Patents

Literature

162results about How to "Improve cutting ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

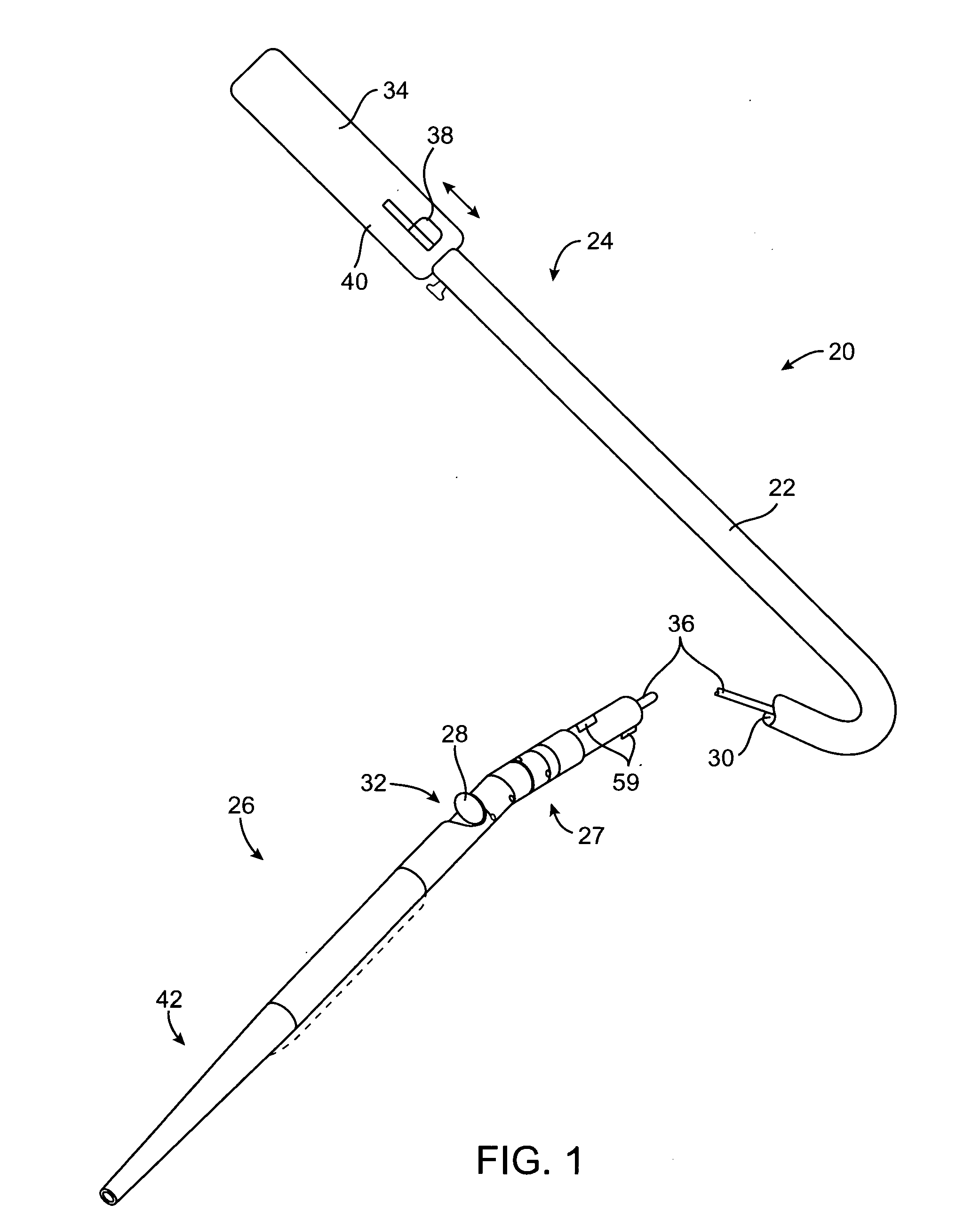

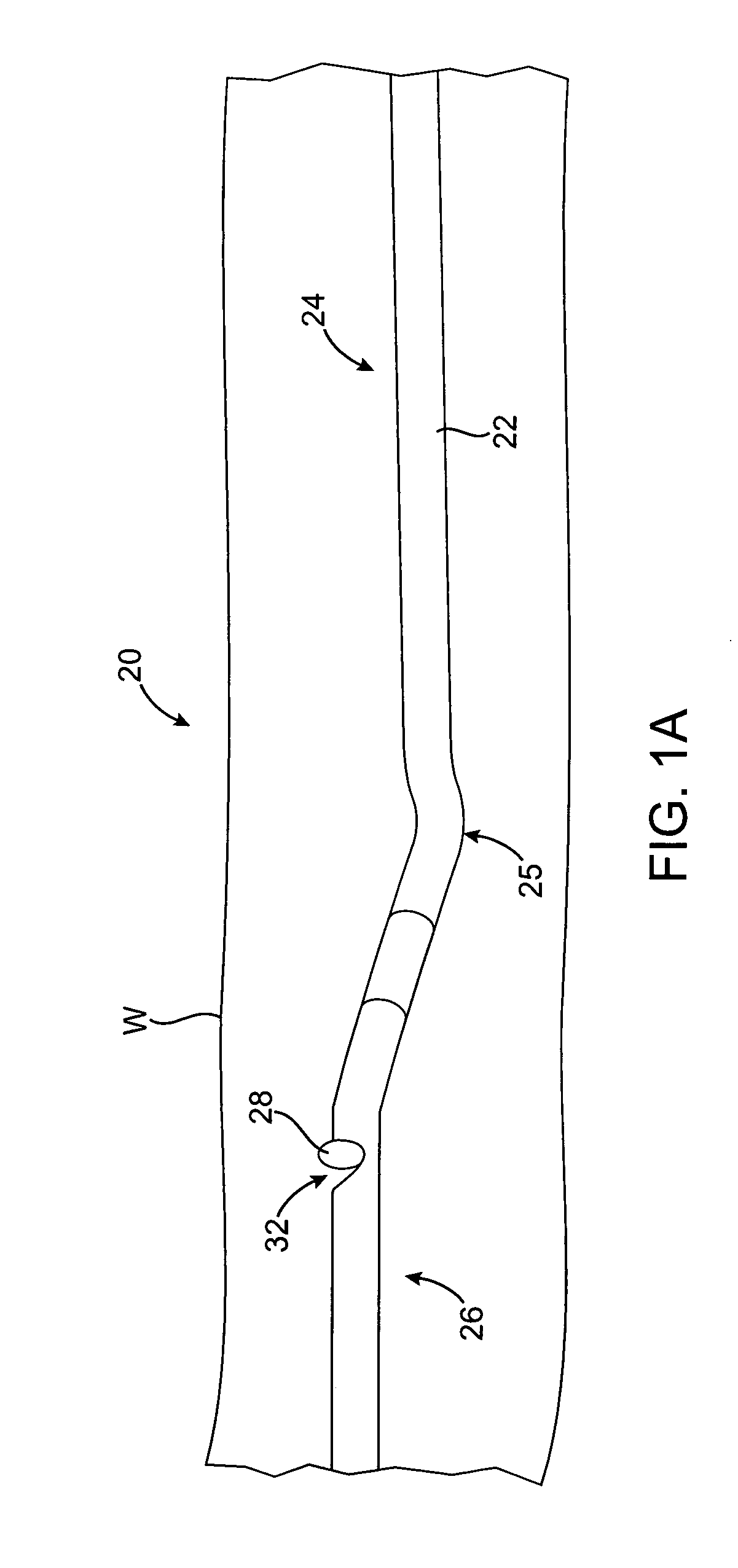

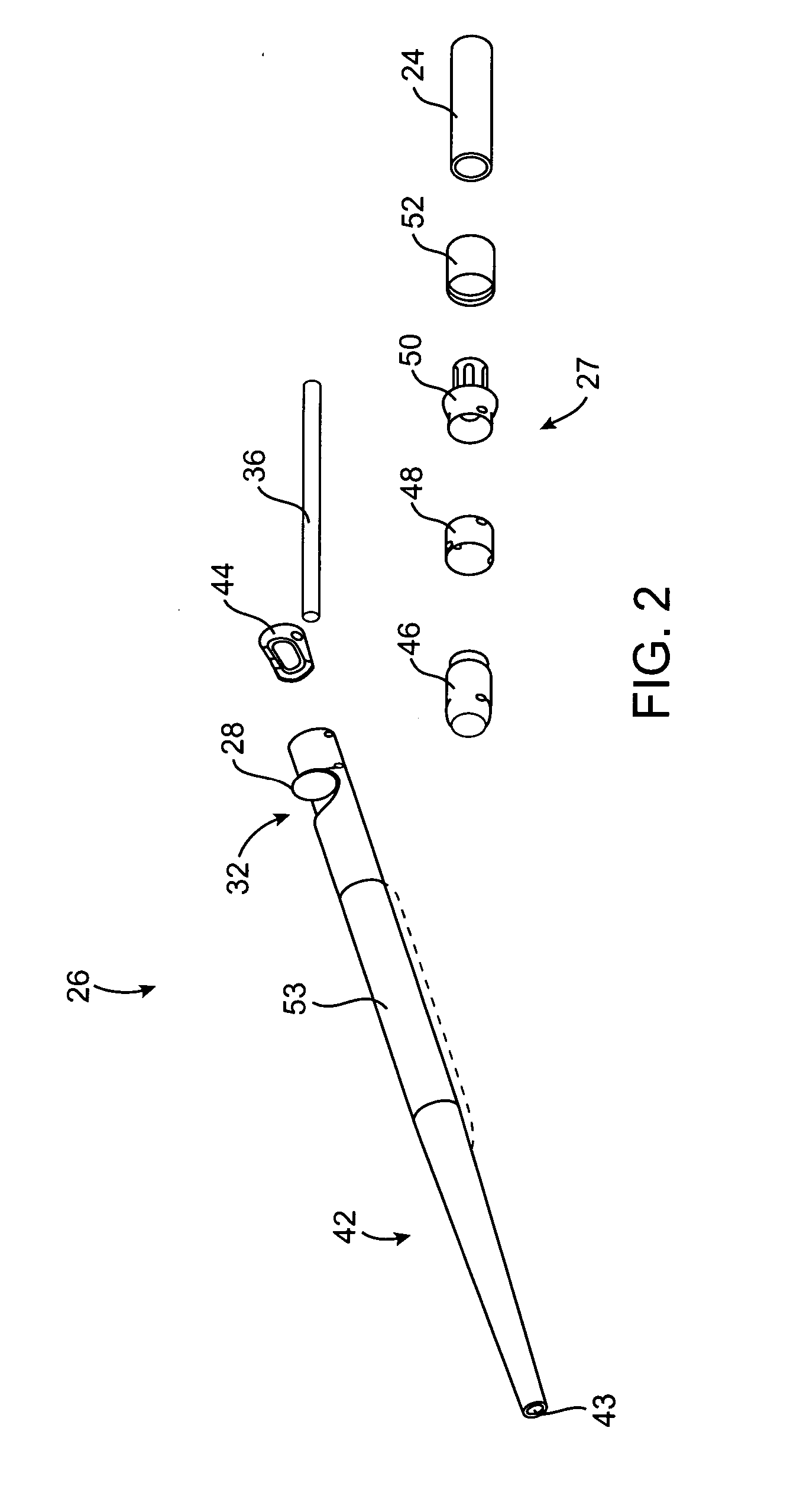

Debulking catheters and methods

InactiveUS20050222519A1Good removal effectFacilitate removal of materialSurgical needlesVaccination/ovulation diagnosticsDistal portionDebulking

A debulking catheter comprising a tissue debulking assembly for removing a continuous strand of material from a body lumen. Catheters of the present invention generally include a catheter body having proximal and distal portions and a tissue debulking assembly disposed at least partially within the distal portion. The tissue debulking assembly is radially movable to expose at least a portion of the assembly through a window on the catheter body. The catheter is advanced transluminally through the body lumen to contact material in the body lumen and remove a plane of continuous material that has a length that is typically longer than a length of the window on the catheter. The continuous material may be directed into a collection chamber. Thereafter, the material may be removed from the collection chamber and preserved or tested.

Owner:TYCO HEALTHCARE GRP LP

Diamond wire saw production method of surface modified diamond

InactiveCN101812710AAchieve electroplating depositionEasy to operateElectrophoretic coatingsElectrophoresisDiamond wire saw

The invention relates to a diamond wire saw production method of a surface modified diamond, which comprises the following steps: 1. removing surface grease and surface metal oxides on the surface of the diamond; 2. placing diamond micropowder into a cationic surfactant solution, applying positive potential and forming a layer of positive charge film on the surface of the diamond under the electrophoretic action by action of a cationic surfactant; and 3. carrying out composite electroplating of a diamond wire saw. In the invention, conductive processing is carried out on the diamond, so that diamond grains can orderly move in a plating solution under the action of an electric field to realize the electroplating deposition on the surface of a metal wire without the influence of the size of the diamond grains; the surfactant is adsorbed on the surface of the diamond, so that a plating layer and the diamond present an infiltrative type interface, and a Ni plating layer has strong holding capability on the diamond; and the diamond micropowder has high utilization ratio. The invention has simple process method and convenient operation, the diamond grains have rapid deposition speed, good deposition uniformity and high deposition density on the metal wire, an electroplating layer has high holding force on the diamond grains, and the diamond micropowder has high utilization ratio. The invention can realize industrialized production and provides a method for efficiently and rapidly producing the diamond wire saw.

Owner:CHANGSHA DIAT NEW MATERIAL SCI & TECH

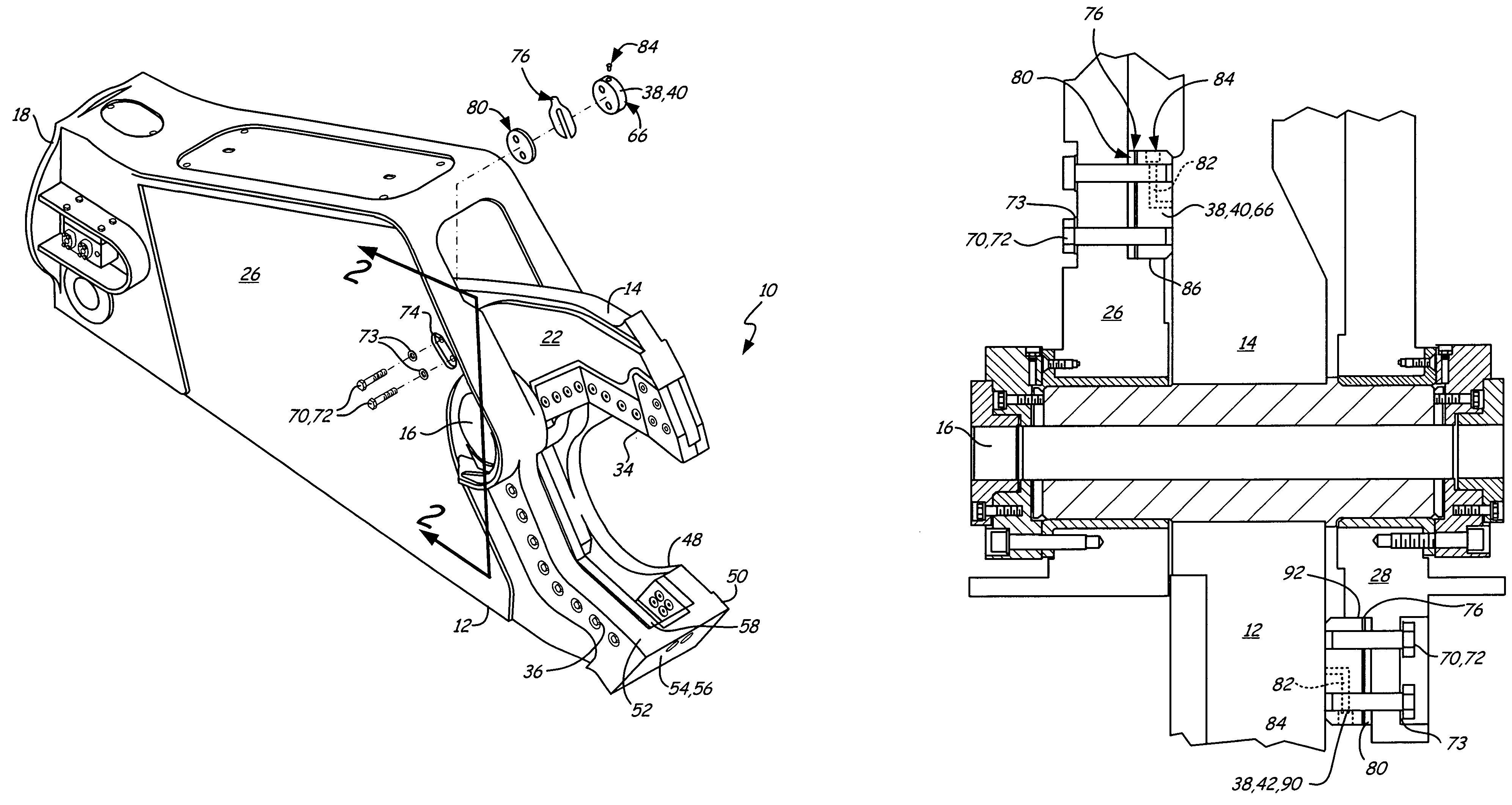

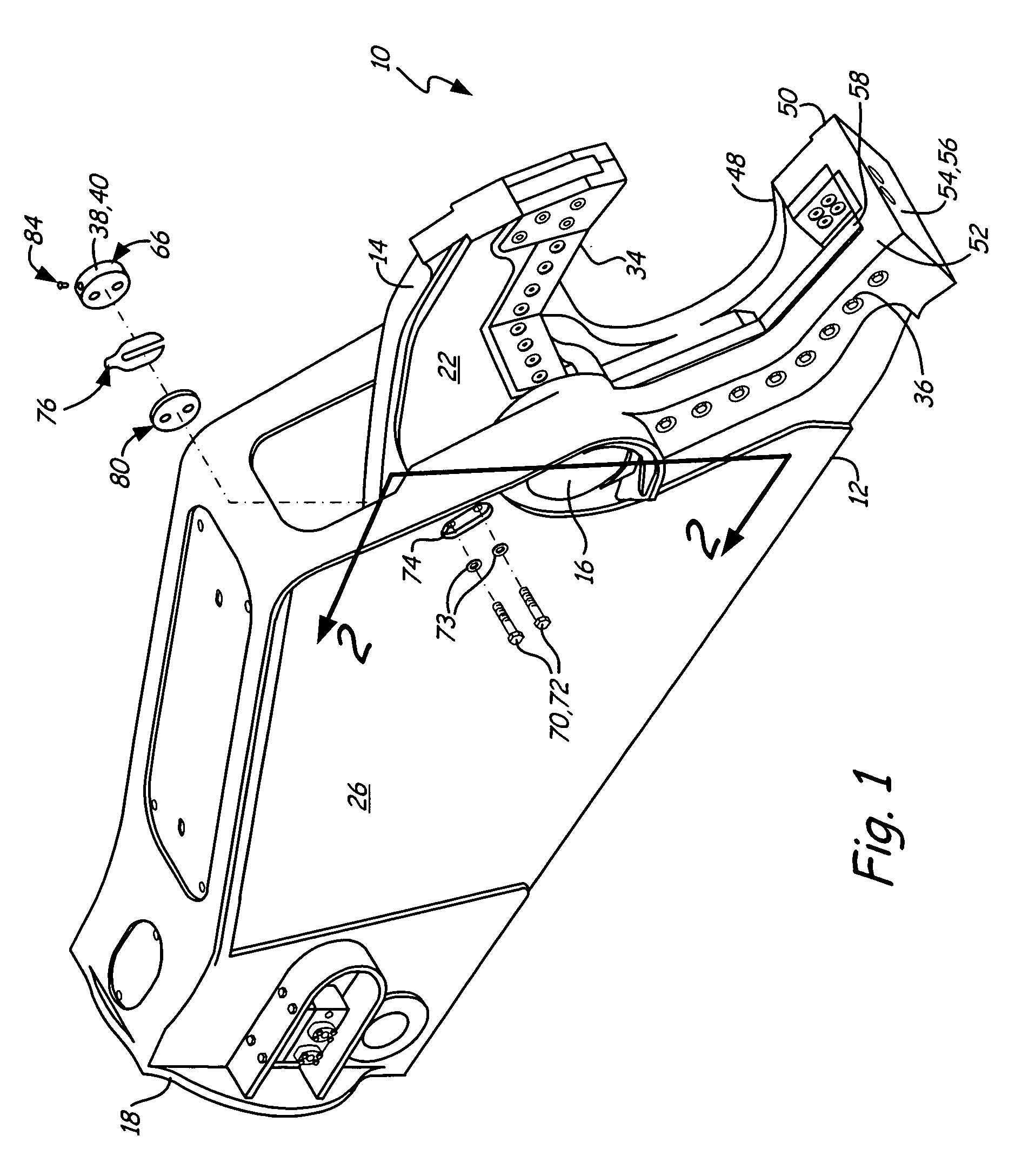

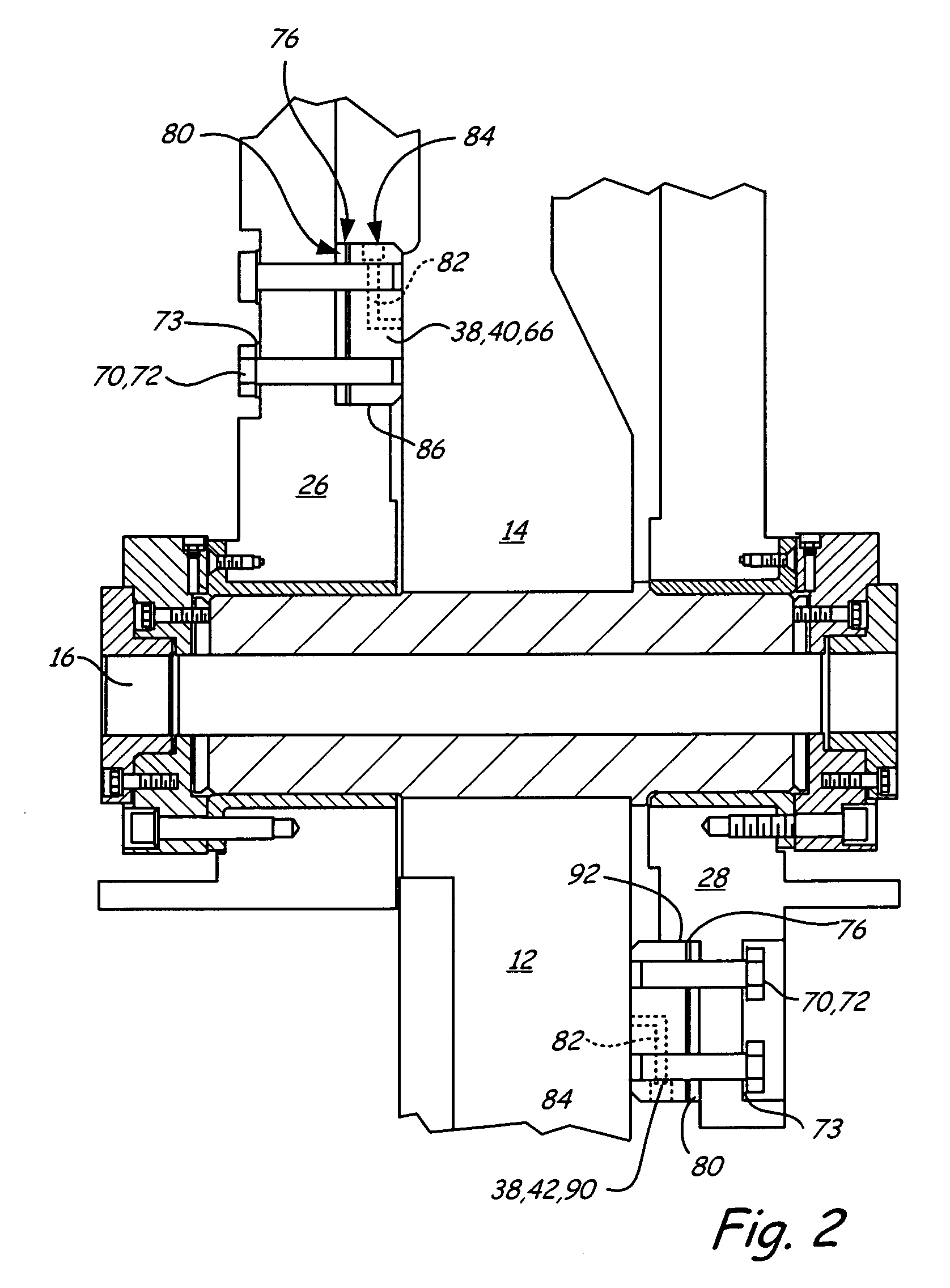

Heavy-duty demolition apparatus with blade stabilizing puck

ActiveUS7216575B2Improve cutting effectReduce lateral stressMechanical machines/dredgersBuilding repairsEngineeringHeavy duty

A blade stabilizer device for a heavy-duty material handling demolition tool for shearing and crushing scrap material which includes a lower jaw connected to the boom structure of a hydraulic system of an excavator has an upper jaw pivotally connected to and closable upon the lower jaw at a pivot point. The blade stabilizing device consists of a wear guide pad supported by the lower jaw adjacent the pivot point slidably engaging the movable upper jaw to keep the upper jaw in close engagement with the lower jaw. The wear guide pad is mounted behind the pivot point. A second wear guide pad may be mounted in front of the pivot point on the opposite side of the upper jaw to cross-brace the upper jaw.

Owner:GENESIS ATTACHMENTS

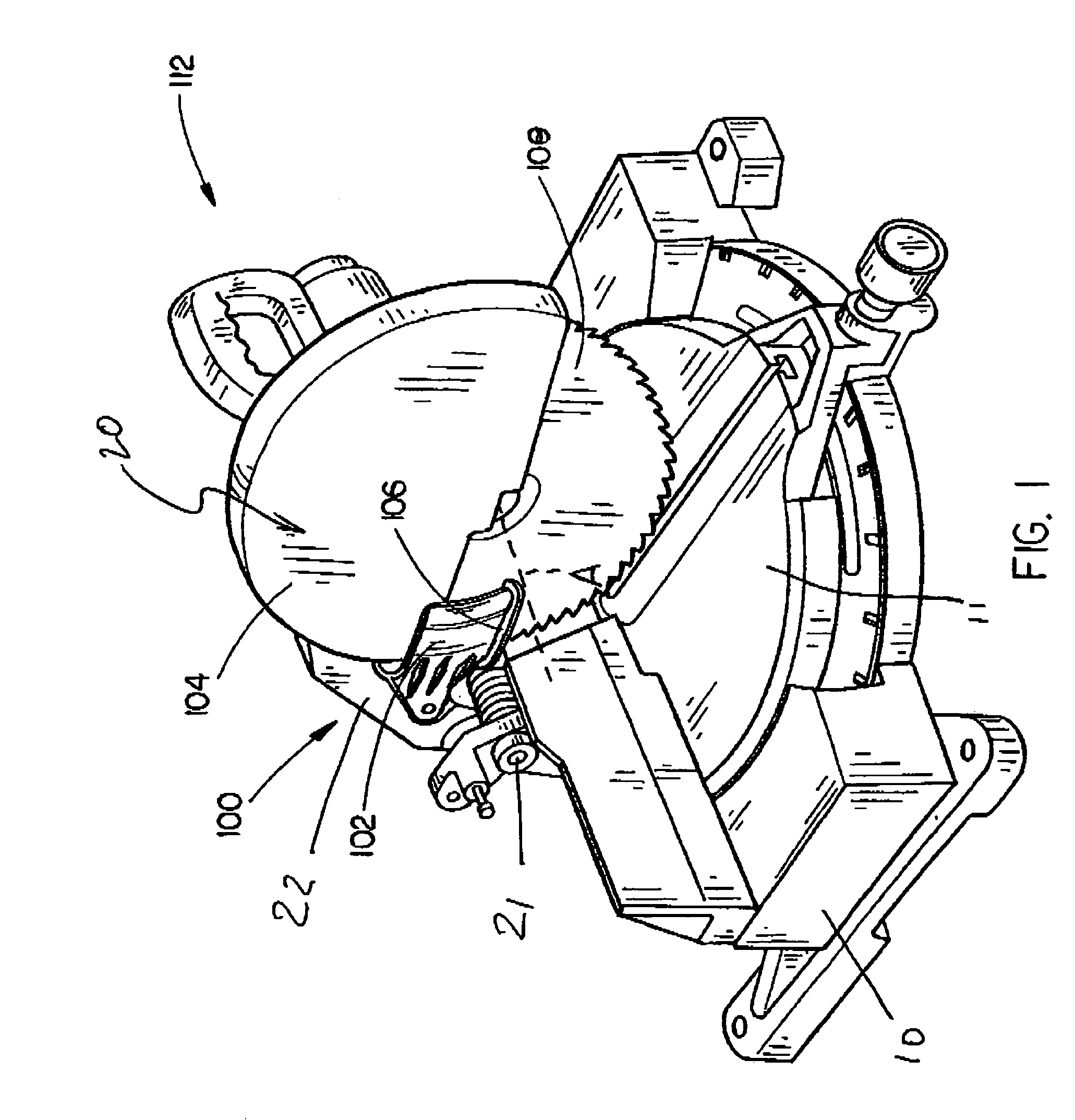

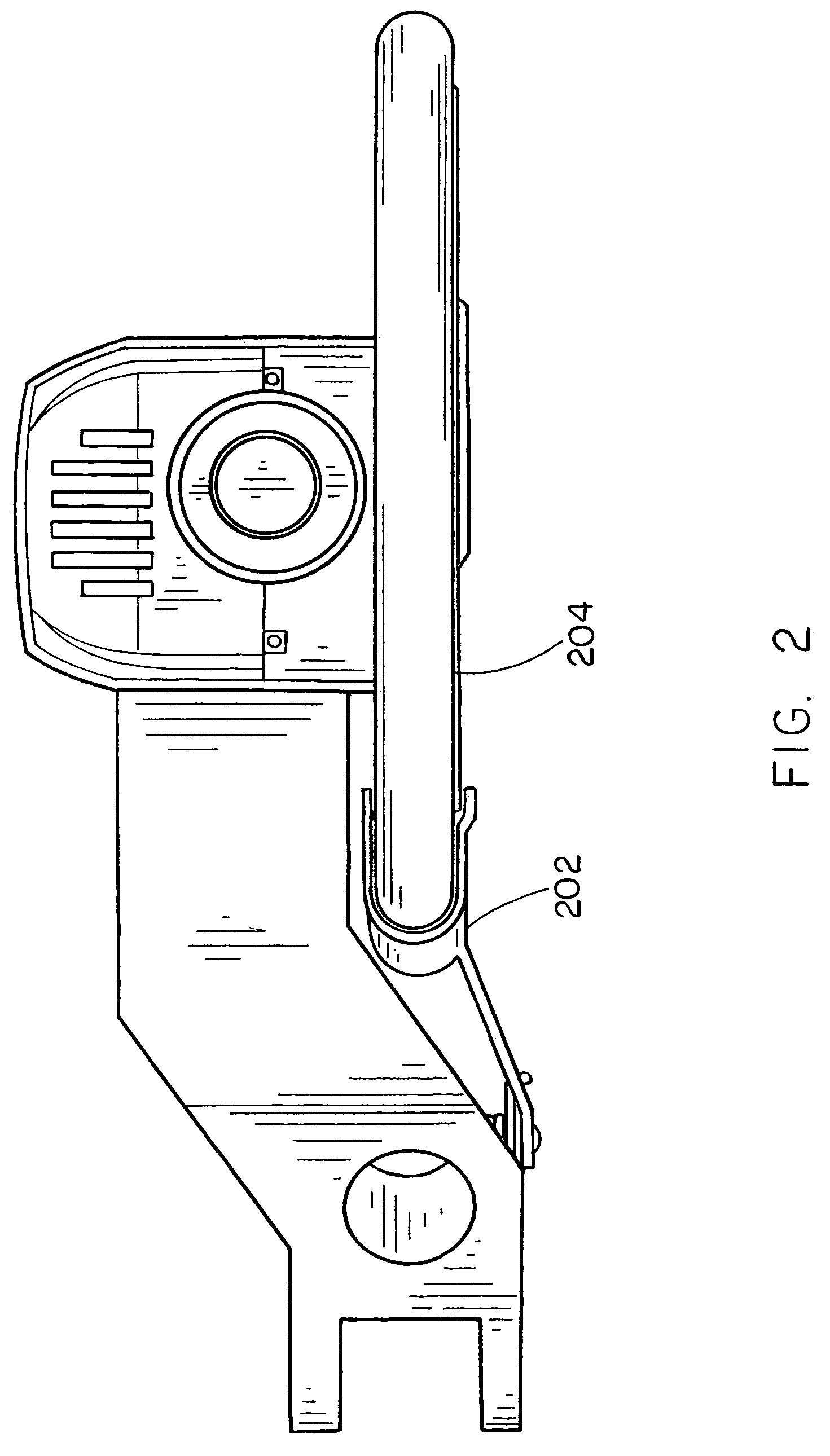

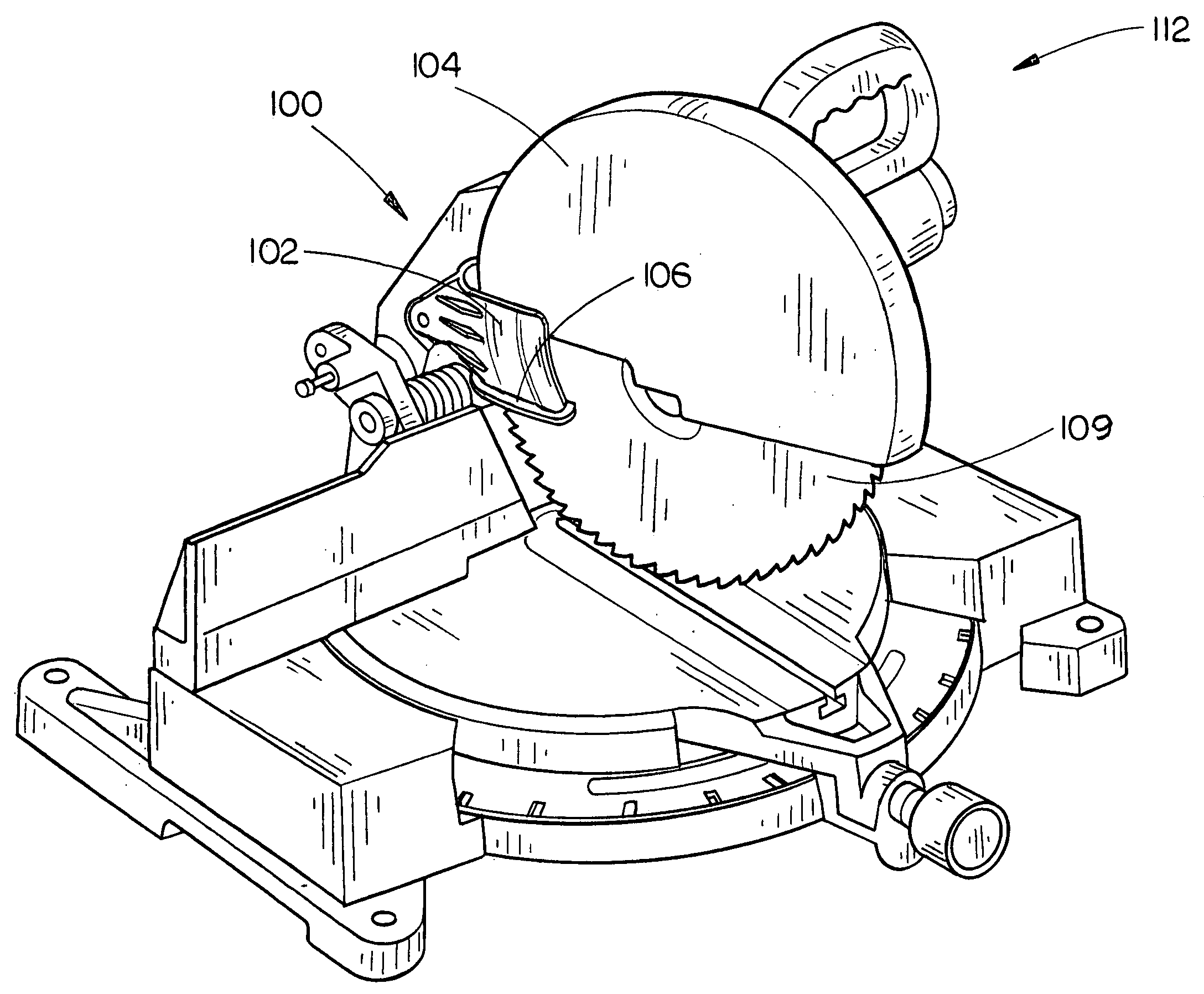

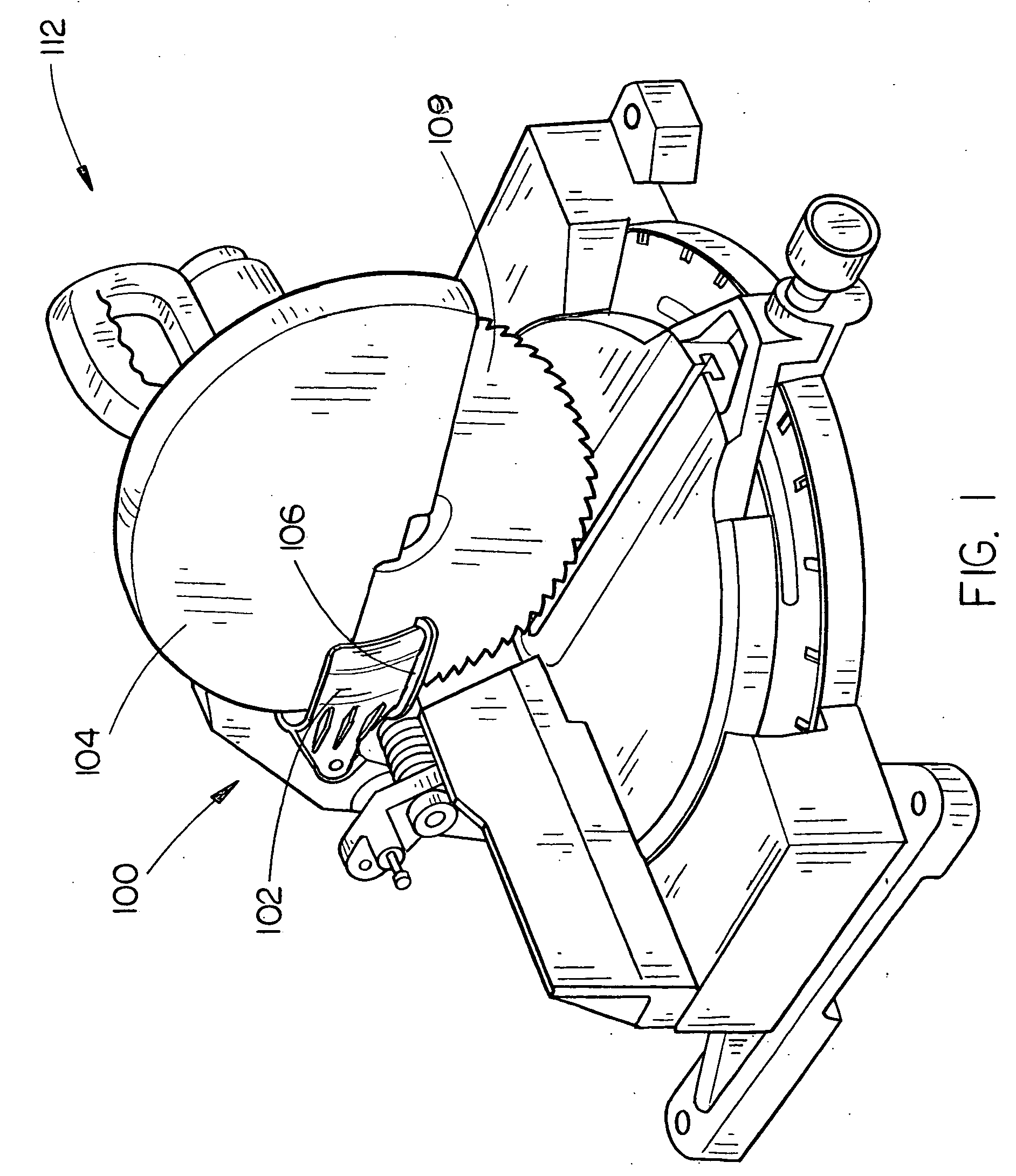

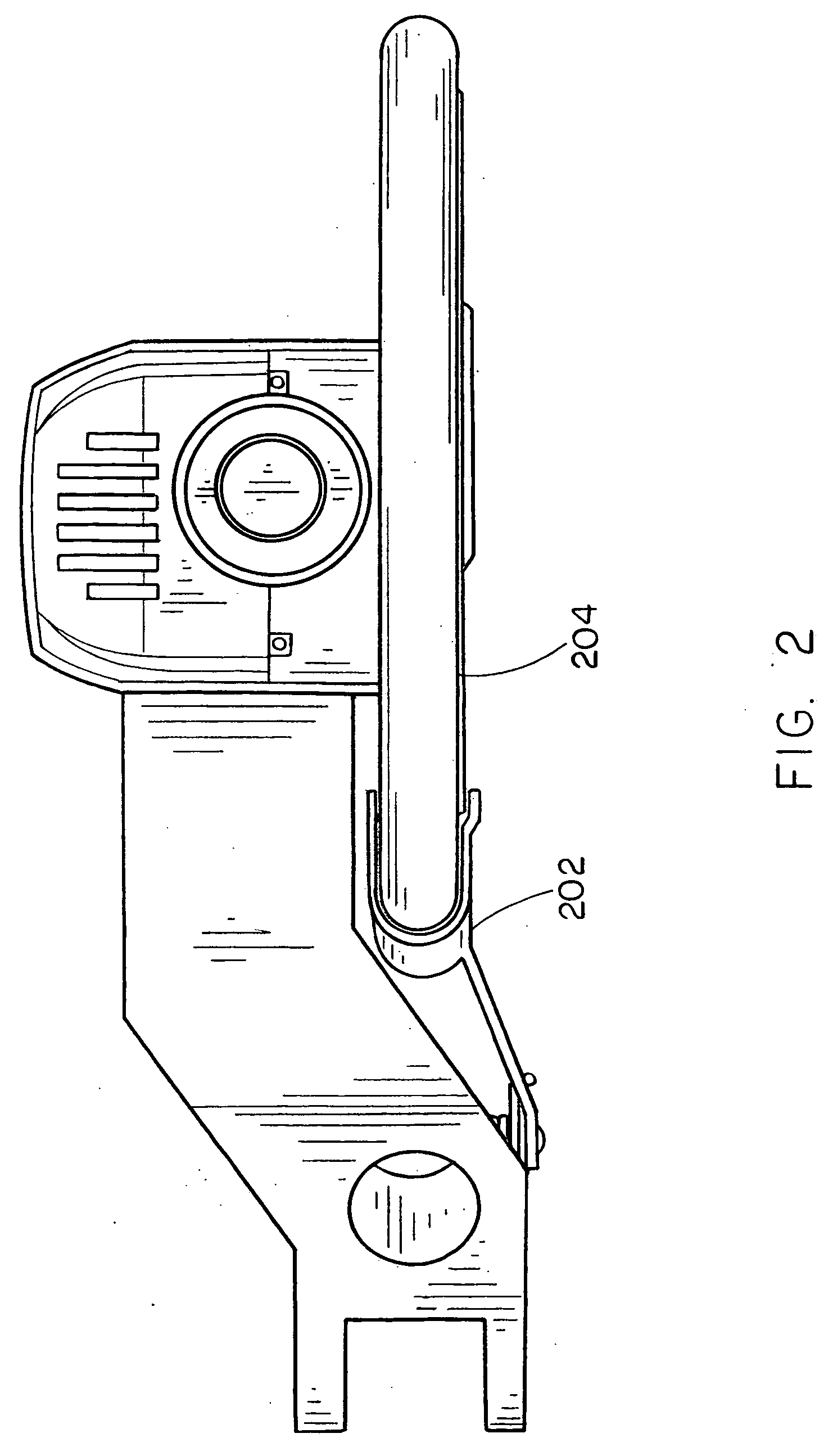

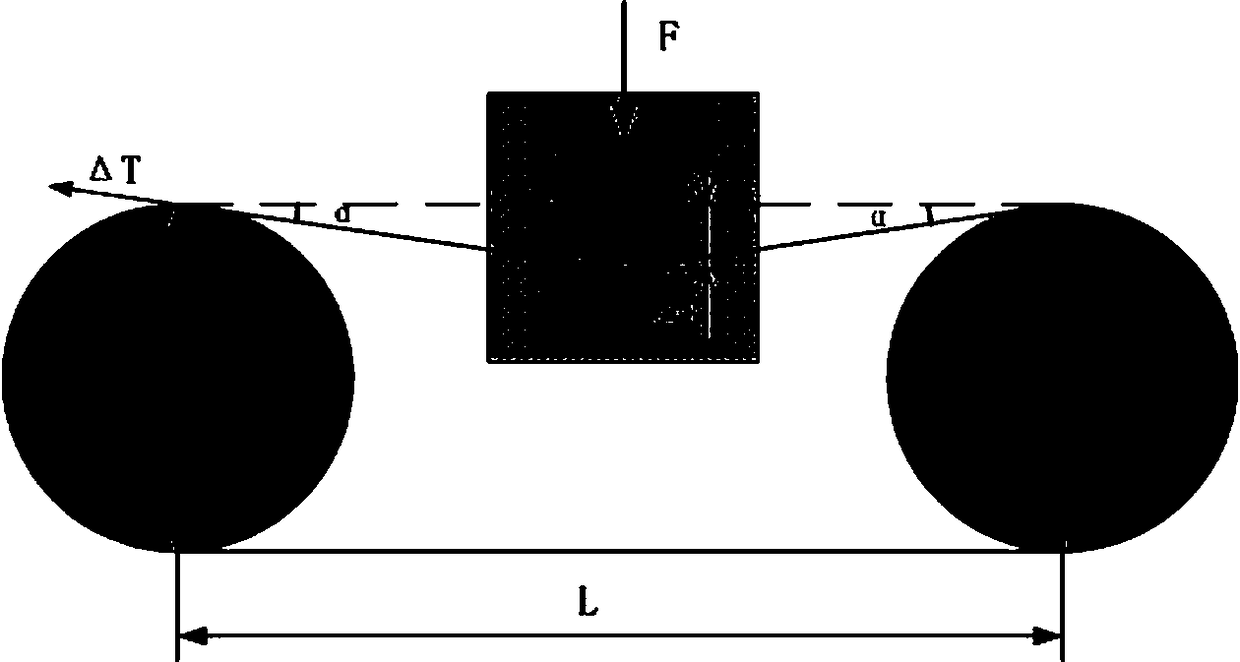

Pivoting rear blade guard

The present invention is directed to a blade guard assembly capable of allowing increased capacity for saws, such as radial arm saw, miter saws, and the like. The assembly includes a U-shaped guard and a pivot pin for allowing the guard to obtain a plurality of positions including a guarding orientation and a cutting orientation. The guard may pivot so as to allow a larger dimension workpiece to be cut without exposing the saw blade unnecessarily. Additionally, a biasing device may be included for generally forcing the guard into a guarding orientation.

Owner:BLACK & DECKER INC

Production process for preparing high-performance diamond wire saw

InactiveCN101591796AUniform electrodepositionConcentration controllableElectrolytic coatingsChemical vapor deposition coatingHydrogenWater vapor

The invention discloses a production process for preparing a high-performance diamond wire saw, which comprises the following steps: firstly, reacting diamond with tungsten oxide, water vapor and hydrogen at a temperature of between 65 and 900 DEG C to form a W-W2C layer on the surface of the diamond so as to realize surface alloyed tungsten of the diamond; secondly, preparing electroplating bath by the diamond of the surface alloyed tungsten and watt type nickel plating solution, and carrying out electroplating by using a nickel plate as an anode and a steel wire as a cathode; making the diamond of the surface alloyed tungsten do electrophoresis motion under the action of an electric field and electrodeposited on the surface of the steel wire, and simultaneously electrodepositing the metal nickel on the surface of the steel wire. The diamond wire saw prepared by the production process has the advantages of even distribution of diamond grain, high mass percentage of a diamond plating layer and high electroplating speed; and the diamond and a nickel matrix are in metallurgical bonding, so the bonding capacity of the matrix for cutting diamond grains is remarkably improved, and the cutting capacity and the service life of the diamond wire saw are greatly improved. The production process is suitable for industrialized production, and can replace the prior production process for the diamond wire saw.

Owner:CHANGSHA DIAT NEW MATERIAL SCI & TECH

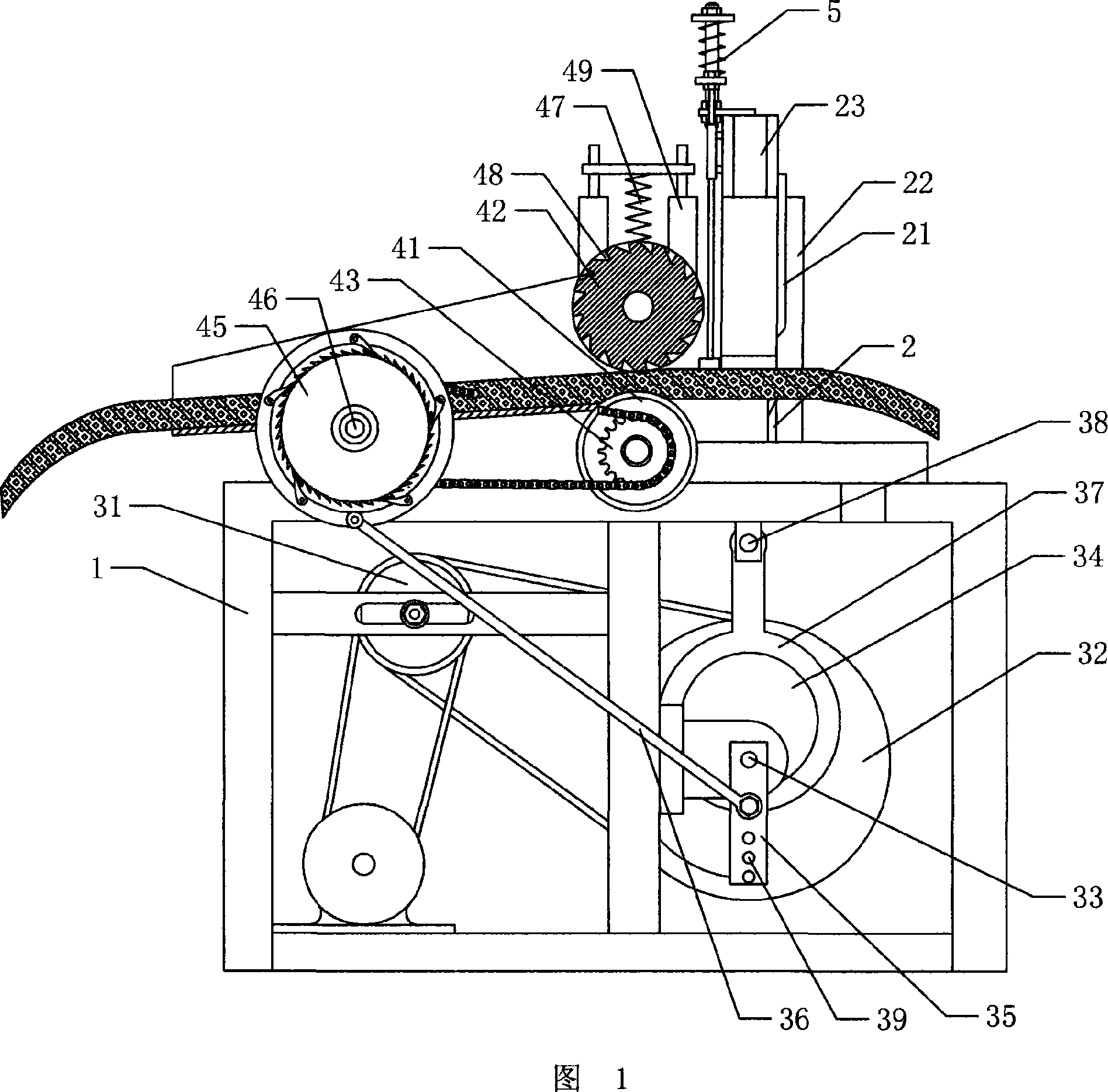

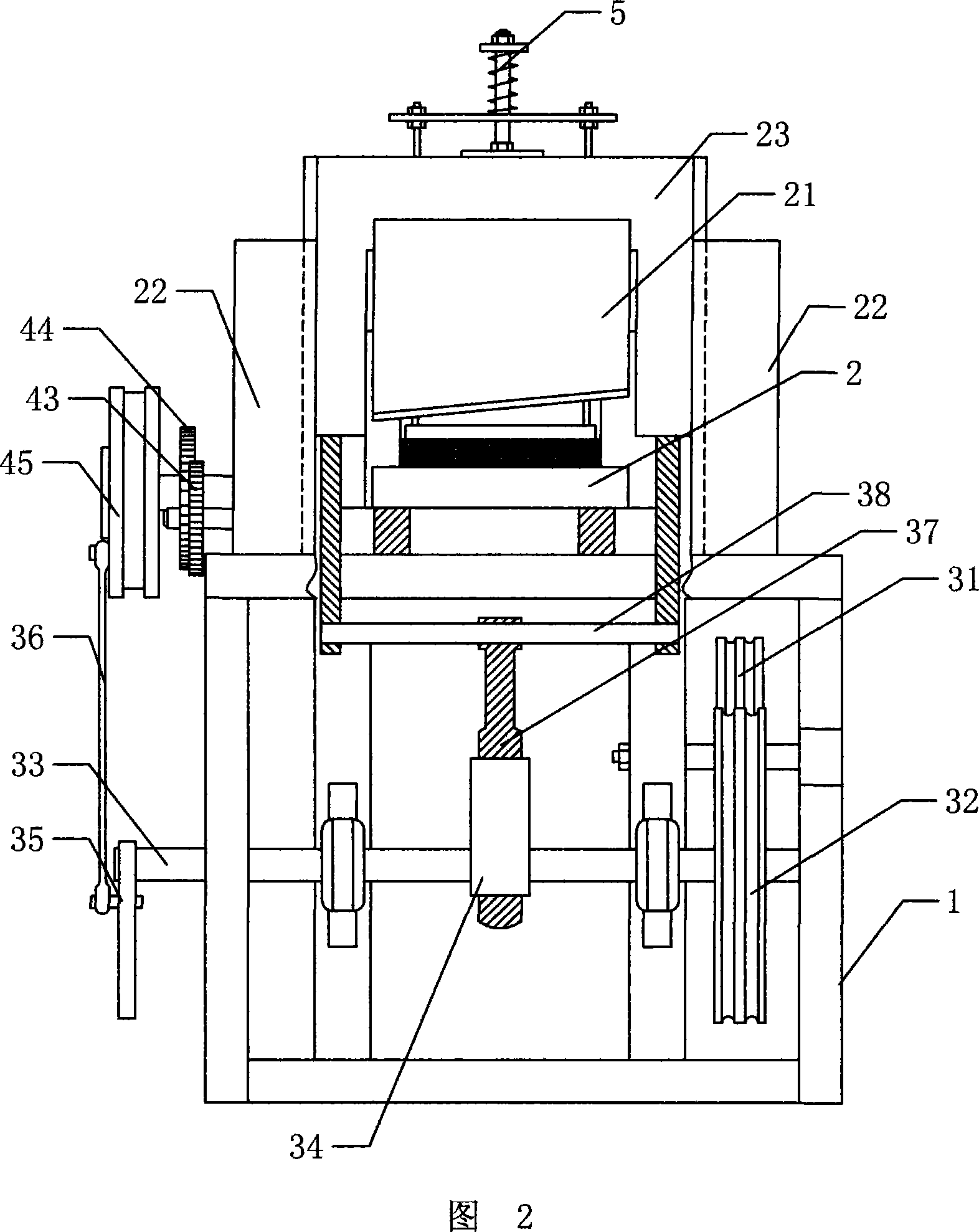

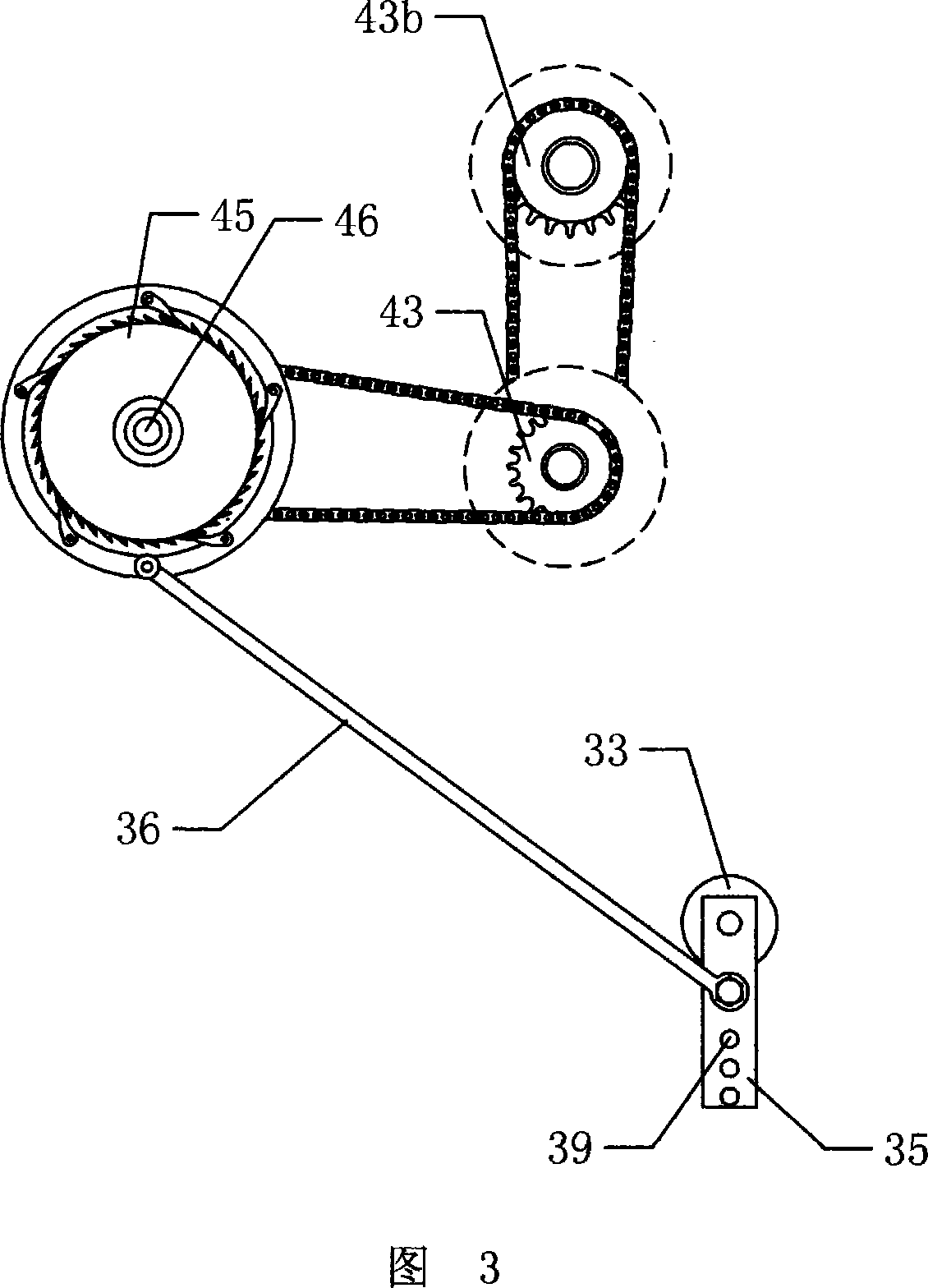

Yarn cutting machine

InactiveCN101082175AReduce labor intensitySimple structureSevering to form staple fibresSevering textilesYarnReciprocating motion

The present invention discloses one kind of yarn cutting machine, which includes one frame, one yarn feeding mechanism, one yarn cutting mechanism, and one intermittent driving mechanism for driving the yarn feeding mechanism and the yarn cutting mechanism. The yarn cutting mechanism includes one fixed cutter mounted on the frame, one moving cutter moving in the direction perpendicular to the yarn feeding direction, one cutter holder for the moving cutter to be mounted on, one yarn clamping unit on the cutter holder and one moving cutter driving reciprocator. The present invention has simple structure, convenient use and great cutting capacity.

Owner:刘成志

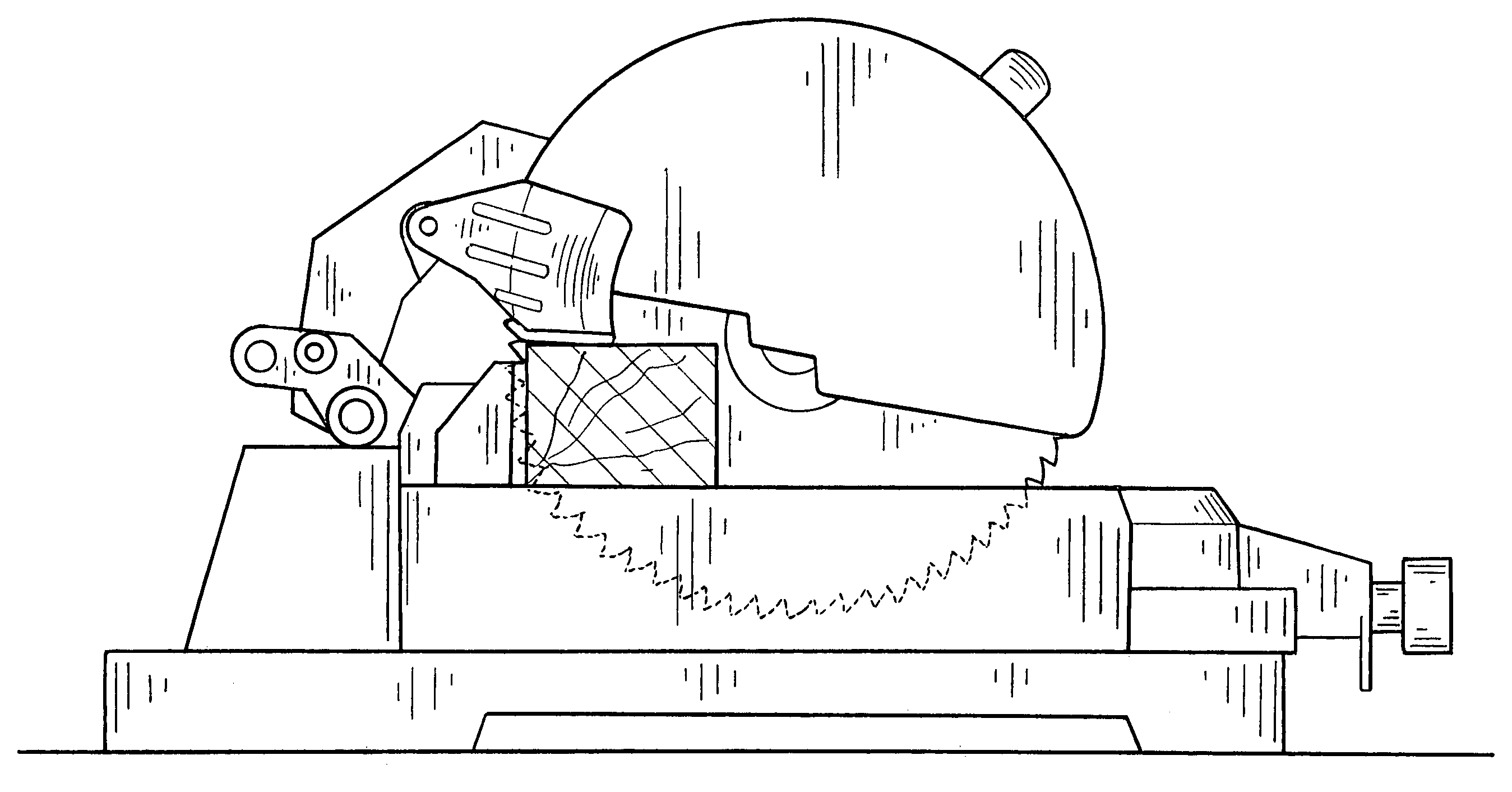

Pivoting rear blade guard

ActiveUS20060101965A1Improve cutting capacityImprove cutting abilityShearing machinesCircular sawsEngineeringKnife blades

The present invention is directed to a blade guard assembly capable of allowing increased capacity for saws, such as radial arm saw, miter saws, and the like. The assembly includes a U-shaped guard and a pivot pin for allowing the guard to obtain a plurality of positions including a guarding orientation and a cutting orientation. The guard may pivot so as to allow a larger dimension workpiece to be cut without exposing the saw blade unnecessarily. Additionally, a biasing device may be included for generally forcing the guard into a guarding orientation.

Owner:BLACK & DECKER INC

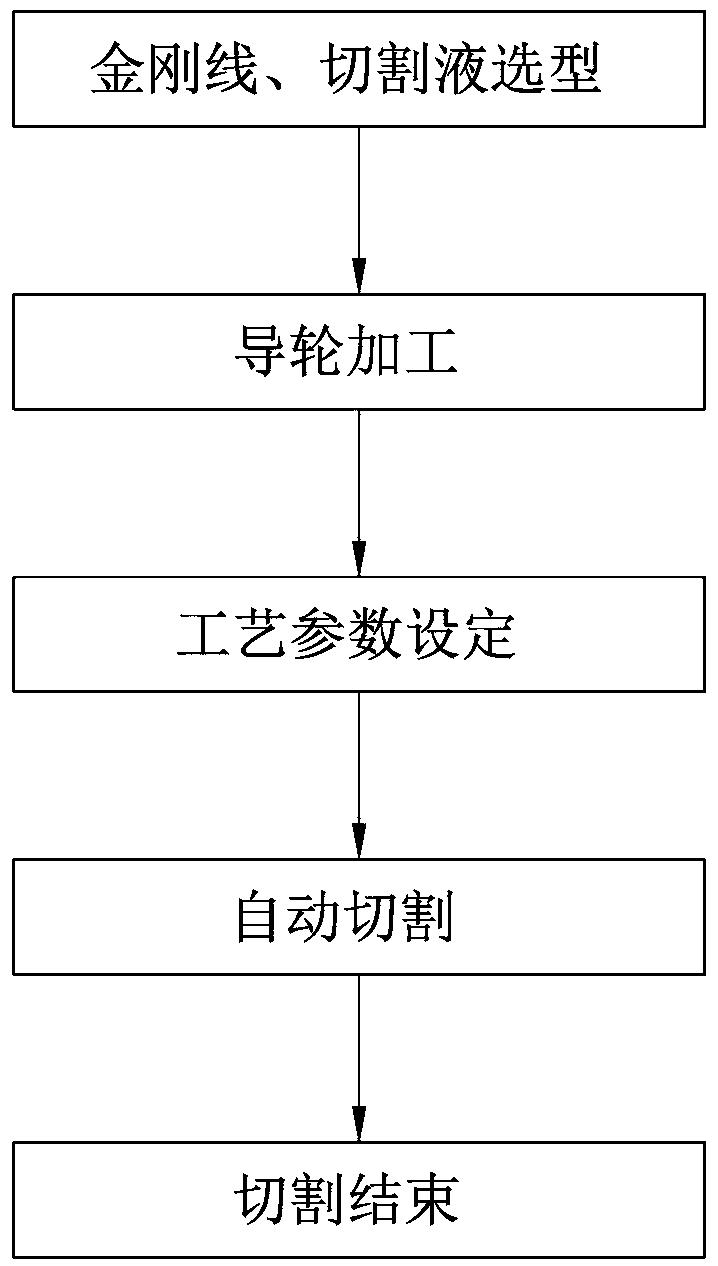

High-efficiency cutting method for crystalline silicon blocks

InactiveCN109304819AThe process takes a short timeIncrease slicing capacityFine working devicesMicrometerCrystalline silicon

The invention discloses a high-efficiency cutting method for crystalline silicon blocks in the field of solar energy application. The high-efficiency cutting method comprises the following steps of 1)diamond wire and cutting liquid selection, wherein a single-polycrystalline mixed sand electroplating diamond wire (the diamond wire diameter ranges from 50 micrometers to 70 micrometers is adopted,the cutting fluid is selected from a low COD coolant and pure water mixture; 2) guide wheel processing; 3) process parameter setting, wherein the diamond wire, the cutting fluid and a guide wheel arematched, after a cutting machine is assembled, the feeding speed of the working table is adjusted to be 800-3000micrometers per minute, the cutting fluid process flow is 110-180 KG / Min, the cutting liquid cooling temperature is 17-23 DEG C; 4) automatic cutting, wherein after the machine is started for warming up by 5-10 minutes, when it is known that the parameters are normal through spot check,automatic cutting starts; and 5) ending of cutting, wherein a rod is lifted to complete silicon block cutting. The high-efficiency cutting method effectively improves the cutting speed and the cuttingefficiency, improves the yield rate, reduces the cost of auxiliary materials like the diamond wire consumption, improves the slice profitability, and can be used for silicon wafer production.

Owner:YANGZHOU RONGDE NEW ENERGY TECH

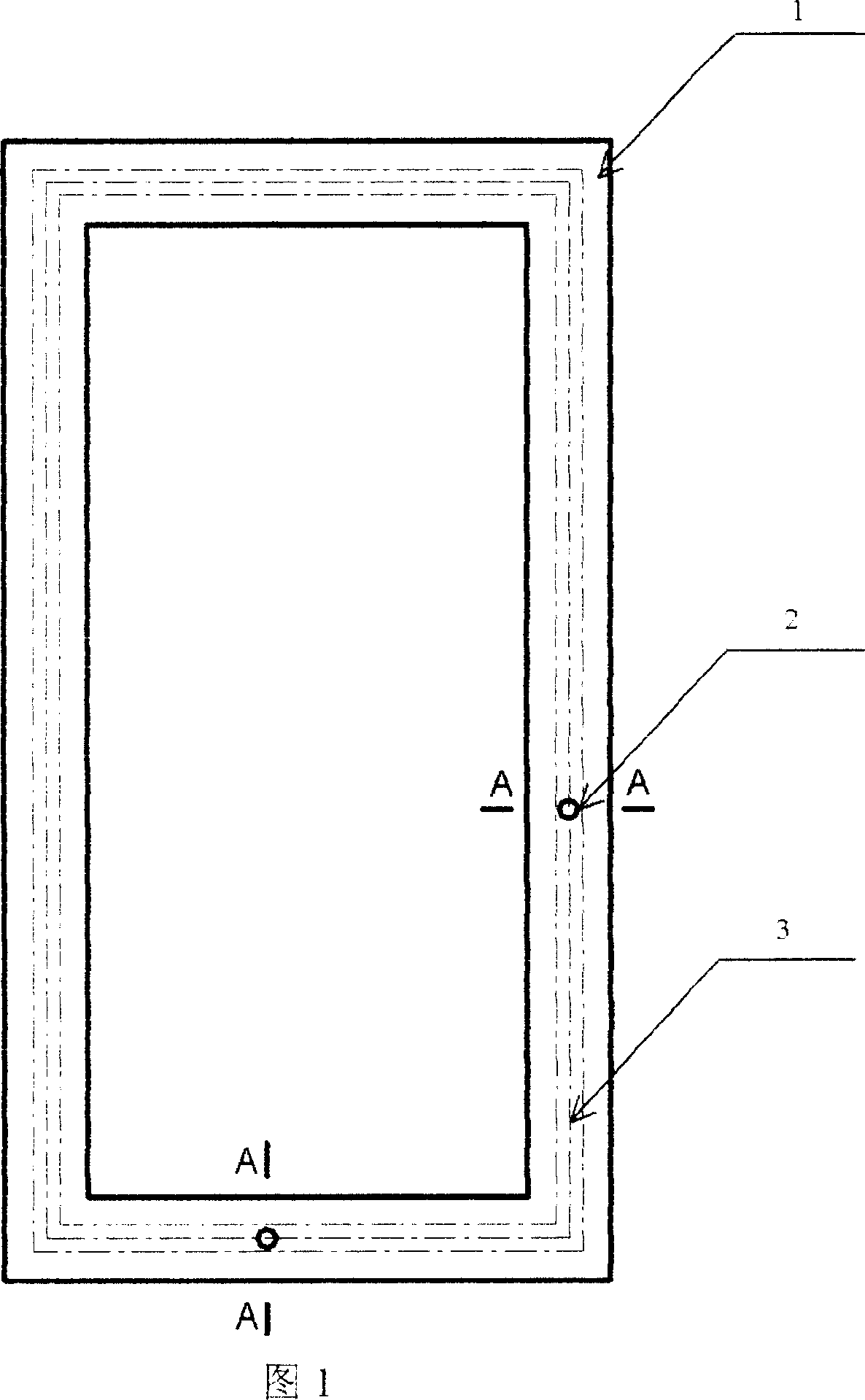

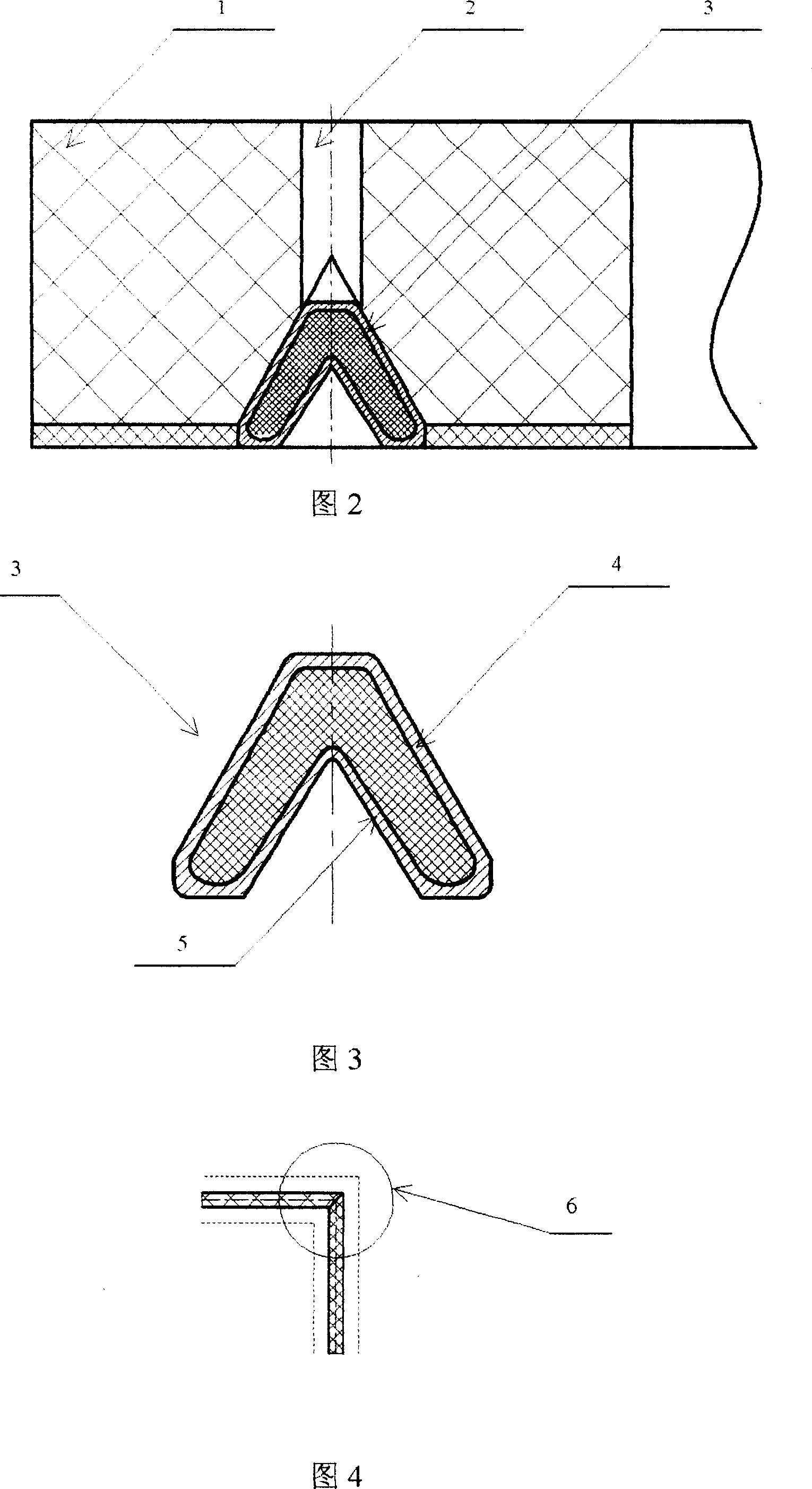

Plane-cabin energy-collected cutting apparatus

InactiveCN1978158AMeet the use requirementsImprove cutting abilityBlastingMetal working apparatusShock waveAirplane

This invention discloses a cumulative cut device for airplane compartments, which fills explosive charges in angles at the corners of the device to transfer the explosion continuously, applies a metal explosive cover not generating pestles to increase the cut depth of non-uniform compound materials when cutting on planes in linearity and applies lags capable of absorbing shock waves and scattered materials to increase the safety.

Owner:XIAN MODERN CHEM RES INST

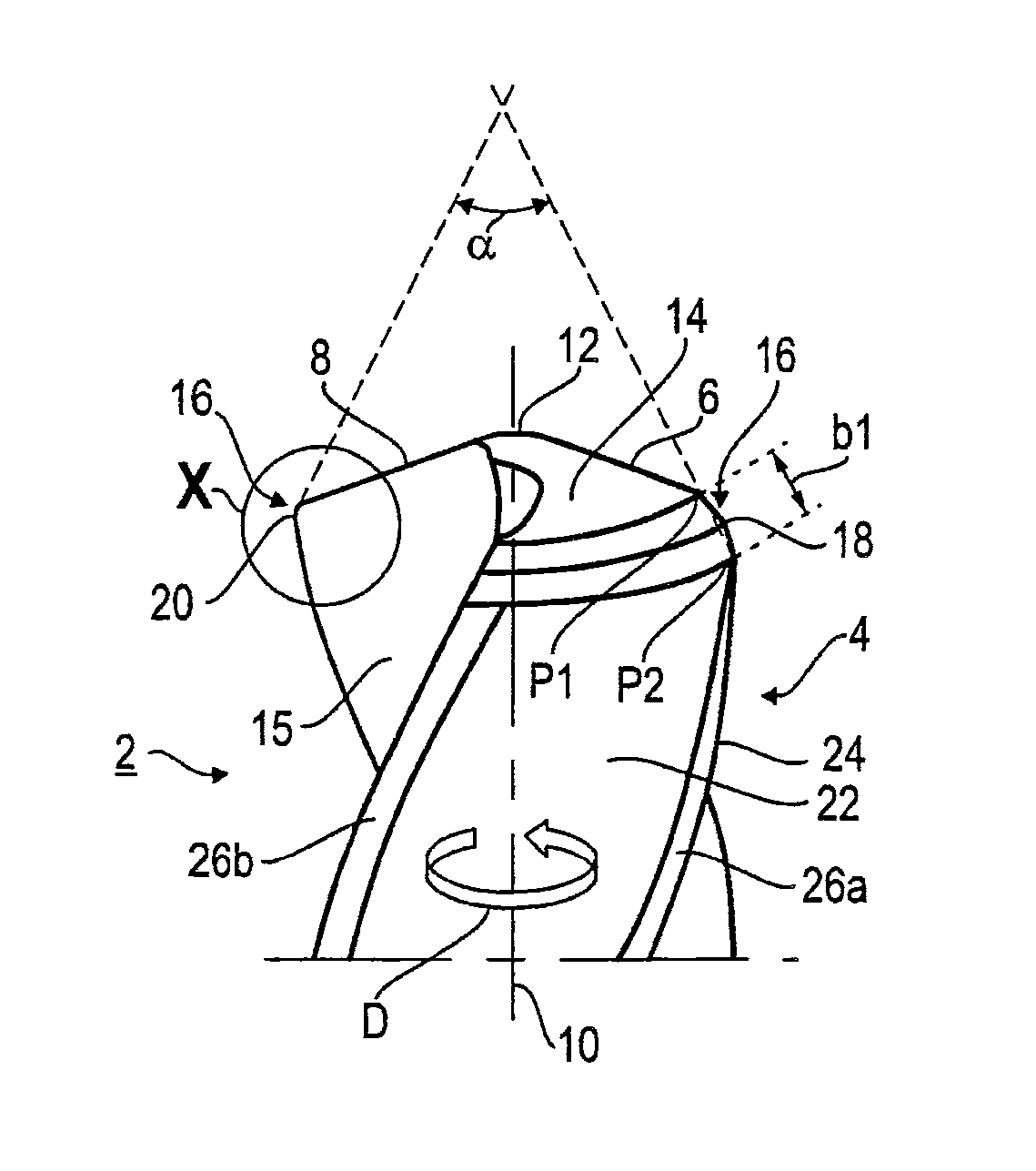

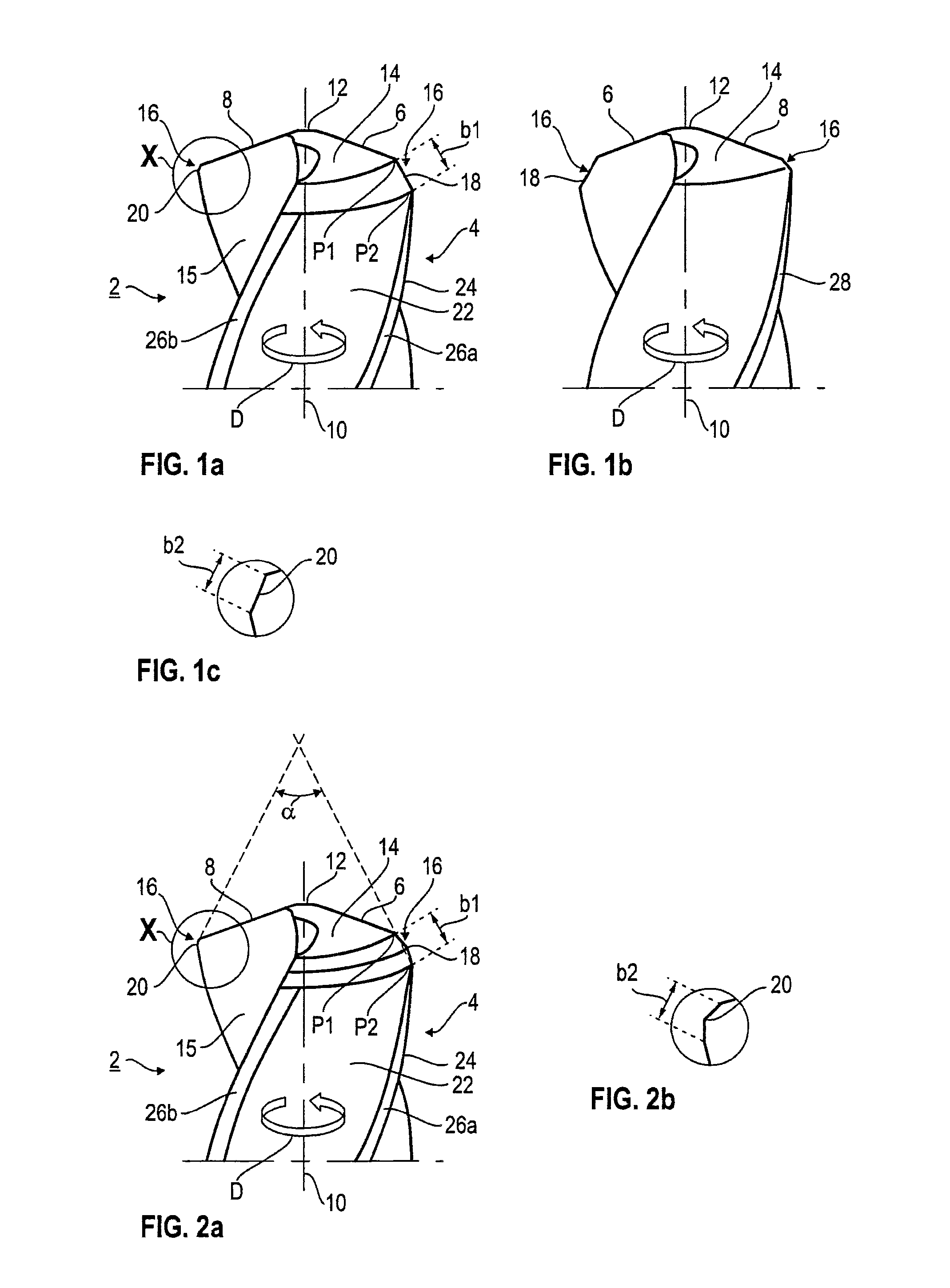

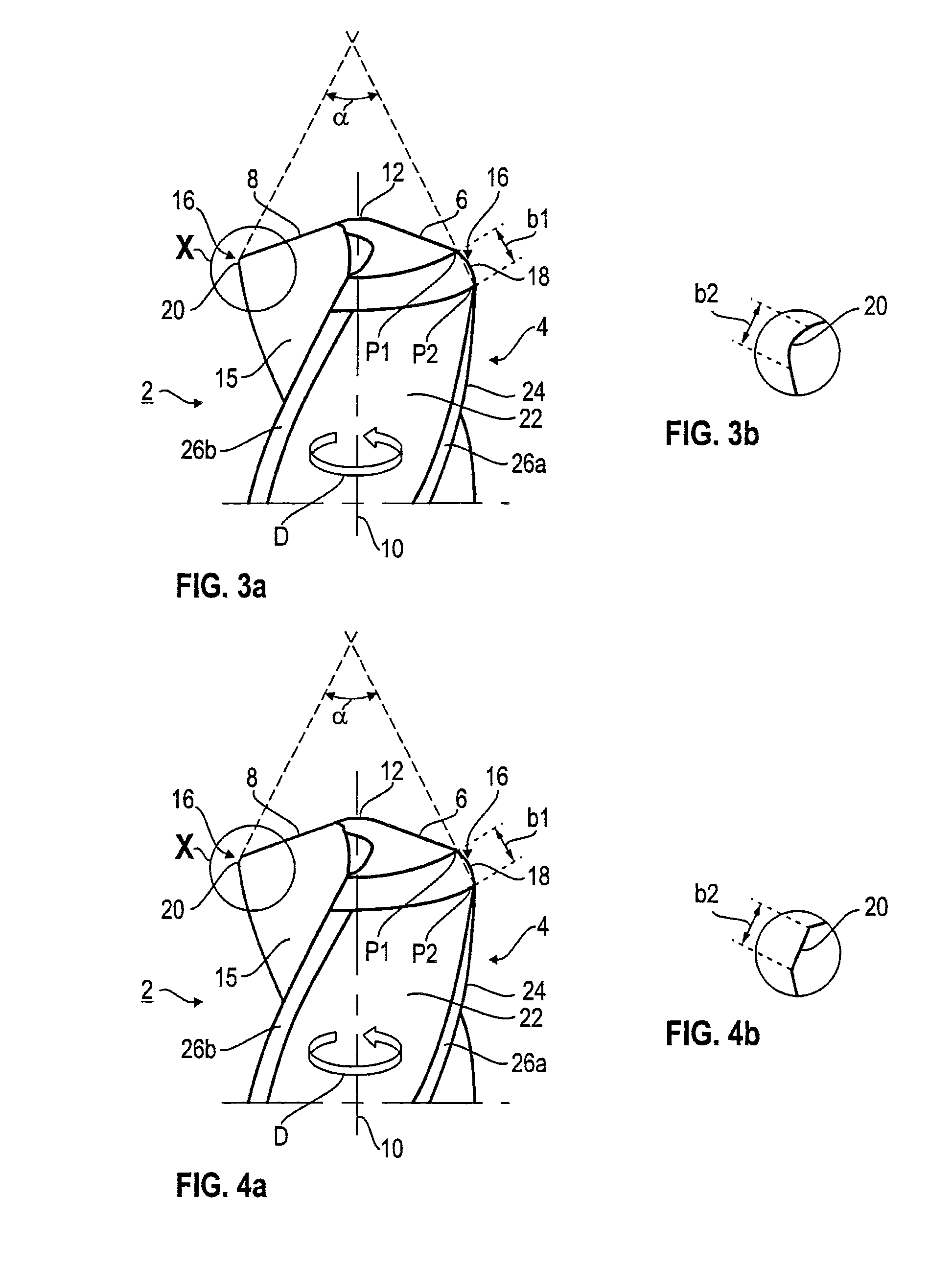

Rotary tool, in particular a drill

ActiveUS8834080B2Reduce cutting loadExtended service lifeWood turning toolsTransportation and packagingRotational axisEngineering

In order to provide a rotary tool, in particular a drill, with a long service life together with high-quality drill holes, particularly in the case of through bores, the invention provides a cutting head which extends along a rotational axis and has a plurality of main cutting edges which extend radially outwards and each end at a cutting corner having a corner bevel, wherein the corner bevels are of differing designs, specifically in the form of a roughing bevel and in the form of a finishing bevel.

Owner:KENNAMETAL INC

Silicon block cutting method

InactiveCN102350741AImprove cutting abilityImprove cutting efficiencyFine working devicesHardnessCooling fluid

The embodiment of the invention discloses a silicon block cutting method which comprises the following steps: driving a cooling fluid into a mortar jar; sequentially winding a diamond steel wire on a pulley and a guide pulley to knit a wire mesh; putting a silicon block on a machine tool, and setting a machine tool zero point and technological parameters in the silicon block cutting process; and cutting the silicon block by using the diamond steel wire. In the cutting method disclosed by the invention, the diamond steel wire is knitted into the wire mesh, and the wire mesh is used for cutting the silicon block, thereby replacing the method for cutting a silicon block by driving mortar with a steel wire in the prior art. Since the diamond grains have high hardness and strong cutting power, the cutting power of the diamond steel wire is stronger than that of the mortar-carrying steel wire, thereby greatly enhancing the cutting efficiency of the silicon block, increasing the cutting speed of the silicon block and lowering the cutting cost.

Owner:YINGLI ENERGY CHINA

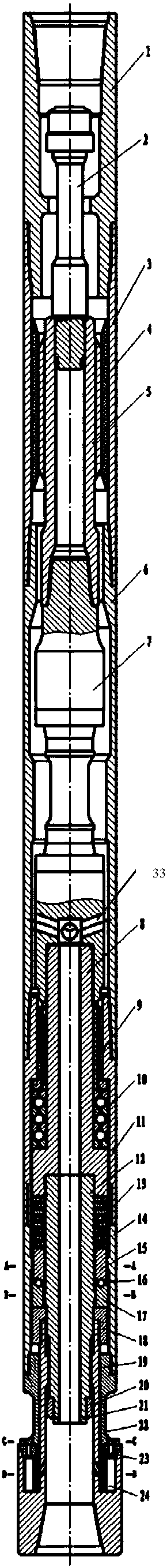

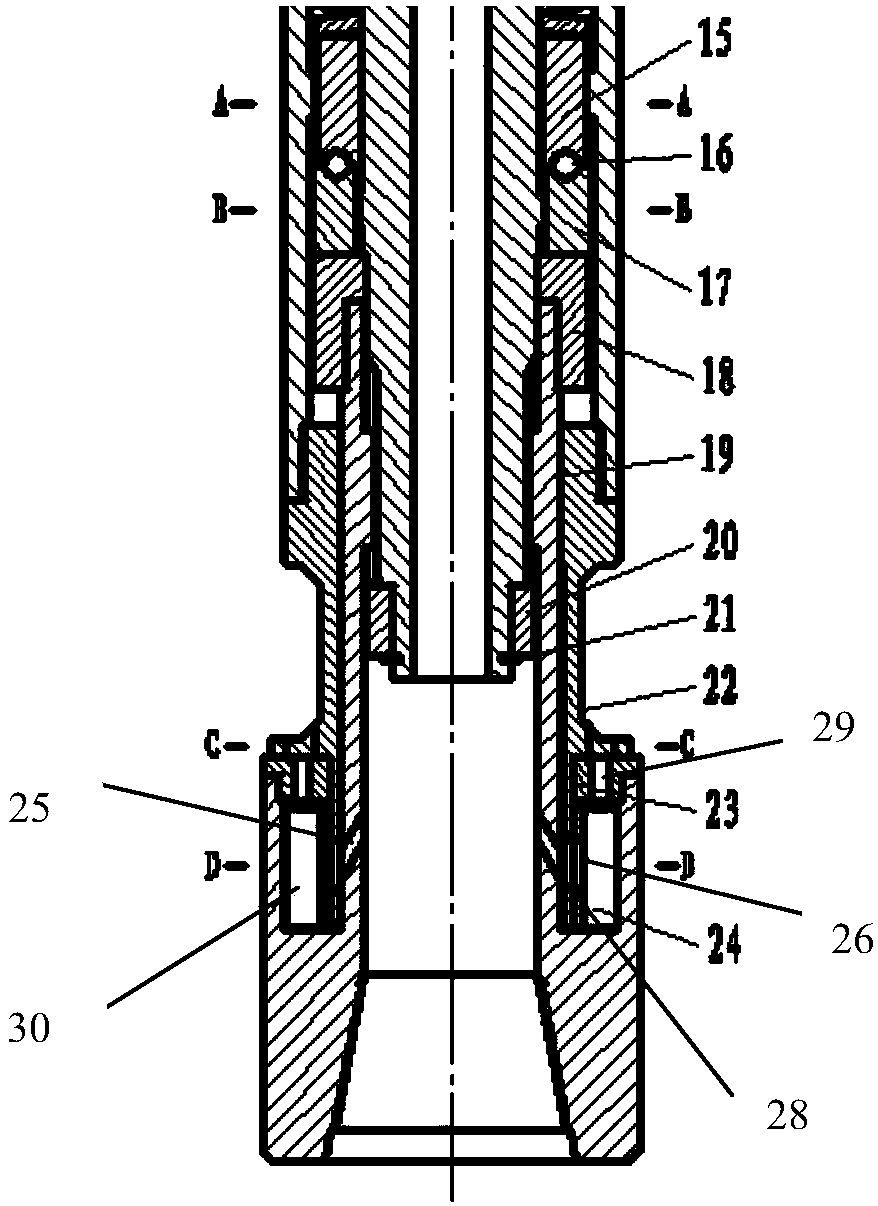

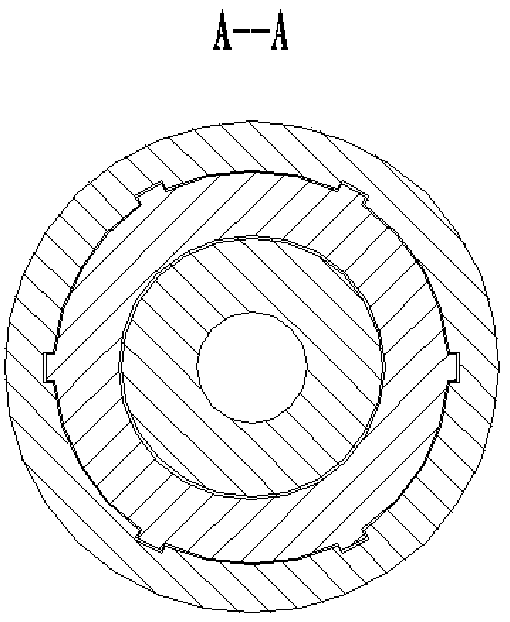

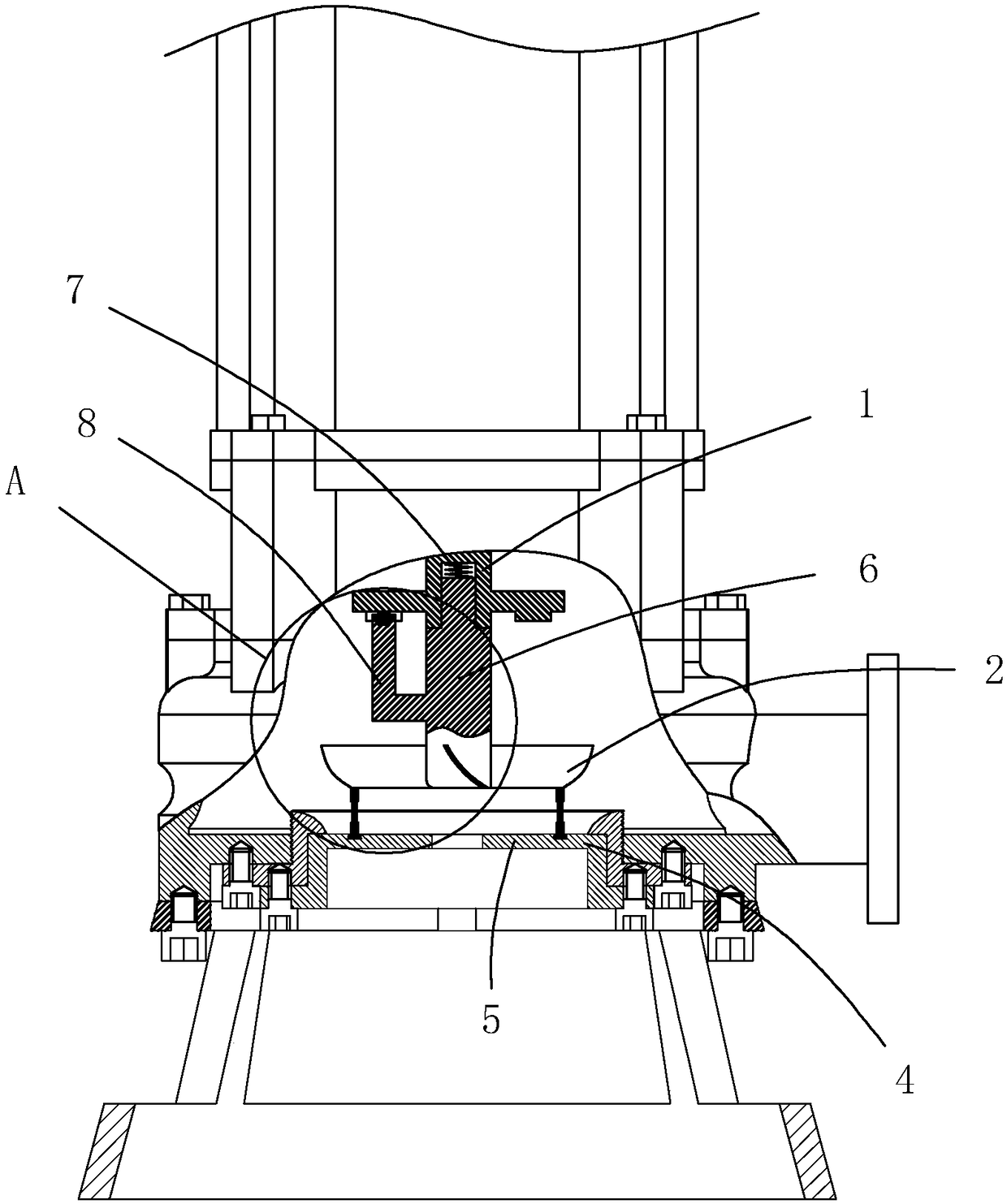

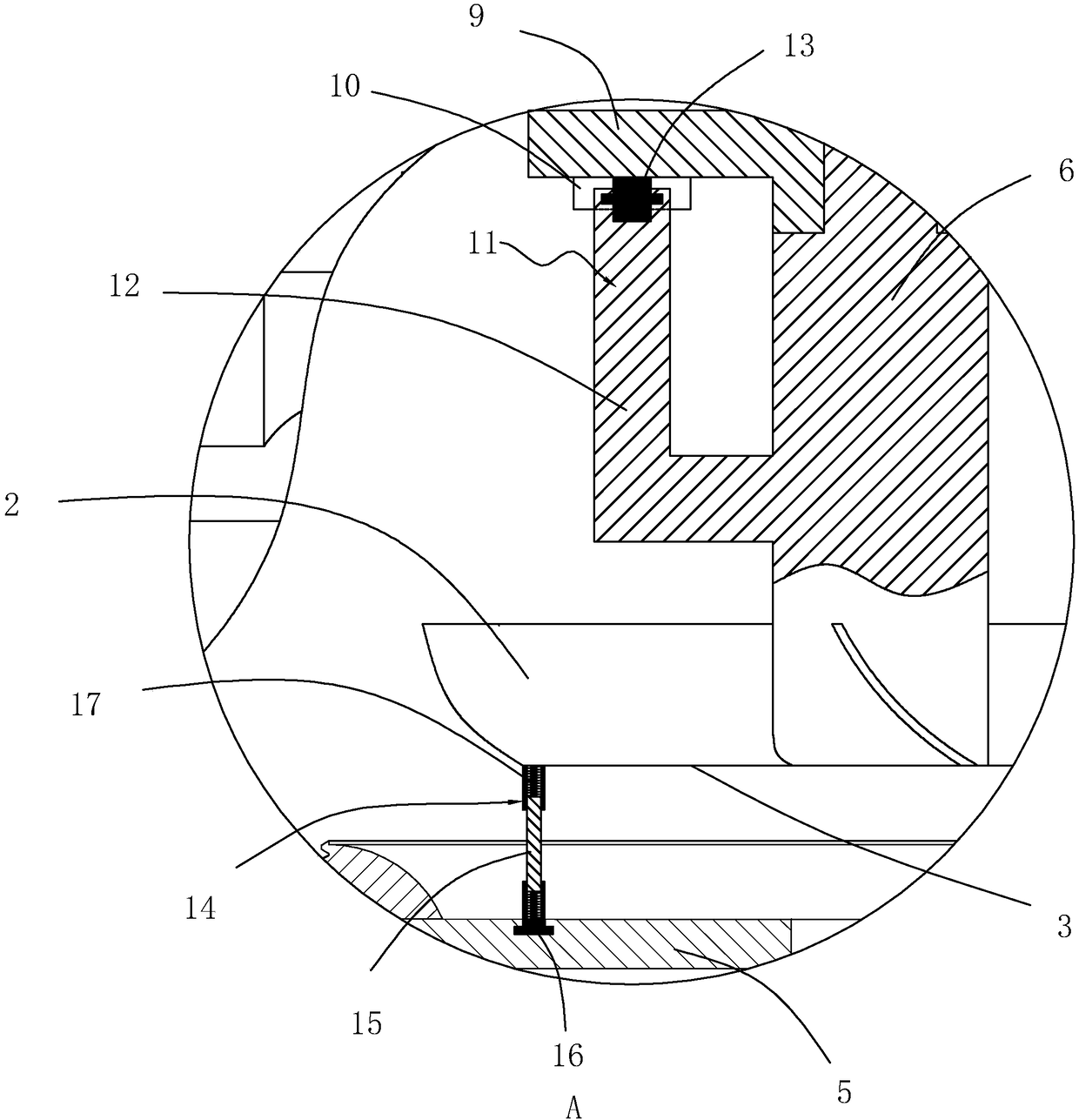

Composite speed-increasing screw drilling tool with axial vibration and circumferential vibration functions

ActiveCN108166928APromote rapid developmentImprove cutting abilityBorehole drivesVibration drillingEngineeringRock breaking

The invention discloses a composite speed-increasing screw drilling tool with axial vibration and circumferential vibration functions. The composite speed-increasing screw drilling tool includes an upper joint, an anti-drop rod, a motor, a cardan shaft, a transmission shaft, bearings, a disc spring, an upper vibrating block, roll balls, a lower vibrating block, an anti-drop cap, a transmission joint, a lock nut, a circlip, a liquid dispensing sleeve, a drainage tray and a pendulum bob; the anti-drop rod is disposed inside the upper joint, and a rotor of the motor is arranged below the anti-drop rod; the cardan shaft is arranged below the rotor, and the transmission shaft below the cardan shaft is composed of an upper transmission shaft and a lower transmission shaft; the bearings are arranged at the outer side of the upper transmission shaft, and the disc spring, the upper vibrating block, the roll balls, the lower vibrating block, the anti-drop cap, the transmission joint, the lock nut and the circlip are arranged at the outer side of the lower transmission shaft; and the liquid dispensing sleeve, the drainage tray and the pendulum bob are sequentially arranged at the outer side of the transmission joint from top to bottom. According to the composite speed-increasing screw drilling tool with the axial vibration and circumferential vibration functions, not only are the basic torque and speed provided for a drill bit, but also the impact vibration energy is added, so that the rock breaking efficiency and the rate of penetration are improved, the drilling cycle is shortened,and the drilling cost is reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

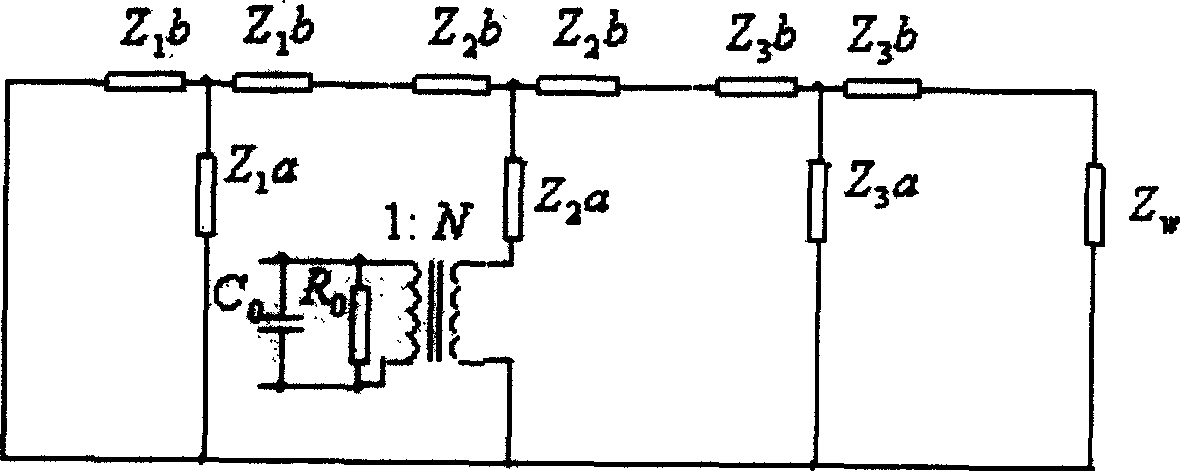

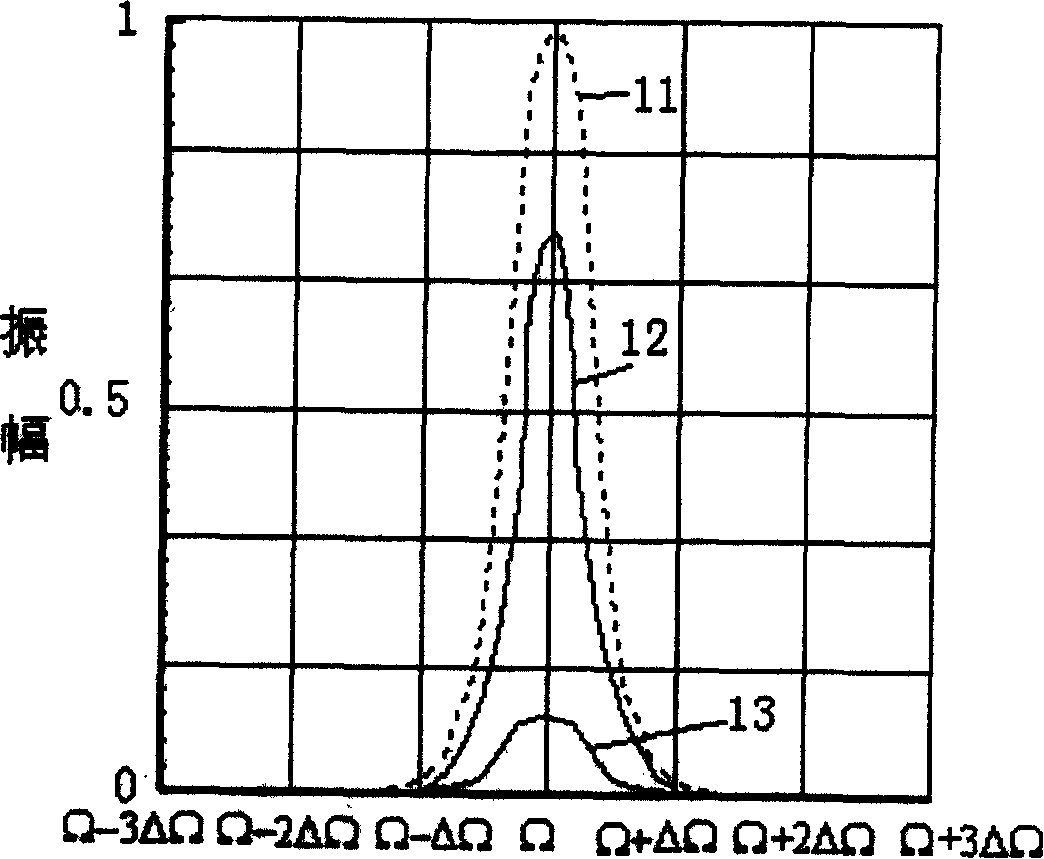

Supersonic skeleton cutting instrument

An ultrasonic bone cutting apparatus is composed of a host consisting of signal generator and powre amplifir, and a handle consisting of sequentially connected composite vibration transducers, ampletude changing rod and cutting tool. Said composite vibration transducer consists of a group of longitudinal polarized piezoelectric plates and a group of tangent polarized piezoelectric plates.

Owner:TSINGHUA UNIV

Water jet cutting system

InactiveCN101301736ARelieve pressureExtend your lifeBlast gunsAbrasive blasting machinesWater flowEngineering

The invention relates to a water jet cutting system used for cutting semiconductor elements, comprising a gantry driving device used for providing the driving force of x-y plane, a high pressure generation device used for generating high pressure water jet and a cutting device which is coupled to the high pressure generation device and the gantry driving device; the semiconductor element is cut by the high pressure water jet under the driving of the gantry driving device.

Owner:FLOW ASIA CORP

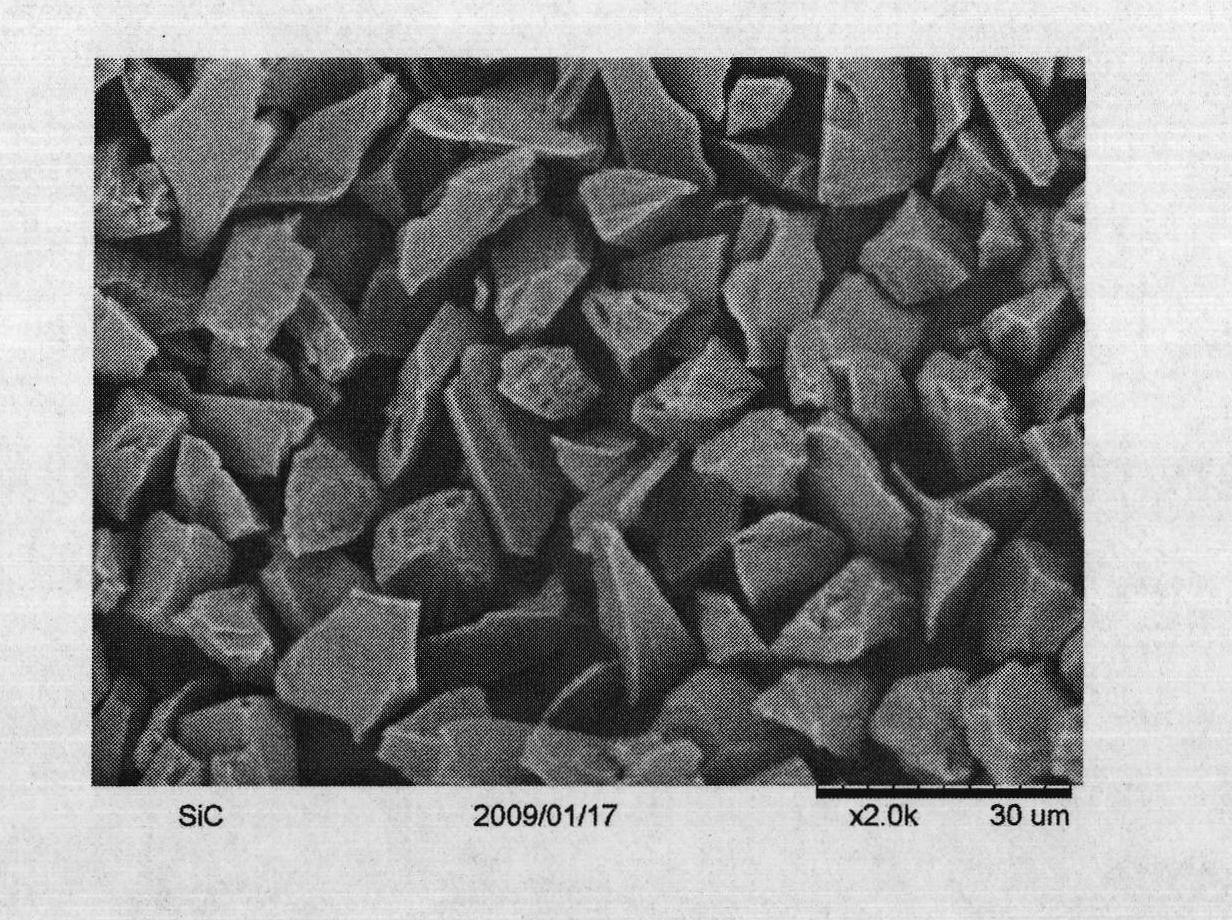

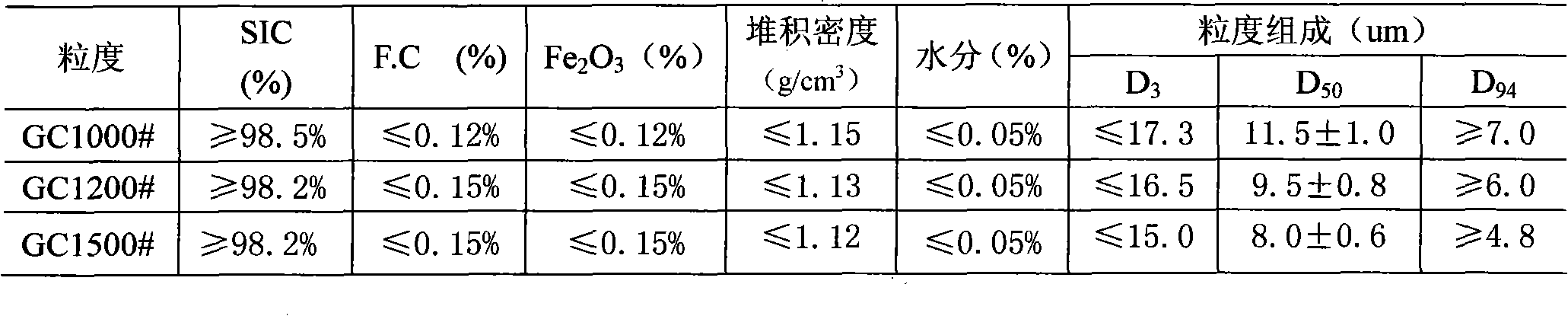

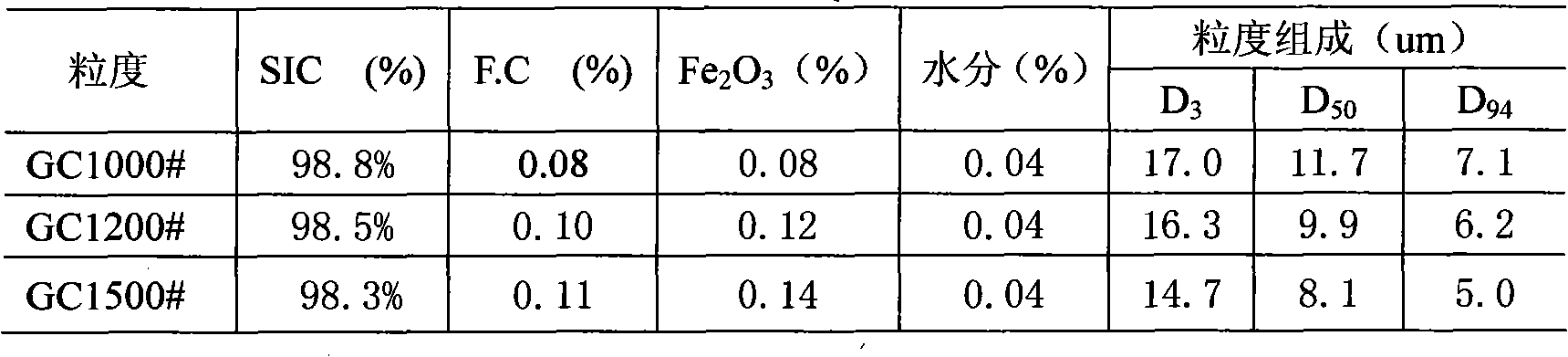

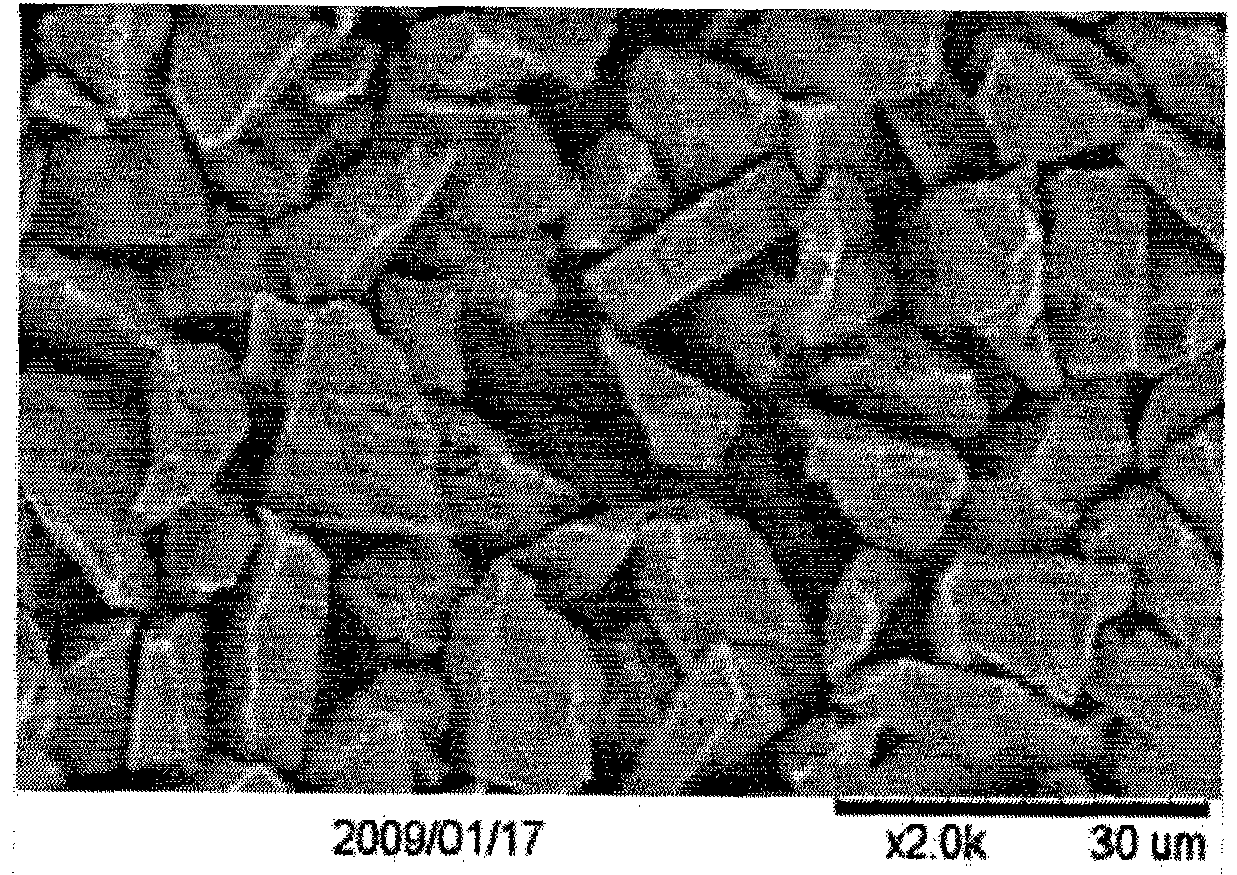

Method for preparing crystal silicon wafer cutting edge material

The invention relates to a method for preparing a crystal silicon wafer cutting edge material. The crystal silicon wafer cutting edge material is prepared from a high-purity green silicon carbide serving as a raw material by using the steps of jaw crushing, sieving, dry ball milling and grading, acid washing, overflowing and grading, concentrating and dehydrating, drying, blending, fine screening and the like. The method has the following advantages that: the prepared silicon carbide edge material has equal volume, keeps acute edge and has strong cutting capability; the TTV of a crystal silicon wafer is minimized; by chemical cleaning, the material has large specific surface area, clean appearance and strong adaptability with cutting solution such as polyethylene glycol and the like; an adopted dry ball milling and grading system integrates ball milling and grading, and can improve the yield and productivity; the finished product rate of the preparation method can reach 52 percent; and the product milled by adopting the process has more uniform grain size distribution and can reach better crystal silicon wafer cutting effect, and the finished product rate (granularity section suitable for silicon wafer cutting) of the milling technology generally adopted in the industry is about 45 percent.

Owner:HENAN XINDAXIN SCI & TECH

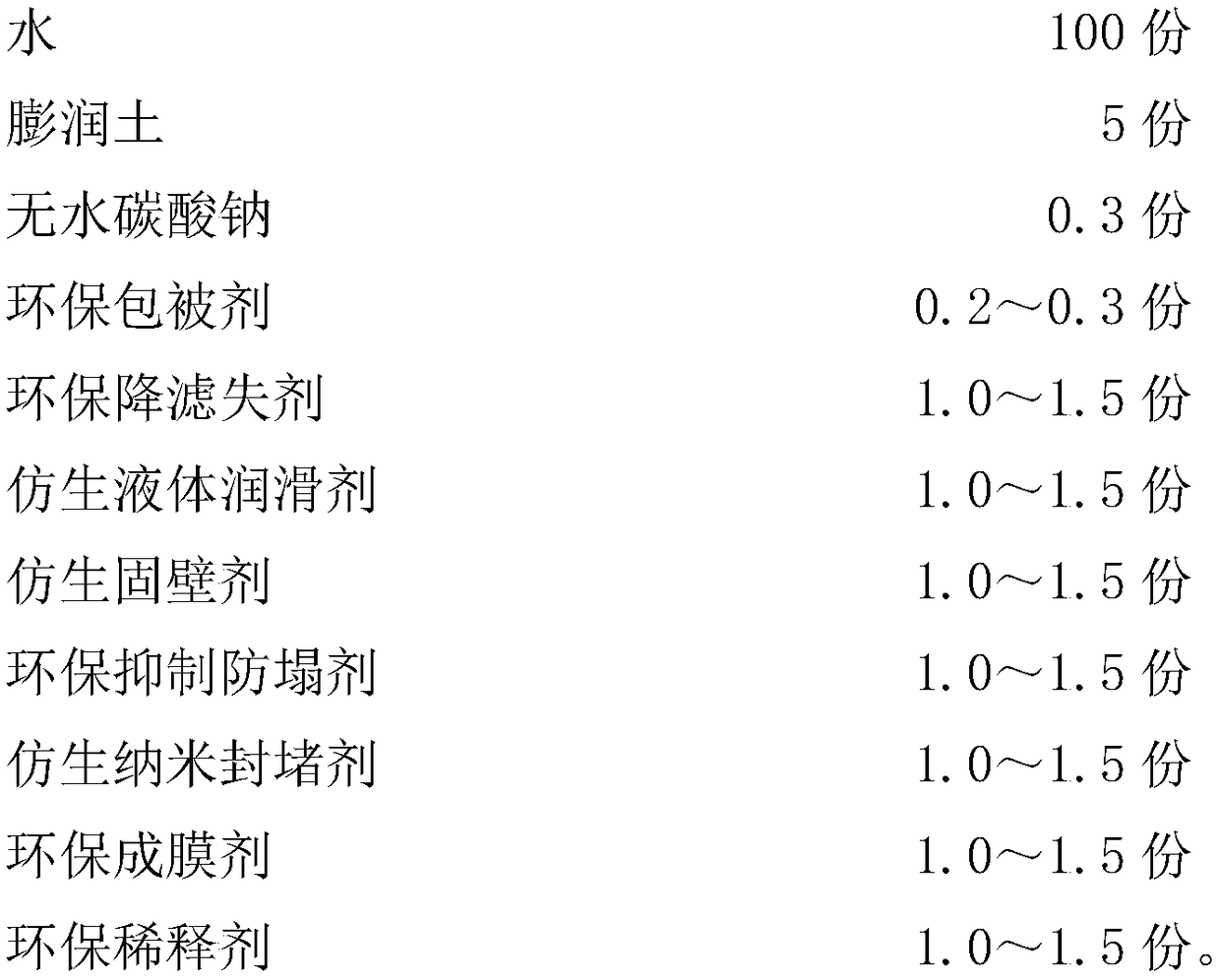

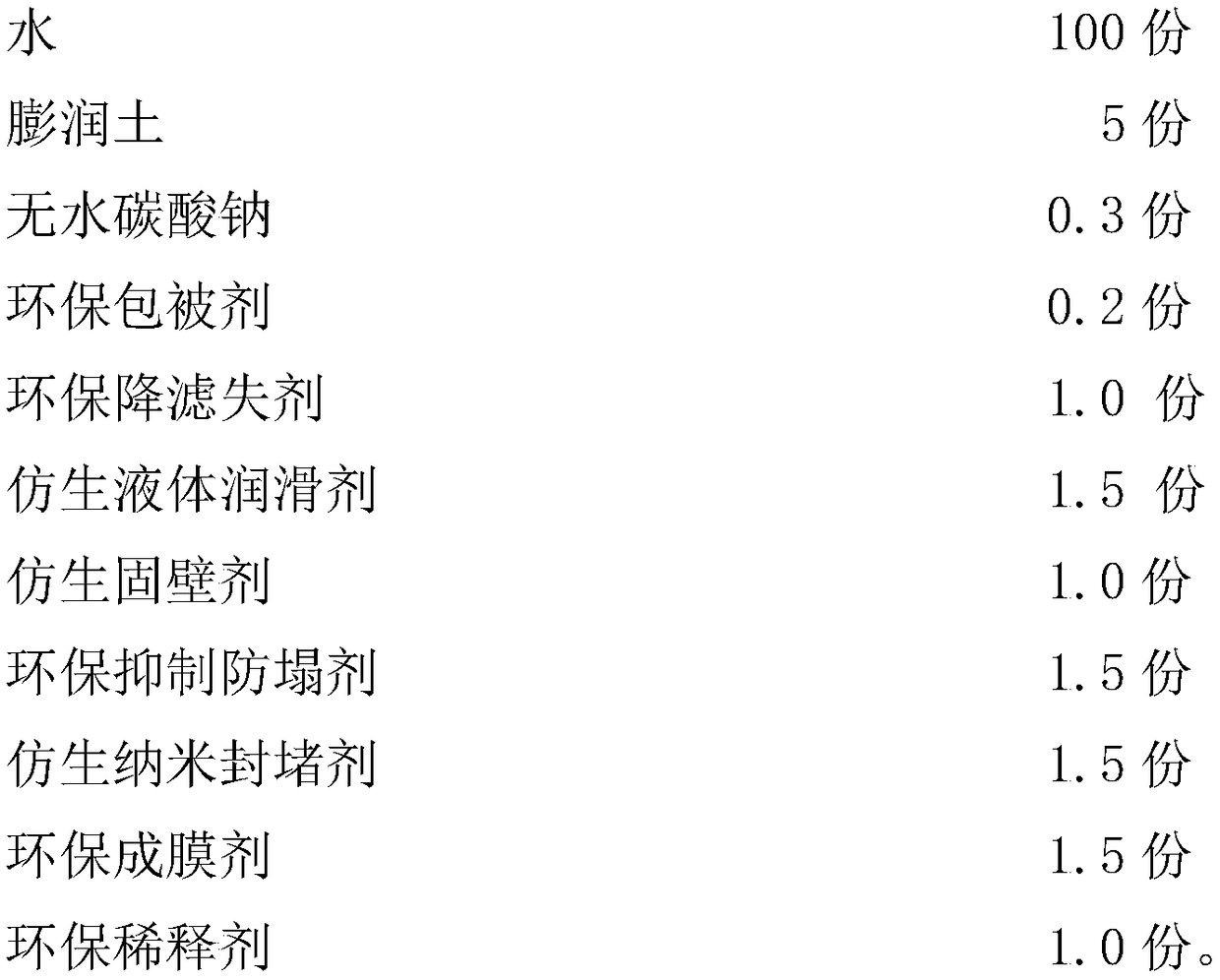

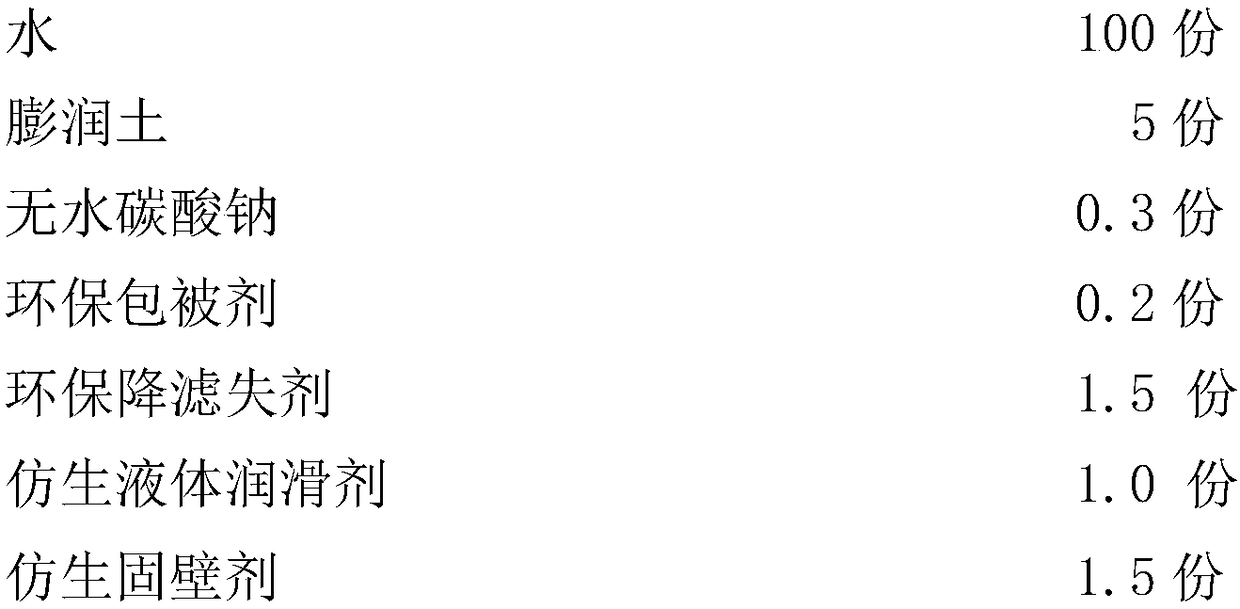

HL-FFQH environment-friendly drilling fluid system and preparation method thereof

ActiveCN108373910AImprove efficiencyEnhanced inhibitory effectDrilling compositionSodium carbonate anhydrousStabilizing Agents

The invention provides an HL-FFQH environment-friendly drilling fluid system and a preparation method thereof. The drilling fluid system is prepared from the following raw materials: water, bentonite,anhydrous sodium carbonate, an environment-friendly coating agent, an environment-friendly filtrate loss reducer, a bionic liquid lubricant, a bionic wall stabilizing agent, an environment-friendly inhibition and anti-collapse agent, a bionic nano plugging agent, an environment-friendly film forming agent and an environment-friendly diluting agent. The preparation method comprises the following steps: adding the bentonite into distilled water, and stirring and mixing; then adding the anhydrous sodium carbonate, sufficiently and uniformly stirring and curing; sequentially adding the environment-friendly coating agent, the environment-friendly filtrate loss reducer, the bionic liquid lubricant, the bionic wall stabilizing agent, the environment-friendly inhibition and anti-collapse agent, the bionic nano plugging agent, the environment-friendly film forming agent and the environment-friendly diluting agent and uniformly stirring to obtain the environment-friendly drilling fluid system.By adopting the HL-FFQH environment-friendly drilling fluid system and the preparation method thereof, mud is prevented from being dispersed and expanded at a mud shale section; the HL-FFQH environment-friendly drilling fluid system has good wall building performance, also has a strong rock fragment carrying capability and is used for effectively washing a wellbore; complicated accidents in a welldrilling process are avoided and the well drilling quality and efficiency are improved.

Owner:石家庄华莱鼎盛科技有限公司

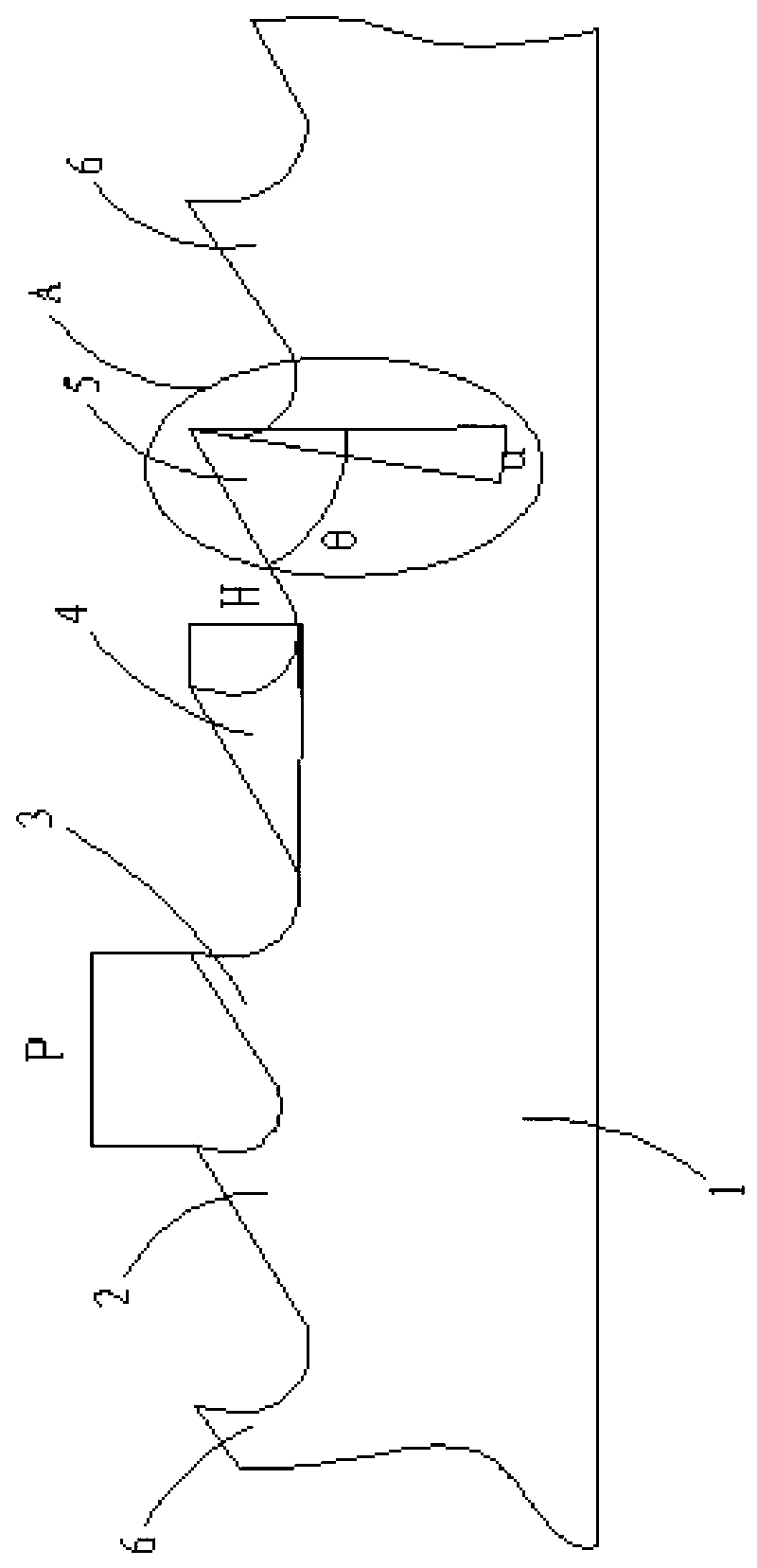

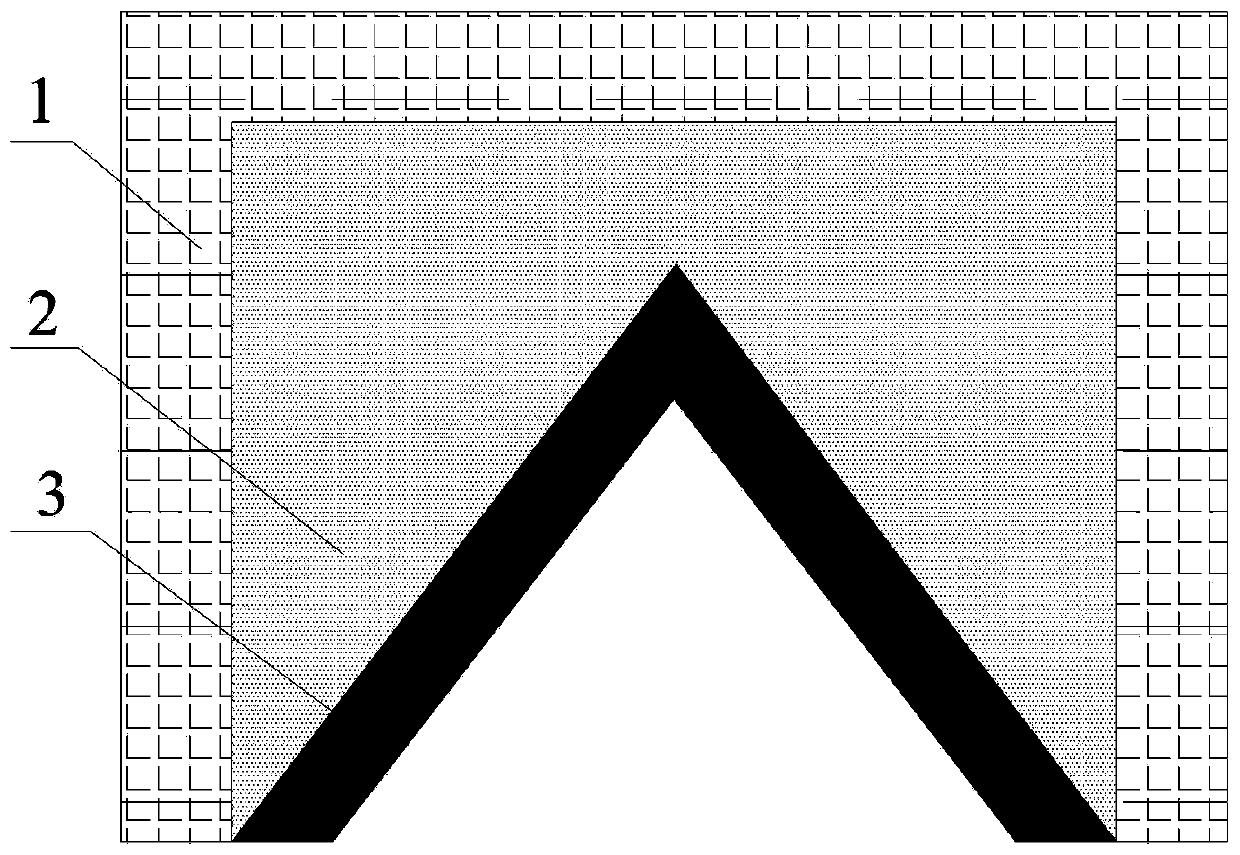

Dispersive type band saw blade

The invention discloses a dispersive type band saw blade. The dispersive type band saw blade is composed of a saw back portion and a saw tooth portion comprising a plurality of repeating units. The distance between tooth tops of two adjacent saw teeth of the saw tooth portion is the tooth diameter P, and the distance between the tooth top portion and the tooth root portion of saw teeth is the tooth height H. Each repeating unit comprises a first saw tooth, a second saw tooth, a third saw tooth, a fourth saw tooth and a fifth saw tooth, wherein the first saw tooth, the second saw tooth, the third saw tooth, the fourth saw tooth and the fifth saw tooth are sequentially and continuously arranged. Through change of the tooth height H and the tooth diameter P, chips are small and can be discharged easily, and cutting resistance is lowered. Through change of the tooth angle theta, cut-in performance of the band saw blade is improved, and therefore pressure on the back portion of the band saw blade from a back pressing block of a tool body can be lowered, the service life of the band saw blade can be prolonged, and the band saw blade is suitable for cutting various medium-diameter and large-diameter materials which are made of tool steel or stainless steel and difficult to cut.

Owner:JIANGYIN JINYUAN SAW

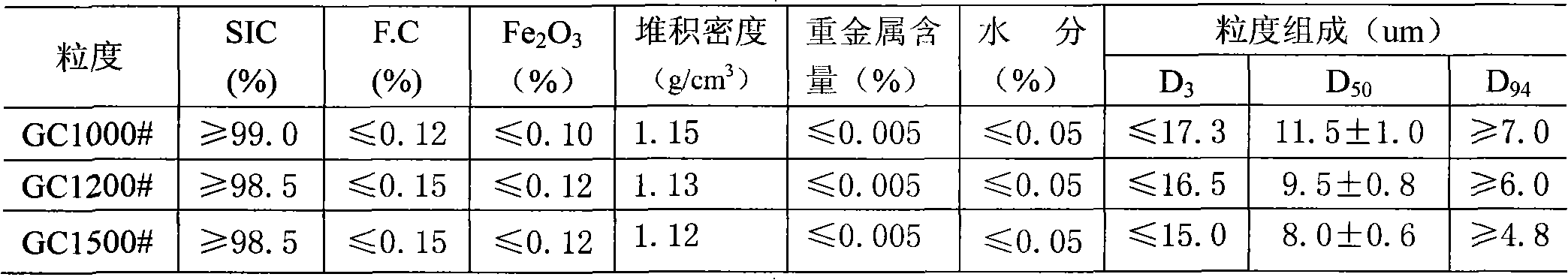

Preparation method of semiconductor wafer cutting blade material

The invention relates to a preparation method of a semiconductor wafer cutting blade material. In the preparation method, high-purity green silicon carbide and black silicon carbide are adopted as raw materials, and a wafer cutting blade material is prepared through the steps of jaw crushing and sifting, wet ball milling classification, pickling, overflow size separation, concentrating and dewatering, drying, blending, fine screening and the like. Silicon carbide blade materials prepared through the method are most in equiareal shape and keep sharp edges and strong cutting power, can minimize TTV of a silicon wafer, and have strong adaptability to cutting fluid such as polyethylene glycol and the like because blade material particles have larger specific area and clean surfaces. Products crushed by a wet ball mill are most in equiareal shape, have high output, and can avoid excessive crushing. The preparation method of the invention can reach over 50% of rate of finished products, and products milled with the technology have more uniform size and distribution of particles, thereby better cutting effect to silicon wafers can be achieved.

Owner:HENAN XINDAXIN SCI & TECH

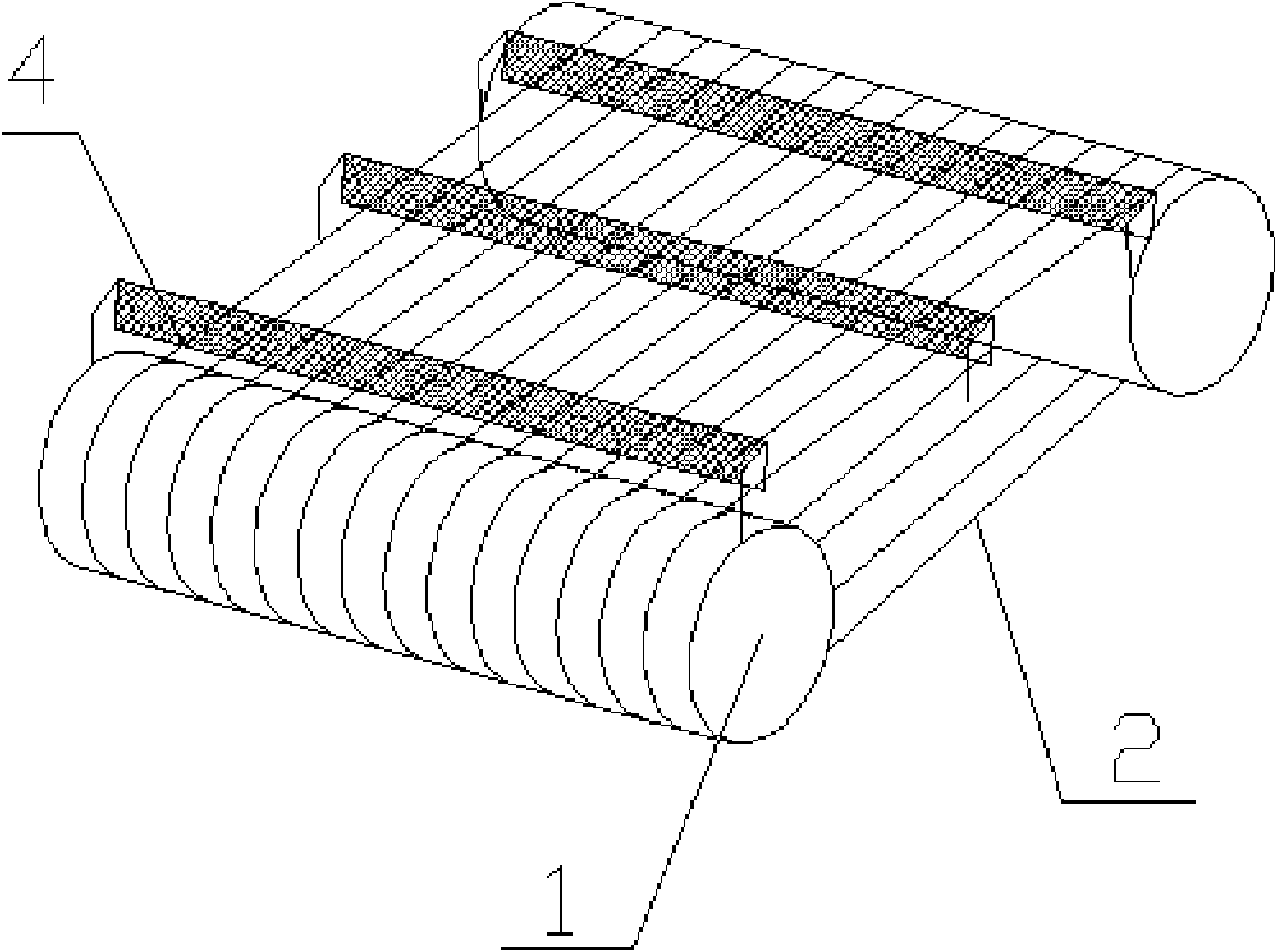

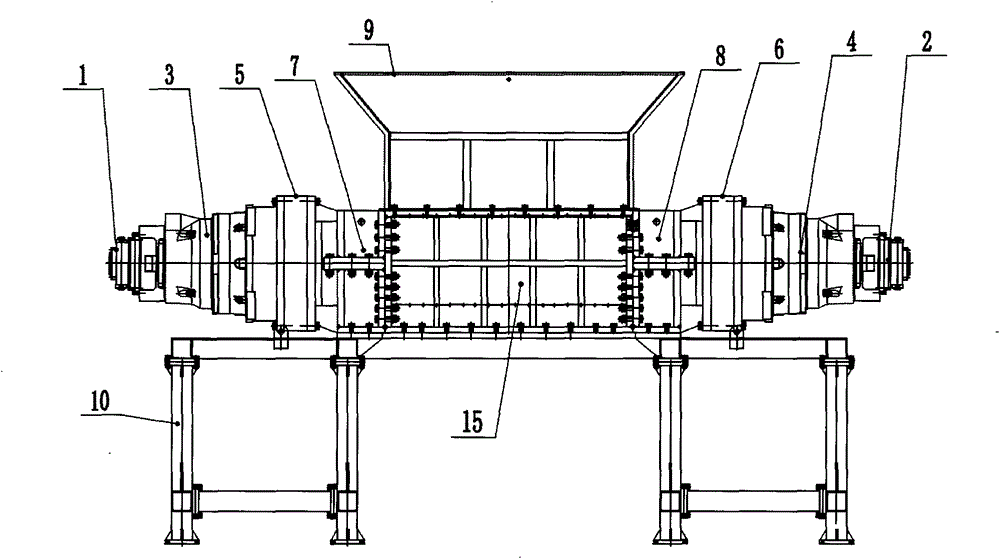

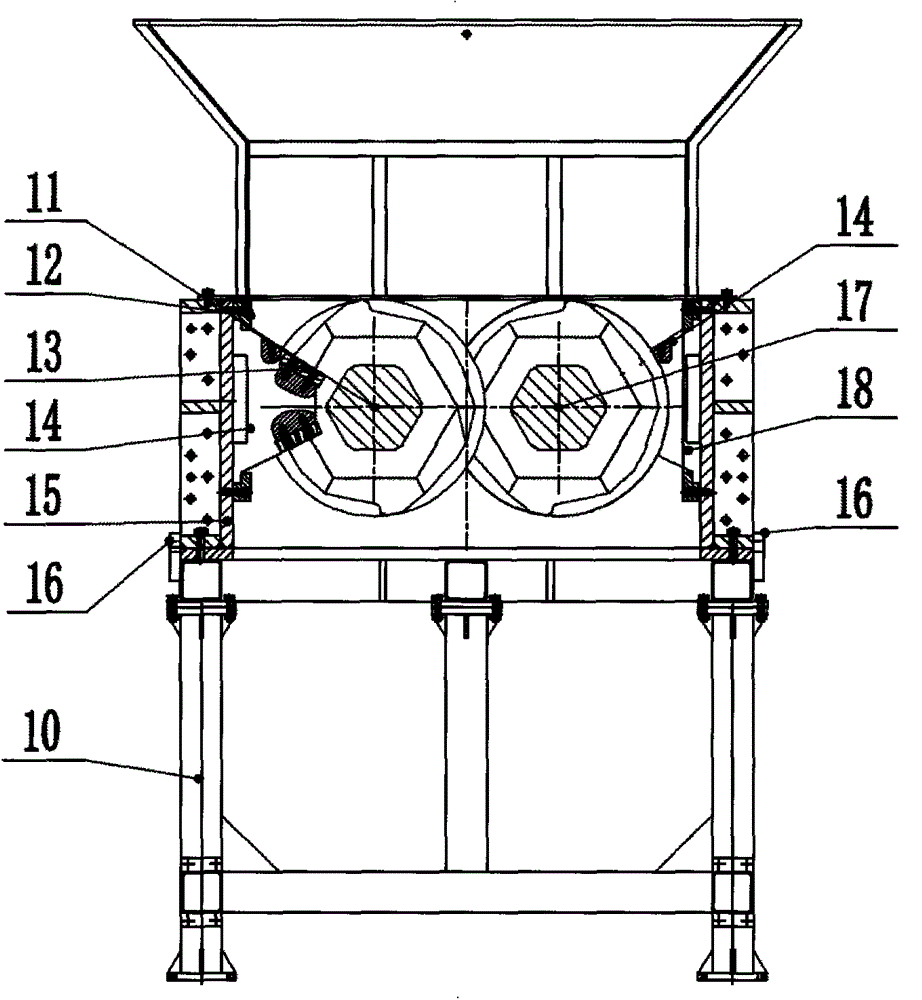

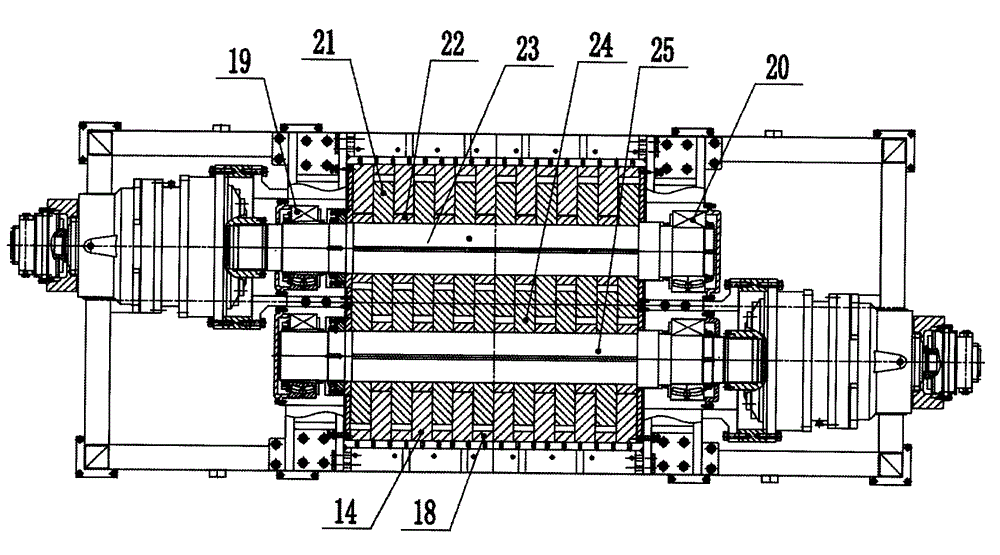

Heavy duty double-shaft scrap steel shredder

The present invention relates to a heavy duty double-shaft scrap steel shredder, which comprises a frame, a box, a material inlet hopper, a left hydraulic motor, a right hydraulic motor, a left speed reducer, a right speed reducer, a left connection flange, a right connection flange, a front cutter roller, a rear cutter roller, left bearing pedestals for arranging the front cutting roller and the right cutting roller, and right bearing pedestals for arranging the front cutting roller and the right cutting roller, wherein the box is arranged on the frame, the top portion of the box is provided with an opening, the material inlet hopper is arranged on the box opening on the top portion, the left side and the right side of the box are respectively provided with the front cutting roller left bearing pedestal, the front cutting roller right bearing pedestal, the rear cutting roller left bearing pedestal and the rear cutting roller right bearing pedestal, the front cutting roller right bearing pedestal is connected with the right flange, the rear cutting roller left bearing pedestal is connected with the left flange, the left speed reducer and the right speed reducer are respectively connected with the left hydraulic motor and the right hydraulic motor, the front cutter roller is arranged on the front cutting roller left bearing pedestal and the front cutting roller right bearing pedestal, the front cutter roller and the rear cutter roller are connected on the left speed reducer and the right speed reducer, and the front cutter roller and the rear cutter roller are provided with a front shaft cutter for shredding the material and a rear shaft cutter for shredding the material. The heavy duty double-shaft scrap steel shredder has advantages of low rotation speed, low noise, high torque, strong medium-thick steel plate shredding ability, low energy consumption, safety, reliability and the like, and can used for batch and mechanized scrap steel material treatment.

Owner:GUANGZHOU 3E MACHINERY

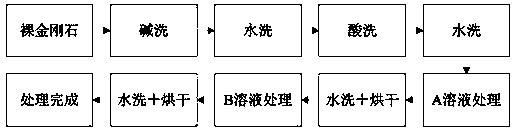

Process for electroplating diamond wire adopting bare powder coating

ActiveCN110076705AReduce pollutionLow costElectrolytic coatingsGrinding devicesChemical treatmentElectrochemistry

The invention relates to the technical field of electroplating diamond wires, in particular to a process for embedding electroplating diamond wire with bare powder. The method comprises the followingsteps that cleaning and chemically treating bare diamond, enabling the surface of the bare diamond to be provided with high-density positive charges, depositing the treated bare diamond on the surfaceof a steel wire in an embedding groove, and performing electrochemical consolidation diamond to prepare the finished product electroplating diamond wire. Compared with a common diamond wire, the diamond used by the diamond wire is free of pre-plating nickel (which can generate a large amount of nickel and phosphorus wastewater to pollute the environment), so that the pollution of the nickel and phosphorus is reduced; and the diamond wire uses the bare diamond, a process of chemical nickel plating is omitted, the diamond cost is reduced by 40%, the diamond on the surface of the bare sand electroplating diamond wire is not coated with a nickel layer, and the cutting capability is stronger; impurities such as nickel or silicon powder are not easy to stick in the cutting process, the cuttingforce in the later stage is not affected, the corrosion problem of the nickel layer does not exist in a plating solution of the diamond used by the bare sand electroplating diamond wire, the sand doesnot need to be subjected to stripping and other treatment, and the labor cost and the machining cost are reduced.

Owner:盛利维尔(常州)金属材料有限公司

Active ion welding gas

This invention relates to an active ionic welding and cutting gas including the following components: potassium permanganate 1-3, toluol 0.5-55, aether substances 4-40, acetone 20-60, burning gas 2000-3000 and also includes the following weight shares: baking soda 0.2, deionized water 0-150, xylene 0-30, toluol 0-30, p-toluene-phenol 0-50 and ring ethane 0-20.

Owner:杨向东

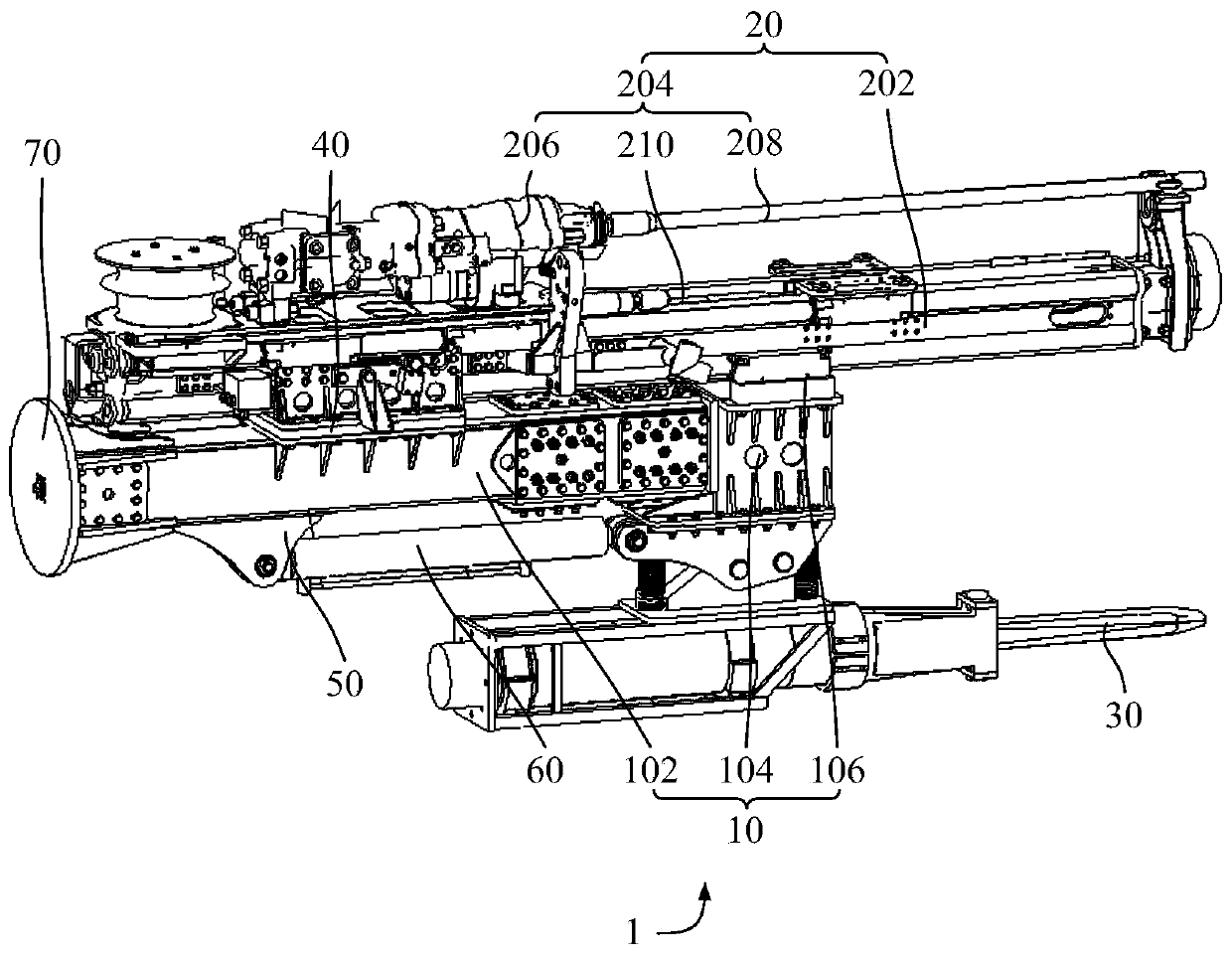

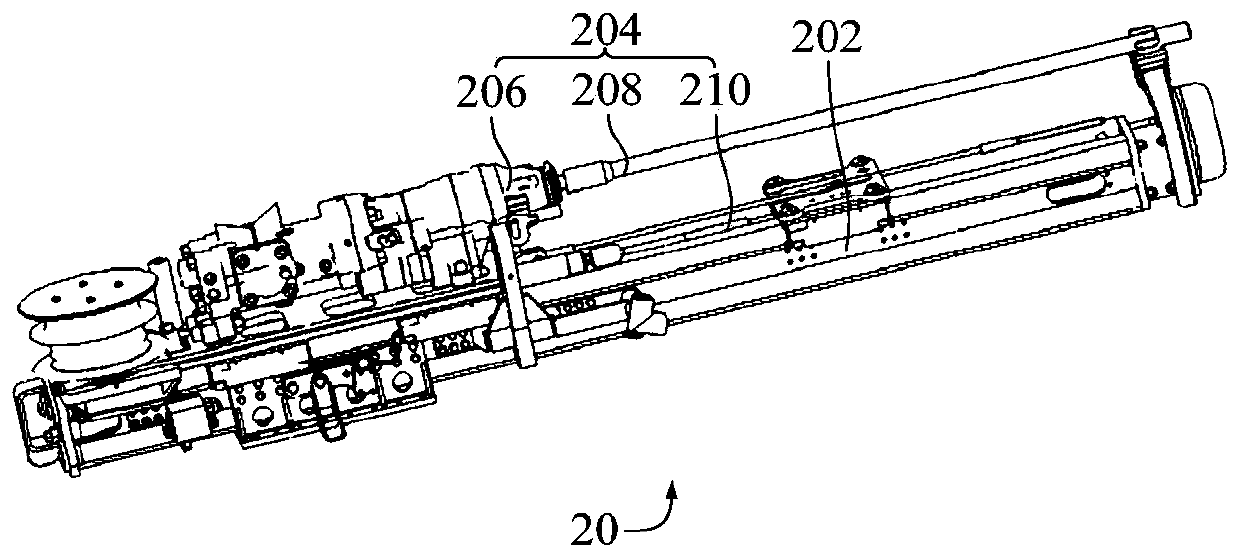

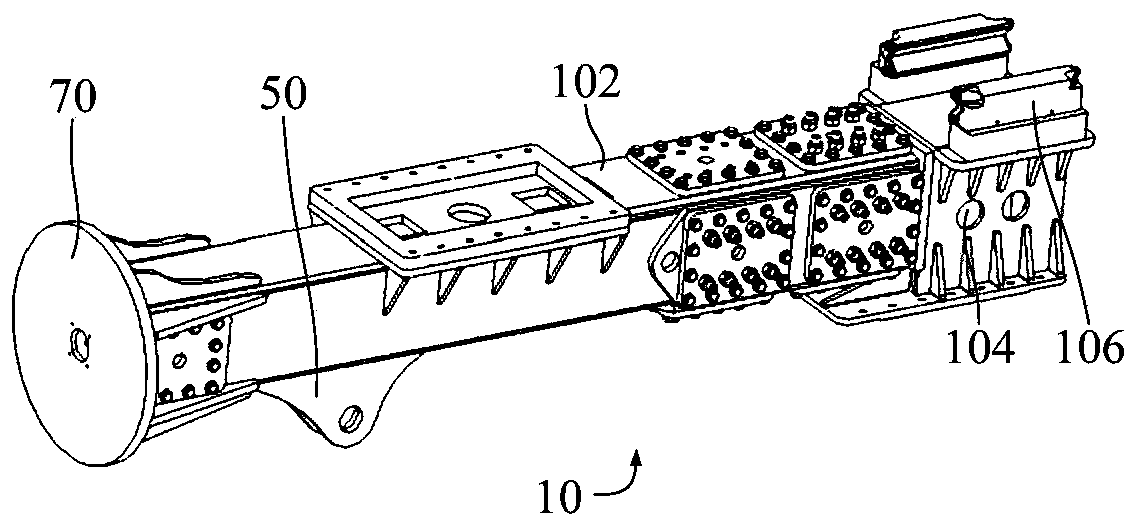

Splitting mechanism and excavating equipment

ActiveCN110242300AImprove safety and reliabilityGuaranteed safety and reliabilityDisloding machinesDriving meansDrill holeGeotechnical engineering

The invention provides a splitting mechanism and excavating equipment. The splitting mechanism comprises a telescopic arm, a drilling part, a splitting part and a rotating part, wherein the drilling part is arranged on the telescopic arm; the splitting part is arranged on the telescopic arm, and the telescopic arm is used for driving the splitting part to perform reciprocating motion; and the rotating part is connected with the telescopic arm and used for driving the telescopic arm to rotate. After the drilling part is used for drilling by the splitting mechanism, the rotating part is used for driving the telescopic arm to rotate, the splitting part is enabled to be aligned to a drill hole, and rock is split from a rock stratum through a splitting mode on the basis of the hole formed after the drilling part operation. By arranging the splitting part, the drilling part and the splitting part can perform position conversion in short time, switch of drilling and splitting operation can be realized, so that the assembly precision of the splitting part relative to the hole is guaranteed, a reliable and accurate structural basis is provided for the splitting operation of the subsequent splitting part, thus, the construction efficiency is improved, and the purpose of efficient, safe and continuous hard rock excavation is realized.

Owner:CHINA RAILWAY CONSTR HEAVY IND

Preparation method for solar silicon wafer linear cutting mortar

ActiveCN101928630AGood stabilityHigh cutting quality rateAdditivesBase-materialsCarbide siliconSilicon chip

The invention provides a novel production method for solar silicon wafer linear cutting mortar. In the production of the cutting mortar, additives (a, polyethylene glycol, b, microparticles (silicon carbide, cerium oxide and abrasive powder), c, a dispersant, d, a surfactant, e, defoamer, f, metal corrosion inhibitor, and g, a nano film molding agent) with different functions and for different purposes are processed into cutting or polishing mortar by a specific processing mode of adding and synthesizing at different time and in different steps. The method can improve the stability, suspension property and re-dispersion capability of the silicon carbide microparticles in the polyethylene glycol or water, improve cutting efficiency and guarantee the long-time stability of the water cutting process at the same time, improves the rate of high-quality products and reduces the comprehensive cutting cost; therefore the solar silicon wafer linear cutting mortar is economical and high-return-rate silicon wafer linear cutting mortar.

Owner:上海甲冠半导体科技有限公司

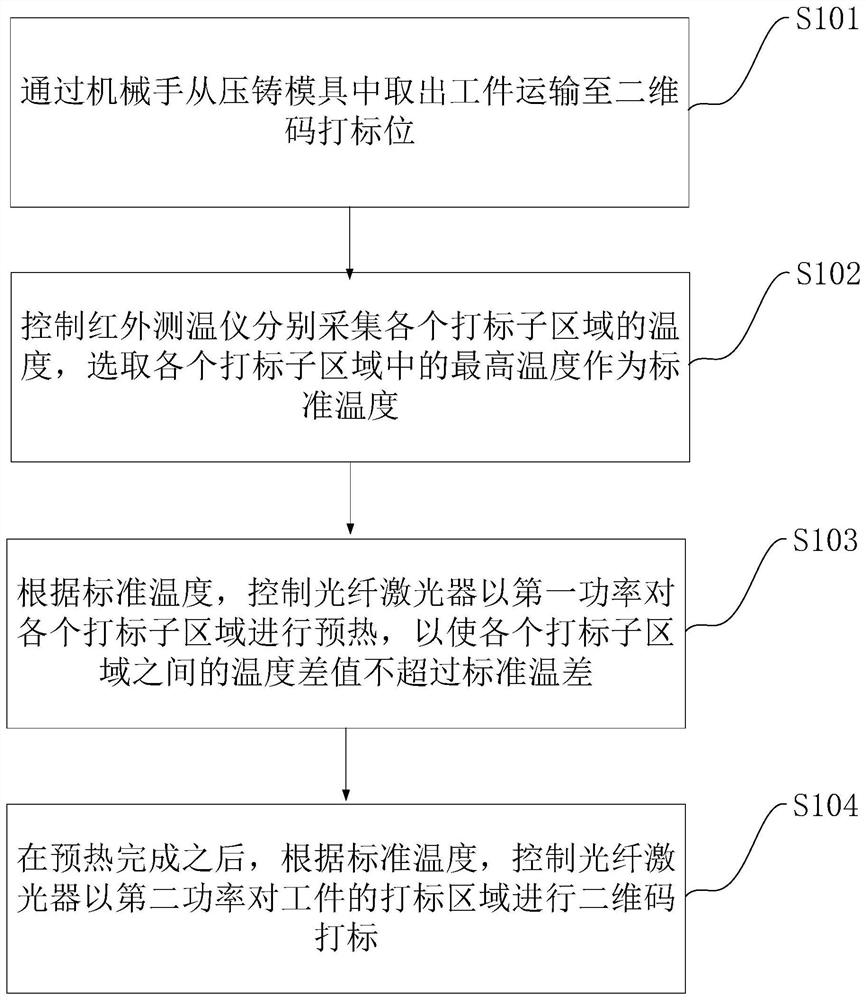

Optical fiber laser assembly line two-dimensional code marking method and system

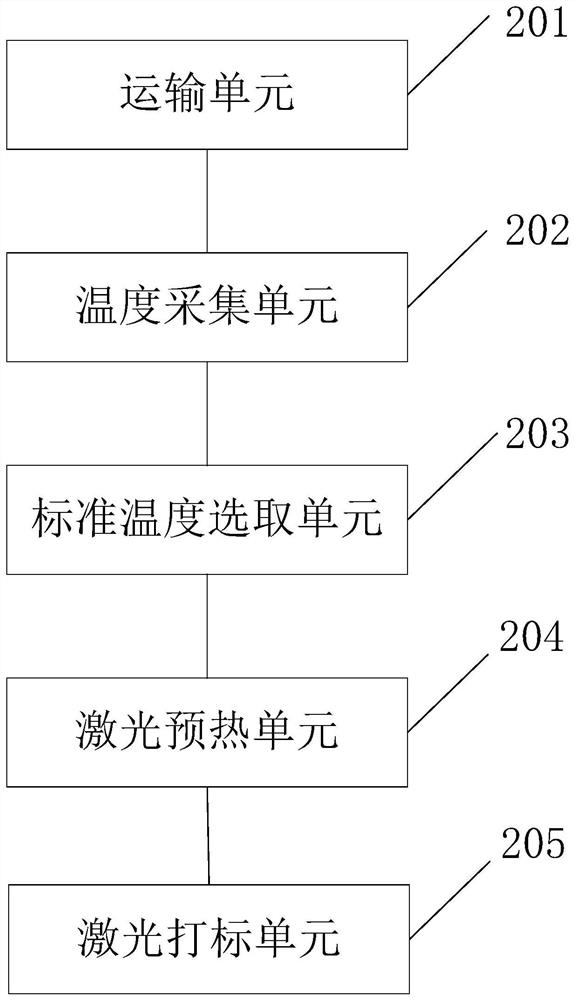

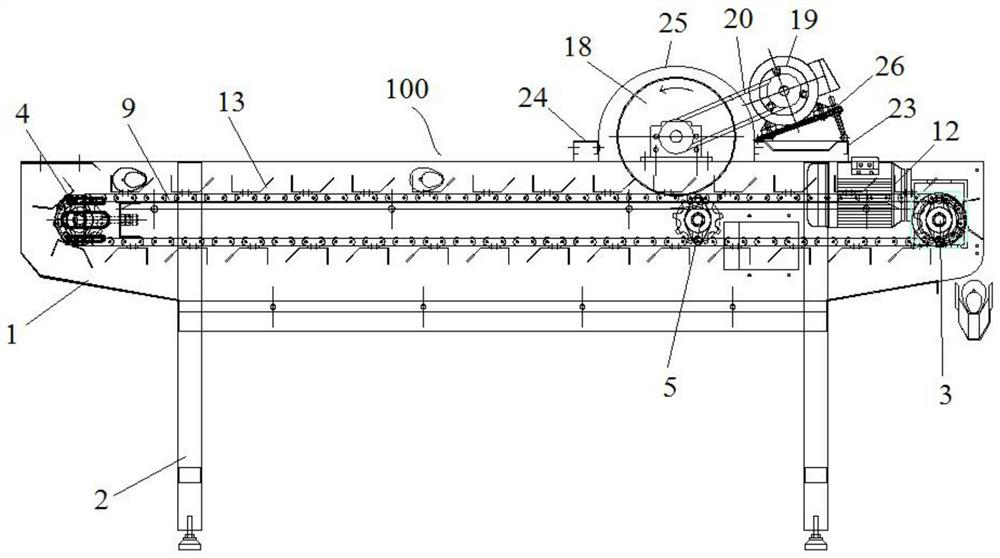

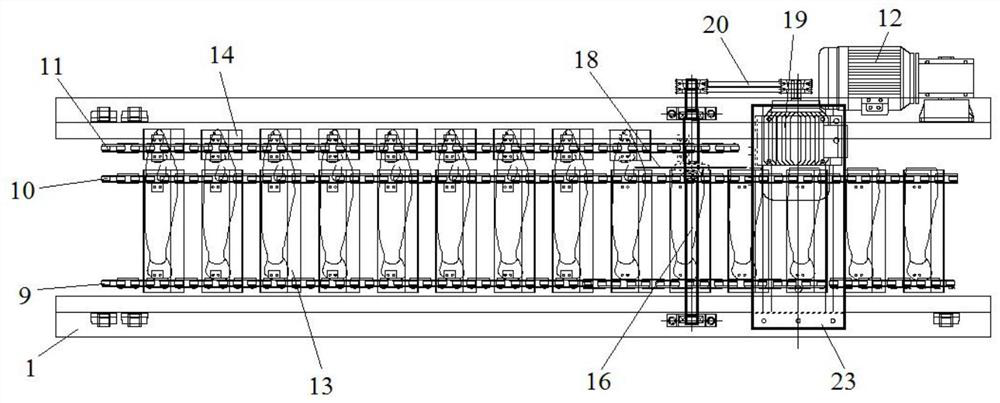

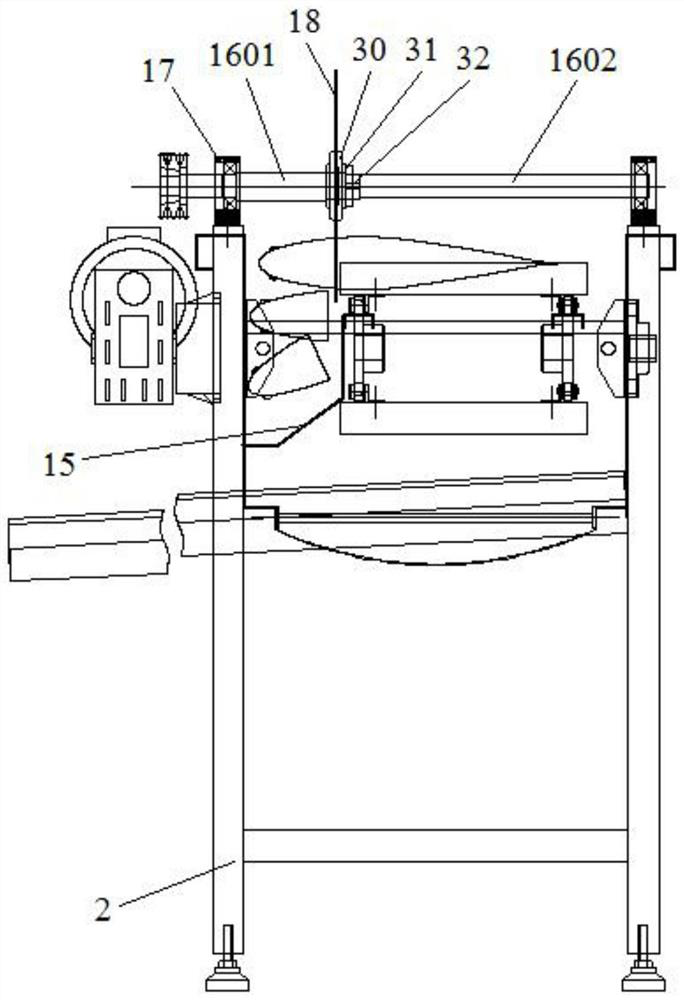

PendingCN114273785AUniform shadeImprove accuracyLaser beam welding apparatusInfrared thermometrySoftware engineering

The invention discloses a fiber laser assembly line two-dimensional code marking method and system, and the method comprises the steps: taking out a workpiece from a die-casting die through a manipulator, and conveying the workpiece to a two-dimensional code marking position; wherein the workpiece comprises a marking area corresponding to a two-dimensional code marking position, and the marking area comprises marking sub-areas divided according to the size of two-dimensional code pixel points; an infrared thermometer is controlled to collect the temperature of each marking sub-area, and the highest temperature in each marking sub-area is selected as the standard temperature; according to the standard temperature, an optical fiber laser is controlled to preheat all the marking sub-areas with first power, so that the temperature difference value between all the marking sub-areas does not exceed the standard temperature difference value; and after preheating is completed, according to the standard temperature, the optical fiber laser is controlled to conduct two-dimensional code marking on the marking area of the workpiece with second power. According to the invention, the two-dimensional code can be uniformly marked, and the recognition accuracy of the two-dimensional code is ensured.

Owner:莆田市鑫镭腾科技有限公司 +1

Fish head removing device

PendingCN113080239ALess squeezeLess prone to displacementFish arrangingClimate change adaptationMarine engineeringFish processing

The invention discloses a fish head removing device, which relates to the technical field of fish processing, and comprises a box body, a bracket, a driving shaft, a first driven shaft, a second driven shaft, a first transmission conveying assembly, a second transmission conveying assembly, a driving part, a wafer cutting machine, a receiving hopper, a plurality of fish body grooves and a plurality of fish head grooves; wherein the driving shaft, the second driven shaft and the first driven shaft are sequentially and rotationally installed in the box body, the multiple fish body grooves are sequentially installed on the first transmission conveying assembly, the fish head grooves are sequentially installed on the second transmission conveying assembly, and the wafer cutting machine is located above the side, close to the first driven shaft, of the second driven shaft and can stretch into the cutting gap; the receiving hopper is fixed to the inner wall of the side, provided with the second transmission conveying assembly, of the box body, and a discharging opening is formed in the side wall of the box body. The device is high in cutting capacity, small in fish extrusion, low in requirement for the body type of the freshwater fish, suitable for cutting most of the freshwater fish and wide in application range, and the fishes are not prone to move.

Owner:JIANGSU ACAD OF AGRI SCI +1

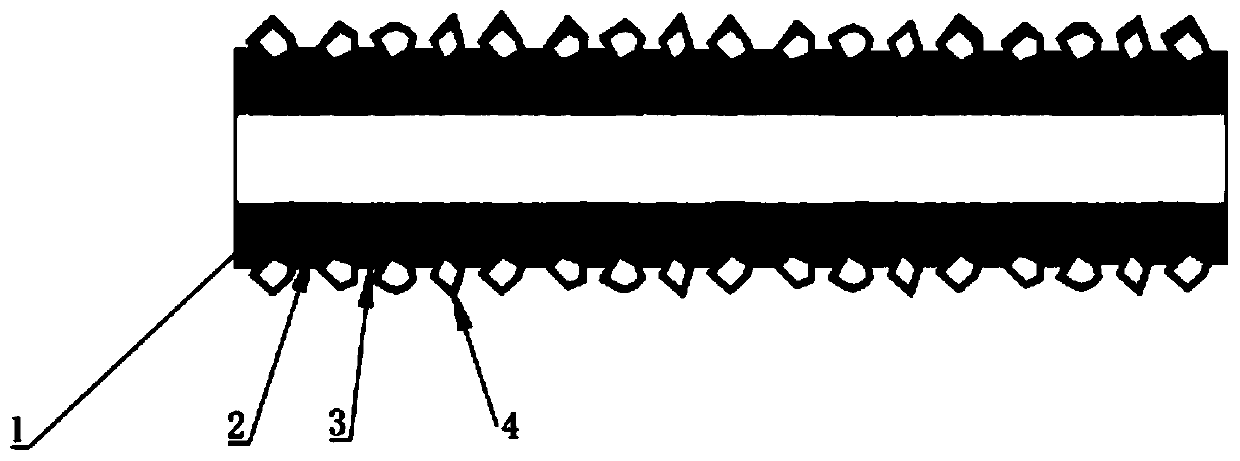

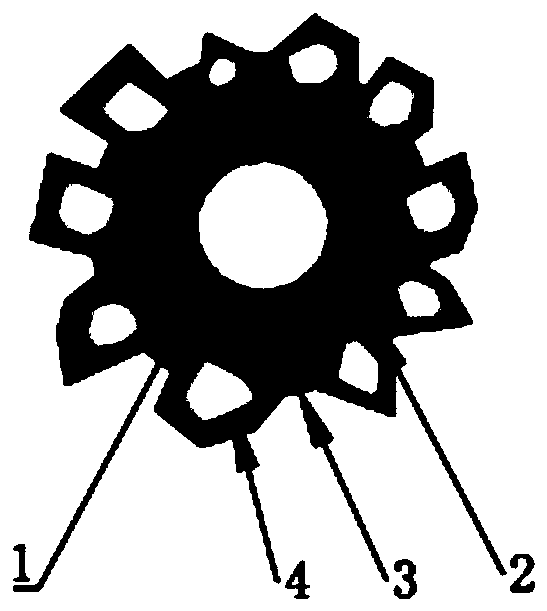

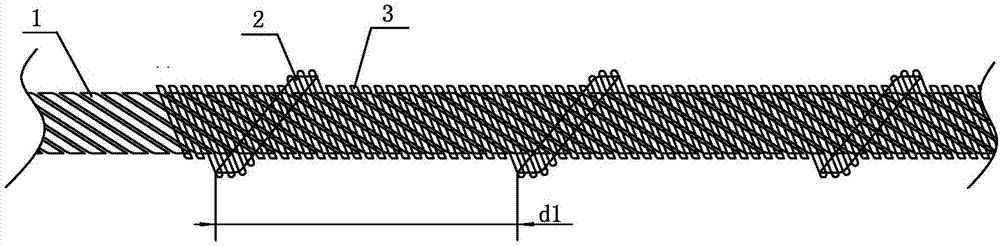

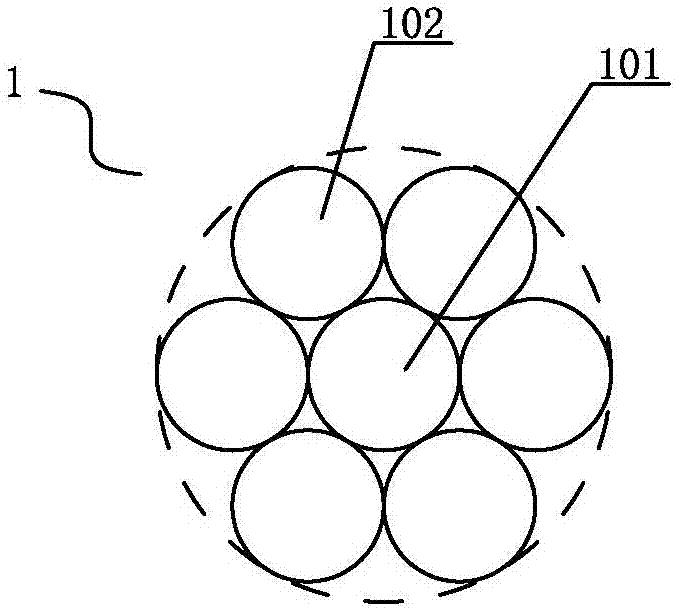

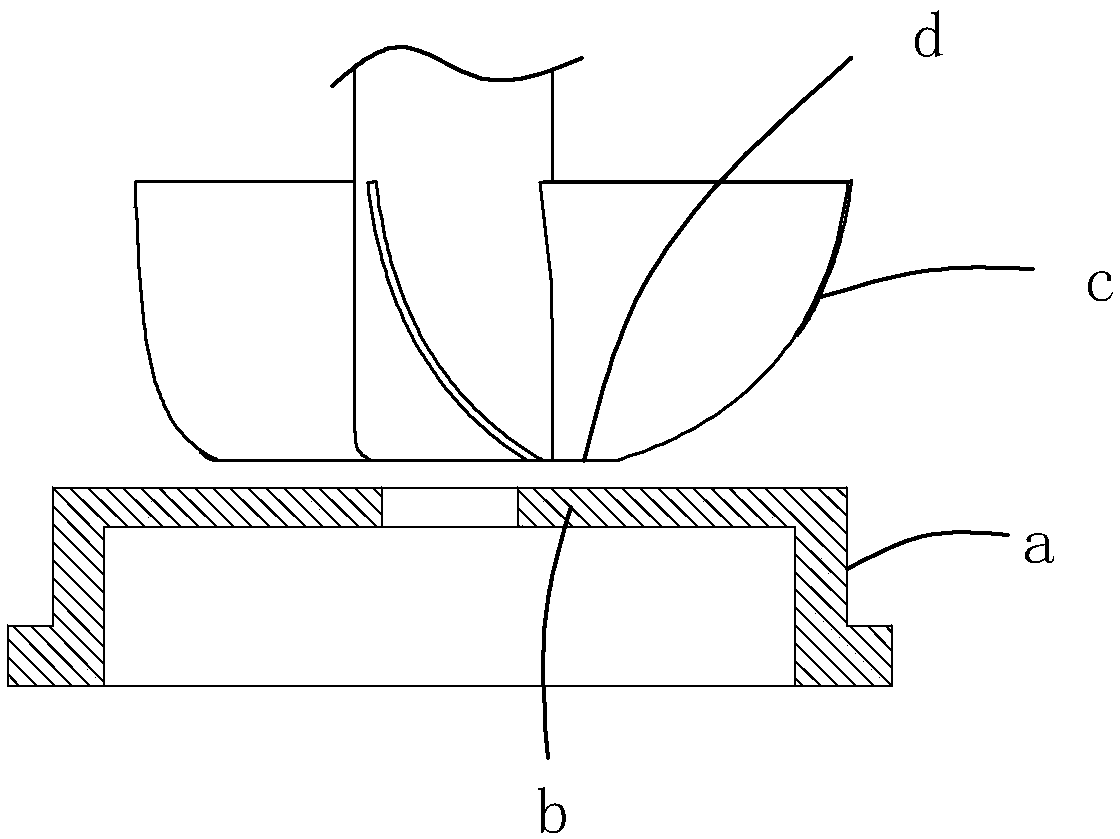

Ring-shaped superhard abrasive wire and manufacturing method thereof

ActiveCN108000735AIncrease chip removal spaceImprove cutting abilityFine working devicesStone-like material working toolsConductor CoilMaterials science

The invention discloses a ring-shaped superhard abrasive wire and a manufacturing method of the ring-shaped superhard abrasive wire. A base body of the ring-shaped superhard abrasive wire is a wire rope. The wire rope is connected end to end into a ring shape. Silk threads are loosely wound around the wire rope. Silk threads with abrasive are tightly wound around the exposed part of the wire ropeand the silk threads. The pitch between every two joints of adjacent silk threads on the wire rope is larger than or equal to 3 times the diameter of the silk threads with the abrasive. Every two joints of silk threads with the abrasive on the wire rope or the silk threads are sequentially arranged and not mutually pressed and stacked, and meanwhile the peripheries of every two joints of adjacentsilk threads with the abrasive are in contact with each other. The ends of the silk threads with the abrasive are buried under the winding-finished silk threads with the abrasive. The ring-shaped superhard abrasive wire has the ultra-high chipping discharge space and the higher cutting capacity, the manufacturing method is simple and easy to implement, and mass production is fast.

Owner:CHINA NONFERROUS METAL (GUILIN) GEOLOGY & MINING CO LTD

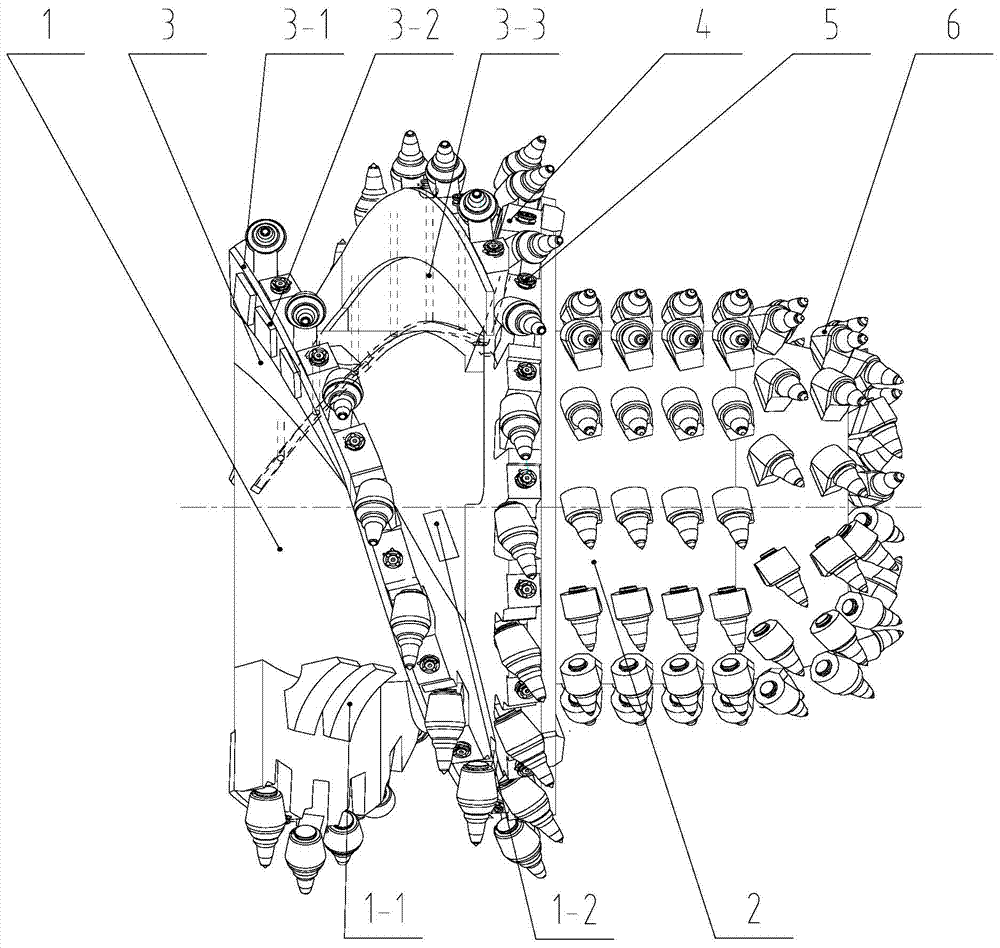

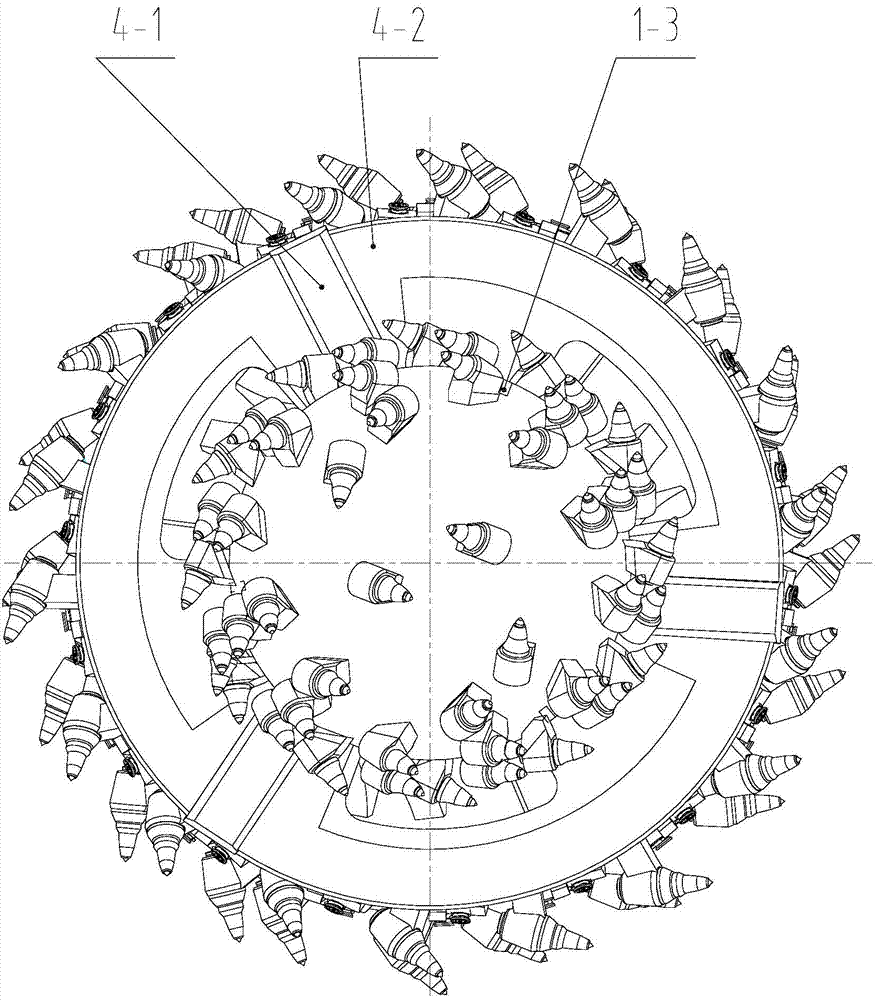

Deep-well high-stress coal rock stepped roller

ActiveCN104712334AGuaranteed water supplyMeet mining needsSlitting machinesCutting machinesSpiral bladeRock cutting

The invention relates to a deep-well high-stress coal rock stepped roller, which comprises a rear cylinder hub, a front cylinder hub, a spiral blade, an end plate, nozzles, pick-shaped cutters. the end plate is arranged at connection place of the rear cylinder hub and the front cylinder, the spiral blade connected to the end plate is arranged on the rear cylinder hub, several pick-shaped cutters and nozzles are distributed on the outer rim of the spiral blade and the end plate at intervals, the pick-shaped cutters with spiral arrangement are fixed on the front cylinder hub; an annular water delivery channel is arranged on the end plate, a nozzle water delivery channel, a wheel hub water delivery channel and an end plate blade water delivery channel which are communicated to the annular water delivery channel are arranged. In the invention, mechanical mining problem of deep-well high-stress coal rock can be solved, and deep-well high-stress coal rock cutting efficiency is increased under explosion-proof motor power is not greatly increased. The structure employing an explosion-proof motor to drive, explosion-proof requirement under well can be satisfied, and the coal cutter roller has the advantages of simple and compact structure.

Owner:江苏中矿汇弘科技有限公司

Water pump and floating type cutting assembly

The invention relates to a water pump and a floating type cutting assembly. The floating type cutting assembly comprises a rotating shaft rotated by a driving source, a cutting blade and a cutting disc in butt joint with the rotating shaft, a cutting strip is arranged on the cutting disc, a cutting edge is arranged at the end of the cutting blade, the cutting edge can mutually mesh with the cutting strip to cut sundries, a movable shaft is arranged on the cutting blade and slidably and movably connected to the end of the rotating shaft in a sleeving mode, and a tension spring is connected between the end of the movable shaft and the rotating shaft; a driving part is arranged on the rotating shaft, a transmission part is connected between the driving part and the movable shaft, and the driving part is transmitted to the transmission part in a power mode. Meshing force between the cutting strip and the cutting blade can act on different positions of cloth, even though cloth strips in thefirst meshing action position are firm and tenacious, as the cutting meshing position changes, the cloth can eventually be cut off, and compared with fixed cutting assemblies, according to the cutting effect of the water pump and the floating type cutting assembly, the cutting effect is relatively good in actual use.

Owner:尤孚泵业集团有限公司

Method for preparing flexible linear cutting cable

ActiveCN110790622AGood flexibilityStrong cutting abilityNon-explosive fillers/gelling/thickening agentsExplosive working-up apparatusMechanical engineeringExplosive Agents

The invention discloses a method for preparing a flexible linear cutting cable. The method comprises the following steps: vulcanizing and curing double-component room-temperature vulcanized silicone rubber by using a vulcanizing agent so as to prepare a cutting cable sheath; filling the sheath with an explosive and the double-component room-temperature vulcanized silicone rubber, and pressing an energy gathering groove; performing vulcanizing and curing by using the vulcanizing agent so as to prepare a cutting cable chemical bar with the energy gathering groove; and further mixing and fillingmetal powder and the double-component room-temperature vulcanized silicone rubber into the energy gathering groove of the cutting cable chemical bar, and performing pressing under the action of vulcanizing and curing of the vulcanizing agent, so as to form an energy gathering cover. The energy gathering cover of the flexible linear cutting cable prepared by using the method not only has very goodflexibility, but also is tightly combined with the cutting cable chemical bar, so that the cutting cable has very good flexibility and bending performance, and the explosion cutting capability can beimproved.

Owner:ZHONGBEI UNIV +1

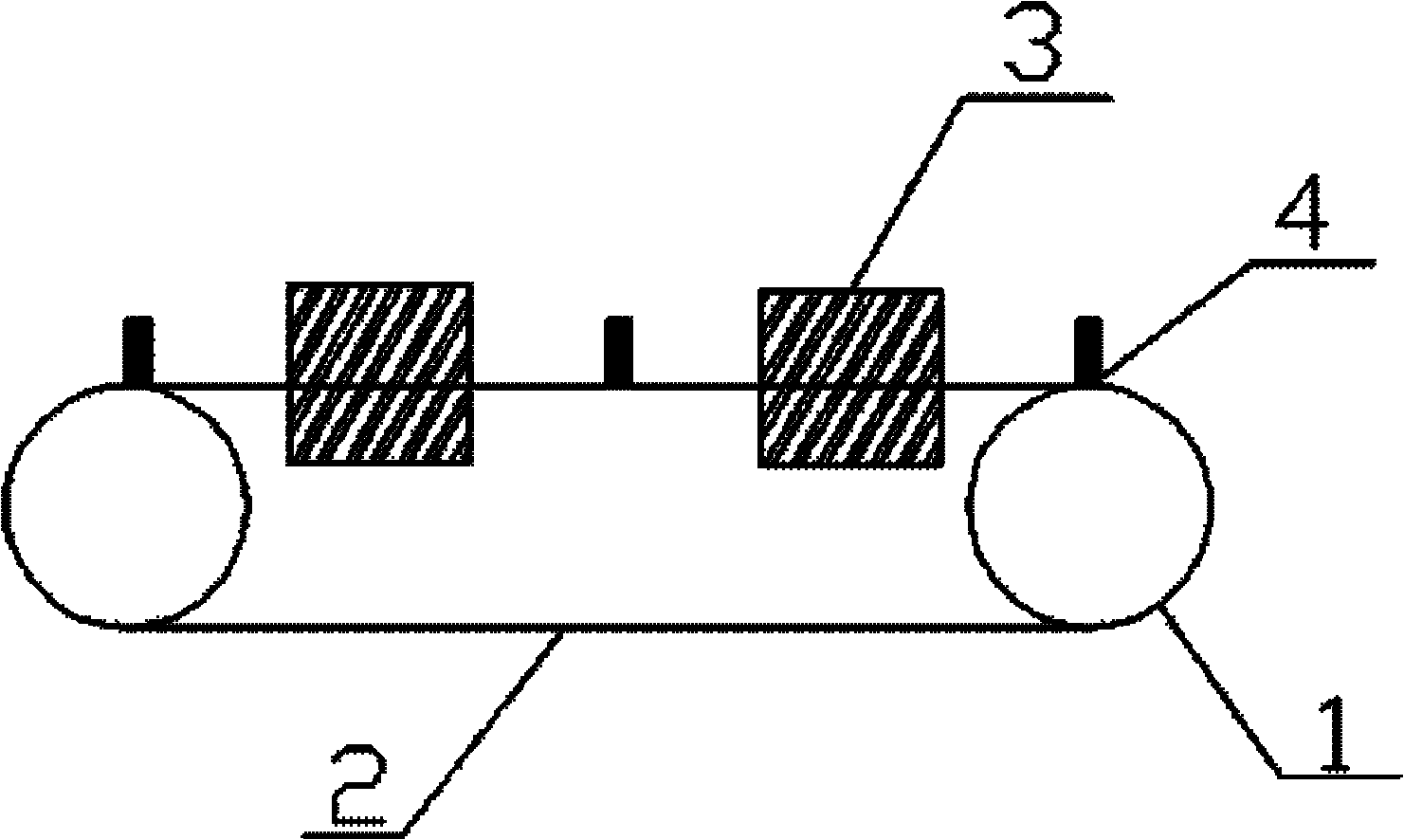

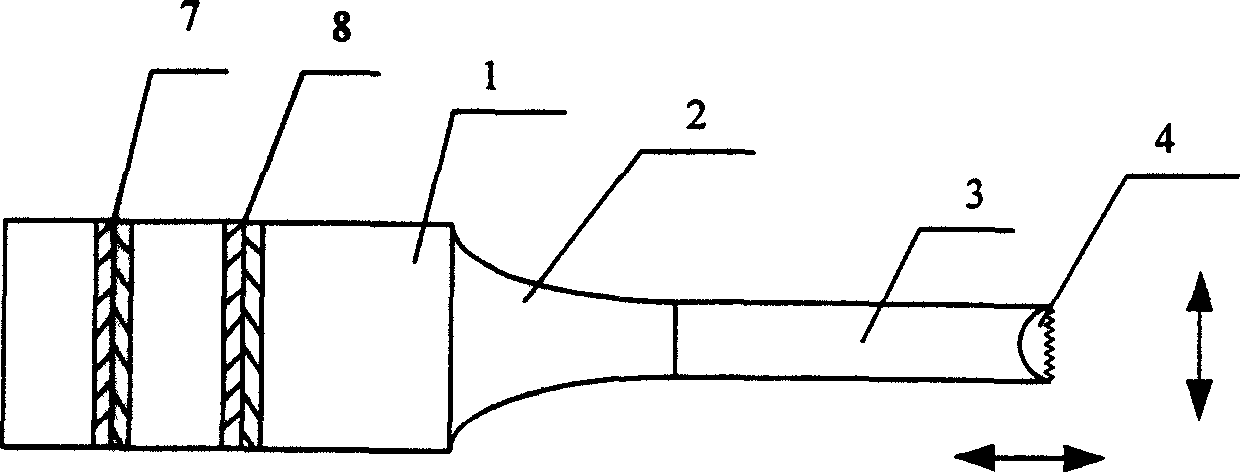

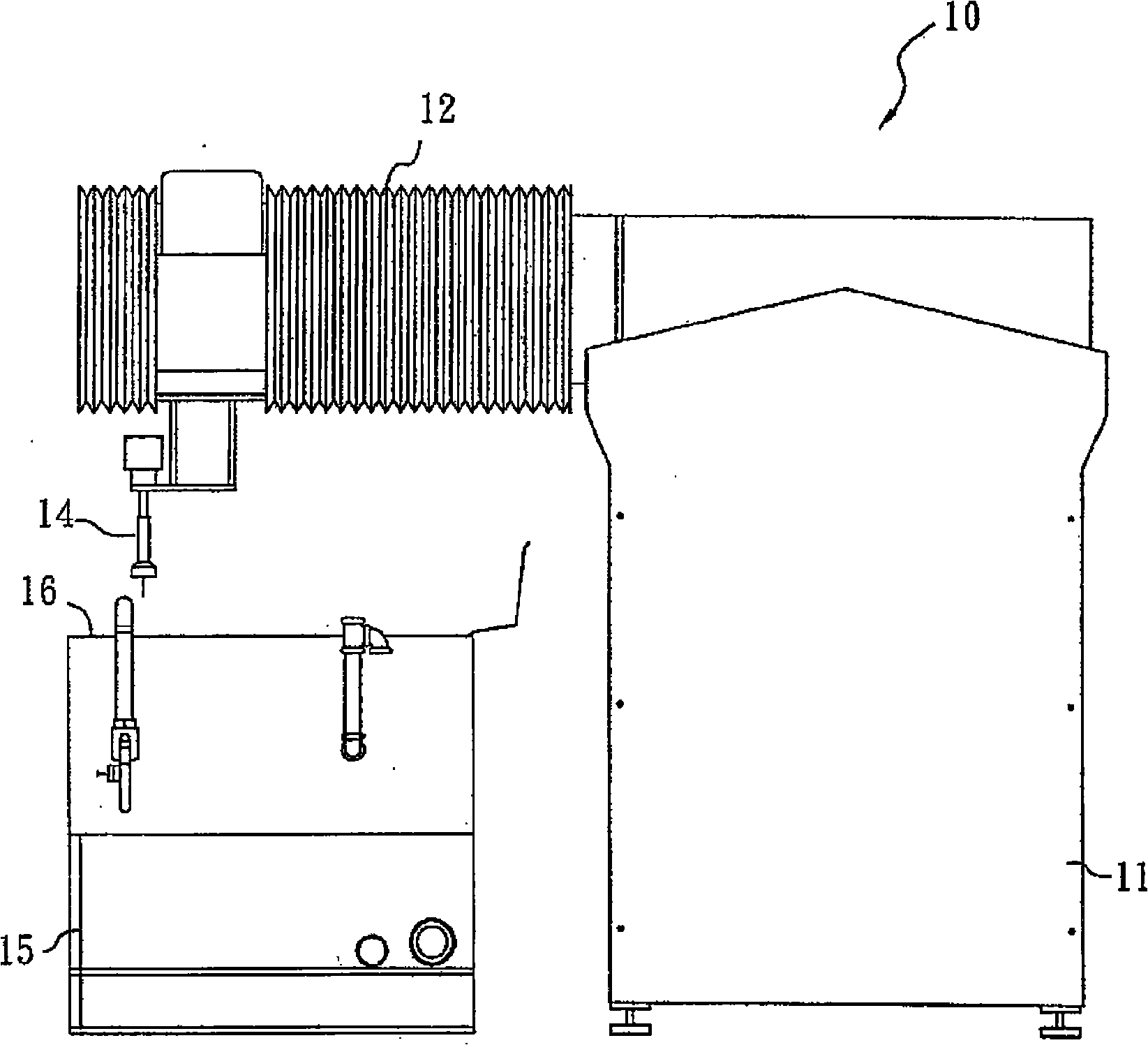

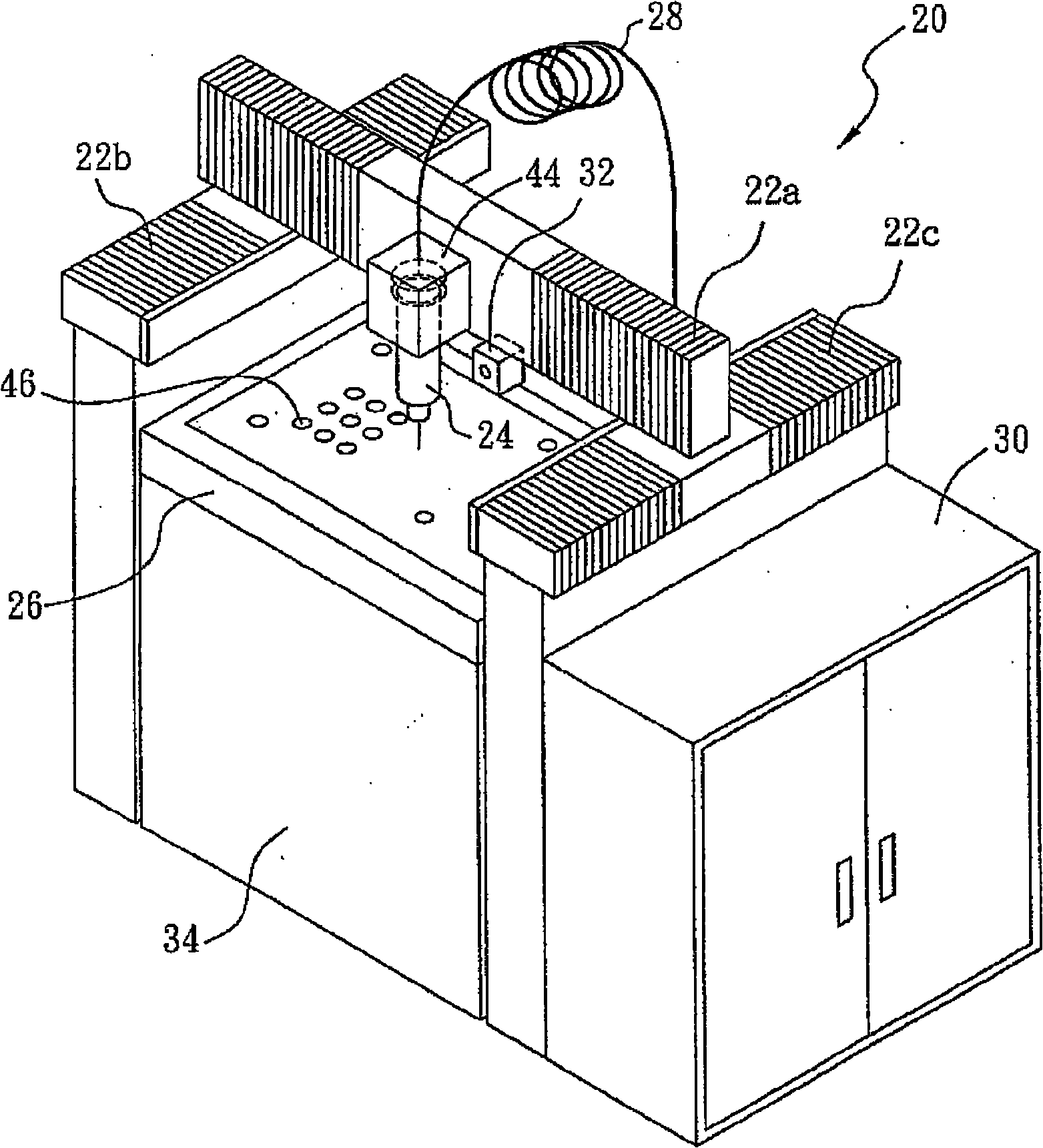

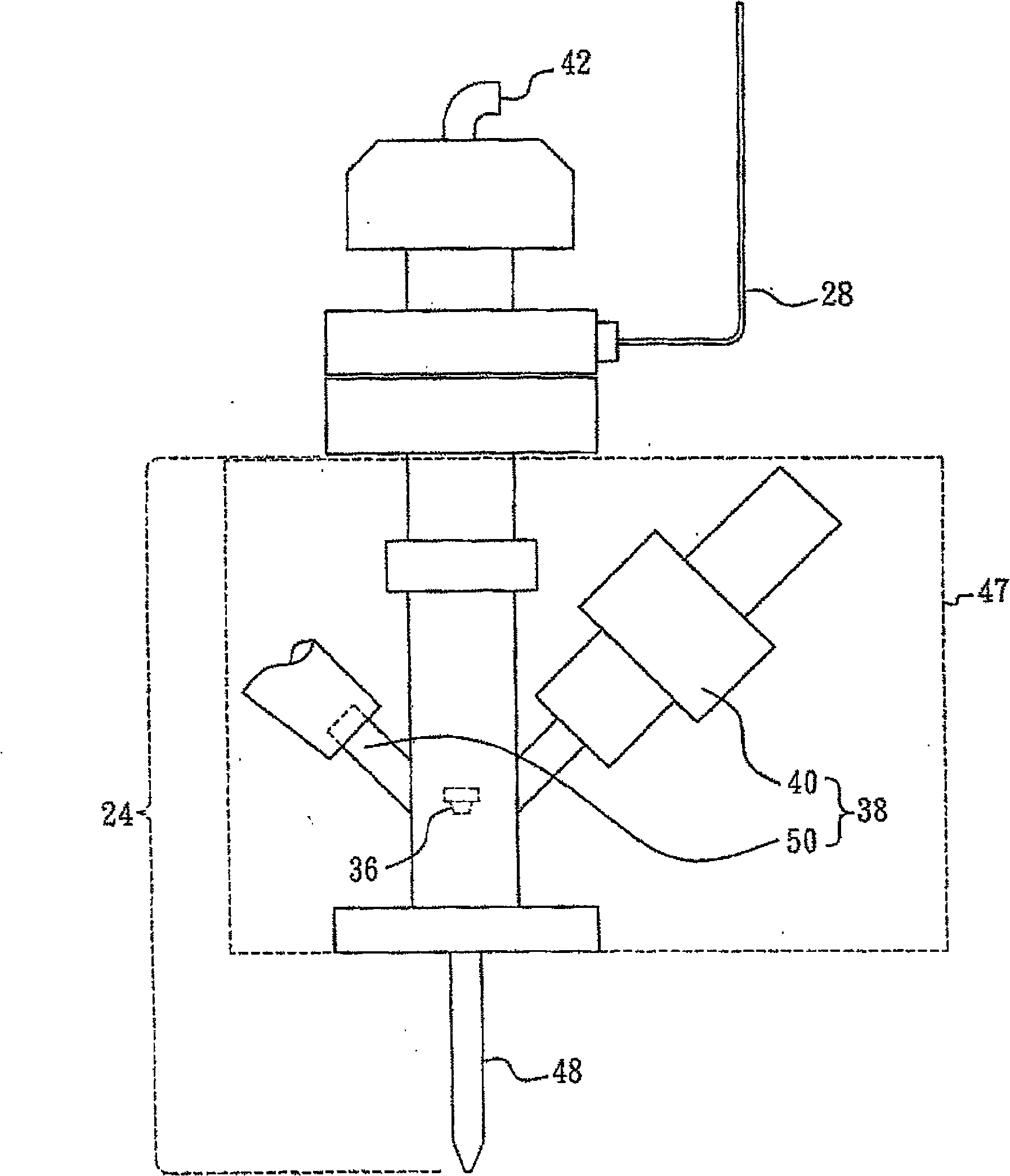

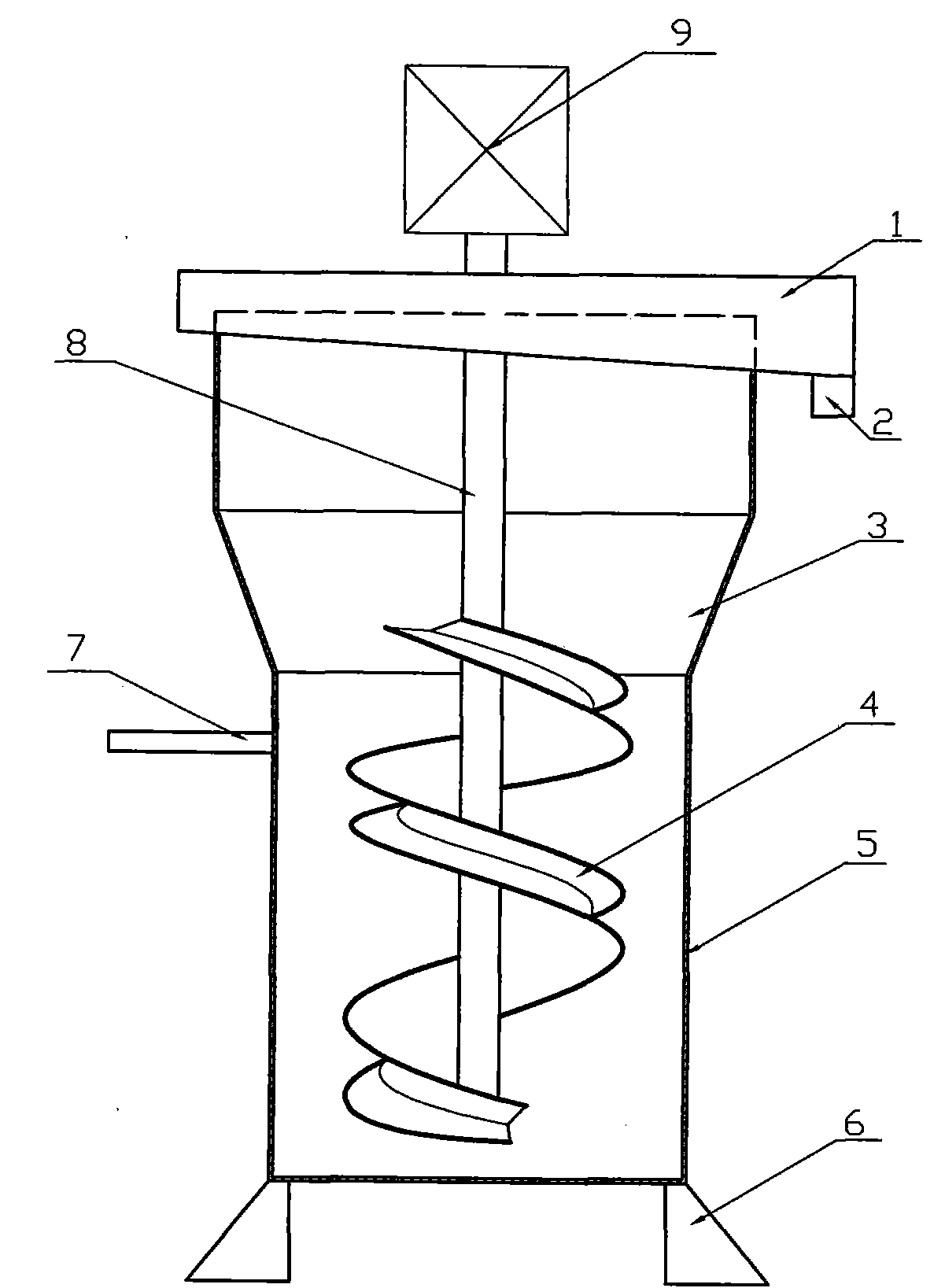

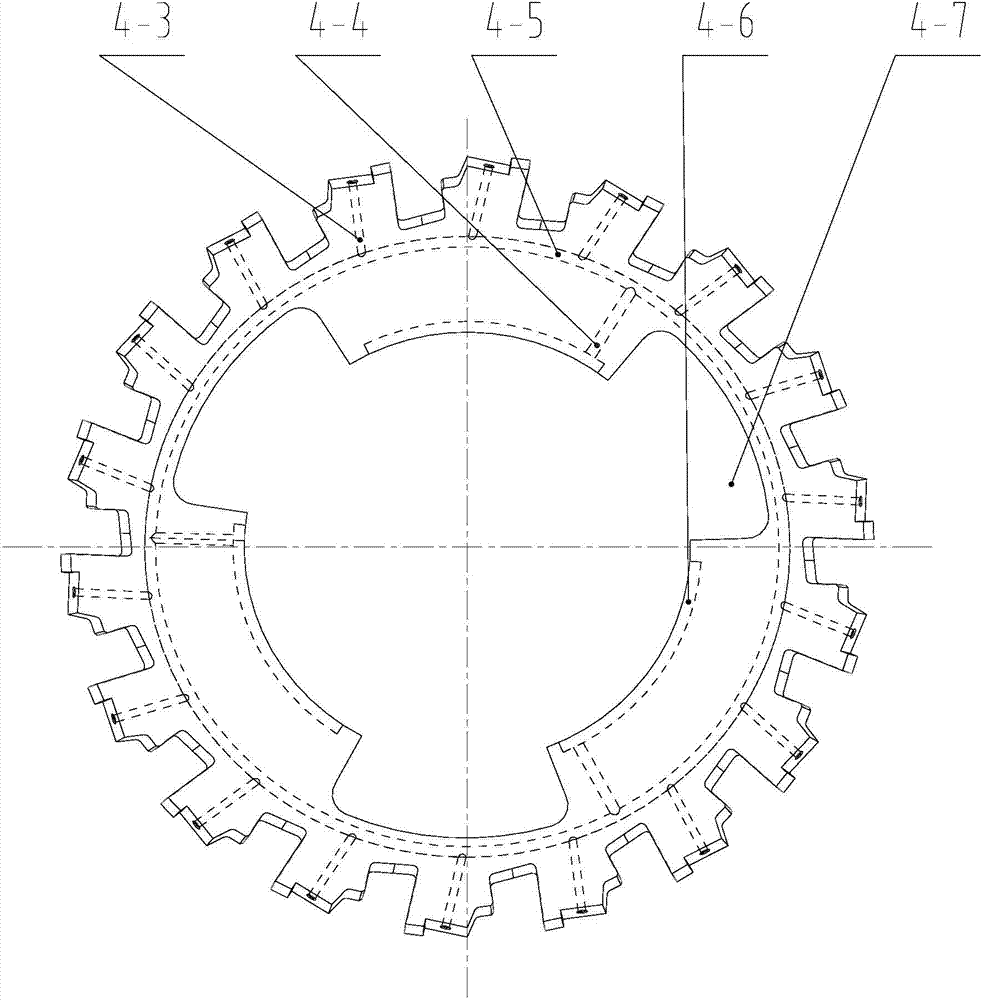

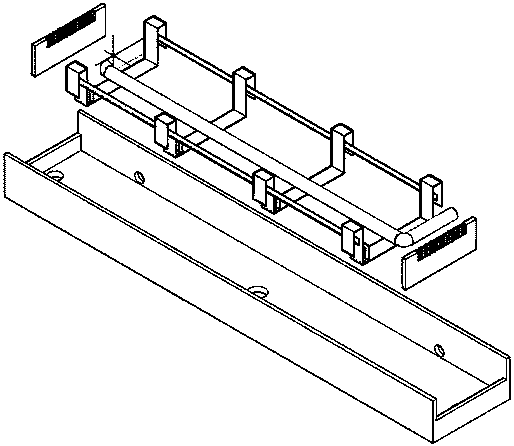

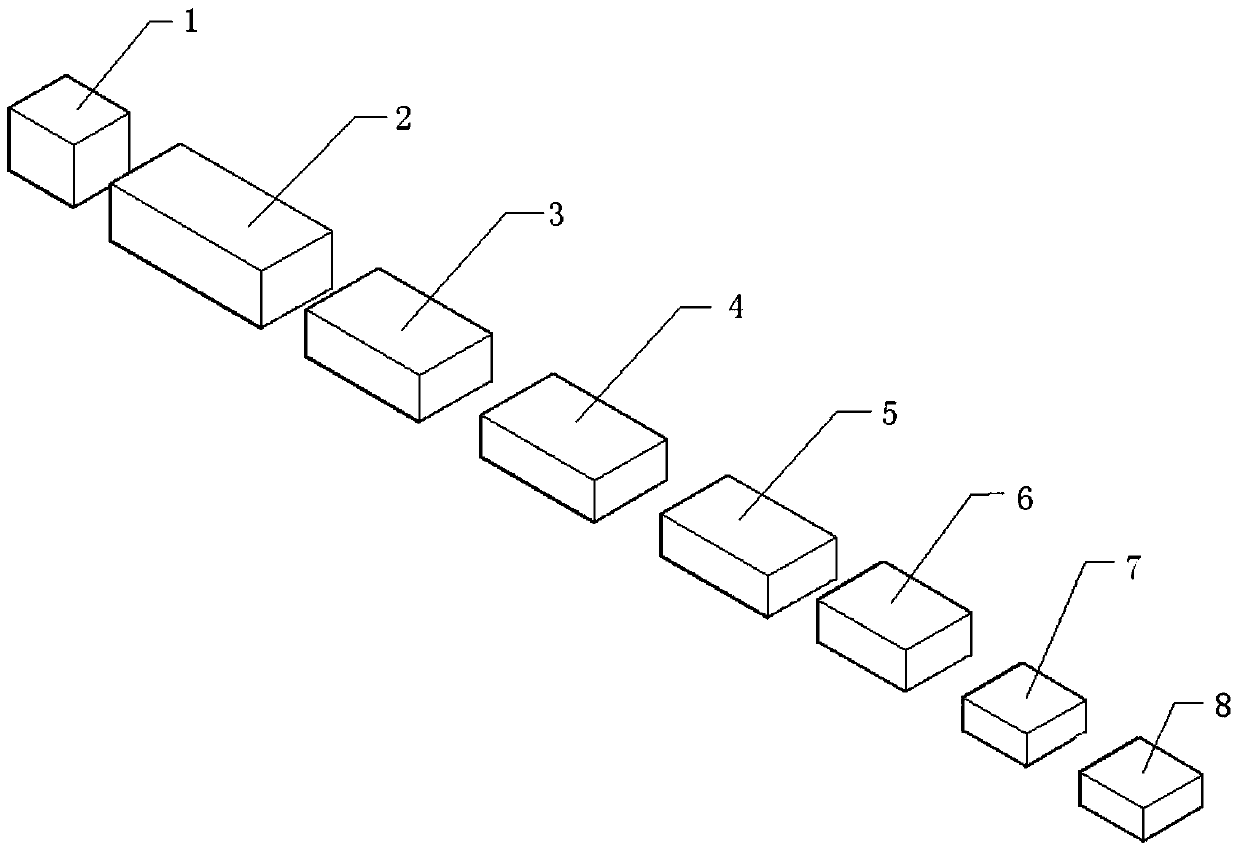

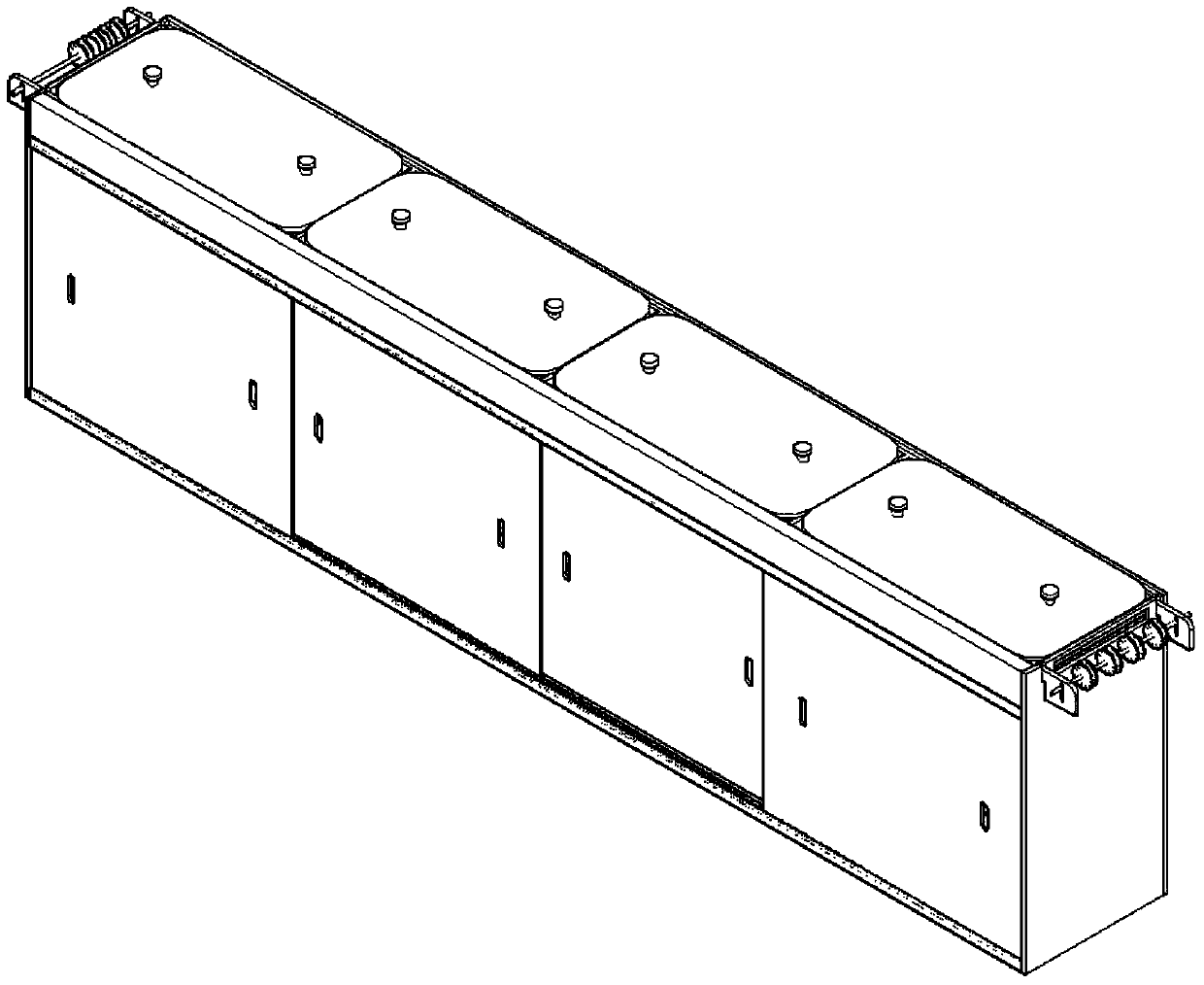

Raw diamond wire saw production system

ActiveCN103952739AImprove cutting abilityNo accumulationElectrolytic coatingsEngineeringLarge capacity

The invention relates to a raw diamond wire saw production system. The raw diamond wire saw production system is characterized by sequentially comprising, from the front to the rear, a wire-pulling device (1), a treatment-before-plating device (2), a pre-plating device (3), a sand-feeding device (4), a curing device (5), a treatment-after-plating device (6), a drying oven (7) and a wire take-up device (8), wherein a sand-feeding groove of the sand-feeding device (4) comprises an upper layer sand-feeding groove (4.1) and a lower layer sand-feeding groove (4.2) which are arranged in the vertical direction, the middle parts of both the upper layer sand-feeding groove (4.1) and the lower layer sand-feeding groove (4.2) are provided with annular sand channels (4.4), sand-feeding wire guide wheels (4.7) are arranged above the front section and rear section of the lower layer sand-feeding groove (4.2), and two sand-feeding pressing rollers (4.6), which are in forward and backward arrangement, are arranged above the sand channels located at the right side of the annular sand channels (4.4). The raw diamond wire saw production system disclosed by the invention has the advantages of high capacity in cutting products, uniform plating of diamond powder and capability in achieving quick mass production.

Owner:铜陵市力博中小企业服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com