechnologyChemical vapor deposition coatingMagnesium matrix compositeNano al2o3

The preparation method of the carbon nanotube-alumina hybrid reinforced magnesium-aluminum alloy composite material of the present invention relates to the manufacture of an alloy containing non-metallic fibers or whiskers by impregnating molten metal with fibers or whiskers and particles, and is a method of producing alloys containing non-metallic fibers or whiskers by floating catalysis In-situ growth of carbon nanotubes on spherical nano-alumina and aluminum particles to prepare in-situ composite carbon nanotube-alumina and in-situ composite carbon nanotube-aluminum hybrid reinforcement phase, and carbon nanotube-oxidation was prepared by pressure infiltration process The method of aluminum hybrid reinforced magnesium-aluminum alloy composite material overcomes the poor synthesis effect of carbon nanotubes in the prior art, poor dispersion effect in the magnesium matrix, prone to structural damage, poor wettability of the reinforcing phase-matrix interface, and easy formation of a weak interface The scale or structure of the combination and composite reinforcement phase makes it unsuitable as a reinforcement phase of magnesium-based composites, resulting in the failure of the excellent reinforcement effect of carbon nanotubes to be fully utilized, and the defects of low comprehensive mechanical properties of magnesium-based composites.

Owner:HEBEI UNIV OF TECH

Wood-plastic composite tray

The invention relates to the technical field of processing of plastic products, and particularly discloses a wood-plastic composite tray. The wood-plastic composite tray comprises the following raw materials in parts by weight: 30-50 parts of a plastic base material, 50-70 parts of modified wood flour, 0.1-2 parts of a coupling agent, 0.1-1 part of a lubricating agent, 0.1-1.5 parts of an antioxidant and 0.1-1 part of a coloring agent. The modified wood flour is obtained by carrying out enzymolysis on wood flour by using pectinase and cellulase and then soaking the wood flour by using a NaOH solution. The mechanical property of the prepared wood-plastic composite tray is excellent, and the ecological benefit and economic benefit are high.

Owner:WUHU ASIA PACIFIC GENERAL TRAY PACKING CO LTD

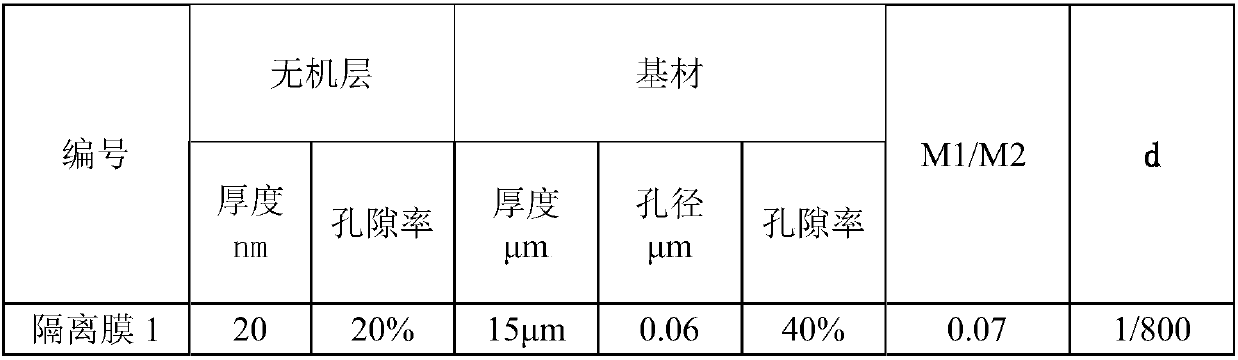

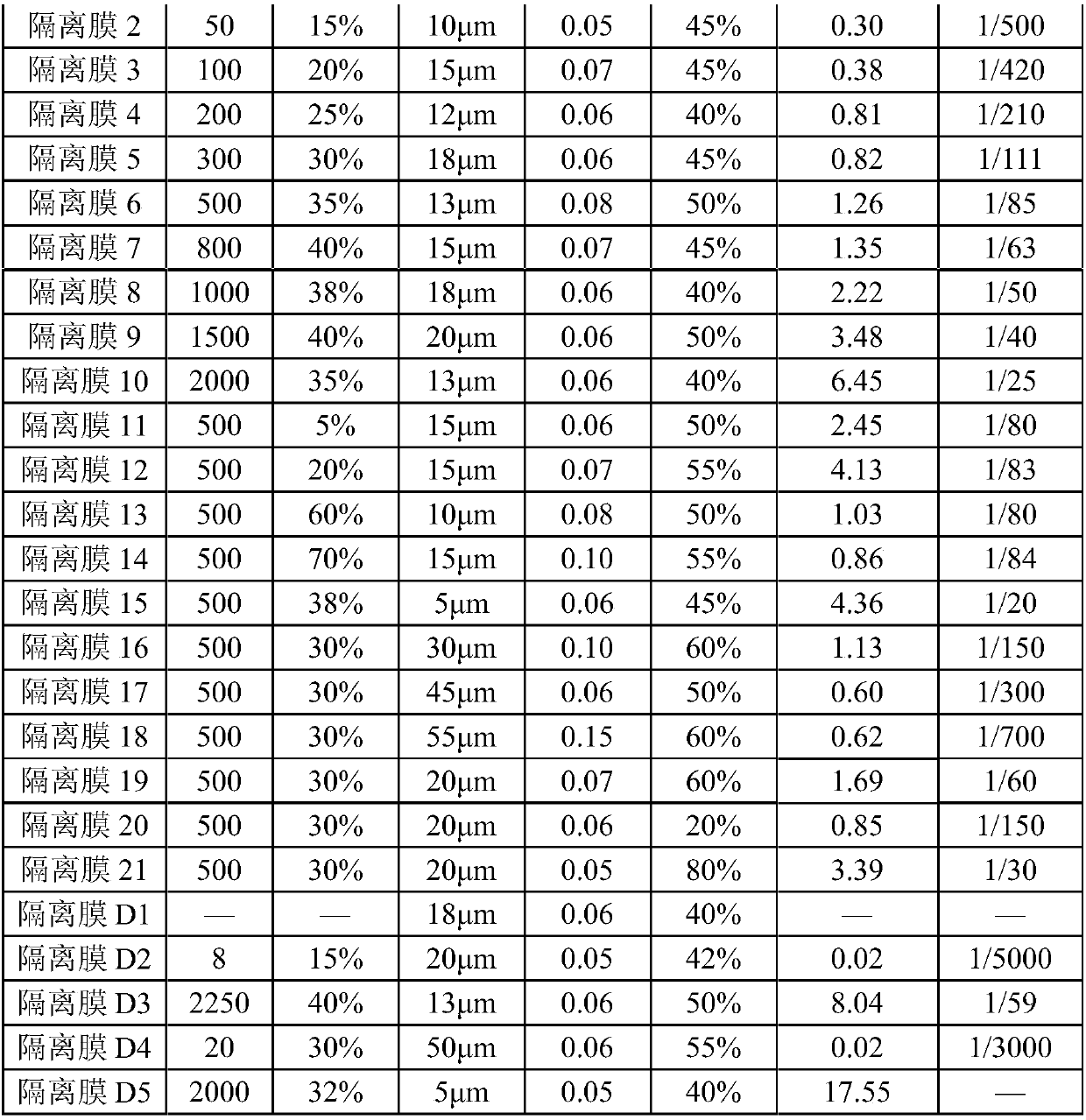

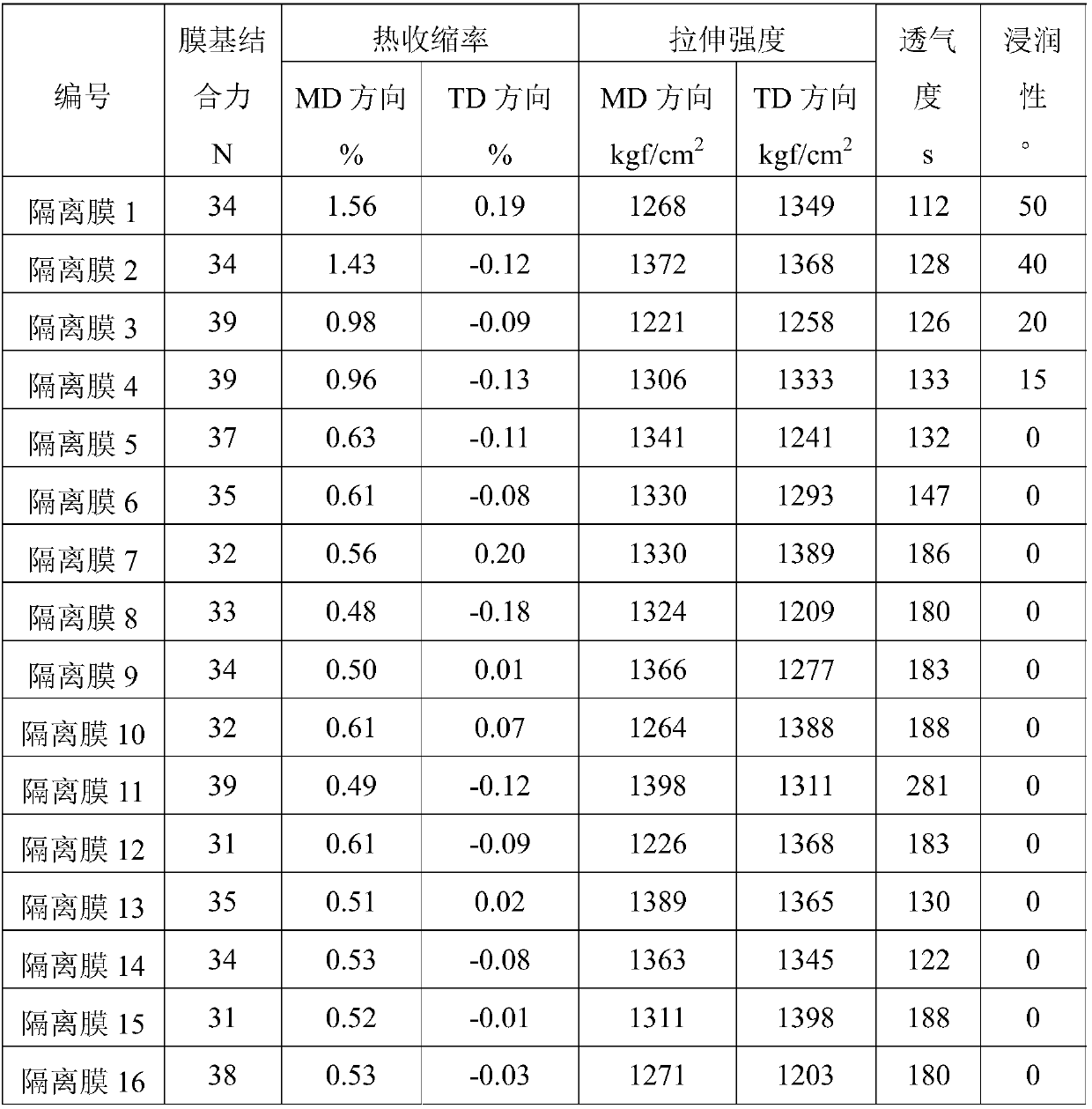

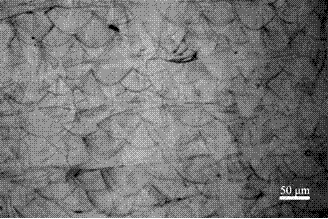

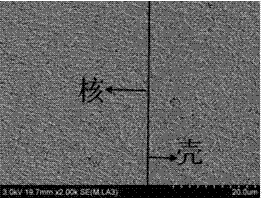

Isolating membrane, preparation method of isolating membrane, and electrochemical device comprising isolating membrane

ActiveCN109994691AGood interface wettabilityImprove heat shrink resistanceVacuum evaporation coatingSecondary cellsAdhesiveElectrochemistry

The invention relates to the field of energy storage materials, in particular to an isolating membrane, a preparation method of the isolating membrane and an electrochemical device comprising the isolating membrane. The isolating membrane comprises a base material and an inorganic layer at least arranged on one side of the base material, wherein the base material is a porous base material, and theinorganic layer is a dielectric layer which does not contain an adhesive; the thickness of the inorganic layer is 20-2000 nm; the ratio of the mass M1 of the inorganic layer to the mass M2 of the base material is M1 / M2, wherein M1 / M2 is greater than or equal to 0.05 and less than or equal to 7.5; and the interface stripping force of the inorganic layer and the base material is not lower than 30N / m. According to the isolating membrane disclosed by the invention, the ultrathin inorganic layer without the adhesive is arranged on the surface of the porous base material, so that the interface wettability and the thermal shrinkage resistance of the isolating membrane are effectively improved, certain mechanical strength is guaranteed, and the problem that the mechanical strength is lowered andthe base material is blocked caused by falling can be avoided, and the safety and the cycle life of the battery are improved and prolonged. By controlling the ranges of the M1 / M2 and the interface stripping force, the energy density is relatively high.

Owner:CONTEMPORARY AMPEREX TECH CO

An aluminum-based in-situ composite material formed based on laser 3D printing and its preparation method

ActiveCN105328186BHigh hardnessImprove mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencyHigh energyAlloy

The invention belongs to the technical field of particle-reinforced aluminum-based in-situ composite materials and discloses an aluminum-based in-situ composite material formed based on laser 3D printing and a preparation method of the aluminum-based in-situ composite material. The preparation method includes the steps that a mixture of Al-Si-Mg alloy powder and Al2O3 powder is prepared; the mixture is ball-milled through an intermittent ball-milling process; a three-dimensional CAD model established through a workpiece is subjected to layered slicing treatment; laser beams are adopted for scanning the laid powder line by line to form a two-dimensional section of the workpiece; and the steps are repeated till the workpiece is machined, and the aluminum-based in-situ composite material with an Al2Si4O10 reinforced element scattered on an Al matrix is formed. The operation method is easy and convenient to carry out, Al-Si-Mg alloy and Al2O3 generate the Al2Si4O10 reinforced phase in situ under the effect of high-energy lasers in the laser forming process, the interface wettability is improved, and then the interface strength of the composite material is enhanced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method for preparing high-performance in-situ TIC-reinforced titanium matrix composite workpieces based on cnts and laser additive manufacturing processing technology

ActiveCN105033254BGood interface wettabilityTightly boundAdditive manufacturing apparatusIncreasing energy efficiencyTitanium matrix compositesCarbon nanotube

The invention discloses a method for manufacturing a high-performance in-situ TiC reinforced titanium-based composite workpiece on the basis of CNTs and a laser additive manufacturing and processing technology. The method includes the following steps that (1) the carbon nano tubes are subjected to preliminary ultrasonic dispersion treatment; (2) pure titanium powder with the average particle size of 45-75 microns is mixed with the carbon nano tubes to obtain a mixture, and CNTs / Ti mixed powder is obtained by ball-milling the mixture through a ball mill under the protection of argon; and (3) the ball-milled CNTs / Ti mixed powder is shaped through a laser additive manufacturing and processing method so as to obtain a high-performance in-situ TiC reinforced titanium-based composite body. The method has the advantages that in-situ TiC reinforcement phases are formed on the basis of a CNTs in-situ reaction and evenly distributed in a titanium substrate, and the interface bonding strength is high; grains of a composite are refined remarkably; net forming or near-net forming of a test piece can be achieved; any complex heterogeneous part can be formed.

Owner:南京瑞德增域三维技术发展有限公司

Preparation method of aluminum-cladding brass alloy strip based on rotary infiltration

InactiveCN106890866AEasy to shapeIncrease cutting forceHot-dipping/immersion processesManganeseLanthanum

The invention provides a preparation method of an aluminum-cladding brass alloy strip based on rotary infiltration. The preparation method comprises the following steps: copper and zinc are adopted as raw materials, the raw materials are dried and then are molten in a smelting device, then neodymium, lanthanum, manganese and iron are added sequentially, mixing is carried out, baked charcoal is adopted for covering, and thus alloy liquid is obtained; the alloy liquid is prepared into a tiny uniform isometric-crystal blank material by adopting a semicontinuous ingot casting process; the blank material is rolled by a hot rolling mill; a strip after the hot rolling is subjected to face milling and cold rolling; the strip after finish rolling is subjected to recrystallization annealing and finish rolling; the strip after heat treatment is completely soaked into a molten aluminum alloy melt, the strip rotates in the molten aluminum alloy melt within the limit that no severe stirring of the molten aluminum alloy melt is caused, and then stops rotating, the strip is taken out and cleaned, and thus the aluminum-cladding brass alloy strip based on the rotary infiltration is obtained. The aluminum-cladding brass alloy strip based on the rotary infiltration prepared by the preparation method is good in strength and ductility, the tensile strength is not lower than 580MPa, and the ductility is not lower than 10%.

Owner:湖州奇奇机电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com