Multiline cutting machine of numerical-control polysilicon silicon

A multi-wire cutting and polysilicon technology, applied in the direction of working accessories, fine working devices, stone processing equipment, etc., can solve the problems of high cost and complicated equipment maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

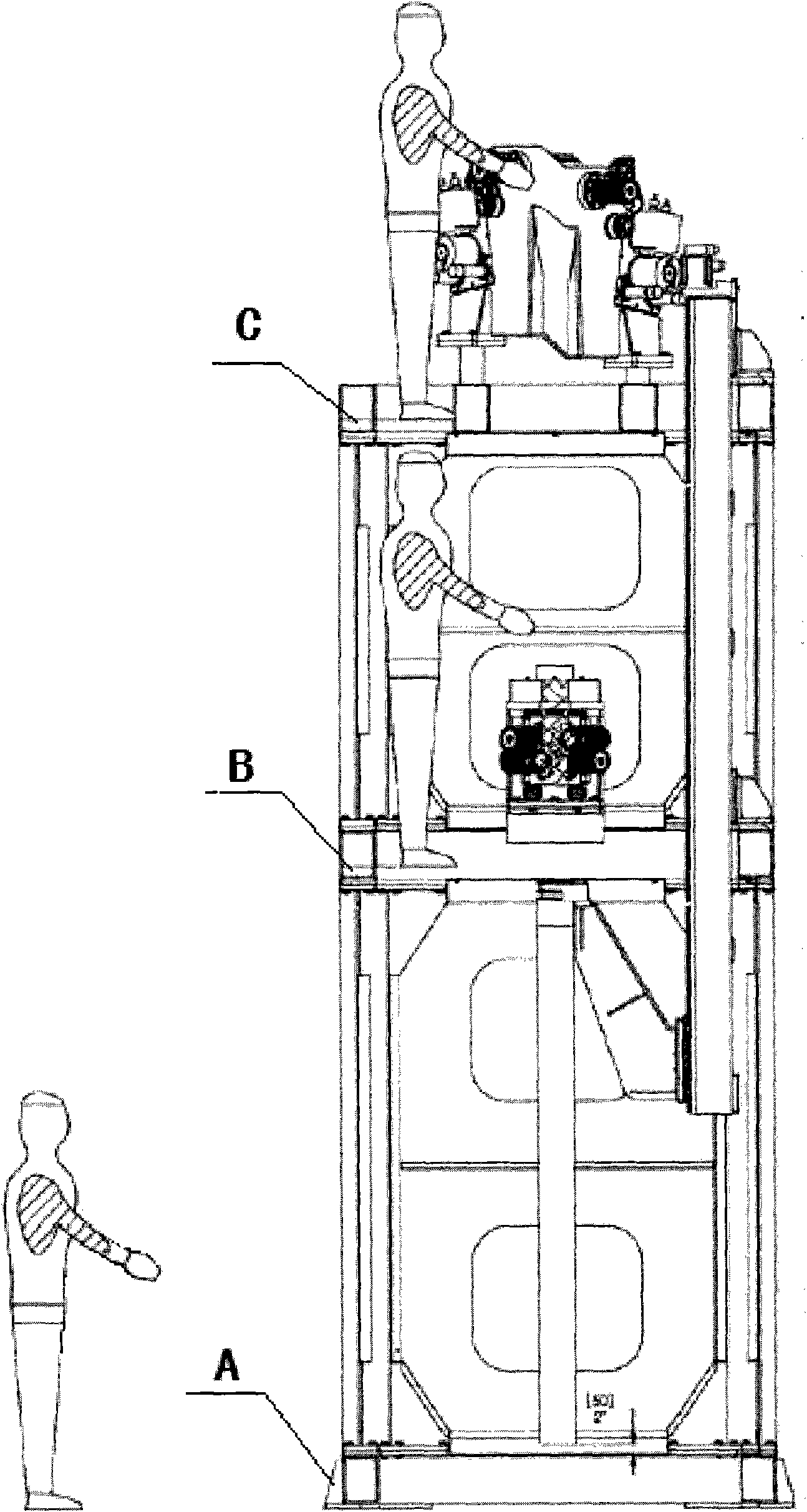

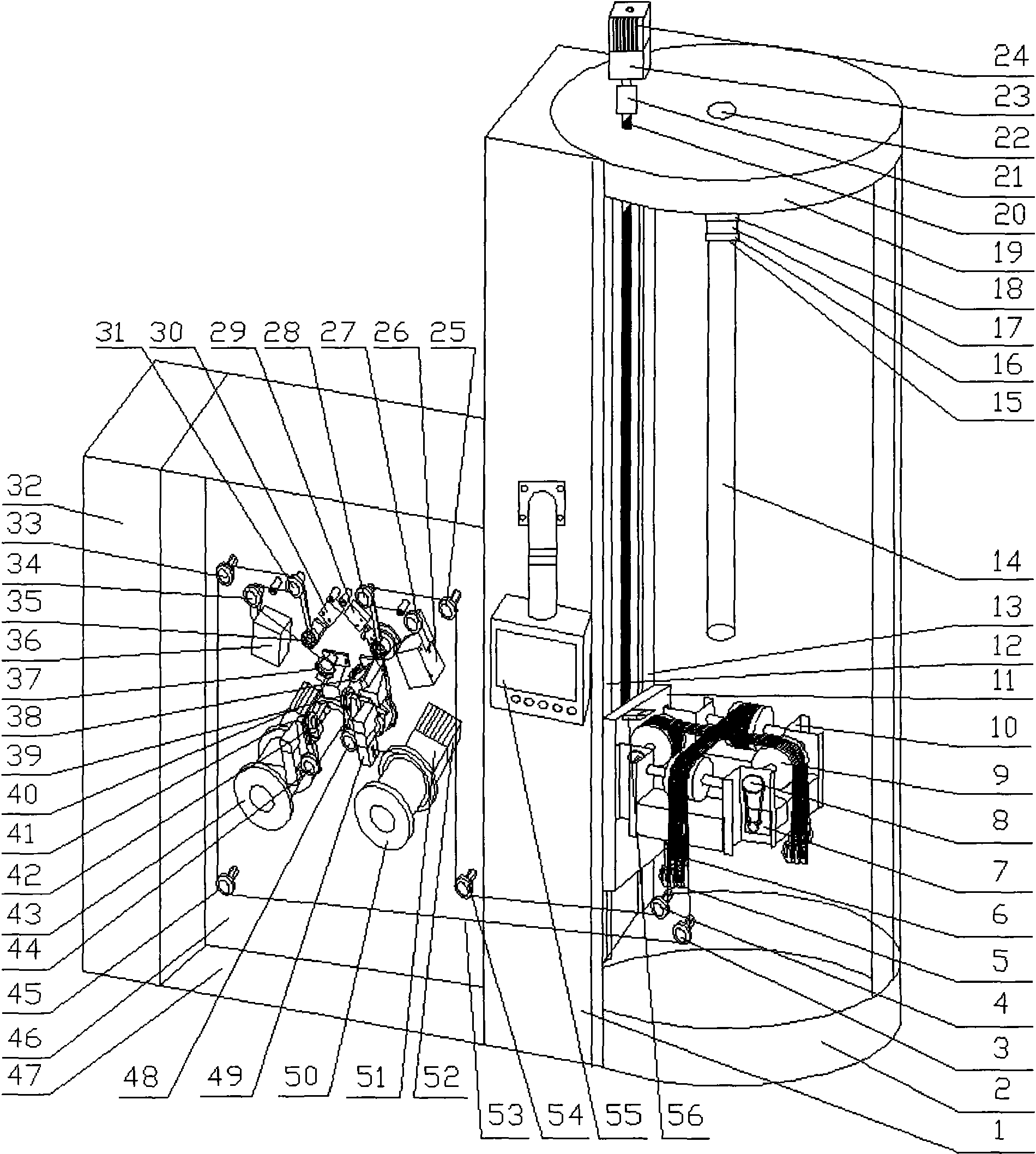

[0041] Such as figure 2 As shown, the feature of this machine tool is that the workpiece 14 to be processed is fixed on the upper part of the machine tool, and the square-shaped cutting guide wheel assembly 10 wound with diamond wire 53 moves from the lower part to the upper part at a set speed to complete the cutting. A unique wiring scheme, the wiring and operation only need to be completed on the ground, without the need to go to the working platform, the surface of the mouth-shaped cutting guide wheel assembly 10 is coated with Out of the steel round drum 9 made of polyurethane material, multi-layer guide wheels 5, 6 which are inclined at a certain angle and arranged in upper and lower layers with the drum are adopted. The guide wheels 5, 6 arranged up and down can be 2-layer, 3-layer or 4-layer The structure can satisfy the operator to complete the wiring on the ground. The square-shaped cutting guide wheel assembly 10 stays at a height of about 1 meter to easily complet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com