Patents

Literature

362results about How to "Increase cutting force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Saw blade having increased tooth stiffness and resistance to fatigue failure

InactiveUS20060065098A1Increase Section WidthPrevent set collapseMetal sawing devicesMetal sawing toolsEngineeringWood cutting

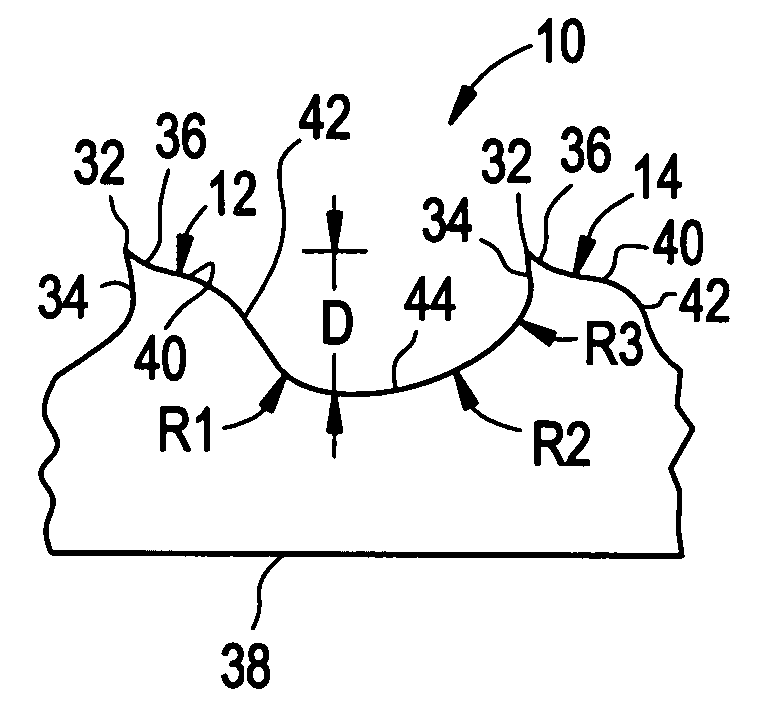

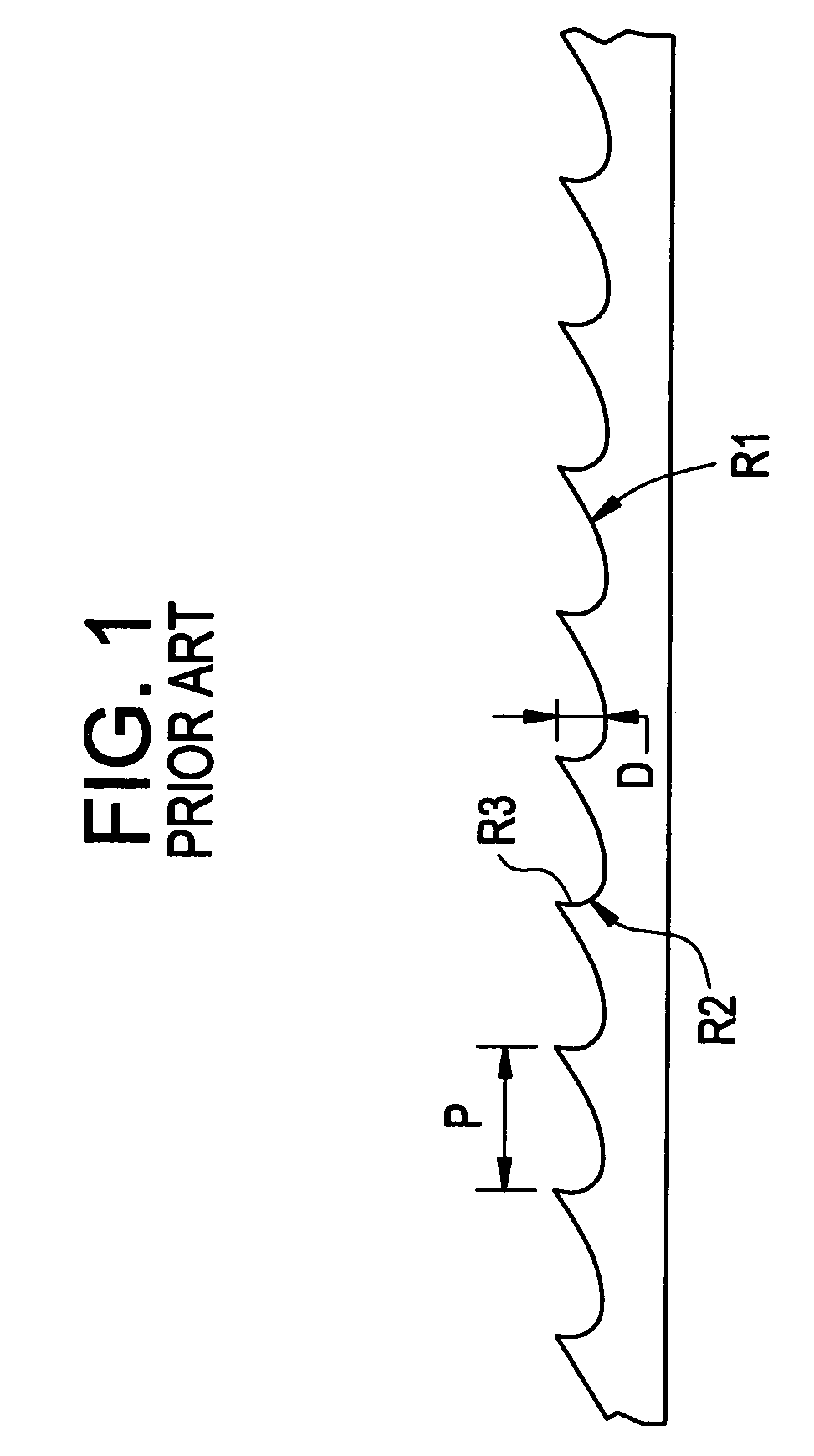

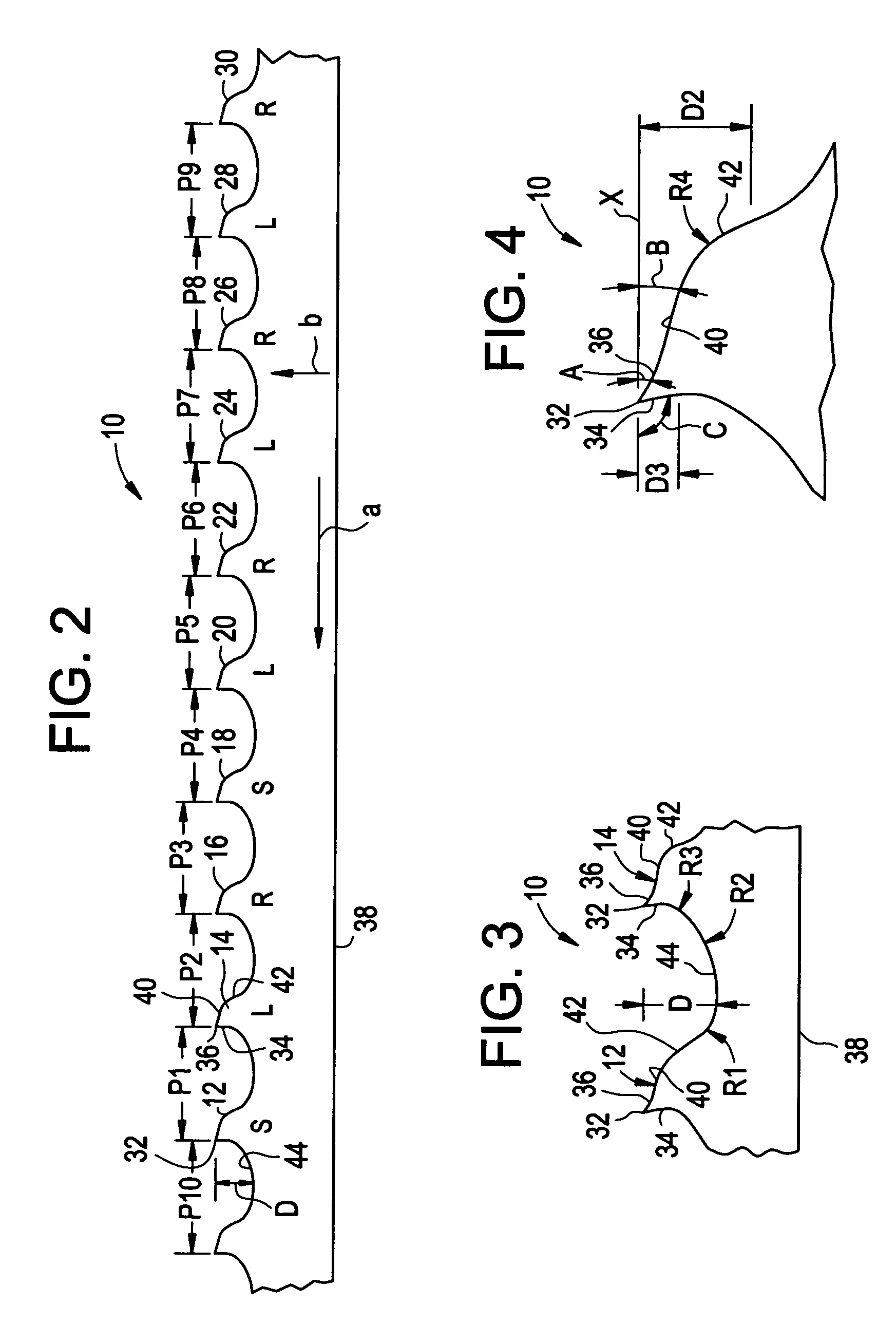

A wood-cutting band saw blade includes a cutting edge defined by a plurality of teeth spaced relative to each other, wherein each tooth includes a tip; a rake face formed on one side of the tip; a primary clearance surface formed on an opposite side of the tip relative to the rake face; a secondary clearance surface formed on an opposite side of the primary clearance surface relative to the tip; a tertiary clearance surface formed on an opposite side of the secondary clearance surface relative to the primary clearance surface; and a gullet located on an opposite side of the rake face relative to the tip and defining a depth (D) between a base surface of the gullet and the tip. Each tooth further defines a first gullet radius (R1) located between the gullet and tertiary clearance surface; a second gullet radius (R2) extending between a base surface of the gullet and the rake face; and a pitch (P) between the respective tooth and a preceding tooth in a cutting direction of the saw blade. In each tooth, R2>D>R1, D / P is within the range of about 25% to about 35% and R2 / R1≧about 1.4. R1 defines a minimum radius (Rmin) at a base of the gullet and Rmin / D>about 20%.

Owner:IRWIN IND TOOL CO

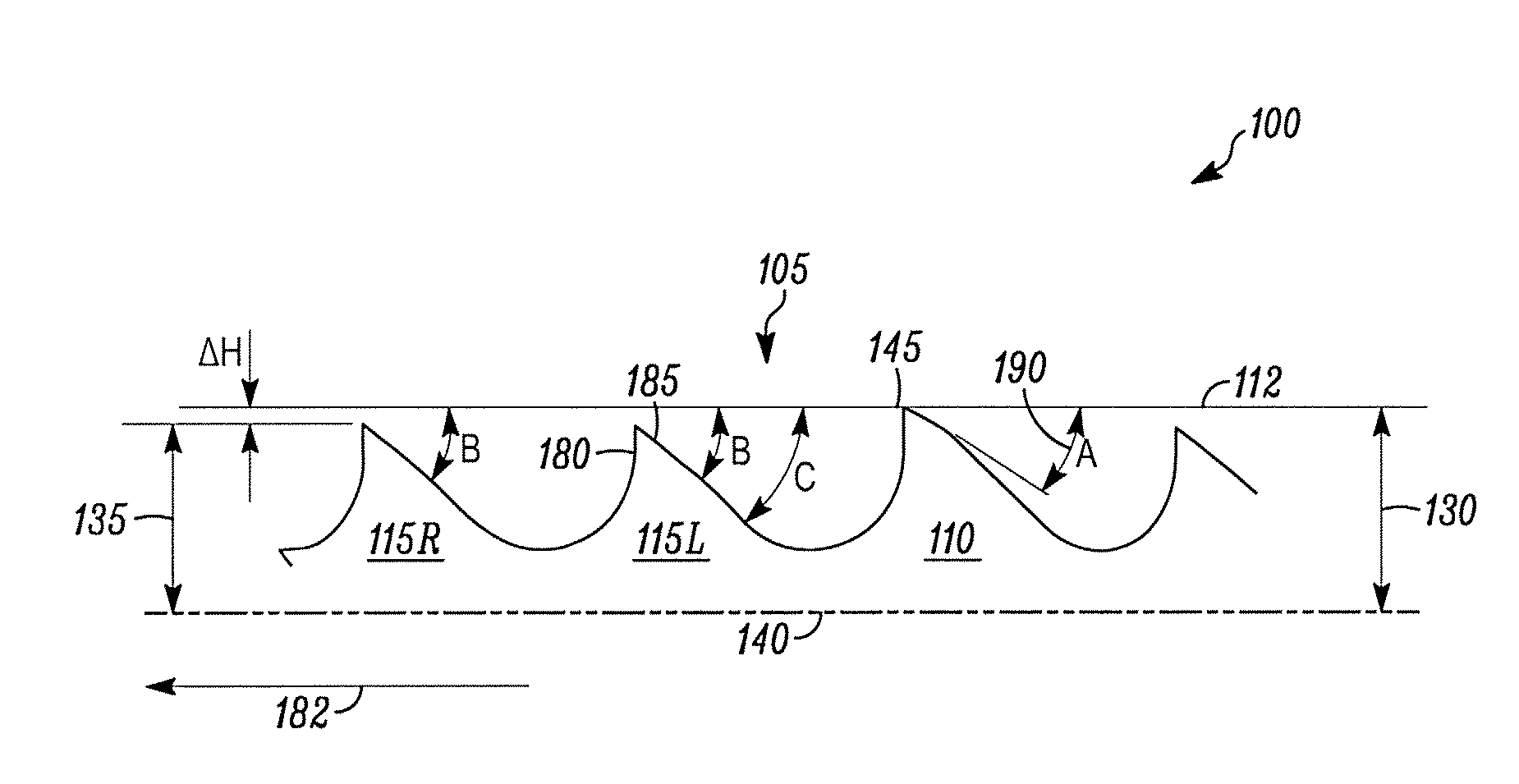

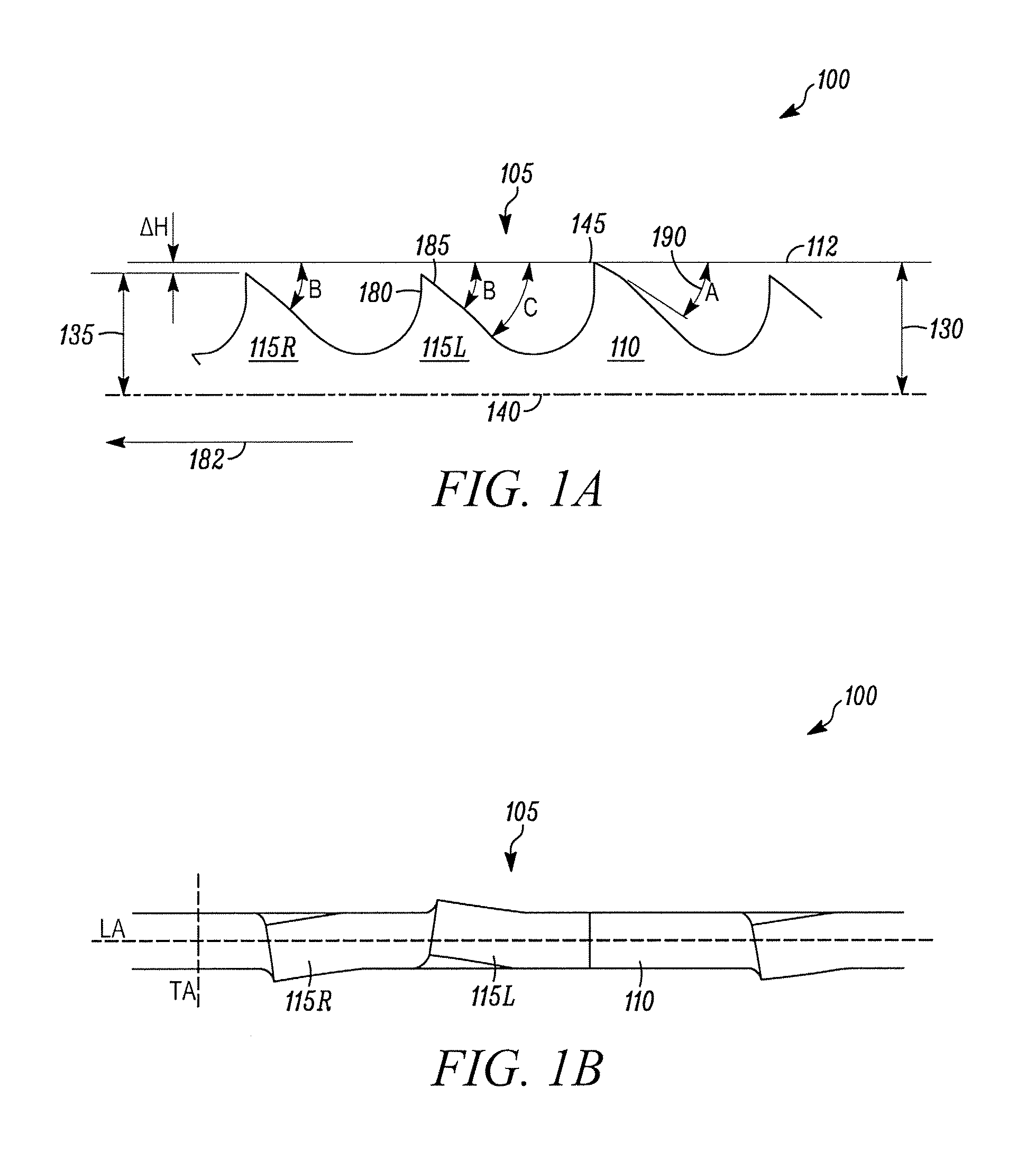

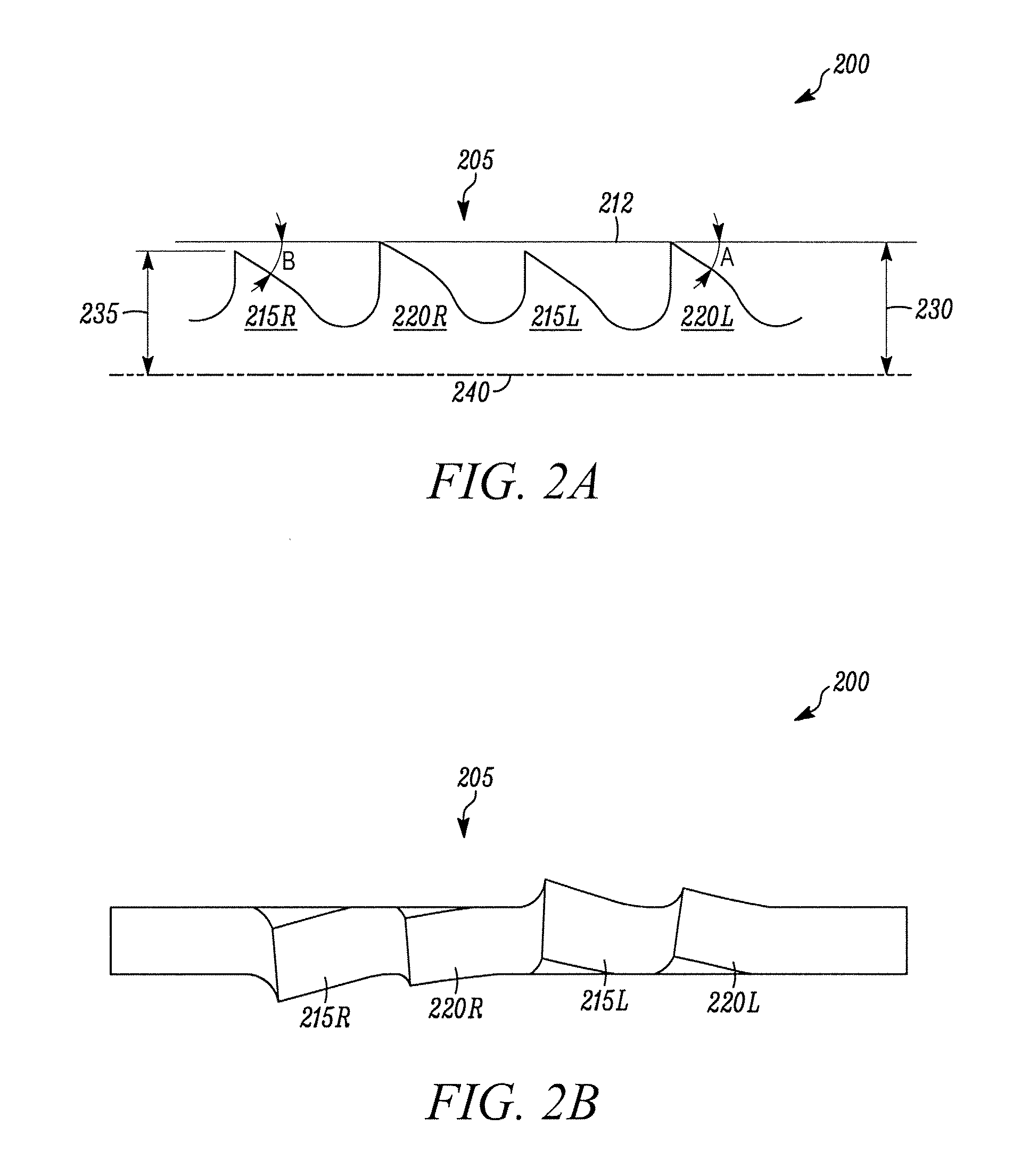

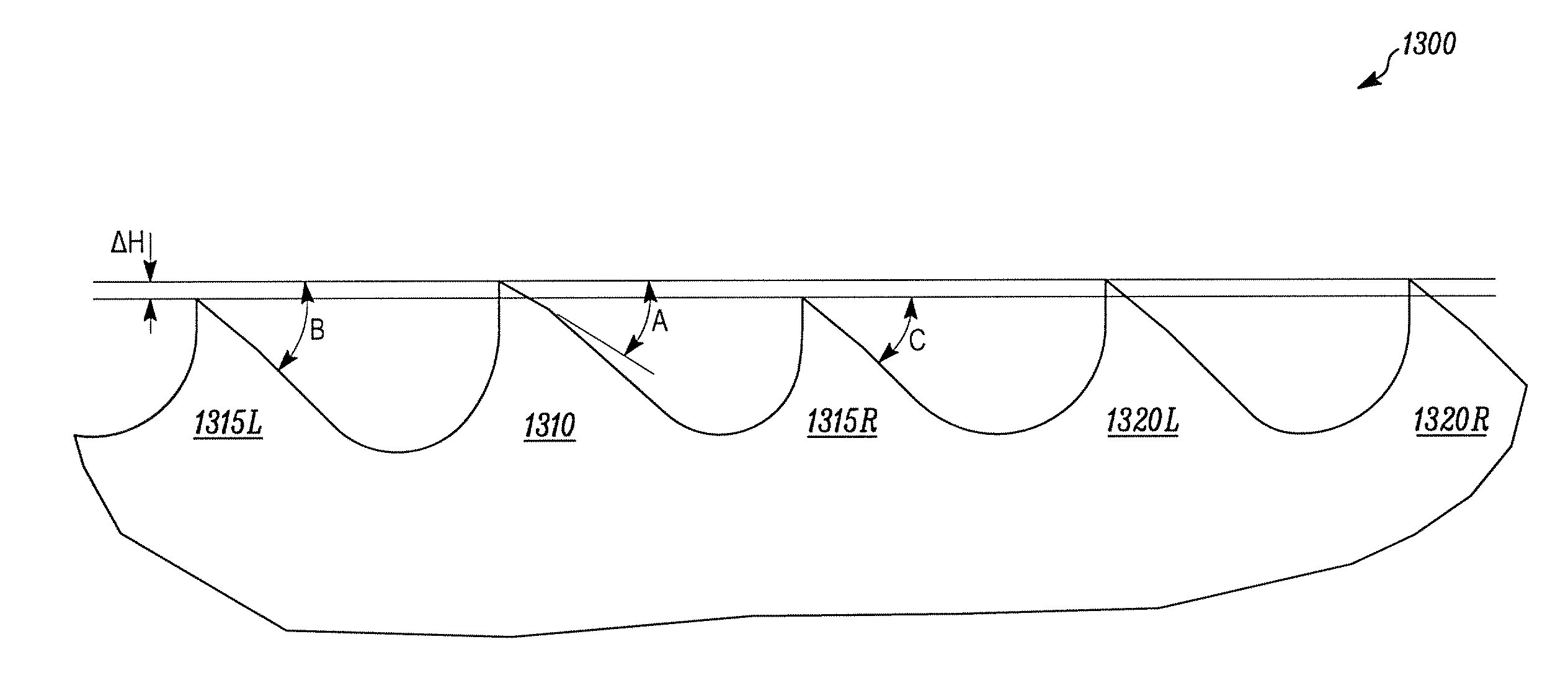

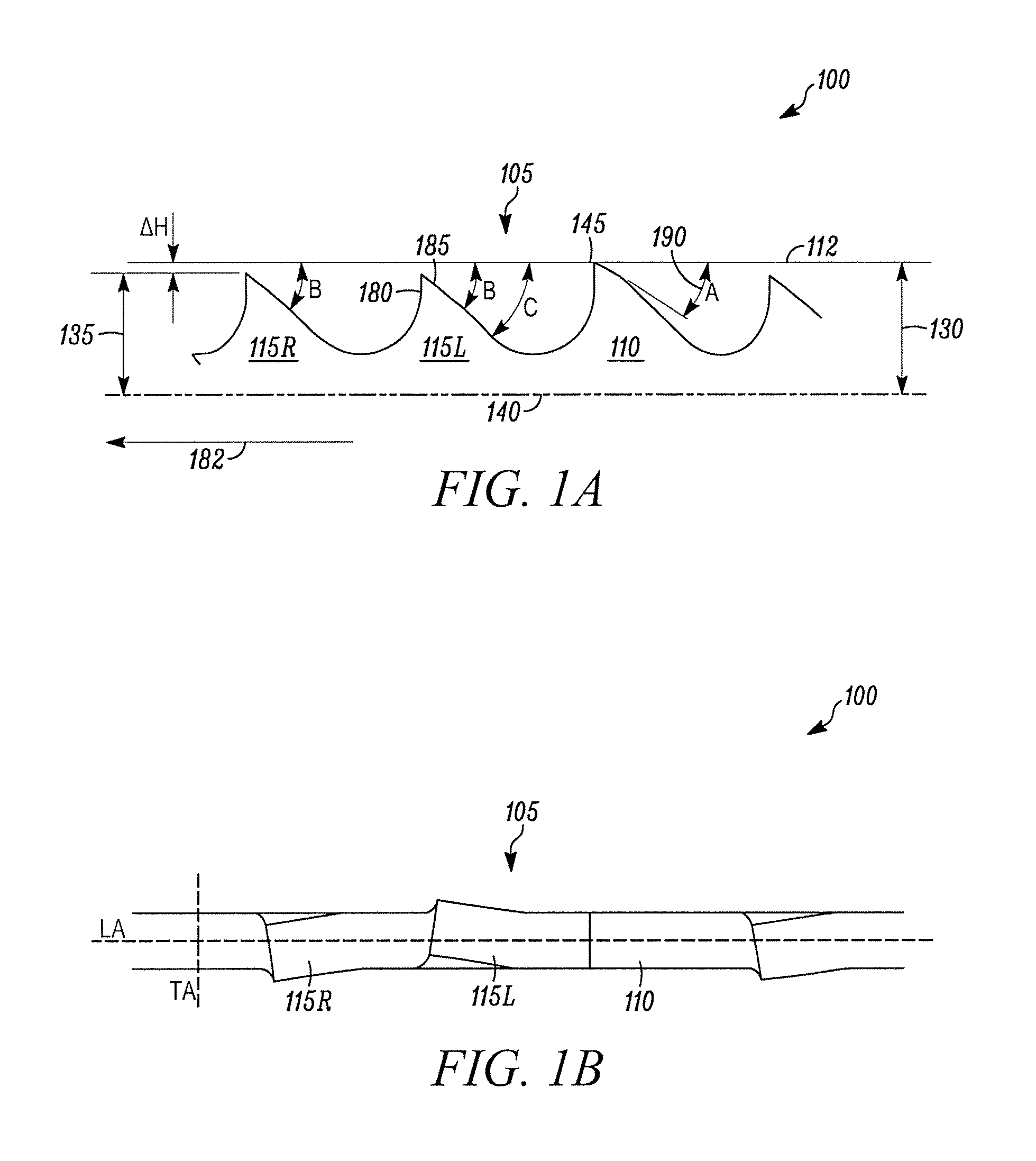

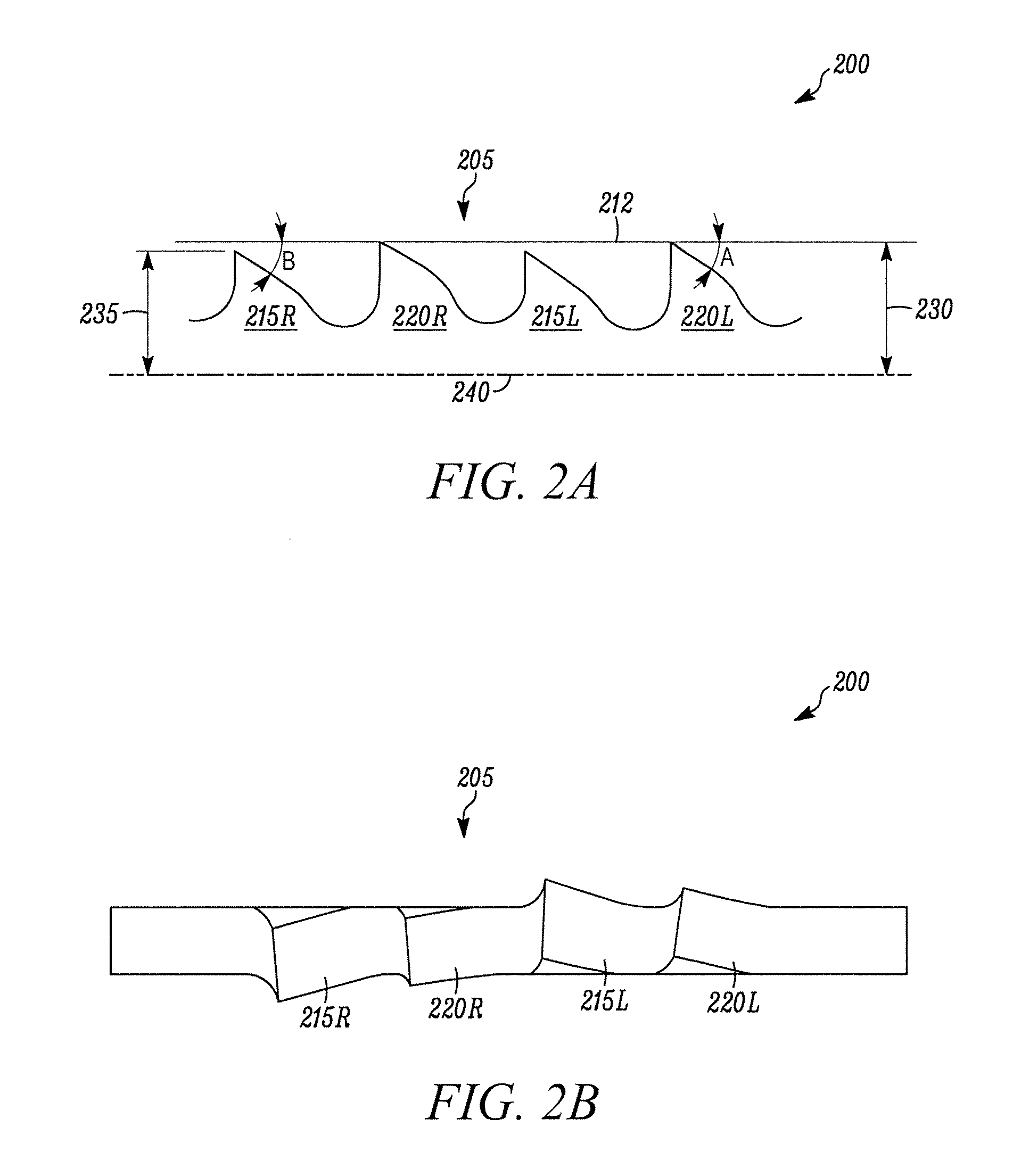

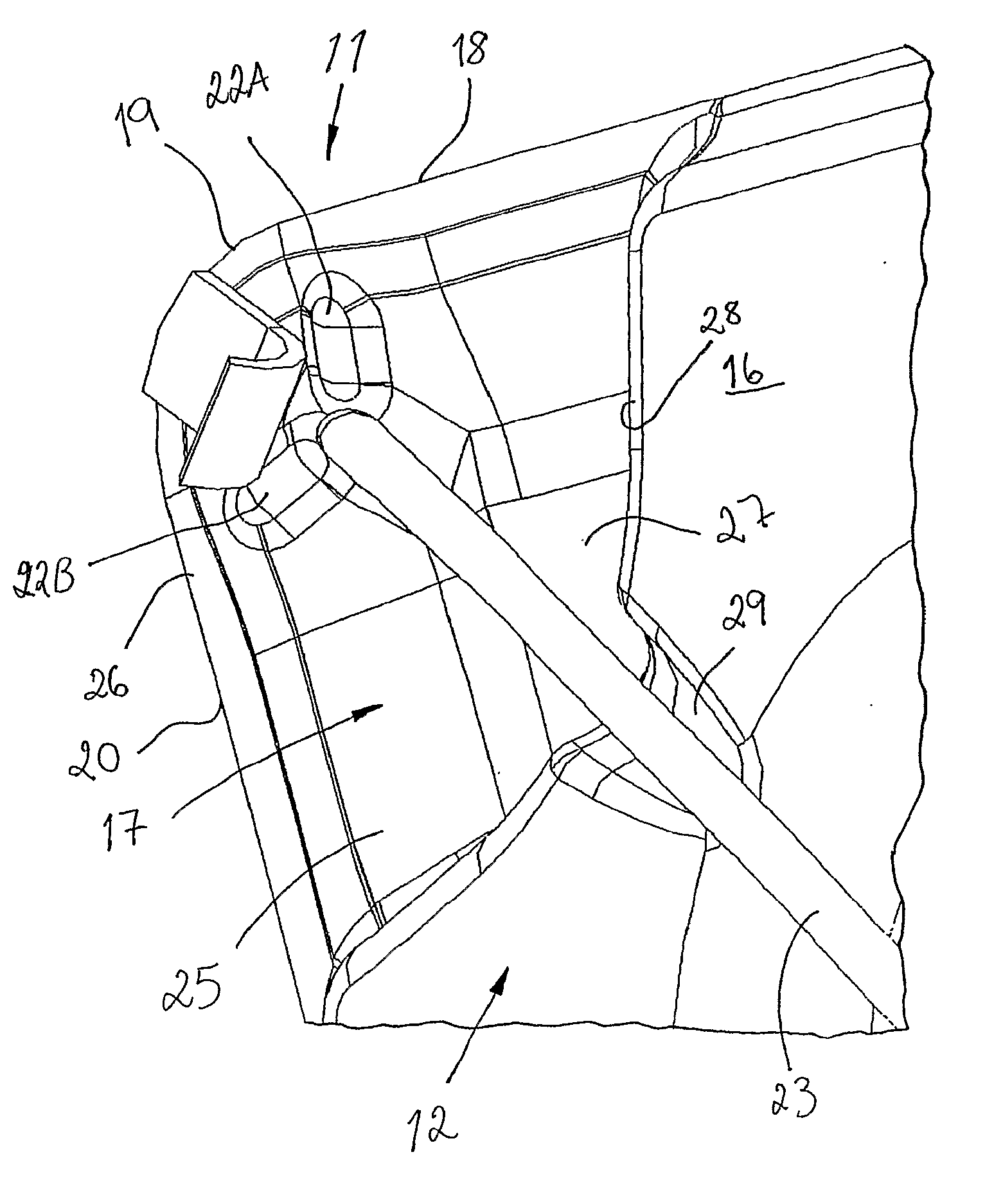

Reciprocating Saw Blade Having Variable-Height Teeth and Related Method

ActiveUS20080307936A1Improve performanceIncrease cutting forceMetal sawing devicesMetal sawing toolsPortable powerEngineering

A reciprocating saw blade, for use in a portable power reciprocating saw including a chuck for releasably engaging the saw blade, includes a tang having an elongated axis and being engageable with the chuck for attaching the saw blade to the reciprocating saw. The saw further includes a blade portion having a cutting edge that defines a plurality of cutting teeth. The cutting teeth define a repeating pattern of successive groups of teeth. Each group of teeth is less than about a half inch in length, and includes a plurality of laterally offset teeth, at least one relatively high first tooth and at least one relatively low second tooth. Prior to tooth set, the at least one relatively high first tooth is at least about 0.002 inch higher than the at least one relatively low second tooth.

Owner:BLACK & DECKER INC

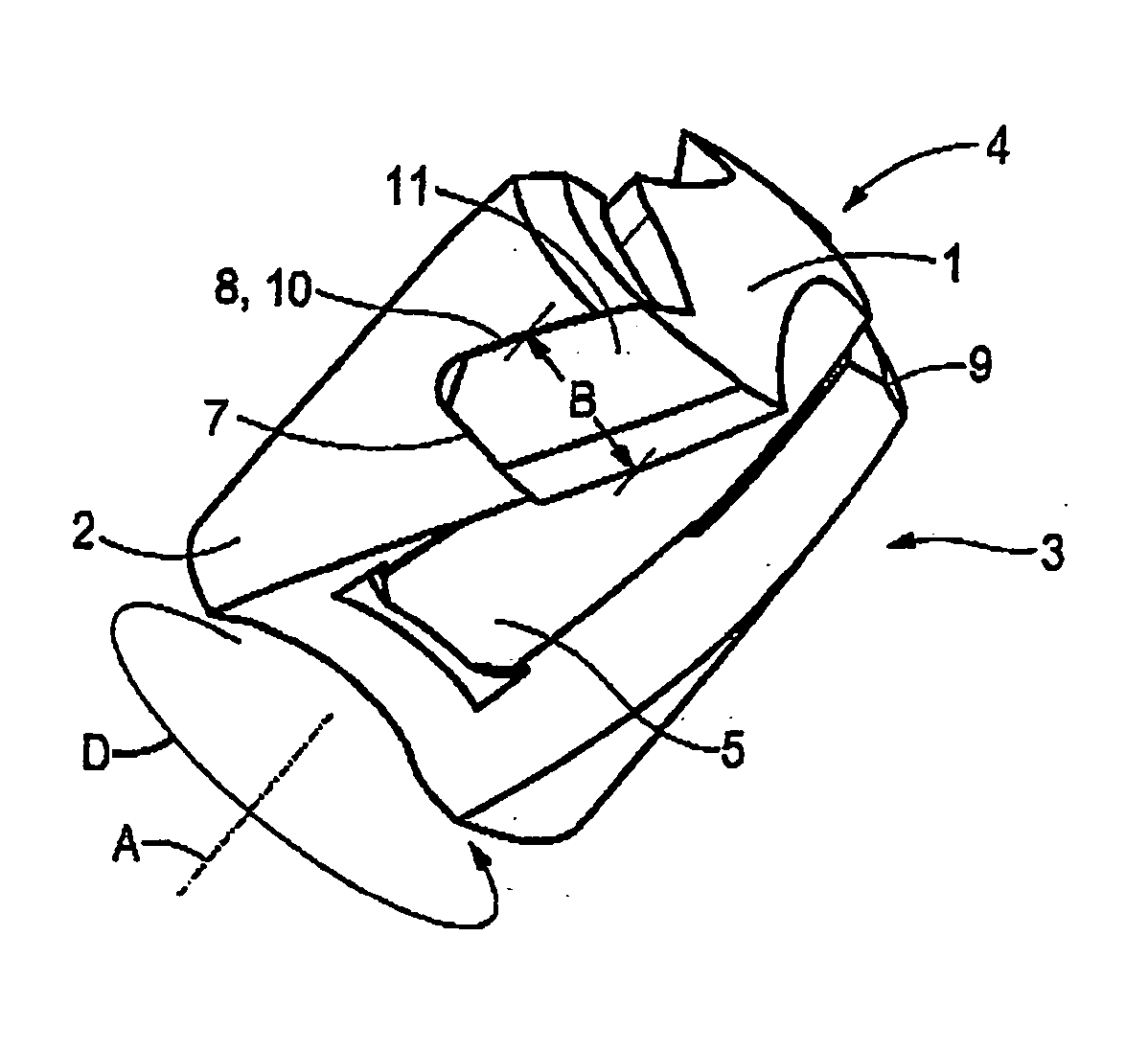

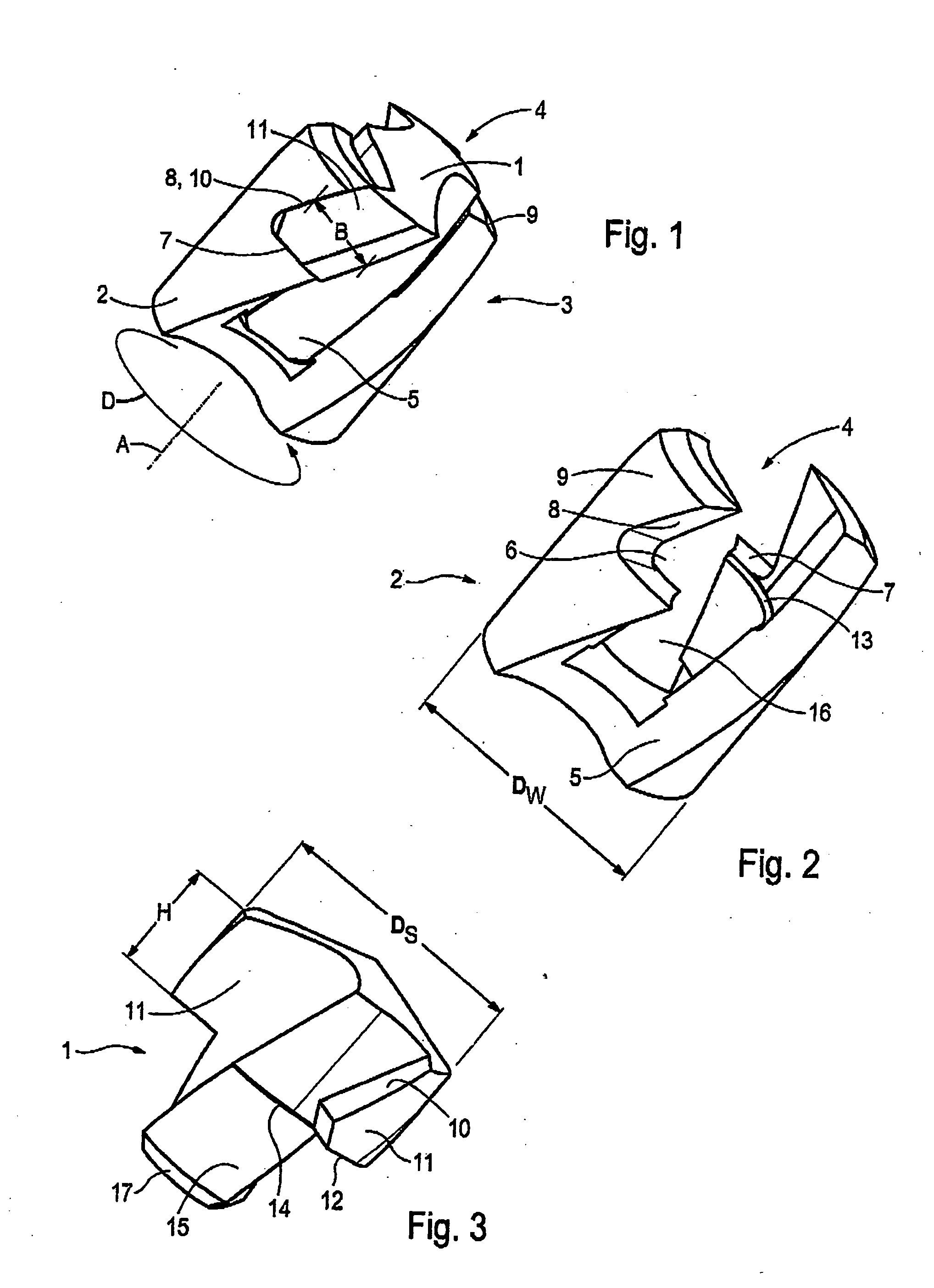

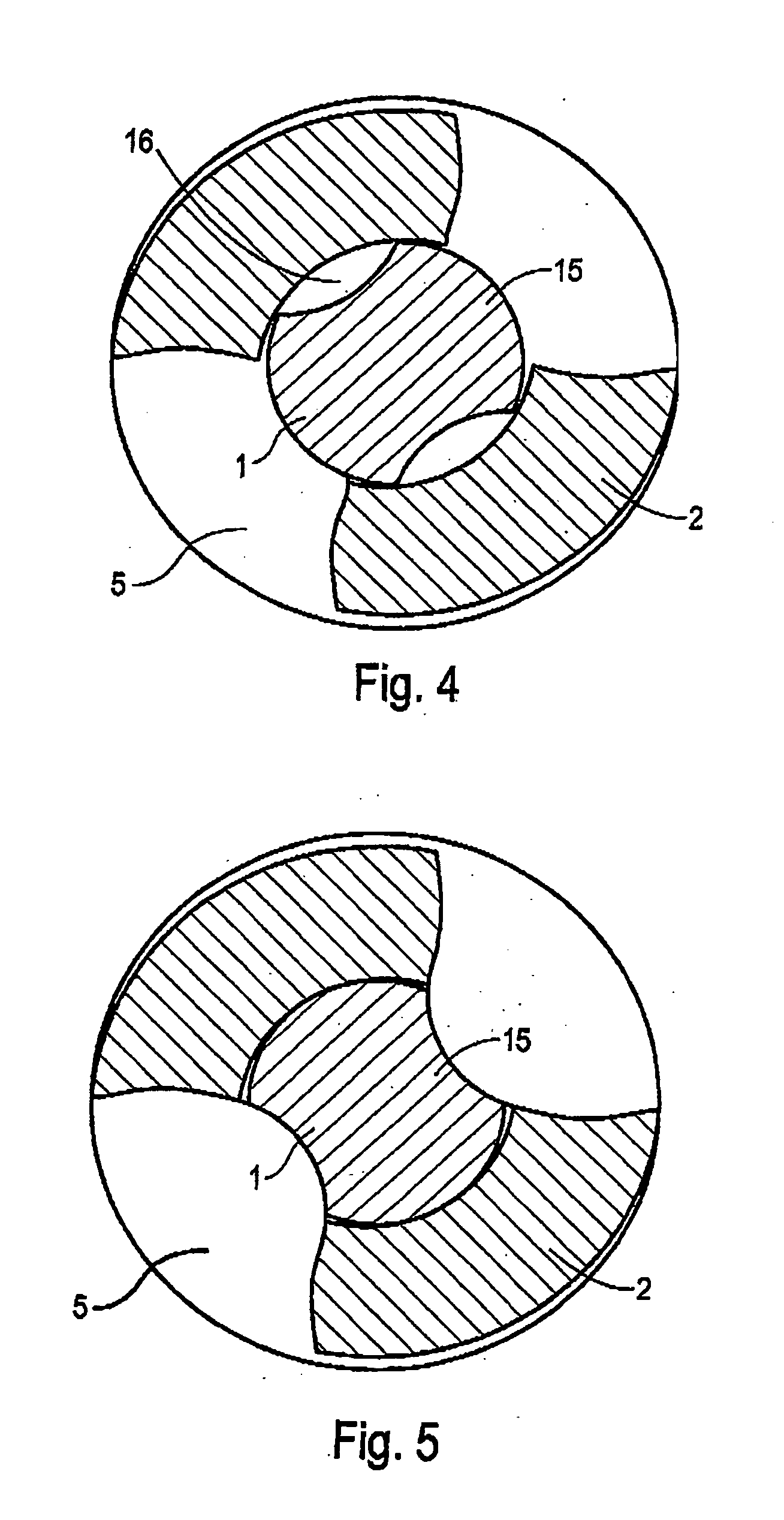

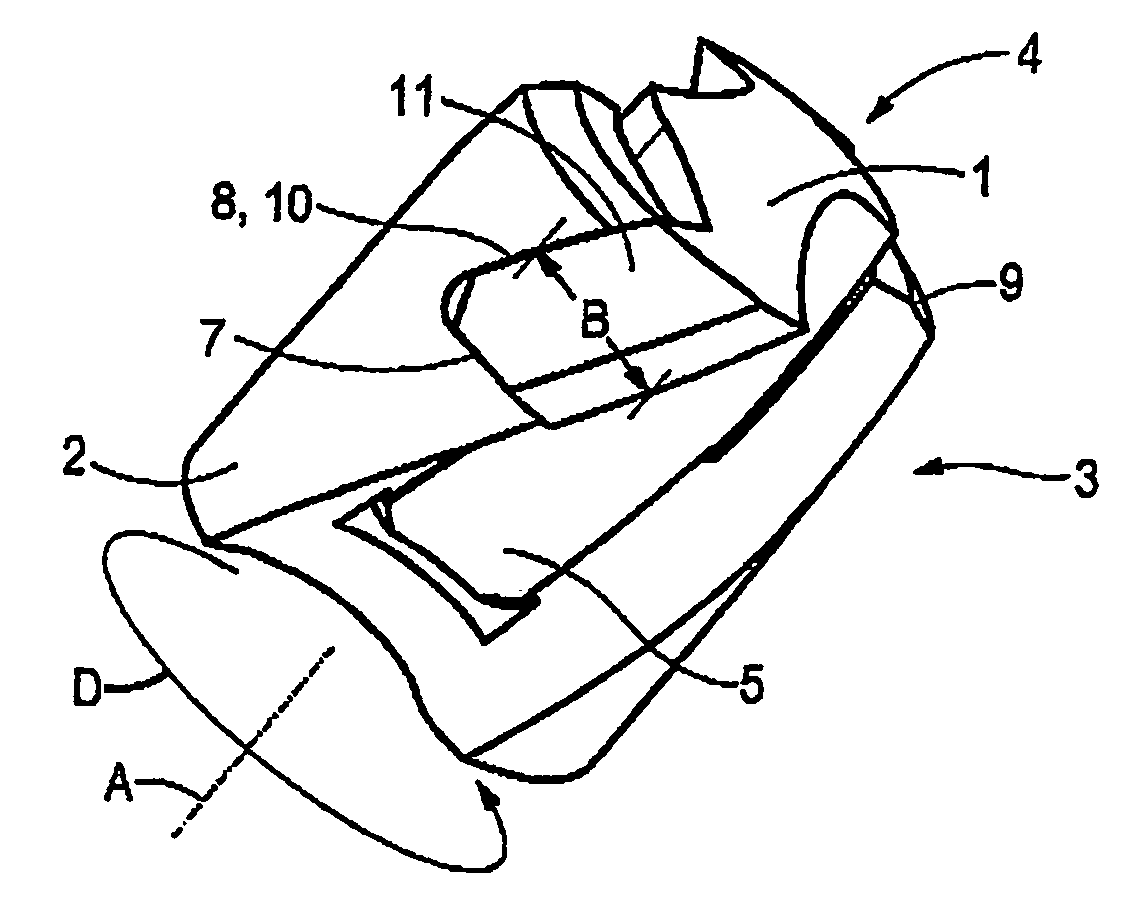

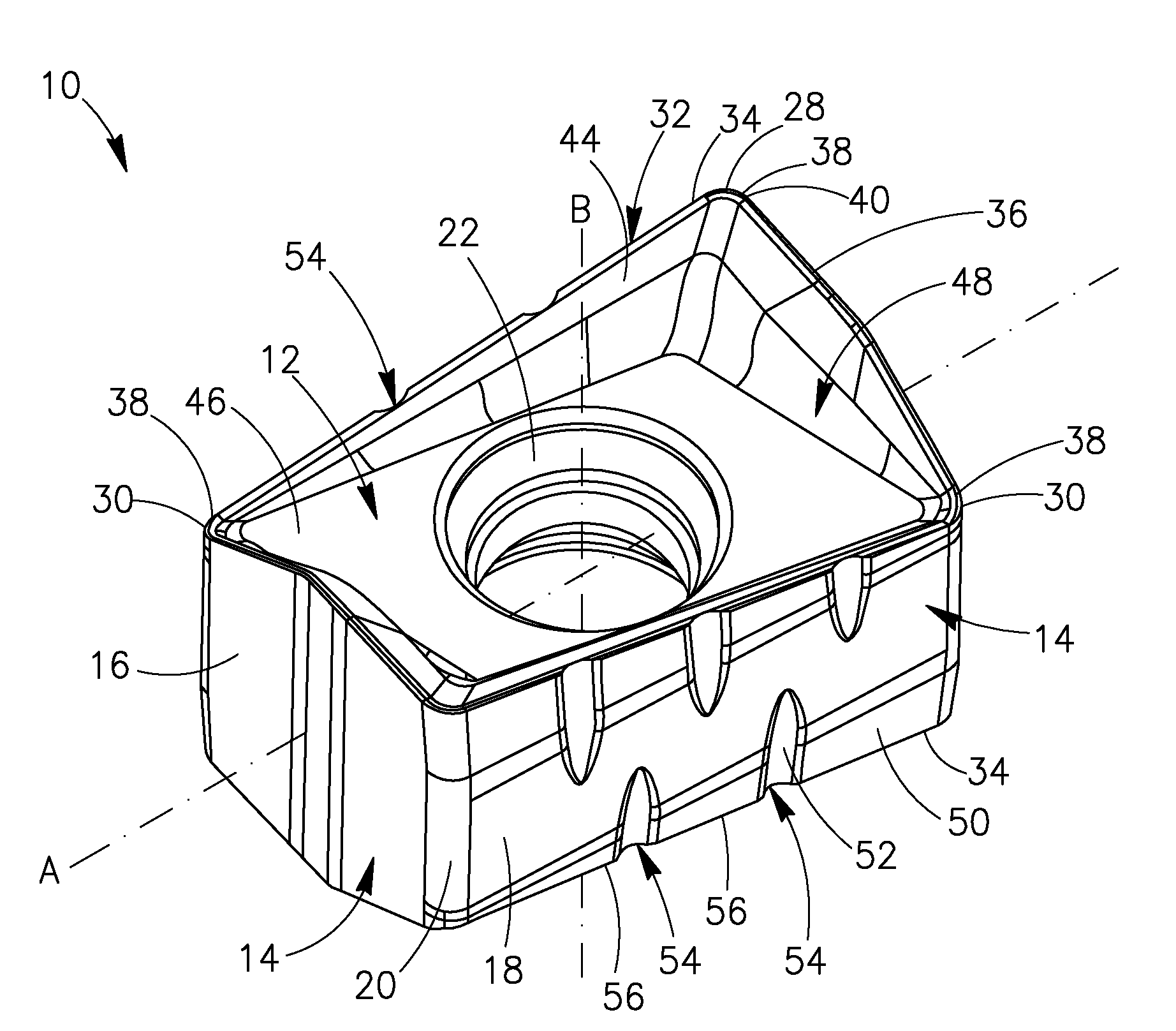

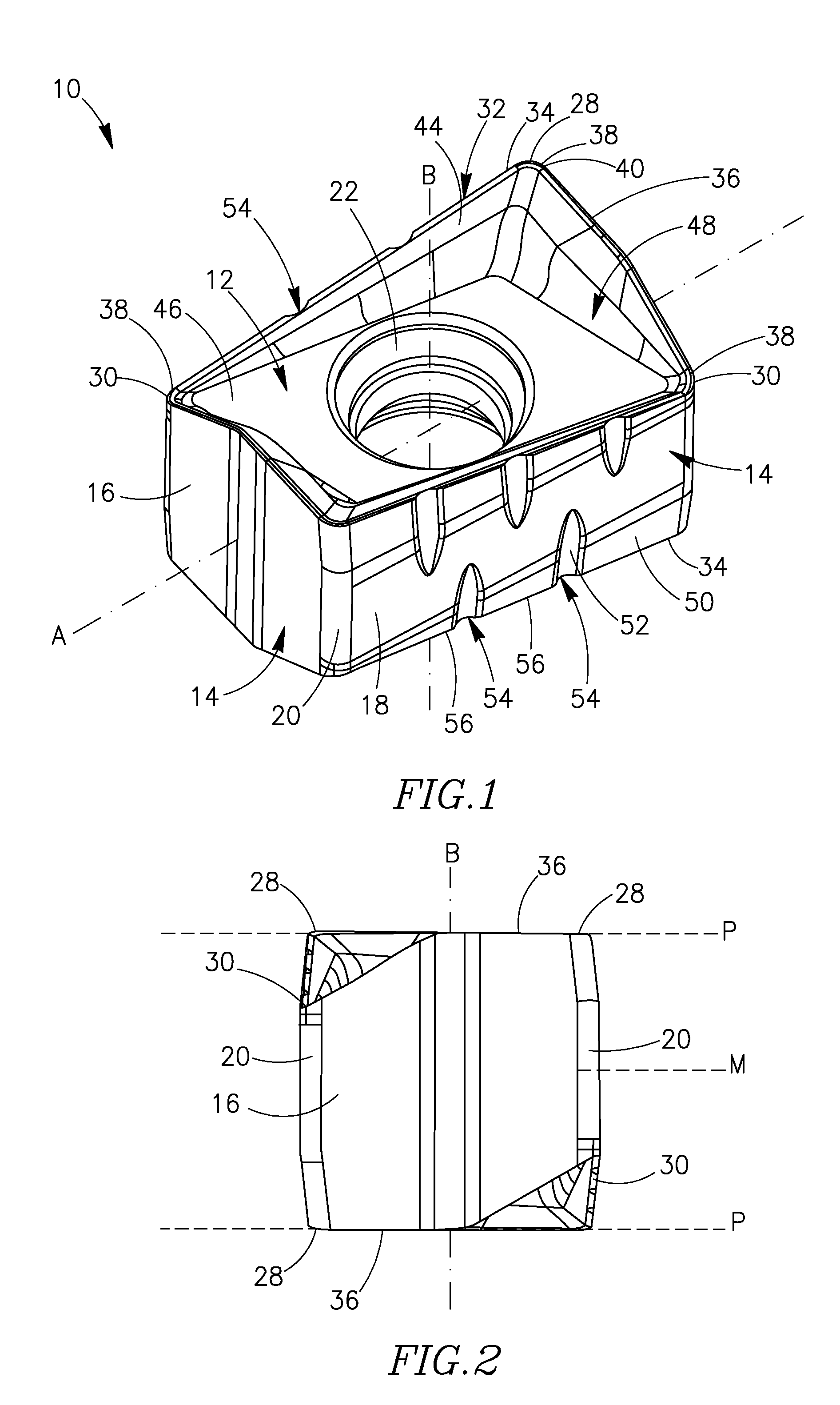

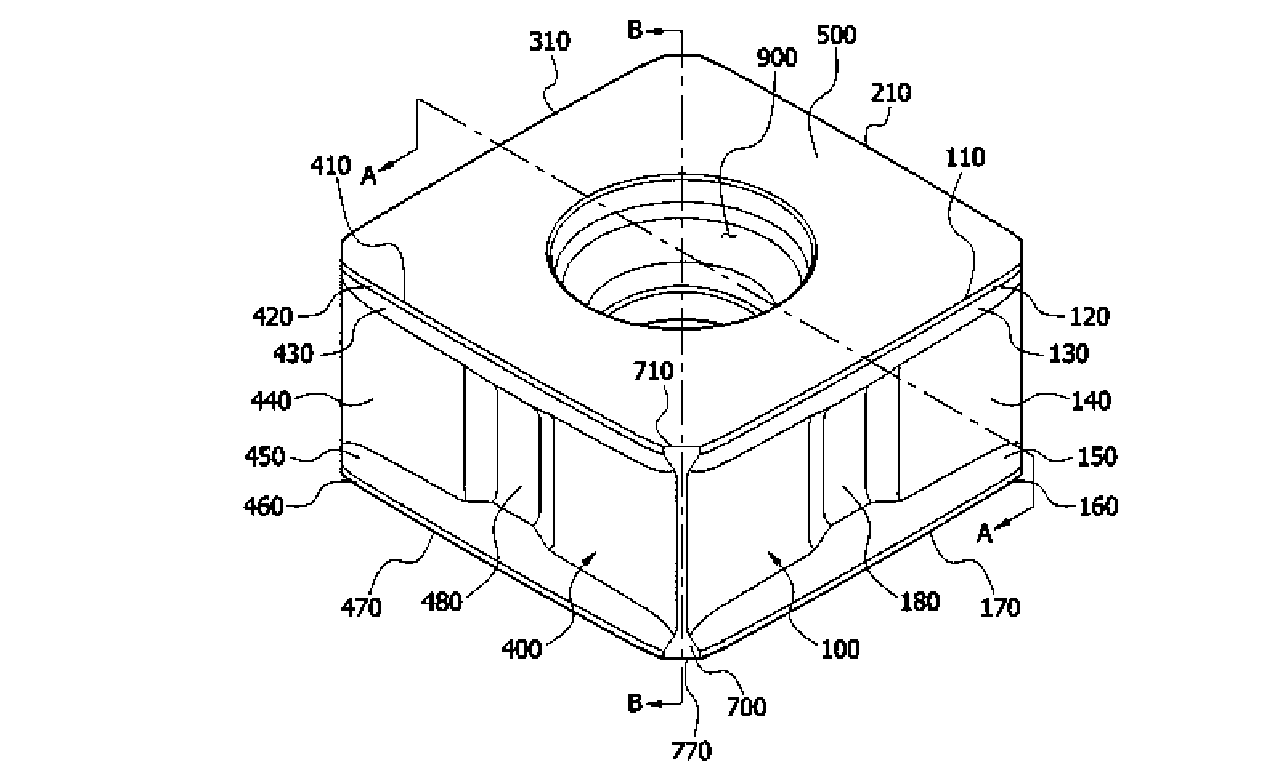

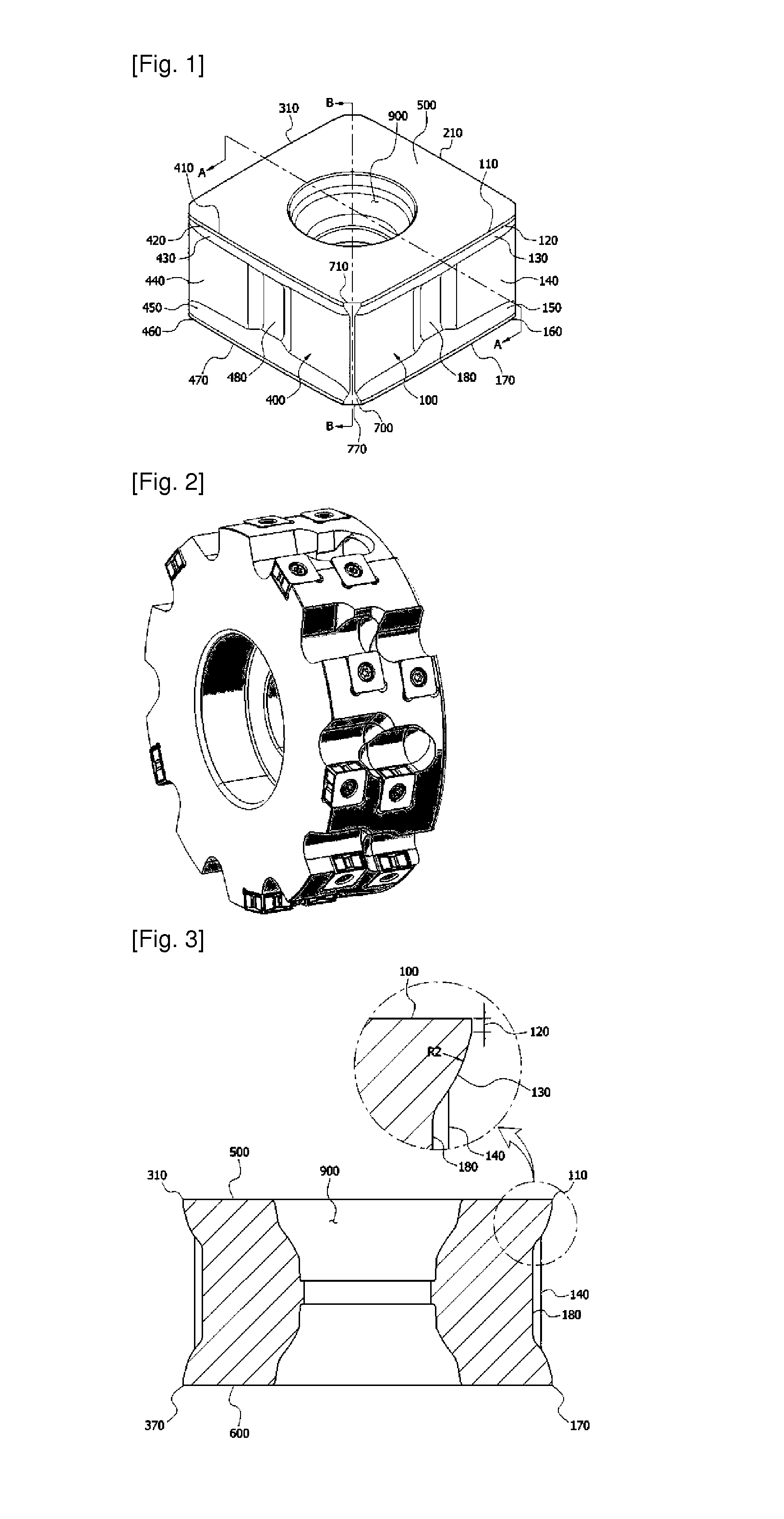

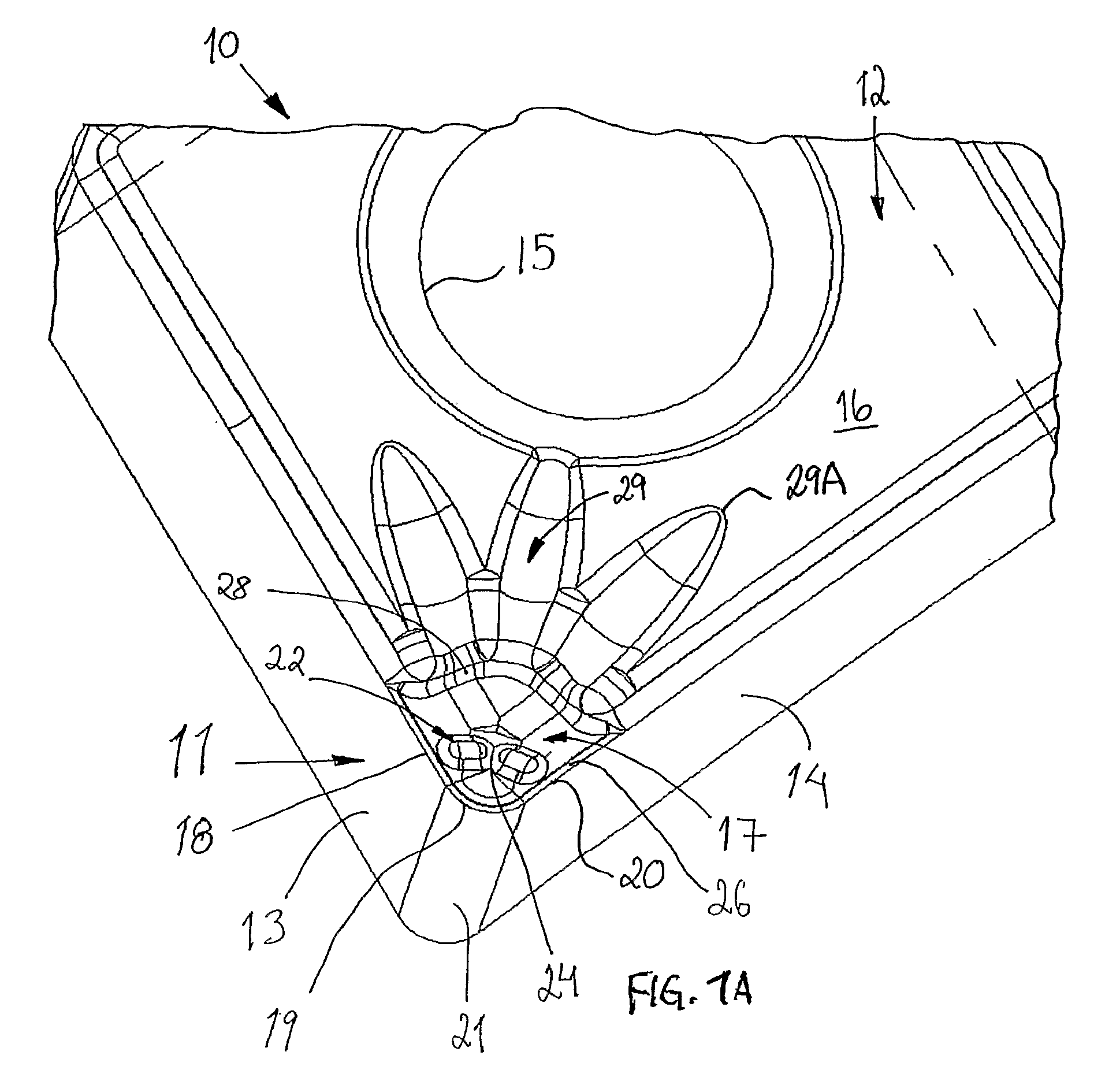

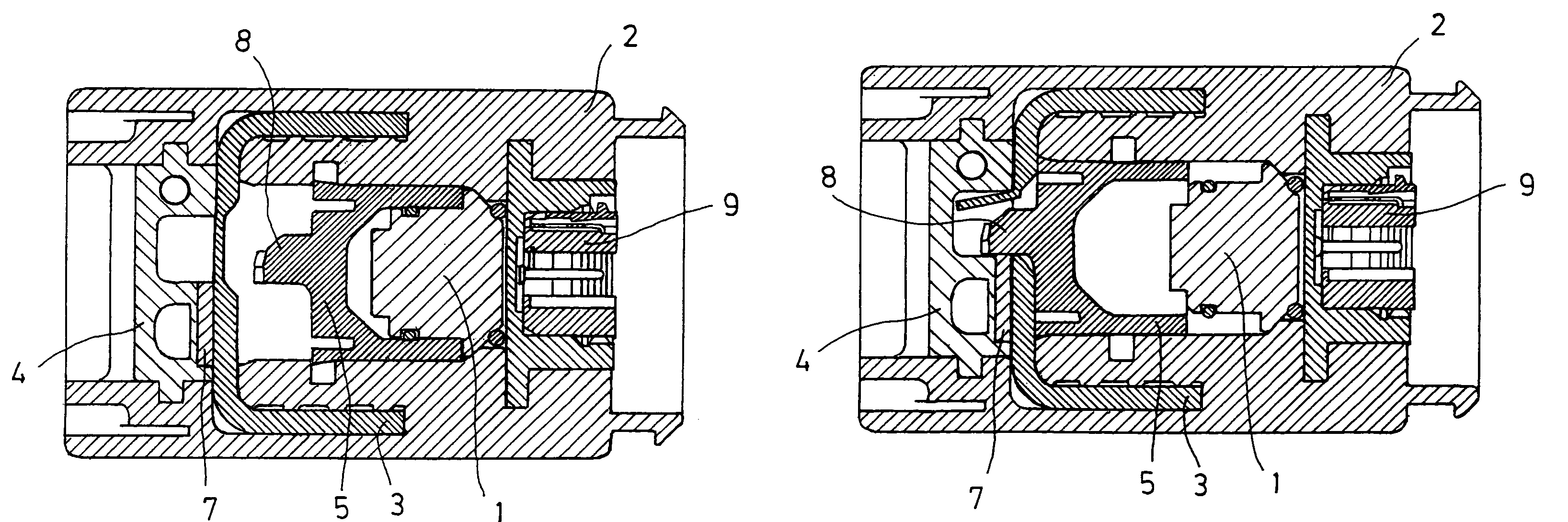

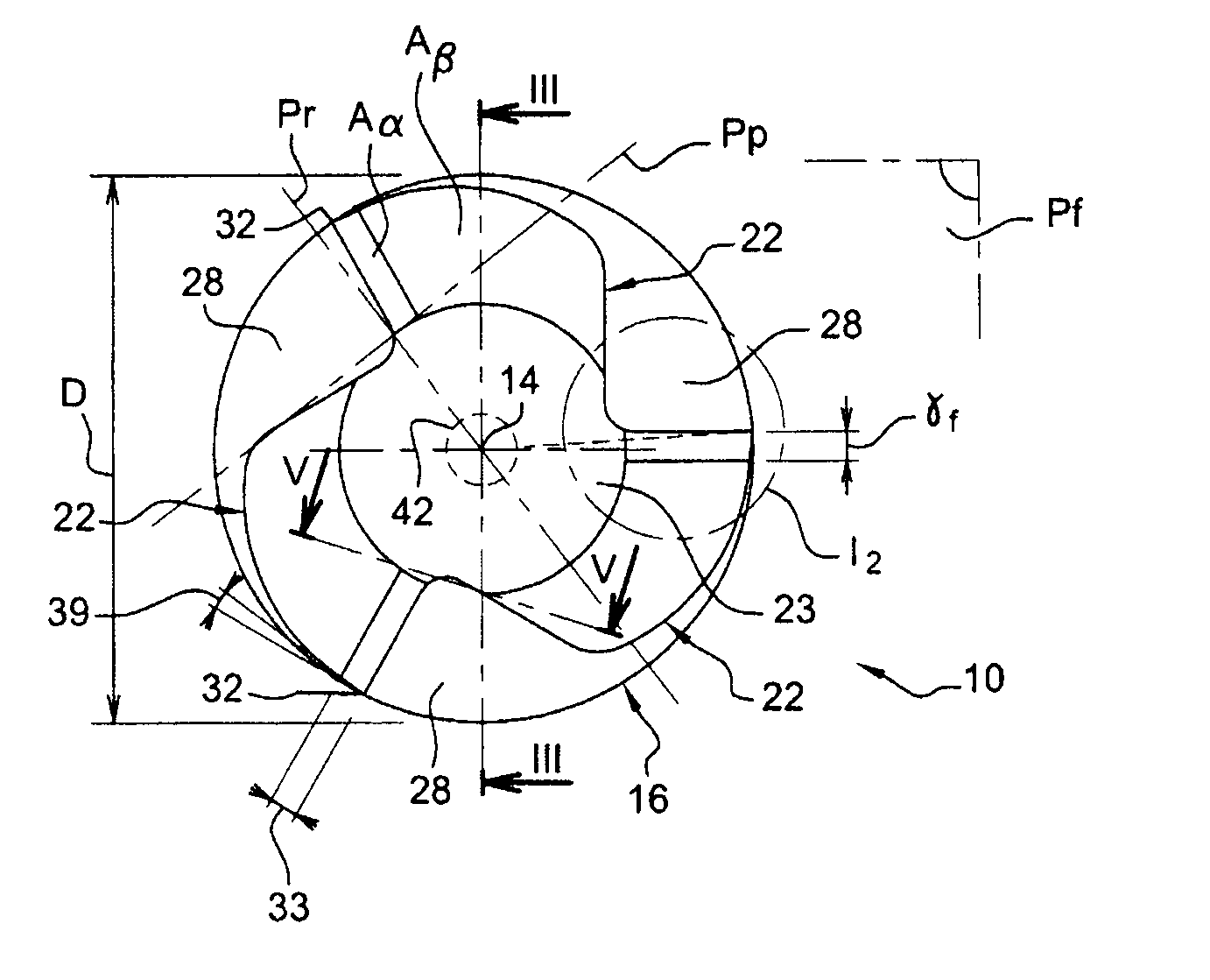

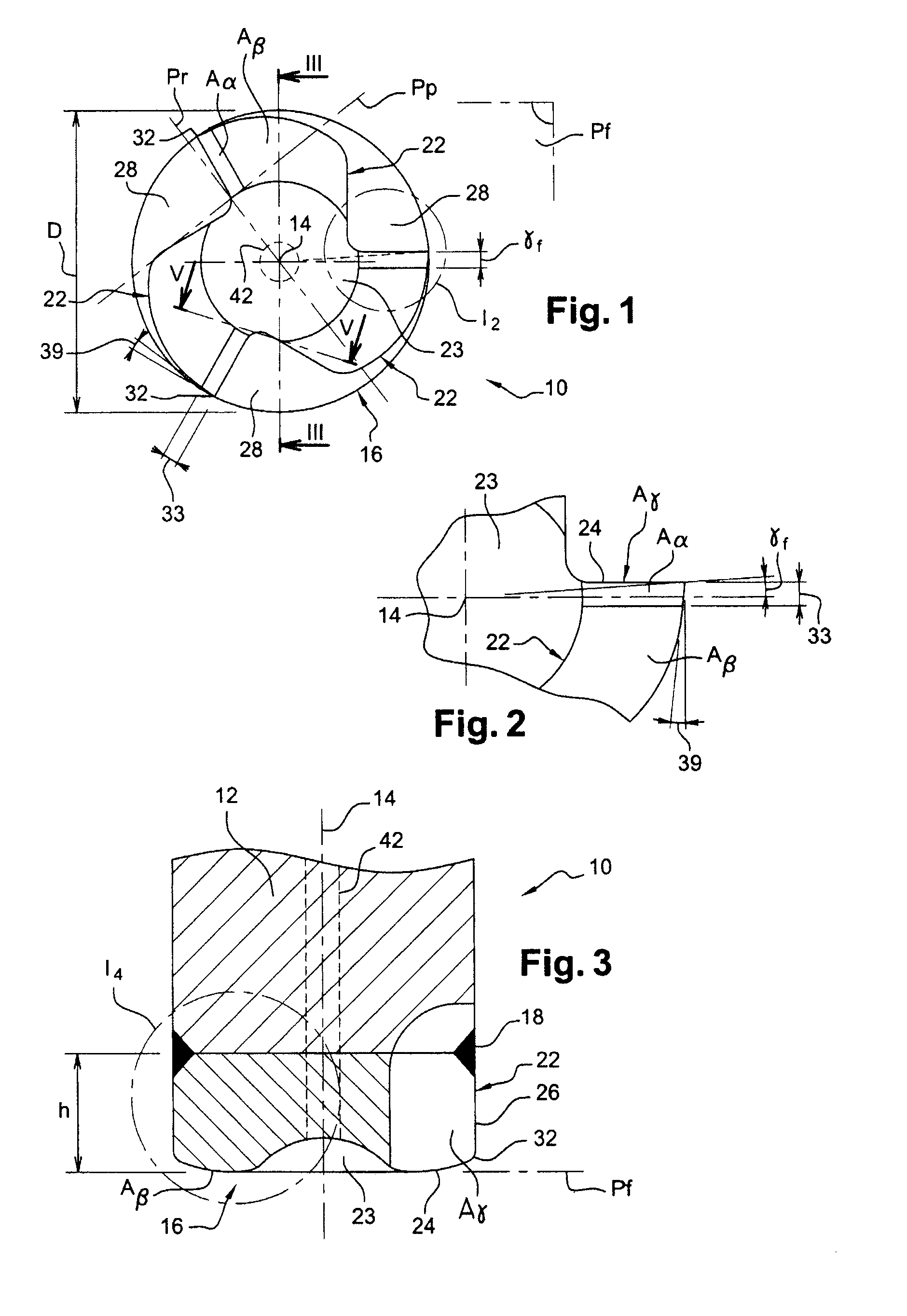

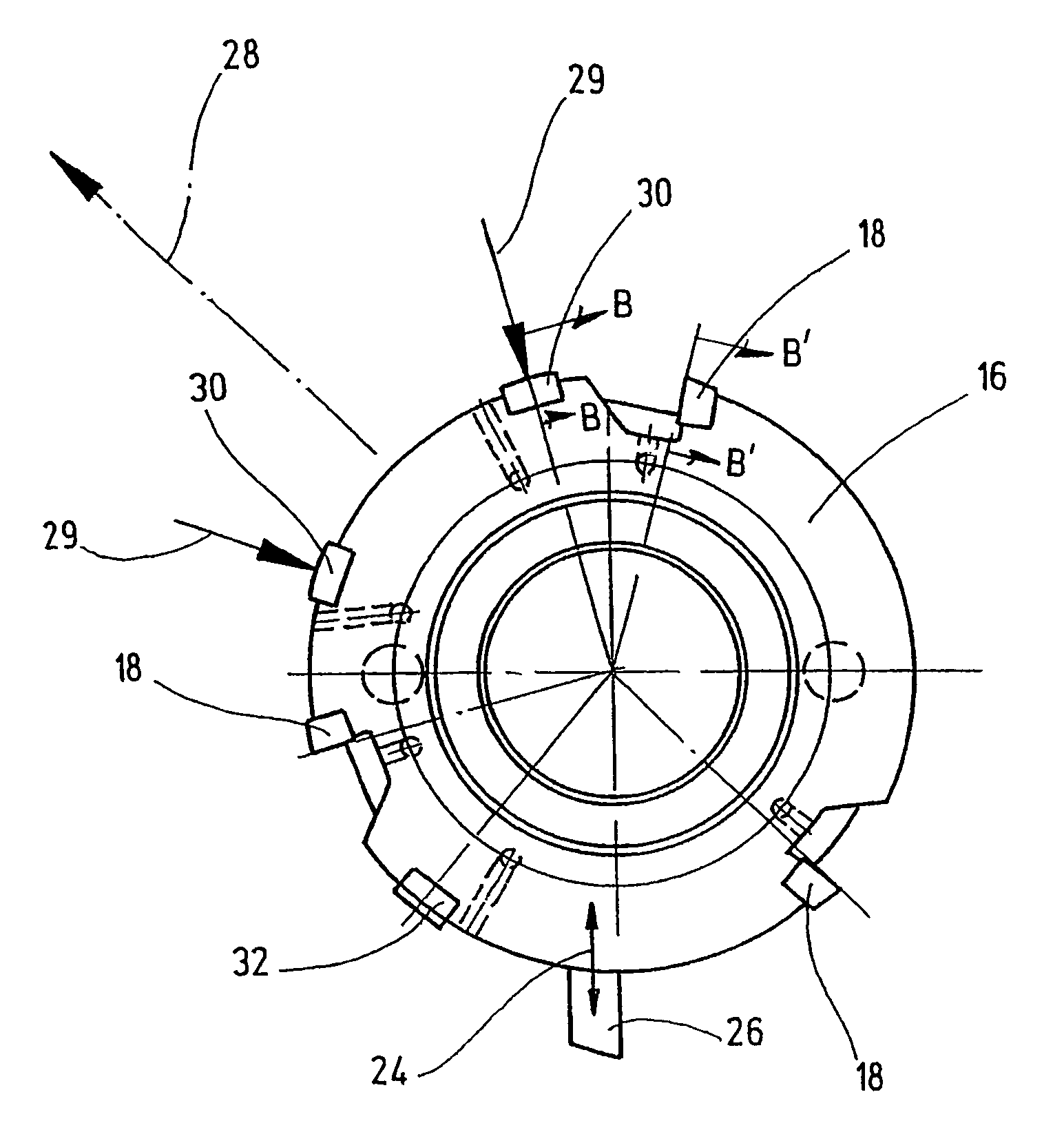

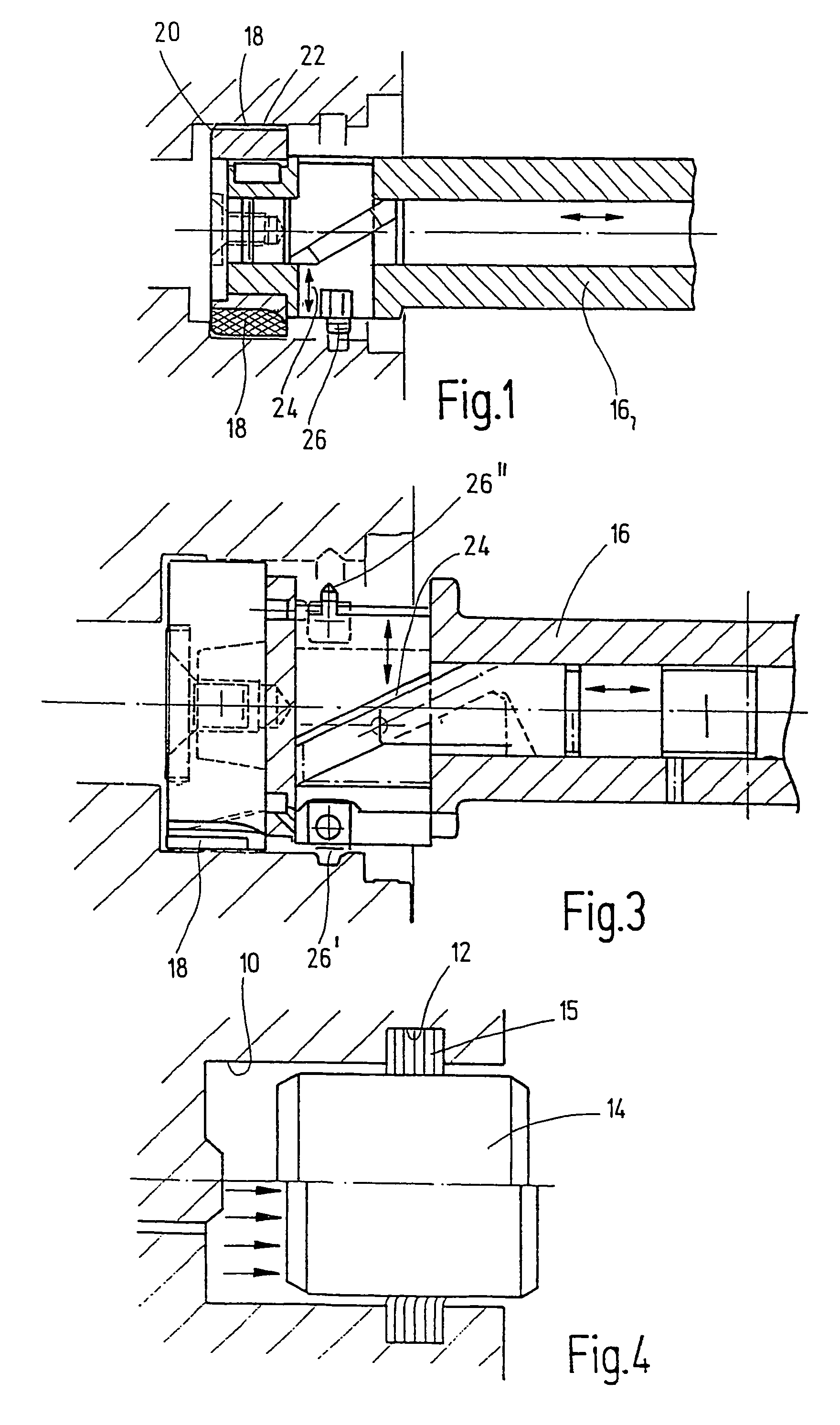

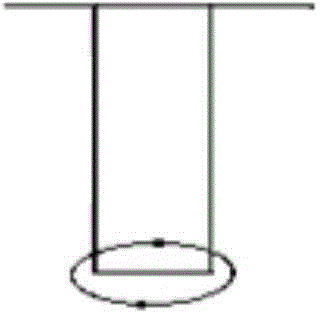

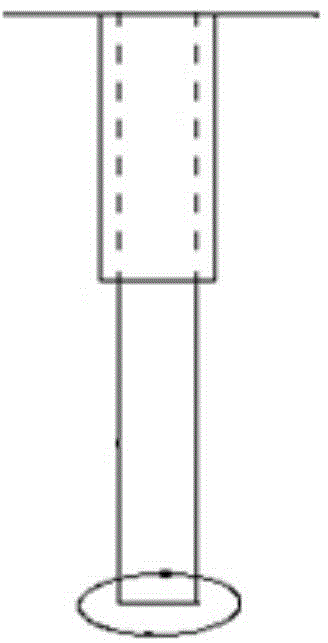

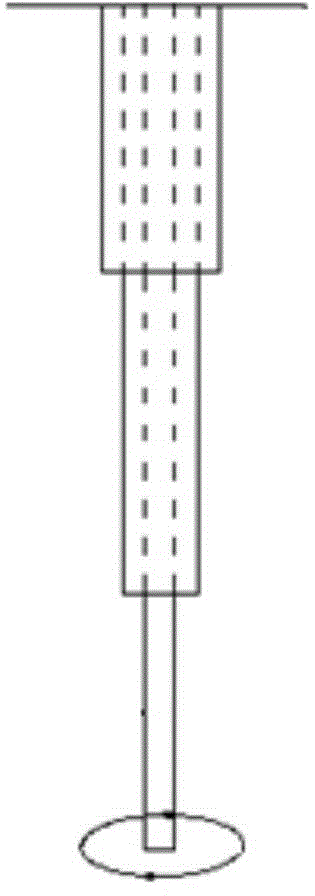

Rotary cutting tool, such as a drill, comprising an exchangeable cutting insert, and an exchangeable cutting insert

ActiveUS20050084352A1Increase cutting forceGreat inclineWood turning toolsTransportation and packagingFluteBearing surface

A rotary cutting tool that is composed of a tool shank with at least one chucking groove or chip flute and one exchangeable cutting insert. At the tip of the shank a recess for accommodating the cutting insert is provided. The tool shank, on its circumference, has a limb with a bearing surface that is inclined relative to the tool axis and that corresponds to a likewise inclined bearing surface on a wing of the cutting insert. The inclination of the bearing surfaces produces an axial force that retains the cutting insert on the tool shank. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KENNAMETAL INC

Rotary cutting tool, such as a drill, comprising an exchangeable cutting insert, and an exchangeable cutting insert

ActiveUS7360974B2Increase cutting forceGreat inclineWood turning toolsTransportation and packagingFluteTrademark

A rotary cutting tool that is composed of a tool shank with at least one chucking groove or chip flute and one exchangeable cutting insert. At the tip of the shank a recess for accommodating the cutting insert is provided. The tool shank, on its circumference, has a limb with a bearing surface that is inclined relative to the tool axis and that corresponds to a likewise inclined bearing surface on a wing of the cutting insert. The inclination of the bearing surfaces produces an axial force that retains the cutting insert on the tool shank. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KENNAMETAL INC

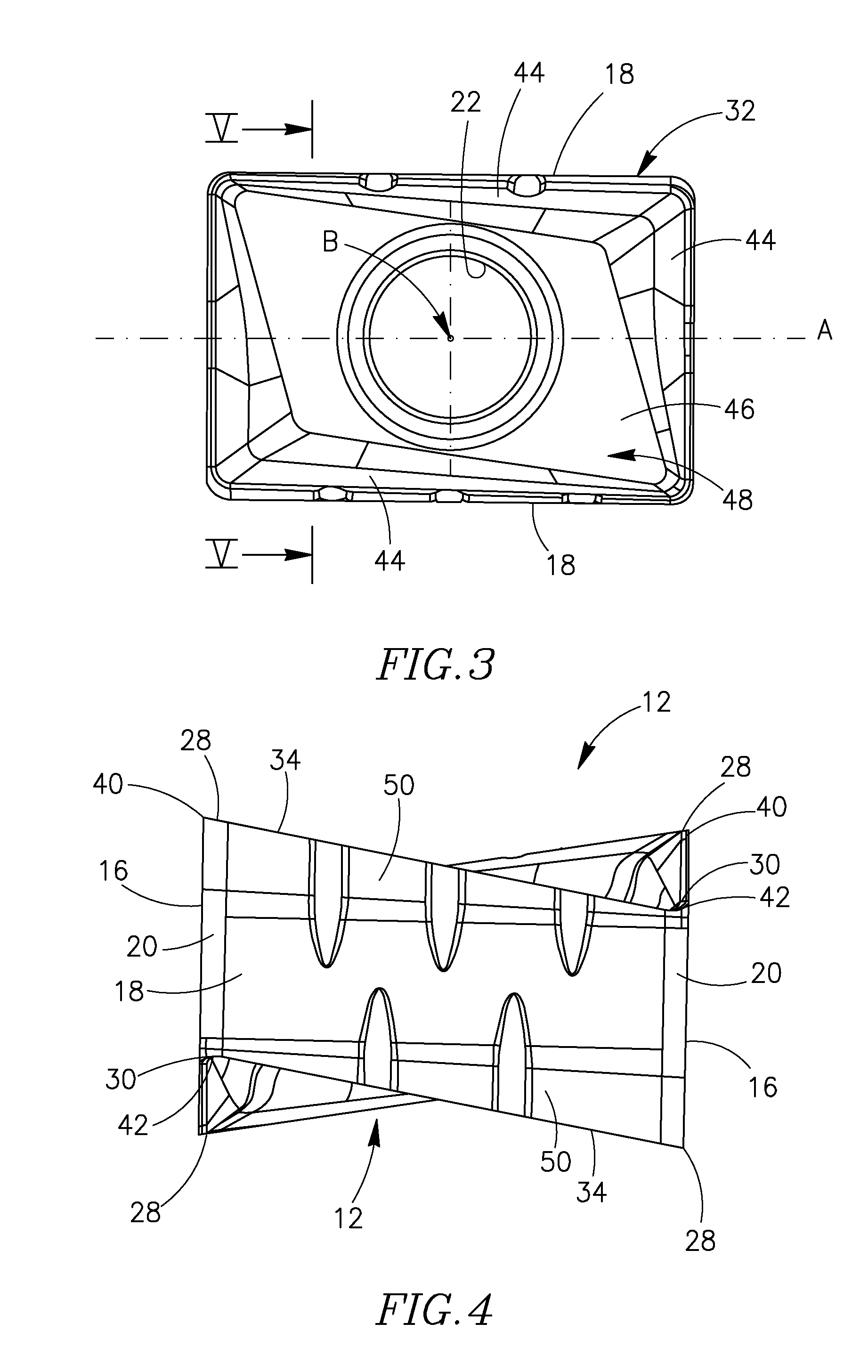

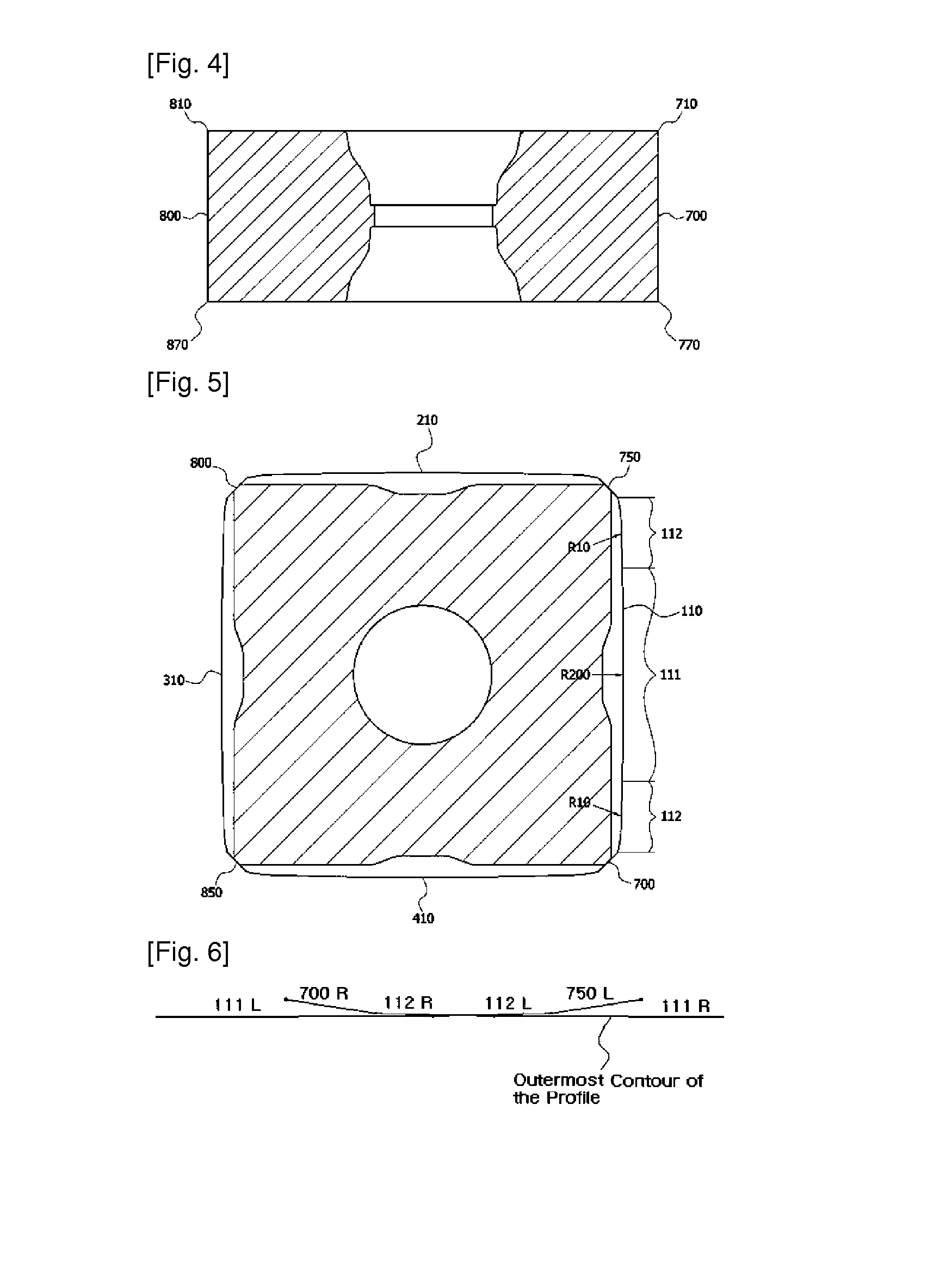

Cutting Insert Having Cutting Edges with Recessed Portions

ActiveUS20110170963A1Improve metal removal rateIncrease cutting forceMilling cuttersTurning toolsEngineeringMechanical engineering

A cutting insert has a cutting edge formed at the intersection of a side surface an end surface. Recesses formed in the side surface interrupt the cutting edge at recessed cutting edge portions. Each recessed cutting edge portion has, in an end view of the cutting insert, a curved central section located between two curved side sections. The central section has a first radius of curvature and each side section has a second radius of curvature, the first radius of curvature being larger than the second radius of curvature.

Owner:ISCAR LTD

Reciprocating saw blade having variable-height teeth and related method

ActiveUS8210081B2Increase loadHigh teethMetal sawing devicesMetal sawing toolsPortable powerEngineering

A reciprocating saw blade, for use in a portable power reciprocating saw including a chuck for releasably engaging the saw blade, includes a tang having an elongated axis and being engageable with the chuck for attaching the saw blade to the reciprocating saw. The saw further includes a blade portion having a cutting edge that defines a plurality of cutting teeth. The cutting teeth define a repeating pattern of successive groups of teeth. Each group of teeth is less than about a half inch in length, and includes a plurality of laterally offset teeth, at least one relatively high first tooth and at least one relatively low second tooth. Prior to tooth set, the at least one relatively high first tooth is at least about 0.002 inch higher than the at least one relatively low second tooth.

Owner:BLACK & DECKER INC

Tangential cutting insert

ActiveUS20130302099A1Avoid scratchesLower resistanceMilling cuttersTurning toolsMachined surfaceMechanical engineering

A hexahedral insert has top and bottom faces and two pairs of opposing side faces with main cutting edges formed on the borders of the top and bottom faces to the side faces and a screw hole passing through each central portion of the top and bottom faces. The top and bottom faces are flat planes parallel to each other; each of the side faces consecutively from top to bottom includes an upper land portion, an upper inwardly-inclined portion, a flat support surface, a lower inwardly-inclined portion, and a lower land portion. Each of two adjacent side faces has a corner surface therebetween which forms corner edges on the borders to the top and bottom faces. The cutting insert enhances the cutting power by reducing cutting resistance and prevents scratches on a machined surface.

Owner:TAEGUTEC

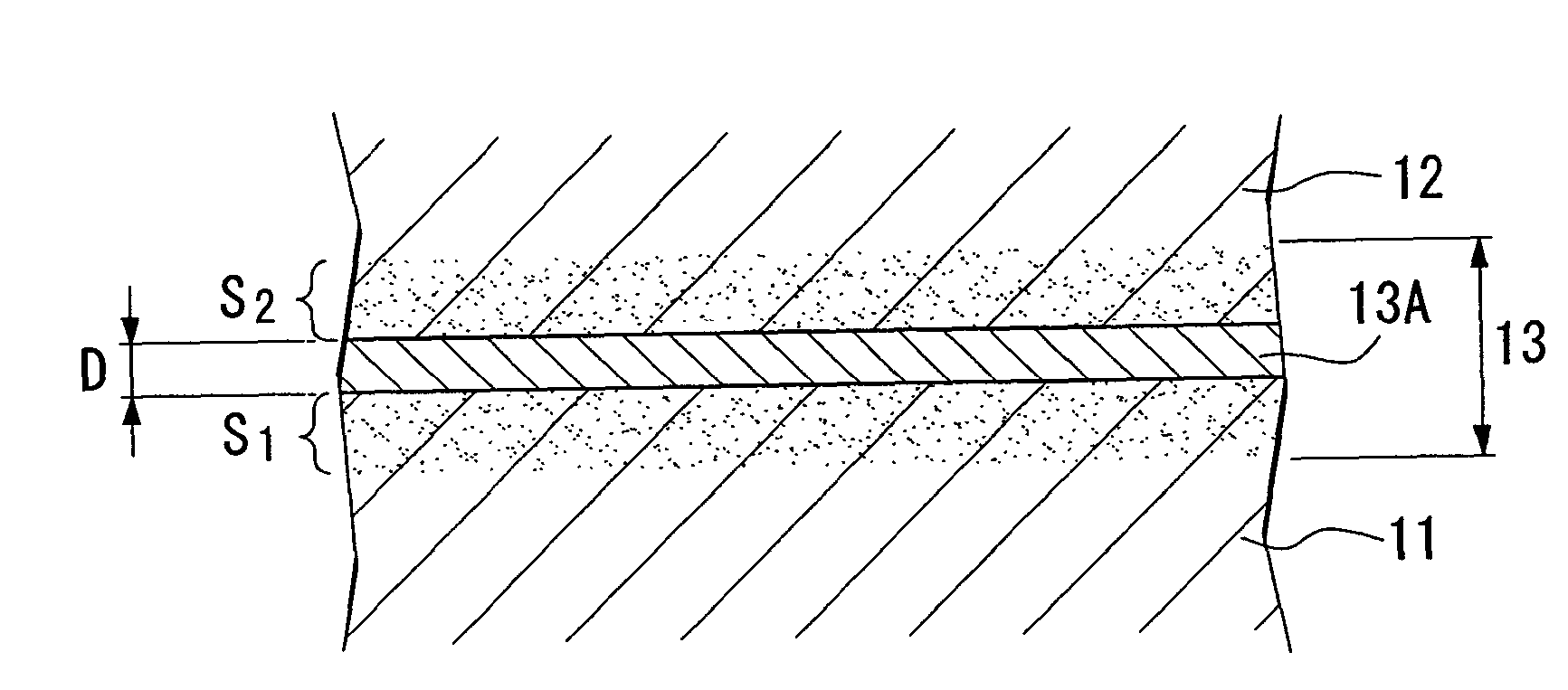

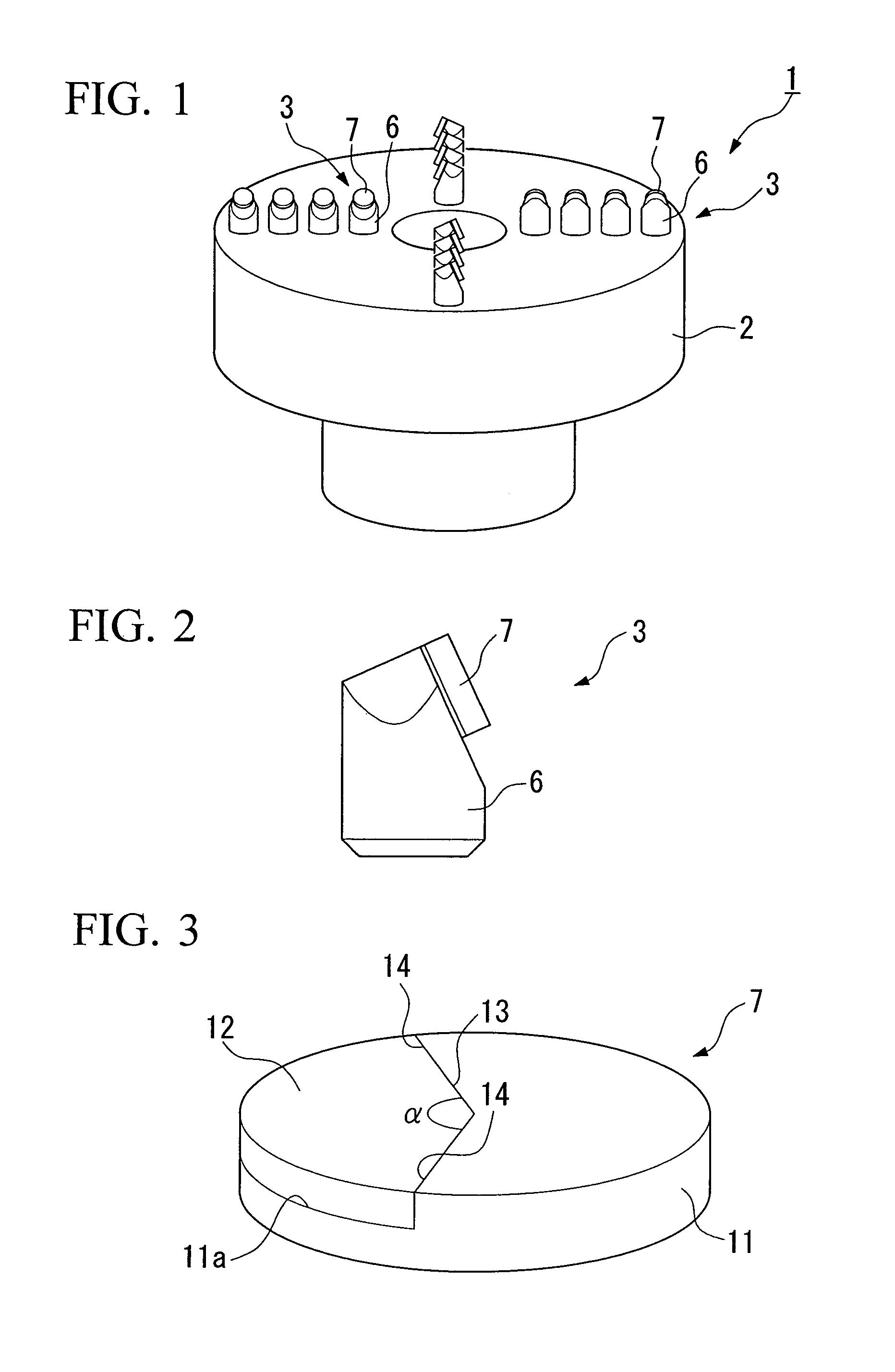

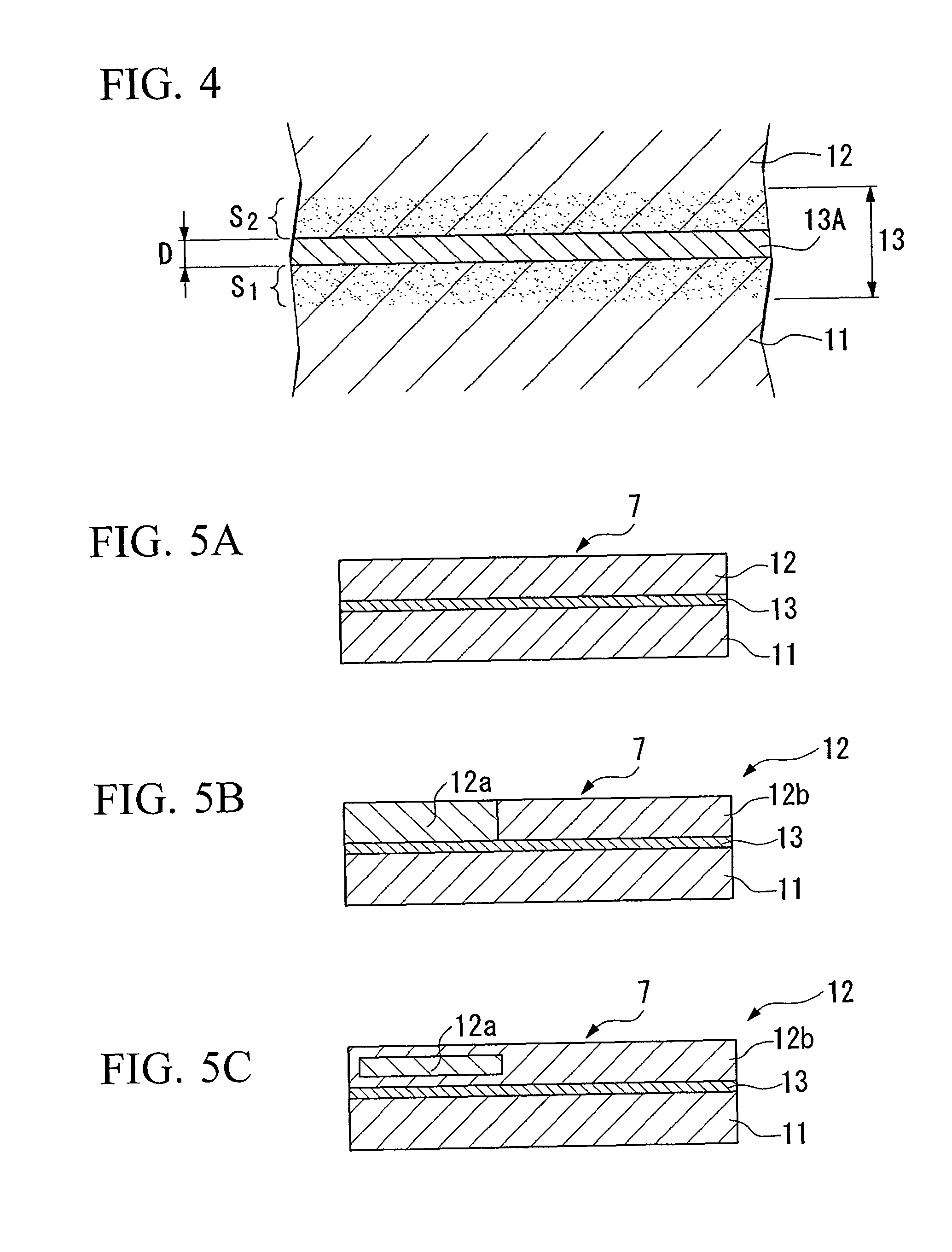

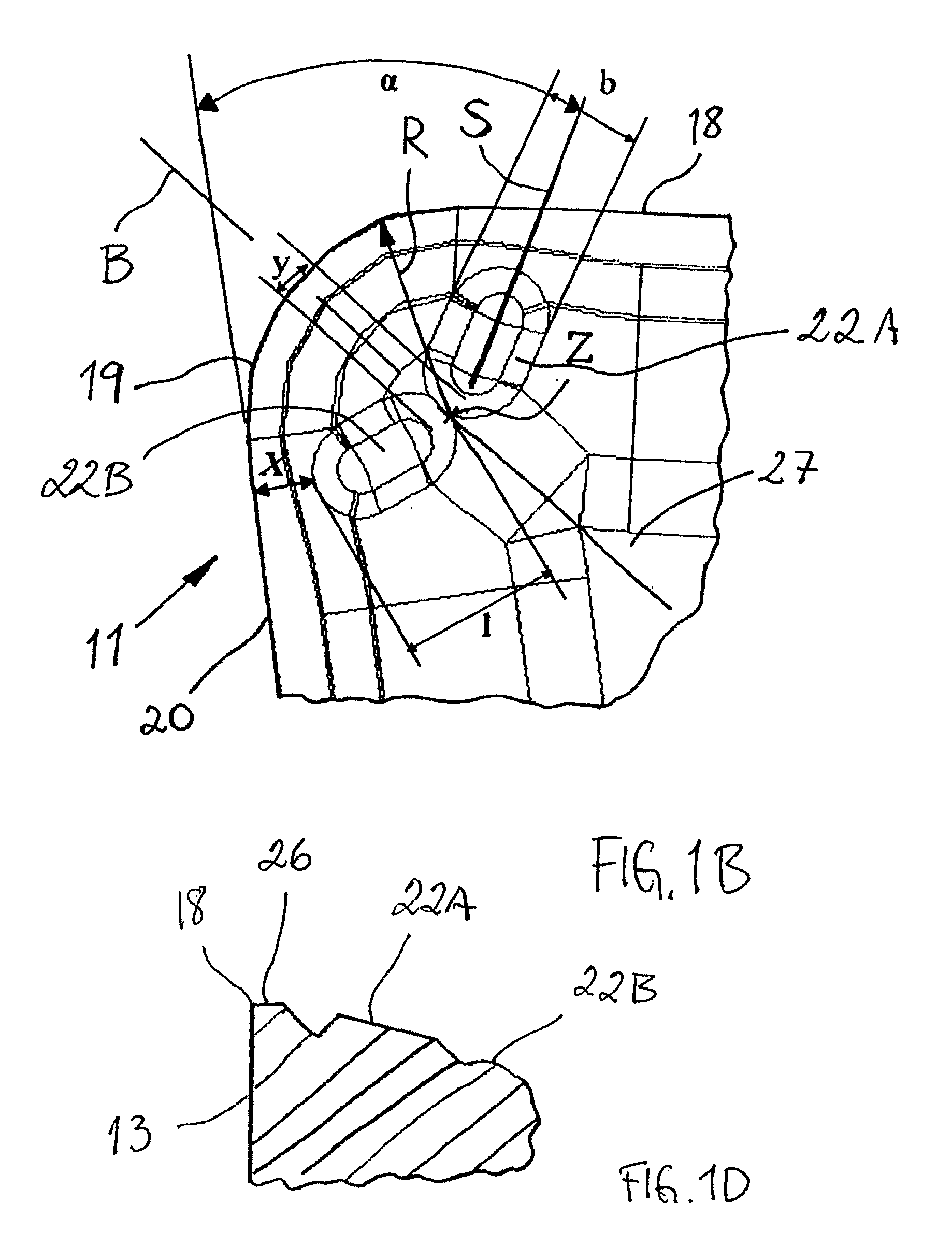

Bonding structure and bonding method for cemented carbide element and diamond element, cutting tip and cutting element for drilling tool, and drilling tool

ActiveUS7261753B2Difficult to separateApplies impactPigmenting treatmentDrill bitsCemented carbideMetal

A cutting tip for a drilling tool includes a cemented carbide cutting base 11, a diamond element 12 supported by the cutting base 11, and a bonding layer formed between the cutting base 11 and the diamond element 12 in order to bond them. The bonding layer 13 includes diffusion layers S1 and S2 in which one or two or more metals selected from a group consisting of Fe, Ni, Co, Ti, Zr, W, V, Nb, Ta, Cr, Mo, and Hf diffuses into at least one of the cemented carbide or the diamond.

Owner:MITSUBISHI MATERIALS CORP

Cutting Insert for Turning with Chip-Breaker Arrangement Providing Room for a Cooling Jet

ActiveUS20080199263A1Increase pressureIncrease temperatureMilling cuttersCutting insertsEdge surfaceWear resistant

A cutting insert includes a polygonal body of a hard, wear-resistant material, which has an upper surface and a lower surface, and a plurality of edge surfaces uniting said surfaces. At least one chip-breaker arrangement is provided in at least one of the lower and upper surfaces. At least one rounded cutting corner, provided with a nose-cutting edge, is formed at a nose portion at the area of the intersection area of two edge surfaces. The cutting corner defines a bisector. The chip-breaker arrangement includes two elongate chip-breaker segments having an opening provided therebetween intended to give room for a cooling jet directed toward the opening.

Owner:SECO TOOLS AB

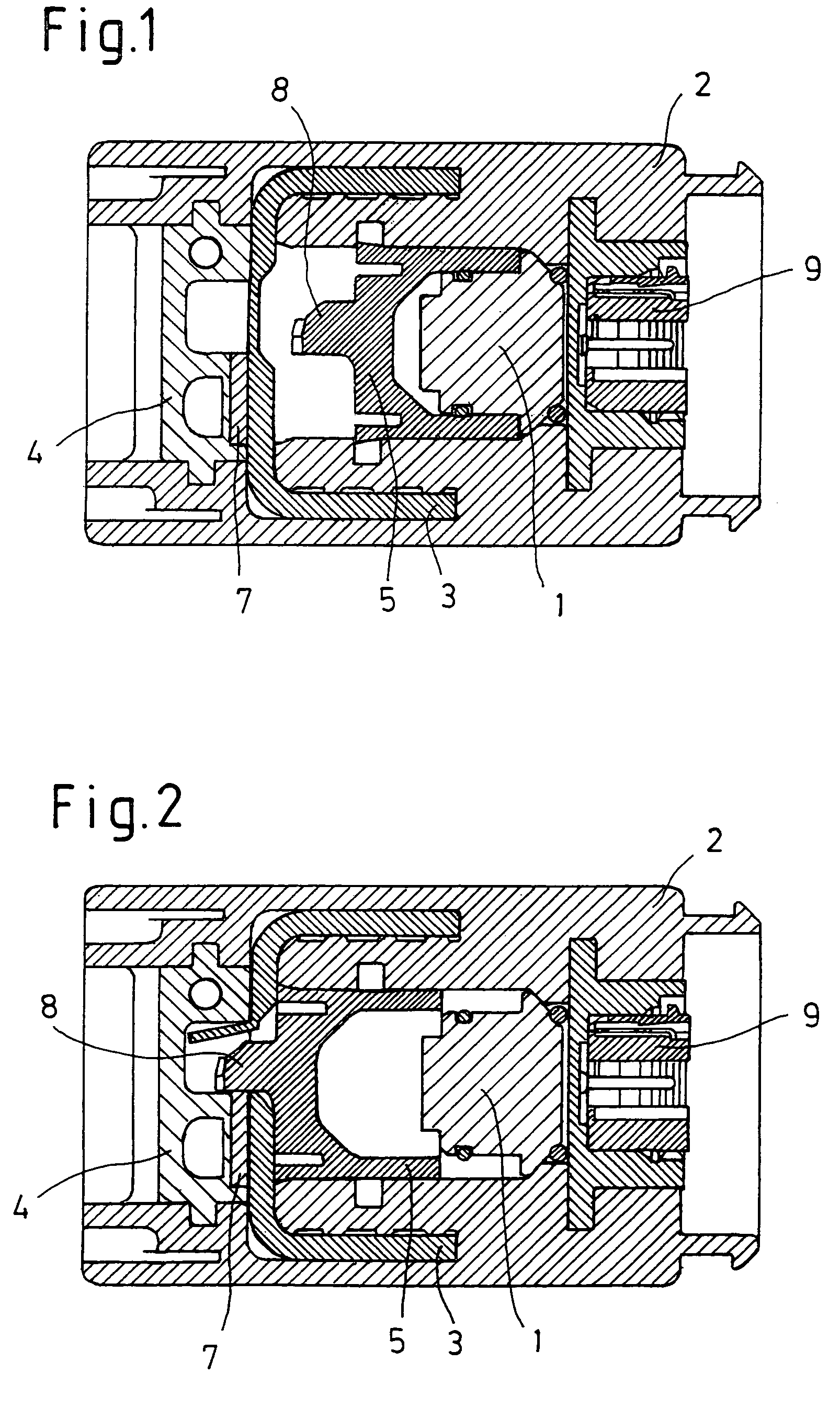

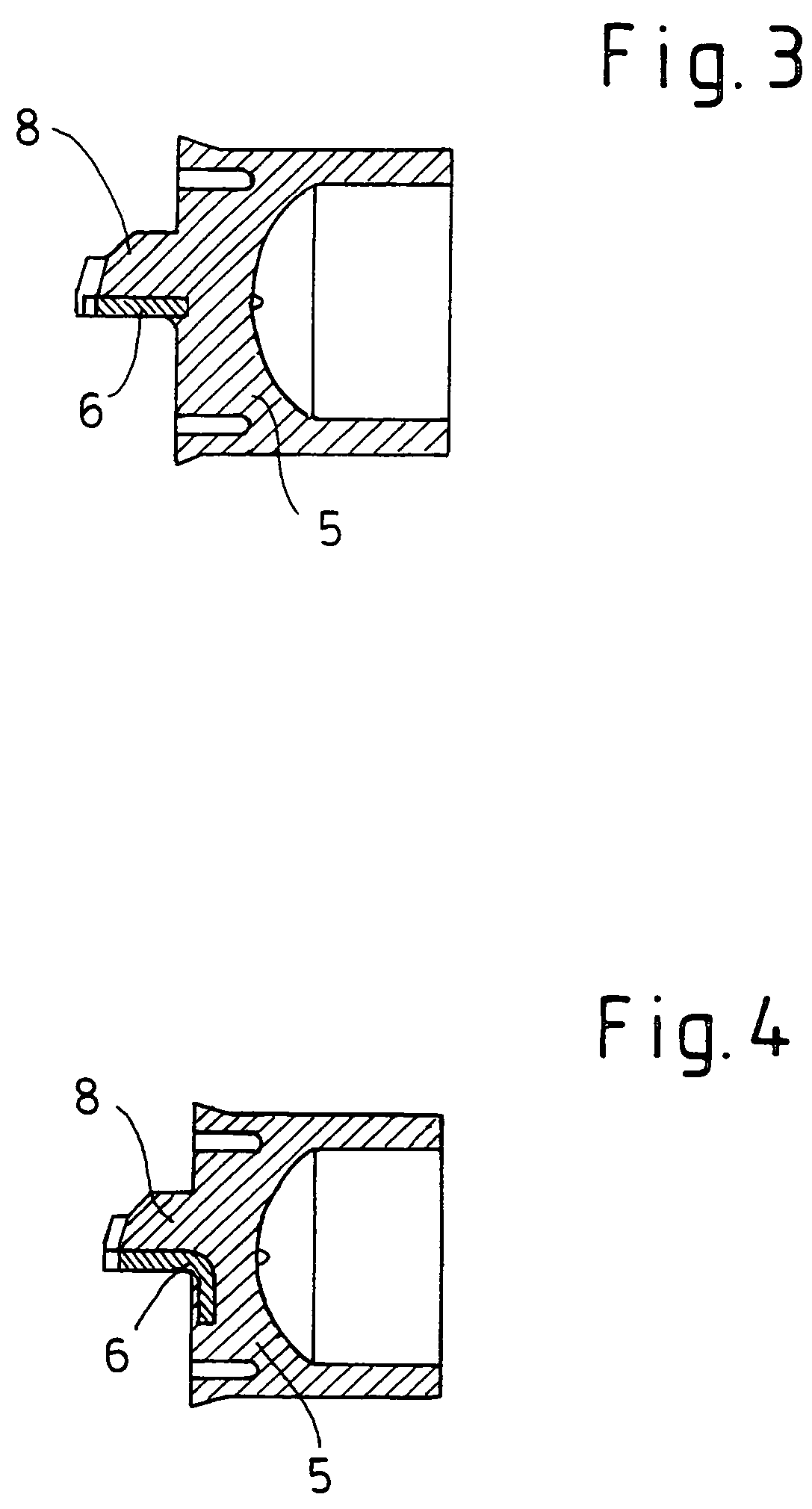

Chisel for a pyromechanical disconnecting device

InactiveUS7205879B2Better pressure distributionIncrease the carrying areaBattery cutoff switchesConductor severing switchesElectrical conductorChisel

The invention relates to a pyromechanical disconnecting device having a housing (2) in which an electrical conductor (3) is arranged, having a cutting plunger (5) and a cutting chisel (8) made of plastic arranged thereon for severing the electrical conductor (3), and having a pyrotechnic igniter (1) in which a pyrotechnic charge is arranged for driving the cutting plunger (5), the cutting chisel (8) having an edge that slides along a mating edge of the housing (2) or of a component (4) of the housing (2) when the cutting plunger (5) or the cutting chisel (8) is driven and when the electrical conductor (3) is severed.In order to achieve better cutting power, it is proposed that the edge of the cutting chisel (8) and / or the mating edge of the housing (2) or of a component (4) of the housing (2) comprise an inserted structural element (6, 7) having a greater hardness than plastic.

Owner:AUTOLIV DEV AB +2

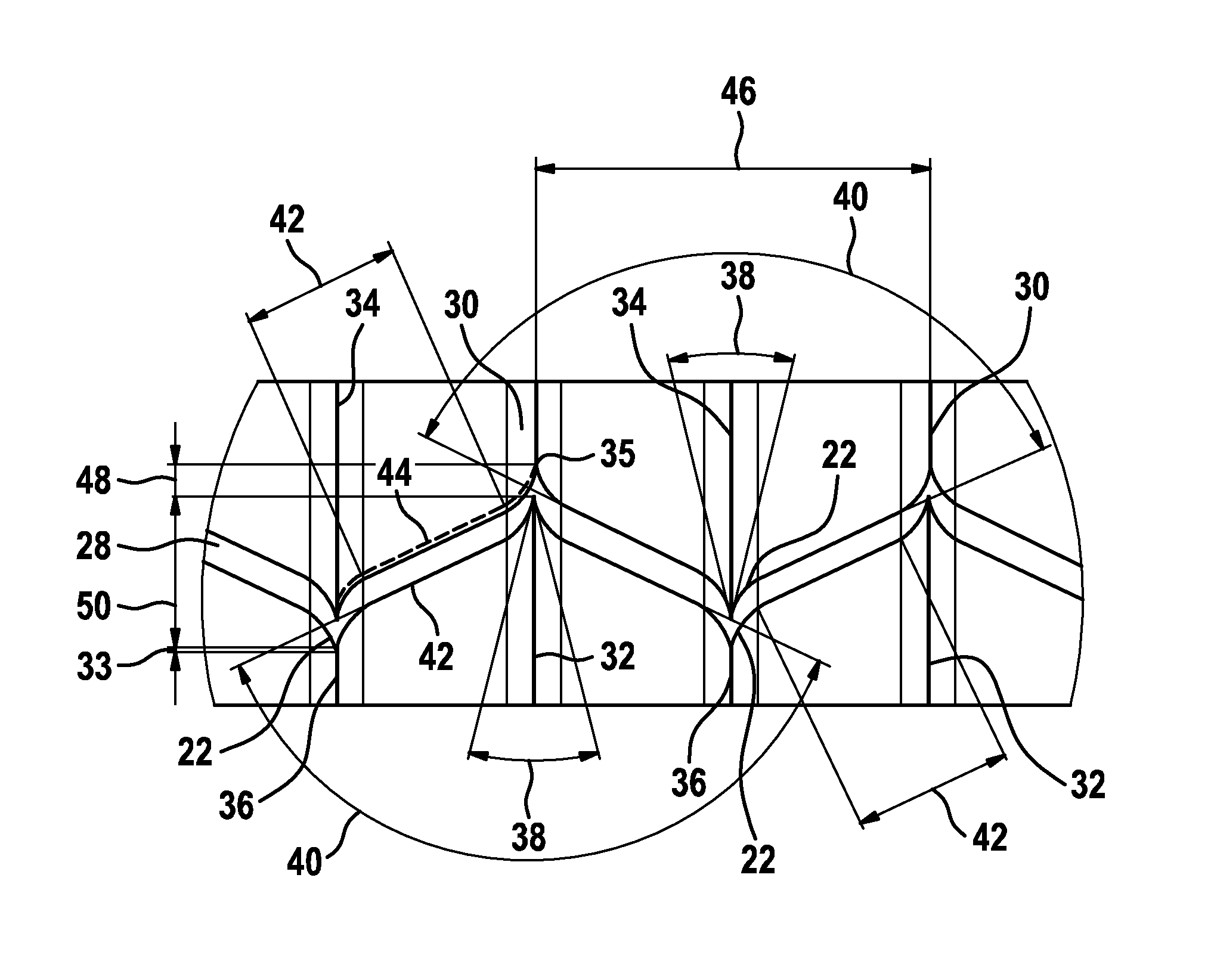

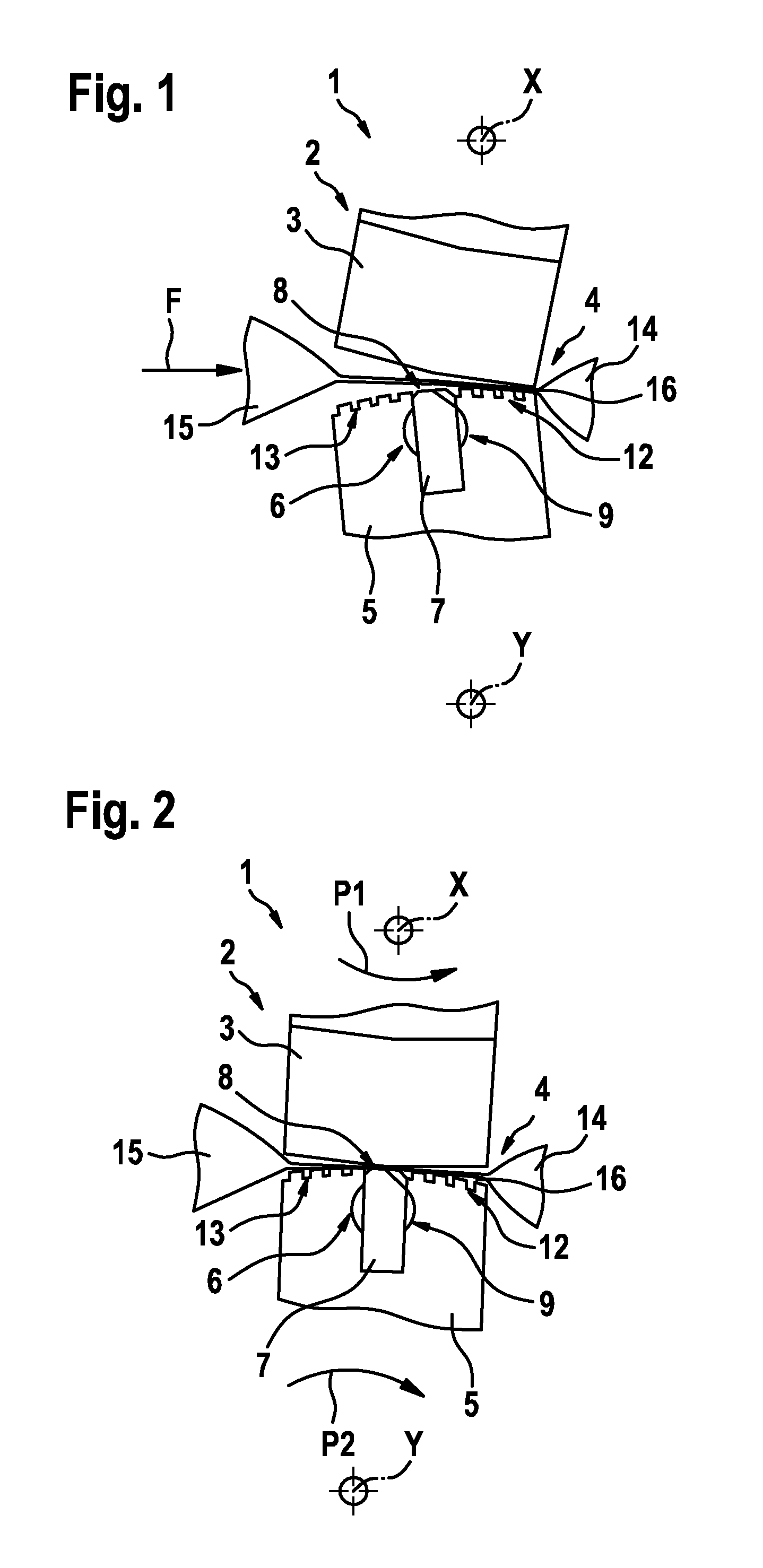

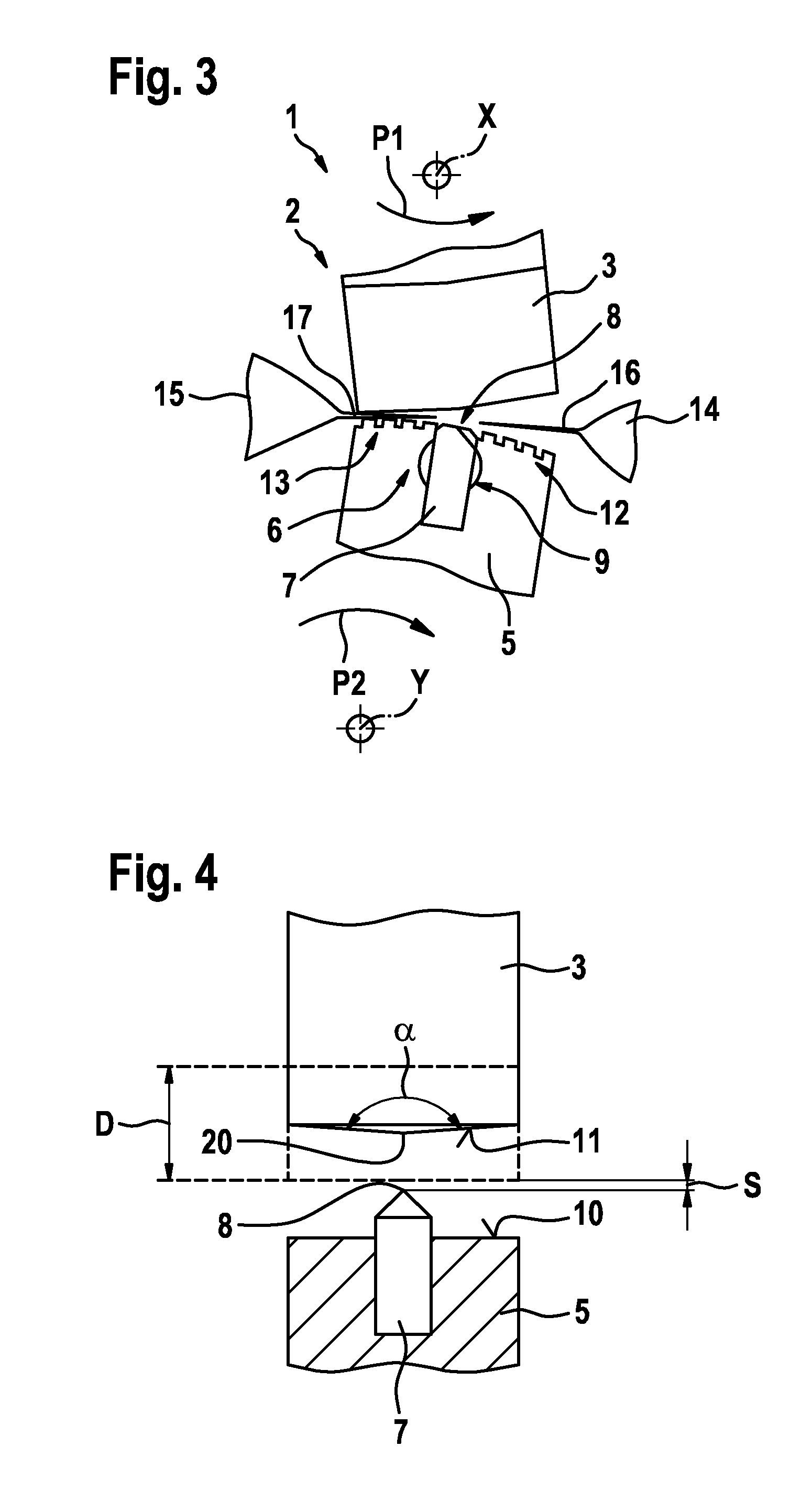

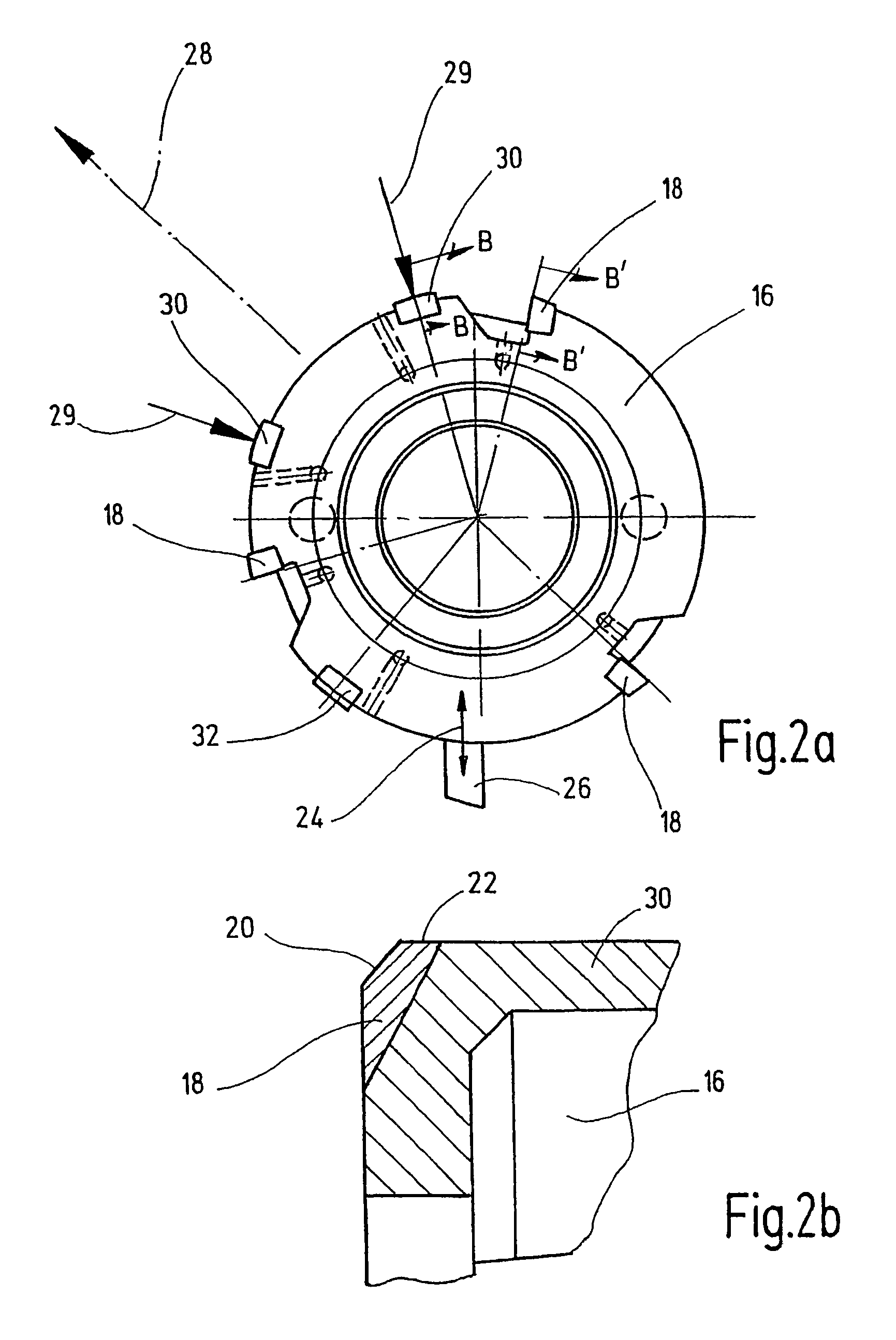

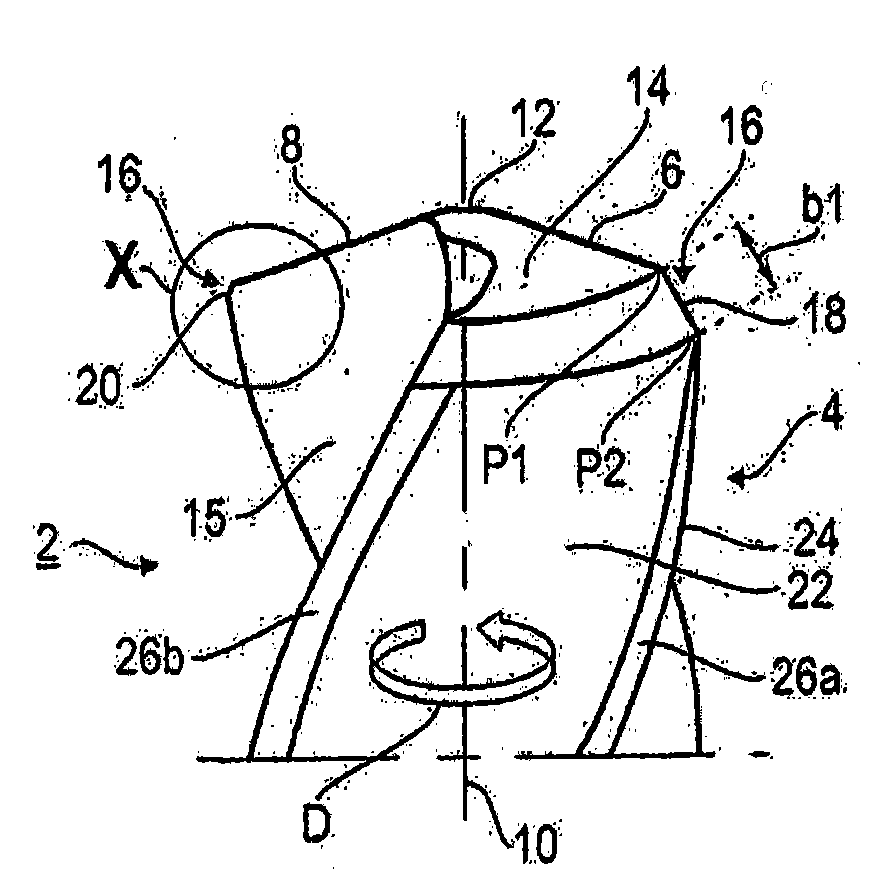

Apparatus for cutting a packaging material for a package

ActiveUS20130228288A1Reduce cutting forceReduce cut lengthLamination ancillary operationsLaminationUltrasonic weldingMechanical engineering

The invention relates to an apparatus for cutting a packaging material (4) for a package, comprising an ultrasonic welding device (2) that includes a sonotrode (3) and an anvil (5) for sealing the packaging material (4), the sonotrode (3) being rotatable about a first axis of rotation (X) and the anvil (5) being rotatable about a second axis of rotation (Y). The apparatus further comprises a cutting device (6) which includes at least one knife (7) for cutting the packaging material (4) and which is arranged within the anvil (5). The invention is characterized in that the knife (7) has a blade (8) with a cutting edge (28) that includes at least two tips (33, 35) and at least two curved sections (22) interconnecting the two tips (33, 35).

Owner:MAHLE INT GMBH +1

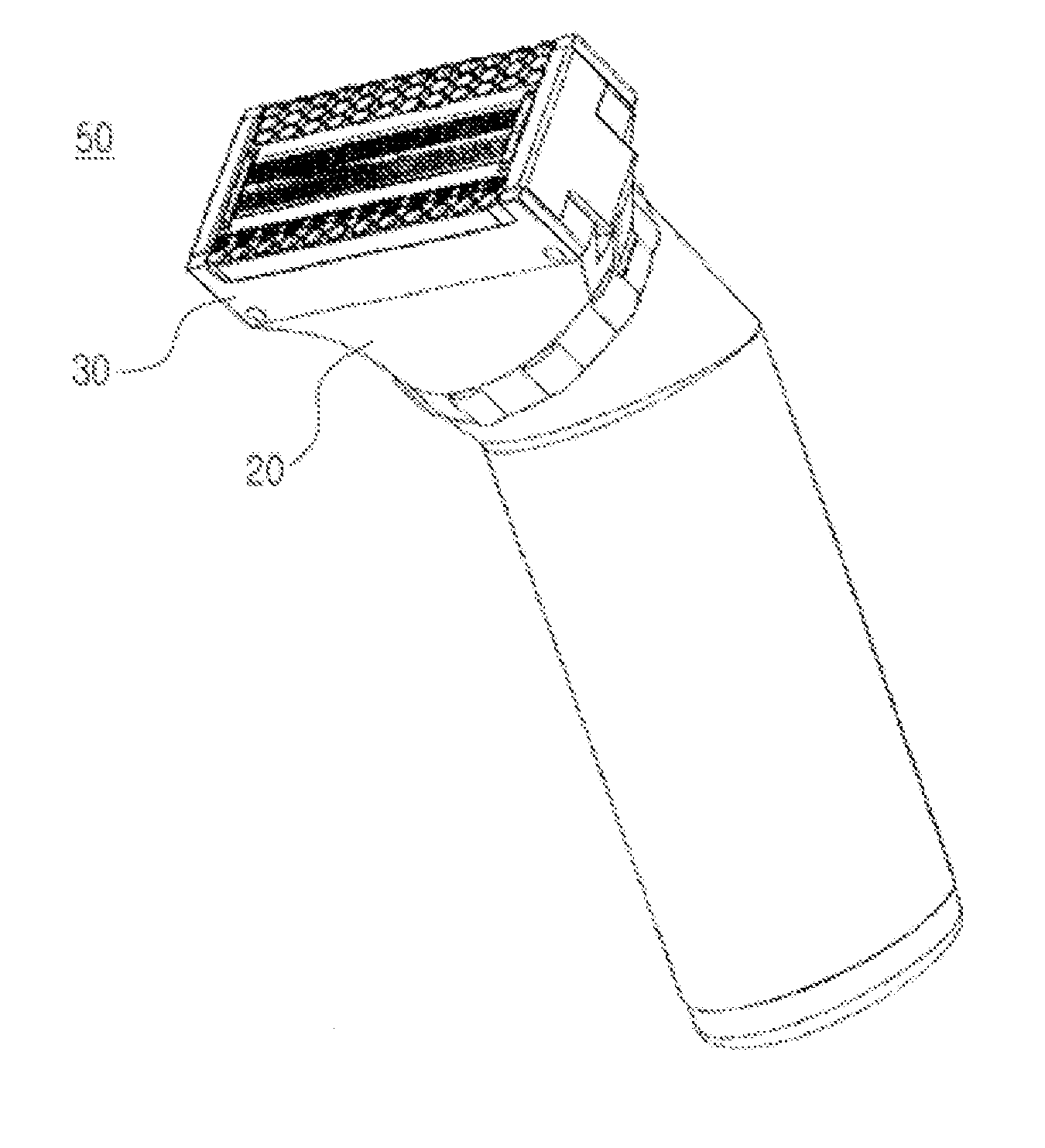

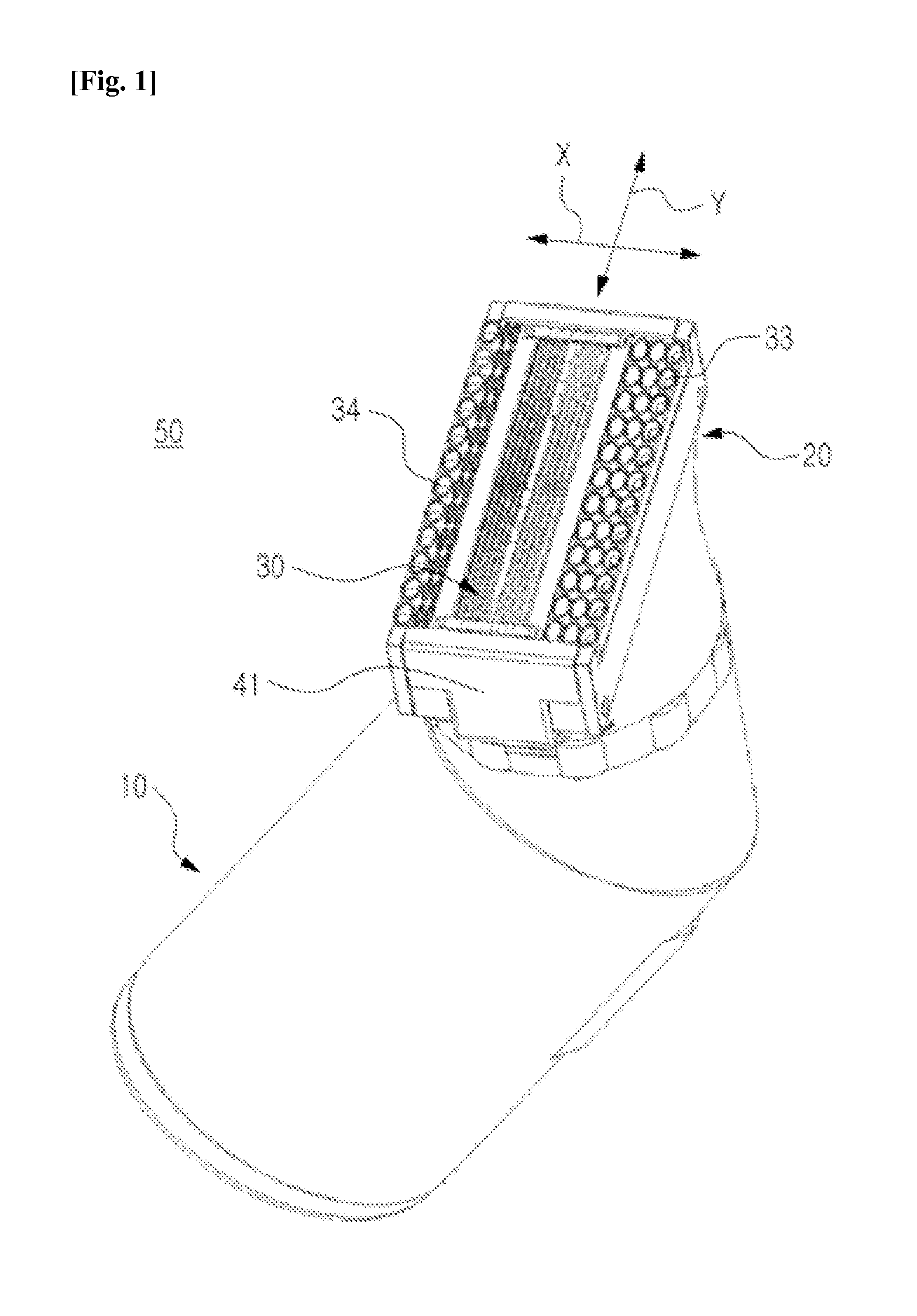

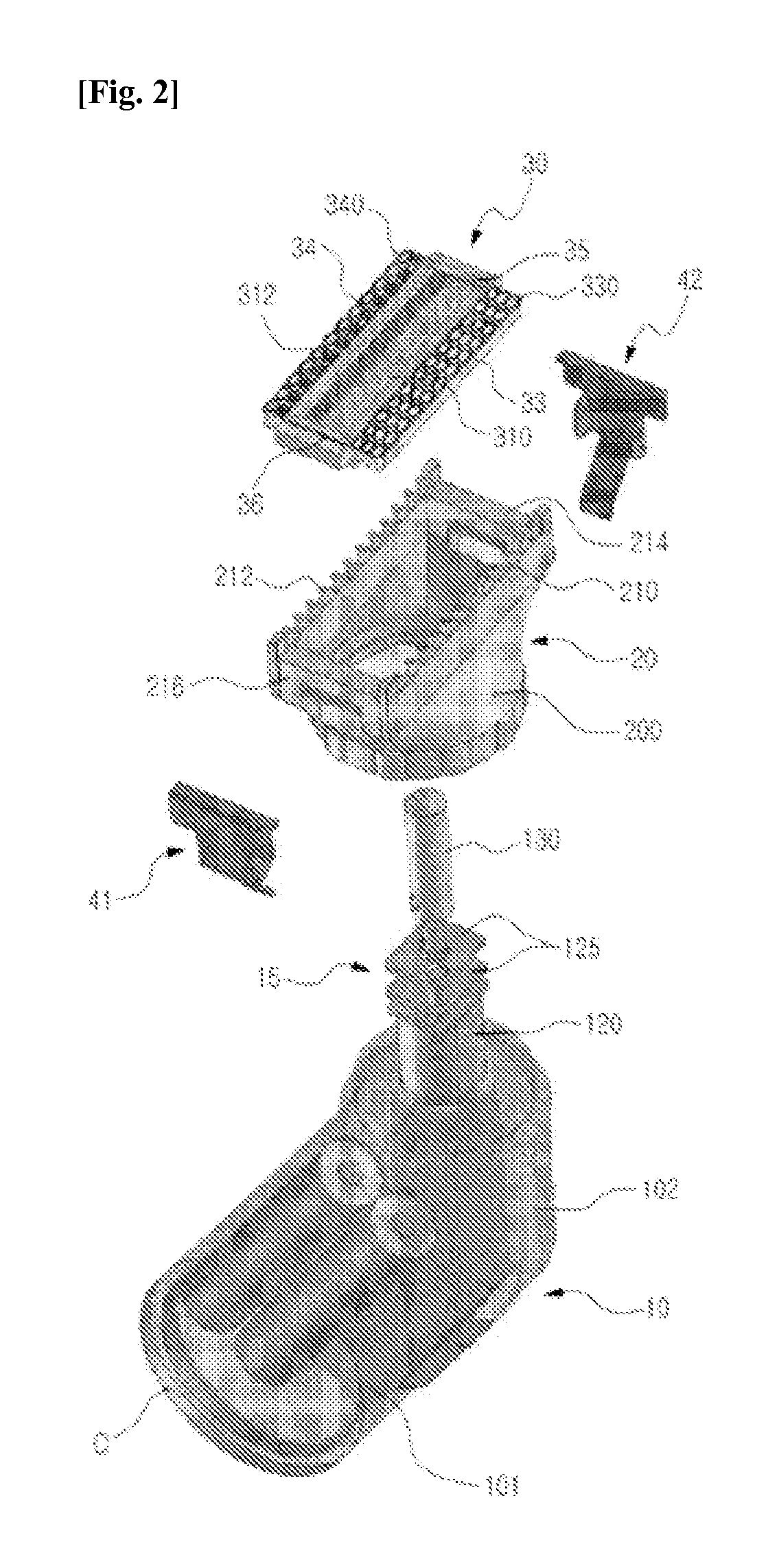

Reciprocating linear razor

ActiveUS20130160296A1Improved in body hair cutting forceIncrease cutting forceMetal working apparatusEngineeringRazor Blade

The present invention pertains to a razor, which includes: a gripping section combined with a housing; a head section coupled at one side of the housing; a razor blade cartridge mounted at a front surface of an upper end of the head section; and an eccentric cam module, which moves the razor blade cartridge to reciprocate in a cutting direction.

Owner:DORCO CO LTD

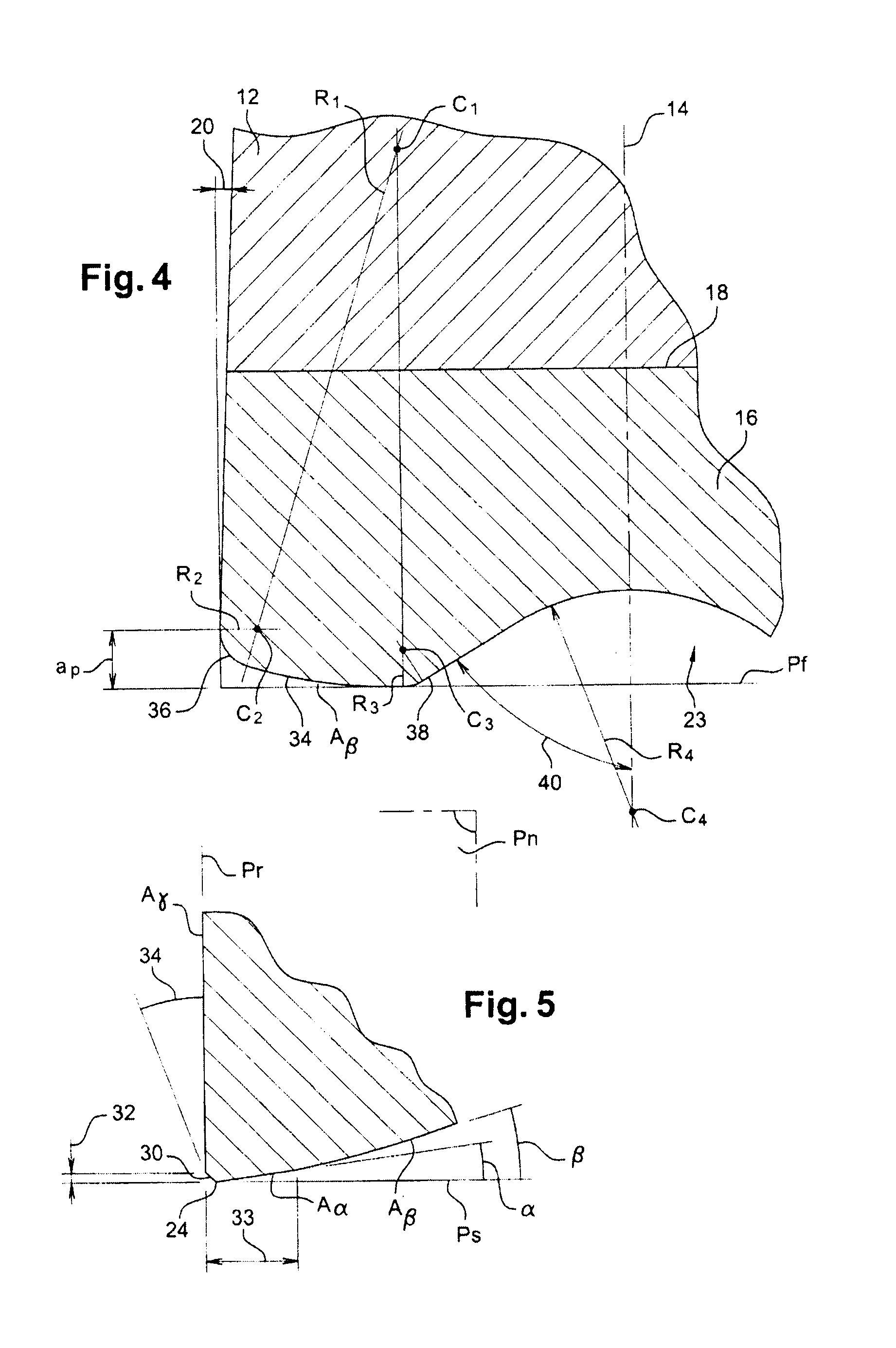

Slotting milling cutter for machining with a high feed and a low pass depth

ActiveUS20090060663A1Reduce shear forceReduce torqueTool workpiece connectionMilling cuttersMilling cutterCarbide

Slotting milling cutter, comprising a carbide body (12) and a ceramic head (16) fixed by brazing to one end of the body, this head having teeth (22), each comprising a cutting edge (24) formed by the intersection between a front cutting face (Aγ) and a lower flank face, in which the milling cutter has a frustoconical general shape, the profile of the flank face, formed by the intersection of the flank face with a plane passing through the axis of the milling cutter, has an outwardly convex rounded shape, and the radial cutting angle is negative.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Glass grinding fluid and preparation method thereof

InactiveCN103275803AGood cleaning penetration performanceGood self-sharpeningLubricant compositionCamera lensCleansing Agents

The invention discloses a glass grinding fluid and a preparation method thereof. A technical scheme in the invention is characterized in that the glass grinding fluid comprises 5-20wt% of a grinding dust settling agent, 2-8wt% of a cleaning agent, 1-20wt% of a pH stabilizing agent, 1-20wt% of a lubricant, 0.3-2wt% of an organosilicon antifoaming agent, and the balance water. The invention also discloses the preparation method of the glass grinding fluid. The glass grinding fluid has good cleaning and penetrating performances, can effectively prevent grinding tools from passivating, has a good self-sharpening effect on the grinding tools, increases the cutting force of diamond tools, and is suitable for grinding common glass, resin glass, optical glass, flat glass, camera lens, spectacle lens, handset cover plates, sapphire glass, optical products of quartz, high-grade marble or superfine granite.

Owner:HENAN NORMAL UNIV

Multiline cutting machine of numerical-control polysilicon silicon

ActiveCN101574836AIncrease cutting forceLow housing requirementsWorking accessoriesFine working devicesNumerical controlUltrasonic sensor

The invention discloses a multiline cutting machine of numerical-control polysilicon silicon, and the silicon which is cut out is used for a reducing furnace used for producing large-diameter polysilicon through modified Siemens Method or silane method. The cutting method comprises the following steps: high-speed reciprocating motion or one-direction movement is carried out on workpieces by using electroplated diamond wires; the workpiece is pressed on a square or a rhombic wiremesh formed by crossing electroplated diamond wires; the workpiece is cut into lathy silicons. The workpiece is mounted on the top of the machine, and cutting can be realized by the bottom-up motion of a rectangle-shaped guide pulley subassembly which is wound with the diamond wires. In the invention, a unique routing scheme is utilized and routing and operation can be realized on ground without on a platform so as to reduce operational complexity greatly, improve work efficiency and safety. An ultrasonic transducer is arranged on the top of the workpiece to lead the workpiece to tremble lightly so that the cutting ability of the diamond wires is improved, cutout grain can be swept away rapidly by cooling water, and the processing speed is enhanced remarkably.

Owner:ECO POWER WUXI

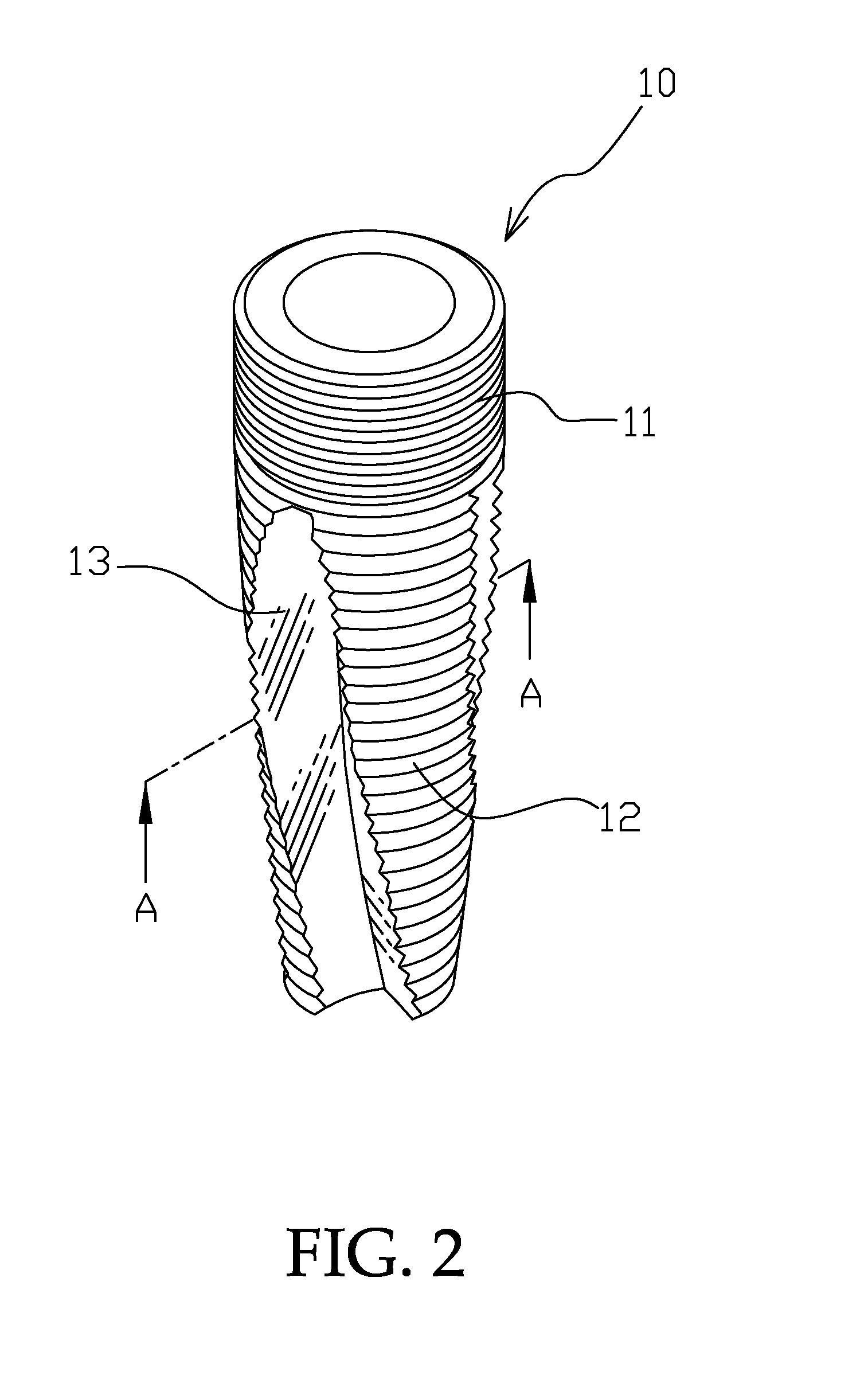

Combination tool

InactiveUS7089837B2Increase cutting forceReduction of anti-penetration actionThread cutting toolsDrilling/boring measurement devicesEngineeringMechanical engineering

Owner:KOMET GROUP GMBH

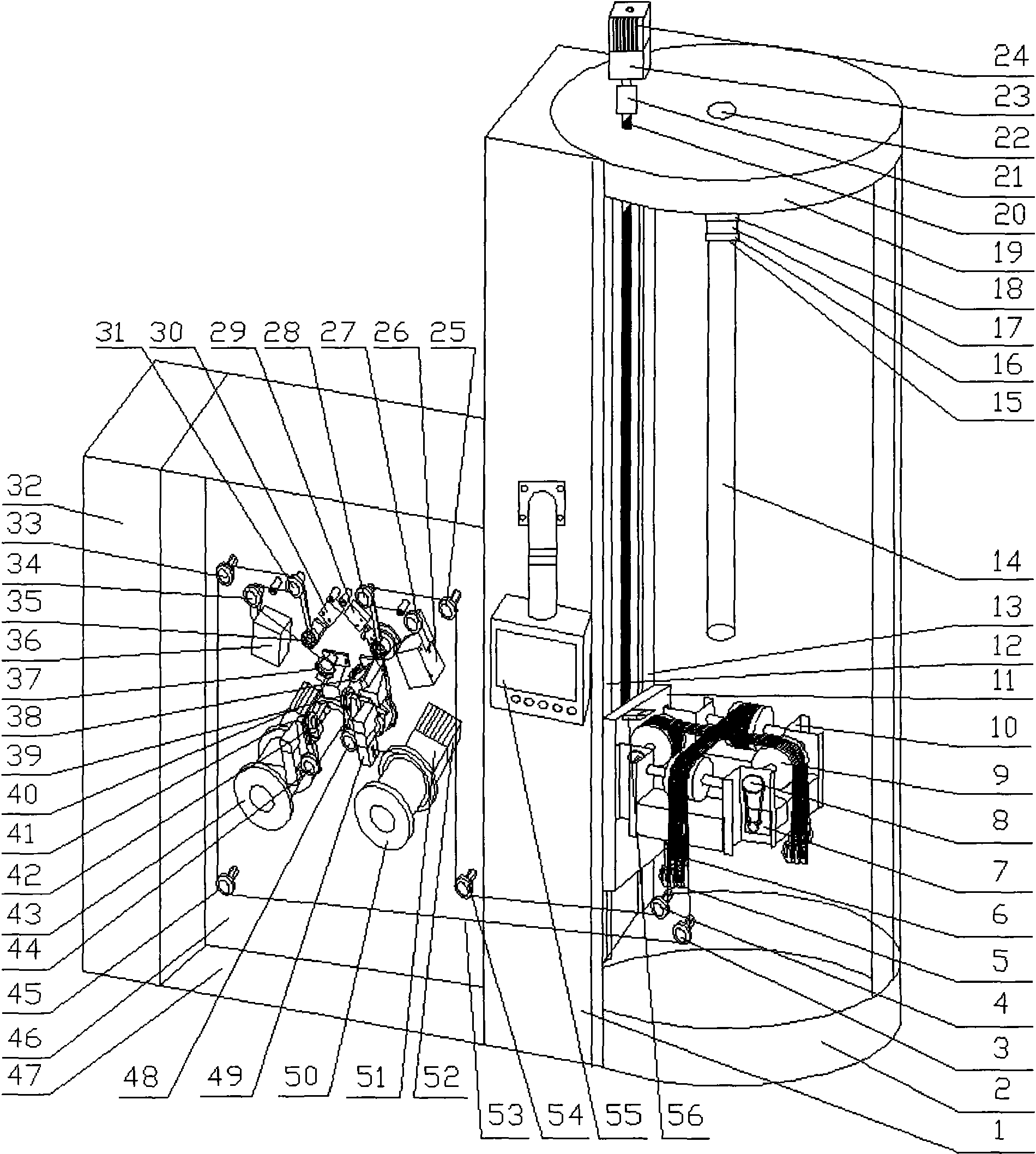

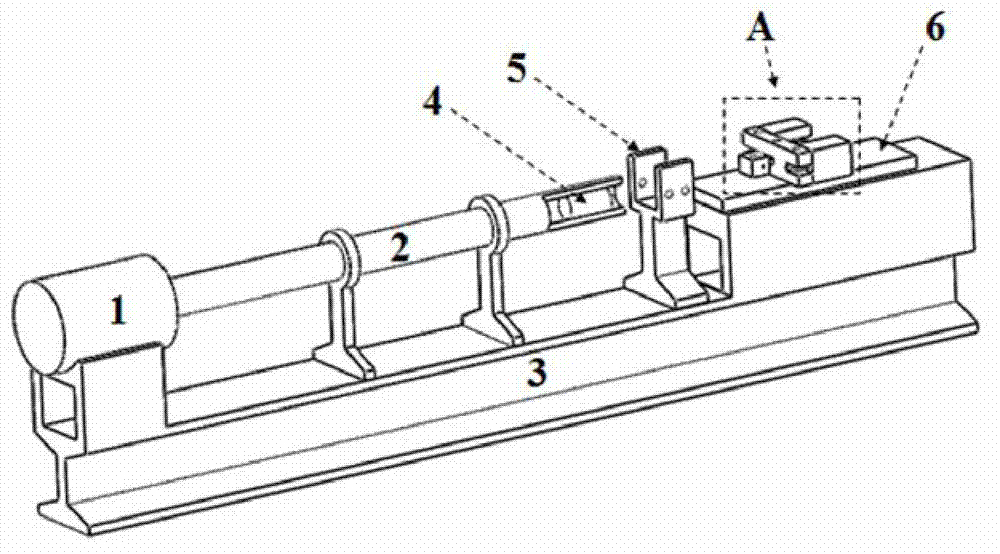

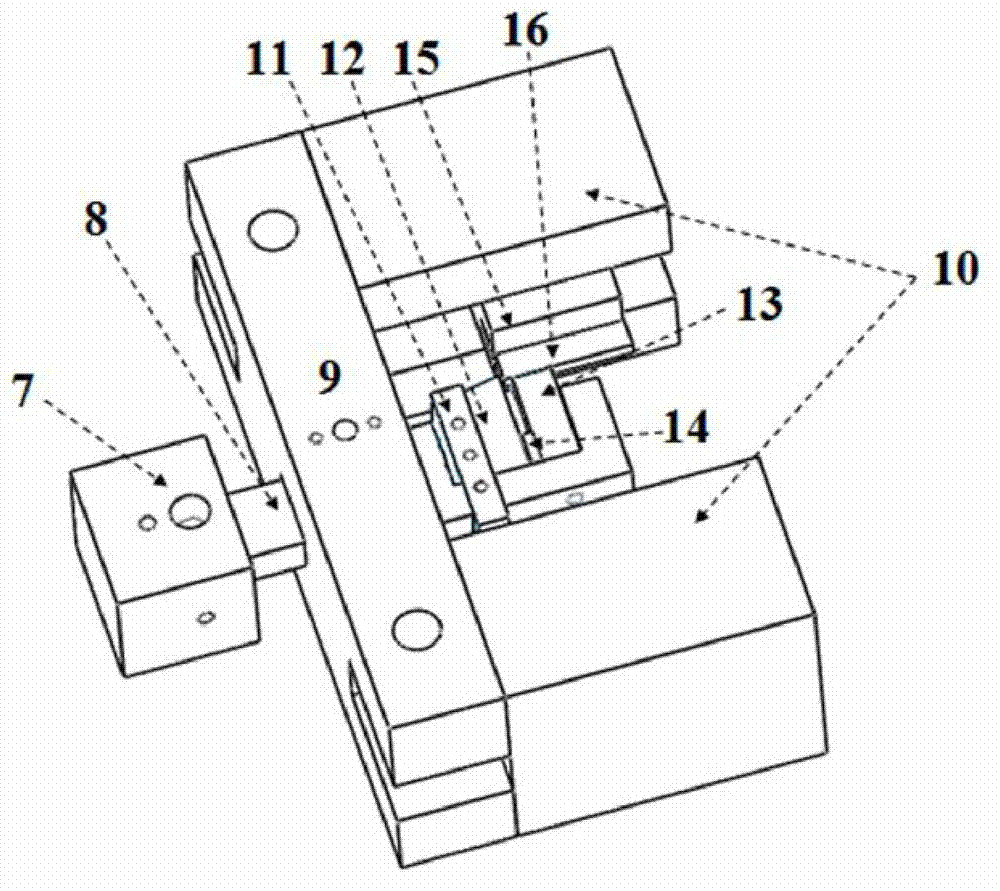

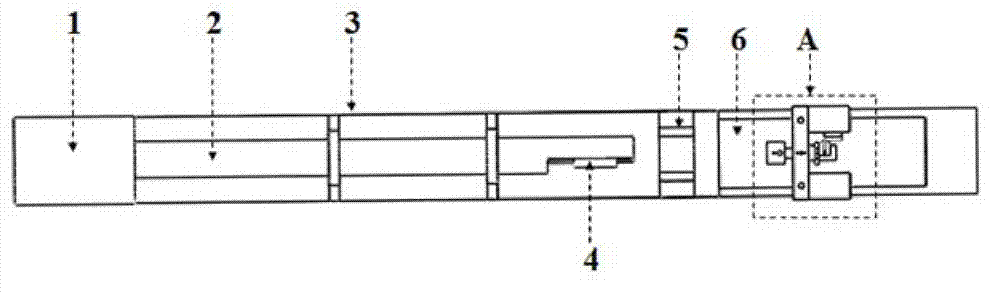

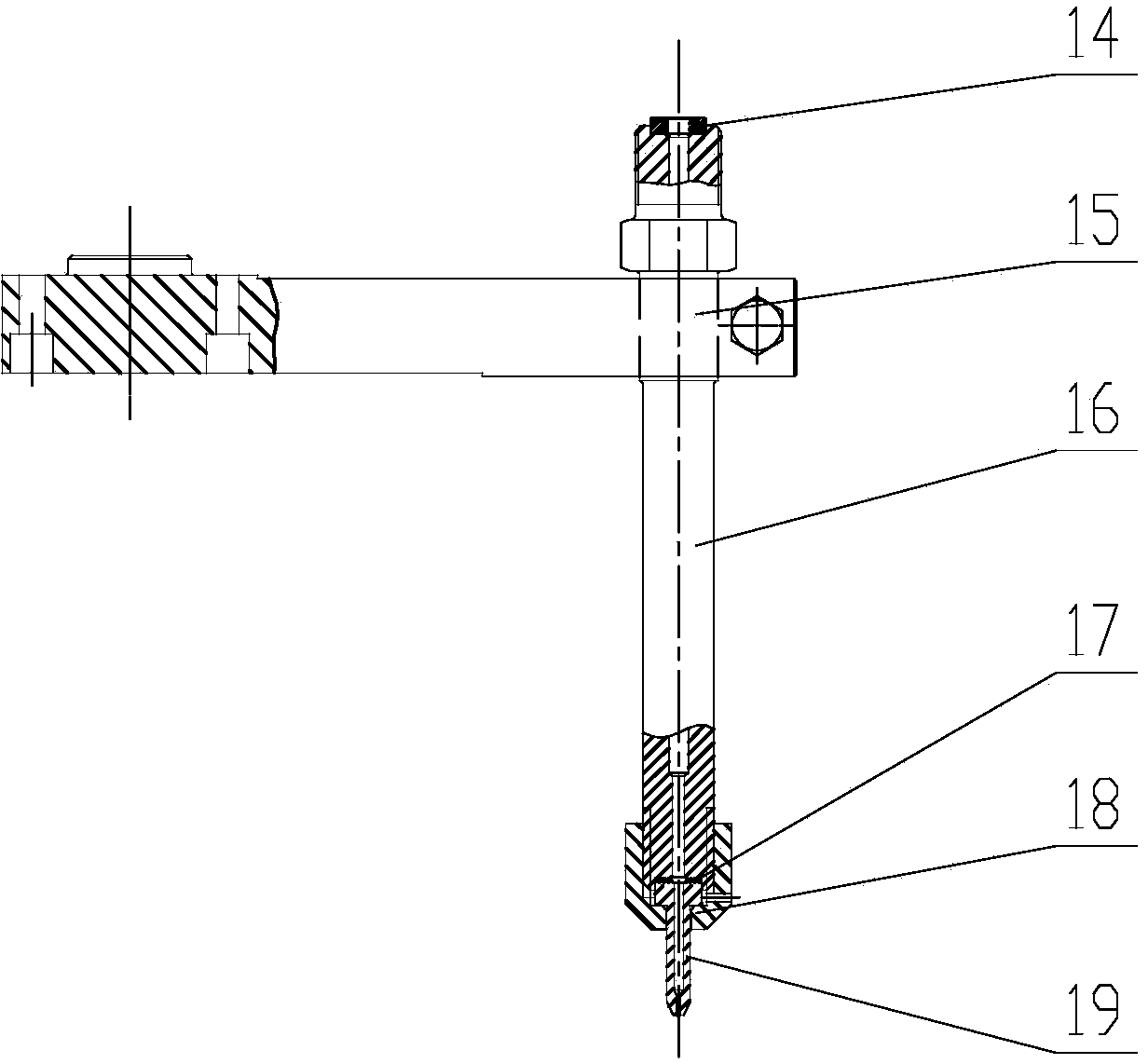

High-speed restrained cutting experimental device based on split Hopkinson pressure bar loading technology

ActiveCN103163037AHigh strain rateConstrained Cutting ExperimentInvestigating machinabilityGun barrelVelocity measurement

The invention discloses a high-speed restrained cutting experimental device based on split Hopkinson pressure bar loading technology. The high-speed restrained cutting experimental device based on the split Hopkinson pressure bar loading technology comprises a Hopkinson pressure bar loading mechanism which is used for pushing a bullet to move along a scheduled track at a scheduled speed, a laser velocity measurement mechanism which is used for measuring a movement speed before the bullet strikes a restrained cutting mechanism, the restrained cutting mechanism which is used for conducting restrained cutting of different plastic deformation degrees on a to-be-processed workpiece, a restrained cutting slideway mechanism which is used for giving a speed direction of restrained cutting, a fixing mechanism which is used for fixing the to-be-processed workpiece and a cutting stopping mechanism which is used for stopping a restrained cutting process. Different cutting speeds are obtained by adjusting pressure of air gun of the Hopkinson pressure bar and an initial position of the bullet in an acceleration gun barrel, different plastic deformation degrees can be obtained by adjusting the space between a tool of the restrained cutting mechanism and a restraining device, the high-speed restrained cutting experimental device based on the split Hopkinson pressure bar loading technology can be utilized to study a material interior microstructure evolution law when the material is with different strain rates and different plastic deformation degrees.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

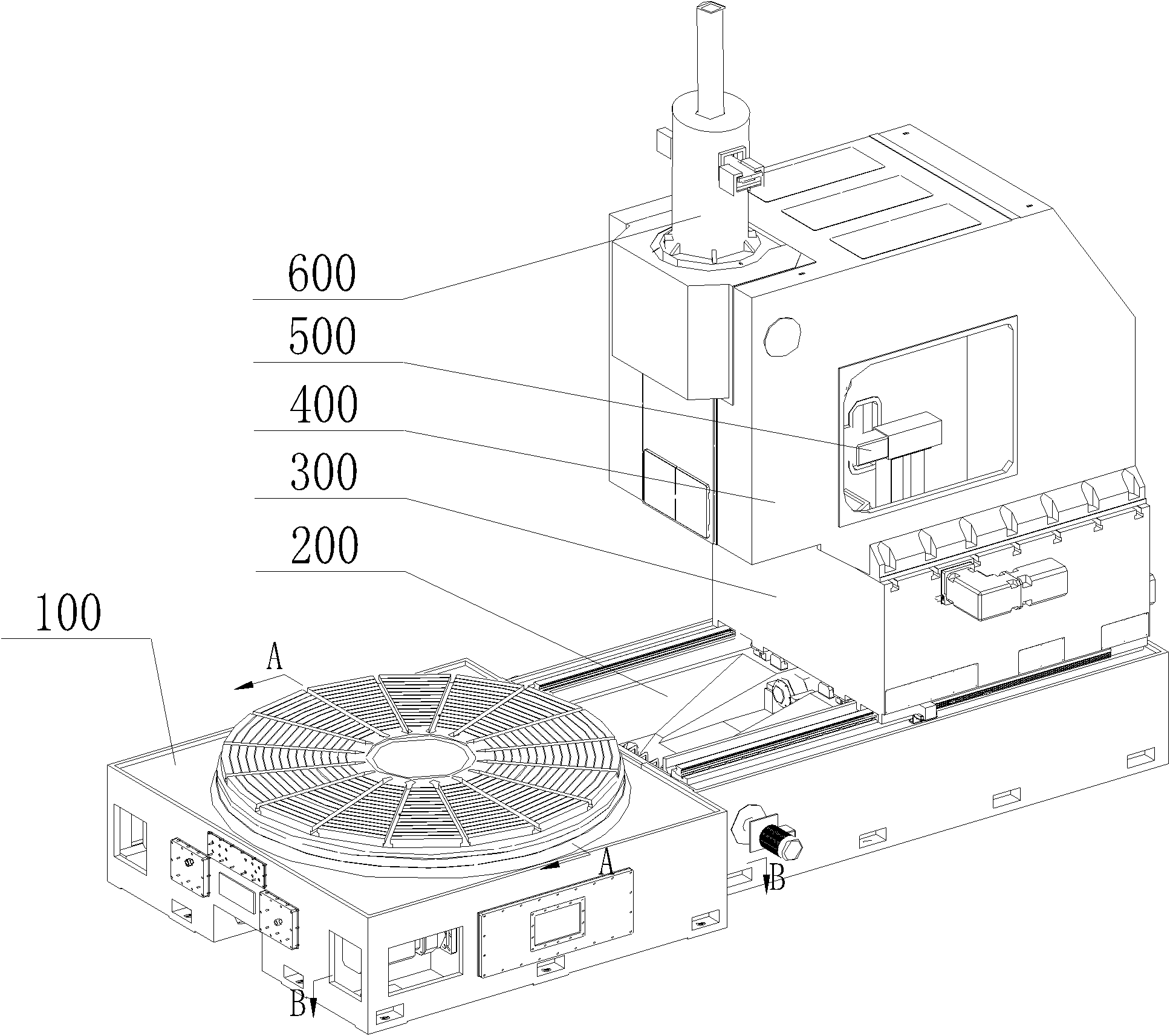

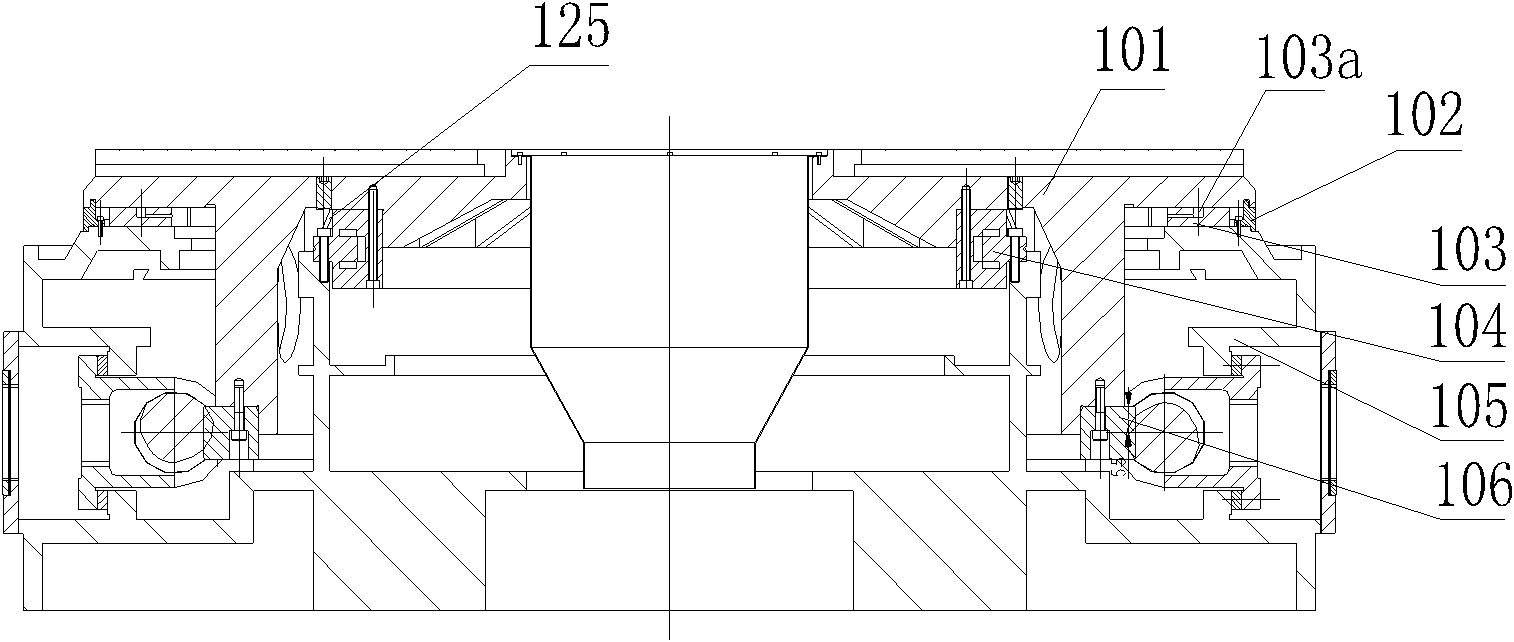

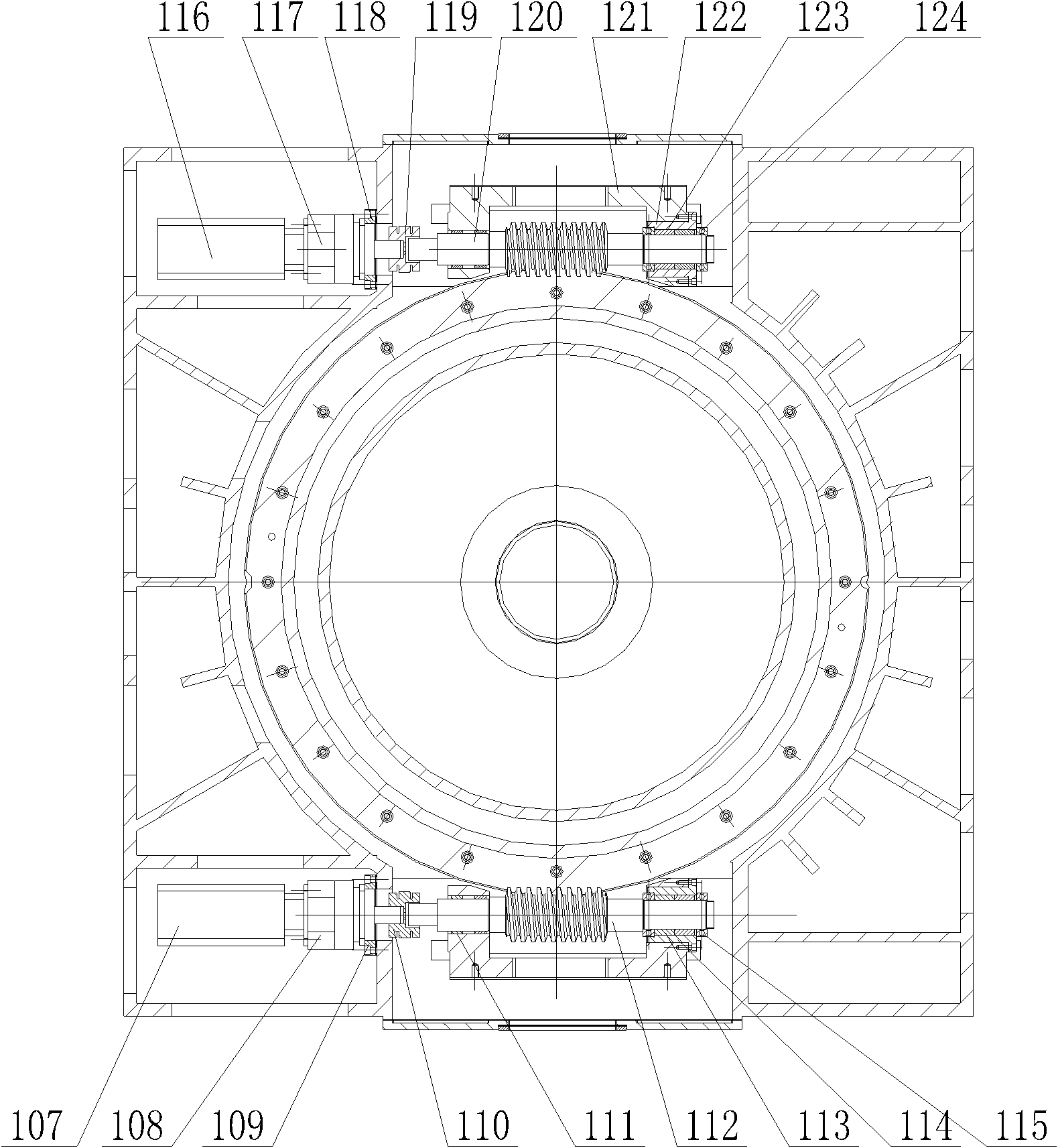

Full closed-loop numerical control gear shaper for large-scale hydraulic main drive cutting

ActiveCN102059402AIncrease cutting forceImprove accuracyGear-cutting machinesGear teethHydraulic cylinderCoupling

The invention relates to a full closed-loop numerical control gear shaper for large-scale hydraulic main drive cutting, comprising a rotary table, a shaper body assembly, an intermediate shaper body assembly, a stand column, a cutter relieving mechanism, a cutter rest mechanism, a numerical control system, a hydraulic system, a lubricating system and a cooling chip removing system. Serve motors are arranged on both sides of the rotary table and are connected with a worm gear motion pair through a shaft coupler to form a dual-driving mechanism of the rotary table; a cutter shaft of the cutter rest mechanism is driven by a hydraulic cylinder to do reciprocating motion; a motor base of the cutter rest mechanism is provided with a servo motor; and the cutter relieving mechanism is provided with camshafts of a conjugate dual cams to connect and drive the servo motor. The invention has the advantages that the gear shaper adopts the servo hydraulic cylinder to drive to provide reciprocating motion of the cutter shaft, adopts a torque motor to provide the rotary motion of the cutter shaft and adopts the servo motor to drive the cutter relieving mechanism to meet the processing requirement of large-scale precise gears; the rotary table bears heavy load and has high operation stability; the processing range, the stroke length and the cutting force are enlarged; the processing precision is high; and the processing flexibility adaptability is strong.

Owner:通用技术集团天津第一机床有限公司

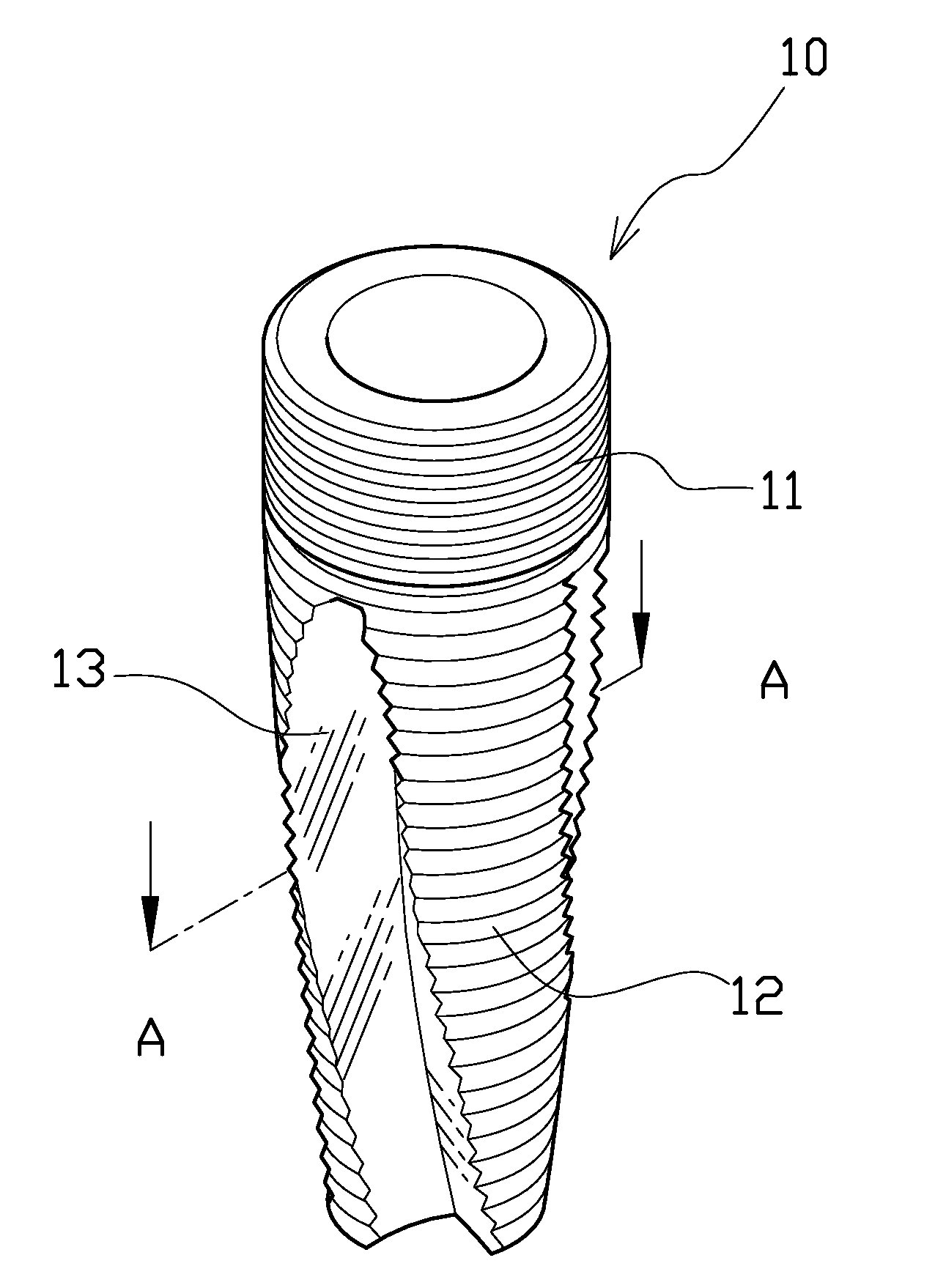

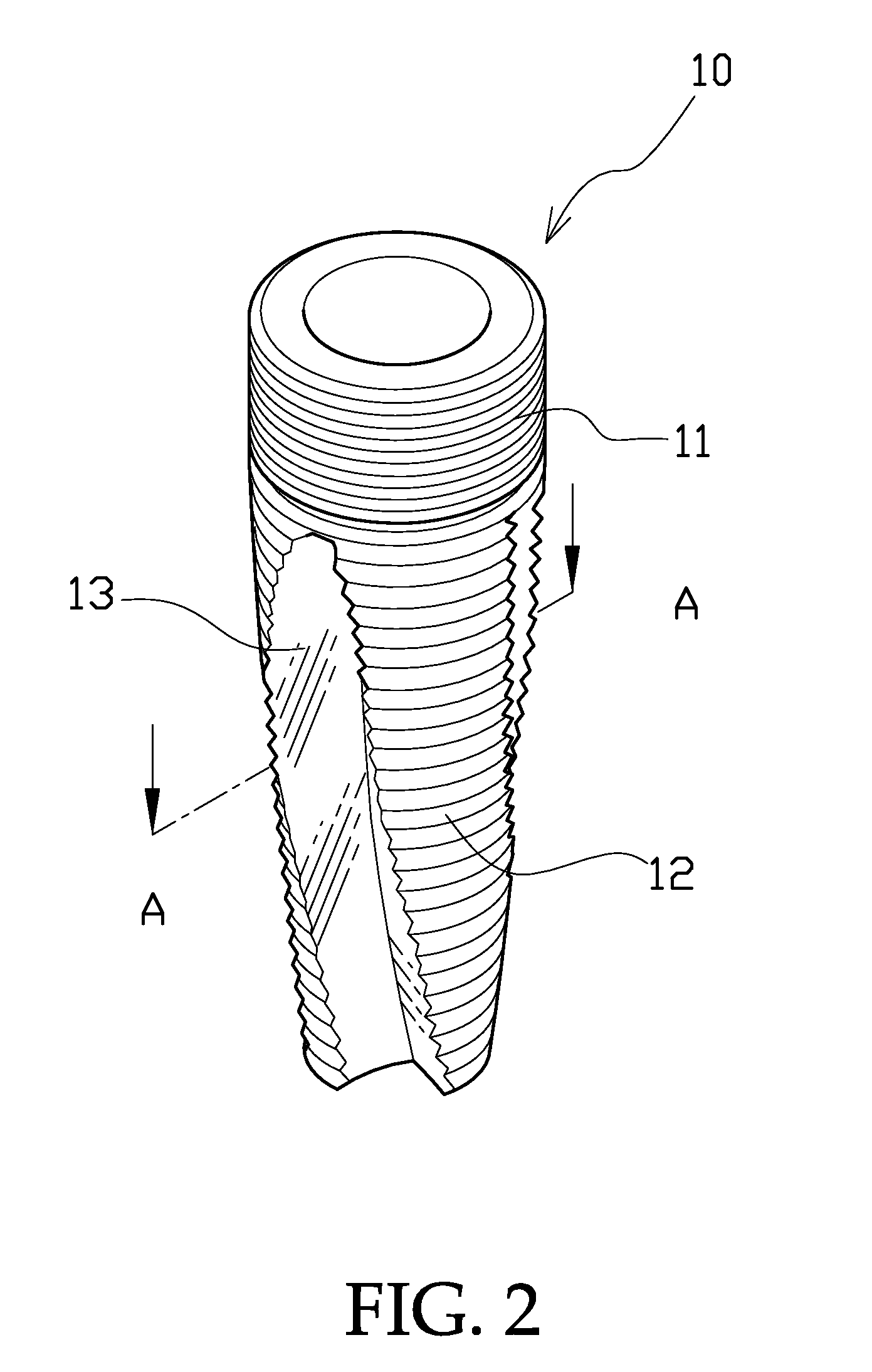

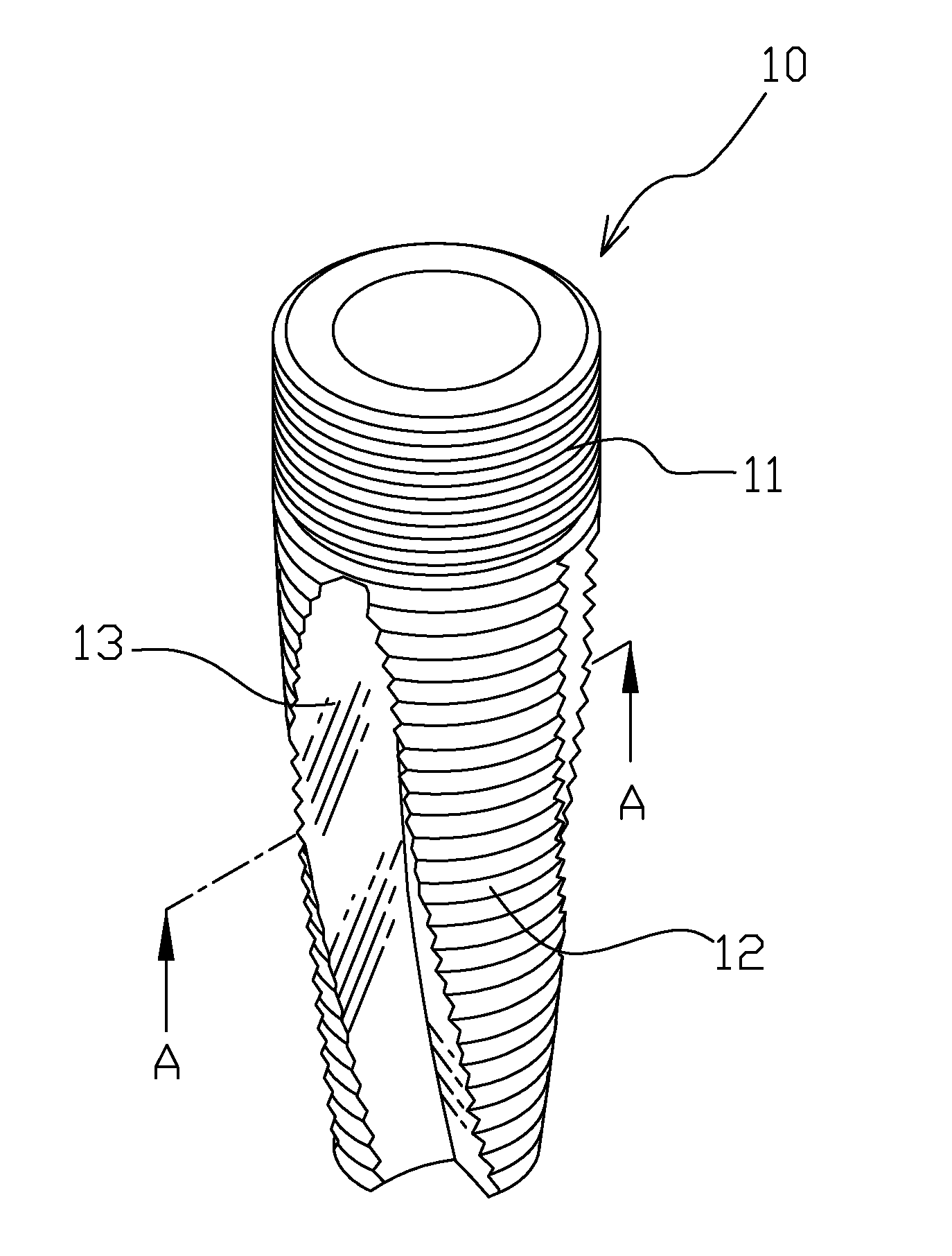

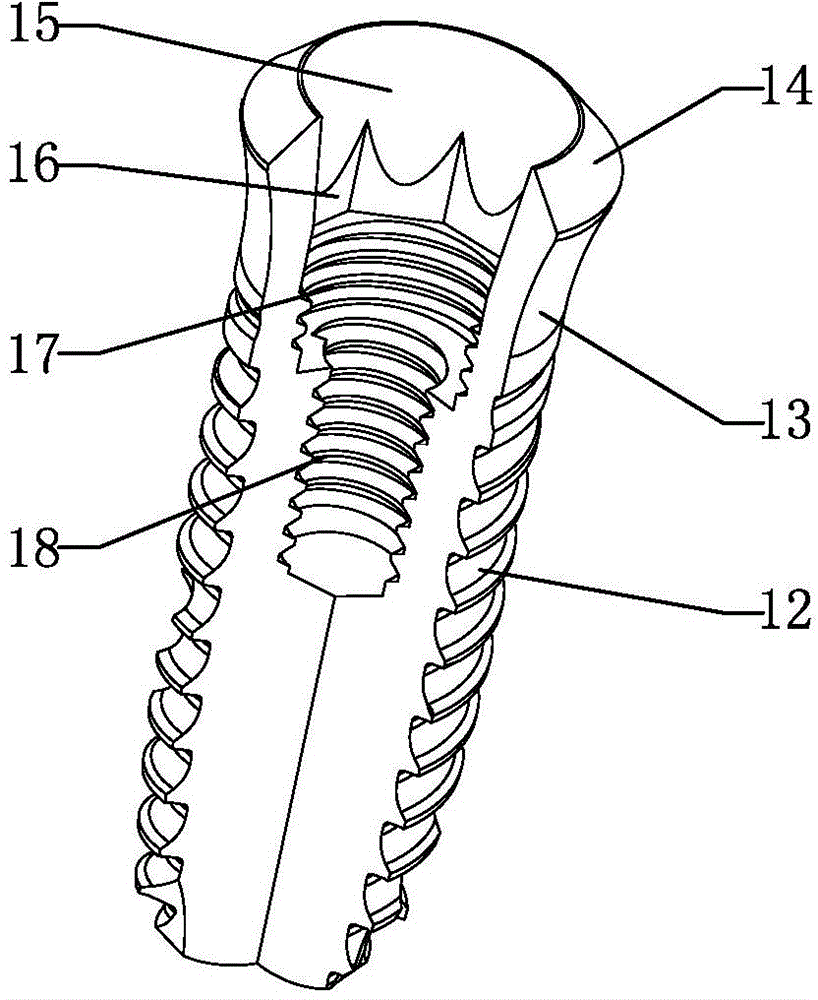

Implant root for tooth implanting

An improved implant root for tooth implanting, a coarse threaded portion of the implant root is formed to have at least two helical treating surfaces each with an HA coating (covered with hydroxyapatite) and each extending in the vertical direction. The areas of the HA coatings can thus be increased in favor of fast growth of a bone of a denture base after implanting into the bone to envelop the implant root; this can shorten the curing process from implanting the implant root to mounting a crown.

Owner:CHEN CHUN LEON

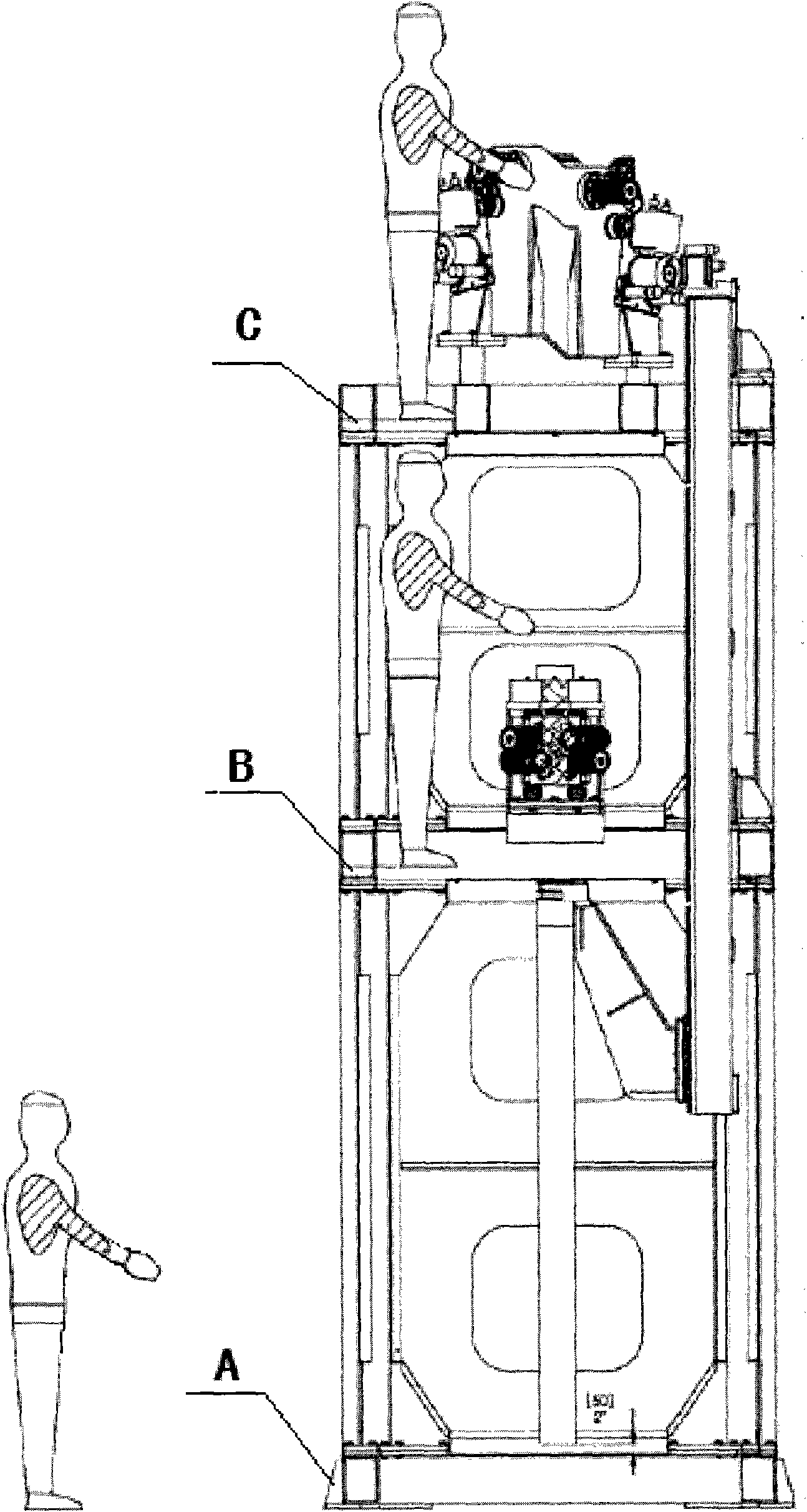

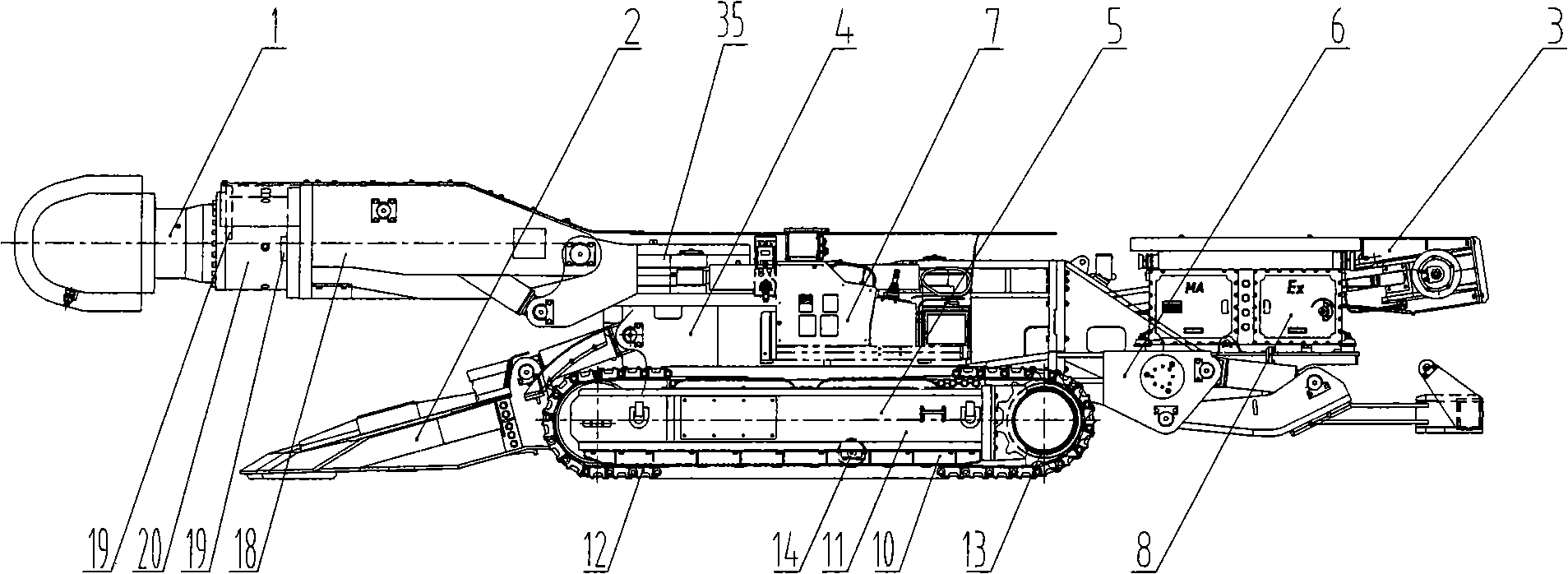

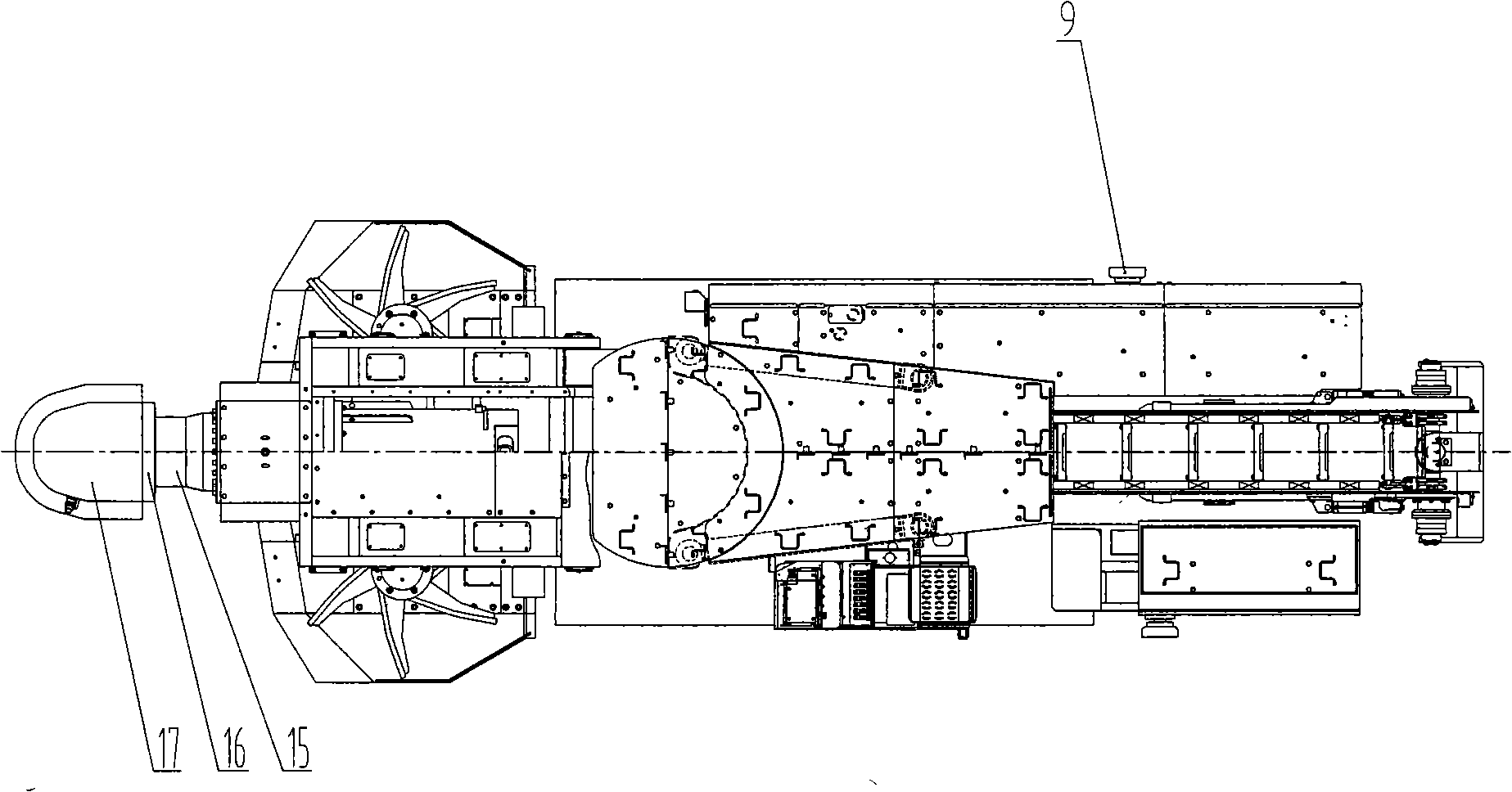

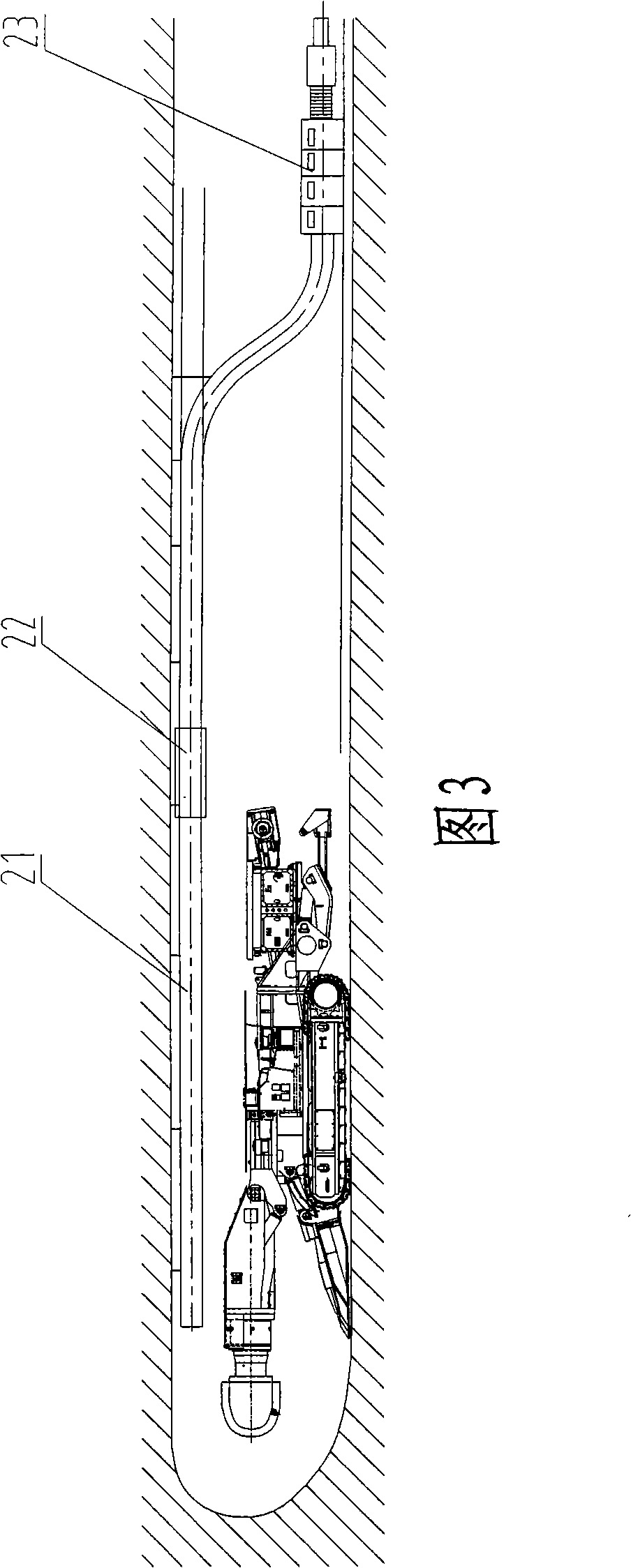

Hard rock tunneling machine

InactiveCN101289936AImprove structural strengthMajorDriving meansCutting machinesWorking environmentHardness

The invention relates to the coal mine roadway drivage machinery, in particular to a heavy hard rock tunneling machine which can cut a semi-rock roadway and a whole-rock roadway with high hardness. The tunneling machine solves the problem that the prior mole is not suitable for rock roadway drivage, can greatly improve the drivage working efficiency of the whole-rock roadway, and dramatically reduce working intensity of operators. The tunneling machine has an integral structure with high strength, a complete machine with heavy weight, a horizontal side support arranged on the back of the machine, and a device with high stability; the machine is provided with a mighty dust absorption system and an inside and outside spray dust suppression system, which effectively improves working environment of the operators; a traction of the tunneling machine adopts a full-sealed structure to increase traction driving force and improve propulsive force of the cutting; the tunneling machine has a small assembly, a large diameter and an inertia cutting head, adopts a reliable and highly-efficient hydraulic system matched with a high-strength point-attack pick, which greatly improves unidentate cutting force, thereby the tunneling machine has the ability of cutting the semi-rock roadway and the whole-rock roadway with high-hardness (f8).

Owner:SANY HEAVY EQUIP

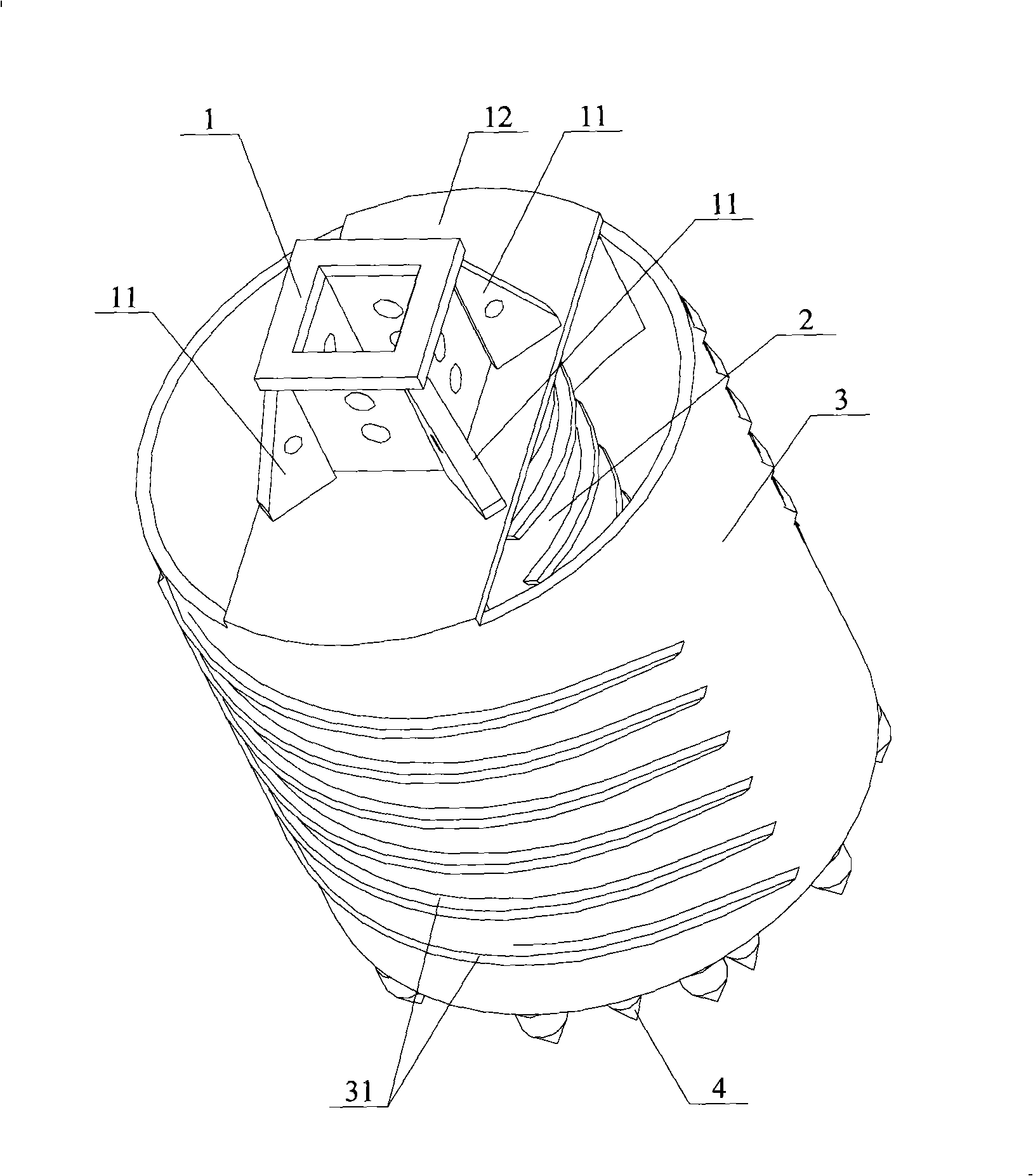

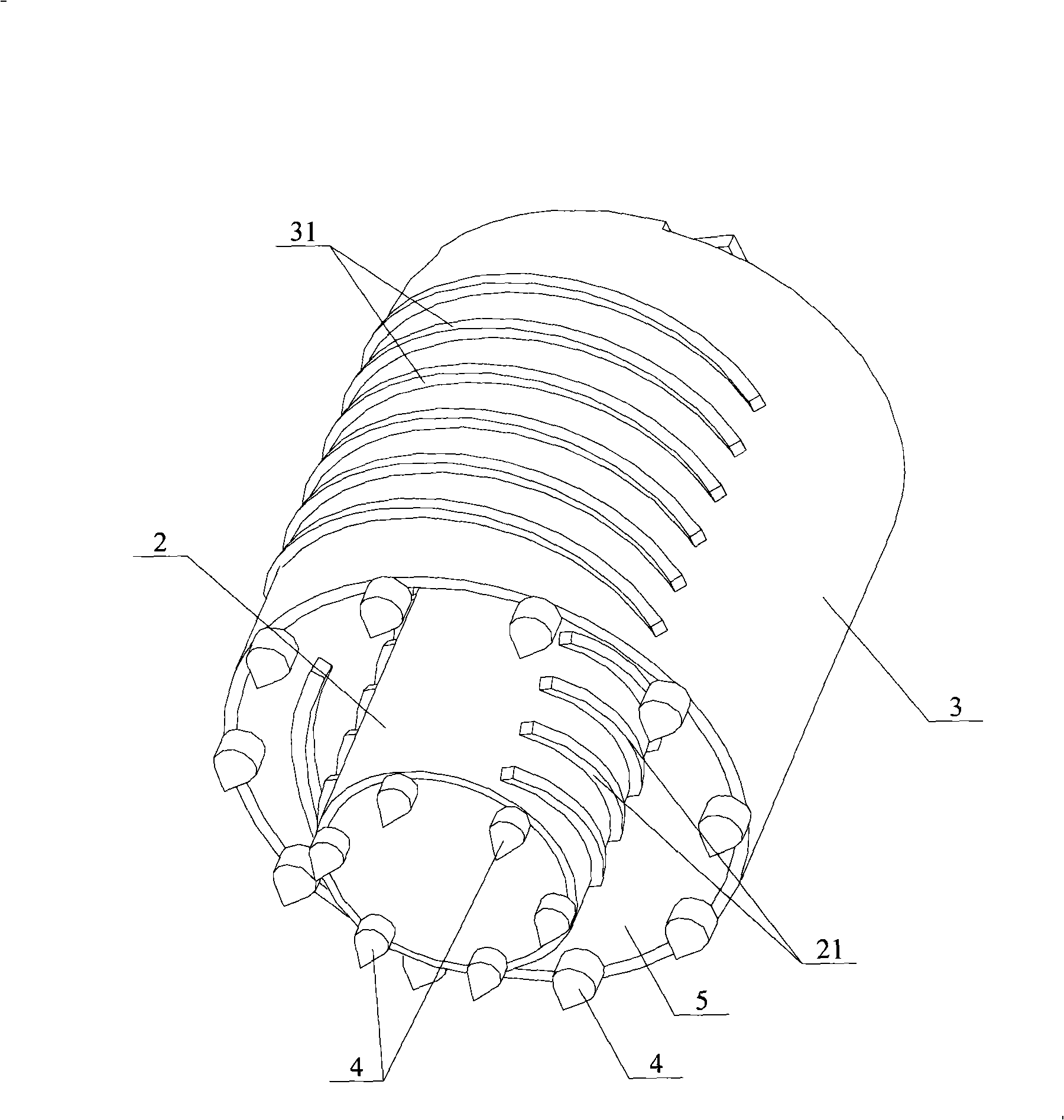

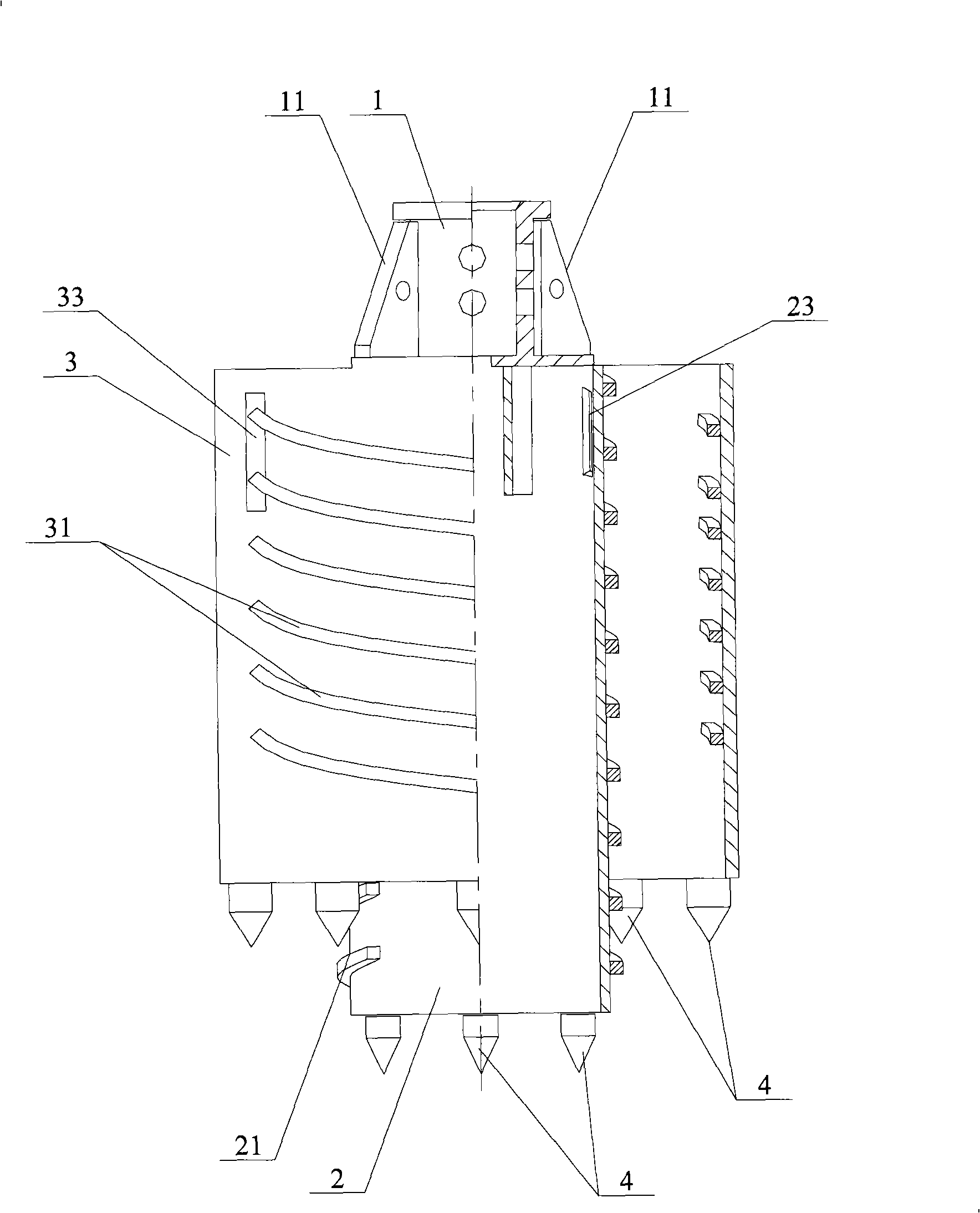

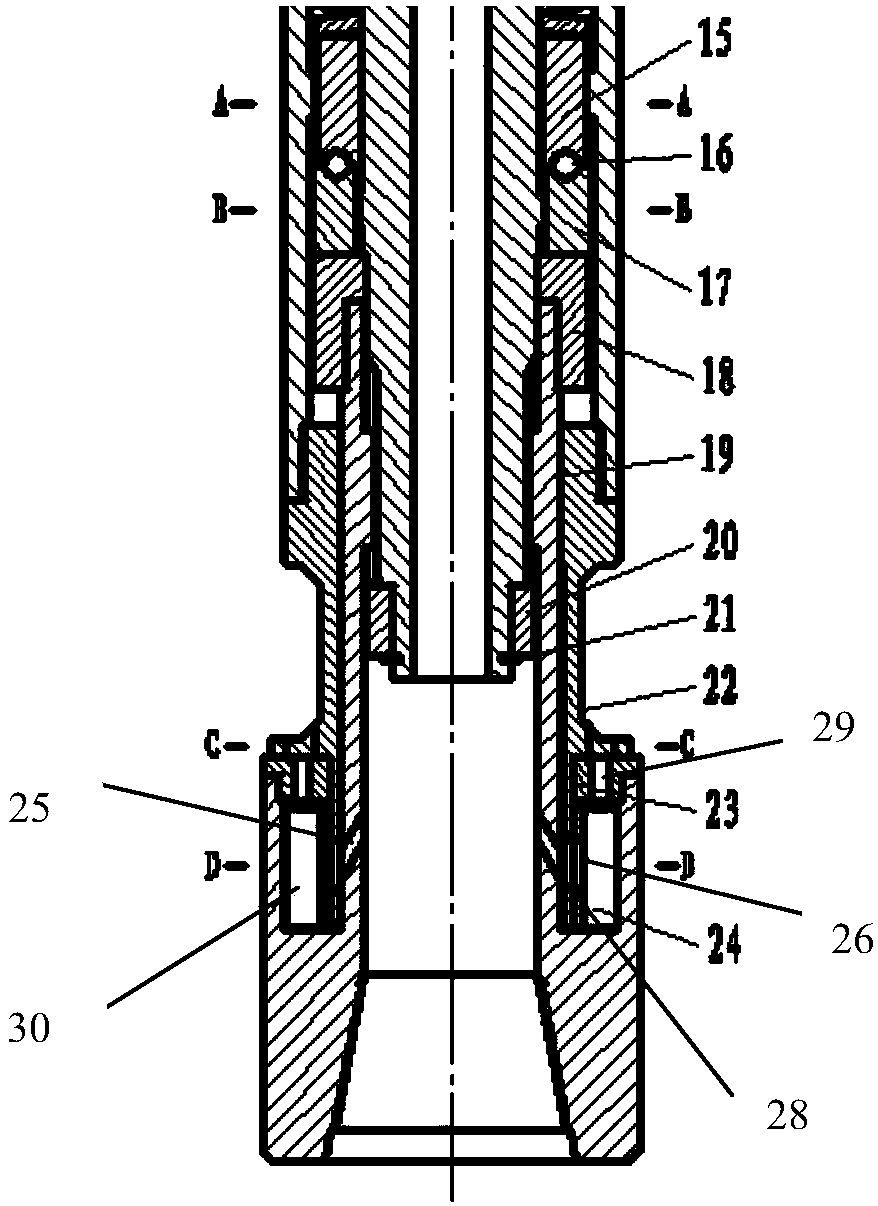

Double-layer barrel type drilling tool

InactiveCN101343982AImprove drilling efficiencyImprove slag carrying capacityDrill bitsEngineeringDrill pipe

The invention discloses a double-layer cylindrical drilling tool, which comprises a connecting part, an inner cylinder body, an outer cylinder body and a plurality of cutting tools. The upper end part of the inner cylinder body is fixedly connected with the connecting part; the outer cylinder body is nested at the outer side of the inner cylinder body, and an annular cavity is formed between the inner cylindrical surface of the outer cylinder body and the outer cylindrical surface of the inner cylinder body; the upper end part of the outer cylinder body is fixedly connected with the connecting part; the plurality of cutting tools are respectively fixedly arranged on the lower edges of the inner cylinder body and the outer cylinder body; and a plurality of guiding strips which present spiral elevating status along the cylindrical surface of the cylinder body are respectively arranged on the inner cylinder body and the outer cylinder body. The space used for carrying boring mud in the double-layer cylindrical drilling tool is divided into two parts, namely the inner cavity of the inner cylinder body and an annular space formed between the inner cylinder body and the outer cylinder body, thereby being favorable for carrying hard boring mud particles, greatly enhancing the mud carrying capability of the drilling tool, further effectively avoiding the accidents of drill pipe sticking and the like and enhancing the drilling efficiency and the hole forming speed.

Owner:BEIJING SANY HEAVY MASCH CO LTD

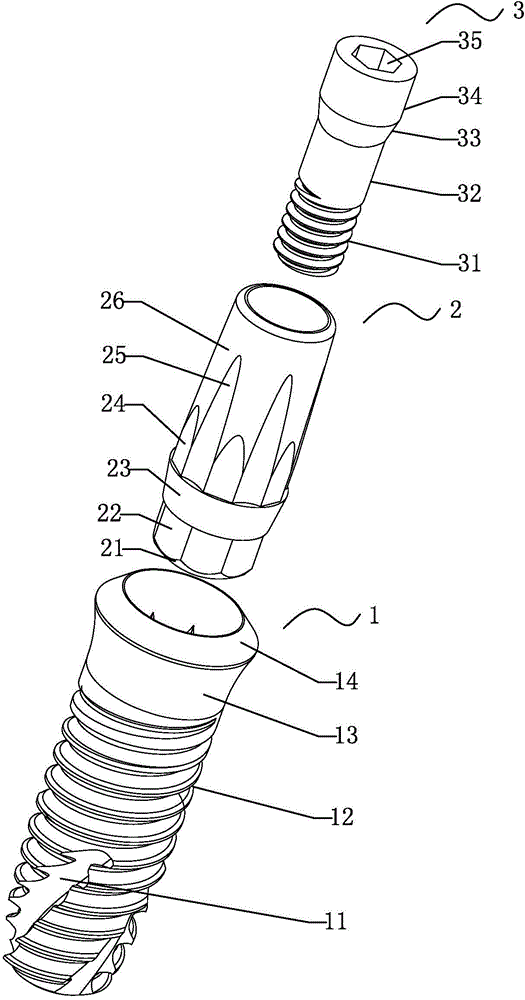

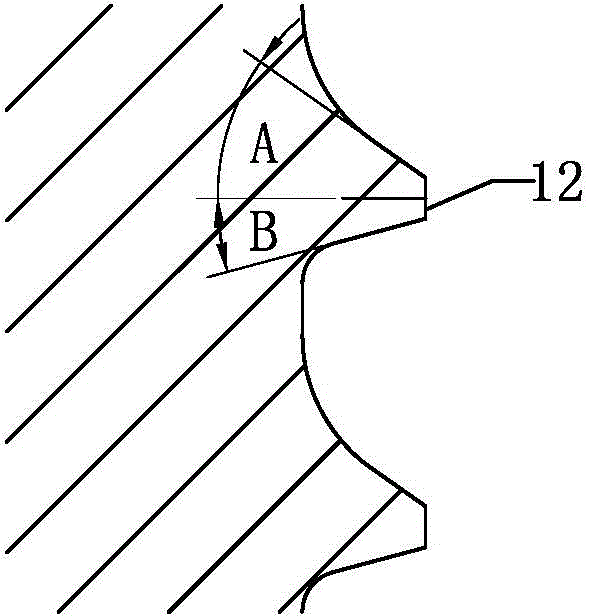

Implant root for tooth implanting

InactiveUS20110033826A1Increase the areaIncrease spacingDental implantsHydroxyapatite coatingDenture base

An improved implant root for tooth implanting, a coarse threaded portion of the implant root is formed to have at least two helical treated surfaces extending from the bottom to the top of the implant root of the coarse threaded portion each being treated with a roughened coating (for example, covered with a hydroxyapatite coating) and extending in the whole length of the coarse threaded portion and each extending in the vertical direction. The areas of the roughened coatings can thus be increased in favor of fast growth of a bone of a denture base after implanting into the bone to envelop the implant root; this can shorten the curing process from implanting the implant root to mounting a crown.

Owner:CHEN CHUN LEON

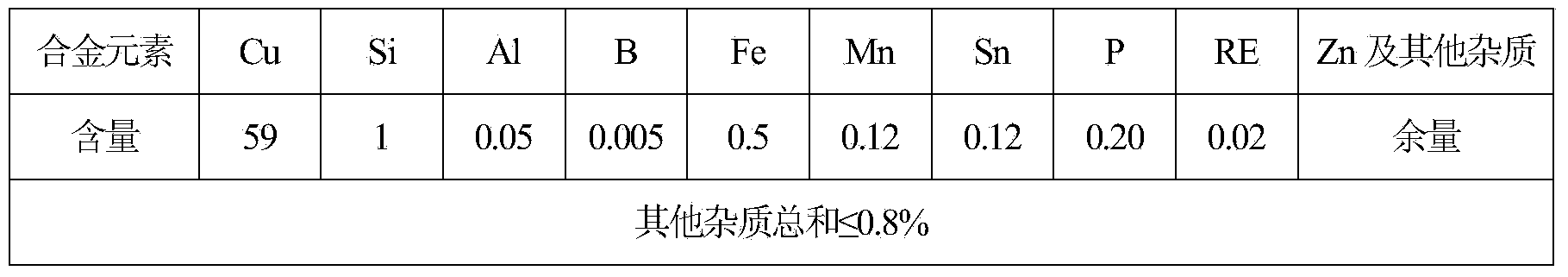

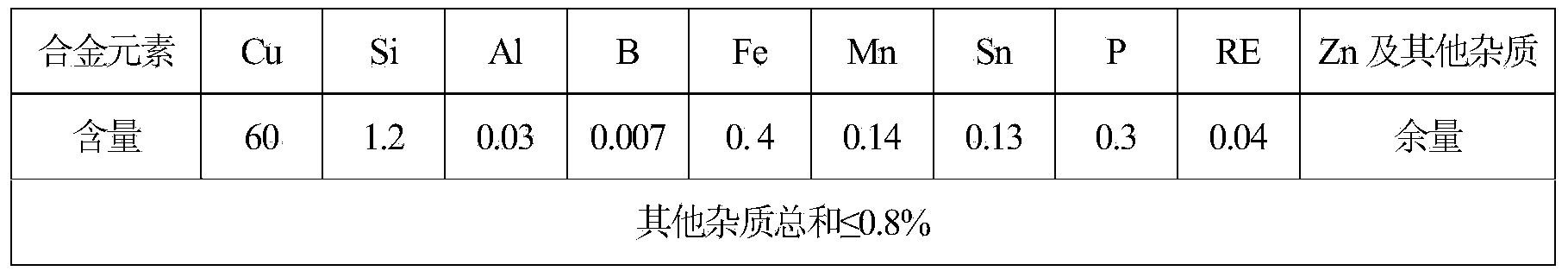

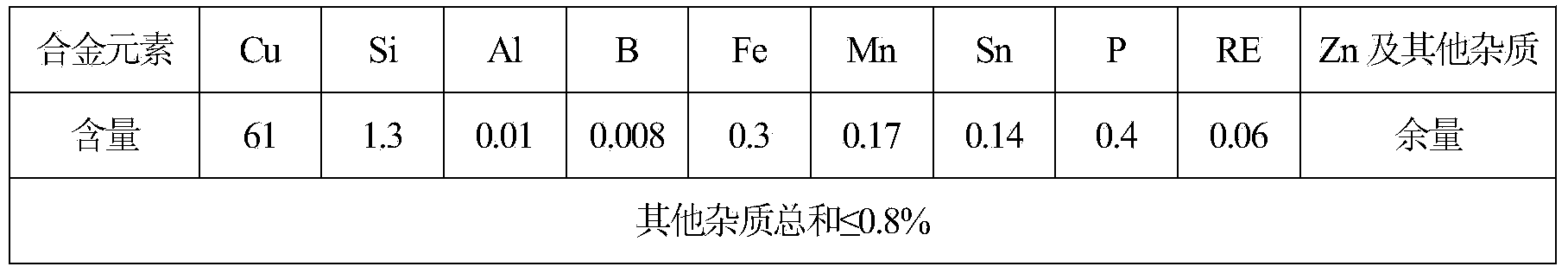

Lead-free silicon brass alloy and preparation method

The invention belongs to the technical field of lead-free silicon brass alloy, especially relates to a free-cutting and corrosion-resistant lead-free silicon brass alloy and a preparation method thereof. The alloy is suitable for replacing the lead brass alloy for machining and is a good environment-friendly green metal material. The lead-free silicon brass alloy comprises the following components in percentage by weight: 59-63% of copper, 1-1.5% of silicon, 0.001-0.05% of aluminum, 0.001-0.01% of boron, 0.1-0.5% of iron, 0.1-0.2% of manganese, 0.1-0.15% of tin, 0.05-0.5% of phosphorus, 0.01-0.07% of rare earth element RE, and the balance of zinc and inevitable impurity. During the preparation, the copper-silicon-zinc alloy is firstly melted, the intermediate alloy of iron and aluminum is added into the completely melted copper-silicon-zinc alloy and the mixture alloy is uniformly stirred, the intermediate alloys of the manganese, the boron, the tin, the phosphorus and the rare earth element are sequentially added into the mixture alloy, the mixture alloy is stirred and slagged off, and finally the alloy ingot is formed after the flaming and gravity casting steps. The silicon is added into the lead-free silicon brass alloy to replace the lead, so that on the premise of not reducing the production cost, the lead-free silicon brass alloy has good cutting performance and excellent cold workability and hot workability.

Owner:沈阳亚欧星海铜业有限公司

Implant root for tooth implanting

InactiveUS20090130631A1Increase areaIncrease spacingDental implantsTooth crownBiomedical engineering

An improved implant root for tooth implanting, a coarse threaded portion of the implant root is formed to have at least two helical treated surfaces extending from the bottom to the top of the implant root of the coarse threaded portion each being treated with a roughened coating (for example, covered with a hydroxyapatite coating) and extending in the whole length of the coarse threaded portion and each extending in the vertical direction. The areas of the roughened coatings can thus be increased in favor of fast growth of a bone of a denture base after implanting into the bone to envelop the implant root; this can shorten the curing process from implanting the implant root to mounting a crown.

Owner:CHEN CHUN LEON

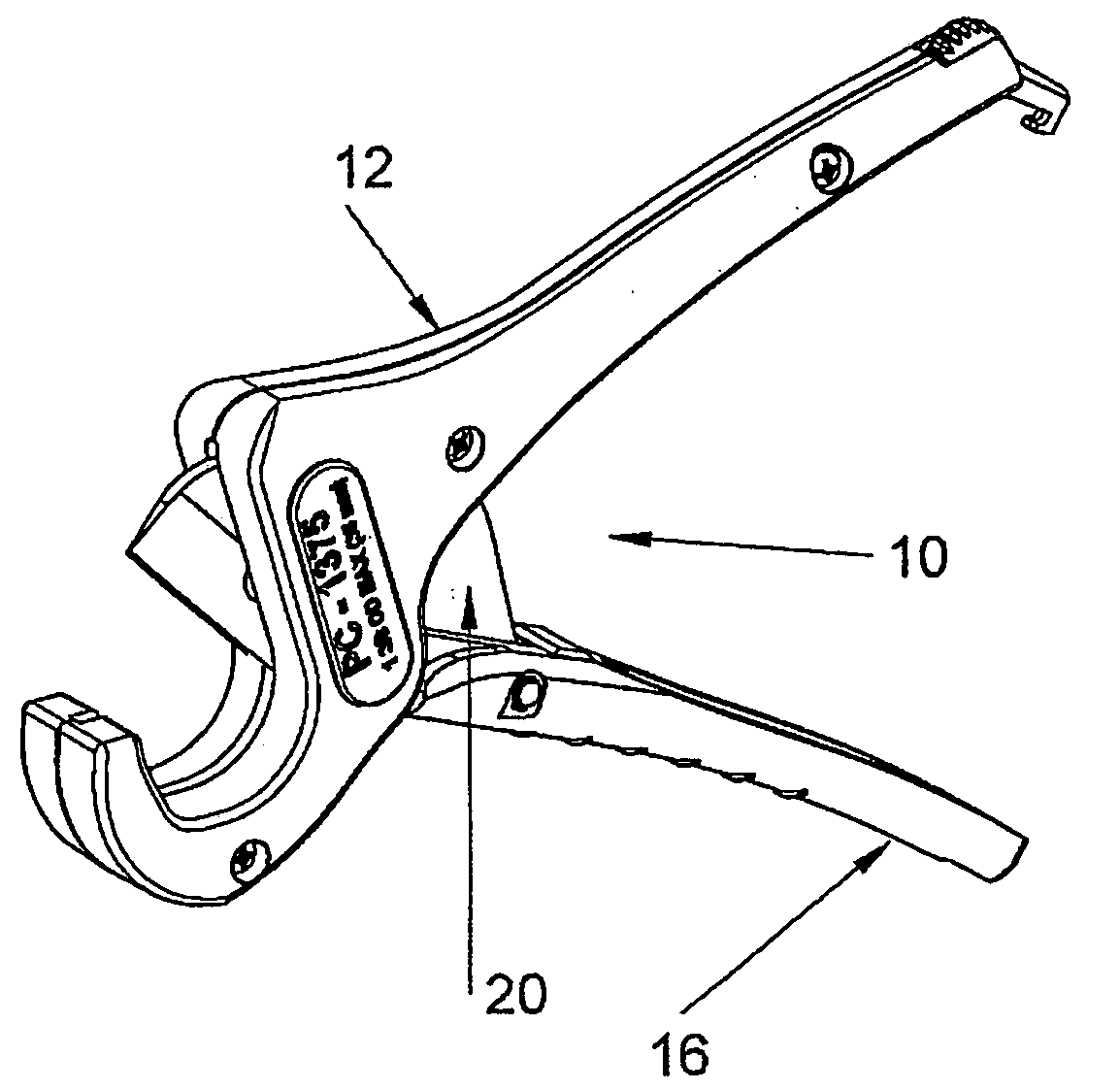

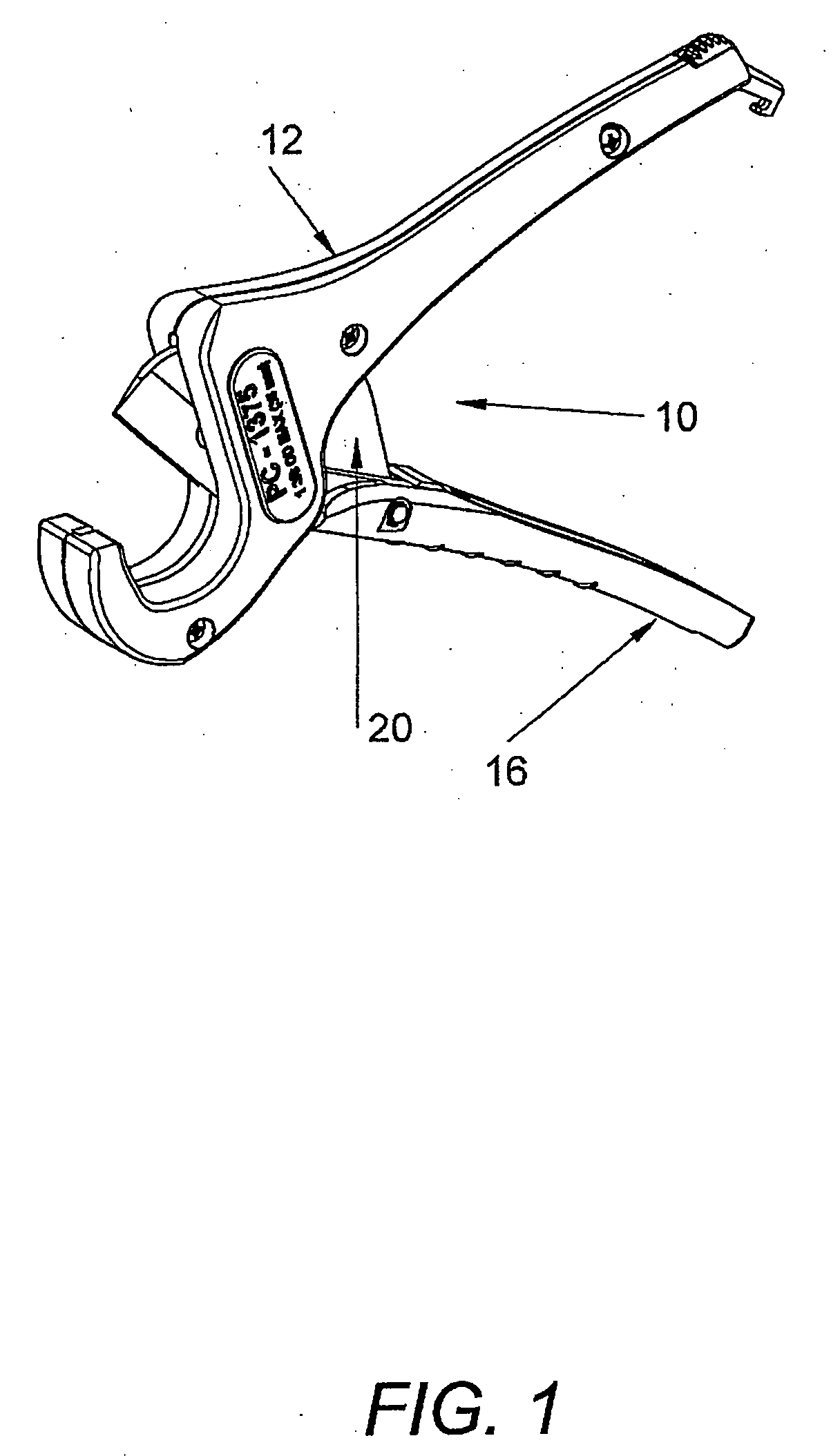

Tubing cutter

ActiveUS20080141538A1Less forceLonger cutting strokeTube shearing machinesMetal working apparatusHigh rateEngineering

A cutter tool includes first and second elongate members carrying a cutting blade pivotally attached with the second elongate member and slidably attached with the first elongate member to enable cutting an associated tubular workpiece with an increased mechanical advantage with the tool in an opened position. The tool is characterized by a first handle having a cradle for supporting a tube to be cut, a second handle pivotally attached to the first handle, a cutter blade attached to the second handle for displacement therewith and relative thereto, and a pin and slot interengagement between the cutter blade and the first handle by which the angular displacement of the cutter blade from an opened to a closed position relative to the cradle is greater than the angular displacement of the handles to achieve such blade displacement. The slot configuration provides for displacement of the blade relative to the cradle to initially apply a higher cutting force which is followed by a transition to a lower cutting force and a higher rate of blade displacement.

Owner:EMERSON ELECTRIC CO

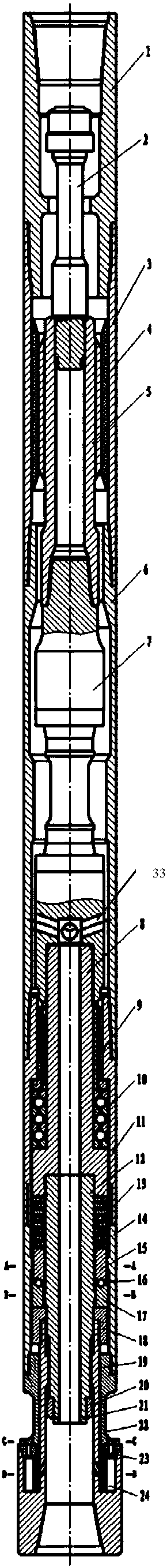

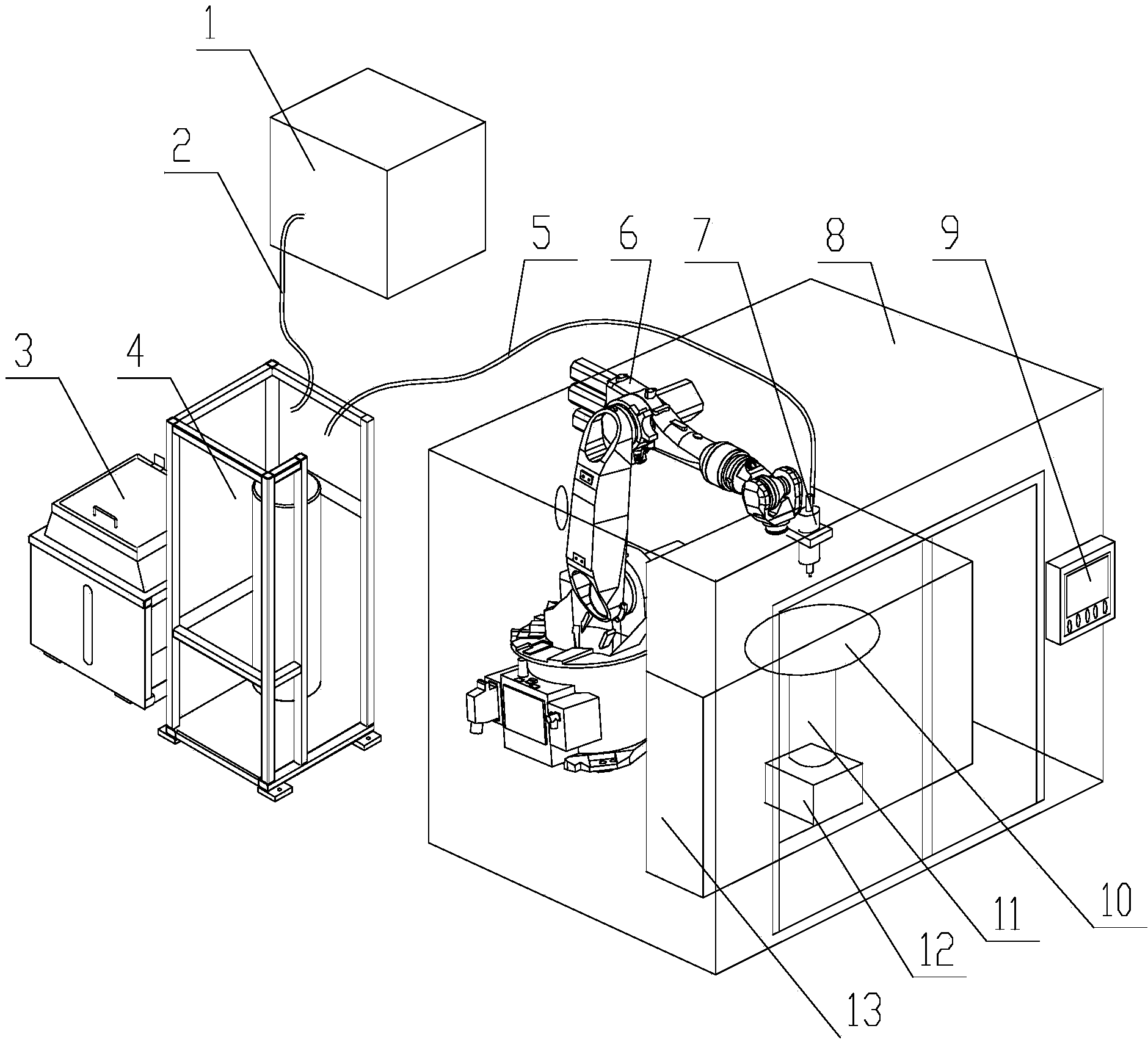

Composite speed-increasing screw drilling tool with axial vibration and circumferential vibration functions

ActiveCN108166928APromote rapid developmentImprove cutting abilityBorehole drivesVibration drillingEngineeringRock breaking

The invention discloses a composite speed-increasing screw drilling tool with axial vibration and circumferential vibration functions. The composite speed-increasing screw drilling tool includes an upper joint, an anti-drop rod, a motor, a cardan shaft, a transmission shaft, bearings, a disc spring, an upper vibrating block, roll balls, a lower vibrating block, an anti-drop cap, a transmission joint, a lock nut, a circlip, a liquid dispensing sleeve, a drainage tray and a pendulum bob; the anti-drop rod is disposed inside the upper joint, and a rotor of the motor is arranged below the anti-drop rod; the cardan shaft is arranged below the rotor, and the transmission shaft below the cardan shaft is composed of an upper transmission shaft and a lower transmission shaft; the bearings are arranged at the outer side of the upper transmission shaft, and the disc spring, the upper vibrating block, the roll balls, the lower vibrating block, the anti-drop cap, the transmission joint, the lock nut and the circlip are arranged at the outer side of the lower transmission shaft; and the liquid dispensing sleeve, the drainage tray and the pendulum bob are sequentially arranged at the outer side of the transmission joint from top to bottom. According to the composite speed-increasing screw drilling tool with the axial vibration and circumferential vibration functions, not only are the basic torque and speed provided for a drill bit, but also the impact vibration energy is added, so that the rock breaking efficiency and the rate of penetration are improved, the drilling cycle is shortened,and the drilling cost is reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

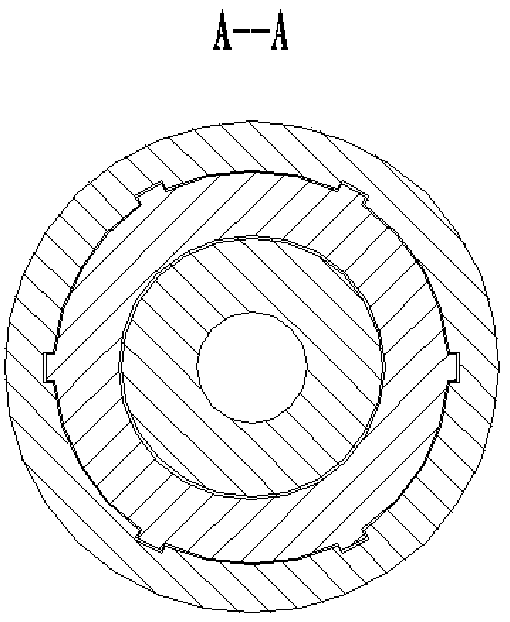

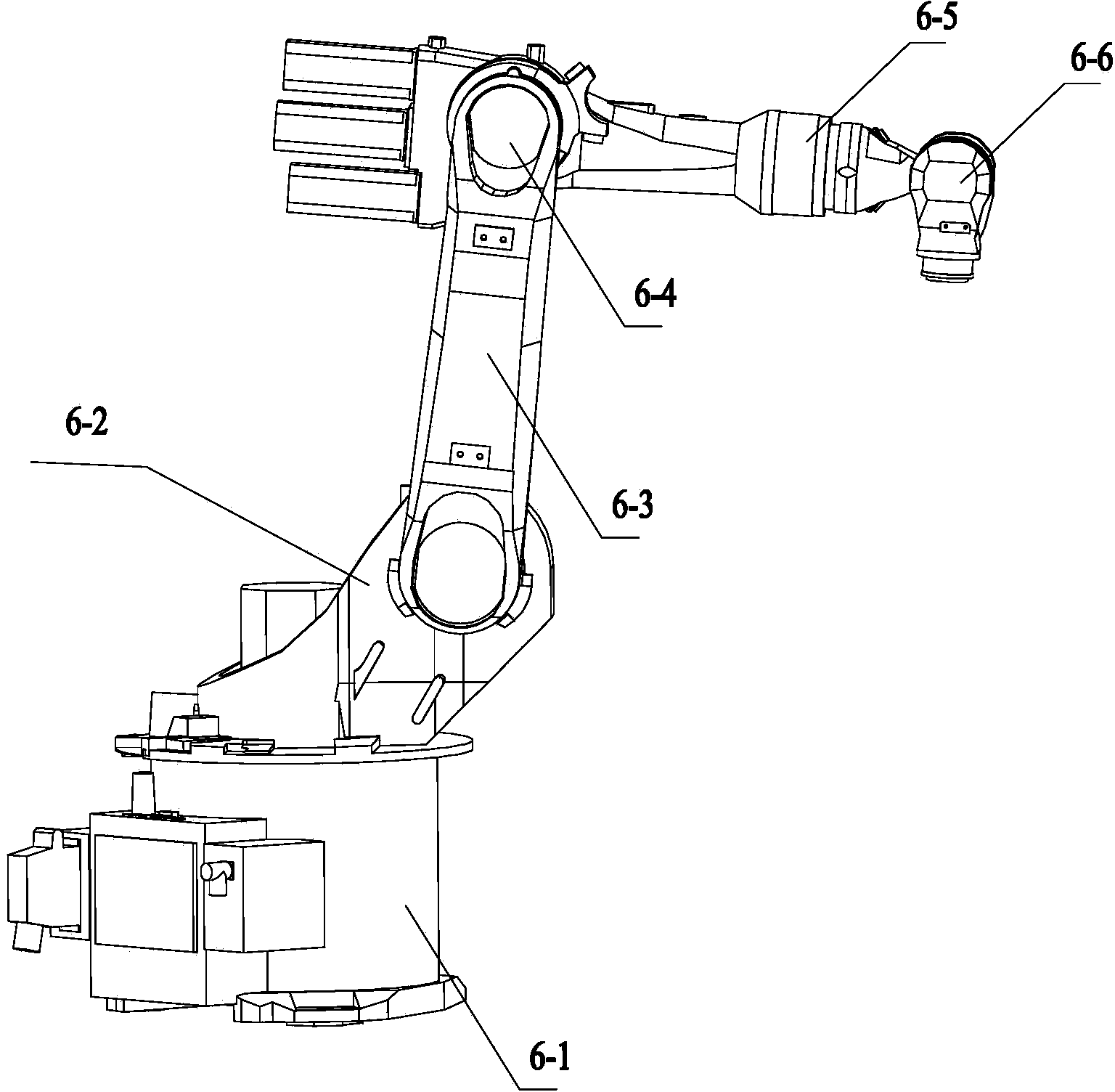

Suspension abrasive water jet cutting equipment

InactiveCN104175230AIncrease flexibilityLong conveying distanceAbrasive machine appurtenancesAbrasive blasting machinesEngineeringHigh pressure water

The invention relates to suspension abrasive water jet 3D cutting equipment adopting a seven-shaft intelligent robot, in particular to suspension abrasive water jet cutting equipment which comprises a high-pressure pump station used for providing cutting power, an abrasive filling device and a suspension abrasive generating device used for producing abrasive, wherein a discharge hole of the abrasive filling device is connected with a feed hole of a high-pressure container arranged in the suspension abrasive generating device through a feed pipe, a water inlet of the abrasive filling device is connected with a water outlet of the high-pressure container arranged in the suspension abrasive generating device through a water inlet pipe; high-pressure water generated by the high-pressure pump station is connected with a tee joint arranged in the suspension abrasive generating device through a high-pressure pipe. The product provided by the invention adopts a pre-mixing suspension abrasive cutting technology, the cutting pressure is low, and the efficiency is high; the equipment adopts a high-pressure hose as a suspension abrasive conveying pipeline, the conveying distance is long, and the equipment ensures that a nozzle device can realize high-precision motion of any track and any angle in space under the drive of a robot actuator.

Owner:西安远诚机电科技有限公司

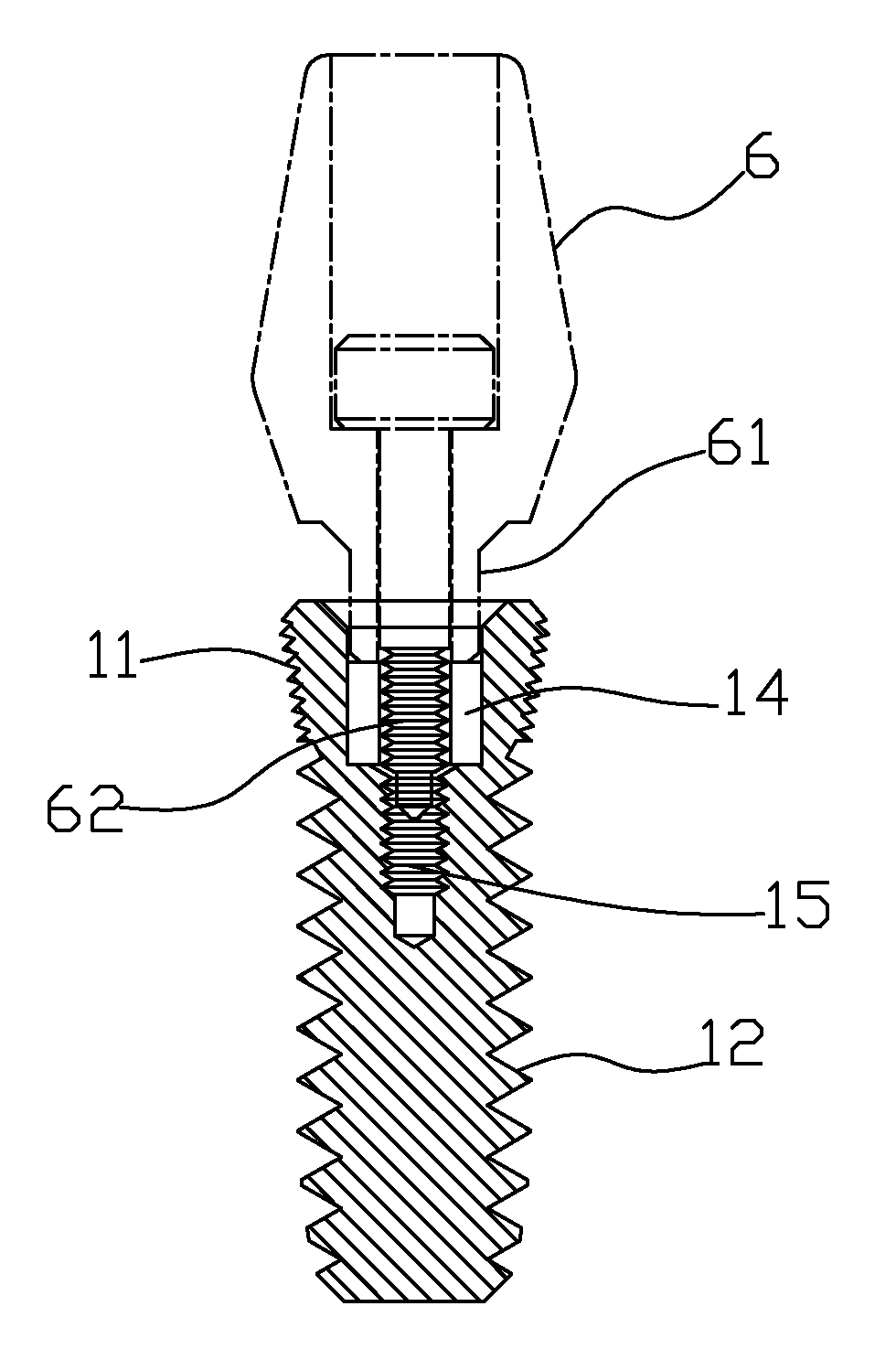

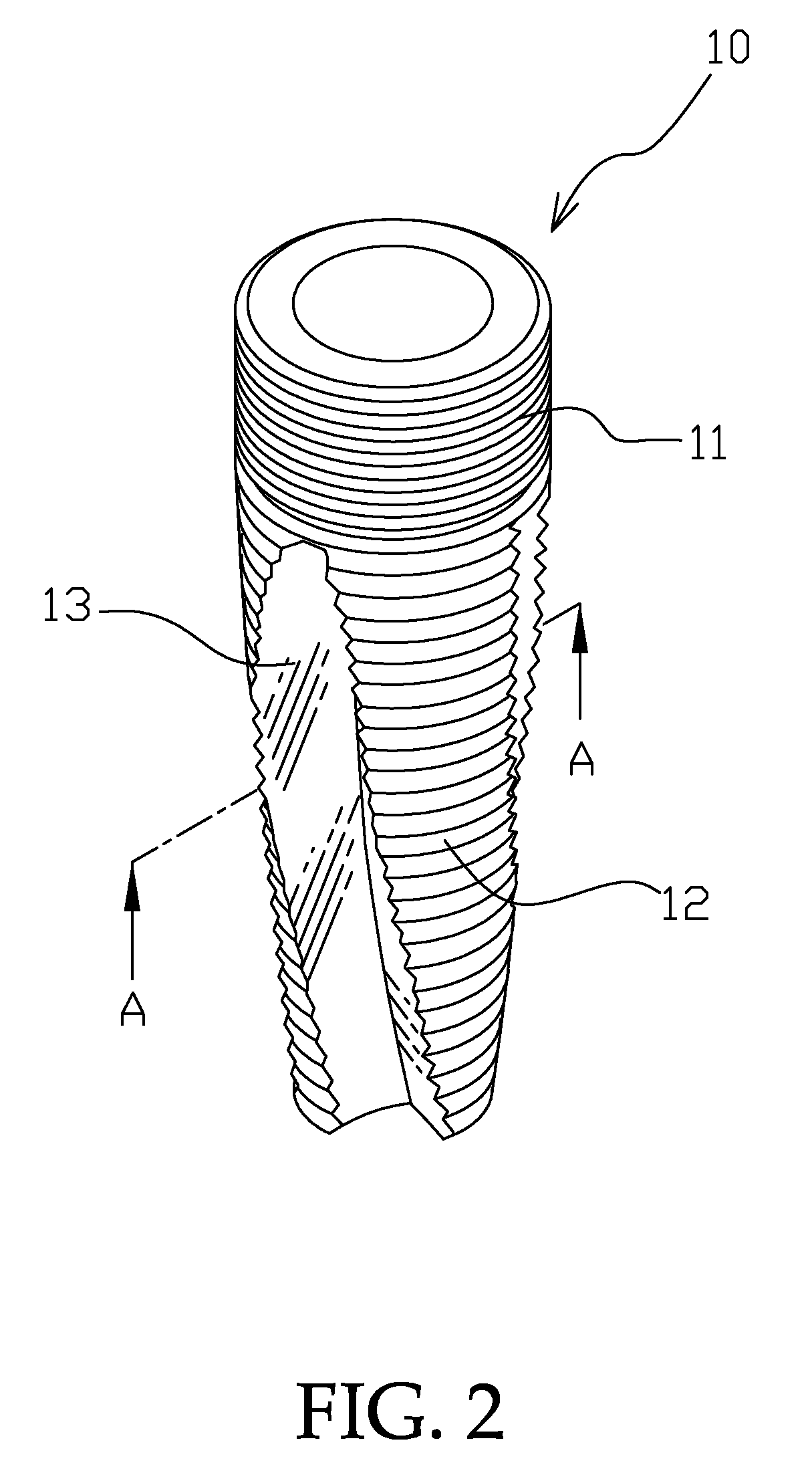

Easily-removing implant device and screwing-out tool thereof

InactiveCN103550003AReduce the risk of absorbingAvoid secondary surgeryDental implantsNeck partsImplanted device

The invention discloses an easily-removing implant device and a screwing-out tool thereof. The easily-removing implant device comprises an implant, a base station and a central bolt; the easily-removing implant device is characterized in that the implant comprises a gum-penetrating neck part and a head part, wherein a thread is formed on the outer surface of the head part, at least two spiral self-tapping grooves are also formed in the outer surface of the head part, a connecting hole coaxial with the implant is formed in the implant, the connecting hole comprises a tapered hole, an anti-rotation hole, an implant taking-out section and a blind threaded hole, which are sequentially connected coaxially, the base station comprises a dental crown connecting section and an implant connecting section, the implant connecting section comprises a conical table and an anti-rotation column, a stepped hole matched with the central bolt is formed in the base station, and the central bolt penetrates through the stepped hole to be connected with the blind threaded hole, so that the base station and the implant are fixed integrally. According to the easily-removing implant device, the implant taking-out section with a reverse thread is additionally arranged in the implant, the problem that a part of the implant, which is remained in dentale due to fracture of the implant, is difficult to take out is solved, and the easily-removing implant device has the advantages of simple structure, strong practicability, and the like.

Owner:DALIAN SANSHENG SCI & TECH DEV

Construction method of ultra-long bored concrete pile with large-diameter casing combination

ActiveCN103603342AIncrease the number of reusesReduce frictionBulkheads/pilesGuide tubeFriction force

The invention relates to a construction method of an ultra-long bored concrete pile with large-diameter casing combination. Construction of bore forming of a pile foundation is completed by means of combination of multiple casings; the gap between every two steel casings is backfilled by sand; a reinforcement cage is hung in the most inside steel casing; concrete pouring is completed section by section through guide ducts; the most inside steel casing is pulled out after concrete pouring of the pile body is completed; then, other steel casings are pulled out so that construction of the bored concrete pile is completed. By the construction method, problems such as drilling difficulty, severe abrasion of the steel casings, proneness of pipe burying and pile breakage which are caused by overhigh friction force between the steel casings and the surrounding soil can be solved. The construction method has the advantages of deep bore, high speed, guaranteed construction quality and the like.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

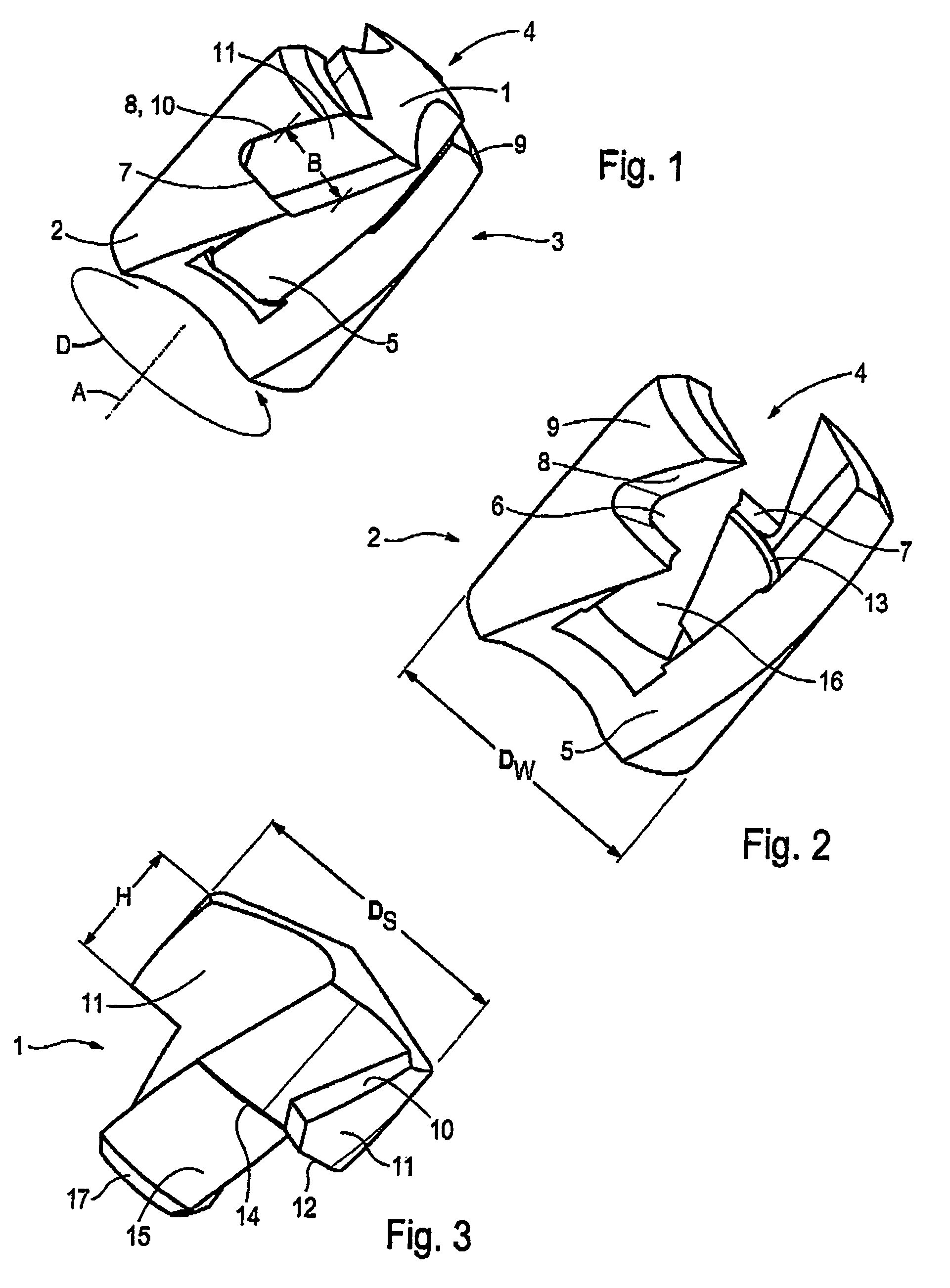

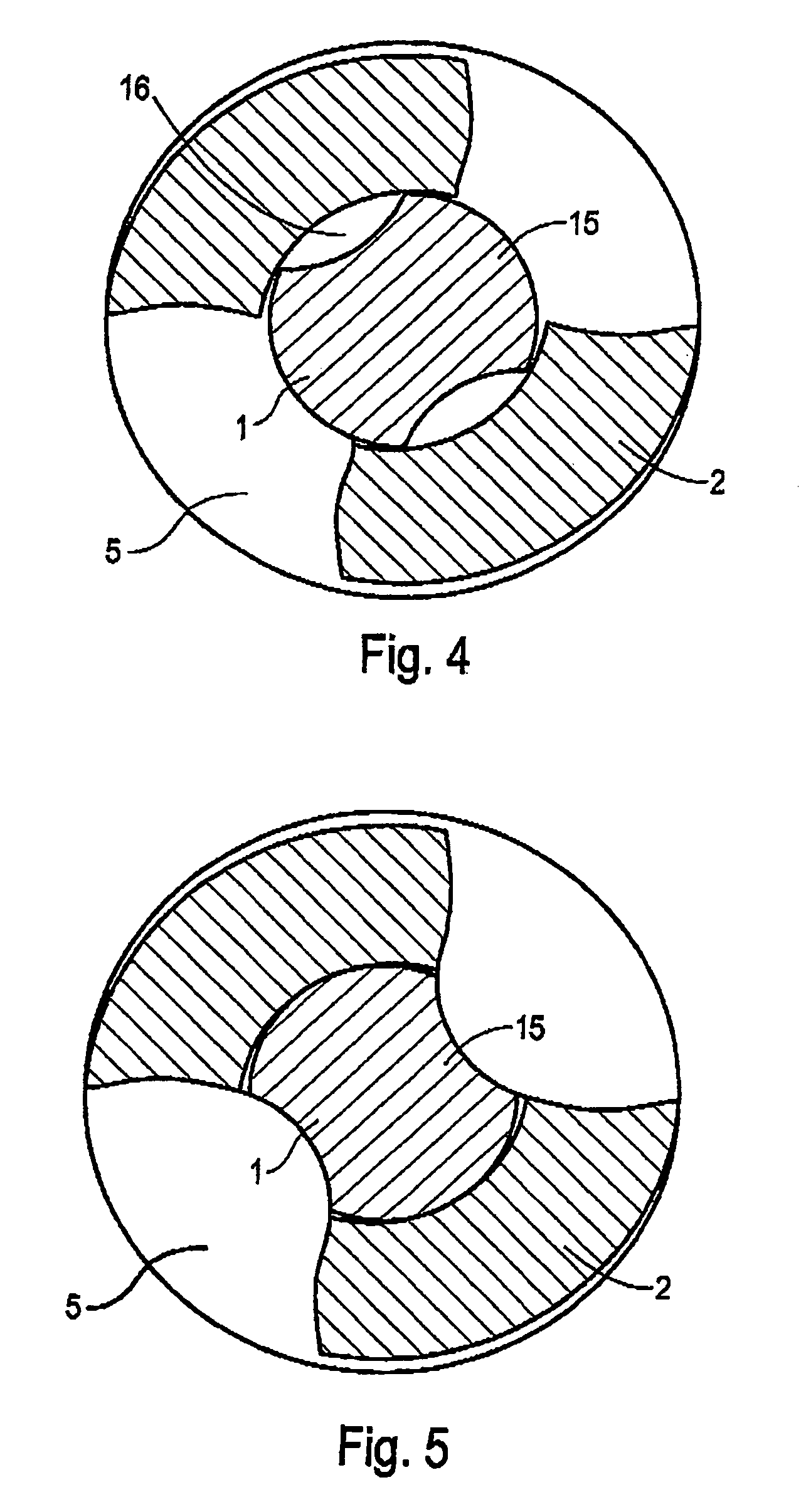

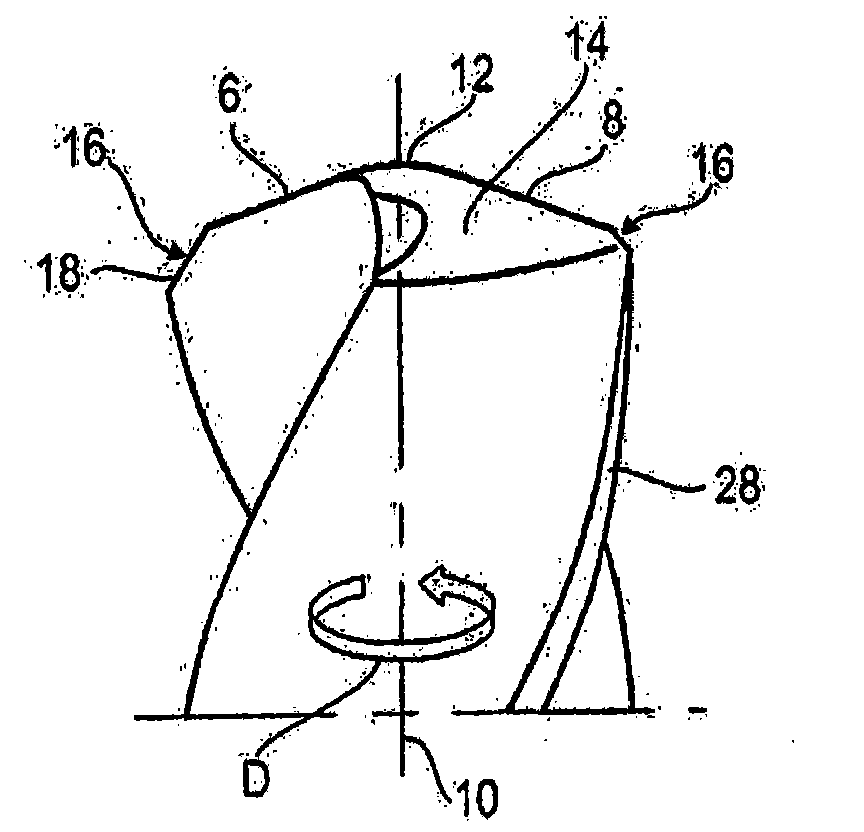

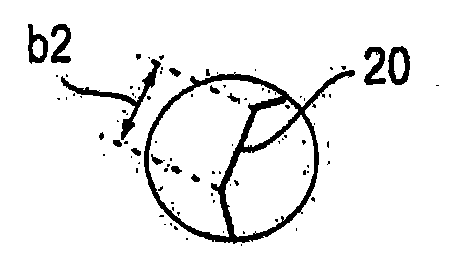

Rotary tool, in particular drill

In order to provide a rotary tool, in particular a drill (2), with a long service life together with high-quality drill holes, particularly in the case of through bores, the invention provides a cutting head (4) which extends along a rotational axis (10) and has a plurality of main cutting edges (6, 8) which extend radially outwards and each end at a cutting corner (16) having a corner bevel, wherein the corner bevels are of differing designs, specifically in the form of a roughing bevel (18) and in the form of a finishing bevel (20).

Owner:KENNAMETAL INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com